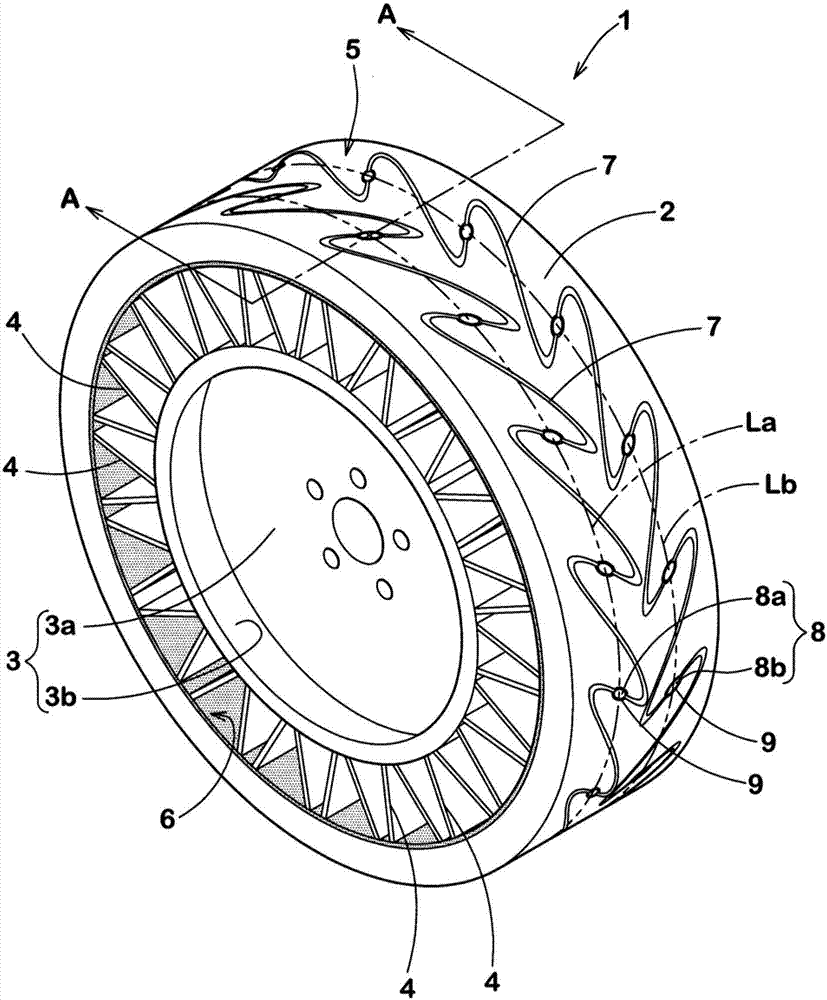

Airless Tire

A technology for airless tires and tires, applied to non-pneumatic tires, tire parts, wheels, etc., can solve problems such as uneven wear and uneven rigidity of tread rings, achieve roughly uniform rigidity, and improve uneven wear resistance , The effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

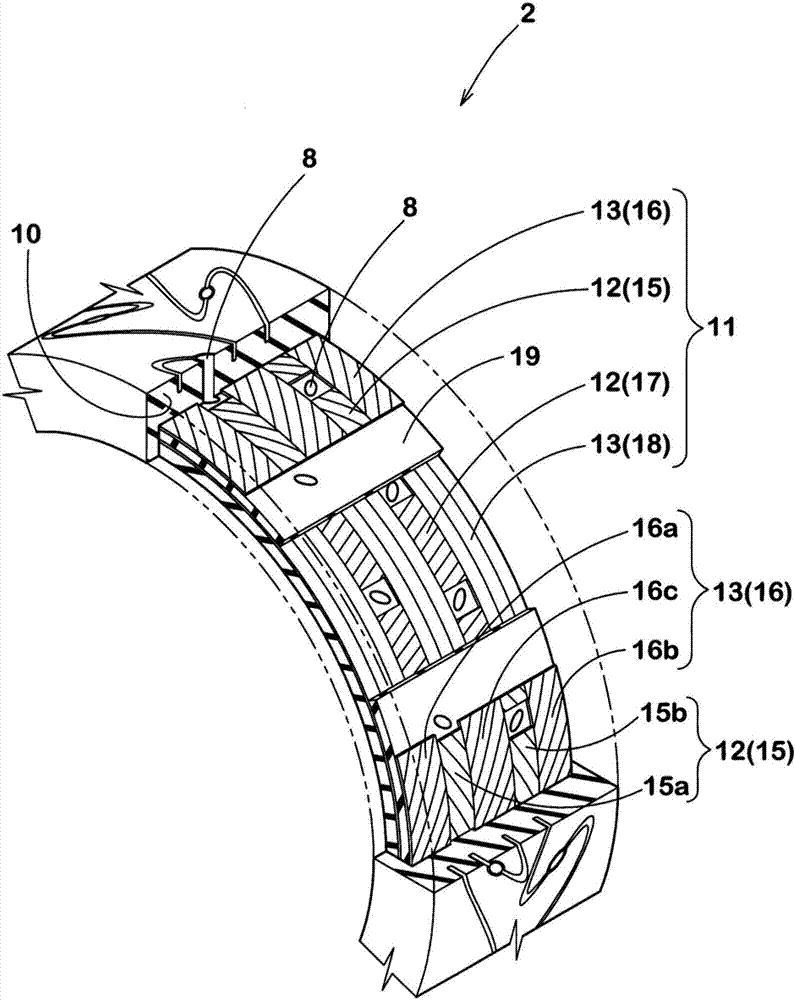

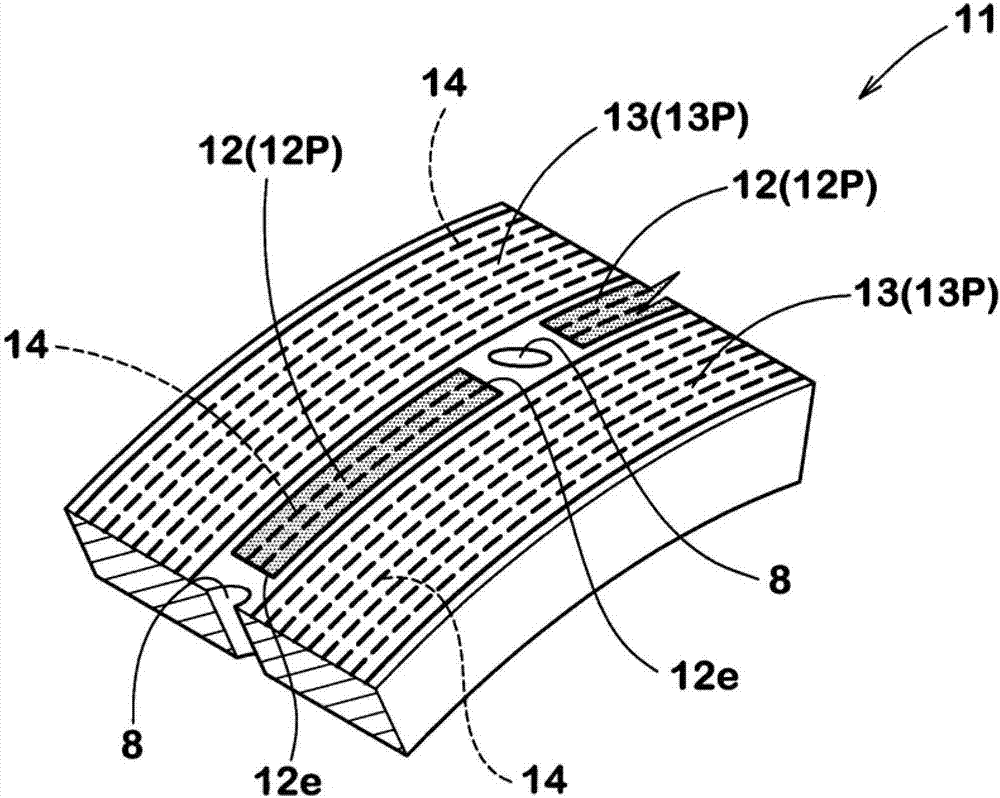

[0064] Prototype formed according to the specifications in Table 1 Figure 1~4 Airless tires of the basic structure (equivalent to tires with a tire size of 125 / 80R13), and tested for water drainage, durability, and uneven wear resistance. The spokes are molded integrally with the tread ring and the hub by polyurethane resin (thermosetting resin) casting. The test method is described below.

[0065]

[0066] Each test tire was mounted on a small passenger car, and a test driver drove along a test road on a paved road in a wet state. The running characteristics related to water drainage at this time were evaluated by the senses of the test driver. The results are an index based on Comparative Example 1 as 100, and a larger value indicates better drainage.

[0067]

[0068] The durability test of each trial tire was carried out under the conditions described below using a roller tester under hot and humid conditions, and each trial tire after the test was cut to check whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com