Control method for electronic expansion valve, self-adaptive control method for heat pump, and device thereof

The technology of an electronic expansion valve and a control method is applied in the self-adaptive control of a heat pump device and the control field of an electronic expansion valve, and can solve the problems of inability to adapt quickly, reliability and safety cannot be guaranteed, and the service life of the system is reduced. The system is self-adapting, efficient and stable operation, reliable and safe operation of protection, and effective overheating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

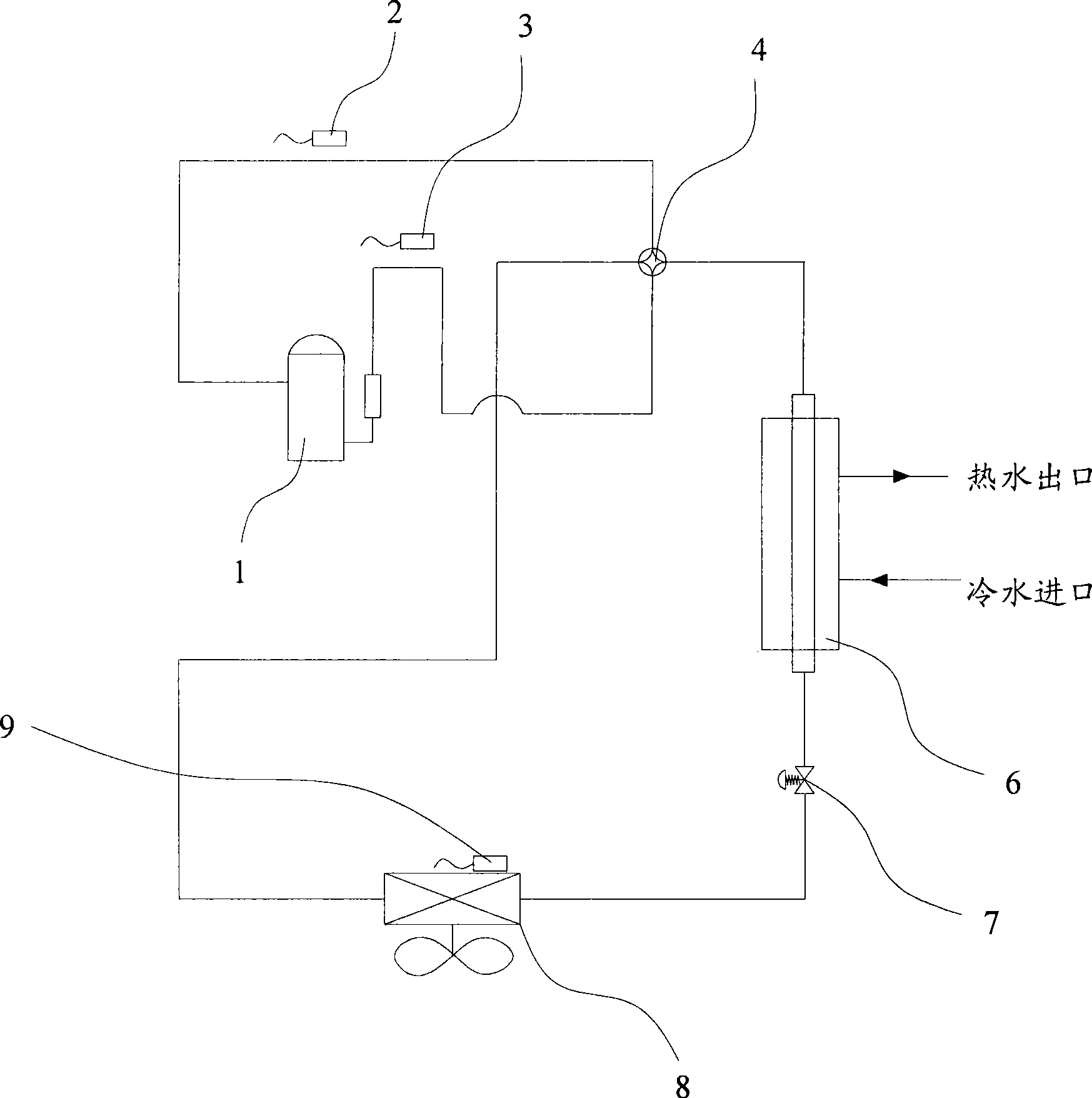

[0042] figure 1 It is a system diagram of a heat pump device. The heat pump device can be a heat pump water heater and a heat pump air-conditioning system. As shown in the figure, the heat exchange working medium in the low-pressure inlet end of the compressor 1 is gaseous, pressurized by the compressor 1, and the gaseous state The heat exchange working medium (refrigerant) is converted into liquid heat exchange working medium in the condenser 6 through the four-way reversing valve 4 to release heat, heat the cold water flowing in from the cold water inlet, and the heat exchange working medium in the condenser 6 After throttling by the electronic expansion valve 7, it flows into the evaporator 8. The heat transfer medium evaporates in the evaporator 8 due to the pressure drop and becomes gaseous, and absorbs heat. The gaseous heat transfer medium ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com