Patents

Literature

45results about How to "Precise control of filling volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

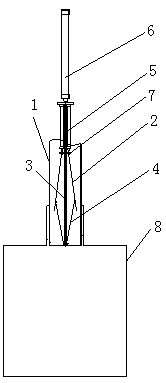

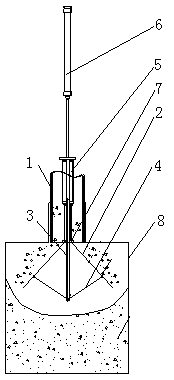

Filling method of phase-change material in phase-change heat pipe

InactiveCN103075904AIncrease temperatureFast filling speedIndirect heat exchangersLiquid statePhase change

The invention discloses a filling method of a phase-change material in a phase-change heat pipe, and the phase-change material is octadecane. The filling method is characterized in that the temperature is greater than 90 DEG C when the phase-change material is filled. According to the filling method, the temperature is increased when the phase-change material is filled, the phase-change material is enabled to be in a liquid state, the filling speed of the phase-change material can be increased, and the filling quantity of the phase-change material can be accurately controlled, thereby eliminating adverse effects on the phase-change heat pipe due to over filling or less filling, so that the safety and the reliability of the phase-change heat pipe are guaranteed.

Owner:SHANGHAI SATELLITE ENG INST

Filling system and filling method by utilizing filling system

ActiveCN104370258AHigh speedReduce generationFilling without pressureLow speedMechanical engineering

Owner:广州隆宝科技技术有限公司

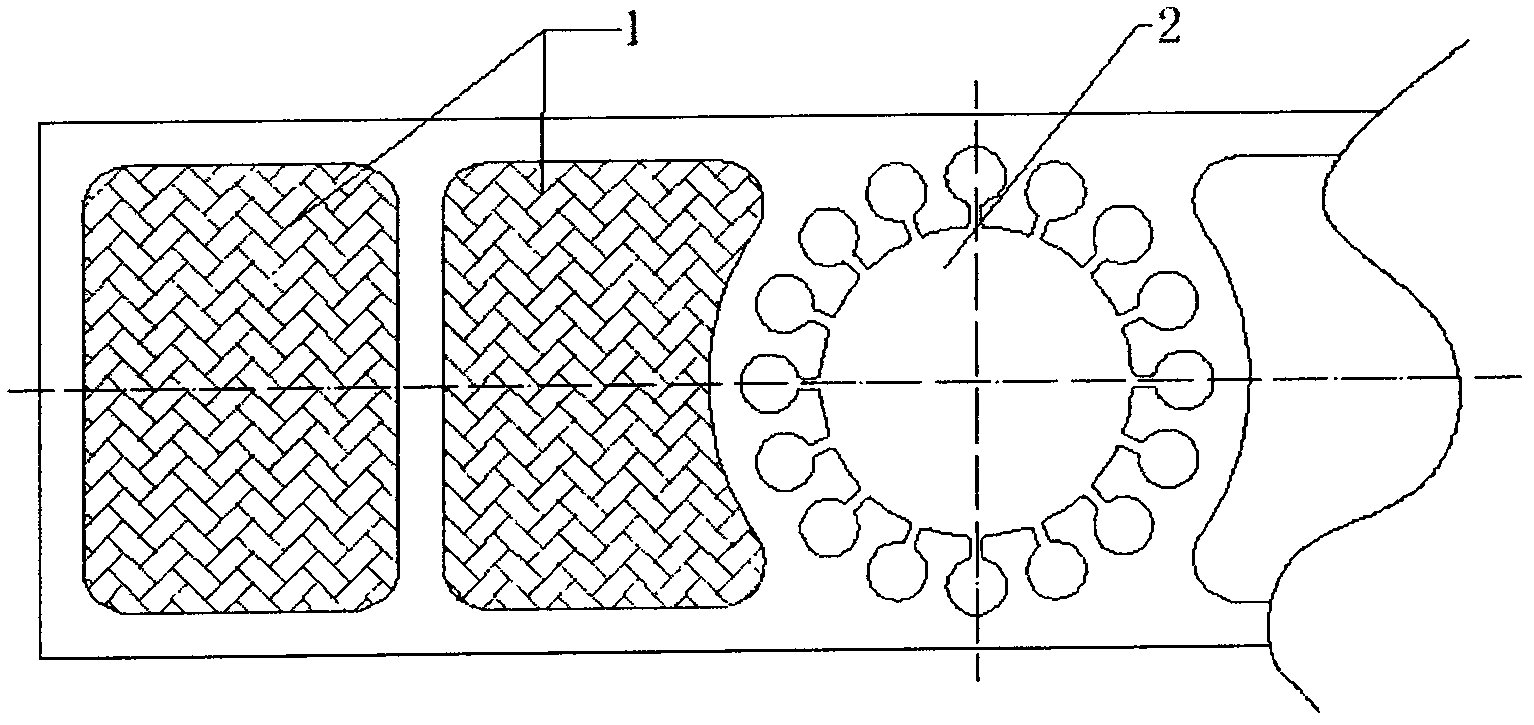

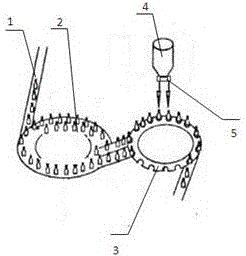

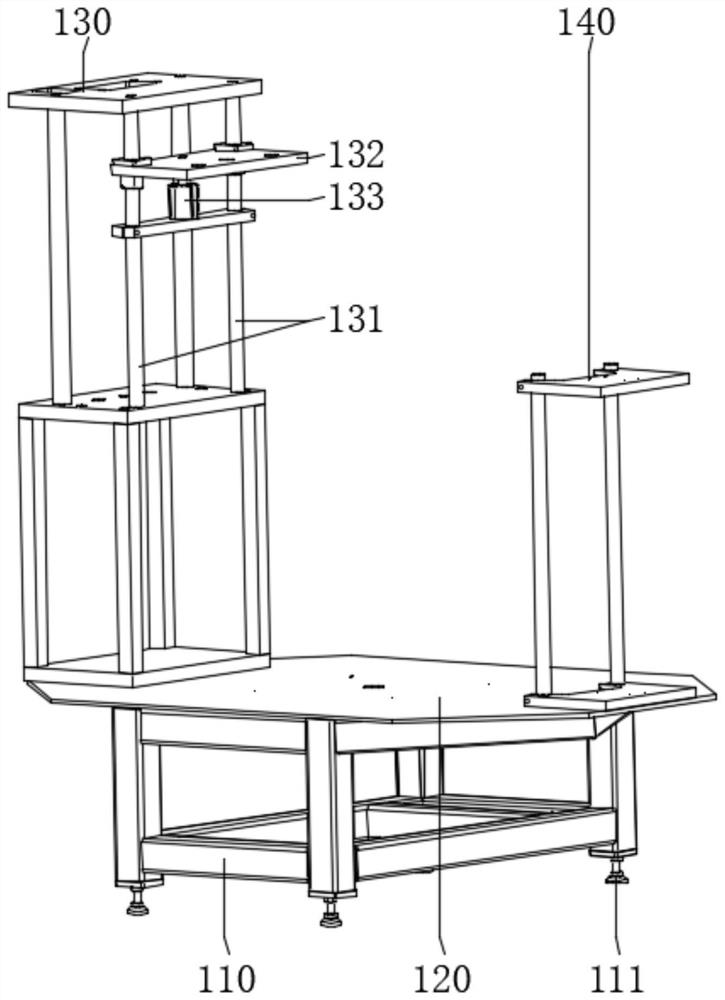

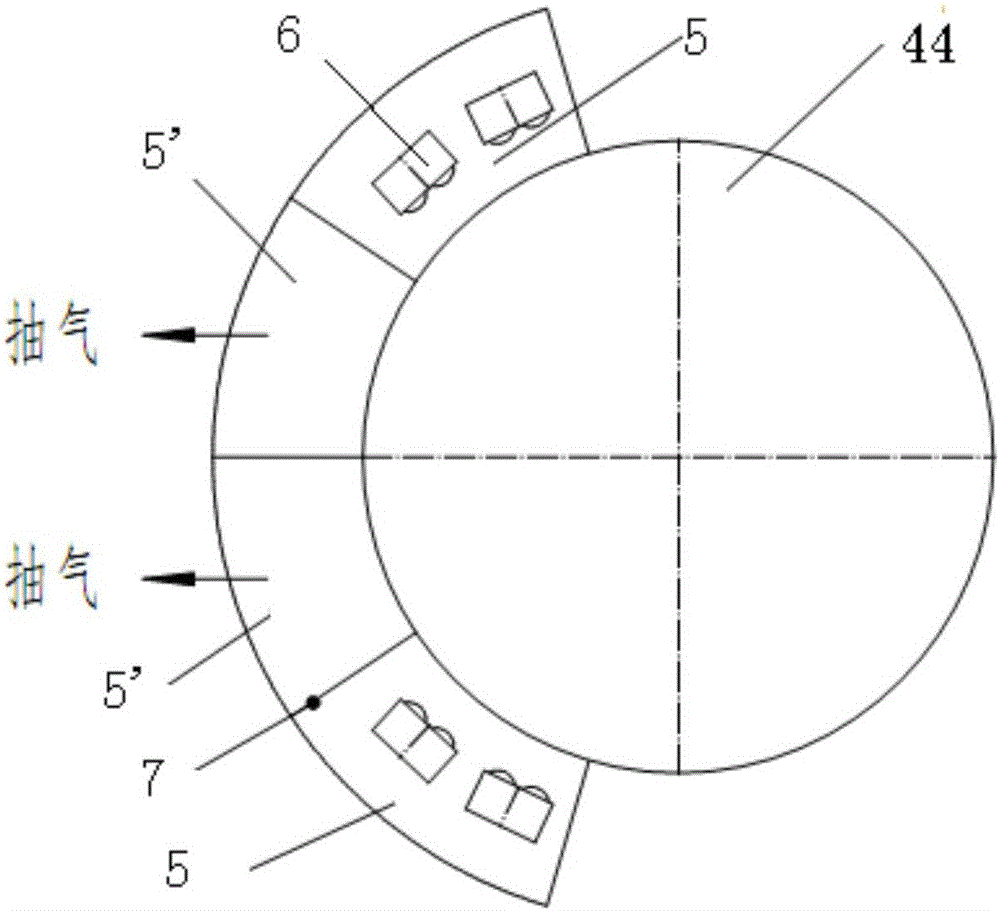

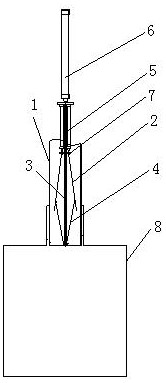

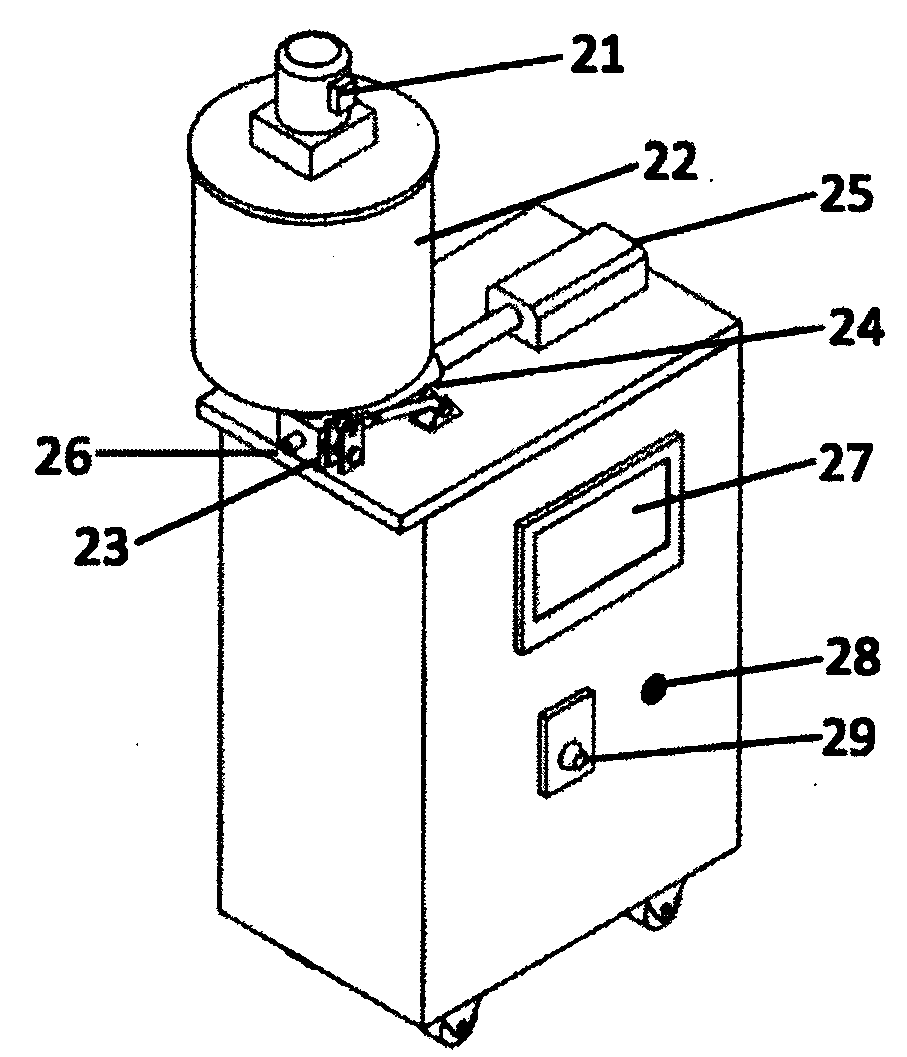

Alloy filling device for pipe bending and filling method thereof

The invention discloses an alloy filling device for pipe bending. The alloy filling device comprises a control system, a low temperature alloy fusion bath, an alloy filling device body, a water bath device comprising a water bath with the water temperature controlled from 30 DEG C to 35 DEG C, a rotating work table and a press machine. A control switch electrically connected with the control system and used for controlling the flow of low temperature alloy is arranged at the discharge port of the alloy filling device body. The rotating work table is arranged in an inclined mode, the included angle between the plane where the rotating work table is located and the horizontal direction ranges from 15 degrees to 30 degrees, and a motor drives the rotating work table to rotate. A plurality of stations where pipe blanks are placed are arranged on the rotating work table in the circumferential direction, the station for filling in the rotating work table is located right below the discharge port, and the station for machining in the rotating work table is located close to the press machine. The rotating work table and the to-be-filled pipe blanks at the station for filling are soaked in the water bath. The alloy filling device has the advantages that the structure is compact, the temperature control effect is better, the low temperature alloy filling effect is better, the cooling mode is more reasonable, and the rejection rate of pipe bending can be controlled better.

Owner:NINGBO SIMING AUTOMOBILE TECH

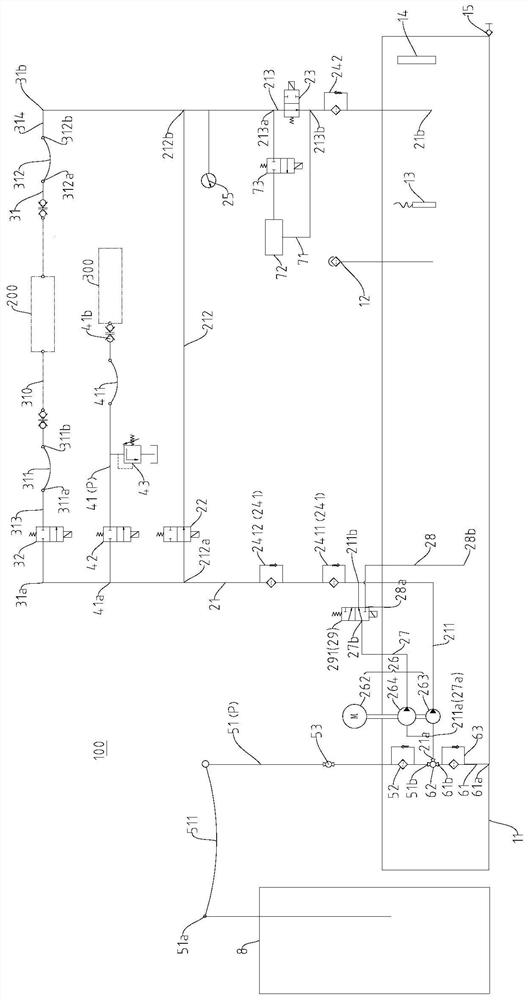

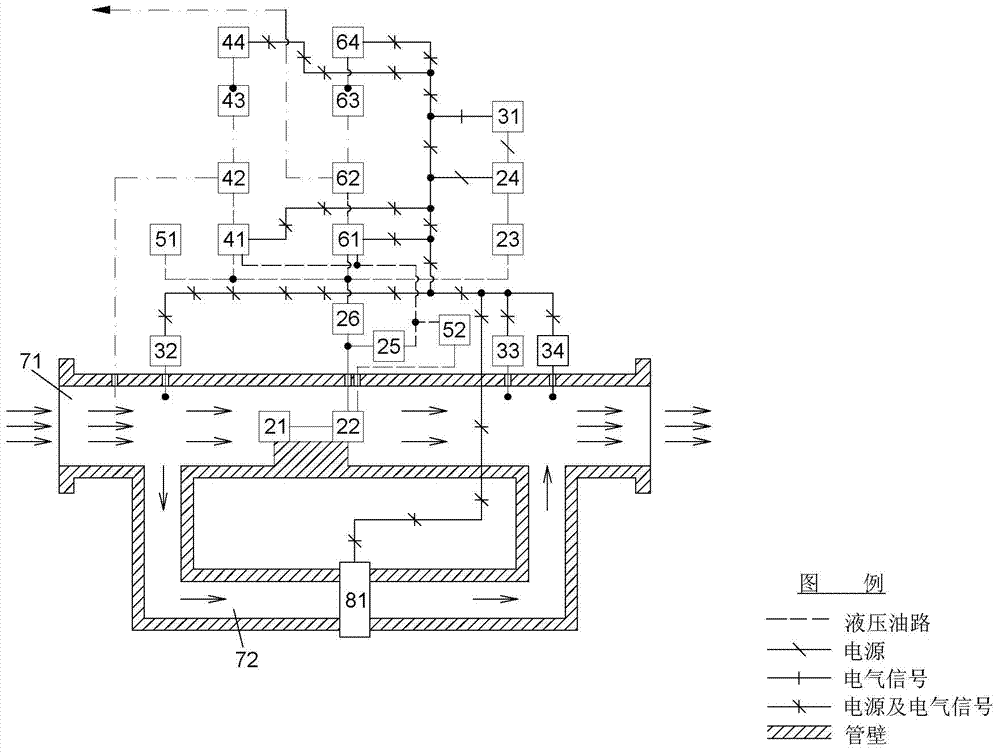

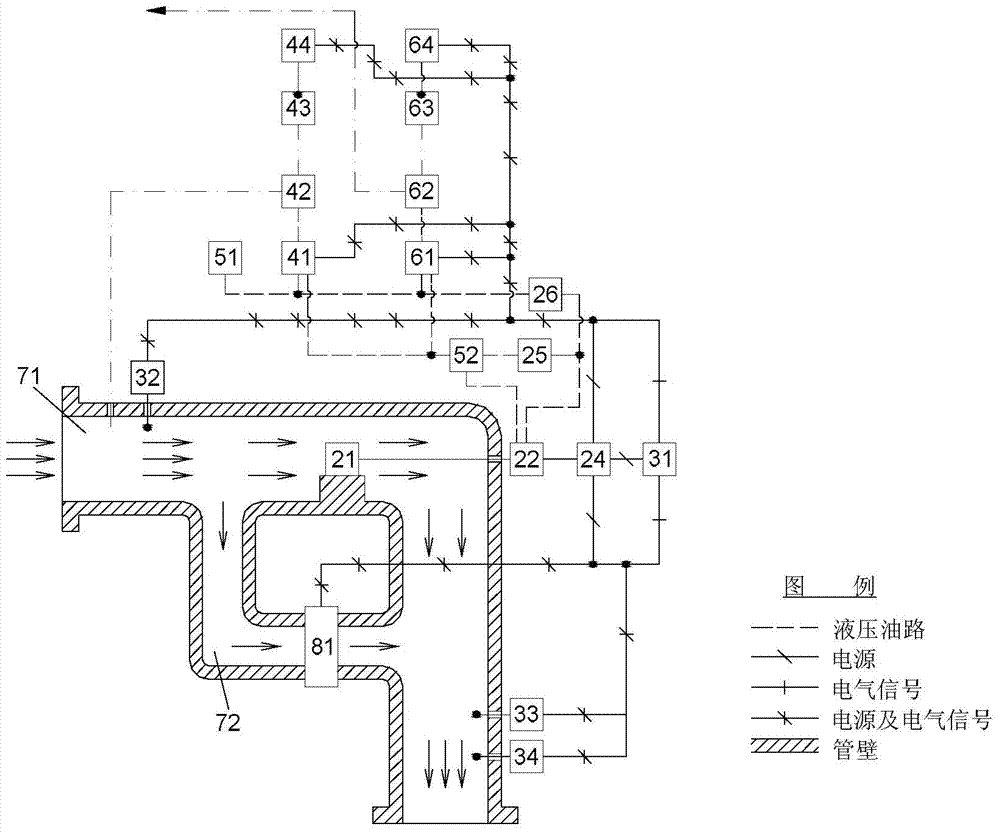

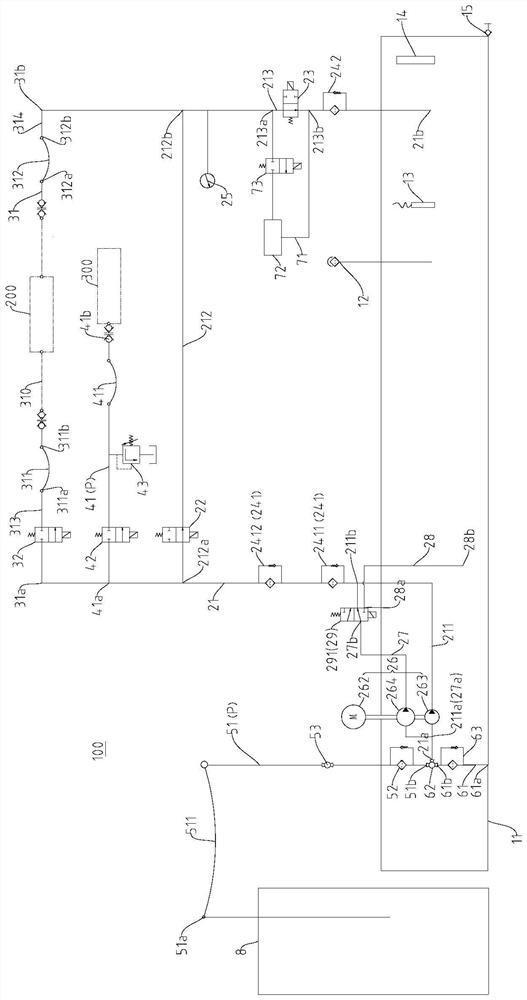

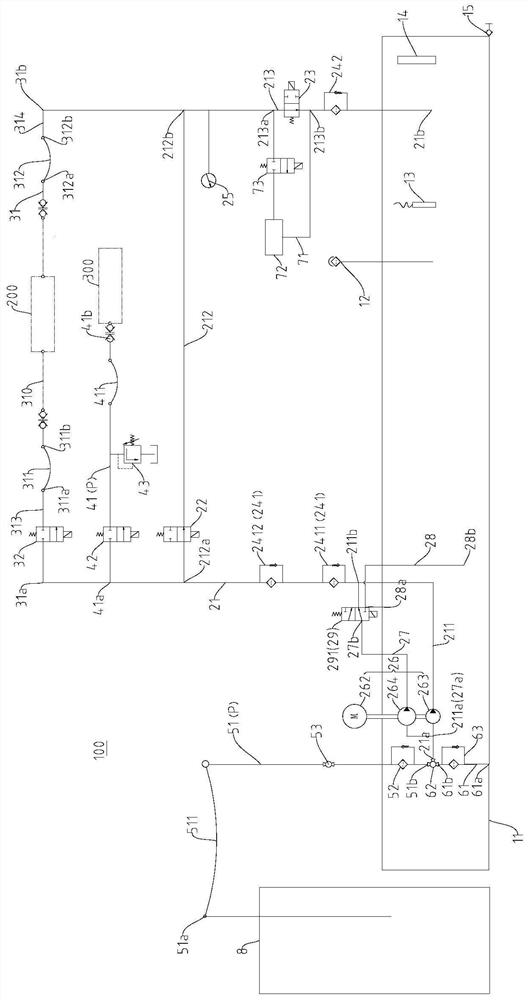

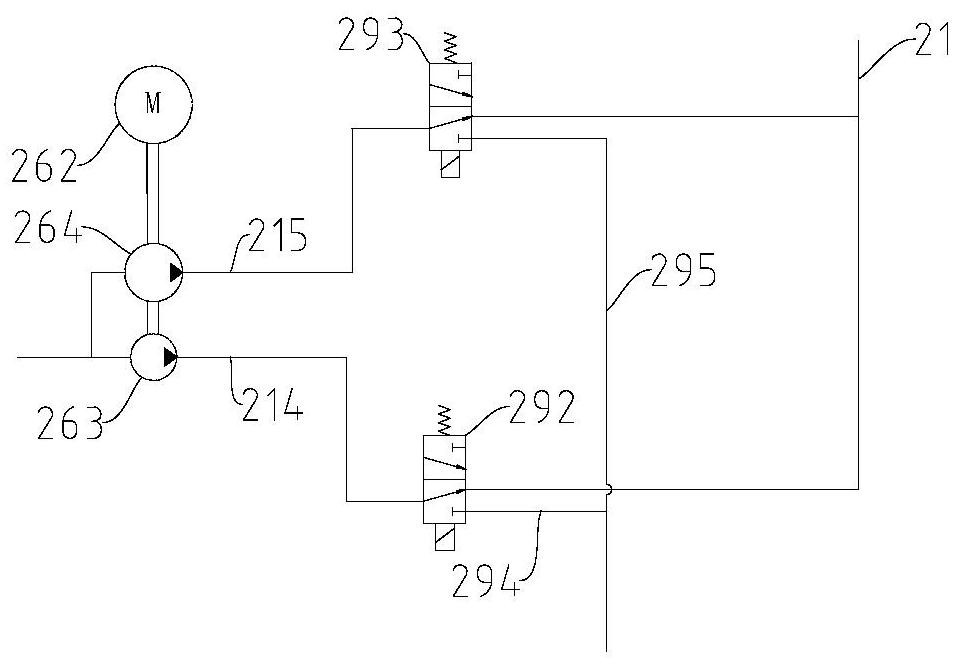

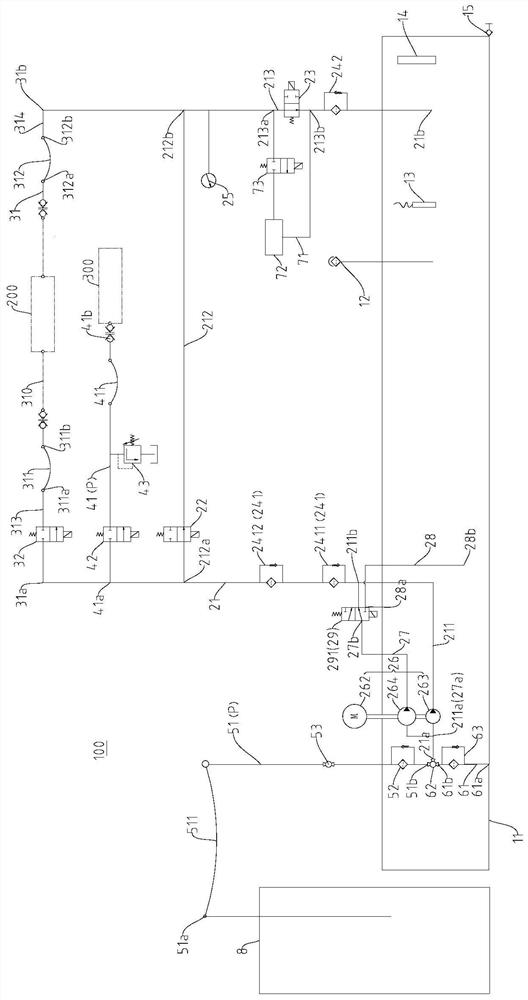

Equipment for processing vehicle hydraulic brake system

ActiveCN112576577AEasy to useIncrease profitServometer circuitsFluid-pressure actuator componentsMarine engineeringHydraulic brake

The invention discloses equipment for processing a vehicle hydraulic braking system. The equipment comprises an equipment oil tank, a main pipeline and an oil filling pipeline, wherein the inlet end and the outlet end of the main pipeline are both in communication to the equipment oil tank, the oil filling pipeline comprises at least one of an external oil filling pipeline and an internal oil filling pipeline, the inlet end of the external oil filling pipeline communicates with the equipment oil tank, the outlet end of the external oil filling pipeline is used for refueling an oil tank of thevehicle hydraulic braking system, the outlet end of the internal oil filling pipeline communicates with the equipment oil tank, and the inlet end of the internal oil filling pipeline is located outside the equipment oil tank and used for refueling the equipment oil tank. According to the equipment for processing the vehicle hydraulic braking system, the oil filling pipeline is arranged, so that the equipment has at least one of the functions of self oil filling and external oil filling, and the equipment is convenient to use.

Owner:BYD CO LTD

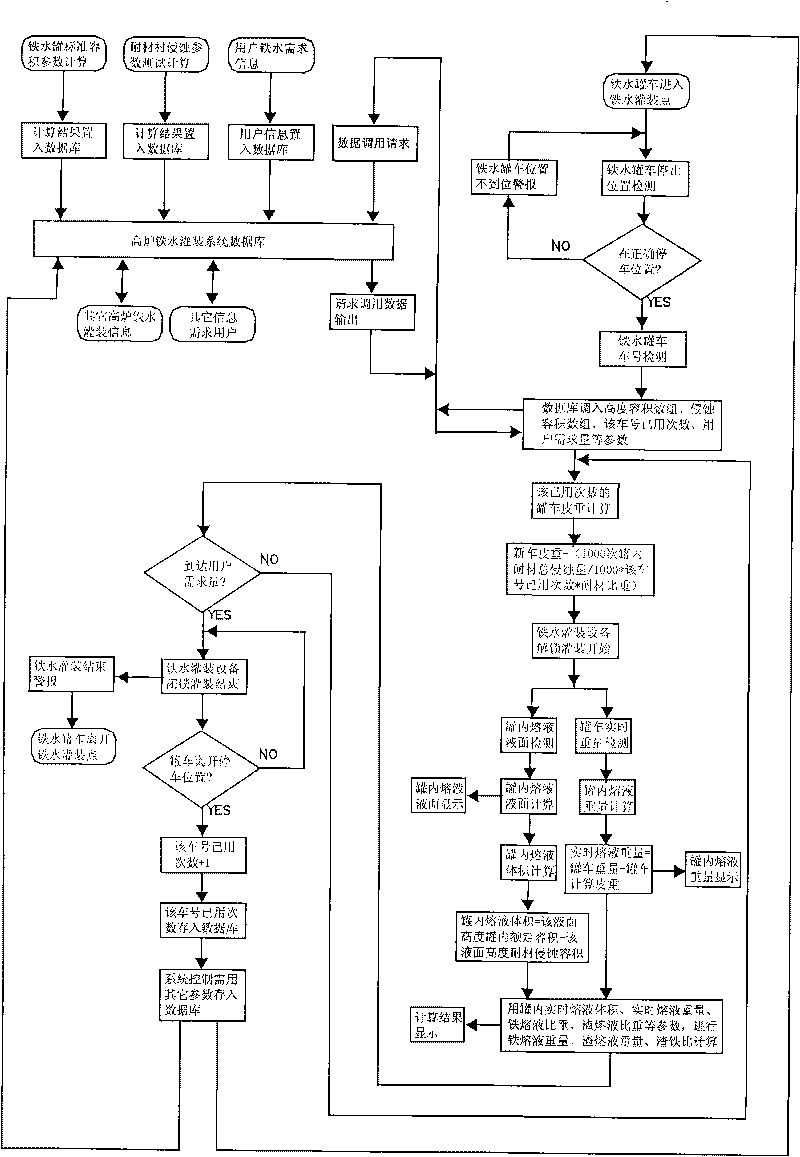

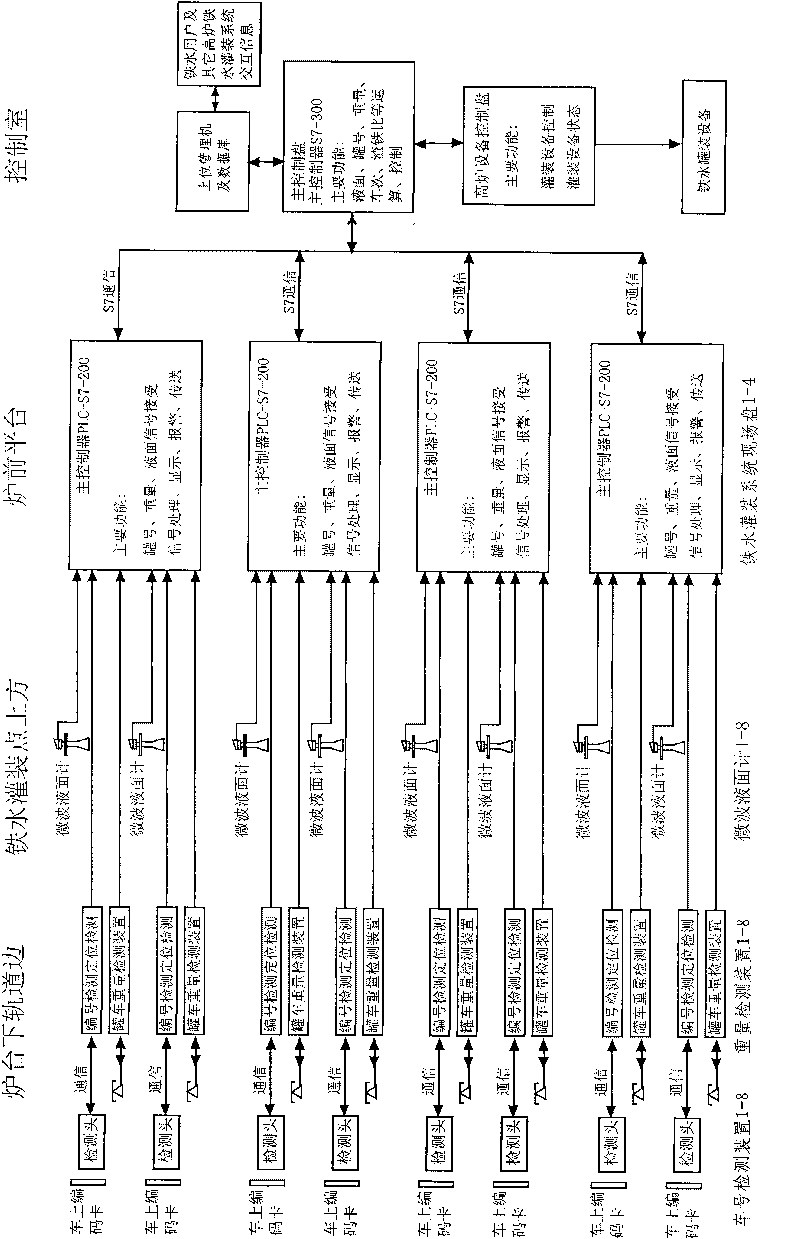

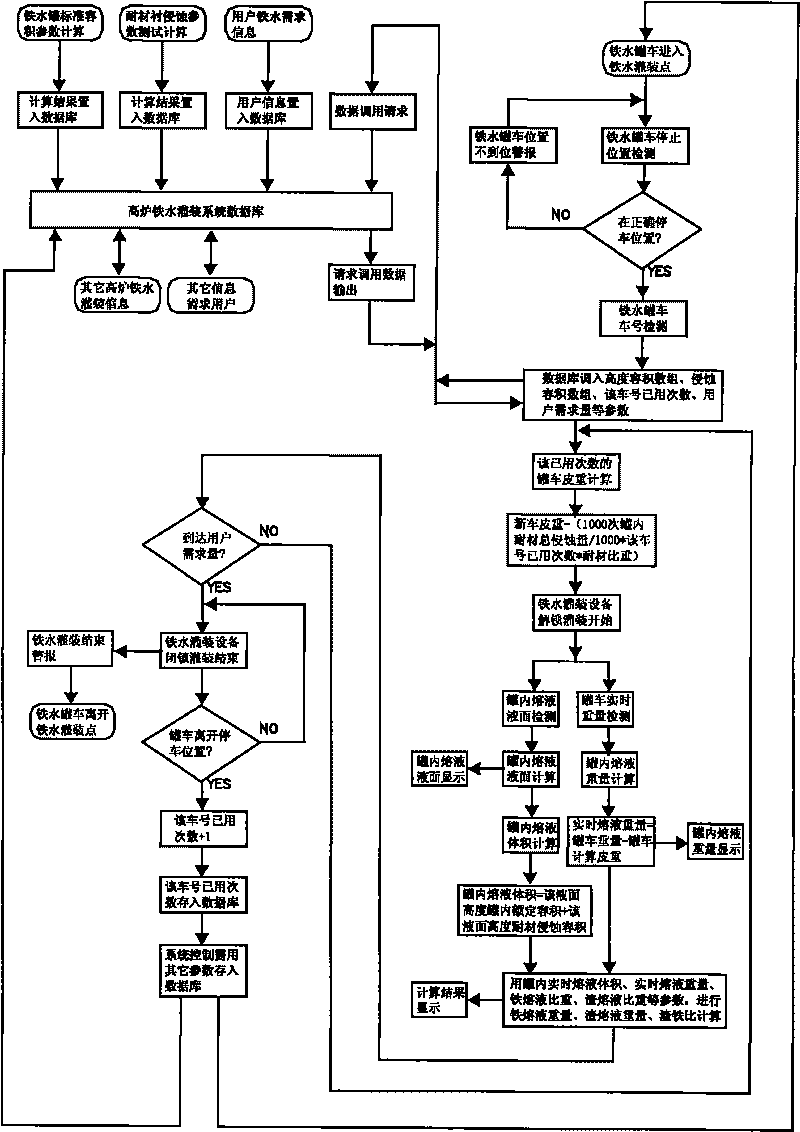

Method for controlling filling quantity of slag-iron mixed molten liquid in ladle of ladle car

InactiveCN101727109AControl filling volumeThe calculation result is accurateMelt-holding vesselsLevel controlSlagFerric

The invention relates to a method for controlling the filling quantity of slag-iron mixed molten liquid in a ladle when molten iron is filled into a ladle car from a metallurgical blast furnace tap hole. The control method comprises the following steps of: obtaining the gross weight of the ladle car through a weighing type weight detecting device, and then obtaining the real-time weight of the slag-iron mixed molten liquid in the ladle through a series of computations; obtaining the liquid level of the slag-iron mixed molten liquid in the ladle through the detection of a molten iron liquid level detecting device, and further computing the real-time volume of the slag-iron mixed molten liquid in the ladle; and then further computing the slag-iron proportion and the slag-iron weight of the slag-iron mixed molten liquid in the ladle by utilizing the real-time weight and volume of the slag-iron mixed molten liquid in the ladle so as to control the filling quantity of the slag-iron mixed molten liquid in the ladle. The automatic detection count for the used times of the ladle of the ladle car is introduced into computation, and a ladle volume increment parameter and a ladle car tare parameter under the specific used times of the ladle are obtained to participate in the computation, so that a computed result is more accurate. The invention enables the filling quantity of the ladle to be more accurate.

Owner:BAOSHAN IRON & STEEL CO LTD

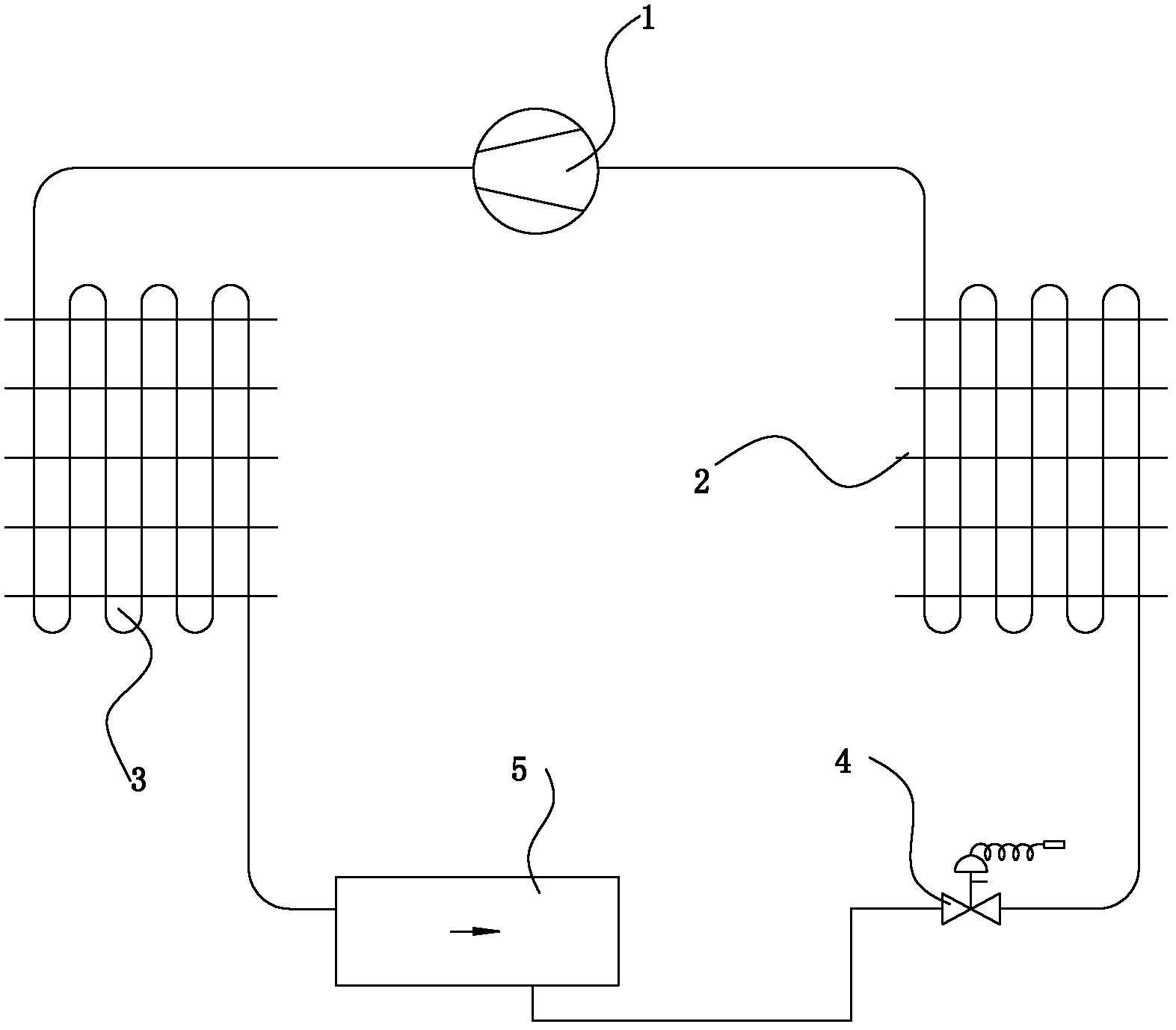

Heat pump system and flow measuring method thereof

InactiveCN102425891APrecise control of filling volumeEasy to measureHeat pumpsVolume/mass flow by electromagnetic flowmetersImpellerMagnetic poles

The invention discloses a heat pump system comprising a first heat exchanger, a second heat exchanger, a compressor and a throttling element which are connected through connecting pipes to form a heat exchange working medium circulation loop, wherein a heat exchange working medium flow meter is arranged on the heat exchange working medium circulation loop, the heat exchange working medium flow meter comprises a shell, an inlet and an outlet are arranged on the shell, a rotating shaft is arranged in the shell, an impeller is arranged on the rotating shaft and between the inlet and the outlet, a magnetic pole is arranged on the rotating shaft, a coil corresponding to the magnetic pole is arranged on the shell, and the coil is electrically connected with a signal analyzing and processing device. The heat pump system disclosed by the invention can more conveniently measure the flow rate of the heat exchange working medium in the heat pump system, and has important directive significance on mass production of new products such as air conditioner or heat pump water heaters and the like.

Owner:苏宇贵

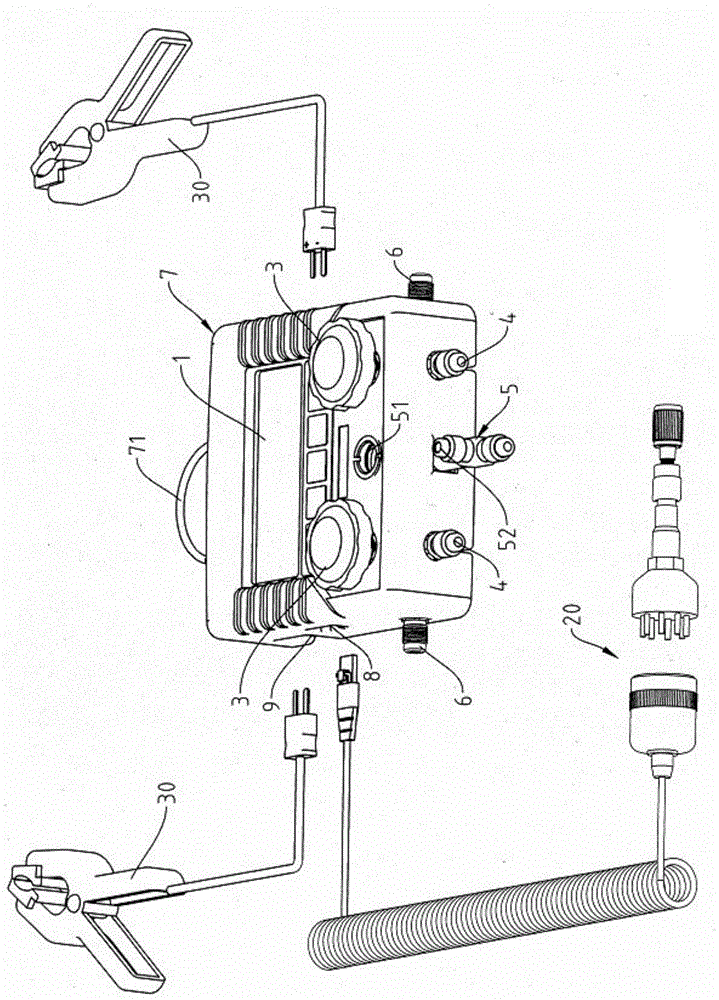

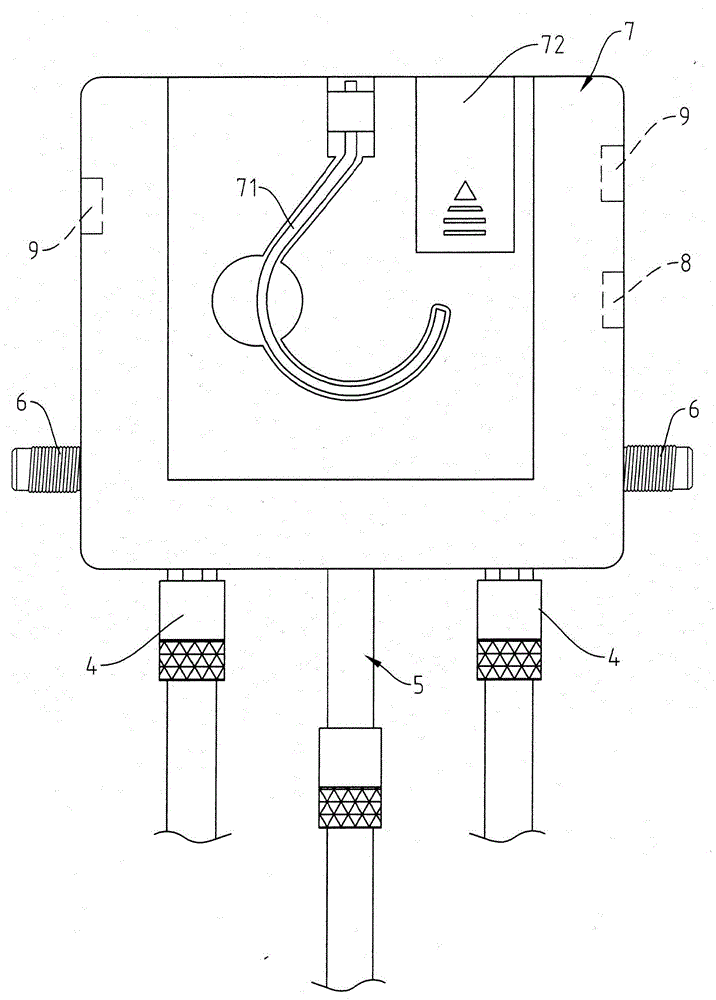

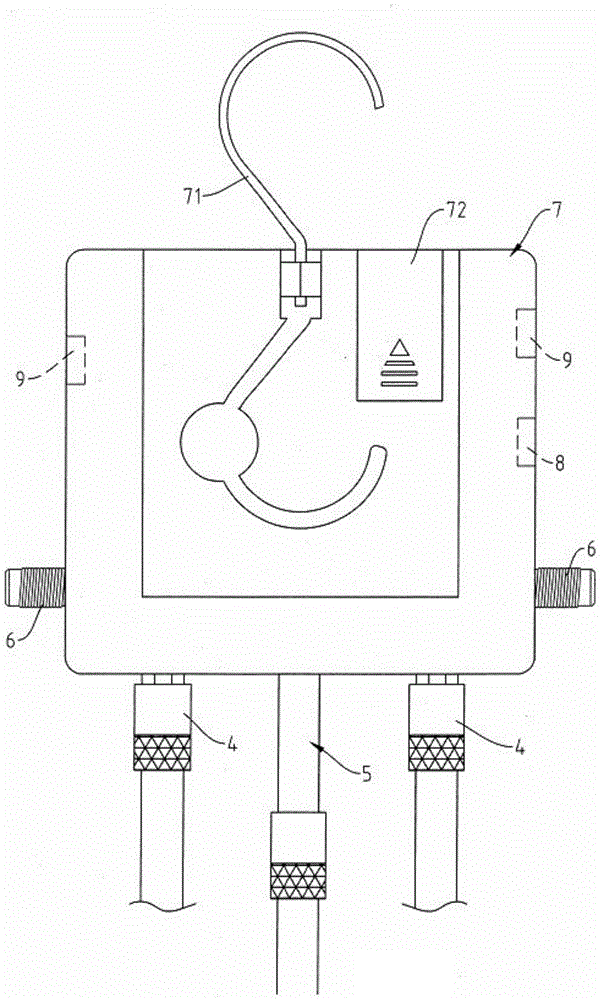

Electronic digital type multifunctional refrigerant pressure meter set

InactiveCN104677546AAccurately know the filling statusPrecise control of filling volumeVacuum gauge using heat conductivity variationLow voltageDisplay device

The invention discloses an electronic digital type multifunctional refrigerant pressure meter set. A housing mainly internally comprises a display, a high / low-voltage temperature inductor, a control switch, a high / low-voltage supply and convey tube and a refrigerant conveying tube, wherein side tubes are fixed at the two sides of the housing; a detachable hanger is arranged on the back surface of the housing; the high / low-voltage temperature inductor of the display of the refrigerant pressure meter set is connected with the control switch; the control switch can be used for controlling refrigerant input amount of the high / low-voltage supply and convey tube; the control switch is connected with the refrigerant conveying tube; the refrigerant pressure meter set circuit comprises a micro processor, an operational amplifier and a multiplexing analog digital converters; a high / low-voltage temperature induction connecting head and a vacuum sensing joint are input to the micro processor after passing through the operational amplifier and the multiplexing analog digital converters; the refrigerant pressure meter set is further provided with the vacuum sensing joint and the high / low-voltage temperature induction connecting head. Operation staff can precisely obtain a refrigerant filling state, so that the refrigerant filling achieves precise value control, and the refrigerant filling amount is precisely controlled.

Owner:SICHUAN FEDSTORE TECH

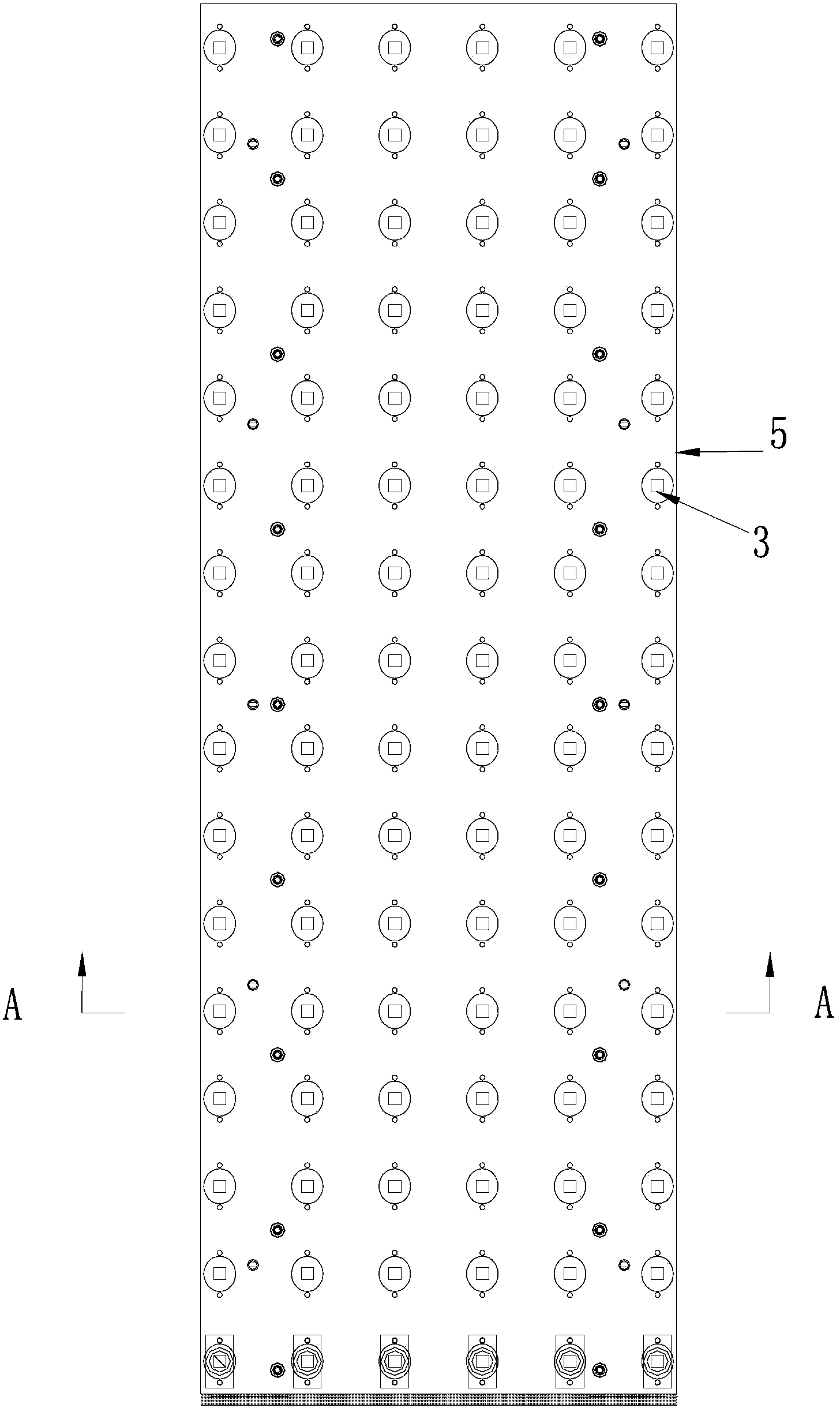

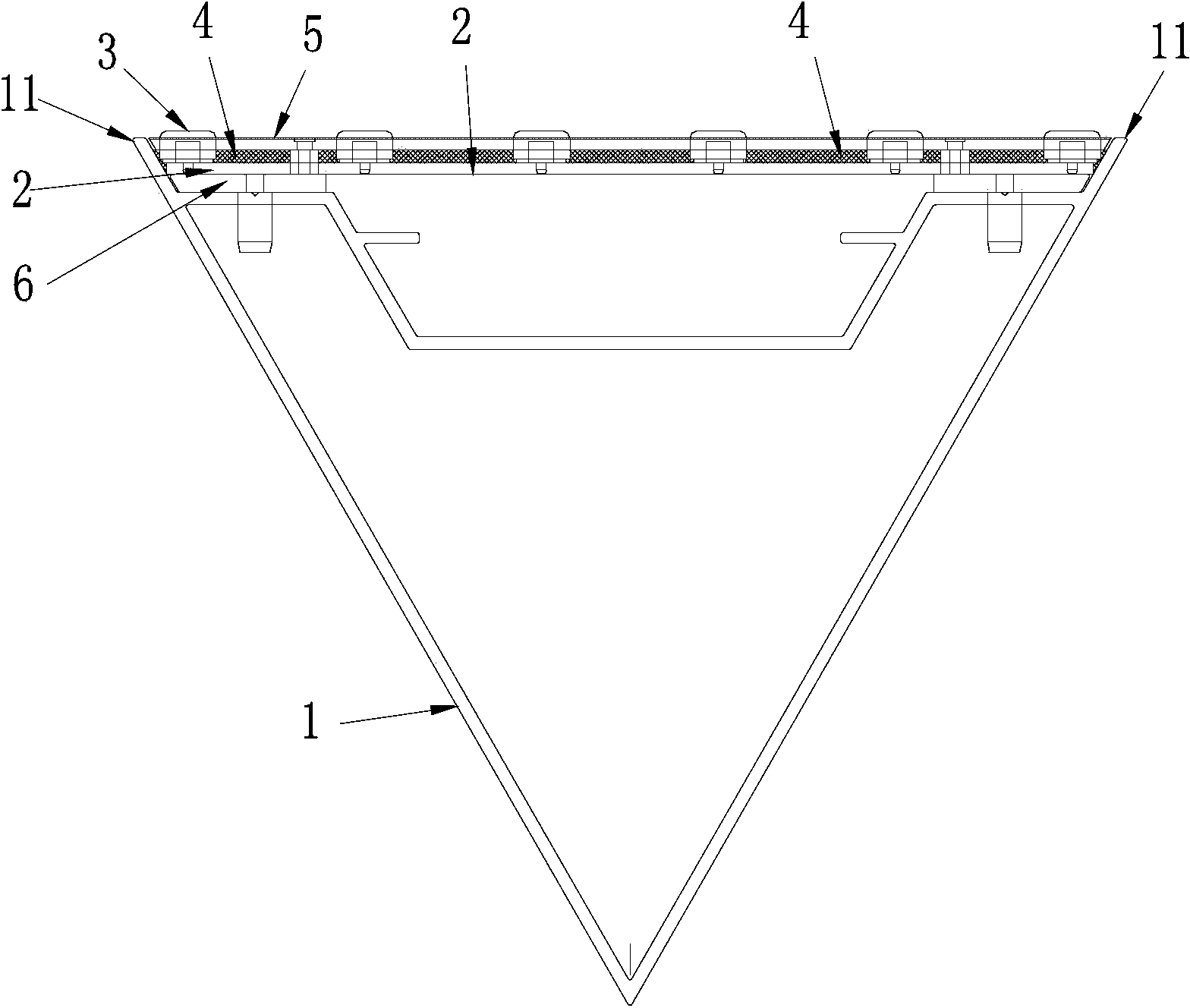

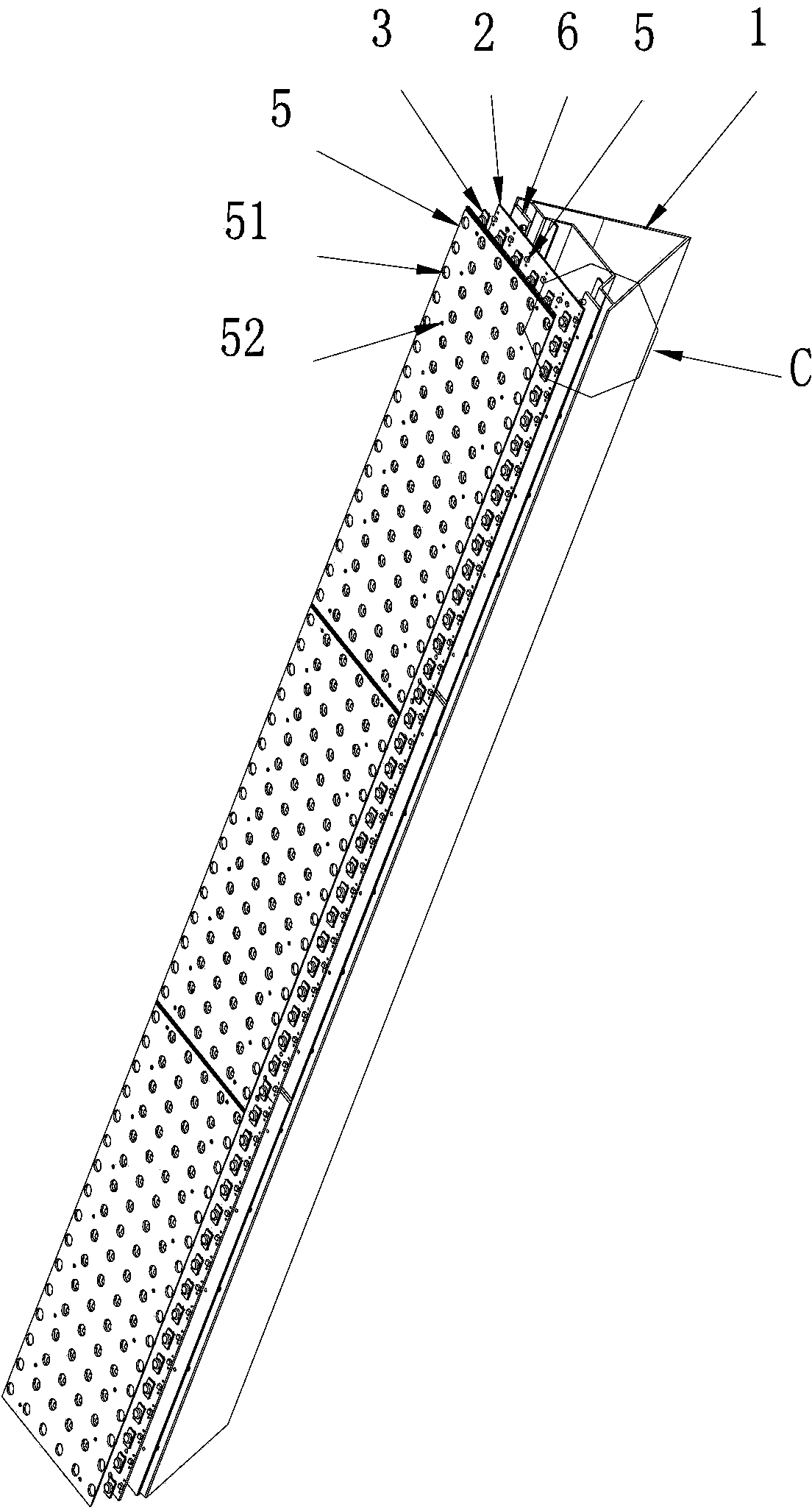

LED two-sided overturning advertisement board structure

ActiveCN102750883BEliminate the problem of leakageImprove reliabilityIdentification meansEngineeringLight head

The invention relates to an LED two-sided overturning advertisement board structure which comprises a triangular prism two-sided aluminum profile and a PCB (Printed Circuit Board) arranged on one side face of the two-sided aluminum profile from bottom to top, wherein a plurality of LED lamps are uniformly arranged on the PCB, and a plurality of independent lamp holders for covering respective LED lamps are mutually independently arranged on the PCB; and extension edges are extended from another two intersecting side faces of the two-sided aluminum profile along the opening direction of an included angle, and a sealing layer is filled in a space surrounded by the extension edges, the PCB and the independent lamp holders. In the invention, the independent lamp holders are adopted and the sealing layer is filled in the whole surface, so that uneven illumination is prevented, the problem that the LED advertisement board is soaked by rainwater in outdoor use is effectively eliminated, the quality reliability and the service life of the advertisement board are increased, and the maintenance frequency is reduced. Meanwhile, the filling amount can be accurately controlled, efficient and automatic production is realized, the processing cost is greatly lowered, and the production efficiency is increased.

Owner:SICHUAN SIMOIRE SCI & TECH CO LTD

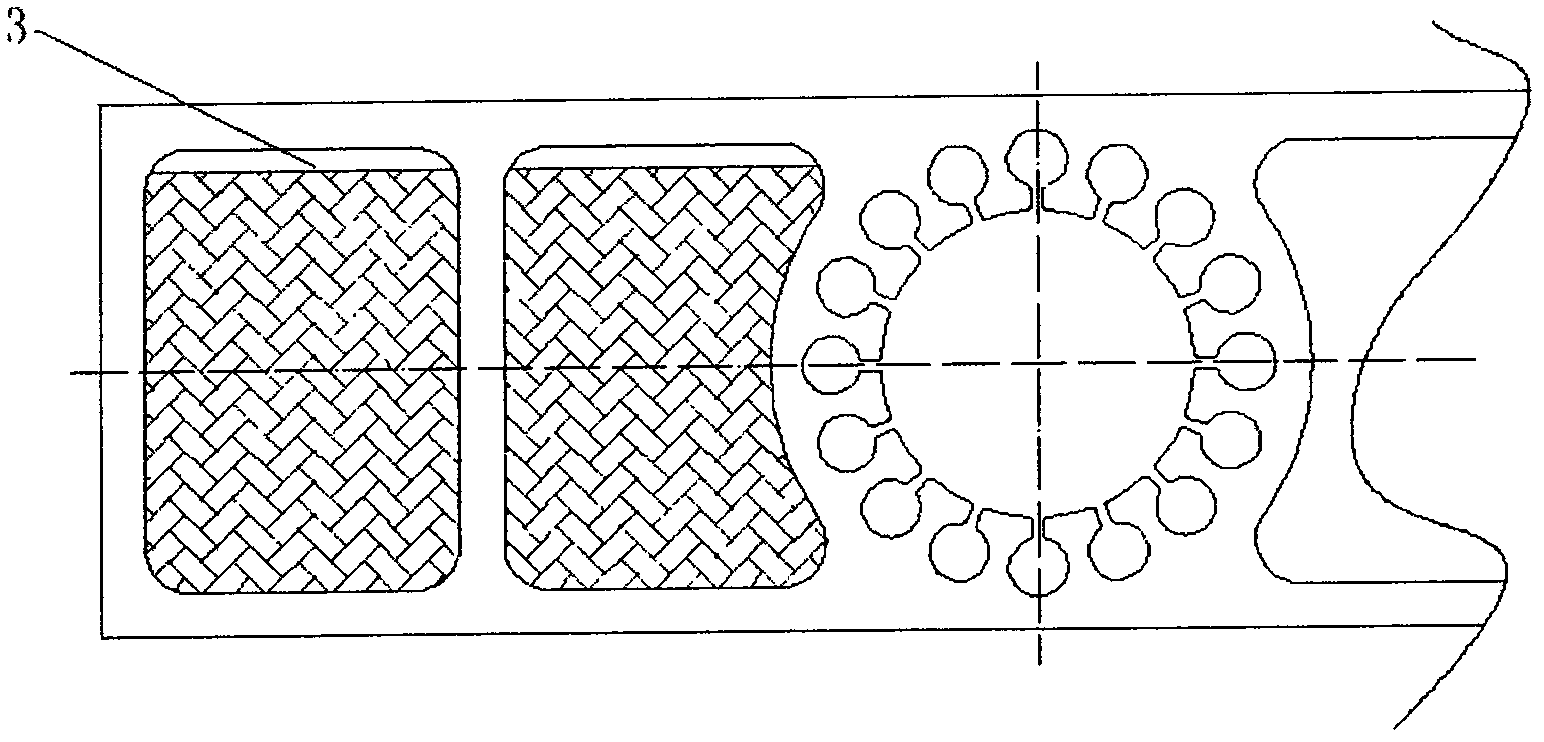

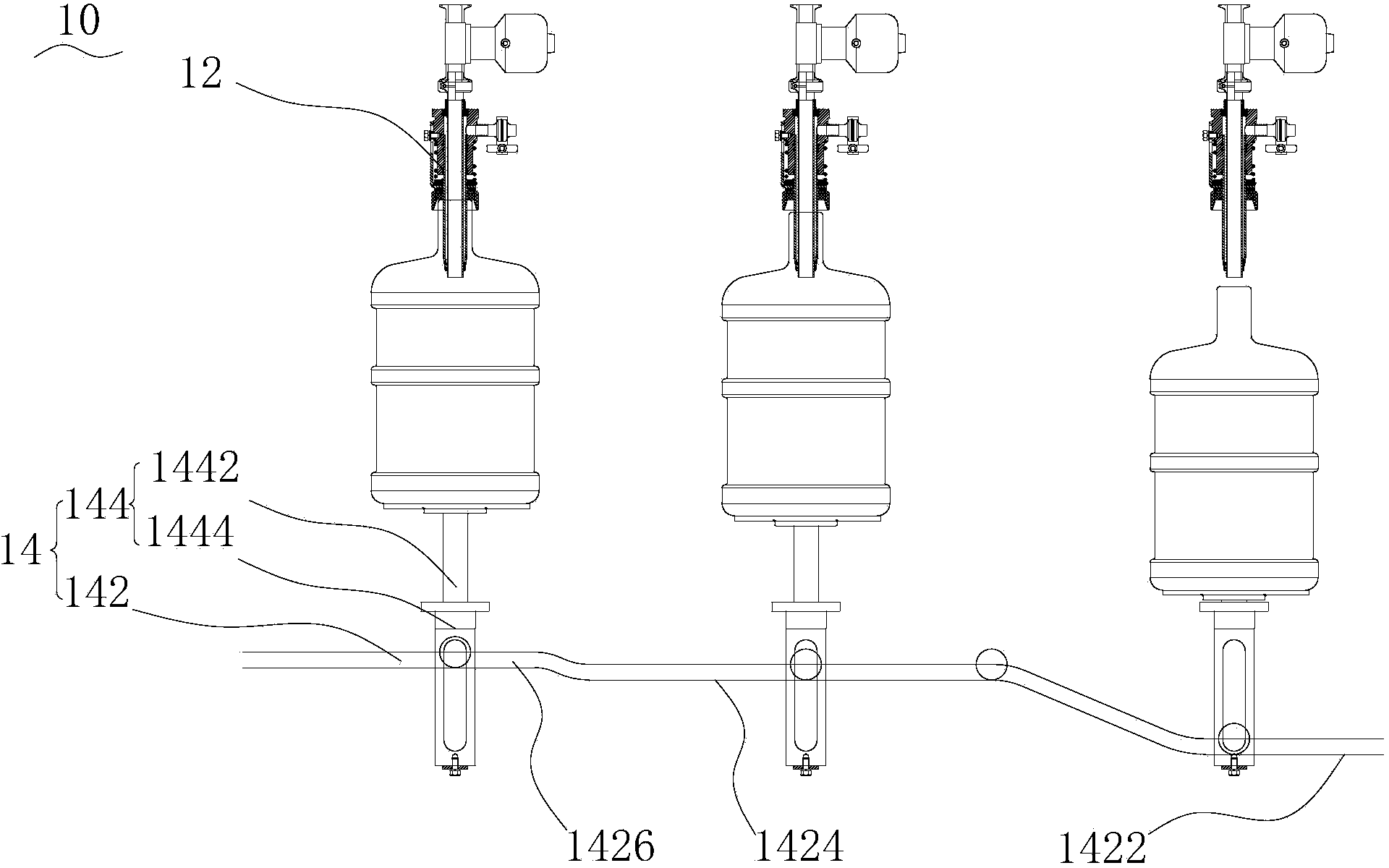

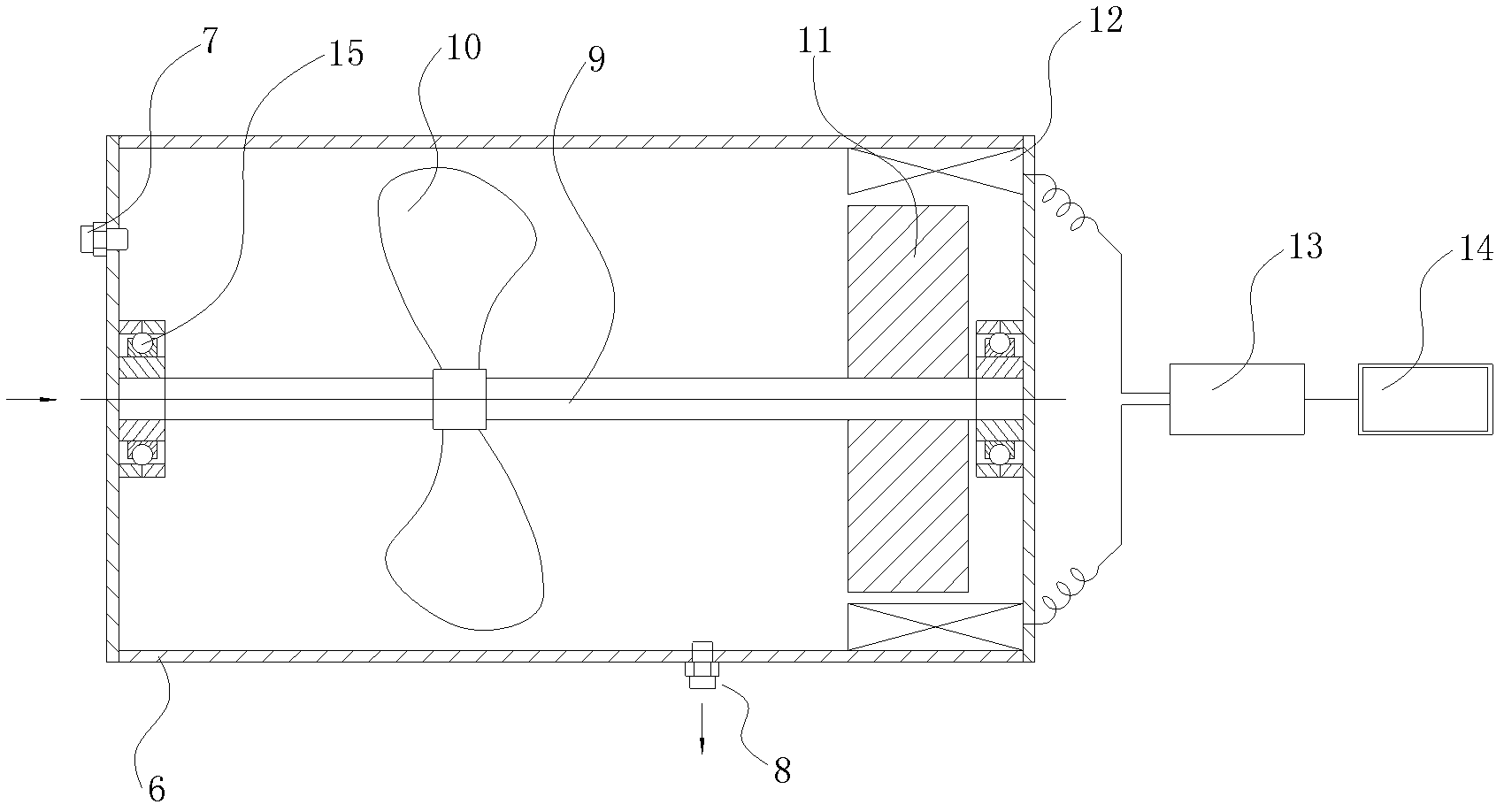

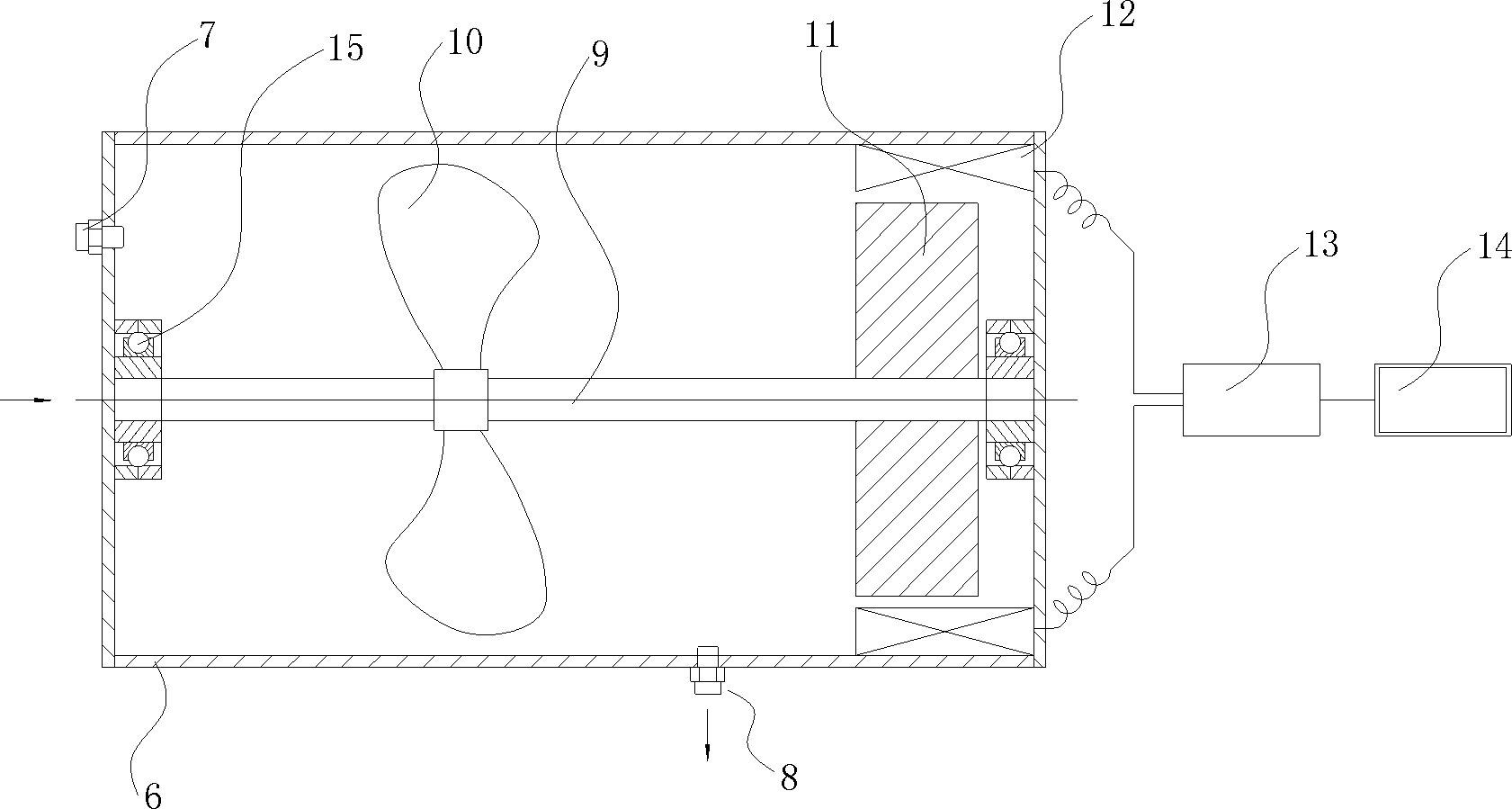

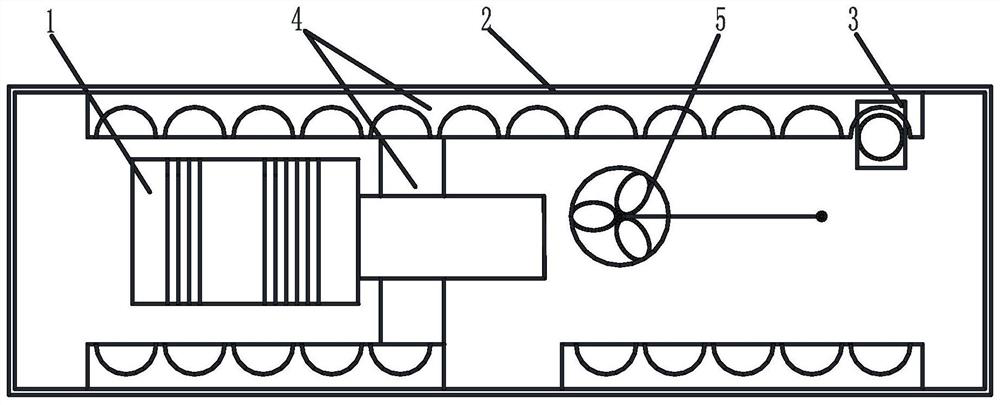

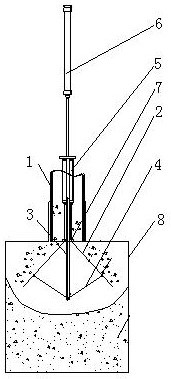

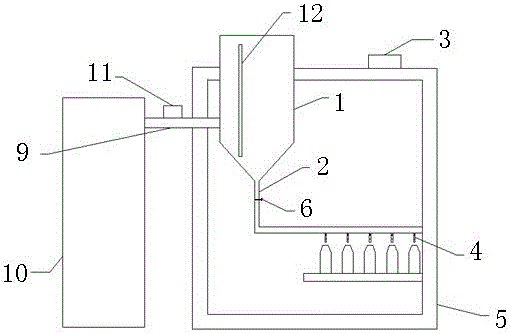

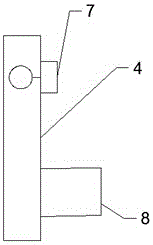

Movable skid-mounted gas cylinder group filling device and method

PendingCN111828838ARealize automatic controlPrecise control of filling volumeContainer filling methodsGas handling/storage purposeGas cylinderControl system

The invention provides a movable skid-mounted gas cylinder group filling device and method. The device comprises a temperature adjusting system, a cold and heat isolation cabinet body, a filling metering control system, a warm ventilation channel system and a hazardous gas detection ventilation system; the temperature adjusting system control the temperature in the cabinet; the cold and heat isolation cabinet body isolates heat conduction between the outside and the cabinet; the filling metering control system is used for controlling the filling amount and the filling program of a gas cylindergroup; the warm ventilation channel system ensures that the temperature around gas cylinders in the cabinet is uniform; the hazardous gas detection ventilation system is used for detecting environmental gas components in the cabinet body and automatically alarming and ventilation when hazardous gas leaks; and a filling cylinder group cabinet can control the environment temperature in the cabinetaccording to the filling medium requirement.

Owner:XINDI ENERGY ENG TECH

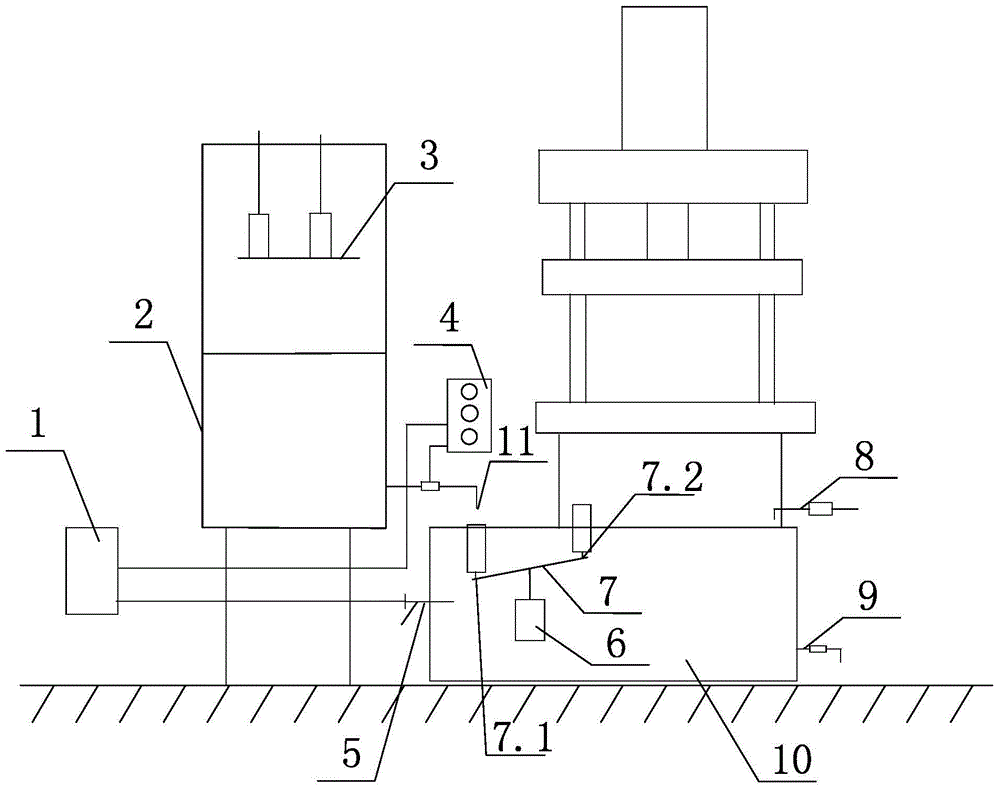

Chemical dosing device for natural gas pipeline

ActiveCN103663333AReduce fill volumePrecise control of filling volumeLiquid transferring devicesElectricityFirst Fill

The invention provides a chemical dosing device for a natural gas pipeline. The chemical dosing device for the natural gas pipeline comprises an energy conversion portion, a first filling portion and an electronic control unit. The energy conversion portion is used for converting pressure of natural gas in the natural gas pipeline into hydraulic energy and electric energy. The first filling portion is communicated with the energy conversion portion and is driven by the energy conversion portion to fill first filling agents into the natural gas pipeline. The electronic control unit is electrically connected with the energy conversion portion and the first filling portion and is used for controlling the filling amount of the first filling portion. By means of the chemical dosing device for the natural gas pipeline, chemical dosing can be carried out under the condition that no extra power source is added, and the chemical dosing amount can be accurately controlled.

Owner:BEIJING LINKFORTUNE

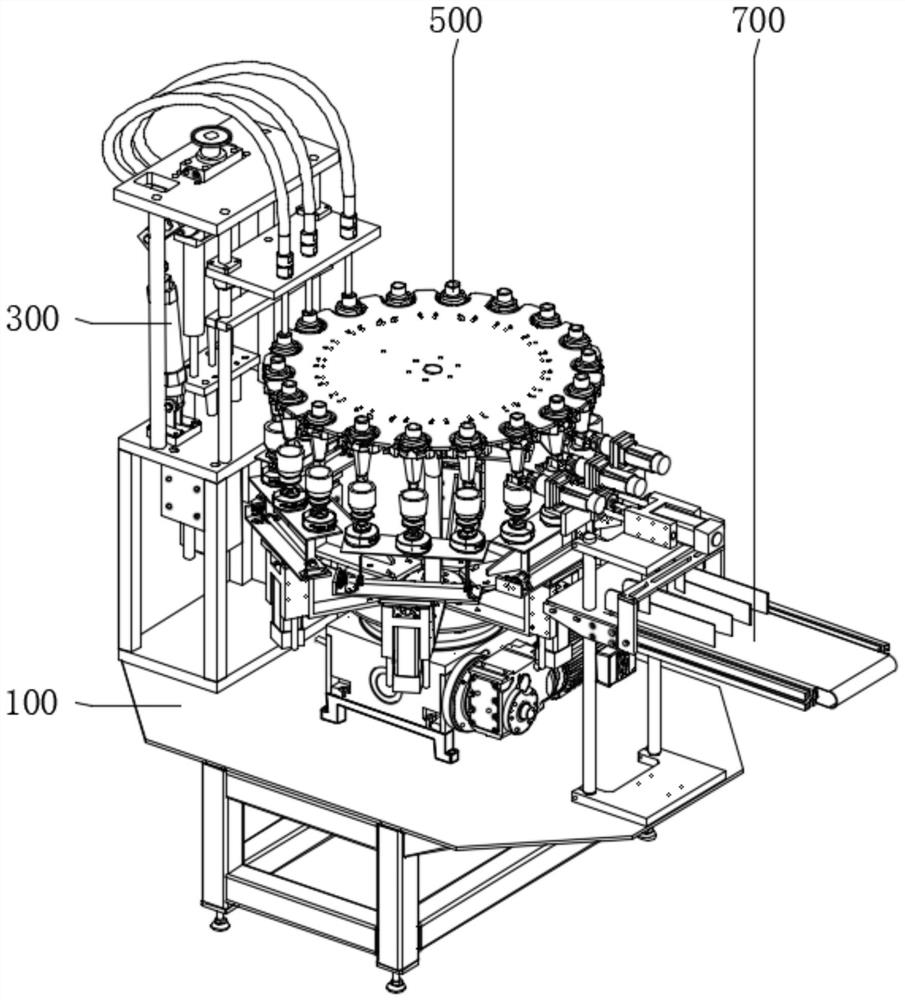

Filling machine capable of being controlled remotely

InactiveCN106629548AHigh degree of automationImprove filling efficiencySafety device in filling machineryEngineeringMaster controller

The invention discloses a filling machine capable of being controlled remotely. The filling machine comprises a bottle conveying mechanism, a bottle separation mechanism, a filling mechanism and a PLC master controller electrically connected with the bottle conveying mechanism, the bottle separation mechanism and the filling mechanism. The PLC master controller can be connected to a monitor terminal through a network interface. The bottle conveying mechanism comprises a conveying guide rail and a bottle selection rotary disc connected with the conveying guide rail. The bottle separation mechanism is a bottle separation locating rotary disc connected with the bottle selection rotary disc. The filling mechanism is located above the bottle separation locating rotary disc. Fixed liquid level filling valves are arranged on filling heads at the lower end of the filling mechanism. In this manner, the filling machine is high in automation degree, filling efficiency and precision and is provided with the monitor terminal connected with the PLC controller, the operating condition of the filling machine can be monitored remotely and operated, and meanwhile the fixed liquid level filling valves are arranged so that the filling quantity can be precisely controlled.

Owner:ZHANGJIAGANG WANJIN MACHINERY CO LTD

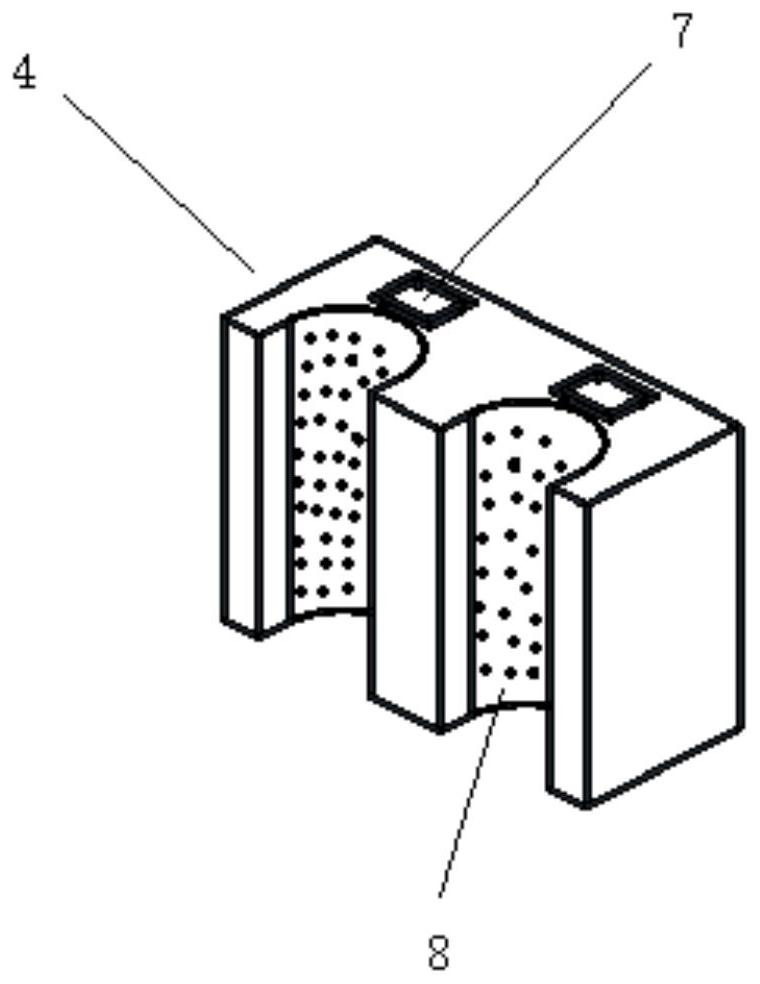

Filling device for emulsion explosive production

ActiveCN112898098AEasy to fillLess squeezeExplosive working-up apparatusHydraulic cylinderExplosive Agents

The invention provides a filling device for emulsion explosive production, and belongs to the technical field of emulsion explosives, and the filling device for emulsion explosive production comprises a supporting assembly and a filling assembly. The supporting assembly comprises a supporting frame, a supporting table, a filling frame and a conveying frame. The filling assembly comprises a flow dividing box, a flow dividing shaft, a metering cylinder, a flow dividing hydraulic cylinder, a metering piston, a metering hydraulic cylinder and a filling head. Emulsion explosive filling is conducted on a plastic film cartridge through positive pressure and negative pressure, extrusion to the emulsion explosive is reduced, piston filling design is adopted, damage to the physical structure of the emulsion explosive in the filling process is reduced through negative pressure extraction and positive pressure filling, and the safety and stability of the emulsion explosive are improved. Through bidirectional metering design, the opening and closing of emulsion explosive filling are accurately controlled by rotating a runner to steer, the single-time filling amount of the emulsion explosive is accurately controlled by sliding the piston, the blasting safety and stability are improved, the emulsion explosive filling safety and stability are good, and emulsion explosive filling is more convenient.

Owner:江西萍乡国泰六六一科技有限公司

Automatic filling device of water-washing machine

PendingCN106939478AAvoid enteringUniform product surfaceTextile treatment machine arrangementsElectric machineryProcess engineering

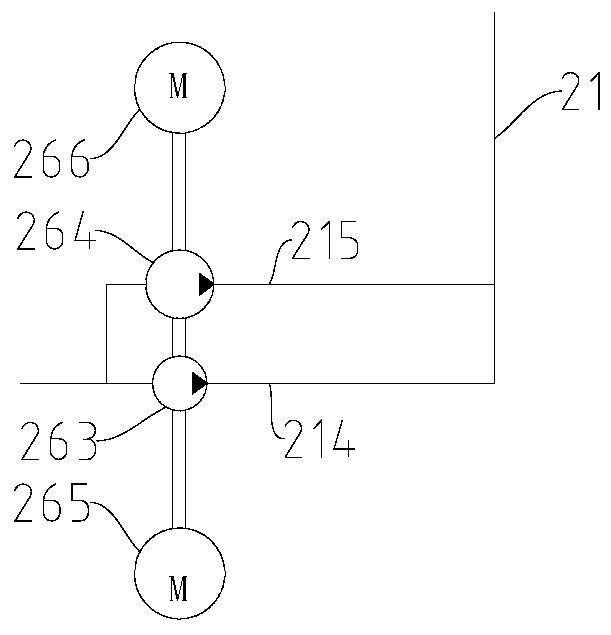

The invention discloses an automatic filling device of a water-washing machine. The automatic filling device of the water-washing machine comprises a main box body, a secondary box body, a first motor and a second motor; a softener is arranged in the secondary box body; mixed liquid containing the softener with the same ratio is arranged in the main box body and a water-washing groove; the first motor pumps the softener in the secondary box body into the main box body; the second motor pumps the mixed liquid in the main box body into the water-washing groove; the water-washing groove and the main box body form a communicating device through a communicating pipe; and a filer screen is vertically arranged in the main box body. The automatic filling device of the water-washing machine, which is disclosed by the invention, is simple in structure, convenient to use and flexible to adjust, overcomes the defect that the traditional process depends on manual power, improves the stability of a product, saves the labor cost, can automatically eliminate impurities from the water-washing groove, and has good popularization value.

Owner:安庆市华兴纤维制品有限公司

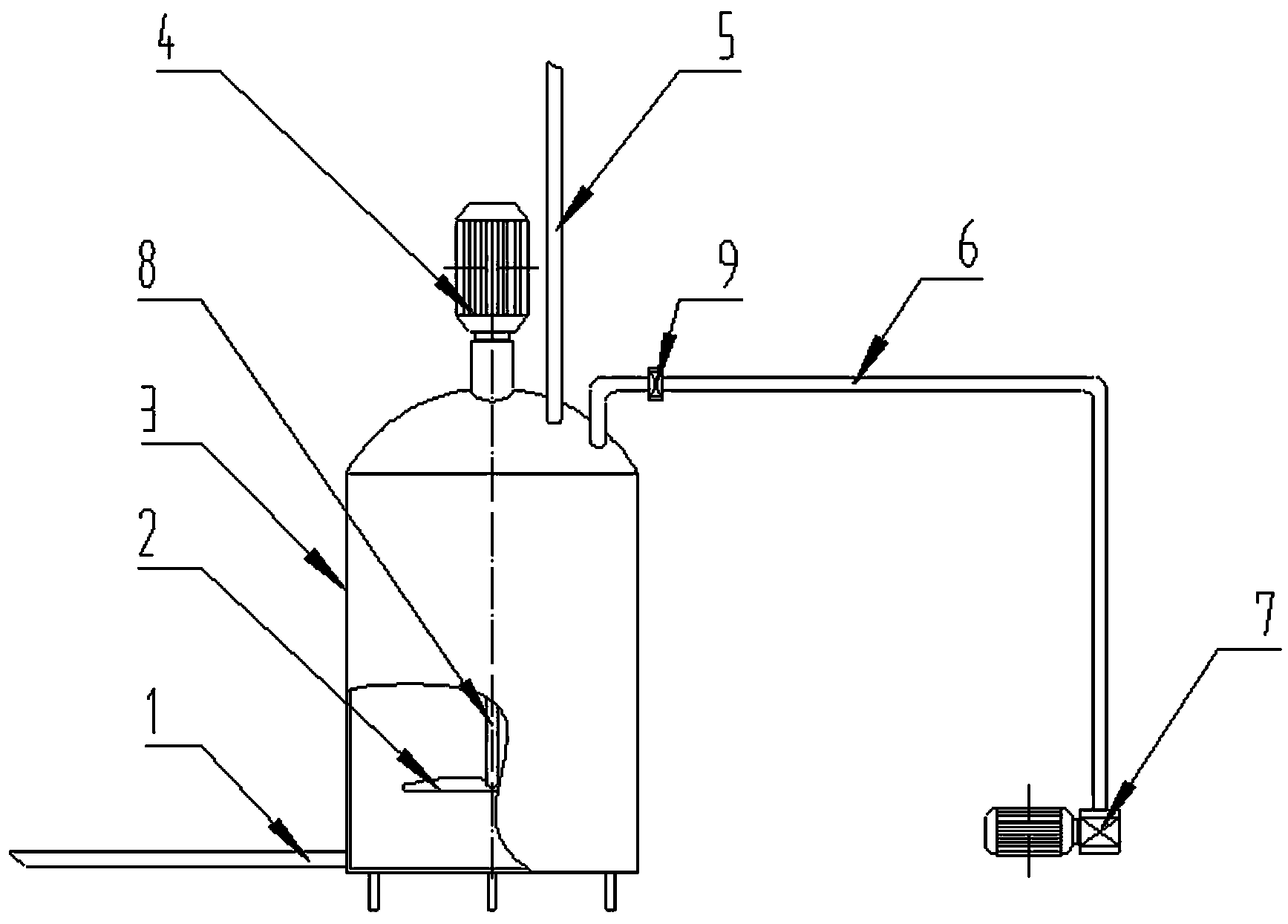

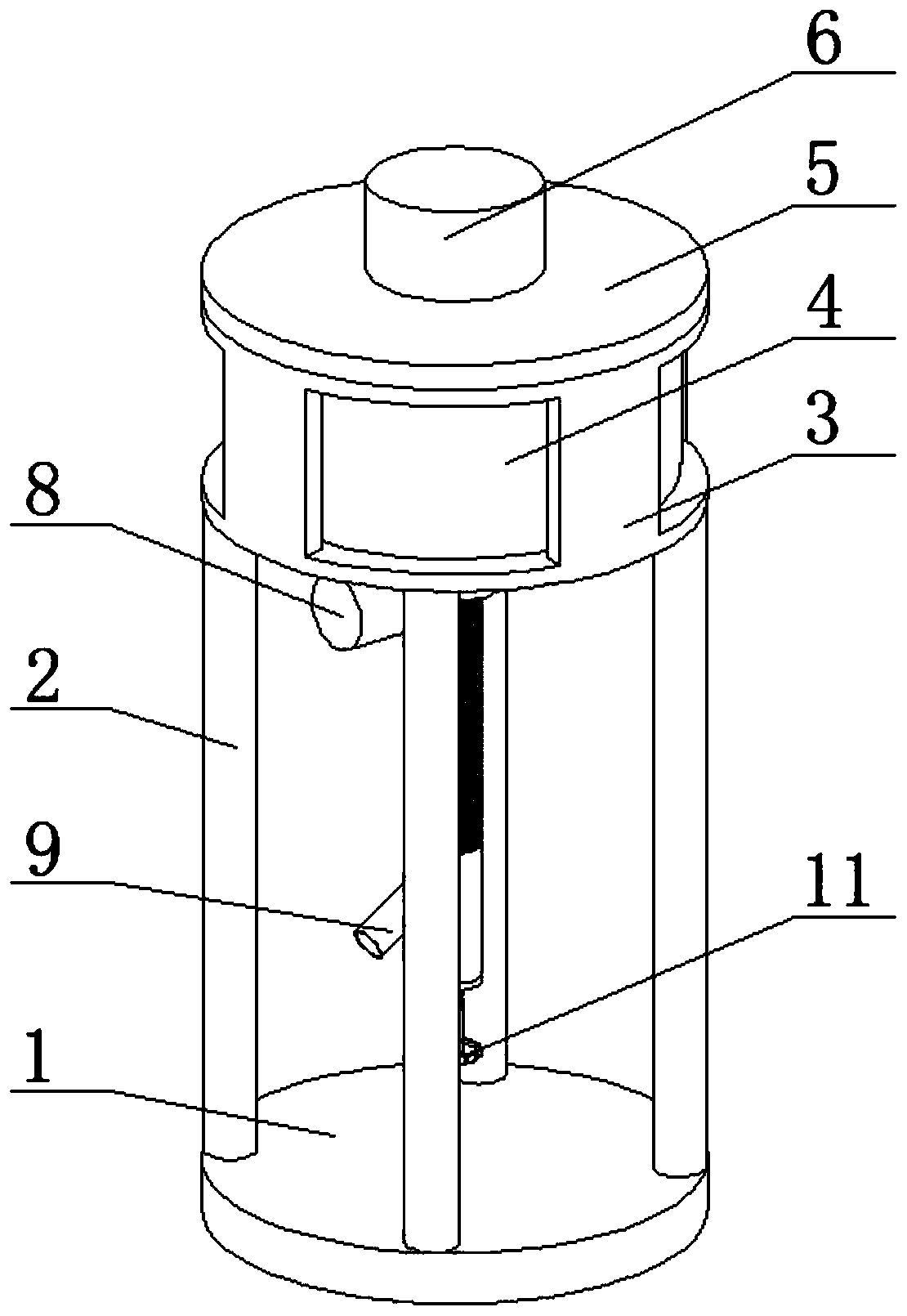

Defoaming device for high-viscosity beverage before filling

InactiveCN103466529AImprove aestheticsEnsure consistencyLiquid bottlingFoam dispersion/preventionDrive motorCheck valve

The invention provides a defoaming device for a high-viscosity beverage before filling. The defoaming device comprises a tank body. A driving motor is arranged on the top of the tank body, a stirring paddle is arranged in the tank body, and the driving motor is connected with the stirring paddle through a stirring shaft; a feed pipe and a gas leading-out pipe are further arranged on the top of the tank body, a check valve is arranged at one end of the gas leading-out pipe, and a vacuum pump is arranged at the other end of the gas leading-out pipe; a discharge pipe is arranged on the bottom of the tank body. The defoaming device is simple in structure and convenient to operate, can efficiently extract gas mixed up with the high-viscosity beverage in the technological process, substantially improves the condition of bottled beverages and facilitates metering and weighing in the filling process.

Owner:ANHUI WANFENG BEE IND GROUP

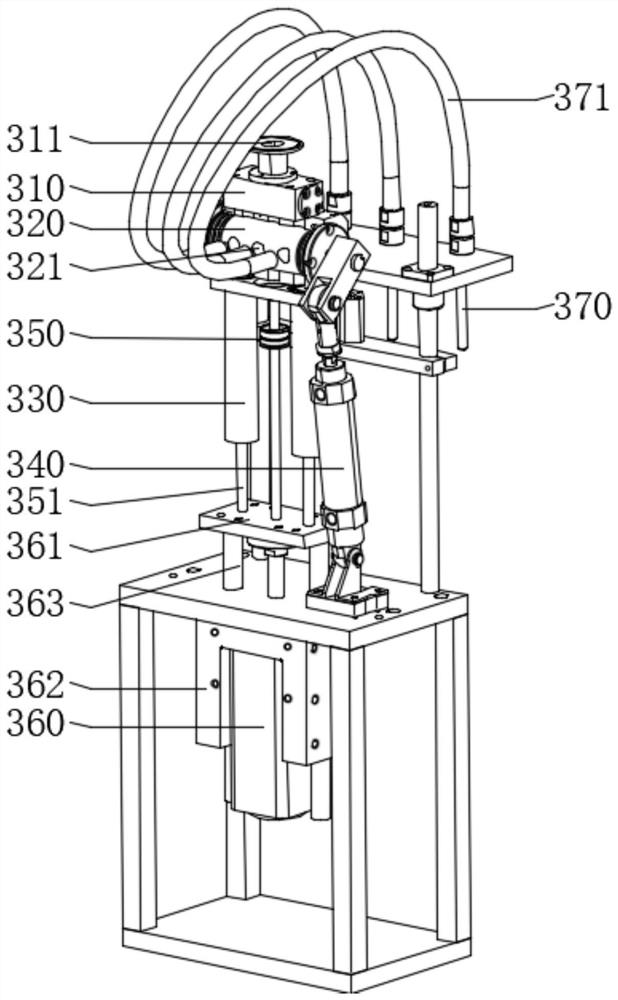

Ton packaging umbrella type filling head and ton packaging method of umbrella type filling head

The invention discloses a ton packaging umbrella type filling head and a ton packaging method of the umbrella type filling head, and belongs to the field of filling equipment. The ton packaging umbrella type filling head comprises a material conveying pipe connected with a material bin, an umbrella surface folding and unfolding device which can extend to the lower part of the material conveying pipe and comprises a conical umbrella surface is arranged in the material conveying pipe, the umbrella cover folding and unfolding device enables the umbrella cover to form different discharging angles;a ton packaging method of the umbrella type filling head comprises the following steps that a, the umbrella surface folding and unfolding device is driven to descend to the lower part of the materialconveying pipe; b, the umbrella surface of the umbrella surface folding and unfolding device is opened; c, a filling program is executed; d. when the filling quantity reaches the set weight, the umbrella surface of the umbrella surface folding and unfolding device is controlled to be recovered and rises to the initial position of the step a. According to the ton packaging umbrella type filling head and ton packaging method, falling objects are uniformly distributed in the packaging bag, the problem that the filling of the packaging bag is not full due to the problem of material accumulation angle is avoided, and the filling efficiency and the packaging amount of the ton packaging bag are improved.

Owner:晨光生物科技集团莎车有限公司

EMI shielding film magnetic control winding coating machine

InactiveCN106011773AIncrease deposition rateMeet the needs of one-time plating multi-layer filmVacuum evaporation coatingSputtering coatingEngineeringMultiple layer

The invention belongs to the technical field of coating equipment and particularly discloses an EMI shielding film magnetic control winding coating machine. The EMI shielding film magnetic control winding coating machine comprises a vacuum room body, a door body and a target room. A winding roller system is arranged in the vacuum room body. A plane magnetic control target system is arranged in the target room. A low-temperature coating roller is partially placed in the target room. The plane magnetic control target system comprises multiple target work sections, multiple pairs of plane magnetic control targets are arranged in at least one target work section, every two adjacent target work sections are separated through a separating plate, and all the plane magnetic control targets are arranged around the low-temperature coating roller in a manner of being away from the surface of the low-temperature coating roller by the equal distance. The coating machine can be used for achieving one-time film walking, all the targets work at the same time, the overall deposition rate can be greatly increased, the requirement for one-time coating of multiple layers of films of multiple materials can be met, in addition, a relatively low temperature can be reached, heat is effectively discharged, and it is ensured that a coated flexible base material cannot be deformed when heated.

Owner:GUANGDONG ZHENHUA TECH CO LTD

A ton-packaging umbrella-type filling head and a ton-packing method for the umbrella-type filling head

ActiveCN109204897BAvoid underfillRegular shapeSolid materialStructural engineeringMechanical engineering

The invention discloses a ton packaging umbrella type filling head and a ton packaging method of the umbrella type filling head, and belongs to the field of filling equipment. The ton packaging umbrella type filling head comprises a material conveying pipe connected with a material bin, an umbrella surface folding and unfolding device which can extend to the lower part of the material conveying pipe and comprises a conical umbrella surface is arranged in the material conveying pipe, the umbrella cover folding and unfolding device enables the umbrella cover to form different discharging angles;a ton packaging method of the umbrella type filling head comprises the following steps that a, the umbrella surface folding and unfolding device is driven to descend to the lower part of the materialconveying pipe; b, the umbrella surface of the umbrella surface folding and unfolding device is opened; c, a filling program is executed; d. when the filling quantity reaches the set weight, the umbrella surface of the umbrella surface folding and unfolding device is controlled to be recovered and rises to the initial position of the step a. According to the ton packaging umbrella type filling head and ton packaging method, falling objects are uniformly distributed in the packaging bag, the problem that the filling of the packaging bag is not full due to the problem of material accumulation angle is avoided, and the filling efficiency and the packaging amount of the ton packaging bag are improved.

Owner:晨光生物科技集团莎车有限公司

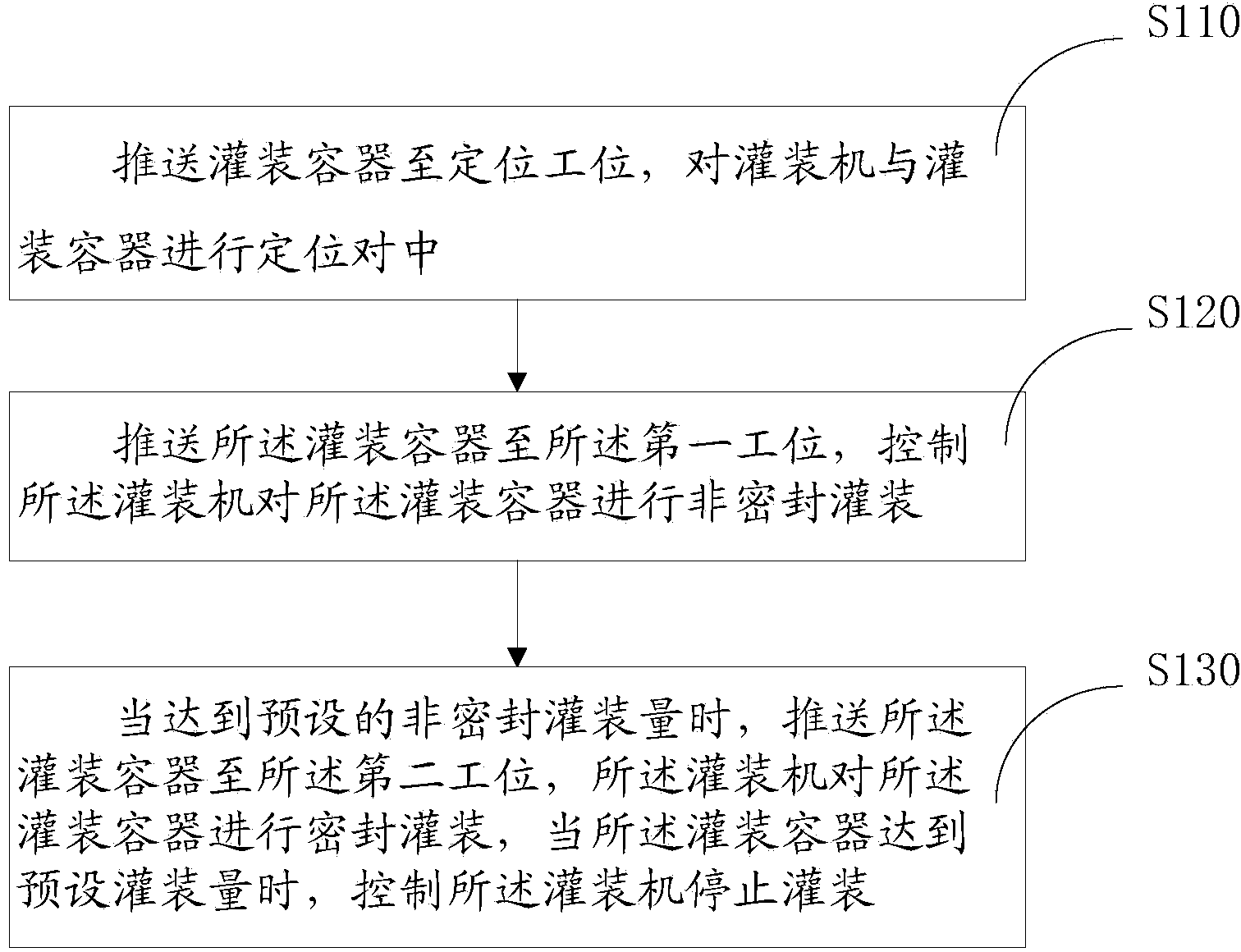

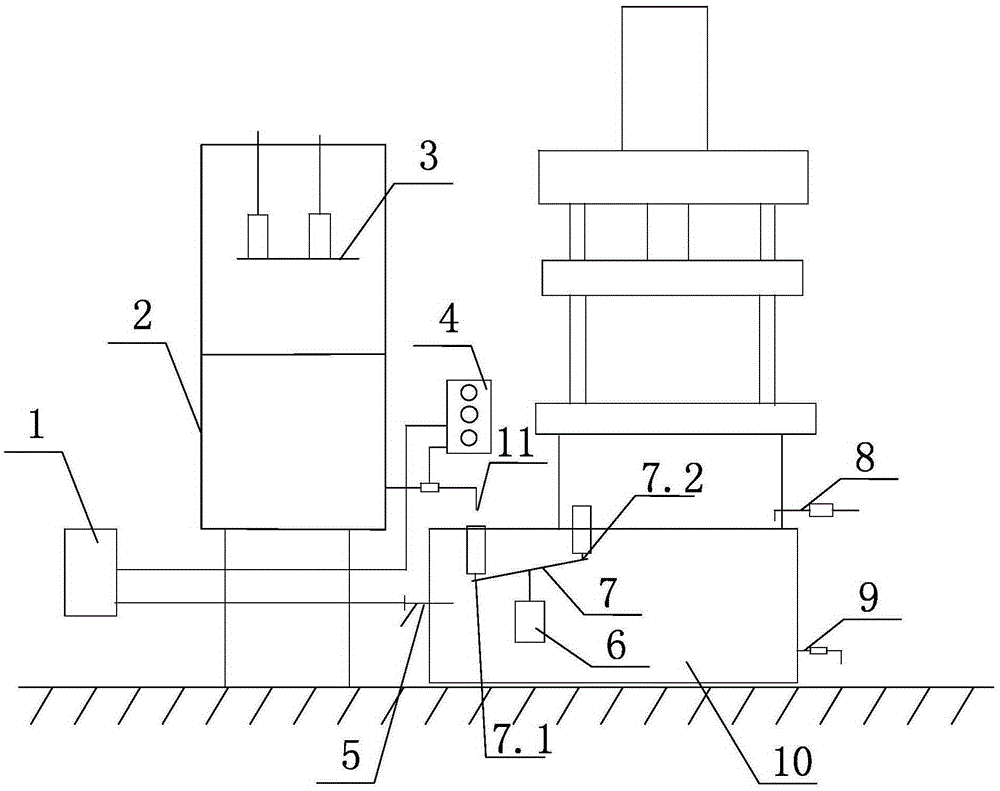

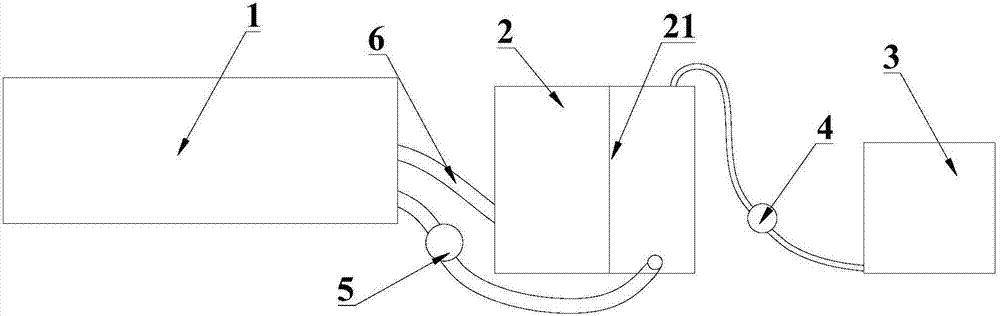

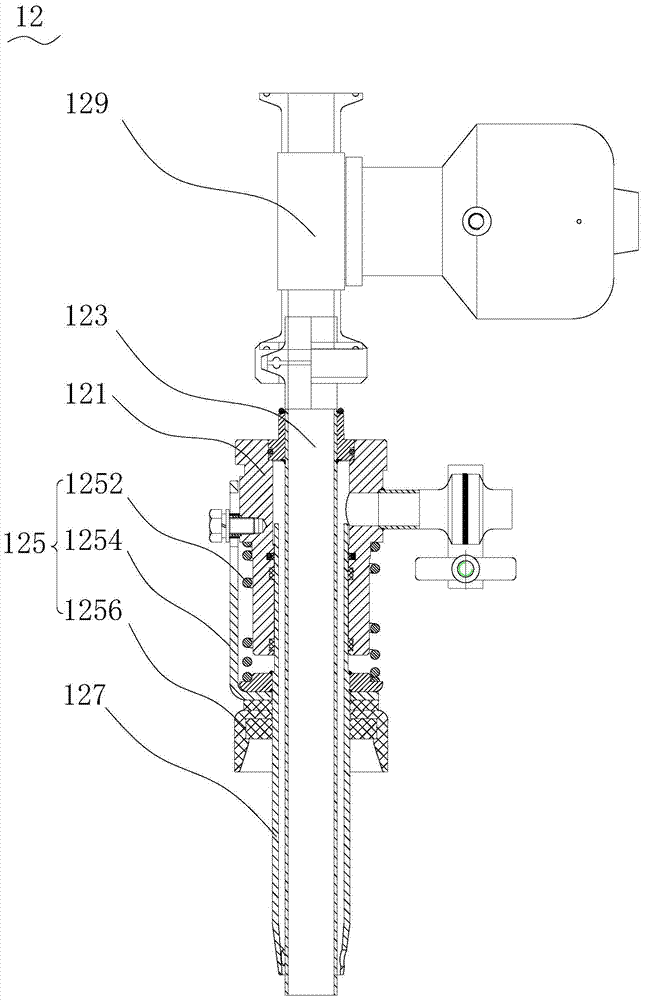

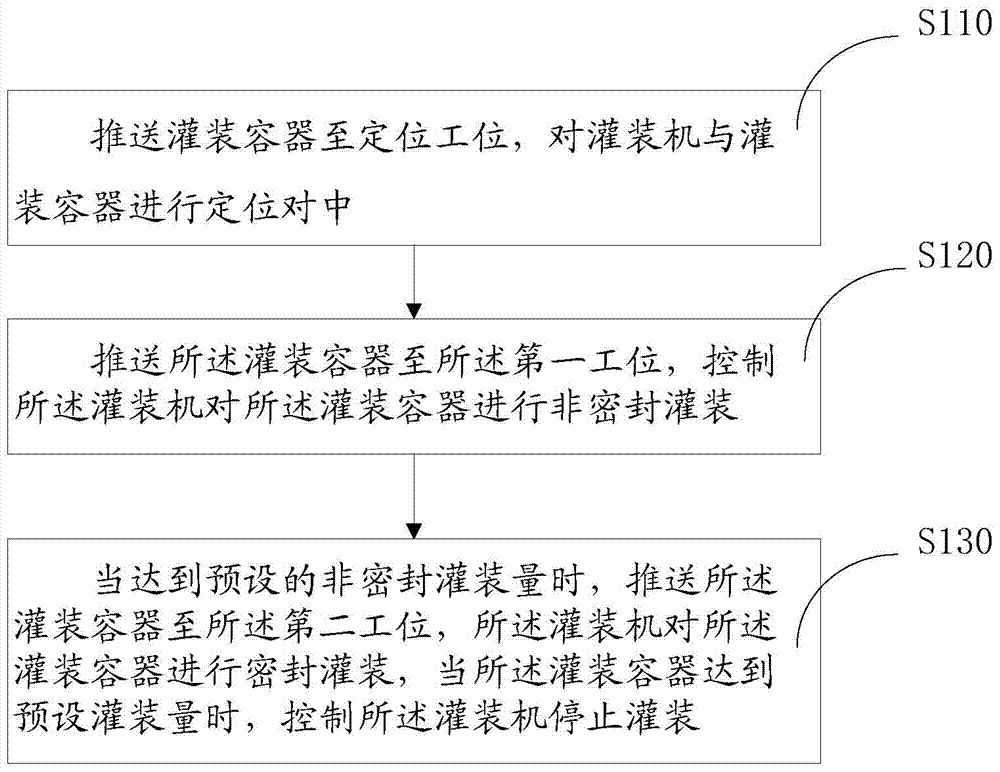

Filling system and filling method using the same

ActiveCN104370258BHigh speedReduce generationFilling without pressureEngineeringMechanical engineering

The invention discloses a filling system and a filling method by utilizing the filling system. The filling system comprises a filling mechanism, wherein the filling mechanism comprises a first station, a second station and a filling machine used for filling a filling medium into a filling container; the first station is used for performing non-sealed filling on the filling container; and the second station is used for performing sealed filling on the filling container subjected to non-sealed filling at the first station. According to the filling system and the filling method, when the filling container is positioned at a positioning station, the filling container is positioned below the filling machine, so as to carry out positioning and centering; when the filling container is positioned at the first station, the container is rapidly filled by the filling machine, gases in the filling container can be discharged through an opening of the filling container, the gas discharge speed is increased, and the filling efficiency is improved; and when the filling container is positioned at the second station, the filling container is subjected to low-speed sealed filling by the filling machine, and air bubbles are reduced.

Owner:广州隆宝科技技术有限公司

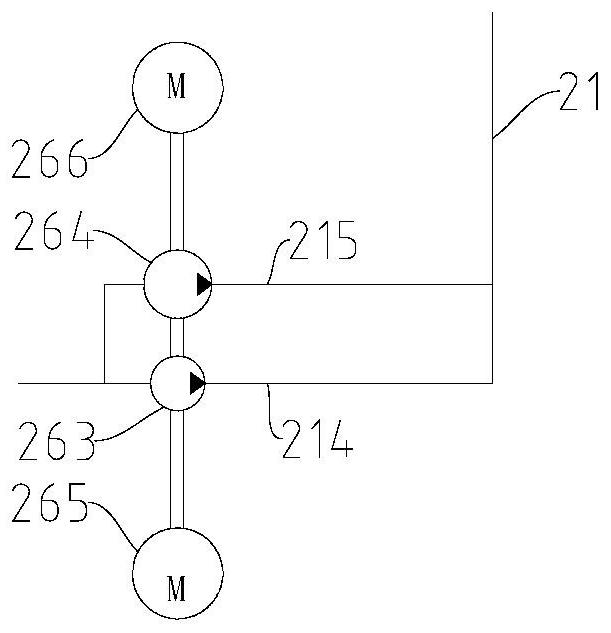

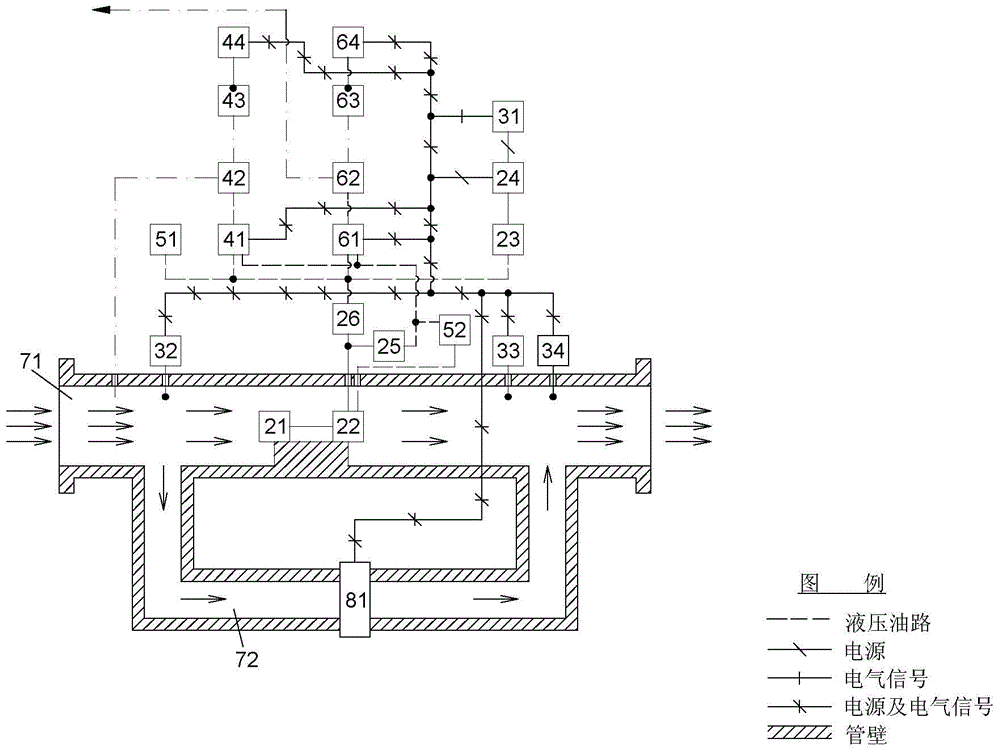

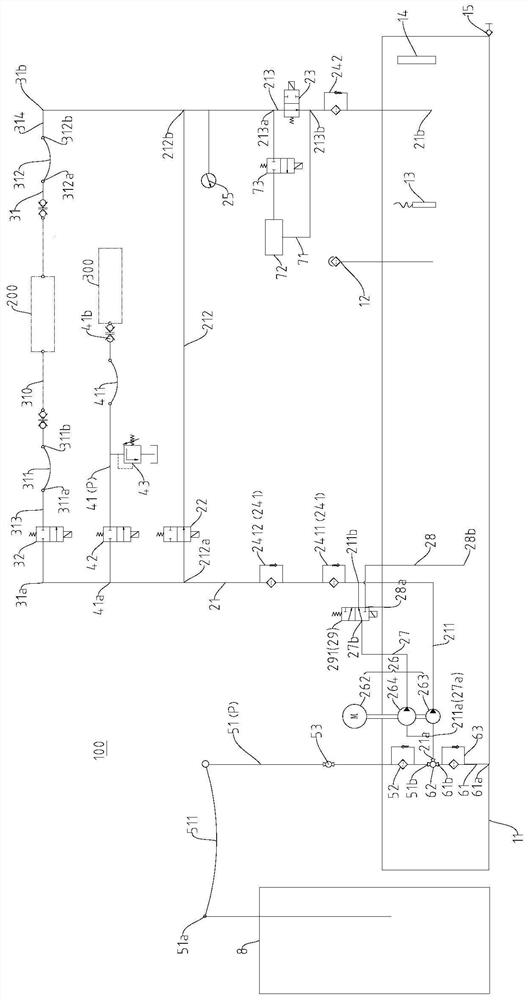

Equipment for processing vehicle hydraulic brake system

ActiveCN112572393AAvoid normal workShorten working hoursMaterial testing goodsBrake safety systemsMarine engineeringHydraulic brake

The invention discloses equipment for processing a vehicle hydraulic braking system. The equipment comprises an equipment oil tank, a main pipeline, a detection pipeline, a dirt detection device and afirst protection device, wherein an inlet end and an outlet end of the main pipeline are communicated with the equipment oil tank, and the detection pipeline is connected with a detection pipeline section on the main pipeline in parallel; the dirt detection device is arranged on the detection pipeline, and the first protection device is arranged on the detection pipeline and used for controllingopening and closing of the detection pipeline. According to the equipment for treating the vehicle hydraulic braking system, by arranging the first protection device, the dirt detection device can work only when needed, and the service life of the dirt detection device is prolonged.

Owner:BYD CO LTD

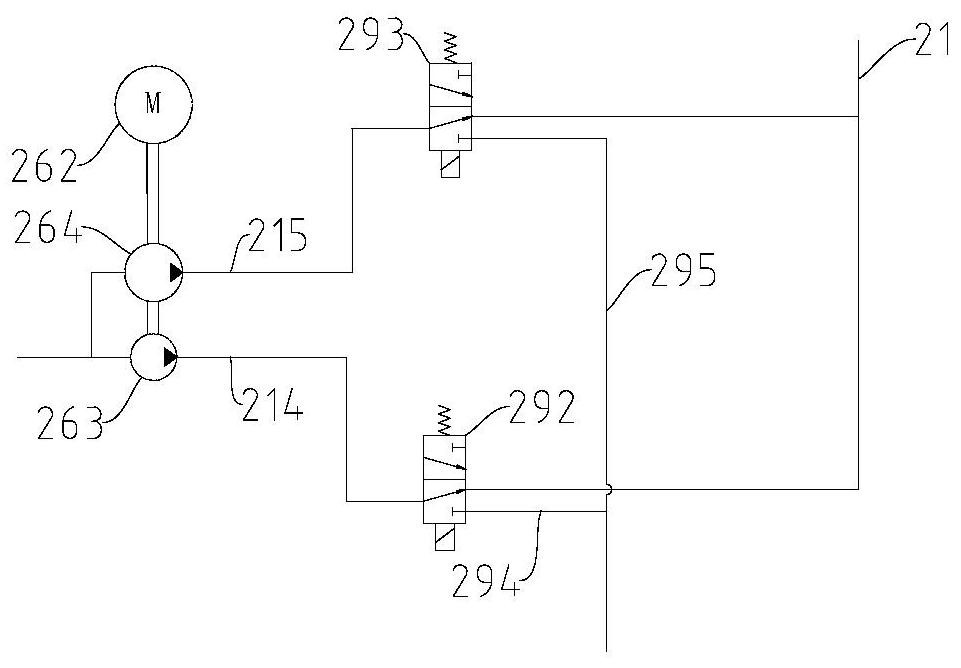

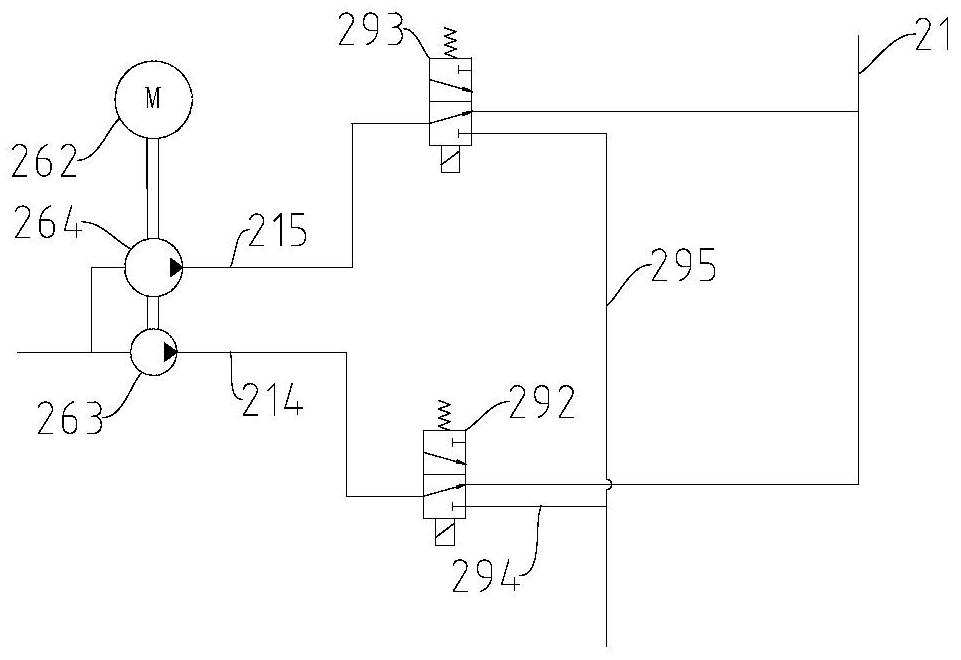

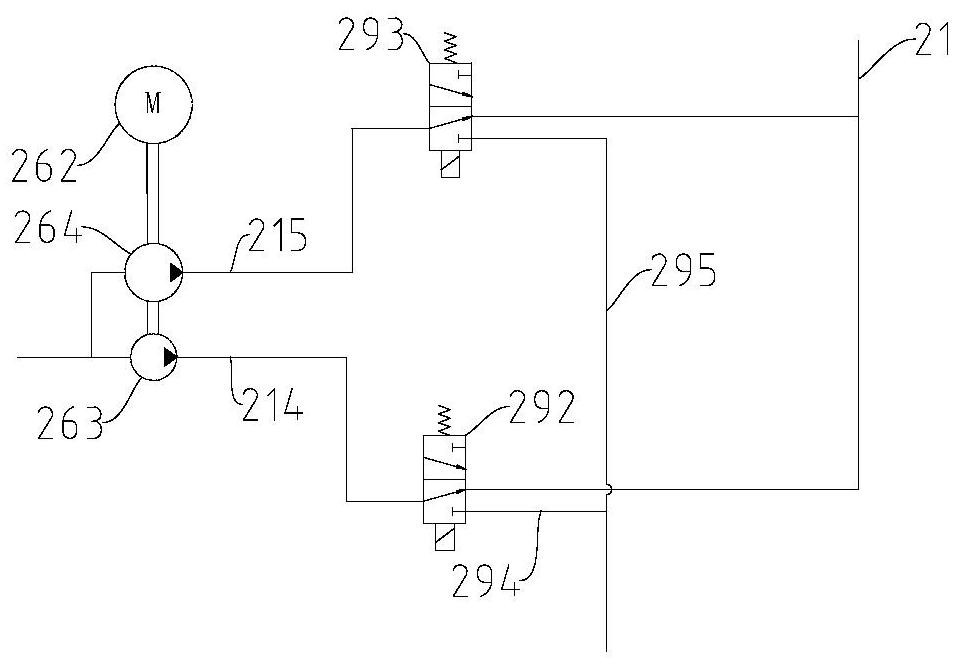

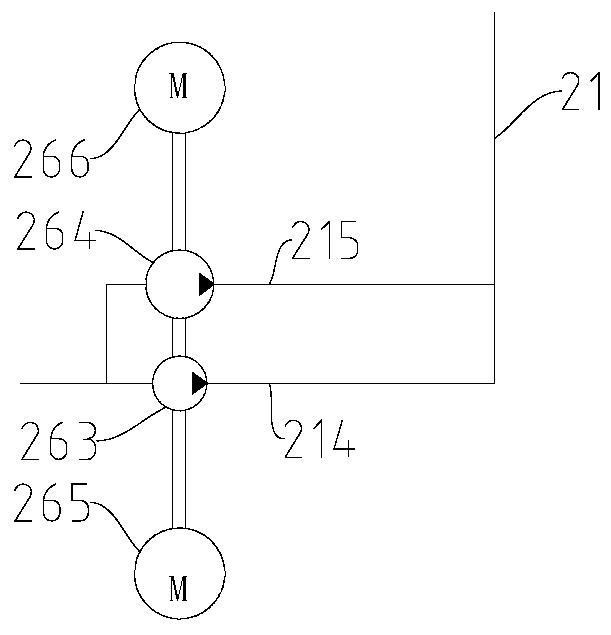

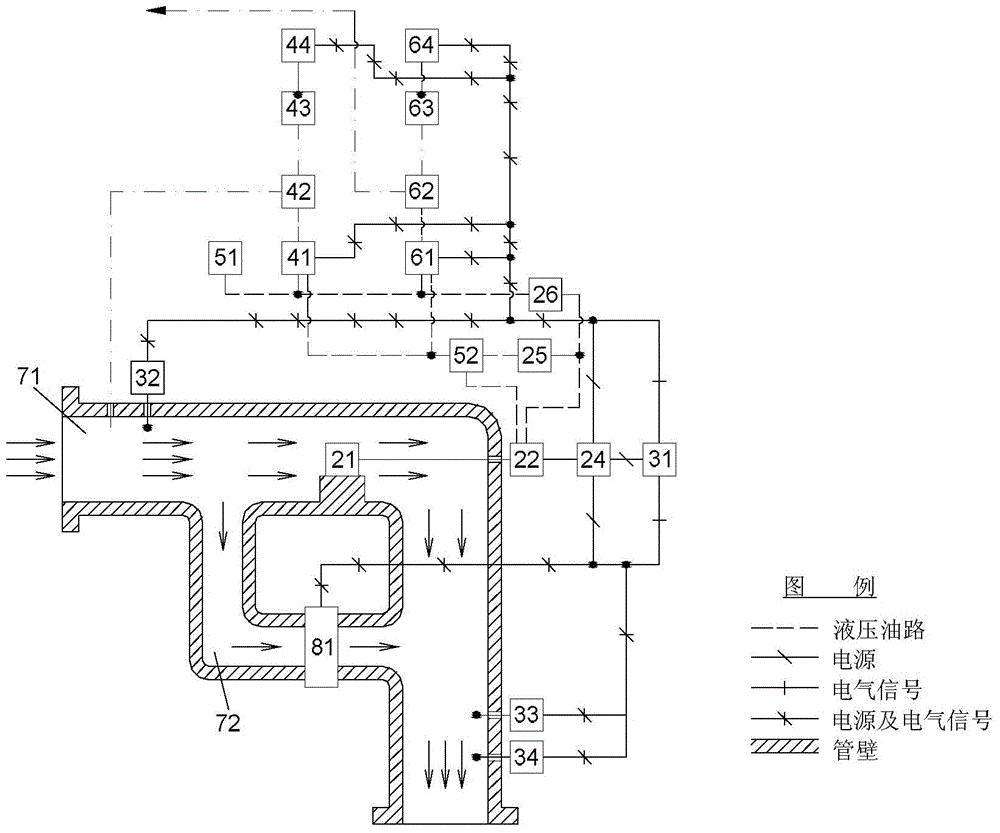

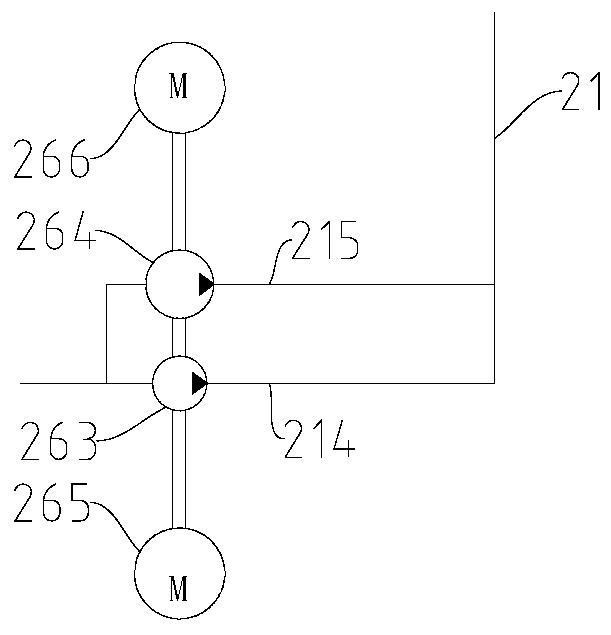

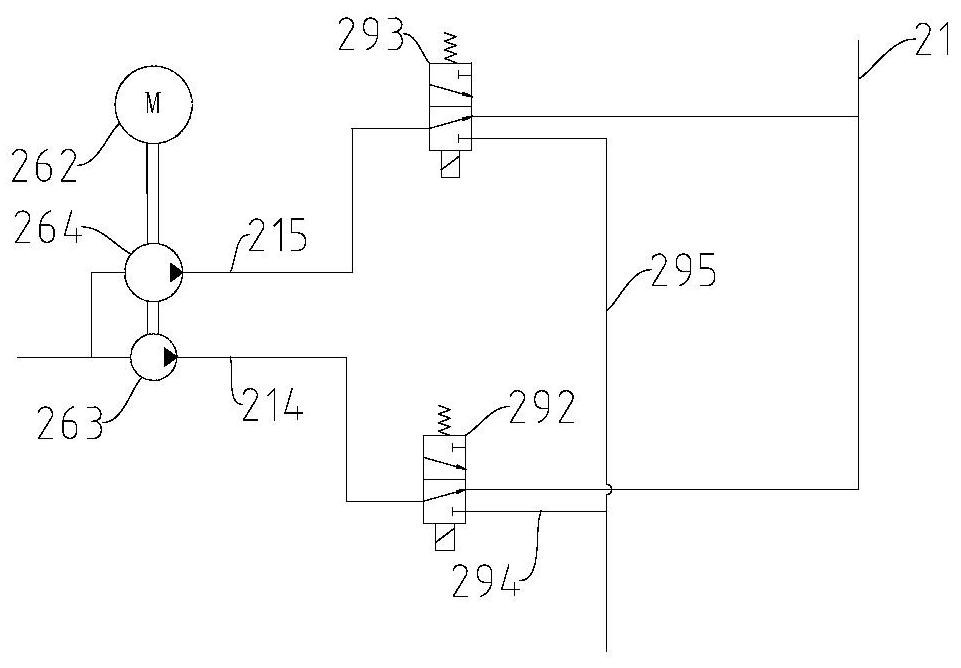

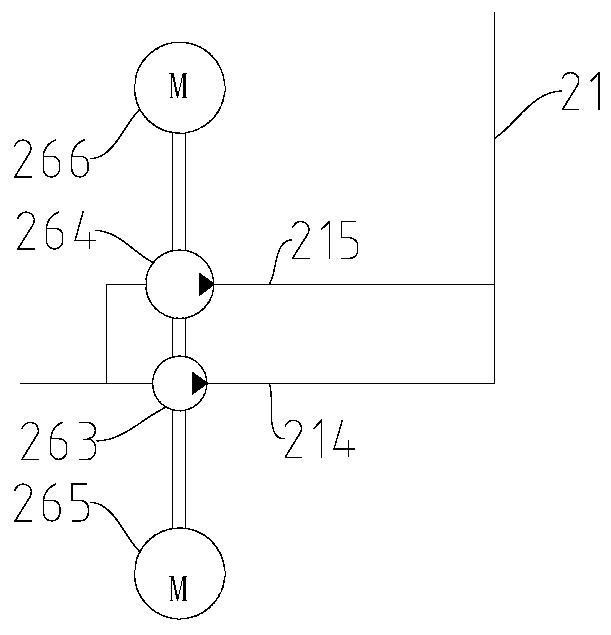

Equipment for processing vehicle hydraulic brake system

ActiveCN112572386AAvoid normal workShorten working hoursBraking action transmissionHydraulic brakeOil pump

The invention discloses equipment for processing a vehicle hydraulic brake system, the equipment comprises an equipment oil tank, a main pipeline, an oil pumping device and a regulation and control device, an inlet end and an outlet end of the main pipeline are both communicated to the equipment oil tank, the oil pumping device comprises a first flow pump and a second flow pump; the flow of the first flow pump is smaller than that of the second flow pump, the first flow pump and the second flow pump are both used for pumping oil in the equipment oil tank into the main pipeline, and the regulation and control device is used for regulating and controlling the oil inlet condition of the main pipeline. According to the equipment for processing the vehicle hydraulic brake system, due to the fact that the oil pumping device comprises the first flow pump and the second flow pump, and the regulation and control device is arranged, the oil quantity of the main pipeline can be regulated and controlled, so that different actual requirements can be better met.

Owner:BYD CO LTD

Filling system for agricultural chemical production of agriculture

InactiveCN106742133APrecise control of filling volumeLiquid materialLiquid bottlingProduction lineEngineering

The invention relates to a filling system for agricultural chemical production of agriculture. The filling system comprises a liquid transporting tank, a filling pipe, a controller, a plurality of pouring nozzles and a machine frame, wherein the liquid transporting tank and the controller are arranged on the machine frame; the filling pipe is a bended pipeline consisting of a vertical part and a horizontal part; the vertical part of the filling pipe is connected with the bottom end of the liquid transporting tank, and a valve is arranged on the vertical part of the filling pipe; the pouring nozzles are arranged at the lower part of the horizontal part of the filling pipe, and communicate with an inner cavity of the filling pipe; a flow sensor is arranged at the upper part of each pouring nozzle, and an electromagnetic valve is arranged at the lower parts of the pouring nozzles; and the flow sensors and the electromagnetic valve are respectively connected with the controller. According to the filling system disclosed by the invention, the controller, the flow sensors and the electromagnetic valve are arranged, so that the filling capacity each time can be accurately controlled, and the problems that a conventional filling machine for an agricultural chemical production line is low in accuracy and complex in structure are solved.

Owner:孙新磊

Natural gas pipeline dosing device

ActiveCN103663333BReduce fill volumePrecise control of filling volumeLiquid transferring devicesElectricityFirst Fill

The invention provides a chemical dosing device for a natural gas pipeline. The chemical dosing device for the natural gas pipeline comprises an energy conversion portion, a first filling portion and an electronic control unit. The energy conversion portion is used for converting pressure of natural gas in the natural gas pipeline into hydraulic energy and electric energy. The first filling portion is communicated with the energy conversion portion and is driven by the energy conversion portion to fill first filling agents into the natural gas pipeline. The electronic control unit is electrically connected with the energy conversion portion and the first filling portion and is used for controlling the filling amount of the first filling portion. By means of the chemical dosing device for the natural gas pipeline, chemical dosing can be carried out under the condition that no extra power source is added, and the chemical dosing amount can be accurately controlled.

Owner:BEIJING LINKFORTUNE

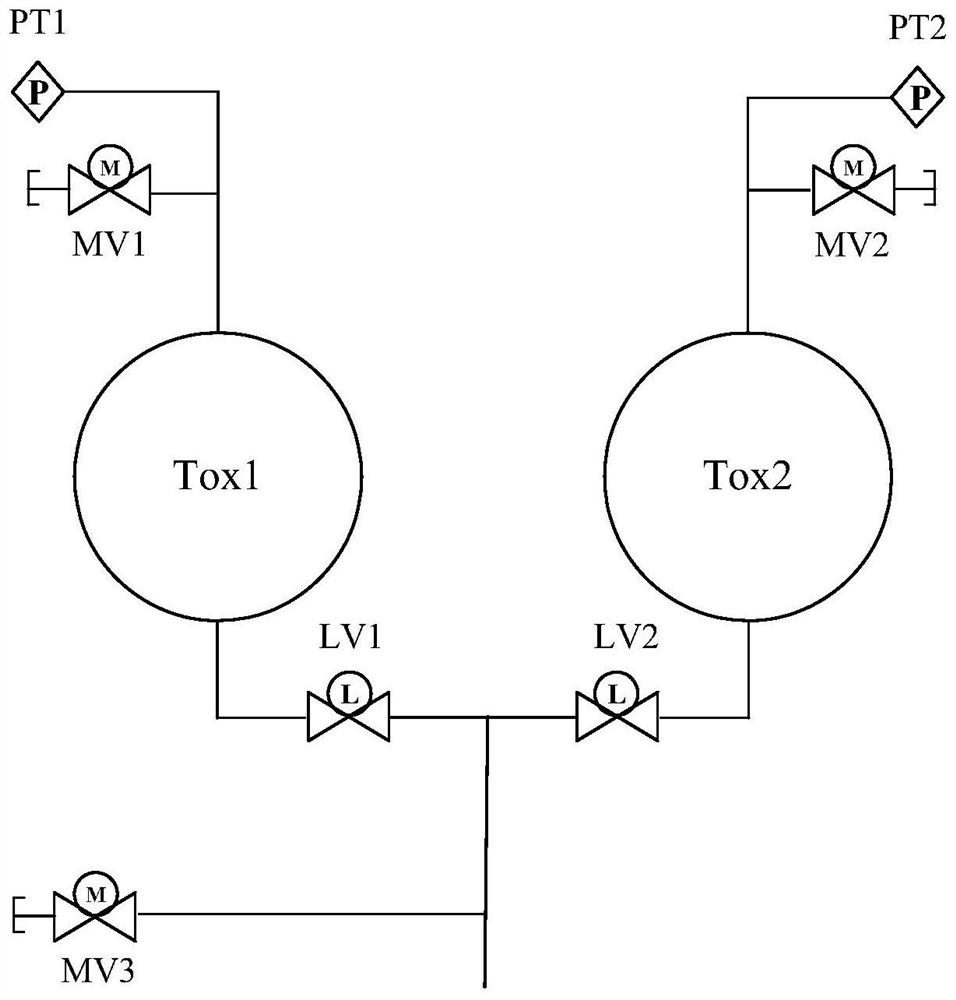

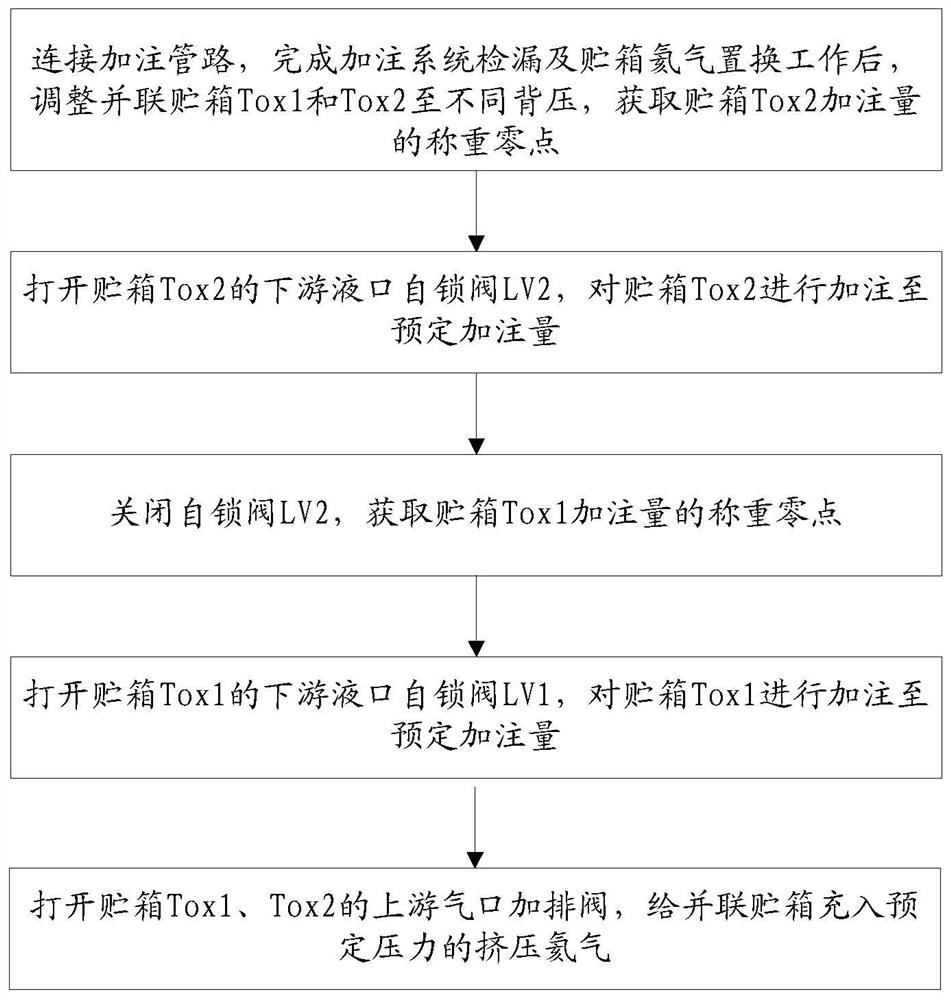

A closed low filling rate parallel tank filling method

The invention discloses a closed low filling rate parallel storage tank filling method. The method includes: when filling the propellant, according to the characteristics of the parallel storage tanks of the propulsion system with a low filling rate, adjusting the parallel storage tanks Tox1 and Tox2 to different back pressures, and obtaining the weighing zero point of the filling amount of the storage tank Tox2; The self-locking valve LV2 of the downstream liquid port of the tank Tox2 is used to fill the storage tank Tox2 to the predetermined filling amount; close the self-locking valve LV2 to obtain the weighing zero point of the filling amount of the storage tank Tox1; open the downstream liquid port of the storage tank Tox1 The self-locking valve LV1 fills the storage tank Tox1 to a predetermined filling amount; finally opens the upstream air port addition and discharge valves of the storage tanks Tox1 and Tox2, and fills the parallel storage tanks with extruded helium at a predetermined pressure. The invention realizes the purpose of filling the parallel storage tanks with low filling rate without venting through the gas port.

Owner:BEIJING INST OF CONTROL ENG

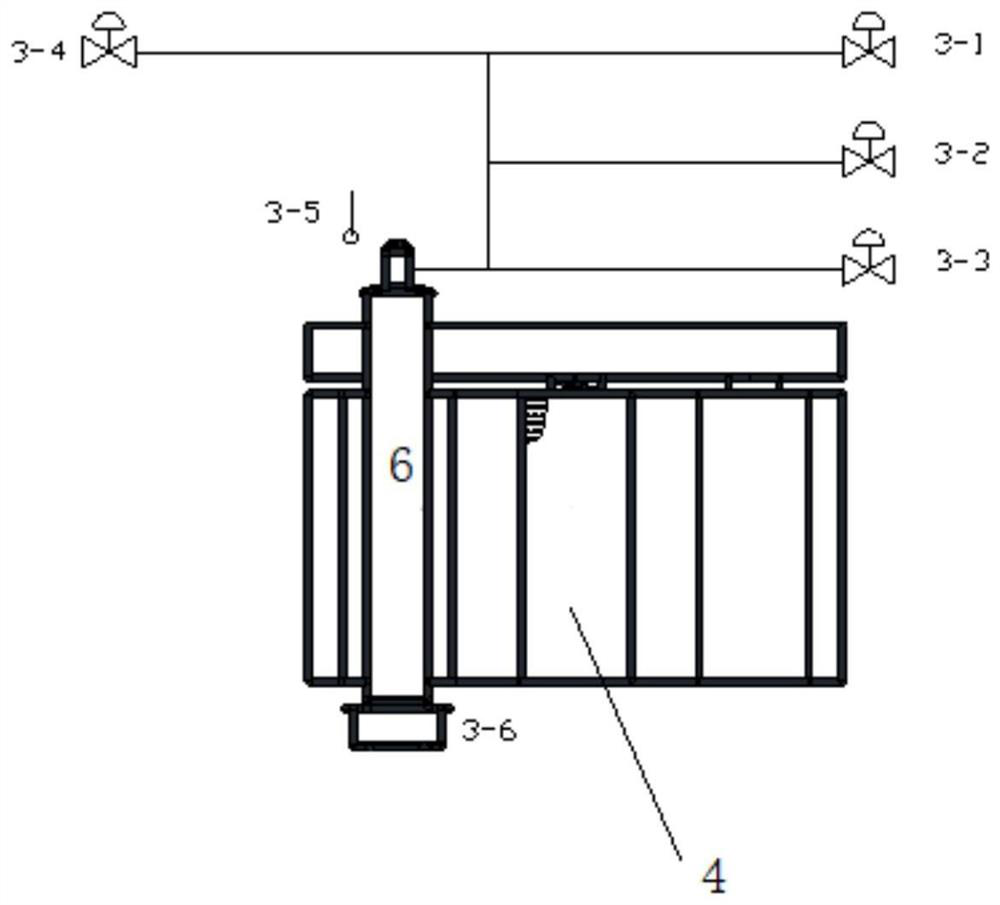

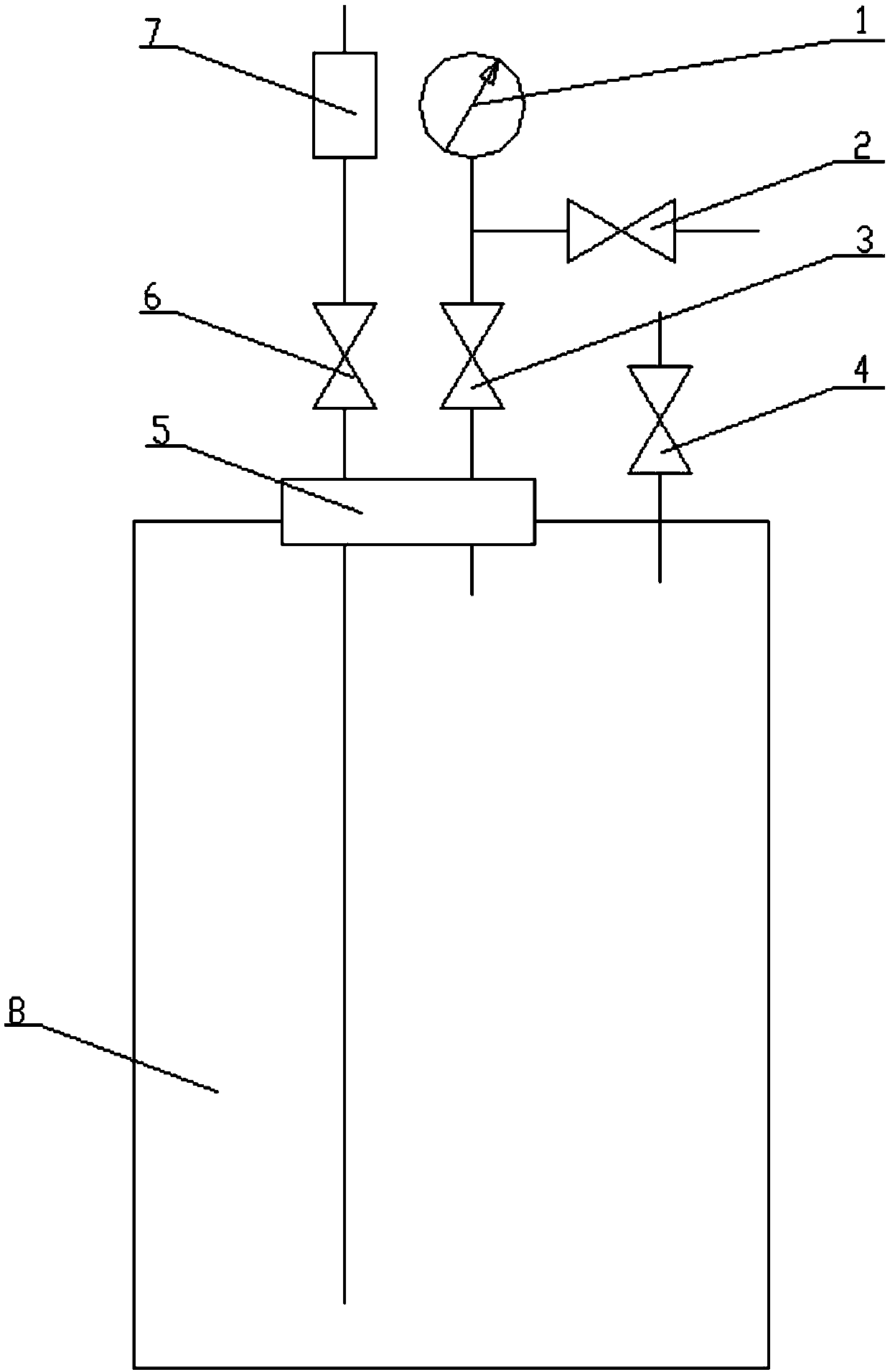

A water-cooled inverter ultra-pure coolant filling storage filling device and filling method

ActiveCN106144997BGuaranteed qualityQuality does not changeFilling using counterpressureEngineeringLiquid tank

The invention relates to the field of charging liquid in a sealing mode, and particularly relates to a filling, storing and charging device and a charging method of ultrapure cooling liquid of a water-cooled frequency converter. According to the filling, storing and charging device and the charging method, a gas path pipe is connected with a second two-way air valve so as to be arranged on the top of a pressure bearing container liquid tank, a liquid path pipe is connected with a two-way liquid valve so as to pass through the top of the pressure bearing container liquid tank to the bottom, the other end of the two-way liquid valve is connected with a liquid path flowmeter, quick change connection are formed on both ends of the liquid path flowmeter, the pressure bearing container liquid tank is made of pressure resistant stainless steel materials, the pressure bearing container liquid tank is integrally sealed, and a safety relief valve is installed on the top of the pressure bearing container liquid tank. The device is sealed in a charging process, so that safety accidents caused by charged elements in a high-voltage environment are avoided; additionally, the charging process is carried out in a sealing state, so that the cooling liquid does not make contact with air, and the quality of the cooling liquid is not changed.

Owner:湖北泽惠科技发展有限责任公司

Equipment for the treatment of the hydraulic braking system of a vehicle

ActiveCN112572386BAvoid normal workShorten working hoursBraking action transmissionOil intakeHydraulic brake

Owner:BYD CO LTD

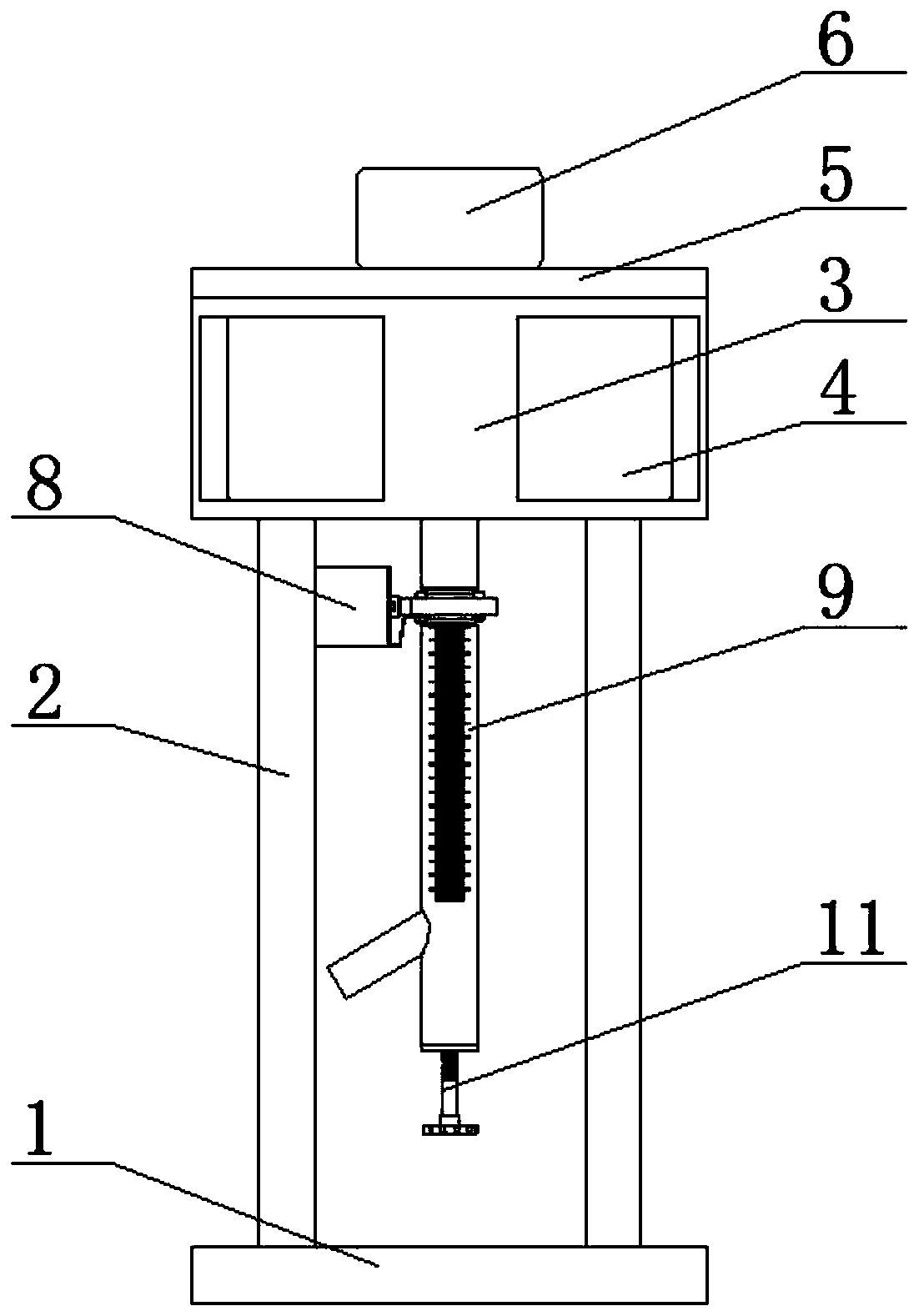

Pectinase Quantitative Injection Device for Corn Stigma White Dry Wine Production

The invention relates to the technical field of wine production device, and discloses a pectinase quantitative injection device for the production of corn stigma white dry wine. The device comprises abase, wherein the top of the base is fixedly installed with four mutually symmetrical support rods, the top of the four support rods is fixedly connected with an upper fixing plate, the interior of the upper fixing plate is fixedly installed with a holding container, the top of the upper fixing plate is clamped with a cover plate, and the top of the cover plate is fixedly installed with a motor.The pectinase quantitative injection device for the production of corn stigma white dry wine, through the cooperation of the weighing device, the fixed plug and the adjusting device, the scale line can be used to measure the pectinase inside the weighing glass tube, so as to obtain an accurate value, and the adjusting device can be used to adjust the volume of pectinase inside the weighing device,so as to accurately control the pouring amount each time, and the quality of the produced wine is better.

Owner:南方葡萄沟酒庄有限公司

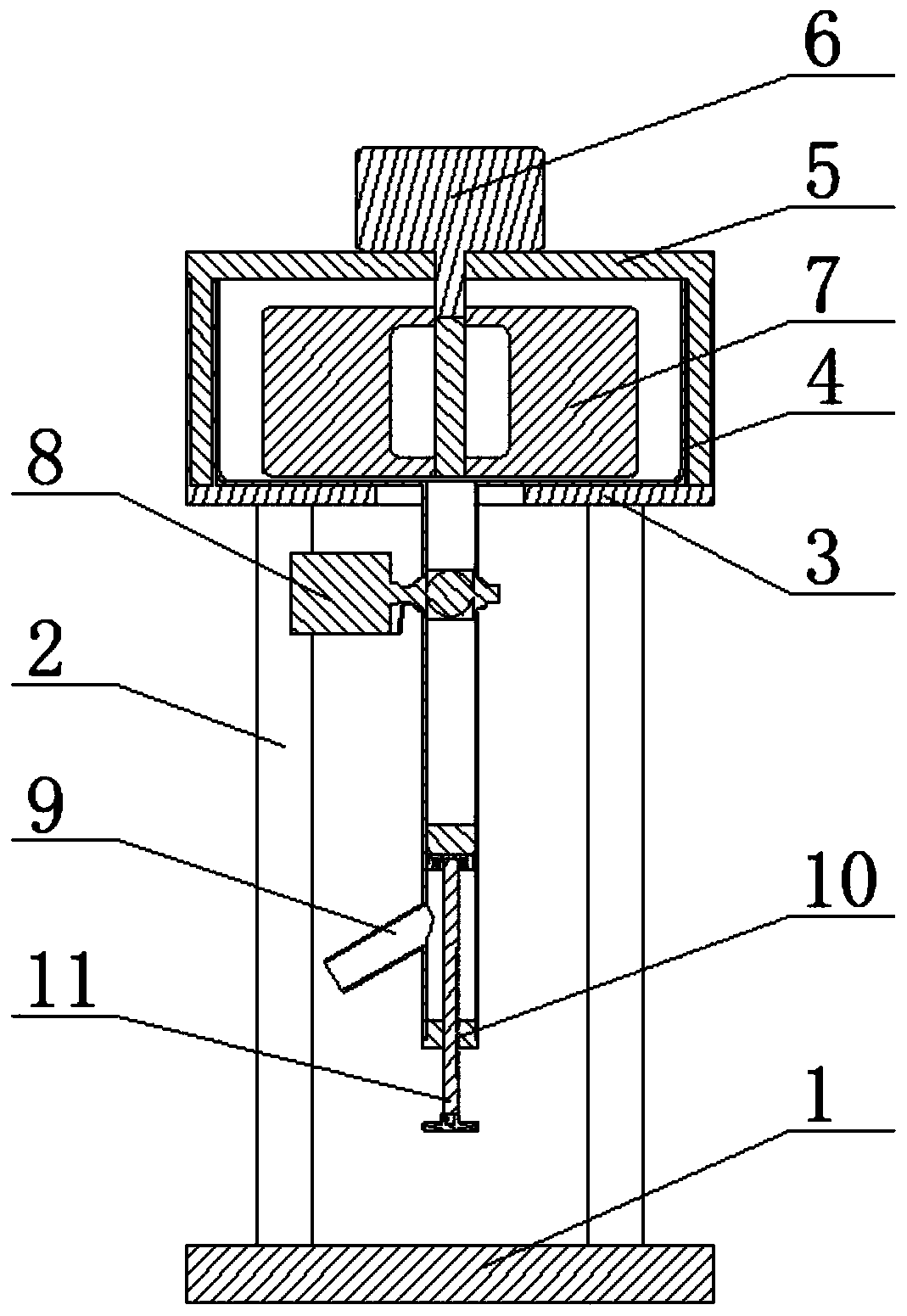

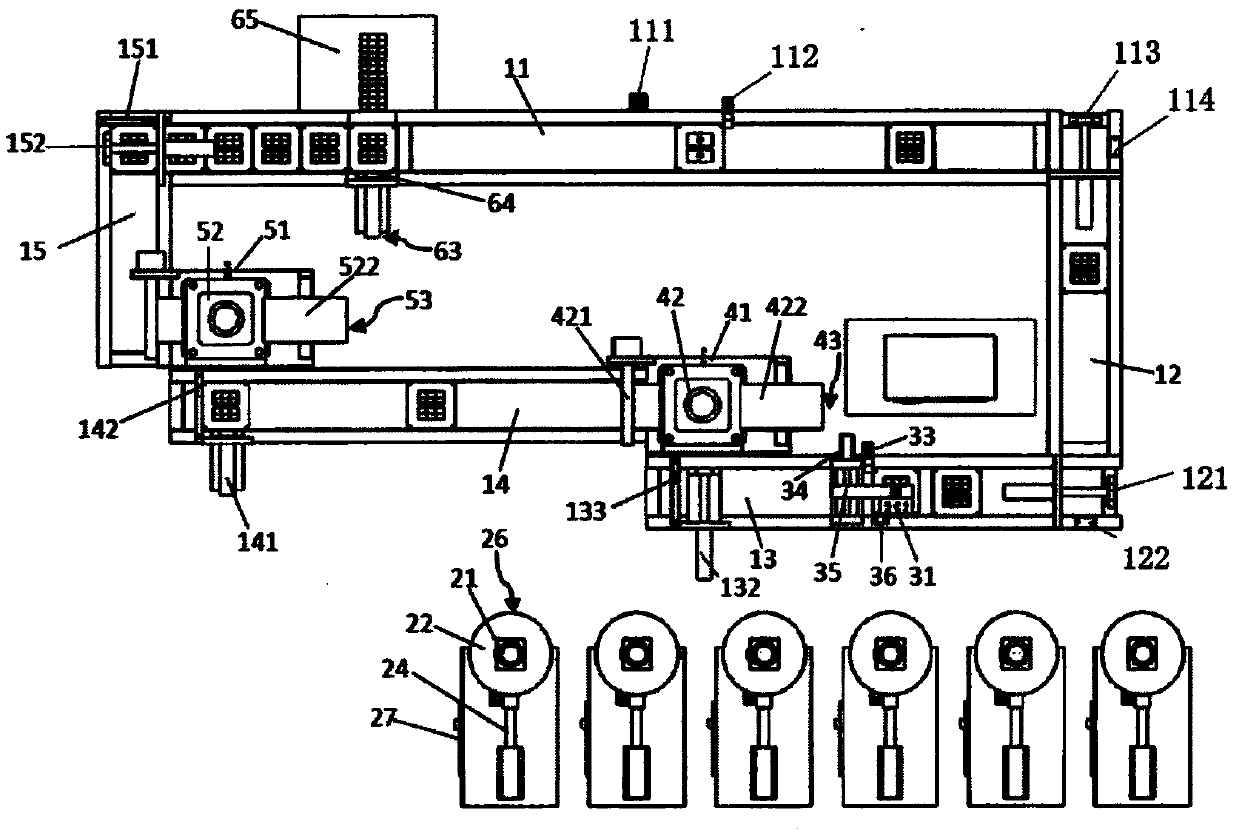

Gas charging apparatus for lighter

ActiveCN107388282APrecise control of filling volumeSimple structureFuel lightersEngineeringSlide plate

The invention discloses a gas charging apparatus for a lighter and relates to the technical field of manufacture of lighters. The gas charging apparatus comprises an ejecting device, a pin lifting device, a gas charging device, a bottom plate and a support. The ejecting device comprises a cylinder, a product carrier plate, a process disc, a Y-axial limiter, an X-axial limiter and a sliding plate. The pin lifting device comprises a positioning plate, a pin lifting plate, a pin lifting tube, a pull rod and an eccentric lift rotor. The gas charging device comprises a cavity plate, gas charging pins and an AB plate; the lateral side of the cavity plate is also provided with a gas inlet that is connected with a gas incoming pipe. The gas charging apparatus is simple in structure and convenient to operate, is suitable for independent operation by a single operator, allows ejection and pin lifting travels to be accurately controlled, and allows gas charging quantity to be precisely controlled, so that reject ratio of a charging procedure is effectively decreased; through alarming of an alarm and a flow controller, the gas charging quantity is under control, waste is avoided, and major safety accidents due to gas leakage are avoided; just after a process disc, a Y-axial positioner and a positioning plate for a corresponding product are renewed, the gas charging apparatus may adapt to various types of lighters and is widely applicable.

Owner:BENXI FENGHE LIGHTER

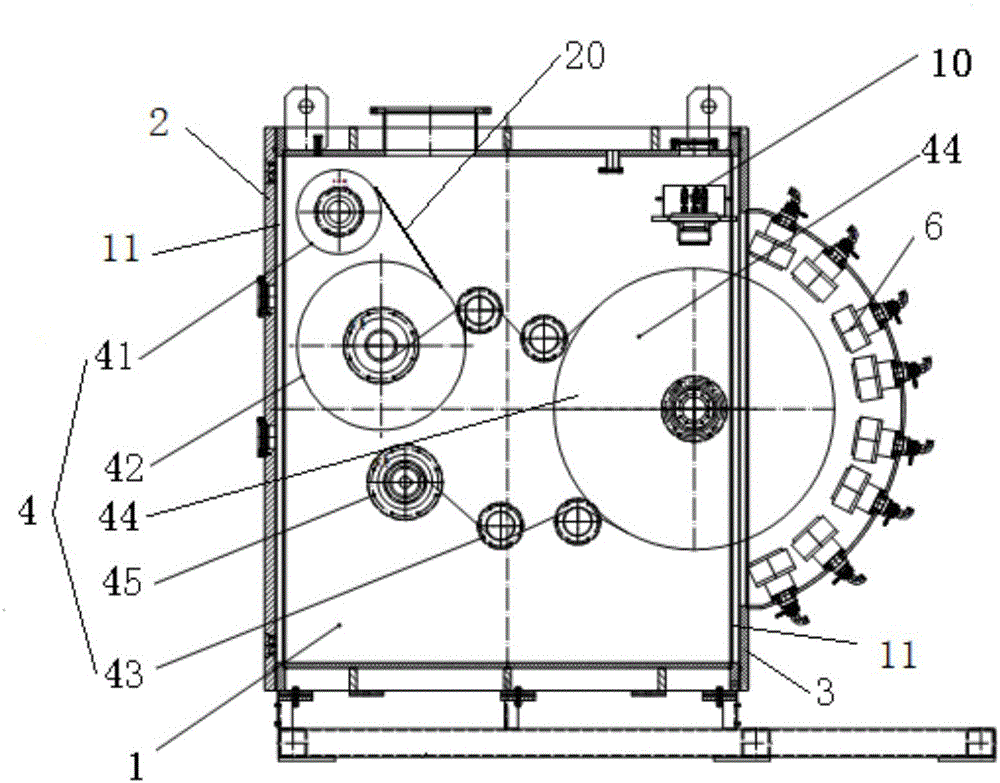

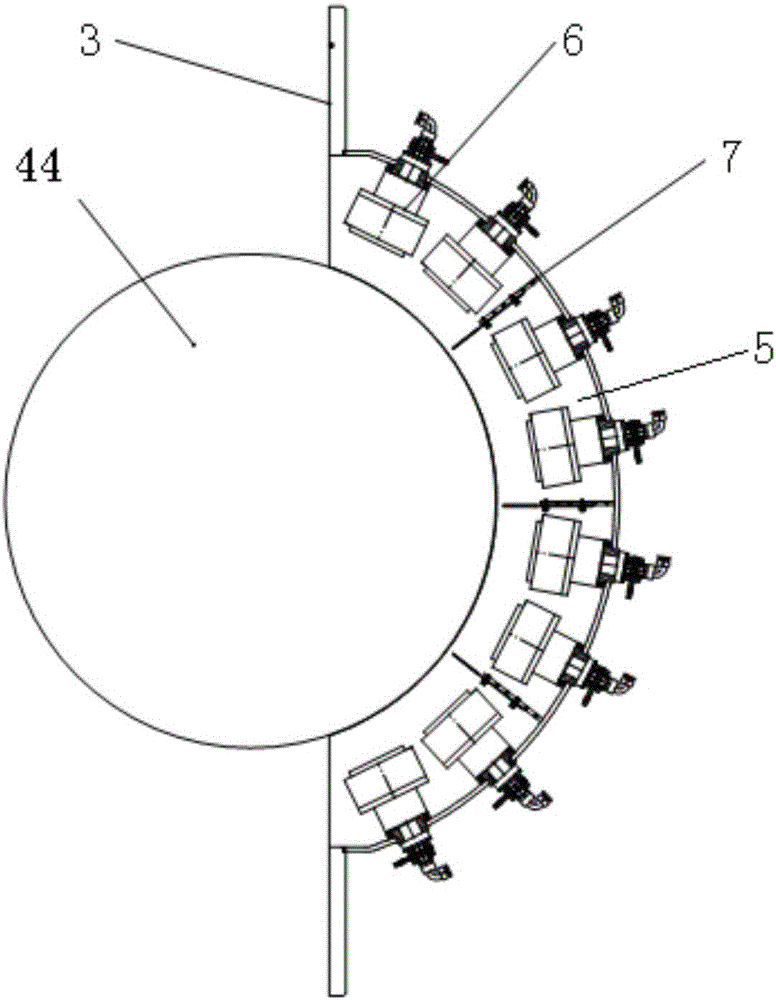

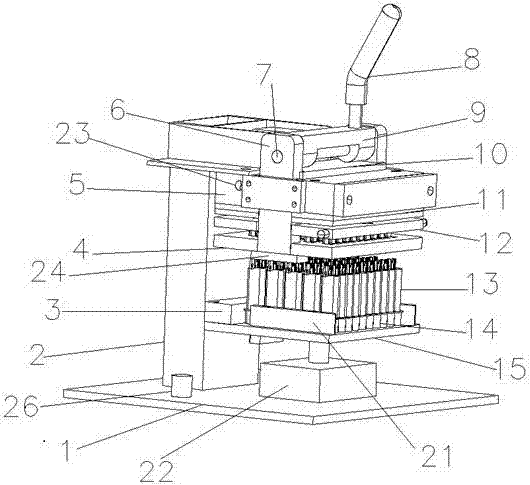

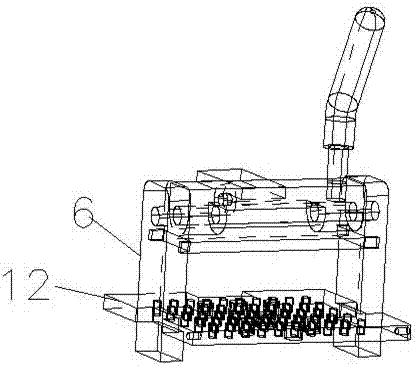

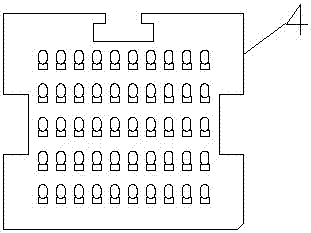

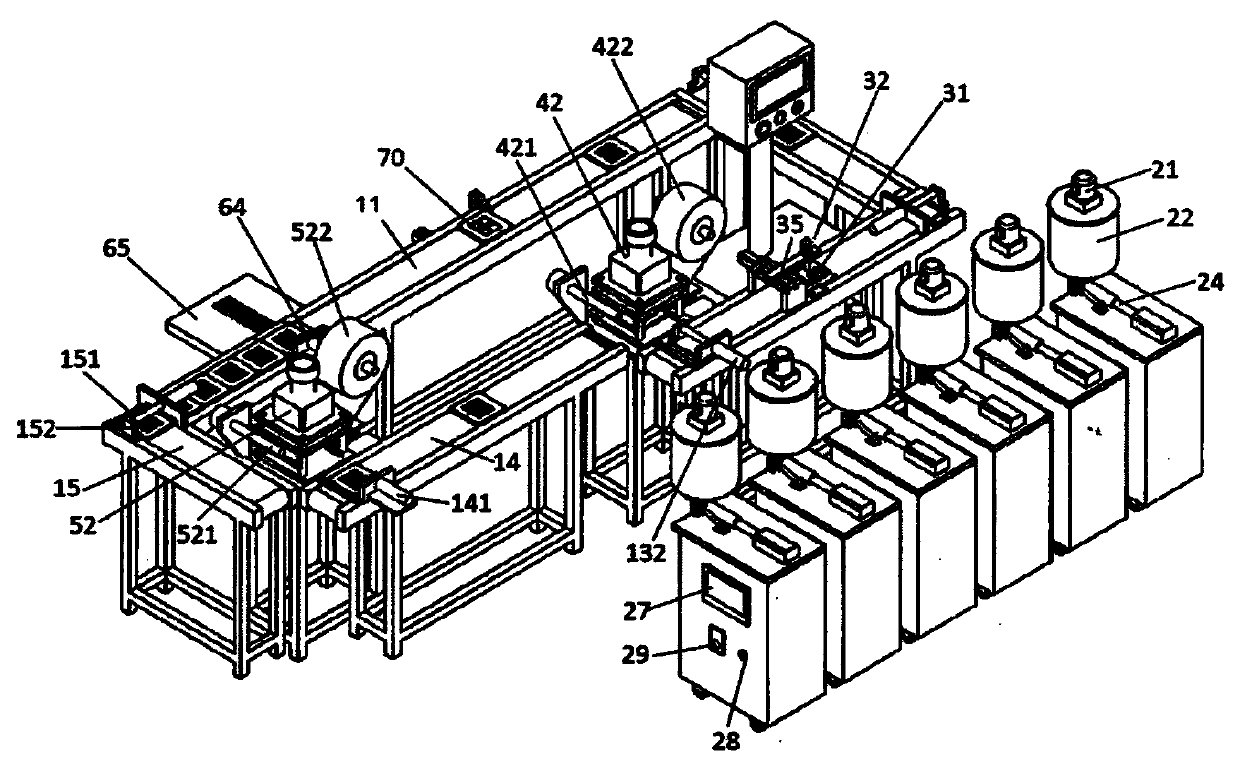

A kind of multi-color bulk powder molding machine and molding method

ActiveCN107116822BUniform automatic productionPrecise control of filling volumeShaping pressEngineeringConveyor belt

The invention provides a multi-color and block-shaped powder forming machine and method. The machine is characterized by comprising a conveying system, a charging unit, a filling unit, a primary pressing unit, a final pressing unit and a product output unit, wherein the conveying system comprises at least one conveyor belt and is capable of conveying a bottom die which is loaded with an inner plate to the filling unit, the primary unit, the final pressing unit and the product output unit in sequence; the charging unit comprises at least two main charging machines for charging different-color materials into the filling unit; the filling unit is capable of filling at least two different-color materials into the inner plate; the primary pressing unit is capable of primarily pressing the materials in the inner plate into multi-color block-shaped powder; the final pressing unit is used for further pressing the multi-color block-shaped powder in the inner plate; and the product output unit is used for outputting the inner plate which is filled with the multi-color block-shaped powder. With the adoption of the machine, a plurality of materials with different colors can be poured to one inner plate and pressed and formed in one time, thus obtaining a multi-color block-shaped powder cosmetic.

Owner:上海浩韵化妆品有限公司

Elbow filling alloy device and filling method thereof

The invention discloses an alloy filling device for pipe bending. The alloy filling device comprises a control system, a low temperature alloy fusion bath, an alloy filling device body, a water bath device comprising a water bath with the water temperature controlled from 30 DEG C to 35 DEG C, a rotating work table and a press machine. A control switch electrically connected with the control system and used for controlling the flow of low temperature alloy is arranged at the discharge port of the alloy filling device body. The rotating work table is arranged in an inclined mode, the included angle between the plane where the rotating work table is located and the horizontal direction ranges from 15 degrees to 30 degrees, and a motor drives the rotating work table to rotate. A plurality of stations where pipe blanks are placed are arranged on the rotating work table in the circumferential direction, the station for filling in the rotating work table is located right below the discharge port, and the station for machining in the rotating work table is located close to the press machine. The rotating work table and the to-be-filled pipe blanks at the station for filling are soaked in the water bath. The alloy filling device has the advantages that the structure is compact, the temperature control effect is better, the low temperature alloy filling effect is better, the cooling mode is more reasonable, and the rejection rate of pipe bending can be controlled better.

Owner:NINGBO SIMING AUTOMOBILE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com