Waterproof structure manufacturing method of caisson-type toilet

A waterproof structure and toilet technology, applied in drainage structures, waterway systems, water supply devices, etc., can solve the problems that the exact cause is difficult to find, shorten the life of waterproof materials, and require high waterproof treatment, so as to avoid the phenomenon of ground springs and avoid long-term exposure to water. Wet environment, avoid the effect of ground springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention includes the manufacture of three parts: the base layer, the overhead layer and the ground layer.

[0019] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings.

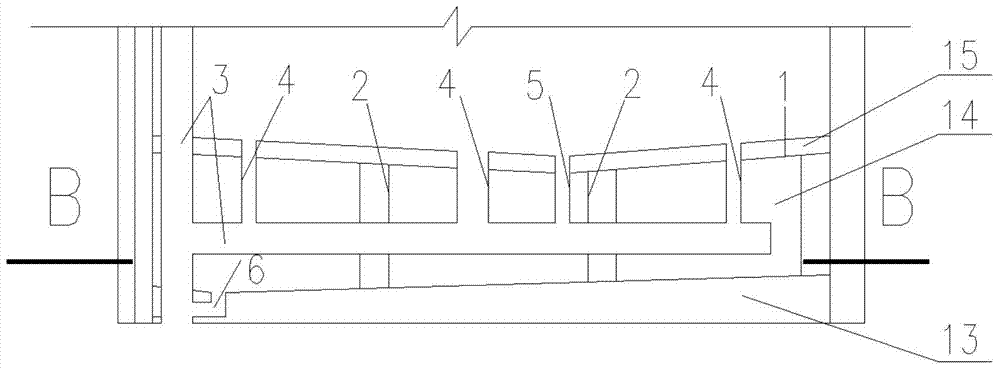

[0020] (1) if figure 2 As shown in the schematic diagram of the toilet elevation, a caisson type toilet waterproof structure is manufactured, including a base layer 13 , an overhead layer 14 and a ground layer 15 . The base layer 13 is provided with a base layer floor drain 6 connected to the main drain pipe 3 , and the base layer floor drain 6 is located at the lowest point of the base layer 13 . The main drainage pipe 3, the equipment drainage pipe 4, and the short column pier 2 are installed in the overhead layer 14, and the short column pier 2 is used as the bearing support of the prefabricated reinforced concrete slab 1 of the ground floor 15 of the bathroom.

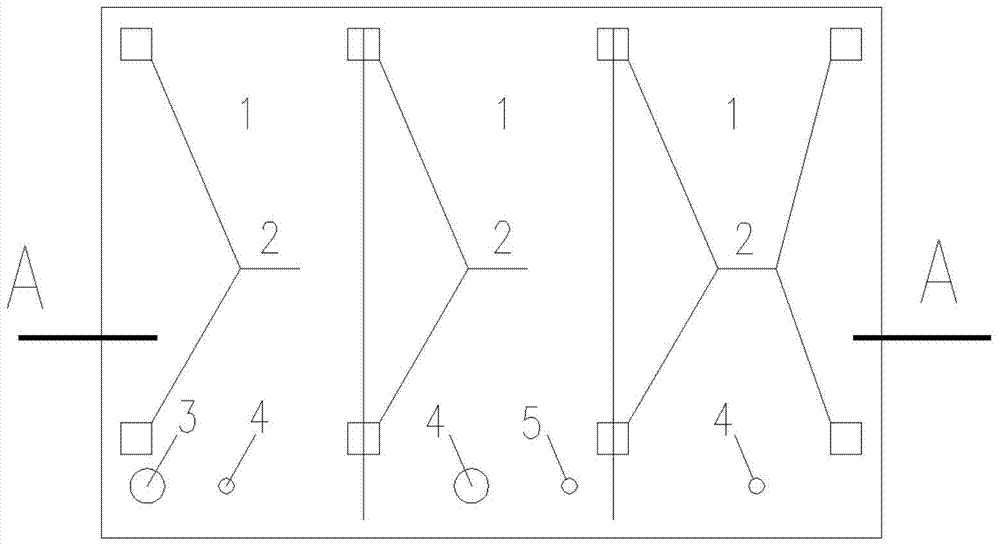

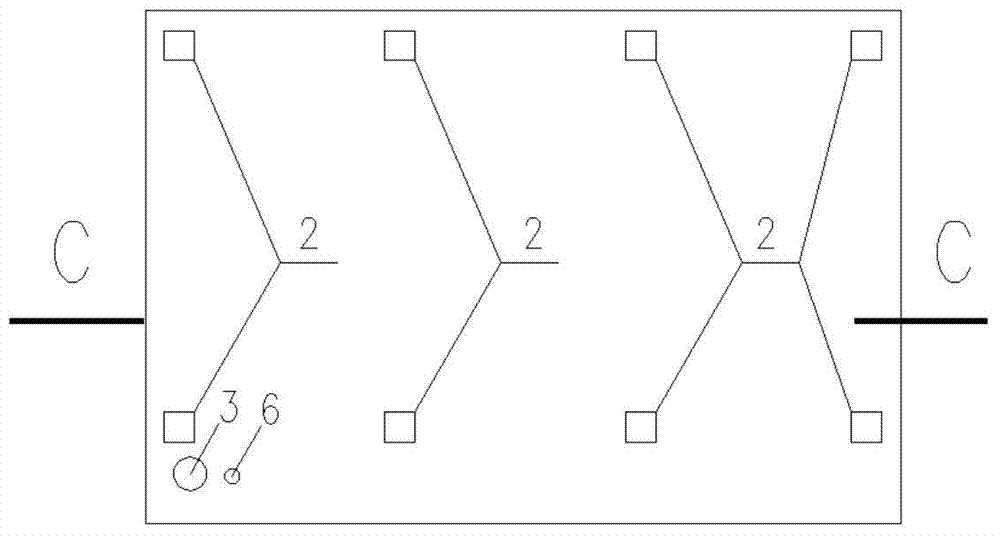

[0021] (2) if image 3 As shown in the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com