Polyolefin-based multilayer microporous film with excellent physical properties and high temperature stability

A technology of microporous membrane and polyolefin, which is applied in the fields of membrane, membrane technology, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

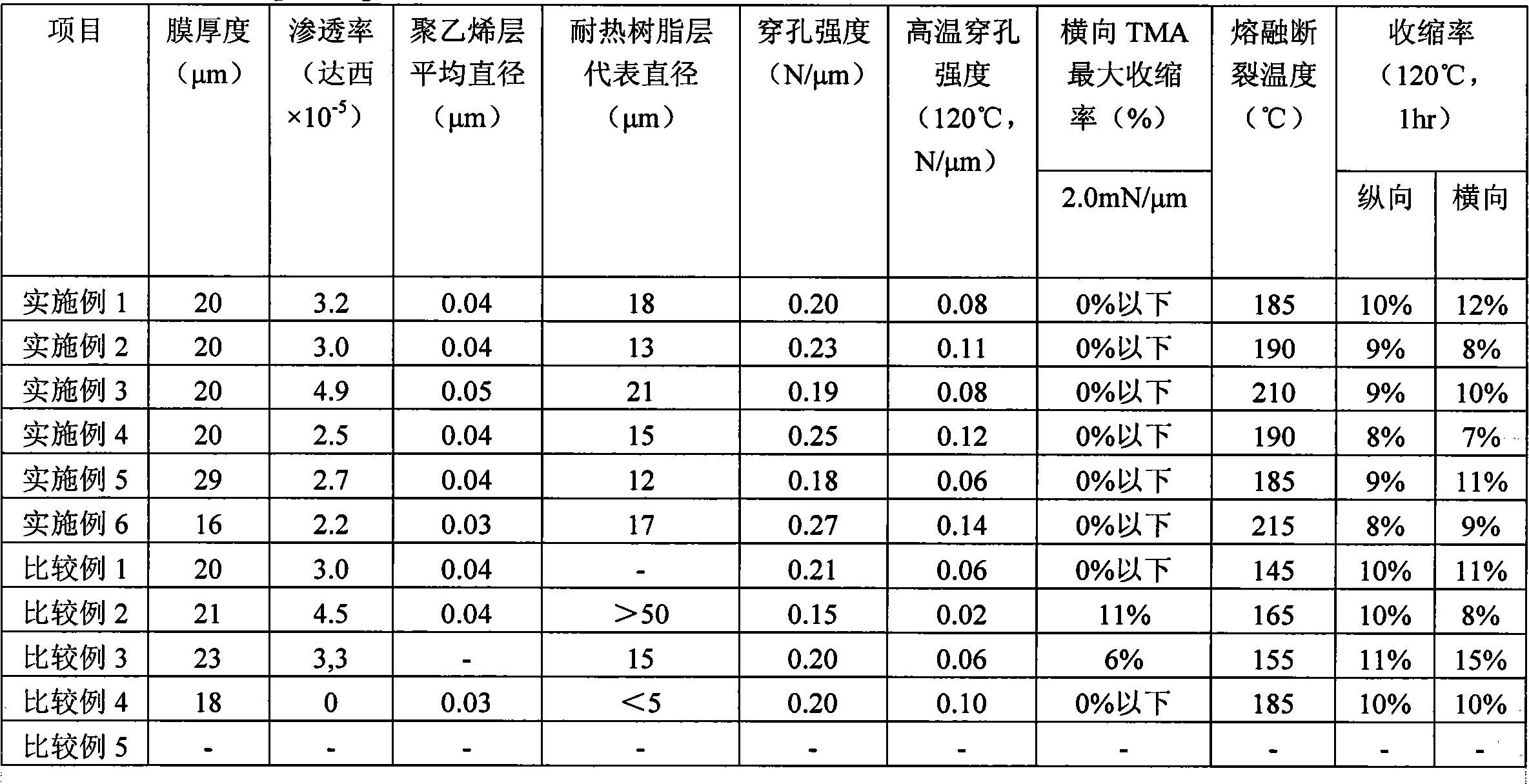

Examples

Embodiment 1

[0115] In the polyethylene layer, a weight average molecular weight of 3.04×10 5 , polyethylene with a melting temperature of 135° C. and paraffin oil with a dynamic viscosity of 95 cSt at 40° C., the contents of the two components are 30% by weight and 70% by weight, respectively. The above-mentioned polyethylene and paraffin oil were mixed in a twin-screw kneader with Φ=46mm, and the mixing temperature was 220°C. The above polyethylene was added using the main hopper and the diluent paraffin oil was added to the extruder using a side feeder. The weight average molecular weight used in the heat-resistant layer is 2.5×10 5 Polypropylene with a melting temperature of 153°C and a crystallinity of 42% using ethylene as a comonomer and CaCO as a filler with an average particle size of 1.5 μm 3 , the contents of the two components are respectively 30% by weight and 70% by weight. The polypropylene and filler of the heat-resistant resin layer were kneaded / extruded in a Φ=40mm twi...

Embodiment 2

[0118] In the polyethylene layer, a weight average molecular weight of 3.0×10 5 , polyethylene with a melting temperature of 135° C. and paraffin oil with a dynamic viscosity of 95 cSt at 40° C., the contents of the two components are 30% by weight and 70% by weight, respectively. The above-mentioned polyethylene and paraffin oil were mixed in a twin-screw kneader with Φ=46mm, and the mixing temperature was 220°C. The above polyethylene was added using the main hopper and the diluent paraffin oil was added to the extruder using a side feeder. Use a weight average molecular weight of 3.5×10 in the heat-resistant resin layer 5 It is mixed with ethylene-propylene rubber (EPR) with a melting temperature of 164°C, polypropylene with a crystallinity of 41%, and polyarylate (Polyarylate) with a glass transition temperature of 200°C as a filler. The contents of the two components are respectively 60% by weight and 40% by weight. The polypropylene and filler in the heat-resistant re...

Embodiment 3

[0121] In the polyethylene layer, a weight average molecular weight of 3.0×10 5 , polyethylene with a melting temperature of 135° C. and paraffin oil with a dynamic viscosity of 95 cSt at 40° C., the contents of the two components are 30% by weight and 70% by weight, respectively. The above-mentioned polyethylene and paraffin oil were mixed in a twin-screw kneader with Φ=46mm, and the mixing temperature was 220°C. The above polyethylene was added using the main hopper and the diluent paraffin oil was added to the extruder using a side feeder. In the heat-resistant resin layer, the weight average molecular weight is 6.0×10 5 , the melting temperature is 231 ℃, the polymethylpentene (poly4-methyl-1pentene) that melting endothermic capacity is 40J / g and the average particle size as filler is the calcium carbonate of 2.5 μm, and the content of two components is respectively 35 weight %, 65% by weight. The polymethylpentene and filler in the heat-resistant resin layer were knead...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com