Patents

Literature

84results about How to "Make sure to form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

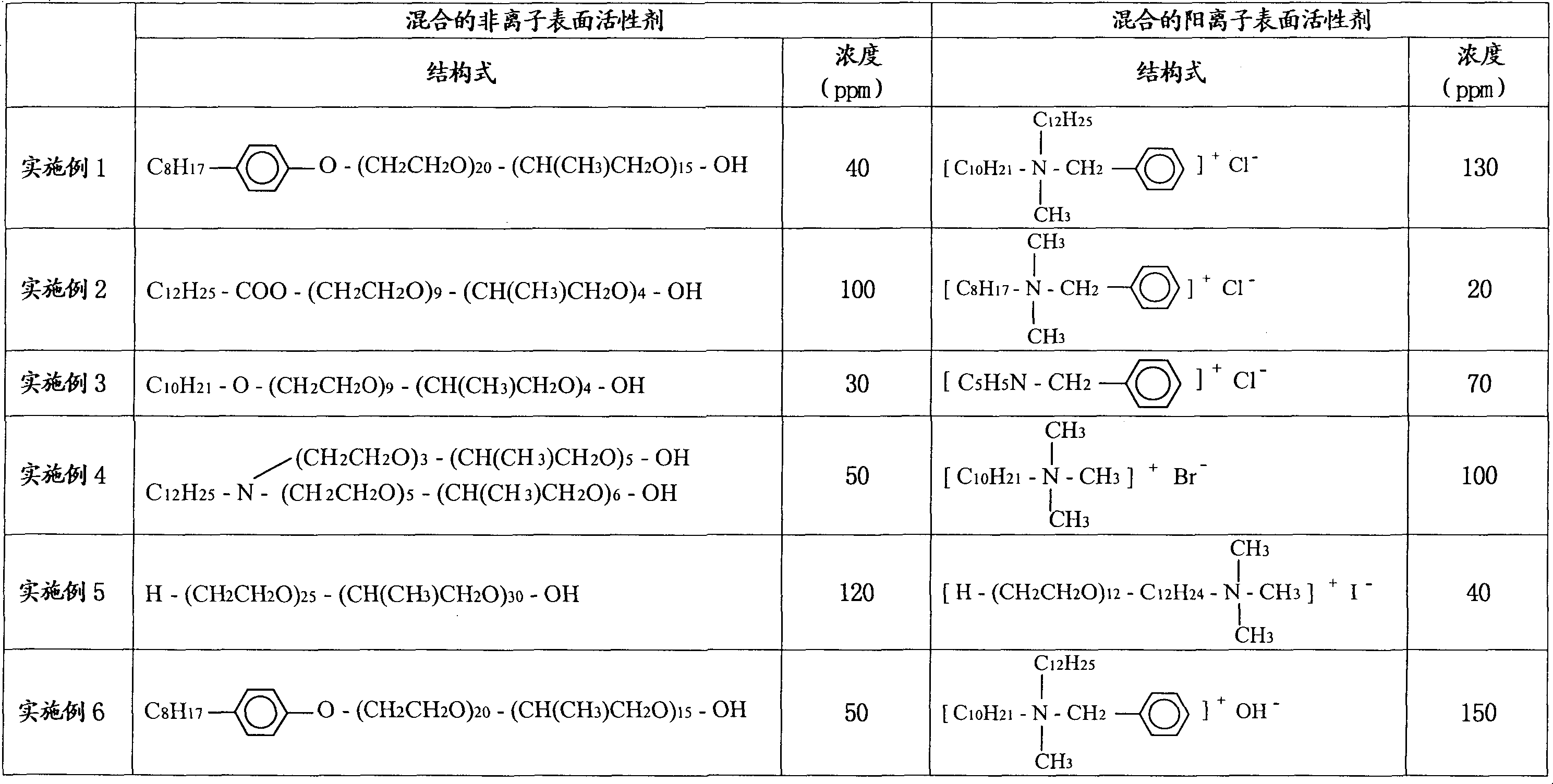

Developing solution for photoresist

InactiveCN1392973AImprove wettabilityImprove solubilitySurface-active detergent compositionsSemiconductor/solid-state device manufacturingSolubilitySURFACTANT BLEND

A photoresist developer which is excellent in the wettability of a non-soluble portion of a photoresist after exposure and the solubility of a soluble portion and controls the dissolving speed of the non-soluble portion effectively. This developer is prepared by adding a nonionic surfactant and a cationic surfactant to an alkali aqueous solution in a total amount of 10 to 5,000 ppm by weight.

Owner:TOKUYAMA CORP

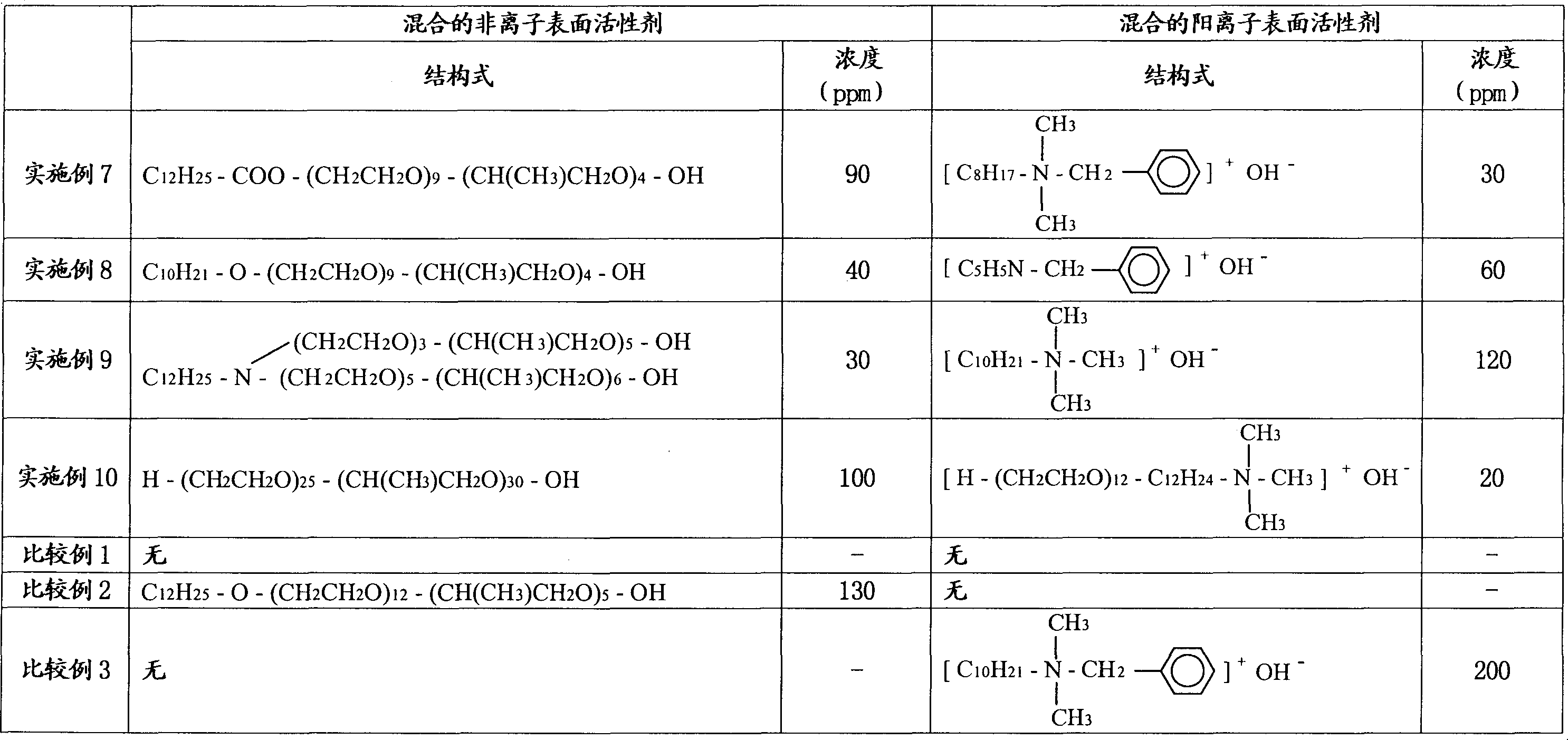

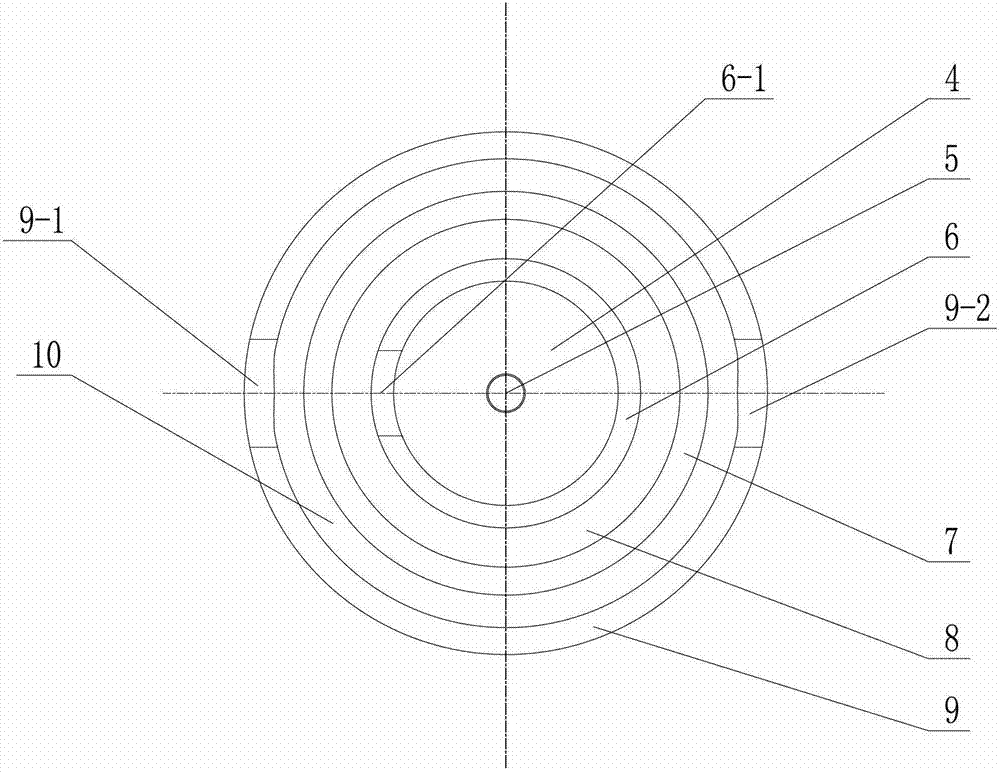

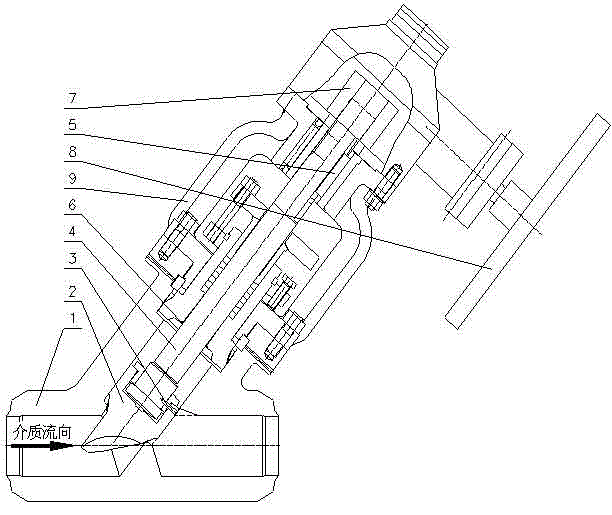

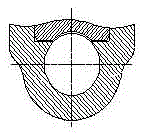

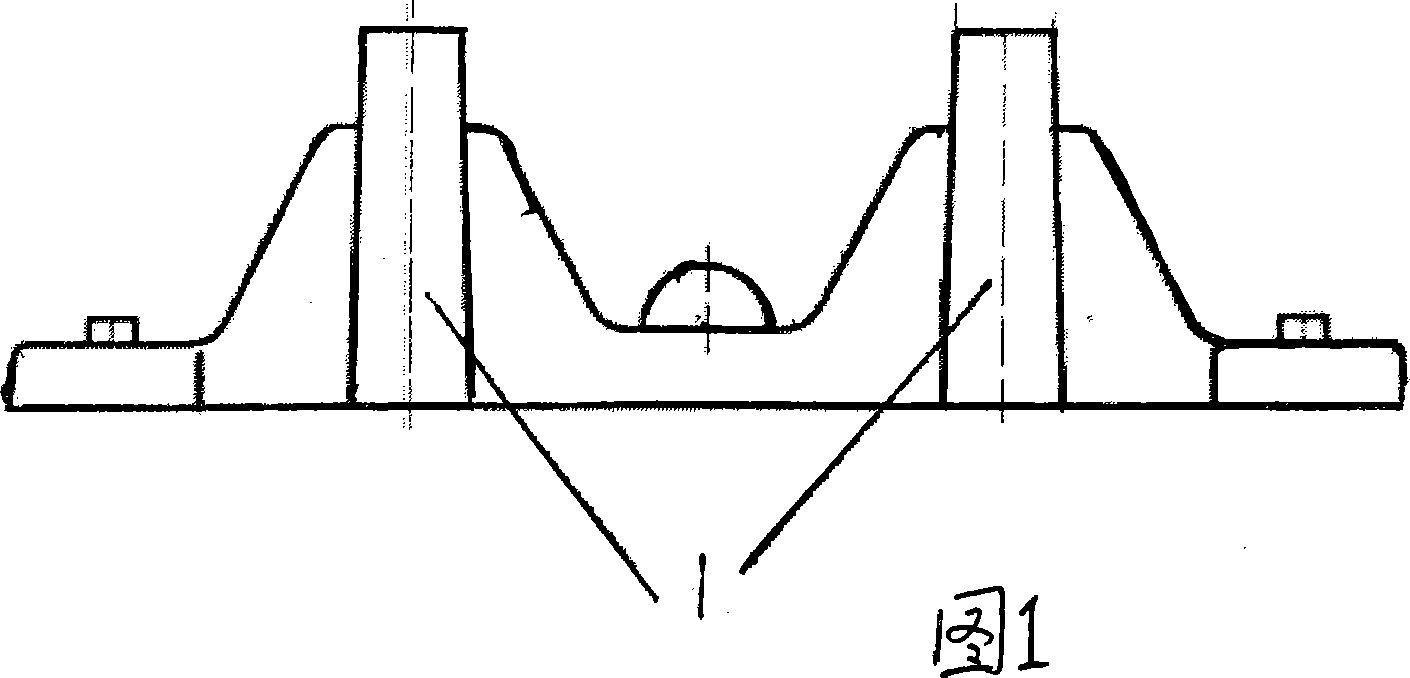

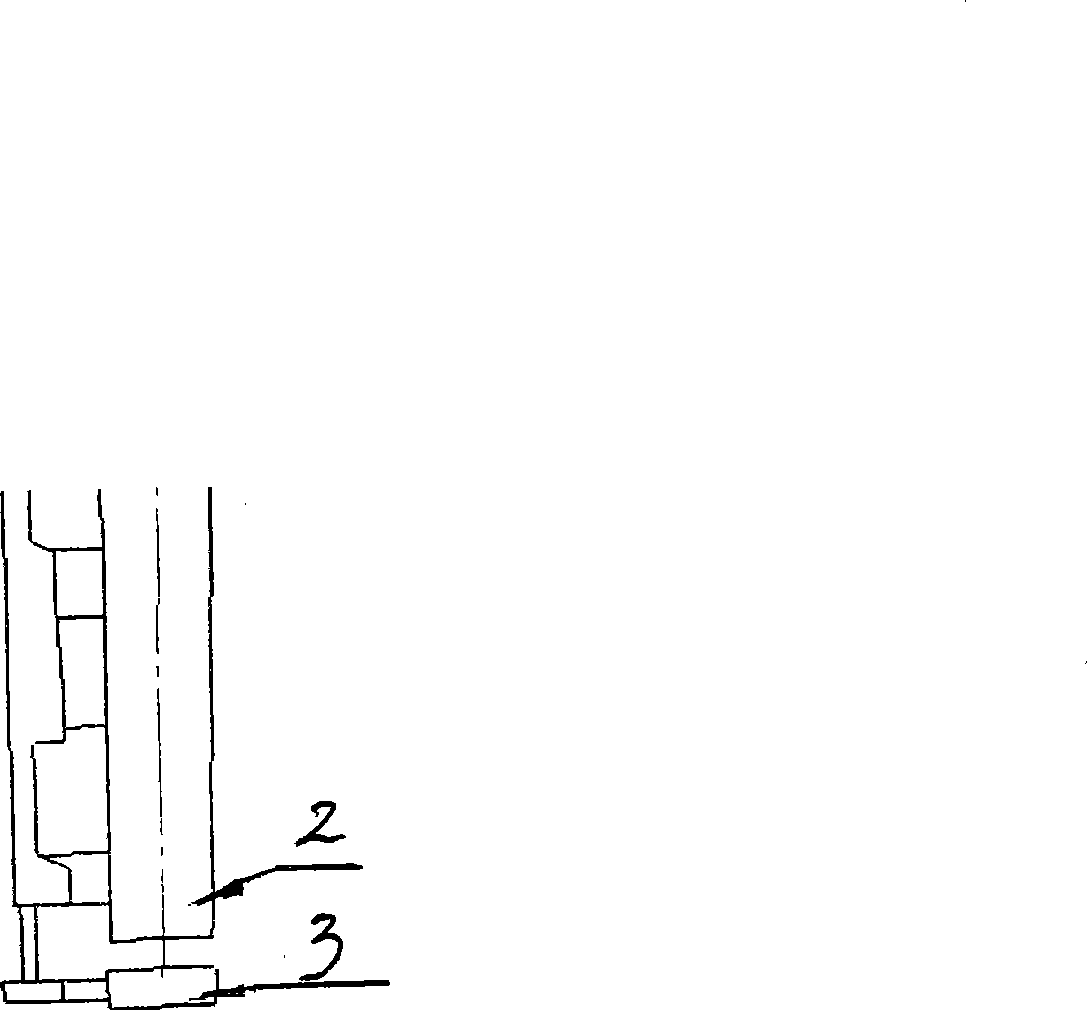

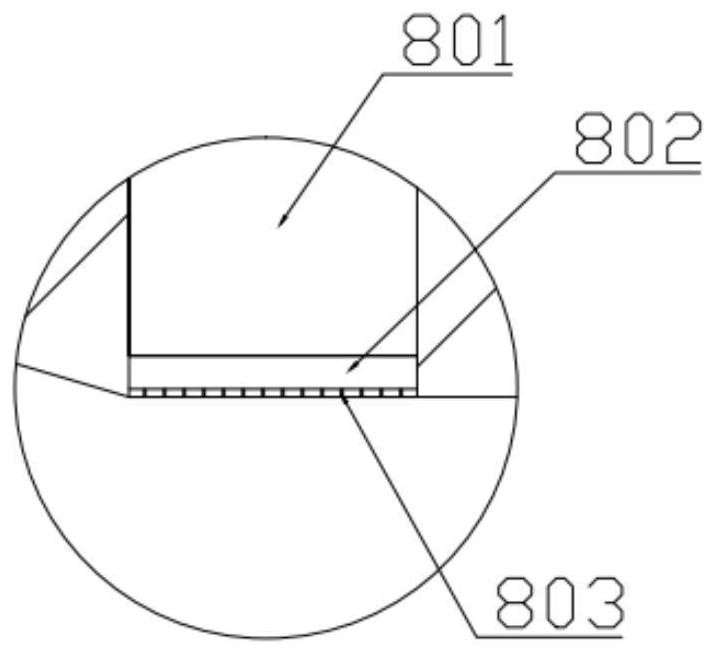

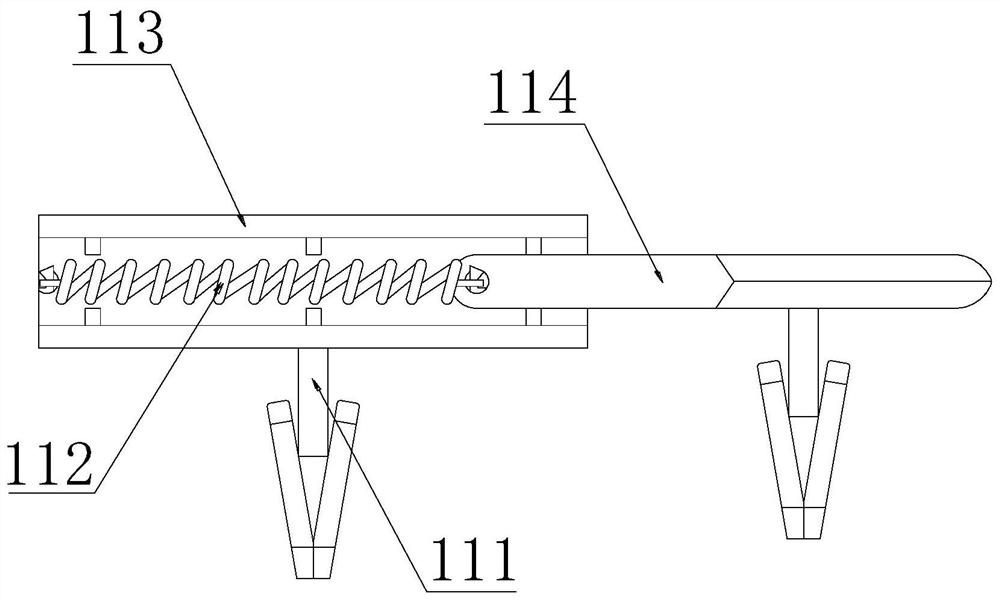

Slipper used for plunger type hydraumatic pump

ActiveCN102926987AAvoid partial wearMake sure to formPositive displacement pump componentsLiquid fuel engine componentsHydraulic pumpEngineering

The invention relates to a slipper.used for a plunger type hydraumatic pump. The slipper comprises a slipper body, wherein one end of the slipper body is provided with a spherical closing port which is matched with a plunger bulb, and the other end of the slipper body is provided with a flat surface contacted with a wobble disc; and the middle of the flat surface has a groove, the middle of the groove has a damping hole, and the damping hole is communicated with the spherical closing port. The slipper is characterized in that the edge of the groove is provided with an annular inner support belt, the annular support belt is provided with a first oil port, the periphery of the annular inner support belt is provided with an annular seal belt, and an annular oil groove is reserved between the annular seal belt and the annular inner support belt; and the periphery of the annular seal belt is provided with an annular outer support belt, the annular outer support belt is provided with a second oil port and a third oil port, and an annular outer oil groove is reserved between the annular outer support belt and the annular seal belt. The slipper provided by the invention has the advantages that a good oil film and good static pressure are established between the slipper and the wobble disc, the problems such as eccentric wear, deformation, slipper dropping and slipper loosing are solved, the reliability of the slipper is improved, and further, the service life and the efficiency of a plunger pump are improved.

Owner:WUXI WEIFU PRECISION MACHINERY MFG

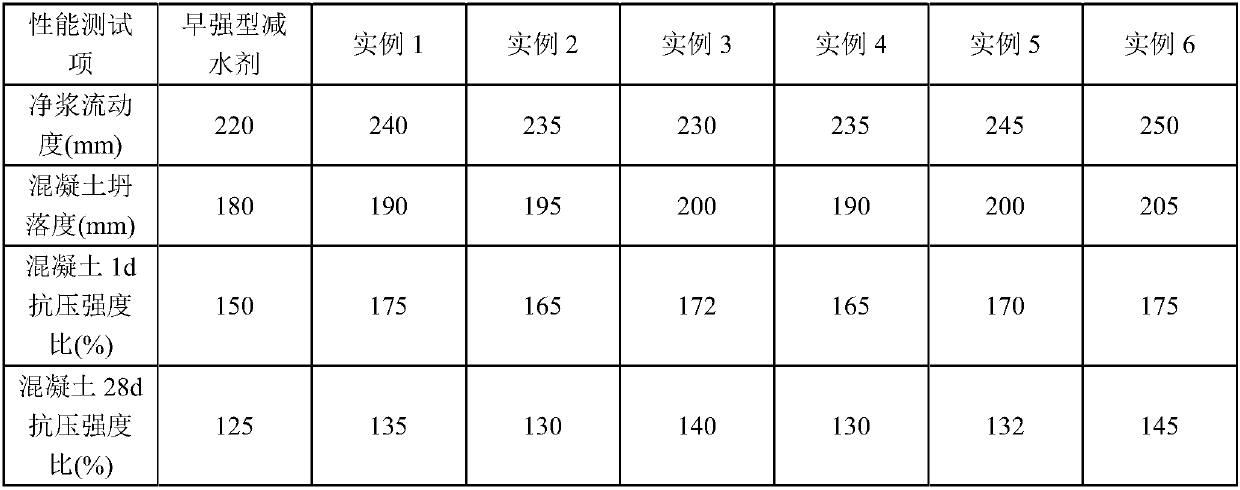

Early-strengthening type composition dispersing agent of cement-based cementitious material

The invention discloses an early-strengthening type composition dispersing agent of a cement-based cementitious material. The dispersing agent is prepared by mixing the following components in percentage by weight: 10-15% of alkylolamide ferroaluminum complex, 2-7% of cationic polymer, 0.5-2.0% of a metal ion chelating agent, 15-25% of metal sulfate, and the balance of water, wherein the alkylolamide ferroaluminum complex in the composition is prepared by synthesizing inorganic acid, a chelating agent, ferrous sulfate, aluminum sulfate and alkylolamide; the cationic polymer is prepared by synthesizing polyether macromonomer, cationic micromonomer, acrylamide, a double-bond-containing silane coupling agent, mercaptoethanol, hydrogen peroxide, ammonium persulfate, sodium formaldehyde sulfoxylate, sodium hypophosphite hydrate and caustic soda liquid. With the adoption of the early-strengthening type composition dispersing agent, the early strength of the cement-based cementitious materialcan be obviously improved under low doping quantity and on the premise that the working mobility of the cement-based cementitious material is basically not influenced.

Owner:HUBEI UNIV OF TECH

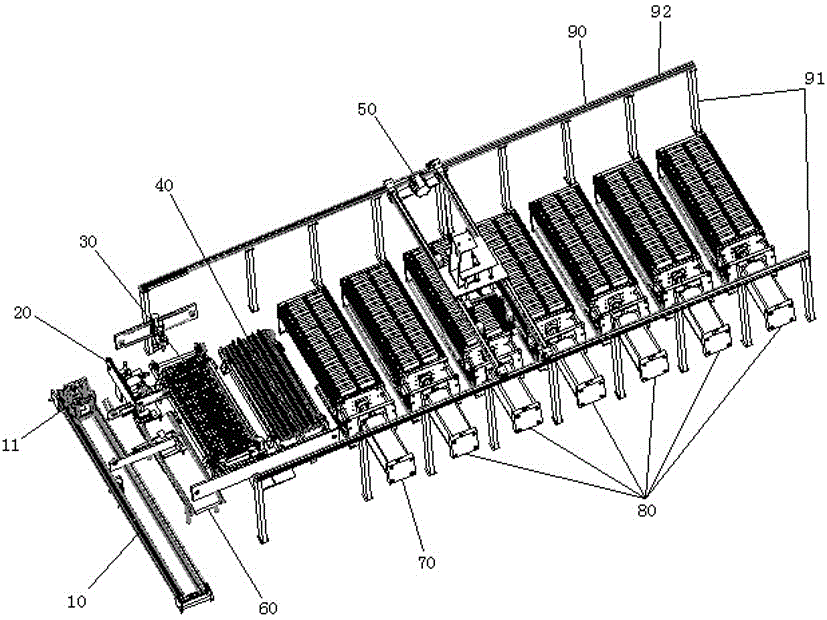

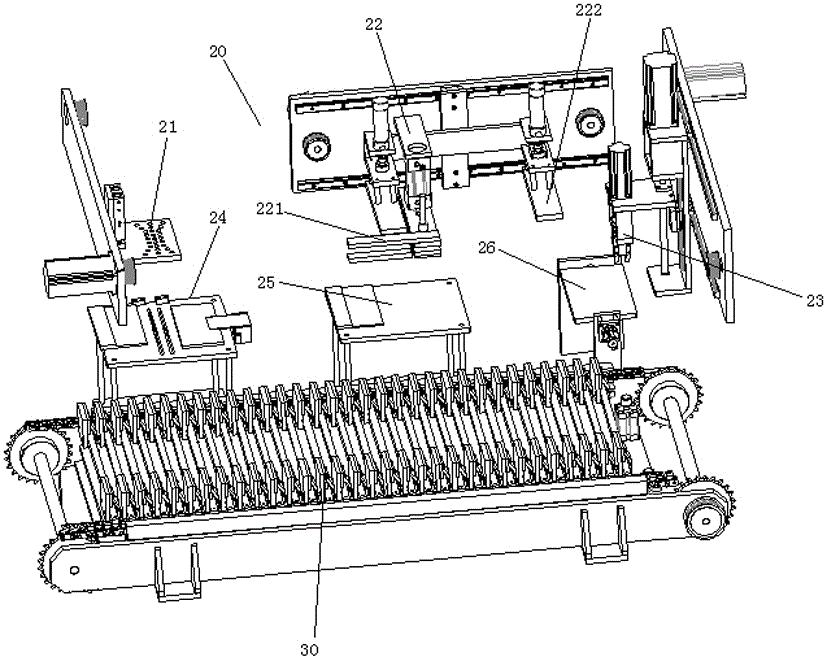

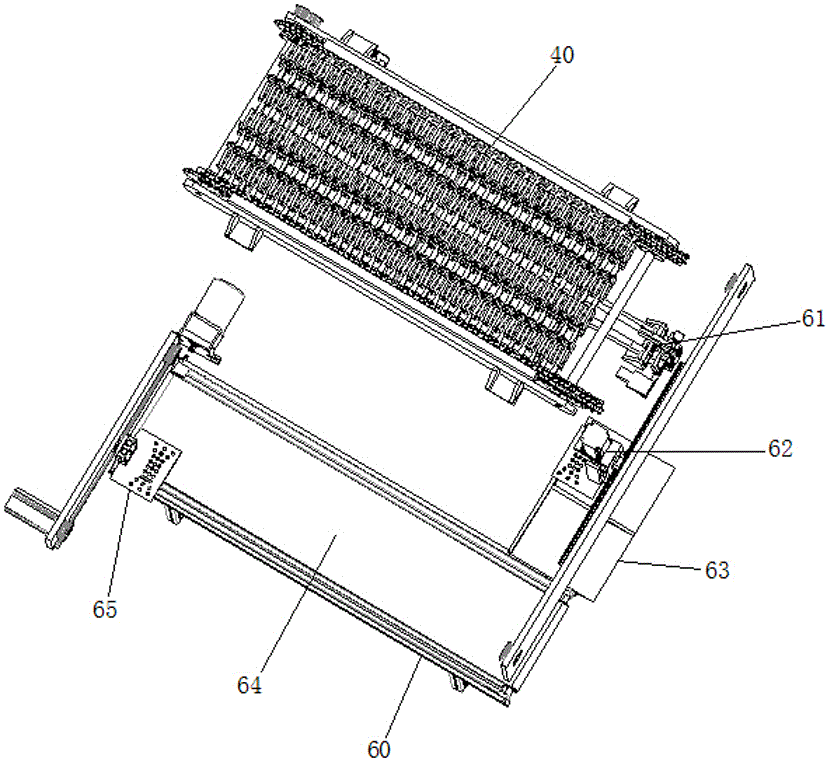

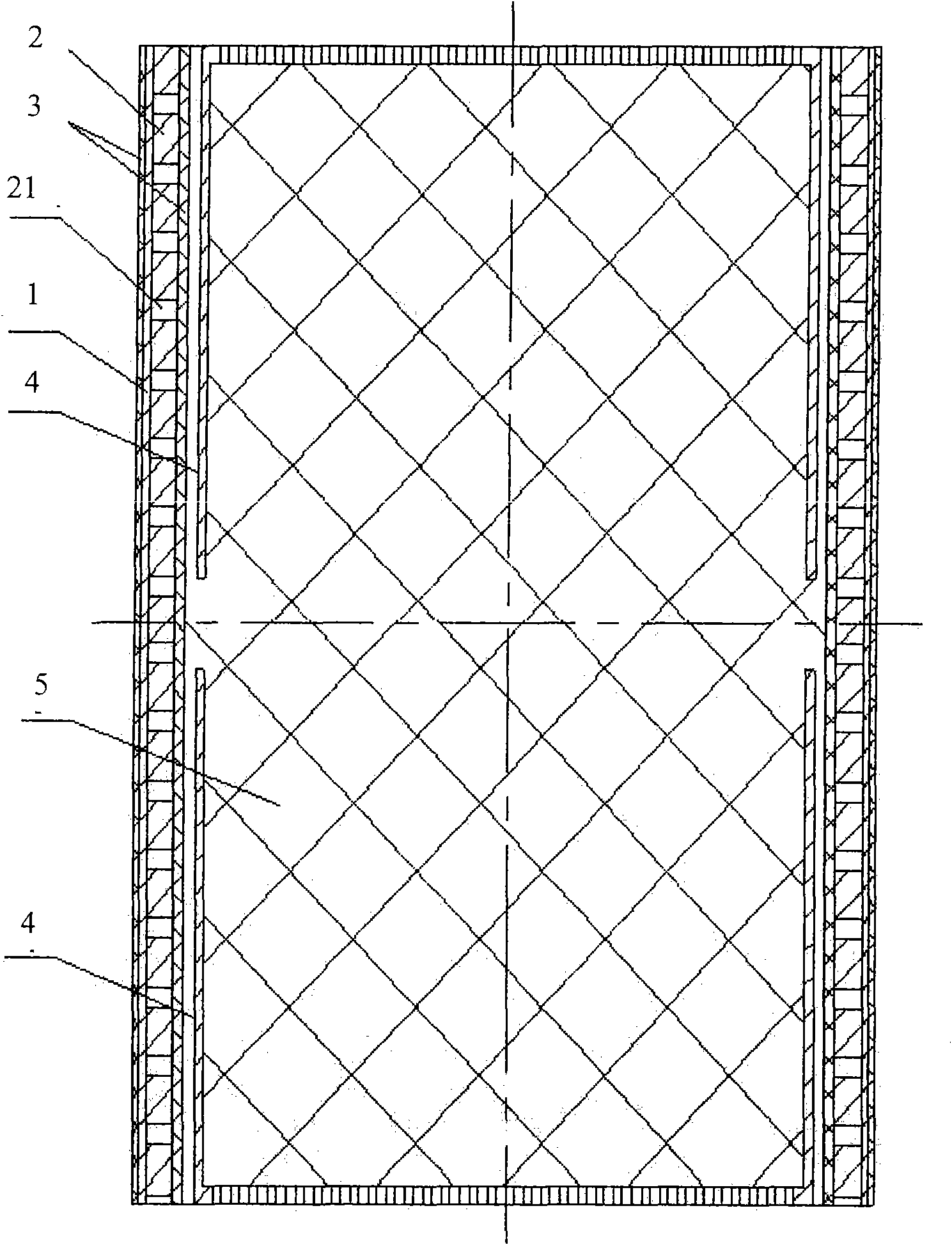

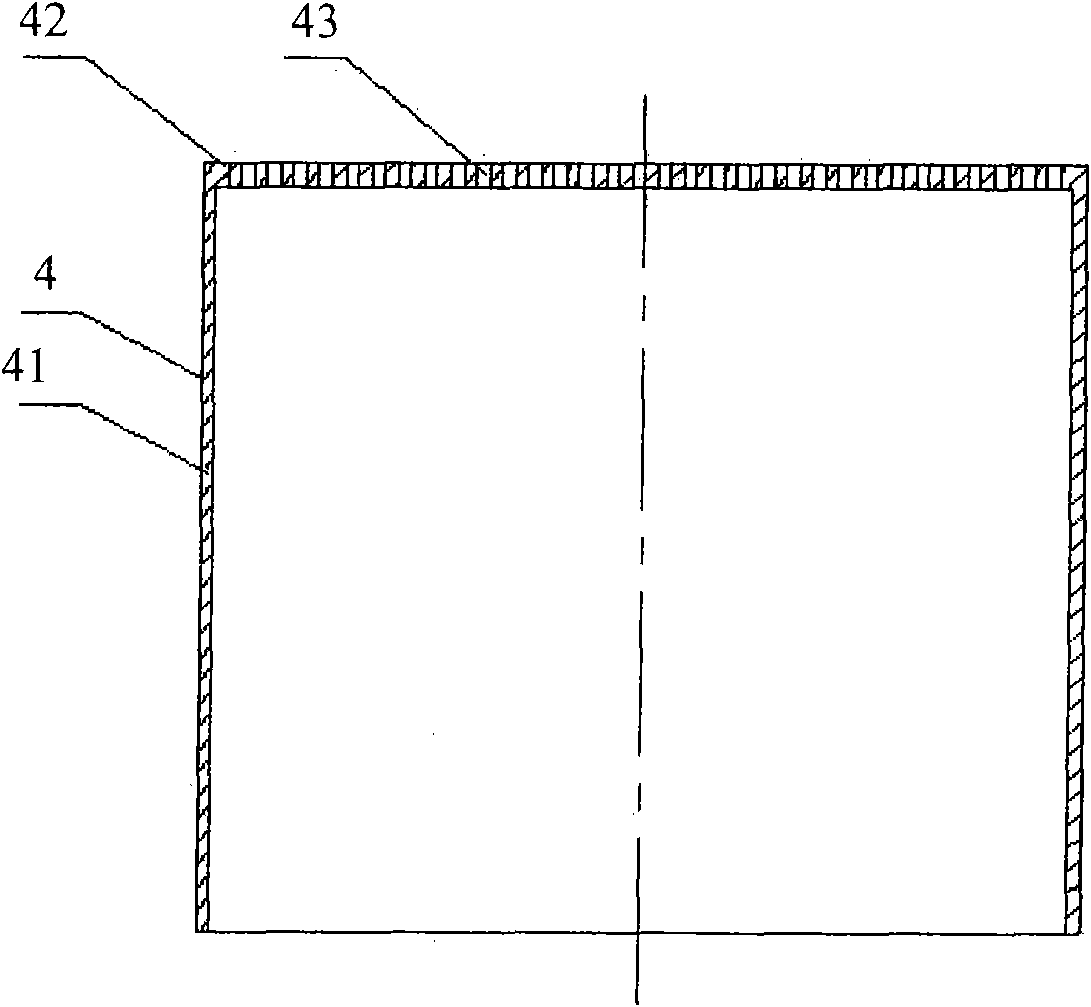

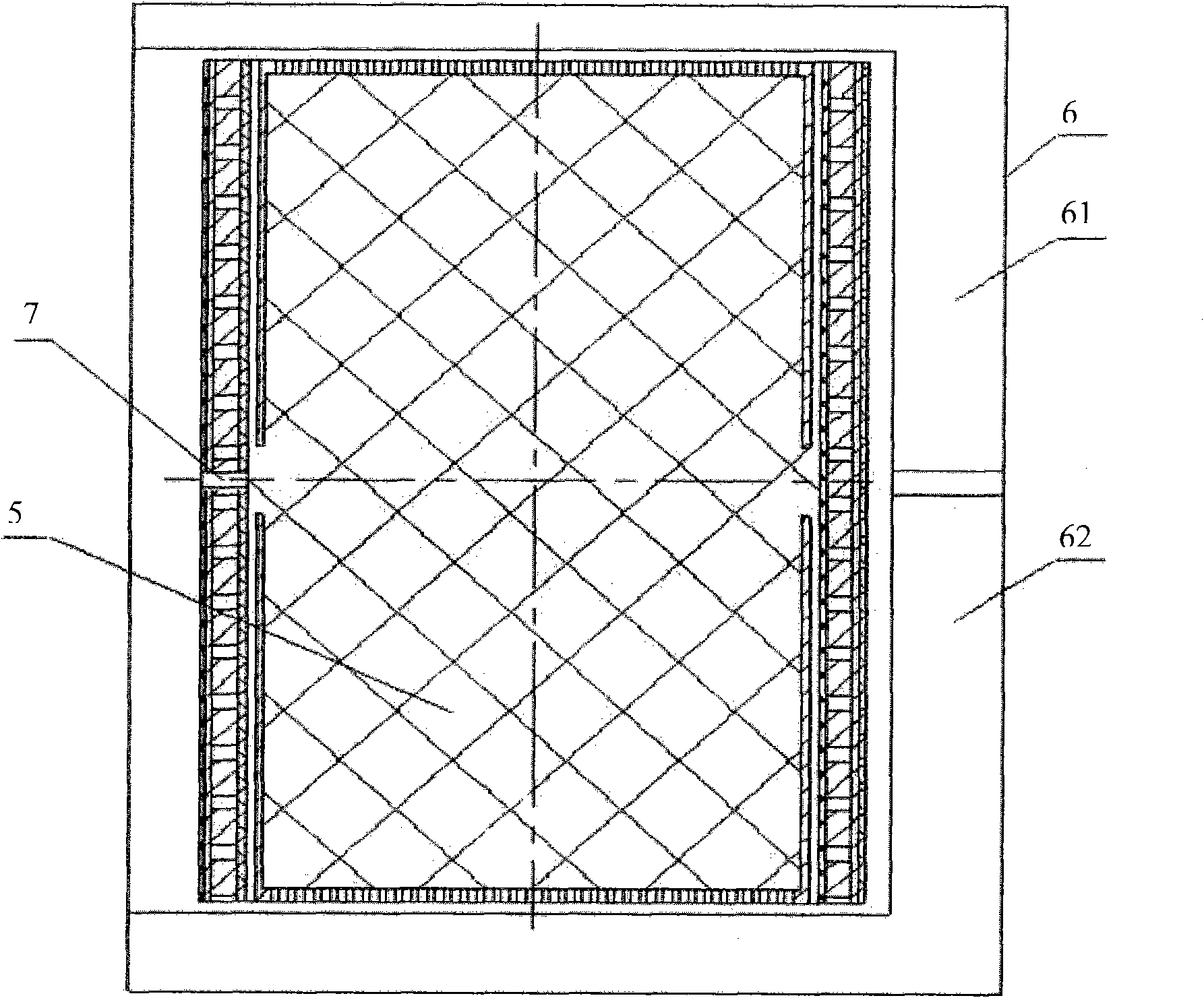

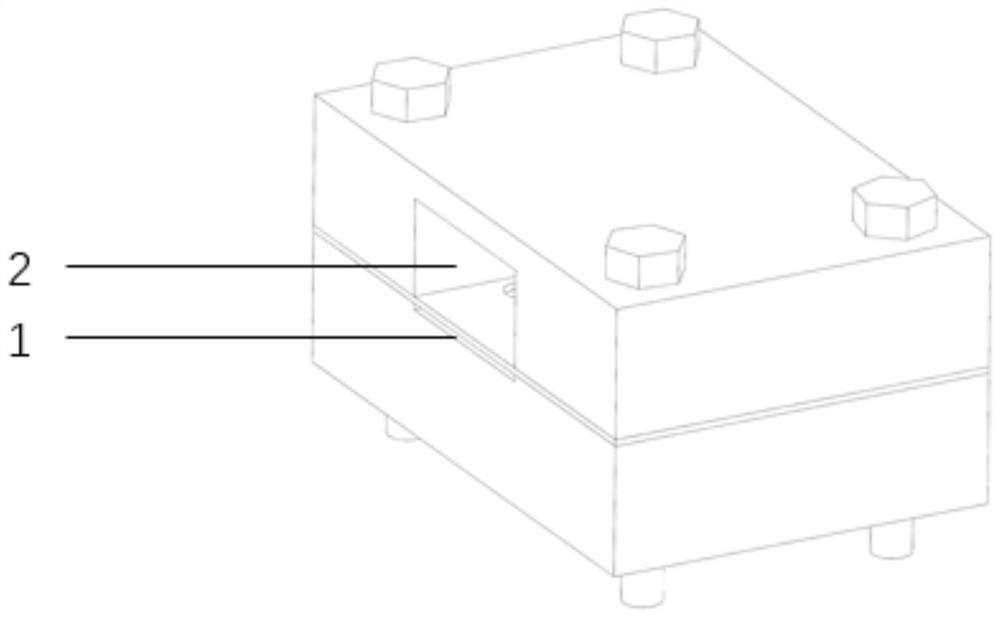

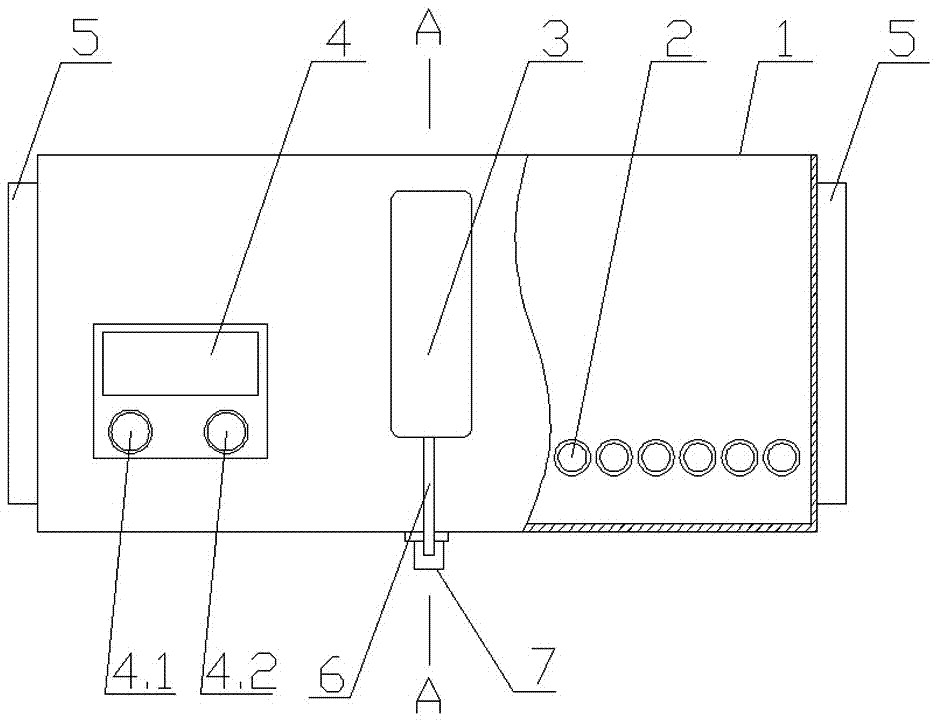

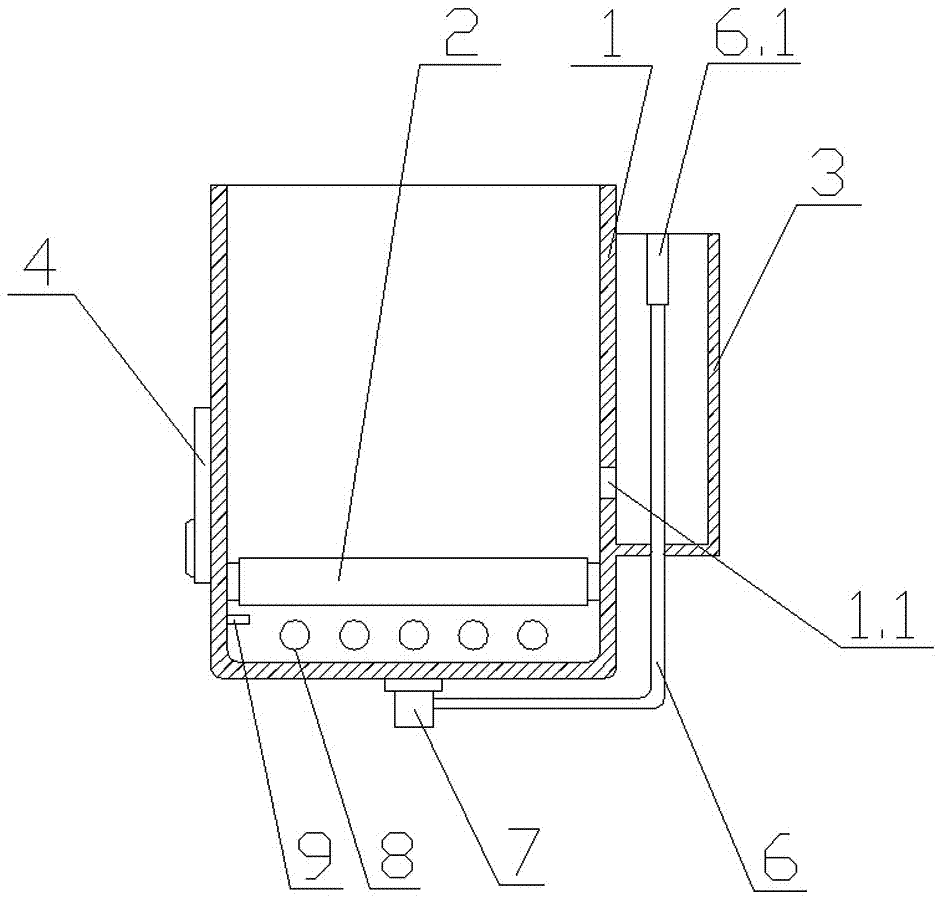

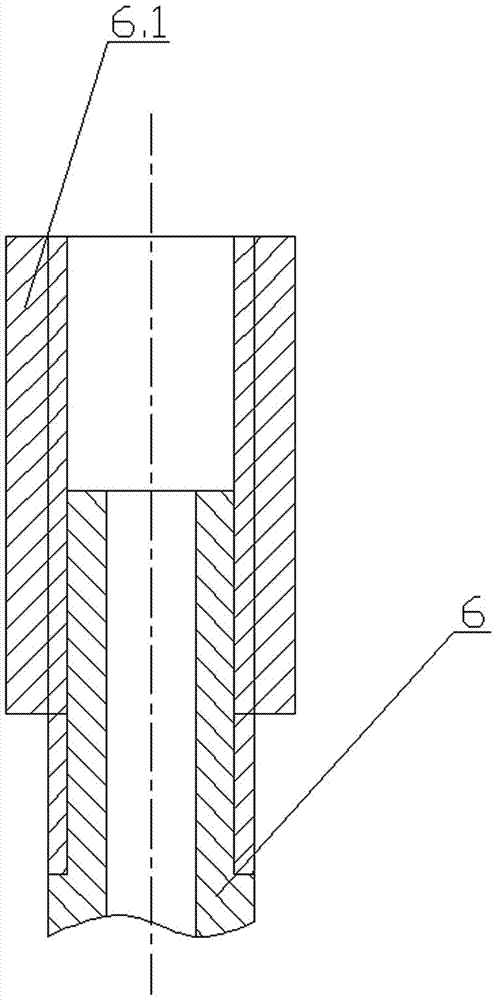

All-in-one machine for polymer lithium battery with functions of formation and capacity grading

PendingCN106129449AGood process continuityGood effectAssembling battery machinesFinal product manufactureCell assemblyManipulator

The invention discloses an all-in-one machine for a polymer lithium battery with functions of formation and capacity grading. The all-in-one machine comprises a cell assembly line, wherein a cell elastic clamp which is fully loaded with cells; a formation and capacity-grading apparatus is arranged on one side of the cell assembly line; the formation and capacity-grading apparatus comprises a material-feeding mechanical arm bracket and a material-discharging mechanical arm bracket; a material-feeding material-waiting frame, a material-discharging material-waiting frame, a group of formation clamps and multiple capacity-grading clamps are arranged in the material-feeding mechanical arm bracket and the material-discharging mechanical arm bracket; the material-feeding material-waiting frame, the material-discharging material-waiting frame, the group of formation clamps and the multiple capacity-grading clamps are arranged in sequence from one side to the other side; a material-feeding mechanism and a material-discharging mechanism are arranged between the material-feeding material-waiting frame and the cell assembly line; the material-feeding mechanism and the material-discharging mechanism are positioned on the front and back sides respectively; and material-moving mechanical arms are arranged on the material-feeding mechanical arm bracket and the material-discharging mechanical arm bracket. The all-in-one machine for the polymer lithium battery with the functions of formation and capacity grading has the advantages of high continuity of capacity-grading processes, high degree of automation, high efficiency, good formation effect, high product quality and the like.

Owner:东莞德方智能装备中心(有限合伙)

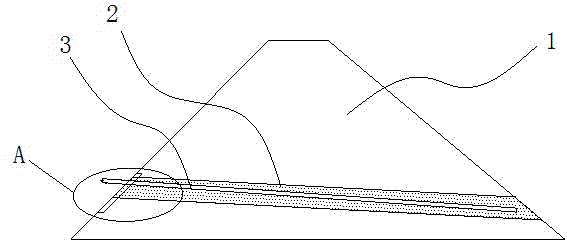

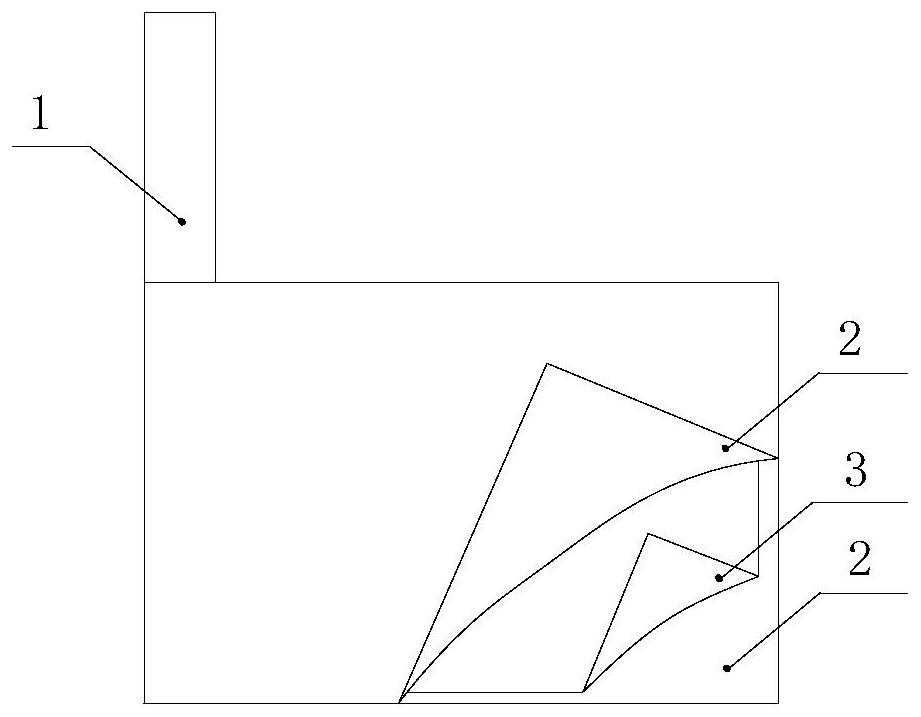

Earth and rockfill dam for simulating piping dam break test

The invention relates to an earth and rockfill dam for simulating a piping dam break test. The earth and rockfill dam comprises a dam body which is built by rock materials, wherein a weak layer capable of generating a piping channel is laid at a set position of the dam body according to the test requirement; a water pipe which penetrates through the dam body is arranged in the weak layer; through holes which are distributed along the axial direction at intervals are formed in a pipe wall of the water pipe; and the water pipe which is positioned at the upstream end of the dam body is provided with a valve. During test, water is injected into the water pipe so as to wash the weak layer, so that the formation of piping channel inside the dam body is simulated and accelerated. The field piping test development time can be controlled, and the phenomena that the field test fails even an unexpected sudden dam break event occurs and losses of life and property are caused because the piping channel formation time cannot be controlled are avoided.

Owner:NANJING HYDRAULIC RES INST

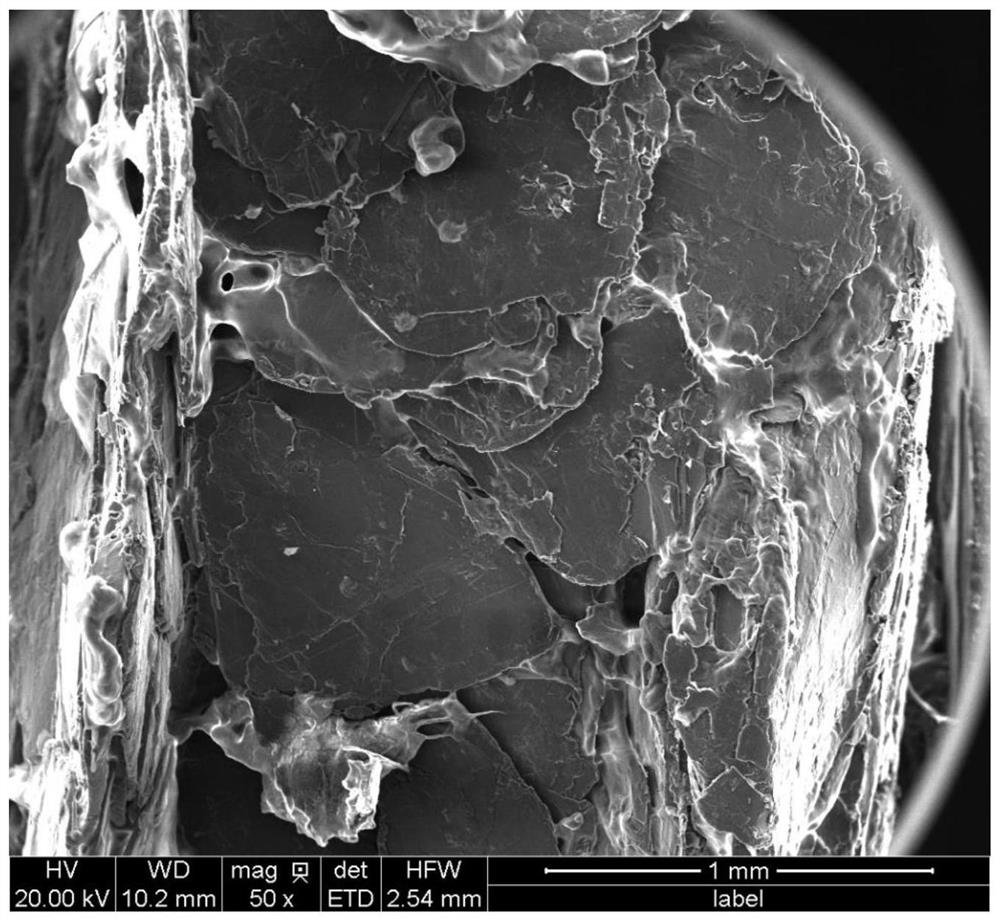

Device of titanium metal wire net cage compounded with titanium metal wire engineering bone and preparation method thereof

ActiveCN102085123ALightweight yet strongExuberant formationBone implantCoatingsTitanium metalInvestment material

The invention provides a device of a titanium metal wire net cage compounded with a titanium metal wire engineering bone and a preparation method thereof, and the device of the titanium metal wire net cage compounded with the titanium metal wire engineering bone comprises a piston type titanium metal wire net cage and a titanium metal wire engineering bone composite filled in the piston type titanium metal wire net cage; and the preparation method comprises the following steps: winding titanium metal wire non-woven fabric on the outer wall of a titanium metal cage body and sintering for preparing a titanium metal wire net cage body, then coating hydroxyapatite on the inner surface and the outer surface of the cage body, and then placing two piston type cap-shaped bodies in an inner cavityof the metal cage body for getting the piston type titanium metal wire net cage; and further uniformly mixing titanium metal wires, a morselized bone, a binding material and auxiliary materials, and filling into the piston type titanium metal wire net cage. The device has good elastic modulus coordination and high strength, and can be used in the field of bone surgery.

Owner:HARBIN MEDICAL UNIVERSITY

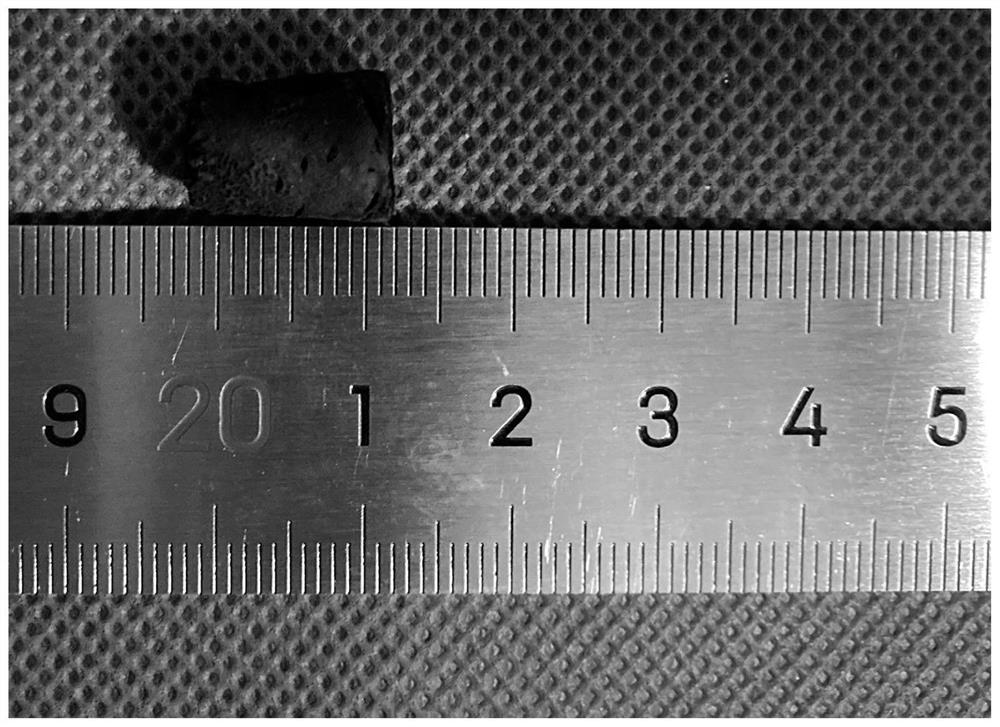

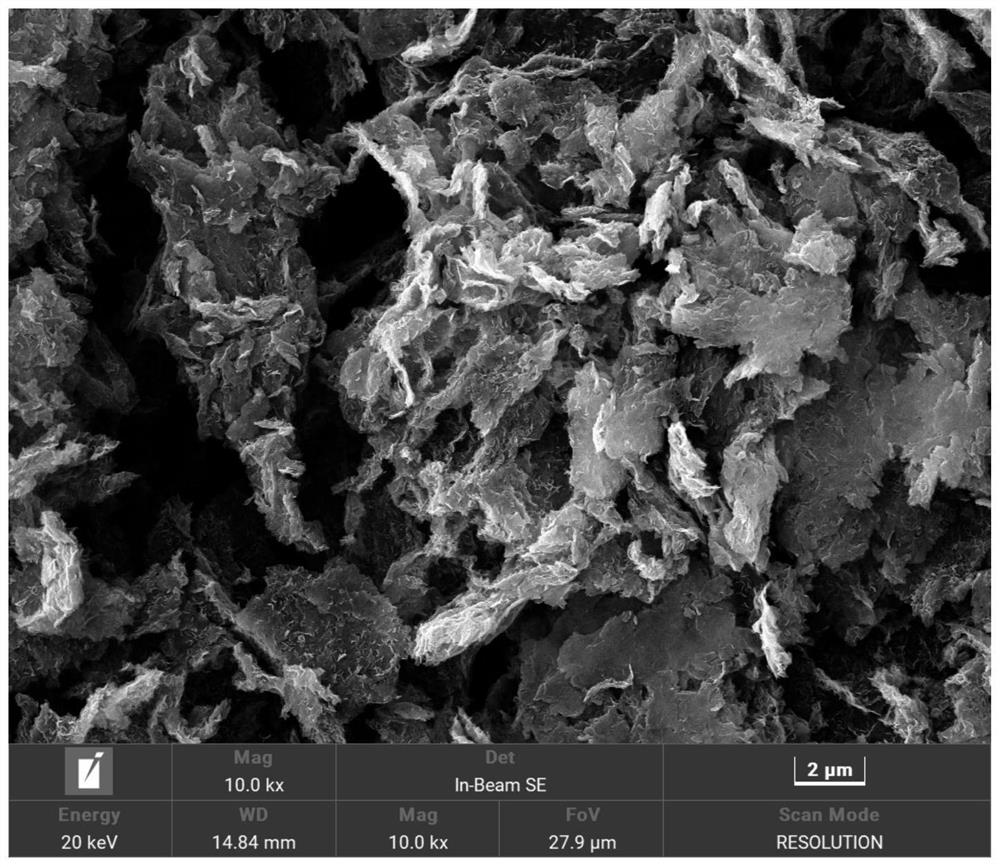

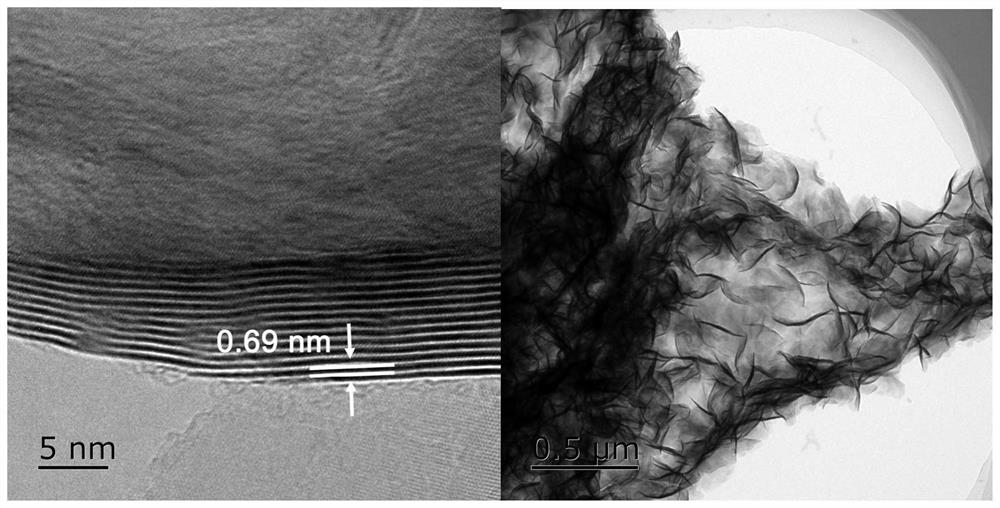

Preparation method and application of graphene hollow carbon nanocages

The invention discloses a preparation method and application of graphene hollow carbon nanocages. The preparation method comprises the following steps: by using crop waste as a solid-phase carbon source and transition metal acetate as a catalyst precursor, putting the solid-phase carbon source on the lower layer of the crucible, putting the catalyst precursor on the upper layer of the crucible to perform covering heat treatment, collecting the upper layer product, and carrying out acid treatment, washing, filtration and drying on the graphene hollow carbon nano cage material. The mass ratio of the solid-phase carbon source to the catalyst precursor is 1:(0.1-0.5); and the acid treatment is implemented by immersing the upper product in 8-12 mol / L hydrochloric acid for 1-3 hours. The method is used for large-scale preparation of the graphene nanocages by using the chemical-vapor-deposition-like technique based on cheap solid-phase carbon source, covering heat treatment and carbonous atmosphere self supply, solves the problems of expensive raw materials, complex equipment, complex operation, difficulty in mass production and the like at present, and is simple, convenient and efficient.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Preparation method of titanium-base titanium oxide-silver chloride composite coating material

InactiveCN103628112AMake sure to formLong-term antimicrobial stabilitySurface reaction electrolytic coatingTio2 nanotubeTitanium alloy

The invention relates to a preparation method of a titanium-base titanium oxide-silver chloride composite coating material, which is characterized by comprising the following steps: by using titanium or titanium alloy Ti6Al4V as an anode, graphite flakes as a cathode and a 10-30 wt% sodium chloride HF solution as an electrolyte in which the HF concentration is 0.1-0.7 wt%, carrying out electrolytic oxidation on the anode titanium to form a chloridion-containing titanium oxide nanotube array on the surface; by using silver nitrate as an immersion solution, immersing the titanium-base titanium oxide nanotube array in the silver nitrate solution, taking out, and carrying out heat treatment to further cure the silver chloride formed in the tube cavity until the titanium oxide nanotube array structure slumps and the crystalline phase structure is converted into an anatase / rutile mixed type, thereby obtaining the titanium oxide-silver chloride composite coating material with antibacterial property and bioactivity. The invention aims to provide a preparation method for preparing a titanium-base titanium oxide-silver chloride composite coating material with antibacterial property and bioactivity on a titanium alloy surface at low cost without expensive equipment.

Owner:INNER MONGOLIA METAL MATERIAL RES INST

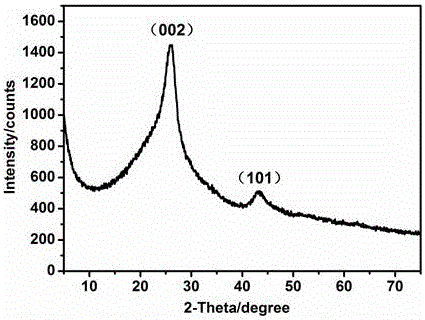

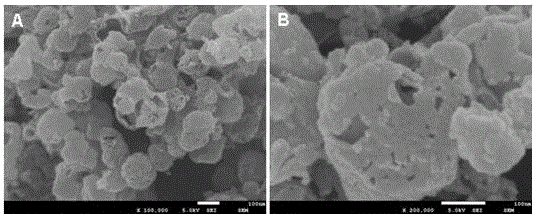

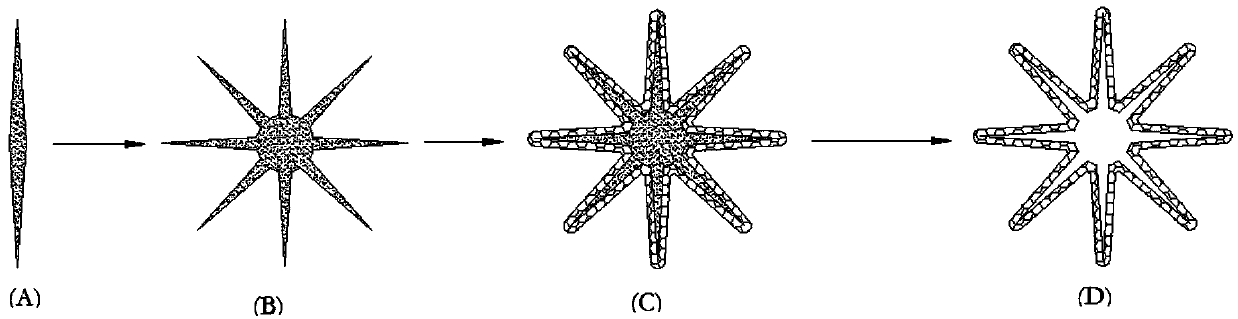

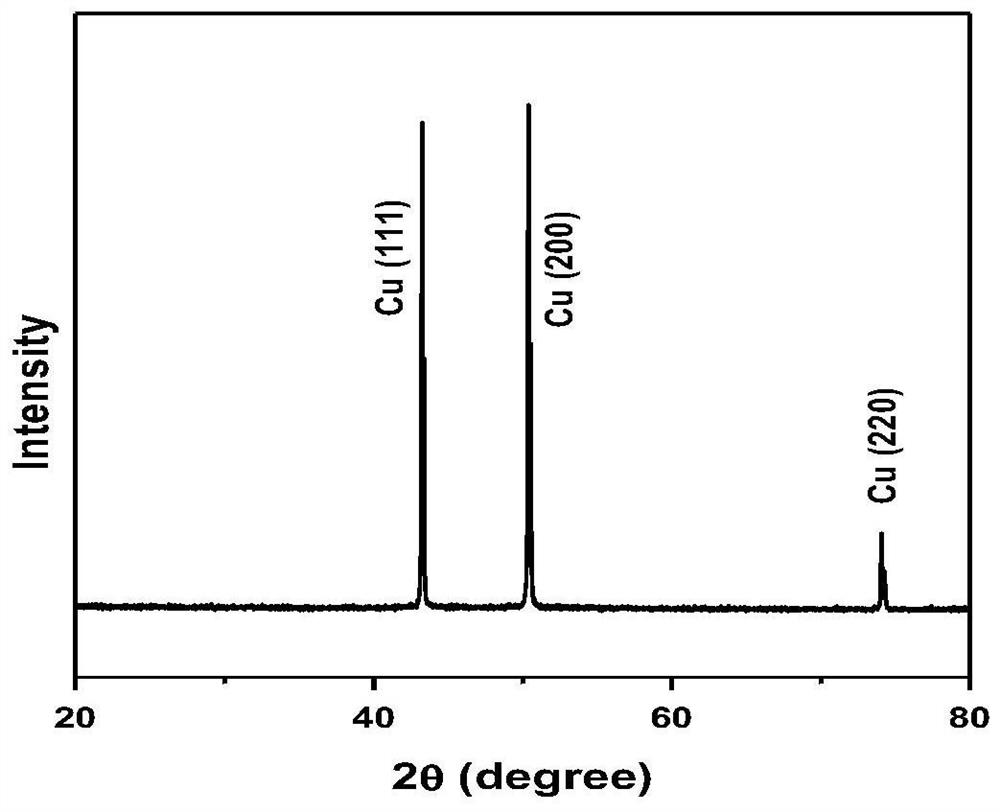

Urchin-like graphene and preparation method thereof

ActiveCN109650381AMake sure to formEnsuring the 3D sea urchin shapeGrapheneCvd grapheneSelf-assembly

The invention discloses urchin-like graphene and a preparation method thereof, and relates to the field of graphene material preparation. The method includes the steps that a nickel salt and a reducing agent react under the alkaline condition, and an urchin-like three-dimensional nickel substrate is formed through self-assembly; graphene is deposited on the urchin-like three-dimensional nickel substrate with the chemical vapor deposition technology; acid is added to remove the nickel substrate, and then the urchin-like three-dimensional graphene is obtained. The urchin-like three-dimensional graphene has a good dispersing type, and the problems of stacking, porosity, unstable structure and the like are effectively prevented. The preparation process is simple, the condition is mild, the rawmaterial source is wide, and the urchin-like graphene is suitable for mass production and has broad application prospects.

Owner:湖南医家智烯新材料科技有限公司

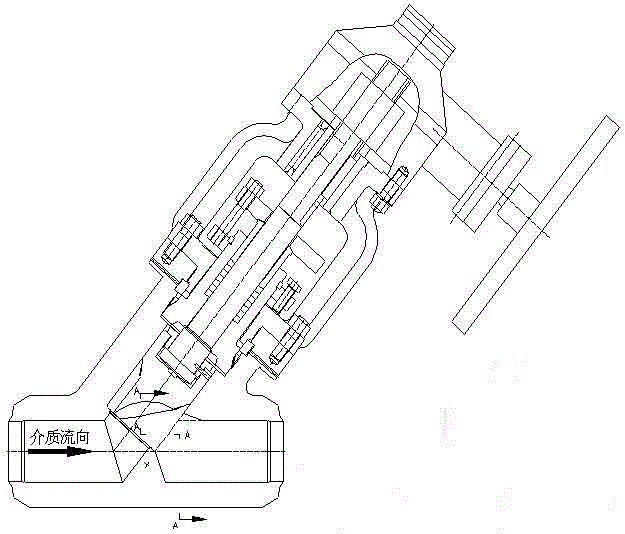

Energy-saving and low-flow-resistance Y-type shutoff valve

The invention discloses an energy-saving and low-flow-resistance Y-type shutoff valve, which comprises a valve body, a valve clack, a valve rod, a valve rod guide device, a valve clack locating pin and an upper seal of a valve cover. The end face of the valve clack is of a concave arc shape, and when the valve clack is in a fully-open state, the concave arc of the end face of the valve clack is of a shape, which forms an overall arc in a manner of being matched with a flow path where the end face of the valve clack is located. The energy-saving and low-flow-resistance Y-type shutoff valve is reasonable in structure, the valve clack is matched with the valve body, when the valve is fully opened, the entrance of the valve clack and a valve seat hole form a matched and smooth curved surface, the exit of the valve clack and a through hole of the valve body form a matched and smooth channel, and the moving direction and the position of the valve clack are determined through the combination of parts, such as the valve body, the valve rod, the valve clack, an upper seal seat, and the guide of the valve clack and the valve rod, so that the correct position of the valve clack is ensured when the valve clack is opened, the forming of a matched flow line of the valve body and the valve clack is ensured, and the effects of energy saving and consumption reducing are reached.

Owner:NANTONG HIGH & HIGH PRESSURE VALVE CO LTD

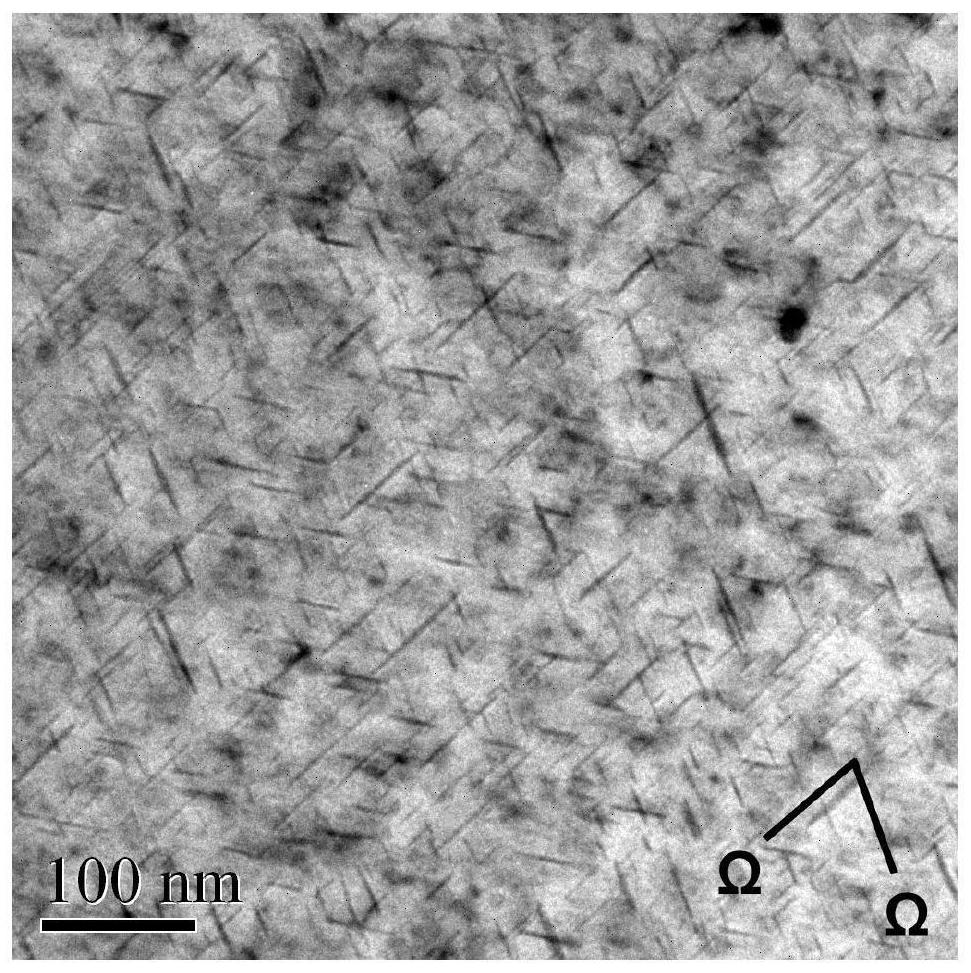

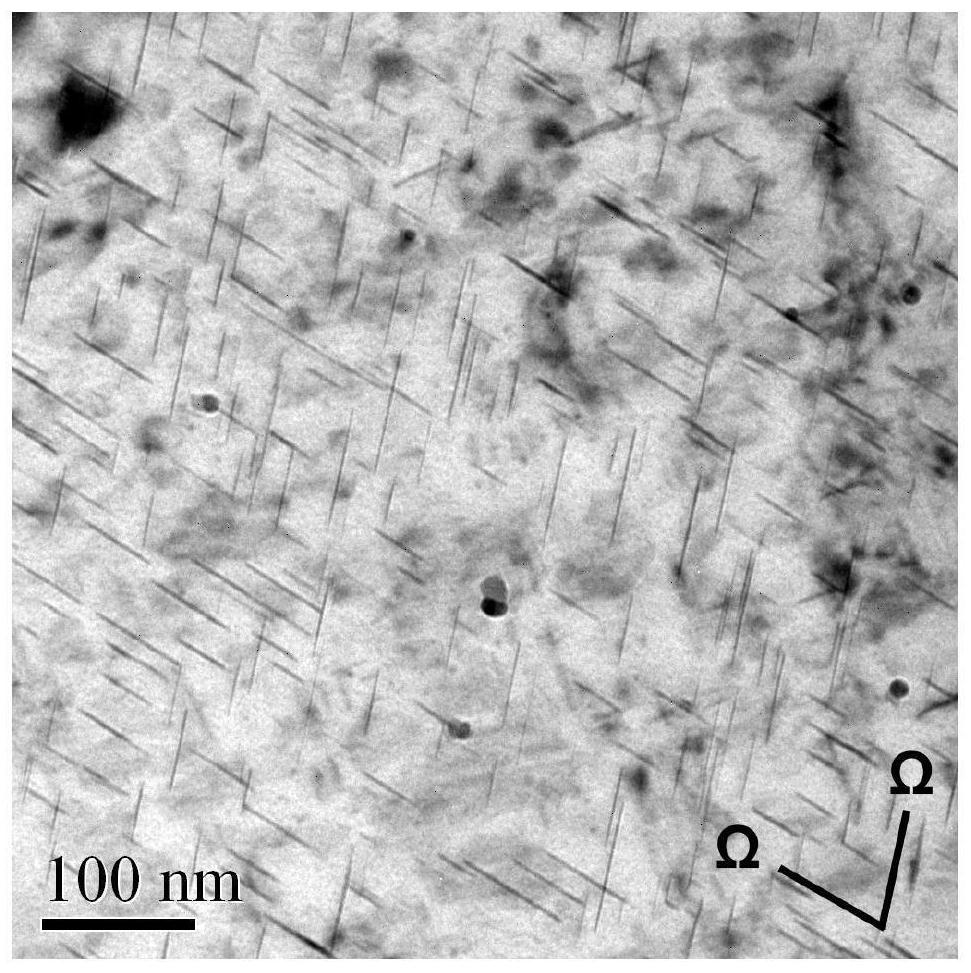

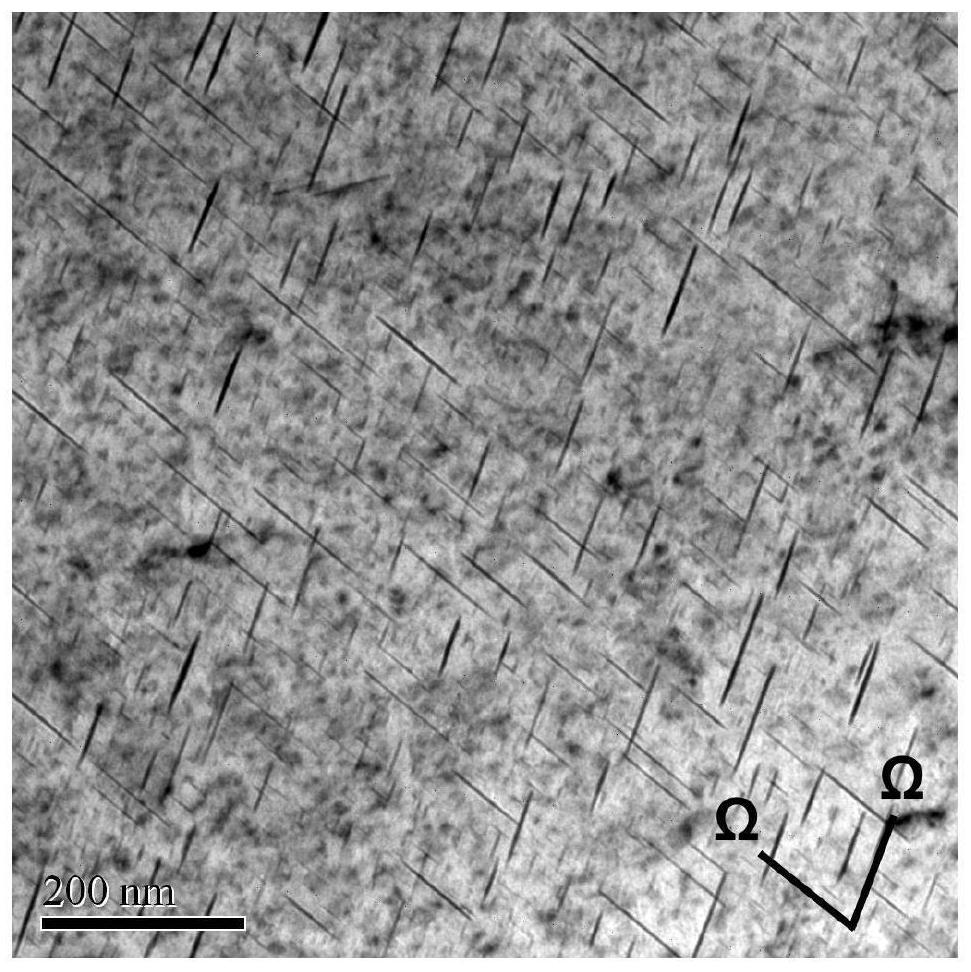

Heat treatment method for improving high-temperature endurance performance of deformed aluminum-copper-magnesium-silver alloy

InactiveCN112662969AExcellent high temperature durabilitySimple heat treatment processAg alloyMagnesium

The invention belongs to the technical field of metal material treatment, and particularly relates to a heat treatment method for improving the high-temperature endurance performance of a deformed aluminum-copper-magnesium-silver alloy. The heat treatment method comprises the steps that S1, the aluminum-copper-magnesium-silver alloy is subjected to solid solution and quenching treatment, and then artificial aging treatment is conducted for 0-1h; and S2, the aluminum-copper-magnesium-silver alloy material treated in the step S1 is subjected to tensile deformation treatment and then subjected to artificial aging treatment for 1-8h, and the deformed aluminum-copper-magnesium-silver alloy with excellent high-temperature endurance performance is obtained. According to the method, the stable formation of the heat-resistant omega phase or the precursor thereof is ensured through short-time artificial aging in advance, so that the heat-resistant omega phase or the precursor thereof can still exist stably after deformation treatment, the mass formation of the heat-resistant omega phase in the subsequent artificial aging process is promoted, and the excellent long-time high-temperature endurance property of the shape-variable alloy is ensured.

Owner:CENT SOUTH UNIV

Light-weight heat-insulating material taking granite waste as raw material and preparation method thereof

InactiveCN103396153AWide variety of sourcesAvoid pollutionSolid waste disposalCeramicwareSodium sulfateBall mill

The invention relates to a light-weight heat-insulating material taking granite waste as a raw material and preparation method thereof. The technical scheme comprises the following steps: mixing 50-65wt% of granite waste fine powder, 10-20wt% of chunk glass powder, 1-5wt% of limestone powder, 5-13wt% of potassium chloride, 5-15wt% of sodium chloride used as raw materials; performing heat treatment at 800-1200 DEG C for 0.5-2 hours, and grounding until the particle size is less than 0.045mm; adding limestone powder, industrial sodium carbonate, white carbon black and sodium sulfate which respectively account for 0.5-3wt%, 5-10wt%, 1-5wt% and 1-10wt% of the raw materials into the ground material, and performing ball milling for 2-5 hours; and adding water which accounts for 3-10wt% of the raw materials into the ball milled material, stirring, pressing into a blank, drying, performing heat treatment at 800-1200 DEG C for 2-5 hours, naturally cooling, soaking with water, and drying at 80-110 DEG C, thus preparing the light-weight heat-insulating material taking granite waste as a raw material. The invention is simple in process, low in production cost, beneficial to comprehensive utilization of resources and friendly to environment; and the product is low in volume density, low in heat conductivity coefficient and high in compression strength.

Owner:WUHAN UNIV OF SCI & TECH

Large medical apparatus aluminium alloy casting stable filling method

ActiveCN101380672AThe filling process is stableReduce washoutMolten metal pouring equipmentsMolten metal conveying equipmentsSlagOxide

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD

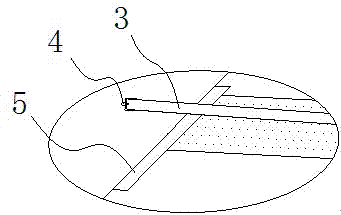

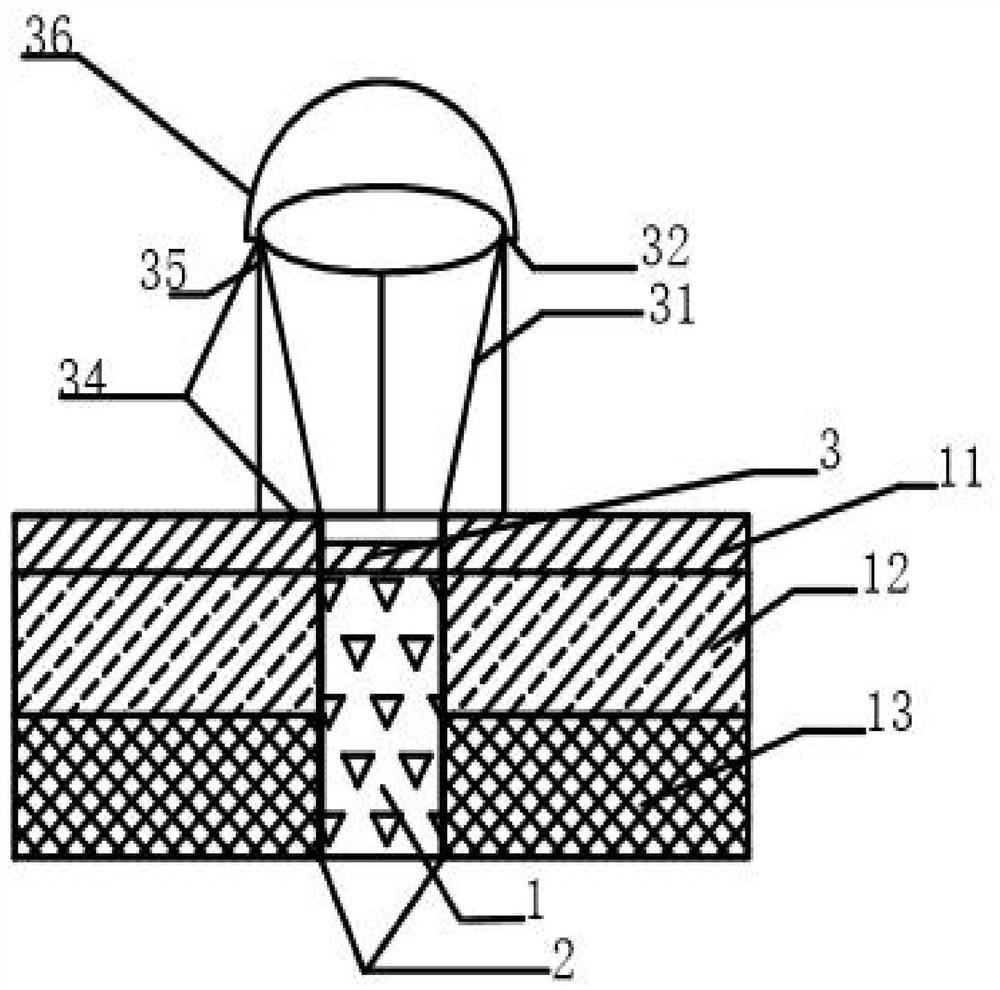

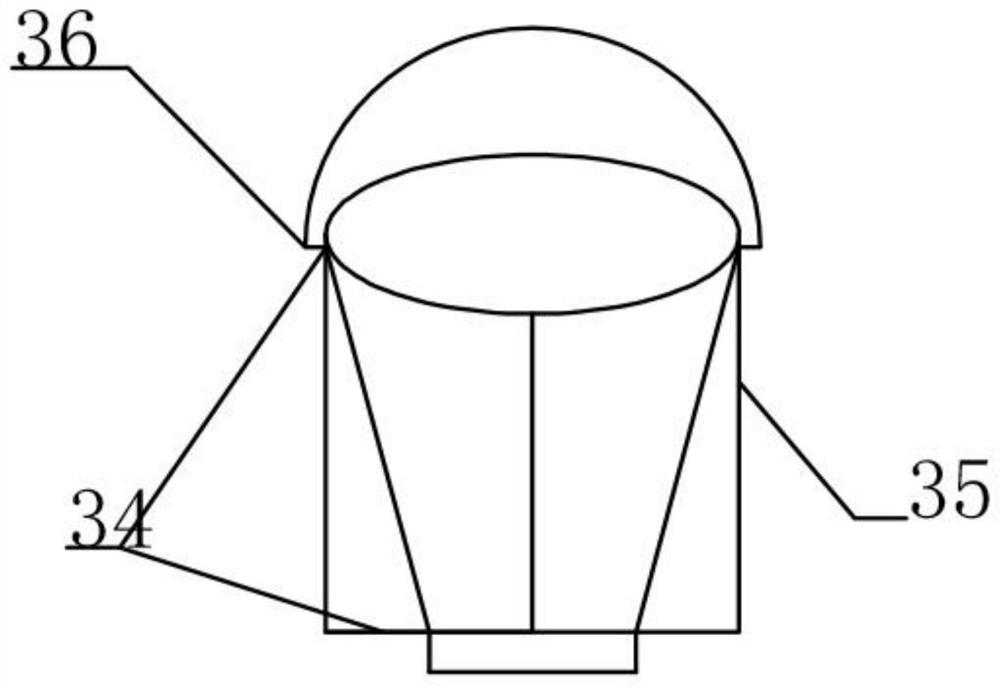

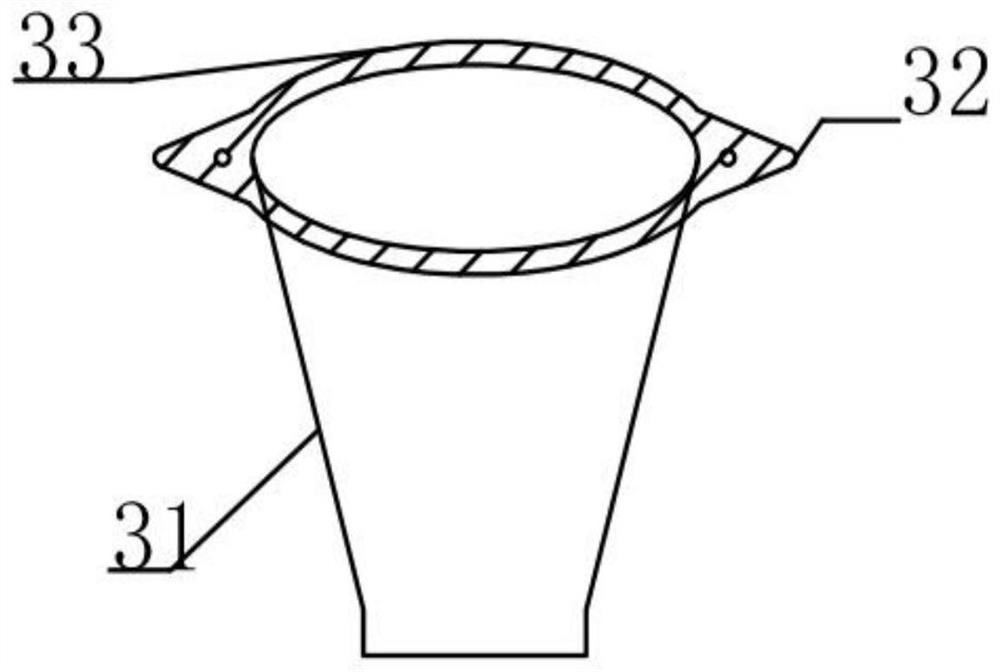

Filling material, equipment and method for bituminous pavement coring test hole

InactiveCN112663463AExtended service lifeImprove performanceRoads maintainenceSocial benefitsPavement engineering

The invention provides a filling material for a bituminous pavement coring test hole, and particularly relates to the technical field of pavement engineering repair. A test hole filling material, a funnel and a tamping rod are included. The test hole filling material is super-toughness quick-setting cement concrete, the test hole filling material is prepared by mixing aggregate, yellow sand, cement, rubber particles, water, an early strength agent and an expanding agent in proportion, a fixing frame is arranged on the funnel, the upper end of the fixing frame is connected with the outer side wall of the funnel, and a handle is arranged on the fixing frame. According to the filling material, equipment and method for the bituminous pavement coring test hole, a test hole filling operation behavior is standardized, and early-stage pavement diseases caused by a test hole filling link are avoided so that the comprehensive performance of a bituminous pavement is improved, the service life of the bituminous pavement is prolonged, and remarkable economic benefits and social benefits are generated.

Owner:JIANGSU MODERN ROAD & BRIDGE +1

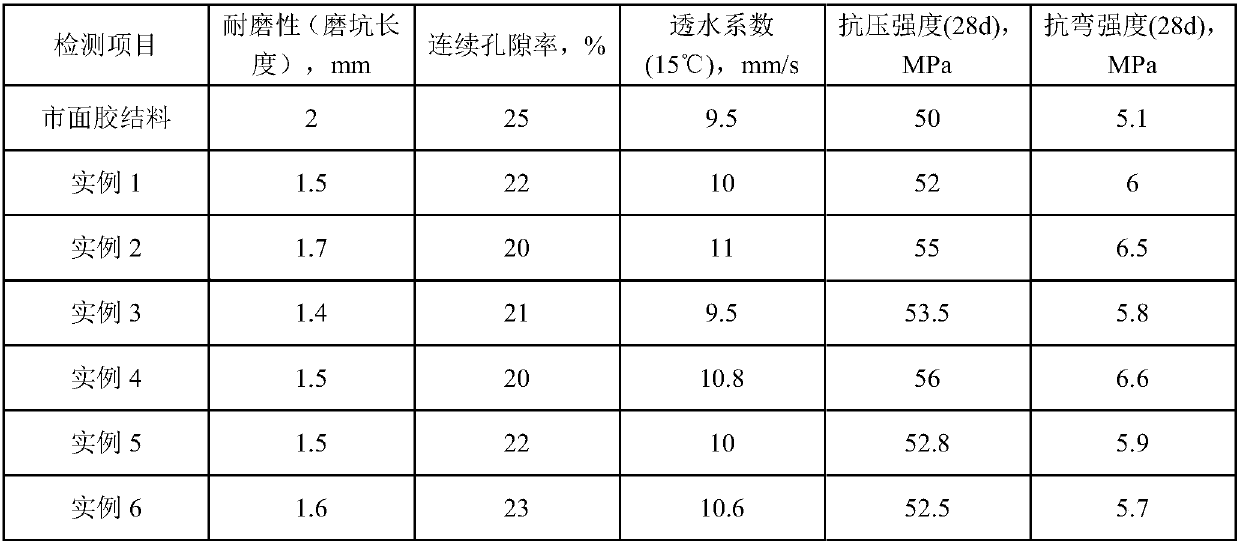

Erosion-resistant water-permeable concrete cementing material

The invention provides an erosion-resistant water-permeable concrete cementing material, made with, by weight, 30-50% of ordinary Portland cement, 10-20% of high-iron calcium aluminate cement, 10-25%of superfine mineral powder, 10-20% of metallic sulfates, 0.5-2.5% of a water-soluble flocculant, 1-5% of a water-absorbing expandable inorganic material, 0.5-2.0% of polycarboxylate superplasticizerpowder, 0.2-0.5% of amino-sulfonate superplasticizer powder, 0.1-0.5% of a wetting agent, 2-7% of a metallic soap waterproof agent and 0.2-0.8% of oil-modifying hydrophobing agent, wherein the high-iron calcium aluminate cement coordinates with the metallic sulfates, the superfine mineral powder and ordinary Portland cement to improve strength of concrete; the water-absorbing expandable inorganicmaterial, the water-soluble flocculant and the wetting agent improve wrapping property and water-holding property of concrete; the polycarboxylate superplasticizer powder, the amino-sulfonate superplasticizer powder and the metallic soap waterproof agent ensure low slump and mobility of the concrete; the metallic soap waterproof agent and the oil-modifying hydrophobing agent can improve lubricating degree of inner and outer surface structures of a cement binding material.

Owner:武汉市恒星防水材料有限公司

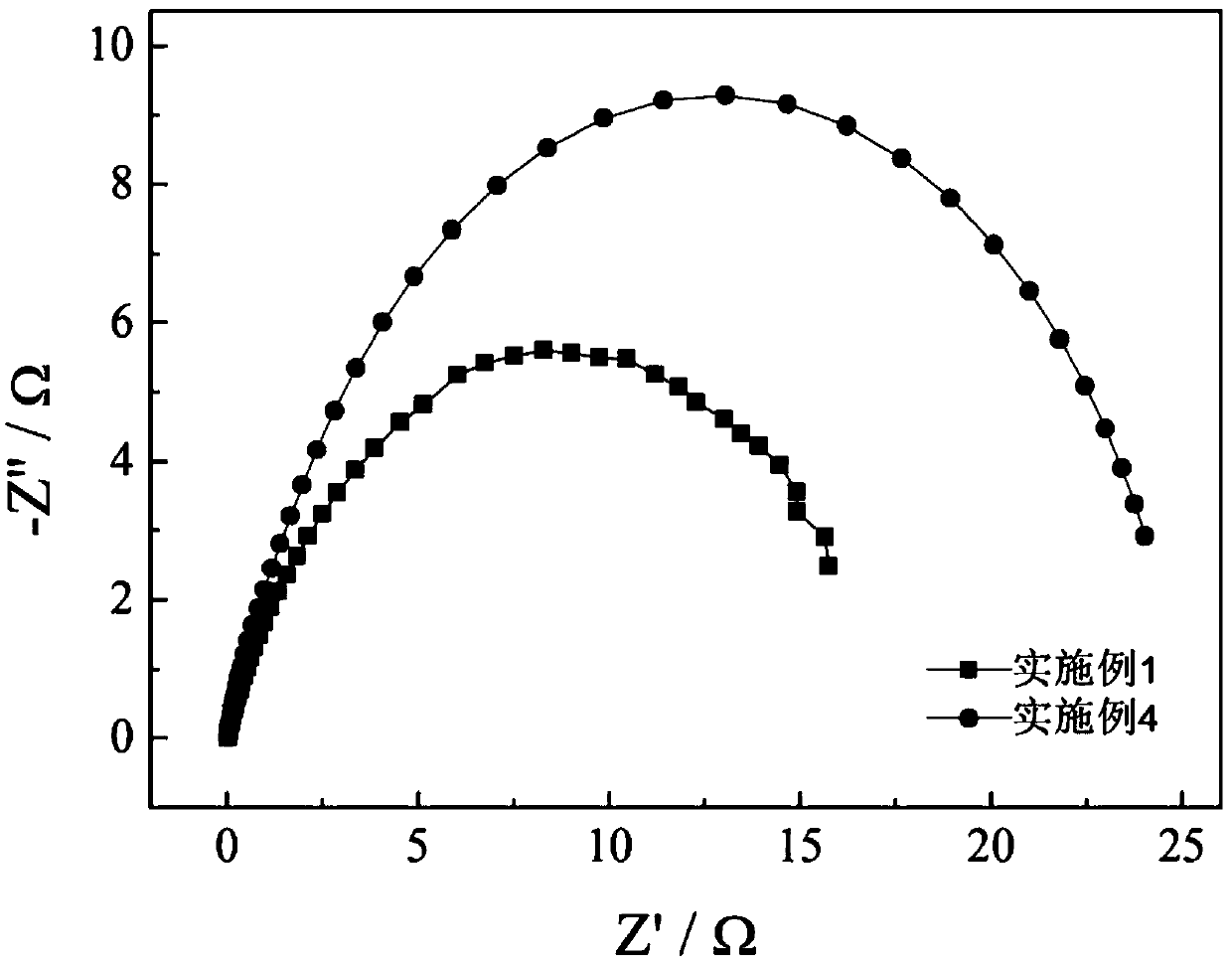

Metal phase layered molybdenum disulfide/reduced graphene oxide composite catalyst carrier and preparation method thereof

PendingCN114505081AHigh catalytic activityHigh activityCatalyst carriersPtru catalystPhysical chemistry

The invention discloses a metal phase layered molybdenum disulfide / reduced graphene oxide composite catalyst carrier and a preparation method thereof.The preparation method comprises the steps that graphene oxide dispersion liquid, sulfur-doped reduced graphene oxide hydrogel and sulfur-doped reduced graphene oxide aerogel are prepared in sequence; and mixing the aerogel with a sulfur source and a molybdenum source at 150-180 DEG C for reaction to obtain the metal phase layered molybdenum disulfide / reduced graphene oxide composite catalyst carrier. According to the preparation method, the anchoring effect of reduced graphene oxide on molybdenum disulfide is improved through sulfur doping, the molybdenum disulfide exists in a metal phase instead of a conventional 2H phase, high conductivity of the catalyst carrier is guaranteed, the oxidation resistance of the catalyst carrier is enhanced through introduction of the metal phase molybdenum disulfide and the sulfur element, and the preparation method is suitable for industrial production. The composite catalyst carrier also has the advantages of large specific surface area, high catalytic activity and the like, and has a good application prospect.

Owner:NAT UNIV OF DEFENSE TECH

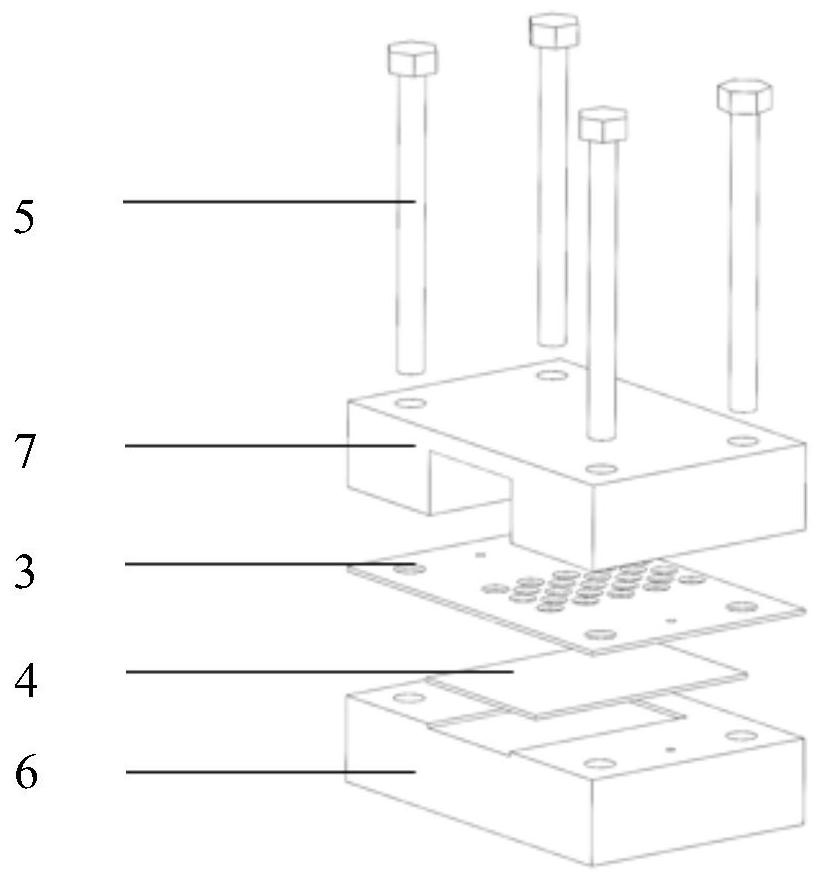

Method and mold for preparing heat-conducting gasket and obtained heat-conducting gasket

ActiveCN114369363AImprove thermal conductivityHigh thermal conductivityDomestic articlesPolymer sciencePolymer chemistry

The invention discloses a method and a mold for preparing a heat-conducting gasket and the obtained heat-conducting gasket. The heat-conducting gasket comprises a heat-conducting filler layer, the heat-conducting filler layer comprises granular heat-conducting filler; the adjacent heat-conducting fillers are in direct contact to form a continuous three-dimensional heat-conducting network containing internal gaps; internal gaps of the three-dimensional heat conduction network are filled with a high-molecular polymer. The heat-conducting gasket is obtained by prefabricating the three-dimensional heat-conducting network of the heat-conducting filler, simultaneously completing orientation of the anisotropic heat-conducting filler and then filling the prefabricated three-dimensional heat-conducting network with the glue, so that direct contact between the fillers is ensured, formation of a heat-conducting three-dimensional heat-conducting passage is ensured, and the heat conductivity coefficient of the heat-conducting gasket is effectively improved. The method is simple, low in cost and good in universality.

Owner:宁波材料所杭州湾研究院 +1

Nano-bubble generating device

ActiveCN112337327AWell mixedSimple structural designFlow mixersMixing methodsMicro nanoMechanical engineering

The invention relates to the technical field of nano-bubble generating devices, in particular to a nano-bubble generating device. According to the nano-bubble generating device, a columnar main body is sequentially provided with a first liquid through hole, a second liquid through hole, a third liquid through hole, a fourth liquid through hole and a fifth liquid through hole, wherein the first liquid through hole, the third liquid through hole and the fifth liquid through hole are each of a tapered conical structure, and the second liquid through hole and the fourth liquid through hole are each of a columnar structure; a first gas inlet channel communicating with the second liquid through hole and a second gas inlet channel communicating with the fourth liquid through hole are formed in the columnar main body; a gas-liquid cutting and mixing mechanism is arranged at the starting end of the second liquid through hole; and a gas-liquid baffling and dissolving mechanism is arranged in thefourth liquid through hole. According to the invention, air is cut at first, then water mist impact is conducted so as to form nano-bubbles with diameters of about 10 microns, and then bubbles whichenter later collide with the nano-bubbles with the diameters of 10 microns while being impacted by a water body, thereby forming a large number of micro-nano bubbles with diameters in a range of 3-6 microns.

Owner:威海金盛泰科技发展有限公司

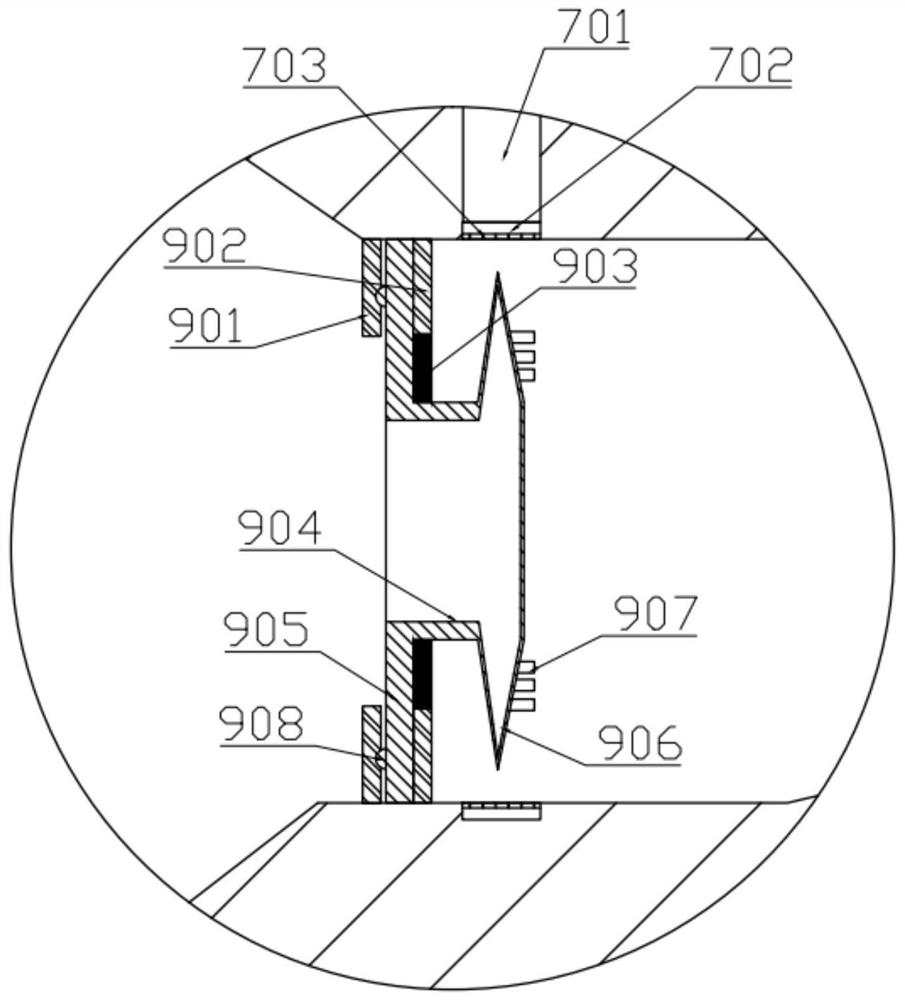

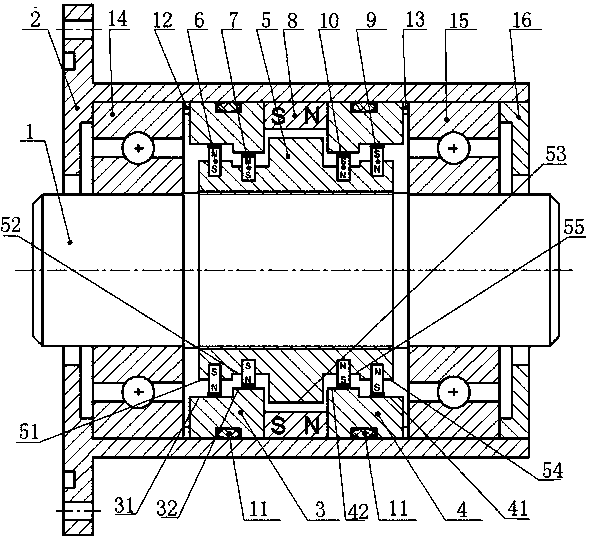

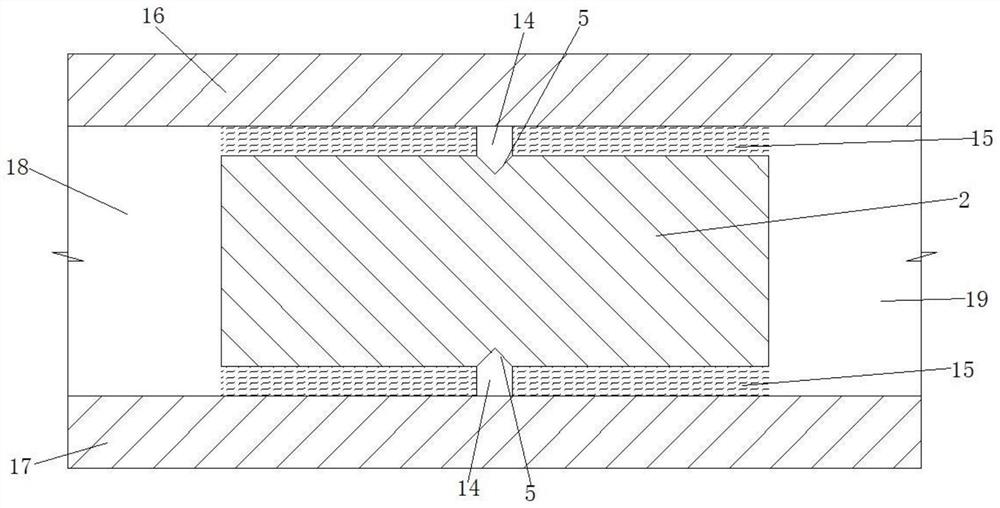

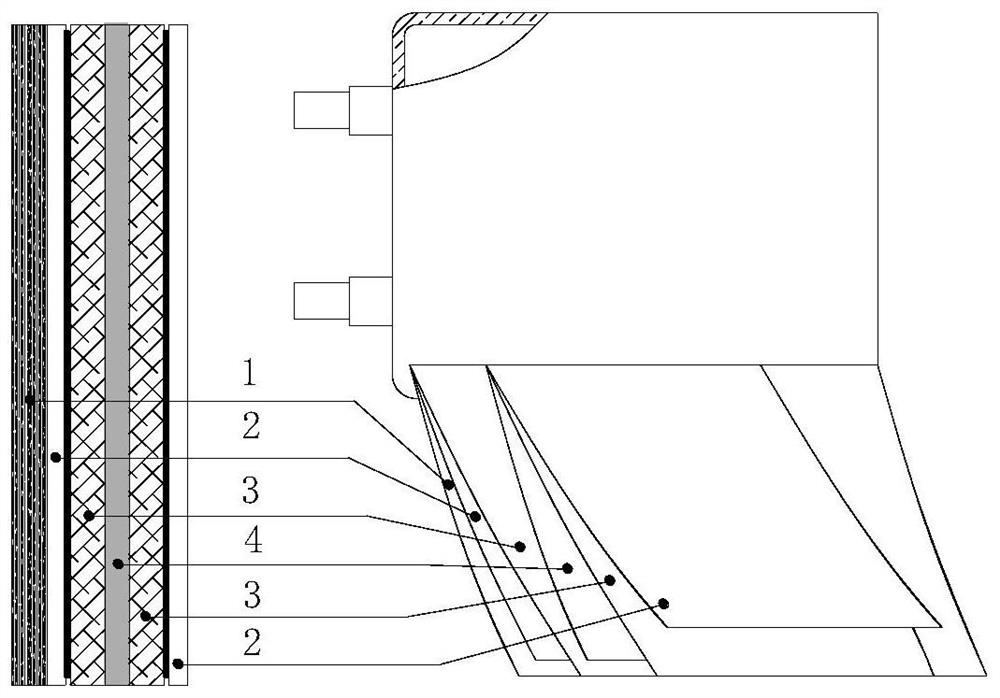

Multi-magnetic-resource sleeve type magnetofluid sealing device

ActiveCN108799507AImprove sealing pressure resistanceImprove self-healing abilityEngine sealsEngineeringMagnet

The invention relates to a multi-magnetic-resource sleeve type magnetofluid sealing device. The device comprises more than one magnetofluid sealing units, wherein each magnetofluid sealing unit comprises a housing, a left pole shoe ring, a right pole shoe ring, a sleeve, a first left permanent magnet ring, a second left permanent magnet ring, an intermediate permanent magnet ring, a first right permanent magnet ring and a second right permanent magnet ring. With the adoption of the device the problem of low pressure resistance of an existing single-magnetic-resource magnetofluid sealing devicecan be solved; in addition, the device is simple to process, and convenient to assemble, so that the sealing technology can be smoothly applied to the fields such as the field of high speed and heavyload.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

High-strength lightweight heat insulation material taking granite waste as raw material and preparation method thereof

InactiveCN103396152AWide variety of sourcesAddress pollution and waste of resourcesSolid waste disposalCeramicwareCarbide siliconSodium carbonate

The invention relates to a high-strength lightweight heat insulation material taking granite waste as a raw material and a preparation method thereof. The technical scheme is as follows: the high-strength lightweight heat insulation material taking the granite waste as the raw material is prepared by firstly taking 60-80wt% of granite waste fine powder, 13-25wt% of talcum powder, 1-5wt% of sodium chloride and 5-10wt% of industrial sodium carbonate as raw materials, uniformly mixing, performing heat treatment for 2-5h at the temperature of 800-1100 DEG C, and grinding to the particle size of less than 0.045mm so as to prepare a powder ground material; then adding 10-30wt% of alumina particles, 8-15wt% of quartz sand particles, 1-5wt% of limestone powder, 0.5-5wt% of silicon carbide powder, 1-10wt% of silicon micro-powder and 3-10wt% of water relative to the raw materials, and stirring to prepare a blank; and performing heat treatment on the blank after drying at the temperature of 600-900 DEG C for 0.5-5h, and further performing heat treatment at the temperature of 800-1200 DEG C for 0.5-5h. The high-strength lightweight heat insulation material provided by the invention has the characteristics of extensive raw material sources, simple process, low production cost and low firing temperature, is conductive to comprehensive utilization of resources and is environment-friendly; and the prepared high-strength lightweight heat insulation material has the advantages of small volume density, low heat conduction coefficient and high compressive strength.

Owner:WUHAN UNIV OF SCI & TECH

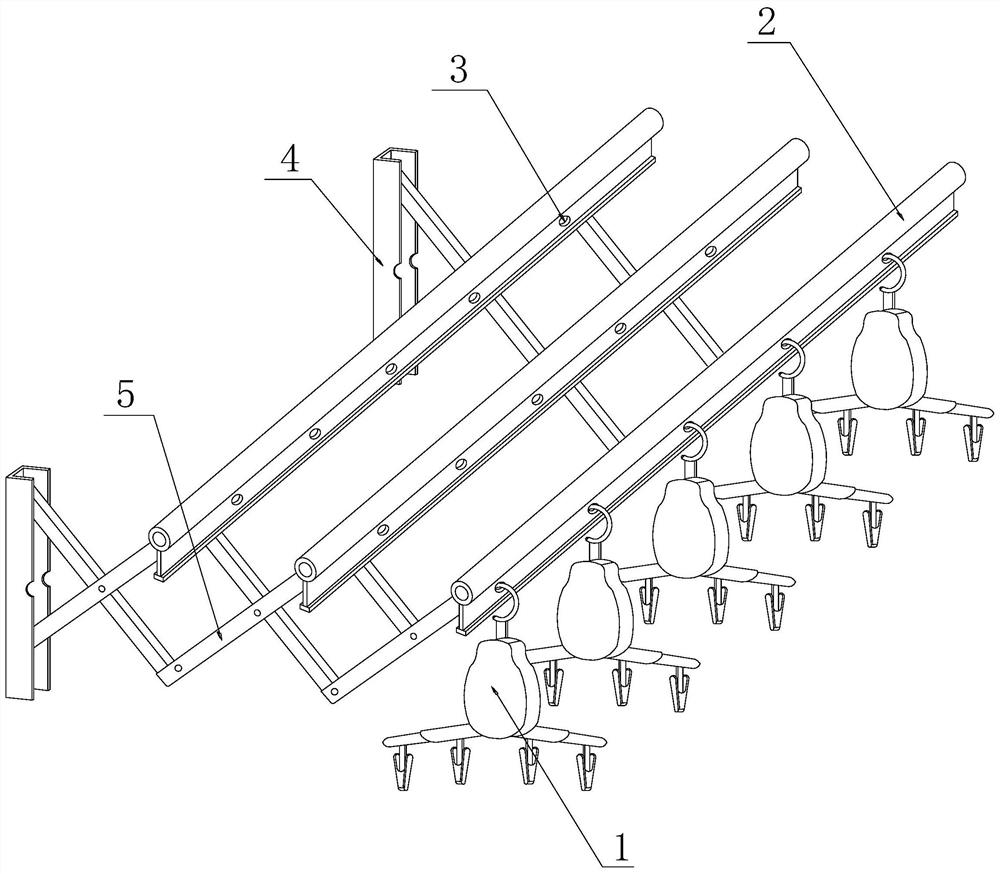

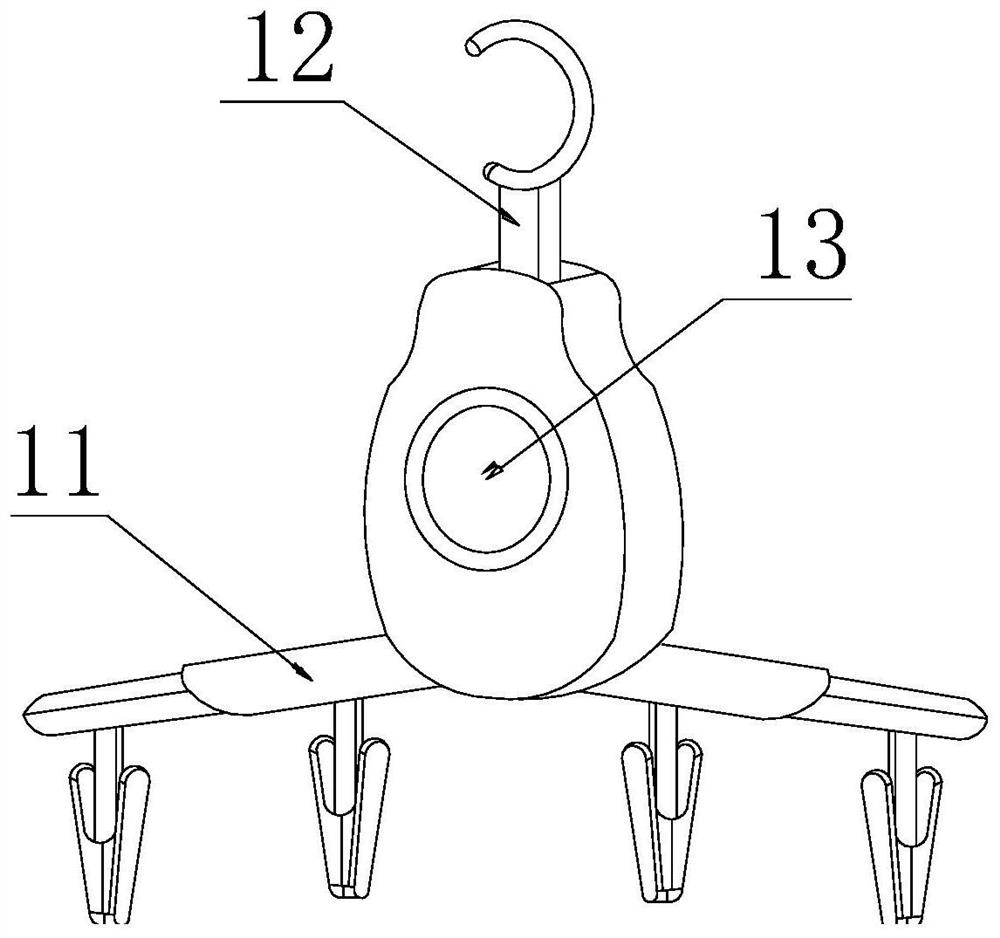

Bacteriostatic bamboo charcoal fiber quilt clamping and airing equipment

InactiveCN112921604AMake sure to formAvoid the problem of slow drying processOther drying apparatusTextiles and paperStructural engineeringMechanical engineering

The invention discloses bacteriostatic bamboo charcoal fiber quilt clamping and airing equipment which structurally comprises quilt clamping frames, bearing rods, fixing holes, supporting seats and folding frames. The tops of the quilt clamping frames are connected with the interiors of the fixing holes in a nested mode; the whole fixing holes are connected with the surfaces of the bearing rods in an embedded mode; the left sides of the bearing rods are fixed to the surfaces of the folding frames through bolts; the tail ends of the folding frames are fixed to bolts in the supporting seats; the quilt clamping frames comprise extension rods, hooks and balance weight seats; the tail ends of the extension rods are matched with the interiors of the balance weight seats in an embedded mode; the tops of the balance weight seats are fixedly connected with the tail ends of the hooks in an embedded mode; and the bottoms of the hooks are in clearance fit with the two ends of the extension rods. According to the bacteriostatic bamboo charcoal fiber quilt clamping and airing equipment provided by the invention, the extension rods extend inside sleeves, extended sliding rods reach specified lengths, and the lengths are changed to cooperate with clamping heads so as to clamp bacteriostatic bamboo charcoal fiber quilts, so that the bacteriostatic bamboo charcoal fiber quilts with different sizes are effectively ensured to form specified lengths in the airing process, and the problem that the airing process is slow due to the fact that the quilt clamping frames are not spaced enough and the quilts need to be overlapped is effectively solved.

Owner:胡宗伟

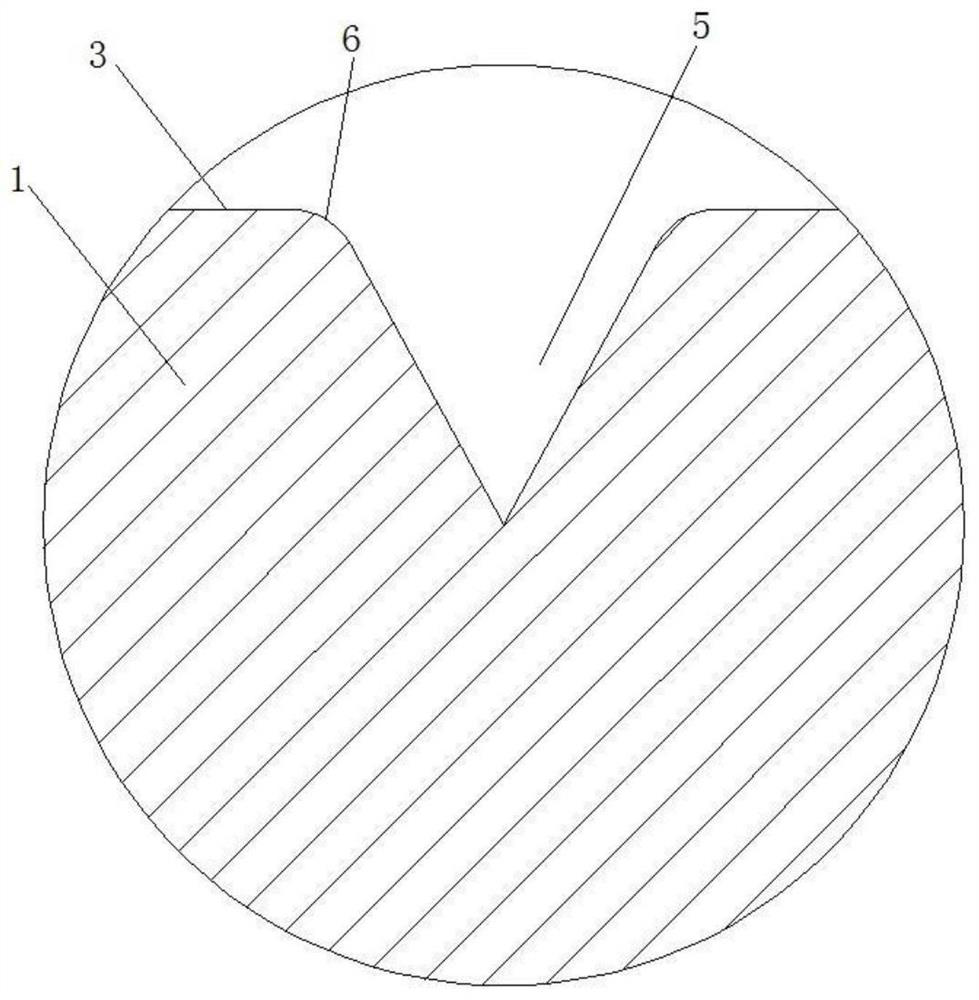

Sealing structure and method for refrigerating rotor compressor

PendingCN111734636ASimple processReduce endoleakSealing arrangement for pumpsRotary/oscillating piston pump componentsOil canCylinder head

The invention discloses a sealing structure and method for a refrigerating rotor compressor. Through formation of an oil groove in the seal face of a rotor and / or the seal face of a sliding block, theinterior of the oil groove contains a small amount of oil; the sealing structure can form small air cavities in a sealing belt between an upper cylinder head of a rotor compressor and a rotor or (and) high and low pressure cavities of the end face of a sliding block, and in a sealing belt between a lower cylinder head of the rotor compressor and the rotor or (and) the high and low pressure cavities of the end face of the sliding block; the small air cavities play a role in buffer seal in the process that high pressure gas flows toward the low pressure cavity, and meanwhile a small amount of oil can be caught for compensating oil films of high and low pressure sealing faces back and forth; the oil film play a sealing role in the clearance of the sealing face; even under the blow-away action of high-pressure end gas, the oil films can be moved at the two sides of an oil groove back and forth, and the oil film is formed on the sealing end face all the time; leakage of the high-pressure end gas to the low-pressure end is reduced, and the gas transmission volume of the compressor is ensured; and the power consumption of the compressor is reduced.

Owner:黄石东贝压缩机有限公司

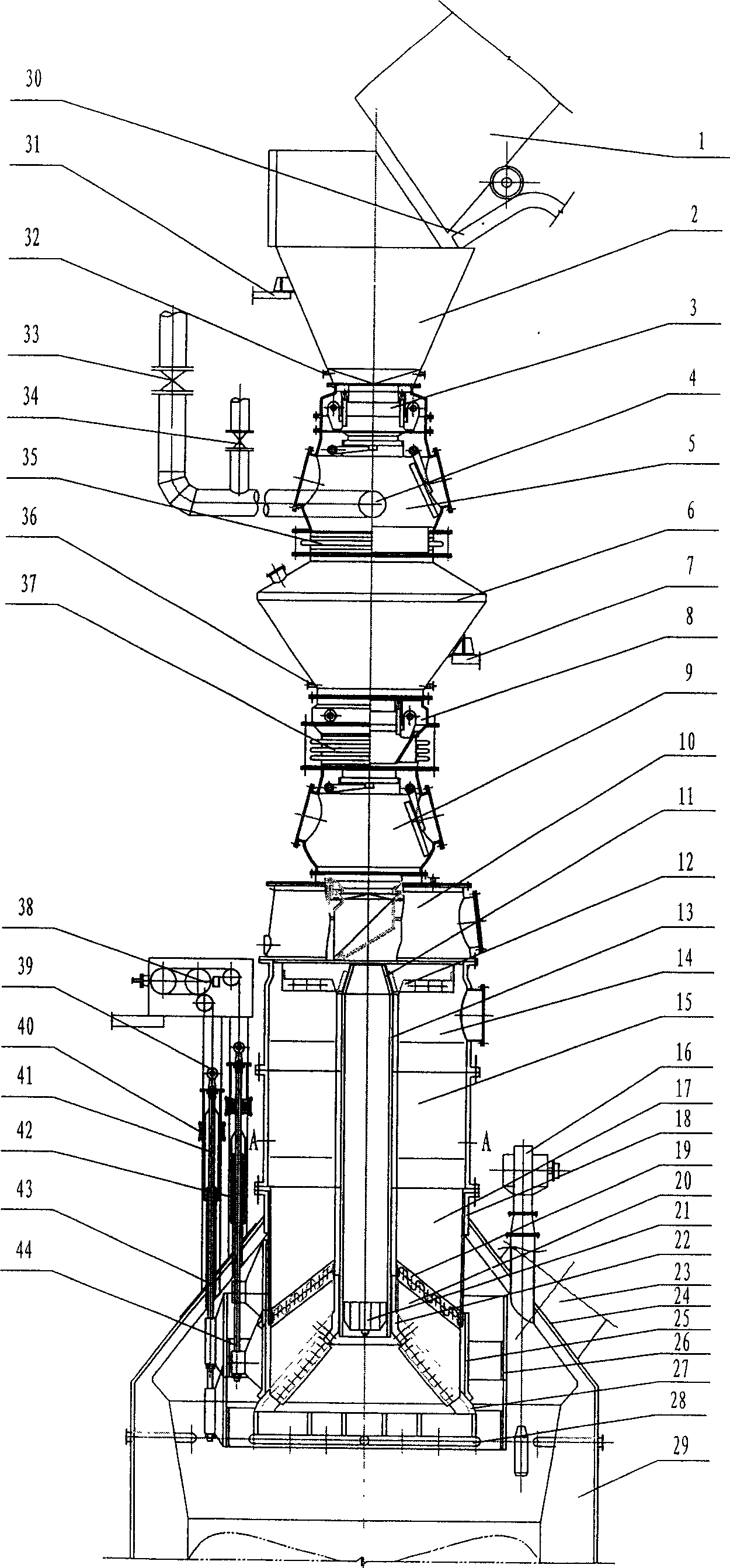

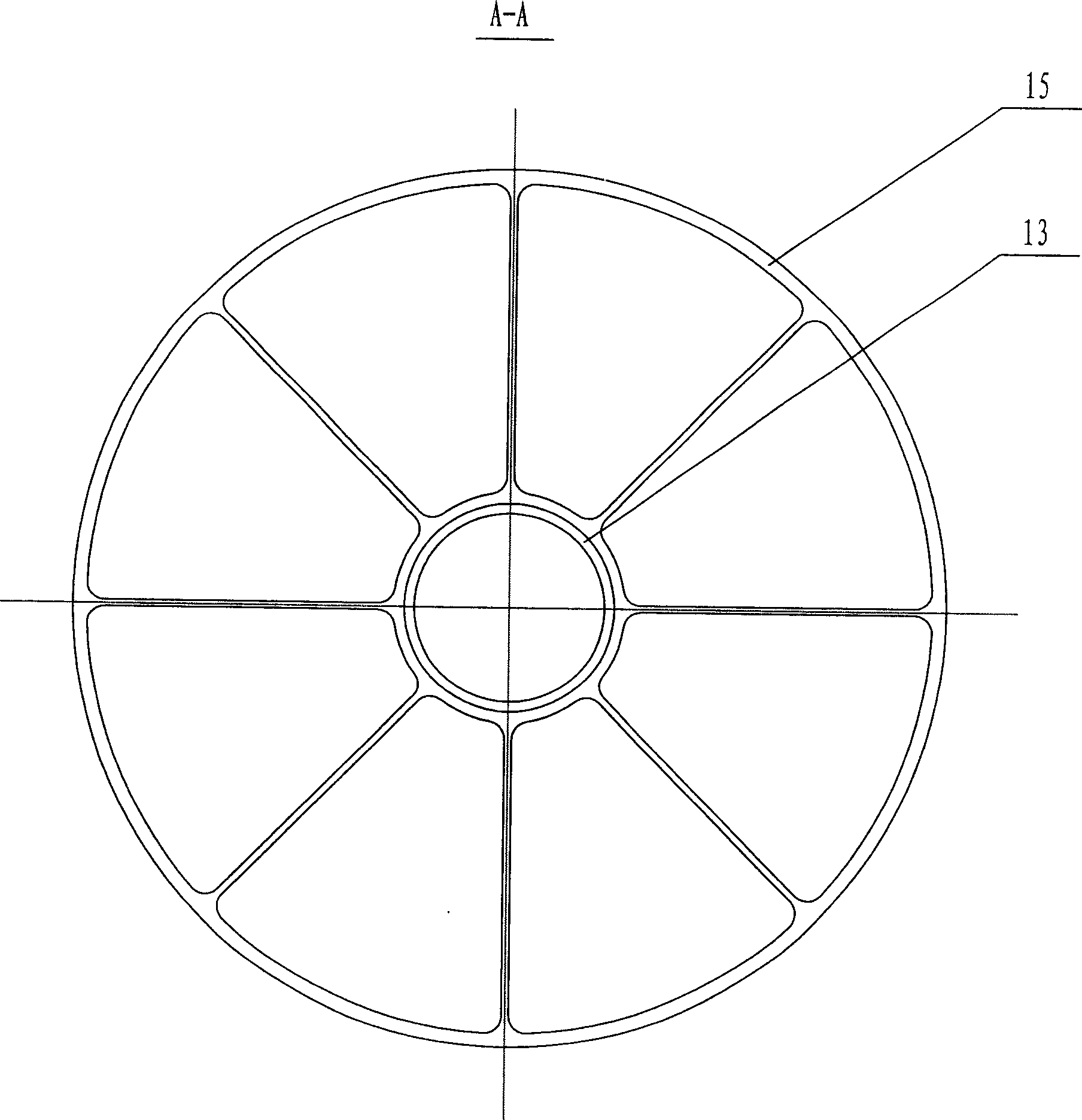

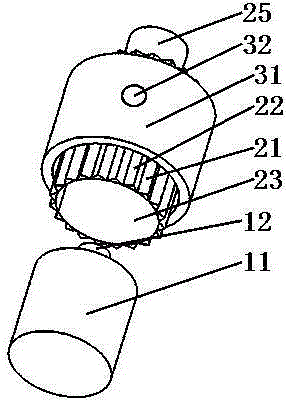

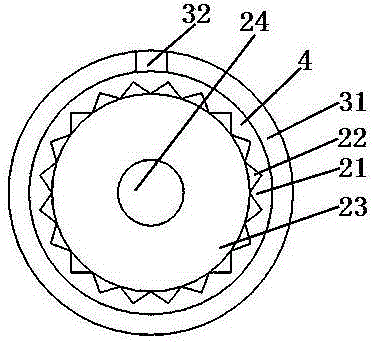

Blast furnace section ore-coke alternating multi-sector step distributing method, and its furnace top device

InactiveCN1850995AImprove generation lifespanExtended service lifeBell-and-hopper arrangementBlast furnace detailsSmelting processTar

The invention provides the method of the blast furnace transect mine charred between the phases several fan surface step advancing the cloth and the roof instrument, it belongs to the puddling. Using the methods of loading the mine, the tar synchronously or loading tar firstly, loading the mine afterward, adopting the several room loading the material and the definite angle of loading the tar, loading the mine and the step advancing angle, the material is loaded with the manner of the mine, tar phases several fan surfaces. The mine and the tar is loaded the surface of the throat of the stove with the shape of the mine, the tar several fan surface, the center sequence clean tar pole in the range of the core of the material pole, at the same time, the tar spinning ladder and the mine spinning ladder which glue the center series clean tar pole is formed in the material pole; the mine, the tar are formed the two, the three, the four loading filling frame which is the shape of the spinning ladder in the stove, the changing of the filling frame of the mine and the tar in the stove to solving the problem of the bad ability of the breathe freely when loading the mine and the tar in the shape of the layer and the standoff airflow, so the smelting process of the blast furnace is level off and controllable.

Owner:祁正坤

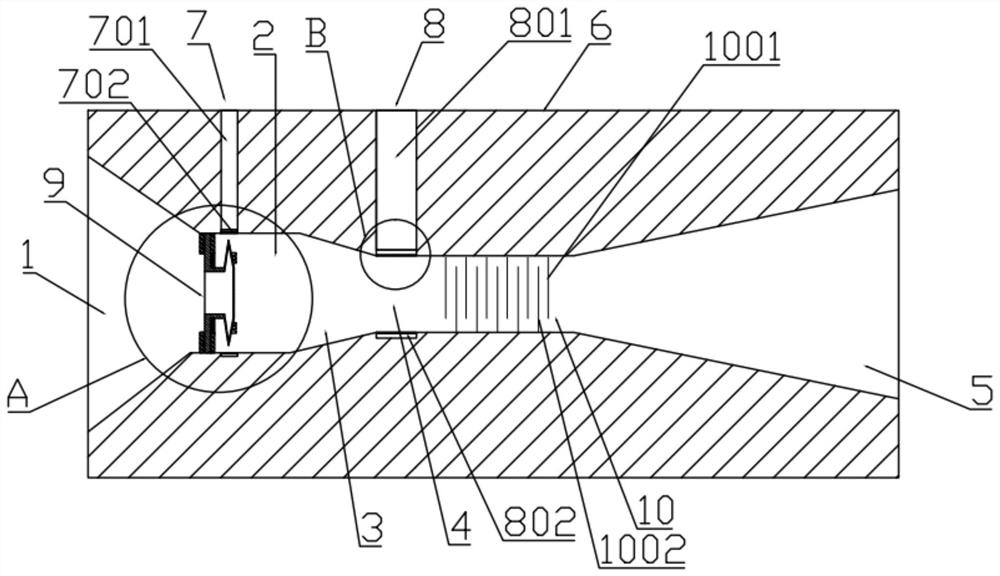

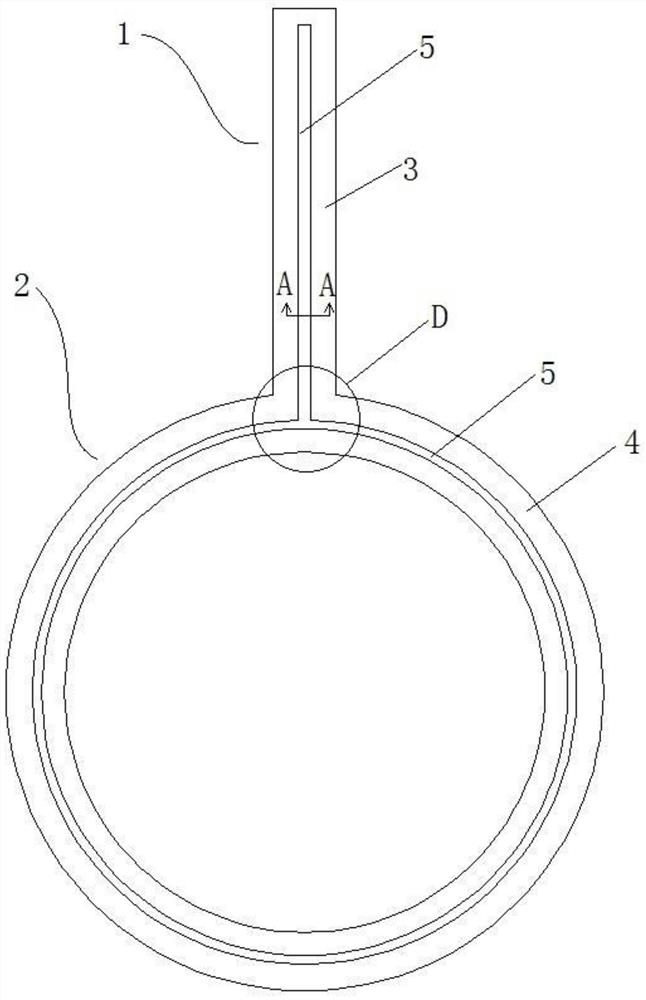

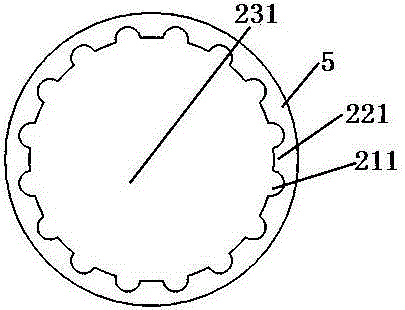

Die assembly for manufacturing air-blowing pipe for cable

ActiveCN105172099AMake sure to formSimple structureTubular articlesStructural engineeringMechanical engineering

The invention relates to a die assembly for manufacturing an air-blowing pipe for a cable. The die assembly is characterized in that the die assembly comprises a die core, a die cover and a plunger body; the die core comprises protruding die core bodies and die core grooves, and the protruding die core bodies and the die core grooves are arranged at intervals to form a cylindrical body with a die core cavity; one end of the cylindrical body is sealed, and the outer side of the sealed end is provided with a die core connector; a die core connection hole is formed in the die core connector; the die cover is provided with a die cover body; a die cover cavity is formed in the die cover body; an injection molding hole is formed in the die cover body; and the plunger body comprises a plunger and a plunger connector. When the air-blowing pipe for the cable is manufactured, the die cover is located outside the die core, the die core is located in the die cover cavity, a part of the plunger body is located in the die core cavity, and the other part extends out of the die core cavity; and the protruding die core bodies do not make contact with the inner wall of the die cover cavity, and the die core cavity does not exceed the end face of the die cover. The die assembly has the beneficial effects that a die structure is simple, easy to manufacture, resistant to wear and easy to use; and the manufactured air-blowing pipe is stable in quality, reliable and resistant to twist.

Owner:GUANGZHOU BAOZHITAI ELECTRONIC TECH CO LTD

Preparation method of composite modified lithium metal soft package battery

InactiveCN112164804AModification method is simpleReduce control requirementsFinal product manufactureElectrode carriers/collectorsMetallic lithiumElectrical battery

The invention relates to the technical field of lithium batteries, in particular to a preparation method of a composite modified lithium metal soft package battery, which comprises the following steps: in the assembly process of the soft package lithium battery, placing microporous copper foils between a metal lithium alloy negative electrode and a diaphragm, and placing the metal lithium alloy negative electrode in two microporous copper foils; the two microporous copper foils being jointly connected to the nickel tab, the microporous copper foils forming a physical protection effect on the lithium metal negative electrode, and arranging the positive plate on the other side of the diaphragm; and inhibiting the growth of lithium metal dendrites by adopting the carbon-coated diaphragm. Themicroporous copper foil modified metal lithium alloy negative electrode provided by the invention realizes good application in a lithium battery, the modification method is simple and easy to implement, the control requirement is low, mass production is easy, no special test environment or special device investment is needed, an original lithium battery production line and equipment can be utilized, a production system does not need to be modified, meanwhile, the electrochemical performance of the metal lithium alloy negative electrode can be improved, and the electrochemical cycling stabilityis improved.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

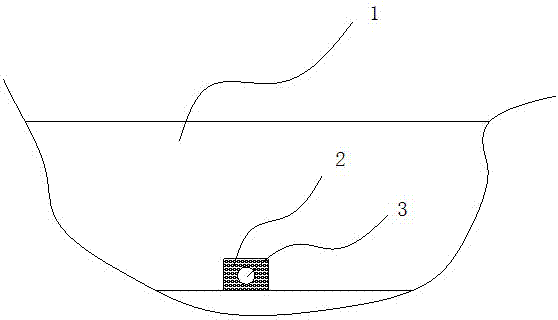

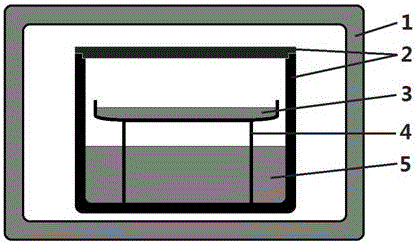

Overflow type lead-acid storage battery formation water bath

InactiveCN107369855ASimple structureHigh degree of automationFinal product manufactureLead-acid accumulators constructionFormation waterEngineering

The invention discloses an overflow type lead-acid storage battery formation water bath. The overflow type lead-acid storage battery formation water bath comprises a bath shell, a roll shaft, a water tank, a temperature controller, a valve, a leak-off pipe, a drainage exit, a heating pipe and a temperature sensor, wherein an overflow port is formed in the lower part at the middle position of the bath shell in a side wall length direction; the water tank is connected to the position of the overflow port of the bath shell in a sealing manner; an opening of the water tank is upward to form a container communicating with the inner cavity of the bath shell; the water tank is internally provided with the vertically arranged leak-off pipe; a pipe opening in the upper end of the leak-off pipe uses the opening of the water tank as an upper limit; and a pipe opening in the lower end of the leak-off pipe passes through a base plate of the water tank and is directly connected to the drainage exit to form a leakage flow passage. The temperature controller is controlled by the temperature sensor, and the water temperature is adjusted by adjusting the opening of a hot water inlet or a cold water inlet at random. The storage level and water temperature inside the overflow type lead-acid storage battery formation water bath are controllable, the overflow type lead-acid storage battery formation water bath is simple in structure and high in degree of automation, constant water temperature is beneficial for improving formation quality, and the labor intensity of operators at the posts can be alleviated, so that the production efficiency is obviously improved.

Owner:SHUANGDENG GRP

Macadimia nut and walnut kernel drink prepared by two-phase conditioning method

InactiveCN107125517ASelf-emulsifying effectAvoid layeringMilk substitutesFood scienceOil phaseOil water

The present invention relates to macadimia nut and walnut kernel drink prepared by a two-phase conditioning method. The method comprises the following steps: raw material treating, water phase conditioning, oil phase conditioning, oil and water merging, homogenizing, filling, sterilizing, etc. The macadimia nut and walnut kernel drink is characterized by using water as a dispersion medium, and walnut kernel proteins, macadamia nut proteins and edible oil are used as a dispersion system of a dispersion phase. By using a special processing, the even and stable ''protein-self-emulsifying stability-oil'' drink is formed.

Owner:NANCHANG UNIV

Nutritional type almond juice produced by use of synchronous conditioning enzymolysis method

The invention relates to a nutritional type almond juice produced by use of a synchronous conditioning enzymolysis method. The method comprises the following steps of raw material treating, aqueous phase conditioning, oil phase conditioning, oil-water blending, homogenizing, filling and sterilizing and the like. Particularly, the nutritional type almond juice is free from adding the emulsifier and the stabilizer, the water is used as the dispersion medium, the almond protein and the edible oil are used as the dispersion phase to form the dispersion system, the uniform and stable almond beverage with protein-self-emulsification stabilization-oil is spontaneously formed through the specific processing.

Owner:NANCHANG UNIV

Multifunctional growth regulator composition for peach trees

InactiveCN106631319APromote growth and developmentPromote growthFertilizer mixturesDifferentiation AgentsBud

The invention relates to a multifunctional growth regulator composition for peach trees and belongs to the field of plant growth regulation. The multifunctional growth regulator composition comprises, by weight, 4-11 parts of gibberellin, 5-10 parts of pimacol, 8-22 parts of diethyl aminoethyl hexanoate, 20-40 parts of auxiliaries and 33-50 parts of additives, wherein the auxiliaries refer to one or more of a fruit expander, a sugar increasing substance, a drought-resistant and water-retaining agent, a flower bud differentiation agent, ferrous sulfate, magnesium sulfate, vitamins and amino acids, and the additives refer to one or more of calcium carbonate, bentonite and kaolin. The multifunctional growth regulator composition for the peach trees has the effects on resisting adverse factors and synergy through synergism through all components and has a variety of efficacy without side effect.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

Production method of coconut milk peanut beverage

The invention relates to a production method of a coconut milk peanut beverage. The method comprises the following steps of raw material treatment, water phase tempering, oil phase tempering, oil water fusion, homogenization, filling, sterilization and the like. The production method is characterized in that a dispersing system using the water as a dispersing medium and using protein and grease as major dispersing phases is used; through the special processing, a protein-self emulsifying stabilizing-grease uniform and stable beverage is formed.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com