Patents

Literature

60results about How to "Uniform rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

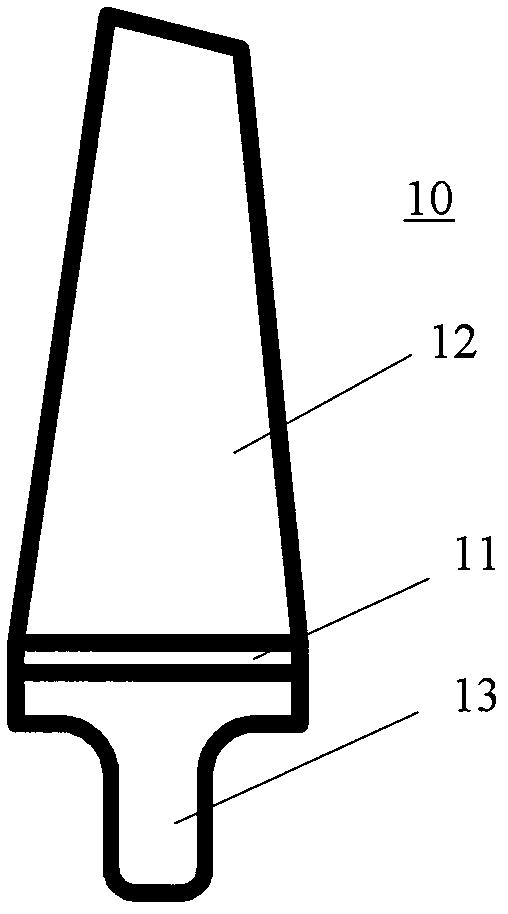

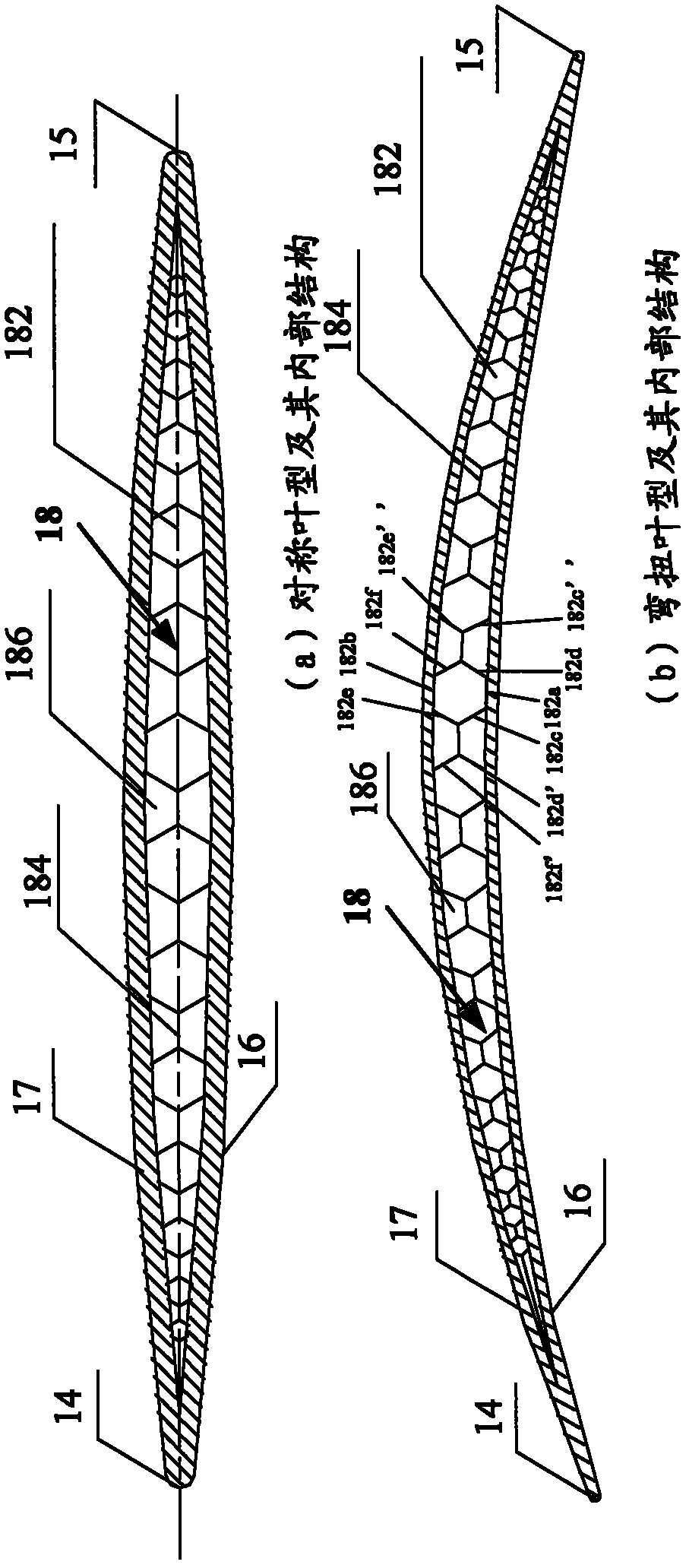

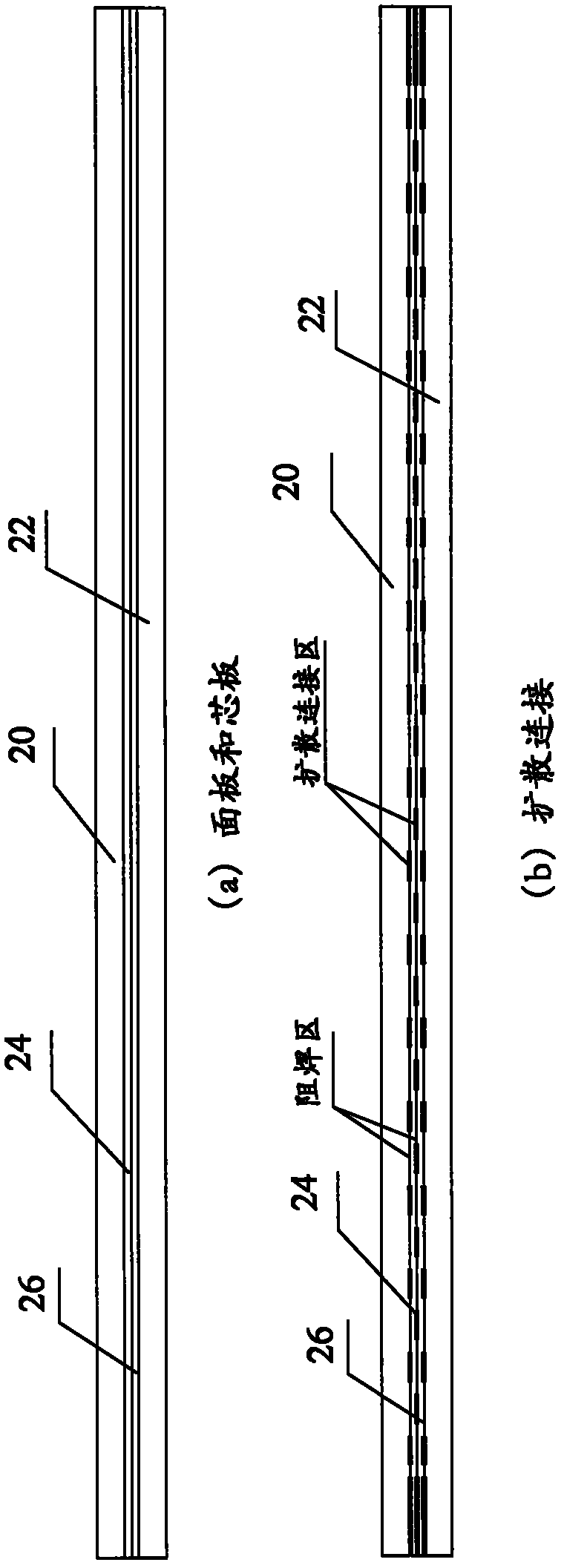

Hollow blade

InactiveCN102996510AImprove impact resistanceUniform rigidityPump componentsPumpsEngineeringFront edge

The invention relates to a hollow blade, which comprises a root tenon and a blade profile part, wherein the blade profile part extends to a top end from the root tenon, and is provided with a front edge, a tail edge, and a pressure surface part and a suction surface part extending from the front edge to the tail edge; the pressure surface part and the suction surface part commonly limit a cavity; and a vibration resistance part is connected onto an inner surface of the cavity, and is provided with a plurality of hollow like hexagonal cylinder structures arranged between the front edge and the tail edge at intervals and extending from the root tenon to the top end. The blade with the hollow hexagonal cylinder structures, so that the rigidity in each direction is balanced, and the impact resistance of the blade in each direction is effectively enhanced.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

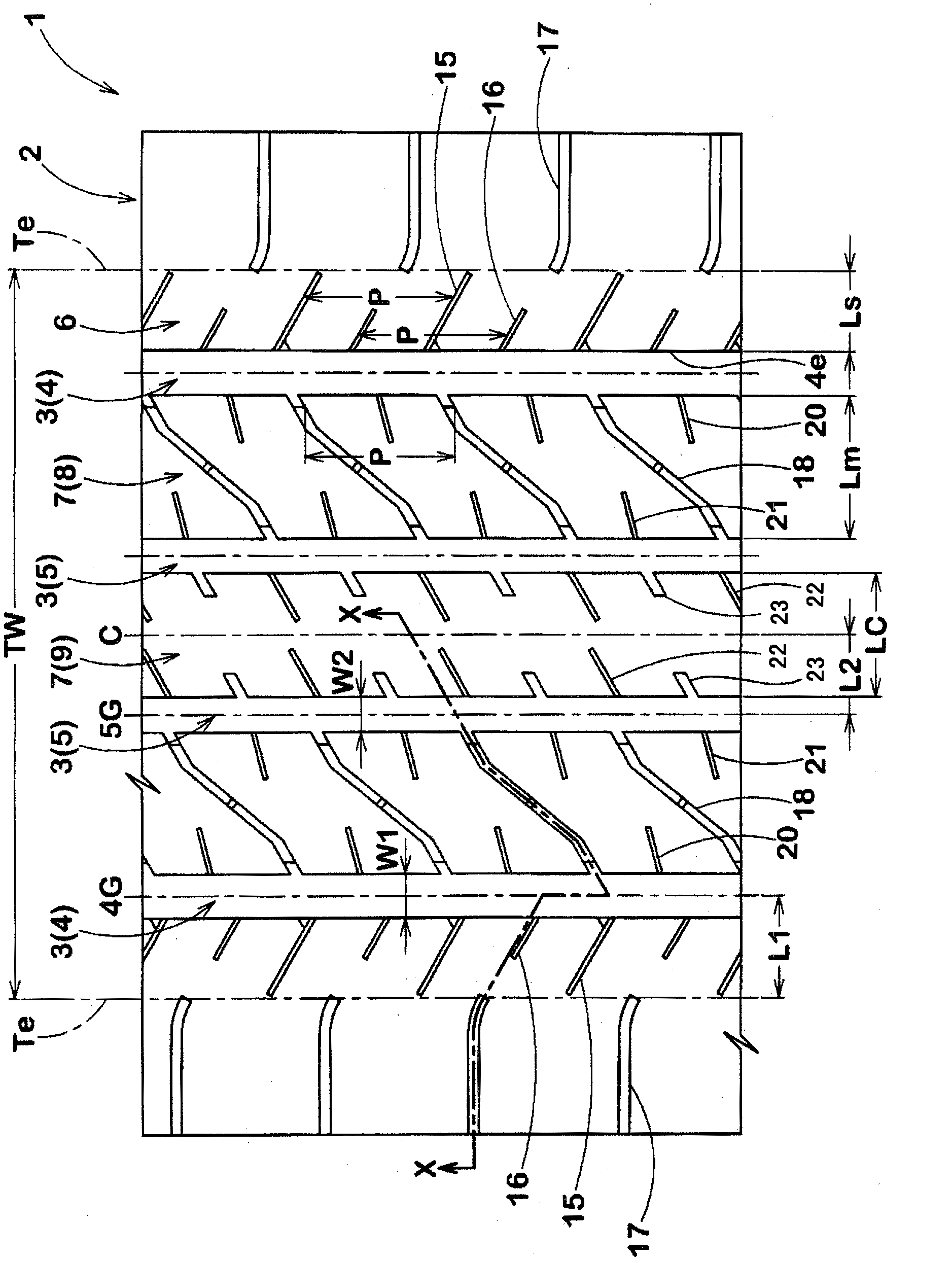

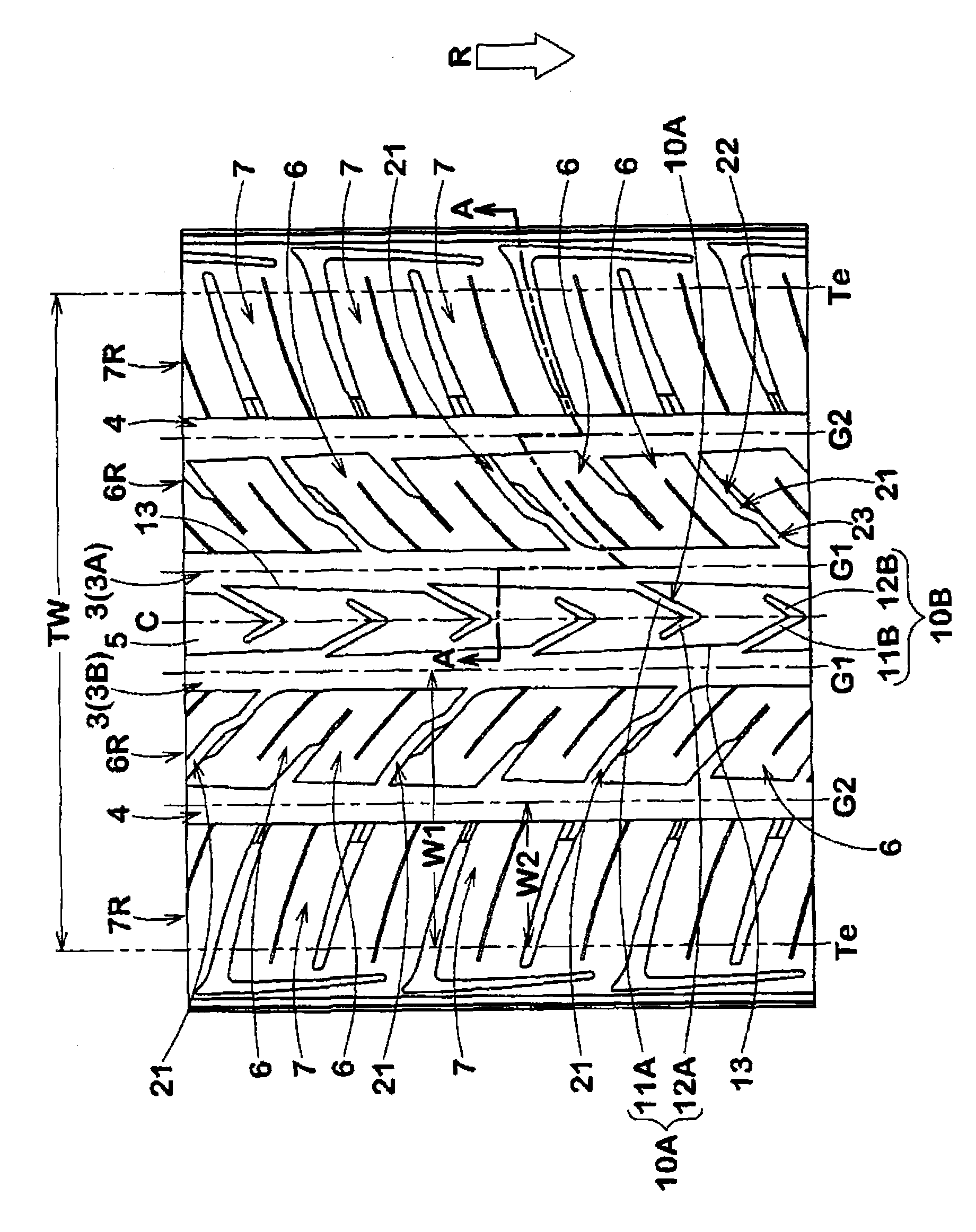

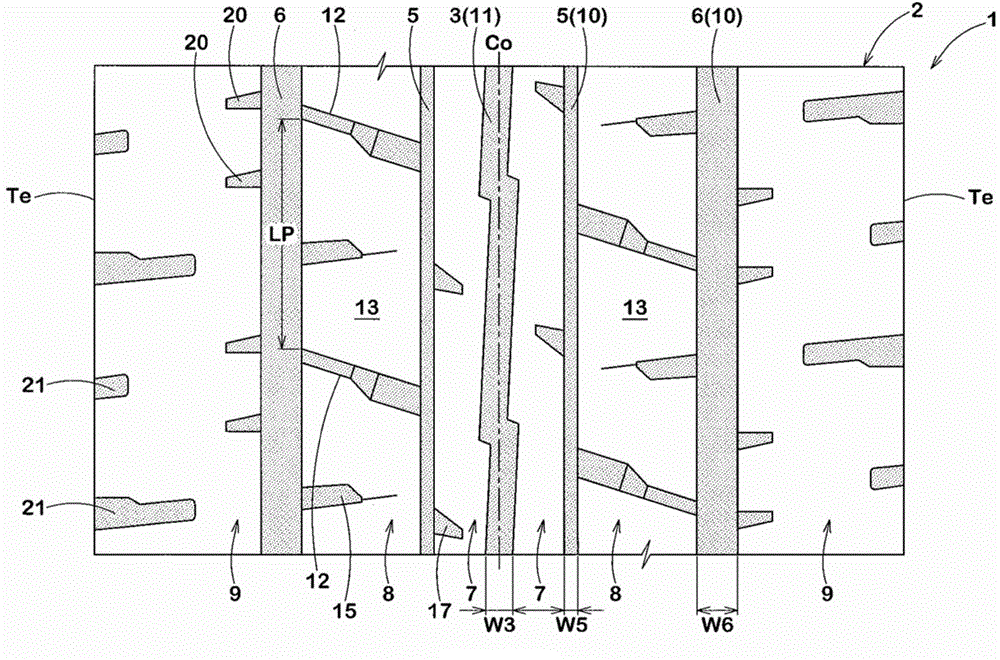

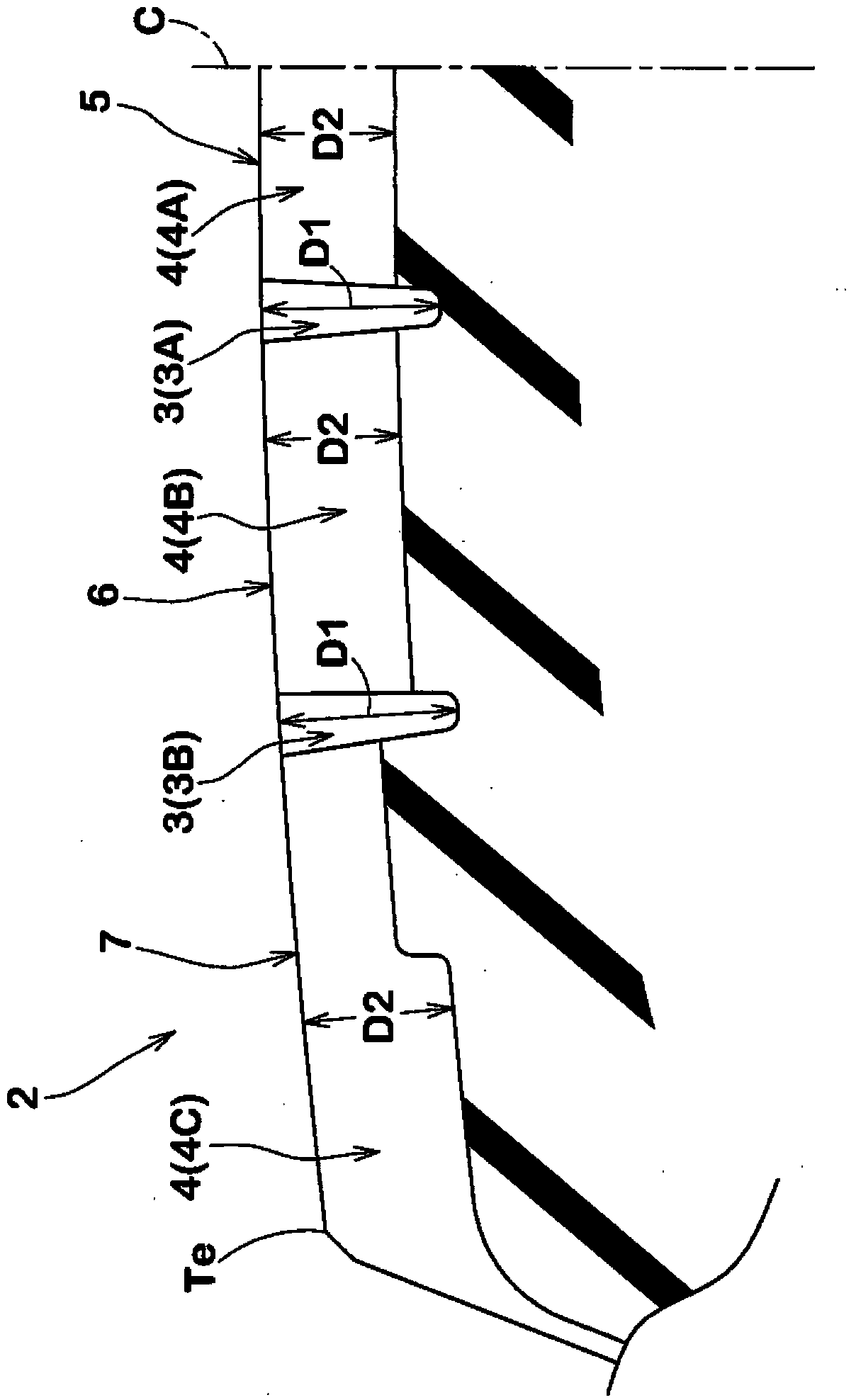

Inflation tire

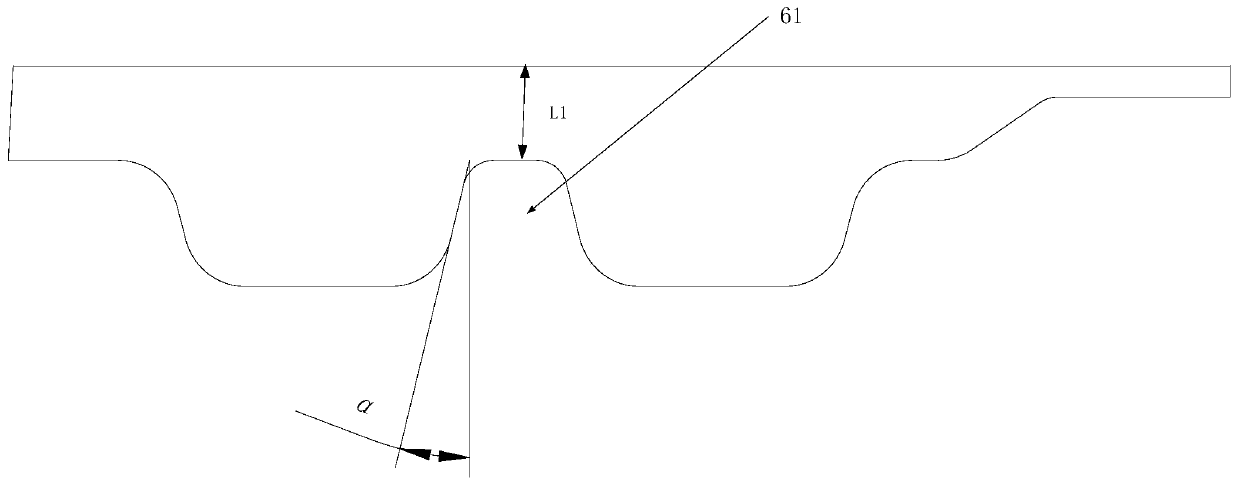

InactiveCN102649389AImprove impactImprove rigidityTyre tread bands/patternsRoad surfaceWear resistance

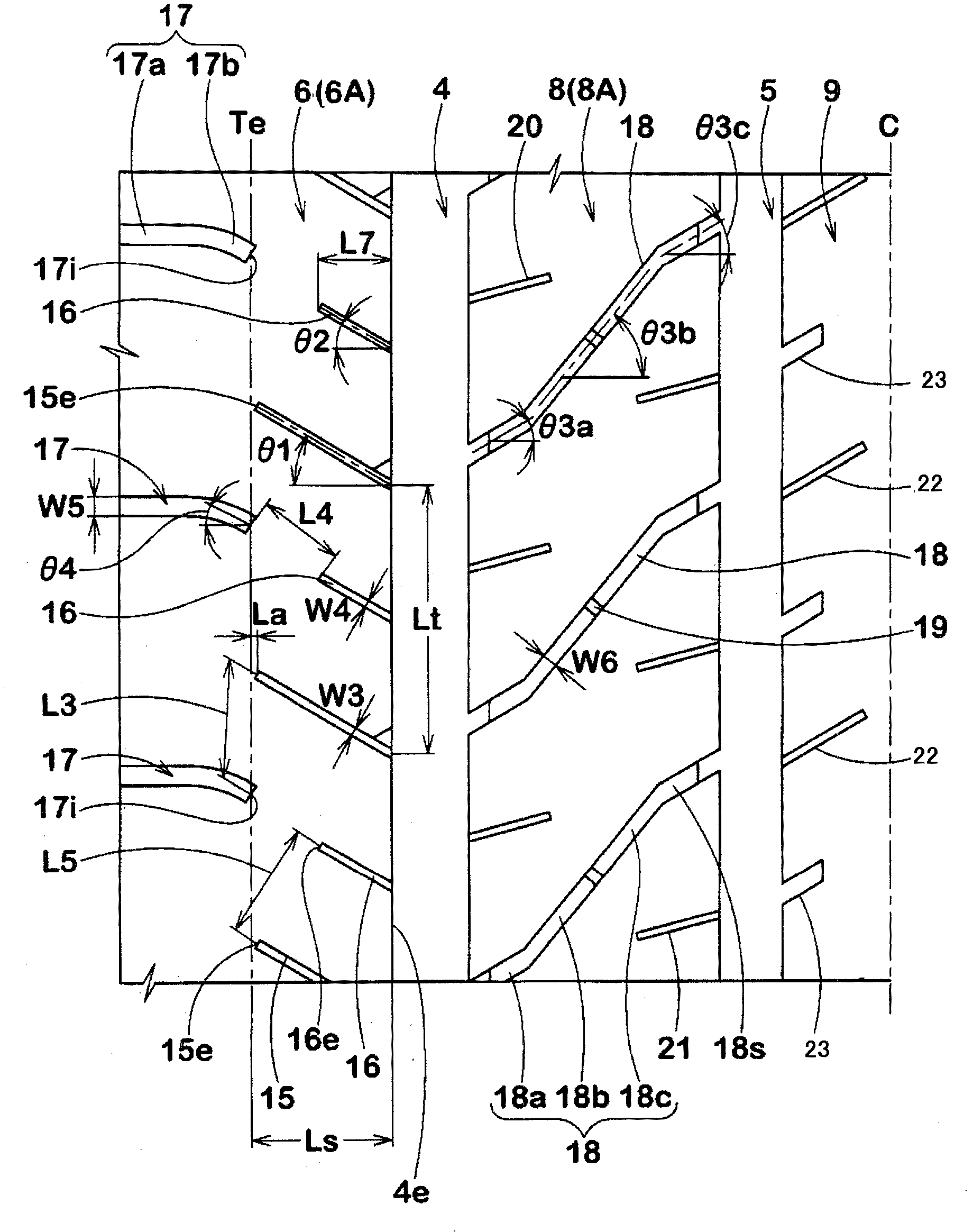

The invention discloses an inflation tire, which can be used to maintain the sideslipping performance, the performance on wet road surfaces of the vehicle, and to improve the heal-and-toe wear resistance performance of the vehicle. The inflation tire (1) is provided with a plurality of grooves(3) of a pair of tire shoulder main grooves(4). A land part width (Ls) of a tire shoulder land part(6) is 10 to 15% of a tire surface grounding width (TW). The tire shoulder land part (6) is provided with a first tire shoulder horizontal groove (15), which extends from the part close to the tire surface grounding end (Te),and is inclined at an angle of 10 to 35 degrees relative to the tire shaft; a second tire shoulder horizontal groove (16), which is inclined from the part between the first tire shoulder horizontal grooves (15, 15) at an angle of 10 to 35 degrees towards the axial direction of the tire, and can form a terminal on the tire shaft more close to the inner side than the first tire shoulder horizontal groove(15); a third tire shoulder horizontal groove (17), which is inclined from the outer side of the tire surface grounding end (Te) of the tire shaft towards the inner side of the tire shaft, and can form a terminal close to the tire surface grounding end(Te).

Owner:SUMITOMO RUBBER IND LTD

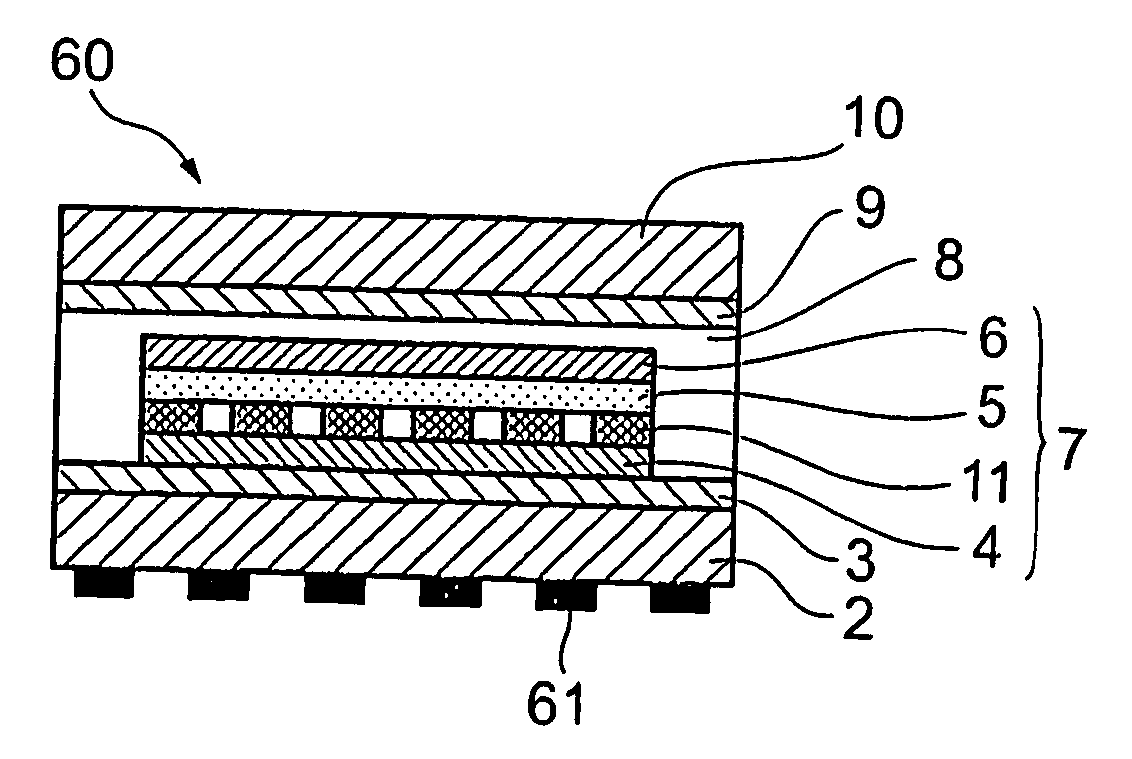

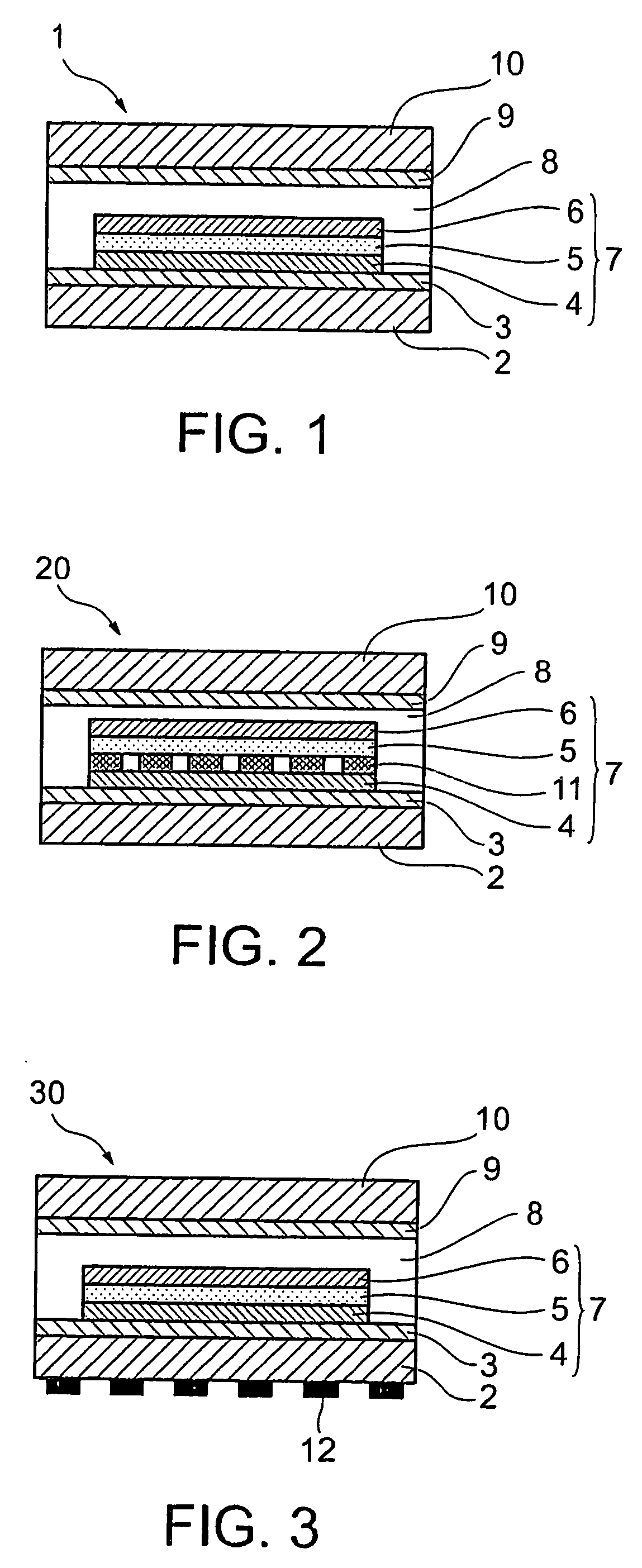

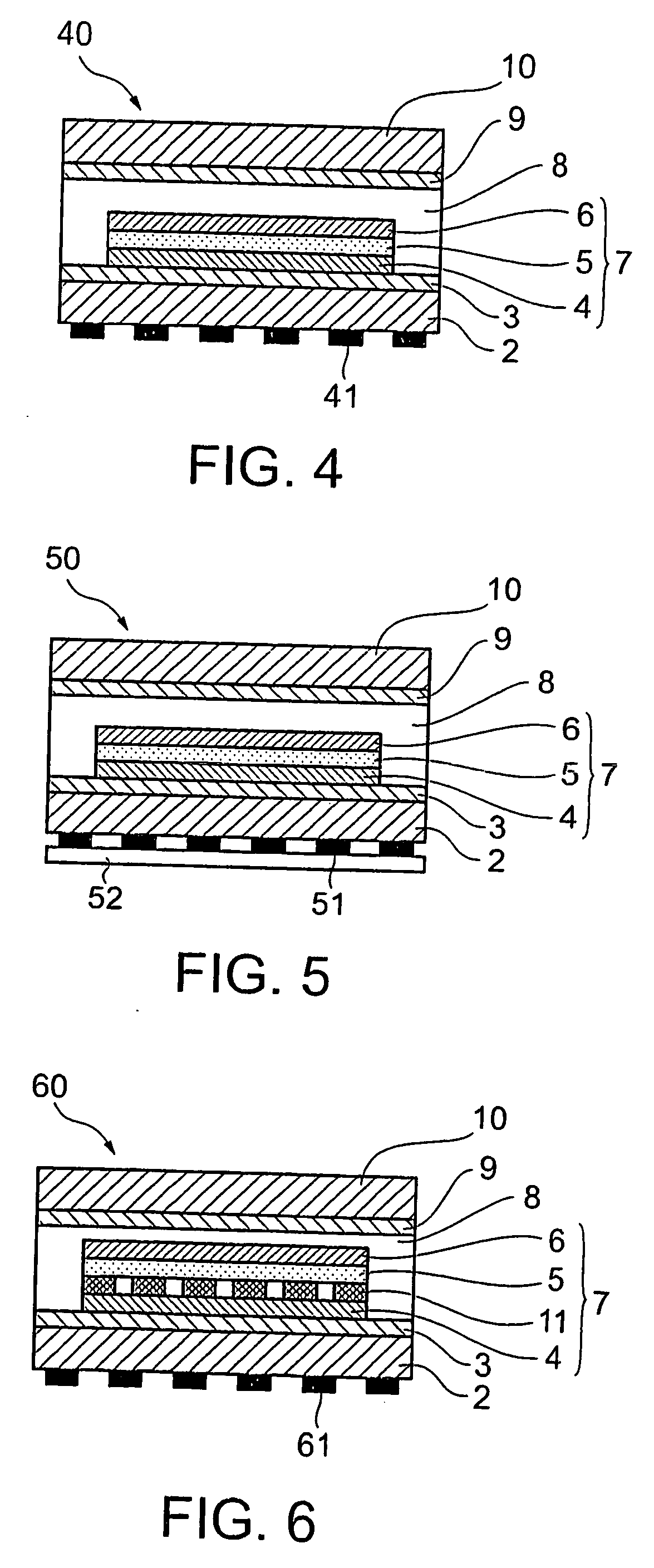

El device and display using same

InactiveUS20050269951A1Uniform rigidityUniform thermal expansionDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceEngineering

Disclosed is an EL element in which the rigidity and thermal expansion of the whole EL element is homogeneous, the spacing between film substrates provided respectively on both sides of the EL element can be kept constant, and the whole EL element is flexible. The EL element comprises a first film substrate, an EL part, and a sealant layer, the EL part comprising a first electrode, an EL layer, and a second electrode and being provided on a part of a surface of the first film substrate, the sealant layer being provided to cover the EL part and to cover the EL part-free part of the surface of the first film substrate in such a manner that the sealant layer covering the EL part is contiguous with the sealant layer covering the EL part-free part of the surface of the first film substrate.

Owner:DAI NIPPON PRINTING CO LTD

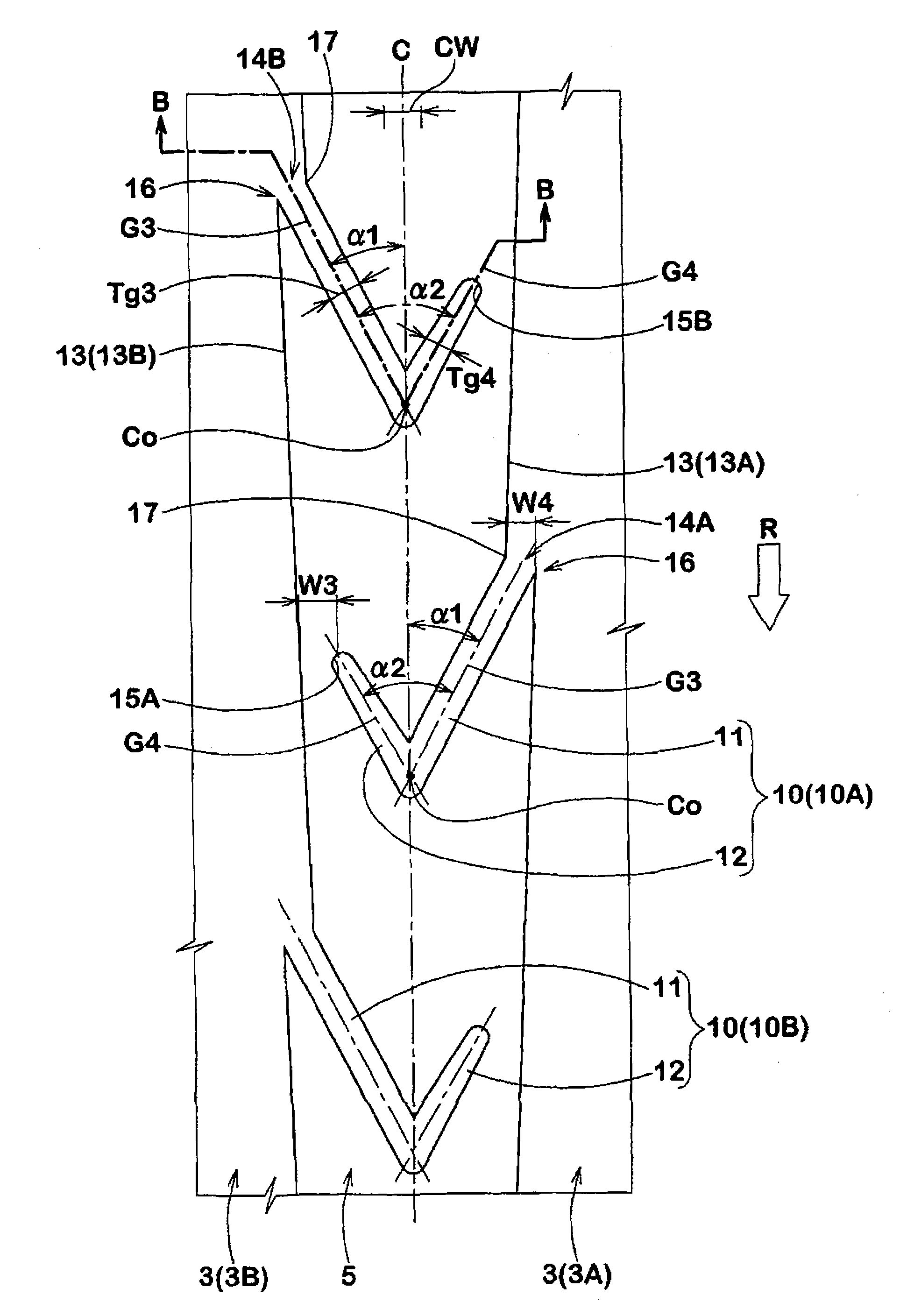

Pneumatic tire

InactiveCN101856954AImprove handling stabilityUniform front and rear rigidityTyre tread bands/patternsEngineeringEquator

The invention provides a pneumatic tire, which can prevent partial abrasion and promote the performance on ice and snow road. A rotating direction (R) is defined on the pneumatic tire. The pneumatic tire has a first V-shaped groove (10A) and a second V-shaped groove (10B), wherein the first and second V-shaped grooves (10A;10B) are terminated within the rib (5); one end (14) of the first V-shaped groove (10A) is communicated with a crown circumferential groove(3A) while the other end (15) exceeds a tire equator (C) but not reach another crown circumferential groove (3B); one end of the second V-shaped groove (10B) is communicated with a crown circumferential groove(3B) while the other end exceeds a tire equator but not reach the crown circumferential groove (3B); and the first and second V-shaped grooves (10A;10B) comprise a primary part (11) which extends from one end to the tire equator along the rotating direction and a bent part (12) which is connected to the primary part and is substantially bent on the tire equator along the direction reverse to the rotating direction.

Owner:SUMITOMO RUBBER IND LTD

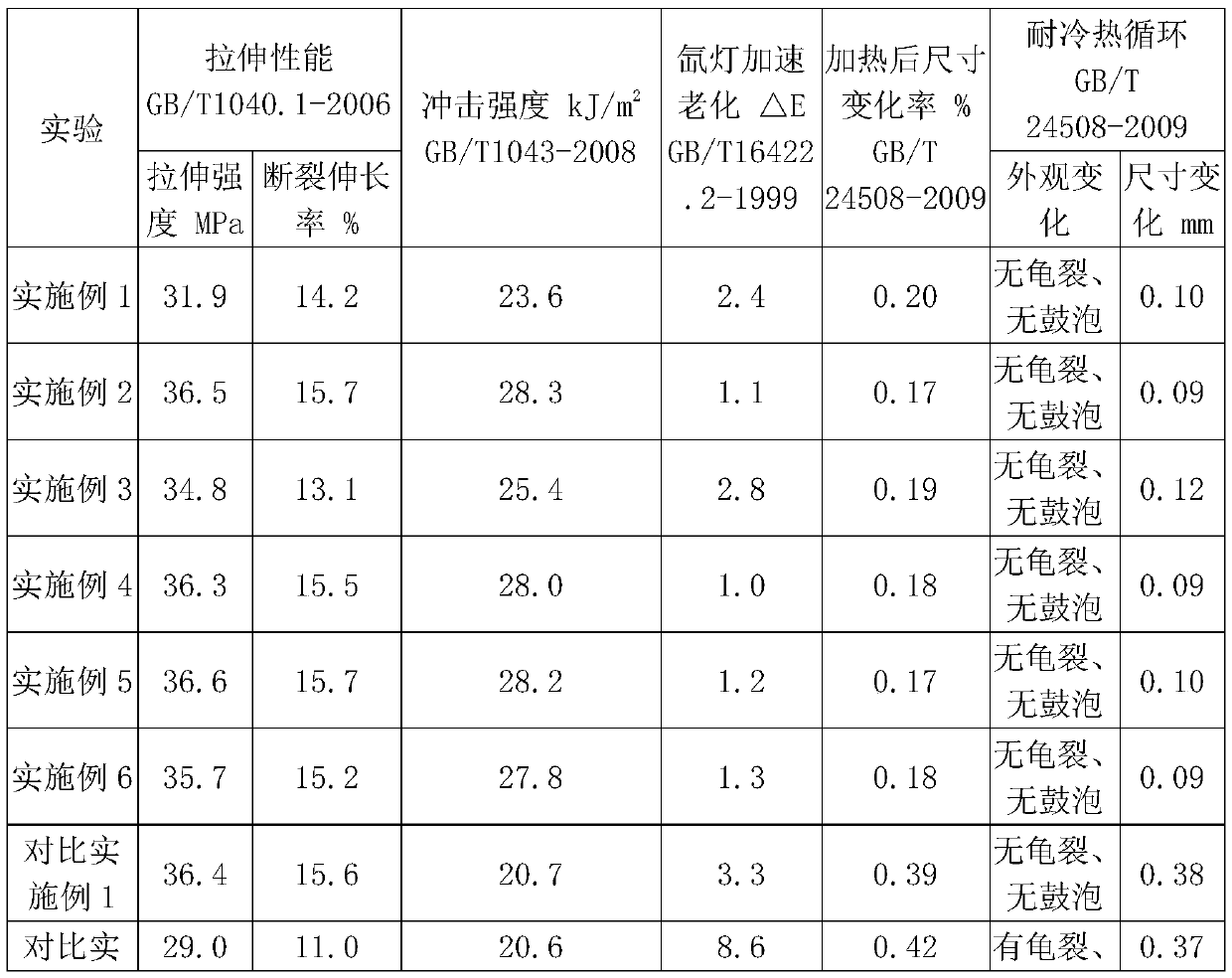

Anti-aging impact-resistant modified wood-plastic composites (WPC) and preparation method thereof

The invention provides an anti-aging impact-resistant modified wood-plastic composites (WPC) and a preparation method thereof. The wood-plastic composites are prepared from the following raw materials in parts by weight: 20-50 parts of polyolefin, 30-70 parts of enzymatic hydrolysis lignin modified vegetable fibers, 1-3.5 parts of polymerized rosin, 0.1-10 parts of an inorganic filler, 0.1-4 parts of an antioxidant, and 0.1-3 parts of an ultraviolet screening agent, wherein the enzymatic hydrolysis lignin modified vegetable fibers are prepared from enzymatic hydrolysis lignin and vegetable fibers through an anhydride reaction. According to the modified wood-plastic composites prepared by the invention, the affinity between the vegetable fibers and plastic is high, the dimensional stability of the composites is high, the rigidity and toughness are balanced, and ageing resistance is also improved at the same time; in the process of preparing the enzymatic hydrolysis lignin, a certain amount of ligninase is added, thus improving the impact resistance of the wood-plastic composites prepared from the enzymatic hydrolysis lignin modified vegetable fibres. Through the method of using the lignin to modify the vegetable fibers provided by the invention, lignin resources are fully used, waste is turned into treasure, and comprehensive utilization of the lignin resources is realized.

Owner:ZHEJIANG LIFAN FURNITURE

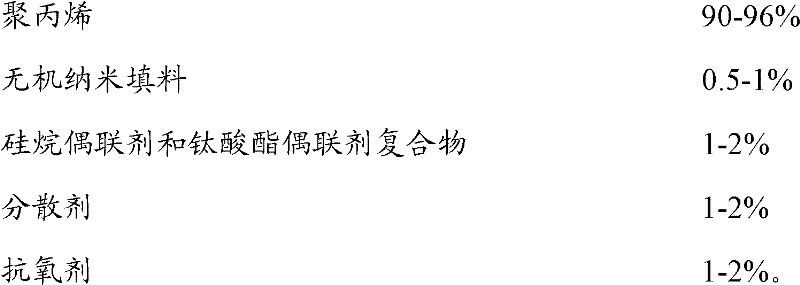

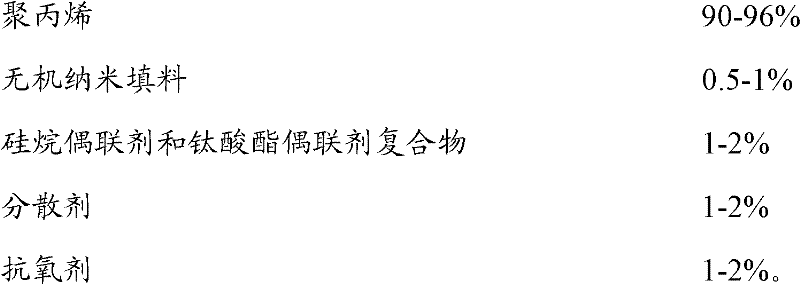

Polypropylene composite material and preparation method thereof

The invention is applicable to the technical field of plastics, and provides a polypropylene composite material and a preparation method thereof. The polypropylene composite material comprises the following components in percentage by mass: 90-96% of polypropylene, 0.5-1% of inorganic filler, 1-2% of a complex of a silane coupling agent and a titanate coupling agent, 1-2% of dispersing agent and 1-2% of antioxidant. The polypropylene composite material provided by the invention uses the silane coupling agent and the titanate coupling agent together, thus uniformly dispersing the inorganic nano filler in the polypropylene composite material, effectively preventing the inorganic nano filler from glomeration and realizing the balance between the toughness and rigidity of the polypropylene composite material. The preparation method of the polypropylene composite material provided by the invention is simple to operate, has the advantages of low cost and high production benefit, and is especially suitable for industrial production.

Owner:SHENZHEN KEJU NEW MATERIAL

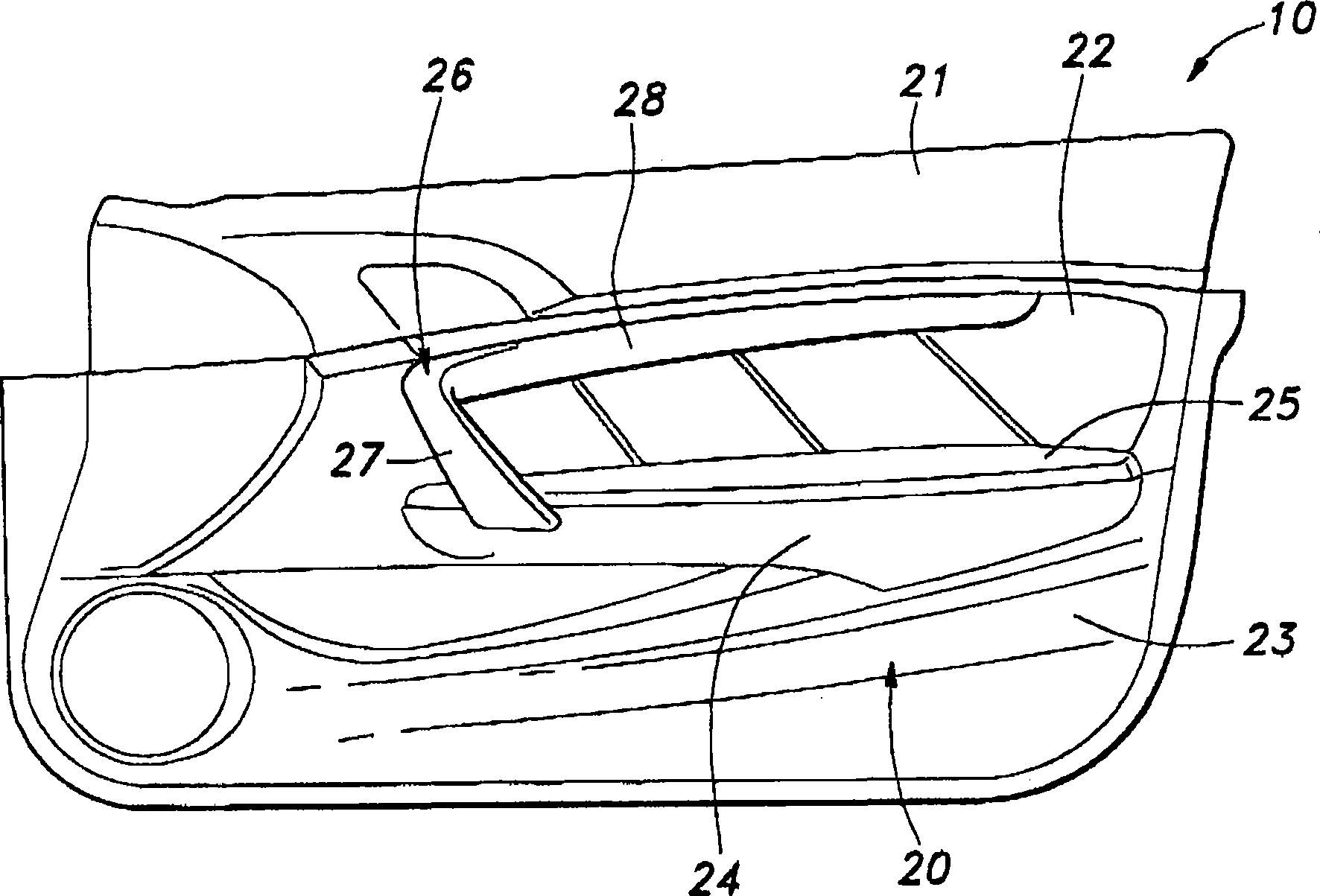

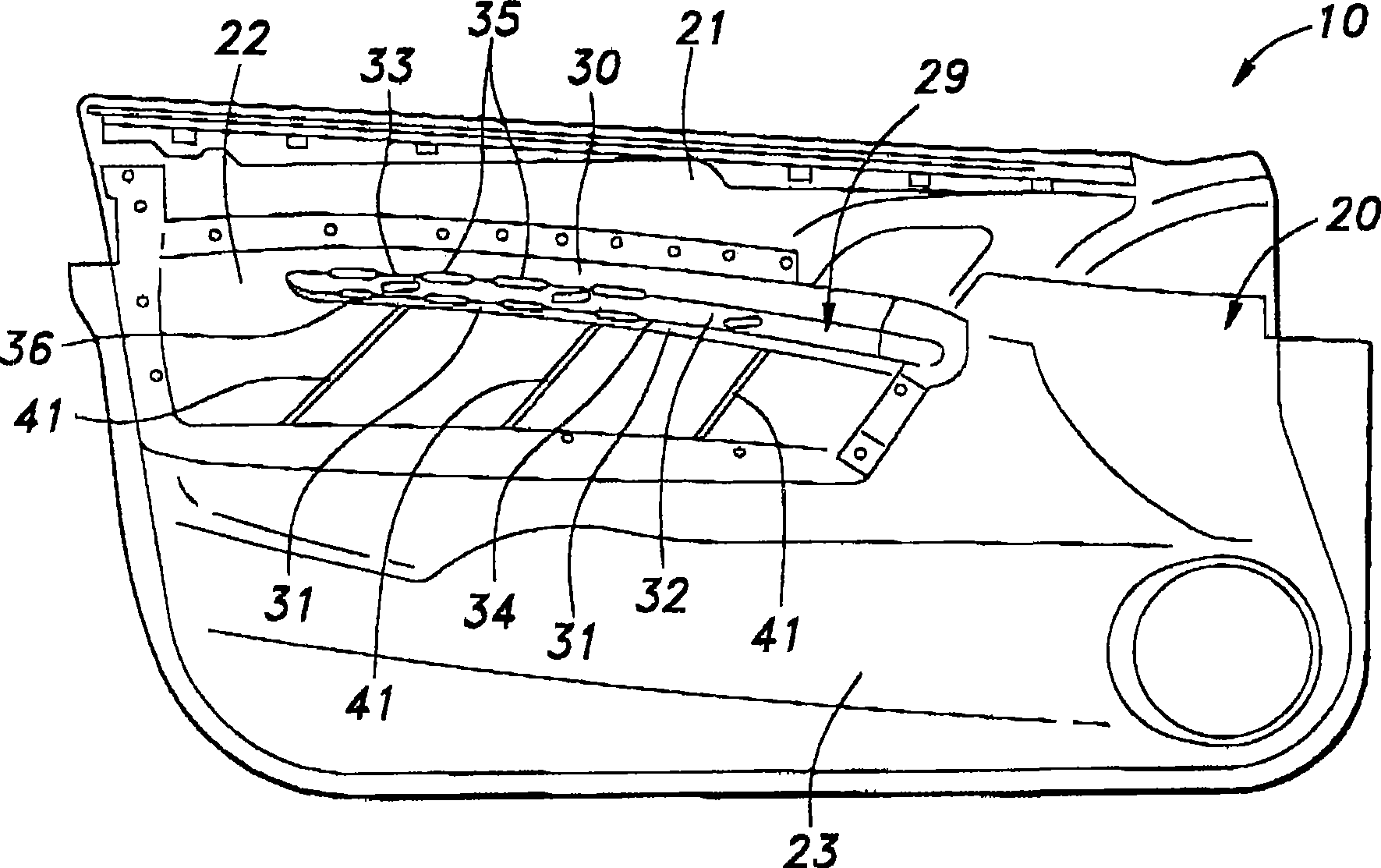

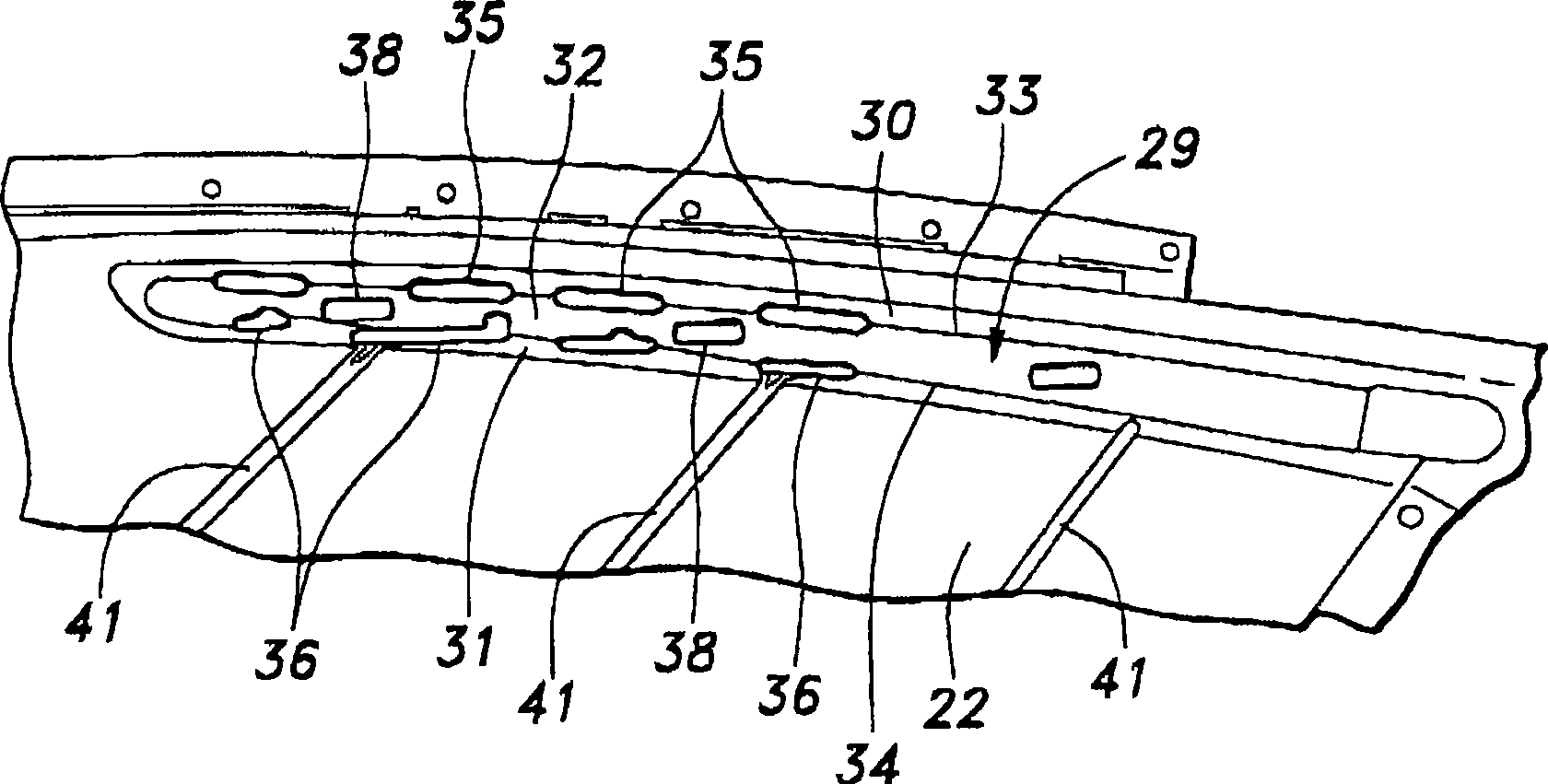

Vehicle door internal lining

InactiveCN101387179AImprove rigidityUniform rigidityDoor/window applicationsDoorsEngineeringDistortion

The invention provides an indoor lining plate for vehicle door. For mounting an inner article (an extending part of a handle component) on main body of the indoor lining plate, a groove part protruding towards outside of vehicle is formed on the main body of the indoor lining plate and an open part is formed on a position including a groove side surface of the groove part and an angle part between groove bottoms. So that, even if the spindly groove part for mounting the inner article on the main body of the indoor lining plate, rigidity of the main body of the indoor lining plate is balanced relative to impact energy absorption and absorption of impact energy can be carried by distortion of the main body of the indoor lining plate.

Owner:HONDA MOTOR CO LTD +1

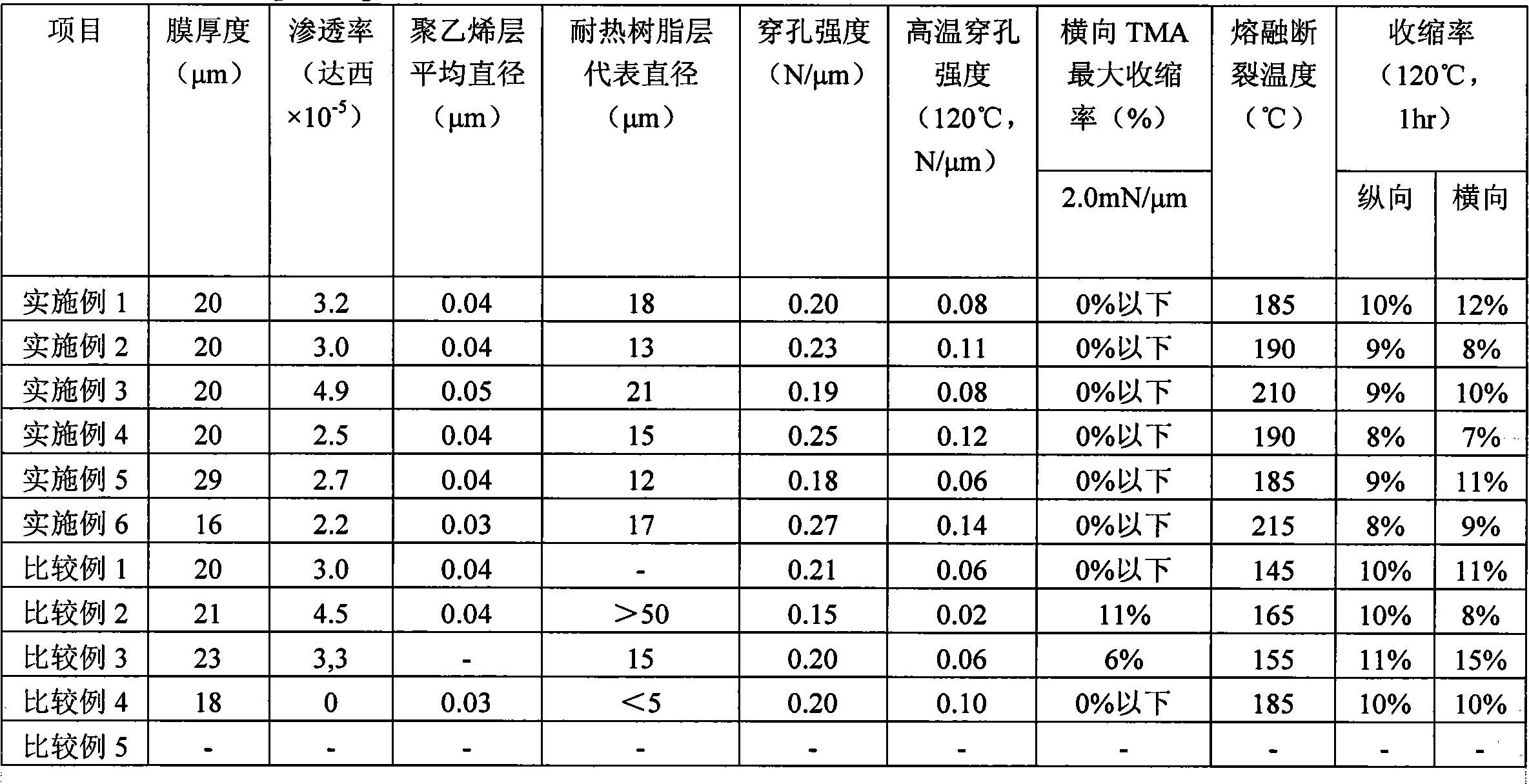

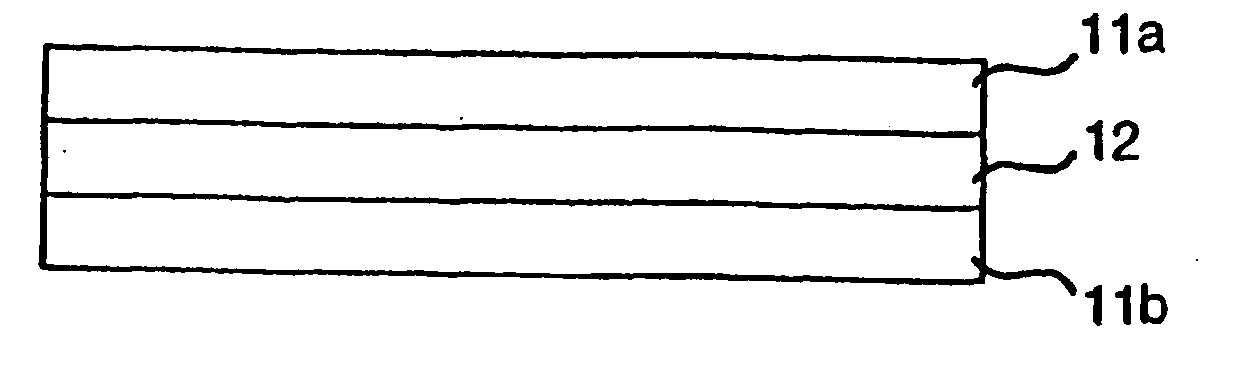

Polyolefin-based multilayer microporous film with excellent physical properties and high temperature stability

InactiveCN102405095AHigh Strength/High Transmission PropertiesUniform rigiditySemi-permeable membranesMembranesPolyolefinCrystallinity

The present invention relates to a polyolefin-based multilayer microporous film which can be used as a battery separator, and to a method for producing the film. The polyolefin-based multilayer microporous film according to the present invention comprises: at least one layer comprising 90 to 100 wt % of polyethylene with a melting point of 130 to 140 DEG C; at least one other layer comprising 20 wt % or more of a heat-resistant resin; and 80 wt % or less of a filler selected from an organic filler, an inorganic filler, and a mixture thereof. The heat-resistant resin is preferably a semicrystalline polymer or an amorphous polymer. The semicrystalline polymer preferably has a degree of crystallinity of 10 to 45 % or a content heat of fusion of 20 to 90 J / g, a crystal melting temperature of 145 to 250 DEG C, and a glass transition temperature of -100 to 90 DEG C. The amorphous polymer has no crystals, and preferably has a glass transition temperature of 90 to 120 DEG C.

Owner:SK INNOVATION CO LTD

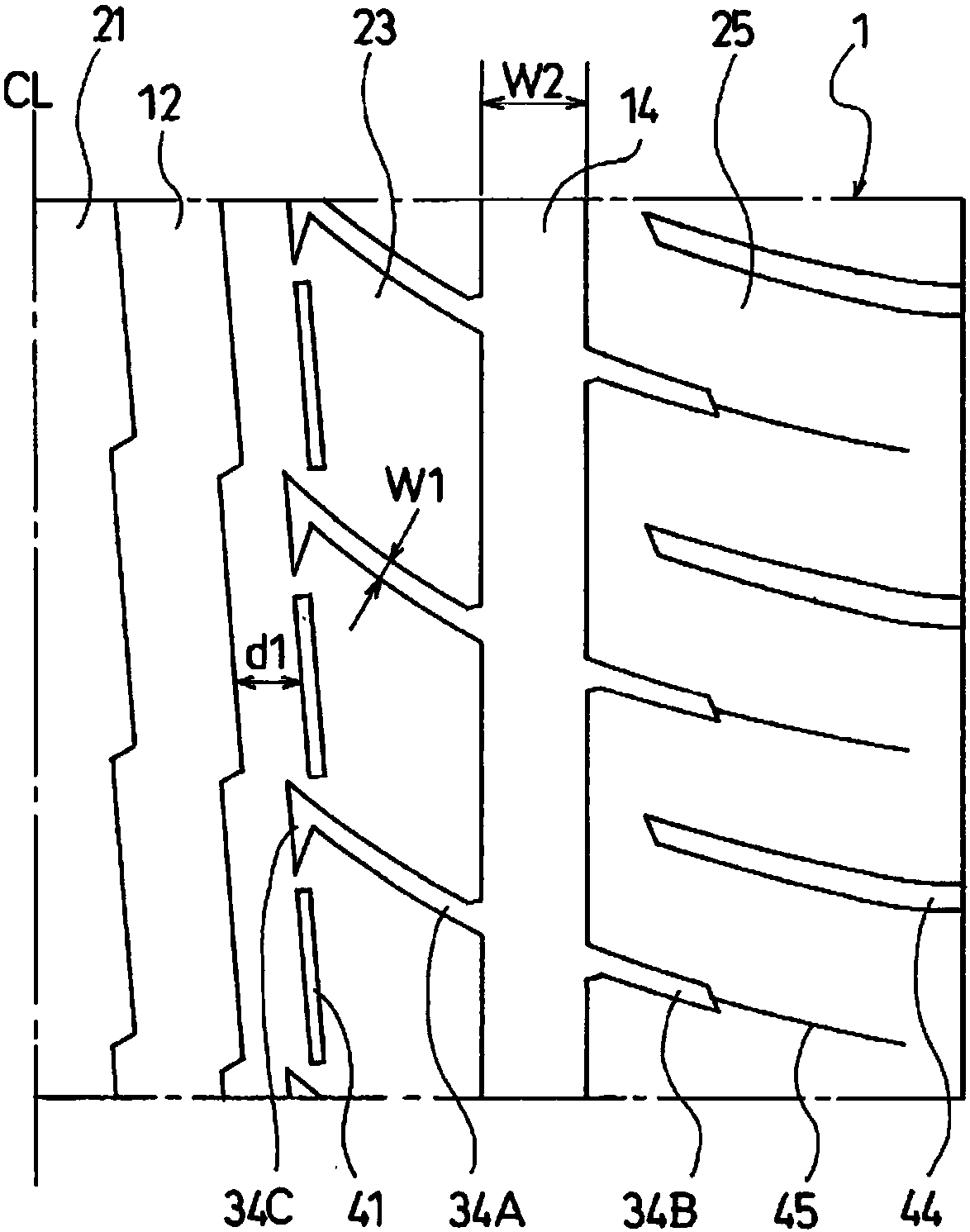

Pneumatic tire with tread having oblong holes

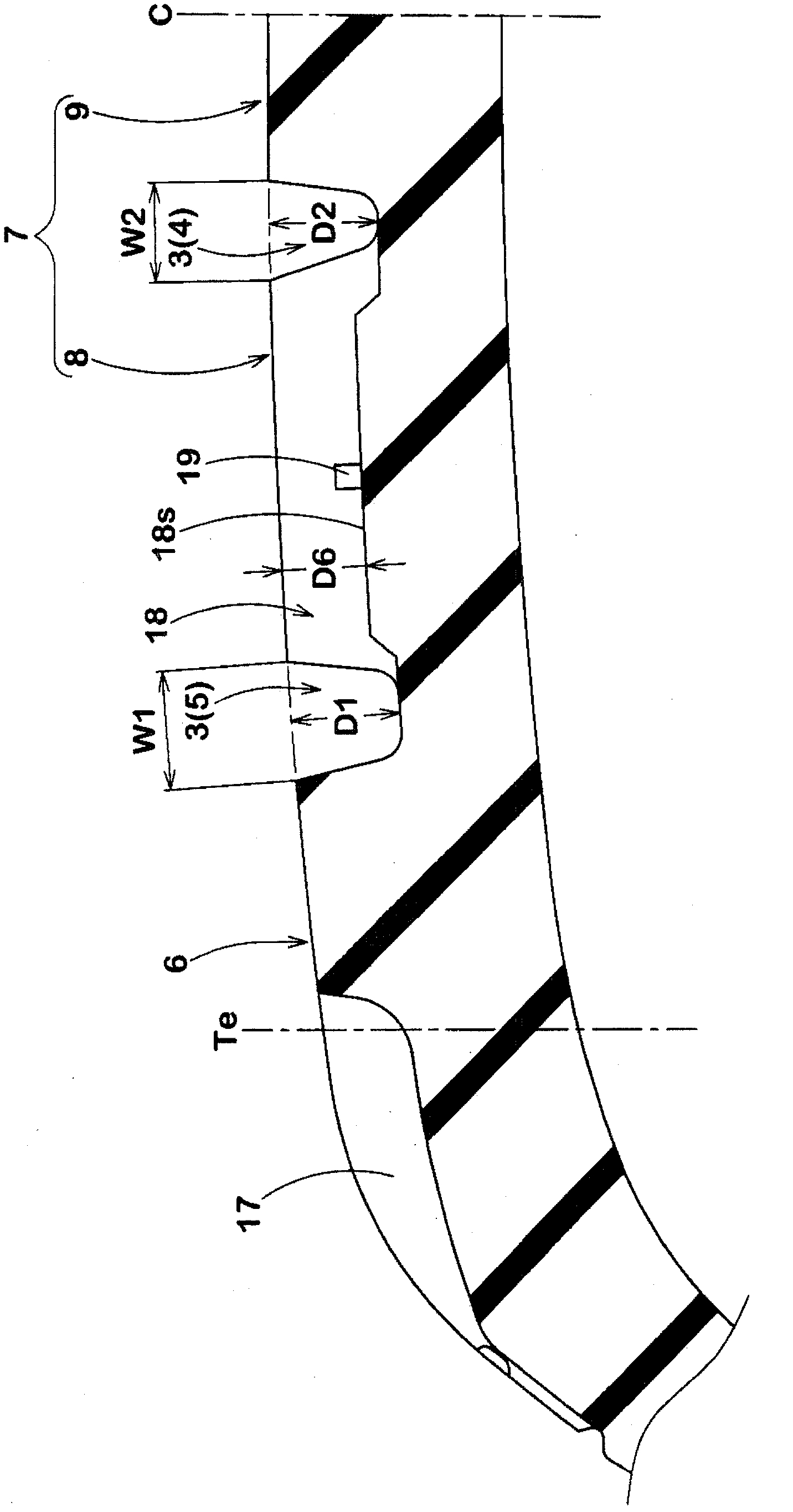

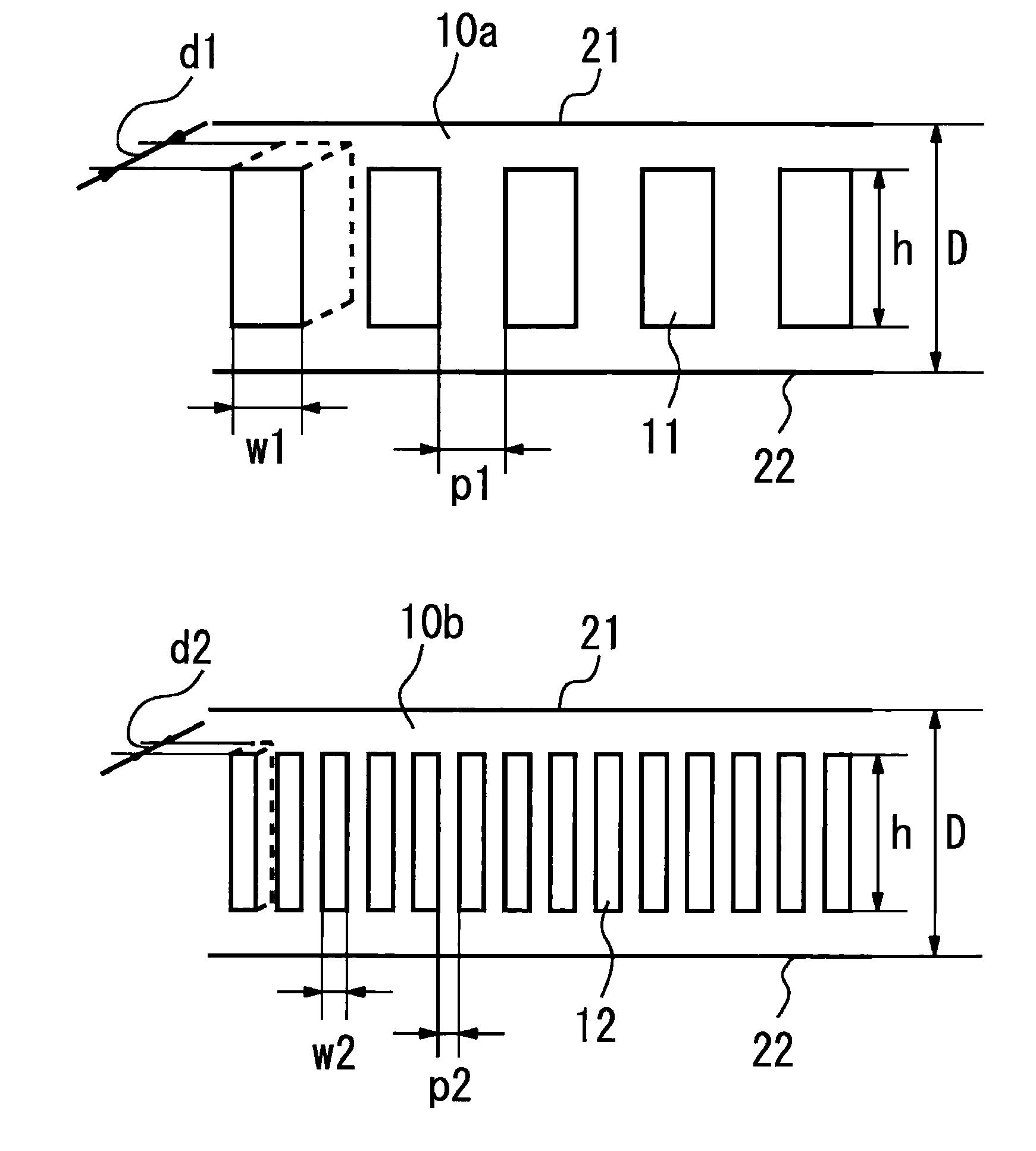

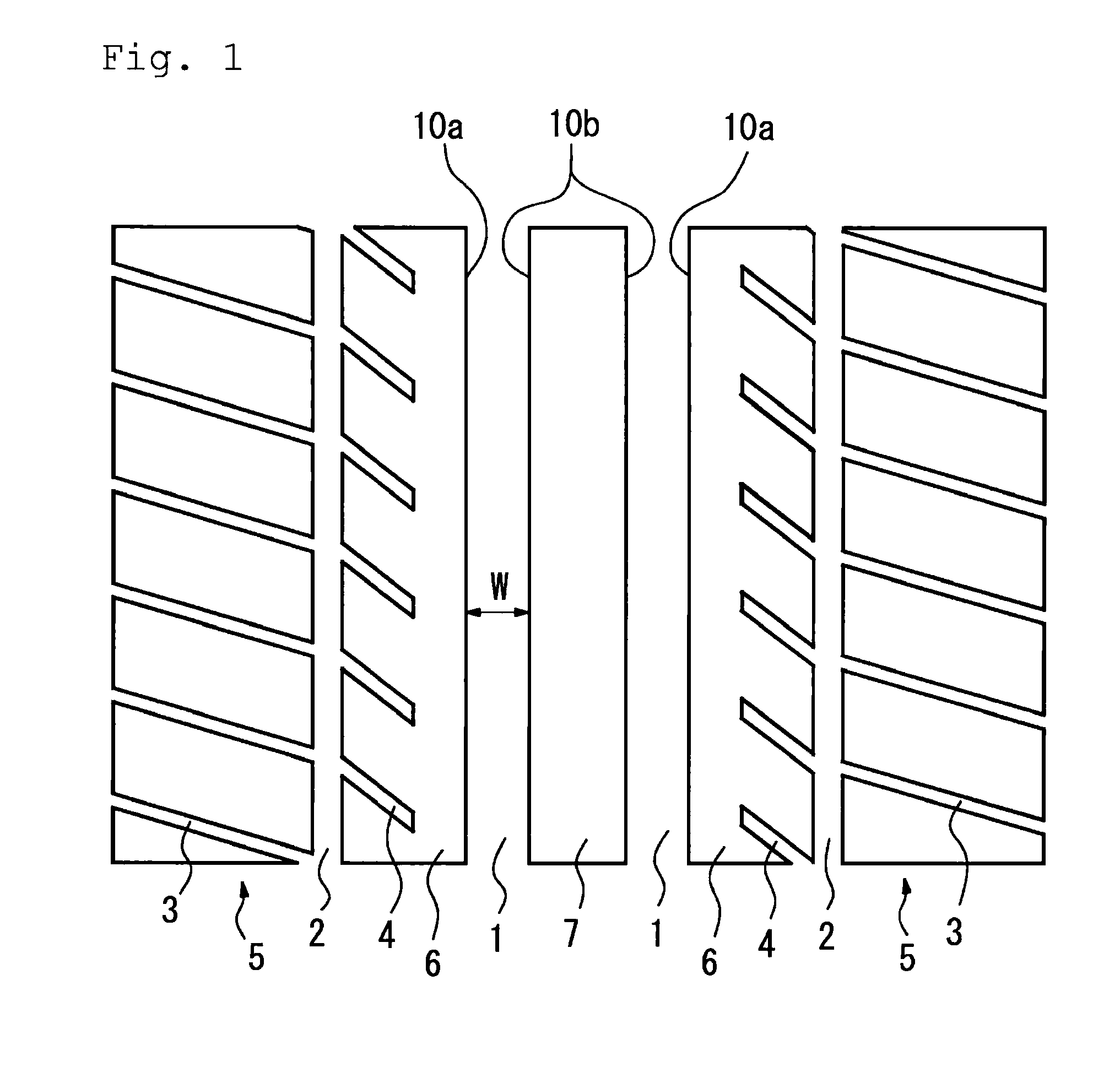

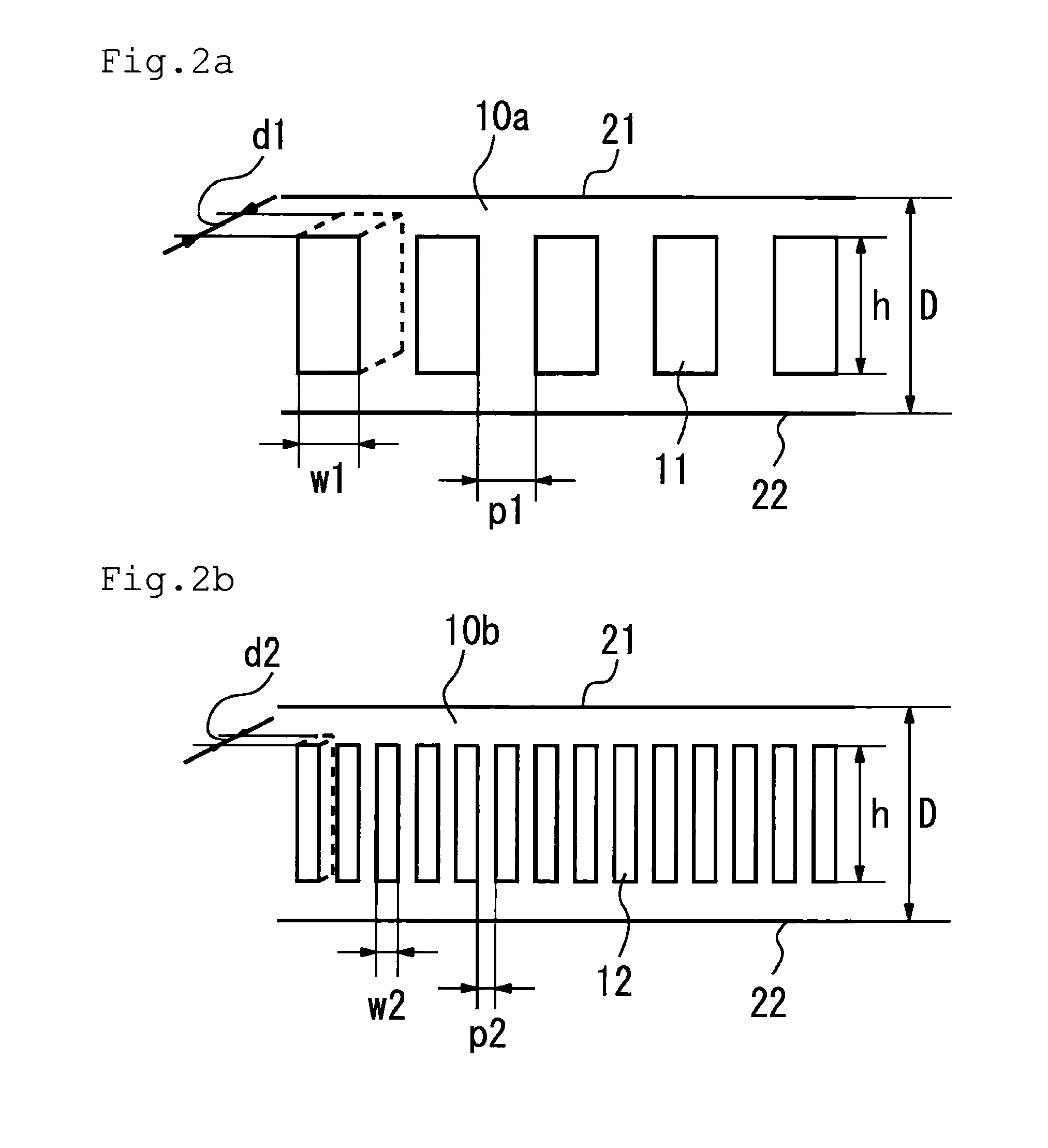

ActiveUS8439093B2Increase resistanceReduce resonance noiseTyre tread bands/patternsNon-skid devicesNoise levelEngineering

The present invention provides a pneumatic tire with reduced air columnar resonance noise level in comparison with the conventional pneumatic tires. The pneumatic tire comprises large-volume oblong holes 11 formed in a sidewall 10a on one side of a main groove 1 and small-volume oblong holes 12 formed in a sidewall 10b on the other side thereof, respectively, in which a width w1 and a depth d1 of the large-volume oblong hole 11 are at least not less than 0.4 mm and more than 0.05 times but less than 0.25 times a width W of the main groove 1, and a space p1 between the large-volume oblong holes 11 is at least not less than 0.8 mm and more than 0.2 times but less than 1.0 times the width W, a width w2 and a depth d2 of the small-volume oblong hole 12 are at least not less than 0.2 mm and more than 0.01 times but less than 0.05 times the width W, and a space p2 between the small-volume oblong holes 12 is at least not less than 0.4 mm and more than 0.04 times but less than 0.2 times the width W, and each height h of the oblong holes 11 and 12 in the depth direction of the main groove 1 is 50 to 80% of a depth D of the main groove 1.

Owner:TOYO TIRE & RUBBER CO LTD

Manufacturing process of automotive interiors

The invention provides a manufacturing process of automotive interiors. The manufacturing process comprises the following steps: adsorbing diaphragms which are designed with different patterns in advance onto the surface of a mold cavity of an injection mold before mold closing, and then mixing and injecting plastics in a molten state, which are mainly PC+ABS materials, into a mold to ensure that the diaphragms and the plastics are fused into a whole; after the diaphragms are manufactured and molded, cutting the diaphragms, molding the diaphragms, trimming the diaphragms, preparing finished products, performing injection molding, and positioning the diaphragms; and then spraying a mold releasing agent onto the surface of a skin forming mold, then spraying in-mold paint, spraying the in-mold paint with different colors according to the product needs, then spraying a liquid-state PU raw material, controlling the thickness of the skin by virtue of a spraying mechanical arm, and finally cooling and stripping the mold, wherein based on different raw material formulas, the curing time is 40-180s. According to the manufacturing process of the automotive interiors, provided by the invention, uniform rigidity of a cover plate can be achieved, and early damages cannot be easily caused.

Owner:LIUZHOU JUNJIE AUTO PARTS MFG

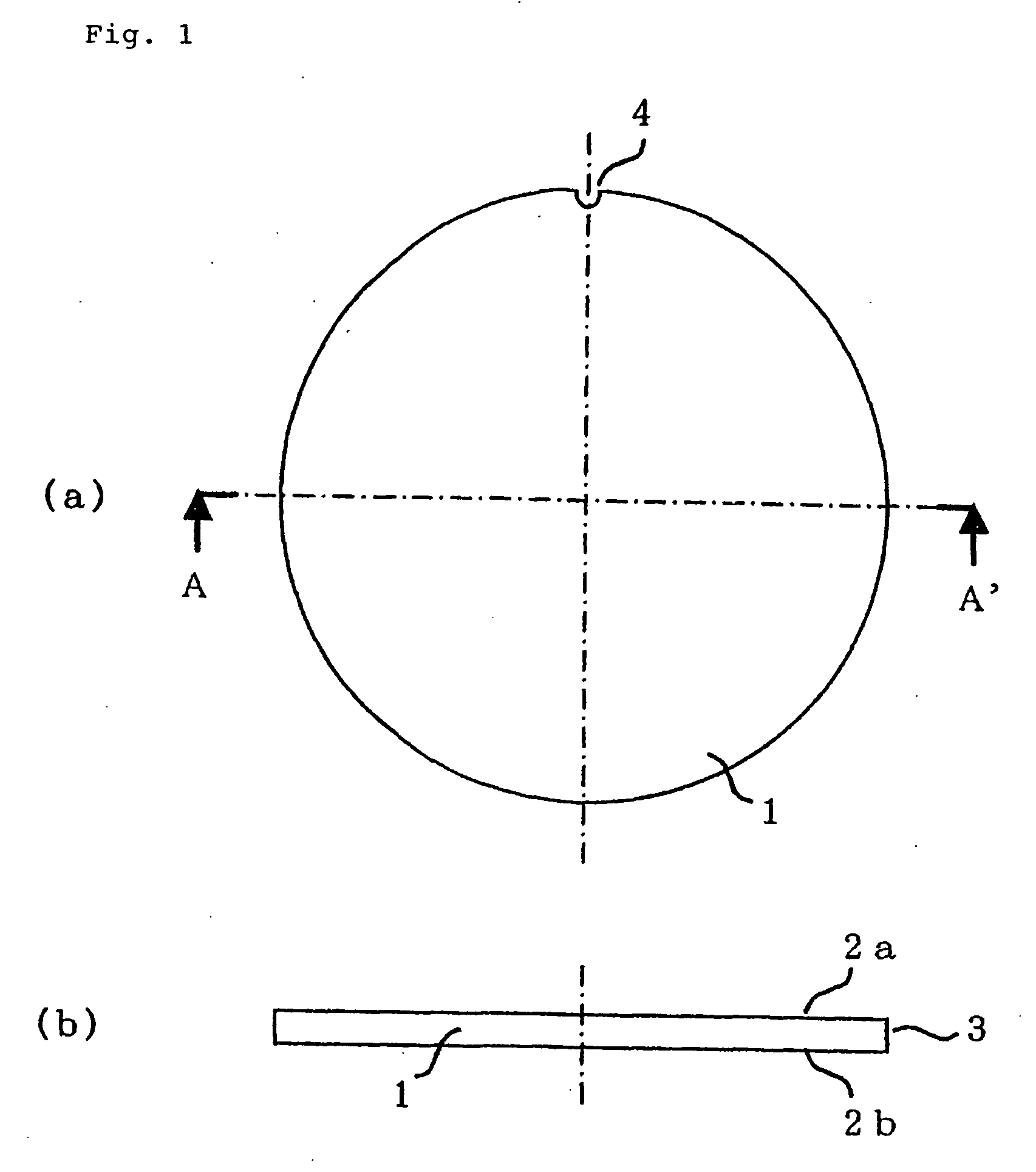

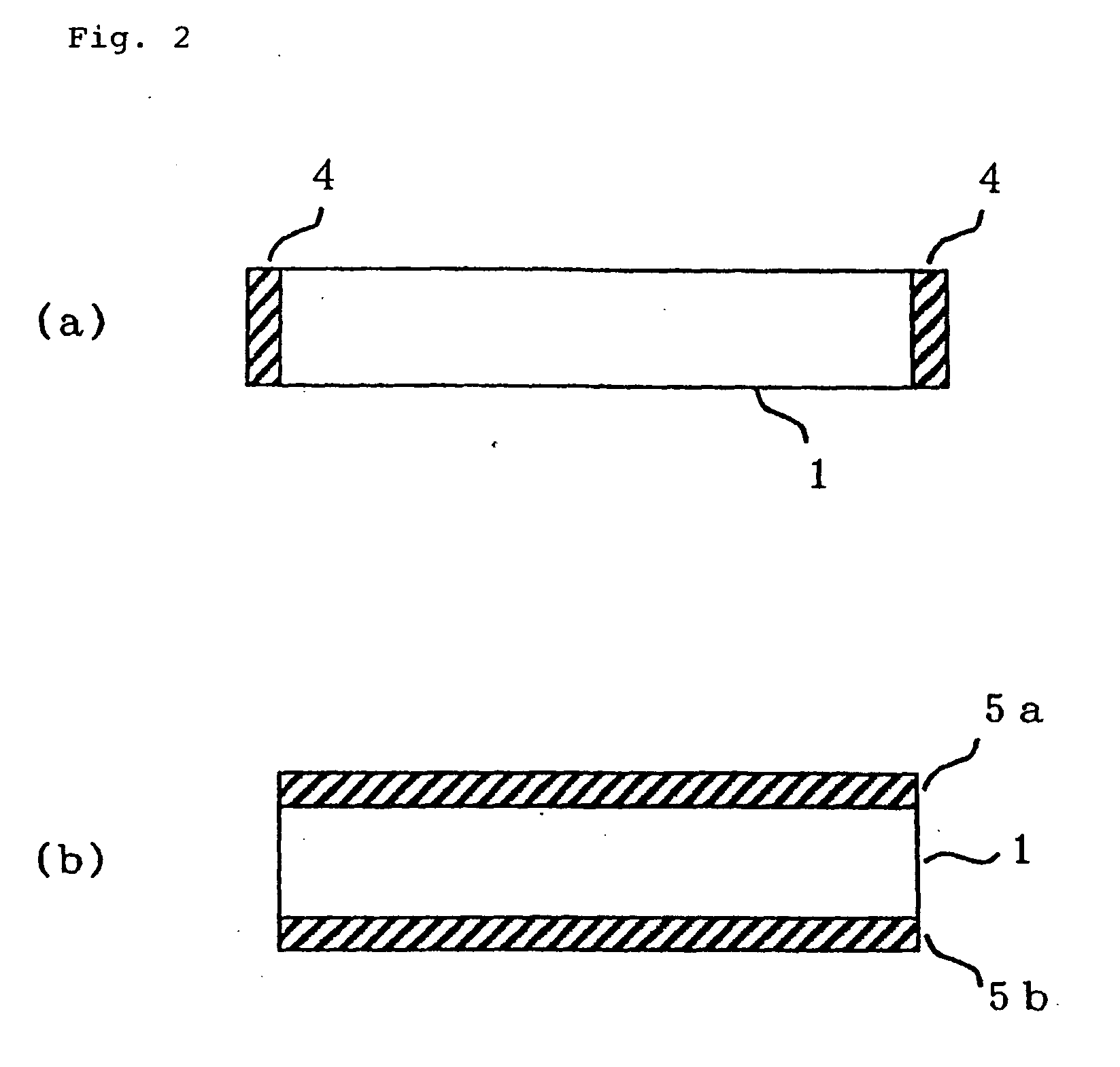

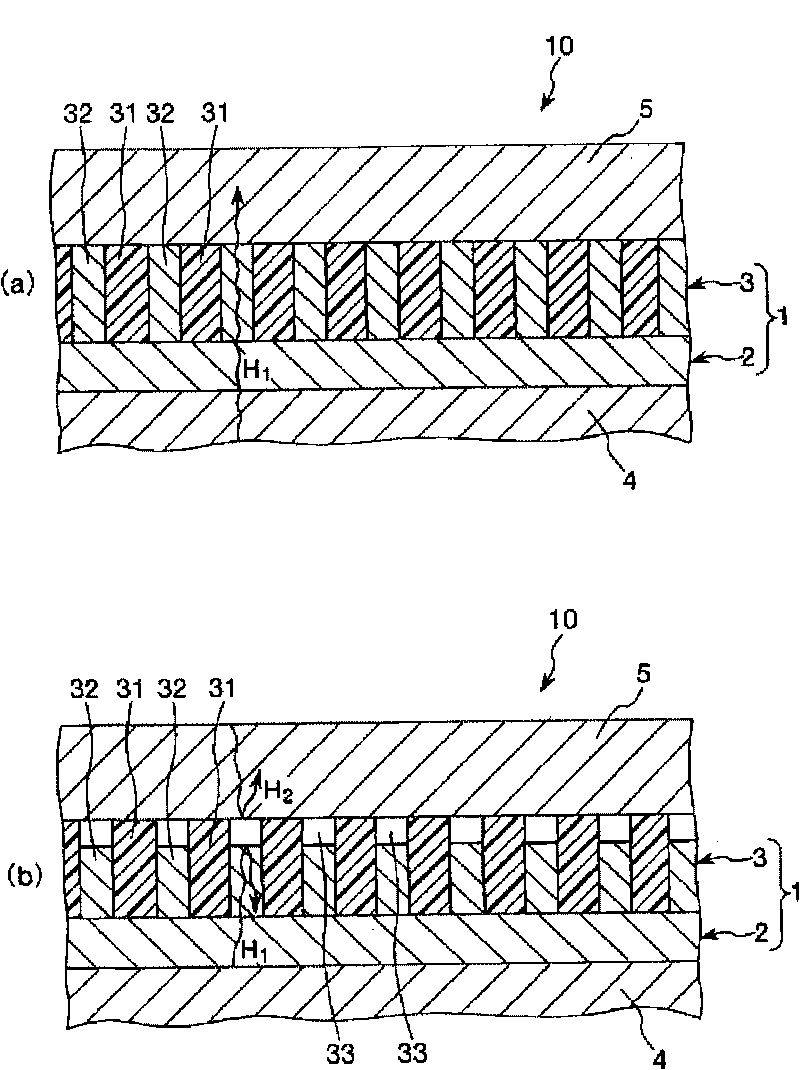

Dummy wafer

InactiveUS20060186404A1High strengthEasily respondsSemiconductor/solid-state device detailsSolid-state devicesFiberCarbon fibers

A dummy wafer including a carbon fiber reinforced plastic (CFRP). Specifically the dummy wafer has a wafer substrate including CFRP, the substrate has two skin layers disposed on respective principal surface side and a core layer interposed between the skin layers, and each of the skin layers has multiple one-dimensionally reinforced layers consisting of a cured and shaped product of unidirectional prepreg. With reference to the orientation direction of one of the one-dimensionally reinforced layers on the side closest to the principal surface (outermost layer) in each of the skin layers, the other outermost layer is oriented in a specific direction; the tensile modulus of CF in each outermost layer is within a specific range; each skin layer has a one-dimensionally reinforced layer that contains CF oriented in a specific direction and has the tensile modulus within a specific range; and the core layer has a one-dimensionally reinforced layer that contains CF oriented in a specific direction and having the tensile modulus within a specific range, and a one-dimensionally reinforced layer that contains CF oriented in a specific direction and having the tensile modulus within a specific range. The dummy wafer has high strength, is inexpensive, and easily responds to light sensors.

Owner:NIPPON OIL CORP

Production technology for high-strength FRP reinforced core

A disclosed production technology for a high-strength FRP reinforced core successively comprises steps of releasing yarn, guiding yarn, immersing, heat-curing, dragging and coiling; and specifically comprises: carrying out releasing yarn and guiding yarn for a glass fibre, then immersing in an immersion groove in which the immersion liquid comprises vinyl resin, curing agents, a mold lubricant and a filling material; placing in a heating die, heat curing by employing a low-medium-high temperature step progressive curing mode, then pulling the heat-cured glass yarn from the heating die via a dragger, and carrying out finished-product coiling. The curing agents ocmprise a low-temperature curing agent bis(4-t-butyl cyclohexyl)peroxy dicarbonate, a medium-temperature curing agent dibenzoyl peroxide and a high-temperature curing agent t-butyl peroxybenzoate; and the heating die is divided into three temperature zones according to the curing temperature, and the initial temperature of the die is 110-120 DEG C. The advantages are that: by employing low-temperature, medium-temperature and high-temperature three curing agents for the low-medium-high temperature step progressive curing mode, the rigidity and the toughness are integrated, the high strength and the good pull resistance are guaranteed.

Owner:南通和泰通信科技有限公司 +1

Heat transfer sheet and radiator structure

InactiveCN101730936AUniform rigidityUniform heat conductionSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringThermal conduction

A heat transfer sheet comprising a heat transfer layer having a first area and, provided in a position different in planar view from the first area, a second area capable of expansion and contraction at a ratio greater than in the first area along the thickness direction in accordance with temperature changes, wherein in use conditions, when the temperature of the heat transfer layer is a given value or below, a gap is formed between the second part and an opposite party to thereby lower the heat conduction between a radiator object and the opposite party, while when the temperature of the heat transfer layer is not lower than the given value, substantially no gap is laid therebetween to thereby increase the heat conduction between the radiator object and the opposite party.

Owner:SUMITOMO BAKELITE CO LTD +2

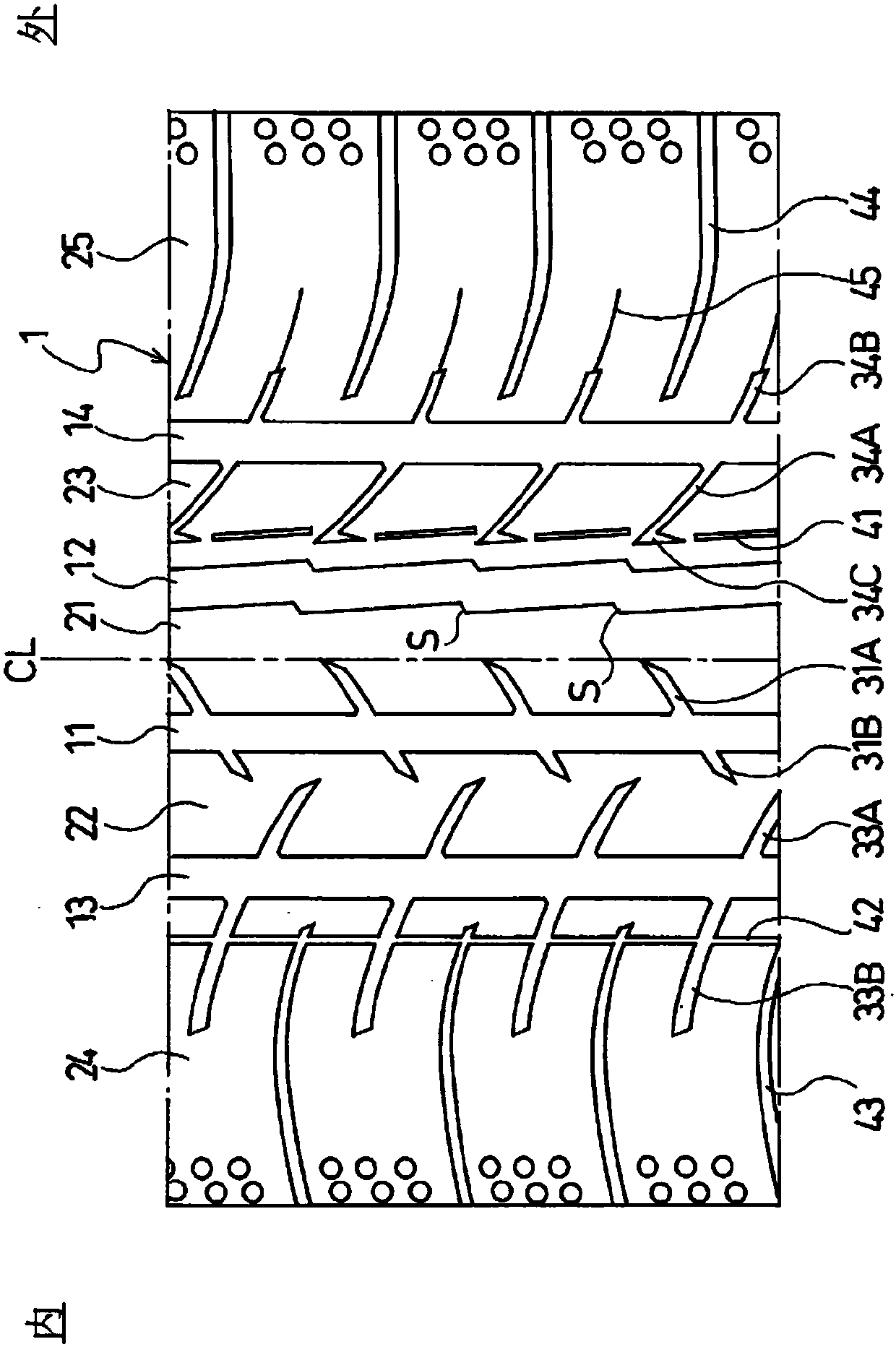

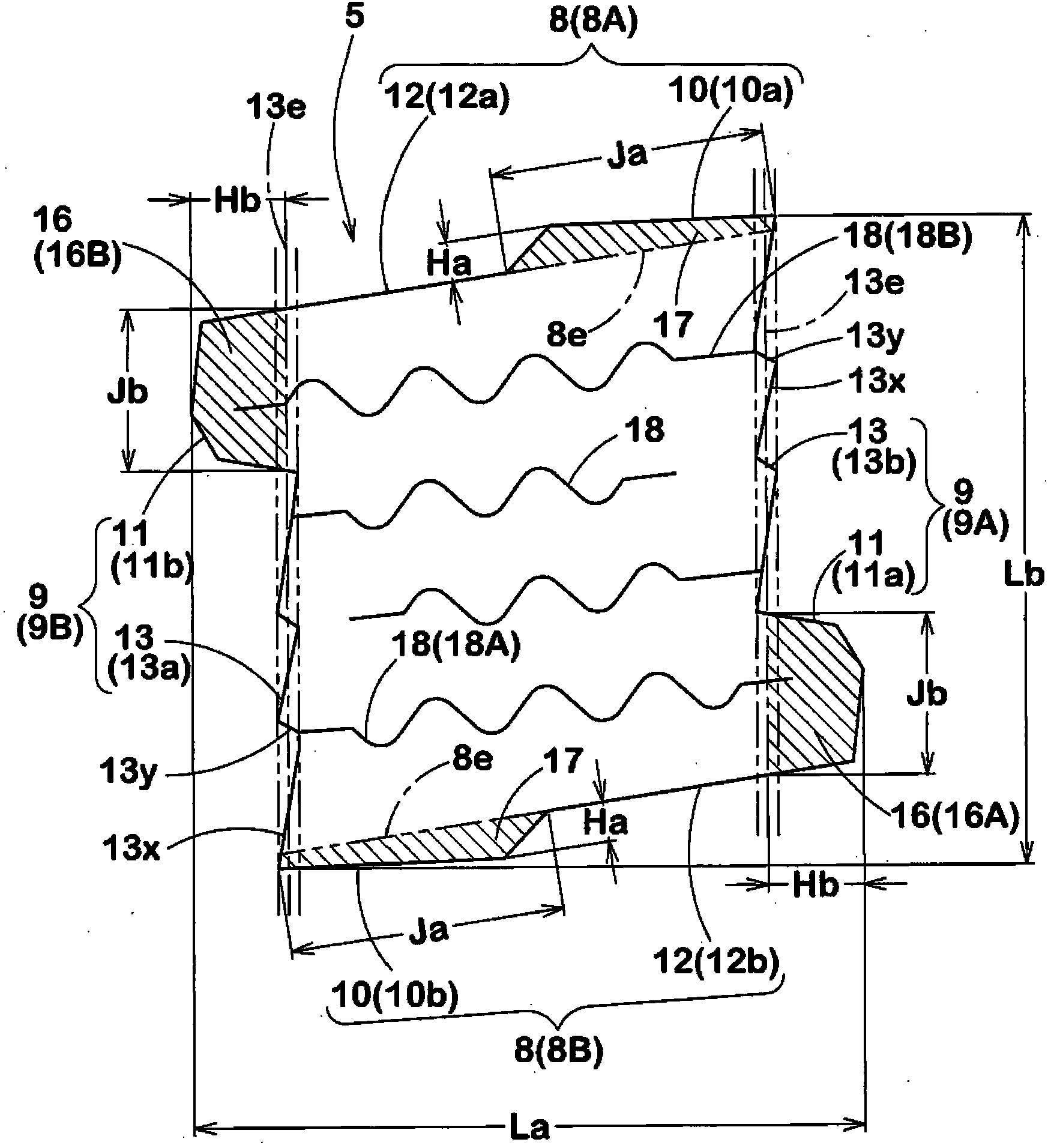

Pneumatic tire

ActiveCN107709047AGuaranteed rigidityImprove driving stabilityInflatable tyresTyre tread bands/patternsRoad surfaceTread

A pneumatic tire is provided which makes it possible to achieve both steering stability on dry road surfaces and steering stability on wet road surfaces. This pneumatic tire is provided with a tread portion, a sidewall, and a bead, and has a mounting direction specified with respect to the vehicle, wherein: four main grooves are provided, which include a pair of center main grooves which extend inthe tread portion in the tire circumferential direction and a pair of shoulder main grooves which are outside of the center main grooves and extend in the tire circumferential direction; five land portions are defined by said main grooves, and the center main groove to the outside of the vehicle has a zigzag shape along the tire circumferential direction; multiple lug grooves are provided in theland portions and extend from the main grooves other than the center main groove that has a zigzag shape, towards both sides in the width direction of the tire, and terminate within the respective land portion.

Owner:THE YOKOHAMA RUBBER CO LTD

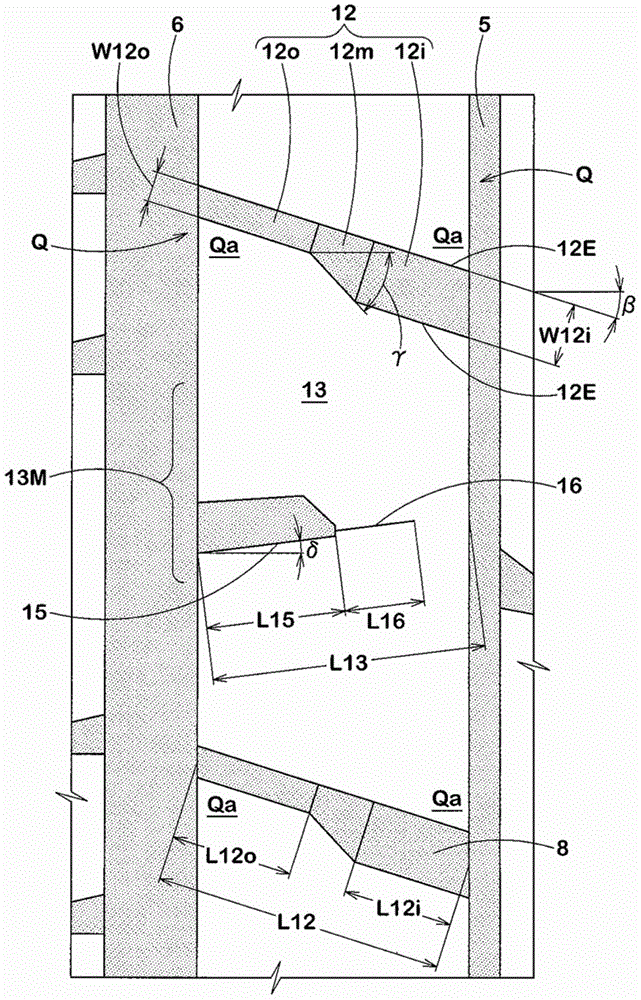

Pneunatic tyre

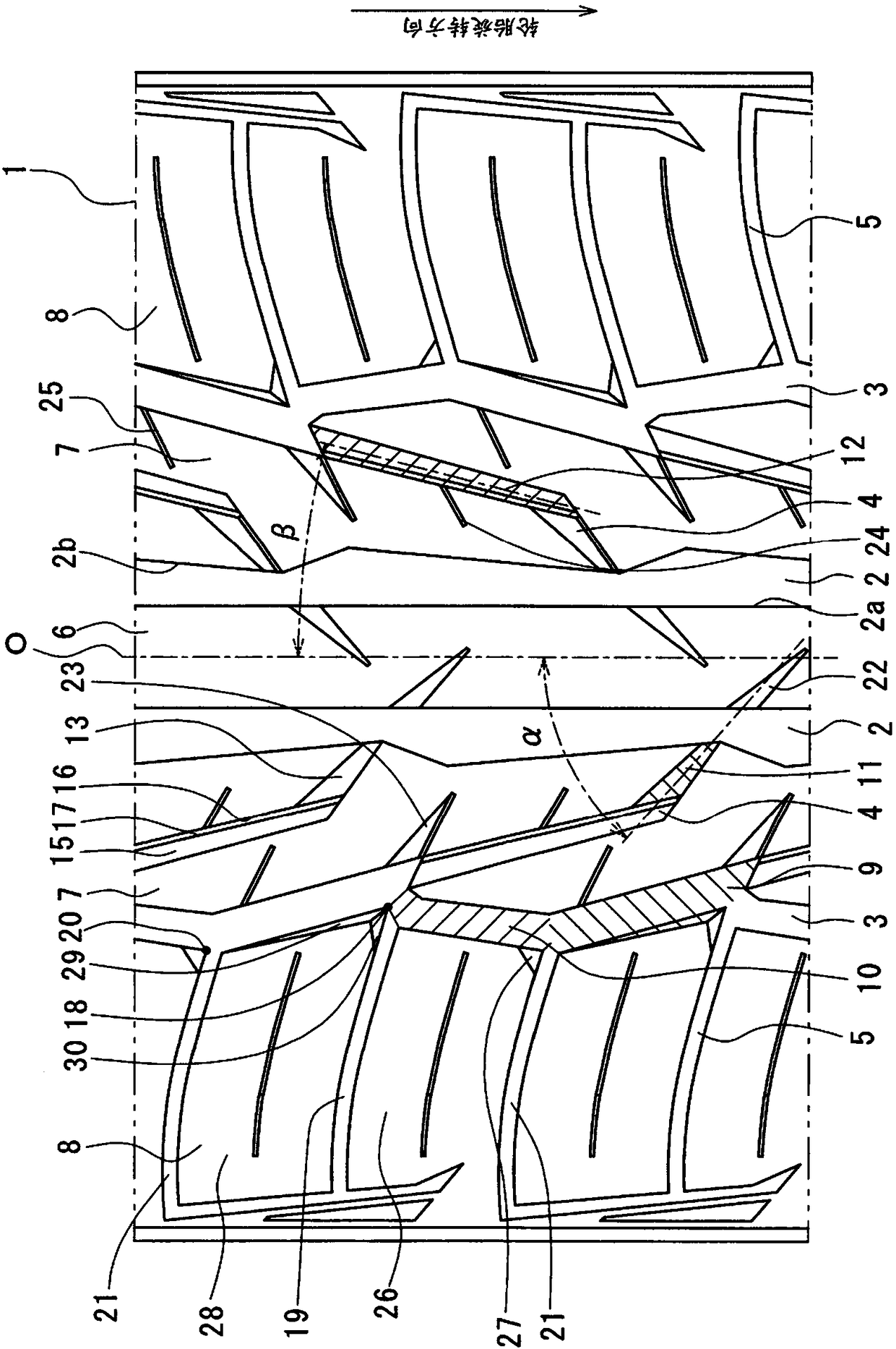

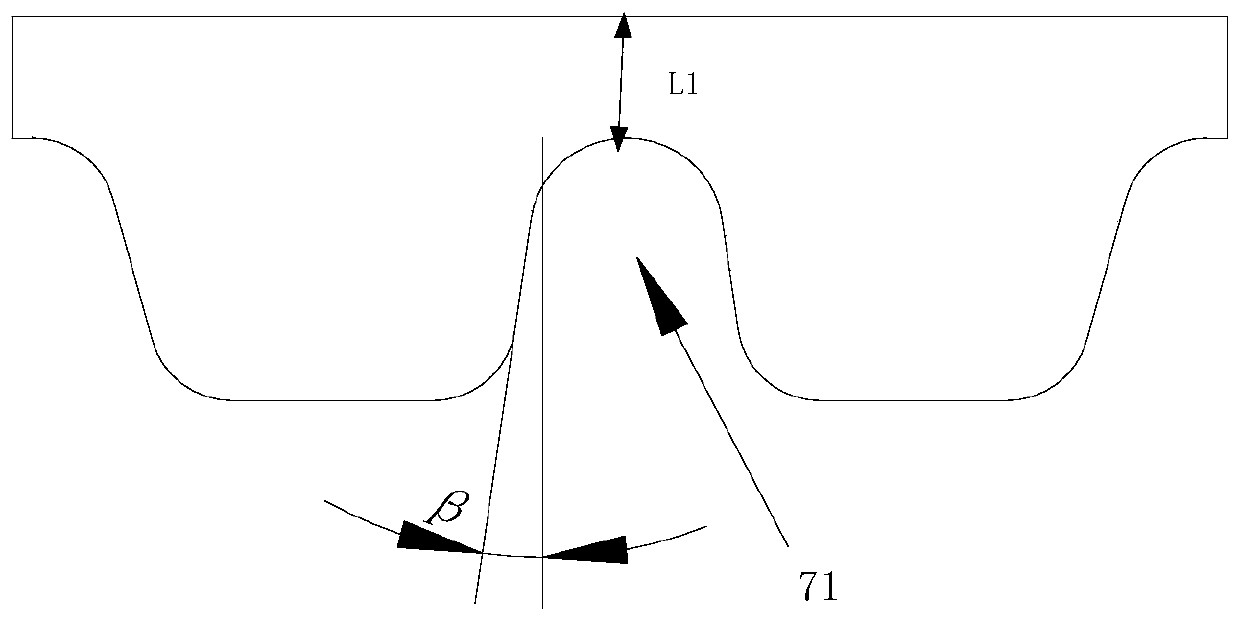

ActiveCN105270097AImprove partial wear resistanceEasy to moveTyre tread bands/patternsTransverse grooveEngineering

The invention provides a pneunatic tyre which prevents water discharging performance and improves uneven wear resistance and noise performance. The tire tread is provided with a central main groove in an equatorial plane of the tire, a pair of central auxiliary grooves at two sides of the central main groove, and a pair of tire shoulder main grooves at two sides, thereby forming central landing parts, middle landing parts and tire shoulder landing parts. Each middle landing part is provided with middle transverse grooves which are separately arranged in a circumferential direction and respectively extend from the central auxiliary groove to the tire shoulder main groove in an angle beta in 10-20 DEG. Each middle transverse groove is composed of a large-width part which is connected with the central auxiliary groove, a small-width part which is connected with the tire shoulder main groove, and a transition part which connects the large-width part with the small-width part. The angle beta of the middle transverse groove is larger than the angle alpha of the grounding front edge part of the middle landing part in the shape of a grounding surface.

Owner:SUMITOMO RUBBER IND LTD

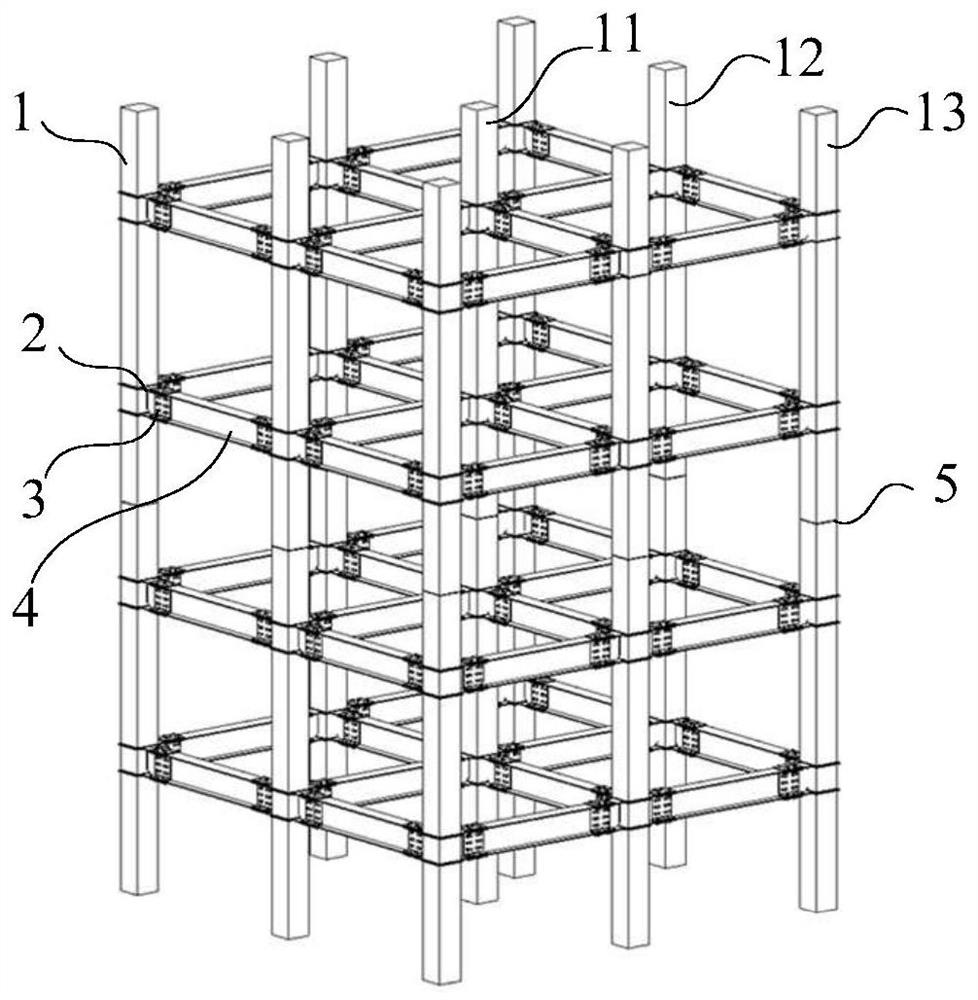

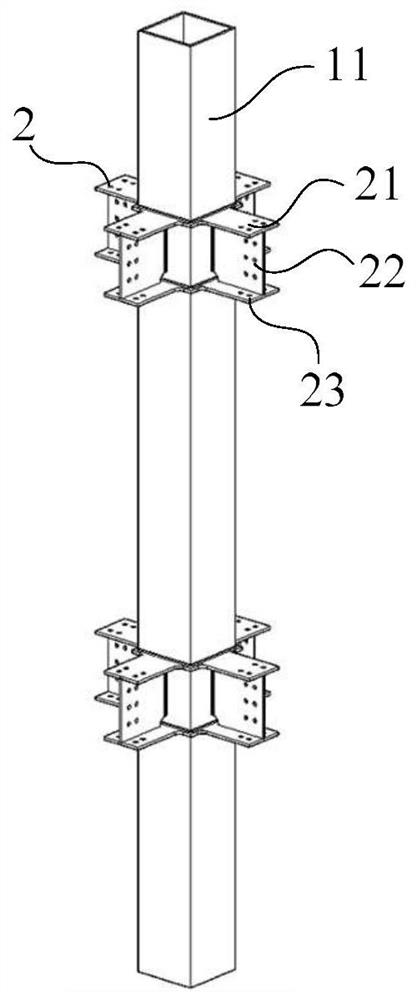

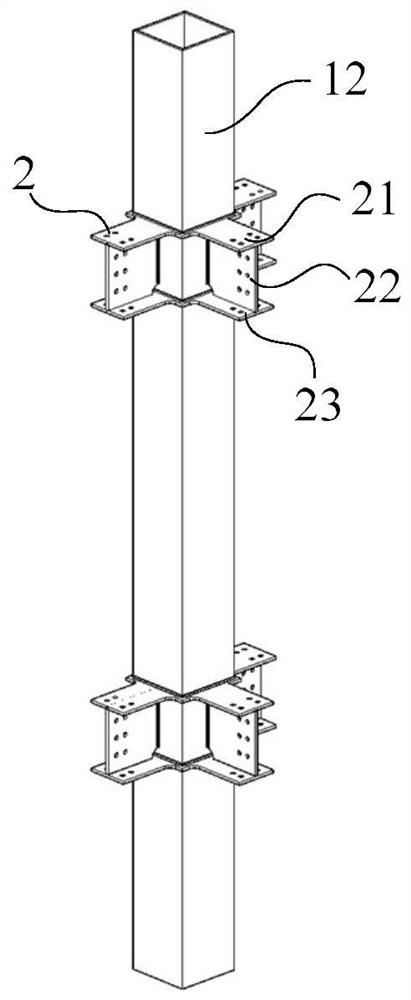

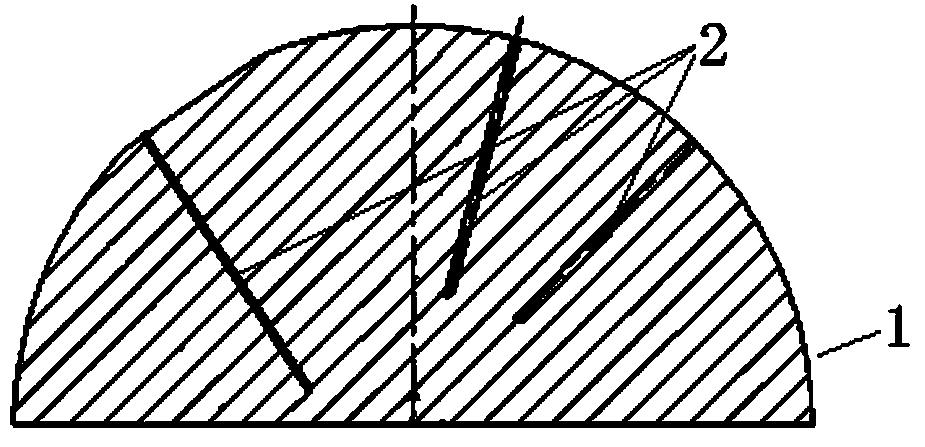

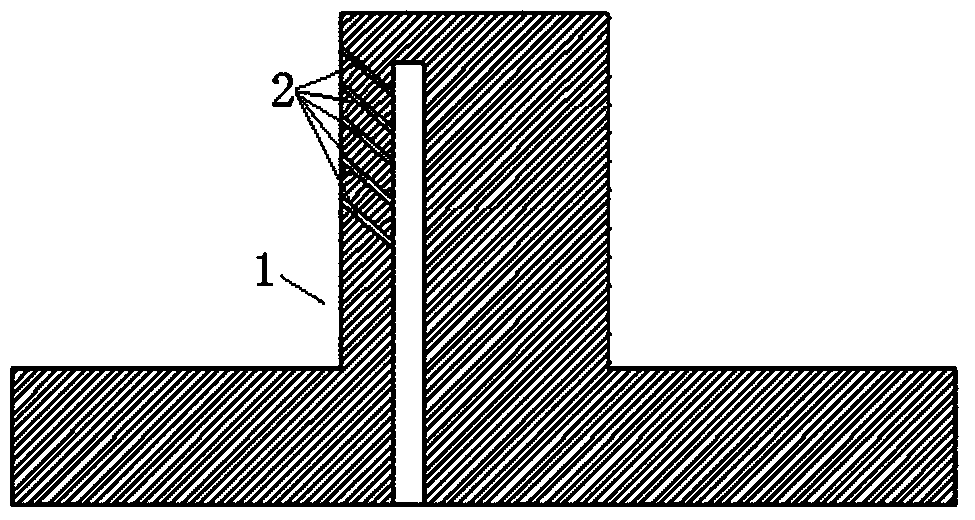

Fully-prefabricated concrete-filled steel tube frame structure and assembling method

PendingCN113216384AGuaranteed StrengthImprove integrityBuilding material handlingMechanical engineeringIndustrial engineering

The invention provides a fully-prefabricated concrete-filled steel tube frame structure and an assembling method. The fully-prefabricated concrete-filled steel tube frame structure comprises stand columns, cross beams, first connecting pieces and second connecting pieces, wherein the stand columns comprise steel tubes and concrete in the steel tubes; prefabricated joints are arranged on the stand columns; cavities are formed in the end parts of the stand columns; connecting parts are arranged at the end parts of the cross beams; the first connecting pieces are arranged between the joints and the connecting parts and used for fixedly connecting the stand columns and the cross beams; the second connecting pieces are arranged between the two stand columns in the same vertical direction and are provided with ends corresponding to the cavities; and the two ends of each second connecting piece are correspondingly embedded into the cavities of the ends of the two stand columns, so that each second connecting piece is used for fixedly connecting each two stand columns in the same vertical direction. According to the fully-prefabricated concrete-filled steel tube frame structure and the assembling method provided by the invention, horizontal connection is achieved through the joints and the first connecting pieces, vertical connection is achieved through the second connecting pieces, and compared with on-site construction, the manufacturing quality and the stress performance of components are improved, construction is convenient, and the assembly efficiency is high, so that assembly type development of square steel tube concrete structures is easily promoted.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Machining method of micro deep hole of steel with carbon content of less than or equal to 0.6%

InactiveCN110181094AStable jobNo offsetBoring/drilling componentsMaintainance and safety accessoriesMilling cutterAlloy

The invention discloses a machining method of a micro deep hole of steel with the carbon content of less than or equal to 0.6%. According to the machining method of the micro deep hole, a workpiece formed by steel with the carbon content of less than or equal to 0.6% is taken as a machined object. The technological measures adopted by the machining method of the micro deep hole comprises the following steps that a five-axis linkage high-speed machining center serves as a machining machine tool, a hard alloy key groove milling cutter is adopted for milling a positioning face on the surface of adesigned opening position on the workpiece, a hard alloy miniature drill bit is adopted for machining a hole pattern meeting the design requirement on the positioning face of the workpiece in a high-speed pecking drilling mode, and a high-pressure cooling liquid is added in the high-speed pecking drilling machining process. According to the machining method, the micro deep hole of the steel withthe carbon content of less than or equal to 0.6% (especially of stainless steel) is machined, the machining efficiency is improved, the machining period is greatly shortened, the machining yield and the machining precision are increased, the machined micro deep hole can effectively meet the technical requirements of the use environment, and meanwhile, the machining cost is effectively reduced.

Owner:SICHUAN ENG TECHN COLLEGE

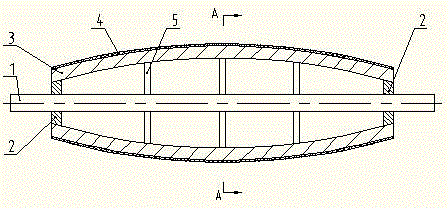

Anti-adhesion composite arc cloth guide roller

InactiveCN104444521AImprove structural rigidityImprove structural strengthWebs handlingPolyether ether ketoneMechanical engineering

The invention discloses an anti-adhesion composite arc cloth guide roller comprising a bearing shaft, a cylinder and end covers. The bearing shaft penetrates through the cylinder. The end covers are fixedly connected between the bearing shaft and the cylinder and located at the two ends of the cylinder. The cylinder is of a hollow structure. The outer surface of the cylinder is an arc cylinder with the high middle and the two low sides in the axis direction. A supporting mechanism is arranged at the position, between the end covers at the two ends, in the cylinder, and comprises a plurality of supporting rods. The supporting rods are fixedly connected between the outer wall of the bearing shaft and the inner wall of the cylinder. The anti-adhesion composite arc cloth guide roller is characterized in that the multiple rows of supporting rods are distributed in the axial direction of the bearing shaft, each row of supporting rods are annularly distributed between the outer wall of the bearing shaft and the inner wall of the cylinder in an array mode with the bearing axis as the center axis, the outer wall of the cylinder is provided with a polyether-ether-ketone coating, the lateral outline of the cylinder is a complete arc, and the radian of the arc ranges from 4 degrees to 6 degrees. The anti-adhesion composite arc cloth guide roller is high in strength and rigidity, good in cloth guide effect, and resistant to adhesion, corrosion, abrasion and high temperature.

Owner:泰州市恒丰染整设备有限公司

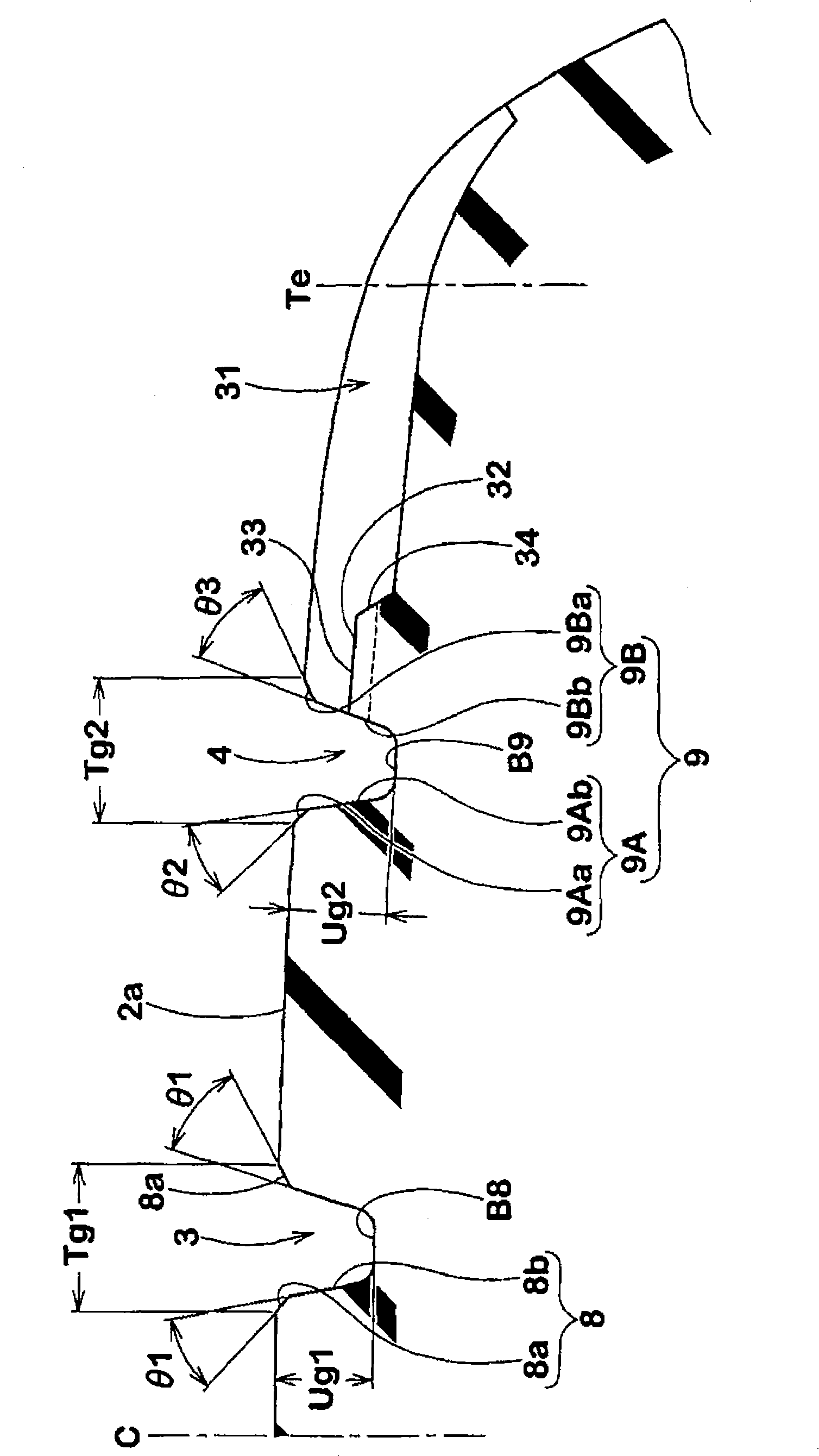

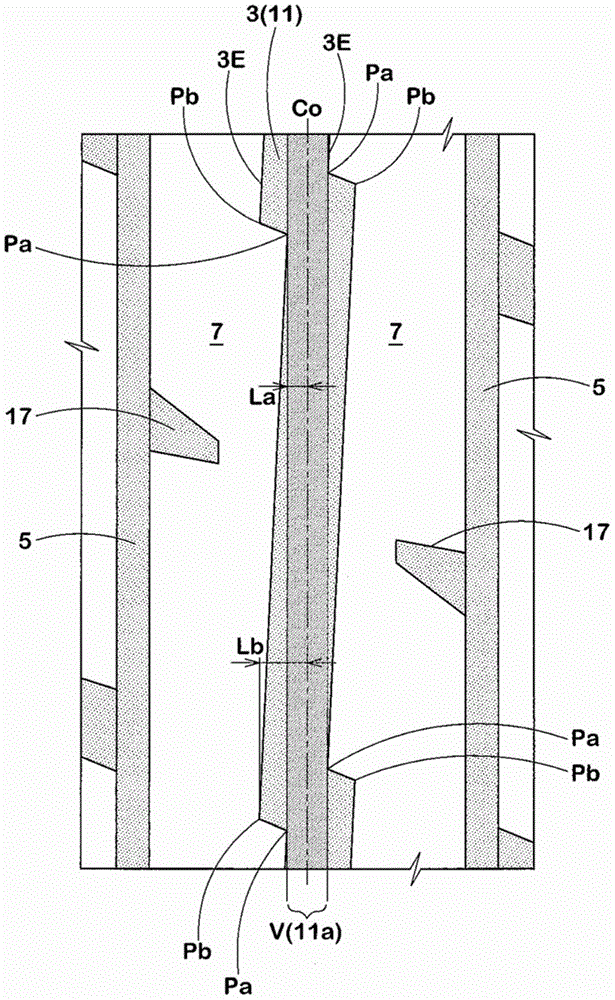

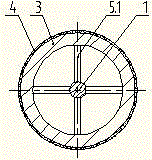

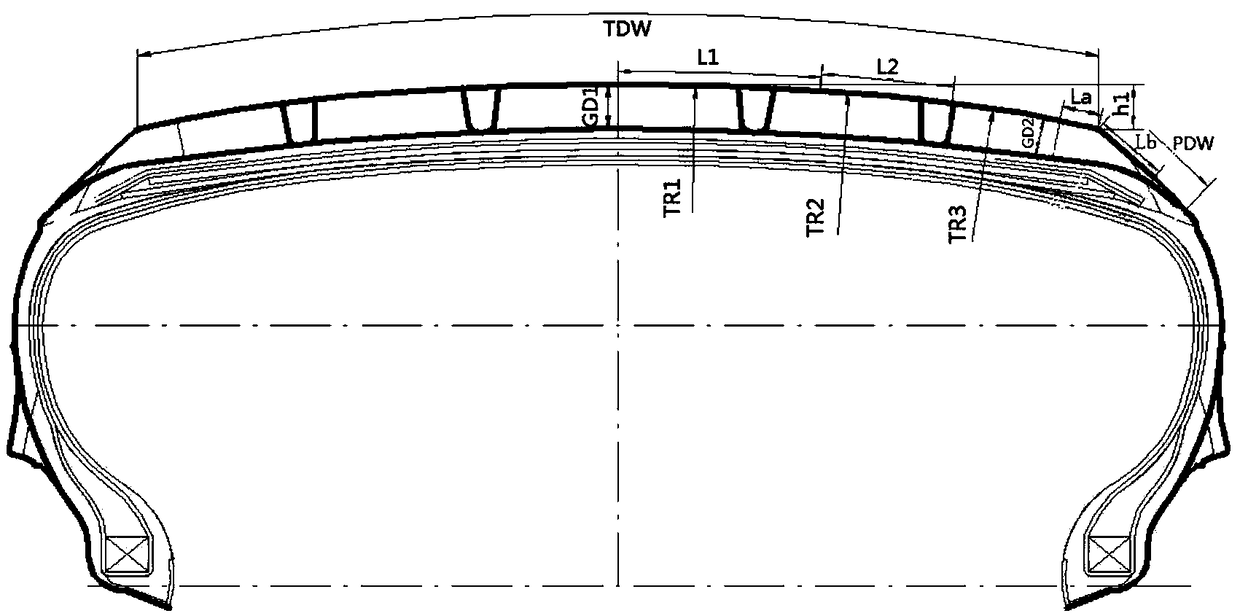

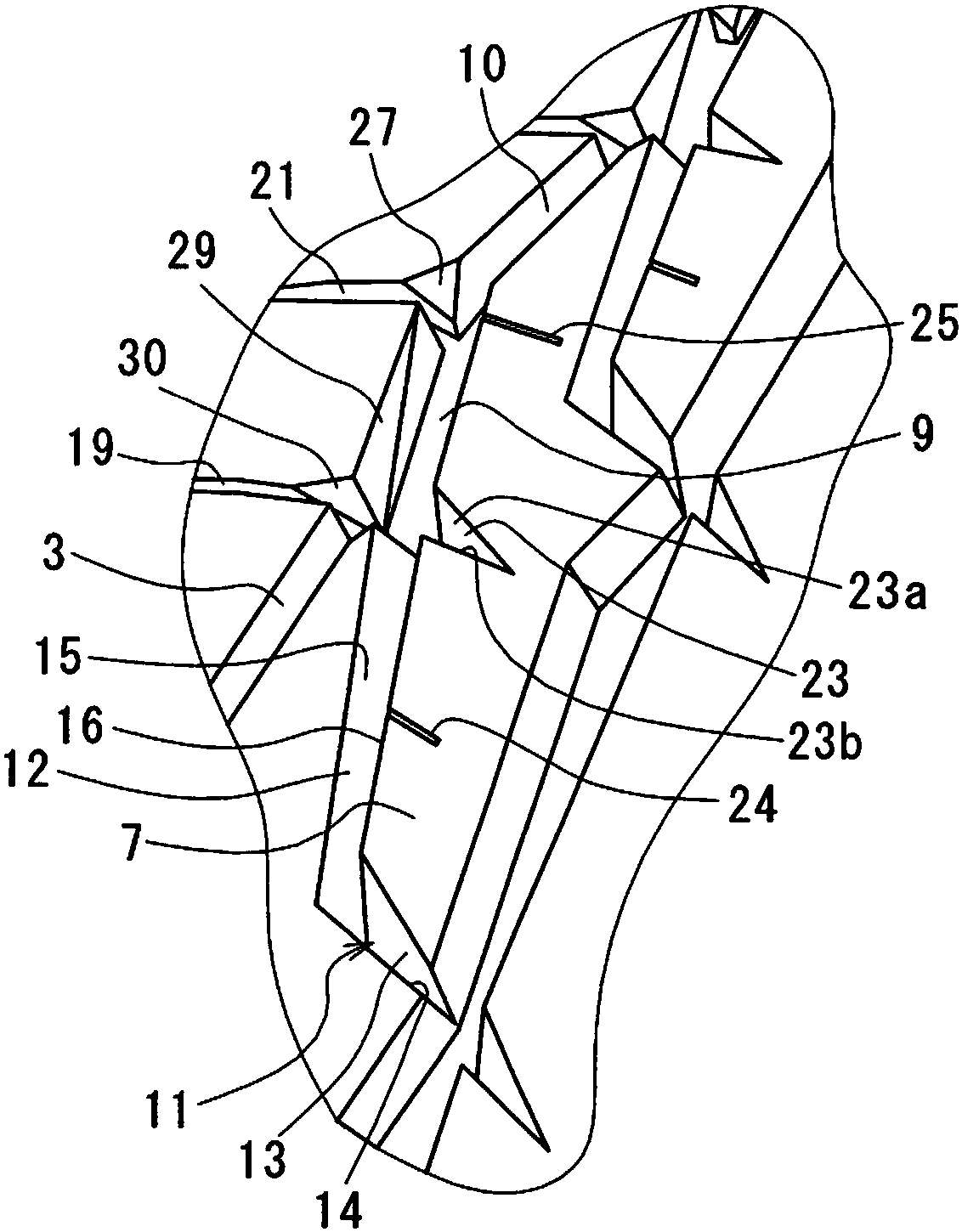

Pneumatic tire

ActiveCN104139672AIncrease the edgeImprove cornering performanceTyre tread bands/patternsVertical projectionEngineering

A pneumatic tire according to the invention is capable of suppressing a decrease in drainage performance and snow-covered road performance and improving icy road performance. The pneumatic tire is provided with a pair of center pattern blocks (5) divided by center main grooves (3A, 3A) and a plurality of center lateral grooves (4A, 4A) on a tread portion (2) with intervals. The center pattern blocks (5) includes: end edges on two sides of the center pattern blocks (5) in the circumferential direction of the tire, that is a pair of lateral pattern block edges (8, 8), and end edges on two sides of the center pattern blocks (5) in the axial direction of the tire, that is a pair of vertical pattern block edges (9, 9). The lateral pattern block edges (8, 8) respectively has lateral projections (10, 10) protruding outwardly in the circumferential direction of the tire, the vertical pattern block edges (9, 9) respectively has vertical projections (11, 11) protruding outwardly in the axial direction of the tire, and a ratio (Lb / La) of the maximum length (Lb) of the center pattern blocks (5) in the circumferential direction of the tire and the maximum length (La) of the center pattern blocks (5) in the axial direction of the tire is 0.80 to 1.00.

Owner:SUMITOMO RUBBER IND LTD

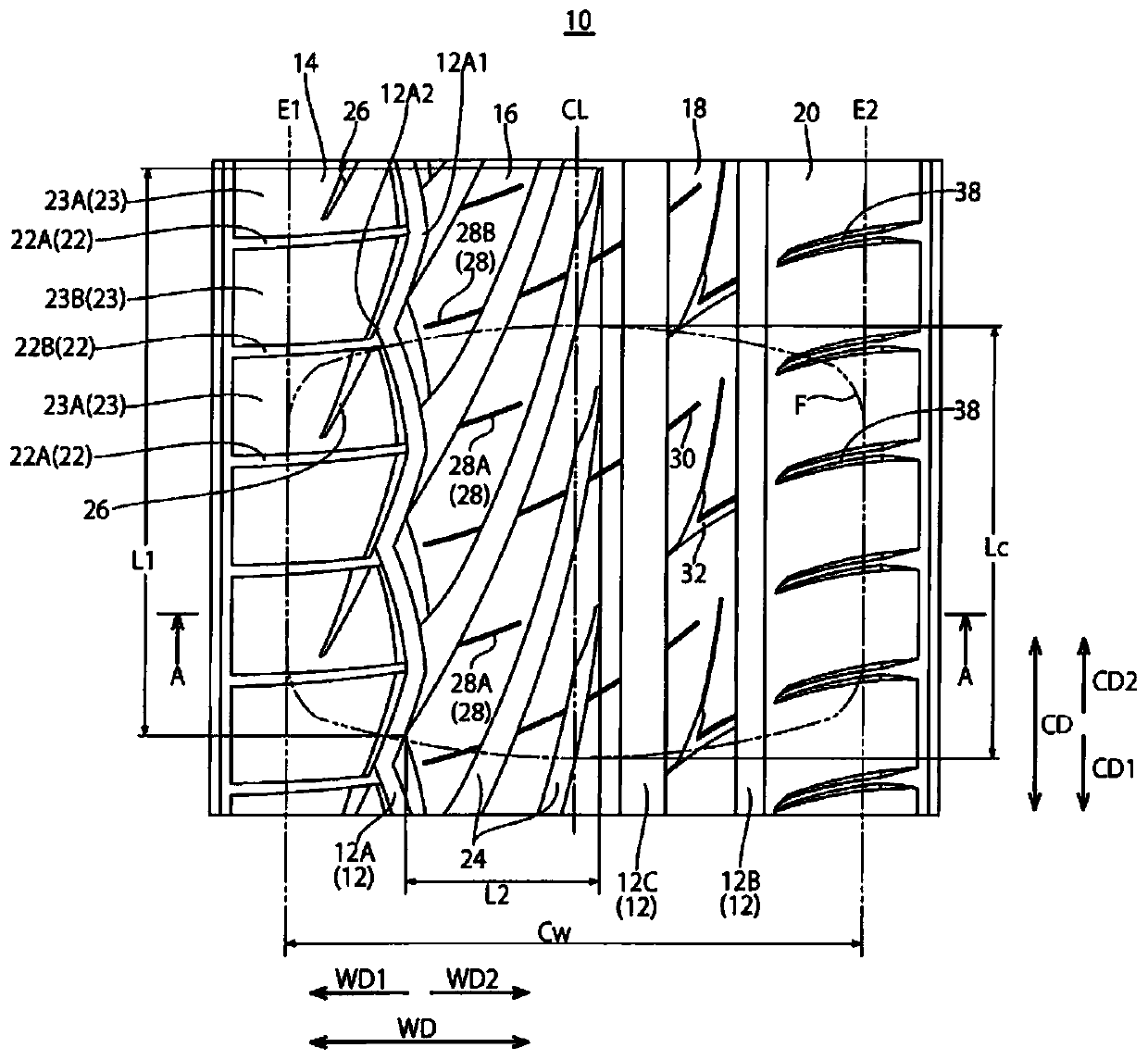

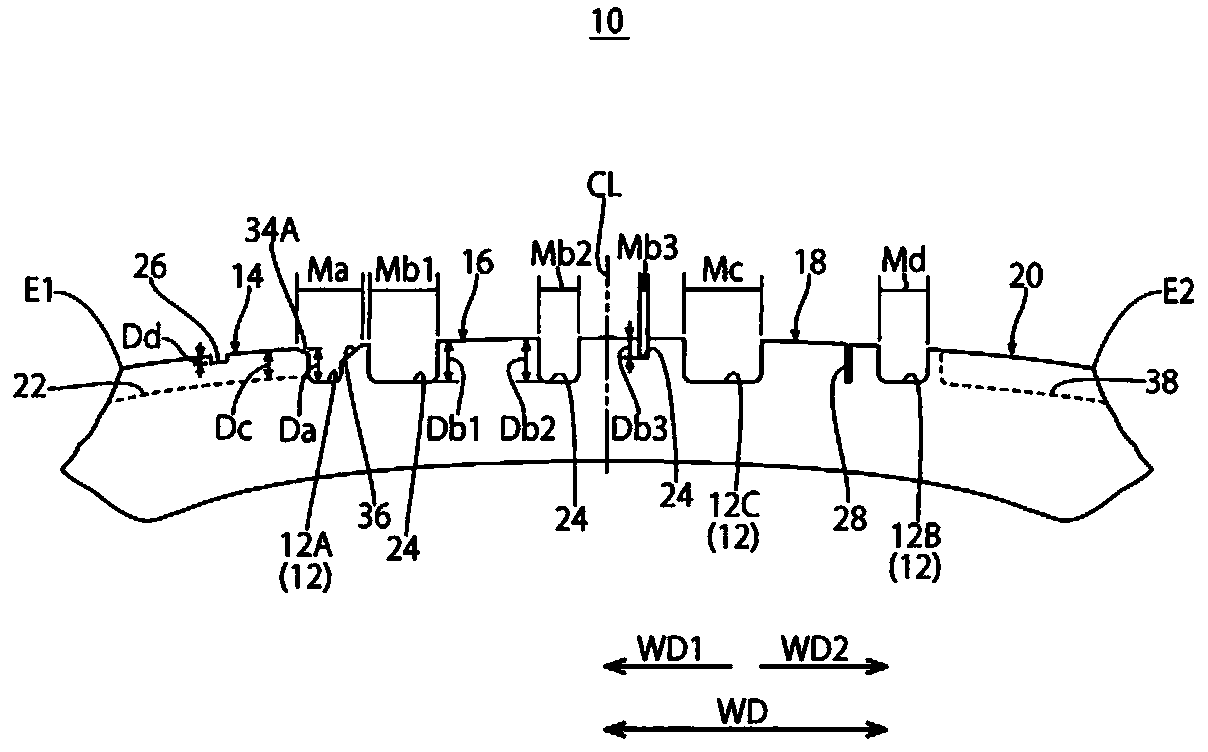

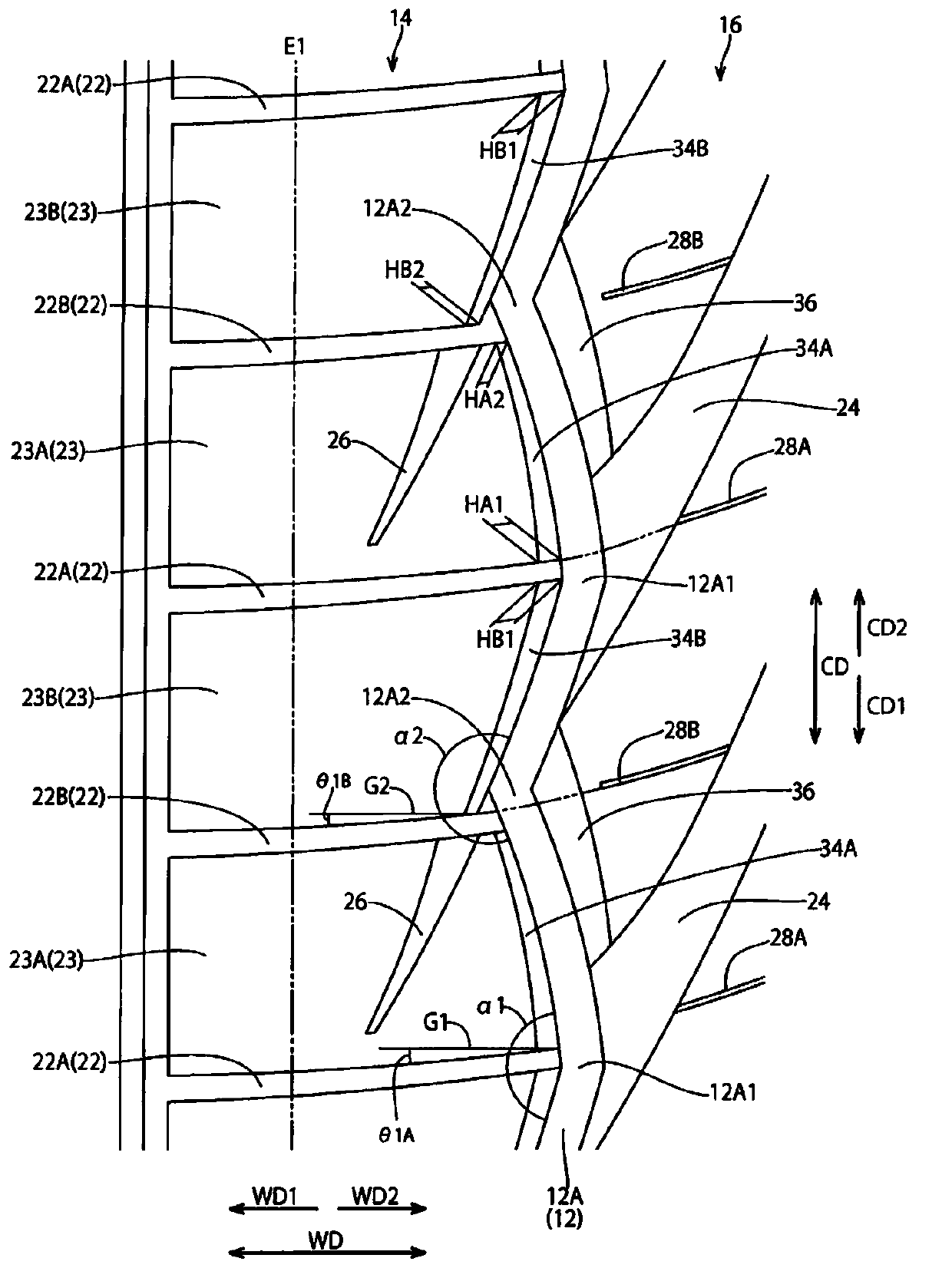

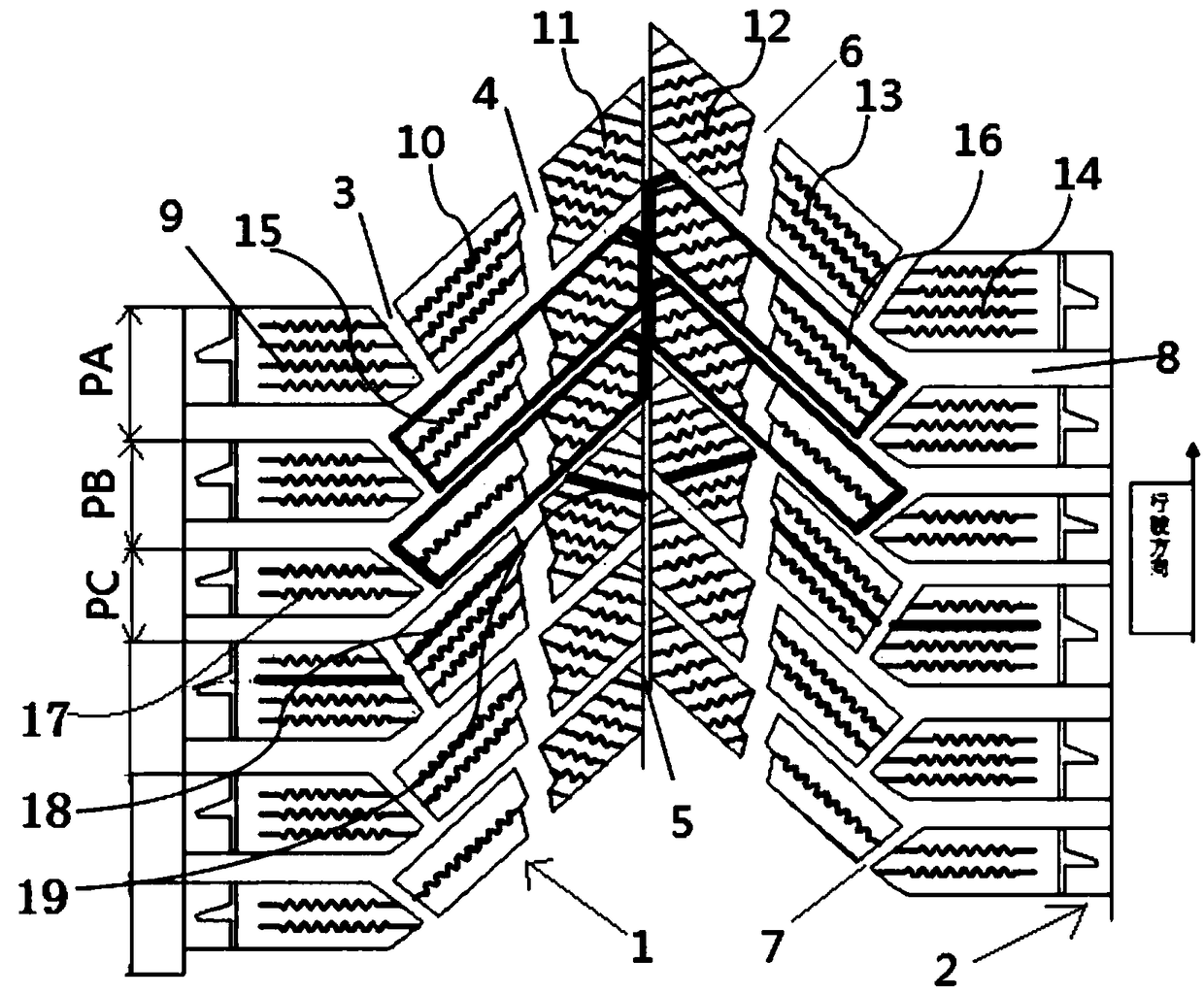

Pneumatic tire

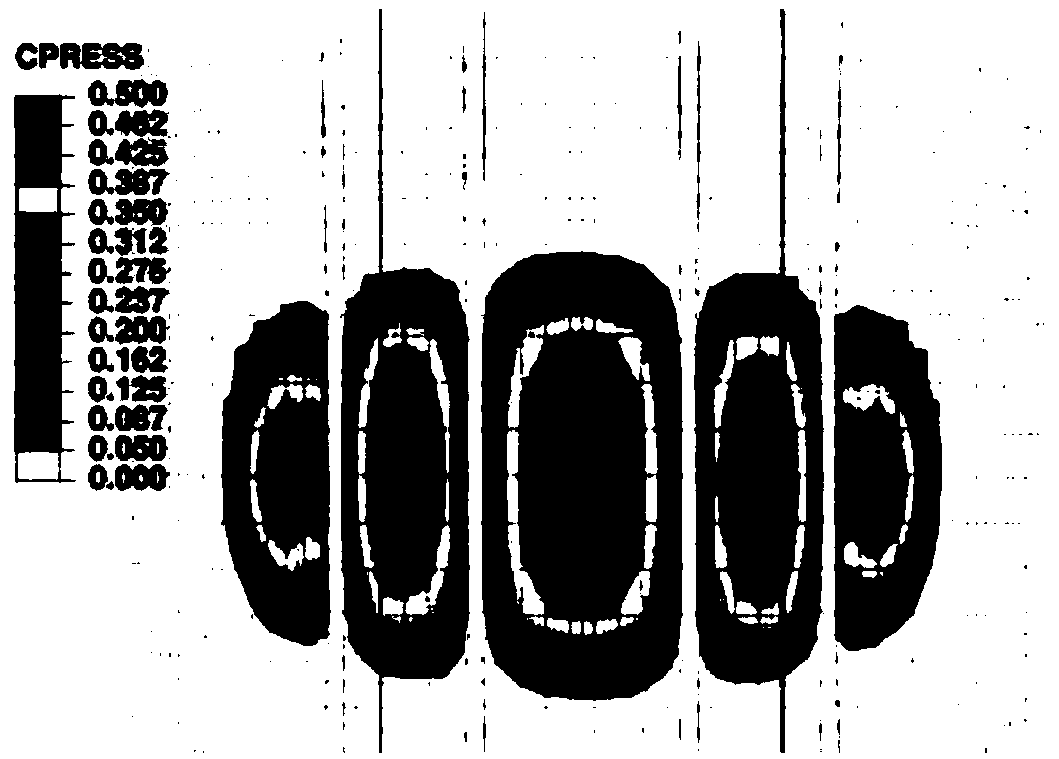

ActiveCN110497741AReduce rigidityUniform rigidityTyre tread bands/patternsGround contactMechanical engineering

Provided is a pneumatic tire in which a shoulder land section formed between a zigzag shoulder main groove and a ground contact end is divided into a plurality of blocks in the circumferential direction of the tire by slits, and uneven wear of blocks having different shapes can be suppressed. The pneumatic tire according to the present embodiment includes a shoulder land portion (14) that is formed between a ground contact end (E1) and a shoulder main groove (12A), and a plurality of slits (22) that divide the shoulder land portion into a plurality of blocks (23) in a tire circumferential direction (CD), in which the shoulder main groove is formed of a zigzag groove in which an inward bent portion (12A1) and an outward bent portion (12A2) are alternately and repeatedly disposed, the slit is connected to the inward bent portion and the outward bent portion, in the shoulder land portion, a chamfered portion (34) is provided on a groove wall facing the shoulder main groove, and in the chamfered portion, a surface width of the chamfered portion is set to increase from the outward bent portion side toward the inward bent portion side.

Owner:TOYO TIRE & RUBBER CO LTD

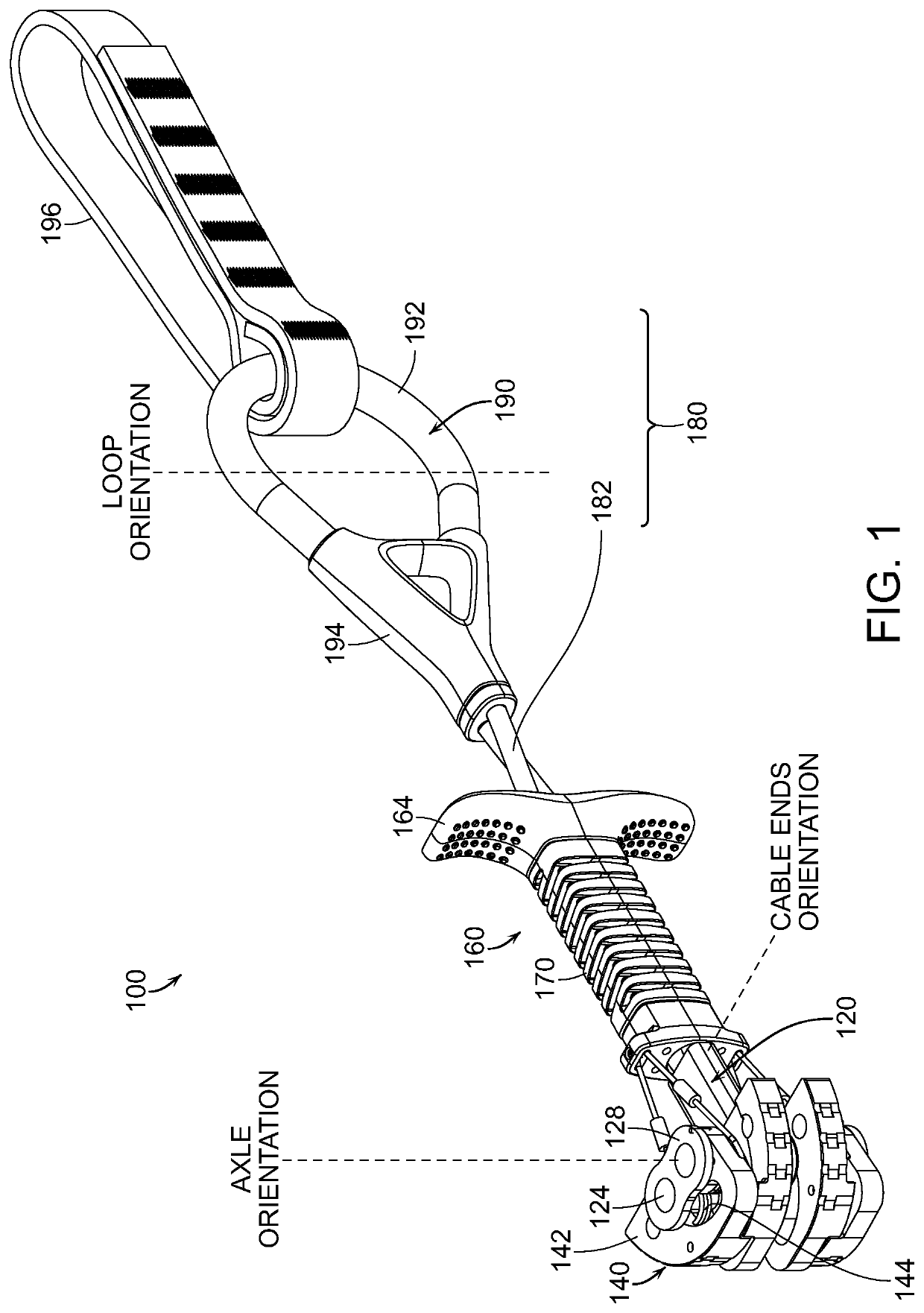

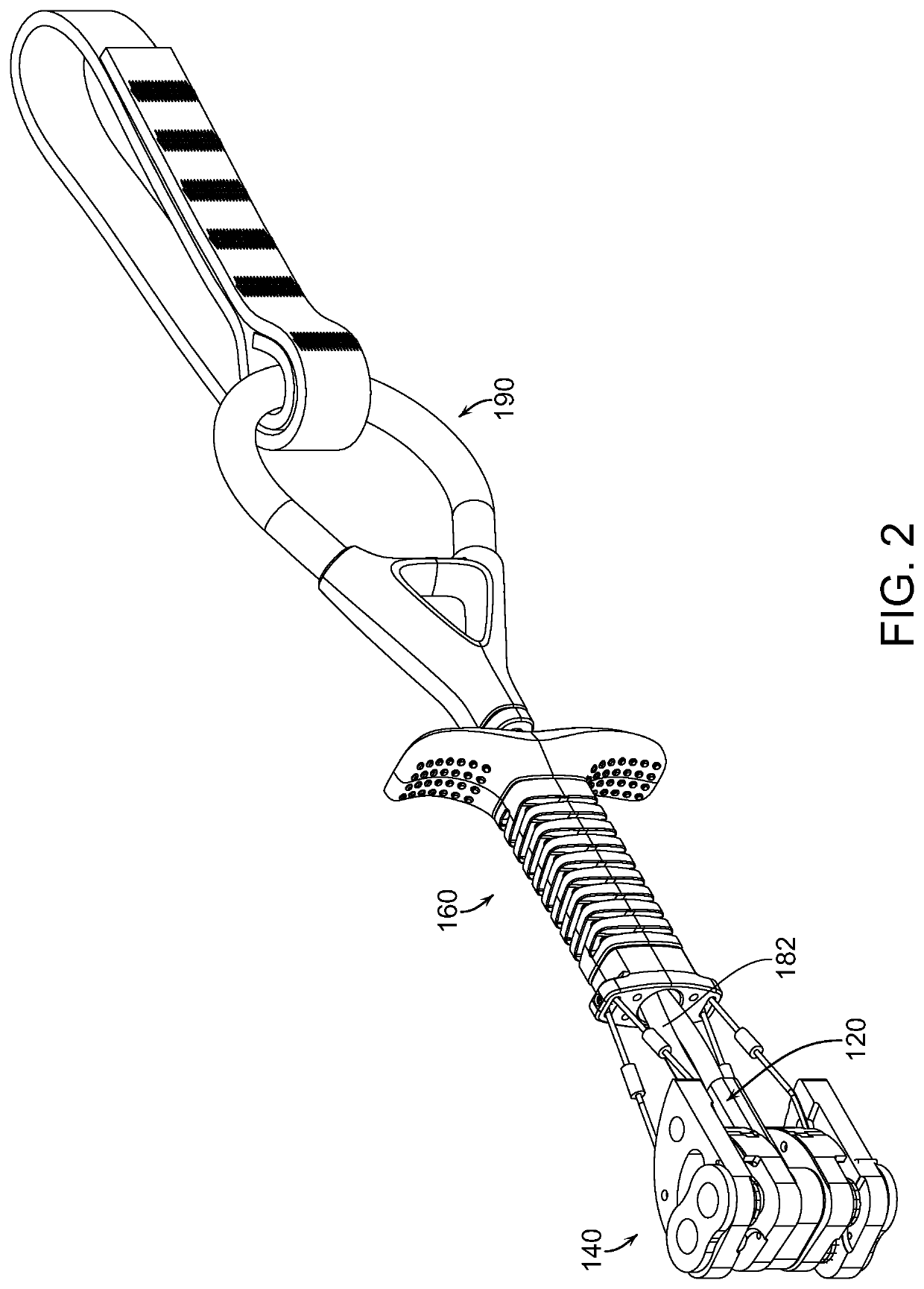

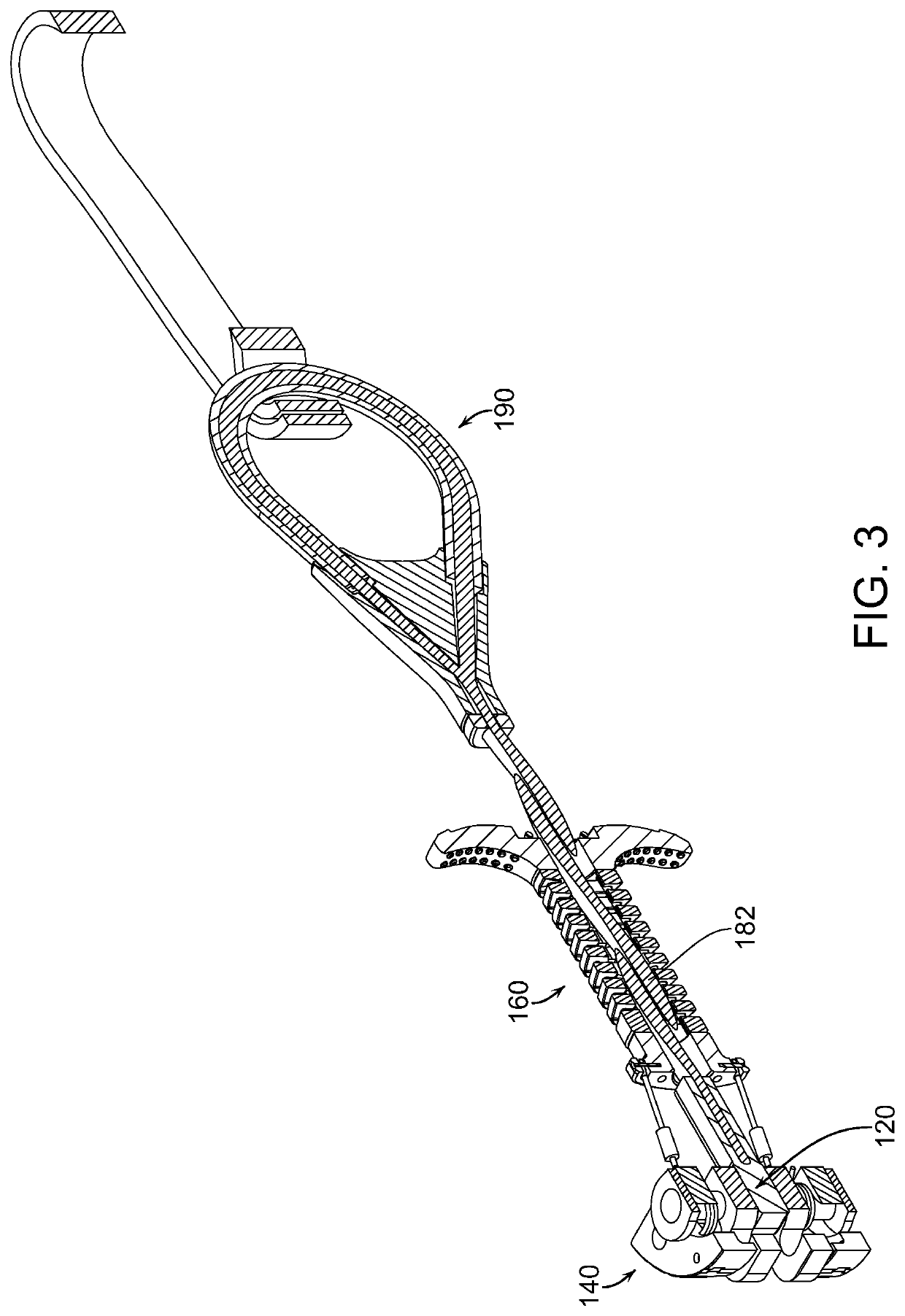

Camming stem system

One embodiment of the present invention relates to an improved camming stem system including a head member, a plurality of cam lobes, a connection system, and a retraction system. The cam lobes may be selectively rotatable between an extended state and a retracted state with respect to at least one axle of the head member. The connection system may create an elongated, substantially rigid region by intercoupling the head member with a loop. The connection system is configured to create an elongated partially rigid region by intercoupling the head member with a loop, wherein the connection system comprises a twisted cable coupled between the head member and the loop, and wherein the loop is oriented substantially parallel to the at least one axle, and wherein the twisted cable includes a twisting radial angle of at least 90 degrees.

Owner:BLACK DIAMOND EQUIPMENT

Commercial light truck tire

ActiveCN106864176AMake up braking forceMake up for lack of tractionHeavy duty tyresHeavy duty vehiclePolygonal lineTruck

The invention discloses a commercial light truck tire. The tread of the tire is provided with three circumferential main grooves which are in a polygonal line shape. Four circumferential pattern blocks are formed between the three circumferential main grooves and the inner and outer shoulders of the tire in a dividing mode. A circumferential coherent Z-shaped steel piece penetrates through the middle of each circumferential pattern block. The circumferential pattern blocks and the circumferential coherent Z-shaped steel pieces are each provided with a plurality of sections of grains parallel to the circumferential direction of the tire. The circumferential main grooves and the circumferential coherent Z-shaped steel pieces are synchronous in a concave and convex mode in the axial direction of the tire. A plurality of transverse Z-shaped three-polygonal-line steel pieces are arranged between each circumferential coherent Z-shaped steel piece and the circumferential main grooves adjacent to the circumferential coherent Z-shaped steel piece. The circumferential pattern blocks of the whole tread also adopt unequal-pitch pattern blocks. Under the condition that road holding force of the tire is ensured, drainage performance is further improved, energy of the voice frequency peak is reduced, and therefore noise of the tire is lowered.

Owner:KENDA RUBBER CHINA

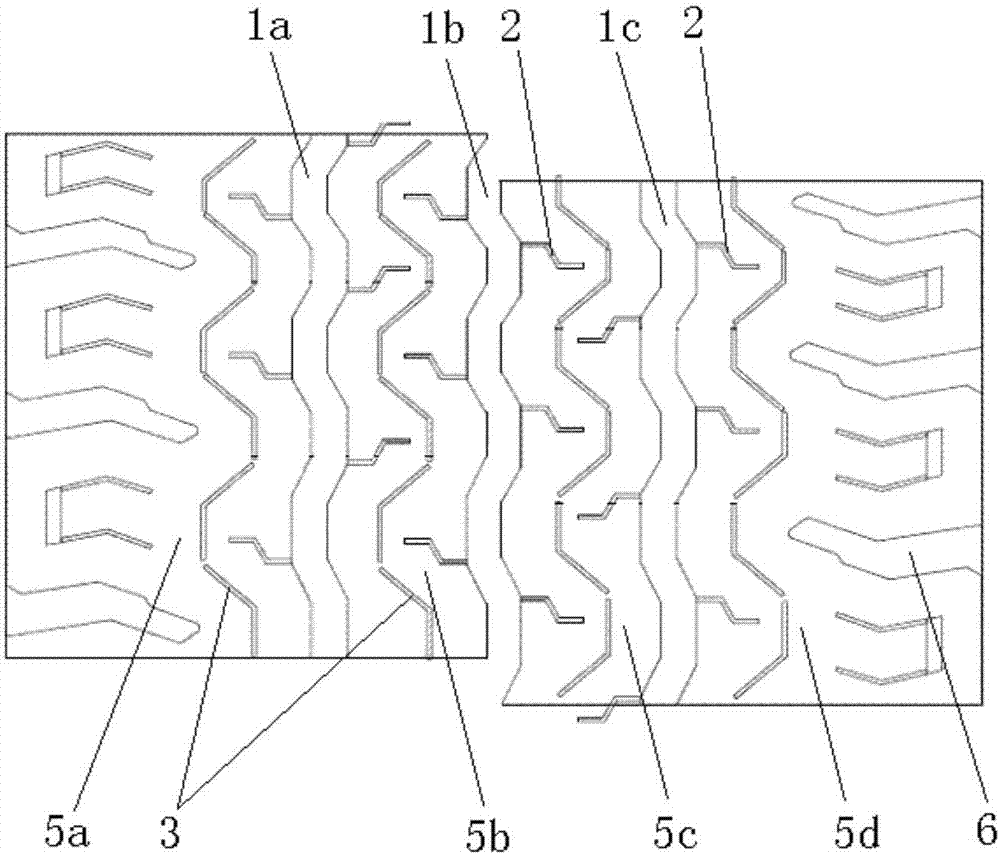

Winter tire which adopts tread pattern block of tunneling blade set

The invention provides a winter tire which adopts a tread pattern block of a tunneling blade set, which includes crown and shoulder; the crown comprises a first circumferential main groove, a second circumferential main groove, a third circumferential main groove, a fourth circumferential main groove and a fifth circumferential main groove arranged in sequence from an outer side of the tire to aninner side of the tire, and a plurality of transverse grooves arranged circumferentially along the tread; the first circumferential main groove, the second circumferential main groove, the third circumferential main groove, the fourth circumferential main groove and the fifth circumferential main groove define a first pattern block, a second pattern block, a third pattern block, a fourth pattern block, a fifth pattern block and a sixth pattern block in conjunction with the transverse grooves respectively; The pattern blocks and steel plate grooves can improve the grip of a snow tire, the contour design can ensure the largest ground contact, pattern joints and the steel plate grooves can reduce noise so as to achieve low noise, and then the winter tire has a strong ground grip force and good safety performance, and can effectively improve the driving safety in rain and snow weather.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

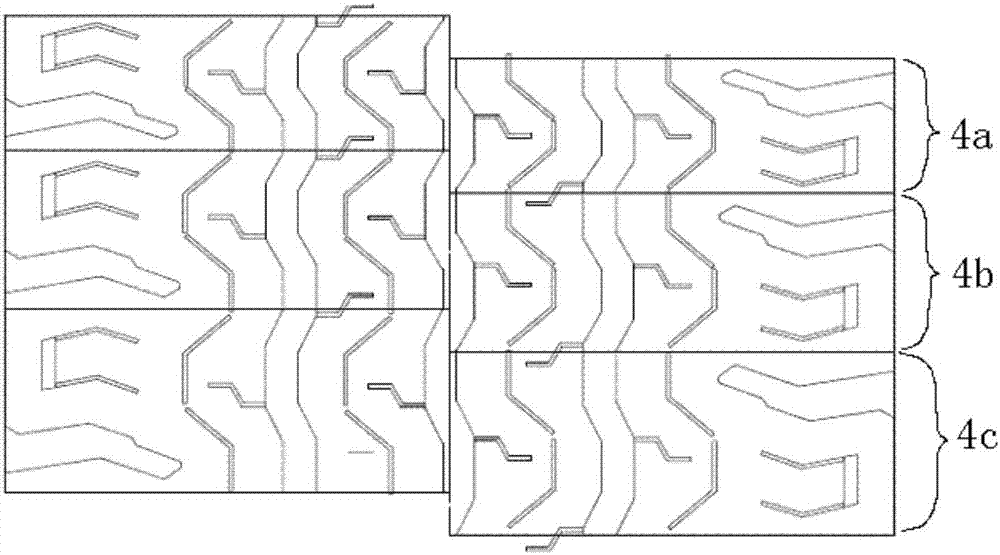

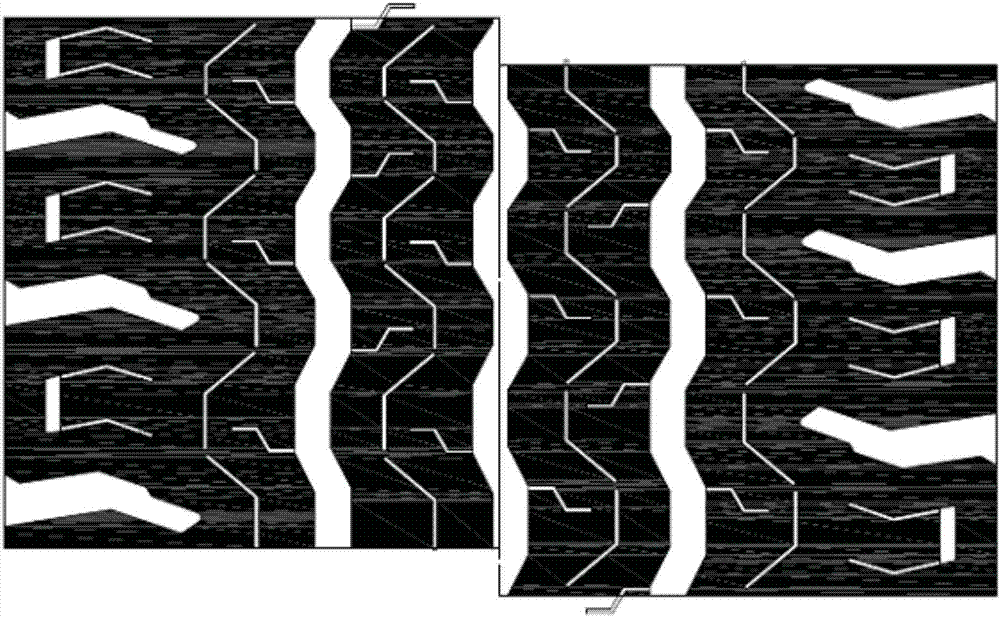

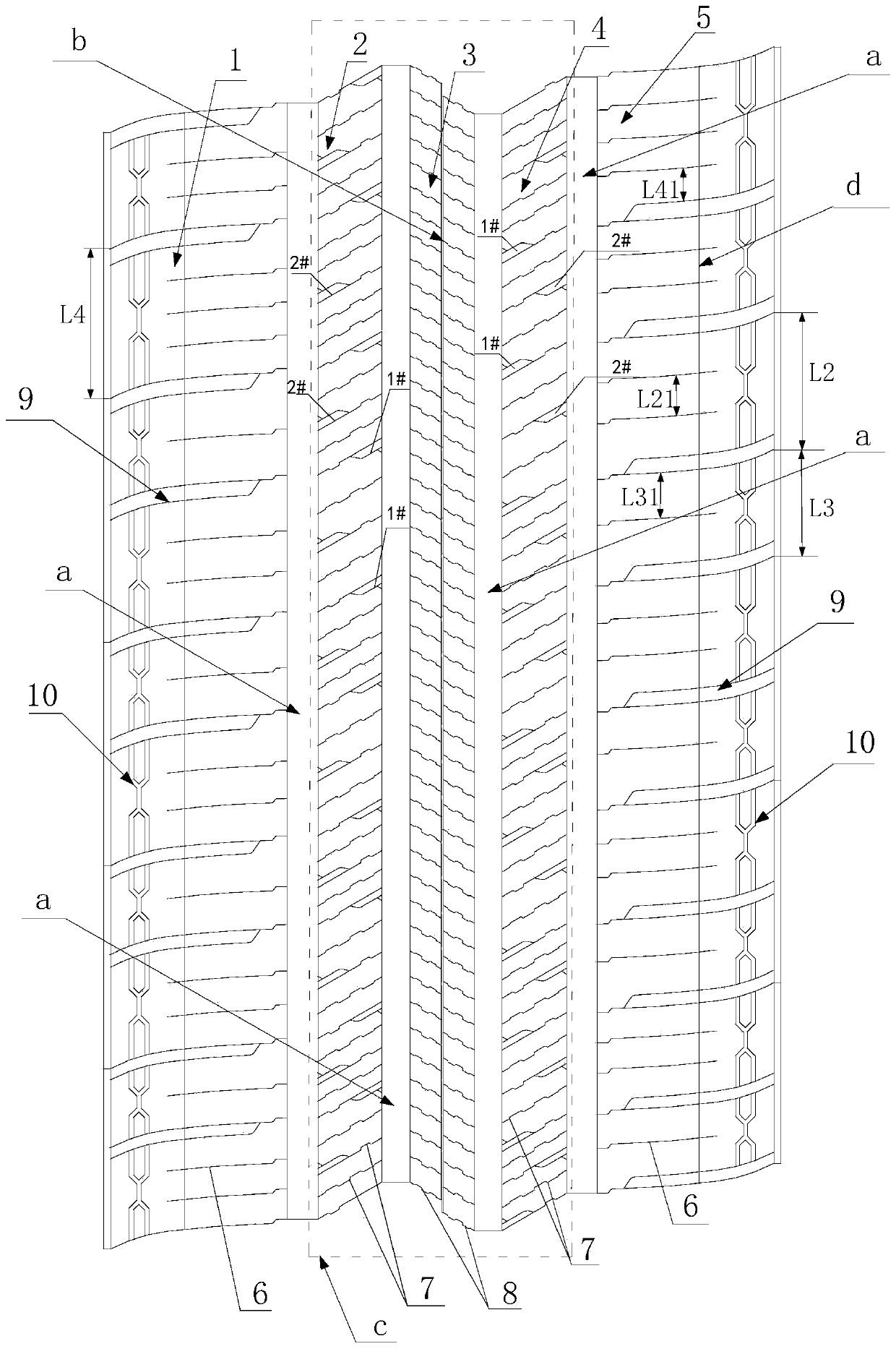

Pneumatic tire

ActiveCN108162696AUniform width dimensionUniform rigidityTyre tread bands/patternsEngineeringWear resistance

The invention provides a pneumatic tire which can exhibit excellent performances in all of wet property, uneven wear resistance and straight traveling performance of the tire. A pneumatic tire comprises on a tread surface (1) thereof: a center main groove (2) extending in a tire circumferential direction; a shoulder main groove (3) extending in the tire circumferential direction at a position awayfrom the center main groove (2) in a tire width direction; and inclined grooves (4) formed at predetermined intervals in the tire circumferential direction, wherein each inclined groove includes a first inclined portion (11) extending from the center main groove (2) toward the shoulder main groove (3) while increasing a width thereof, the first inclined portion 11 extending at a first angle alphawith respect to the tire circumferential direction, and a second inclined portion (12) continuously formed with the first inclined portion, the second inclined portion (12) extending at a second angle beta smaller than the first angle alpha with respect to the tire circumferential direction.

Owner:TOYO TIRE & RUBBER CO LTD

All-weather SUV radial tire

PendingCN109941048AImprove rigidityImprove traction performanceTyre tread bands/patternsEngineeringDriving safety

Provided is an all-weather SUV radial tire. The all-weather SUV radial tire comprises a first pattern part, a second pattern part, a third pattern part, a fourth pattern part and a fifth pattern part,wherein the first pattern part, the second pattern part, the third pattern part, the fourth pattern part and the fifth pattern part are partitioned by four vertical grooves. By adopting a certain tire sea-land ratio of a braking area, a cutter groove reinforcement design and the like, the braking performance and off-road traction performance under the influence of ice and snow of the all-weatherSUV radial tire are improved effectively. Under the condition that the total sea-land ratio is not changed, the total area of pattern blocks in the braking area and the total area of the braking areaare designed to be in the range from 69% to 71%, and the braking performance can be improved without influencing the performance of a snowfield. According to different pattern parts, three different cutter groove styles are adopted, different types of reinforcing blocks are additionally arranged on different cutter grooves to improve the rigidity of the pattern blocks, and by simulating the anglesand proportions of the reinforcing blocks and obtaining the optimal angle and the optimal volume proportion according to different parts, the braking performance is improved to the greatest extent onthe basis of effectively ensuring the ice-snow resistance performance and uniform abrasion; by combining with an under-shoulder chain-shaped pattern design, the lateral traction performance in the snowfield is improved, the braking performance is effectively improved, and the driving safety is improved.

Owner:SAILUN GRP CO LTD

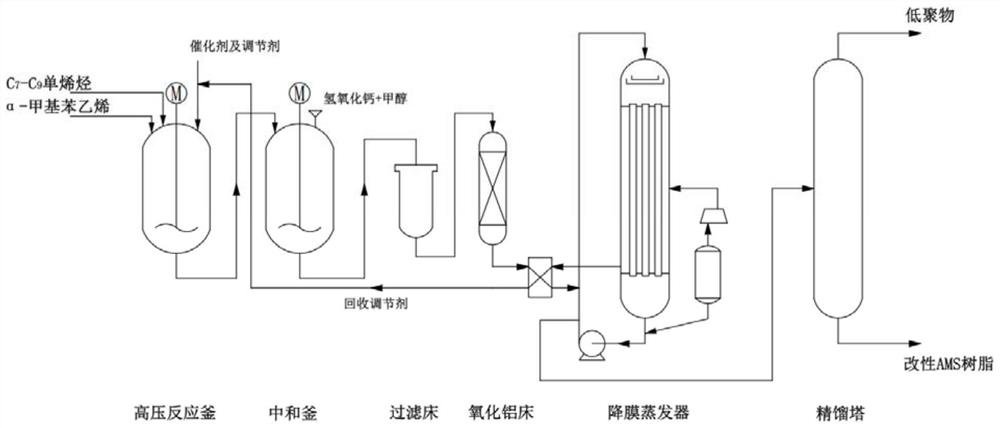

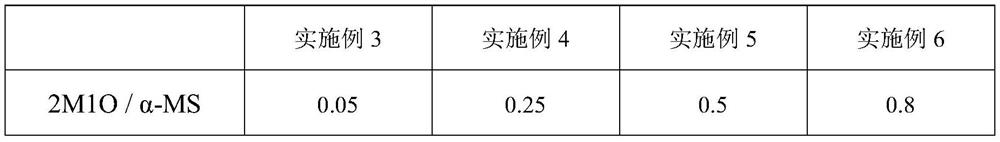

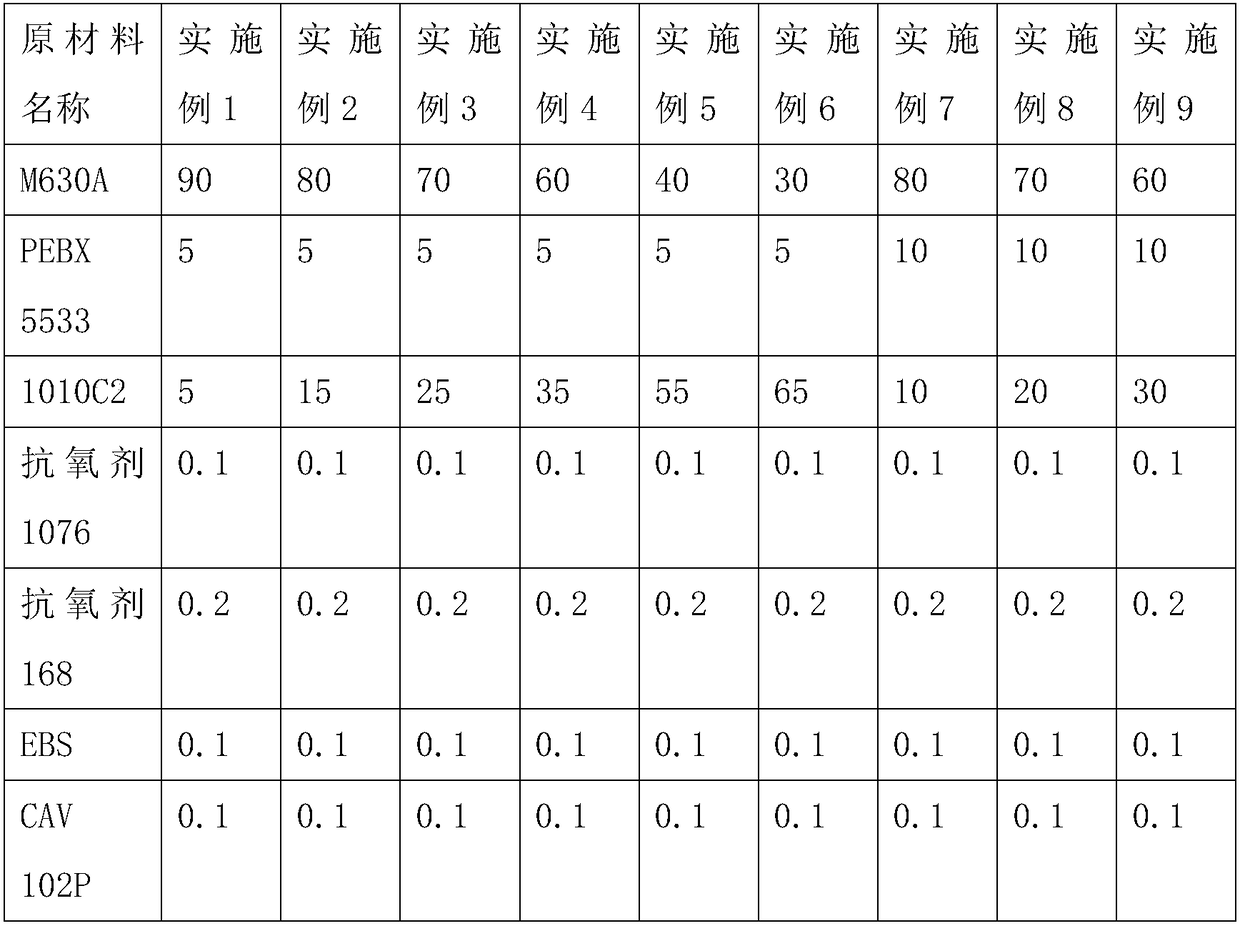

Preparation method of flexible poly-alpha-methylstyrene resin

The invention relates to a preparation method of flexible poly (alpha-methylstyrene) resin, which comprises the following steps: mixing alpha-methylstyrene or a mixture of alpha-methylstyrene and styrene derivatives with C7-C9 chain aliphatic monoolefine to serve as a raw material, adding a polarity regulator, and performing cationic catalytic polymerization to obtain the flexible poly (alpha-methylstyrene) resin with proper softening point and molecular weight, extremely light color number and high flexibility. The invention relates to flexible poly-alpha-methylstyrene resin with relatively low glass transition temperature. Through cationic polymerization, a proper amount of aliphatic chain groups are introduced into an aromatic resin structure with relatively high rigidity, so that the flexibility of the aromatic resin structure is improved, the modified resin with balanced rigidity enhancing performance and toughness enhancing performance is obtained, and the modified resin can be applied to modification of metallocene polyolefin, polypropylene, APAO and the like.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

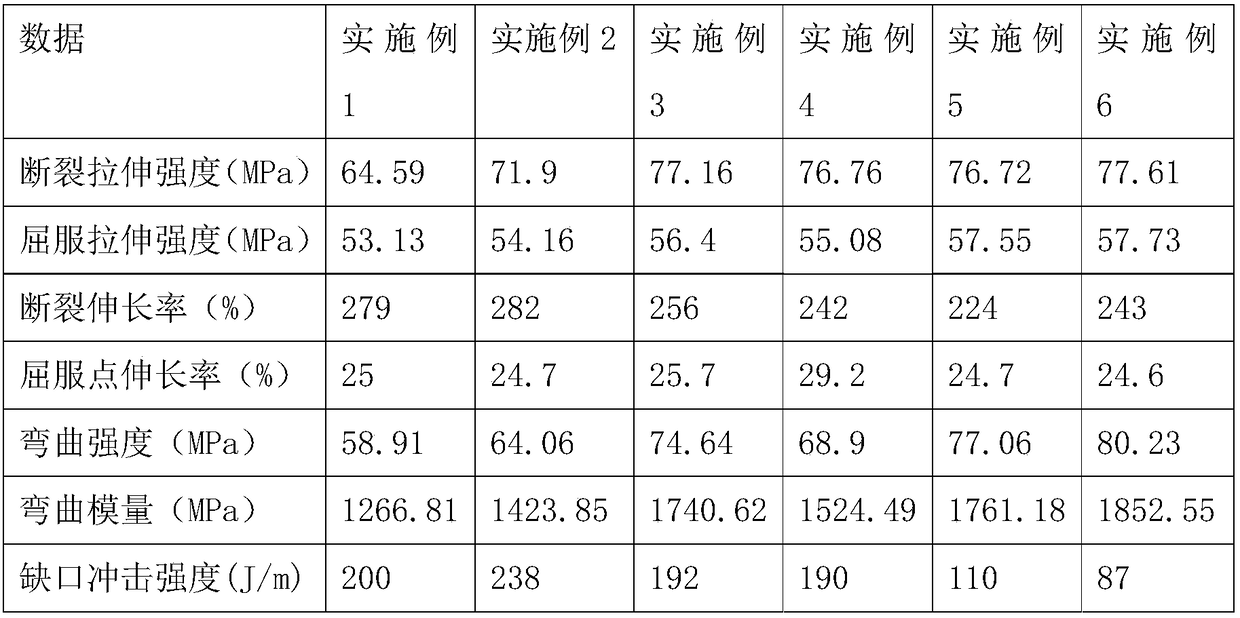

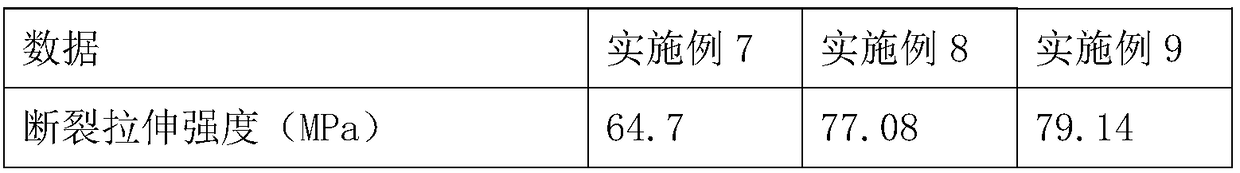

Stiffness and toughness balanced ternary blend alloy material and preparation method thereof

The invention discloses a stiffness and toughness balanced ternary blend alloy material which is prepared from the following components in parts by weight: 30-90 parts of POK polyketone, 5-30 parts ofnylon elastomers, 5-70 parts of PA6, 0.05-0.3 part of a nucleating agent, 0.05-1 part of a lubricating agent, 0.05-0.3 part of a primary antioxidant and 0.05-0.3 part of an auxiliary antioxidant. Theinvention further provides a preparation method of the ternary blend alloy material. The preparation method comprises the following steps: mixing the components in parts by weight, and performing melt extrusion granulating by a twin-screw extruder unit, thereby obtaining the ternary blend alloy material disclosed by the invention. Compared with ordinary POK or nylon, the ternary blend alloy material disclosed by the invention maintains low water-absorbing quality and high wear resistance of the POK material, the characteristics of the nylon material such as high modulus and excellent chemicalresistance are additionally increased, and another function that is not owned by the two is increased, namely, the excellent characteristic of high toughness.

Owner:SHANGHAI GAOXINKE PLASTIC PROD

Manufacturing process of automobile cover plate

The invention provides a manufacturing process of an automobile cover plate. The manufacturing process comprises the following steps: laying a material: tiling a surface material on a net chain, positioning and nailing; flatly placing a PP (Propene Polymer) fly ash plate at a specified position of another net chain without fixing through nailing; adopting a retainer to retain the outer edge of a mix on the four sides; performing baking temperature softening: feeding the PP fly ash plate laid on the net chain into a baking box to perform the baking temperature softening, wherein the baking temperature is 200-400 DEG C and the baking temperature is 85-105 s; determining single-action drawing die blank holder stroke, wherein the size of the stroke guarantees that the plate is placed on the blank holder without lapping on a drawing male die and is 10-20 mm higher than a molded surface of the male die; when a single-action drawing die blank holder is ejected, the effective contact area of a slide guide surface of the blank holder is greater than 50-80 mm; upper and lower dies are guided by using a guide plate and are guided in for at least 50 mm before drawing is performed. According to the manufacturing process of the automobile cover plate, the rigidity of the cover plate is uniform, and early damage does not occur easily.

Owner:LIUZHOU JUNJIE AUTO PARTS MFG

Production method of woolen light and thin cashmere fabric

The invention discloses a method for producing woolen light and thin cashmere fabrics. The technological process includes the following steps in sequence: selecting raw material fiber → blending wool → surface PVA → carding roving → spun yarn → de-PVA → winding → weaving → finishing → obtaining Woolen light and thin cashmere fabric; wherein, the selection of raw material fiber process selects cashmere fibers, including cashmere long fibers; the surface PVA process includes drying the cashmere long fibers after the wool treatment in PVA solution; the de-PVA process It is PVA on the surface of the yarn after washing with water to remove the spun yarn. The invention breaks through the limitations of woolen spinning, introduces long cashmere fibers into woolen spinning, and makes cashmere long fibers fully exert the advantages of reinforcing yarns by hardening cashmere fibers, and obtains fluffy, light and soft cashmere fabrics through the woolen spinning method, and the process is environmentally friendly and efficient. It saves time and effort, and the source of raw materials is more abundant.

Owner:江苏烨天羊绒科技有限公司

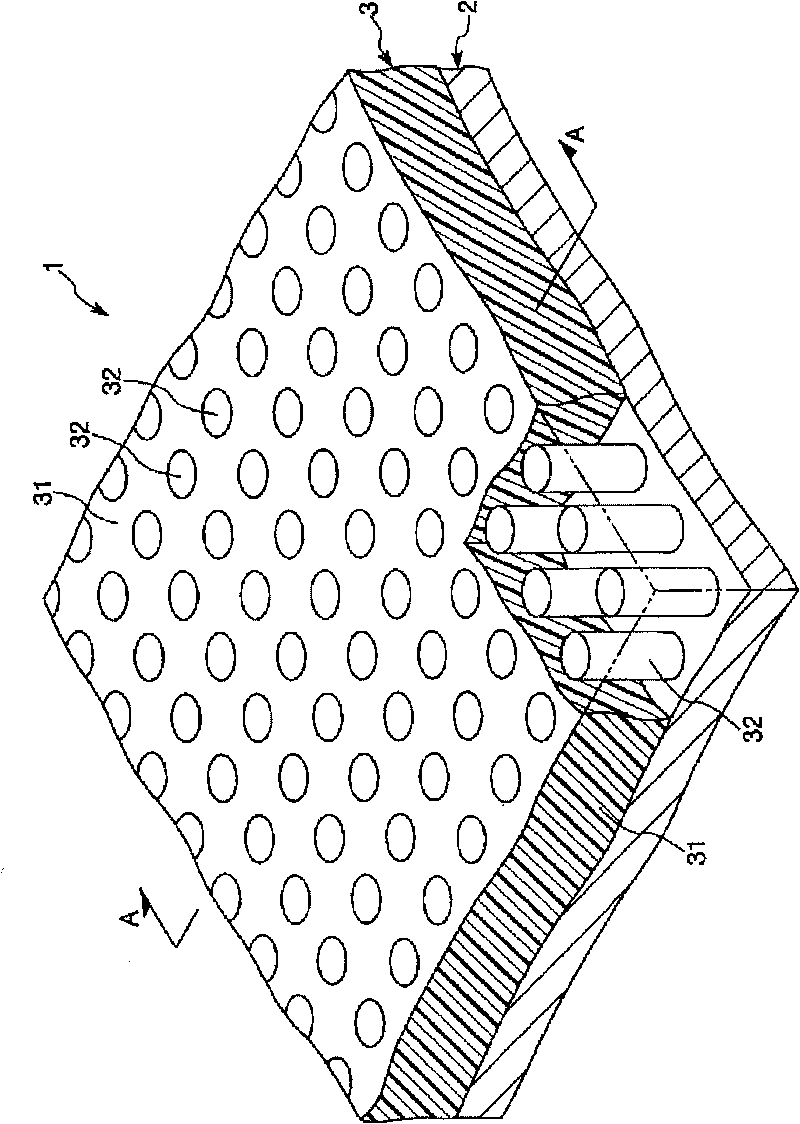

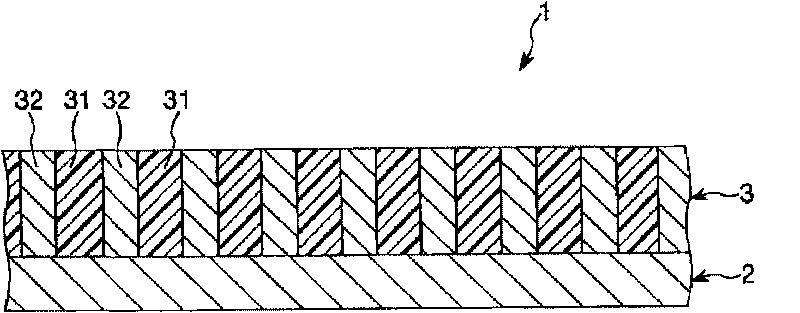

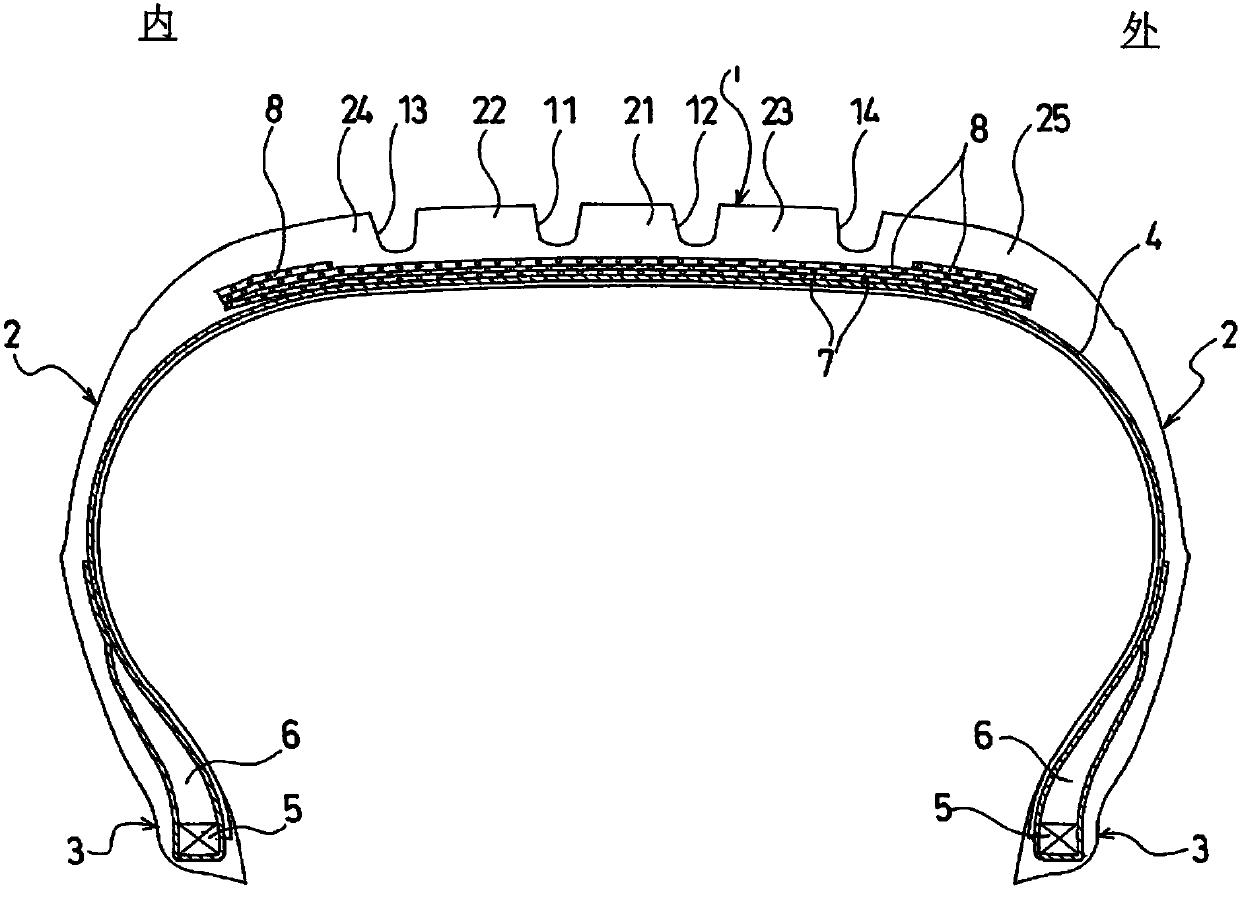

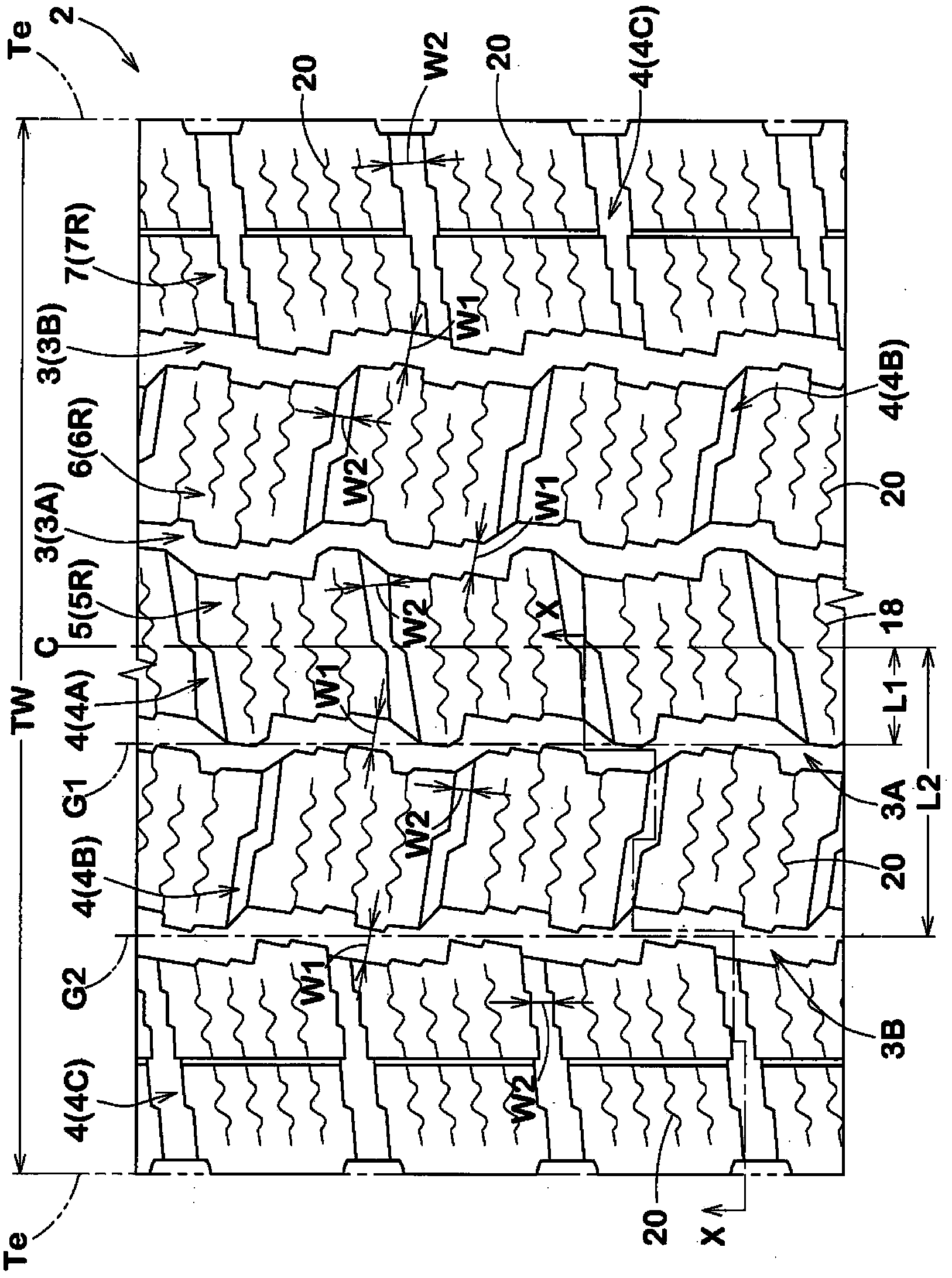

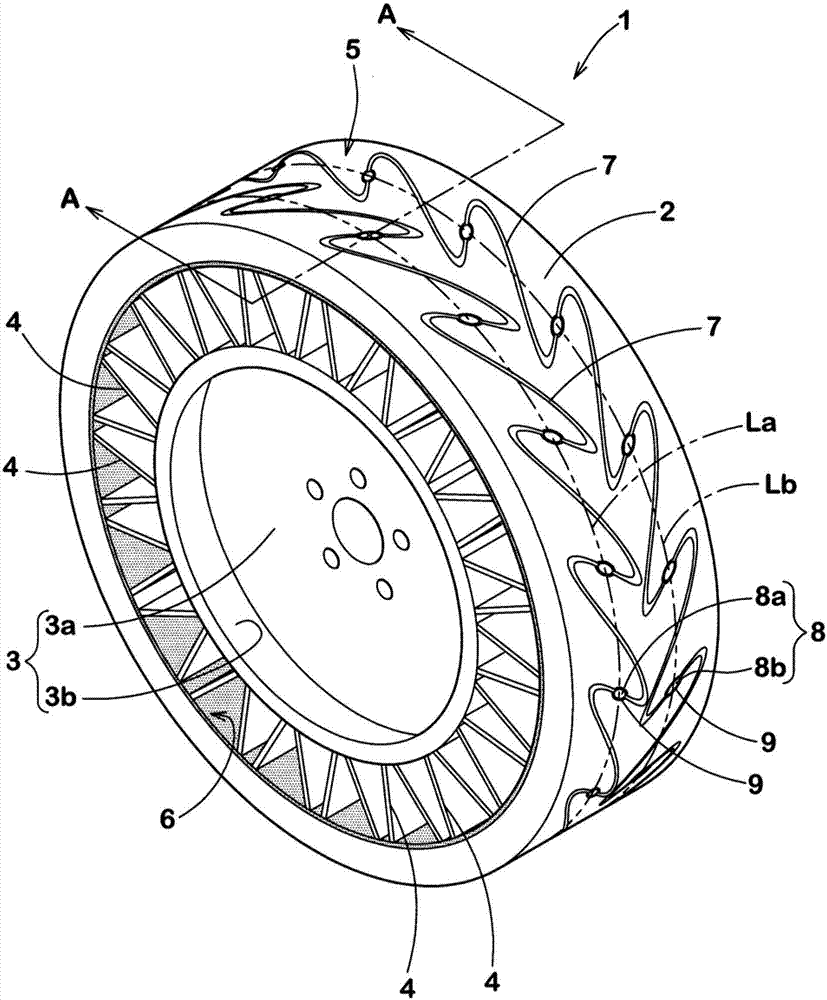

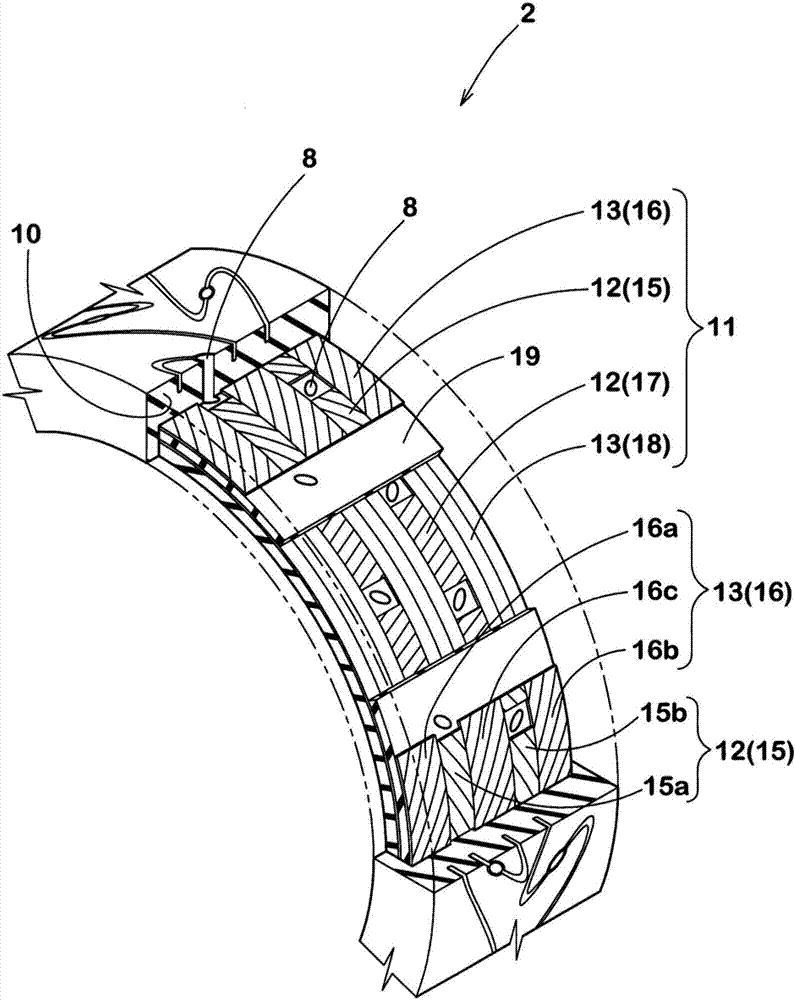

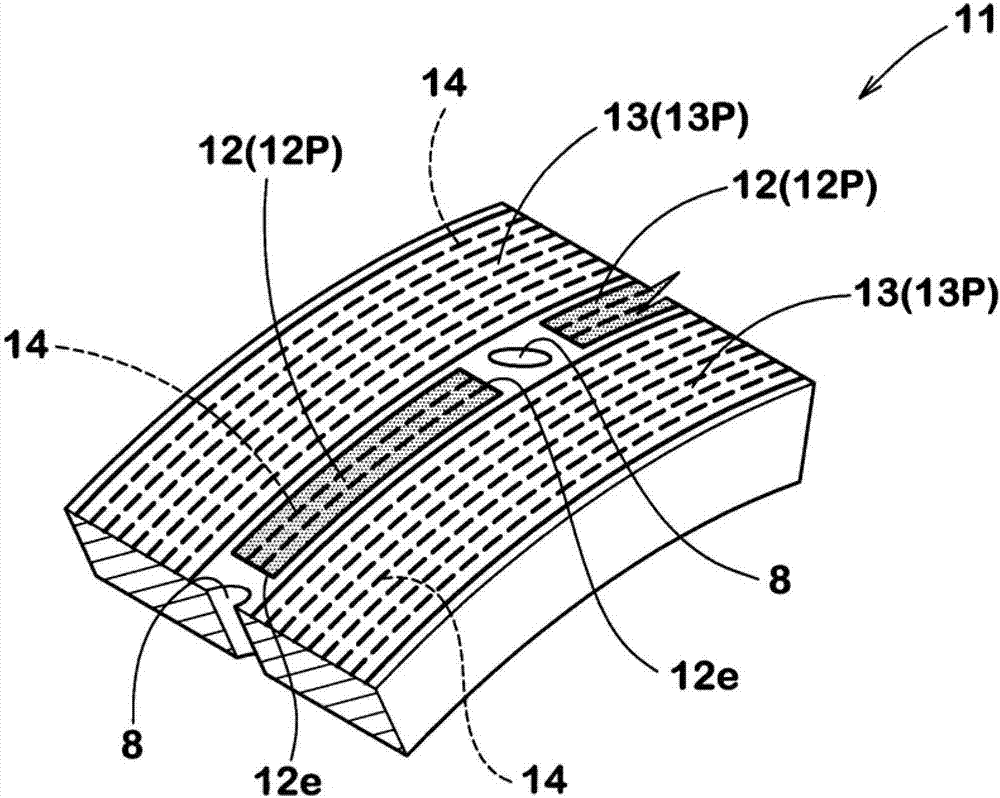

Airless Tire

ActiveCN107031288AImprove drainage capacityImprove handling stabilityNon-inflatable tyresTyre tread bands/patternsGround contactEngineering

[Problem to be Solved] To provide an airless tire that allows both good drainage performance and good durability to be achieved and allows uneven wear resistance to be improved. [Solution] An airless tire 1 is provided that includes a cylindrical tread ring 2 that has a ground contact surface 5. Multiple through holes 8 and a reinforcing body 11 are provided in the tread ring 2, the multiple through holes 8 penetrating the tread ring 2 in a thickness direction of the tread ring 2. The multiple through holes 8 are arranged at intervals along a tire circumferential direction. The reinforcing body 11 includes a first reinforcing body 12 that extends in the tire circumferential direction in regions between adjacent through holes 8. Both ends (12e) of the first reinforcing body 12 in the tire circumferential direction terminate without being exposed from inner peripheral surfaces of the through holes 8.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com