Patents

Literature

3657results about "Gas handling/storage purpose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

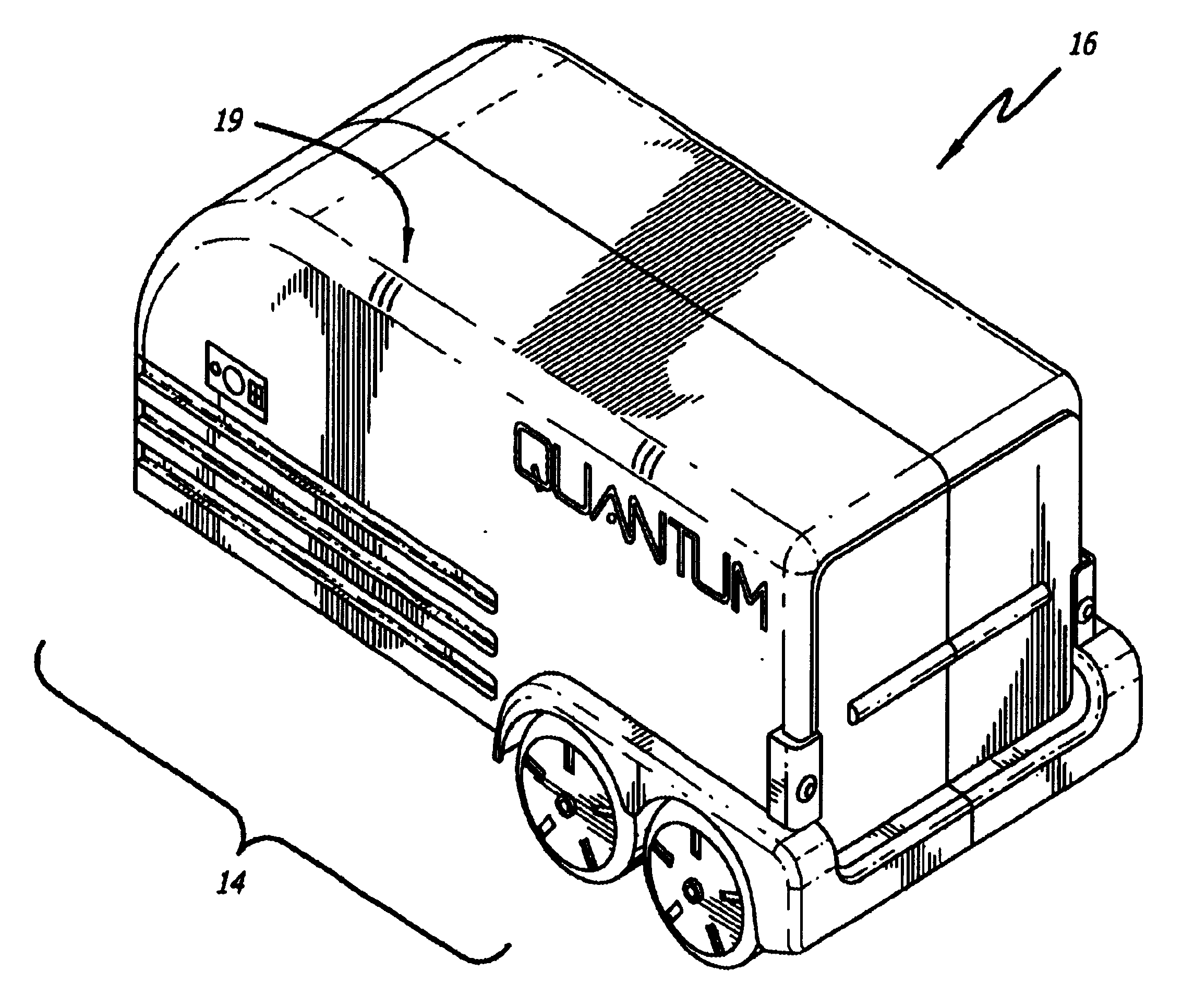

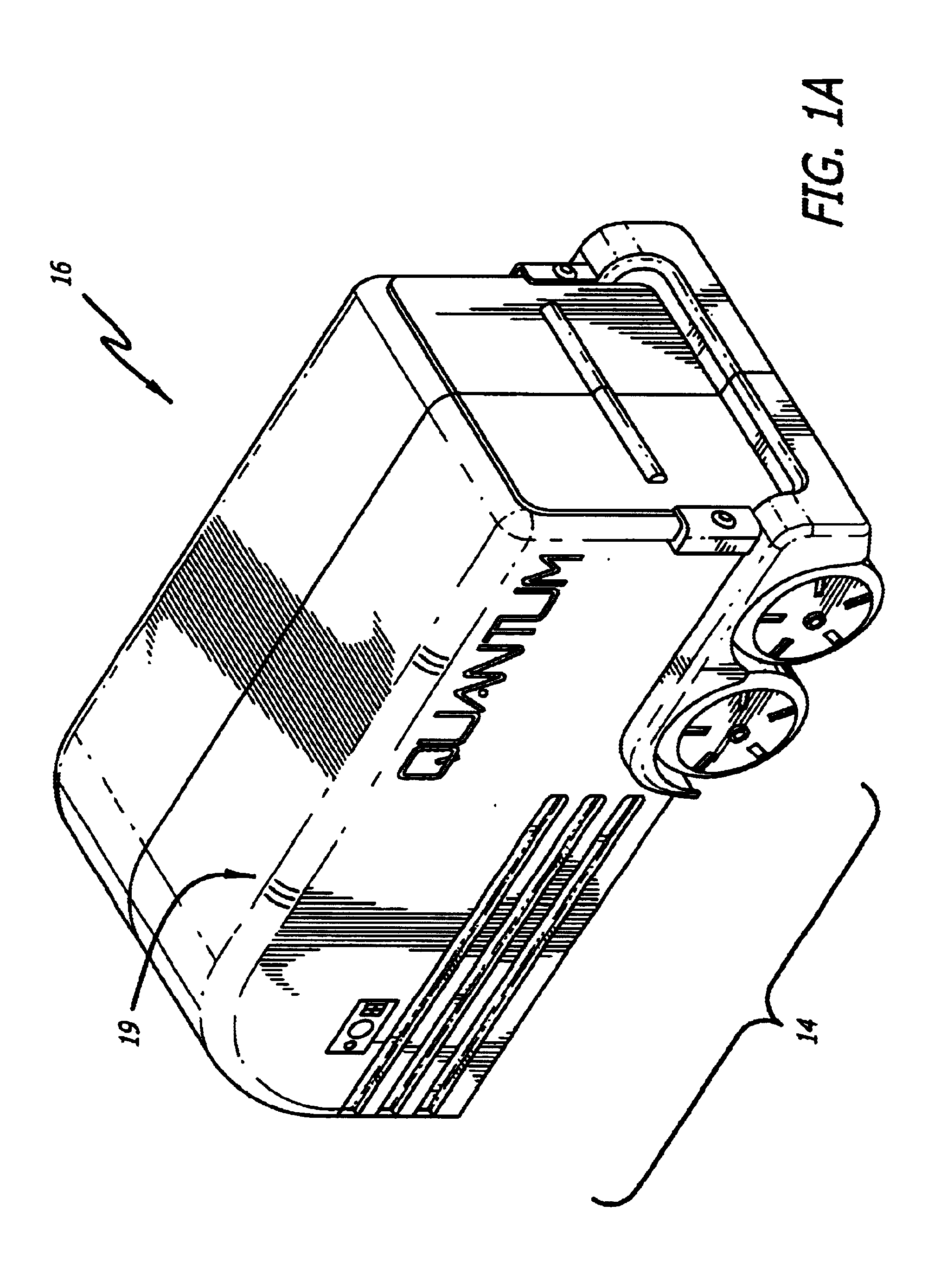

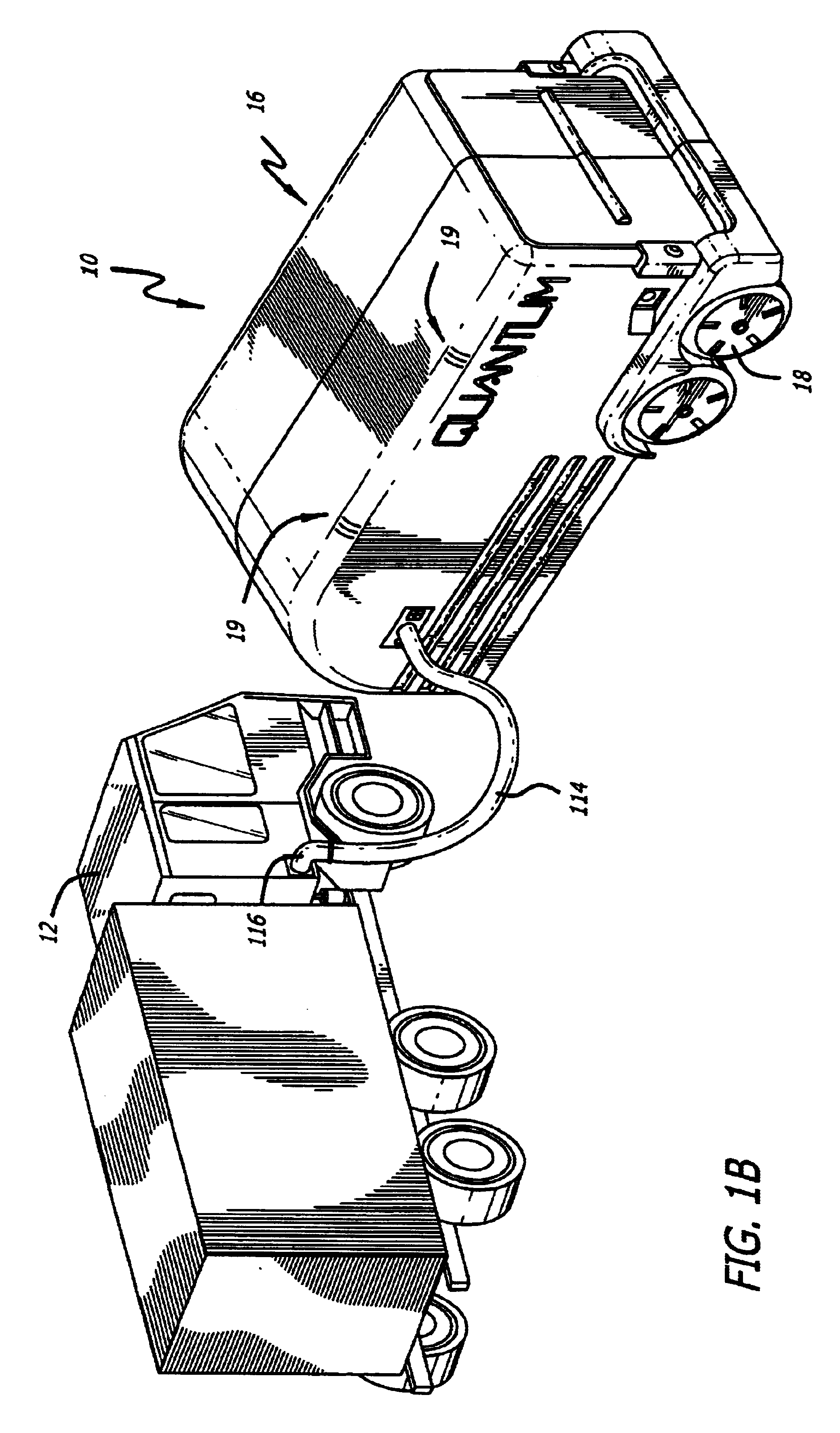

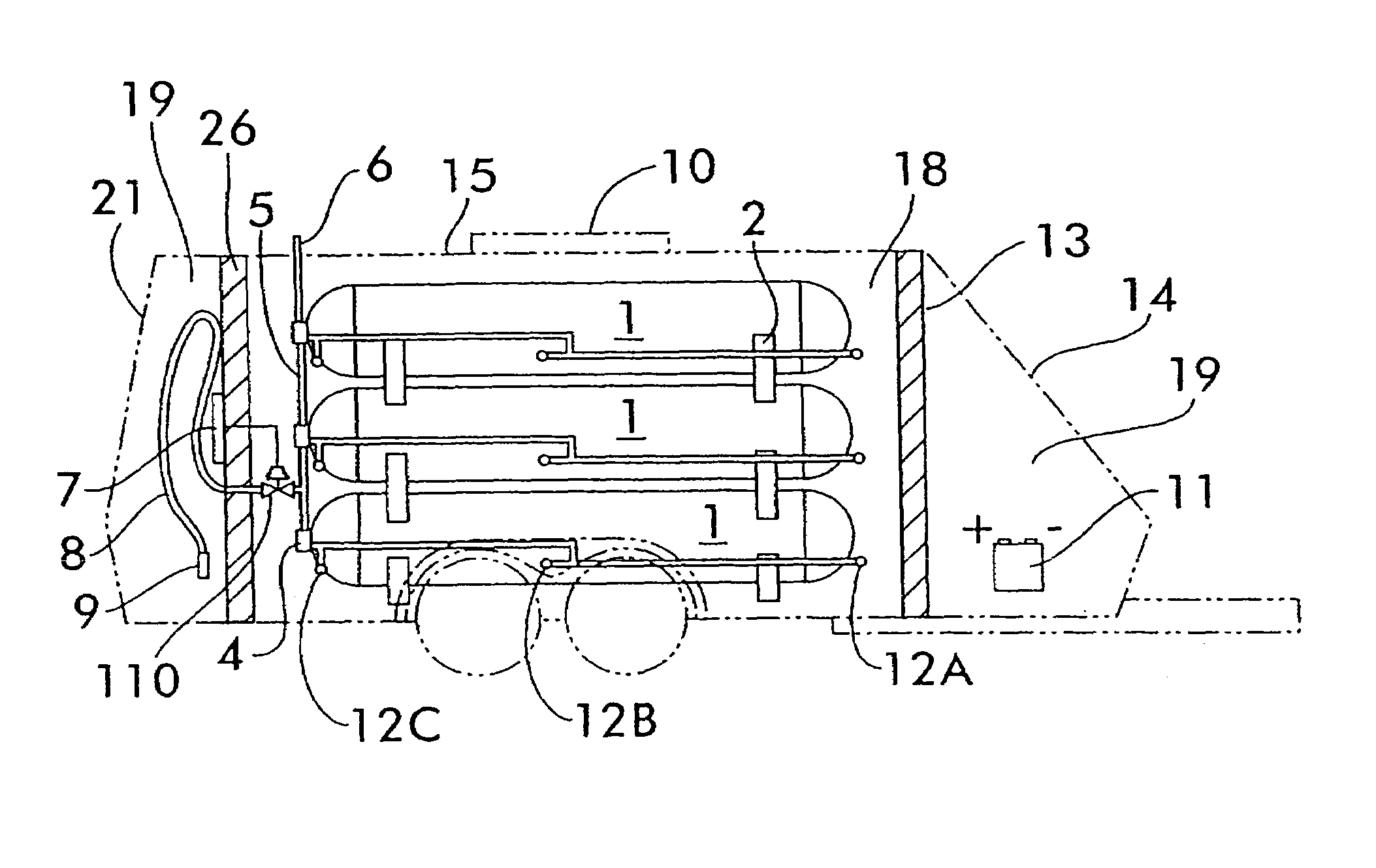

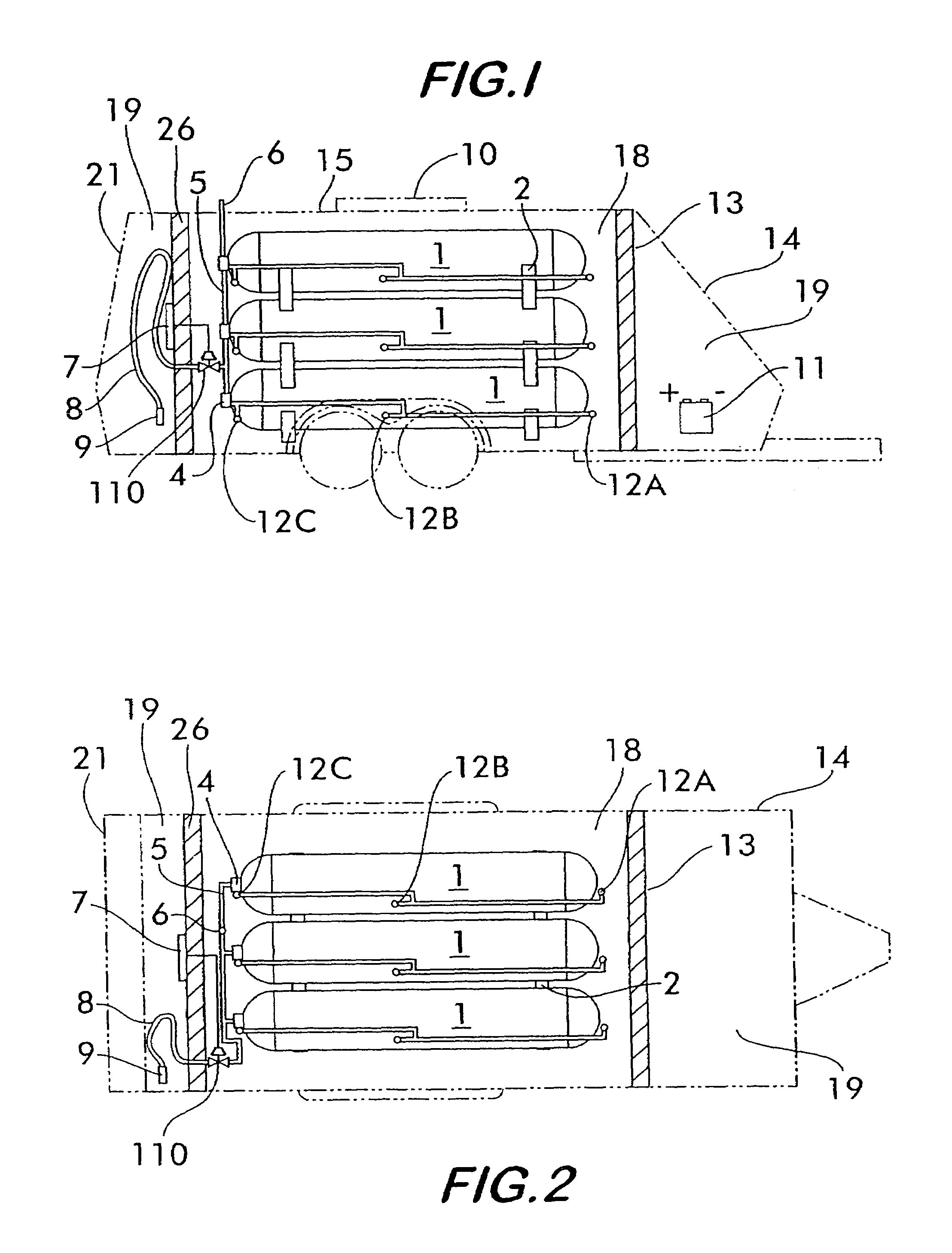

Transportable hydrogen refueling station

InactiveUS6755225B1Easy to monitorReduce riskTank vehiclesGas handling applicationsHigh pressureGaseous hydrogen

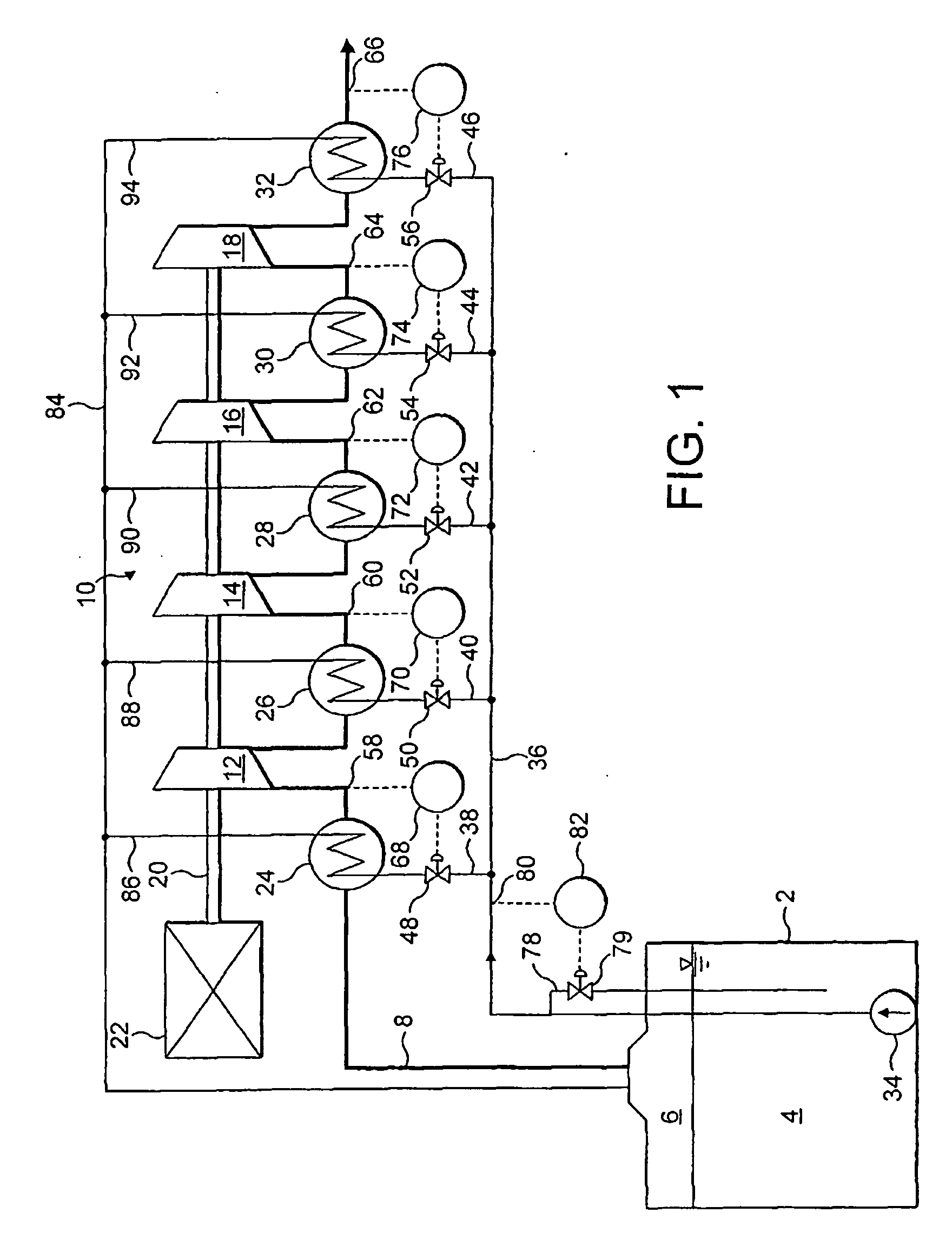

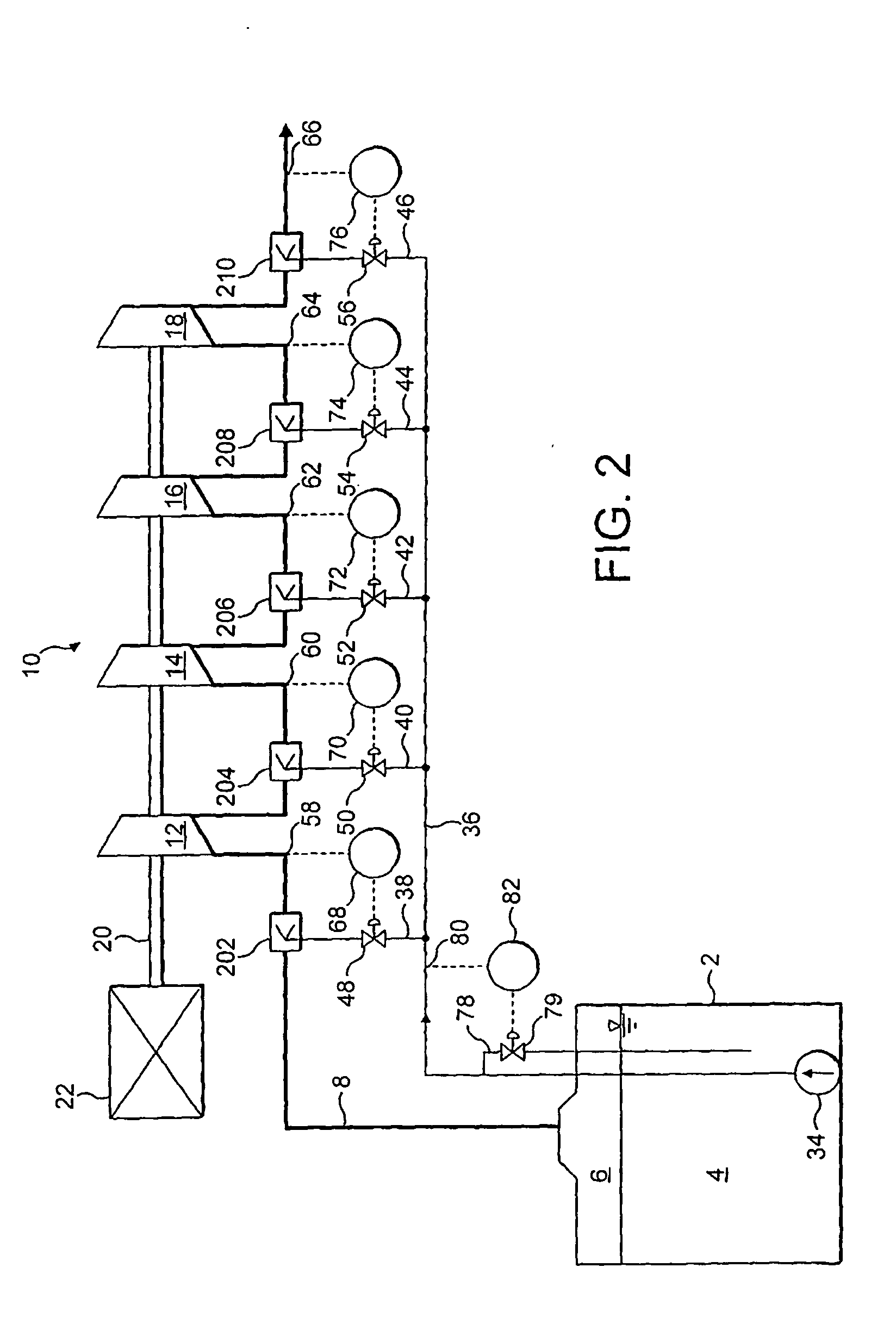

A portable hydrogen refueling stations which can dispense gaseous hydrogen from one or more internal high pressure tanks. The refueling station can be refilled with a lower pressure hydrogen gas feed and then compressed for storage within the refueling station.

Owner:QUANTUM FUEL SYST TECH WORLDWIDE INC

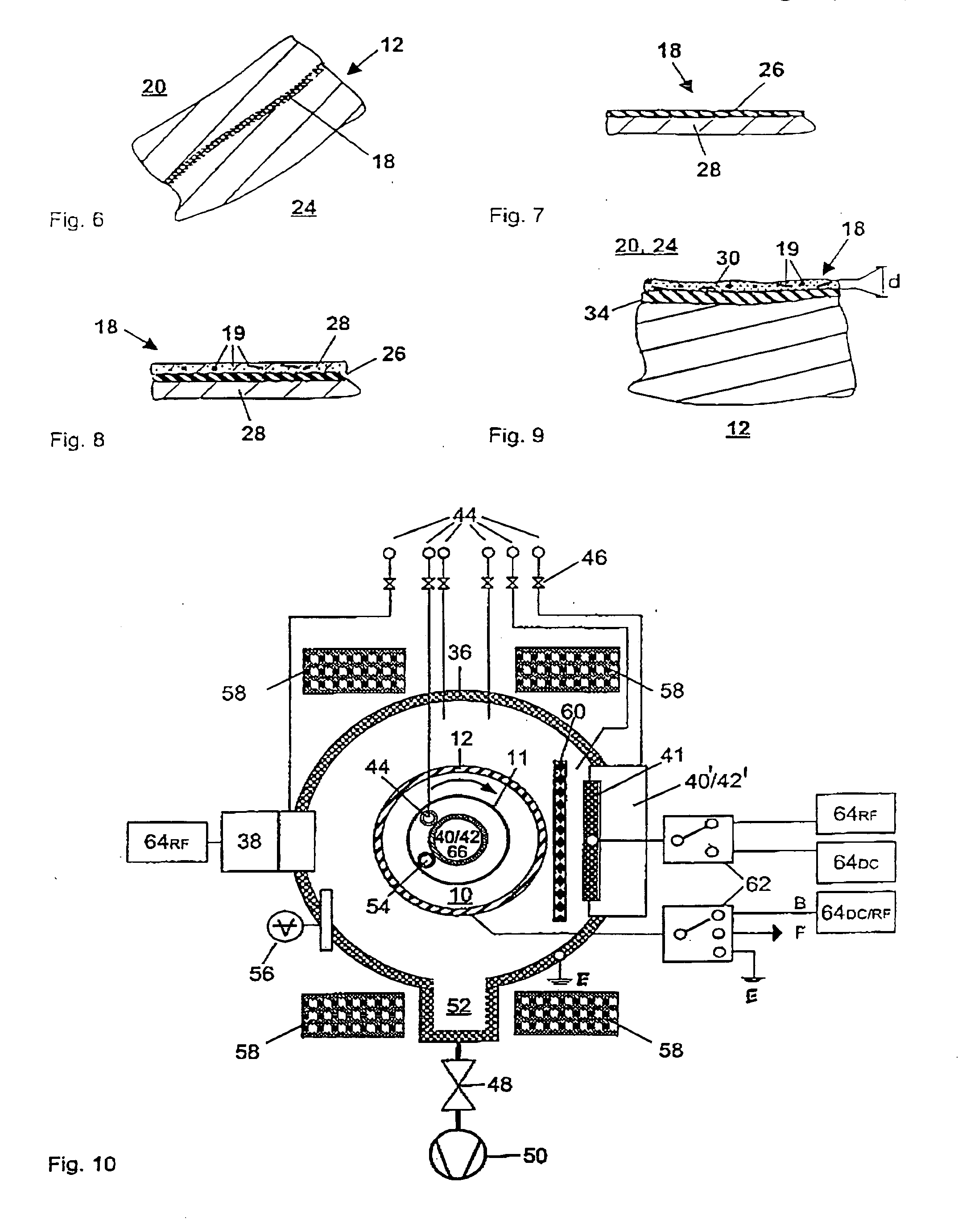

Method of passivating a gas vessel or component of a gas transfer system using a silicon overlay coating

A method of passivating the interior surface of a gas storage vessel to protect the surface against corrosion. The interior surface of the vessel is first dehydrated and then evacuated. A silicon hydride gas is introduced into the vessel. The vessel and silicon hydride gas contained therein are heated and pressurized to decompose the gase. A layer of silicon is deposited on the interior surface of the vessel. The duration of the silicon depositing step is controlled to prevent the formation of silicon dust in the vessel. The vessel is then purged with an inert gas to remove the silicon hydride gas. The vessel is cycled through the silicon depositing step until the entire interior surface of the vessel is covered with a layer of silicon. The vessel is then evacuated and cooled to room temperature.

Owner:SILCOTEK CORP

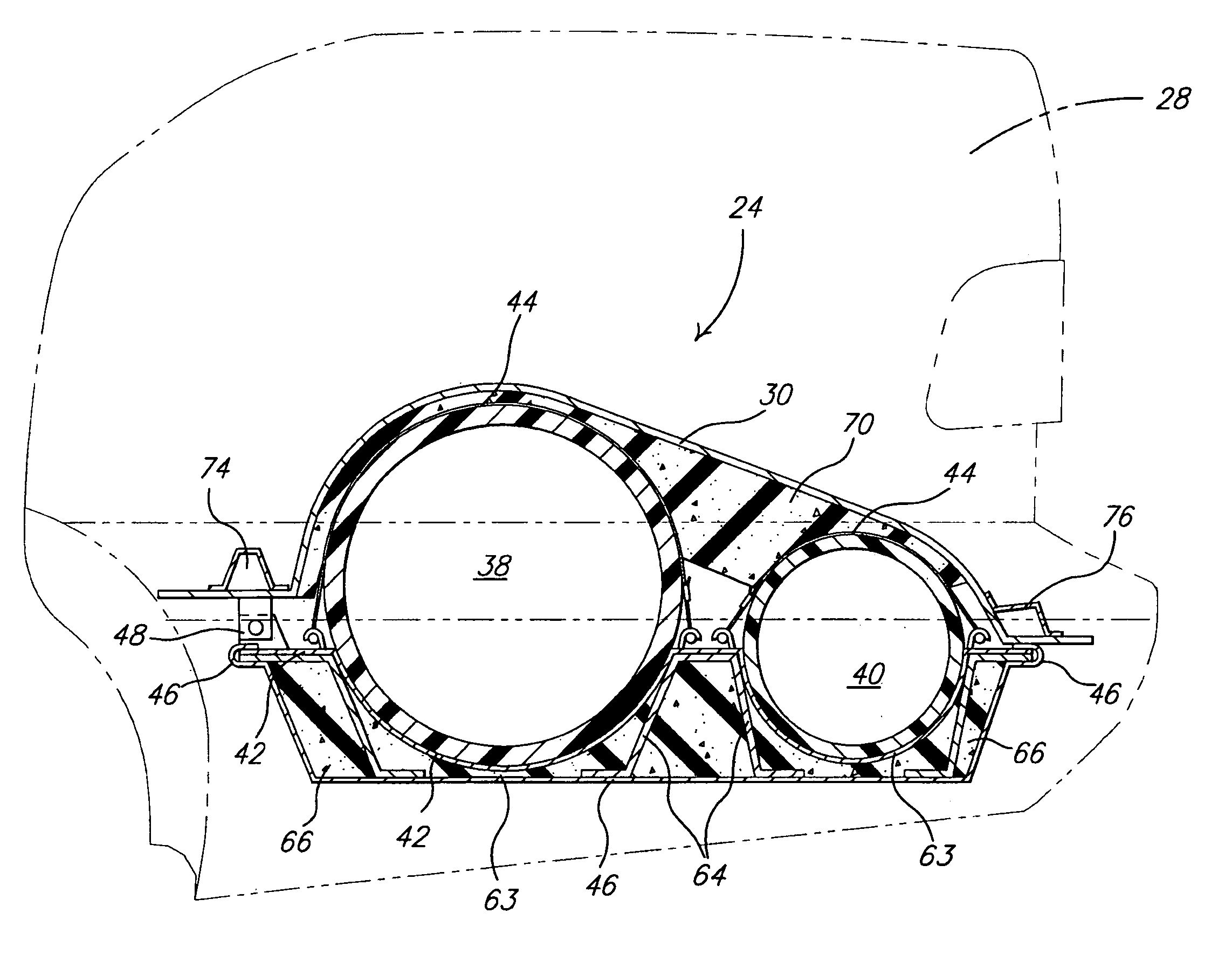

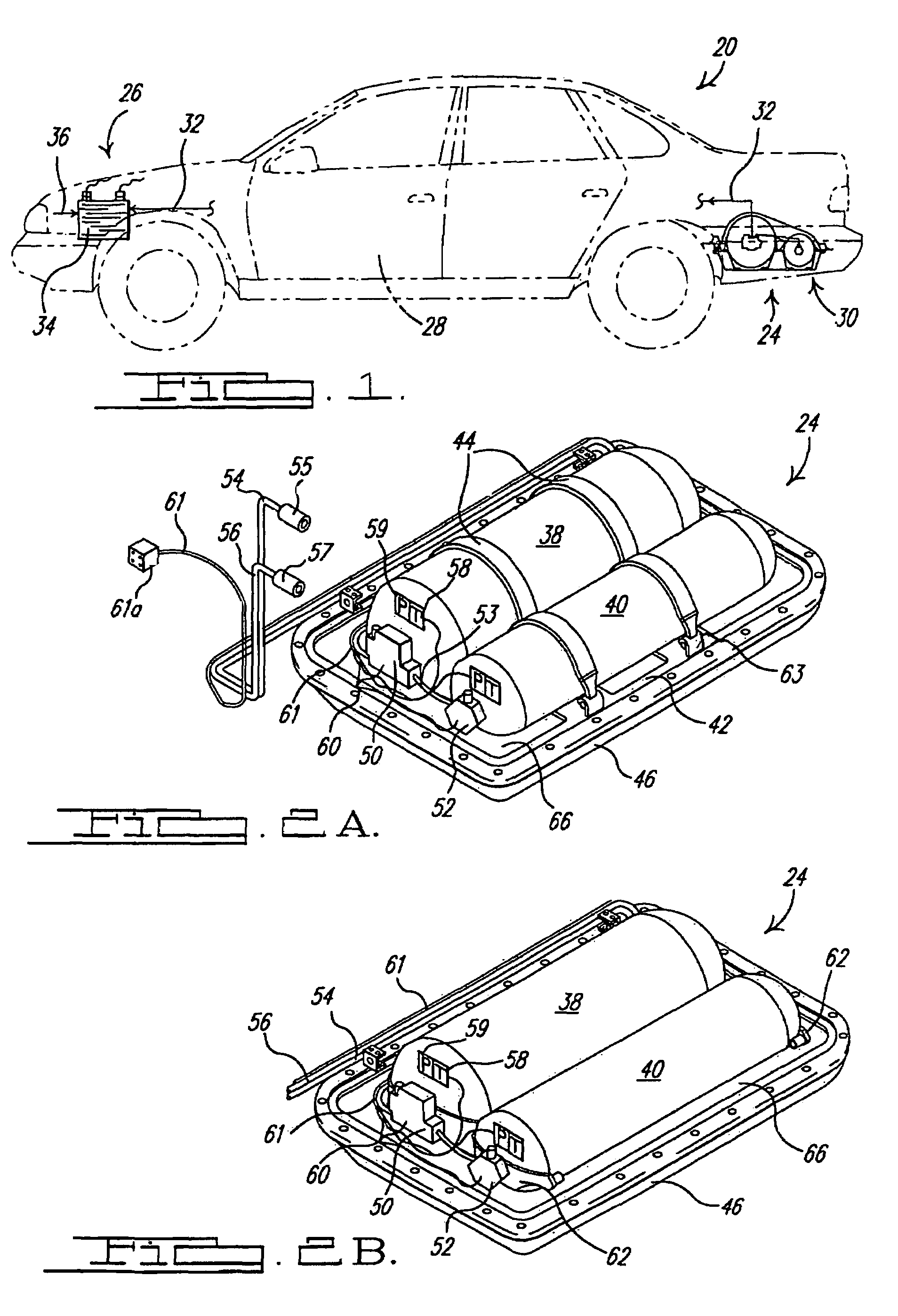

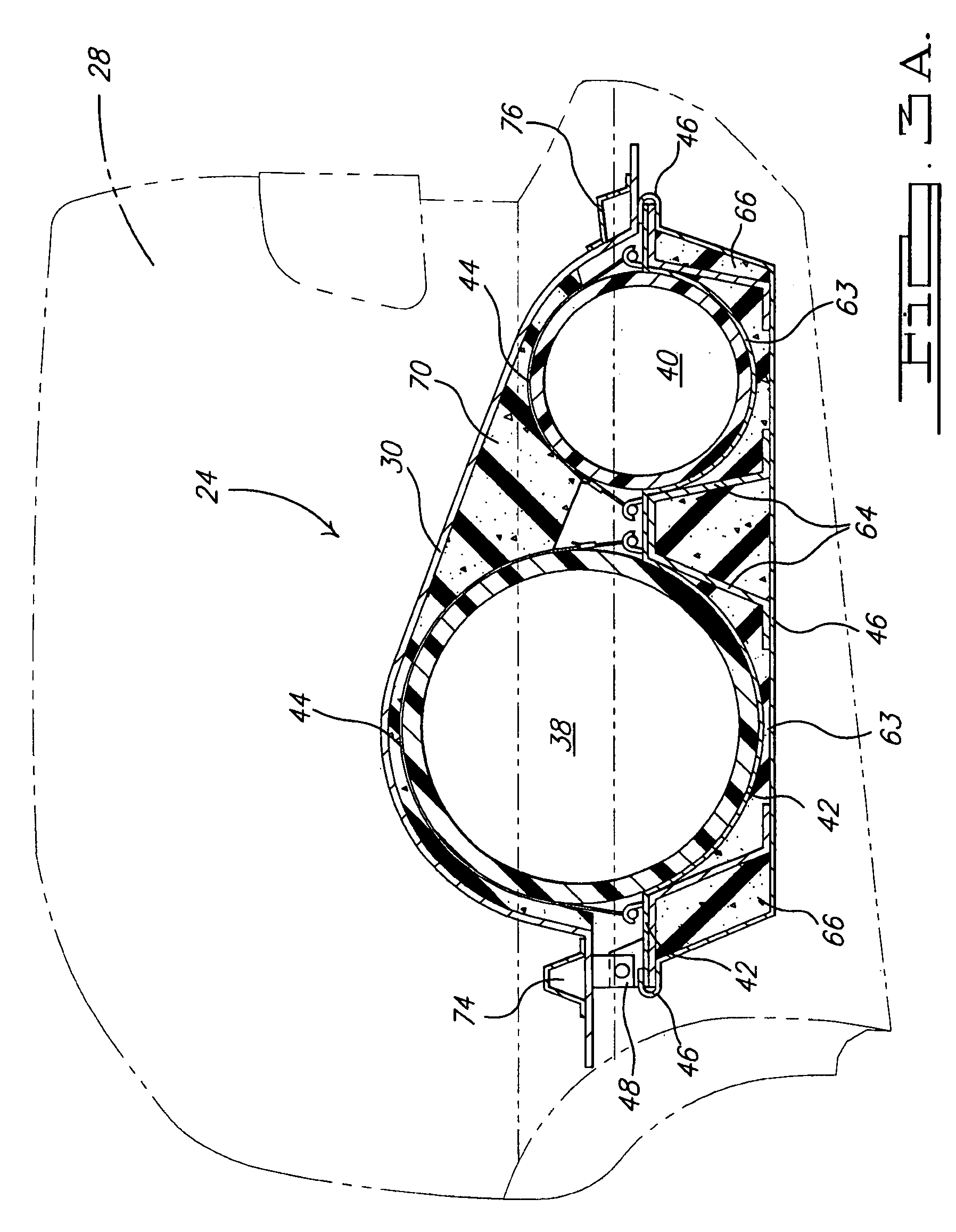

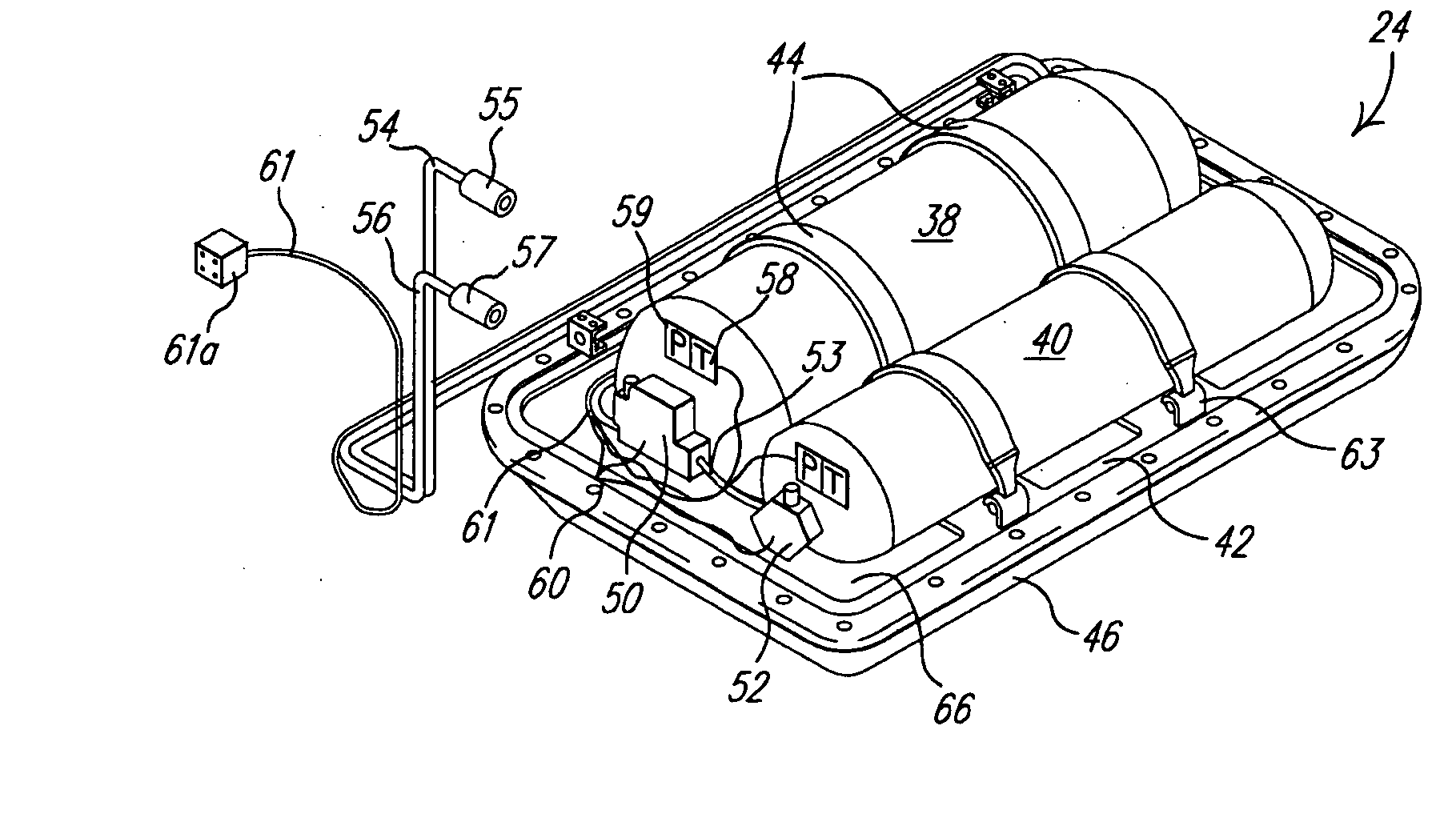

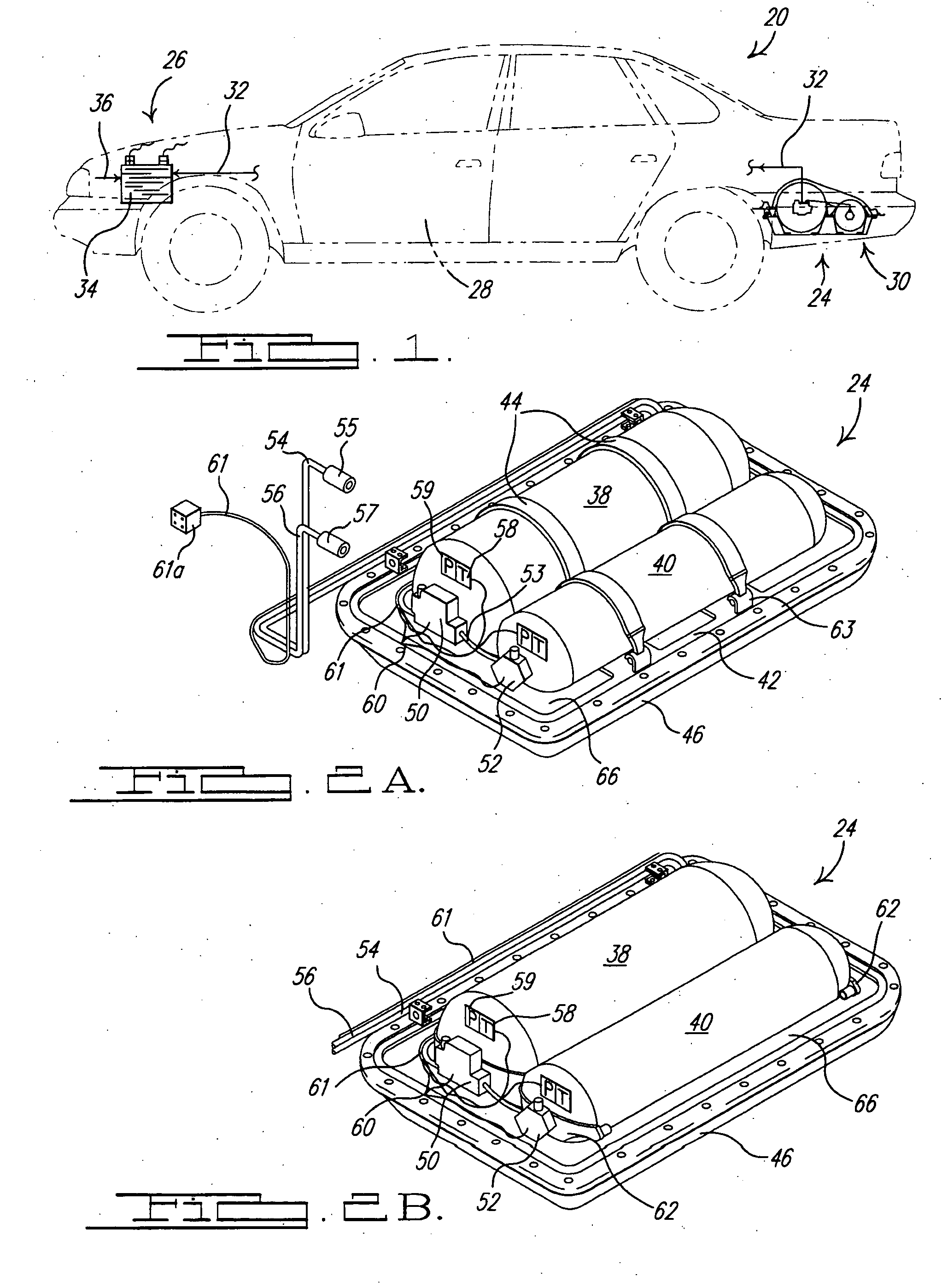

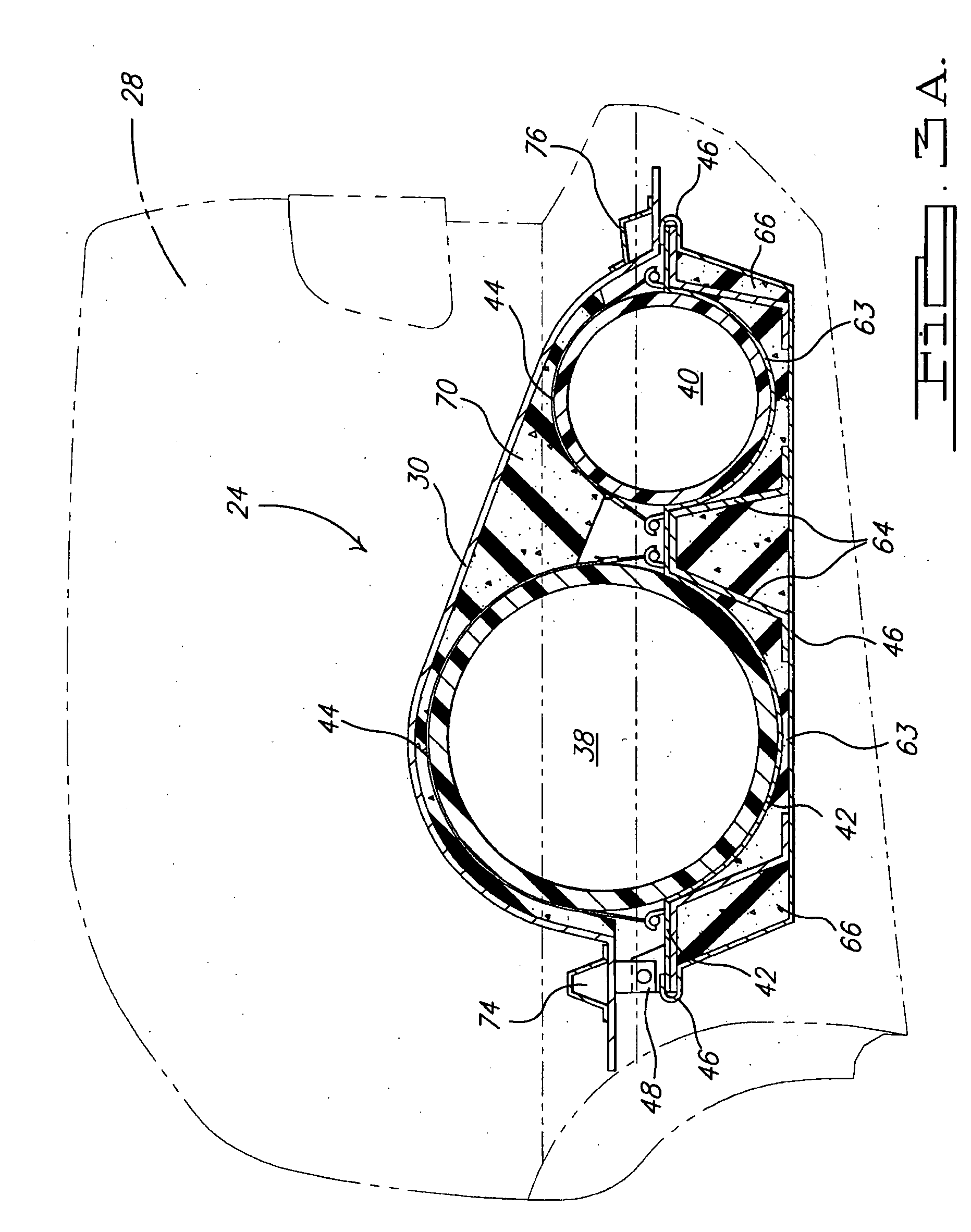

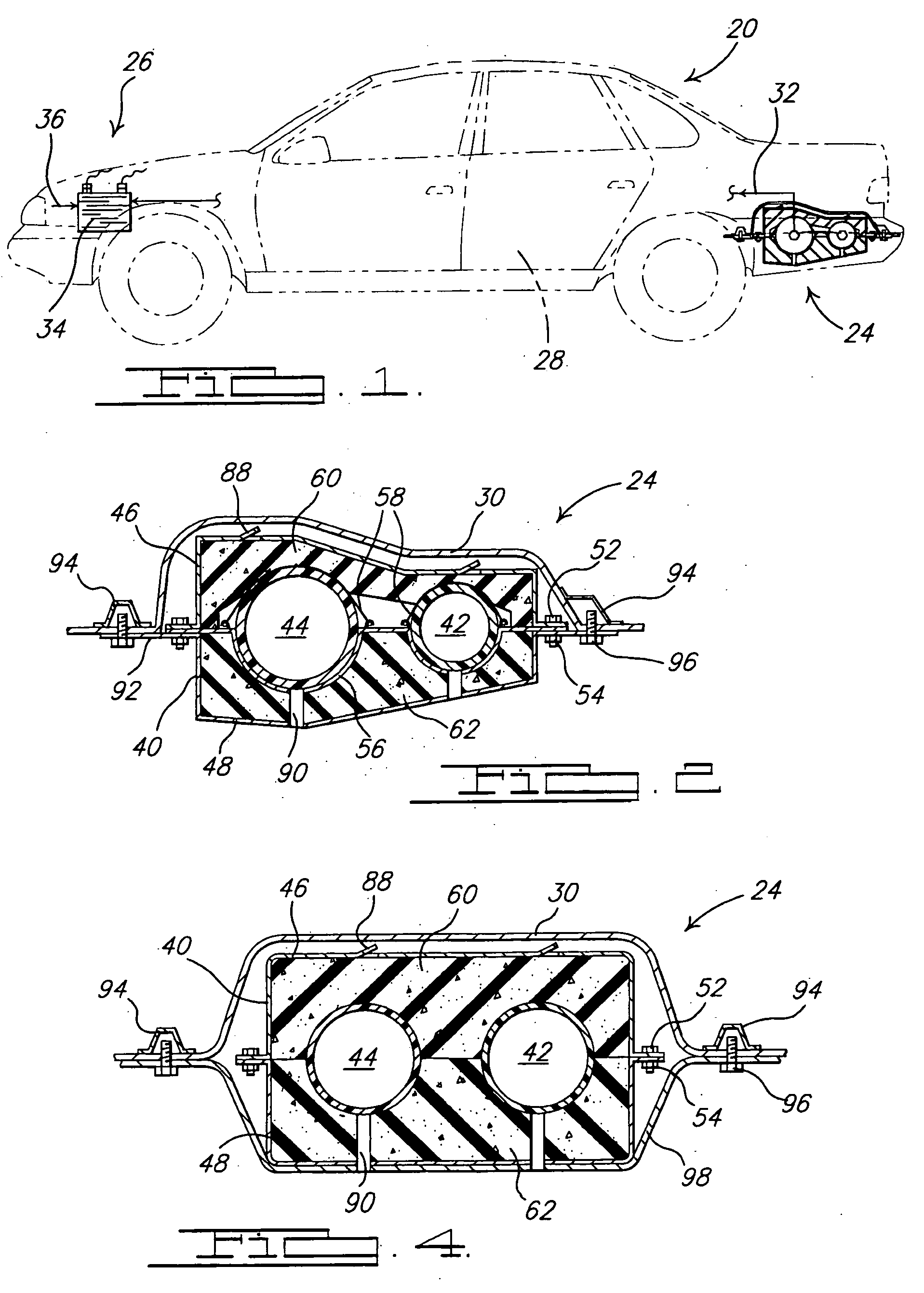

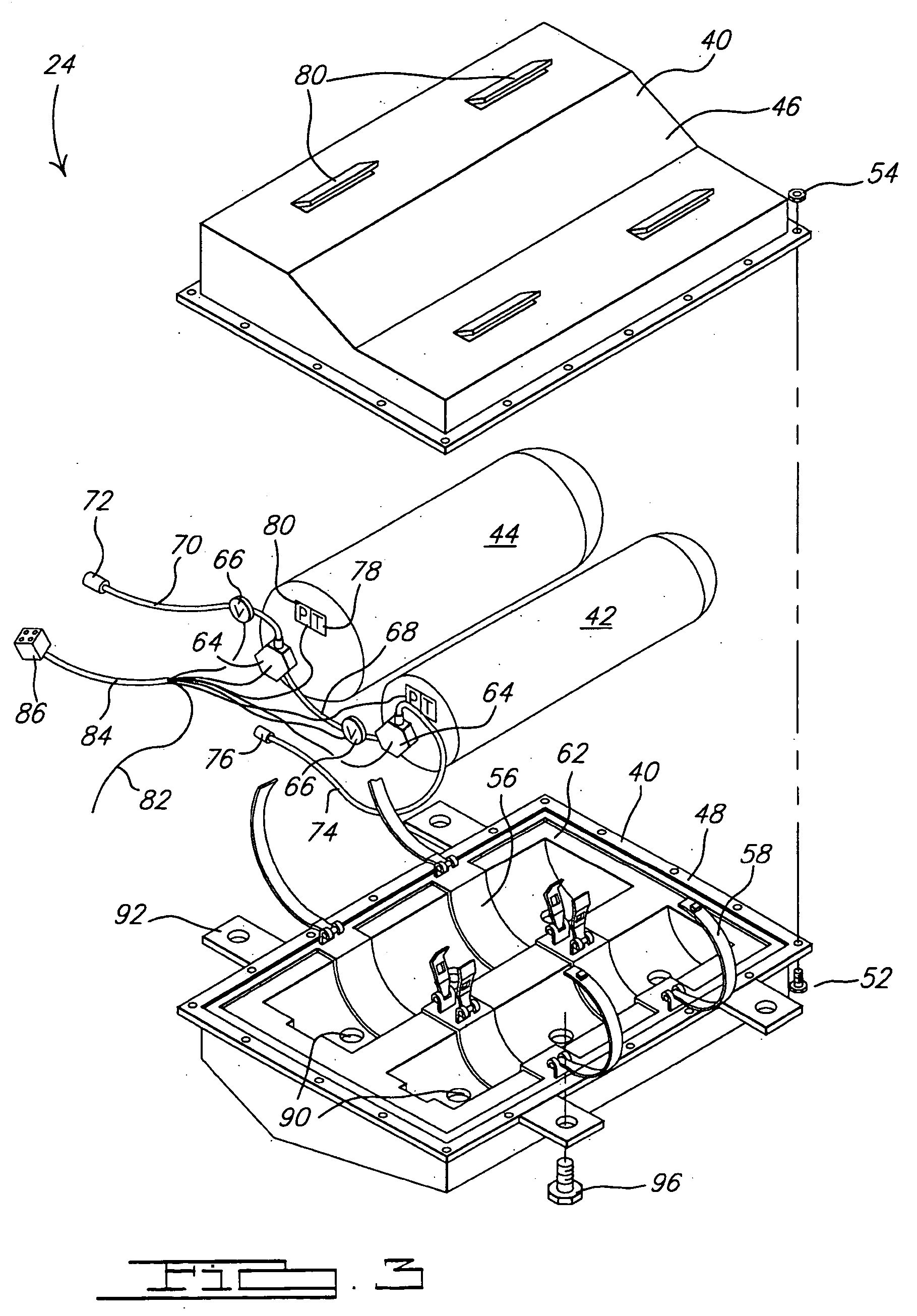

Modular fuel storage system for a vehicle

A gaseous fuel storage system for a vehicle is disclosed. The fuel storage system can be installed as a modular unit in the vehicle. The fuel storage system is pivotable relative to the vehicle to allow easy accessibility to the storage tanks without requiring the storage tanks to be unmounted from the vehicle. The fuel storage system also provides protection for the storage tanks through the use of shielding and energy absorbing material.

Owner:GM GLOBAL TECH OPERATIONS LLC

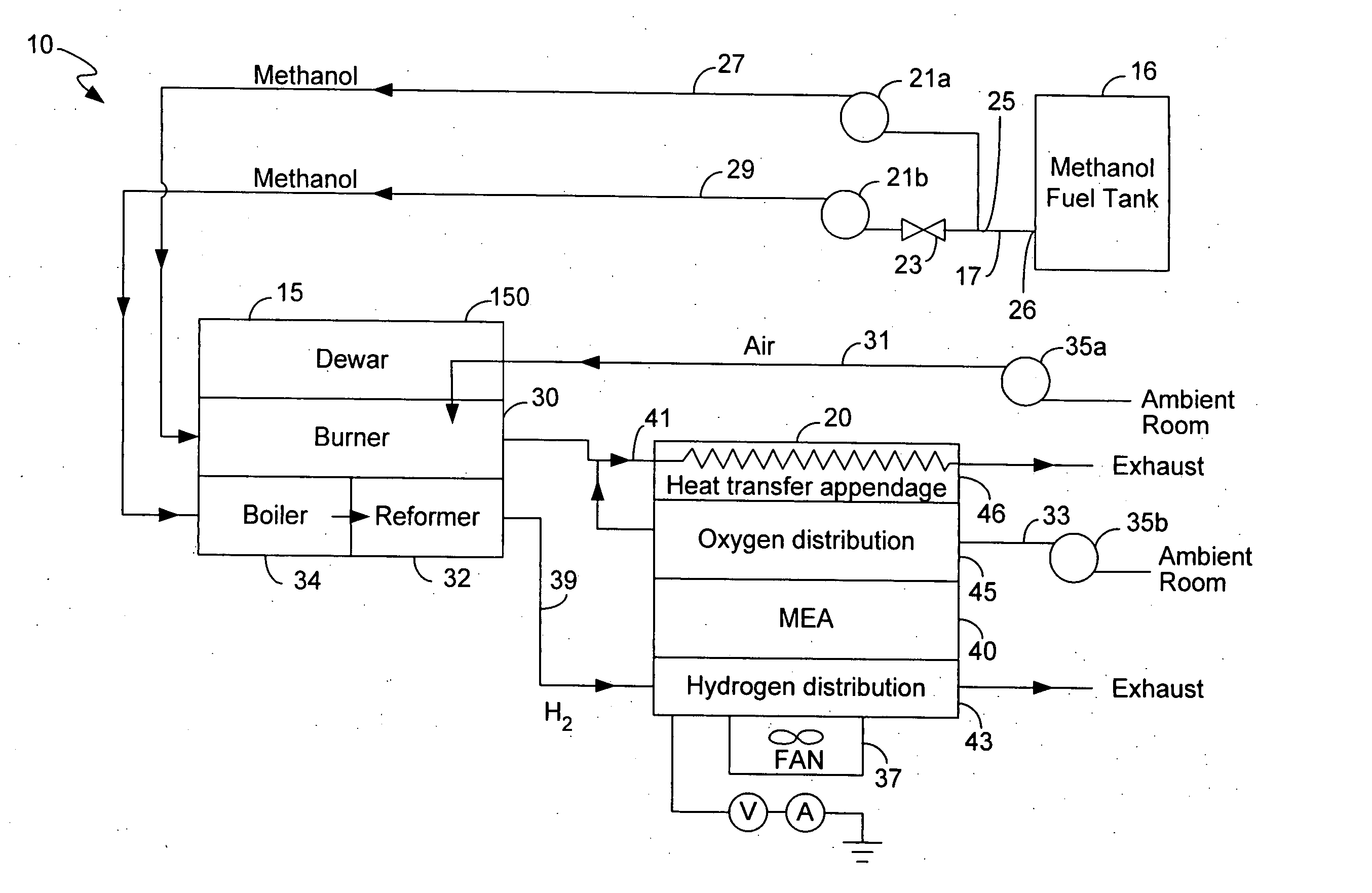

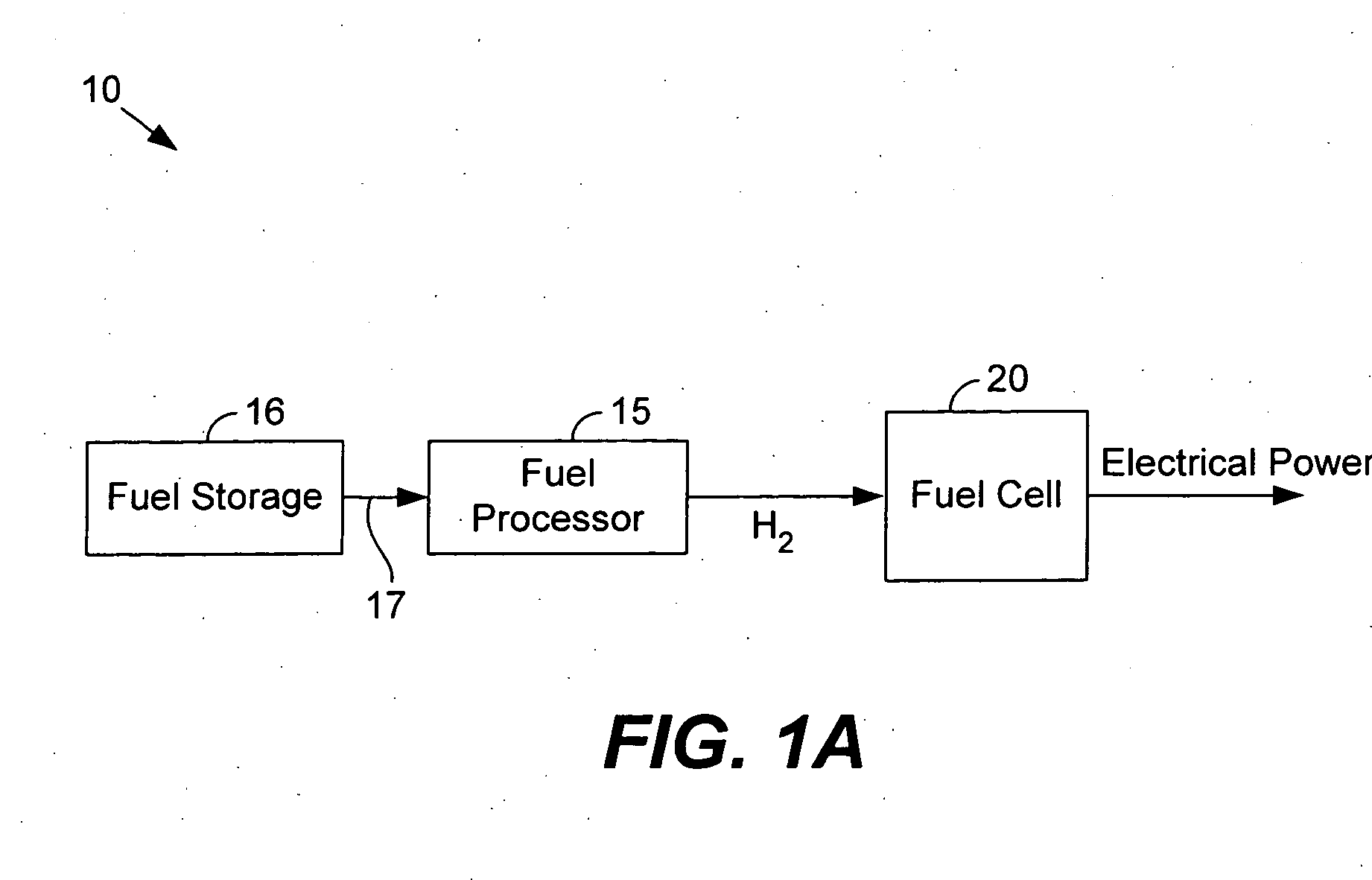

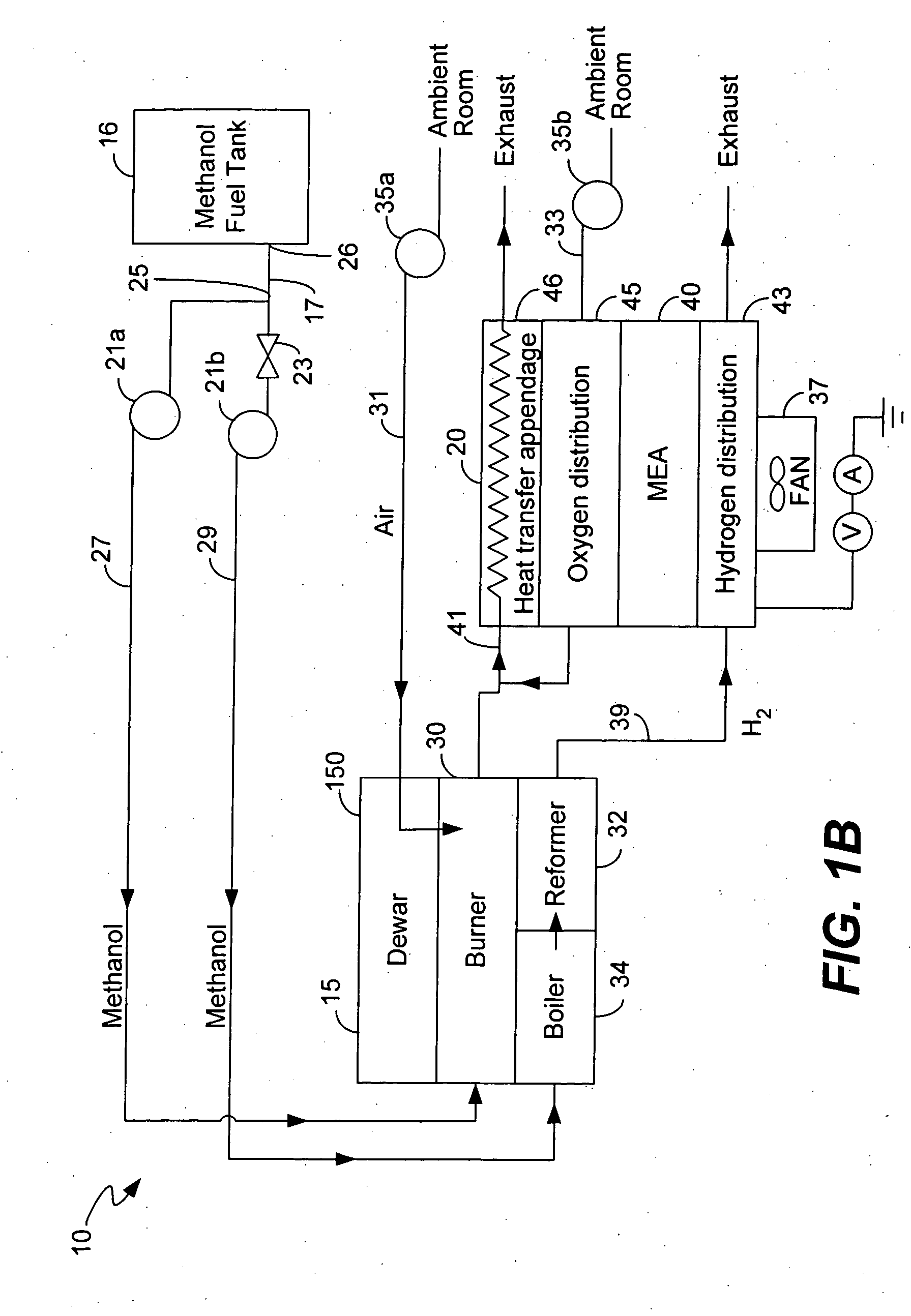

Portable fuel cartridge for fuel cells

InactiveUS20050008908A1Promote hydrogen productionPromote productionFuel cell heat exchangeReactant parameters controlHydrogen fuelElectron

Described herein is a portable storage device that stores a hydrogen fuel source. The storage device includes a bladder that contains the hydrogen fuel source and conforms to the volume of the hydrogen fuel source. A housing provides mechanical protection for the bladder. The storage device also includes a connector that interfaces with a mating connector to permit transfer of the fuel source between the bladder and a device that includes the mating connector. The device may be a portable electronics device such as a laptop computer. Refillable hydrogen fuel source storage devices and systems are also described. The refillable system comprises a hydrogen fuel source refiner that includes the mating connector and provides the hydrogen fuel source to the storage device. Hot swappable fuel storage systems described herein allow a portable hydrogen fuel source storage device to be removed from a fuel processor or electronics device it provides the hydrogen fuel source to, without shutting down the receiving device or without compromising hydrogen fuel source provision to the receiving device for a limited time.

Owner:ULTRACELL LLC

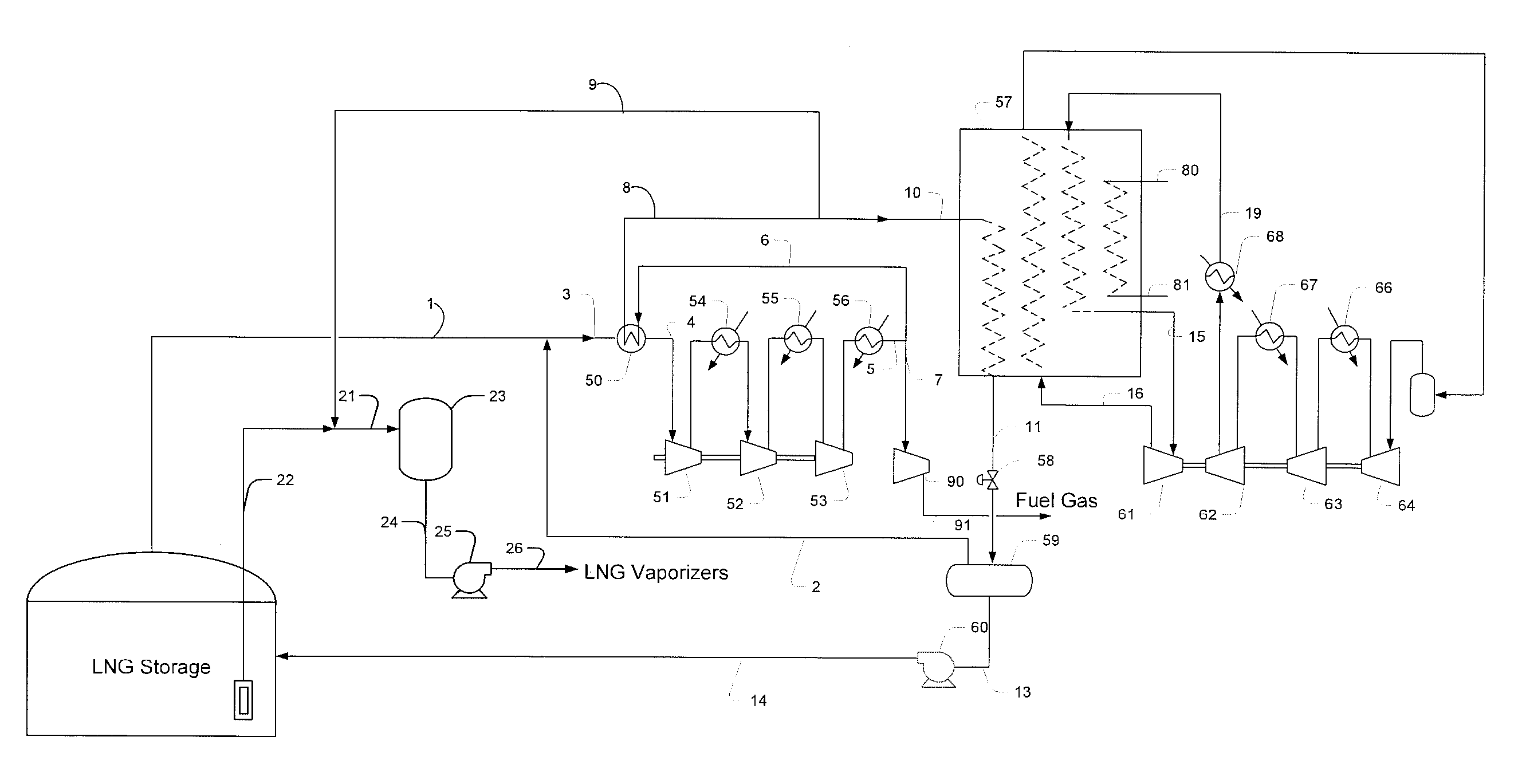

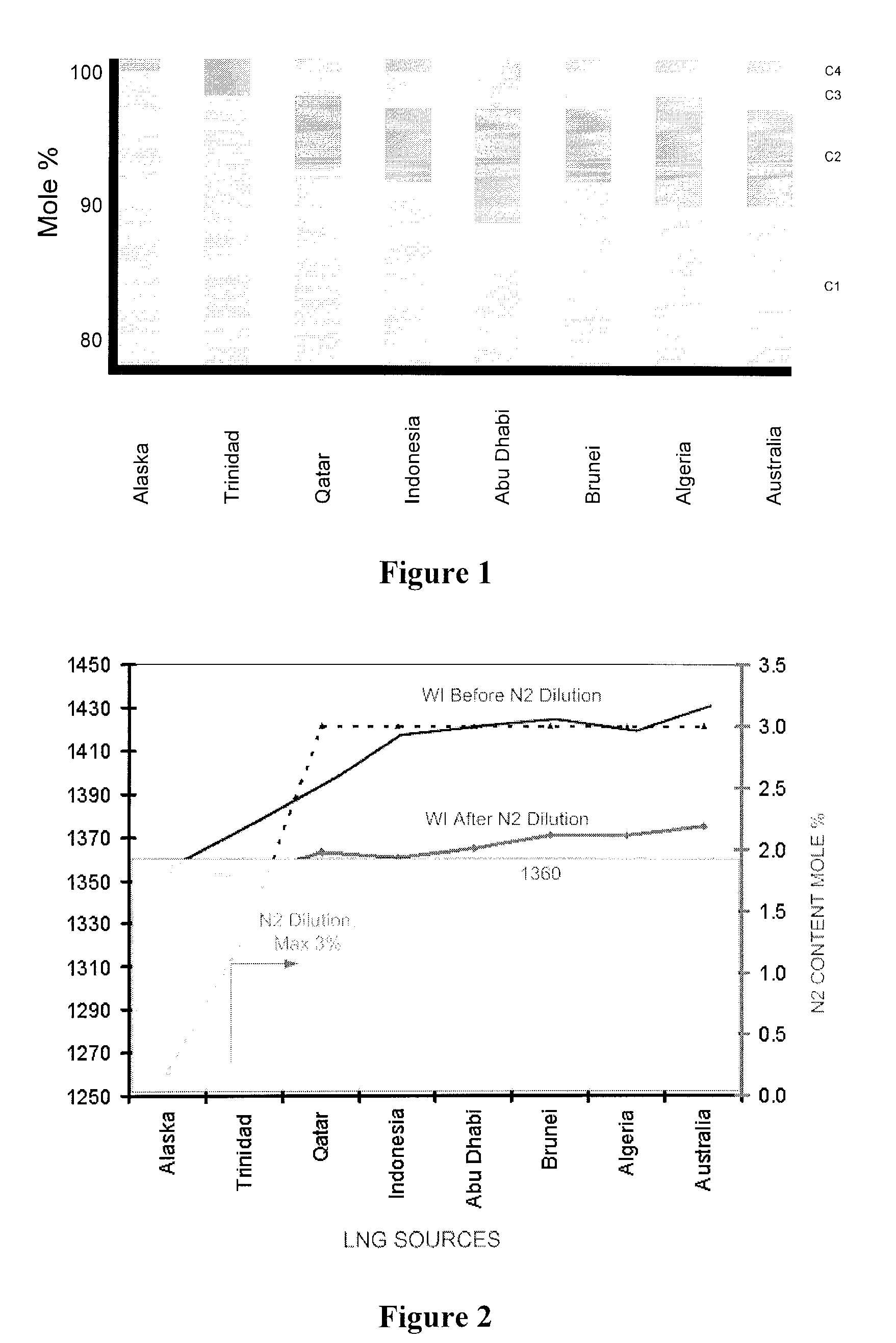

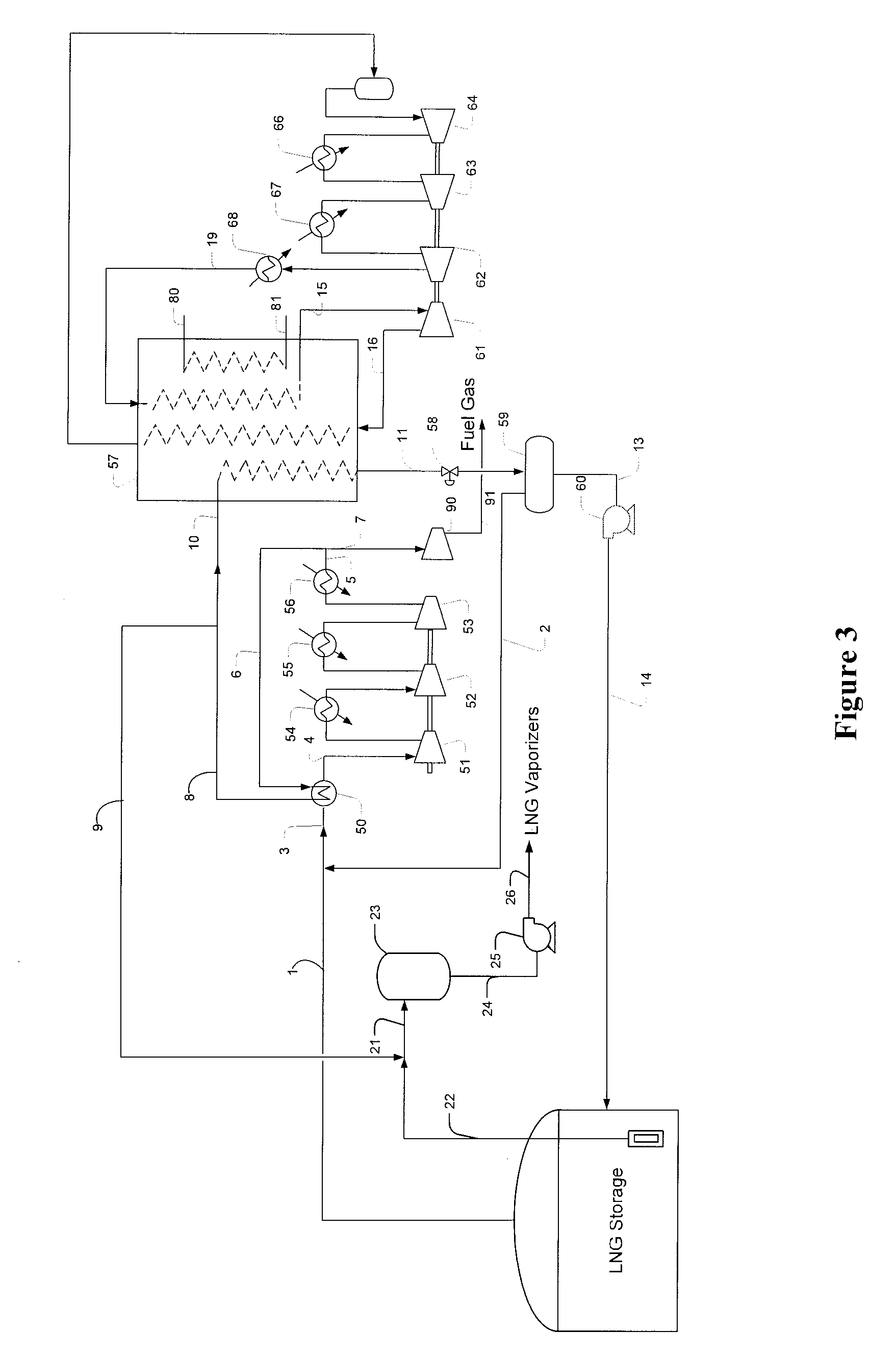

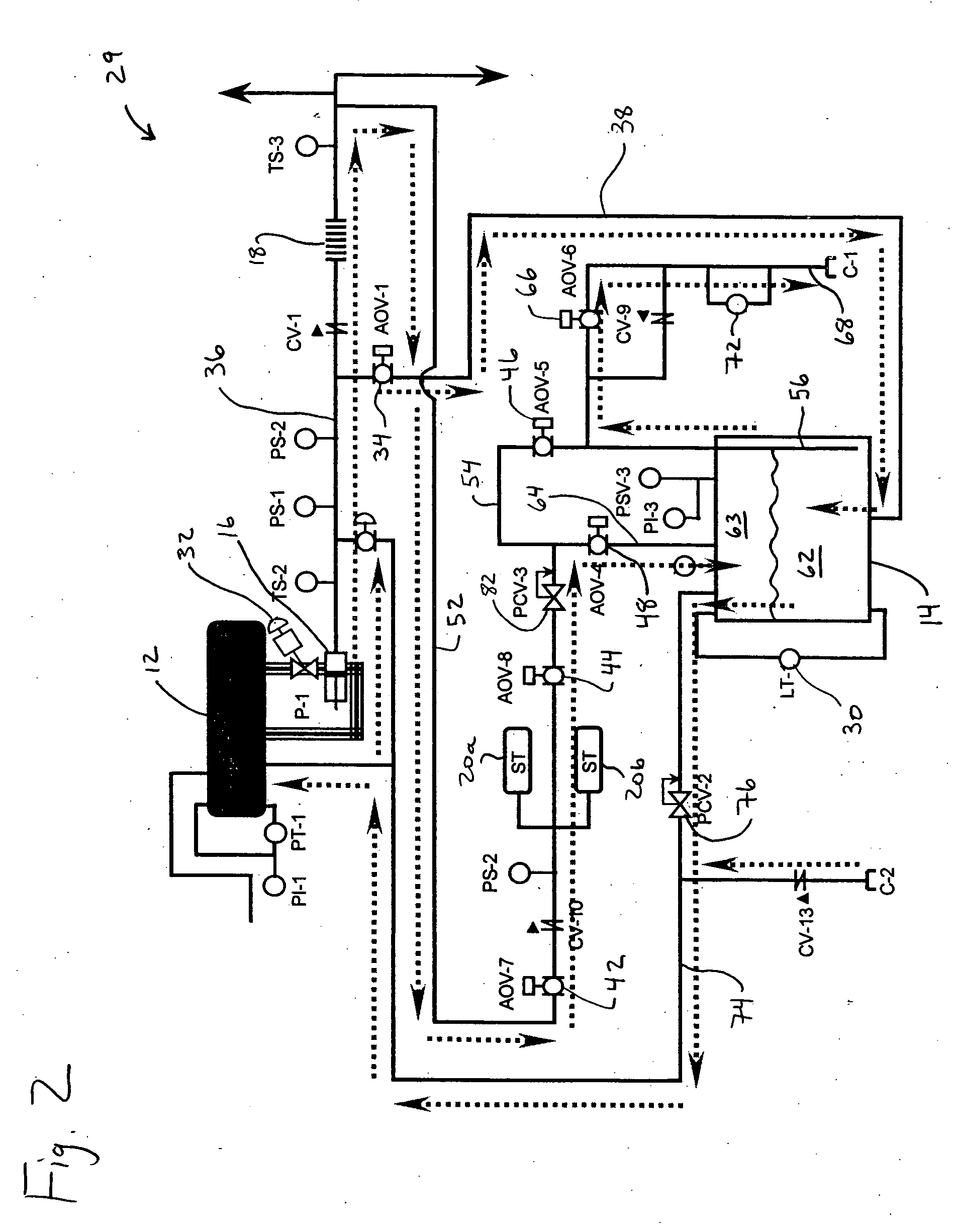

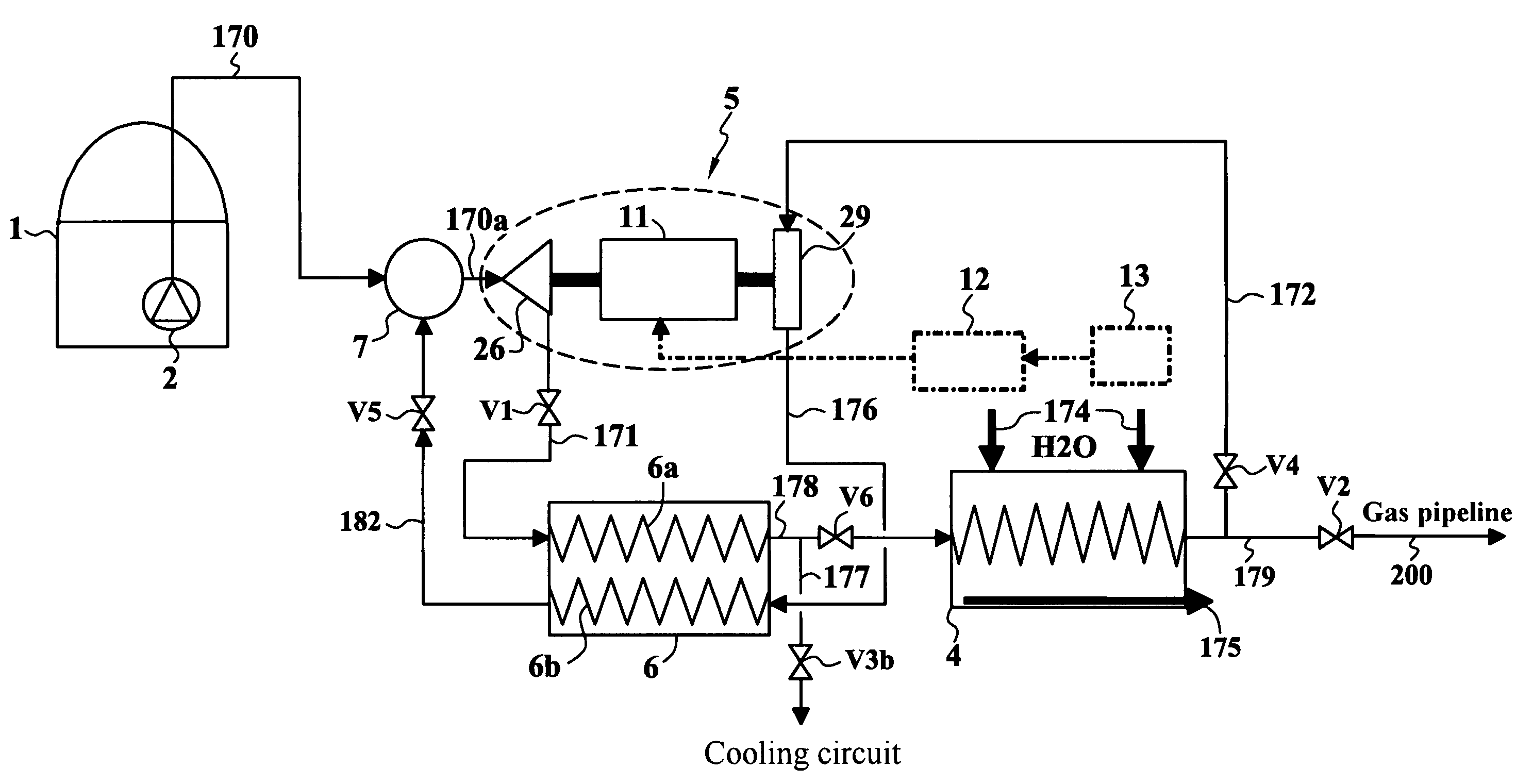

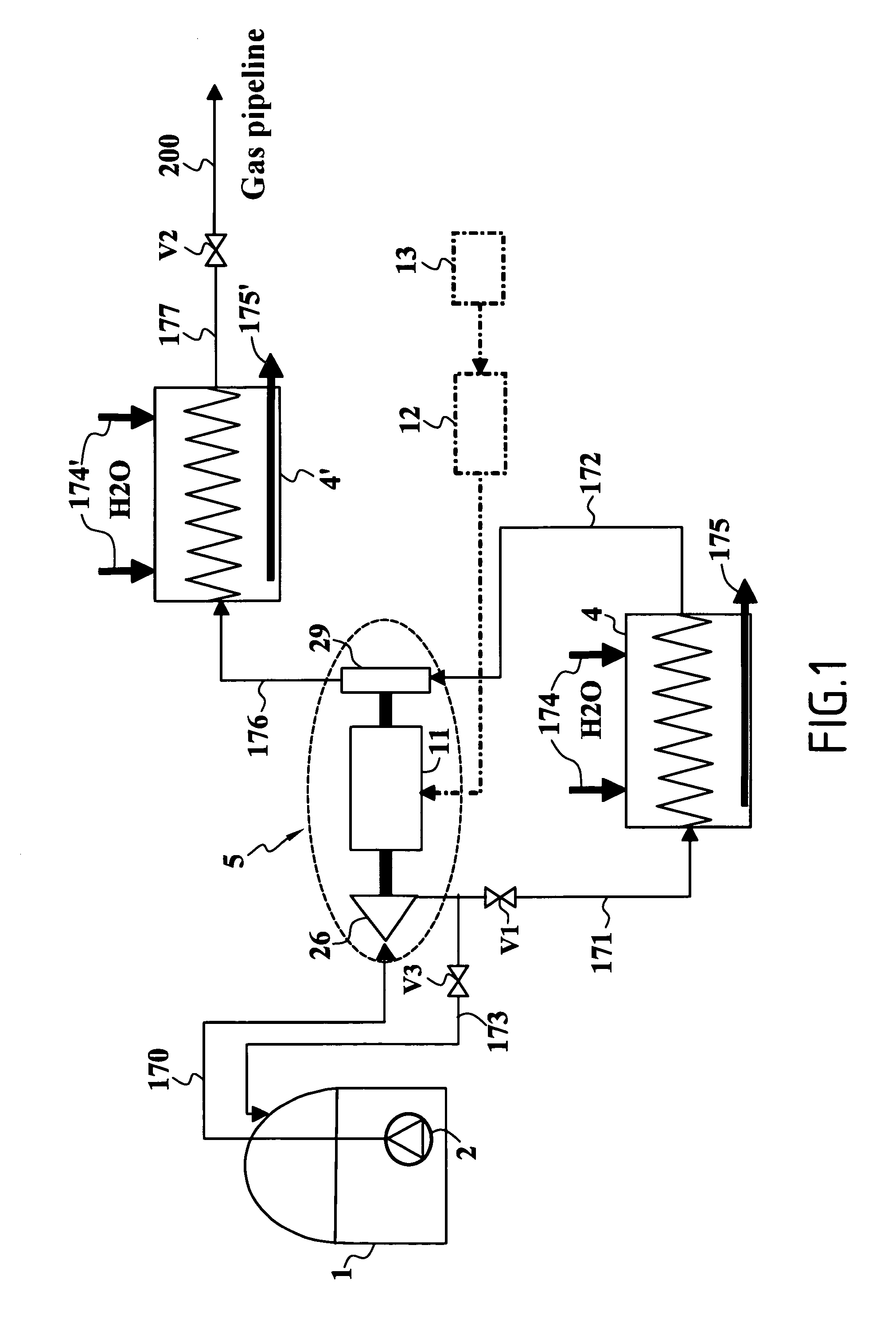

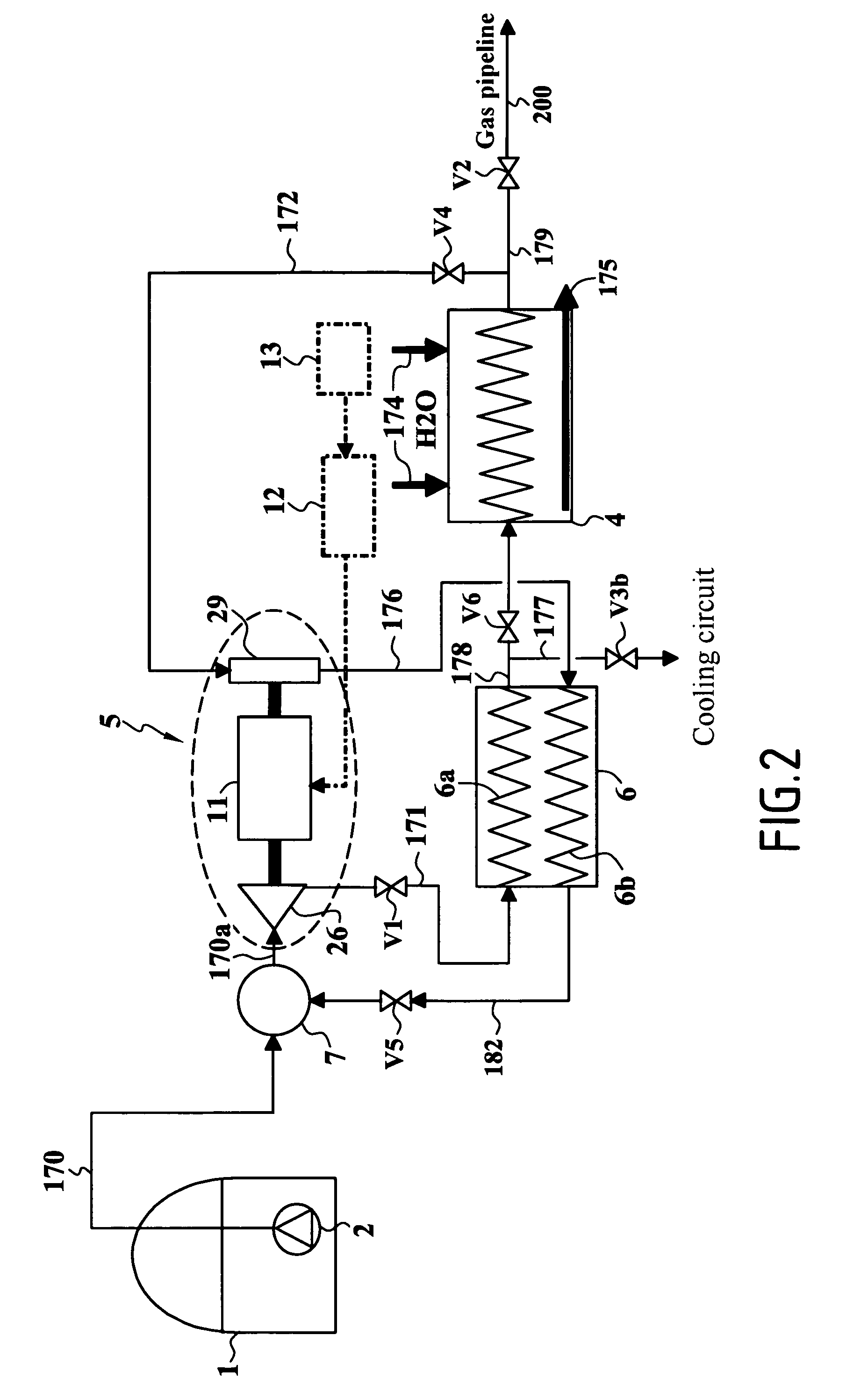

Methods and Configurations of Boil-off Gas Handling in LNG Regasification Terminals

InactiveUS20110056238A1Stable storage tank pressure controlStable controlSolidificationLiquefactionProcess engineeringWobbe index

A LNG storage and regasification plant includes a reliquefaction unit in which boil-off vapors from the storage tanks are re liquefied and recycled back to the LNG storage tanks for tank pressure and Wobbe index control. Preferably, LNG cold is used for reliquefaction and operational flexibility is achieved by feeding a portion of the pressurized boil-off gas to a fuel gas header and / or to be recondensed by the sendout LNG.

Owner:FLUOR TECH CORP

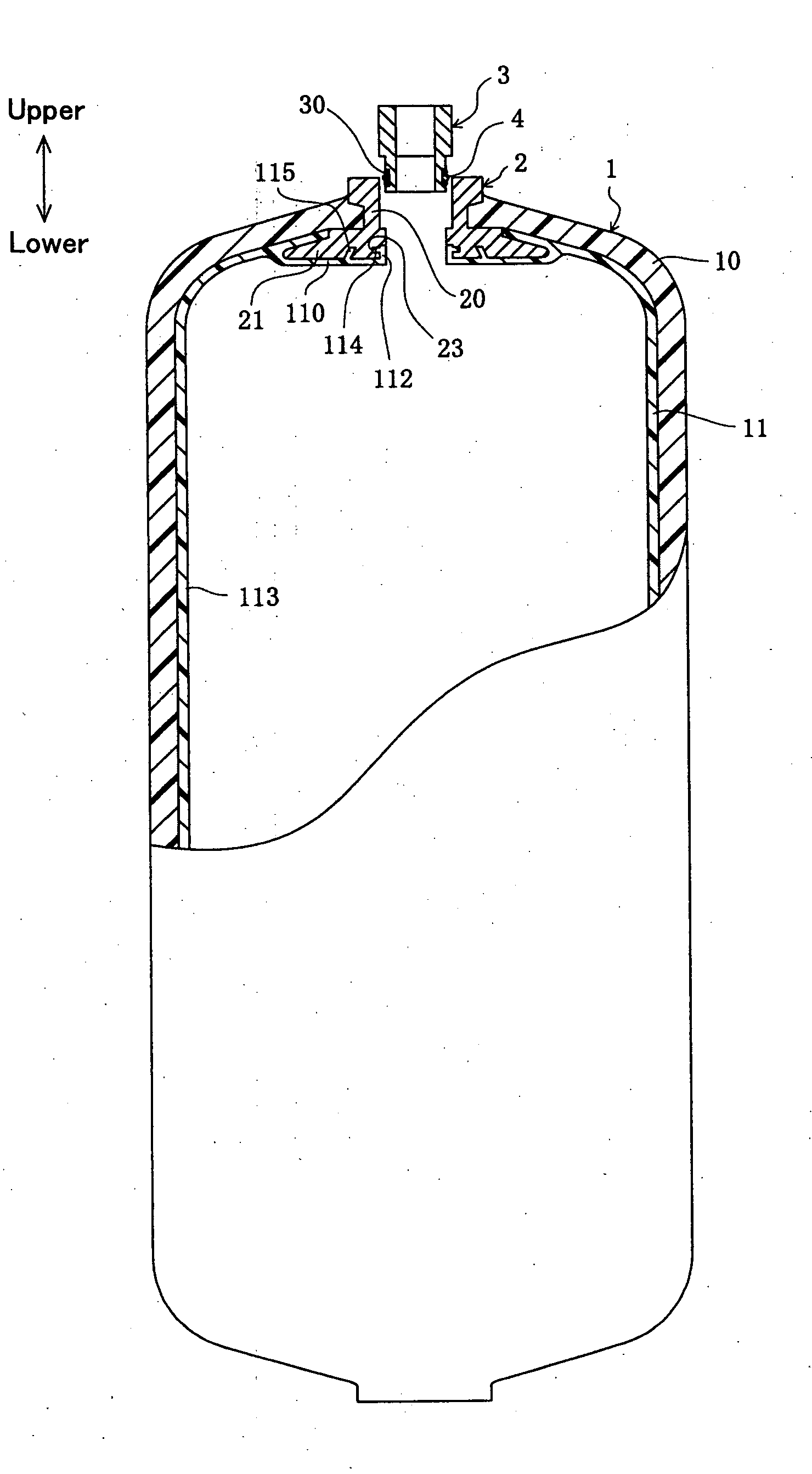

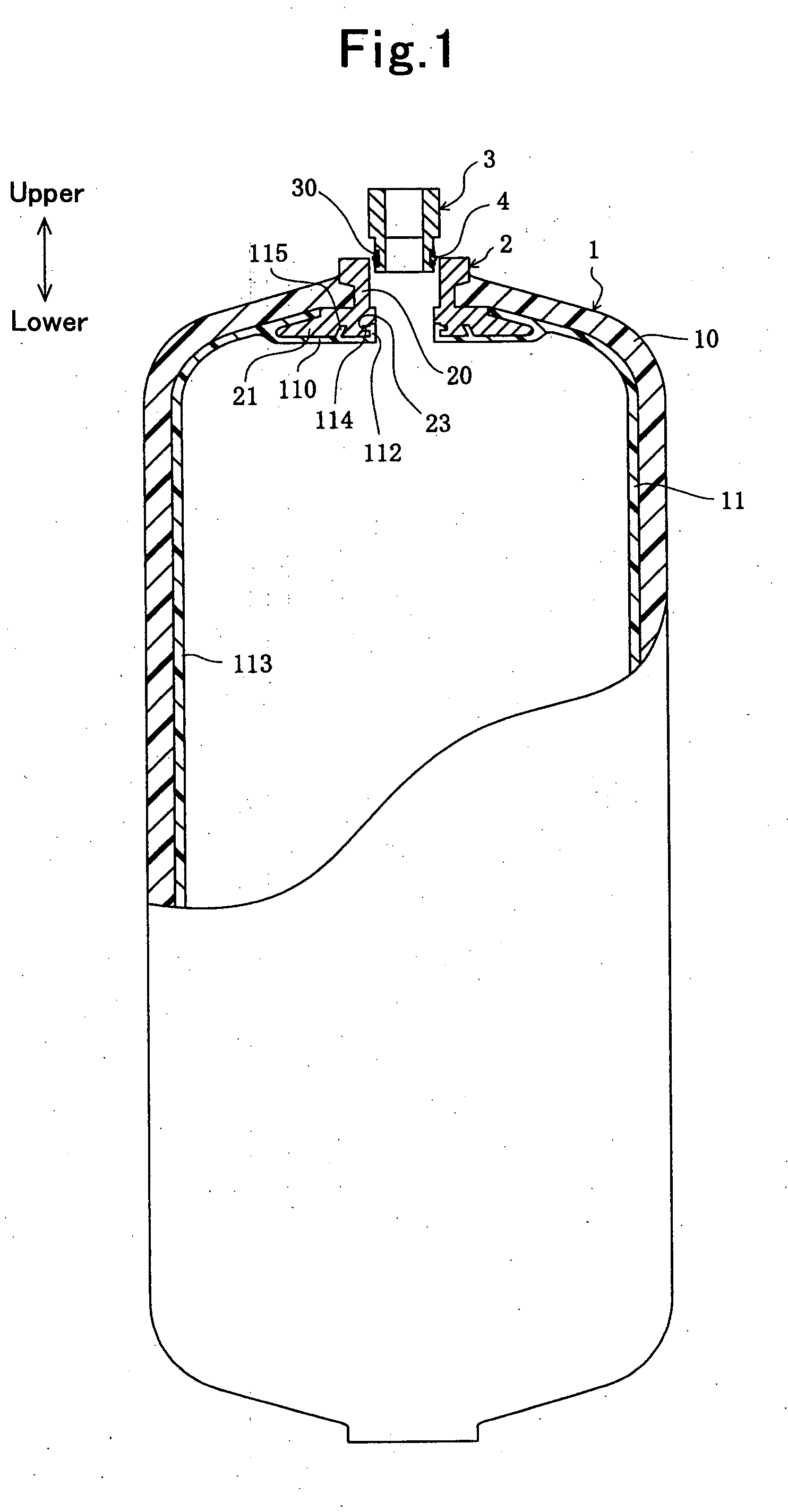

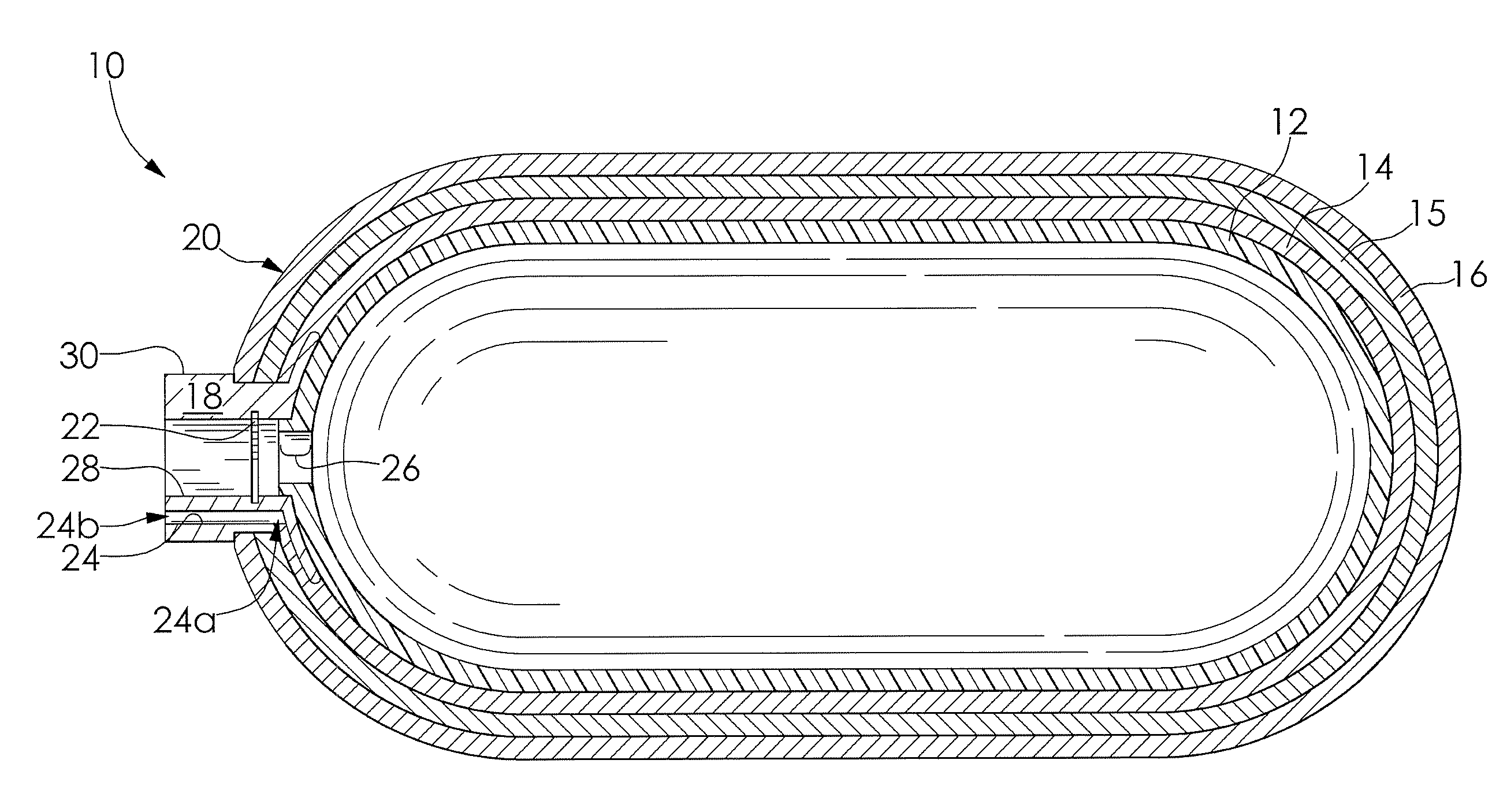

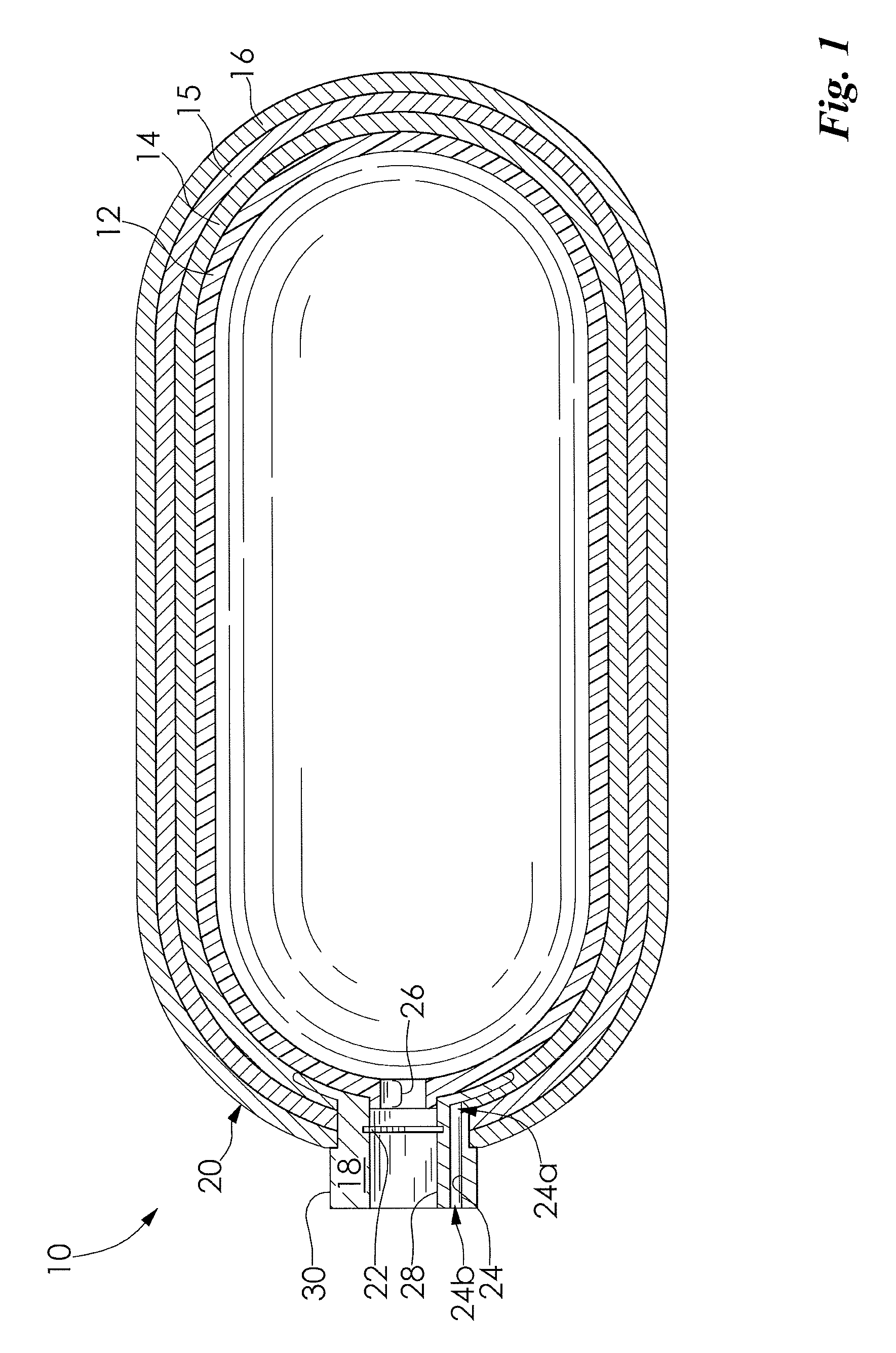

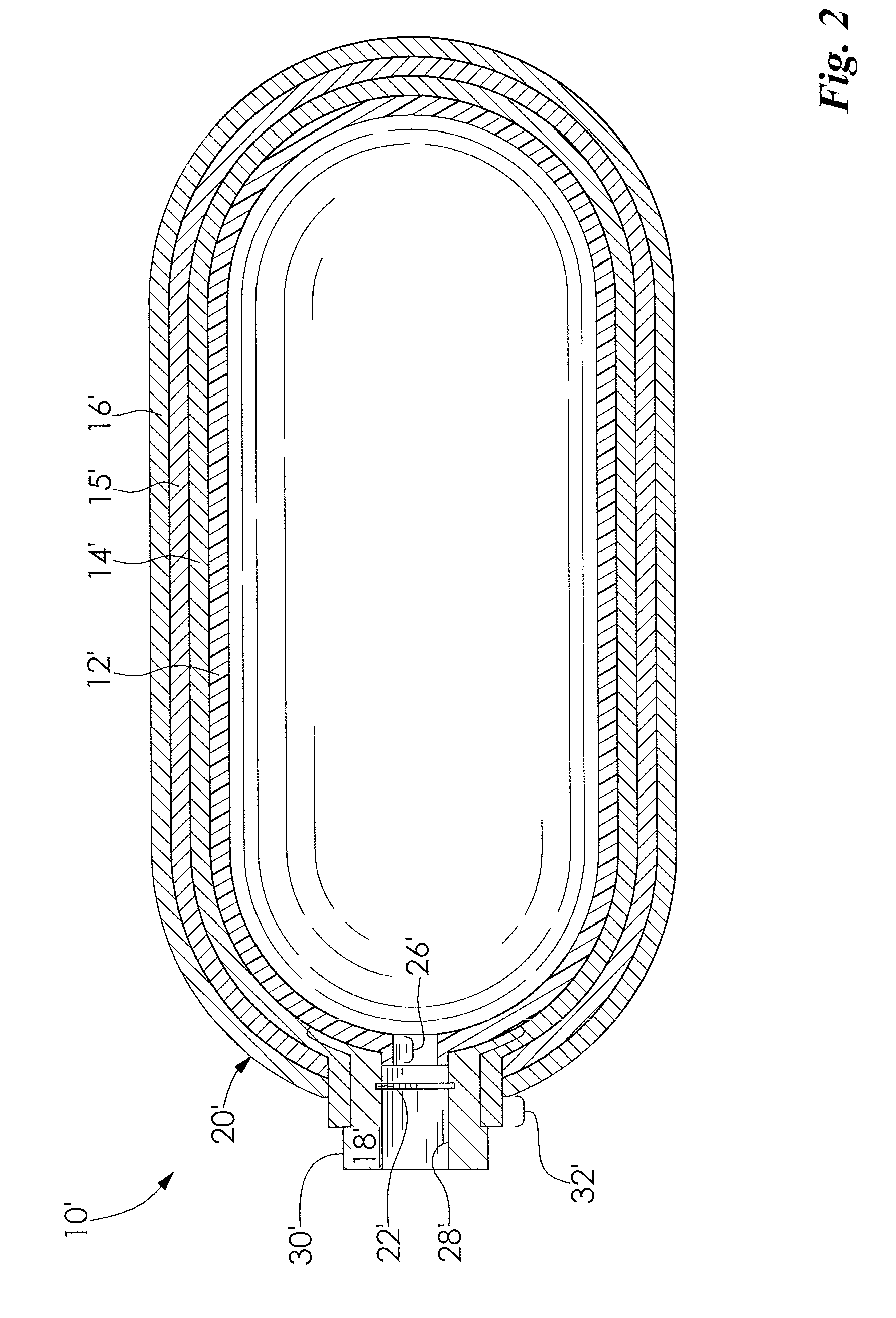

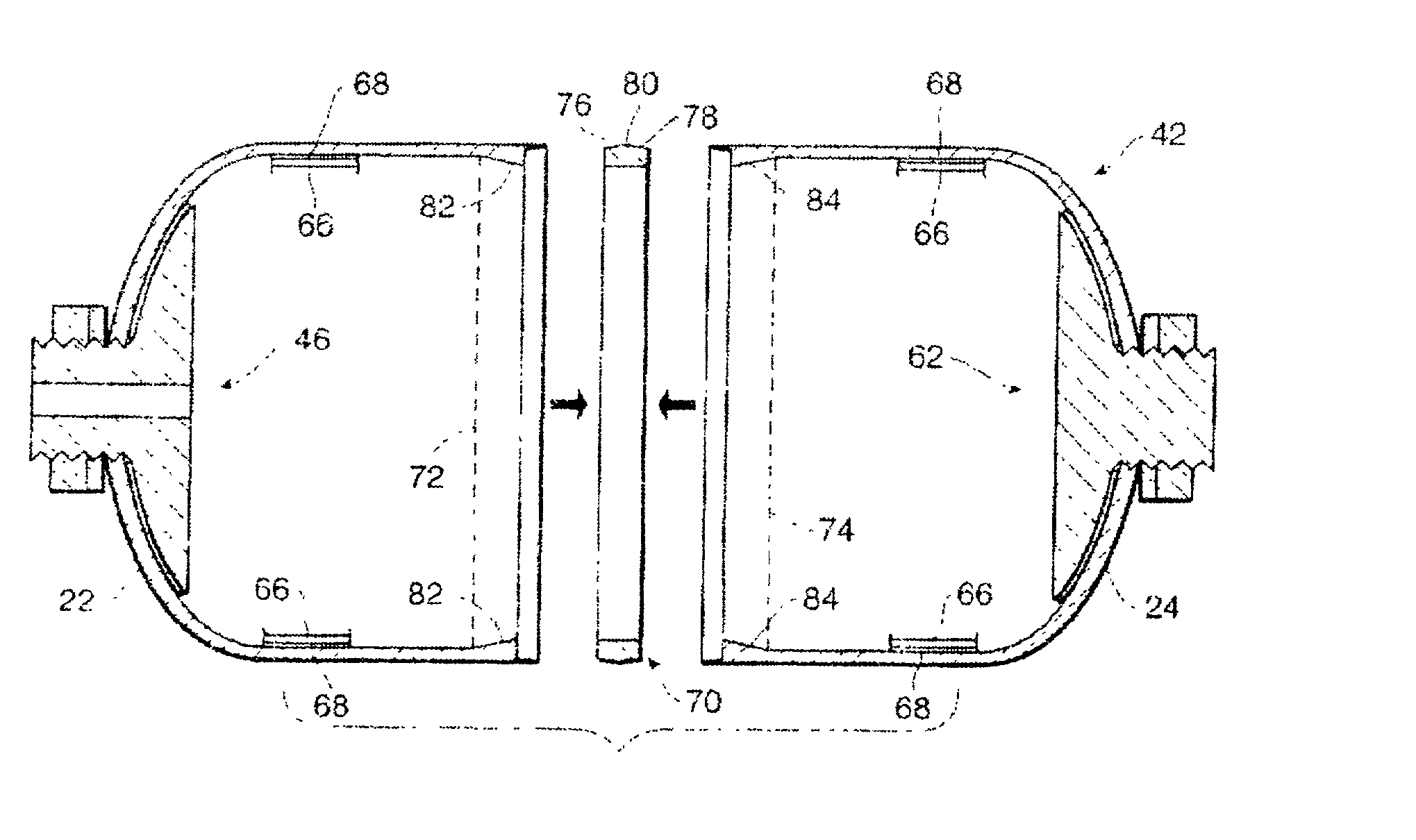

Pressure vessel

A pressure vessel capable of securely sealing a mouth ring with a liner portion, and being manufactured at low costs. A boss seal part 112 is provided in a liner portion 11 of the pressure vessel, and an inner peripheral surface of a boss part 20 of a mouth ring 2 is covered with the boss seal part 112. A boss-side collar part 114 is provided in the boss seal part 112 so as to project outwardly, and a sealing member 4 composed of a resilient body is disposed in a space between an inner peripheral surface of the boss seal part 112 and an outer peripheral surface of the valve 3.

Owner:TOYODA GOSEI CO LTD +1

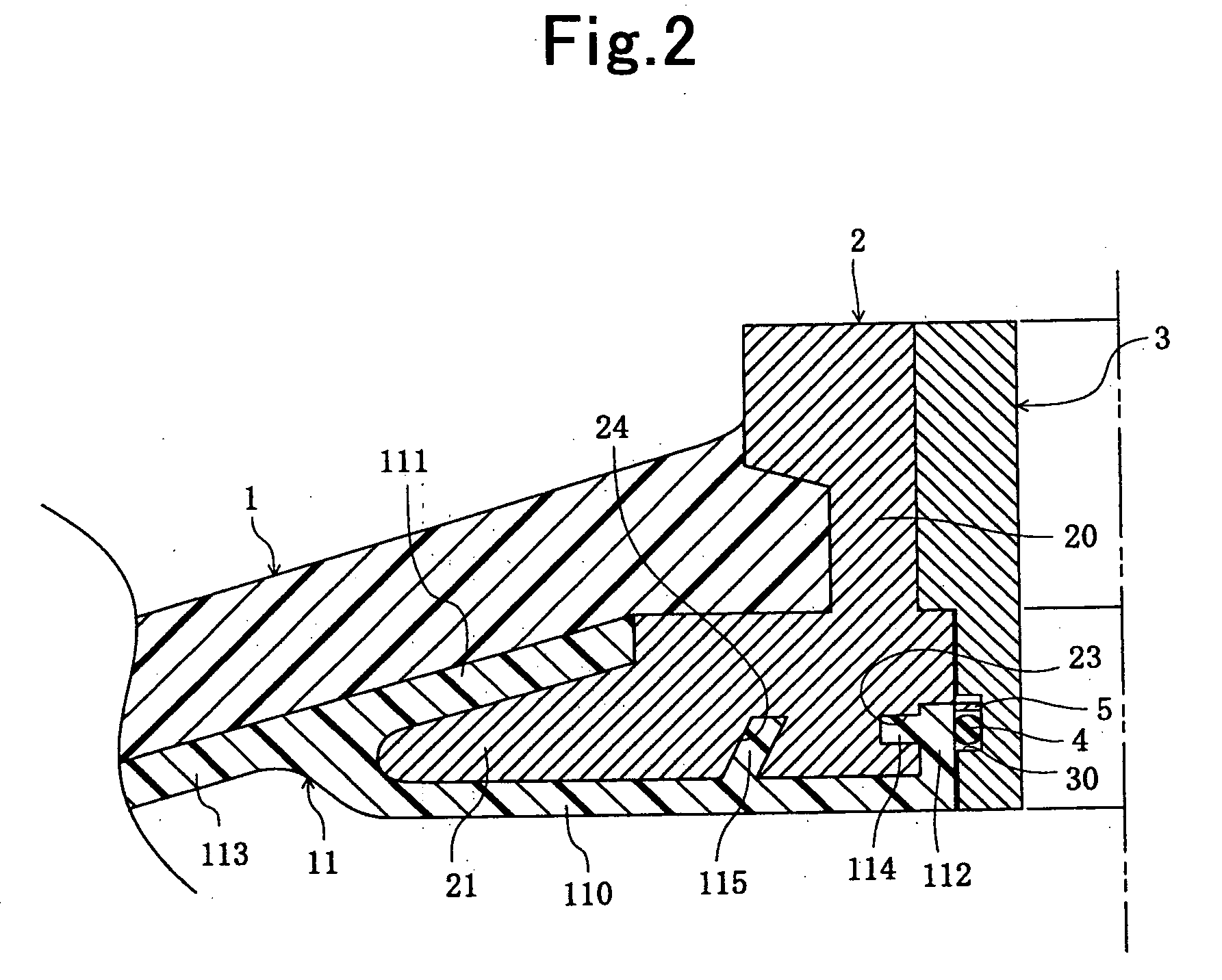

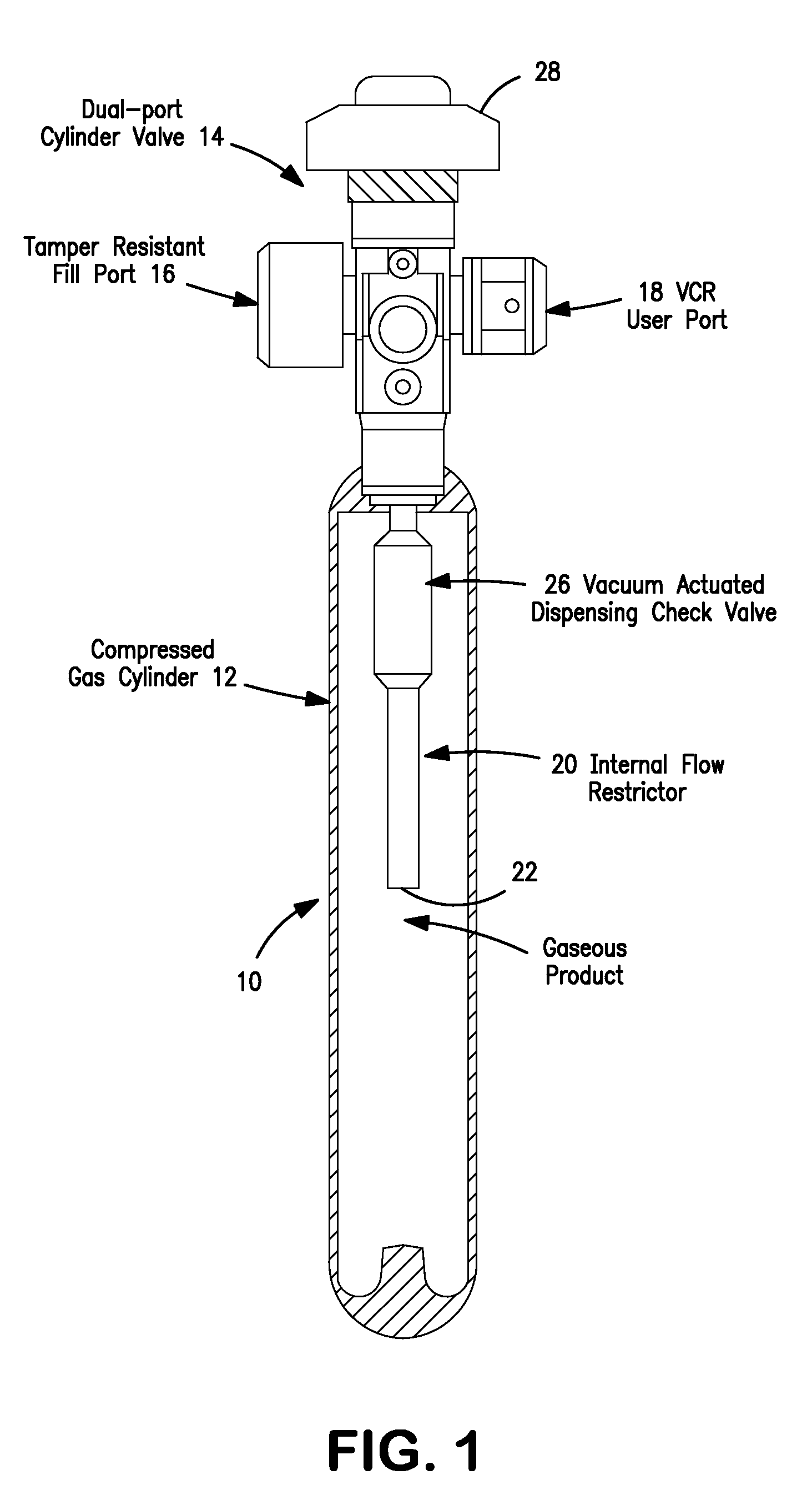

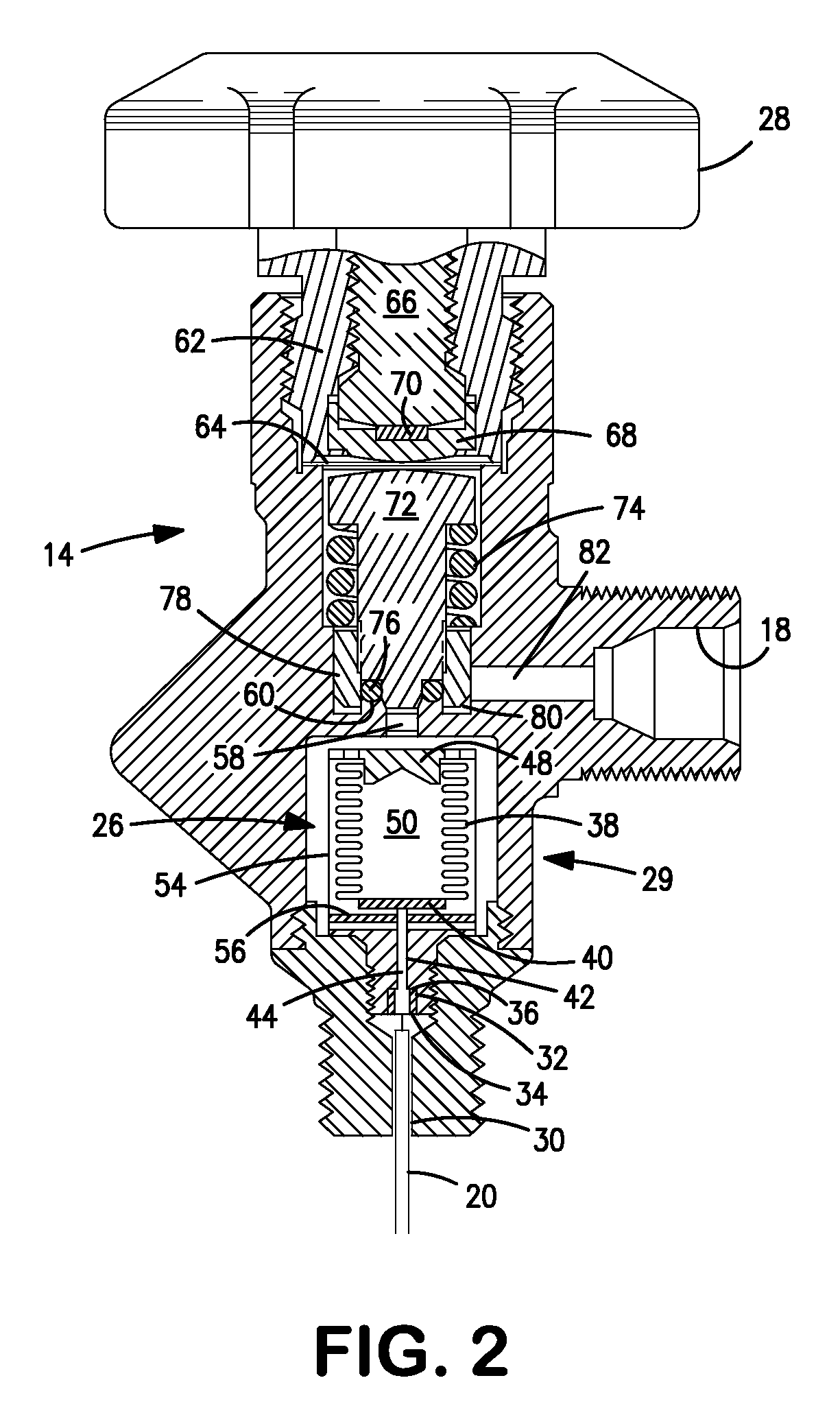

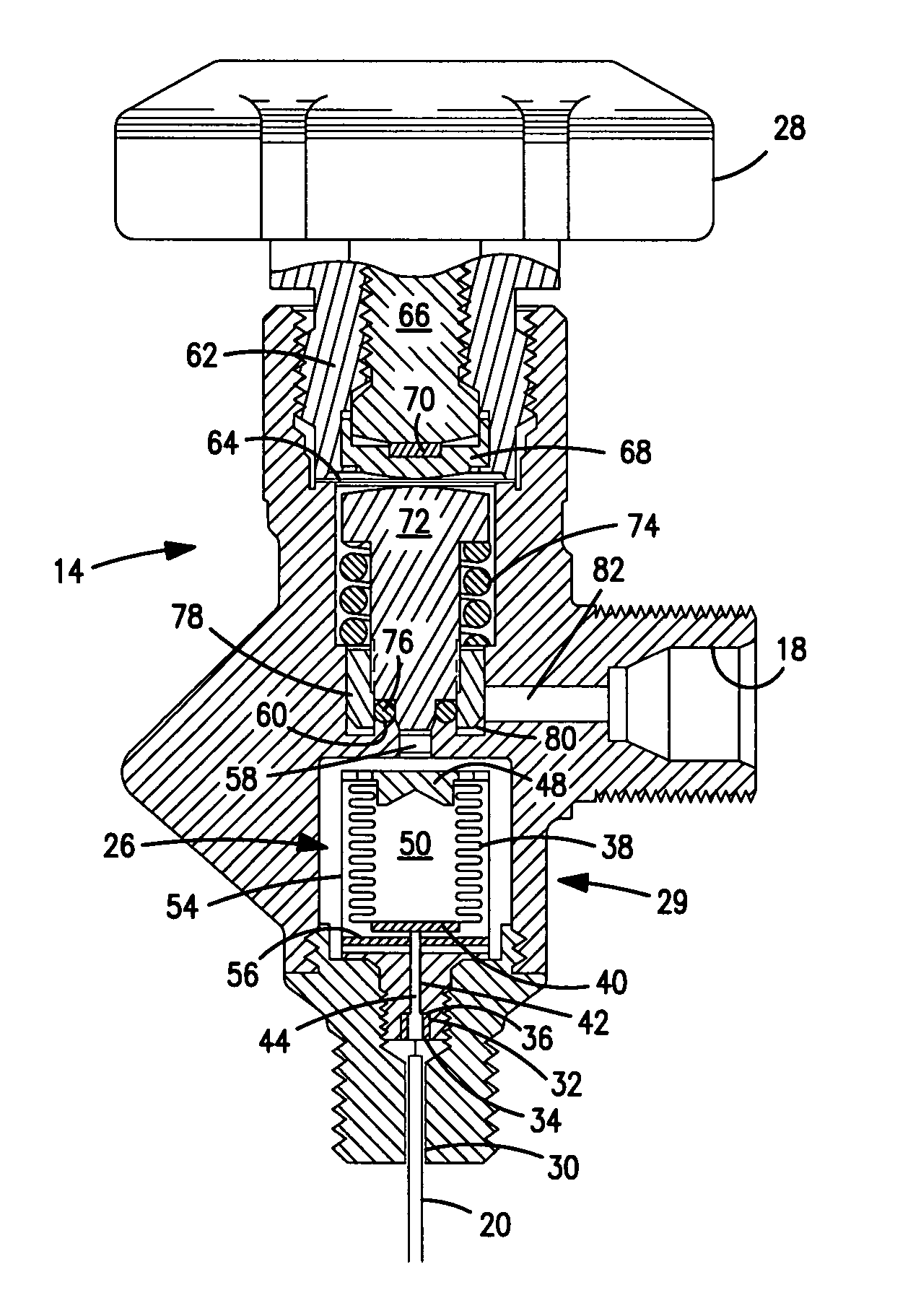

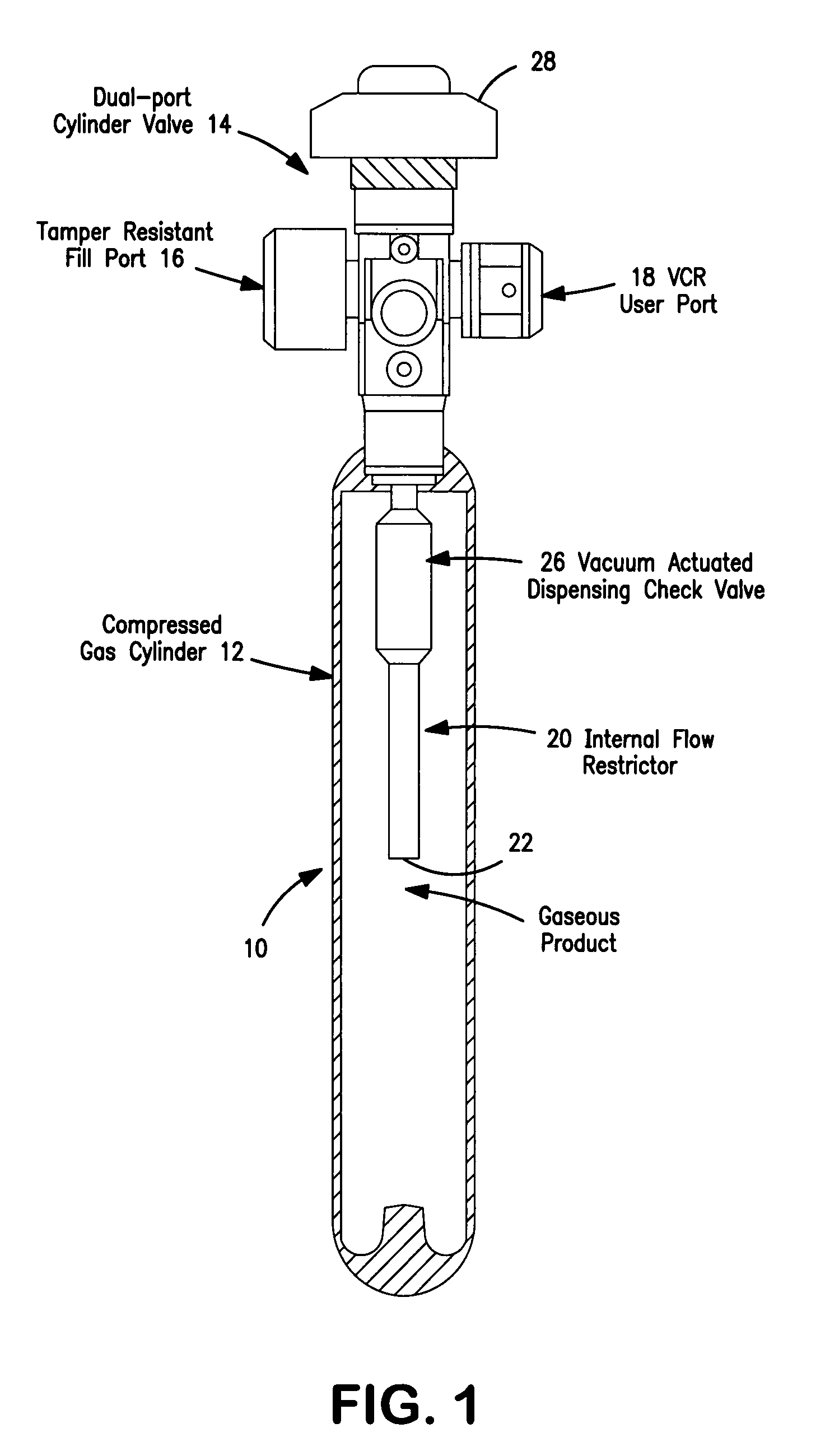

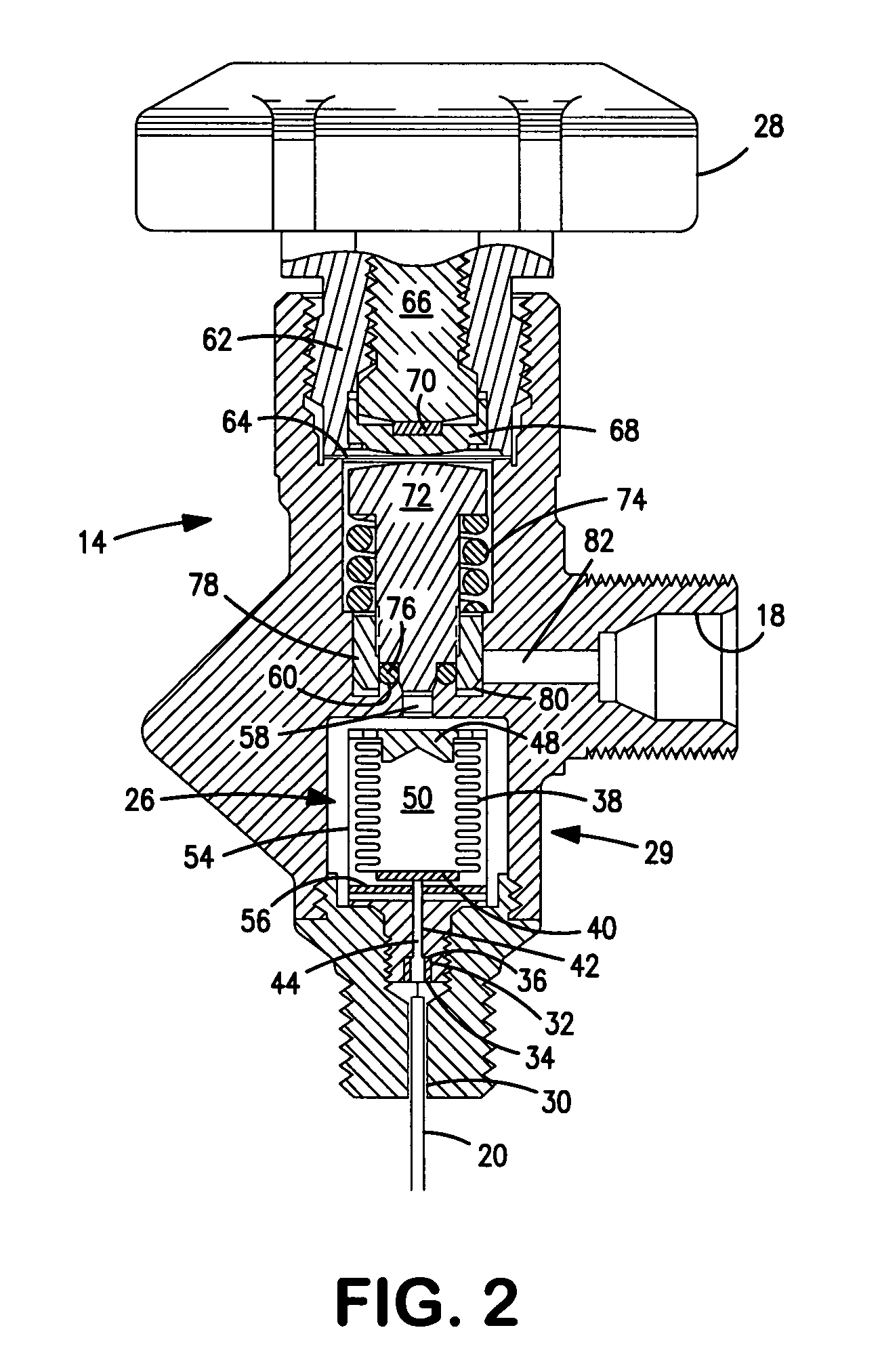

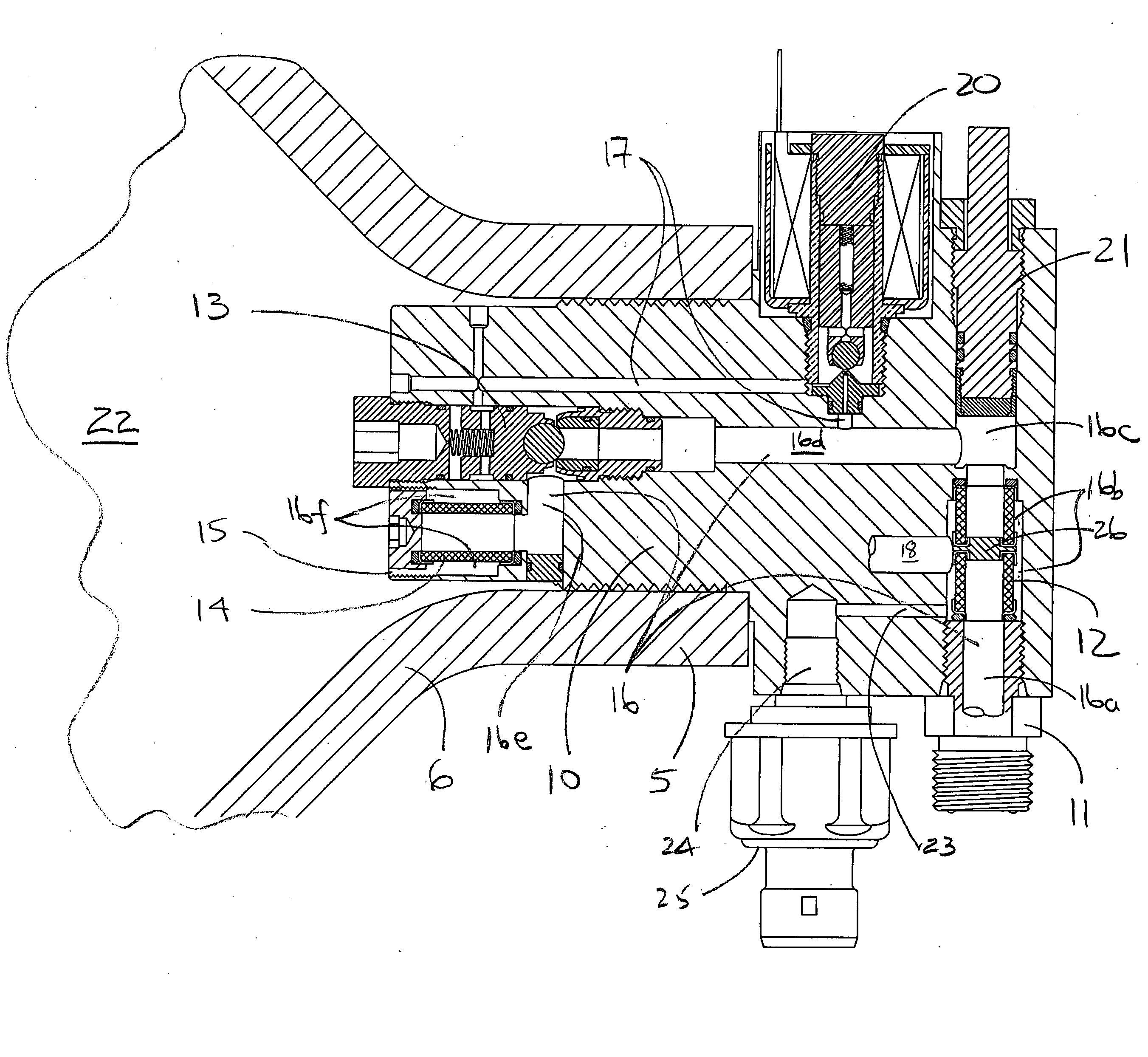

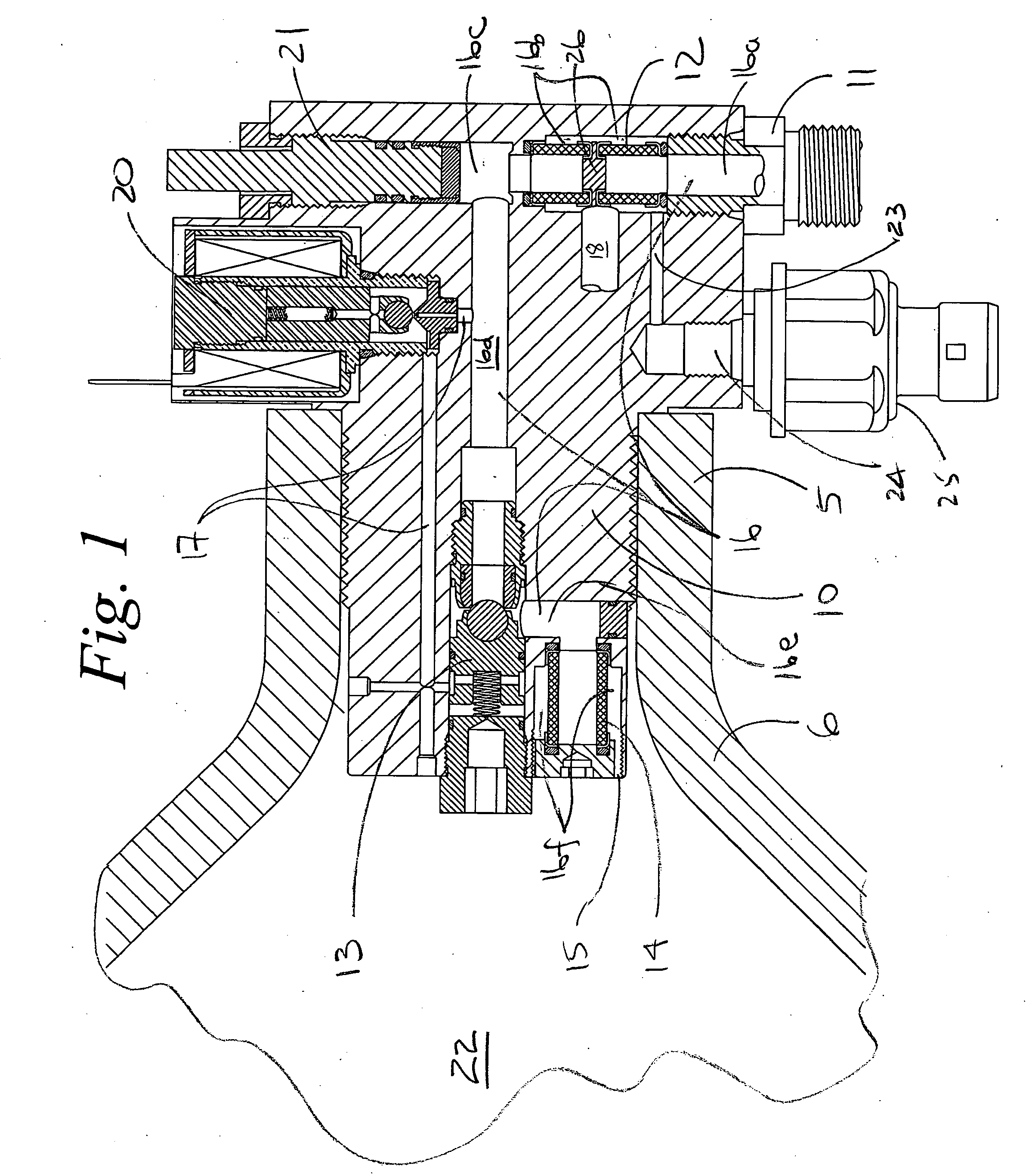

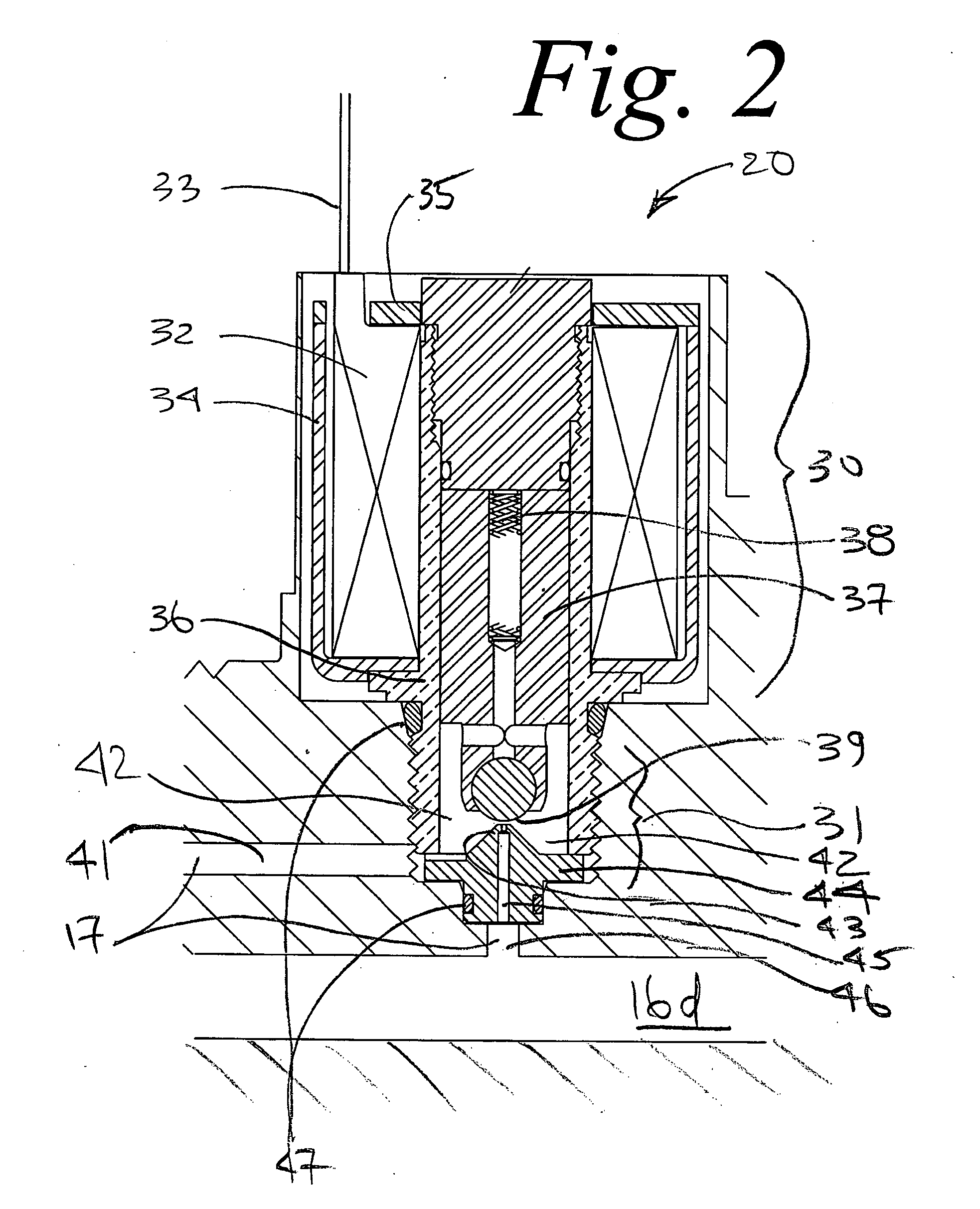

Vacuum actuated valve for high capacity storage and delivery systems

The invention relates to a re-configured valve design to accommodate a high volume of product in the delivery system and the dispensation of product upon the application of a predetermined vacuum condition on the downstream side of the valve.

Owner:PRAXAIR TECH INC

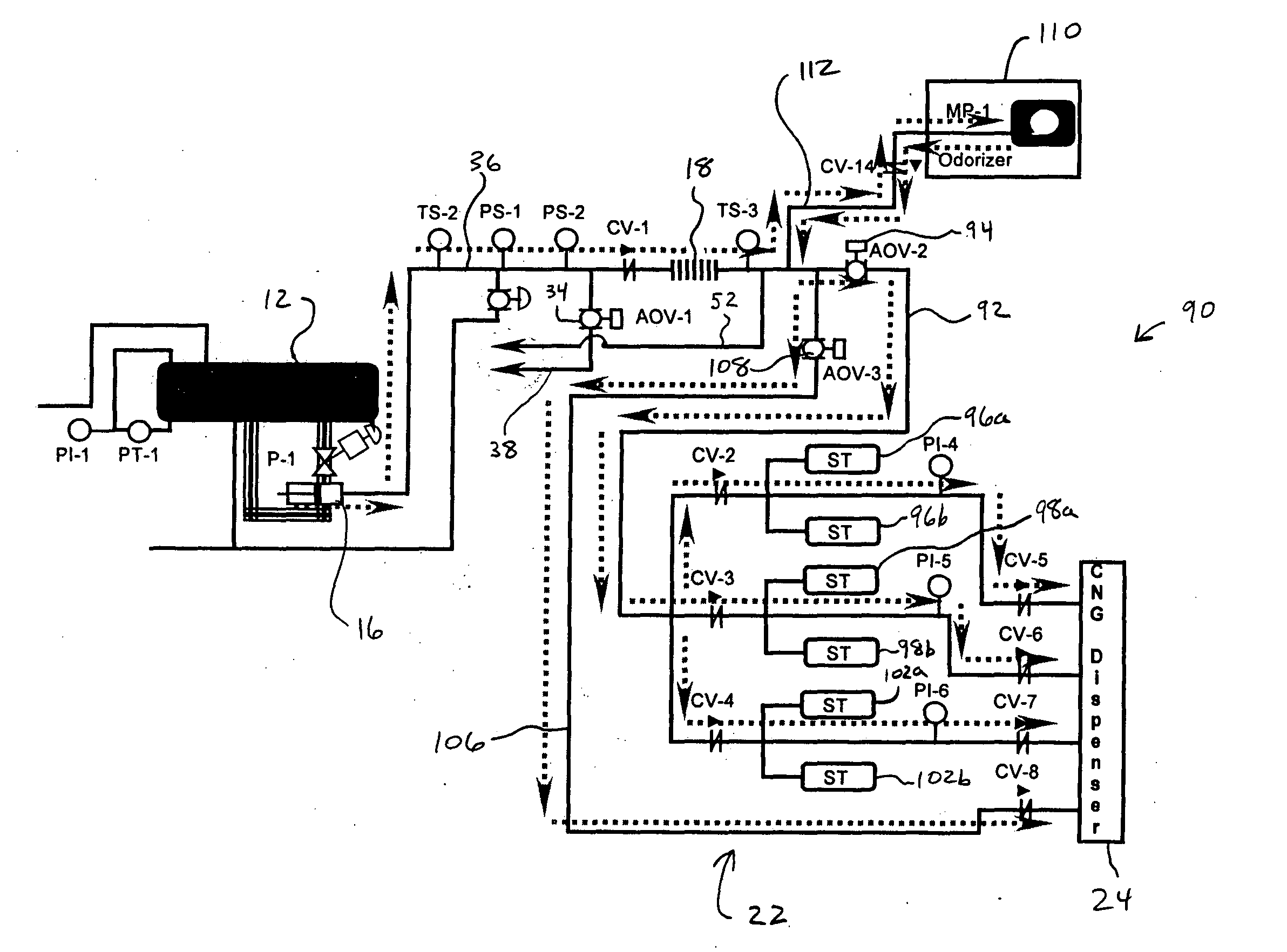

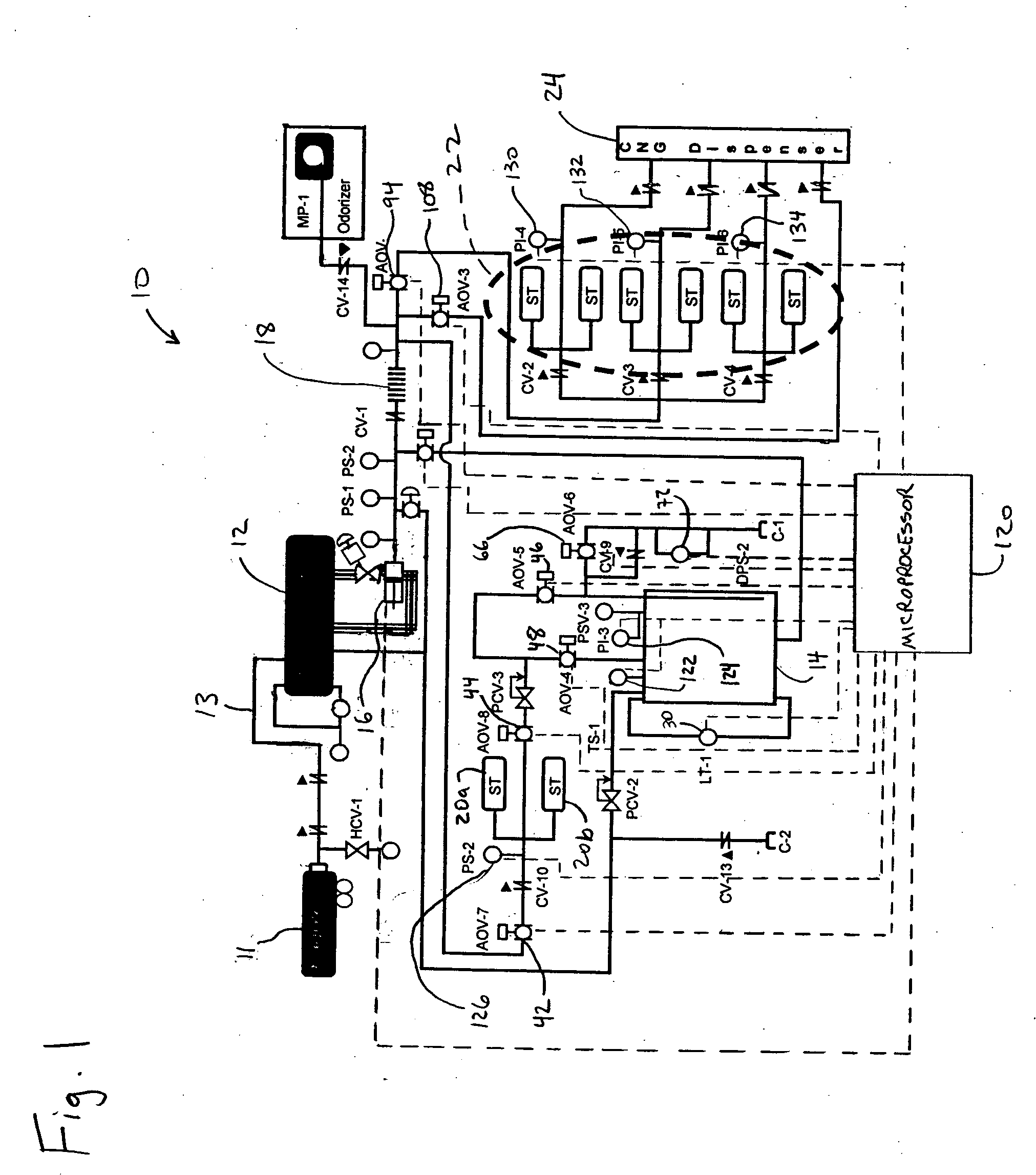

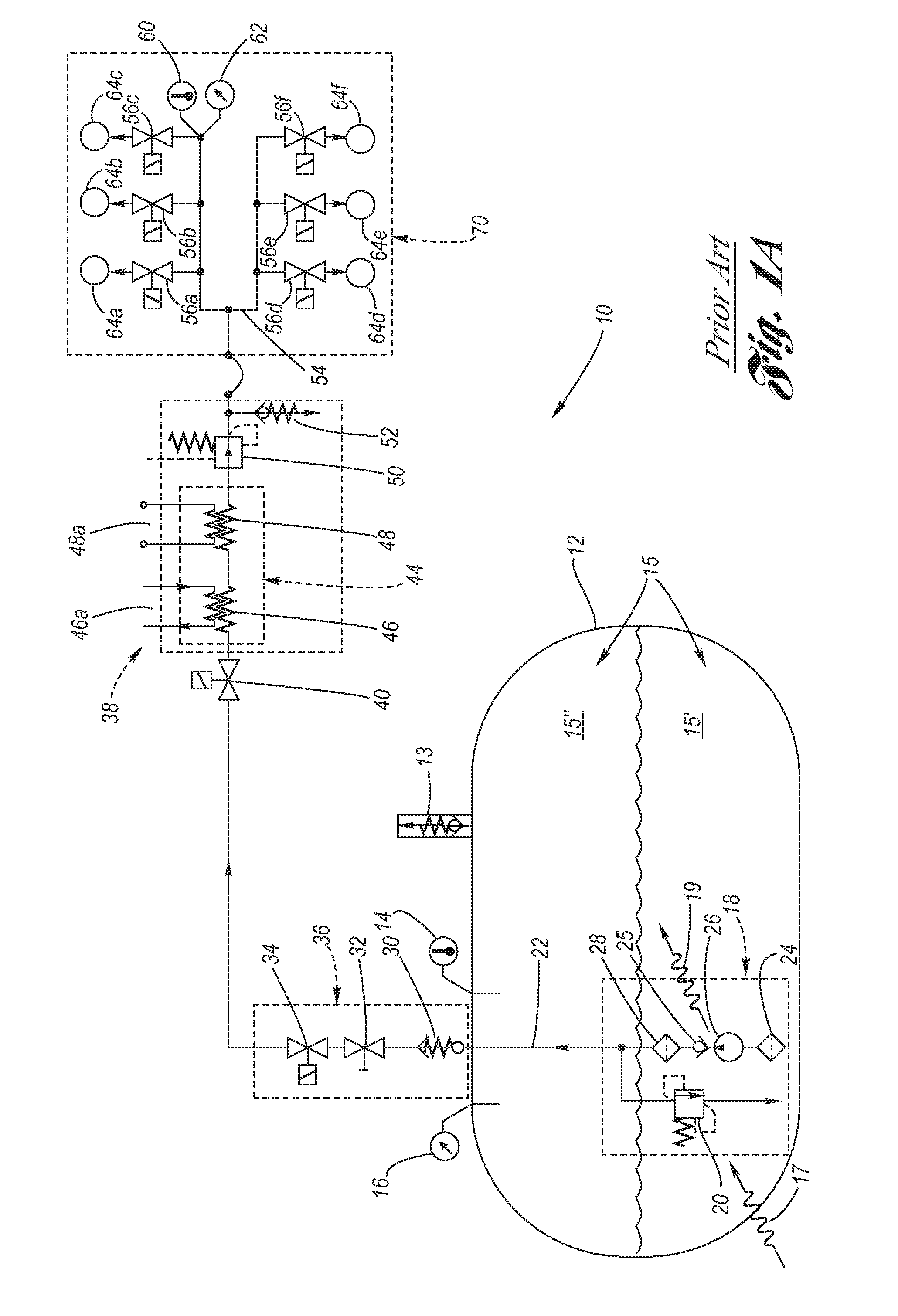

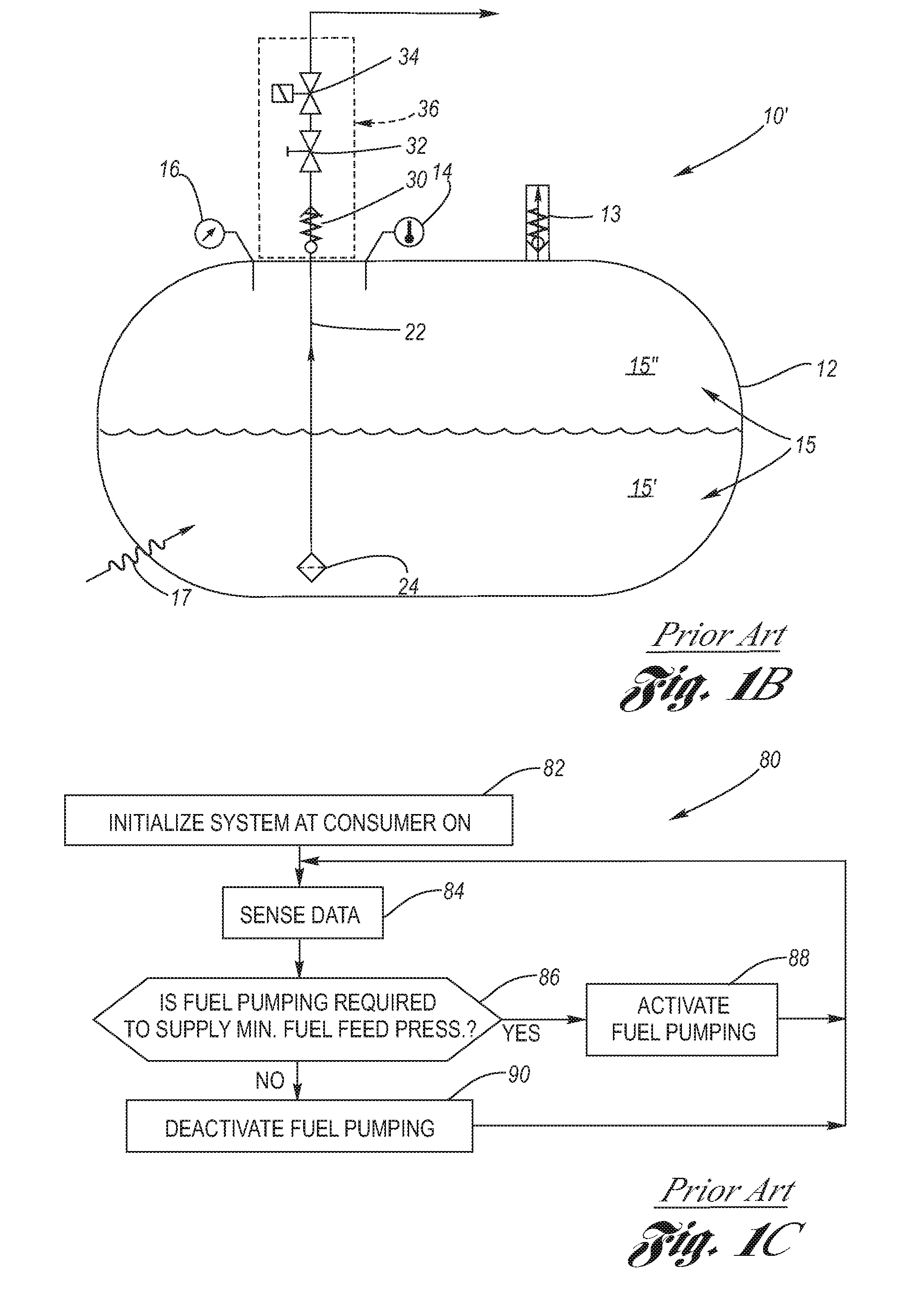

Liquid and compressed natural gas dispensing system

InactiveUS20050016185A1Distribute quicklyEliminate timeGas handling applicationsGas handling/storage effectsCompressed natural gasProcess engineering

A system dispenses both liquid natural gas (LNG) and compressed natural gas (CNG). A bulk tank contains a supply of LNG which is pumped to a smaller storage tank. After the storage tank is refilled, LNG from the bulk tank is pumped to a vaporizer so that CNG is produced. The CNG may be routed to the LNG in the storage tank to condition it. It is also used to recharge a pressurizing cylinder that is placed in communication with the head space of the storage tank when it is desired to rapidly dispense LNG to a vehicle. A bank of cascaded storage cylinders alternatively may receive CNG from the vaporizer for later dispensing through the system CNG dispenser. The CNG from the vaporizer may also be dispensed directly via the system CNG dispenser.

Owner:CHART INC

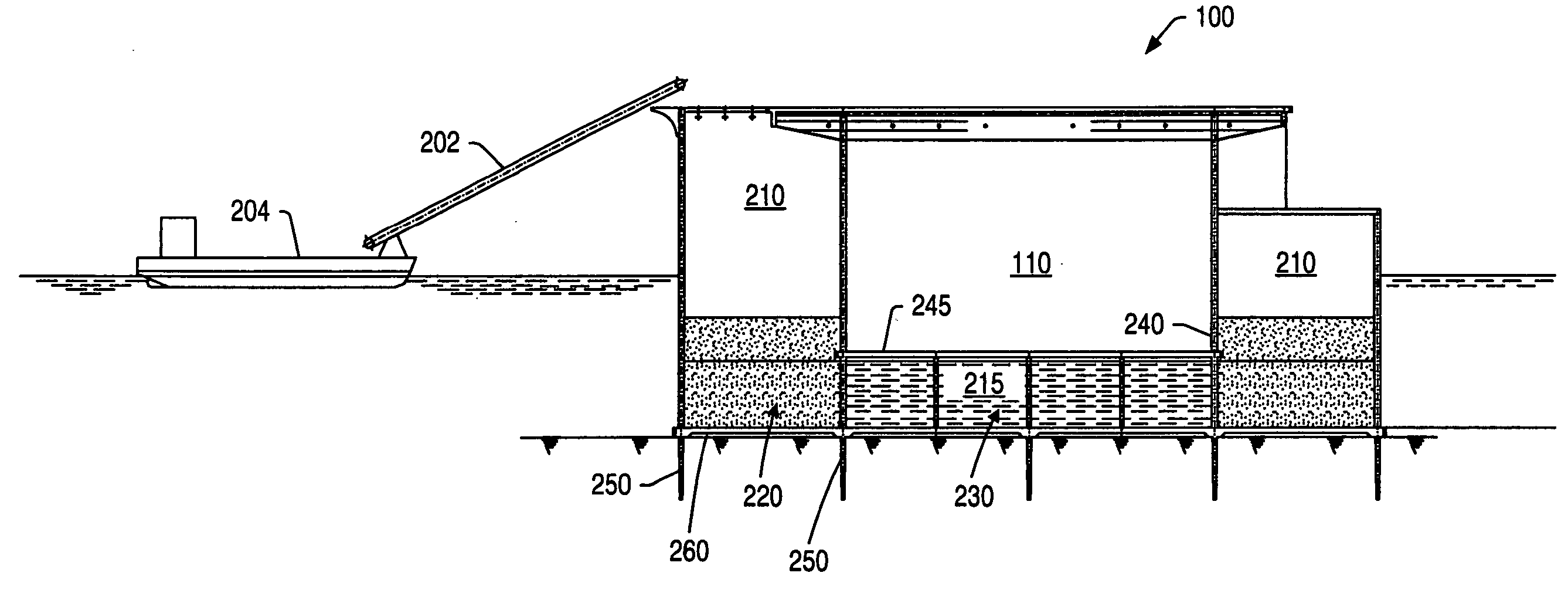

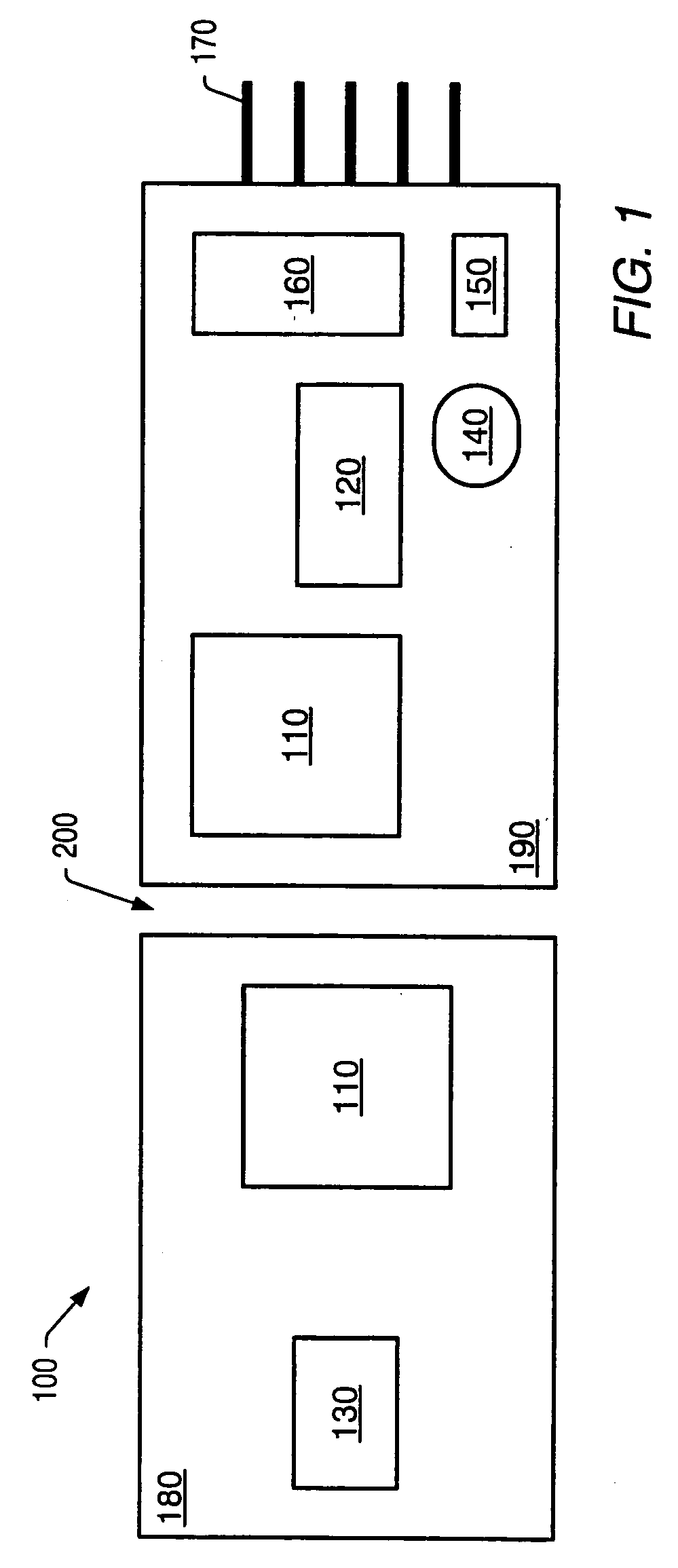

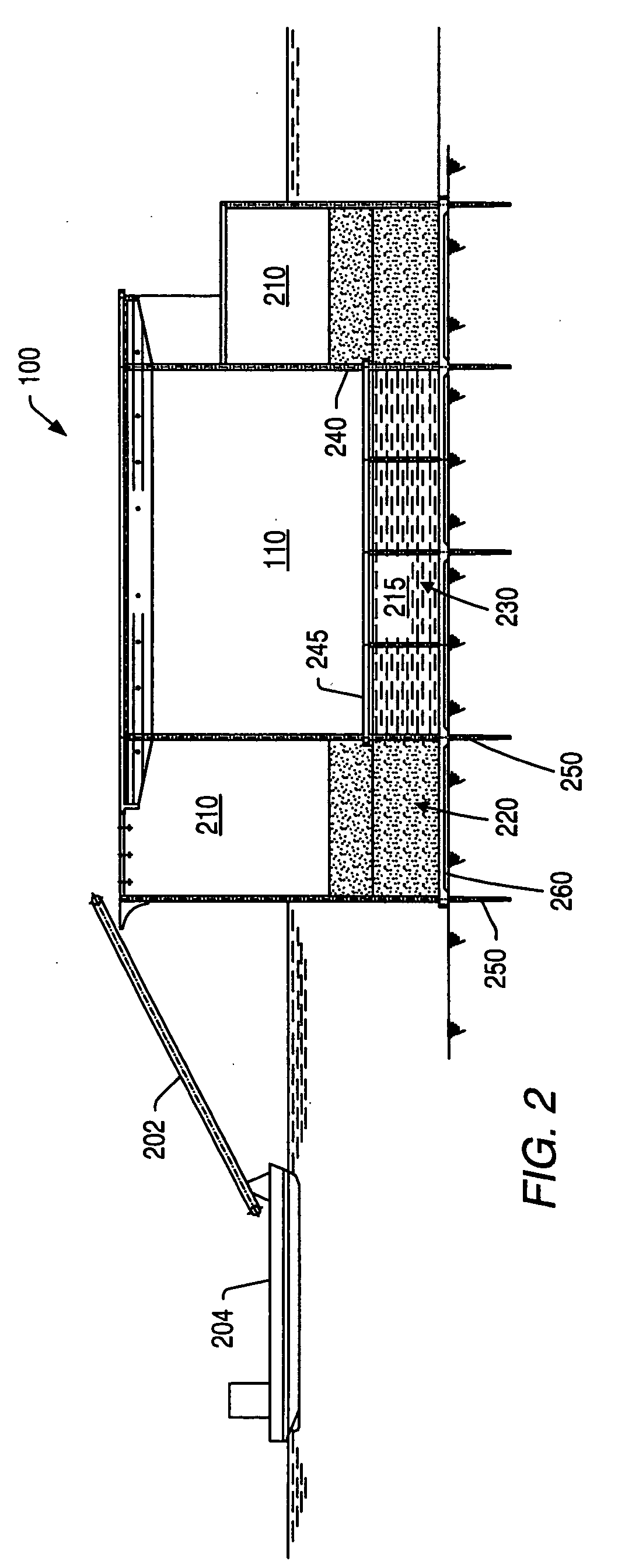

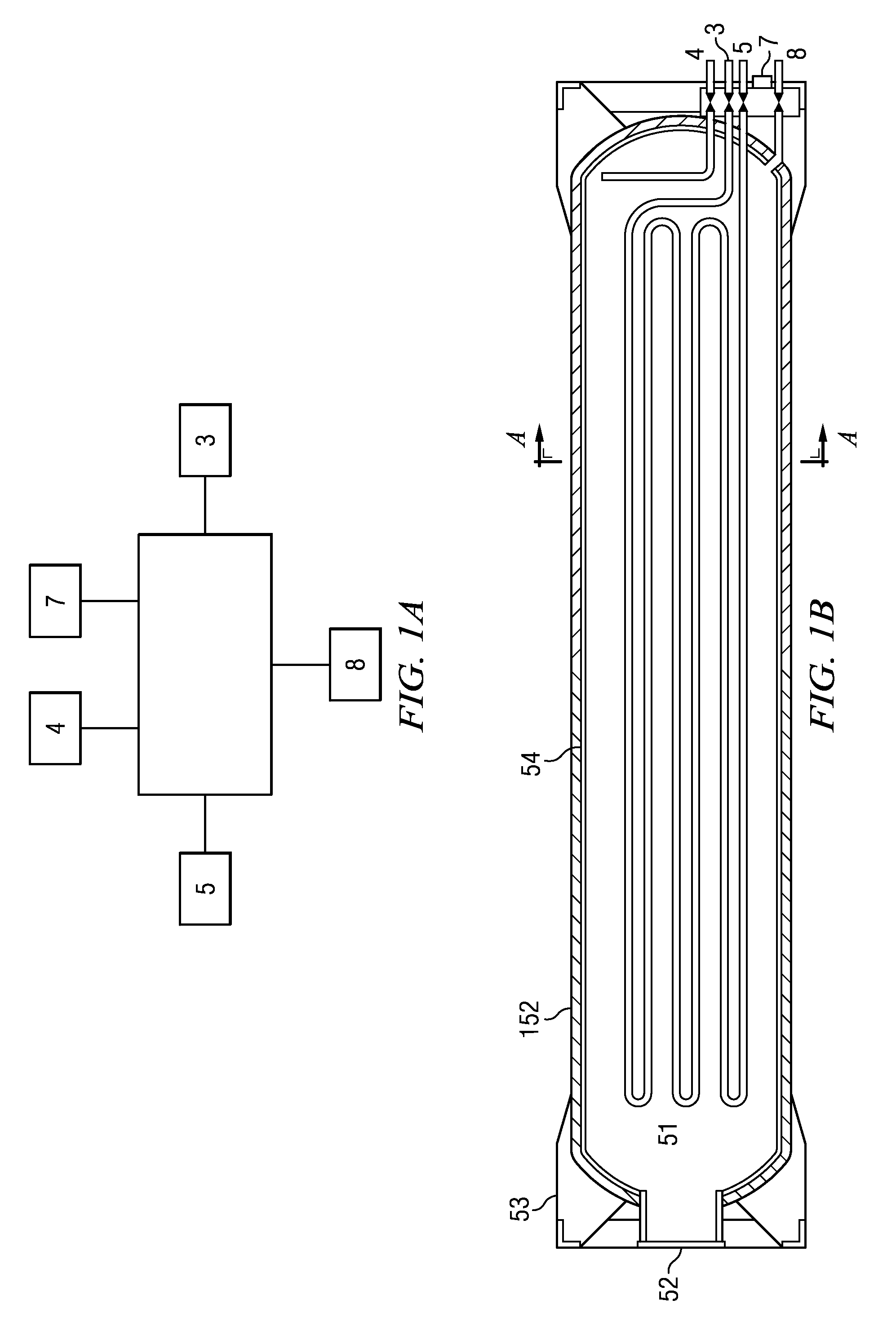

Liquefied natural gas structure

InactiveUS20050115248A1Easy transferProvide protectionGas handling/storage effectsSolid materialMarine engineeringTower

An offshore liquefied natural gas structure may receive, store, and process liquefied natural gas from carriers. A structure may be a gravity base structure. A structure may include a system of ballast storage areas, transfer equipment to offload liquefied natural gas from a carrier, docking equipment to allow direct mooring with carriers, platforms to elevate equipment, water intake systems to provide water to the structure, wave deflectors, and / or projections extending from a bottom of the structure. A portion of the structure may be composed of lightweight concrete. Pipelines may be coupled to the structure to export processed natural gas onshore. Living quarters, flare towers, and export line metering equipment may be included on the structure.

Owner:SHELL OIL CO

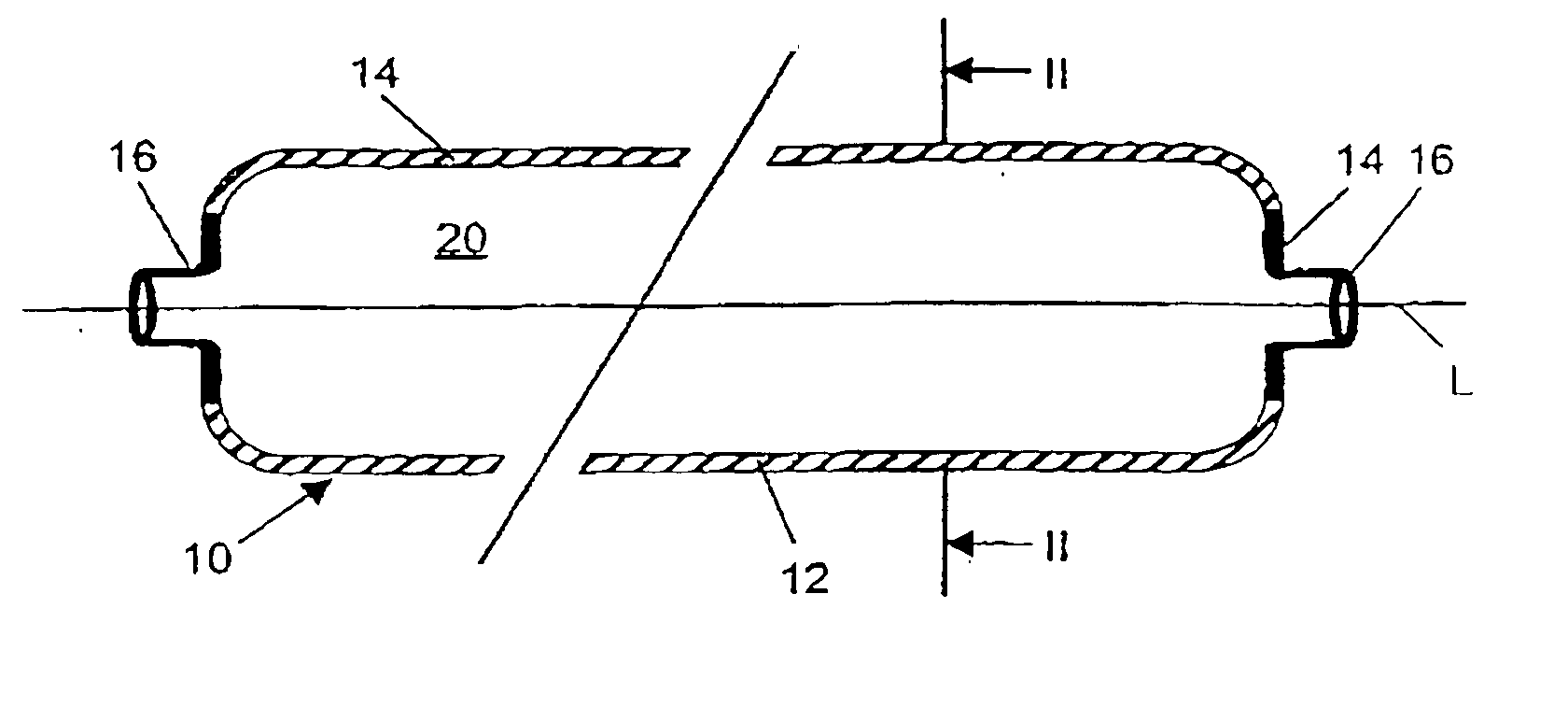

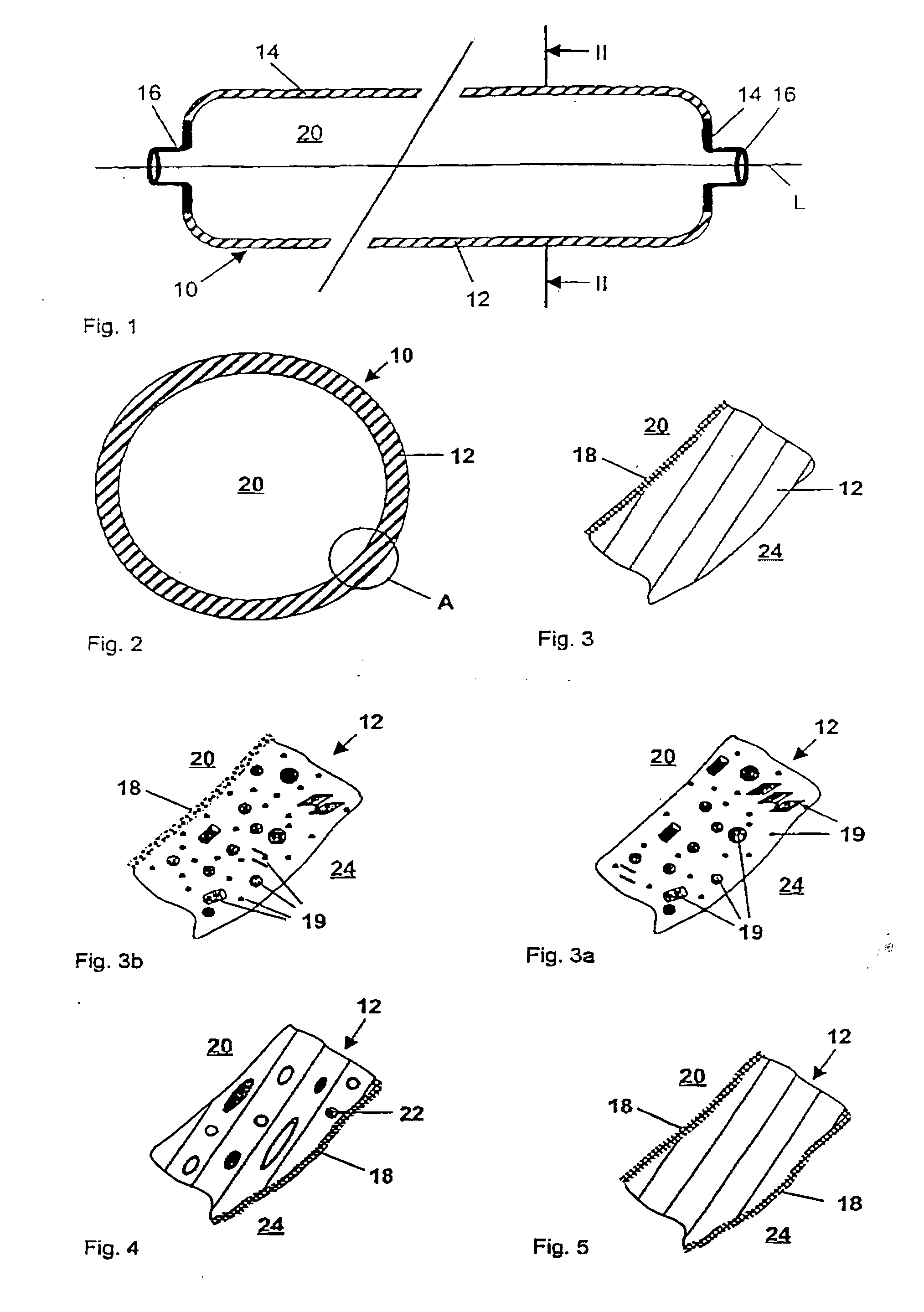

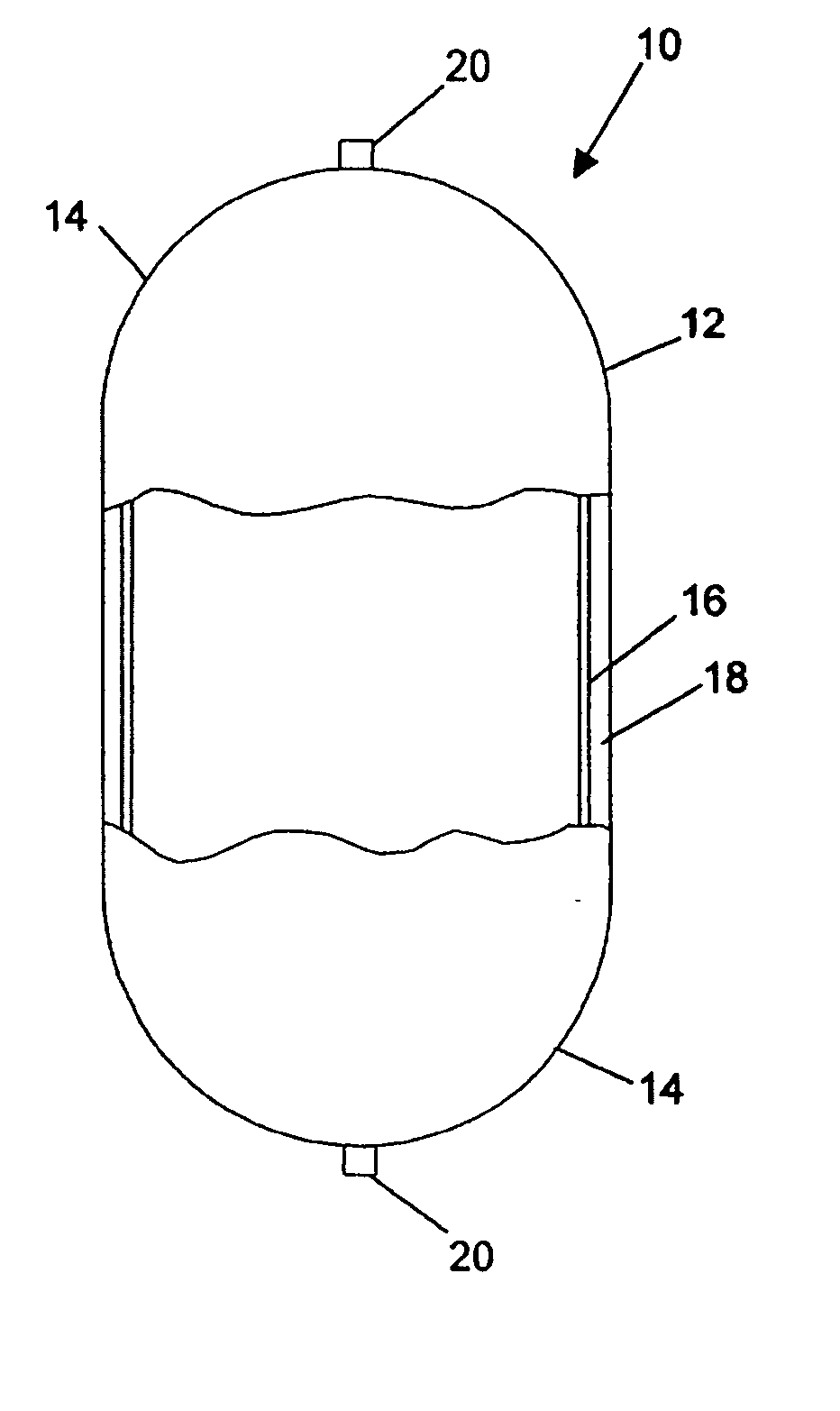

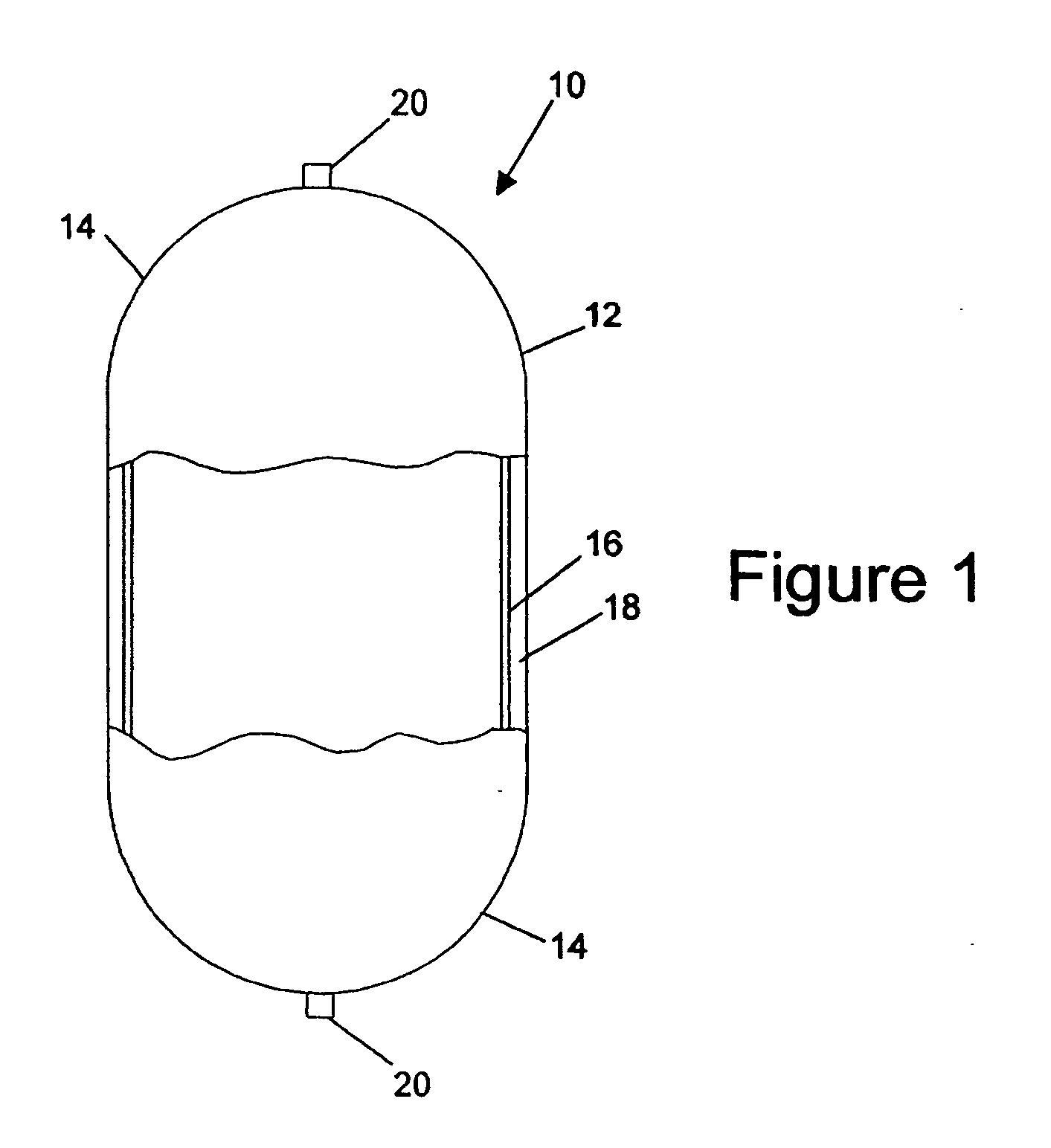

Gastight container

InactiveUS20040149759A1Reduce quality problemsNegligible in recyclingAircraft componentsVessel mounting detailsHydrogenComposite film

The invention relates to a gastight, pressure-resistant storage and / or transport container (10) for low-molecular, reactive filling media, especially for hydrogen, oxygen, air, methane and / or methanol. Said container has a high filling pressure and is embodied in an essentially rotationally symmetric manner, having at least one connector cap (15) with a sealing device (16). The wall (12) of the container is essentially comprised of a thermoplastic synthetic material having at least one diffusion barrier (18, 19) system and / or a diffusion barrier and anti-corrosion system (18, 19). In order to offer protection for hydrogen and oxygen containers, the diffusion barrier system can be embodied in the form of at least one compact layer and / or can contain finely dispersed, distributed reactive nanoparticles (18) in the wall (12) of the container, in at least one composite film (28) and / or in at least one diffusion barrier layer (18).

Owner:MOSER EVA MARIA +1

Clathrate hydrate modular storage, applications and utilization processes

Methods, apparatuses and systems directed to clathrate hydrate modular storage, applications and utilization processes. In one implementation, the present invention provides a method of creating scalable, easily deployable storage of natural gas and thermal energy by assembling an array of interconnecting, modular gas clathrate hydrate storage units.

Owner:SOLID GAS TECH

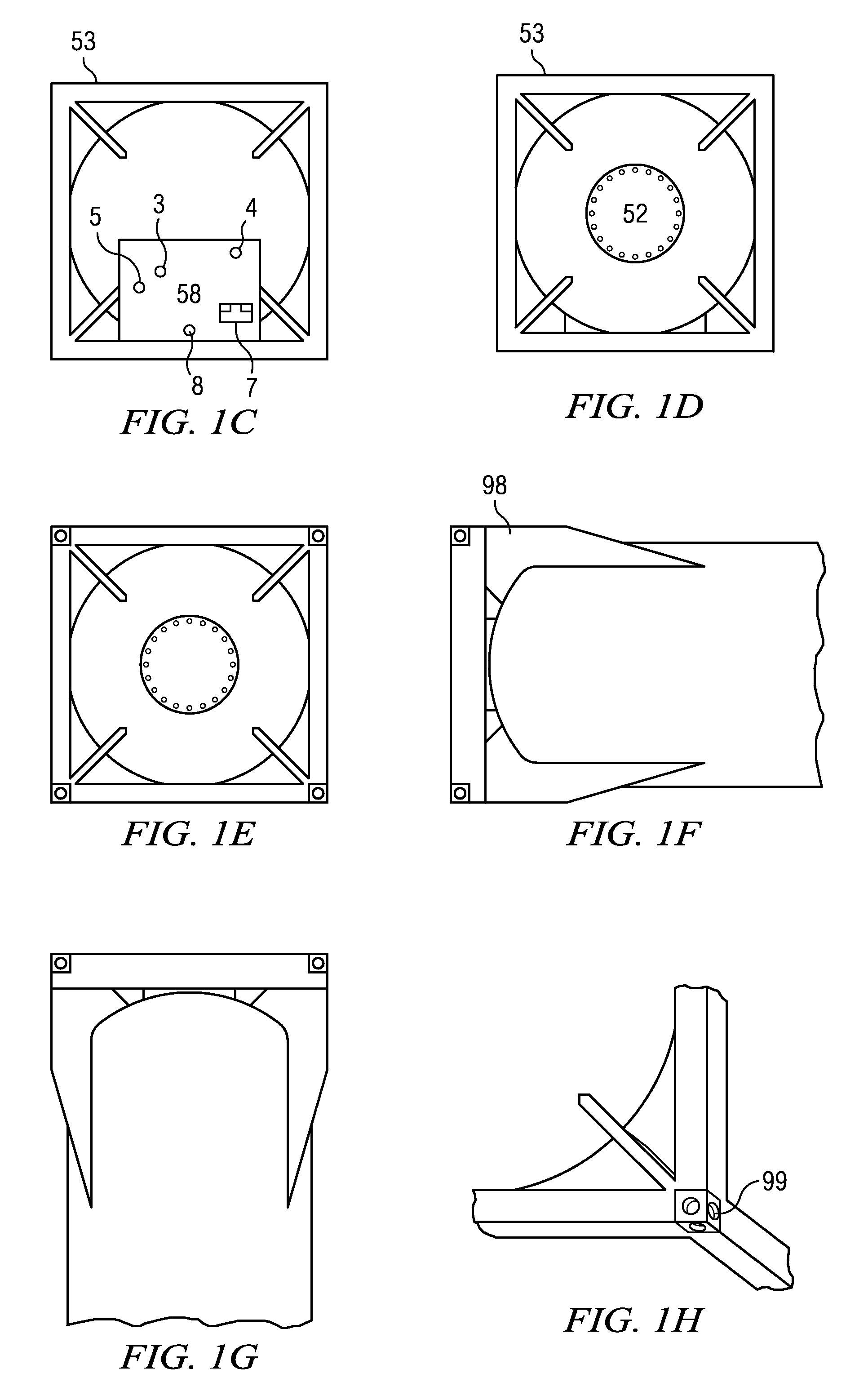

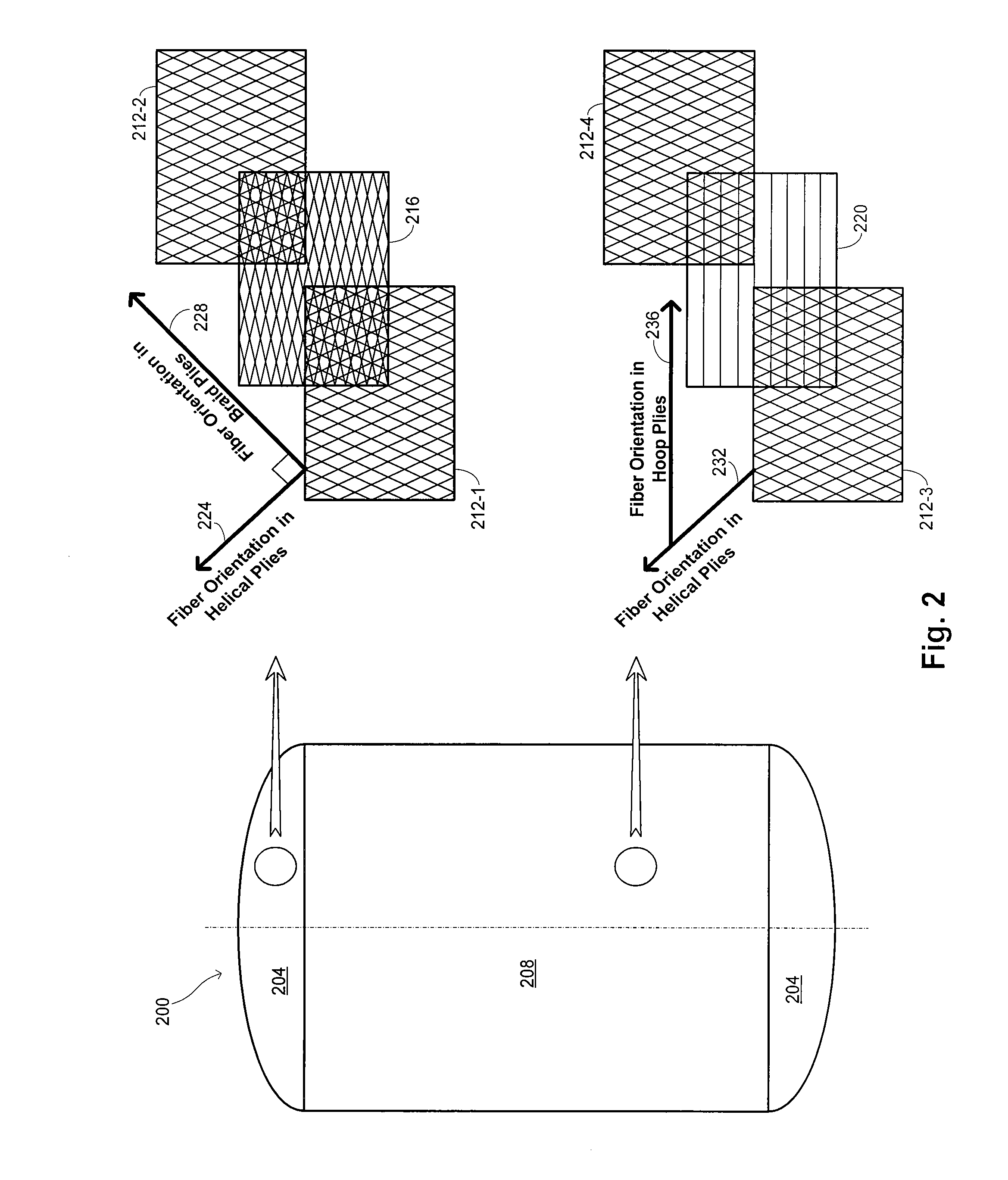

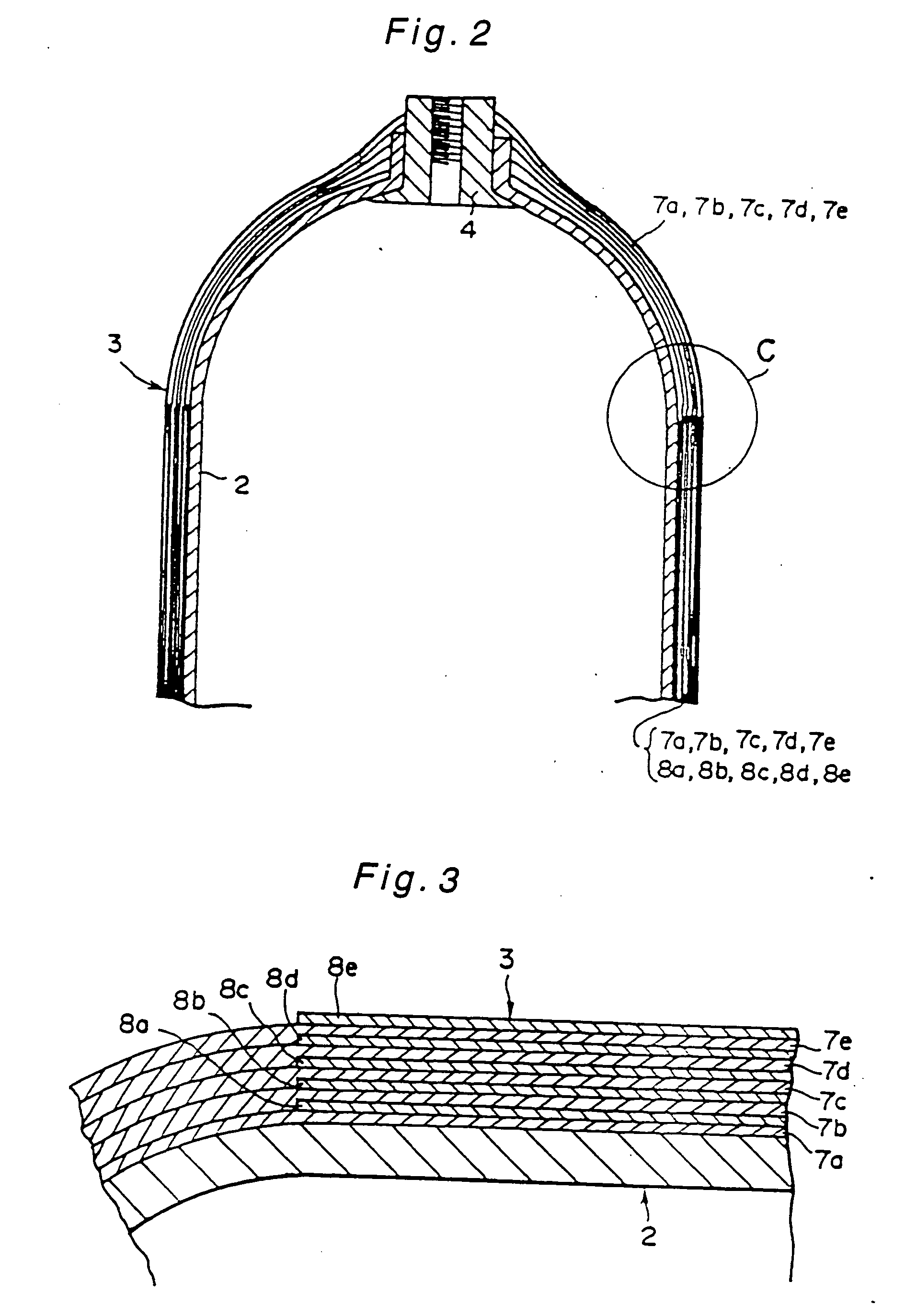

Damage and leakage barrier in all-composite pressure vessels and storage tanks

ActiveUS20090314785A1Superior barrier against leakageStrengthAdhesive processesGas handling applicationsFiberAxis of symmetry

A linerless tank structure has a body that defines an enclosed interior volume. The body has a cylindrical section having an axis of symmetry and a dome section coupled with the cylindrical section. The construction of the pressure vessel includes multiple fiber plies. At least one of the fiber plies is a helical ply having fibers traversing the dome helically about the axis of symmetry. At least a second of the fiber plies is a braided or woven ply.

Owner:COMPOSITE TECH DEV

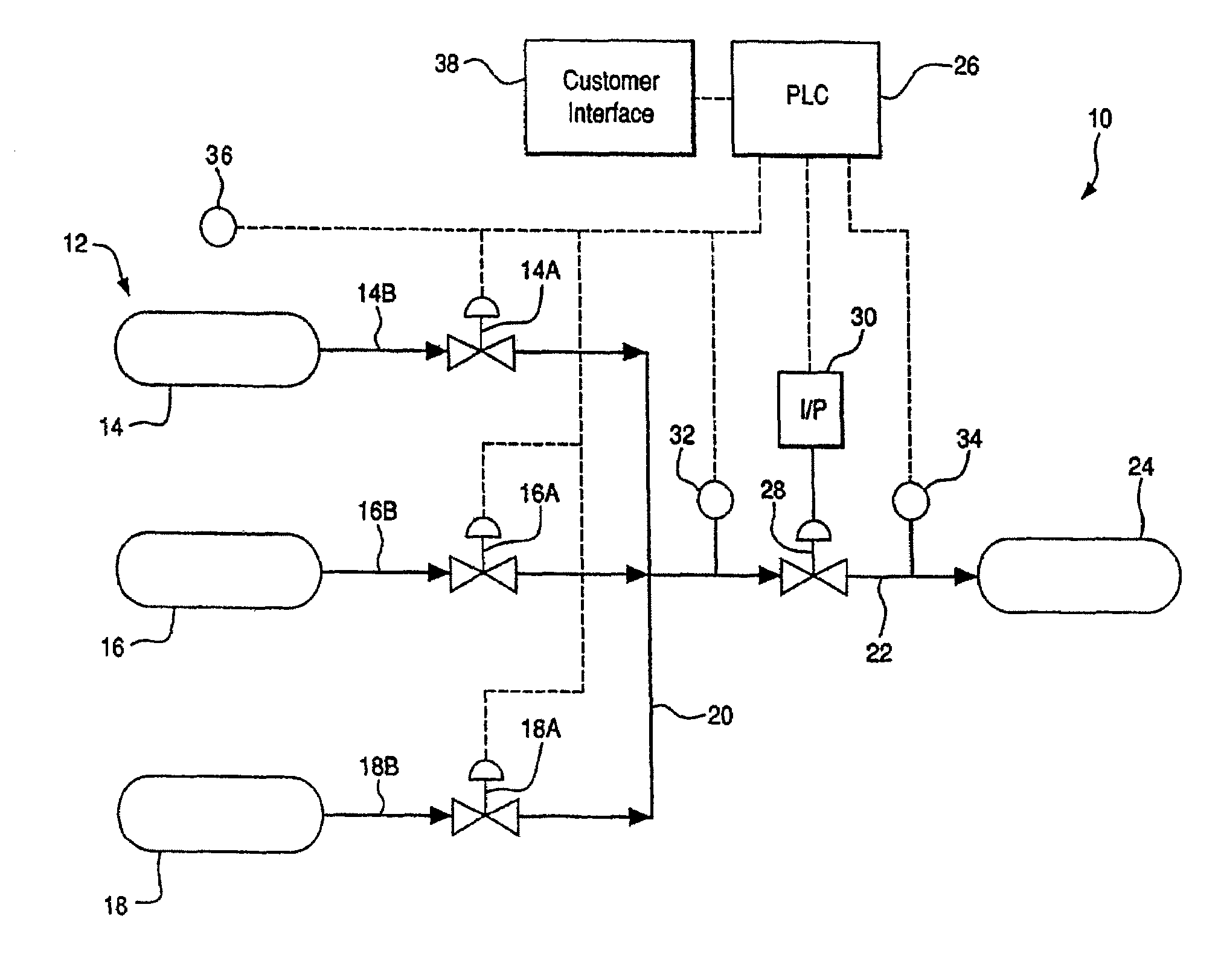

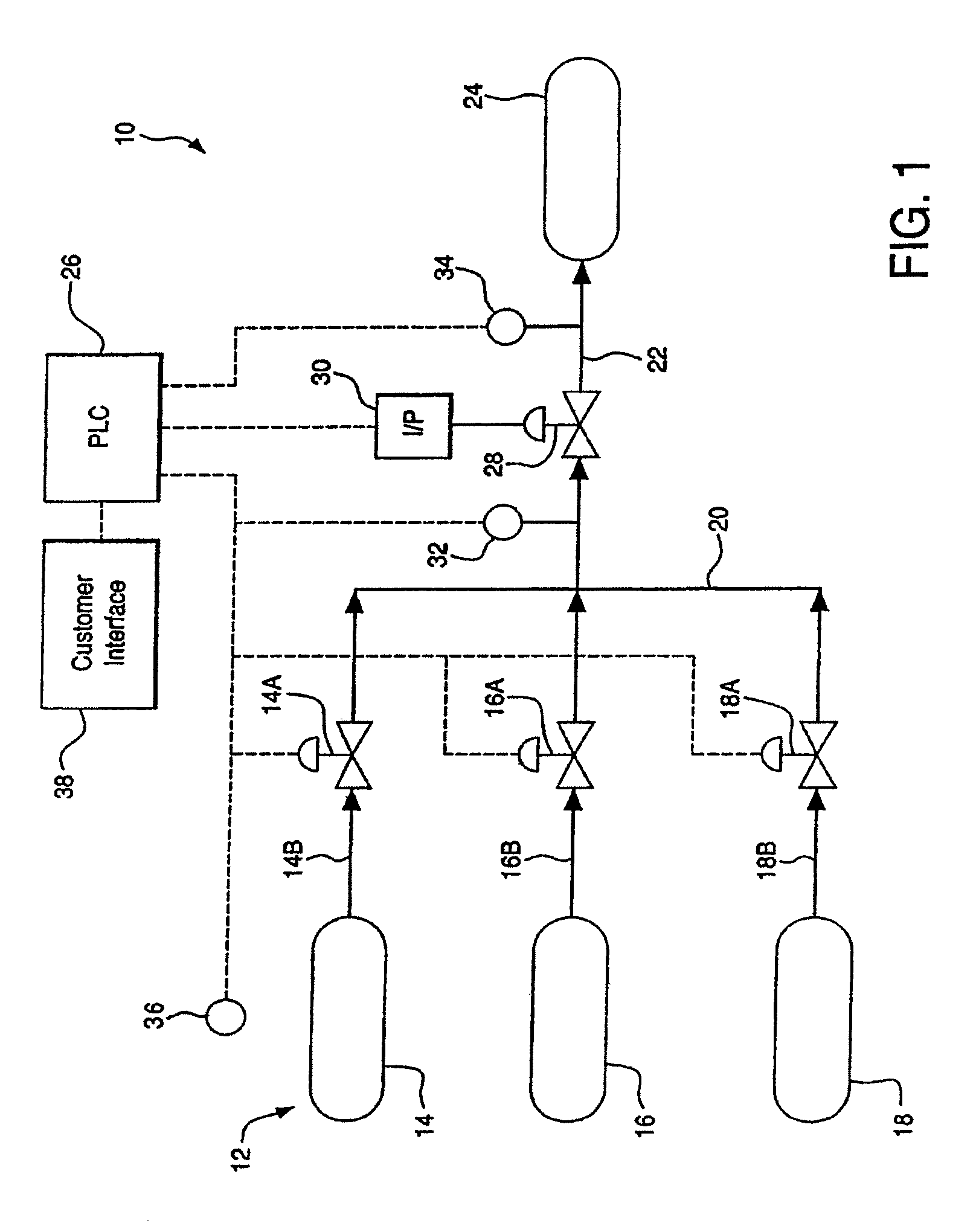

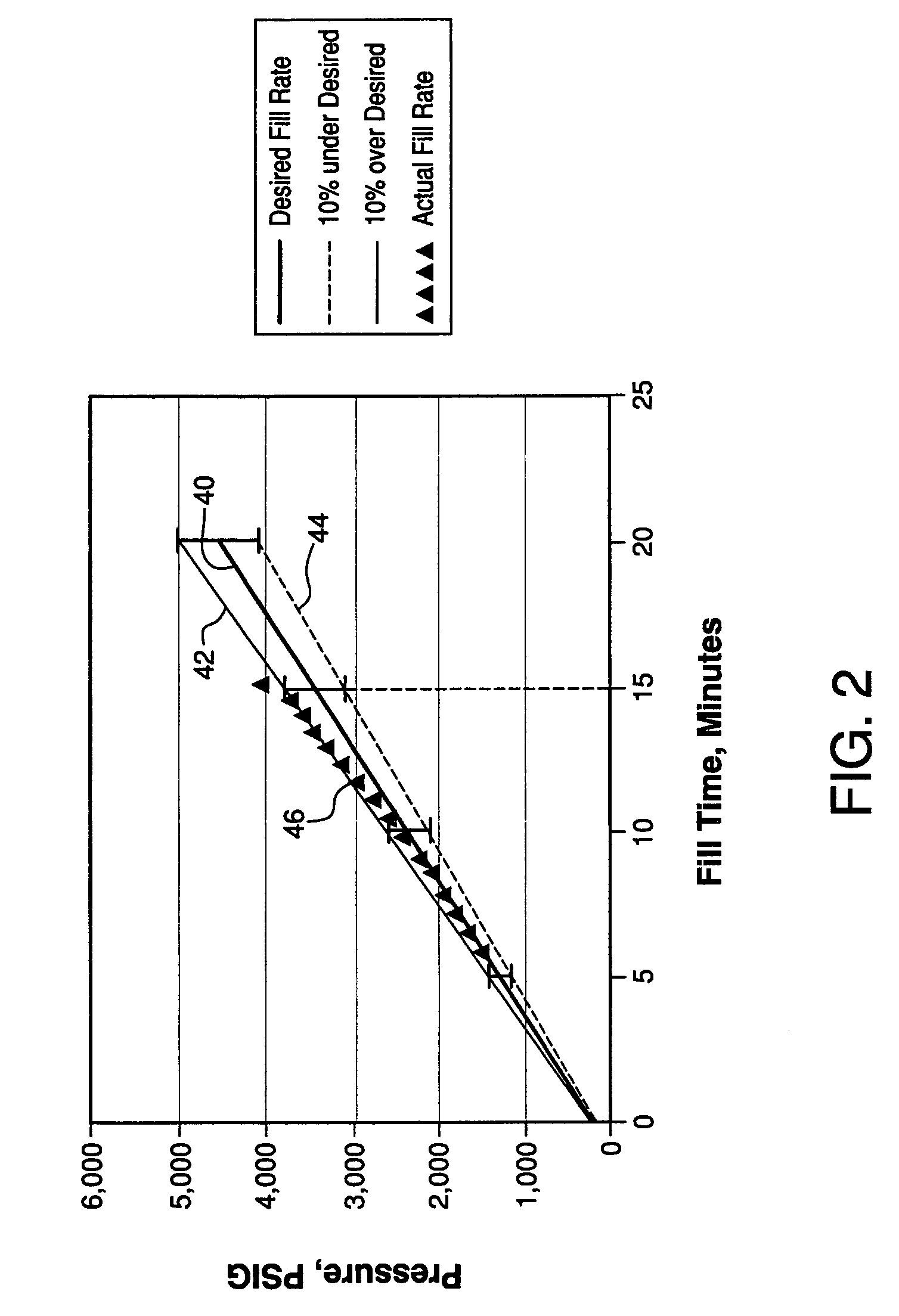

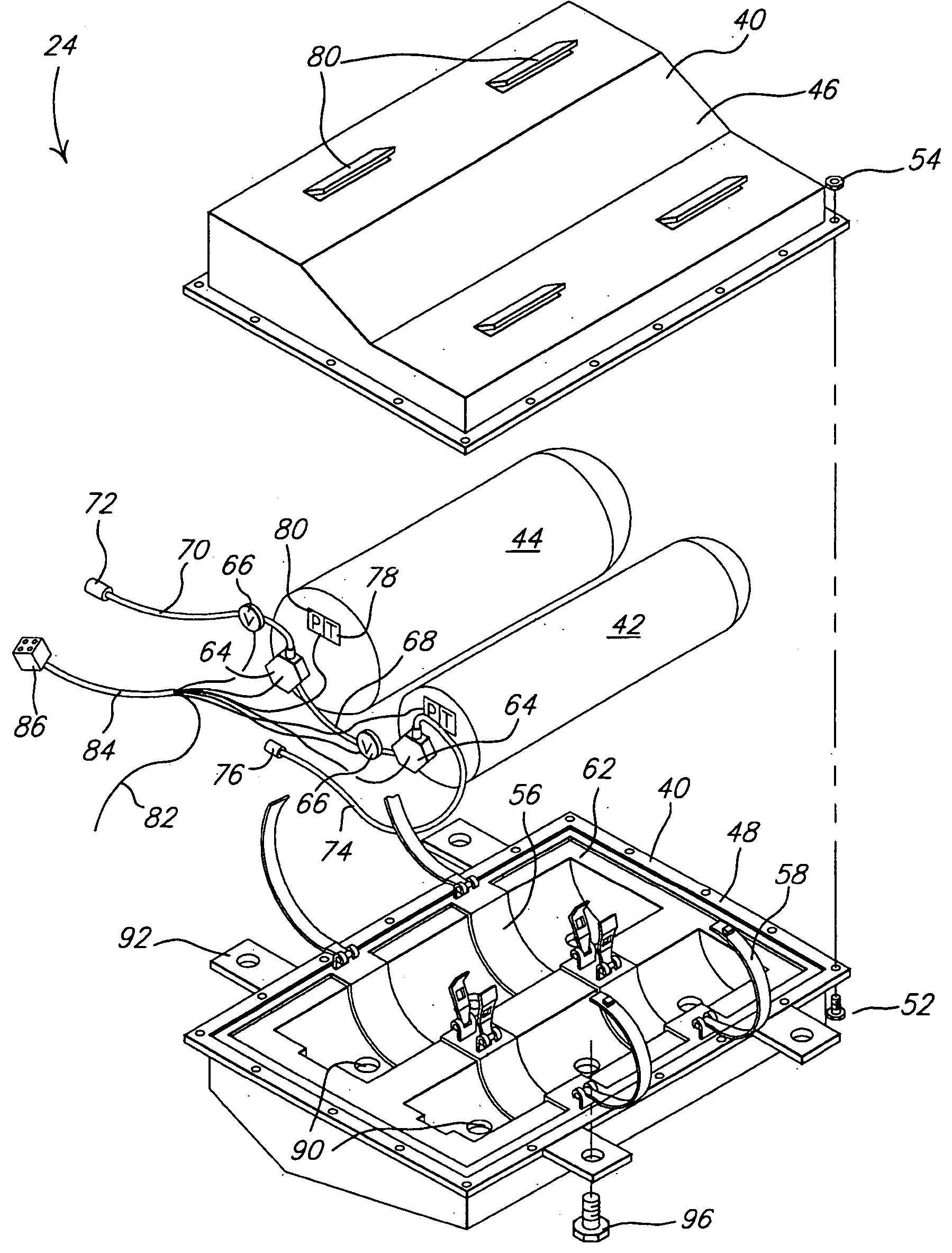

Diagnostic method and apparatus for a pressurized gas supply system

ActiveUS7568507B2Prevent excessive pressure risePreventing a potentially dangerous overheating problemLiquid fillingGas handling applicationsLine tubingEngineering

A diagnostic method for a gas supply system includes: determining a desired ramp rate for filling a vessel from a supply of compressed gas; monitoring the actual pressure of gas entering the vessel; and discontinuing the flow of gas into the vessel when the actual pressure deviates from the intended pressure at the desired ramp rate by an undesired amount. A system for carrying out the method includes a flow controller for controlling operation of the supply system to deliver compressed gas from a source to a vessel through a supply line at a desired ramp rate. The system employs a pressure monitor downstream of a control valve for measuring the pressure of gas directed into the vessel and transmitting pressure-related data to the flow controller, which closes the control valve to discontinue filling of the vessel if the actual pressure exceeds a permissible deviation from the intended pressure.

Owner:AIR PROD & CHEM INC

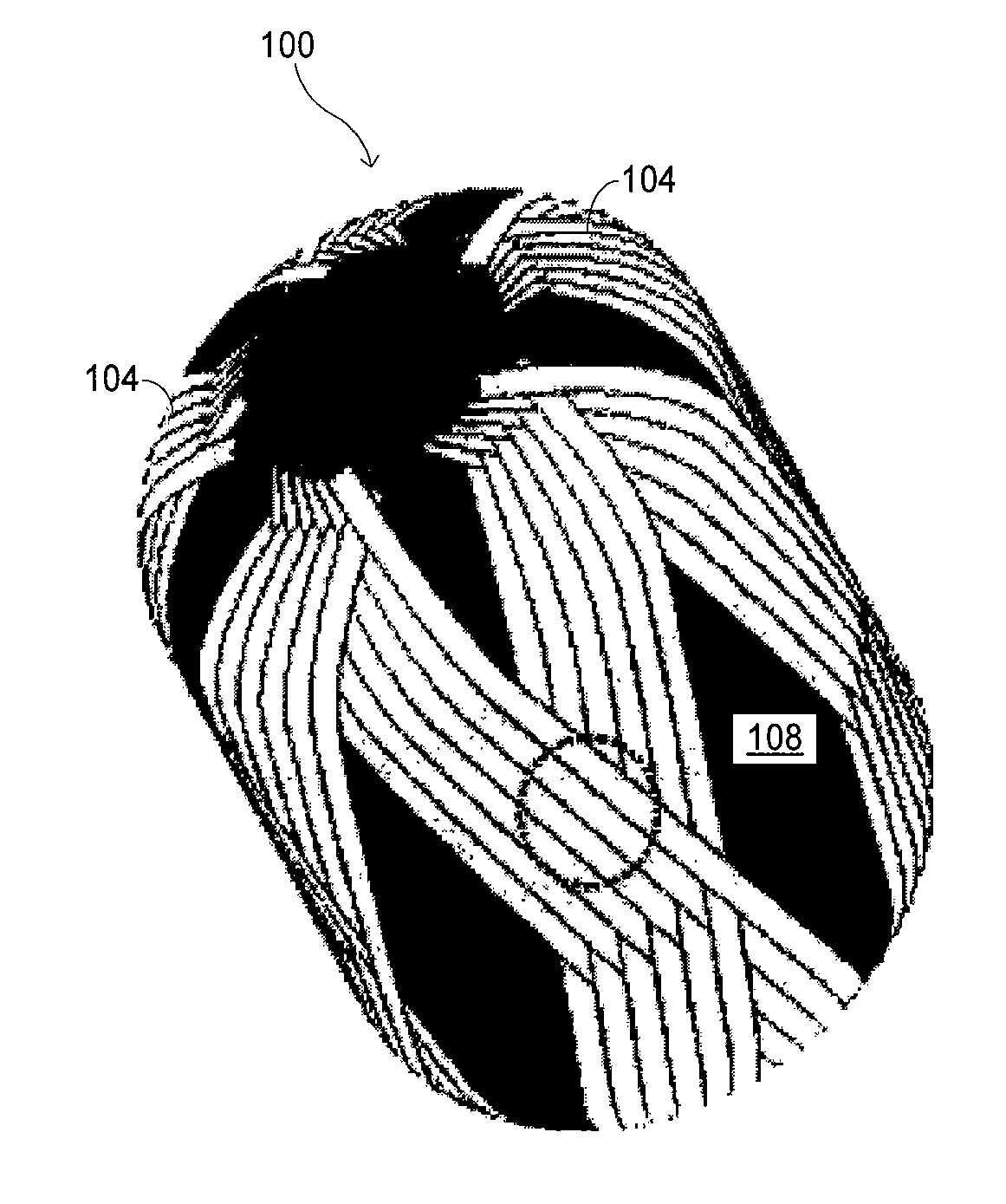

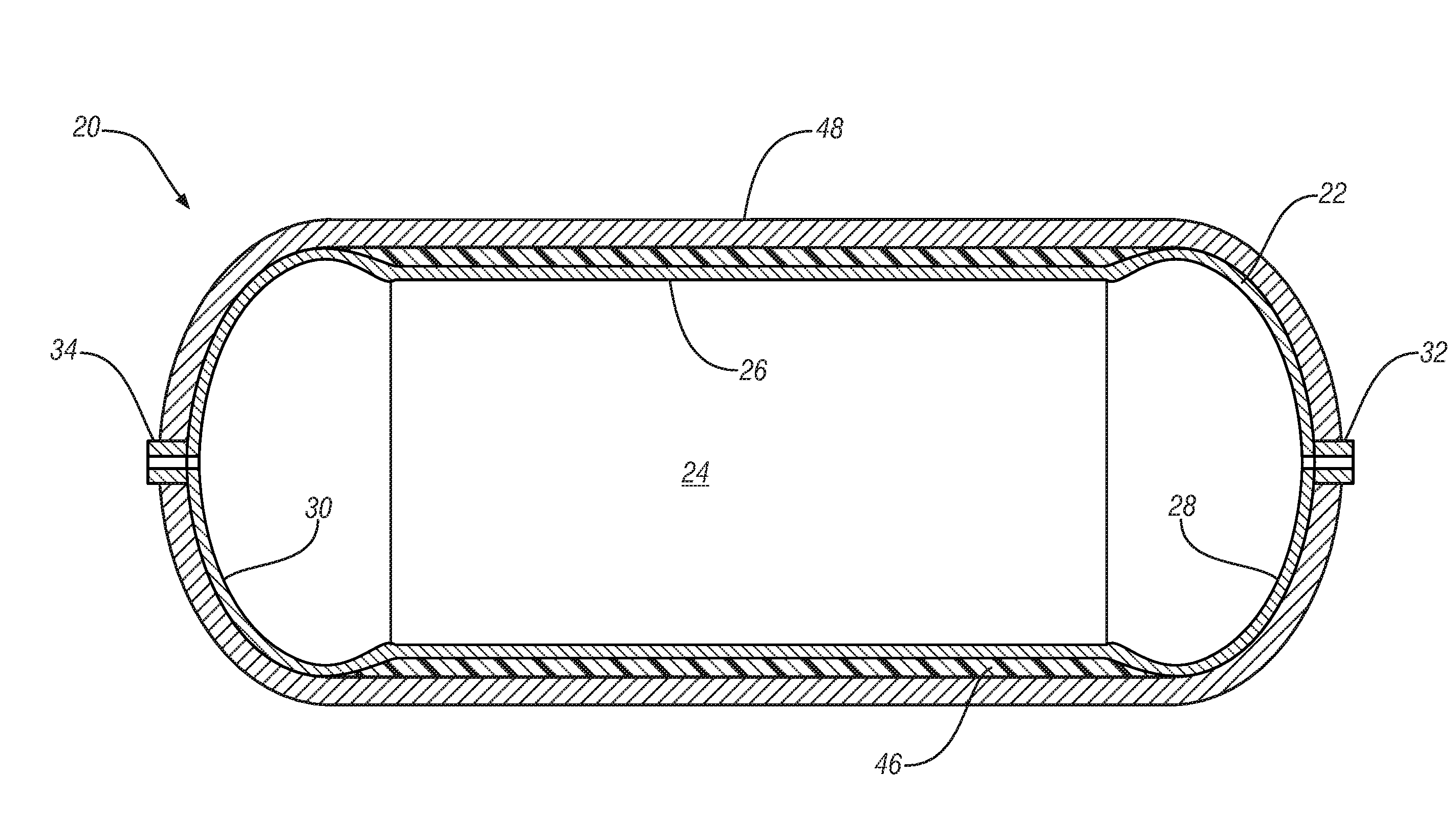

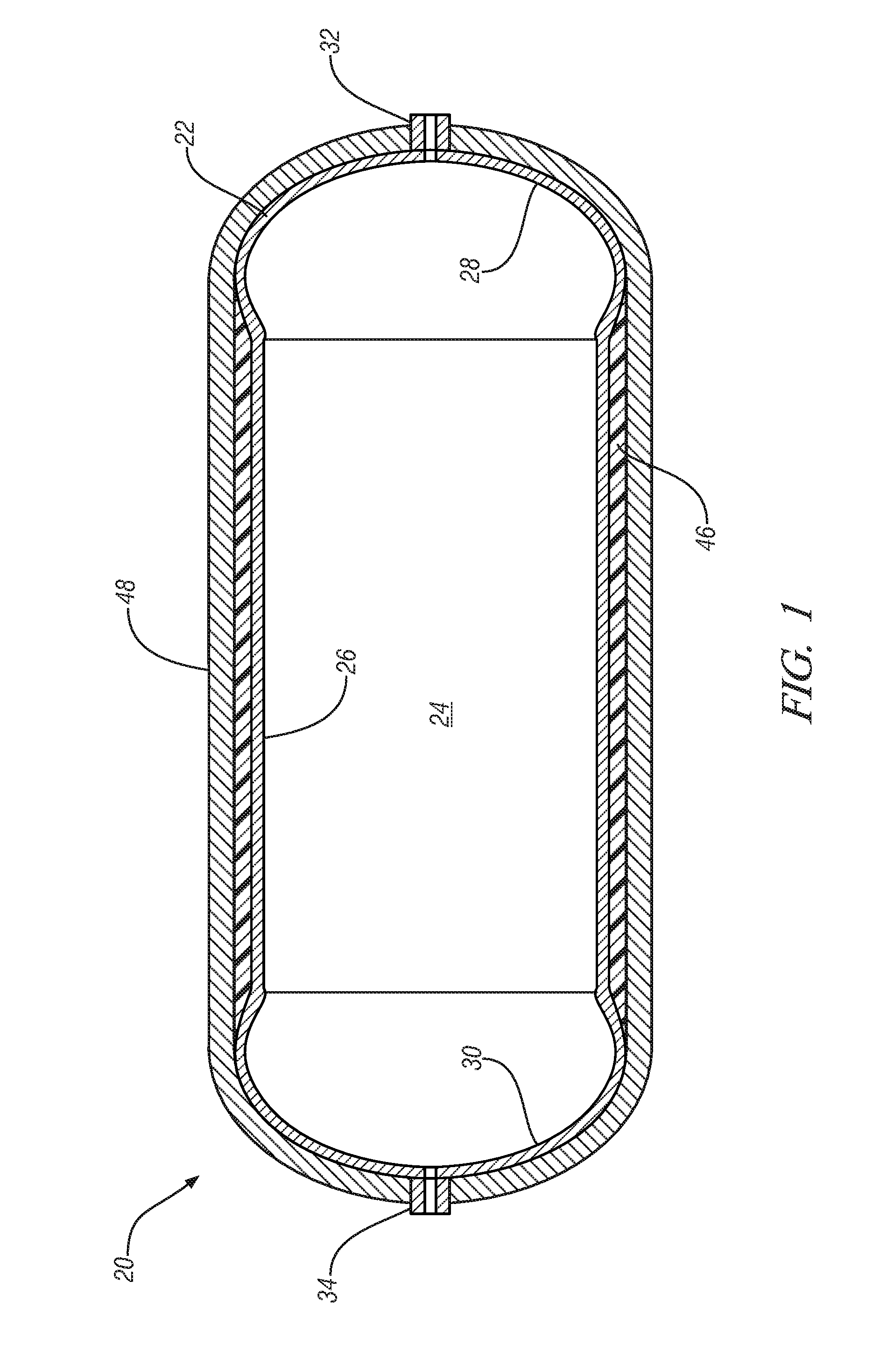

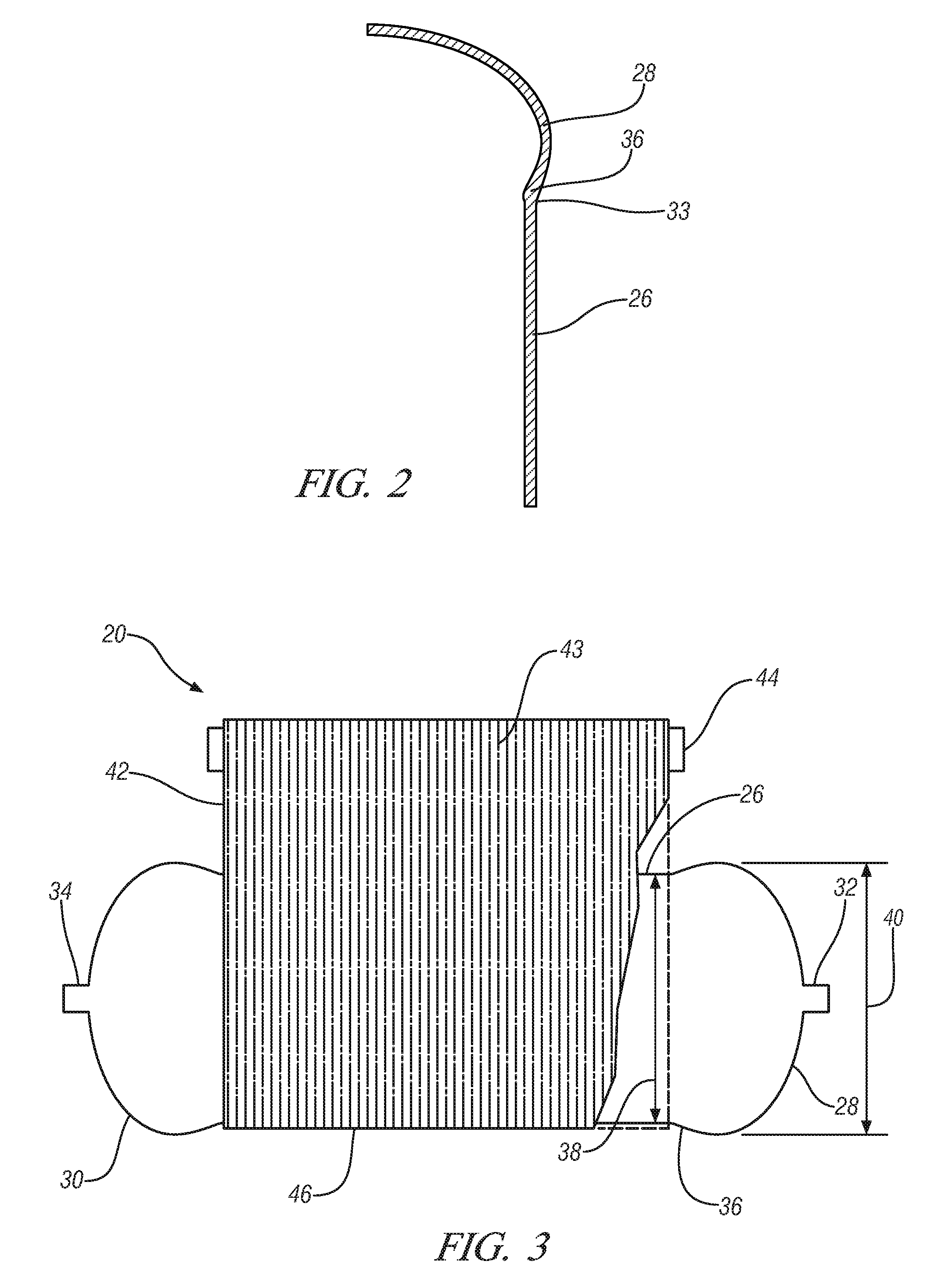

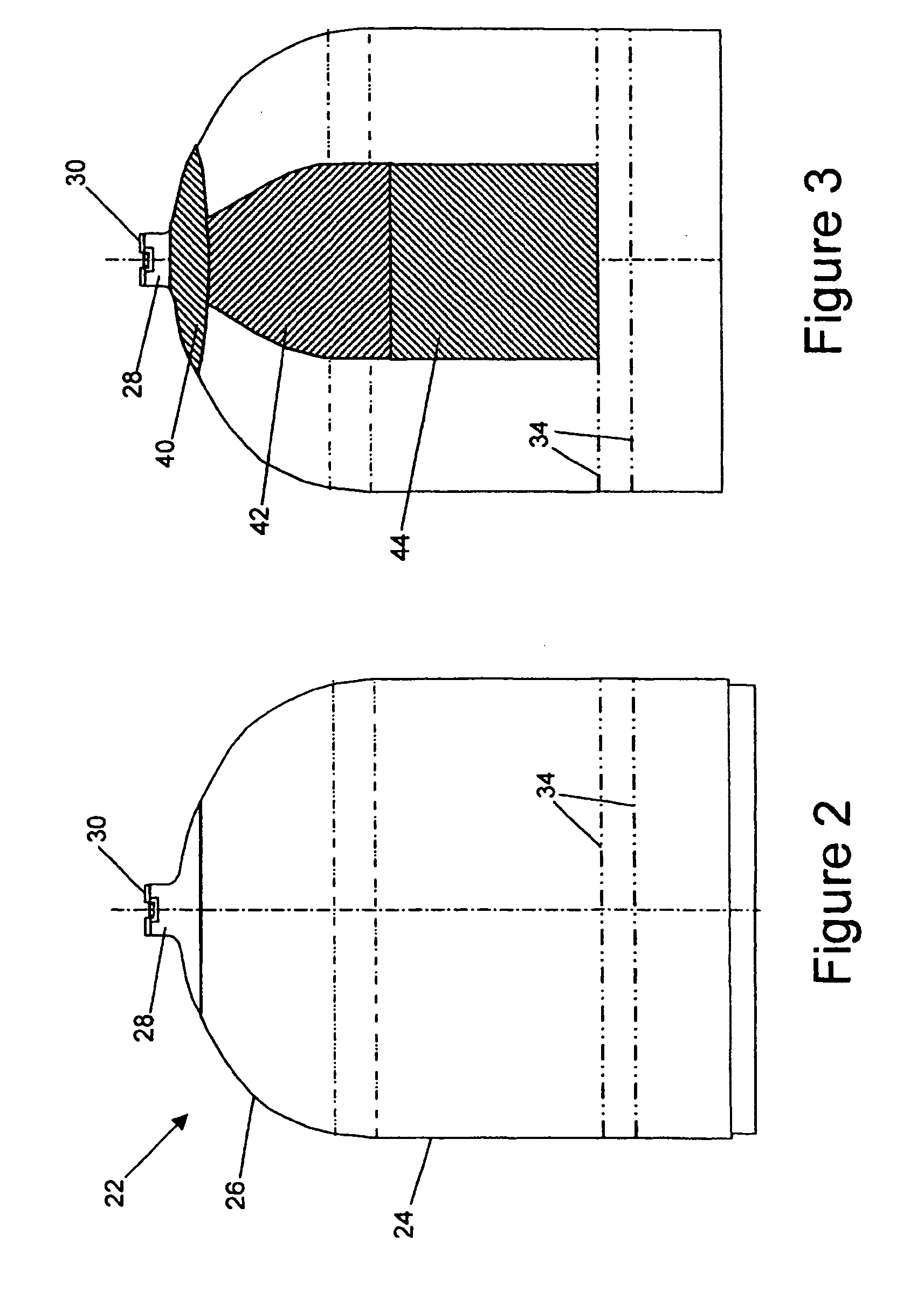

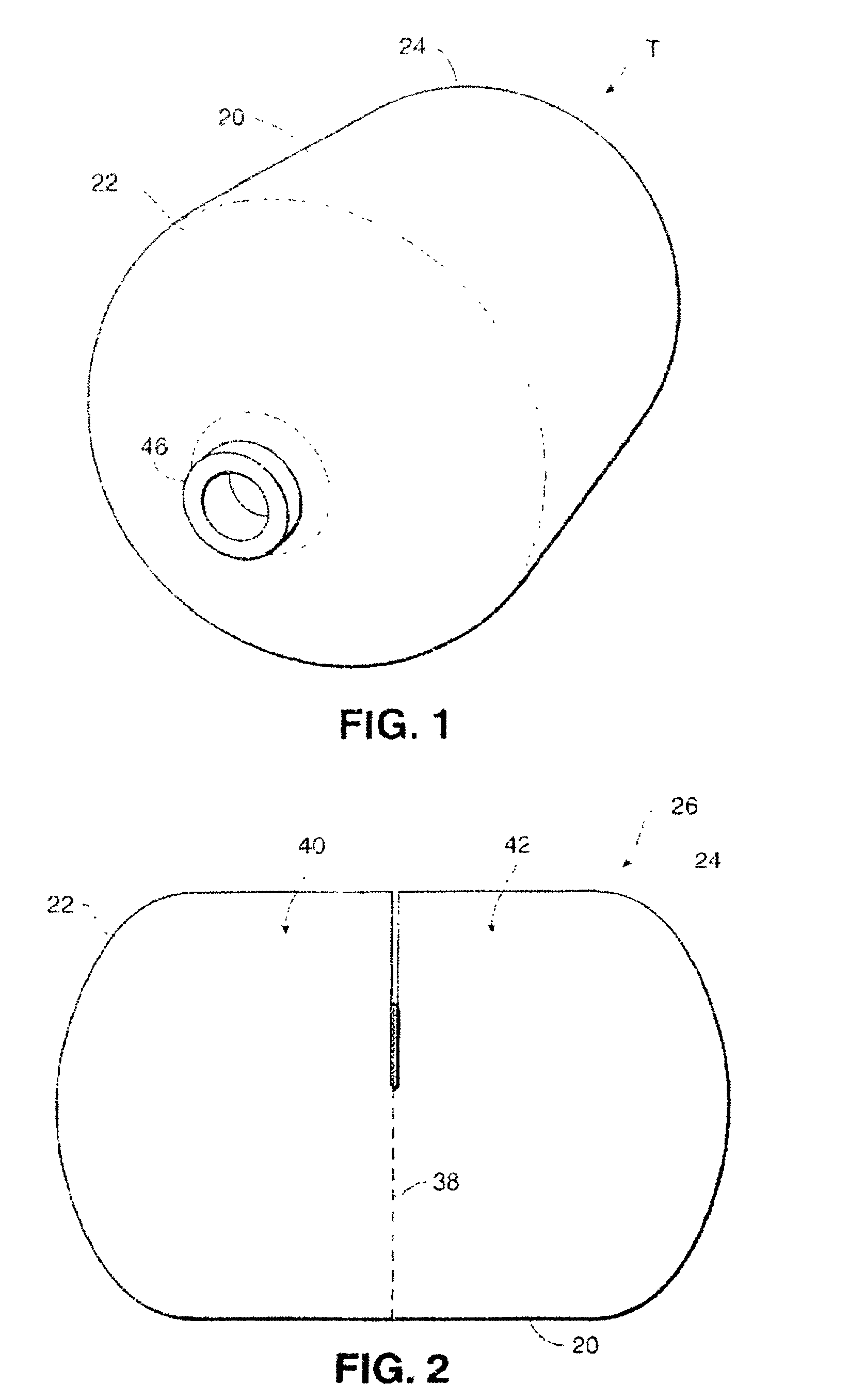

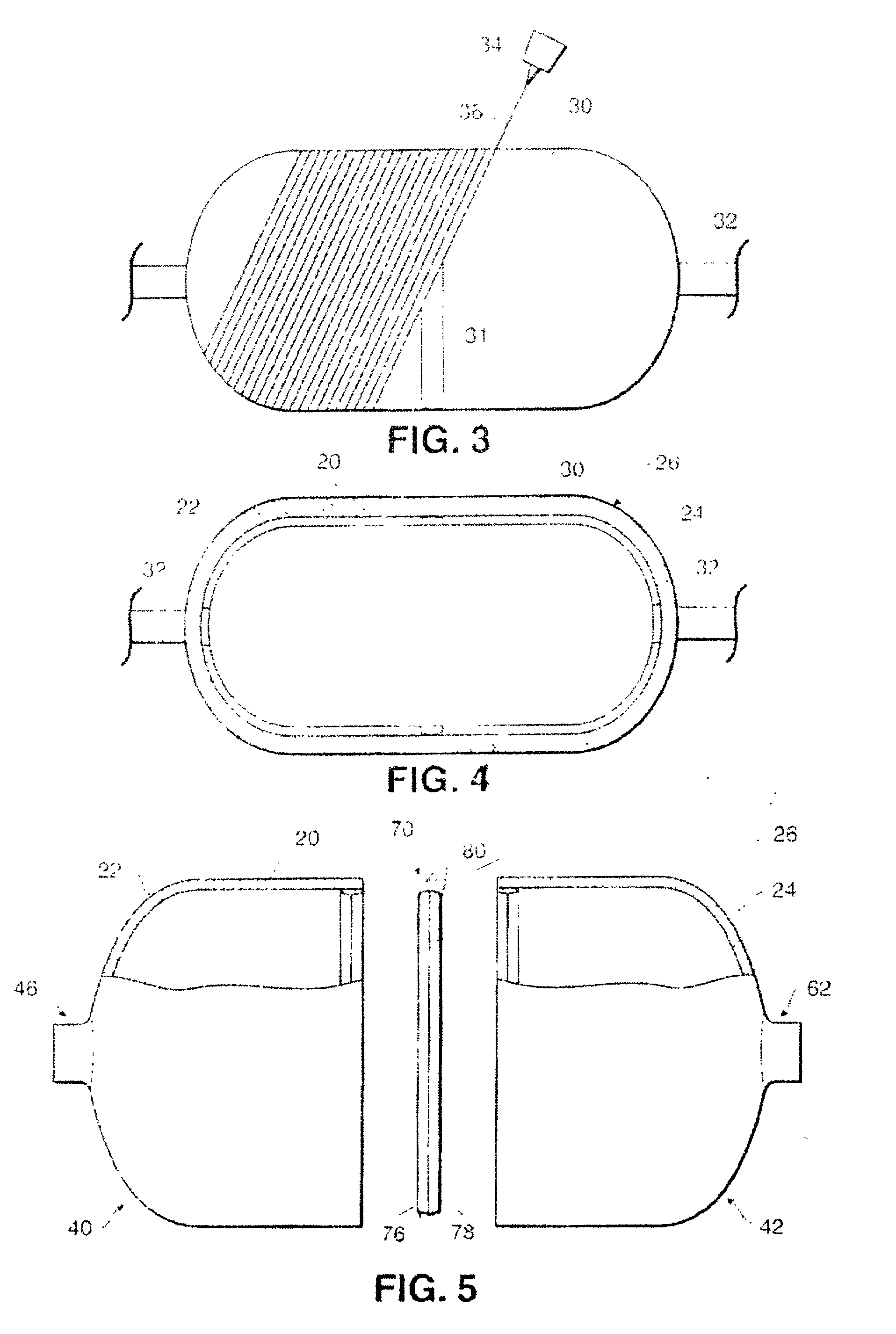

Storage vessel and method of forming

A storage vessel, such as vessels used in storing high pressure gas is provided. The storage vessel includes a liner having a center portion and a first and second end dome. A first composite layer is disposed circumferentially about the center portion. A second composite layer is disposed about said first composite layer and the first and second end dome. In some embodiments, the second composite layer is formed from a knitted or braided sleeve that is tightened over the liner and first composite layer by pulling the sleeve.

Owner:GM GLOBAL TECH OPERATIONS LLC

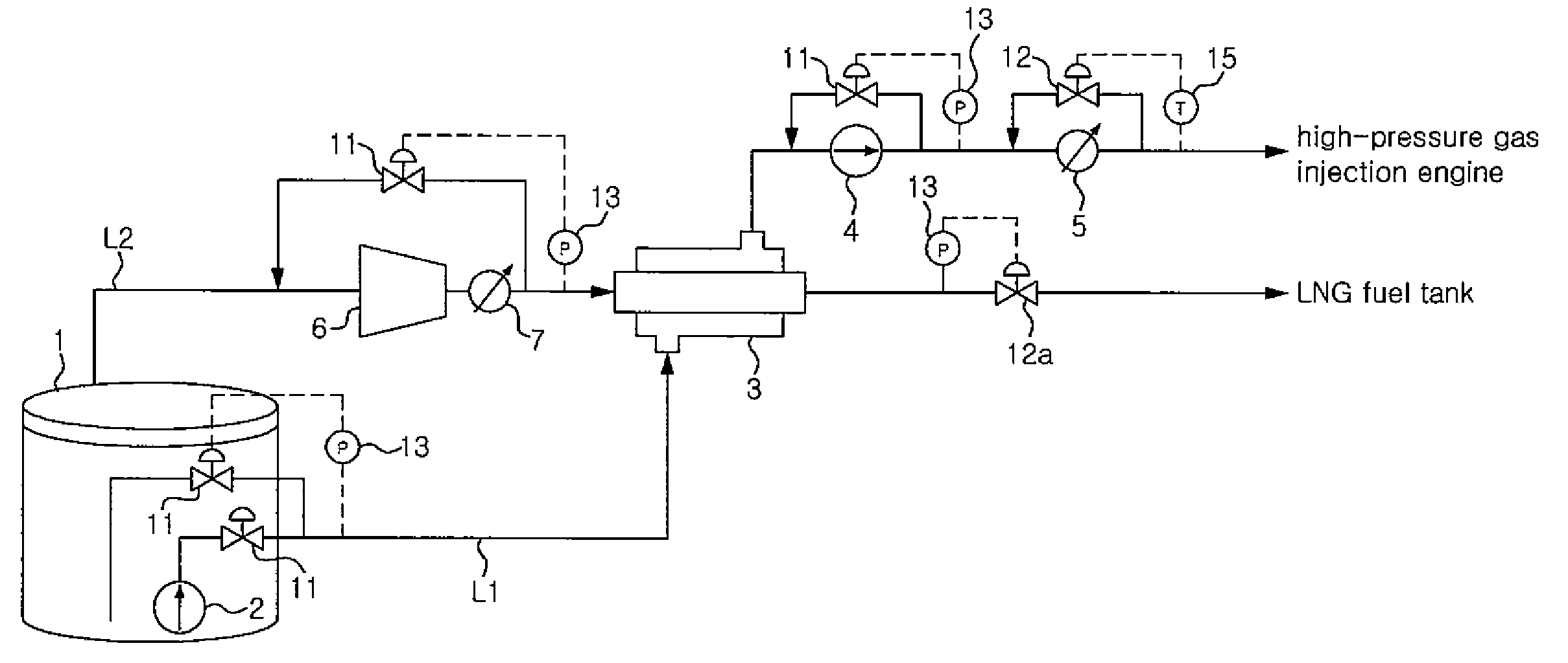

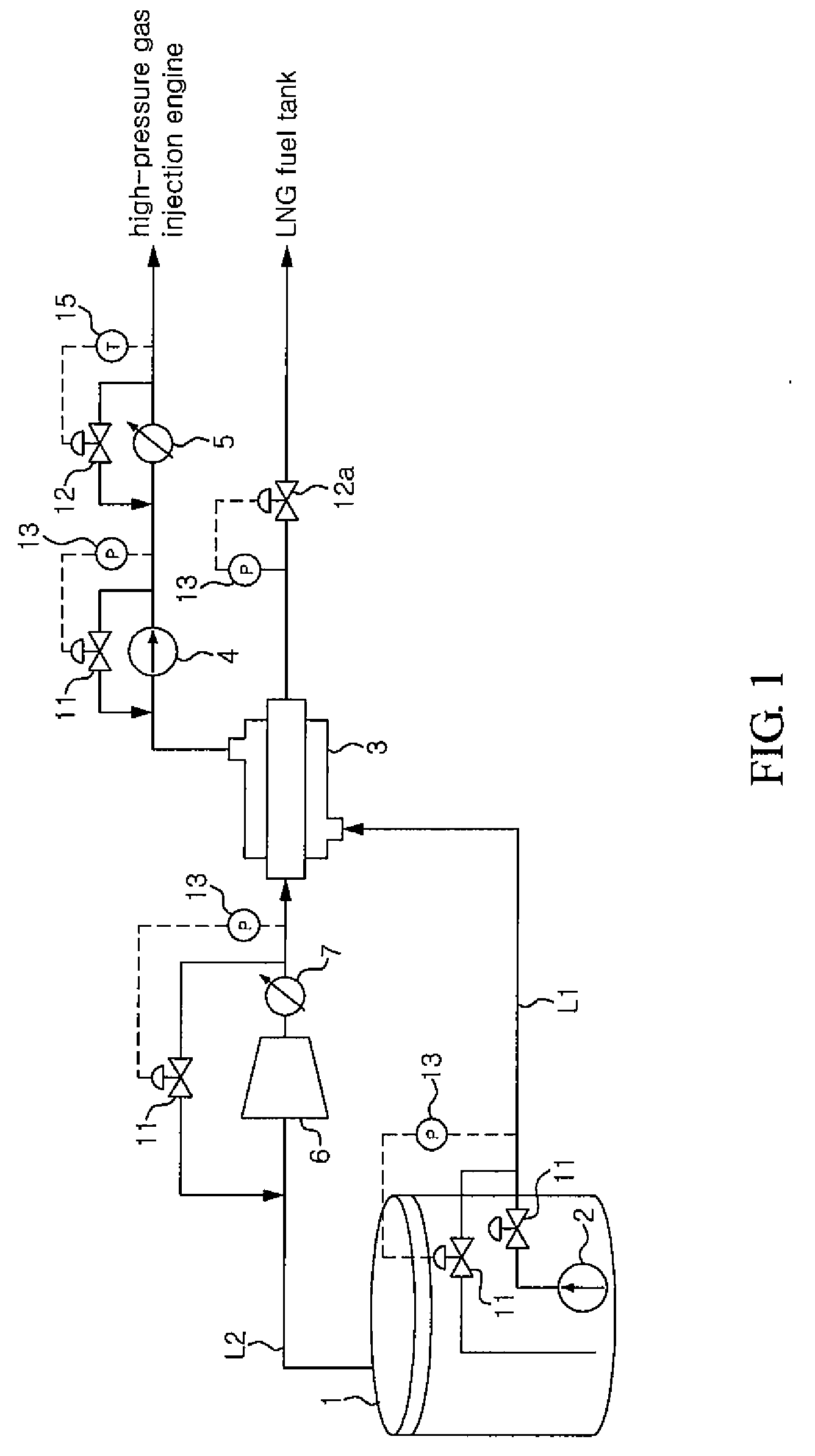

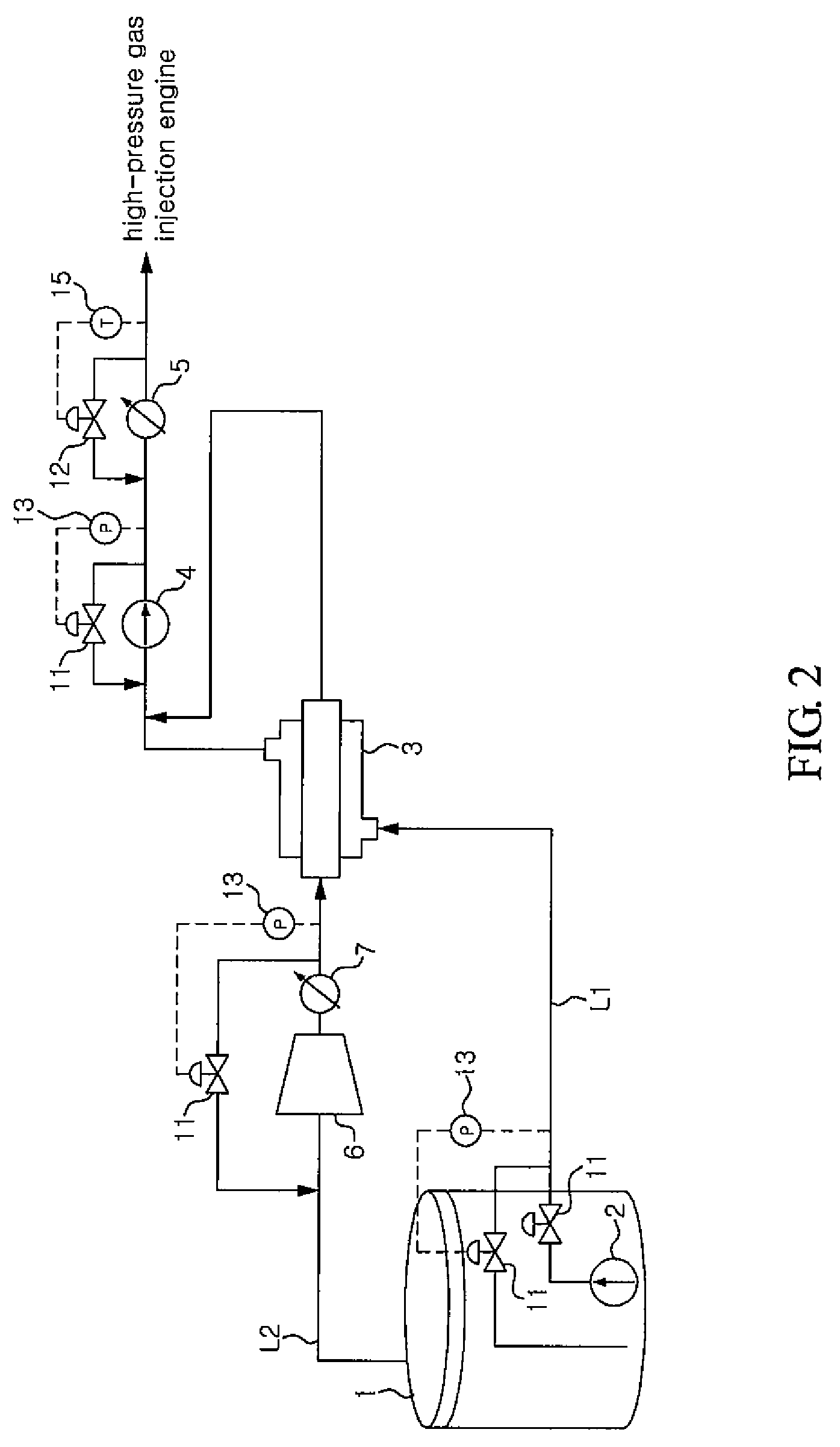

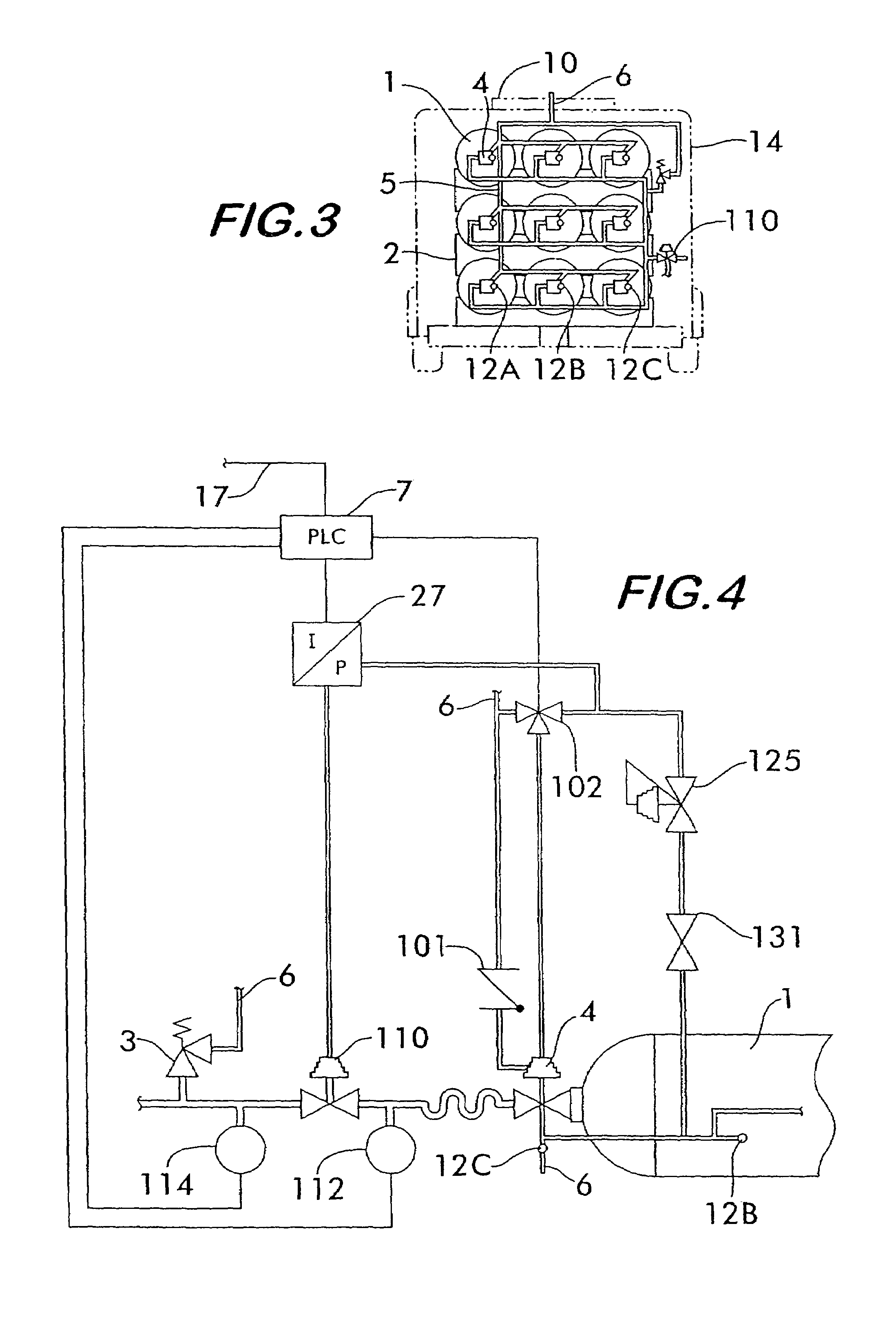

Fuel gas supply system and method of a ship

InactiveUS20080276627A1Prevent excessive pressure increaseSimple configurationInternal combustion piston enginesContainer filling methodsFuel tankProduct gas

A fuel gas supply system of a ship is provided for supplying fuel gas to a high-pressure gas injection engine of the ship, wherein the ship has an LNG fuel tank for storing LNG as fuel and LNG is extracted from an LNG fuel tank of the ship, compressed at a high pressure, gasified, and then supplied to the high-pressure gas injection engine.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

Modular fuel storage system for a vehicle

A gaseous fuel storage system for a vehicle is disclosed. The fuel storage system can be installed as a modular unit in the vehicle. The fuel storage system is pivotable relative to the vehicle to allow easy accessibility to the storage tanks without requiring the storage tanks to be unmounted from the vehicle. The fuel storage system also provides protection for the storage tanks through the use of shielding and energy absorbing material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Fail-safe vacuum actuated valve for high pressure delivery systems

A high pressure storage and delivery system having a fail-safe vacuum actuated valve is provided. In particular, through the innovative design of the vacuum actuated check valve, the system can accommodate up to three times the volume of product in similar size cylinders.

Owner:PRAXAIR TECH INC

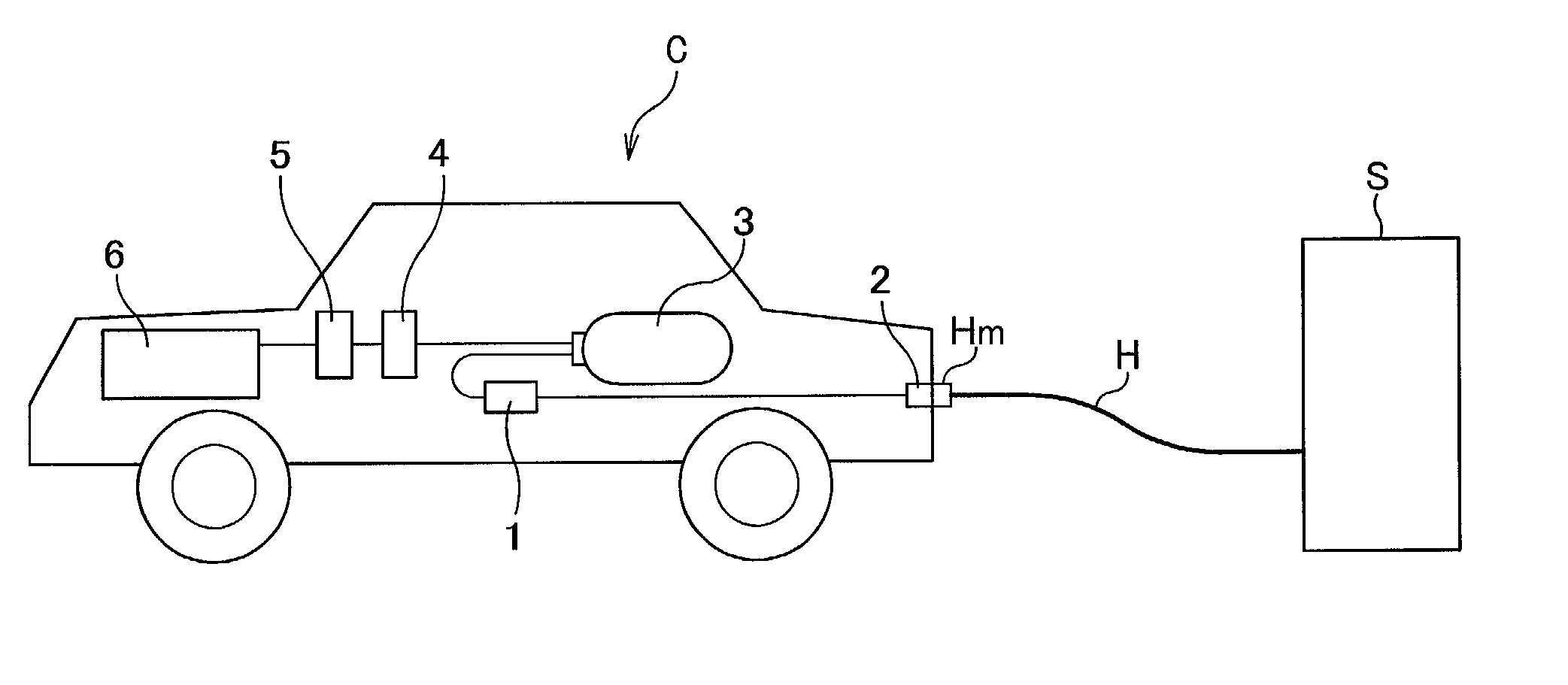

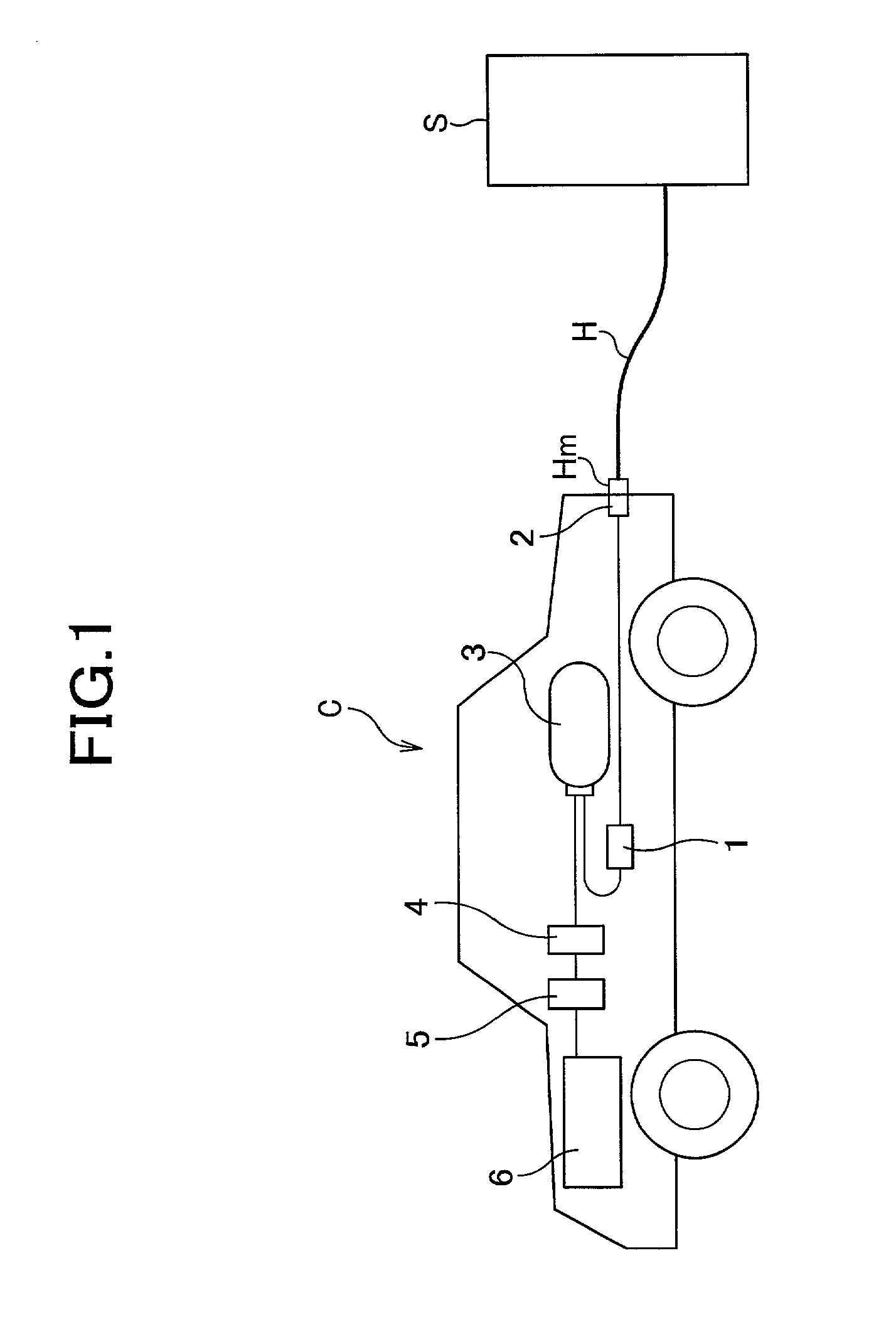

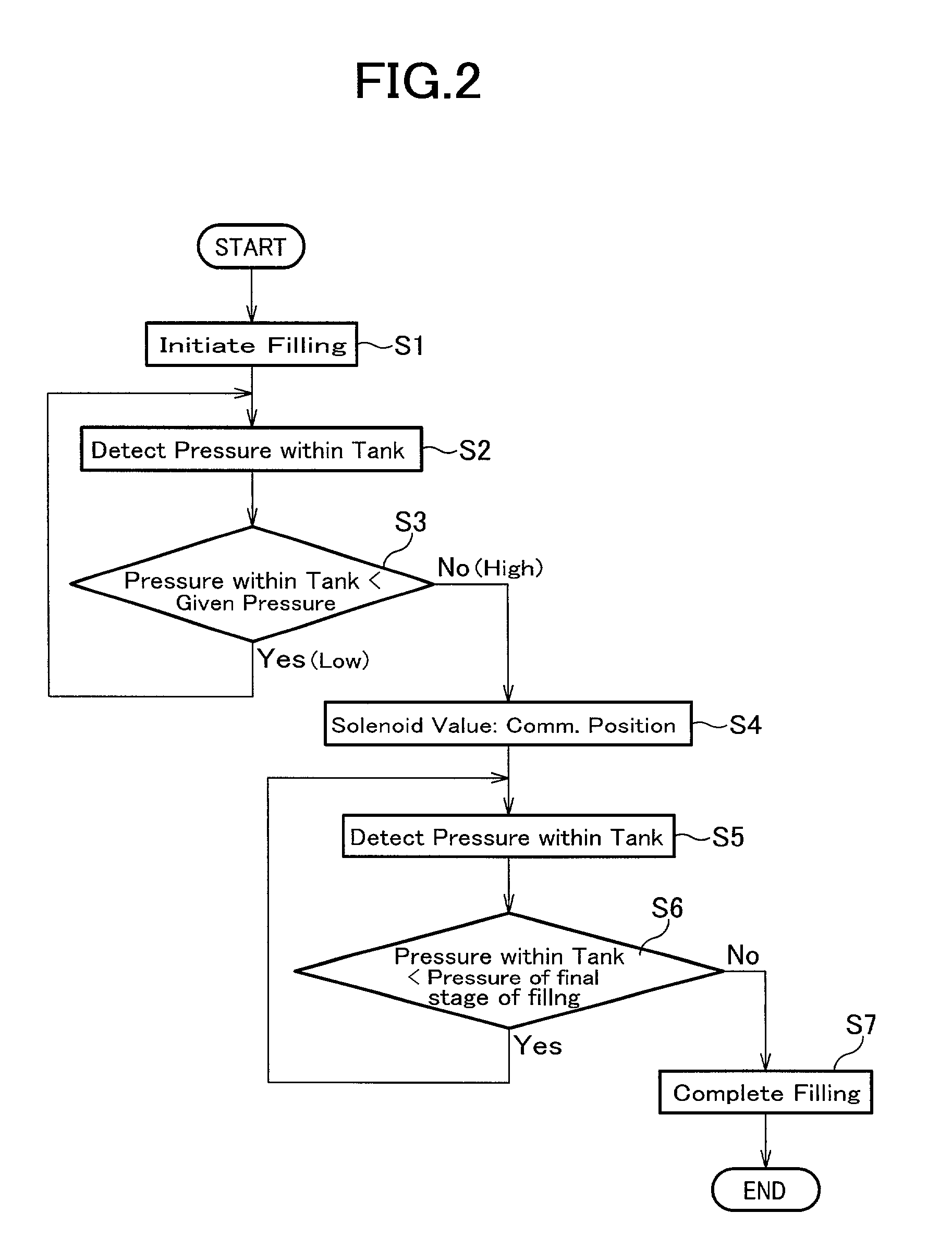

Apparatus and process for rapidly filling with hydrogen

InactiveUS20020014277A1Increase heatIncrease rangeLiquid fillingGas handling applicationsFilling rateDelayed time

An apparatus for rapidly filling a hydrogen tank with a hydrogen gas comprises a hydrogen source; a hydrogen tank; a passage which connects the hydrogen source and said hydrogen tank; and a mechanism for varying the hydrogen-filling rate. The mechanism for varying the hydrogen-filling rate changes the hydrogen-filling rate depending upon the pressure within said hydrogen tank. The apparatus can suppress heat generation at the initial filling stage where the temperature is easily increased. Also, even if it takes longer time for increasing the pressure within the hydrogen tank at the initial filling state, the delayed time can be caught up and, the apparatus and the process of the present invention can totally attain a rapidly filling with hydrogen.

Owner:HONDA MOTOR CO LTD

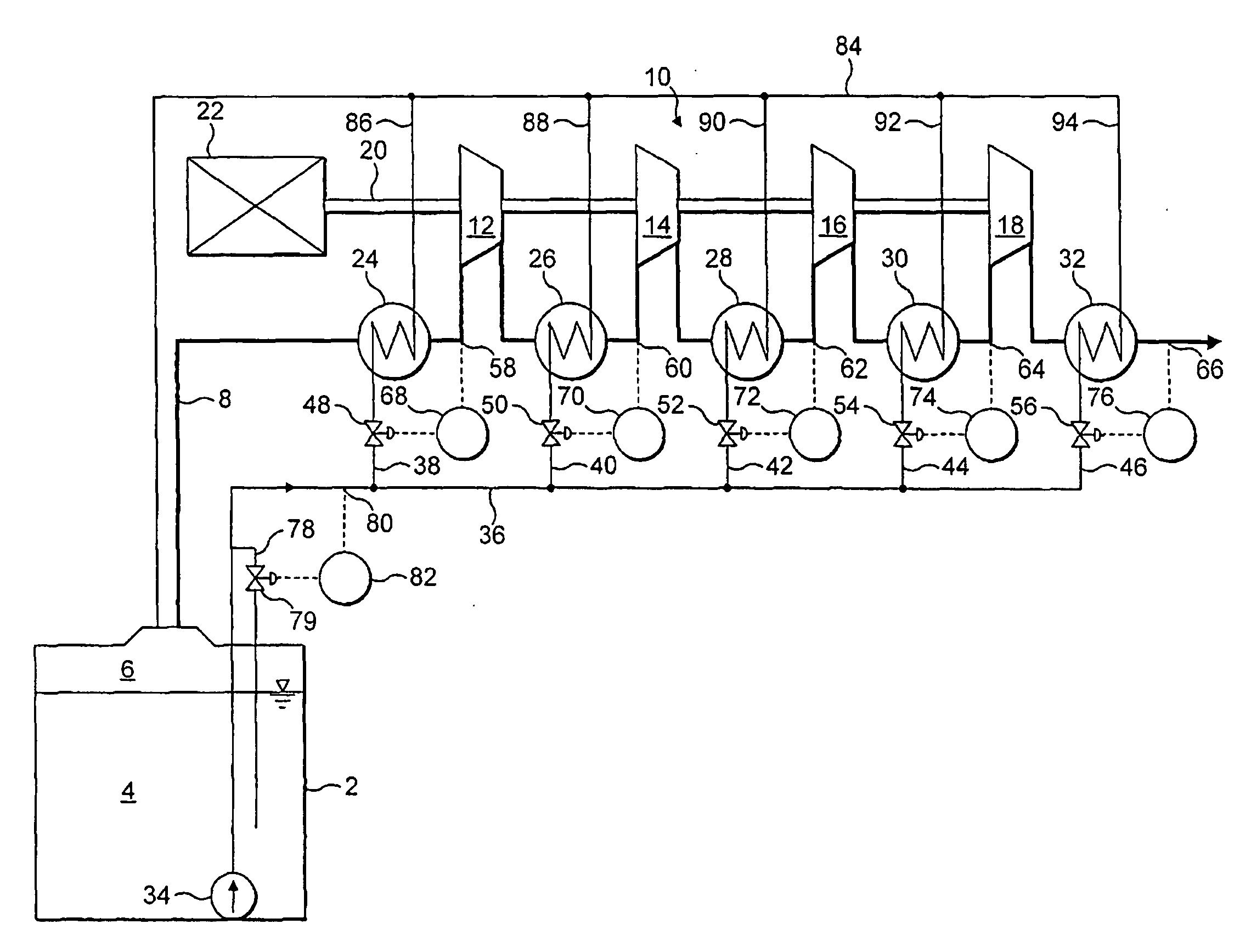

Compressor

InactiveUS20080008602A1Reduce consumptionSmall sizeAuxillariesContainer filling methodsEngineeringControl valves

A rotary liquefied natural gas boil-off compressor has a series of compression stages. A gas passage passes through the series of compression stages. The gas passage extends through and is in heat exchange relationship with cooling means in the form of indirect heat exchangers. Each of the heat exchangers is cooled by LNG supplied from a pipeline. Flow control valves are provided for controlling the flow of LNG to the heat exchangers respectively. The valves are controlled in response to temperature sensors respectively, so as to maintain the inlet temperature of each of the compression stages at a chosen sub-ambient temperature or between chosen sub-ambient temperature limits.

Owner:THE BOC GRP PLC

Container for gas storage tanks in a vehicle

ActiveUS20060032532A1Maximize available spaceEasy to disassembleContainer filling methodsGas handling/storage effectsPressure regulatorVALVE PORT

A container for gas storage tanks in a vehicle is disclosed as part of a fuel storage system. The container is dimensioned to include one or more storage tanks along with a flow control device, such as a pressure regulator or automatic valve. The container does not form a fluid-tight containment around the storage tank and includes one or more ventilation openings to allow a gas within the container to be vented therefrom. There is also one or more drain openings in the container to allow liquid within the container to be drained therefrom.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

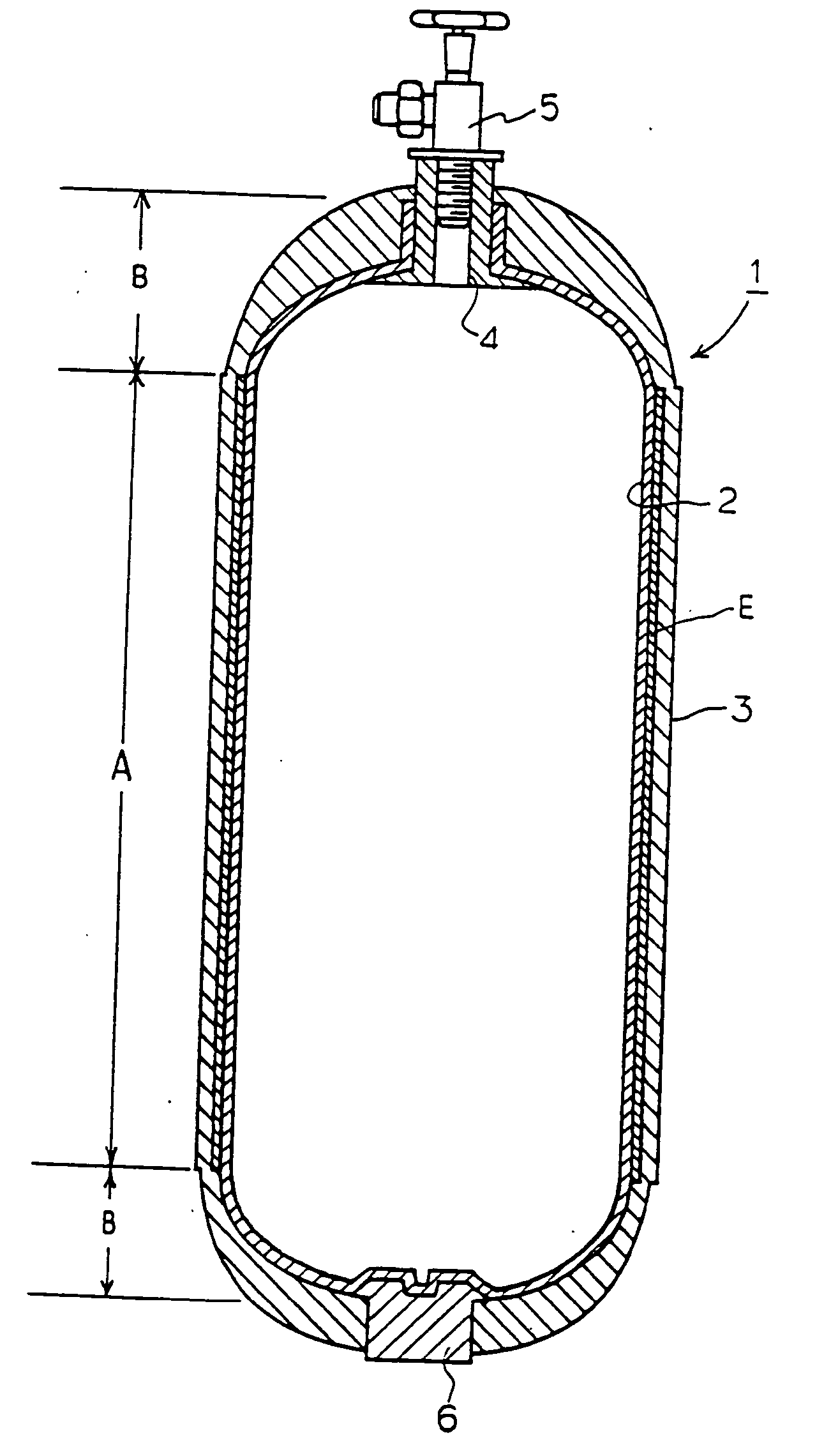

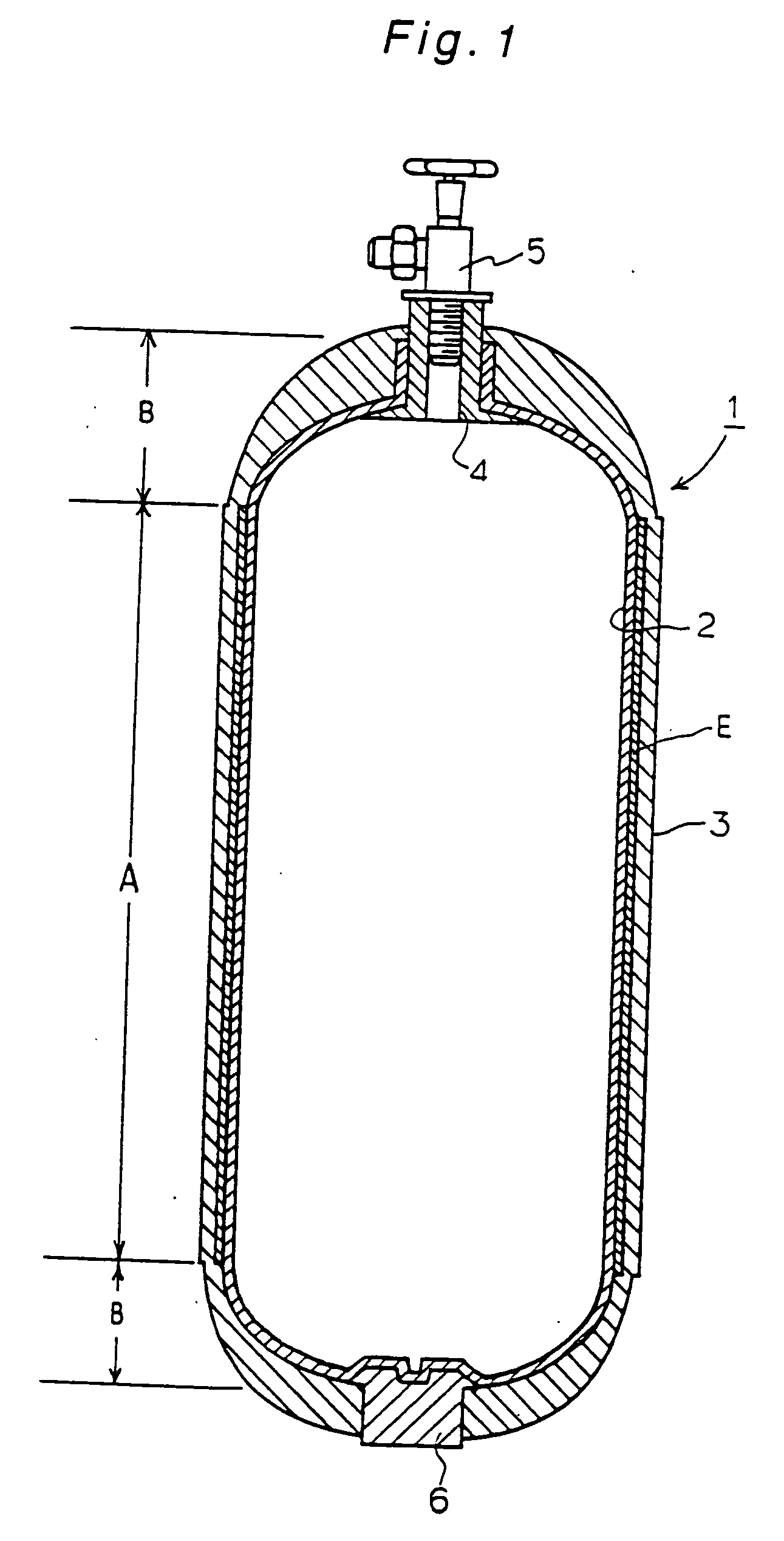

Pressure vessel and process for producing the same

InactiveUS20040206762A1Light weightIncrease pressureVessel mounting detailsVessel manufacturingInternal pressureEngineering

The pressure vessel of the present invention comprises an inner shell capable of serving as a gas barrier and a pressure resistant outer shell provided to cover the inner shell, said outer shell being made of an FRP comprising reinforcing fibers and a resin and is 35 GPa or more in tensile modulus and 1.5% or more in tensile breaking strain. The present invention can provide a pressure vessel not only light in weight,.but also excellent in retaining its internal pressure against repetitive impacts and also excellent in reliability. The process for producing a pressure vessel of the present invention comprises the step of forming a pressure resistant outer shell made of an FRP comprising reinforcing fibers and a resin and is 35 GPa or more in tensile modulus and 1.5% or more in tensile breaking strain, around an inner shell capable of serving as a gas barrier, by a filament winding method or a tape winding method. The present invention can produce a pressure vessel excellent in retaining its internal pressure, excellent in reliability, and light in weight at a low cost.

Owner:TORAY IND INC

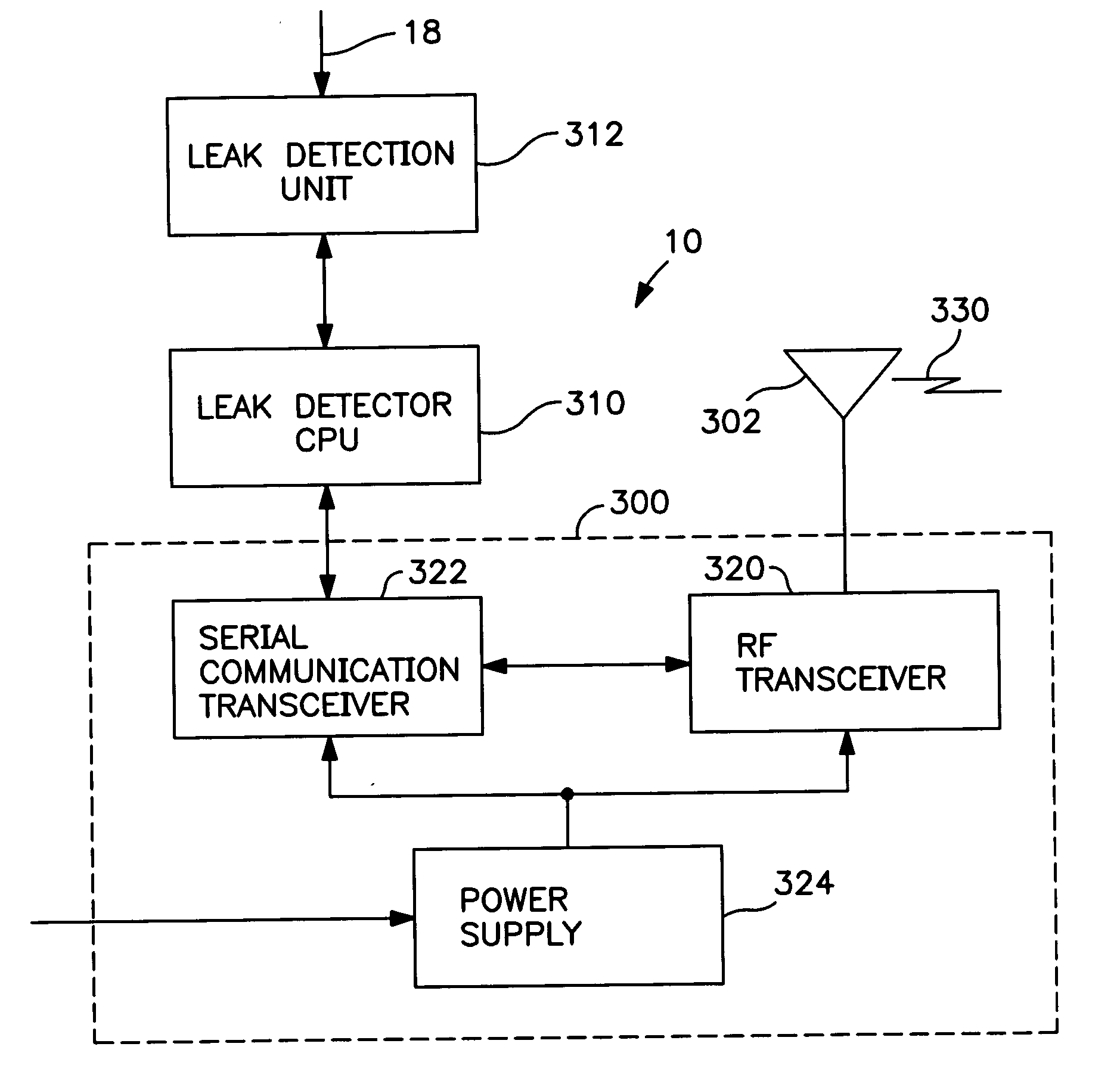

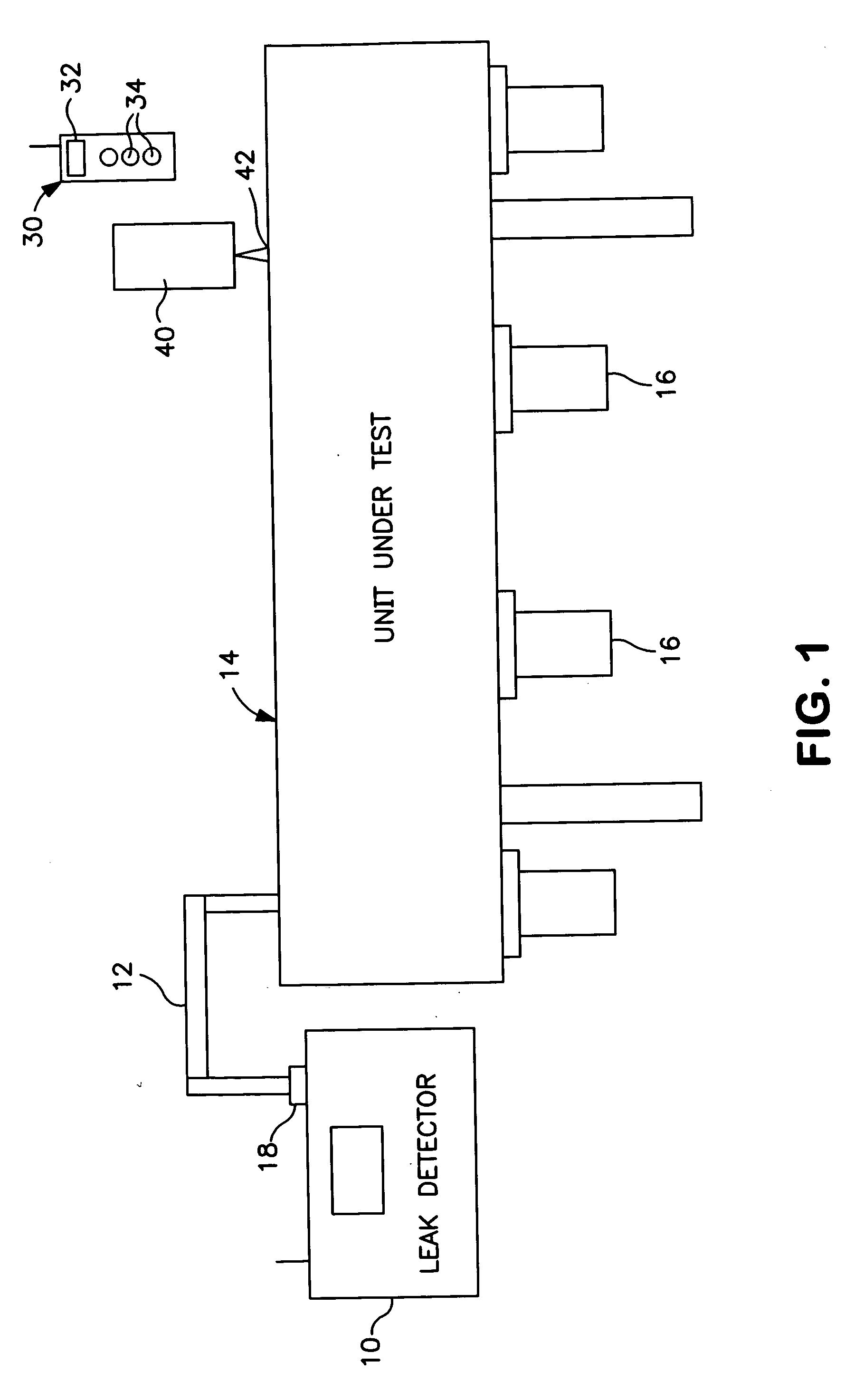

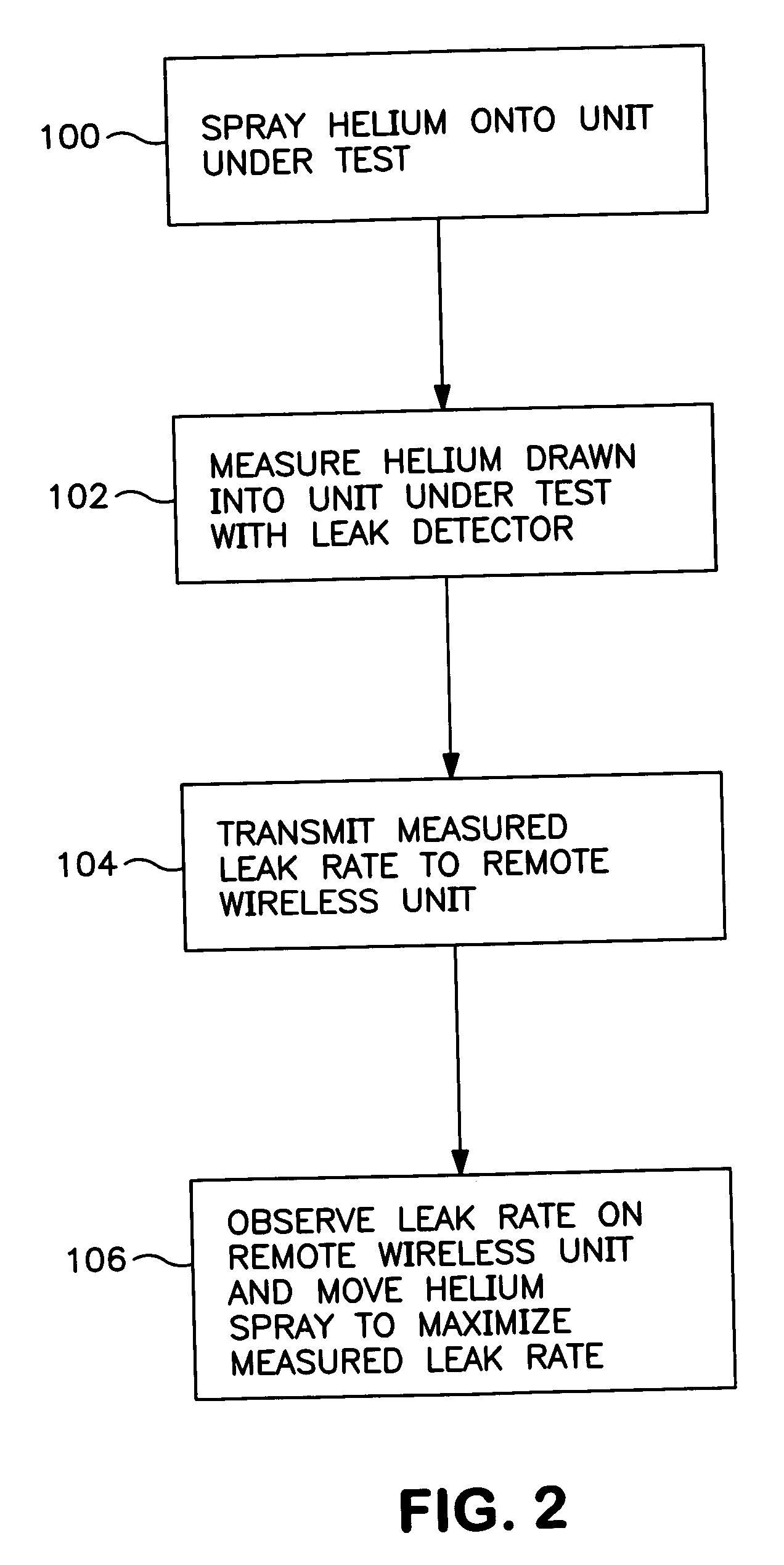

Leak detection system with wireless remote unit

InactiveUS20070000310A1Detection of fluid at leakage pointTransmission systemsWireless transceiverTransceiver

A leak detection system includes a trace gas leak detector having a wireless base unit, and a handheld wireless remote unit to generate an alphanumeric display of leak rate measured by the leak detector, in response to leak detector information received by wireless link from the leak detector. The remote unit may include a wireless transceiver to communicate with the wireless base unit of the leak detector, a display unit and a controller, responsive to the received leak detector information, to generate the display on the display unit. The remote unit may be configured to control the leak detector and may be configured to display a leak detector operating mode.

Owner:VARIAN INC

Composite pressure tank and process for its manufacture

InactiveUS20070205201A1Reduce weightLow costVessel mounting detailsVessel manufacturingBody shapeMaterials science

A pressure vessel and method for producing a pressure vessel is disclosed. The pressure vessel comprises a liner shell fabricated from composite material applied to a soluble mandrel having a body shaped to pattern an interior of the pressure vessel, the liner shell having an opening, a boss having an aperture therethrough, the boss sealingly bonded to the liner shell with the aperture adjacent the opening, and an outer shell fabricated from plies of composite material filament impregnated with matrix material wound over the liner shell and the boss, but not over the aperture.

Owner:MICROCOSM INC

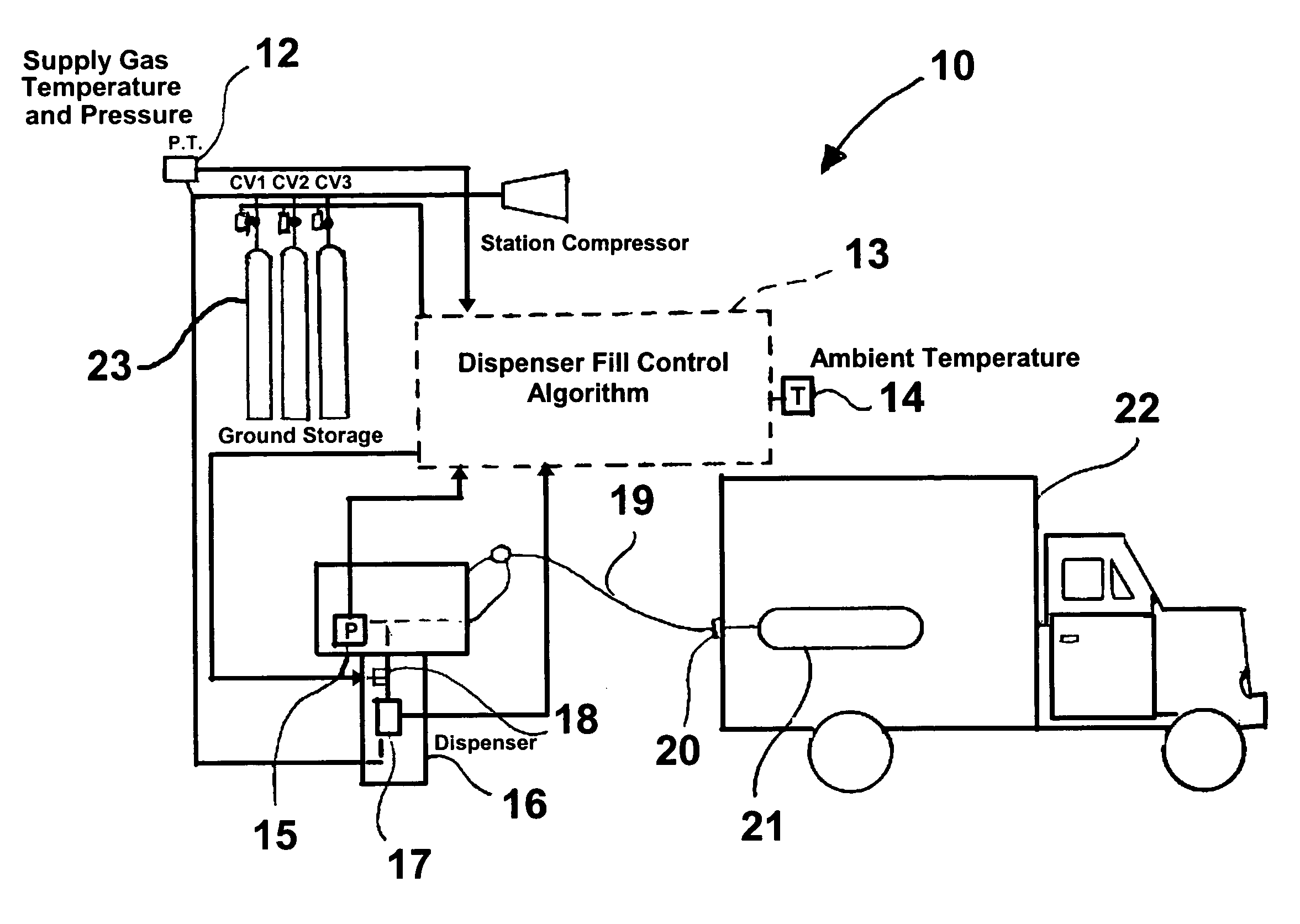

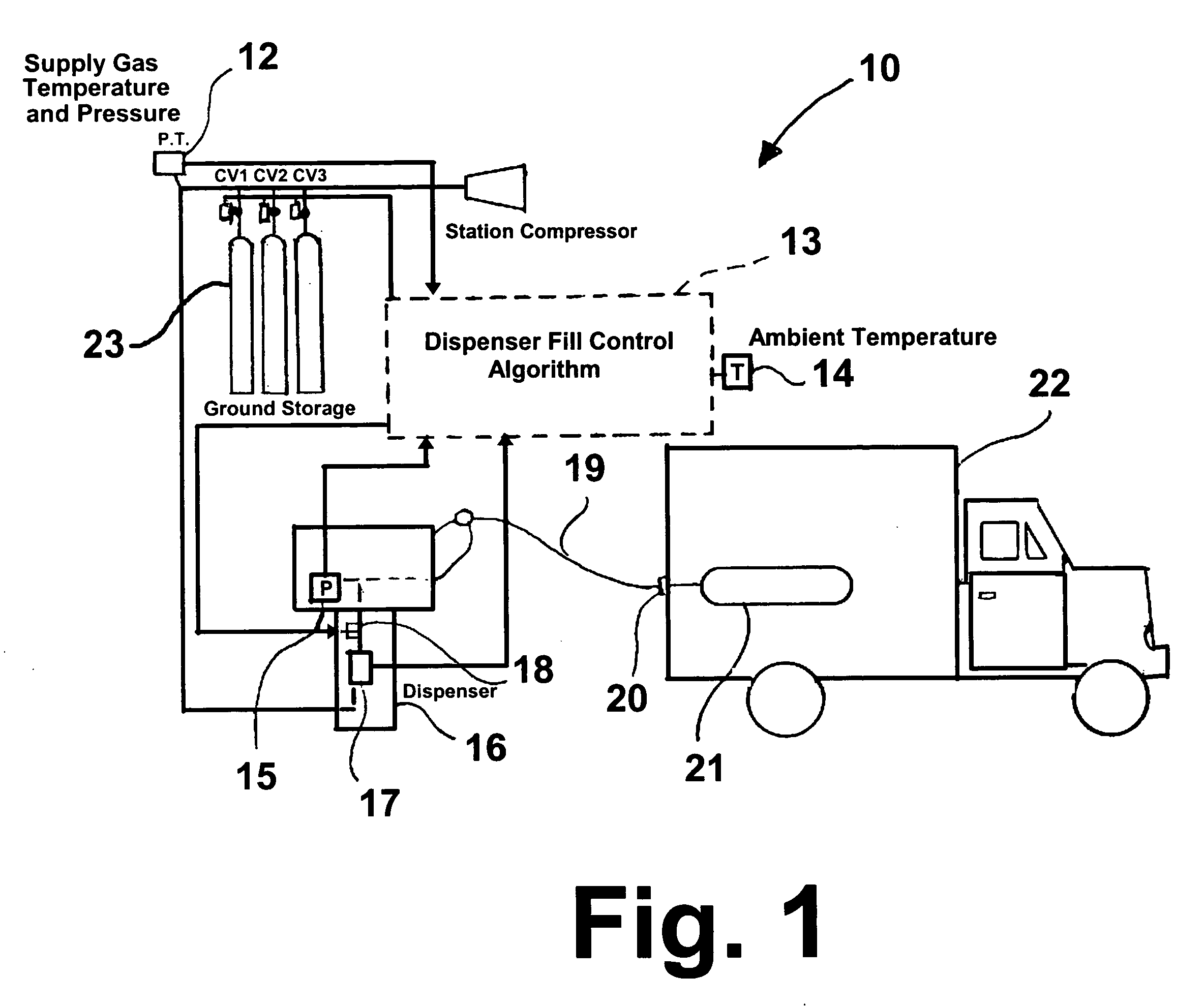

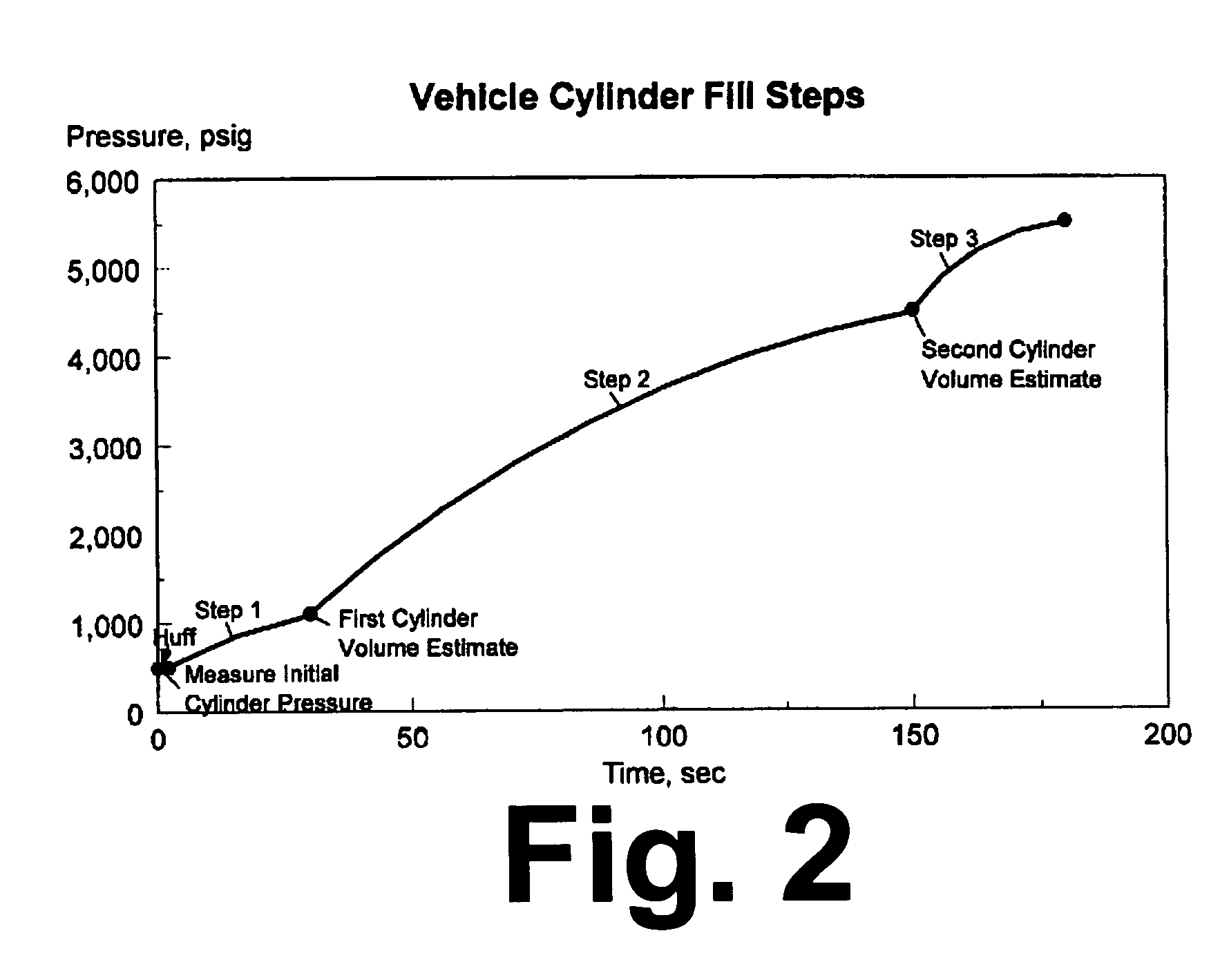

Control method for high-pressure hydrogen vehicle fueling station dispensers

InactiveUS7059364B2Reduces potential for underfillingFast fillGas handling applicationsGas handling/storage effectsHigh pressure hydrogenHigh pressure

A method for quick filling a vehicle hydrogen storage vessel with hydrogen, the key component of which is an algorithm used to control the fill process, which interacts with the hydrogen dispensing apparatus to determine the vehicle hydrogen storage vessel capacity.

Owner:GAS TECH INST

Diffusion layer for pressure vessels

ActiveUS20090057319A1Improve fluid flowVessel mounting detailsVessel manufacturingEngineeringDiffusion layer

Owner:GM GLOBAL TECH OPERATIONS LLC

Compression-evaporation system for liquefied gas

InactiveUS7406830B2Reduce and even eliminate consumptionGas handling applicationsGas handling/storage effectsEvaporationEngineering

The compressor-evaporator system for liquefied gas contained in a tank comprises, in addition to a deice for evaporation by heat exchange with a liquid and devices for conditioning and transferring gas to a pipeline, a motor-driven turbopump comprising a rotary assembly of high bending stiffness on a common shaft line, with at least one high pressure pump, a turbine, and a central electrical machine capable of being used in motor mode or in generator mode. The rotary assembly of the motor-driven turbopump is adapted to present a high speed of rotation, greater than 12,000 rpm, while remaining outside ranges for exciting critical speeds in rotation. All of the internal portions of the motor-driven turbopump are immersed in a cryogenic fluid that is the same as the liquefied gas contained in the tank. The internal cavities of the motor-driven turbopump that are under different thermodynamic conditions are separated by contactless dynamic seals. Electronic power circuits connected to an electricity network control the central electrical machine in motor mode or generator mode.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Low weight high performance composite vessel and method of making same

InactiveUS20040026431A1Light weightSignificant portionVessel mounting detailsVessel manufacturingMechanical engineeringComposite material

Owner:KAISER COMPOSITEK

Self-contained mobile fueling station

A mobile self-contained self-powered station having a plurality of vessels delivers a pressurized fluid to a receiving tank (e.g., a fuel tank of a hydrogen-powered vehicle) without using mechanical compression, external electric power, or other external utilities. The station includes first and second vessels, a conduit in fluid communication with the receiving tank and each of the first and second vessels, means for transferring at least a portion of a quantity of the pressurized fluid from the first vessel to the receiving tank, means for measuring continuously a pressure differential between the increasing pressure in the receiving tank and the decreasing pressure in the first vessel, means for discontinuing the transfer from the first vessel when a predetermined limit value is reached, and means for transferring at least a portion of a quantity of the pressurized fluid from the second vessel to the receiving tank.

Owner:AIR PROD & CHEM INC

Flow control system for a valve

ActiveUS20050103382A1Vessel mounting detailsOperating means/releasing devices for valvesDifferential pressureControl system

A fluid-flow control system for a valve comprises a valve body and a bi directional main flow passage between a first and second fluid areas. The shuttle piston having a first face in direct communication with the second area and a second face in communication therewith through a bleed orifice. The second face is alternately exposed to the first fluid area through a backpressure passage and second orifice which alters the pressure differential across the shuttle piston. A second valve such as a solenoid operates to either close the second orifice wherein the shuttle piston is operable under differential pressure between the first and second pressure areas, or to close the second orifice wherein the shuttle piston is operable under differential pressure between the second pressure area and the backpressure passage. Filters at the fluid inlet and outlets protect the sealing components therein.

Owner:LUXFER CANADA

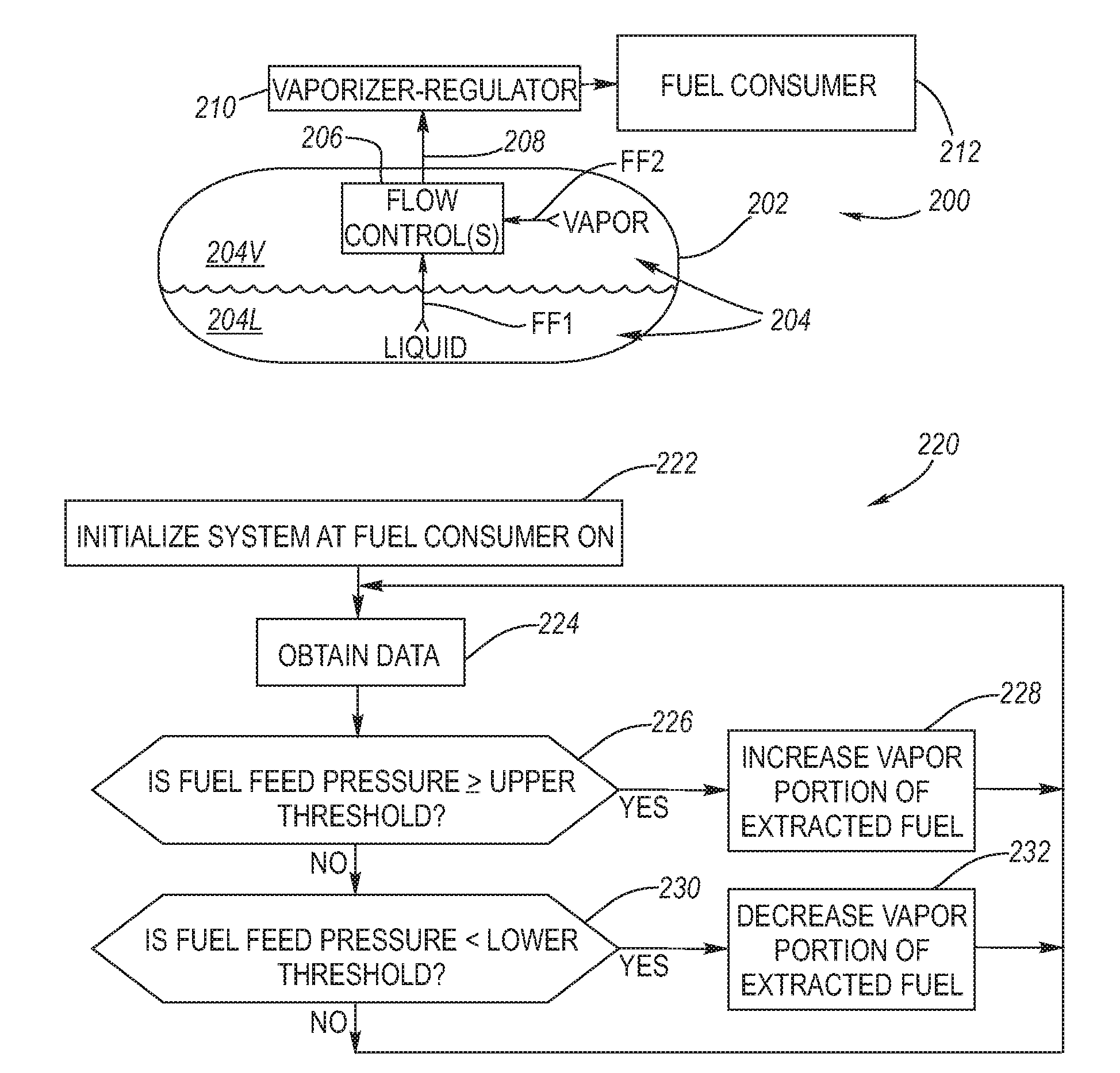

Fuel Tank Temperature and Pressure Management Via Selective Extraction of Liquid Fuel and Fuel Vapor

InactiveUS20120060935A1Low vapor pressureImproved vaporizationElectrical controlInternal combustion piston enginesLiquid fuelFuel vapor

A method and apparatus for managing temperature and pressure of fuel in a fuel tank stored at or near its vapor pressure. In response to fuel feed pressure, a variable ratio of liquid fuel to fuel vapor is extracted from the fuel tank in order to regulate temperature and pressure of the fuel for the purpose of keeping the pressure lower in anticipation of refilling or to assist a vaporizer of the fuel system which is incompletely vaporizing the fuel.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com