Slipper used for plunger type hydraumatic pump

A hydraulic pump and plunger-type technology, which is applied in the field of sliding shoes for plunger-type hydraulic pumps, can solve the problems of eccentric wear, deformation, boot removal, loose boots, etc. The effect of eccentric wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings.

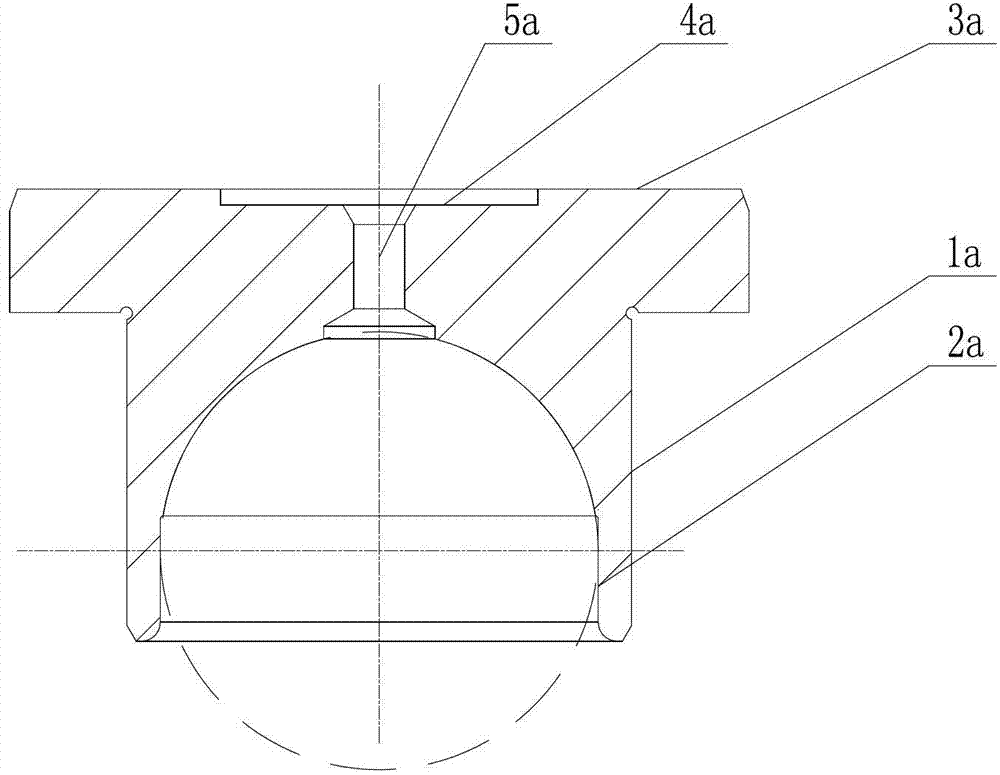

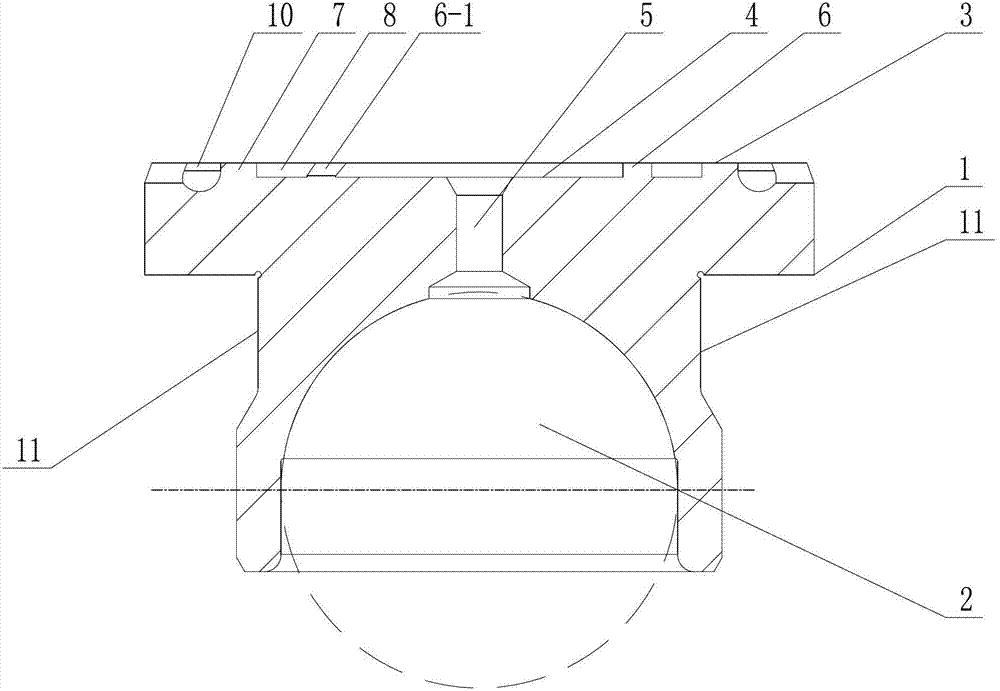

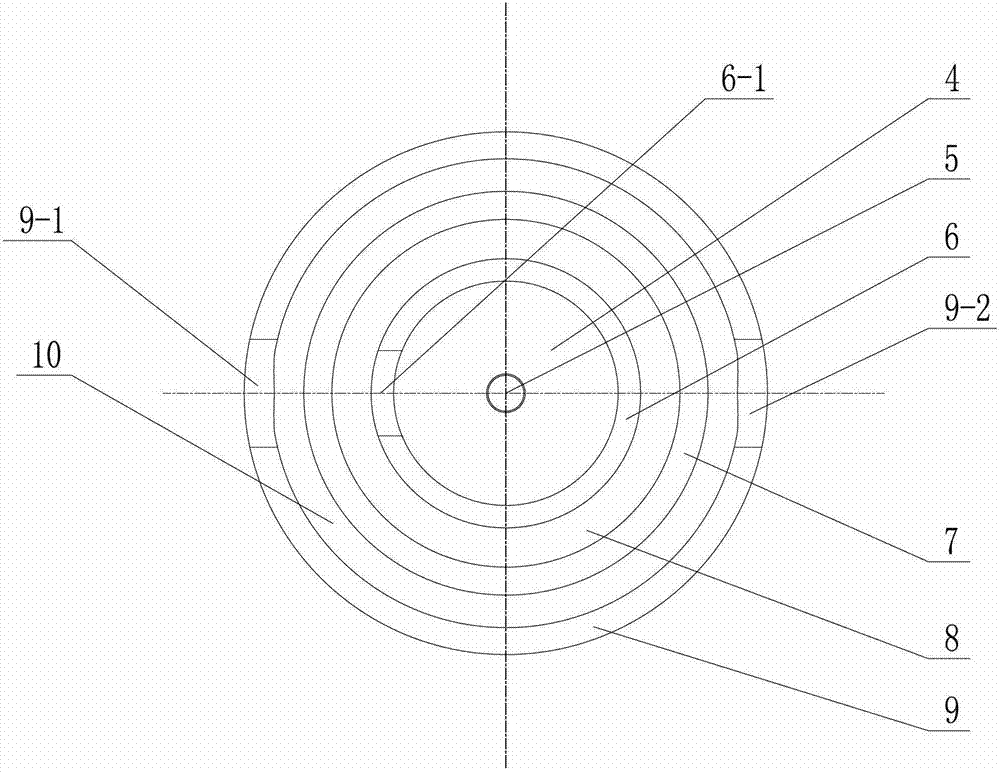

[0016] Such as figure 2 with image 3 As shown, the sliding shoe for the plunger hydraulic pump includes a sliding shoe body 1, a spherical neck 2, a plane 3, a groove 4, a orifice 5, an annular inner support belt 6, a first oil port 6-1, an annular seal Belt 7, annular inner oil groove 8, annular outer support belt 9, second oil port 9-1, third oil port 9-2, annular outer oil groove 10, recessed area 11, etc.

[0017] Such as figure 2 As shown, the present invention includes a sliding shoe body 1. One end of the sliding shoe body 1 is provided with a spherical constriction 2 that matches the plunger ball head, and the other end is provided with a plane 3 contacting the swash plate. The middle of the plane 3 A groove 4 is provided, a damping hole 5 is provided in the middle of the groove 4, and the damping hole 5 is communicated with the spherical neck 2; image 3 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com