EMI shielding film magnetic control winding coating machine

A technology of shielding film and coating machine, applied in the field of EMI shielding film magnetron winding coating machine, can solve the problem of inability to evaporate high-melting-point materials and multi-component materials, and achieve the improvement of the overall deposition rate, strong applicability, and flexible combination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

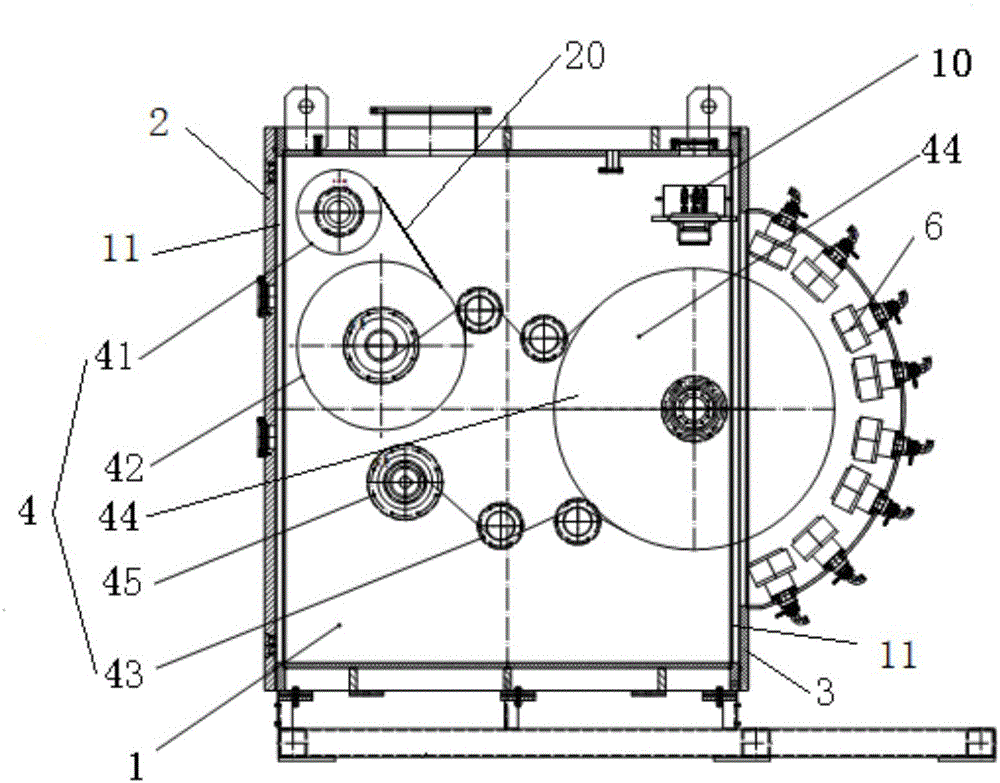

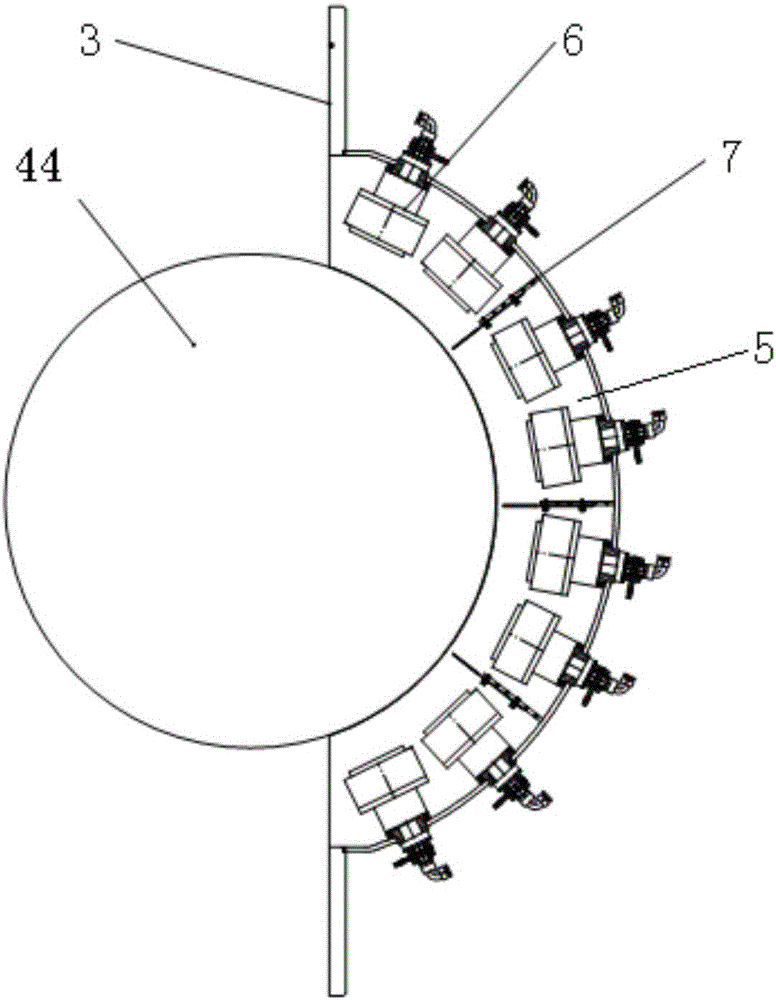

[0028] Such as figure 1 As shown, a kind of EMI shielding film magnetron roll-to-roll coater of the present invention comprises vacuum chamber body 1, door body 2 and target chamber 3, and described vacuum chamber body 1 is provided with winding roll system 4 and ion Source 10, the target chamber is provided with a planar magnetron target system, and the winding roll system 4 includes a protective film winding roll 41, an unwinding roll 42, four guide rolls 43, a low-temperature coating roll, and a protective film wound sequentially. 44 and winding roll 45, the right side of the low temperature coating roll 44 is partially placed in the target chamber 3, the planar magnetron target system includes four target working sections 5, each target working section 5 is provided with a pair of The planar magnetron target 6, the adjacent target working area 5 is separated by the partition plate 7, and each planar magnetron target 6 is arranged around the low-temperature coating roll 44 ...

Embodiment 2

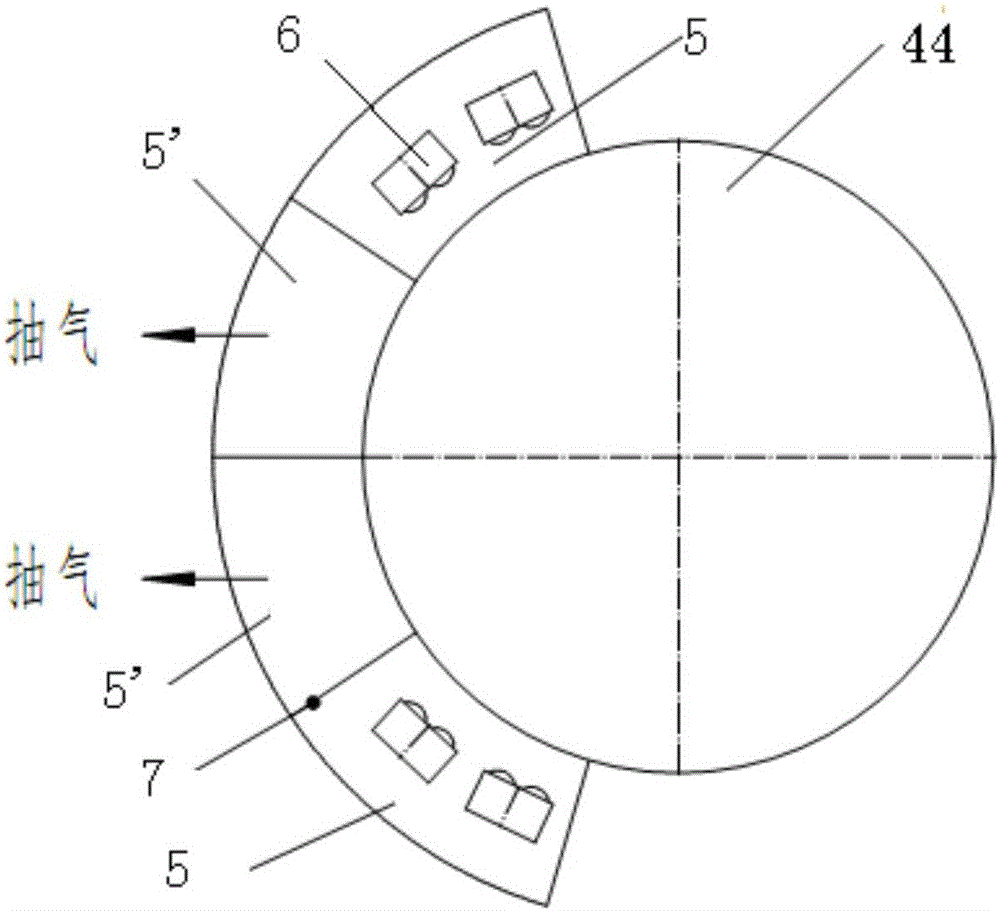

[0037] This embodiment is basically the same as Embodiment 1, the difference is that: there are four target working areas 5, and the two target operating areas 5 placed in the middle are air extraction compartments 5 without planar magnetron targets 6 installed. ', there are two planar magnetron targets 6 in the target working area 5 placed on both sides, so that the different gases in the front and back areas can be effectively blocked to achieve the effect of not affecting each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com