Pneumatic tire

一种充气轮胎、轮胎的技术,应用在轮胎零部件、轮胎胎面/胎面花纹、运输和包装等方向,能够解决胎块刚性下降、偏磨损、干燥路面操纵稳定性能恶化等问题,达到排水性能提高、抑制偏磨损、实现刚性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

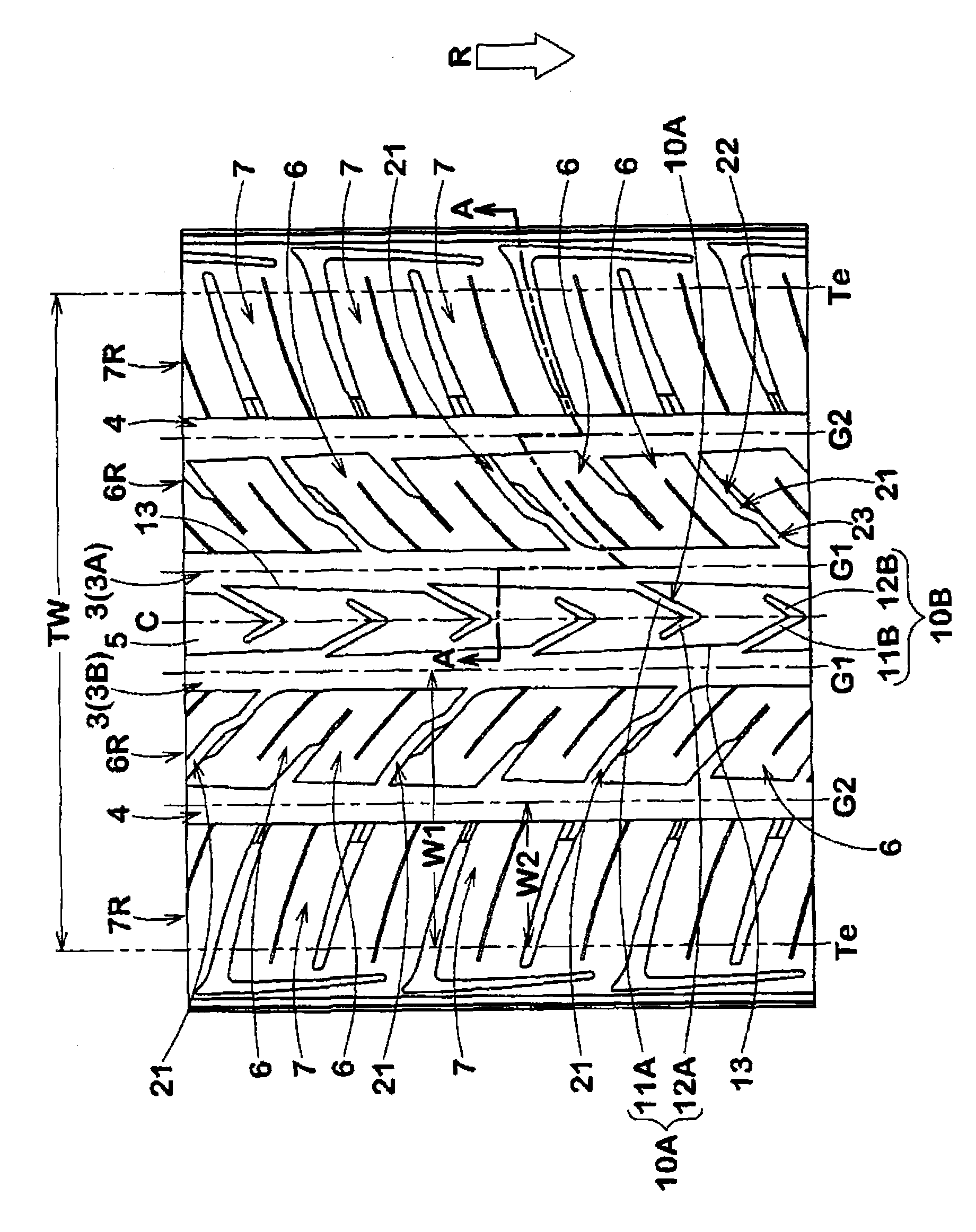

[0071] In order to confirm the effect of the present invention, there is figure 1 A 225 / 45R17 passenger radial tire was trial-manufactured based on the pattern and specifications in Table 1. Then, these tires were tested for braking performance on ice, driving performance on snow, and partial wear resistance. In addition, the parameters other than those shown in Table 1 are the same.

[0072] In addition, the common specifications are as follows.

[0073] Tread contact width TW: 201mm

[0074] Gentle slope of the middle transverse groove: yes

[0075] Gently sloped part of shoulder transverse groove, groove rib and sipe: Yes

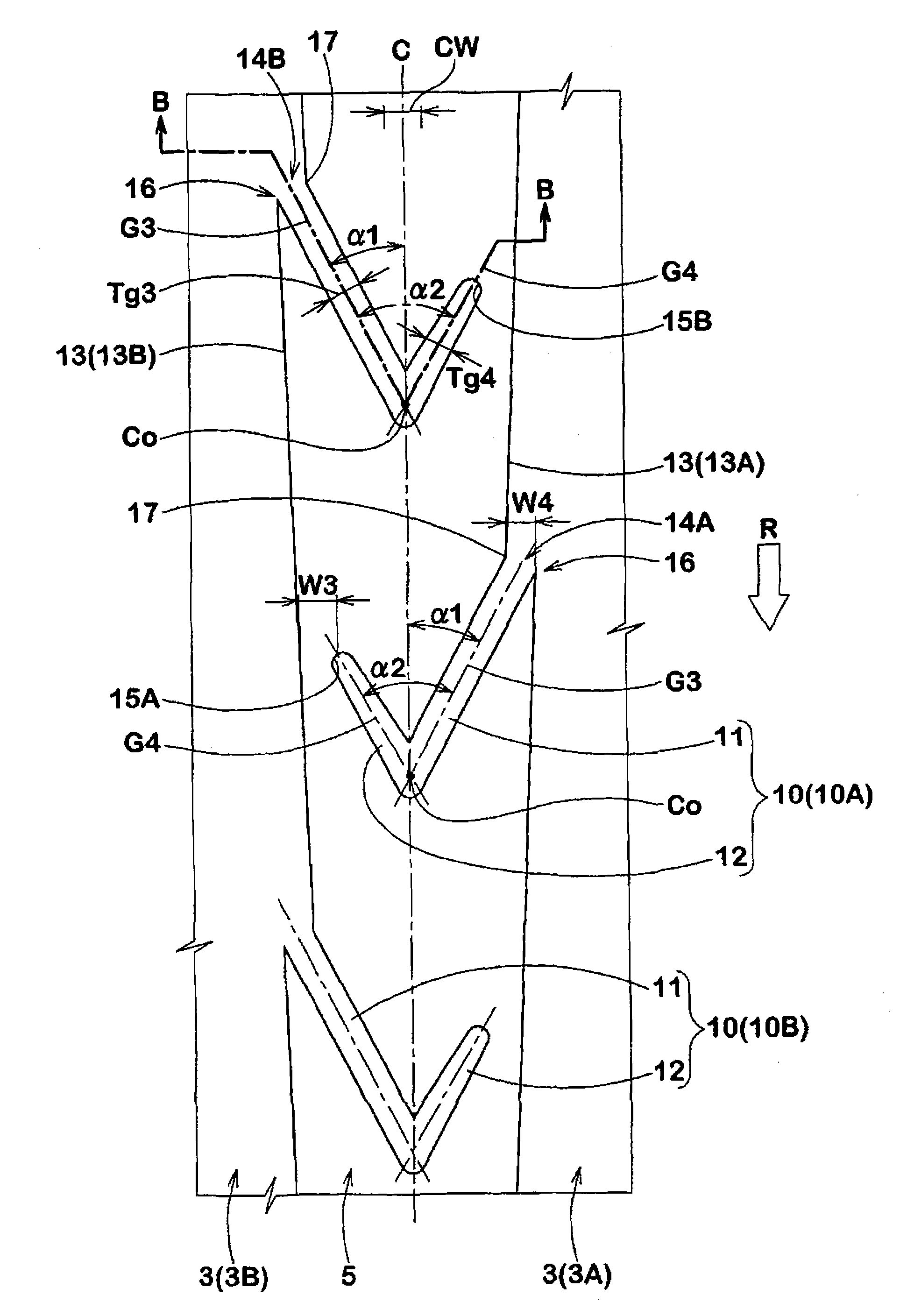

[0076] The groove shape on the side of the tread ground contact end of the crown circumferential groove: parallel to the tire equator C.

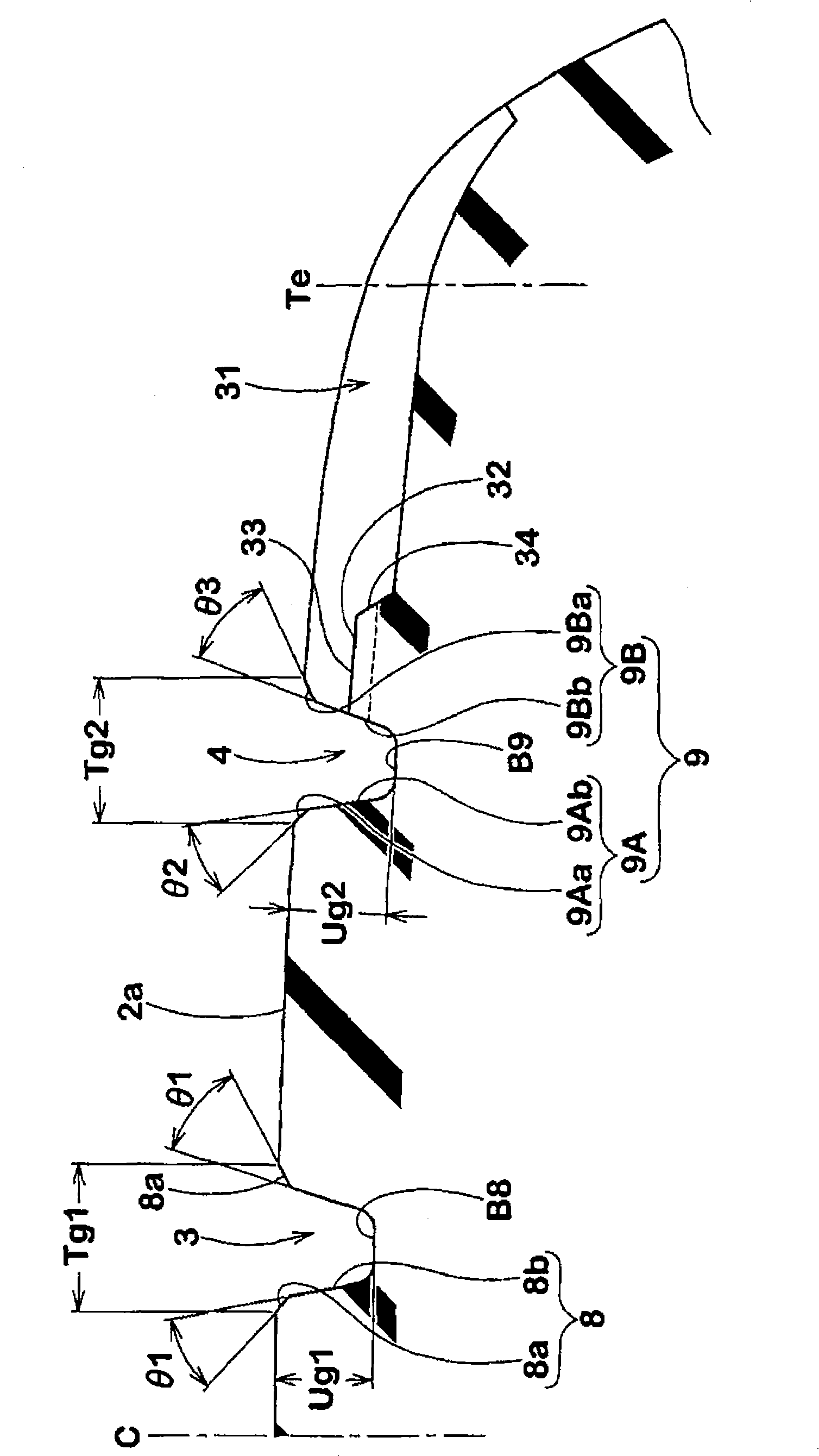

[0077] Groove width Tg1 / TW of crown circumferential groove: 5%

[0078] Groove width Tg2 / TW of shoulder circumferential groove: 4%

[0079] Groove width Tg3 / TW of the main portion of the crown transverse groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com