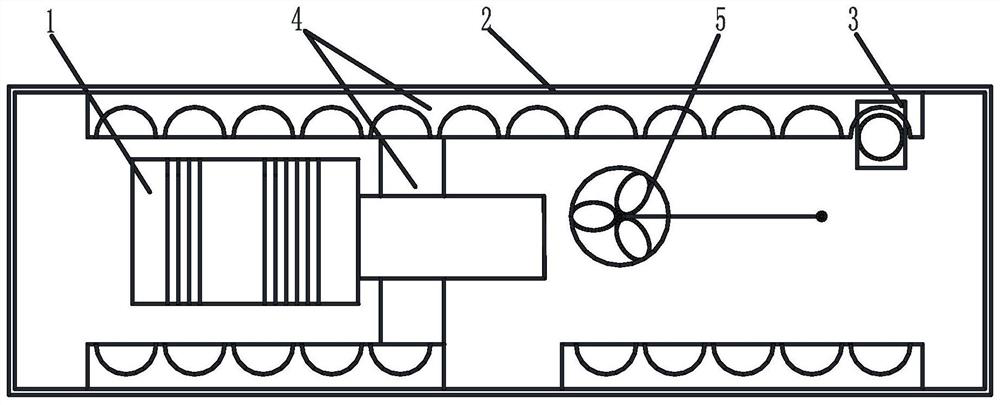

Movable skid-mounted gas cylinder group filling device and method

A gas cylinder and skid-mounted technology, which is applied in the field of a movable skid-mounted gas cylinder group filling device and method, can solve the problems of narrow temperature control range, high energy consumption, uneven heating of the cylinder group, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

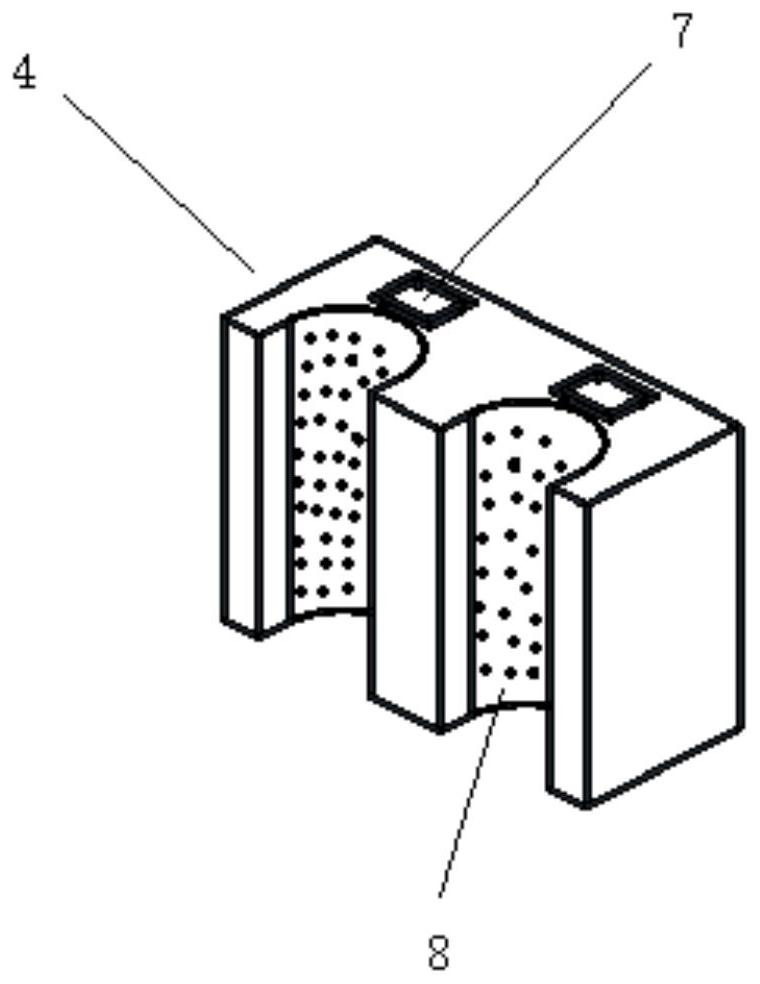

Method used

Image

Examples

Embodiment 1

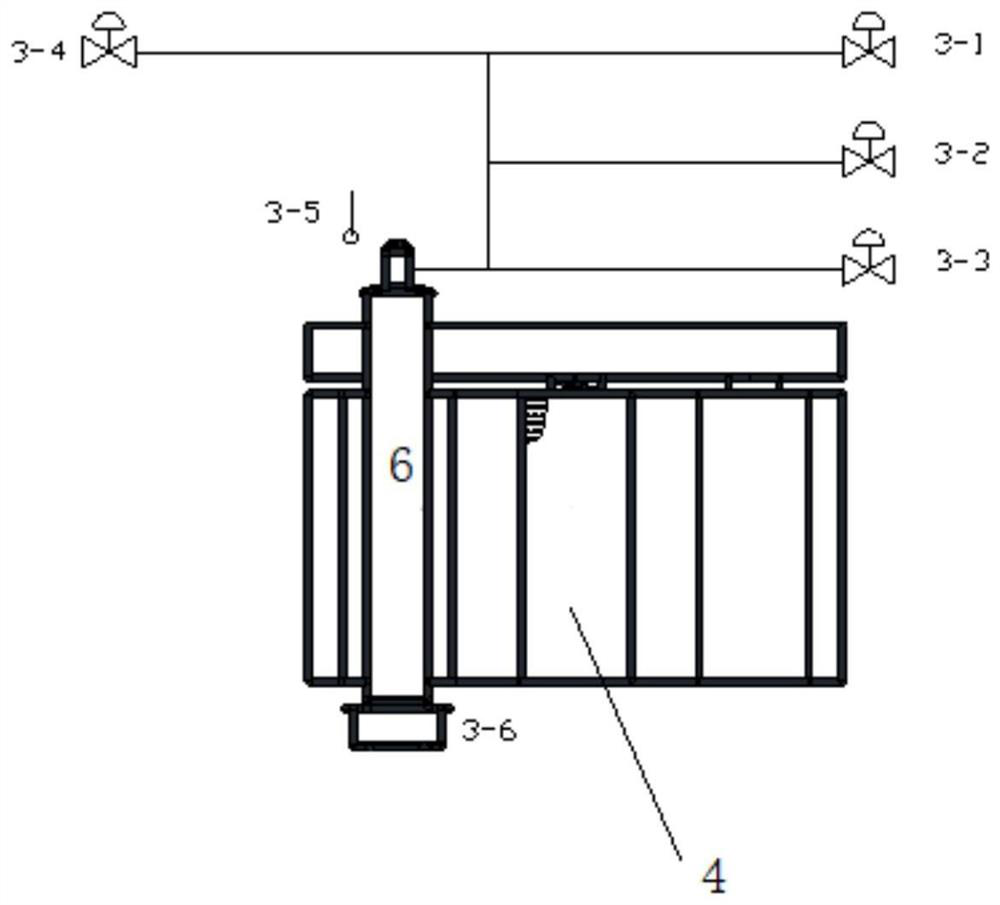

[0041] The filling method using the movable skid-mounted gas cylinder group filling device includes the following steps:

[0042]The cabinet-type heating and cooling air-conditioning unit (dedicated air-conditioning cabinet) is heated by electric heating tubes, and the cooling coil is connected to the cooling medium for cooling to control the temperature inside the cabinet.

[0043] Filling measurement control system 3 adopts electronic scale 3-6 for weighing, uses program controller and electronic scale to control bottle clearing, purging, leak detection, filling process, opens recovery valve 3-1 and uses temperature adjustment system when clearing bottle Heating and heating duct system raises the ambient temperature around the bottle body to about 10°C higher than the bubble point temperature of the medium in the bottle, and steams the residual gas in the bottle to the recovery pipeline; after clearing the bottle, open the purge valve 3-2 and fill it with helium Replace the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com