Control method for high-pressure hydrogen vehicle fueling station dispensers

a technology of hydrogen fueling station and control method, which is applied in the direction of container discharging method, liquid handling, packaged goods type, etc., can solve the problems of increasing the manufacturing cost and vehicle weight of the station, severe underfilling, and reducing the density of hydrogen gas, so as to achieve the effect of reducing dispenser and vehicle cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

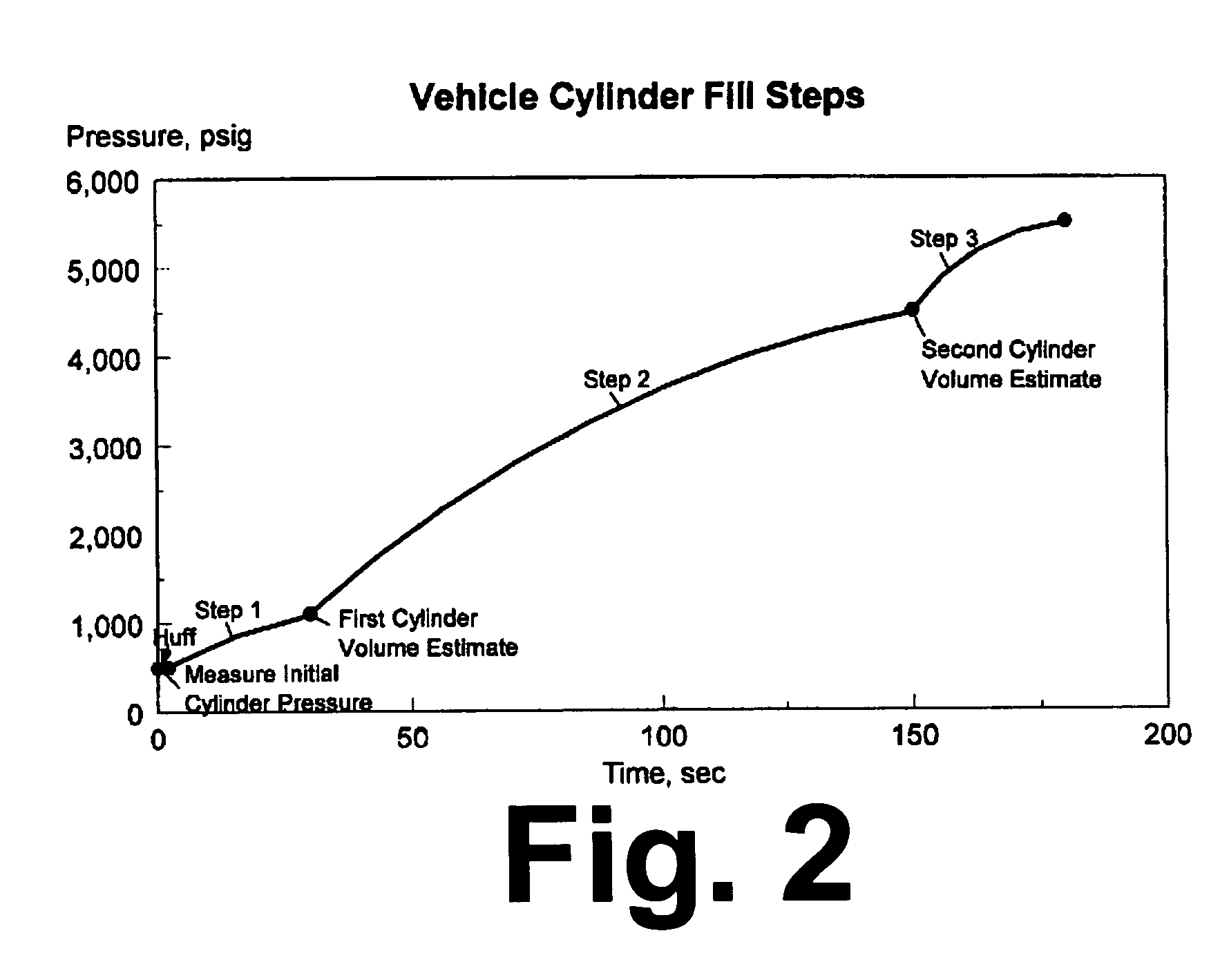

[0021]We have developed a unique and dynamic model of a hydrogen fast fill process, called CHARGEH2, and have correlated the results of that model output to experimental data on actual vehicle hydrogen storage vessel fill cases, over a wide variety of supply, ambient, and vessel gas conditions. Regression equations were fitted with the results obtained from the model to permit relatively easy implementation in the software available on current microprocessors, and a hydrogen dispenser control algorithm was developed, enabling use of minimal dispenser instrumentation.

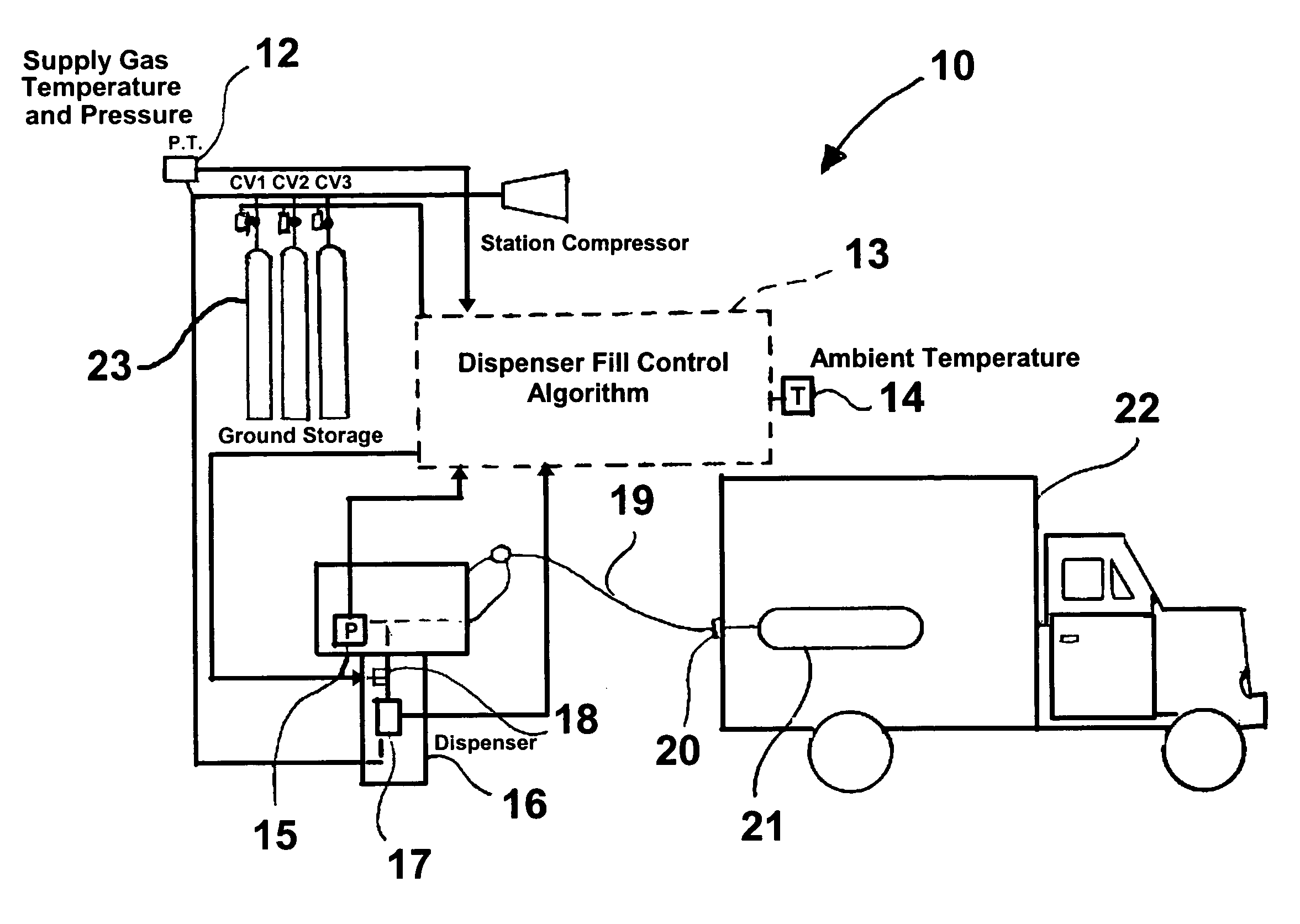

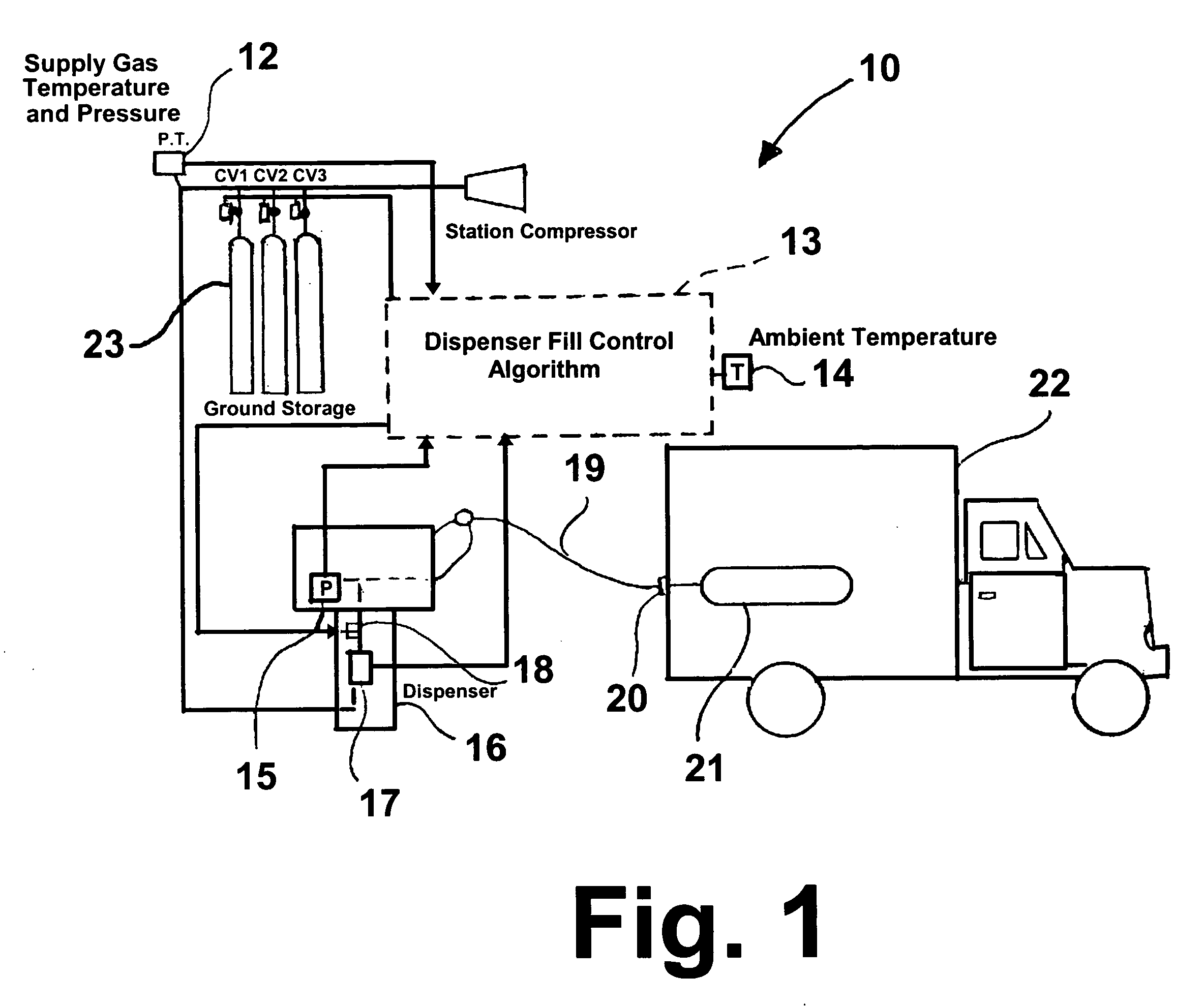

[0022]FIG. 1 shows a hydrogen gas dispenser control system 10 in accordance with one embodiment of this invention suitable for carrying out the method of this invention. The system comprises a ground storage facility comprising a multi-stage or cascade supply unit in the form of cylinders 23, each of which is equipped with a control valve labeled CV1, CV2, and CV3 for controlling the particular cascade cylinder supplying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| gas temperature | aaaaa | aaaaa |

| gas temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com