Patents

Literature

408results about How to "Avoid partial wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

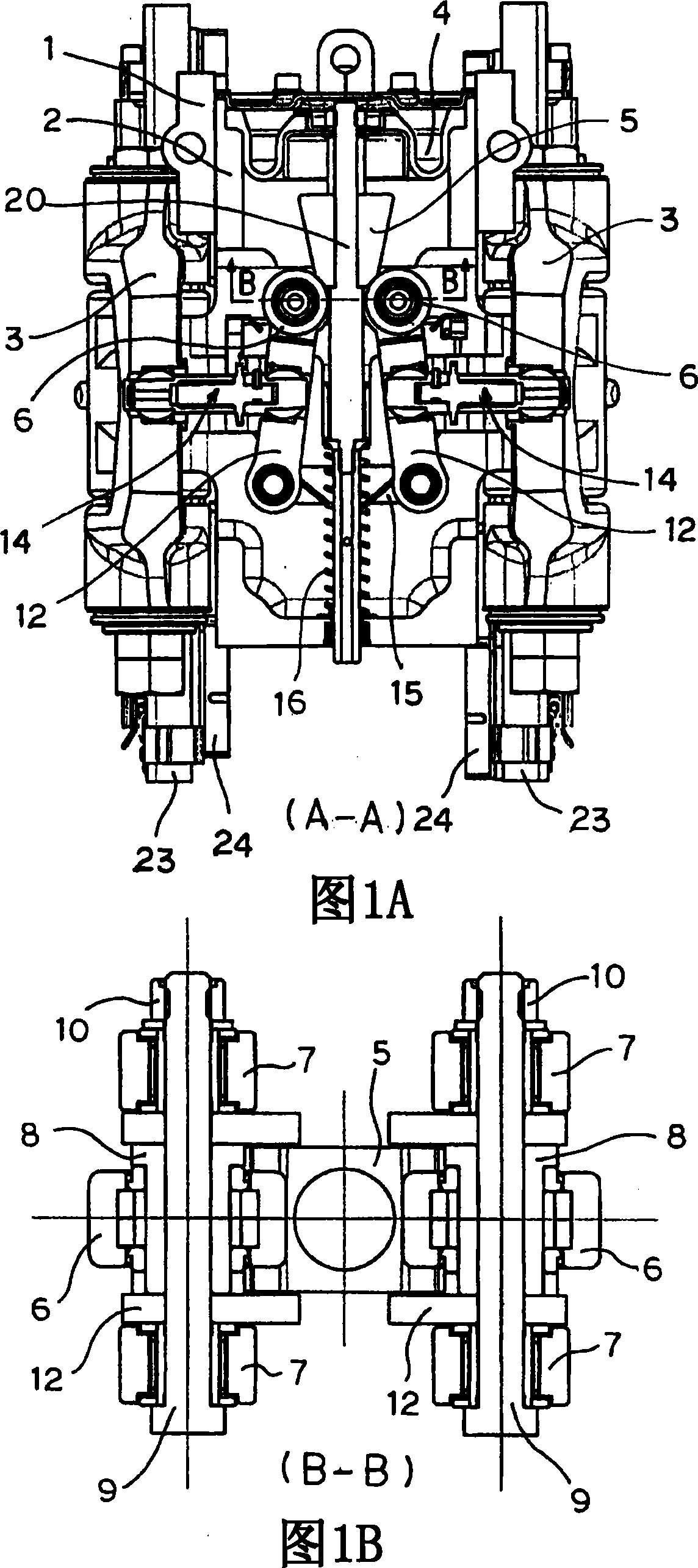

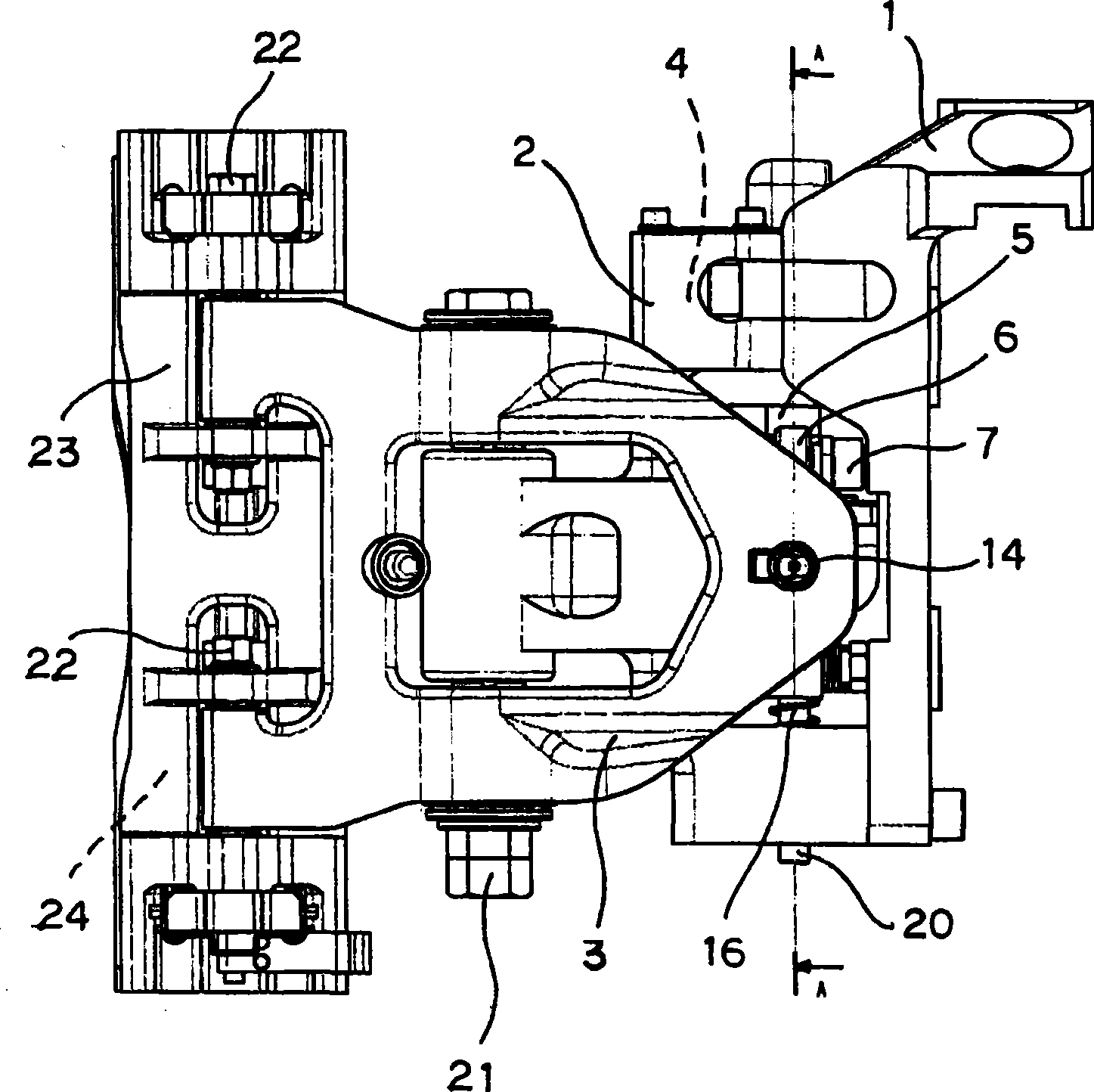

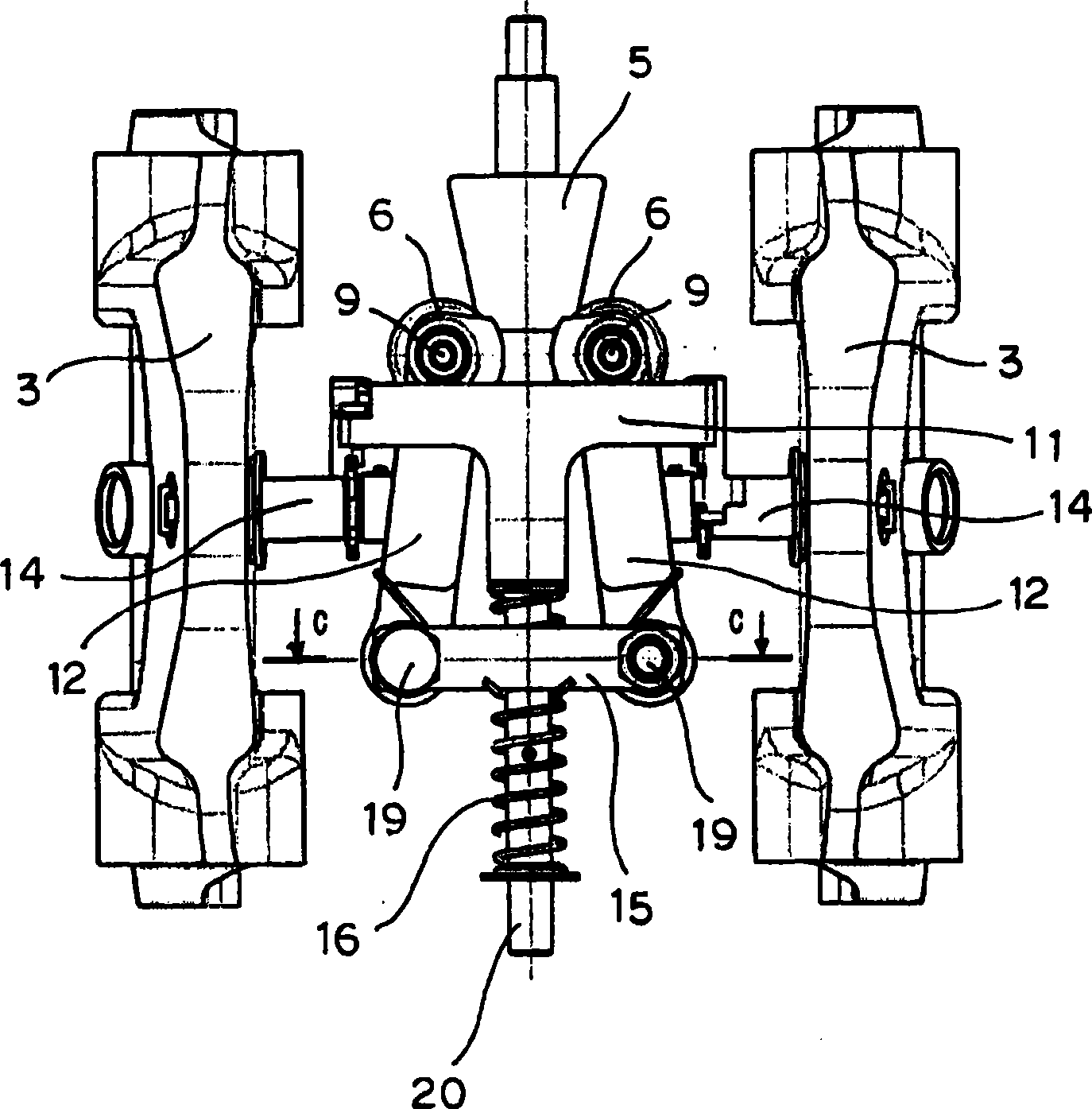

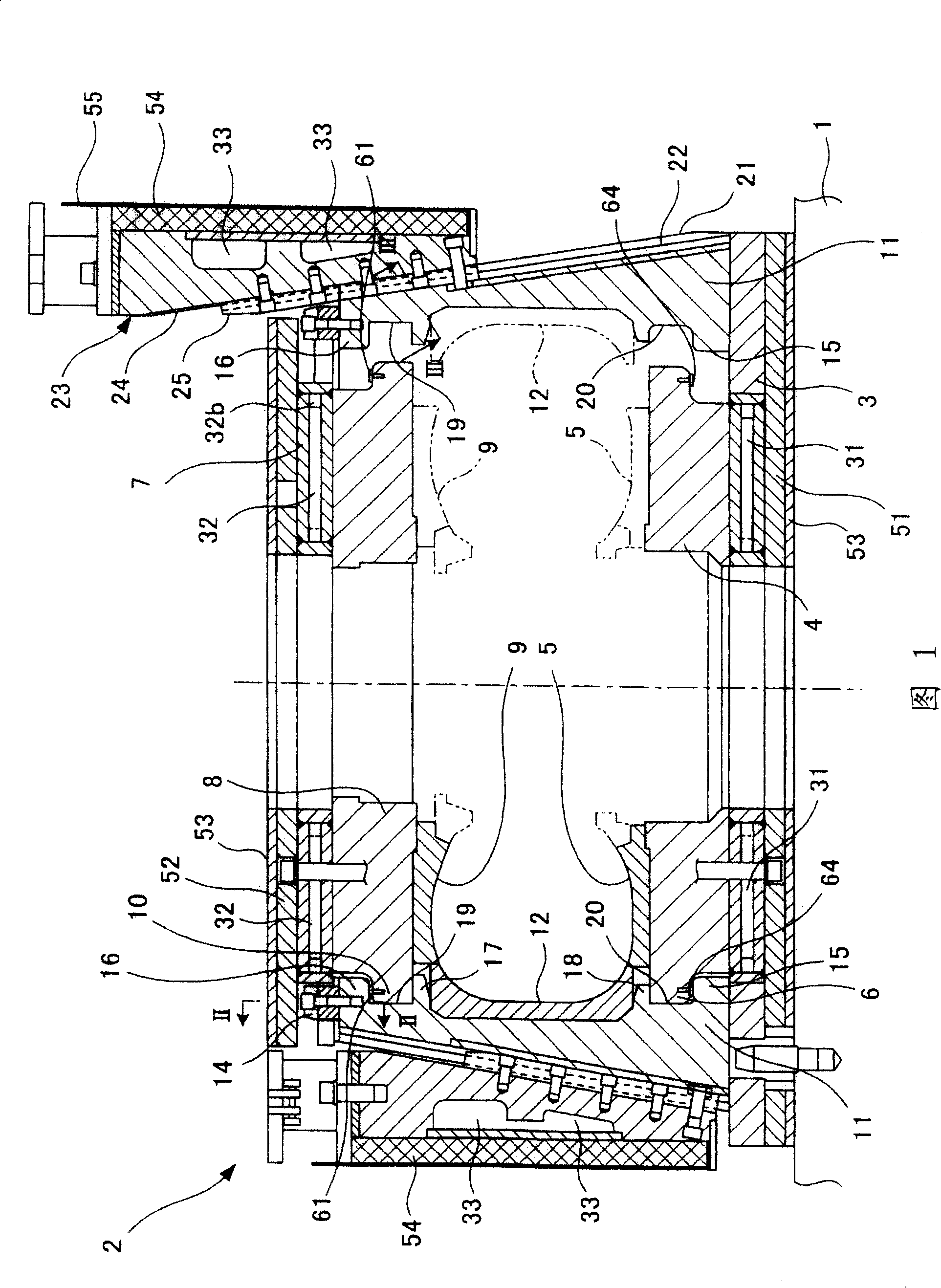

Pressing and actuating mechanism of disc brake device

ActiveCN101387324ALow sliding resistanceIncreased power efficiencyAxially engaging brakesBrake actuating mechanismsEngineeringActuator

A disc brake device is provided with a wedge rod (20) axially moved by an actuator (4) and orthogonally arranged to a wheel axle, a wedge (5) mounted on the wedge rod (20) and having an inclined surface, a main roller (6) rolling on the inclined surface, and a link (12) rocking in accordance with a movement of the main roller (6). An intermediate portion of the link (12) and a base end of the brake arm (3) are coupled via a gap adjusting mechanism (14). The base end of the brake arm (3) is boosted, pressed, and expanded in accordance with the movement of the main roller (6), and a brake pad disposed at a rocking end of the brake arm (3) is pressed and actuated. A pair of sub-rollers capable of rolling on guide rails are disposed coaxially with the main roller (6) on both sides of the main roller (6).

Owner:AKEBONO BRAKE IND CO LTD

Off-the-road tire

InactiveCN1538916AProgress in Preventing CrackingExcellent abrasion resistanceHeavy duty tyresTyre tread bands/patternsGround contactWear resistance

Owner:BRIDGESTONE CORP

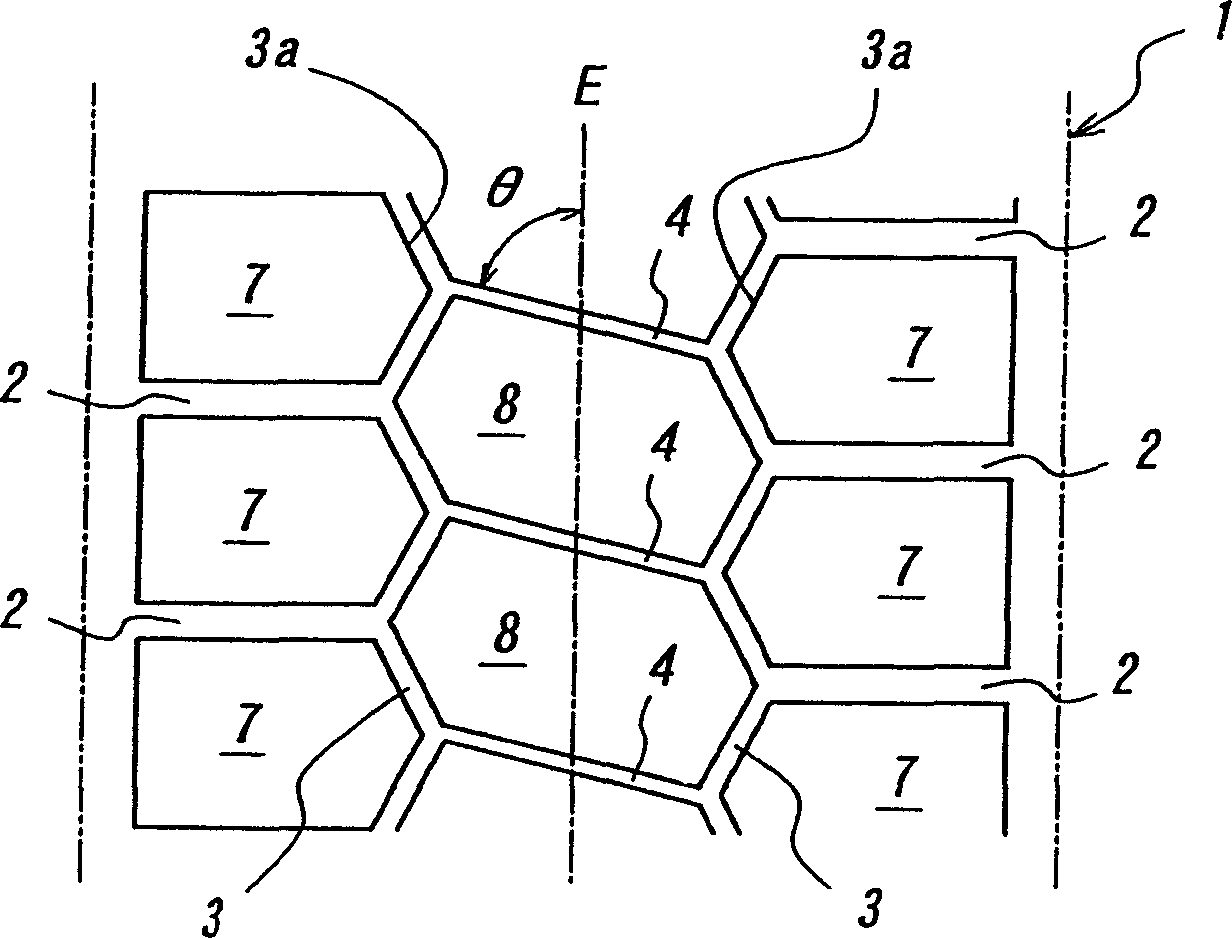

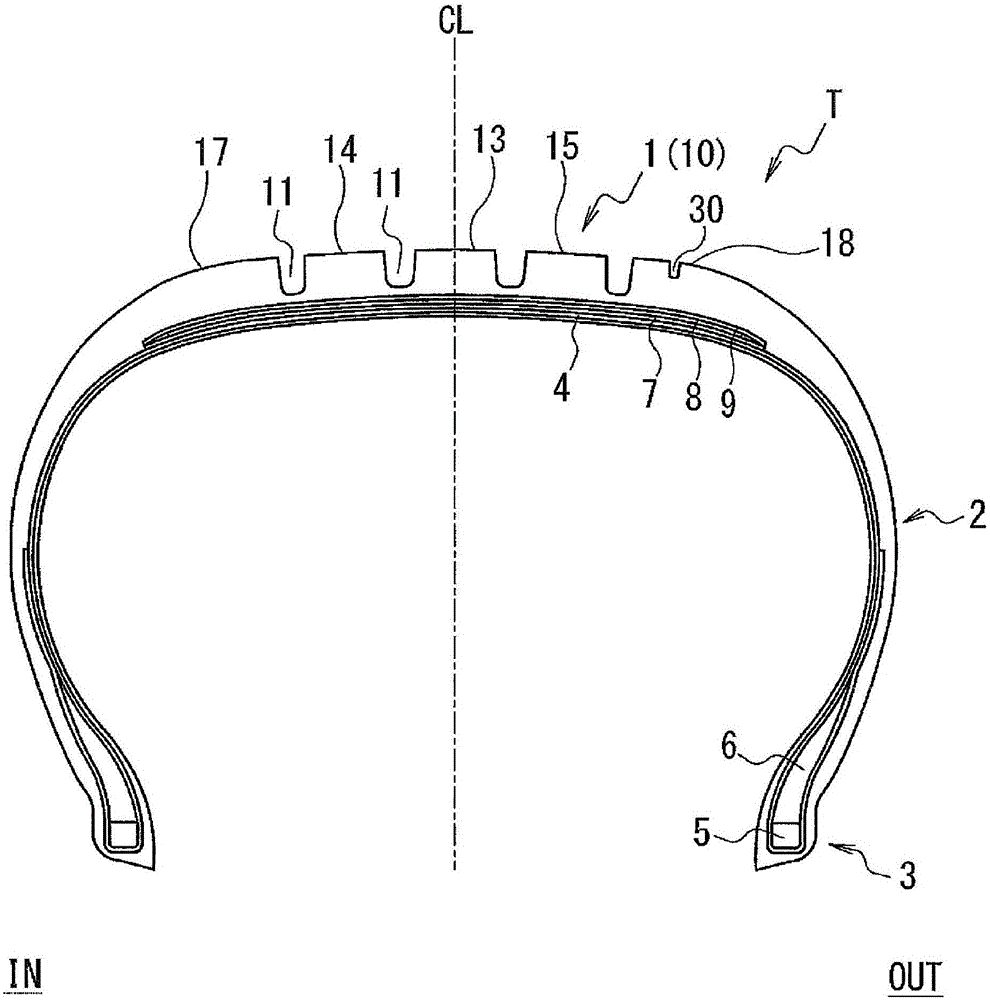

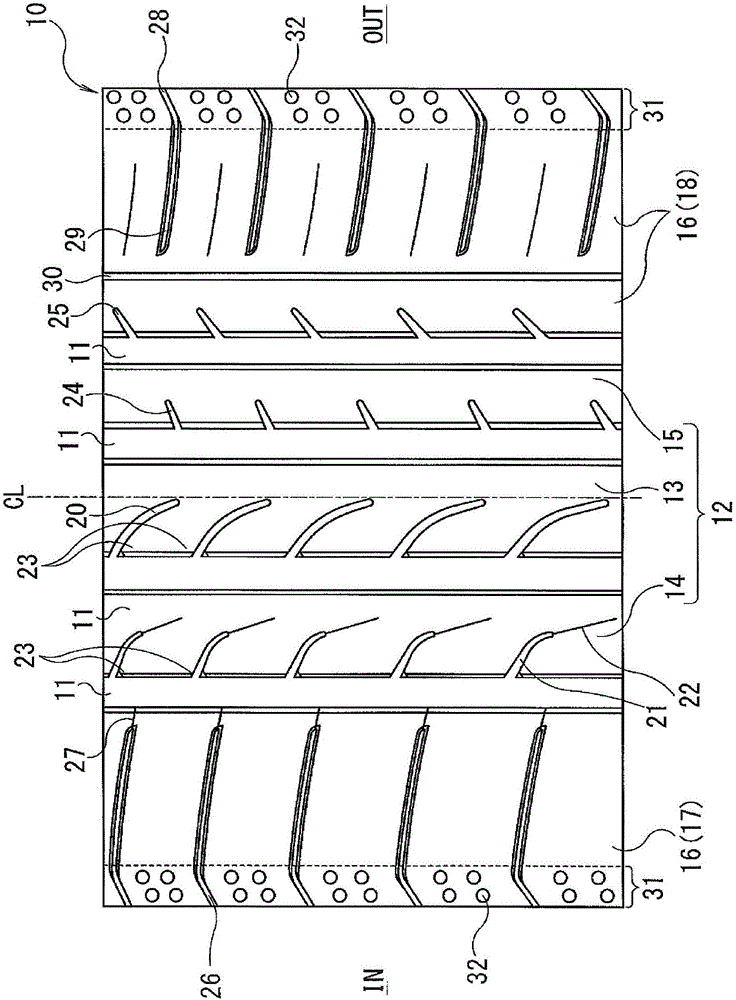

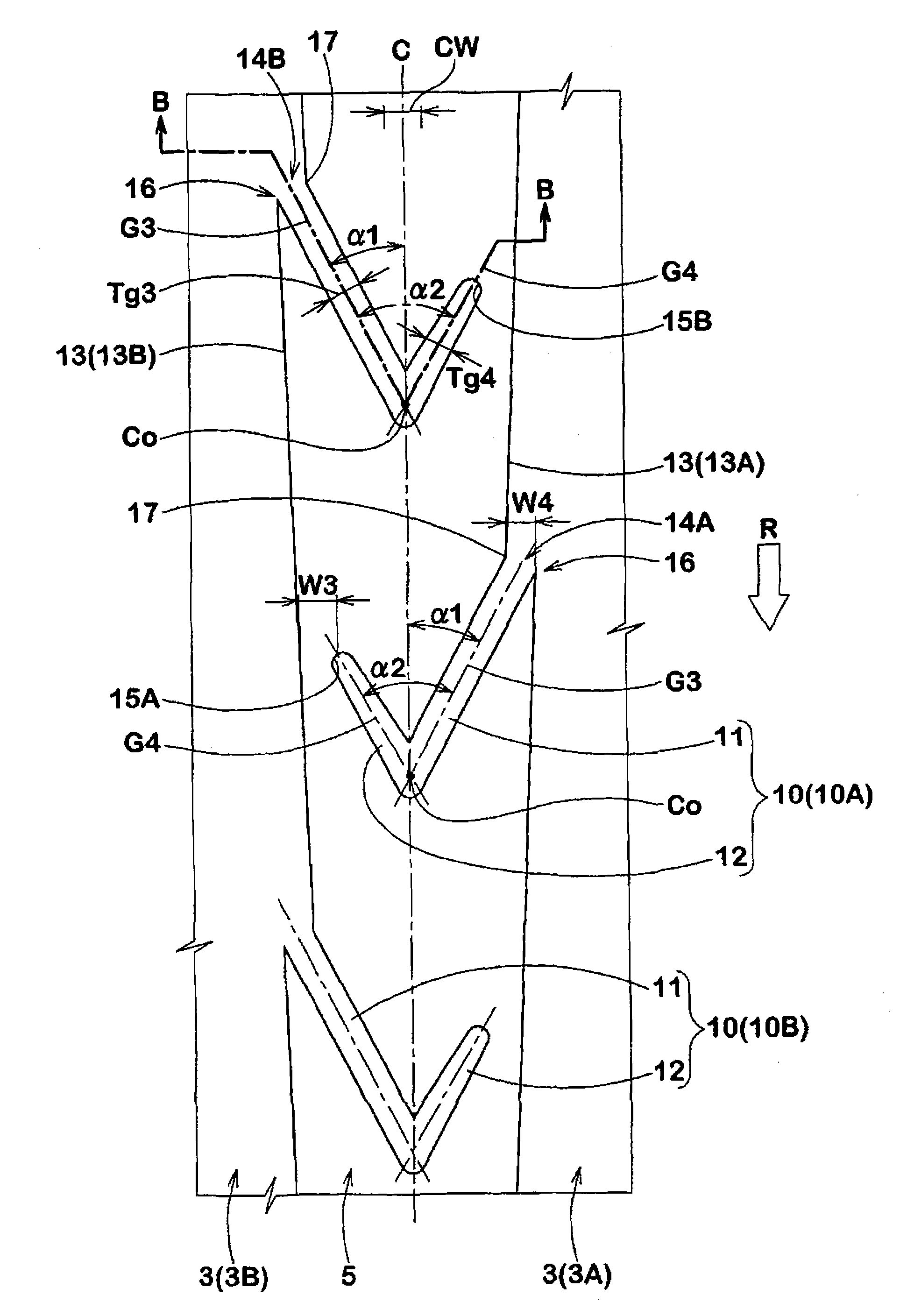

Pneumatic tire

ActiveCN106132729AReduce outside noiseGood drainageInflatable tyresTyre tread bands/patternsRoad surfaceAerospace engineering

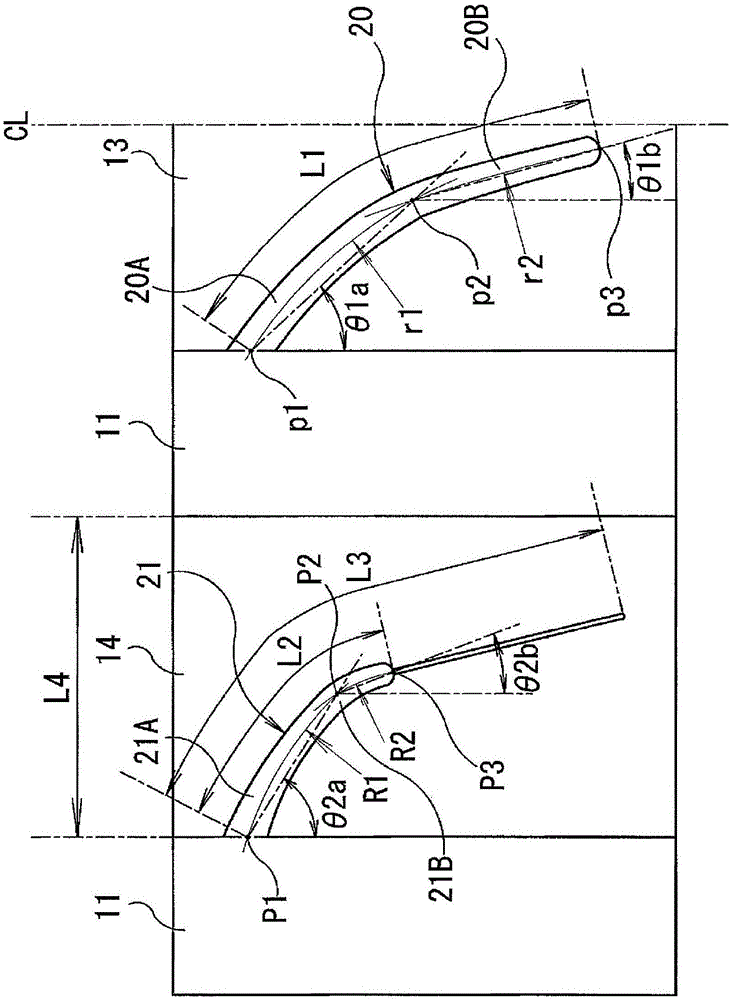

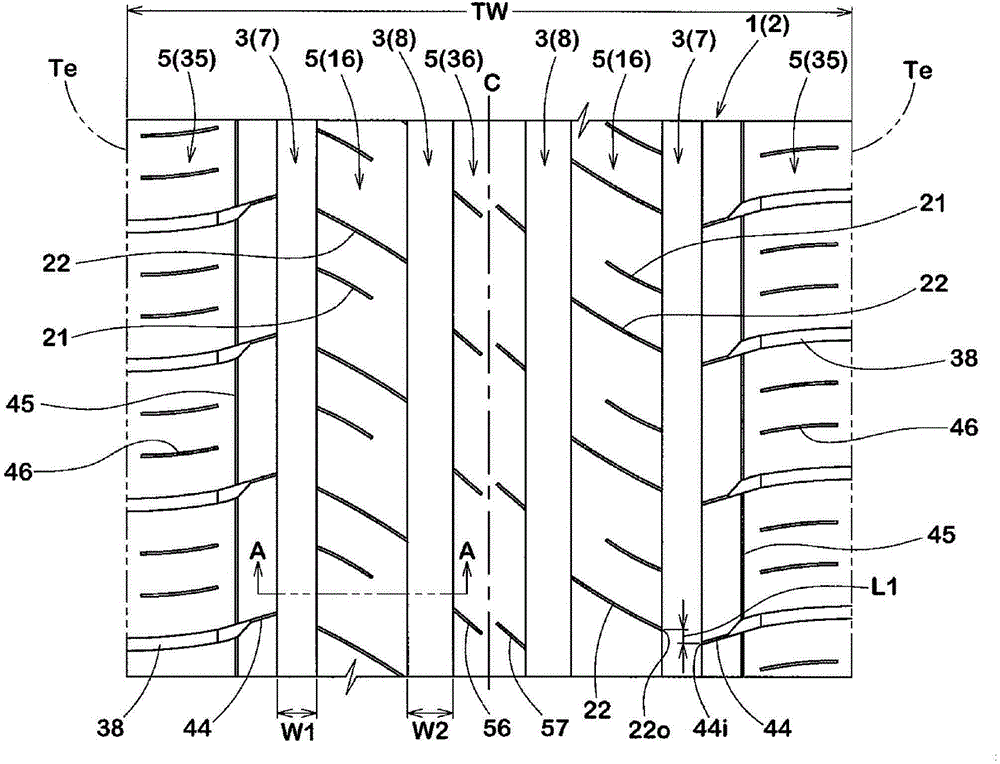

Provided is a pneumatic tire enabling an increase in noise performance while achieving both steering stability on dry road surface and driving performance on wet road surface. In a pneumatic tire (T) including a center land portion (13), an inner central land portion (14), an outer central land portion (15), an inner shoulder land portion (17), and an outer central land portion (18) which are separately formed by at least four main grooves (11), the pneumatic tire having a designated vehicle mount direction, the center land portion (13) is formed with center lug grooves (20) that open only to one of the main grooves (11) on the vehicle inner side, the inner central land portion (14) is formed with inner central lug grooves (21) that open only to another of the main grooves on the vehicle inner side, each of the lug grooves (20, 21) comprising a first inclination portion (20A, 21A) positioned on an opening end side and having a relatively large inclination angle and a second inclination portion (20B, 21B) positioned on a terminal side and having a relatively small inclination angle, and an inner central sipe (22) is formed at the terminal portion of each of the inner central lug grooves (21) terminating within the inner central land portion (14), wherein the relationships L1 ;gt; L2 and L3 ;gt; L4 are satisfied, where L1 is the length of the center lug groove (20), L2 is the length of the inner central lug groove (21), L3 is the sum of the length L2 and the length of the inner central sipe (22), and L4 is the width of the inner central land portion (14).

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire

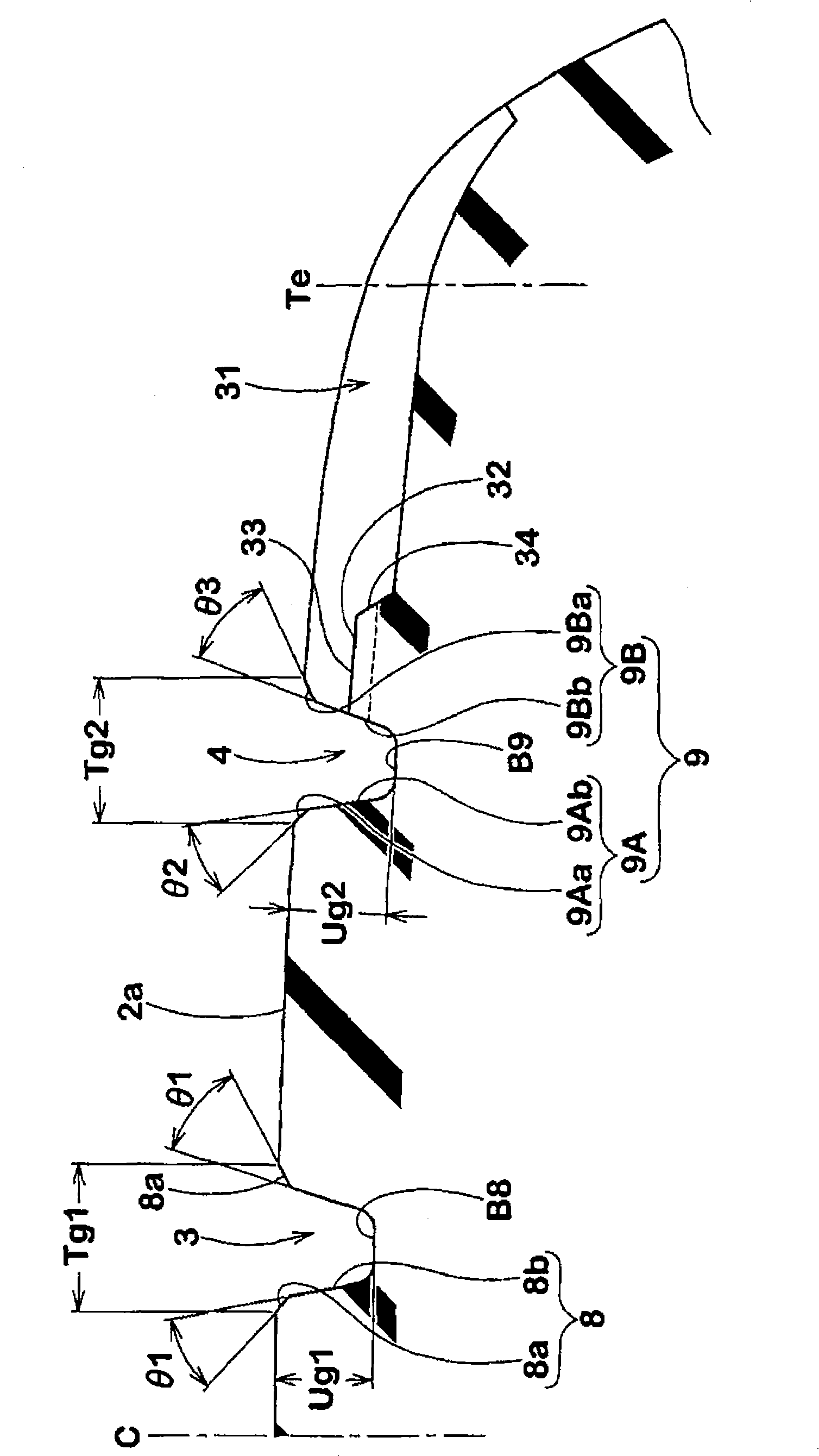

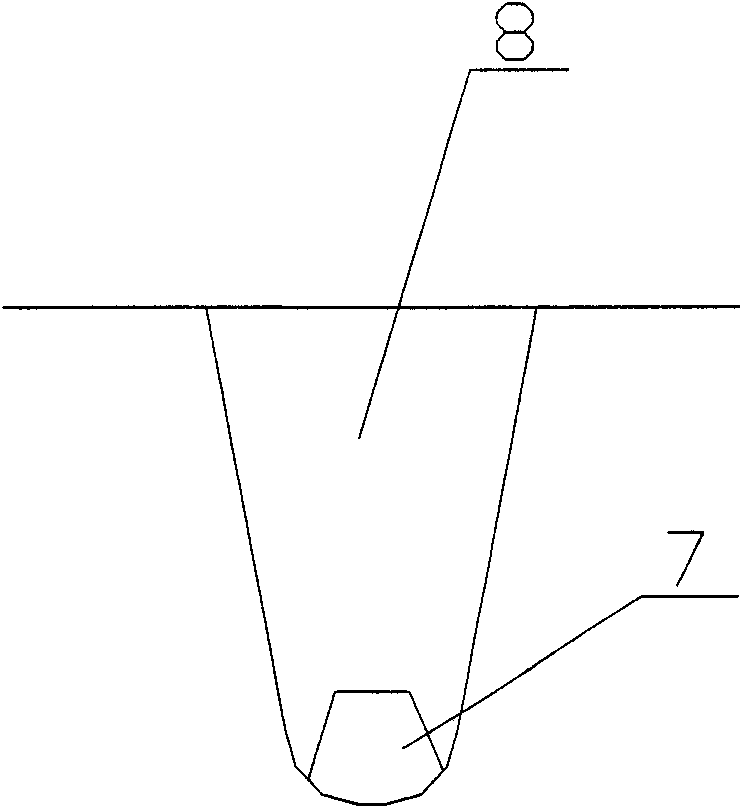

ActiveCN105270101AImprove on-snow performanceIncrease frictionTyre tread bands/patternsMain channelEngineering

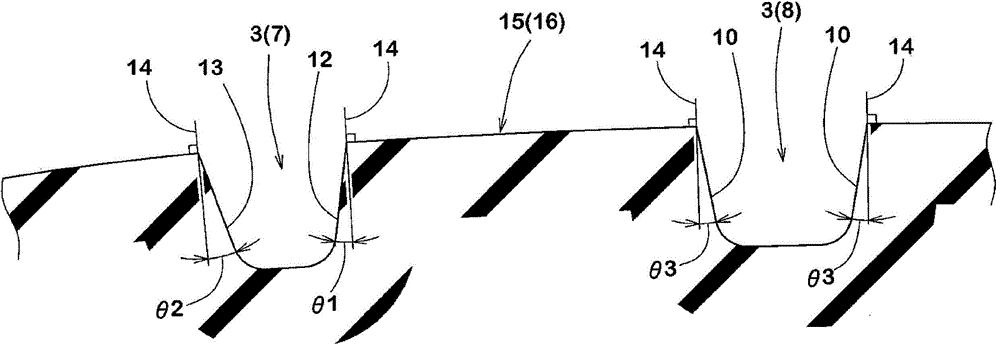

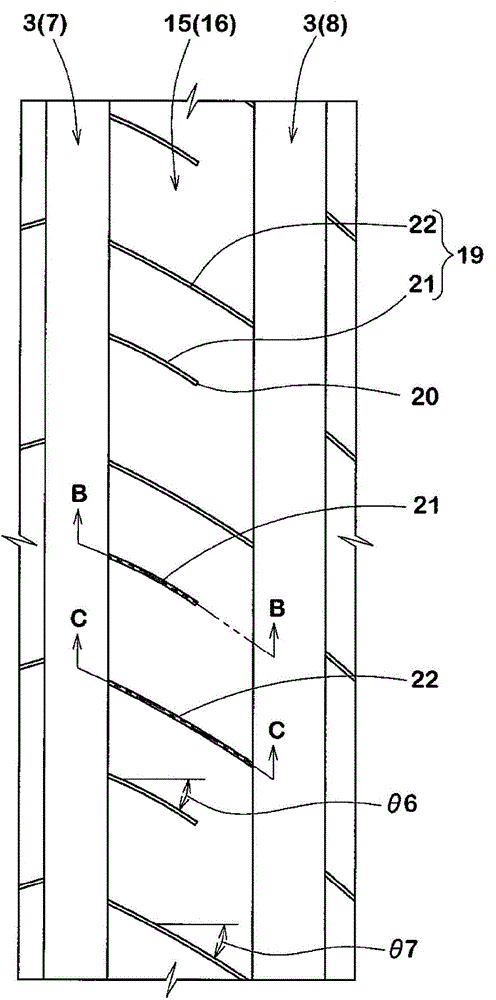

The present invention provides a pneumatic tire capable of maintaining the properties of a trunk road and a wet road while improving the performance of the pneumatic tire on the snow. The tread (2) of the pneumatic tire (1) comprises a main channel (3) and a land part (5). The main channel (3) is composed of an inner trench wall (12) on the side of a tire equatorial (C), and an outer trench wall (13) on the side of a tread end (Te). The tilt angle of the outer trench wall (13) is larger than that of the inner trench wall (12). The land part (5) is composed of an inner land part (15) adjacent to the tire equatorial (C) of the main channel (3). The inner land part (15) is provided with a siping (19) in communication with the main channel (3). The siping (19) is composed of a bottom surface (24) and a shallow bottom part (25) that is raised at the end portion of the main channel (3).

Owner:SUMITOMO RUBBER IND LTD

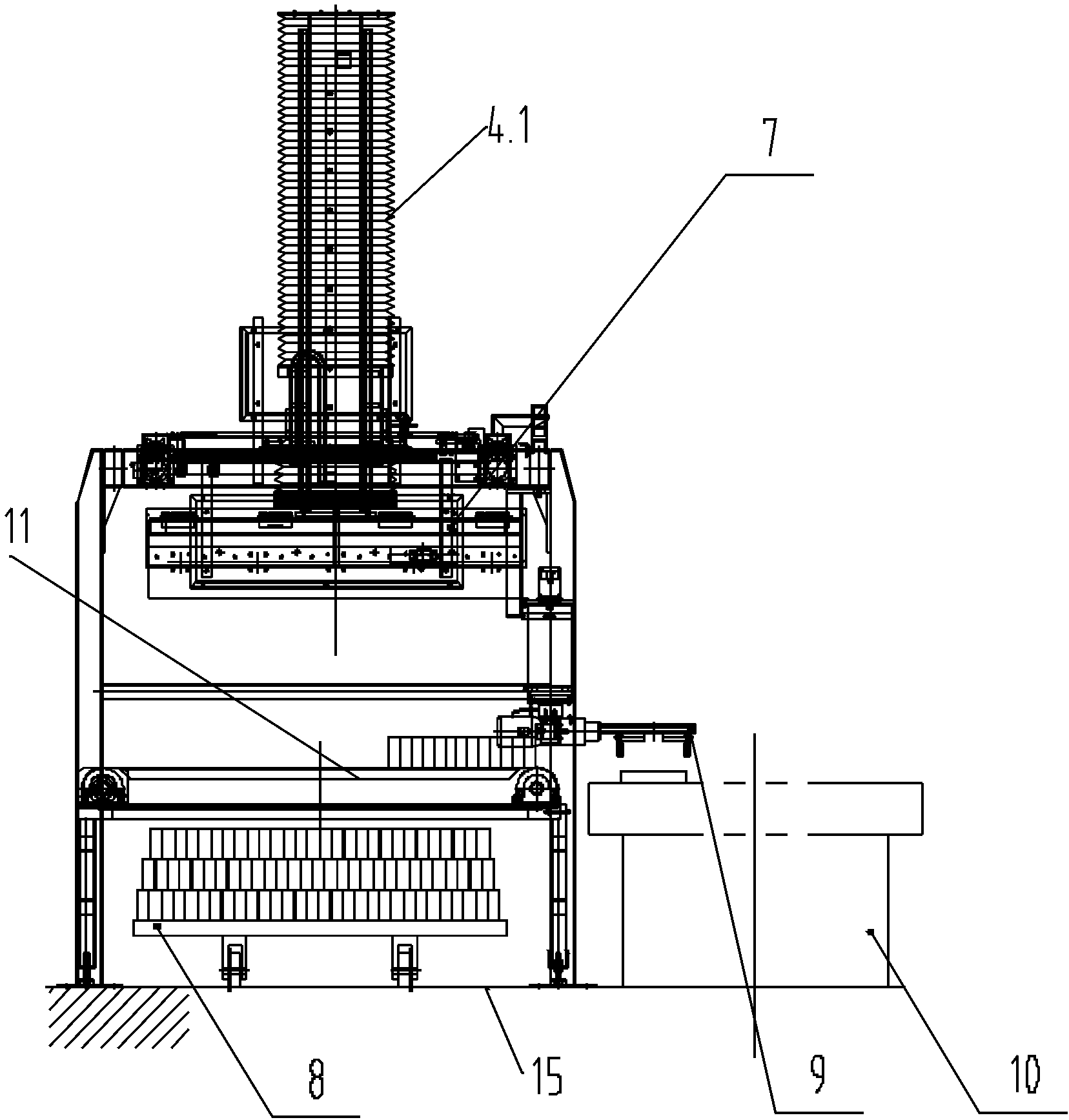

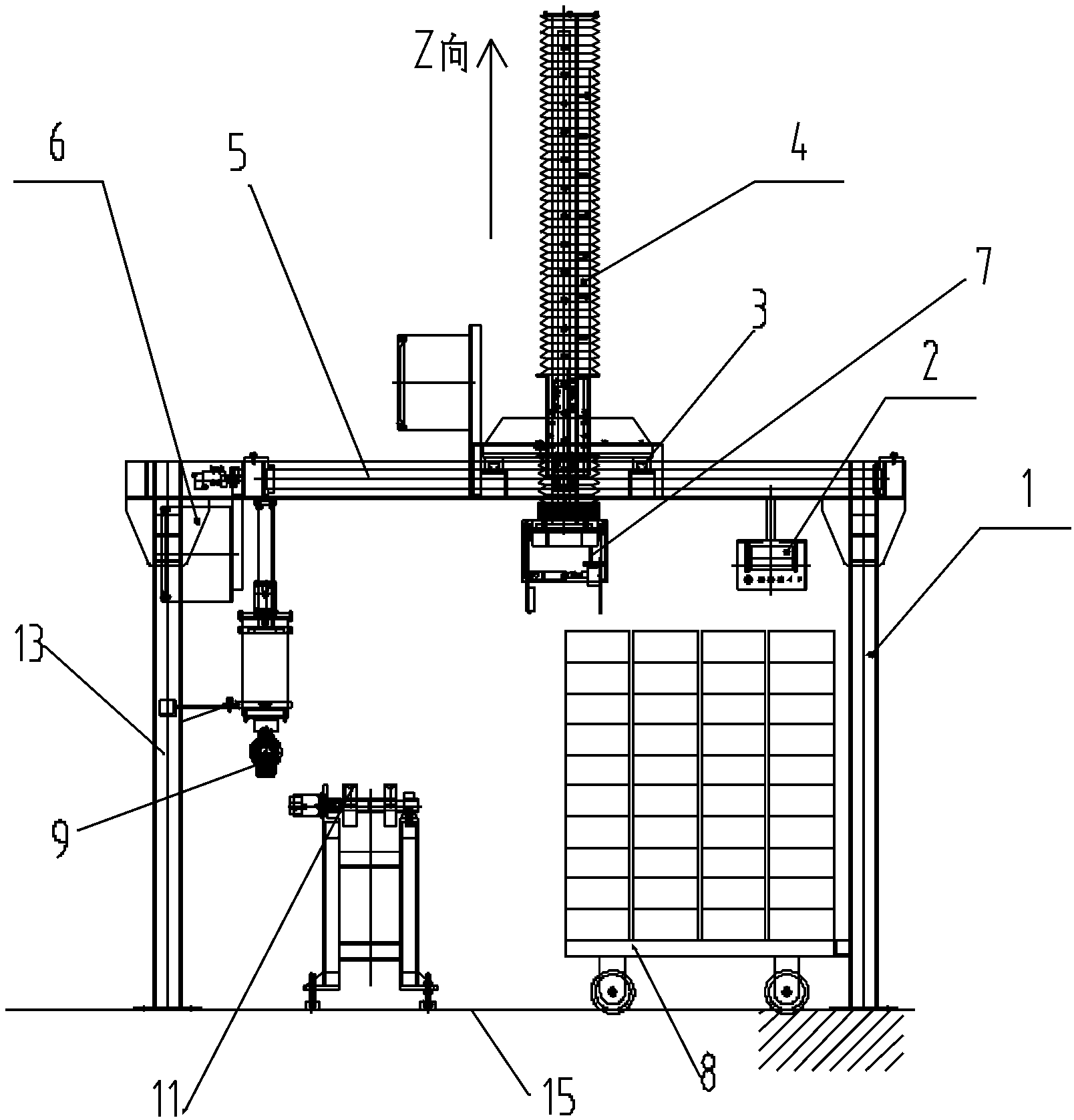

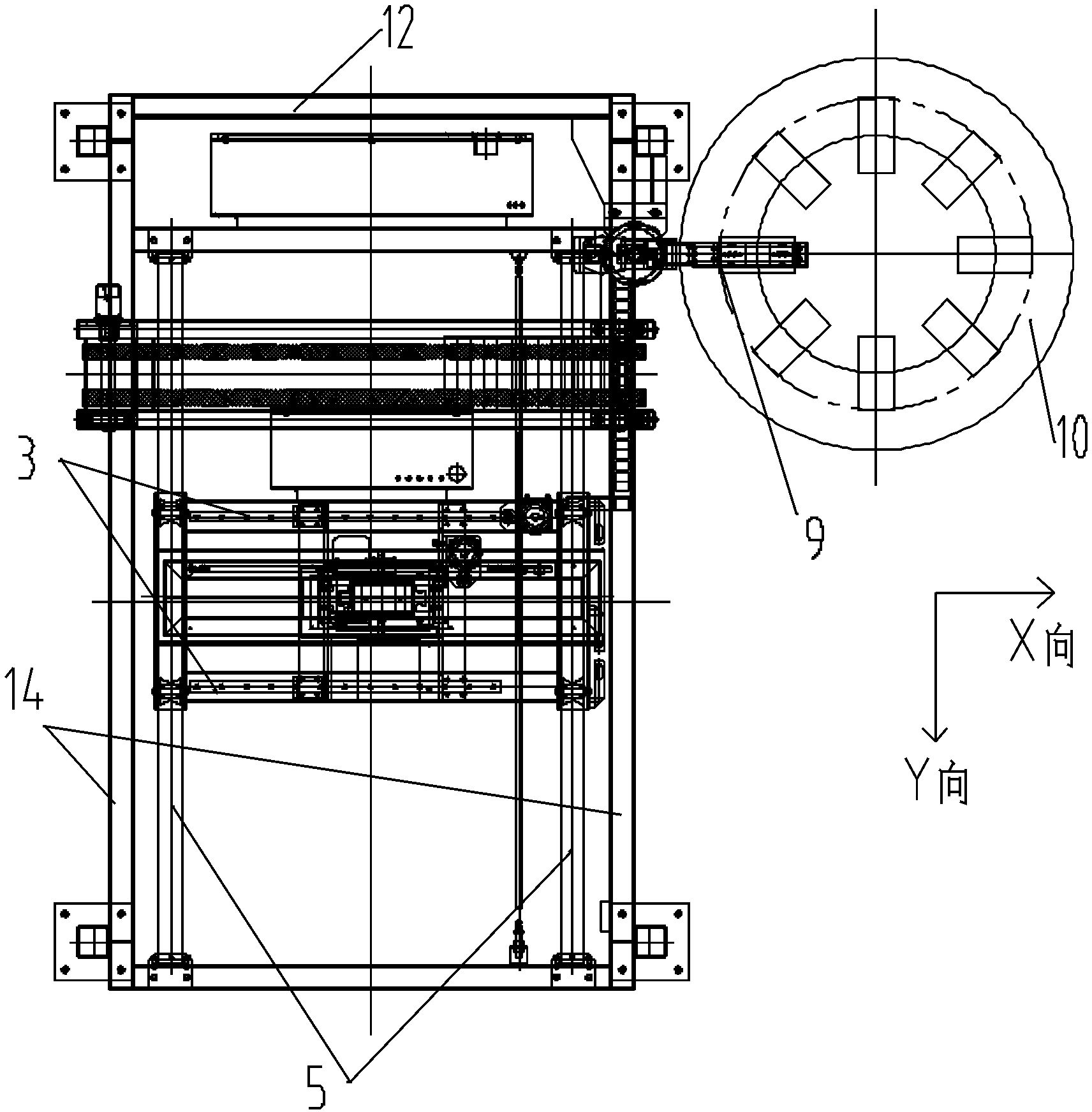

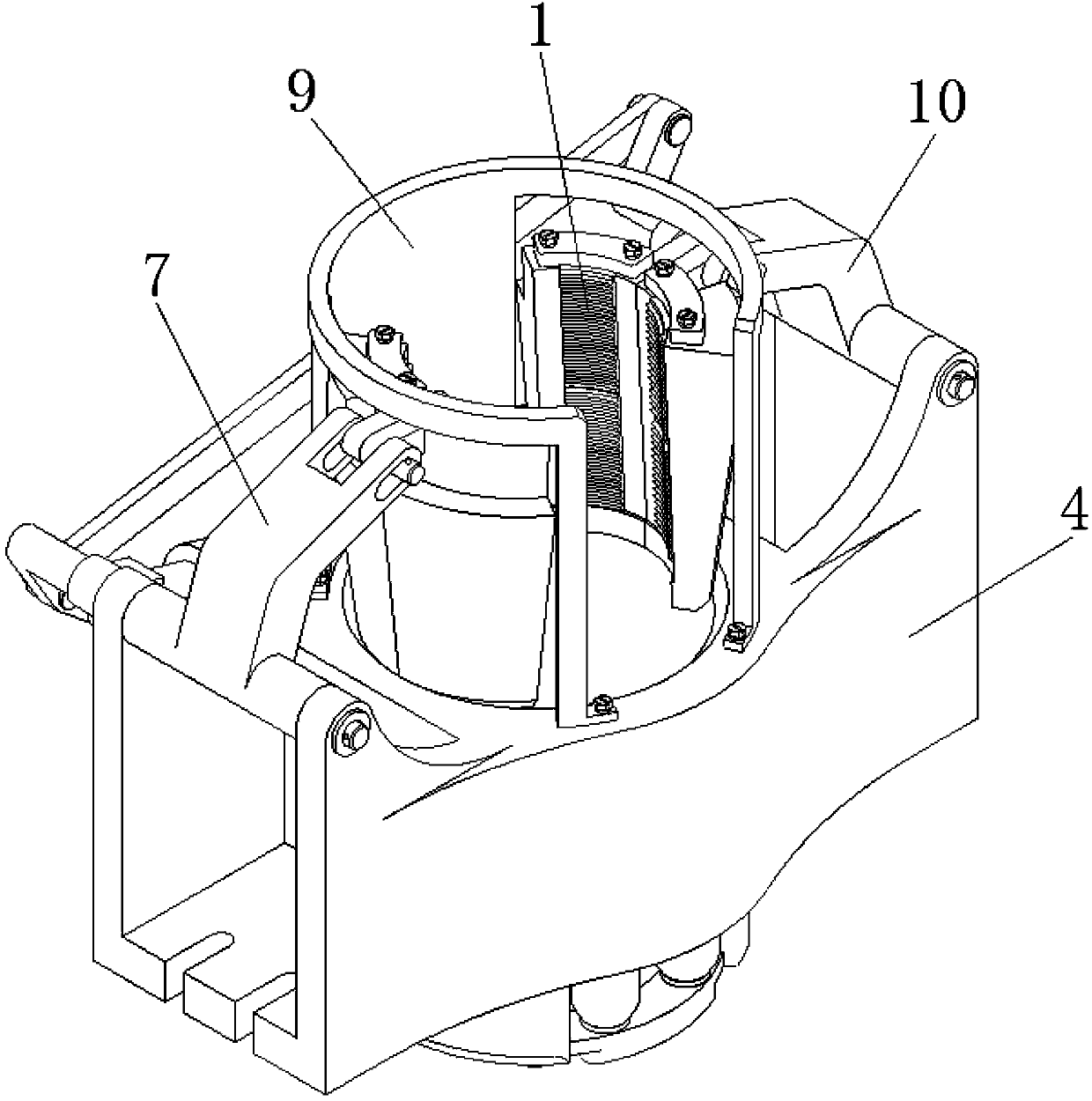

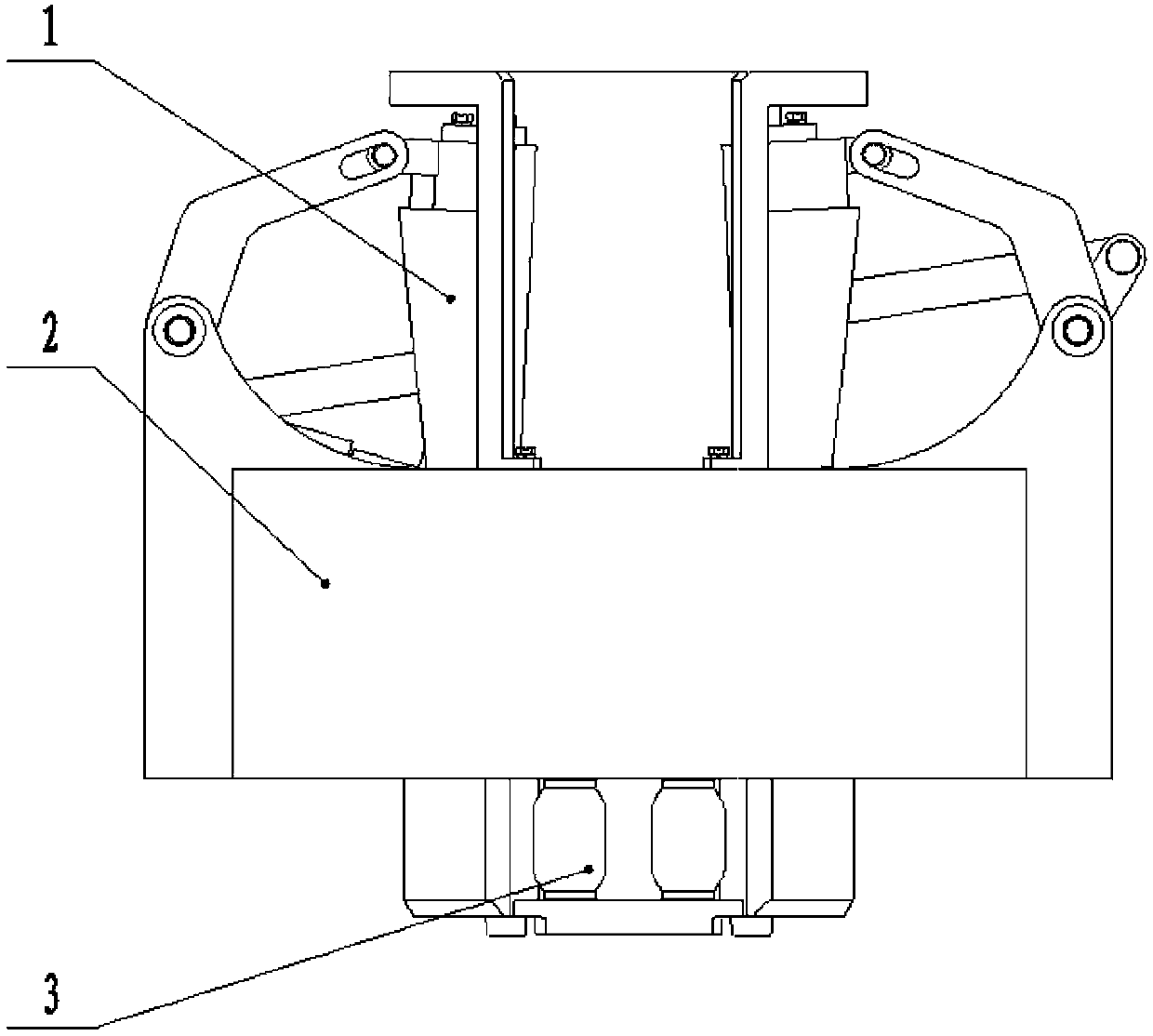

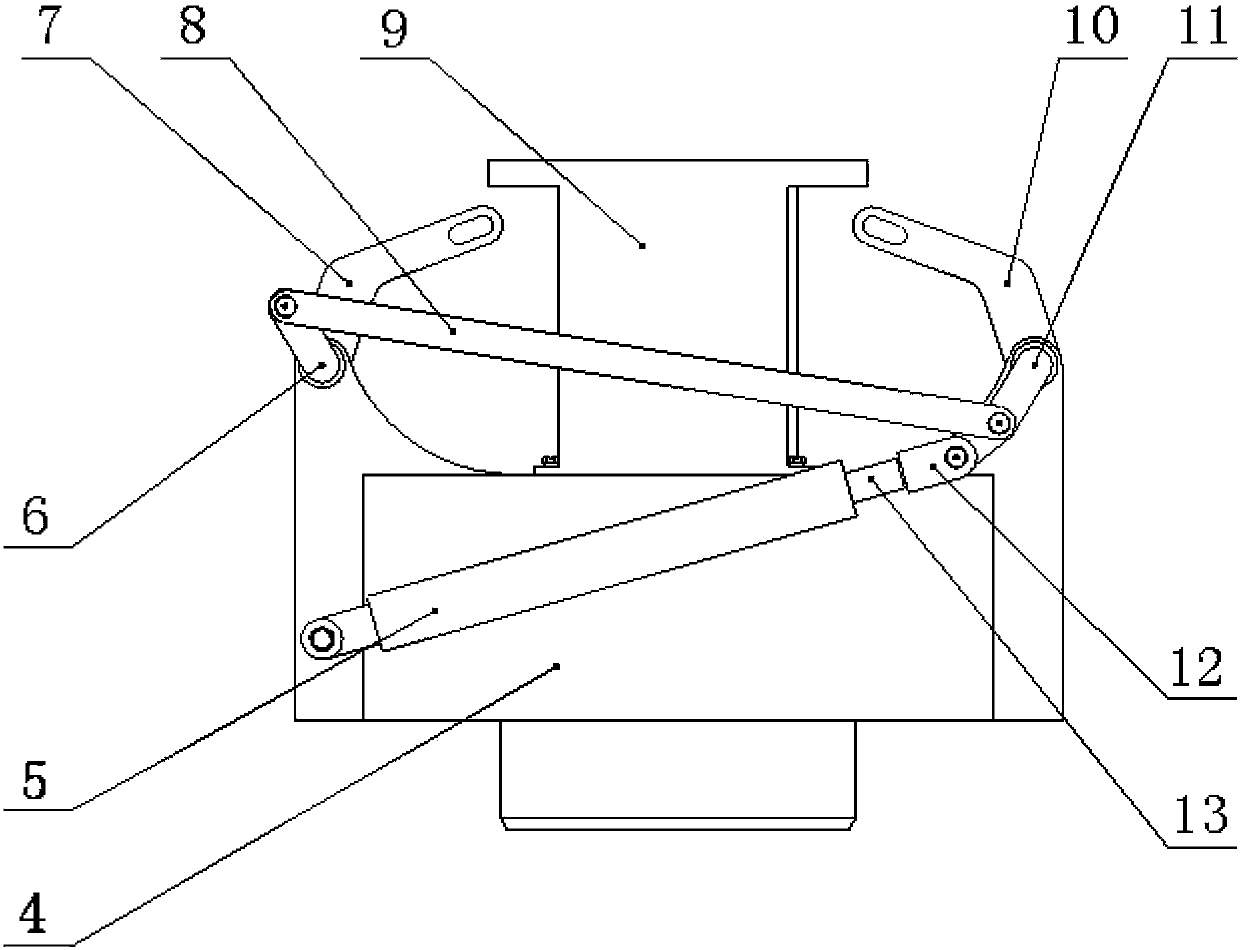

Air brick stacking manipulator system and control method

ActiveCN103832840AImprove beat matching problemsIncreased coherence of movementConveyorsStacking articlesBrickBarrel Shaped

The invention discloses an air brick stacking manipulator system and a control method. An air blank grabbing manipulator and an air brick stacking manipulator are integrated into a uniform connecting body through a portal frame foundation, after air bricks are grabbed by the air brick grabbing manipulator, the air bricks are transferred and carried subsequently by the air brick stacking manipulator, movement continuity is enhanced, working efficiency is substantially improved, the takt matching problem between two work procedures is solved, a lifting and swinging device of the whole small manipulator is integrated in a closed barrel-shaped structure, and the system is simple in structure, small in size, beautiful in appearance and convenient to mount in an inverted hanging mode; double-side supporting is formed by the large manipulator through an X-direction guide rail and a Y-direction guide rail on the two sides, and the problems that a traditional stacking manipulator is of a single stand column cantilever structure and is uneven in stress, and eccentric abrasion to the rails is caused are solved; both the two manipulators are installed in the inverted hanging mode, idle space in the portal frame space is utilized, the space utilization rate is high, and operation is not disturbed.

Owner:湖北成吉智能机械科技有限公司

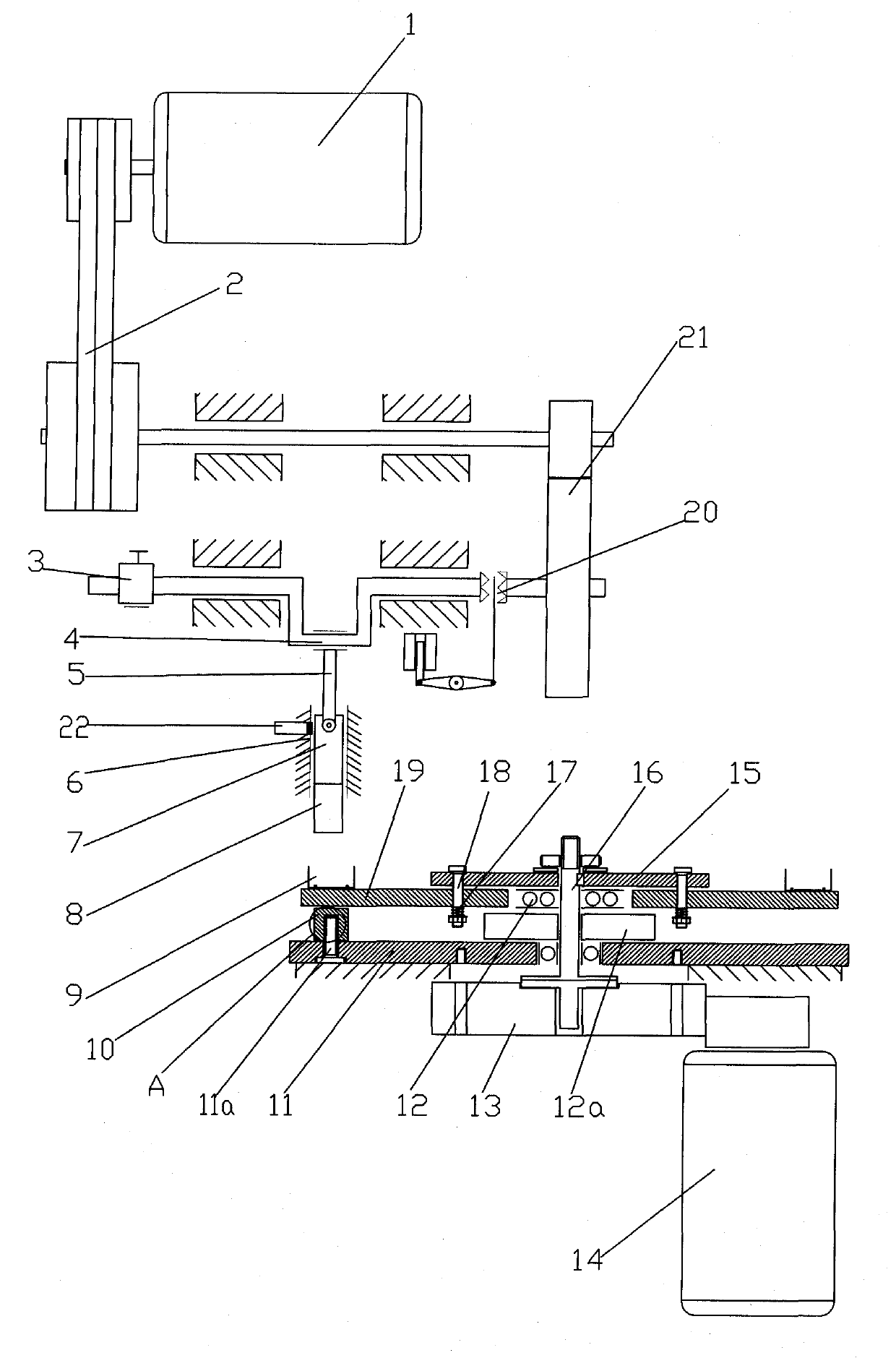

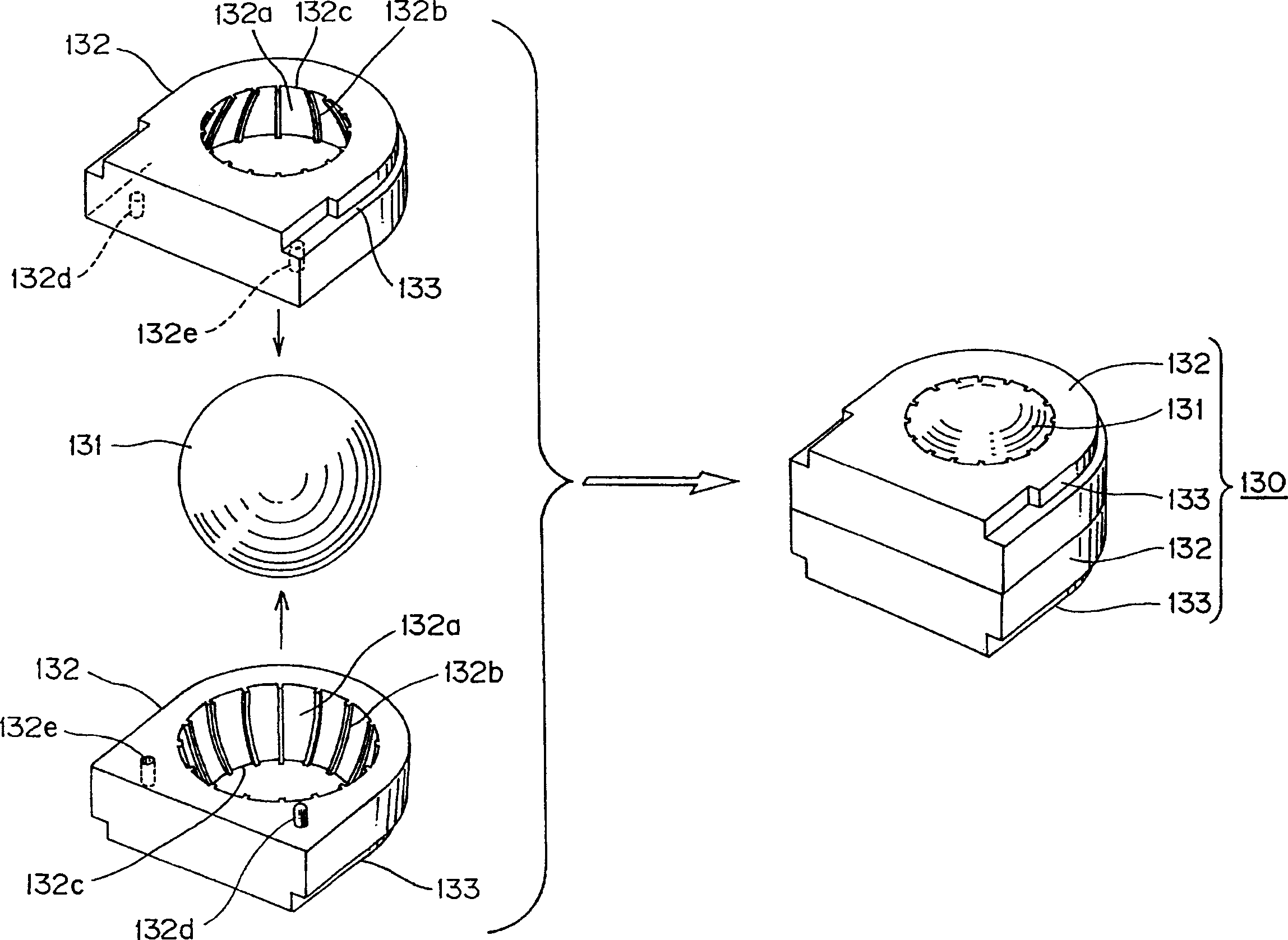

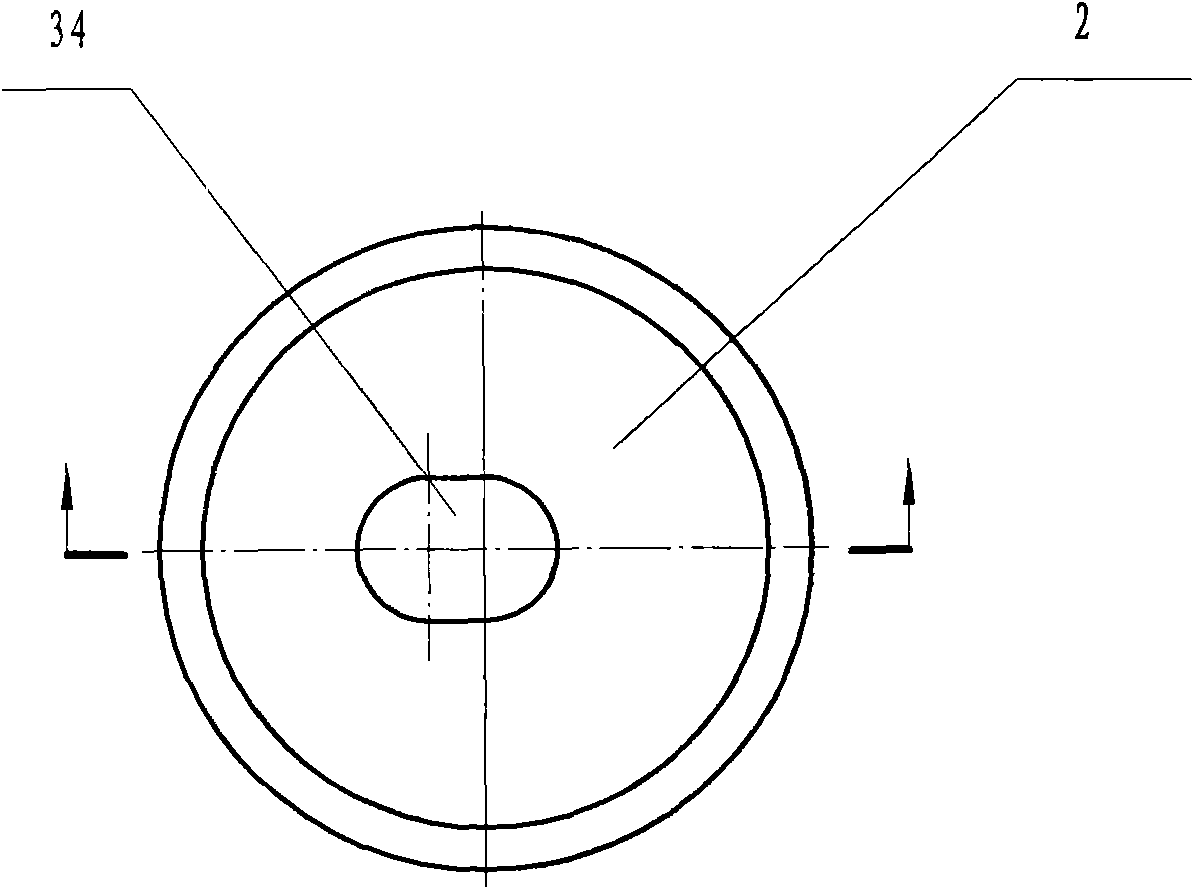

Automatic stamping machine and stamping method thereof

The invention discloses an automatic stamping machine, which comprises an upper die assembly and a lower die assembly, the lower die assembly comprises a lower die and a lower die driver, and the lower die driver comprises a turntable assembly and a turntable drive motor. The invention can ensure that an operation position of a stamping operator can be isolated from a stamping position by a turntable, consequently, an enough safe distance exists between the operation position and the stamping position when an upper material and a lower material are stamped, the hands of the operator can be protected from injury when misoperation or a mechanical fault occurs, and thereby safety is high; because an automatic control system controls the stamping process, human intervention is reduced, safety accidents caused by human subjectivity are eliminated, and the working efficiency is increased; because the combined structure of a central disk and an annular bearing platform is provided with buffer springs, the eccentric wear between the central disk, a drive shaft and bearings can be effectively prevented, the transmission of stamping force can be effectively obstructed as well, so that the central disk and the drive assembly thereof can be prevented from being affected by the stamping force, and thereby the service lives of the stamping turntable and the driver thereof can be prolonged.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

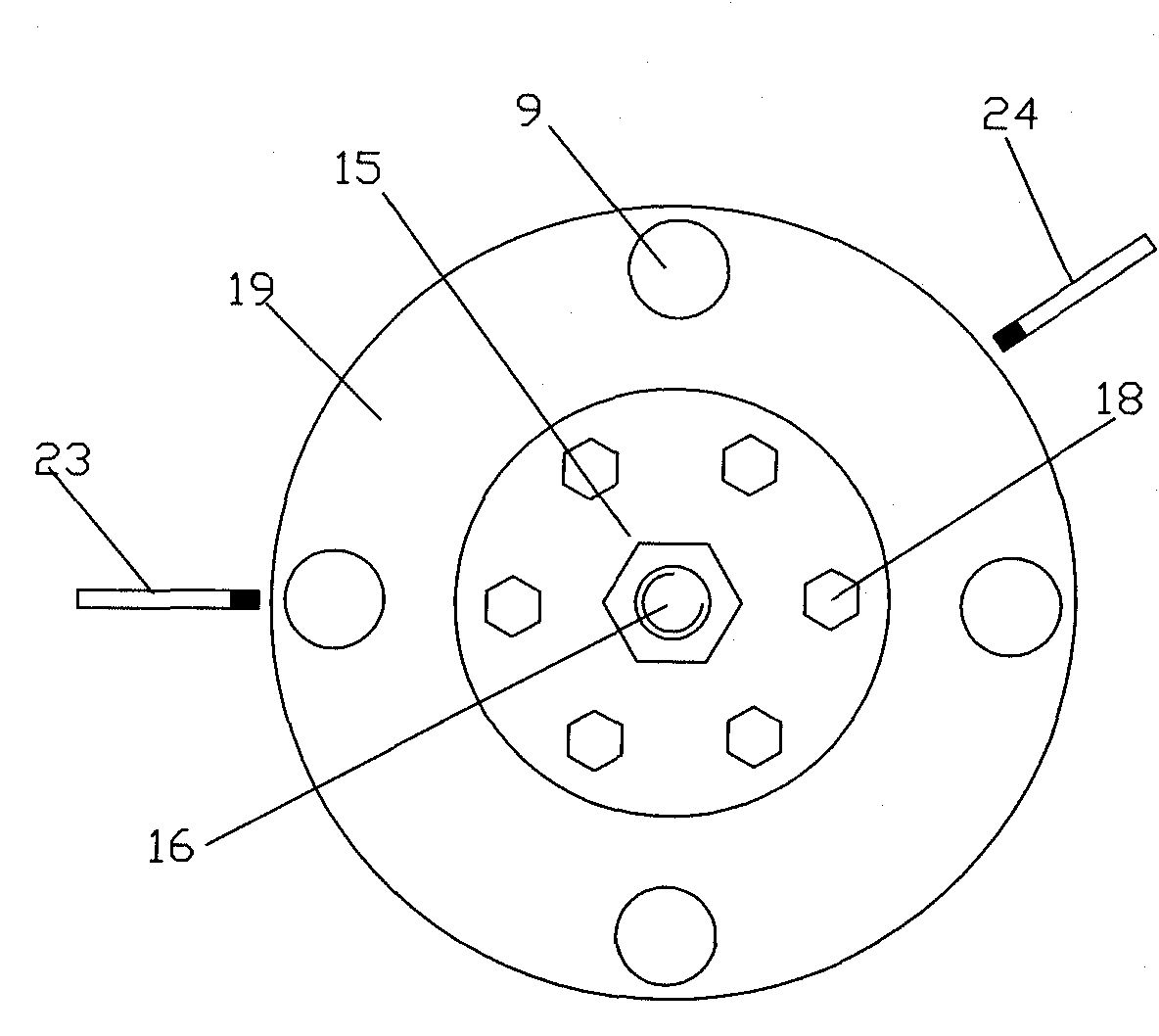

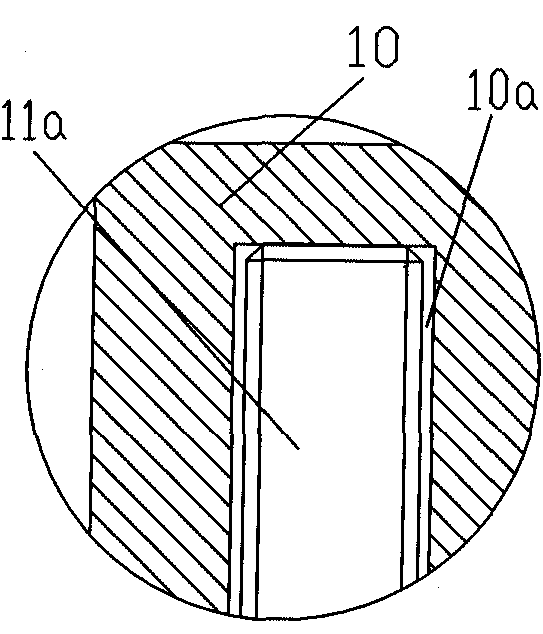

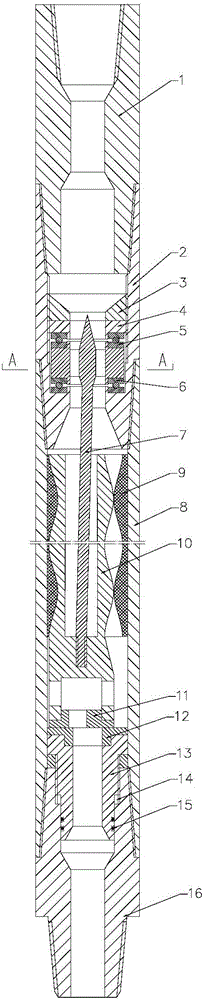

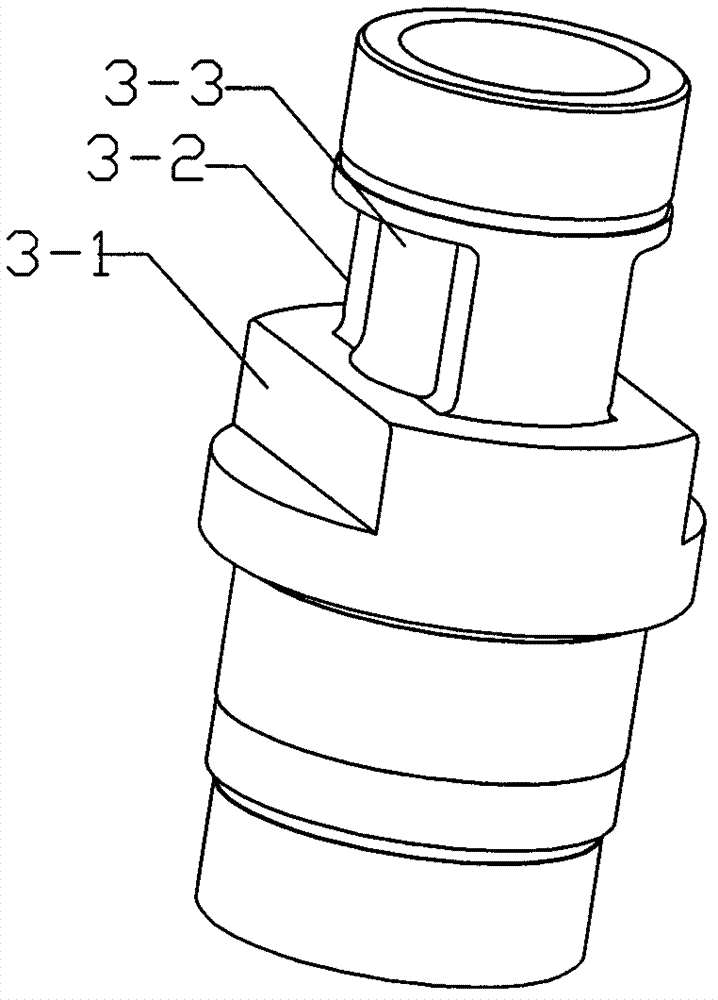

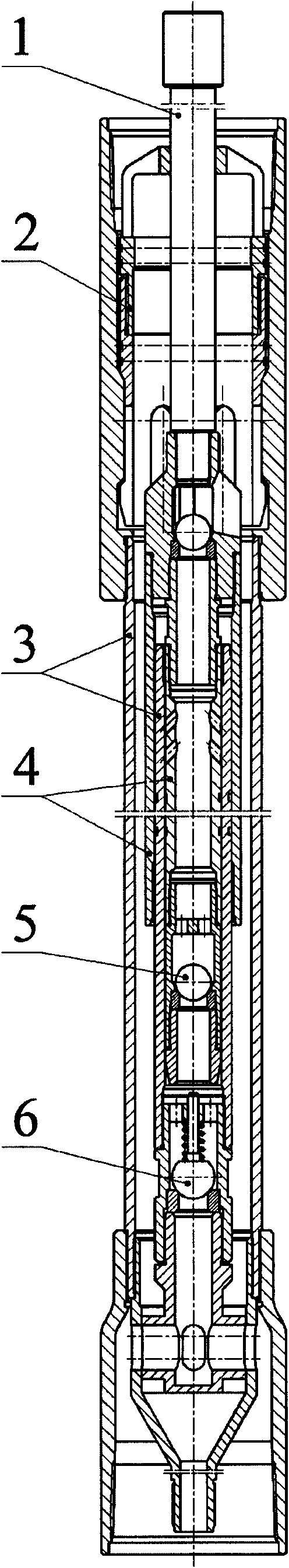

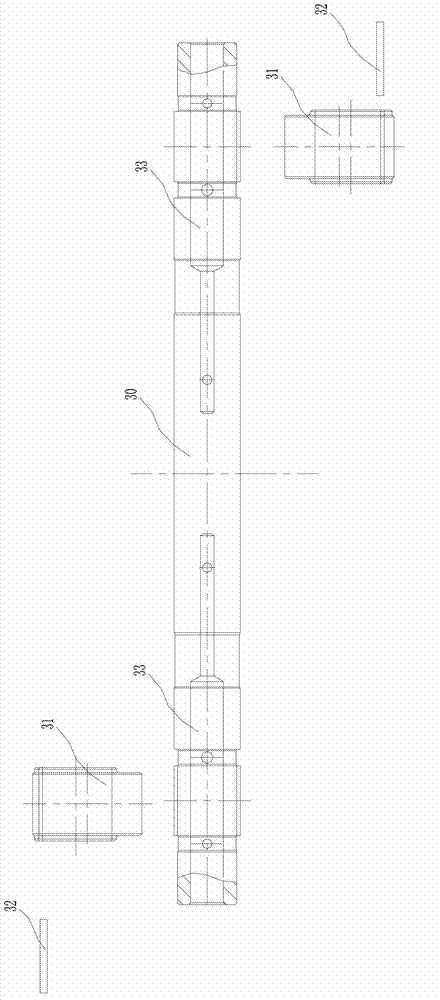

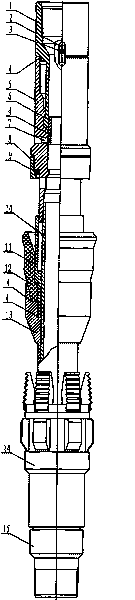

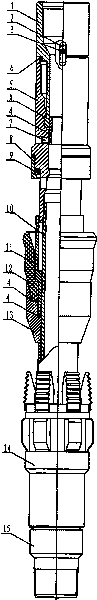

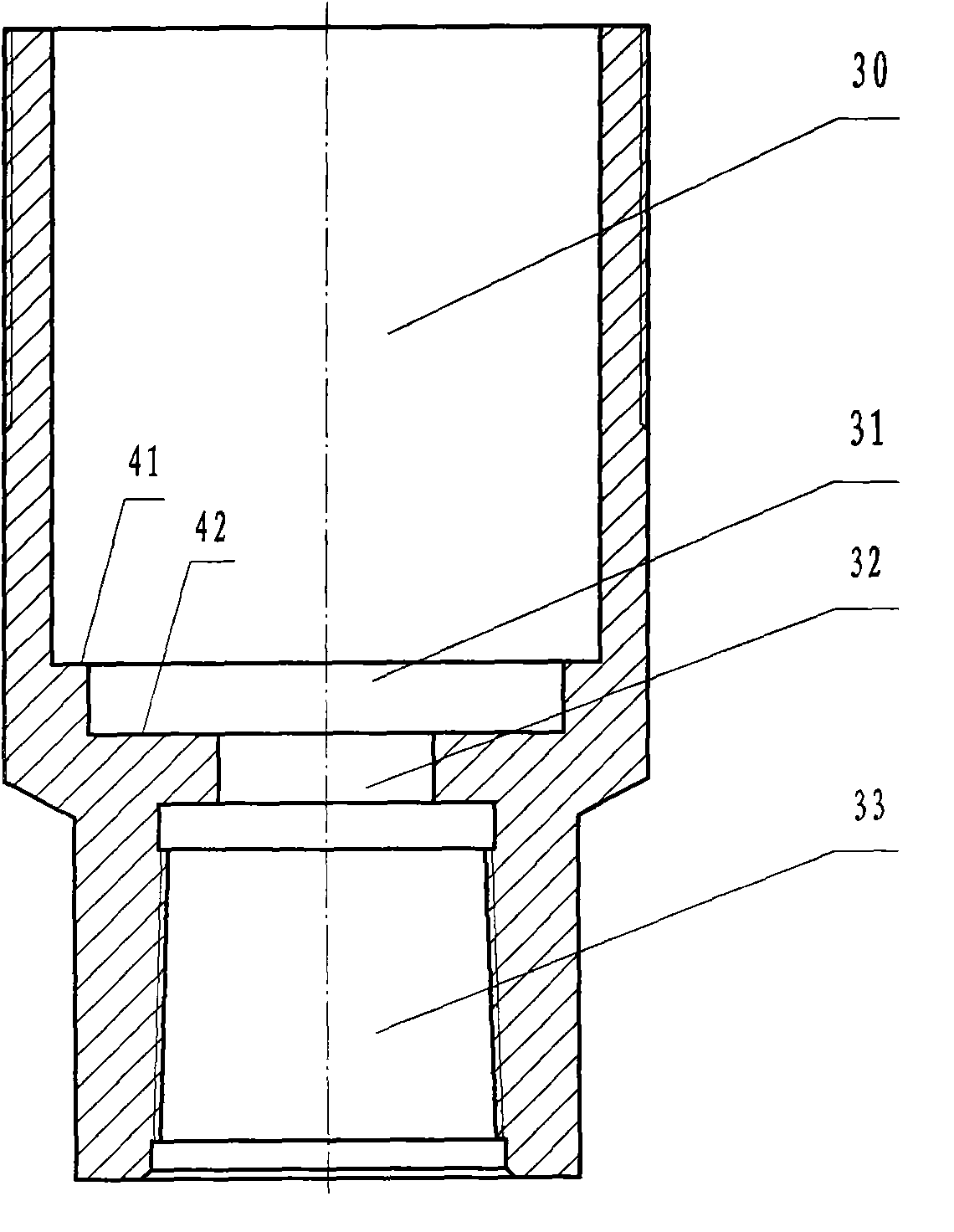

Shock-resisting downhole screw type pulse generator

ActiveCN106014316AAvoid impact crushingAvoid direct contactConstructionsVibration devicesThrust bearingEngineering

The invention provides a shock-resisting downhole screw type pulse generator which comprises an outer shell, a lock nut, a gland nut, an upper thrust bearing, a lower thrust bearing, a flexible rod, a stator rubber tube, a hollow rotor, a movable valve disk and a fixed valve disk. The flexible rod is arranged on the inner side of the outer shell and comprises a disk-shaped structure; a plurality of tap holes are formed in the disk-shaped structure; the lower thrust bearing is arranged below the disk-shaped structure; the upper thrust bearing is arranged on the disk-shaped structure; the gland nut is arranged on the upper thrust bearing; the lock nut is arranged on the gland nut; the hollow rotor is arranged on the inner side of the stator rubber tube; the lower end of the flexible rod is fixed to the hollow rotor; and the movable valve disk is located below the hollow rotor. The interval between the movable valve disk and the fixed valve disk of the shock-resisting downhole screw type pulse generator can be adjusted, and installation and adjustment of the whole machine are facilitated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Inclining and vertical well drilling rig automatic drill pipe slip device

InactiveCN103397856AReduce labor intensityAvoid partial wearDrilling rodsDrilling casingsHydraulic cylinderWell drilling

The invention relates to a land petroleum drilling rig device, in particular to an inclining and vertical well drilling rig automatic drill pipe slip device. A slip seat device of the inclining and vertical well drilling rig automatic drill pipe slip device comprises a slip seat and a shield, wherein the shield is installed on the slip seat, a hydraulic cylinder is hinged to a hinge pin which is fixedly welded to the slip seat, a piston rod which is used in cooperation with the hydraulic cylinder is hinged to a double-lug ring through a hinge pin, a driving rotary shaft is hinged to both the double-lug ring and a transmission connecting rod through hinge pins, the transmission connecting rod is hinged to a driven rotary shaft through a hinge pin, the driving rotary shaft and the driven rotary shaft are installed in round holes formed in the upper end of the slip seat, a left lifting arm is fixedly connected with the driven rotary shaft, and a right lifting arm is fixedly connected with the driving rotary shaft. The inclining and vertical well drilling rig automatic drill pipe slip device has the advantages that a drill rod is clamped and held in the process of tripping operation, the labor intensity of workers is relieved, a drill stem is prevented from wearing a well opening in an eccentric mode when an inclining well is drilled, and safety and the working efficiency are improved. The inclining and vertical well drilling rig automatic drill pipe slip device overcomes the defect that a drill stem wears the well opening in an eccentric mode when the inclining well is drilled through an existing drill pipe slip device.

Owner:CHINA PETROLEUM LIAOHE EQUIP

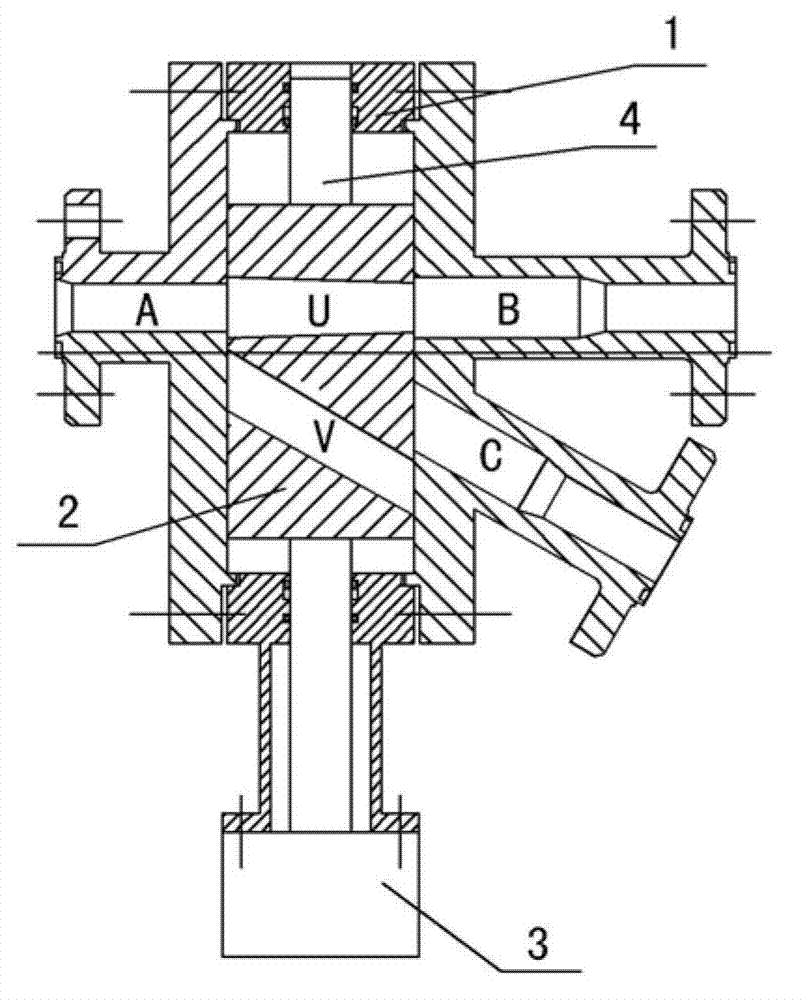

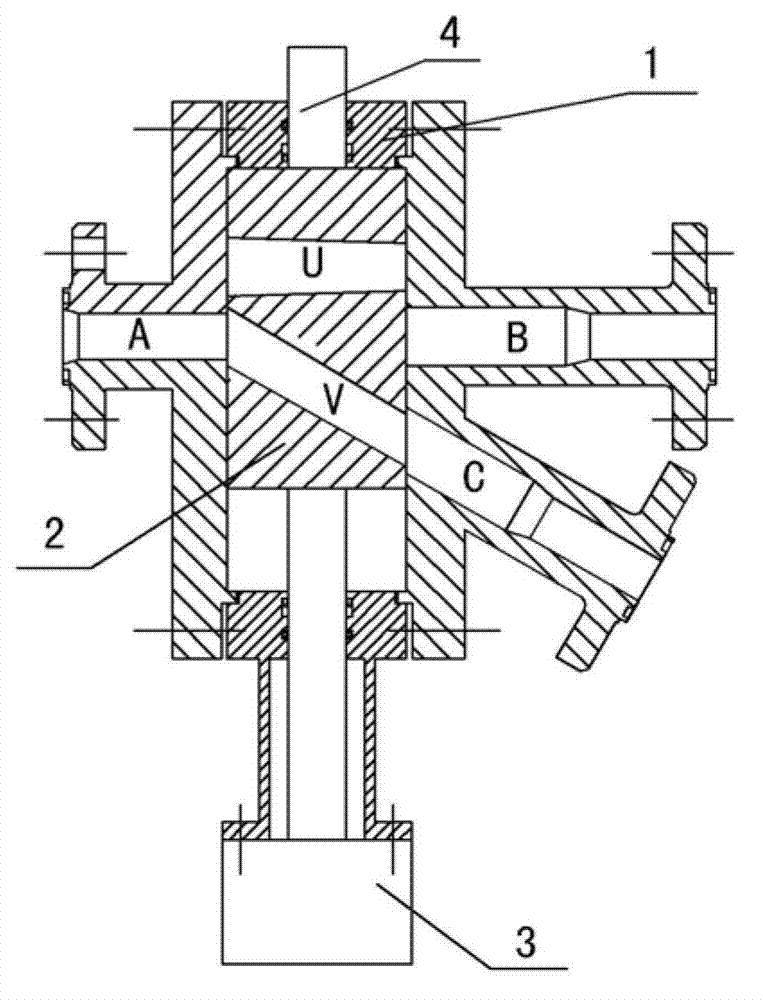

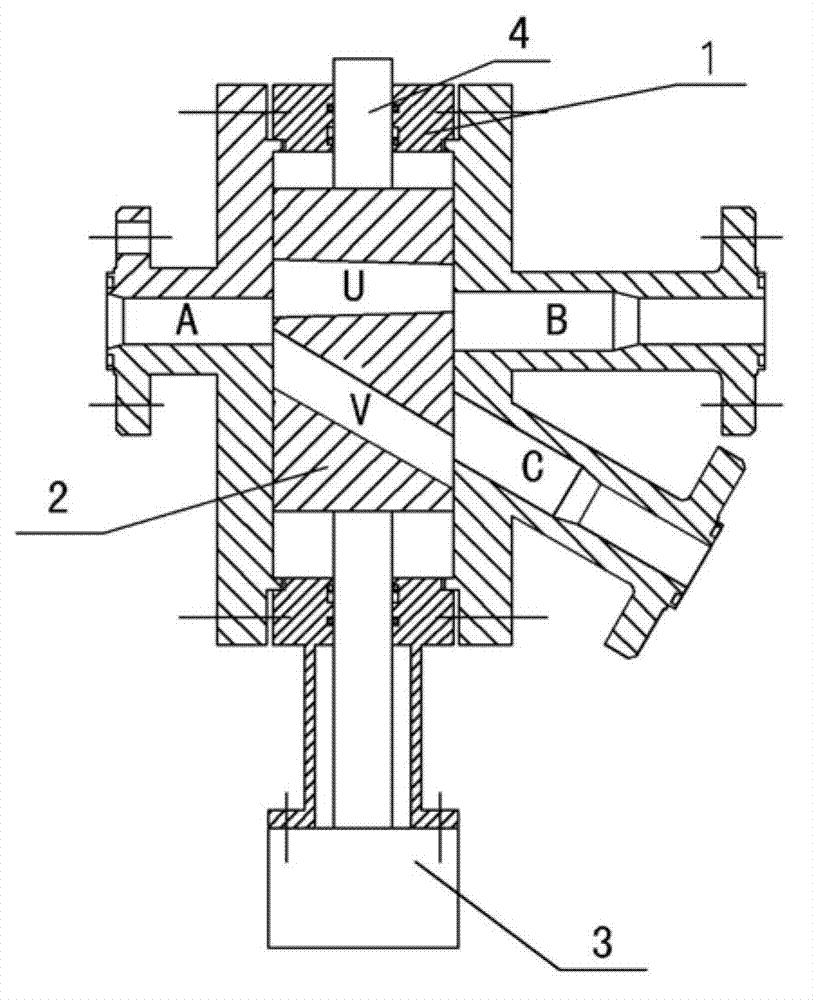

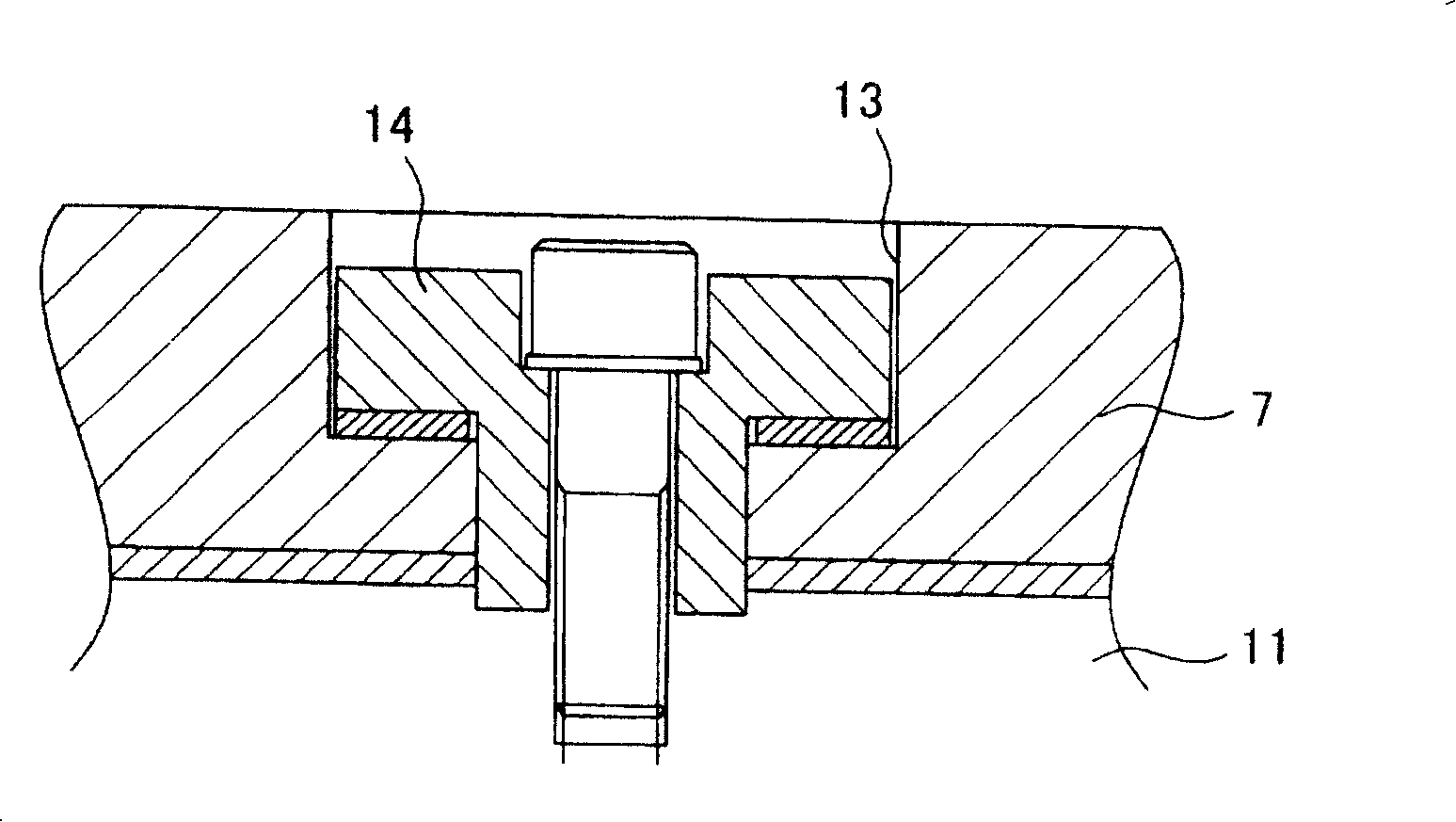

Slide powder-feeding three-way reversing valve

ActiveCN102818047AReduce wearPrevent compactionMultiple way valvesValve housingsEngineeringOperational stability

The invention discloses a slide powder-feeding three-way reversing valve which is characterized in that a columnar valve cavity is reserved in a valve body with one inlet and two outlets, a double-flow-passage columnar spool which can slide linearly along the columnar valve cavity is disposed in the same; a valve body inlet passage A, a valve body outlet passage B and a valve body outlet passage C are arranged on the valve body; the a valve body outlet passage B is coaxial with the valve body inlet passage A, an acute included angle a is formed by outflow directions of the valve body outlet passage B and the valve body outlet passage C, axis of each valve body passage is on a plane M; a spool passage U and a spool passage V are arranged in the columnar spool; and different positions of the columnar spool in the columnar valve cavity correspond to different on and off states. By the slide powder-feeding three-way reversing valve, operational stability of a powder feeding device is improved effectively and service life of the device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +2

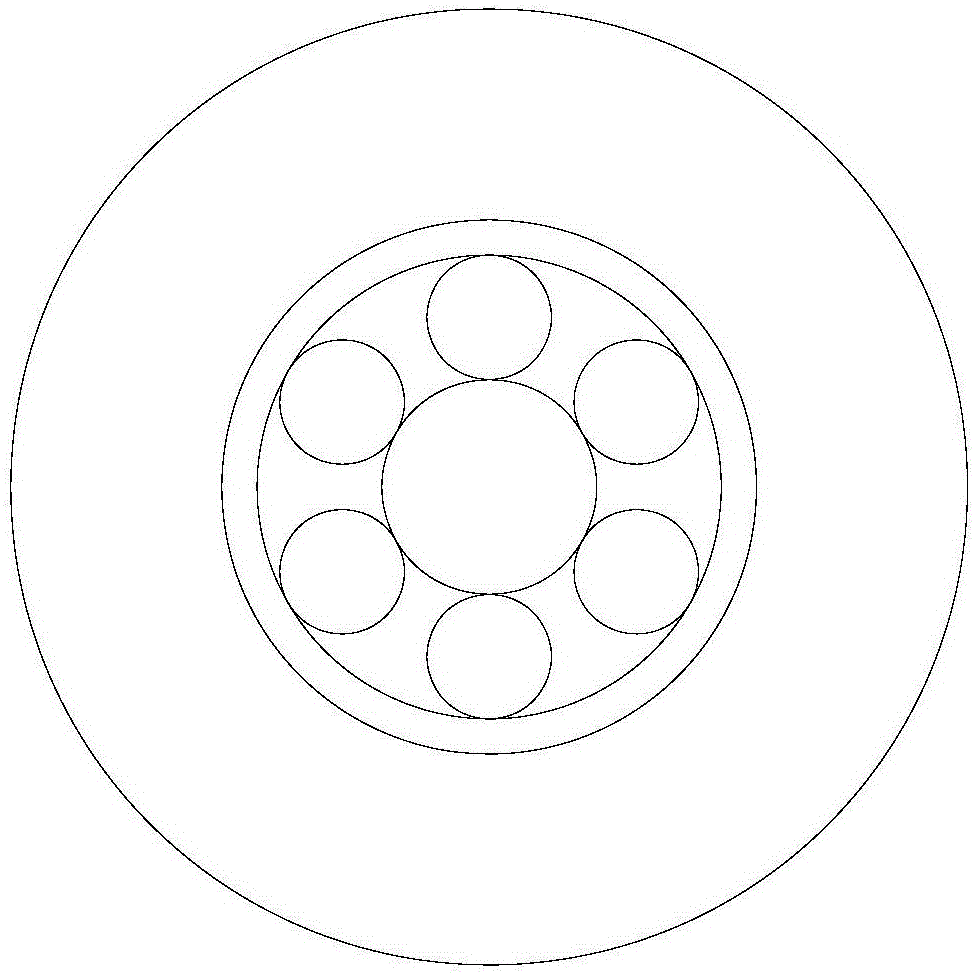

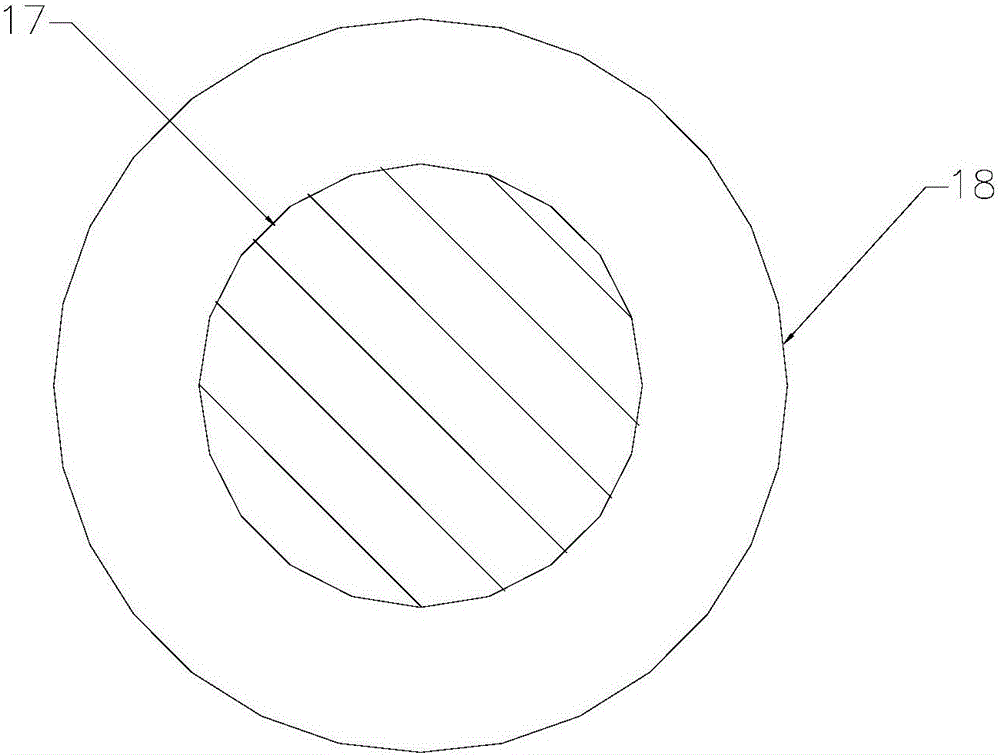

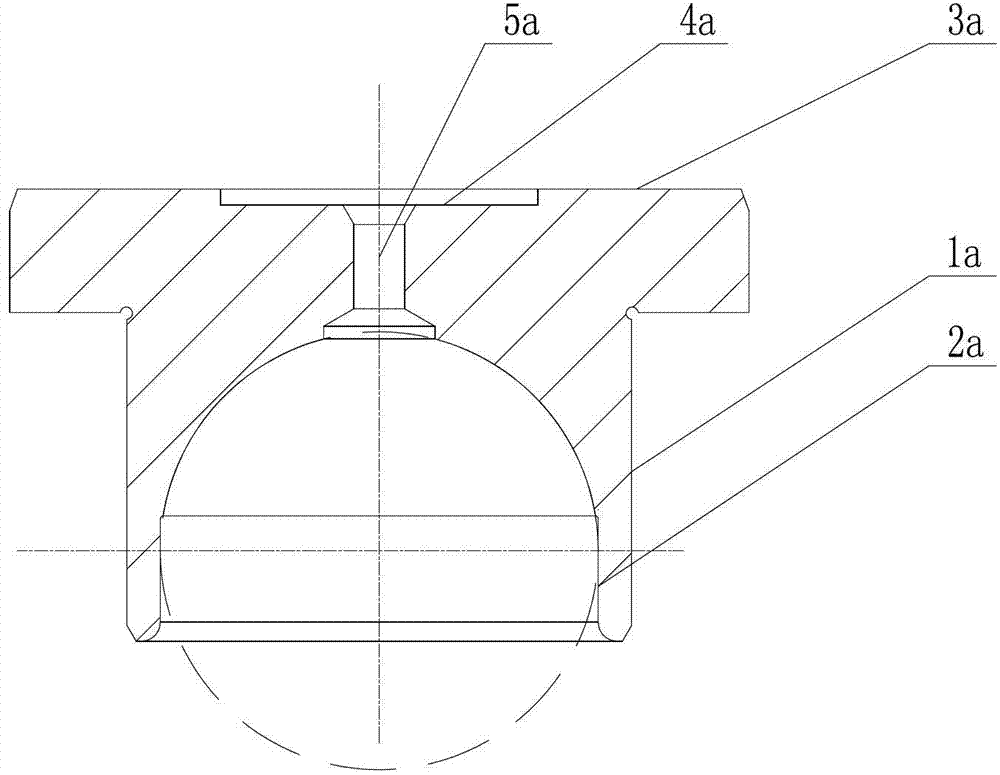

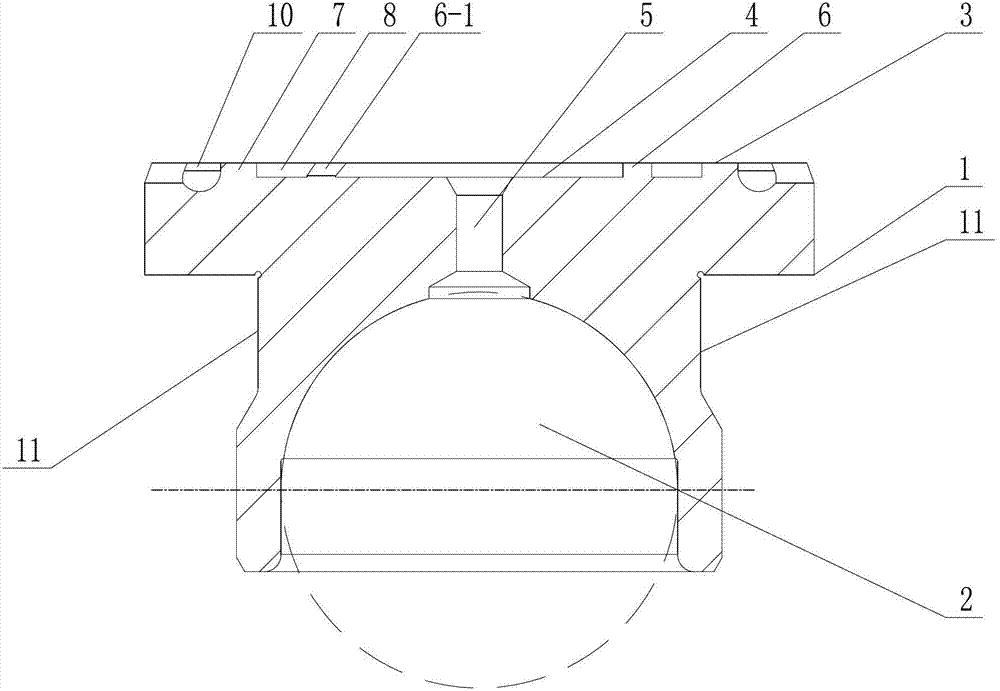

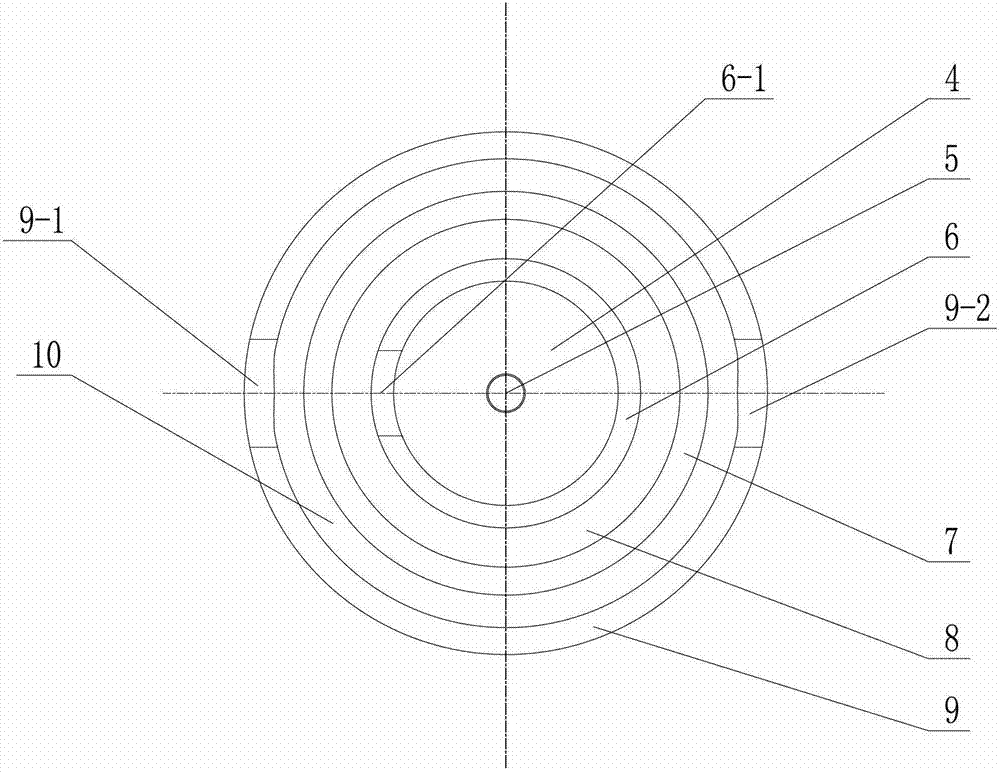

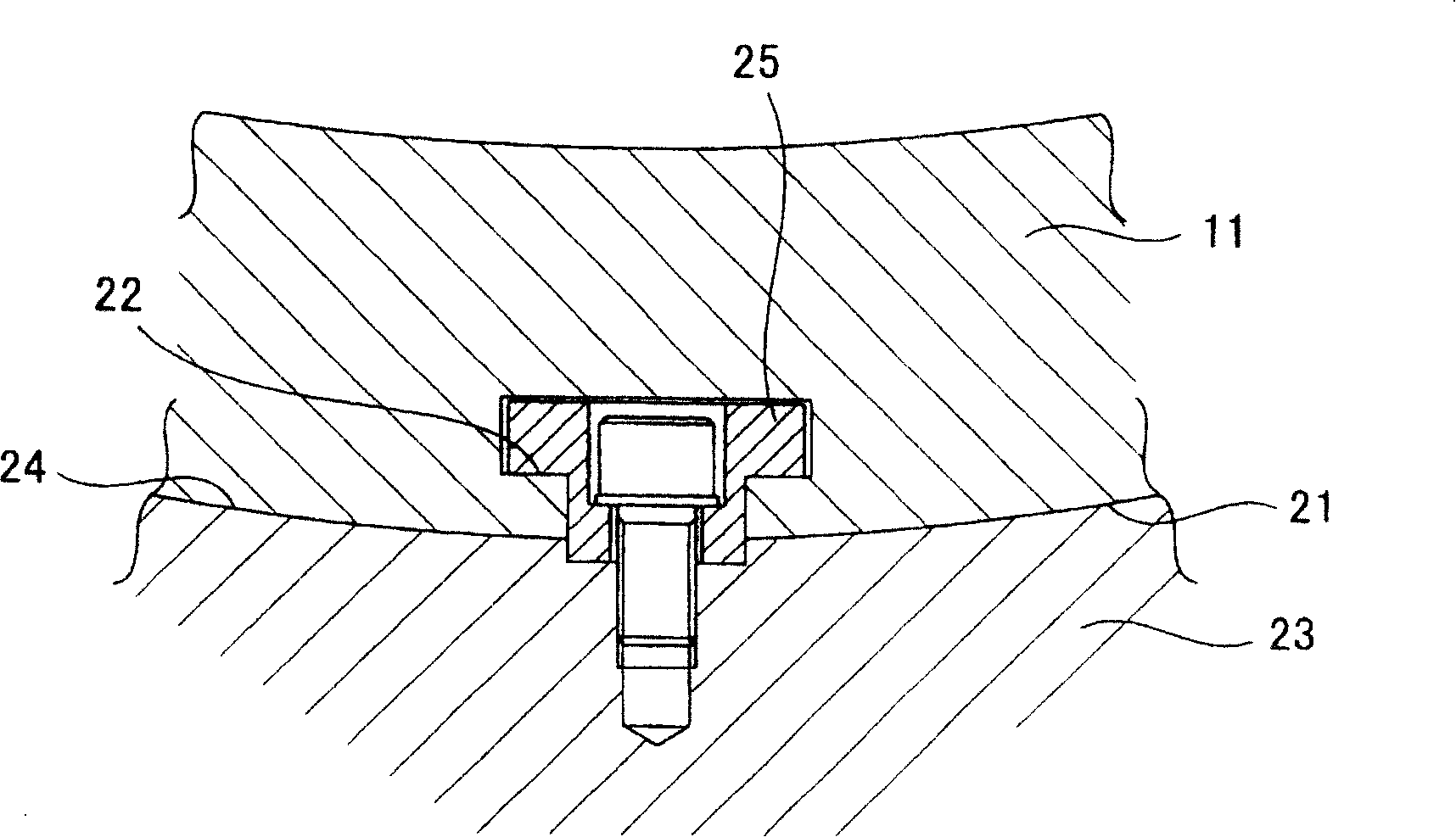

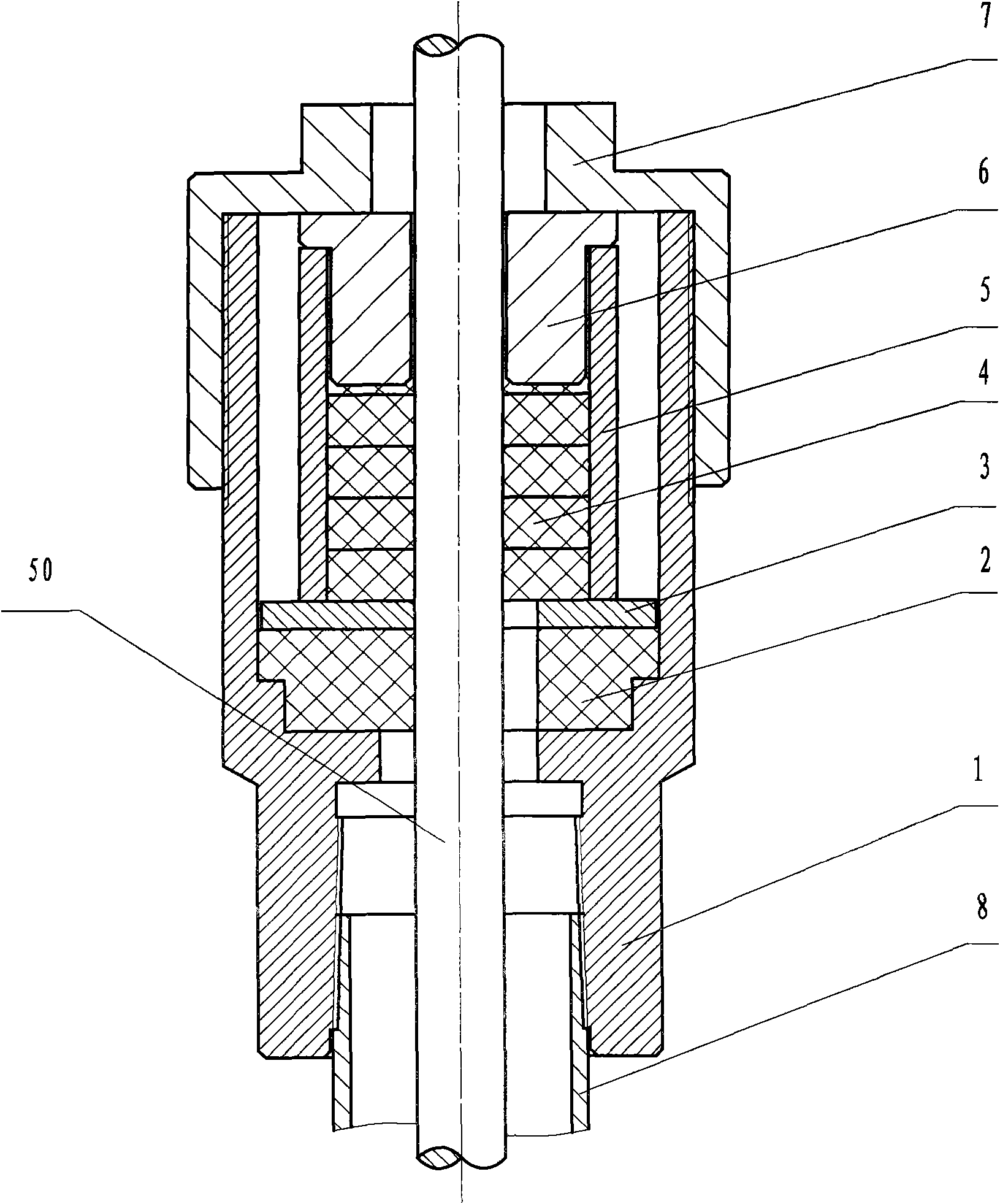

Slipper used for plunger type hydraumatic pump

ActiveCN102926987AAvoid partial wearMake sure to formPositive displacement pump componentsLiquid fuel engine componentsHydraulic pumpEngineering

The invention relates to a slipper.used for a plunger type hydraumatic pump. The slipper comprises a slipper body, wherein one end of the slipper body is provided with a spherical closing port which is matched with a plunger bulb, and the other end of the slipper body is provided with a flat surface contacted with a wobble disc; and the middle of the flat surface has a groove, the middle of the groove has a damping hole, and the damping hole is communicated with the spherical closing port. The slipper is characterized in that the edge of the groove is provided with an annular inner support belt, the annular support belt is provided with a first oil port, the periphery of the annular inner support belt is provided with an annular seal belt, and an annular oil groove is reserved between the annular seal belt and the annular inner support belt; and the periphery of the annular seal belt is provided with an annular outer support belt, the annular outer support belt is provided with a second oil port and a third oil port, and an annular outer oil groove is reserved between the annular outer support belt and the annular seal belt. The slipper provided by the invention has the advantages that a good oil film and good static pressure are established between the slipper and the wobble disc, the problems such as eccentric wear, deformation, slipper dropping and slipper loosing are solved, the reliability of the slipper is improved, and further, the service life and the efficiency of a plunger pump are improved.

Owner:WUXI WEIFU PRECISION MACHINERY MFG

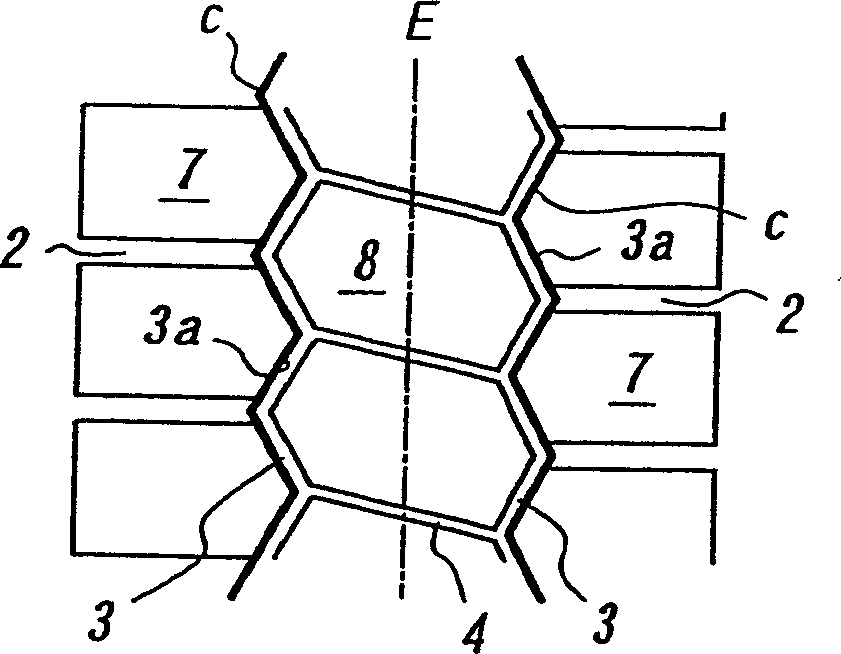

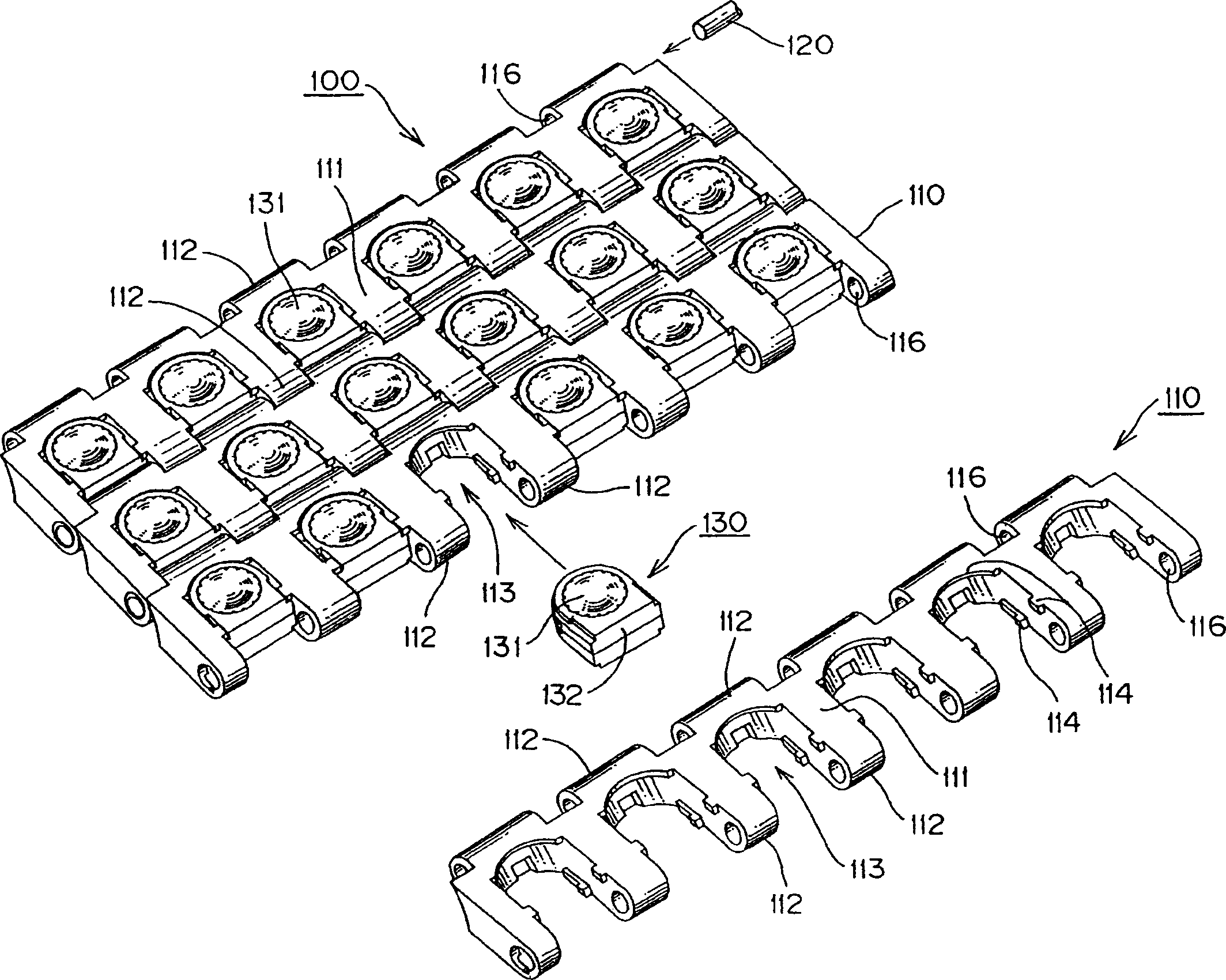

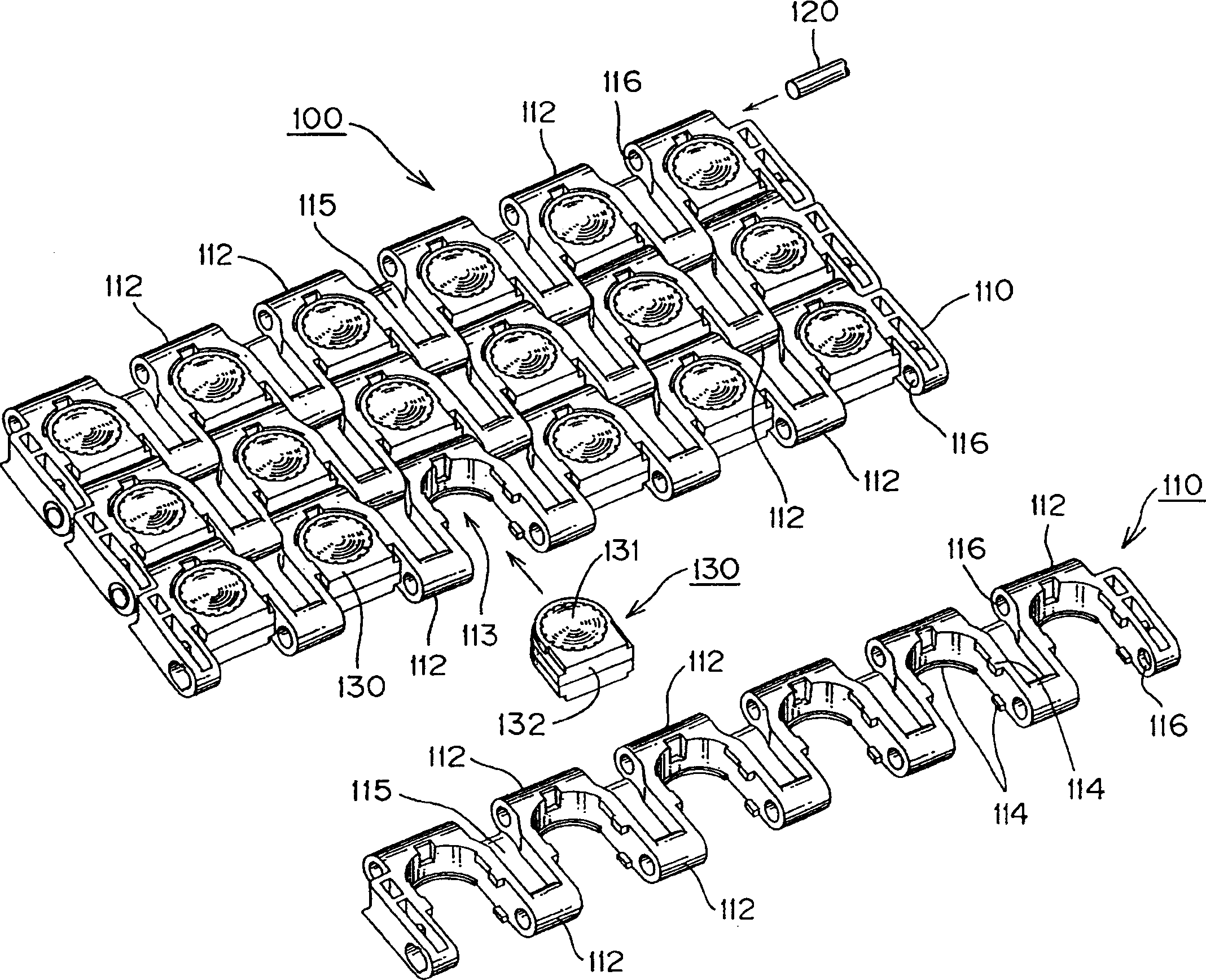

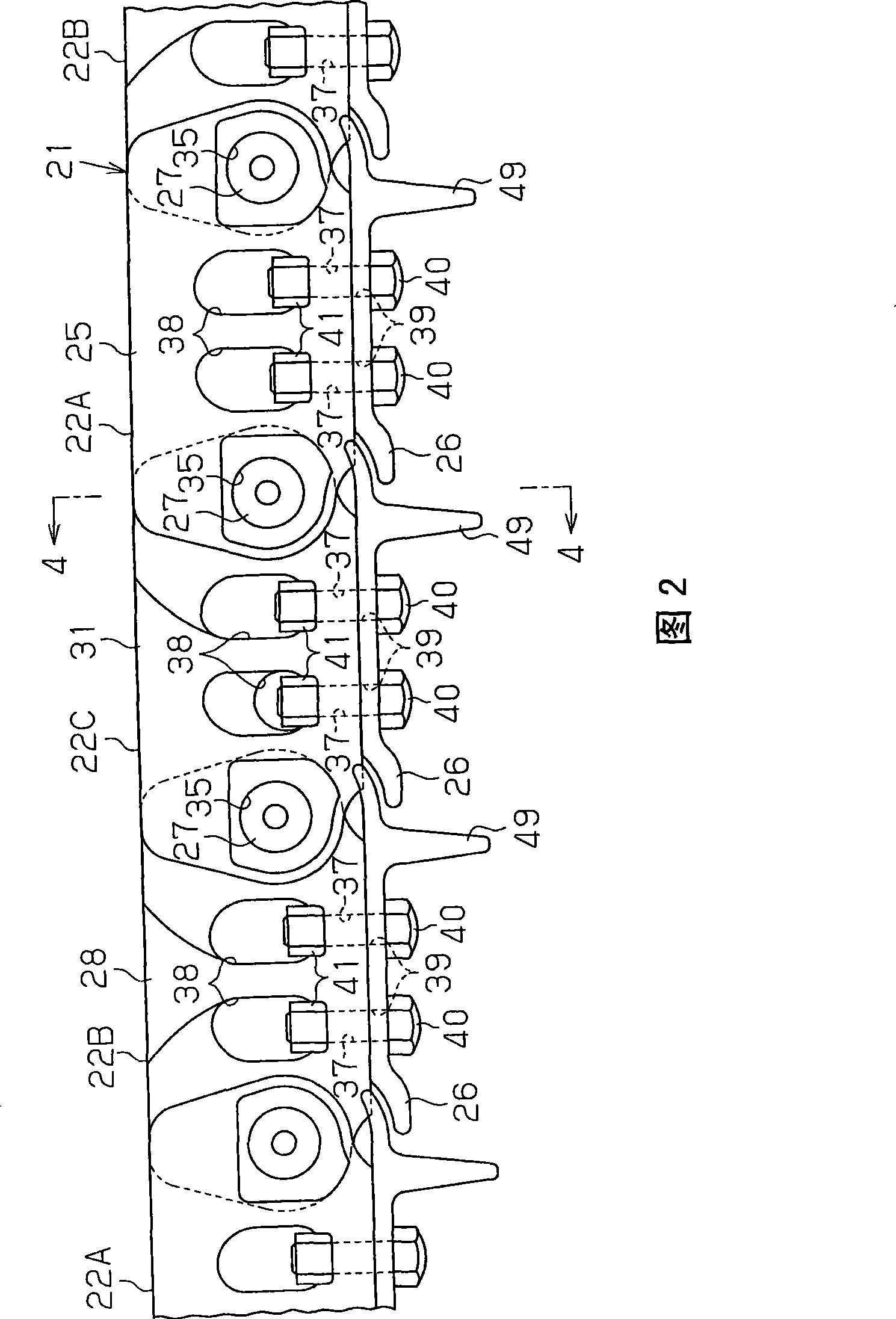

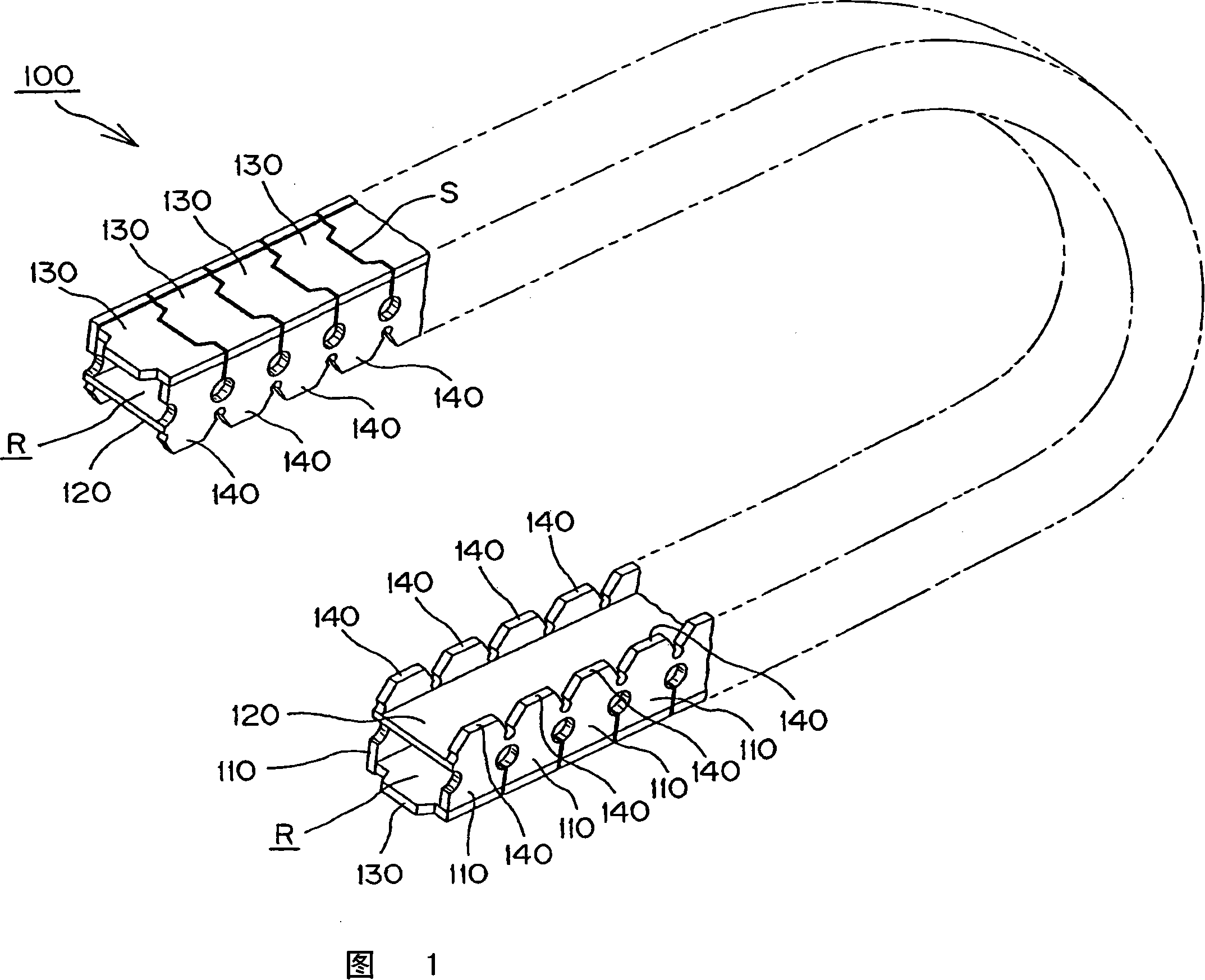

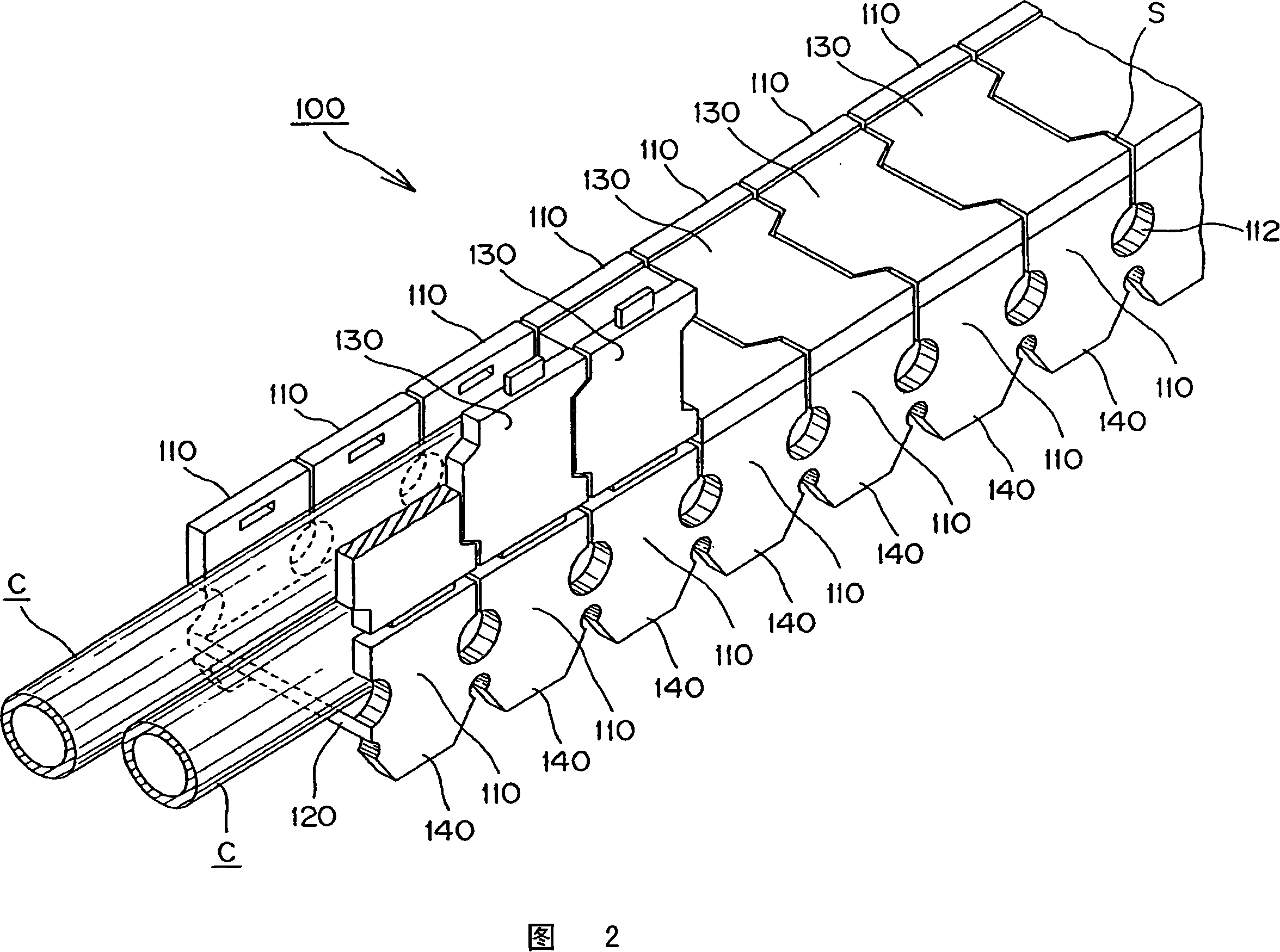

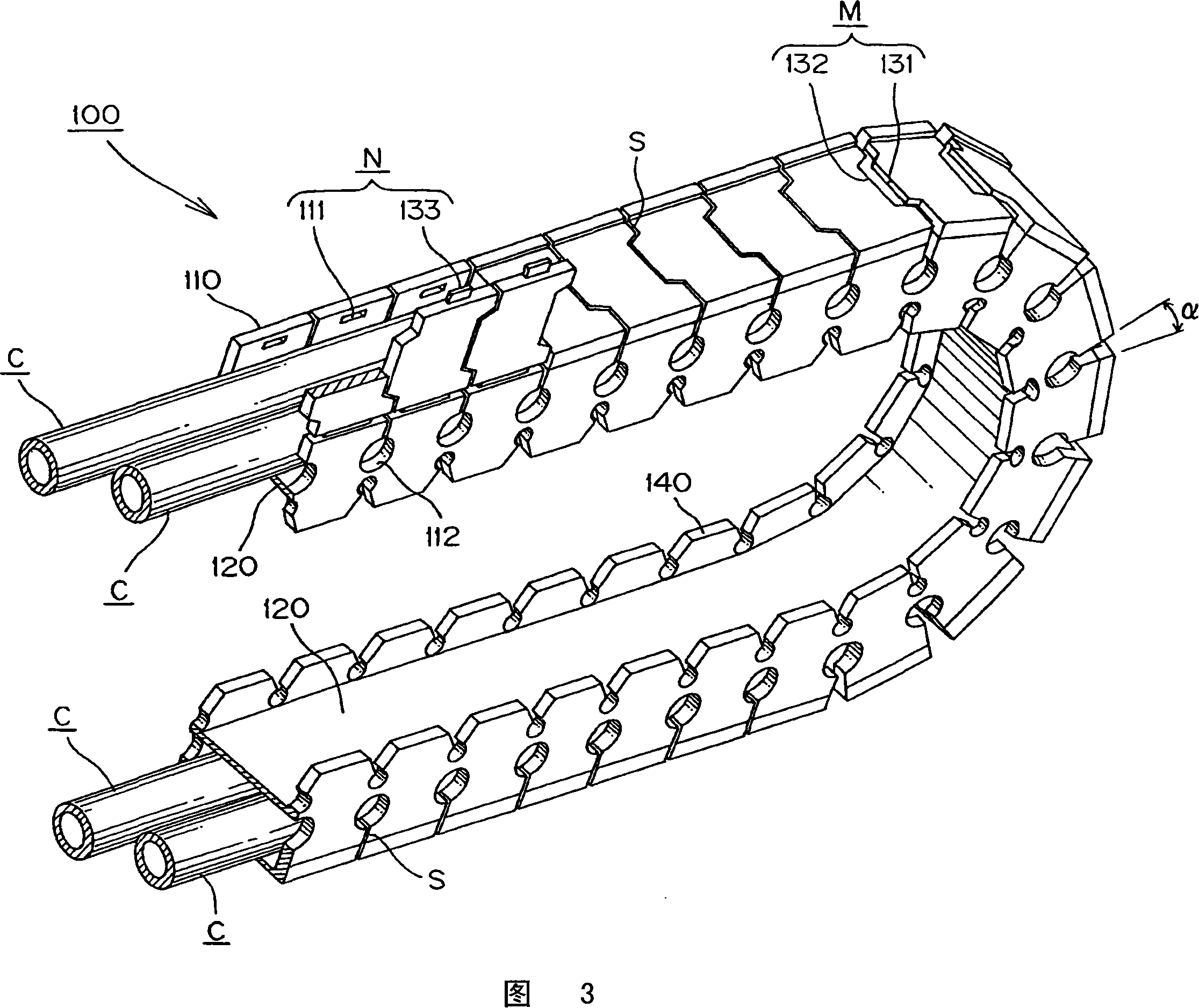

Conveyor chain

ActiveCN1868836AInhibit wearGood self-lubricating performanceConveyorsPackagingPolyesterFree rotation

Conveyor chains are provided which comprise free balls which are free to rotate in all directions thereby allowing for the stable conveyance of articles in any direction in the entire horizontal plane and at an increased speed in the direction of conveyance with reduced contamination in the conveyance environment. A conveyor chain 100 comprises a number of chain links 110 comprising a plurality of hinge portions 112 in a zigzag formation protruding from the front and rear end edges that are connected to each other in the longitudinal direction of the chain through hinge pins 120 . Free balls 131 protrude from both the surface and back sides of the chain link 110 and are free to rotate while held in the chain link 110 . Either the free balls 131 or ball holding portions 132 , which hold the free balls 131 , is made of polyacetal while the other is made of polyamide or polyester.

Owner:TSUBAKIMOTO CHAIN CO

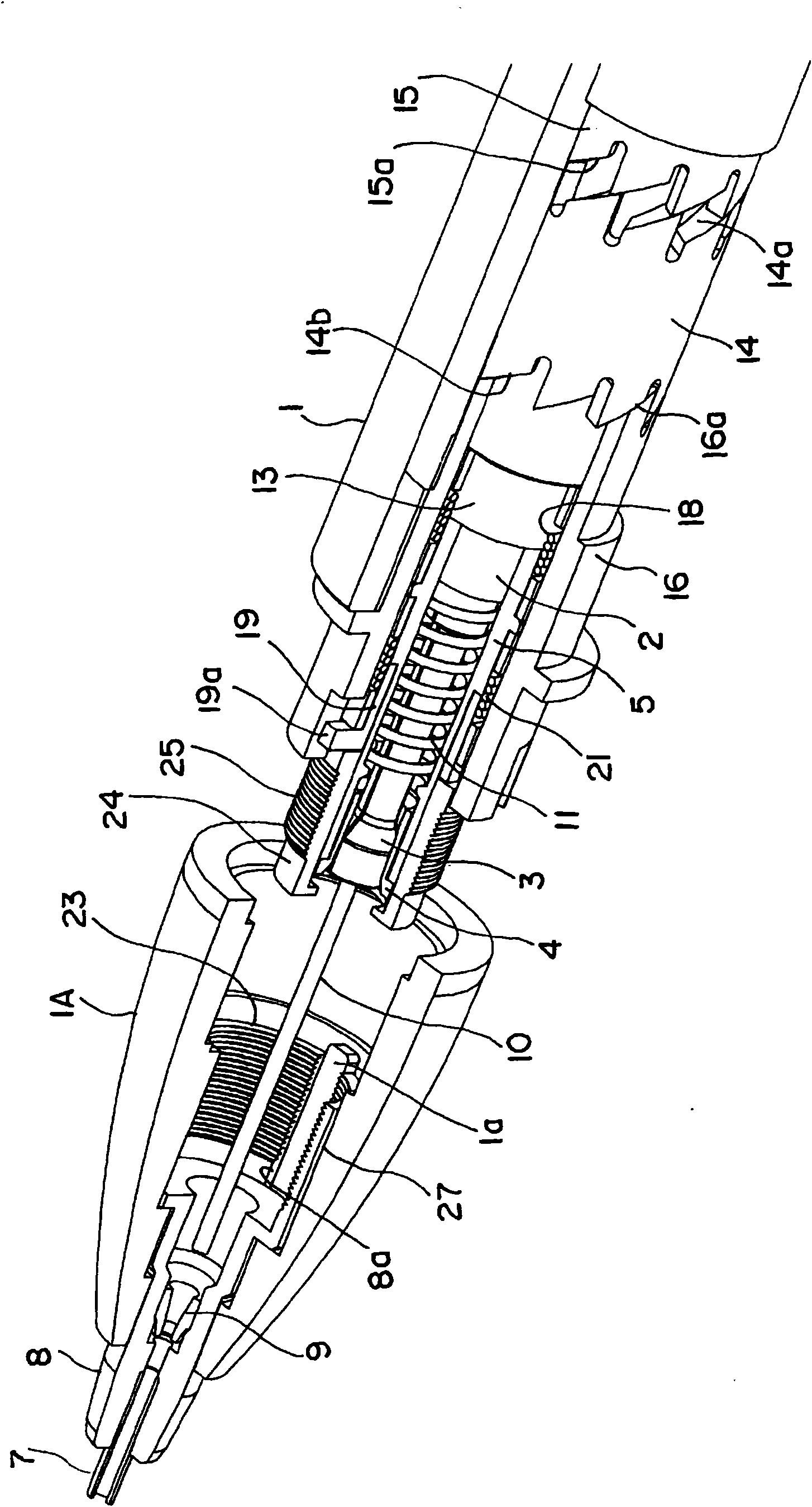

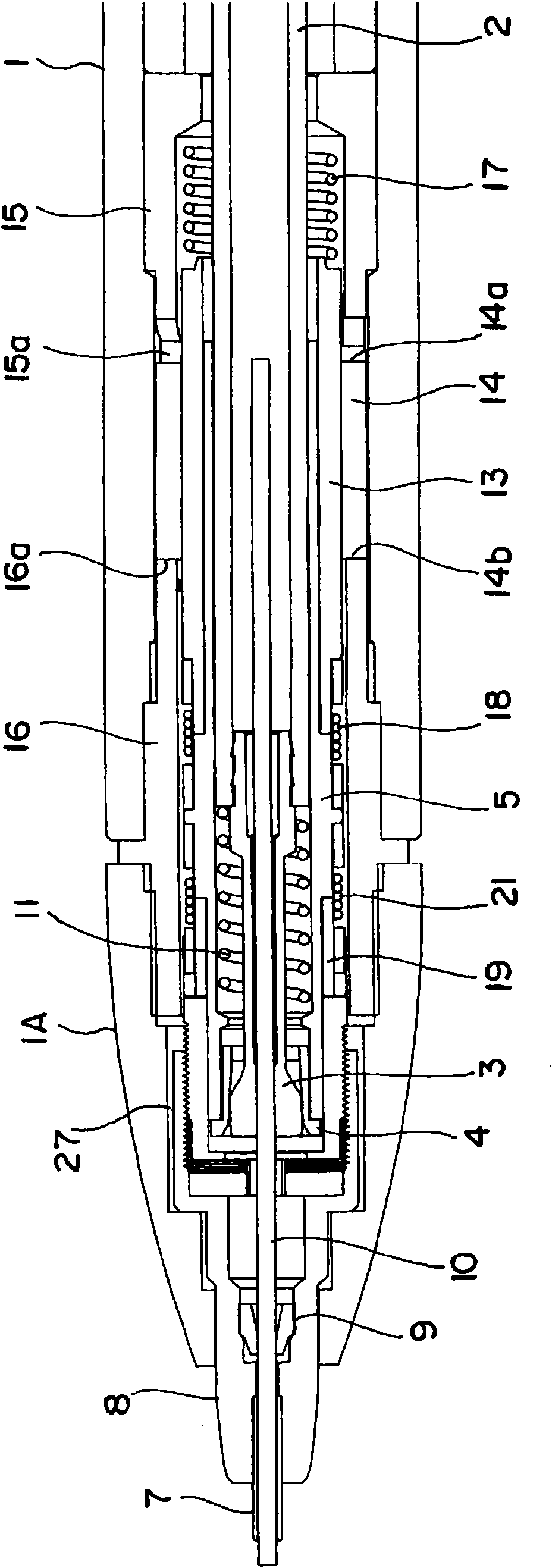

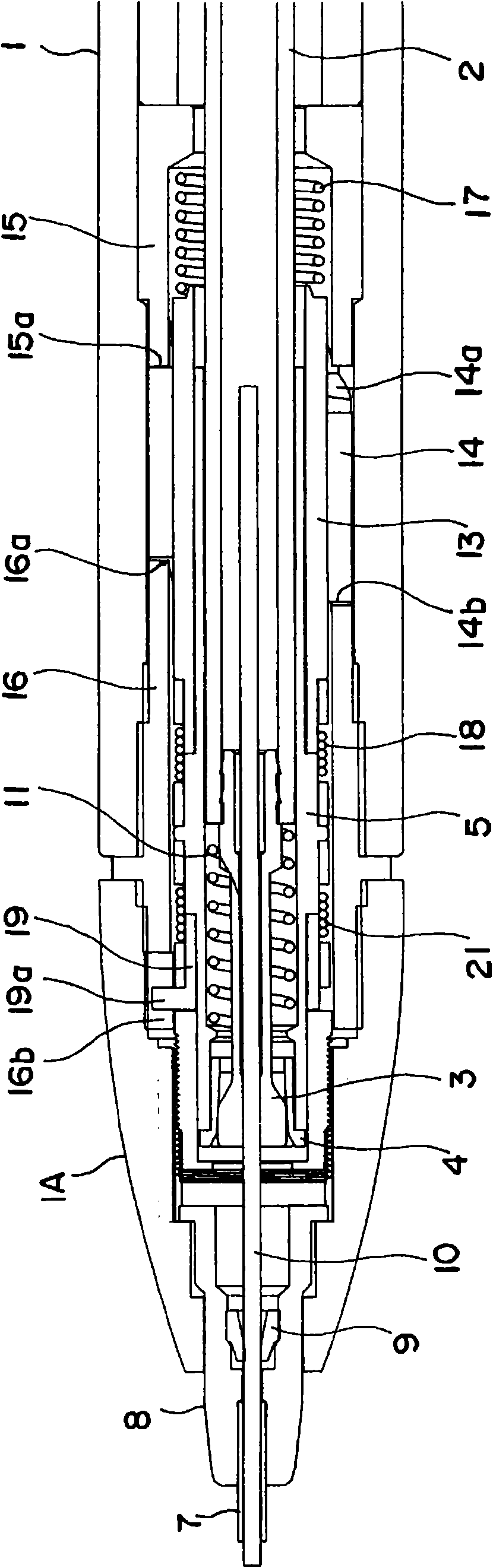

Mechanical pencil

ActiveCN101977779AReduce the degree of occurrenceAchieve outstanding actionPropelling pencilsPipe support

This aims to provide a pipe-slide type mechanical pencil capable of confining the protrusion of a writing lead from a tip pipe, within a predetermined range. The mechanical pencil comprises a rotary drive mechanism constituted to let off a writing lead (10) forward by the forward and backward movements of a chuck (3) arranged in a cylinder (1) thereby to release and grip the writing lead, and to turn a rotor (5) in one direction in response to both the backward motion by a writing pressure received by the writing lead and the forward motion by the release of the writing pressure. Further comprised are a pipe supporting member (8) accommodated in a tip unit (1A) forming the tip of the cylinder, for supporting a tip pipe (7), and a backward drive mechanism for moving back the tip pipe supported by the pipe supporting member, gradually toward the cylinder in response to the rotary drive action of the rotor constituting the rotary drive mechanism.

Owner:MITSUBISHI PENCIL CO LTD

Jigsaw

InactiveCN1590056APrevent peelingInhibit sheddingAbrasion apparatusGrinding machinesProject areaAdhesive materials

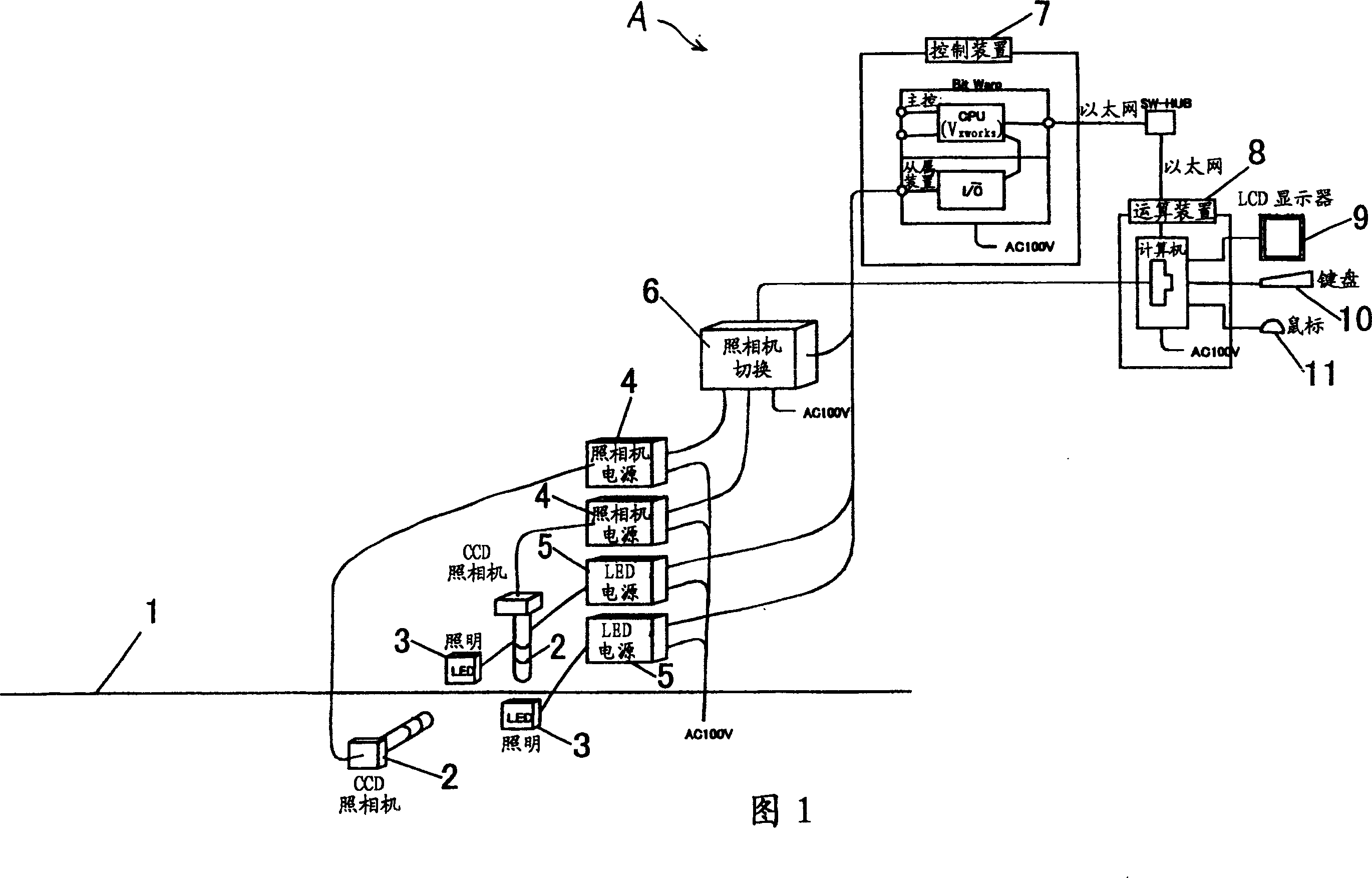

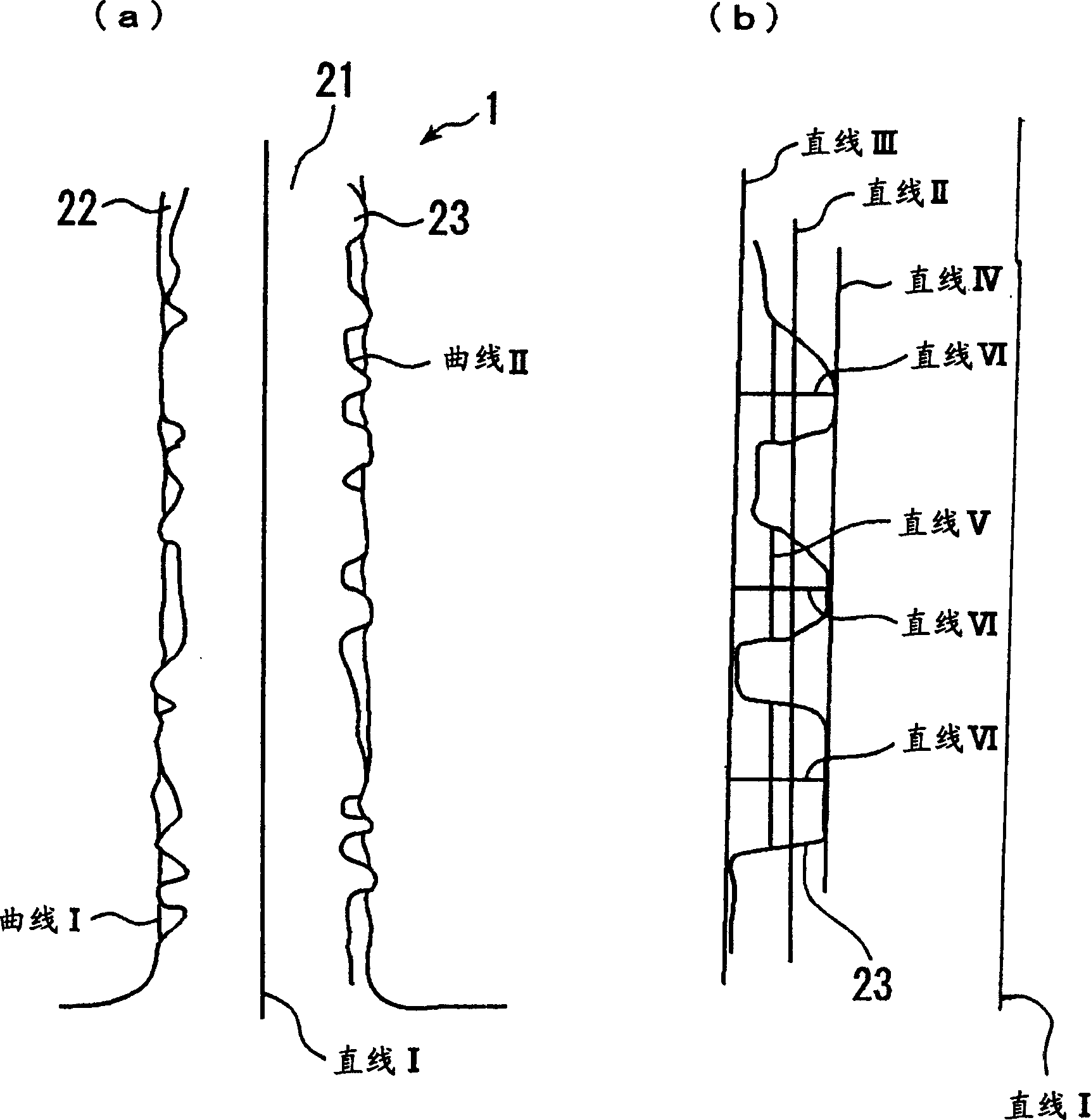

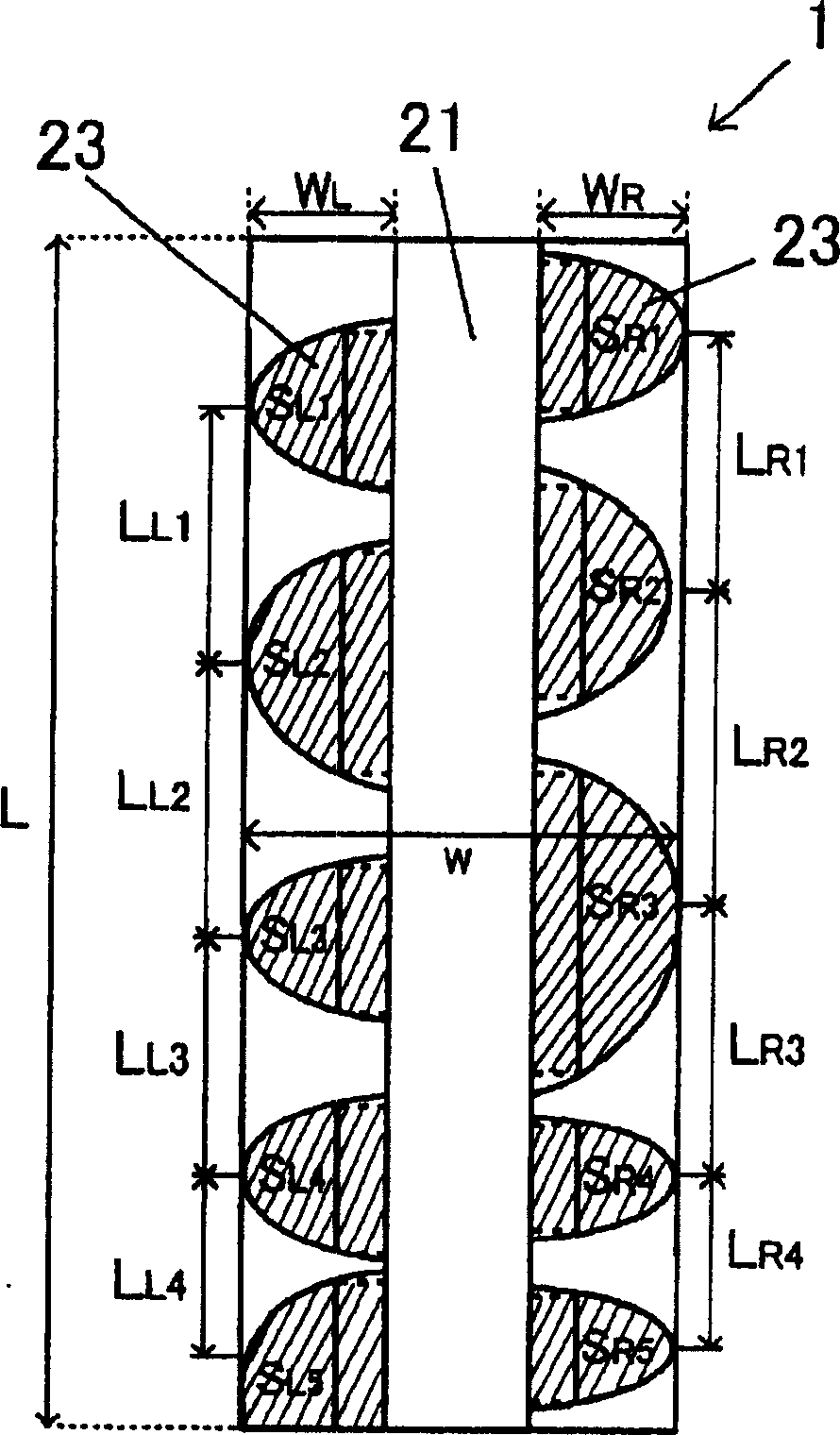

The present invention provides a linear saw which can optimize the number, distance and core deflecting amount of the abrasive grain adhered on the linear saw thereby effectively preventing the falling off of the abrasive grain. The linear saw is formed by the following mode, namely, the light permeating the linear saw which is fixed with abrasive grain by the adhesive material at the periphery of the core wire is used to shoot the image of the linear saw, the profile of the abrasive grain is detected according to the brightness of the image of the shot linear saw and does detection thereby mastering the position of the abrasive grain, at least the number, distance and projected area of abrasive grain are detected thereby detecting the respective condition of the abrasive grain and therefore lead to that the projected area of the abrasive grain is 2026300660r above or is 801r below relative to the projected area of the abrasive grain layer, leads to that the standard deviation of the distance of the abrasive grain is 200 mu m or below, and leads to that the ratio between thickness of thin abrasive grain layer to the thickness of thick abrasive grain layer is 0.6 or above for the abrasive grain layer which is spaced with a core wire and is formed at the two side of the core wire.

Owner:NORITAKE SUPER ABRASIVE CO LTD +1

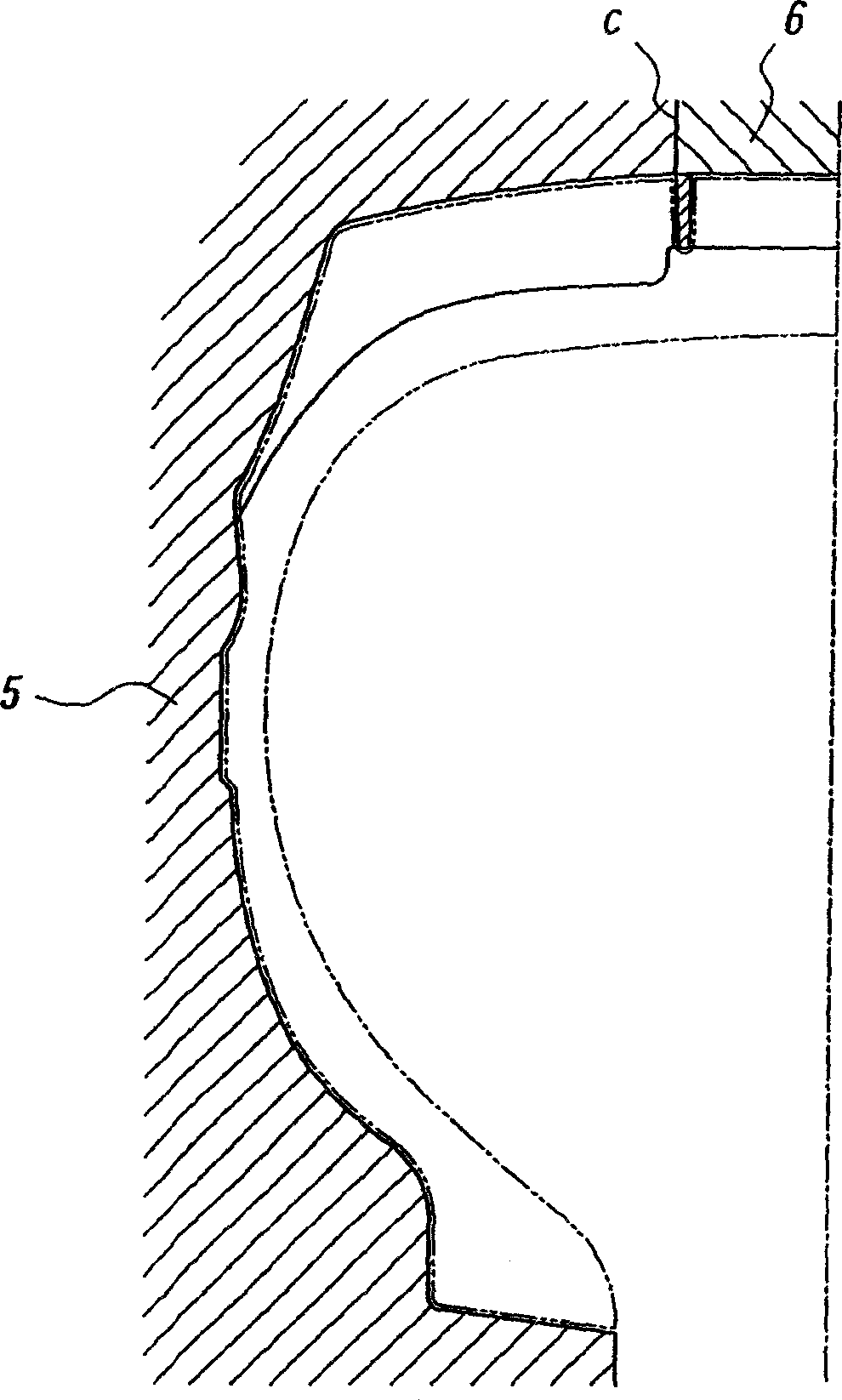

Tire vulcanizing apparatus

ActiveCN101186090AGuaranteed sizeGuaranteed dimensional accuracyTyresEngineeringMechanical engineering

Owner:MITSUBISHI HEAVY IND MACHINERY SYST LTD

Metering pump with entire solid eccentric wheel travel adjustment mechanism

ActiveCN103362769AImprove bearing capacityGreatly increase the carrying capacityPump controlPumpsRelative motionMetering pump

The invention discloses a metering pump with an entire solid eccentric wheel travel adjustment mechanism. The metering pump comprises an amount adjustment lead screw, a moving shaft, a hollow shaft, a connection rod, the entire eccentric wheel, a worm gear, a worm and a slide rod, wherein one end of the amount adjustment lead screw is connected with the moving shaft in a mode of coaxial relative motion, the moving shaft is sleeved in the hollow shaft, a chute is formed in the moving shaft, a slide block is arranged in the chute, the entire eccentric wheel is sleeved on the hollow shaft and fixed with the connection rod, the connection rod is connected with the slide rod, and the worm wheel is in cup joint to the hollow shaft and is meshed with the worm. The metering pump is large in bearing capacity, high in metering precision and long in service life.

Owner:DEPAMU HANGZHOU PUMP TECH

Long plunger type double barrel anti-coal powder drainage pump

InactiveCN102287358AAvoid swingingAvoid depositionPositive displacement pump componentsFlexible member pumpsCouplingInlet valve

The invention provides a long-plunger type dual-barrel coal-dust resistant discharging and extracting pump capable of preventing eccentric wear and coal dust from burying pump, blocking pump and prolonging the pump detection period. The pump consists of a centering body, a pump barrel assembly, a piston assembly, a liquid outlet valve and a liquid inlet valve assembly; a centering locking claw is inserted in a lock sleeve of an upper coupling to realize positioning and sealing of the centering body and avoiding eccentric wear between the plunger and the pump barrel; an internal barrel can prevent the deposited coal dust in the annulus of a bar pipe from entering the gap between the plunger and the pump barrel; the coal dust is dropped back to a tail pipe through the annual cavity between the external barrel and the pump barrel to prevent the coal dust from burying the pump; the structure of the long-plunger short pump barrel can promptly discharge the coal dust in the gap between the plunger and the pump barrel, so as to protect the internal and external working surfaces of the pump barrel and preventing the pump from being blocked; the well liquid stored in the coal-dust resistant tank washes the coal dust in the liquid outlet valve cover and the coal dust deposited at the upper part of the liquid outlet valve through a jet orifice, so as to realize an automatic washing function of the liquid outlet valve and preventing the coal dust from jamming the pump; and a spring is cooperated with a liquid inlet valve ball positioning pin, so that the liquid inlet valve ball can be fast reset, and the pump valve under a low submergence can be realized in smooth on and off.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

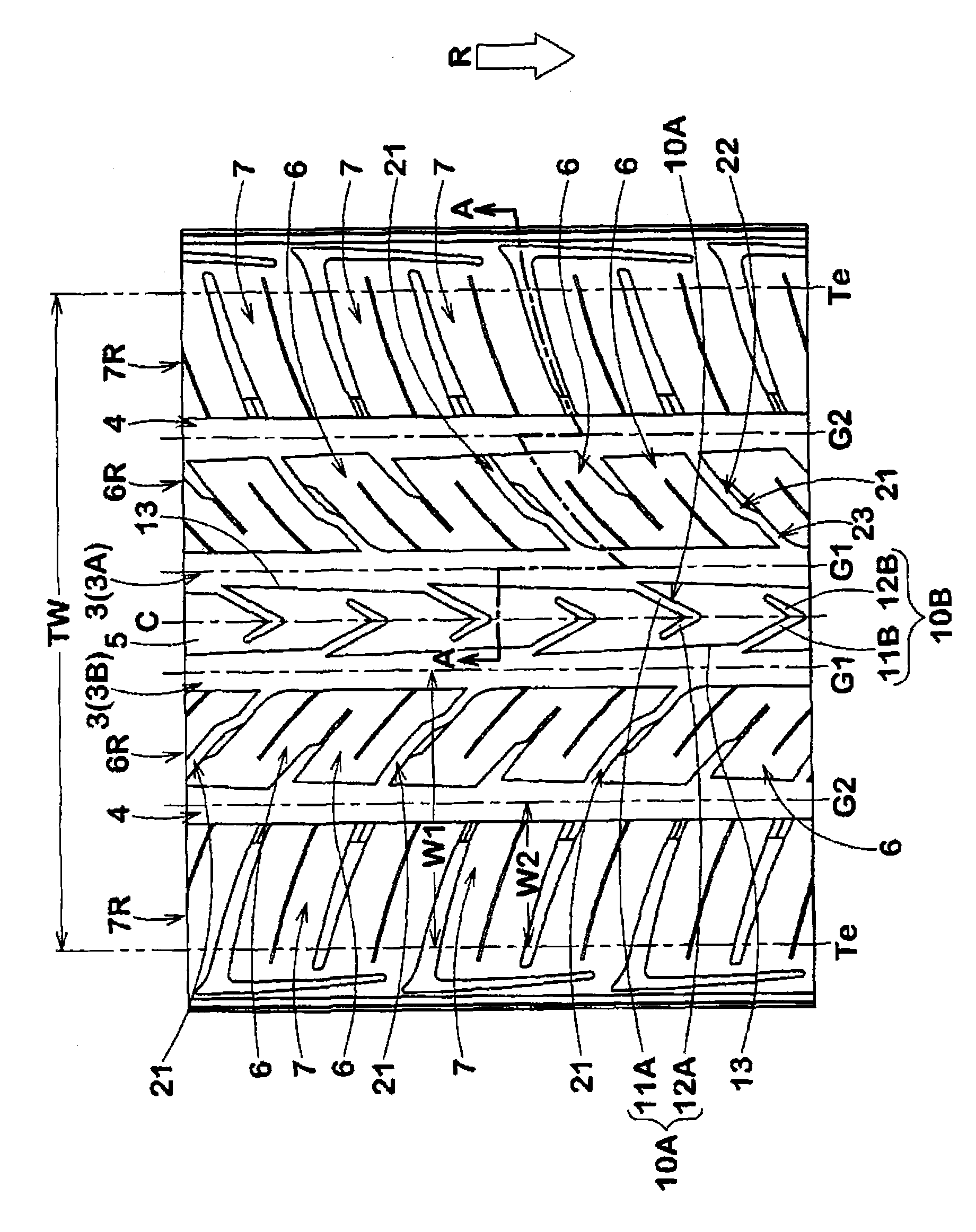

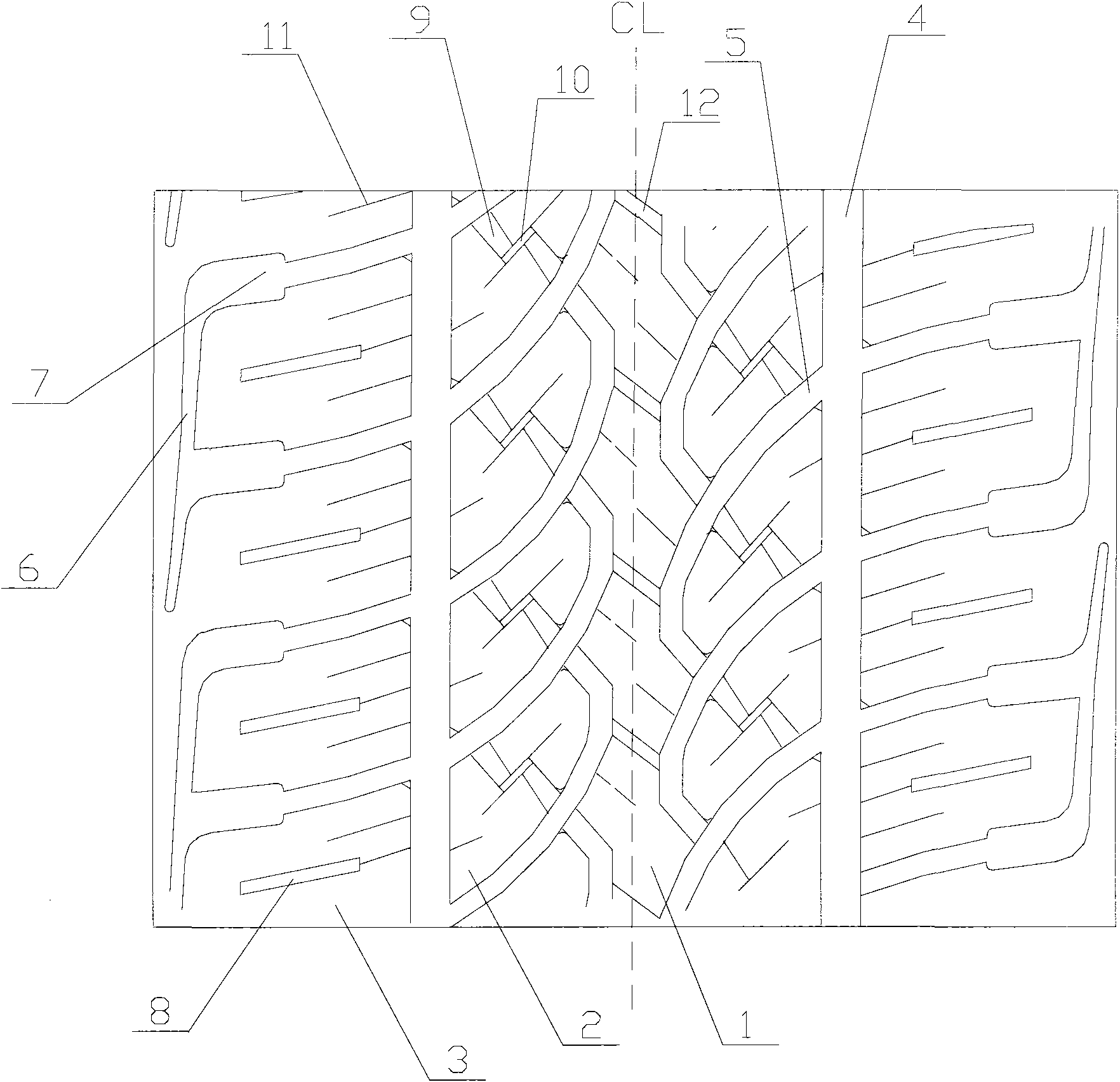

Pneumatic tire

InactiveCN101856954AImprove handling stabilityUniform front and rear rigidityTyre tread bands/patternsEngineeringEquator

The invention provides a pneumatic tire, which can prevent partial abrasion and promote the performance on ice and snow road. A rotating direction (R) is defined on the pneumatic tire. The pneumatic tire has a first V-shaped groove (10A) and a second V-shaped groove (10B), wherein the first and second V-shaped grooves (10A;10B) are terminated within the rib (5); one end (14) of the first V-shaped groove (10A) is communicated with a crown circumferential groove(3A) while the other end (15) exceeds a tire equator (C) but not reach another crown circumferential groove (3B); one end of the second V-shaped groove (10B) is communicated with a crown circumferential groove(3B) while the other end exceeds a tire equator but not reach the crown circumferential groove (3B); and the first and second V-shaped grooves (10A;10B) comprise a primary part (11) which extends from one end to the tire equator along the rotating direction and a bent part (12) which is connected to the primary part and is substantially bent on the tire equator along the direction reverse to the rotating direction.

Owner:SUMITOMO RUBBER IND LTD

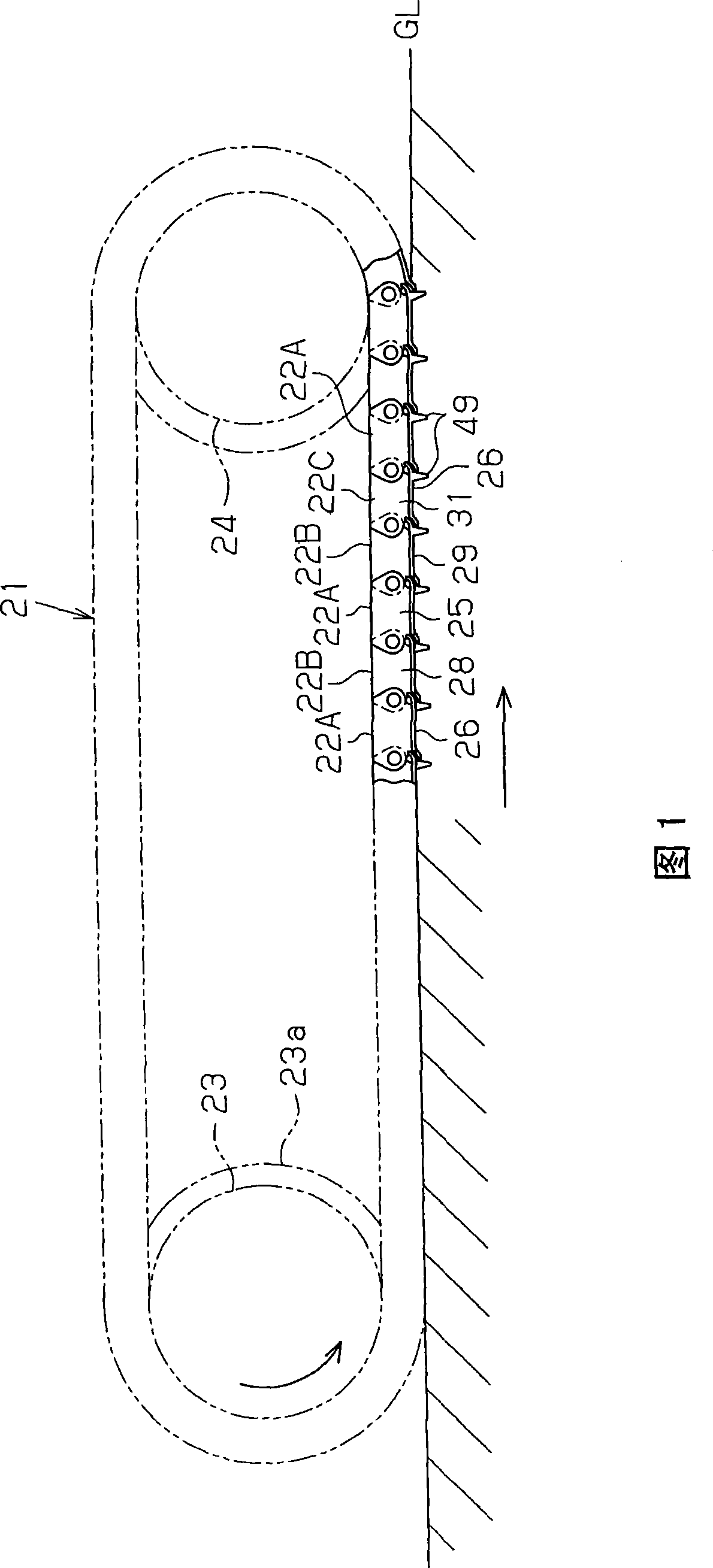

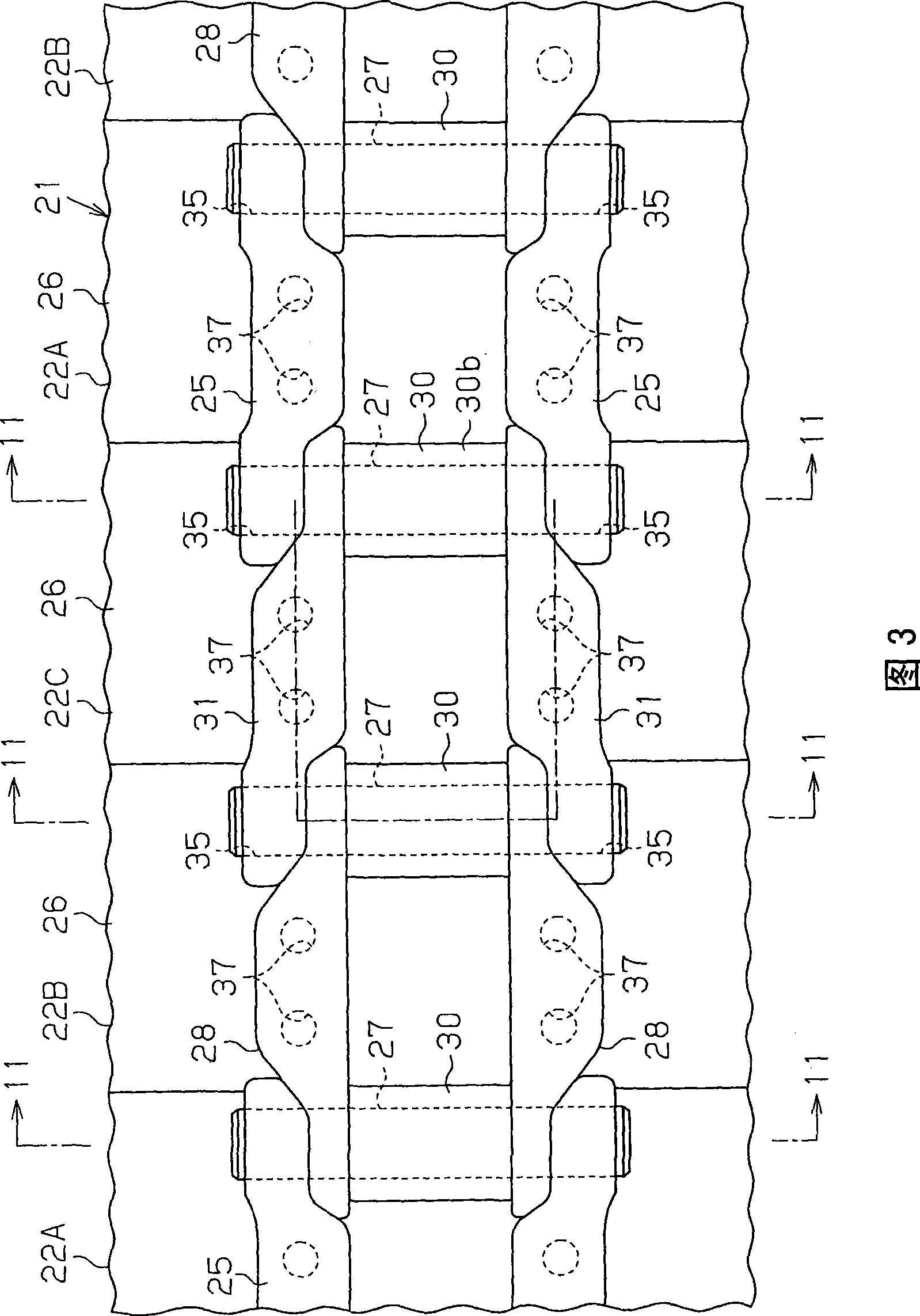

Crawler belt

InactiveCN101421149AReduce intensityReliable and reliableEndless track vehiclesMechanical engineeringEngineering

A crawler belt including a first assembly (22A) and a second assembly (22B). The first assembly (22A) has a pair of first links (25) parallel with each other, and a second assembly (22B) has a pair of second links (28) parallel with each other. The sleeves (30) at both ends of the second assembly (22B) are fitted onto the support shafts (27) at both ends of the first assembly (22A). When the total number of the assemblies is odd, a third assembly (22C) is interposed between the first and second assemblies (22A), (22B). The sleeves (30) of the second assembly (22B) are fitted onto the support shafts (27) of the third assembly (22C), and the sleeves (30) of the third assembly (22C) are fitted onto the support shafts (27) of the first assembly (22A). Consequently, even when the total number of the crawler belt assemblies is odd, the crawler belt can adopt a parallel link type.

Owner:KOMATSU LTD

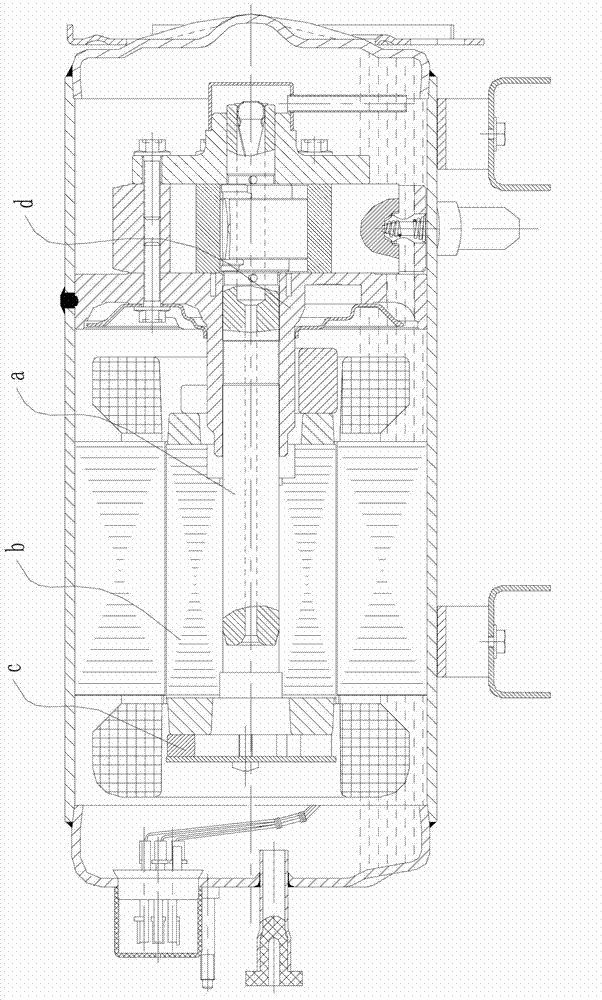

Horizontal compressor having symmetrical double cylinders

InactiveCN102900670AGuaranteed uptimeLarge displacementRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsEngineeringMechanical engineering

The present invention discloses a horizontal compressor having symmetrical double cylinders. The horizontal compressor comprises a housing, a motor and a crankshaft, wherein the crankshaft is assembled on a rotor of the motor, the motor of the compressor is sealed inside the housing, a first compression unit and a second compression unit are respectively and symmetrically arranged inside the housing on both ends of the motor,and are driven by a left end portion and a right end portion of the crankshaft, the crankshaft comprises a linear main shaft and a pair of eccentric shaft sleeves, and the eccentric shaft sleeves are symmetrically arranged on both ends of the main shaft by adopting the axis core line of the main shaft as the center line.

Owner:GREE ELECTRIC APPLIANCES INC +1

Cable protection guiding apparatus

ActiveCN101141055AEasy maintenanceEasy to operateHauling chainsHoisting chainsEngineeringSynthetic resin

The present invention provides a cable or the like protection and guide device which accommodates a cable or the like while allowing for examination of the cable. Smooth linear and flexional movement is achieved while not compromising the form stability of the cable accommodation space. Partial or local wear is suppressed. The device is made of a synthetic resin and accommodates a cable in a rectangular cable accommodating space. The accommodating space is surrounded by the outer circumferential wall portion, which is openable, a pair of side wall portions, and an inner circumferential wall portion. Inserting protrusion mechanisms, engagement mechanisms, slits, opening windows and flexion restricting piece portions contribute to the stability and usefulness of the device.

Owner:TSUBAKIMOTO CHAIN CO

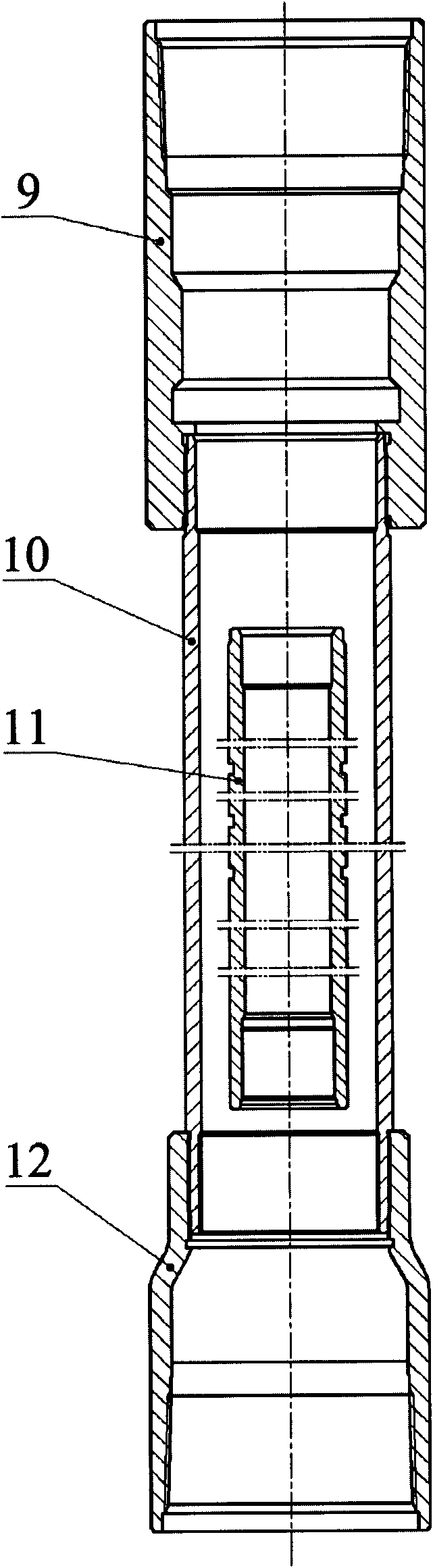

Hanging type oil layer protection packer

The invention relates to a packer, in particular to a hanging type oil layer protection packer, which belongs to a packer particularly suitable for the underground oil layer production of low-pressure wells or water-sensitive oil reservoirs. The hanging type oil layer protection packer comprises a back-off sub, a rotation prevention key, a screw, an upper joint, a slide sleeve, a shear pin, a press cap, a sealing pad, a center pipe, a lining sleeve, a leather cup type rubber tube, a cone body, a slips assembly and a lower joint, wherein a groove is formed on the inner side of the upper part of the upper joint, the upper end of the slide sleeve is inserted into the back-off sub, the slide sleeve is fixed on the upper joint, the upper joint is connected with the press cap, the cone body is sheathed on the leather cup type rubber tube and is directly connected with the lining sleeve, and the lining sleeve, the leather cup type rubber tube, the cone body and the slips assembly are sheathed on the center pipe. The hanging type oil layer protection packer has a reasonable and compact structure, can be operated without hands, and can also be operated with hands, the structural conversion is flexible, the self sealing type rubber rube has reliable sealing, a flow discharge passage is designed in the tool structure, and the pumping generated in the pipe column dismounting process can be avoided. The construction working procedure is convenient, the oil layer can be protected, and the well flushing and oil extraction requirements can be met.

Owner:新疆石油管理局采油工艺研究院

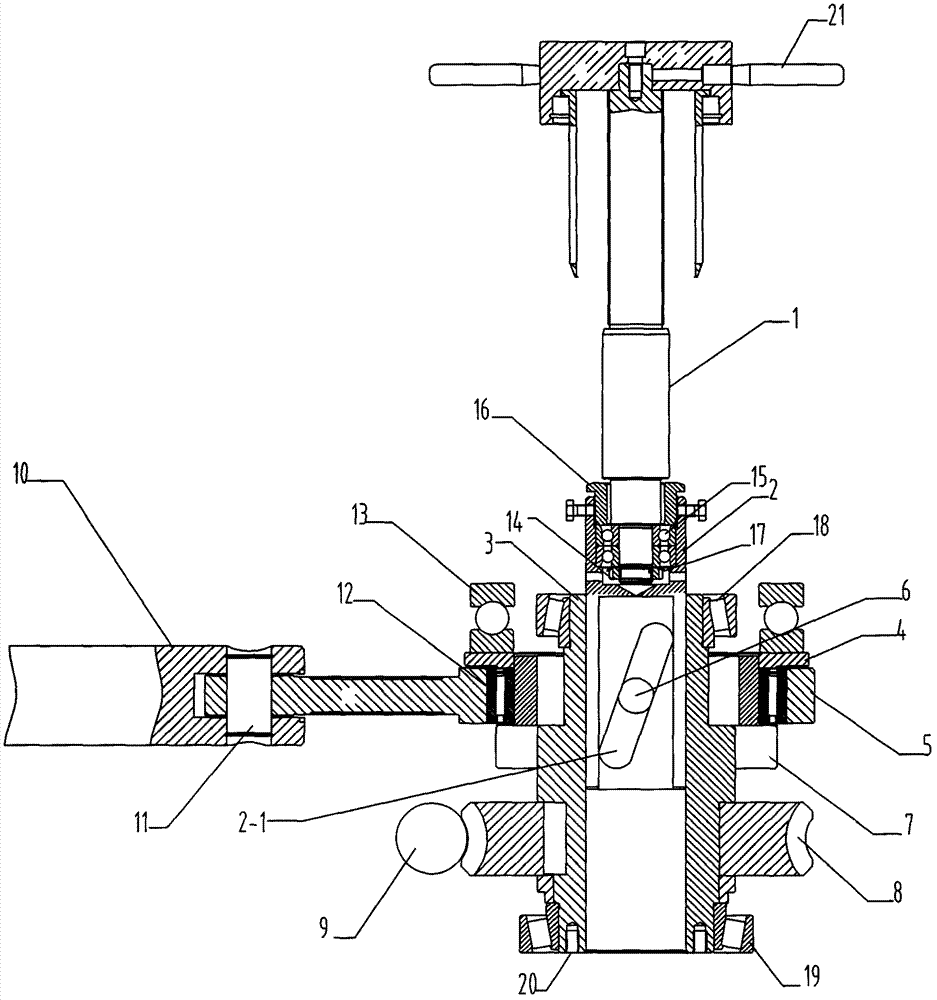

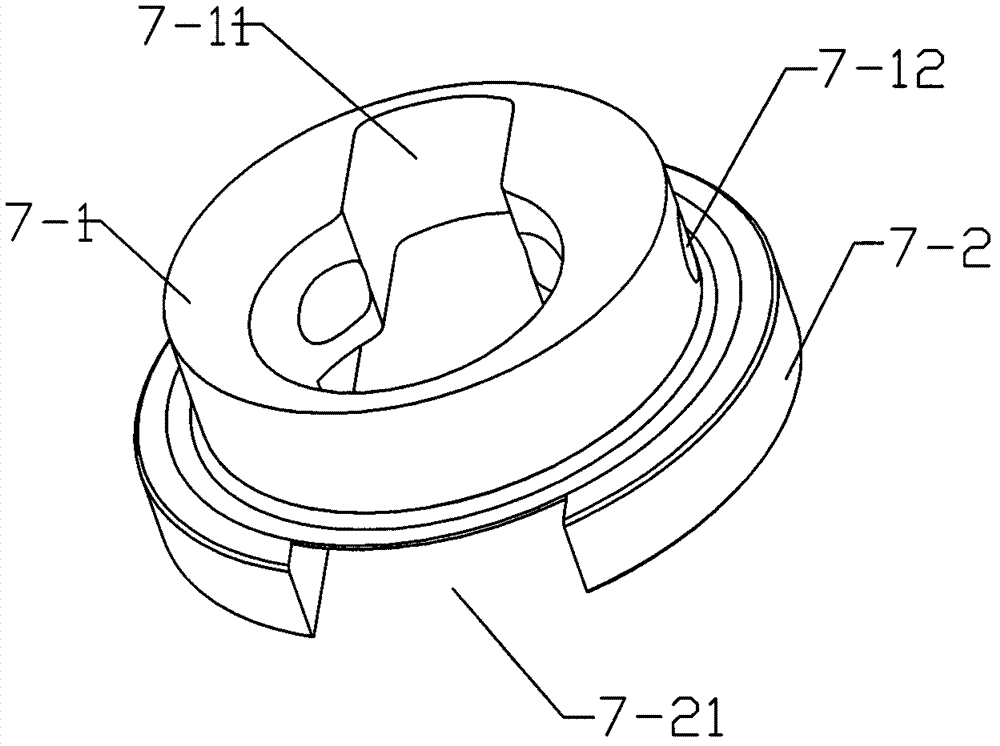

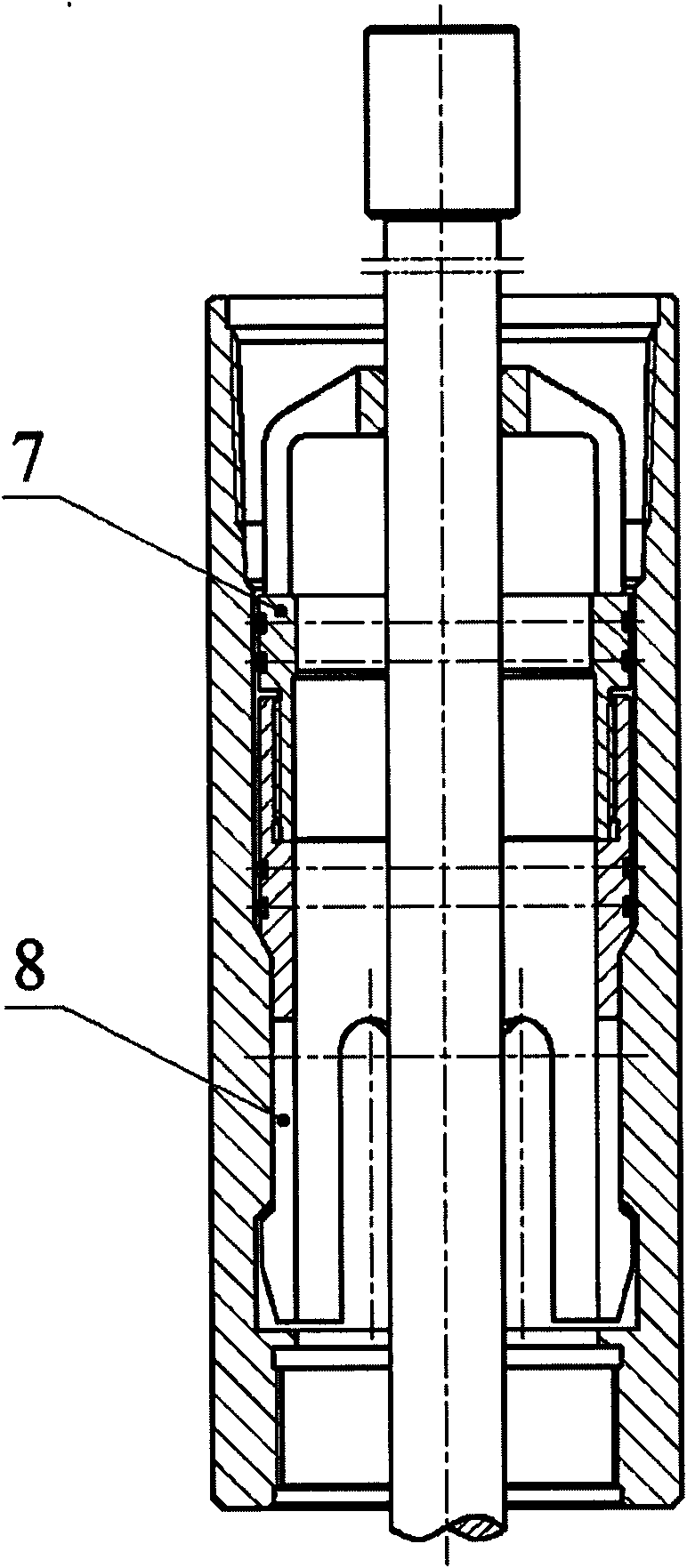

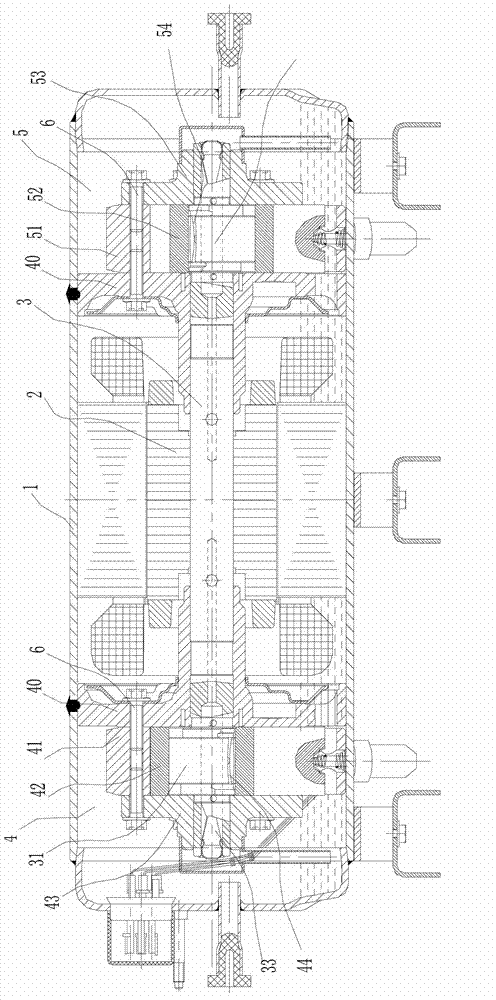

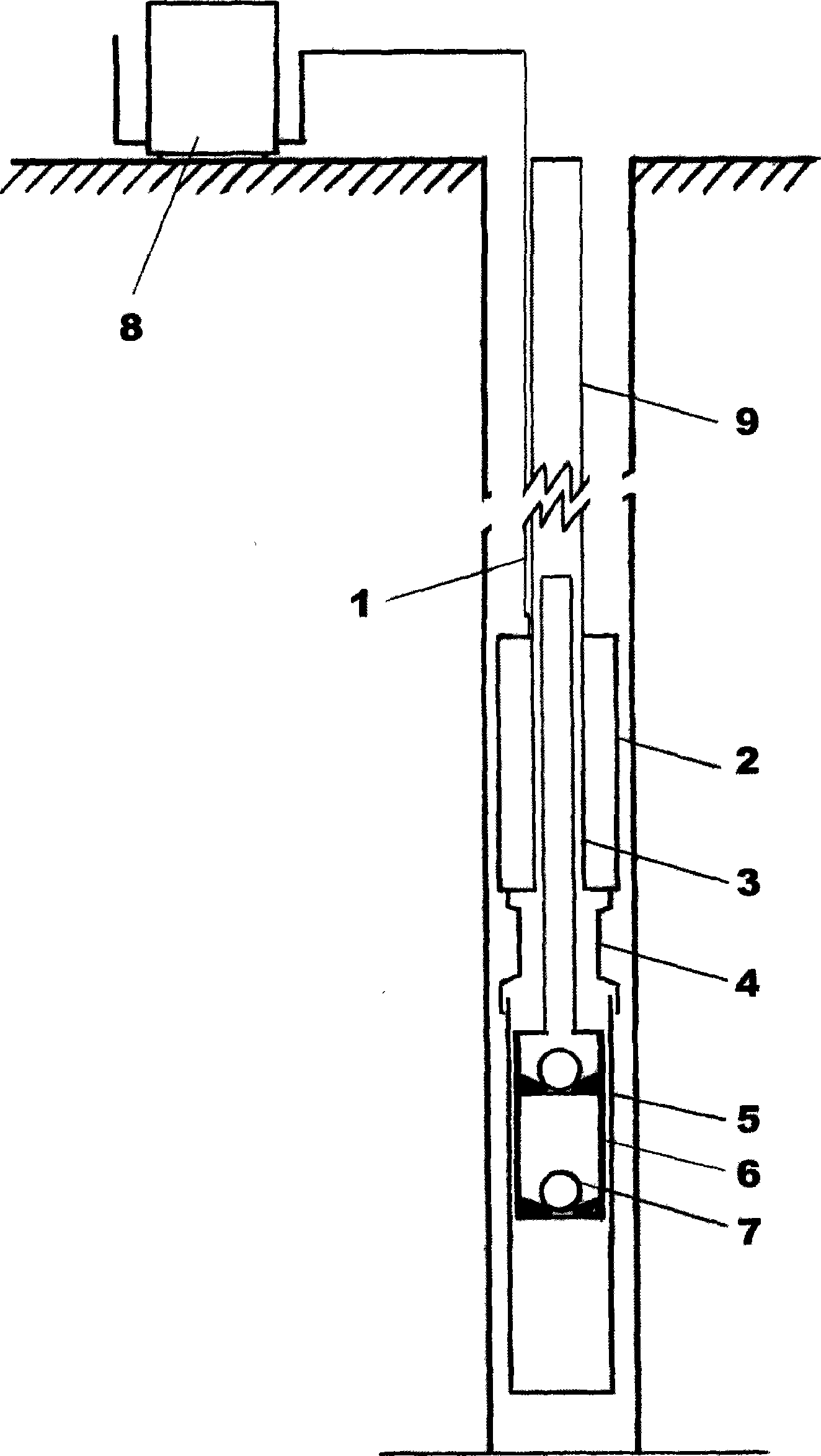

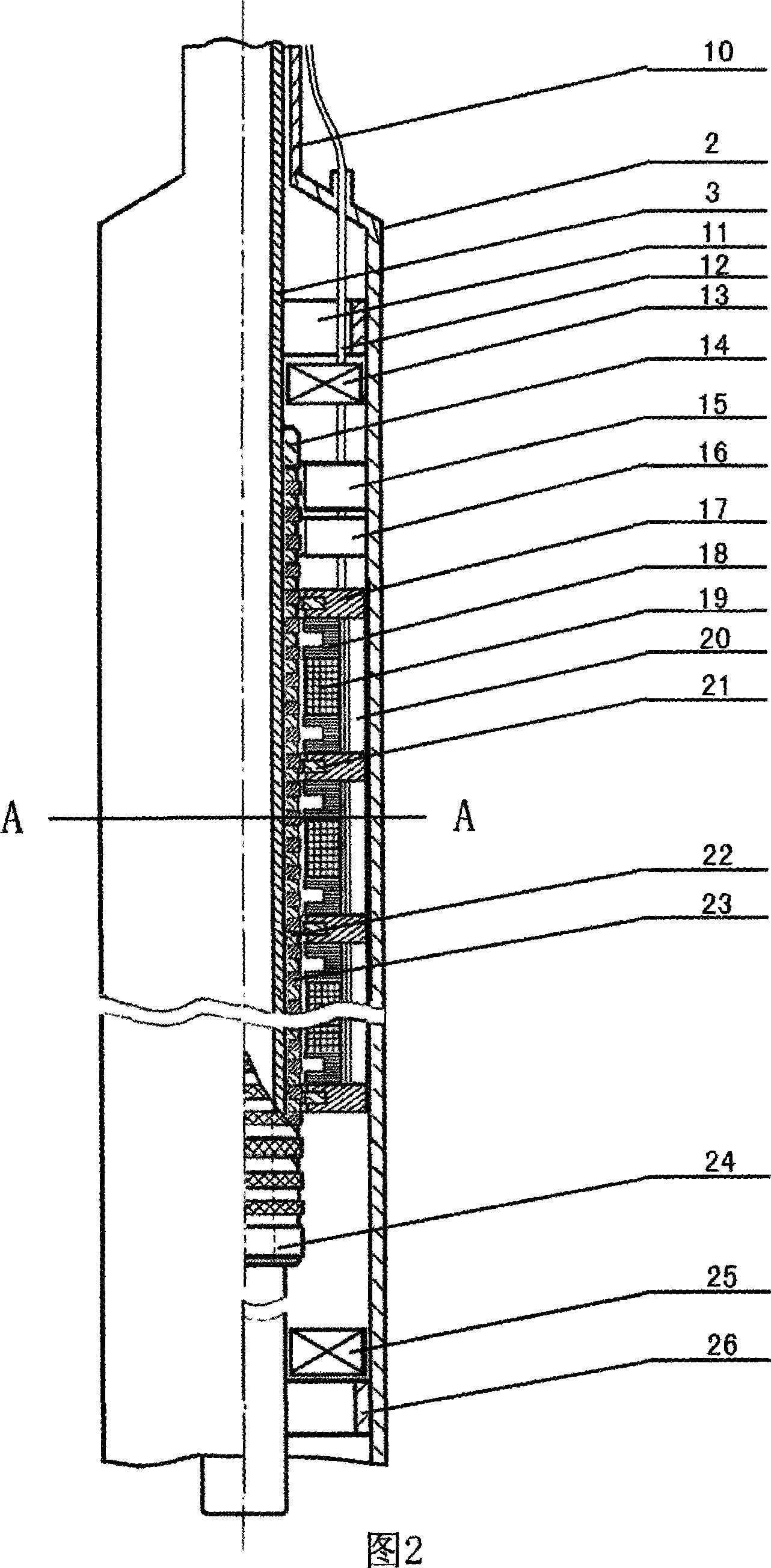

DC stepping permanent magnetism straight line motor drive type oil-submersible extracting pump

InactiveCN101377195AAvoid partial wearNovel structureFlexible member pumpsPositive-displacement liquid enginesMotor drivePermanent magnet linear motor

The present invention relates to a submersible oil extraction pump driven by a direct-current magnetoelectric linear stepper motor. The oil extraction pump is composed of a cable (1), a motor cylinder (2), a motor mover (3), a diameter-variable sheath (4), a pump cylinder (5), a plunger (6) and a ball valve set (7); wherein, the upper and the lower ends of the cable (1) are respectively connected with coils arranged in a ground control cabinet (8) and the motor cylinder (2); the upper and the lower ends of the motor cylinder (2) are respectively connected with an oil pipe (9) and the diameter-variable sheath (4) by means of threads; the lower end of the diameter-variable sheath (4) is connected with the pump cylinder (5) by means of threads; the motor mover (3), the plunger (6) and the ball valve set (7) are respectively arranged in the motor cylinder (2) and the pump cylinder (5); and the lower end of the motor mover (3) is connected with the upper end of the plunger (6). With a novel structure, the oil extraction pump rejects the complex, large ground oil extraction pump and the 1000-meter sucker rod and can avoid the eccentric abrasion of the sucker rod and reduce operation cost. Compared with the prior centrifugal electric submersible pump, the oil extraction pump has the advantages of low energy consumption and fault rate, long service life, etc. and can be used in a deep well.

Owner:张洪新 +2

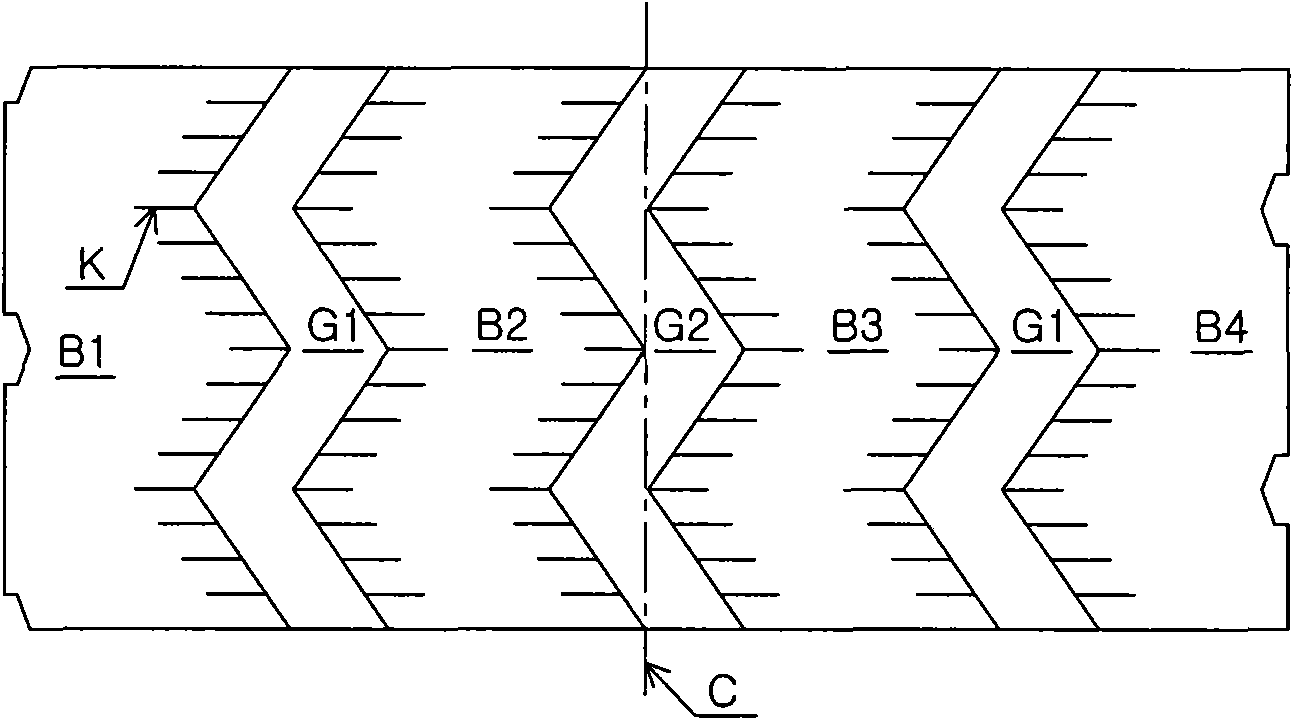

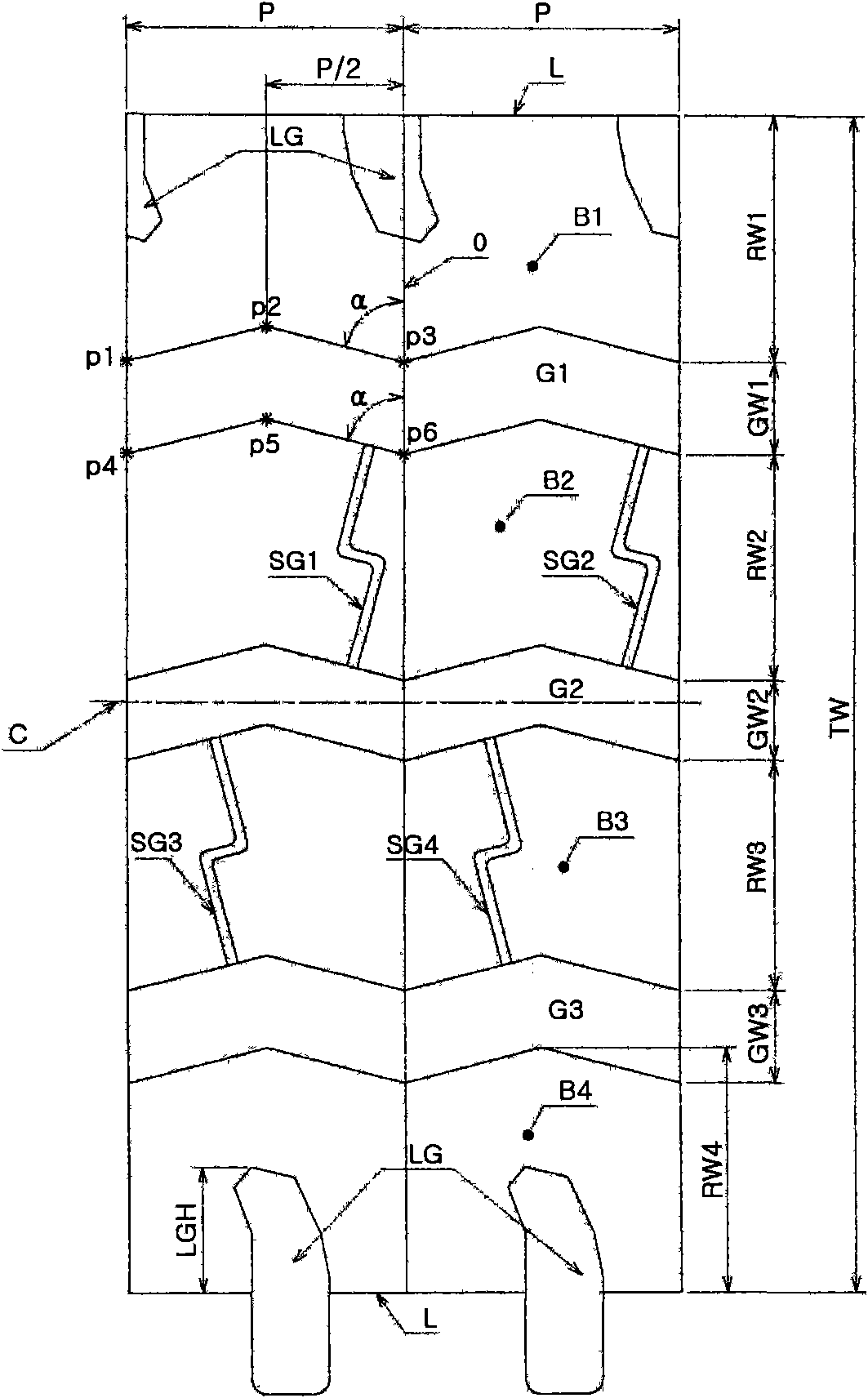

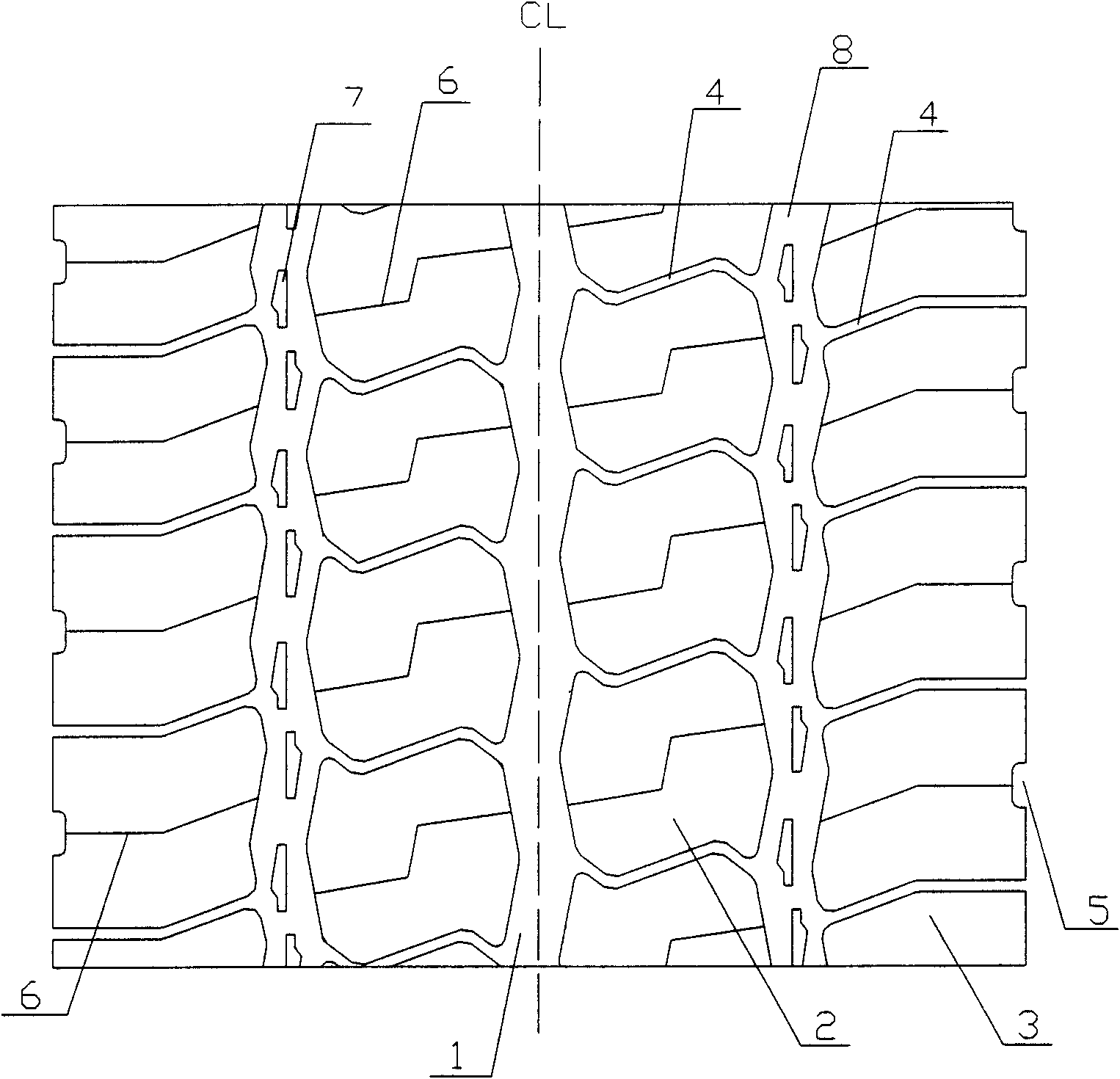

Inflatable radial ply tyre for over loading

InactiveCN101524950AIncreased drive and braking powerPrevent peelingTyre tread bands/patternsRadial tireEngineering

The invention provides a pattern structure of an inflatable radial ply tyre for over loading, which can effectively prevent uneven wear such as wheel track wear generated at the edge of the pattern block in driving and prevent peeling due to heating in driving in the condition of improving the brake force and drive force but not reducing any performance so as to increase the endurance life of the tire. The invention is characterized by comprising half pattern grooves (SG1, SG2, SG3, SG4) with a step shape, which take a center pattern groove (G2) as center and are obliquely arranged with an interval corresponding to each pitch on the center blocks (B2, B3) at two sides of the center pattern groove to communicate a center pattern groove (G2) and side pattern grooves (G1, G3), wherein the center pattern groove (G2) is formed in a sawtooth shape in the center of the tire tread and the side pattern grooves (G1, G3) are formed in a sawtooth shape at two sides. The half pattern grooves (SG1, SG2) formed on the center pattern block (B2) and the half pattern groove (SG3, SG4) formed on the center pattern block (B3) are intercrossed and have different oriention. A transverse pattern groove (LG) is formed by bending an angle to the width direction of the tire tread.

Owner:KUMHO TIRE CO INC

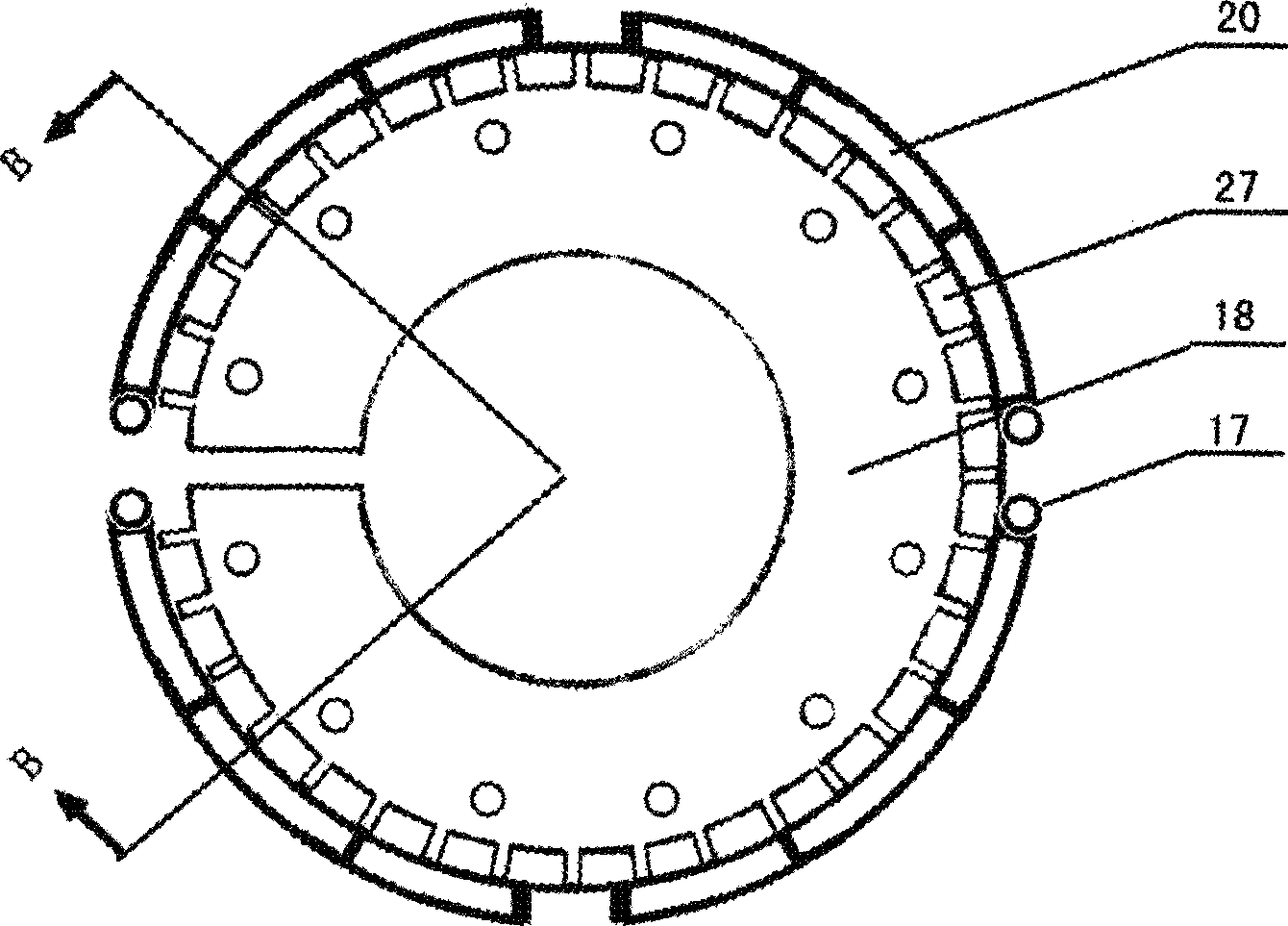

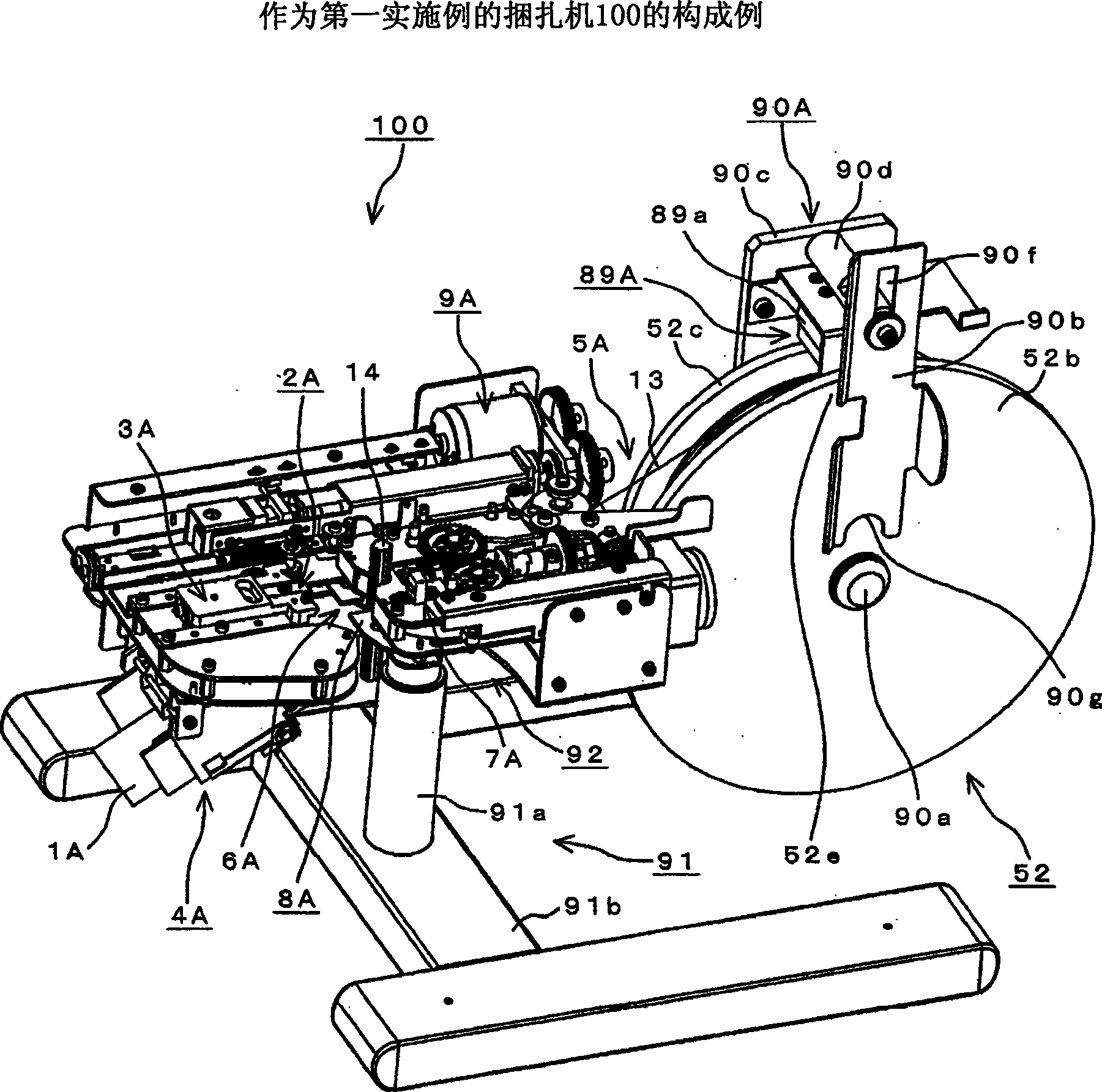

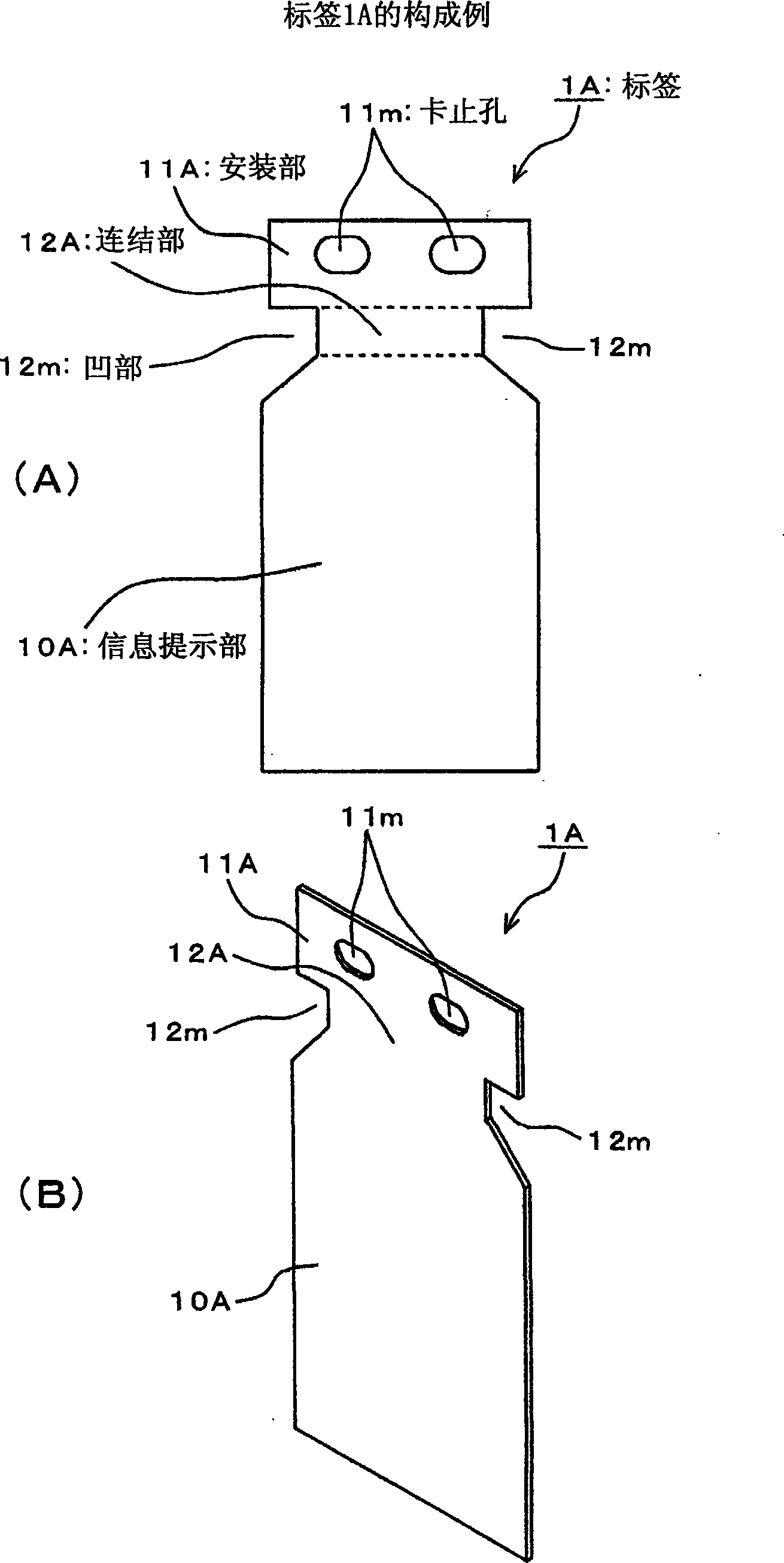

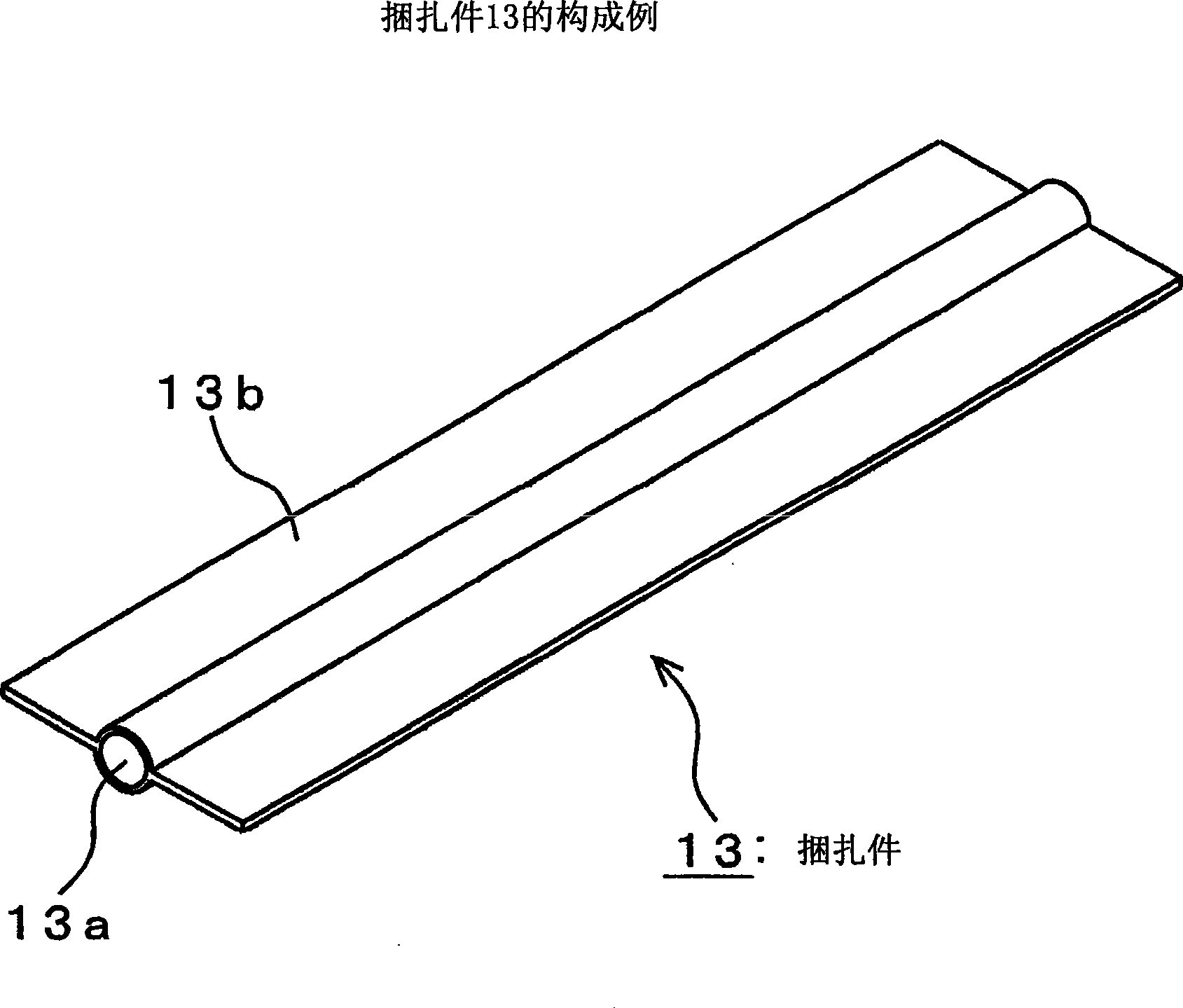

Coiler

InactiveCN101544286AInhibit wearAvoid partial wearAffixing tagsWrapper twisting/gatheringCircular discBobbin

The present invention provides a coiler which can increase the braking force of the coiler and can restrain the coiler abrasion and deformation caused by the braking. The coiler is provided with a bobbin (52) which has a disc outside plate (52b) that is formed to a large shape compared with a disc inner plate (52c). A braking mechanism (89A) clamps a large-shaped part (52e) of the disc outside plate (52b) that has a shape larger than that of the disc inner plate (52c) for braking the bobbin (52). In an embodiment of the invention, the braking mechanism (89A) clamps the disc outside plate (52b) through a braking disc (90h) and a pressure lever (90b) of a solenoid (89a) in power failure.

Owner:MAX CO LTD

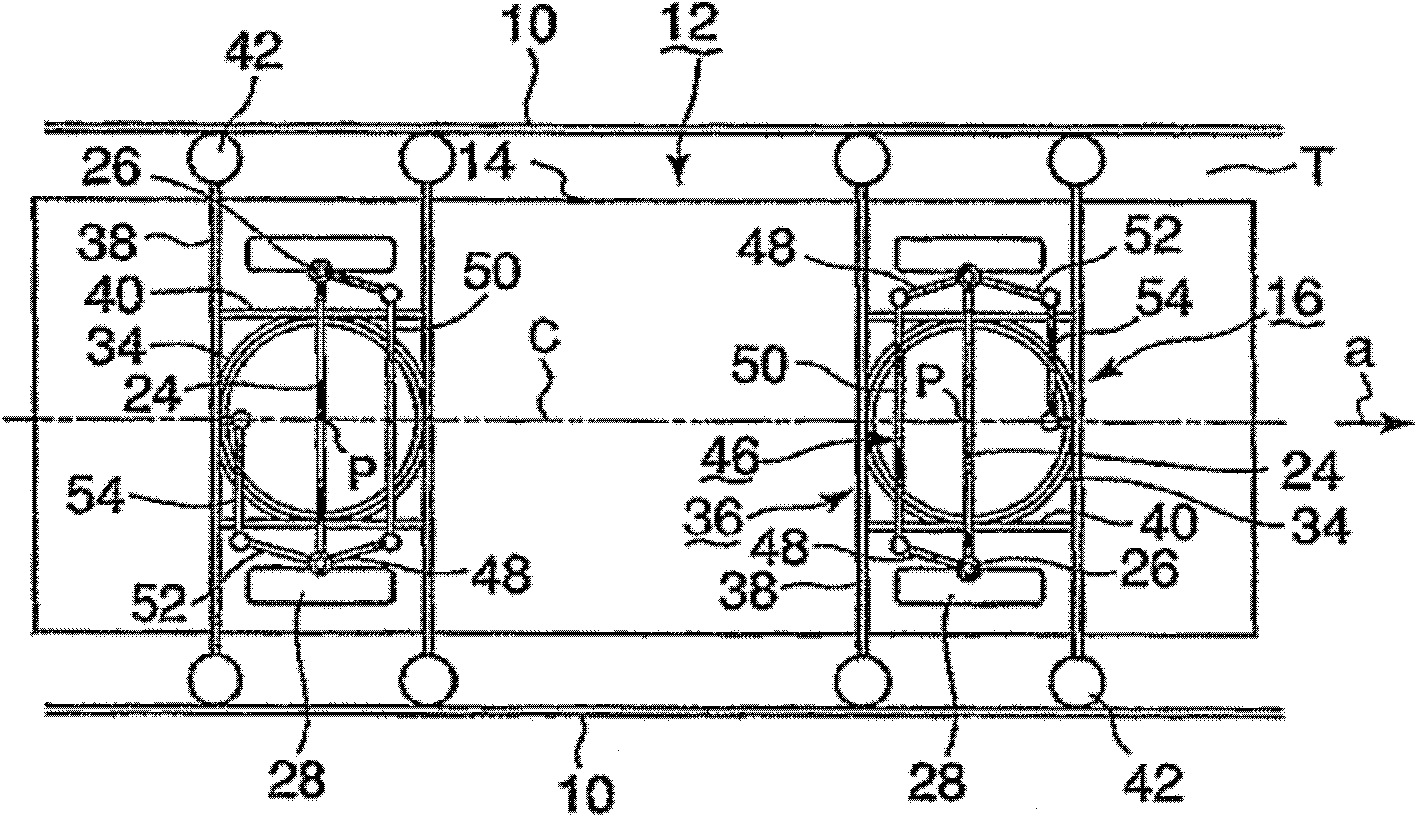

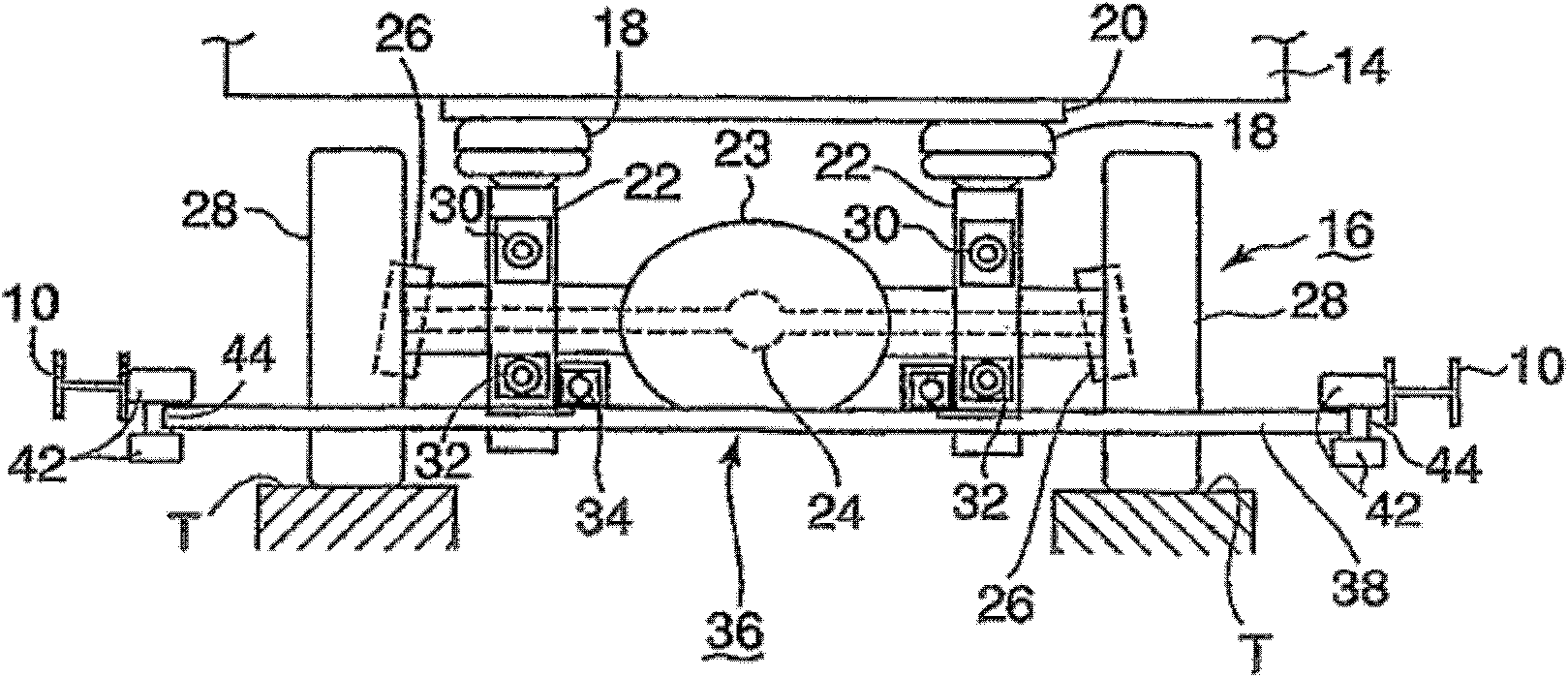

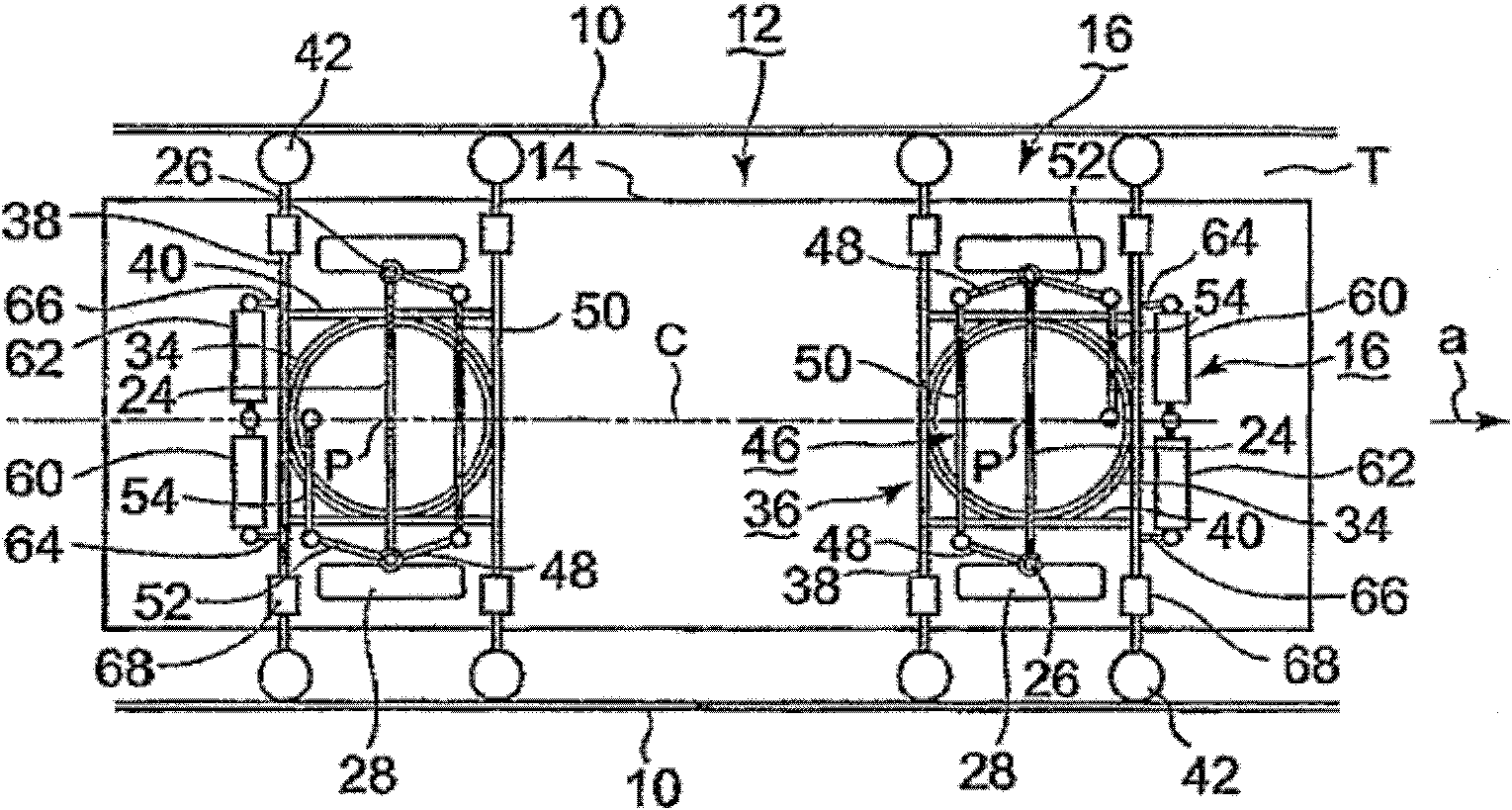

Bogie for guide rail system vehicle

ActiveCN102325682AReduce driving resistanceAvoid partial wearRail derailment preventionSteering controlsBogieEngineering

Owner:MITSUBISHI HEAVY IND LTD

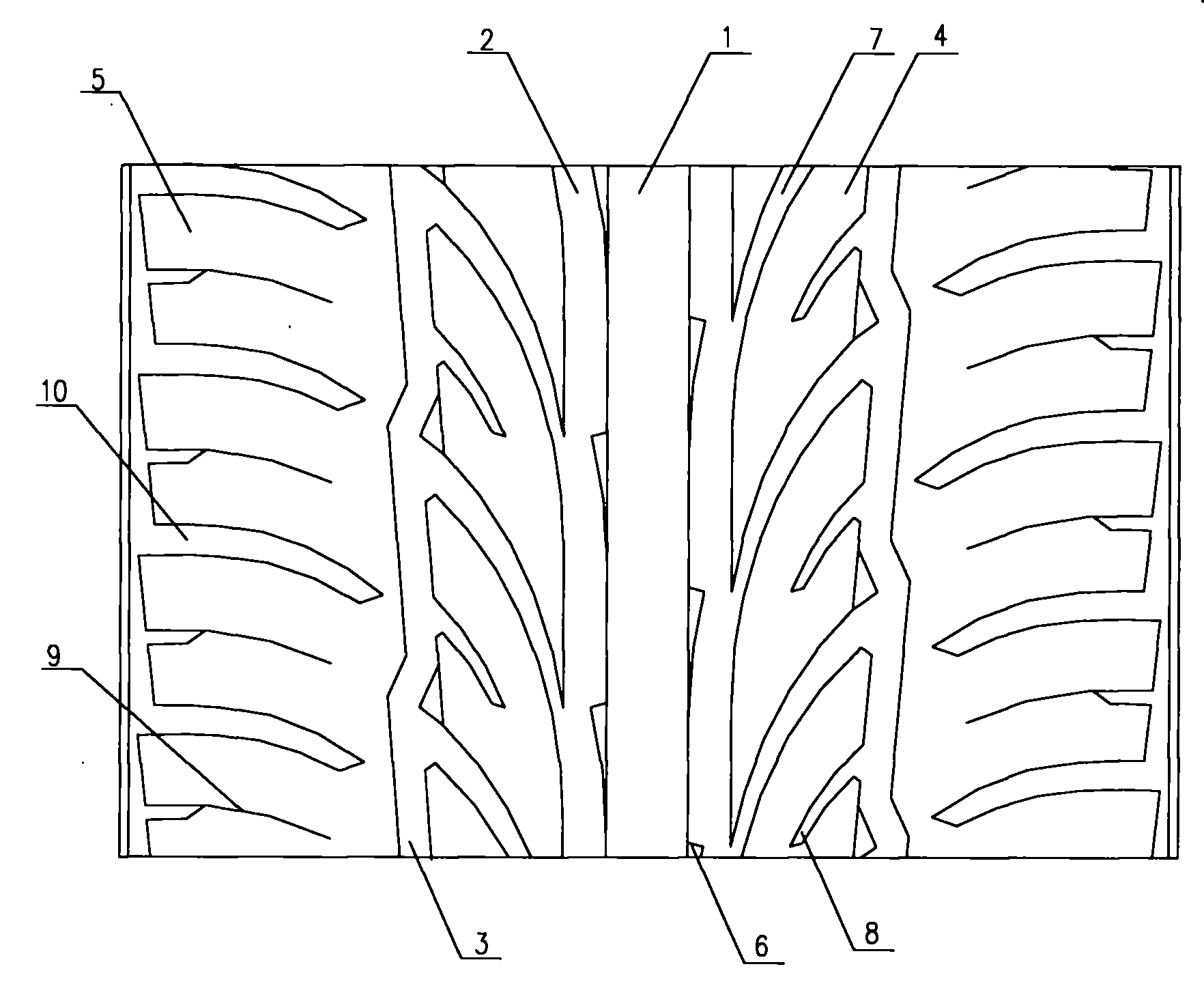

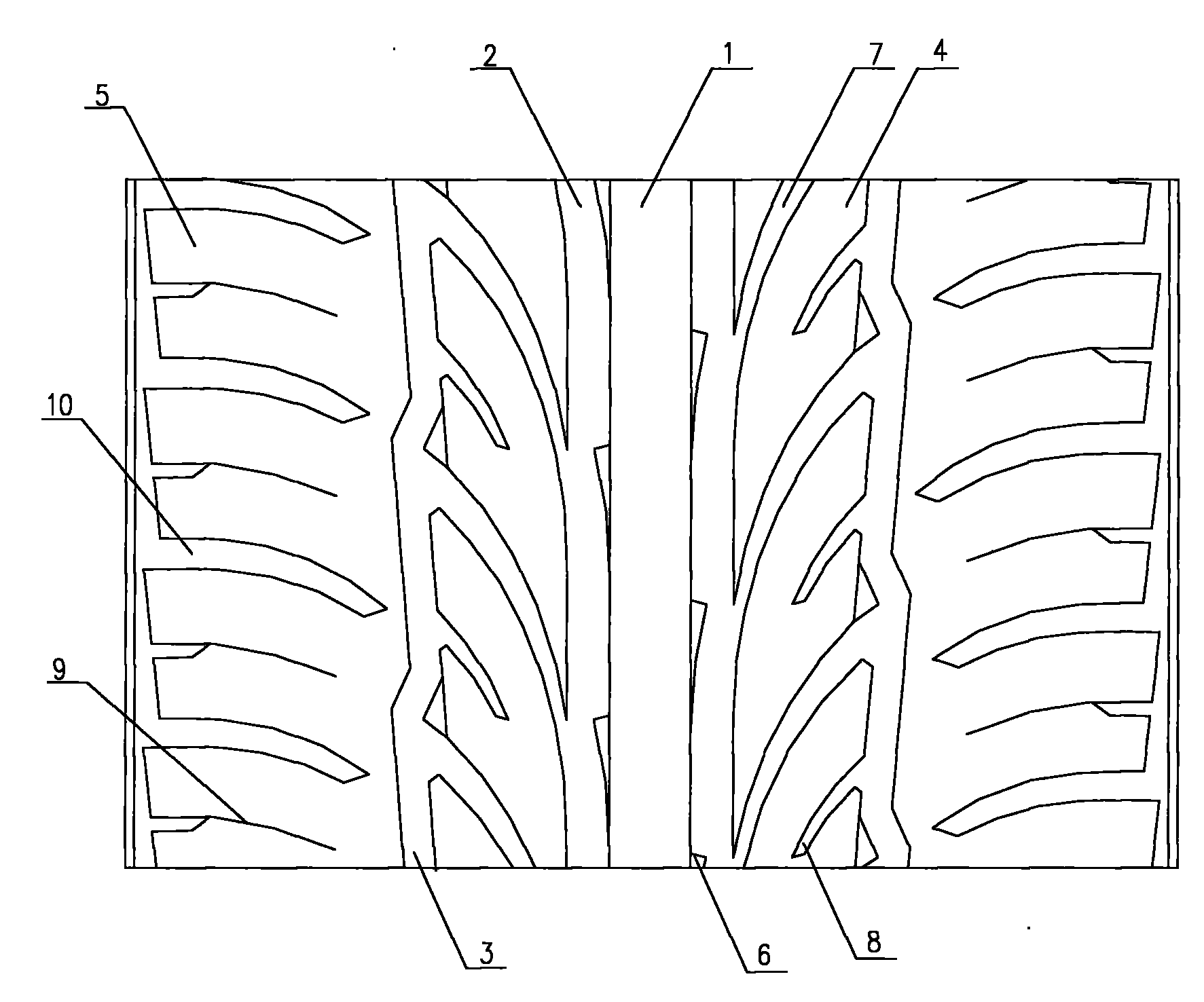

Tire tread of sedan meridian tire

ActiveCN101607512ASufficient braking forceImprove maneuverabilityTyre tread bands/patternsTire beadCentral line placement

The invention relates to a sedan tire structure, in particular to a tire tread pattern structure of a sedan tire. The tire tread of the sedan meridian tire comprises central pattern blocks, lateral pattern blocks and tire shoulder pattern blocks, wherein the central pattern blocks are the longitudinal pattern blocks; the lateral pattern blocks and the tire shoulder pattern blocks are regularly arranged on the left side and the right side of the central pattern blocks from inside to outside in sequence; the central pattern blocks are positioned on the central line position of the tire tread; the same arched pattern ditch is spaced between the central pattern blocks and the lateral pattern blocks, between the two adjacent lateral pattern blocks, and between the two adjacent tire shoulder pattern blocks respectively; an inclined lateral pattern ditch is spaced between the two adjacent central pattern blocks; and a longitudinal circumferential pattern ditch is spaced between the lateral pattern blocks and the tire shoulder pattern blocks. The tire tread of the tire adopts mixed patterns, and has the advantages of sufficient braking force, good control performance and elegant appearance.

Owner:QINGDAO YELLOWSEA RUBBER

Sucker rod deviation-based anti-eccentric wear sealing packing box

The invention discloses a sucker rod deviation-based anti-eccentric wear sealing packing box, which comprises a packing box main body, colloid packing, a steel packing pressure cap and a steel packing pressure cover and is characterized by also comprising a basic rubber cushion, a steel sheet gasket and a steel packing steel jacket. With the unique structure of the packing box main body, eccentric hole structures formed in the middle of the basic rubber cushion and the steel sheet gasket, the matching structure of the steel pacing steel jacket and the steel sheet gasket, the specific structure of the basic rubber cushion and related structures matched with the basic rubber cushion, the whole device enables a deviated sucker rod to drive the circular tube-shaped pacing steel jacket to shift in the derivation direction of an oil-sucking polish rod along the upper surface of the steel sheet gasket so as to drive the round colloid packing placed in the packing steel jacket to shift together, the polish rod is concentric with the packing which penetrates through the polish rod, so that the deviated sucker rod avoids causing eccentric wear of the packing and causing mechanical damage,. Thus, the service life of the packing is prolonged and the packing is intact after being used for one year.

Owner:高洪江

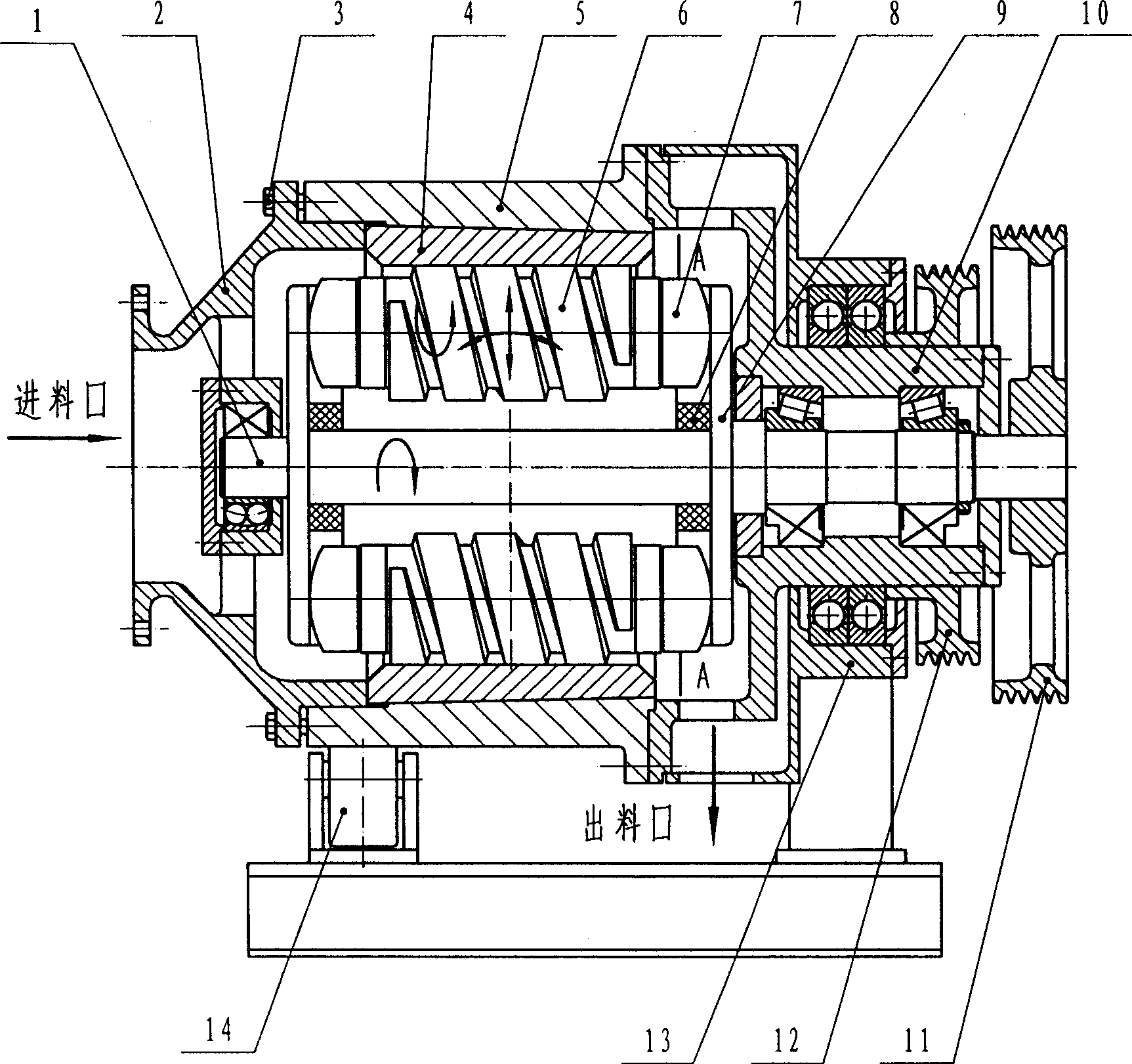

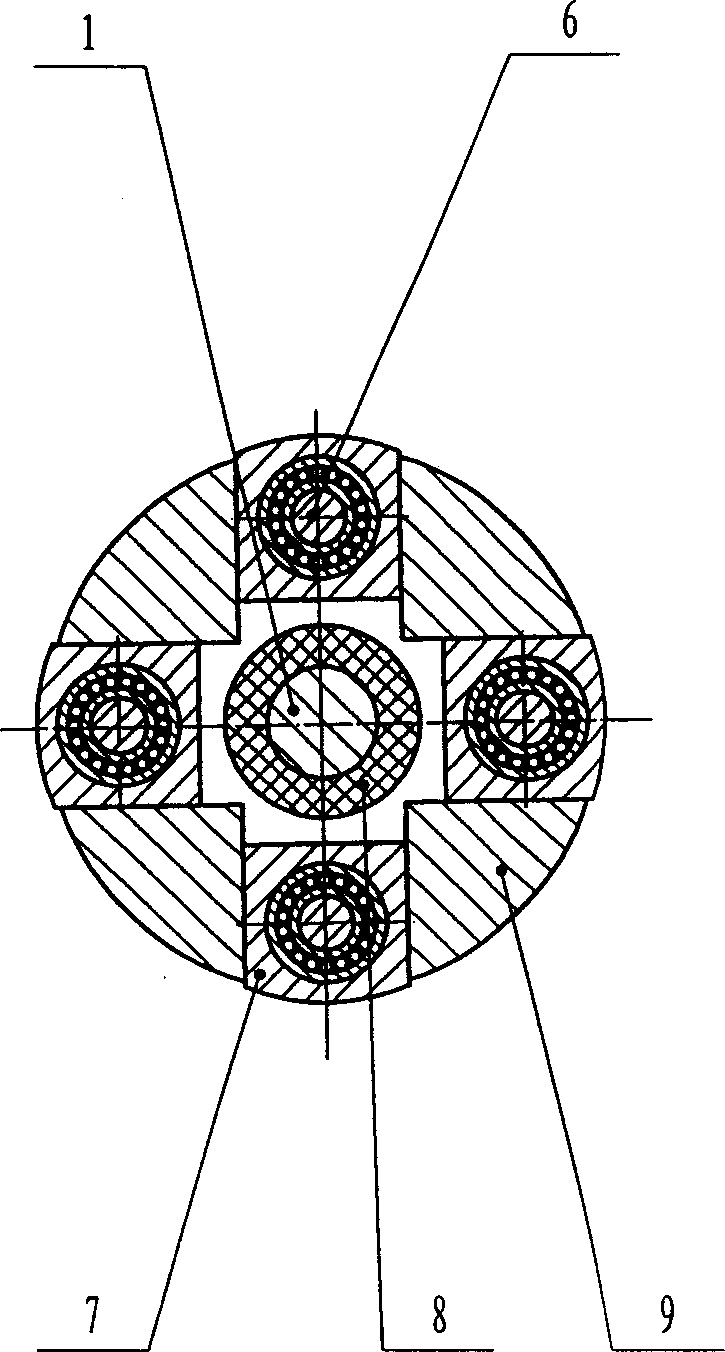

Horizontal high pressure planet roller mill

The present invention relates to a kind of horizontal high-pressure planetary roller mill. The technological scheme is that the planetary roller mill has main shaft installed horizontally in the right and left bearing seats via bearings, right bearing seat installed inside the frame bearing seat, one driving wheel fixed to the end of the right bearing seat, the other driving wheel fixed to right end of the main shaft, mill ring jacket on the support roller, mill ring inside the mill ring jacket, horizontally installed spiral roller inside the mill ring, conic surface connection between mill ring and mill ring jacket, and screw connection between the mill ring jacket and the left bearing seat. The planetary roller mill has the features of homogeneous distribution of material, high crushing efficiency, fine granularity of the product and low power consumption.

Owner:WUHAN UNIV OF SCI & TECH

Truck tyre tread

ActiveCN101618664AAvoid eccentric wearImprove maneuverabilityTyre tread bands/patternsEngineeringTruck

The invention relates to an auto tyre structure, in particular to a tread pattern structure for a tyre of a truck. The truck tyre tread comprises a central vertical circumferential pattern groove arranged on the center position of the tyre tread, namely the center line of the tyre tread, wherein the central vertical circumferential pattern groove equally divides the tyre tread into two eudipleural parts, the left side and the right side of the central vertical circumferential pattern groove are provided with lateral pattern blocks and shoulder pattern blocks in turn regularly from inside to the outside, the lateral pattern blocks and the shoulder pattern blocks are spaced by the vertical circumferential pattern groove, and the groove bottom of the vertical circumferential pattern groove is provided with a bulge which is connected with the two side walls of the circumferential pattern groove; and two adjacent lateral pattern blocks and two adjacent shoulder pattern blocks are spaced by a transverse pattern groove respectively. The tyre tread of the truck tyre adopts mixed patterns and has sufficient braking force, good maneuverability, and elegant appearance.

Owner:QINGDAO YELLOWSEA RUBBER

Tread of meridian tire for car

InactiveCN102248868ASufficient braking forceImprove maneuverabilityTyre tread bands/patternsEngineeringMixed pattern

The invention relates to a tire structure for a vehicle, in particular to a tread of a meridian tire for a car. The tread of the meridian tire for the car comprises a central pattern block, lateral pattern blocks and a tire shoulder pattern block; the central pattern block is an integrative longitudinal pattern block, and the lateral pattern blocks are regularly arranged at left and right sides of the central pattern block sequentially from inside to outside; the central pattern block is located in the centre of the tread; the central pattern block is spaced from the lateral pattern blocks via main longitudinal circumferential pattern grooves; the lateral pattern blocks are spaced from the tire shoulder pattern block via auxiliary longitudinal circumferential pattern grooves; two adjacent lateral pattern blocks are spaced from each other via an inclined lateral pattern groove, and two ends of the lateral pattern blocks are respectively communicated with the main longitudinal circumferential pattern grooves and the auxiliary longitudinal circumferential pattern grooves; and the tire shoulder pattern block is an integrative longitudinal pattern block. The tread of the tire has the characteristics of adoption of mixed patterns, enough braking force, good maneuvering performance and elegant appearance.

Owner:克劳斯玛菲股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com