Patents

Literature

249 results about "Fast filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

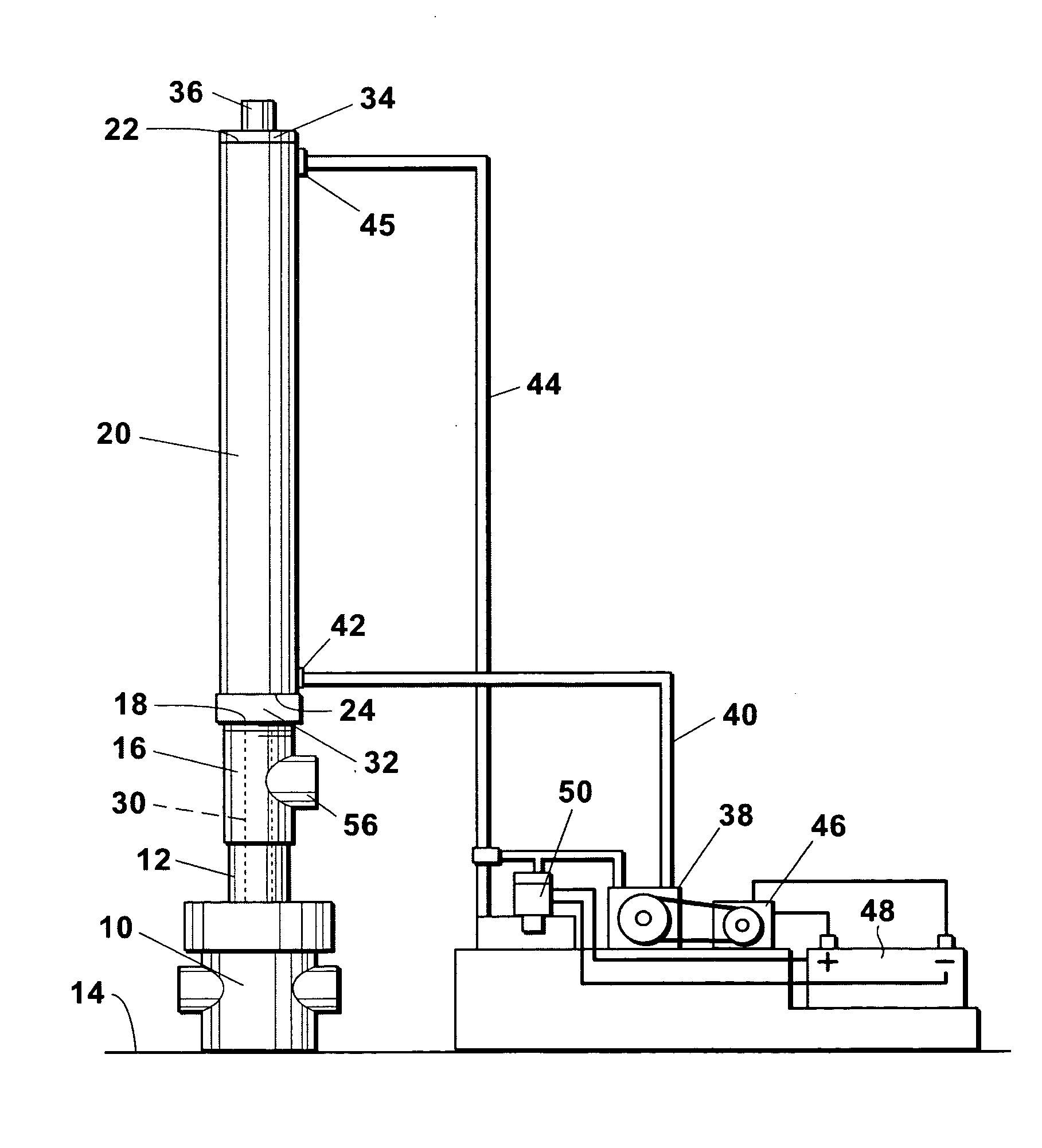

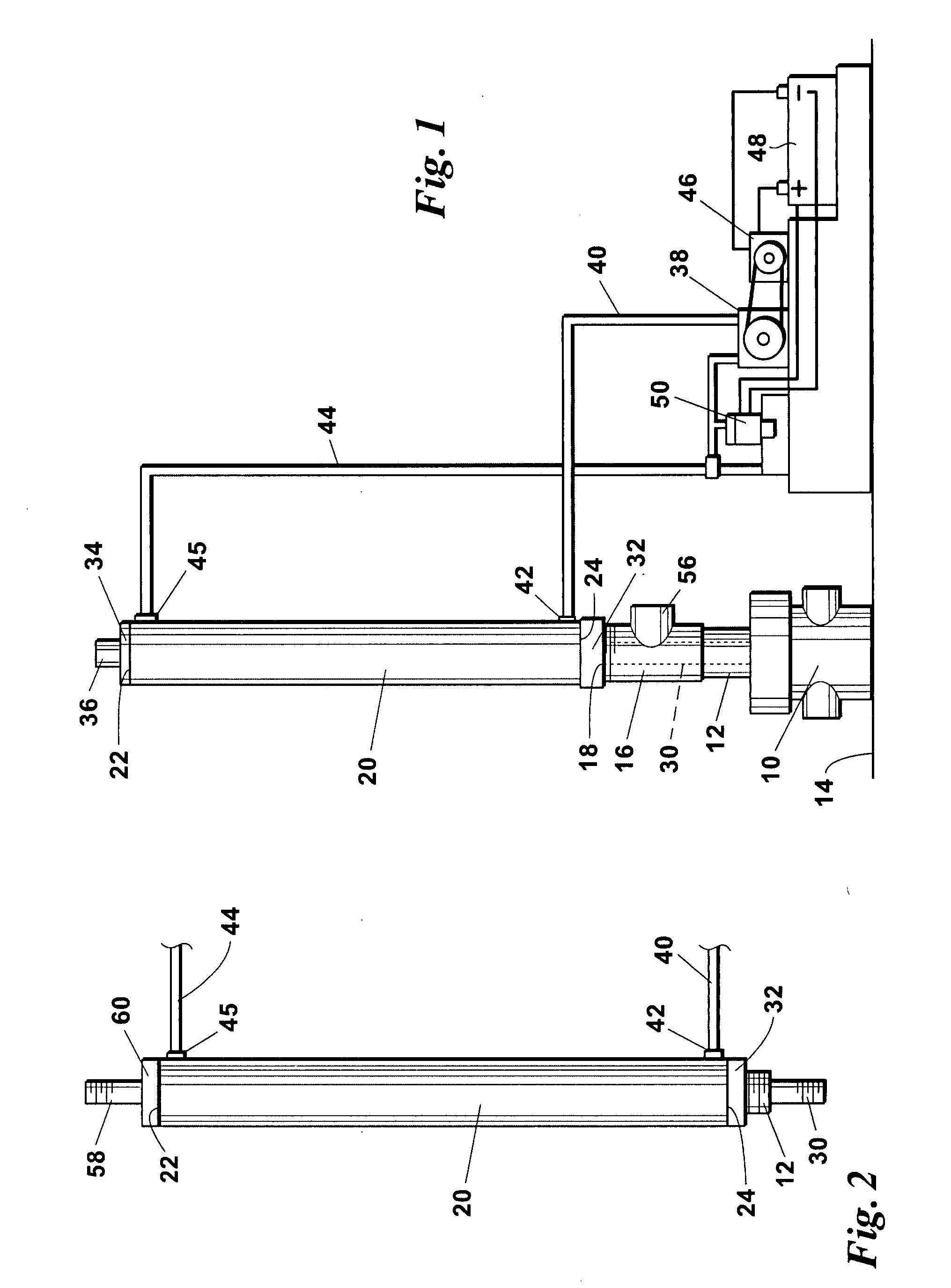

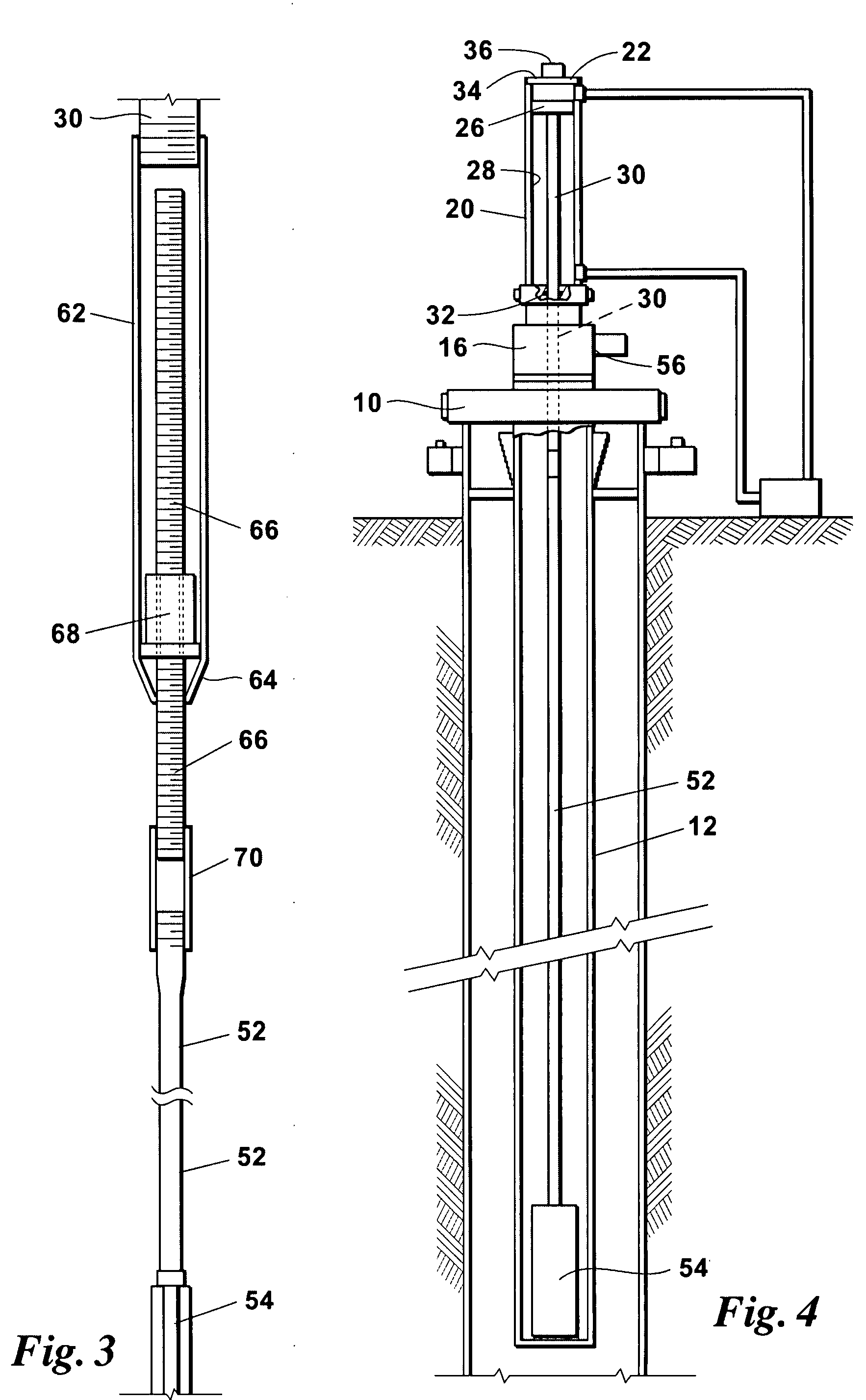

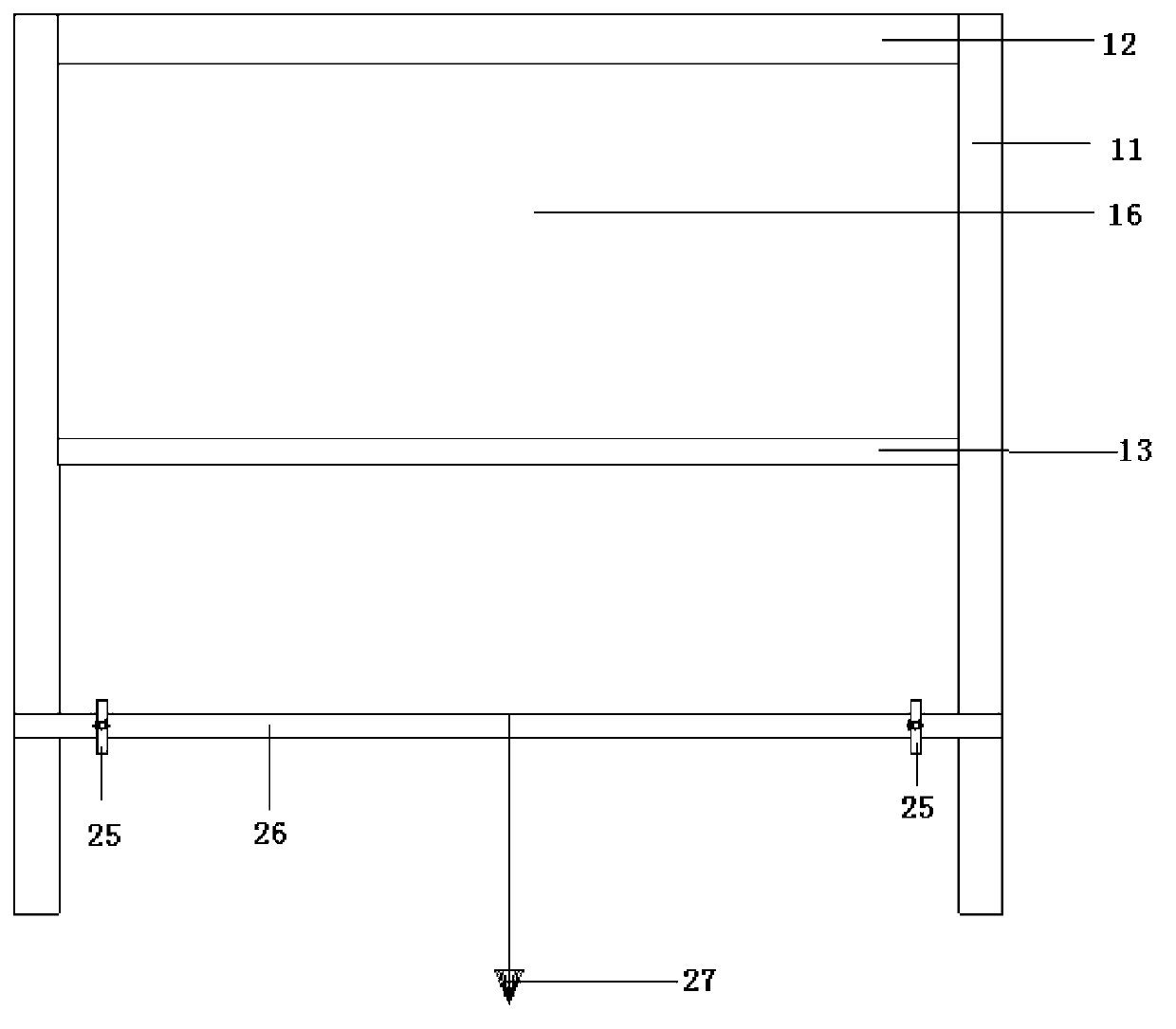

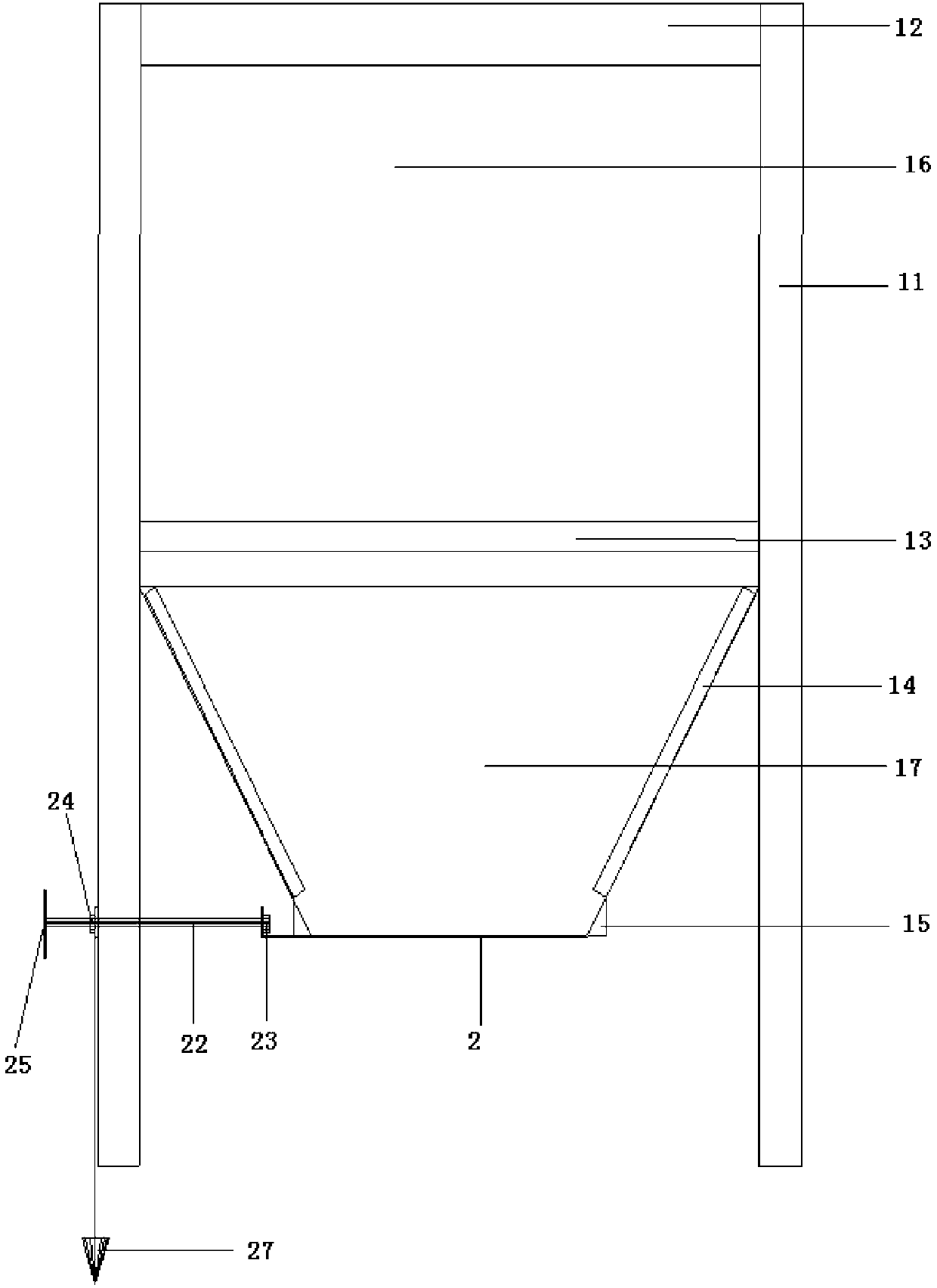

Unlimited stroke drive oil well pumping system

ActiveUS20080314581A1Efficiently actuatedReduce probabilityFluid couplingsConstructionsReciprocating motionFast filling

An unlimited stroke drive method for pumping fluid from an oil well in which the well has a tubing string extending from the earth's surface down to a fluid producing formation. The method includes the steps of positioning a pump barrel within the tubing, an upper end of the pump barrel having communication through a standing valve with the interior of the tubing string, vertically reciprocating a length of flexible cable within the tubing string to vertically reciprocate a plunger within the pump barrel to allow a lower portion to quickly fill with fluid from the producing formation and then to a downward position in which fluid within the pump barrel lower portion is transferred through a traveling valve to an area within the pump barrel above the plunger to move formation fluid from within the pump barrel to the interior of the tubing and thence to the earth's surface.

Owner:HENRY RES & DEV +1

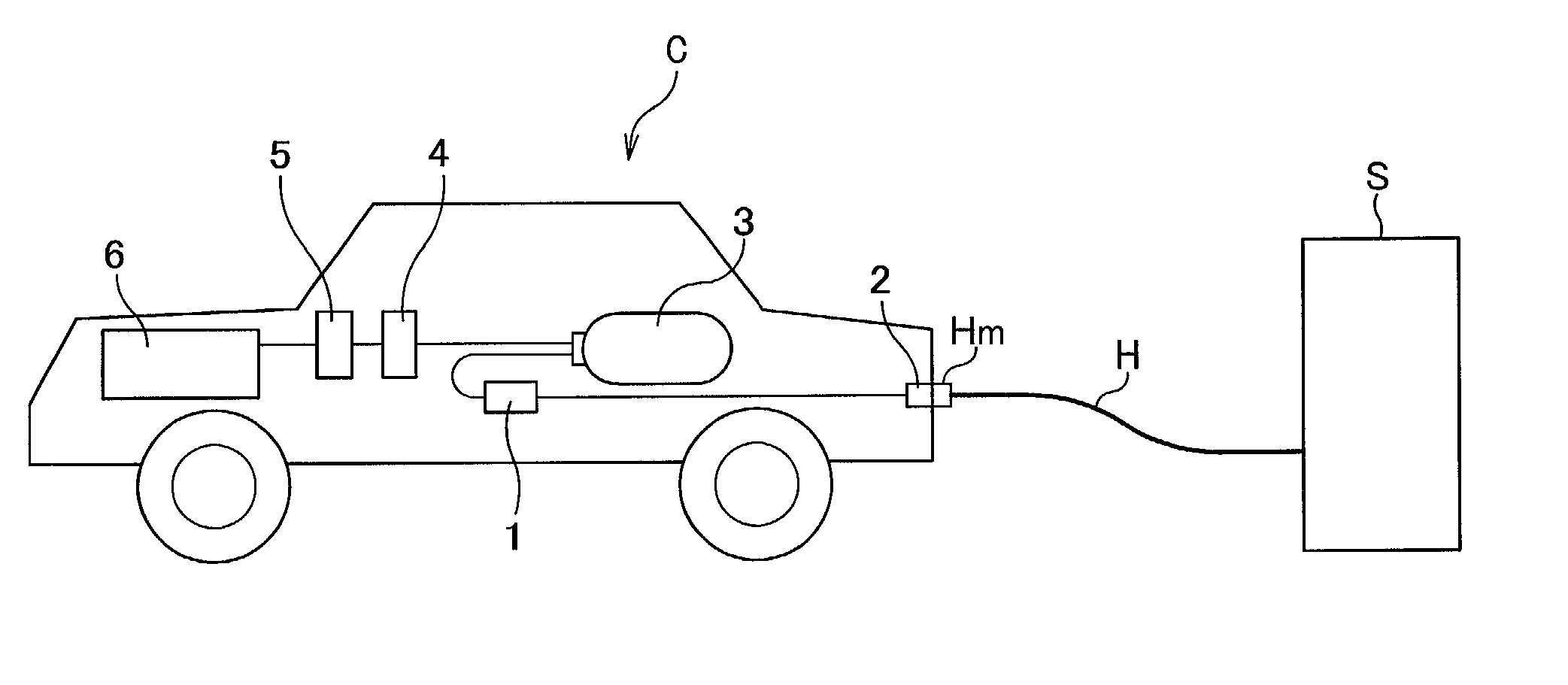

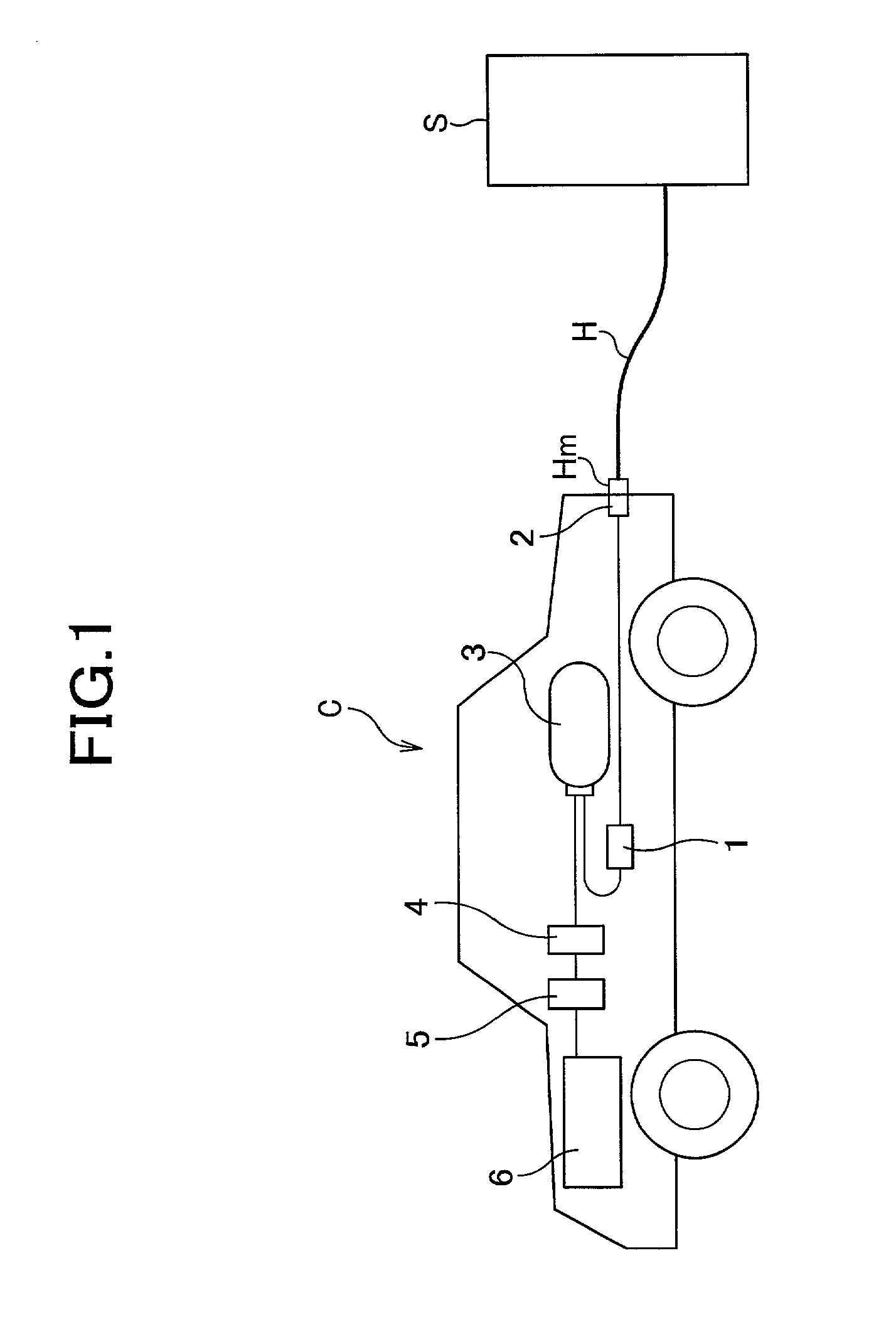

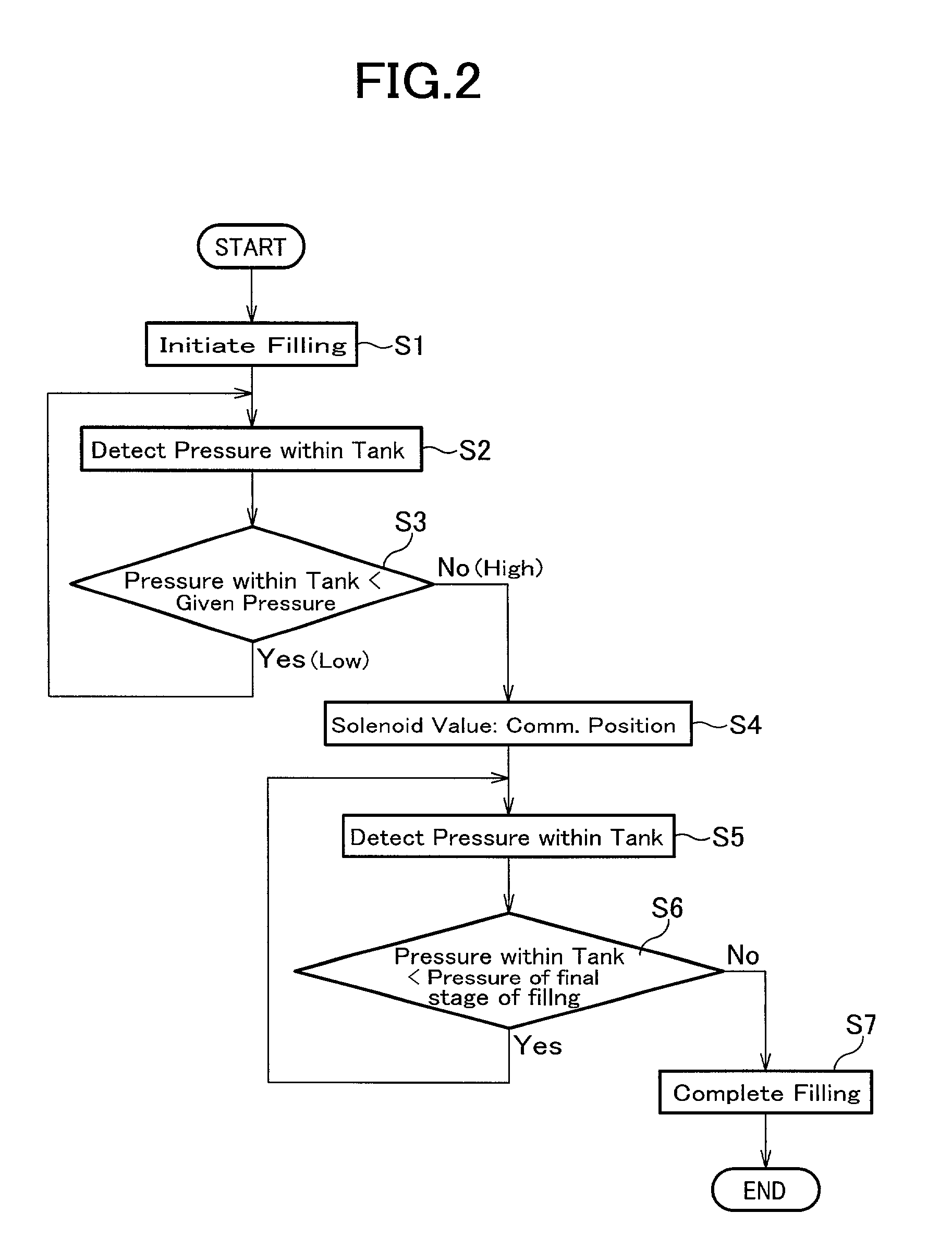

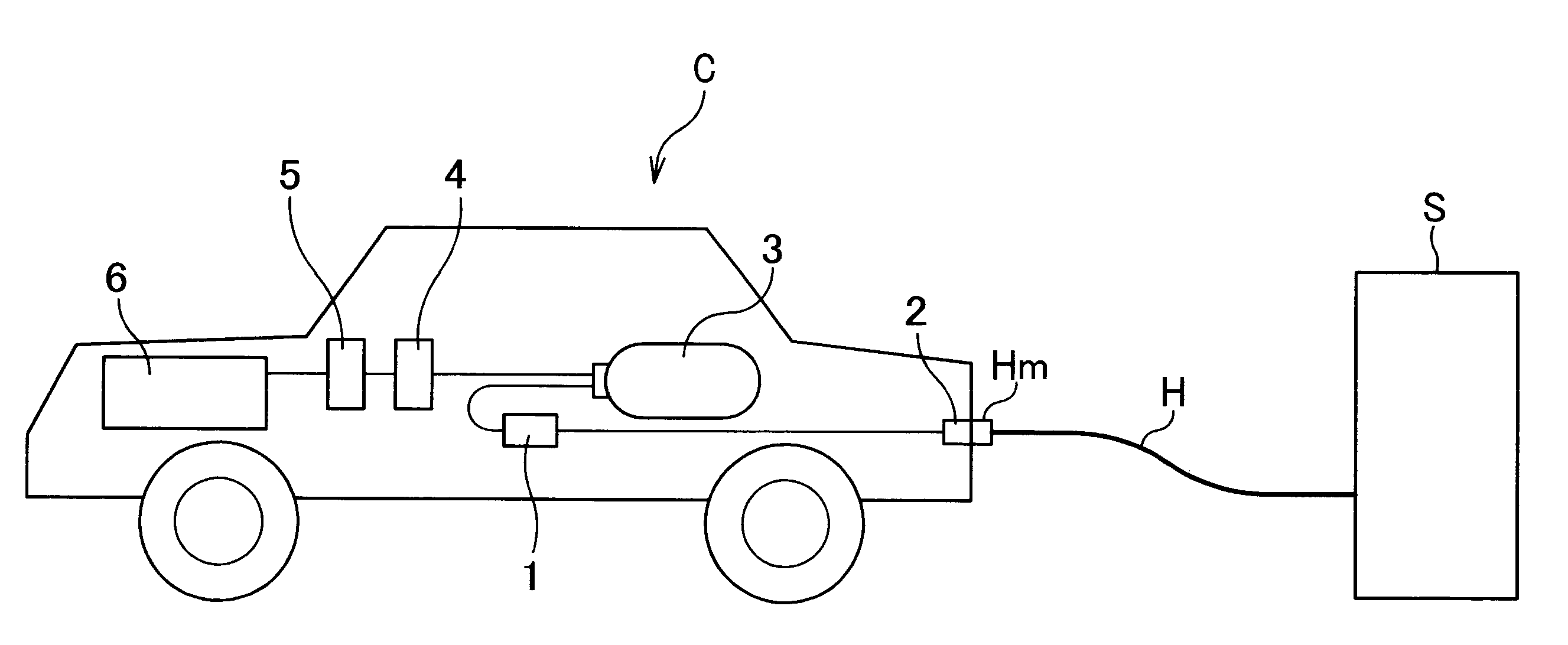

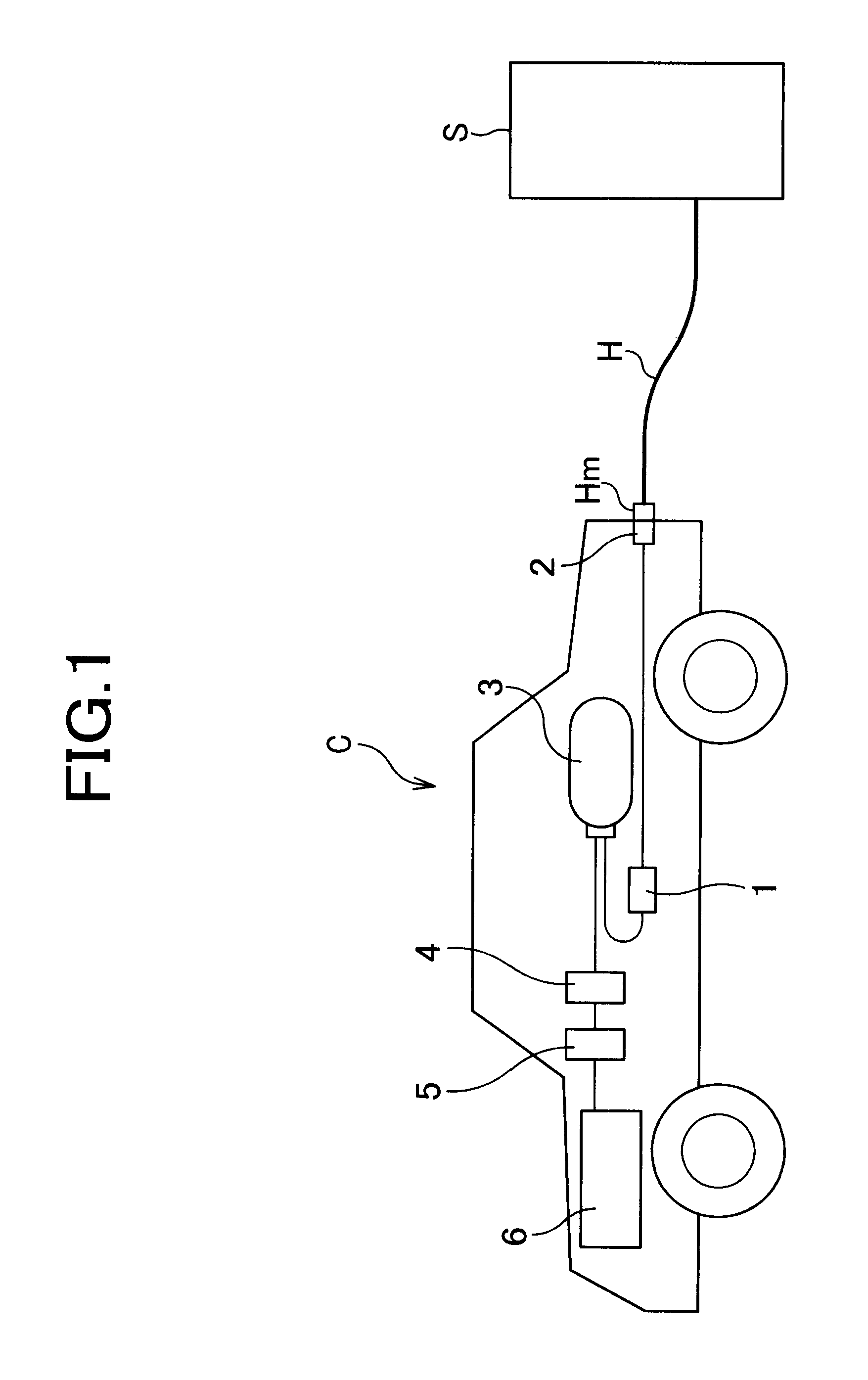

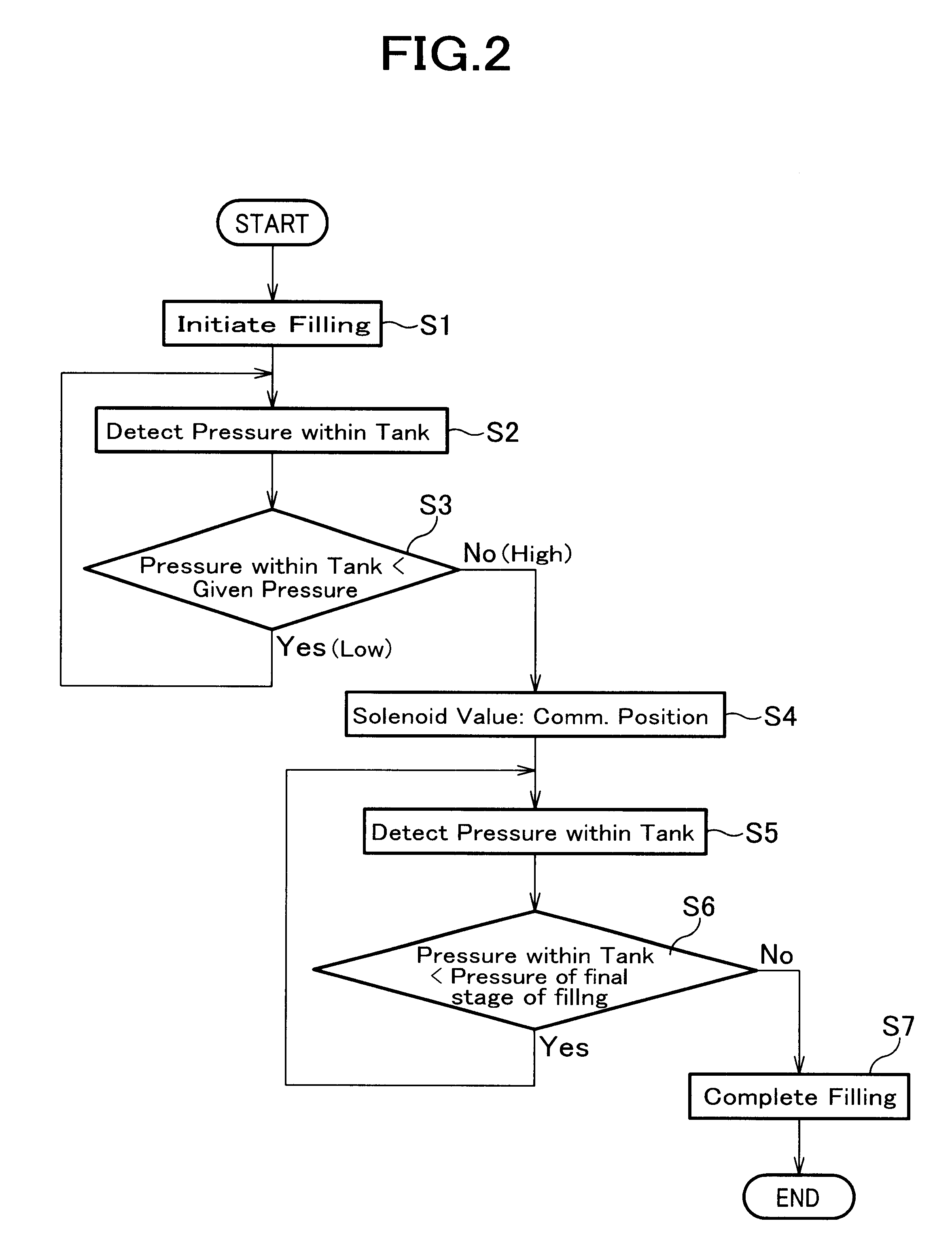

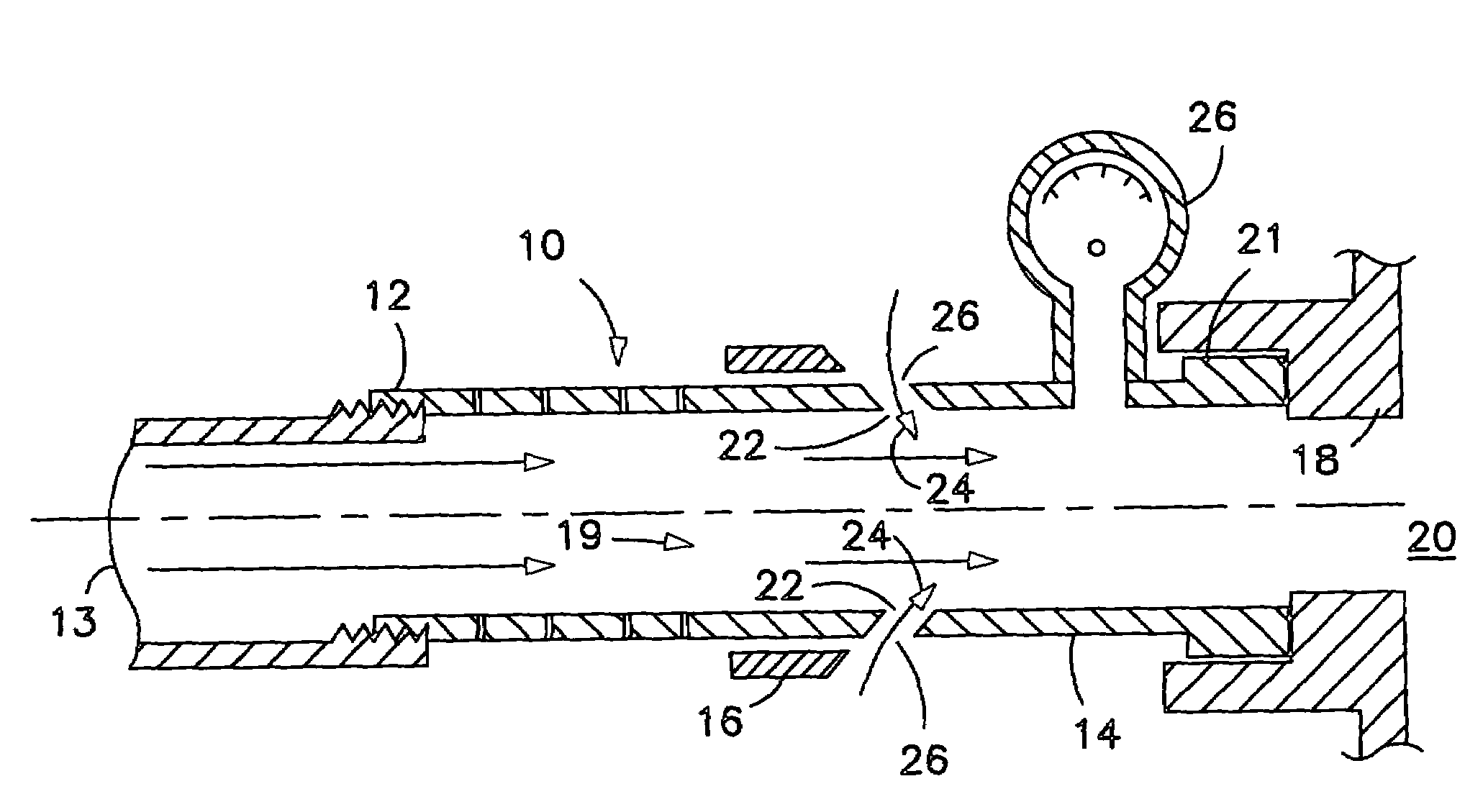

Apparatus and process for rapidly filling with hydrogen

InactiveUS20020014277A1Increase heatIncrease rangeLiquid fillingGas handling applicationsFilling rateDelayed time

An apparatus for rapidly filling a hydrogen tank with a hydrogen gas comprises a hydrogen source; a hydrogen tank; a passage which connects the hydrogen source and said hydrogen tank; and a mechanism for varying the hydrogen-filling rate. The mechanism for varying the hydrogen-filling rate changes the hydrogen-filling rate depending upon the pressure within said hydrogen tank. The apparatus can suppress heat generation at the initial filling stage where the temperature is easily increased. Also, even if it takes longer time for increasing the pressure within the hydrogen tank at the initial filling state, the delayed time can be caught up and, the apparatus and the process of the present invention can totally attain a rapidly filling with hydrogen.

Owner:HONDA MOTOR CO LTD

Apparatus and process for rapidly filling with hydrogen

InactiveUS6598624B2Increase heatIncrease rangeLiquid fillingGas handling applicationsFilling rateDelayed time

An apparatus for rapidly filling a hydrogen tank with a hydrogen gas comprises a hydrogen source; a hydrogen tank; a passage which connects the hydrogen source and said hydrogen tank; and a mechanism for varying the hydrogen-filling rate. The mechanism for varying the hydrogen-filling rate changes the hydrogen-filling rate depending upon the pressure within said hydrogen tank. The apparatus can suppress heat generation at the initial filling stage where the temperature is easily increased. Also, even if it takes longer time for increasing the pressure within the hydrogen tank at the initial filling state, the delayed time can be caught up and, the apparatus and the process of the present invention can totally attain a rapidly filling with hydrogen.

Owner:HONDA MOTOR CO LTD

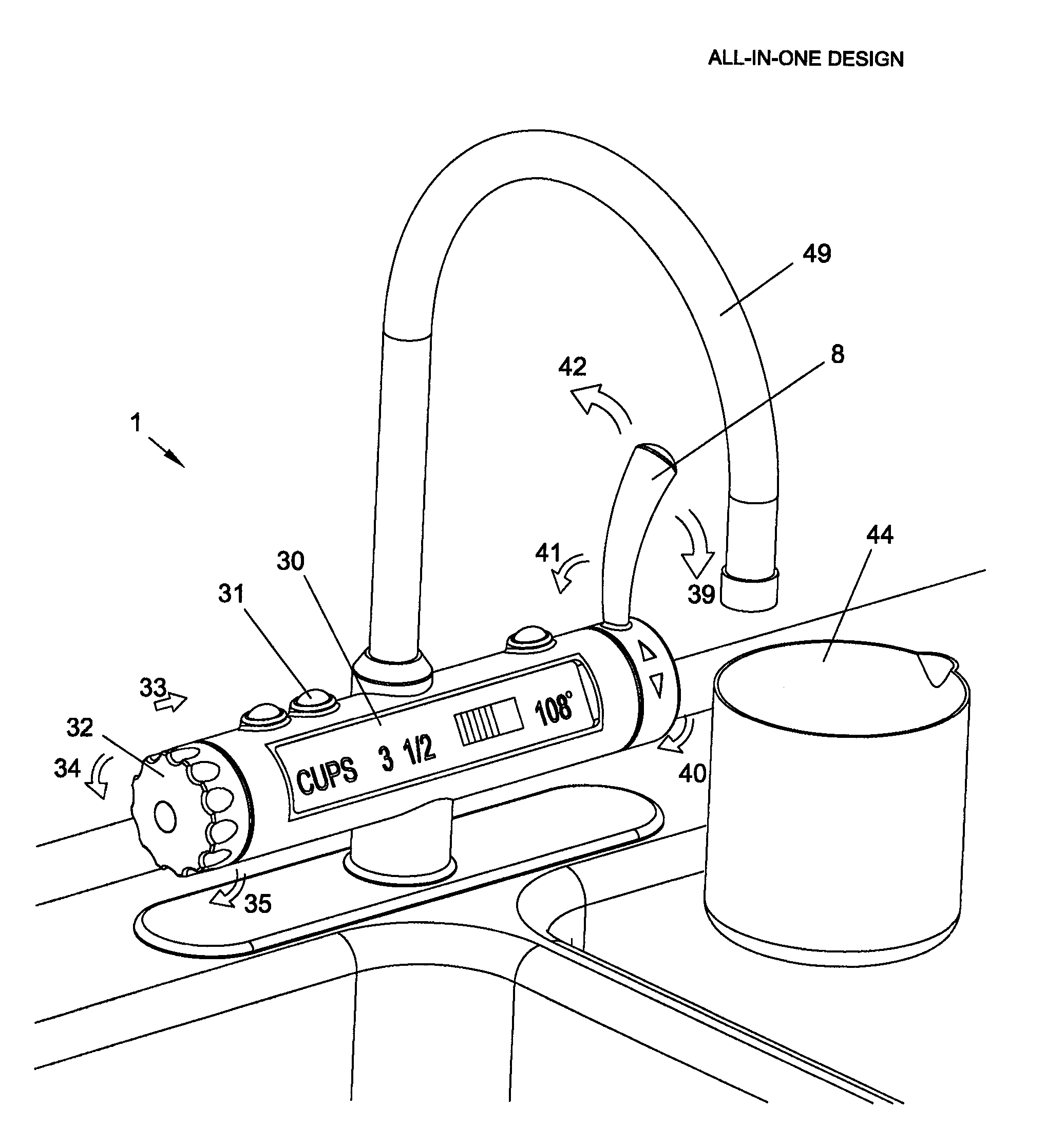

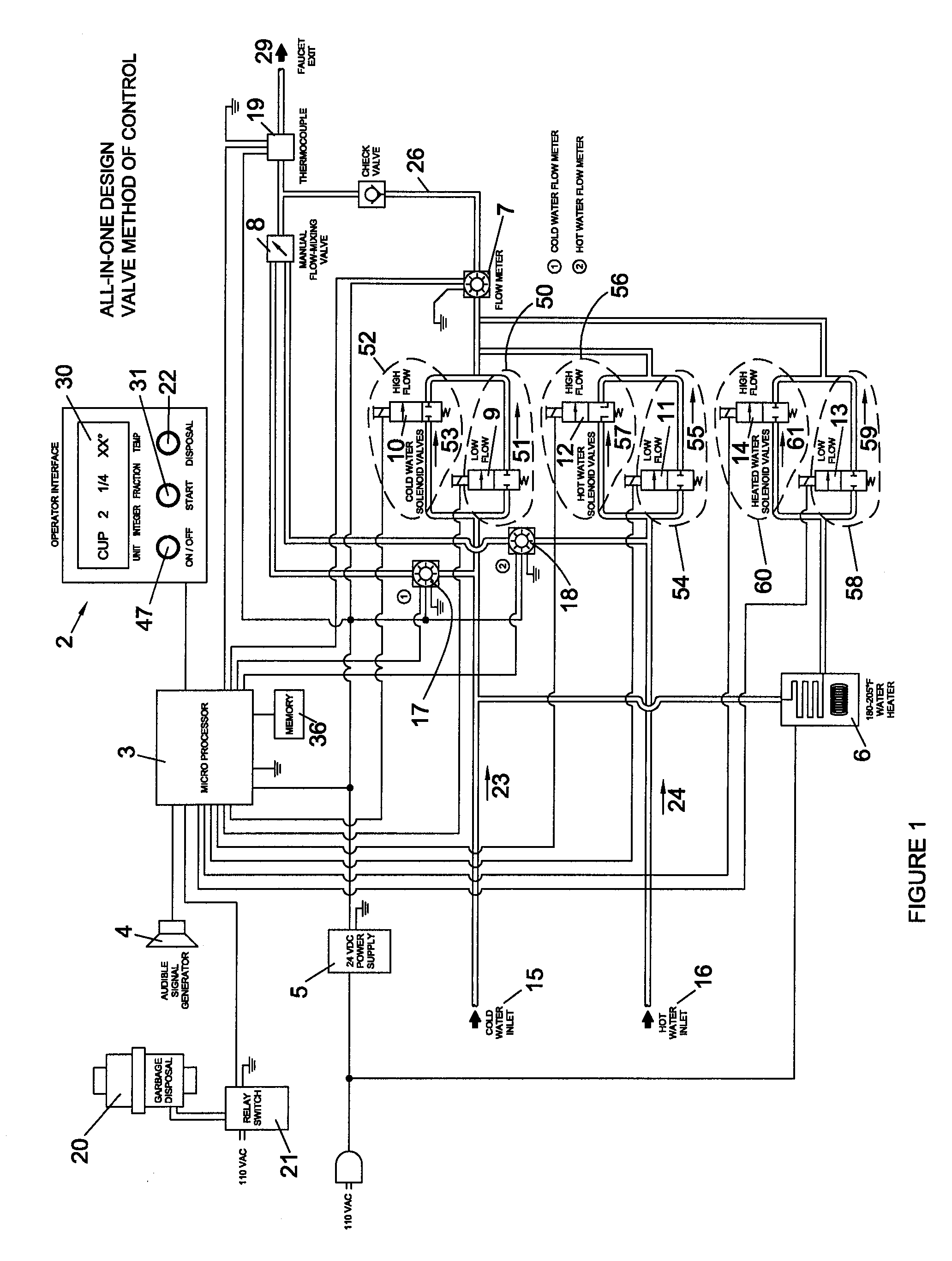

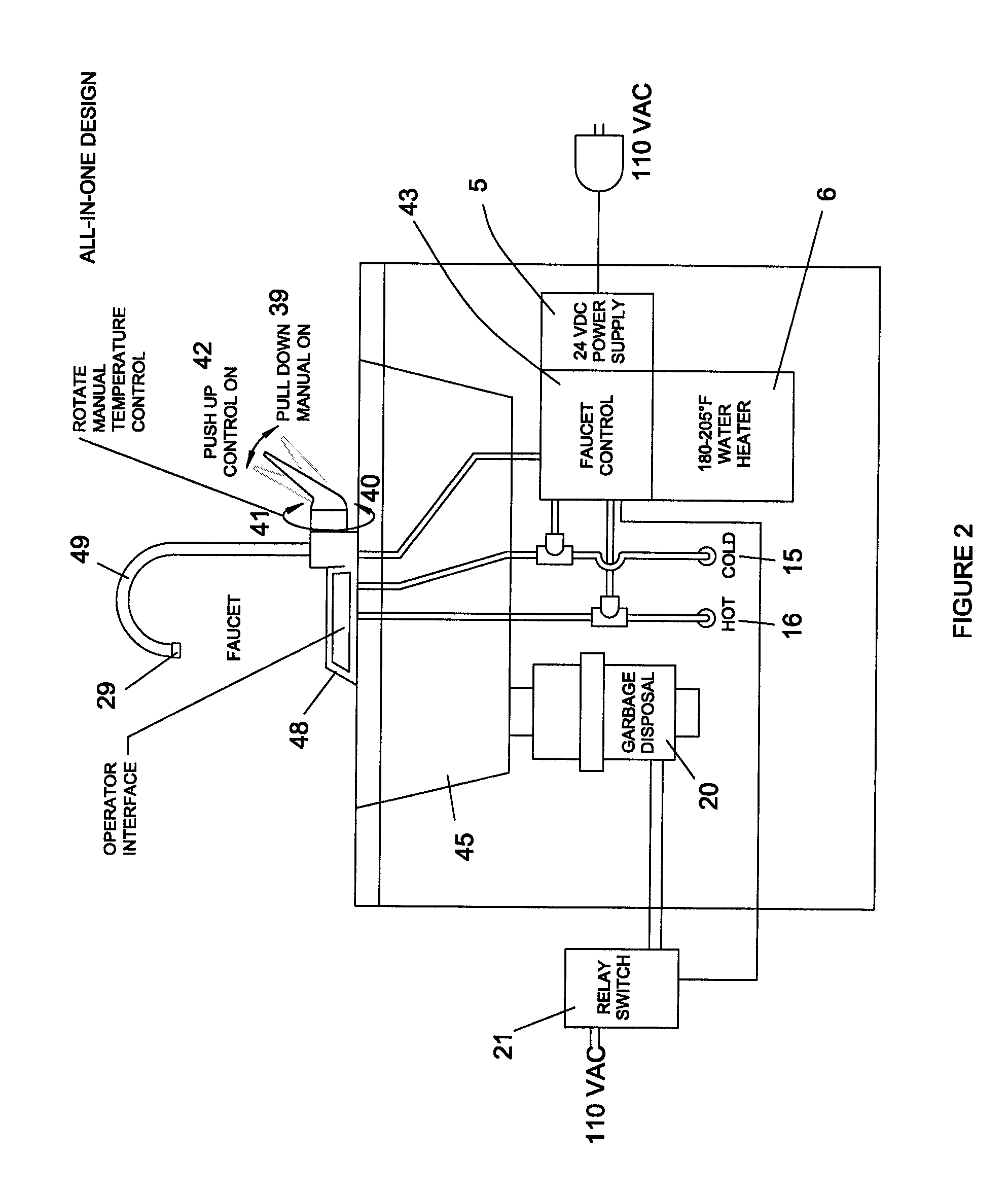

Electronic kitchen dispensing faucet

InactiveUS20070152074A1Avoid damageSufficient volumeTemperature control without auxillary powerDomestic plumbingFlow transducerEngineering

An electronic kitchen faucet dispensing apparatus capable of dispensing measured operator-selectable quantities of hot or cold liquid into a container with a flow rate suitable to prevent splashing and loss of the ensuing mixture while maintaining a rapid flow rate to quickly fill larger containers. The dispensing faucet can be used for measuring liquids required for preparing recipes, making instant beverages, or in the preparation of pre-packaged foods, and may be retrofitted to an existing faucet. The apparatus may utilize various controls to automatically control liquid flow, including 1) flow sensors and control valving; 2) positive-displacement pumps; and 3) flow-restrictors with shut-off valves. Also, it can be connected to a garbage disposal to prevent damage to the disposal.

Owner:EDGEWATER FAUCET

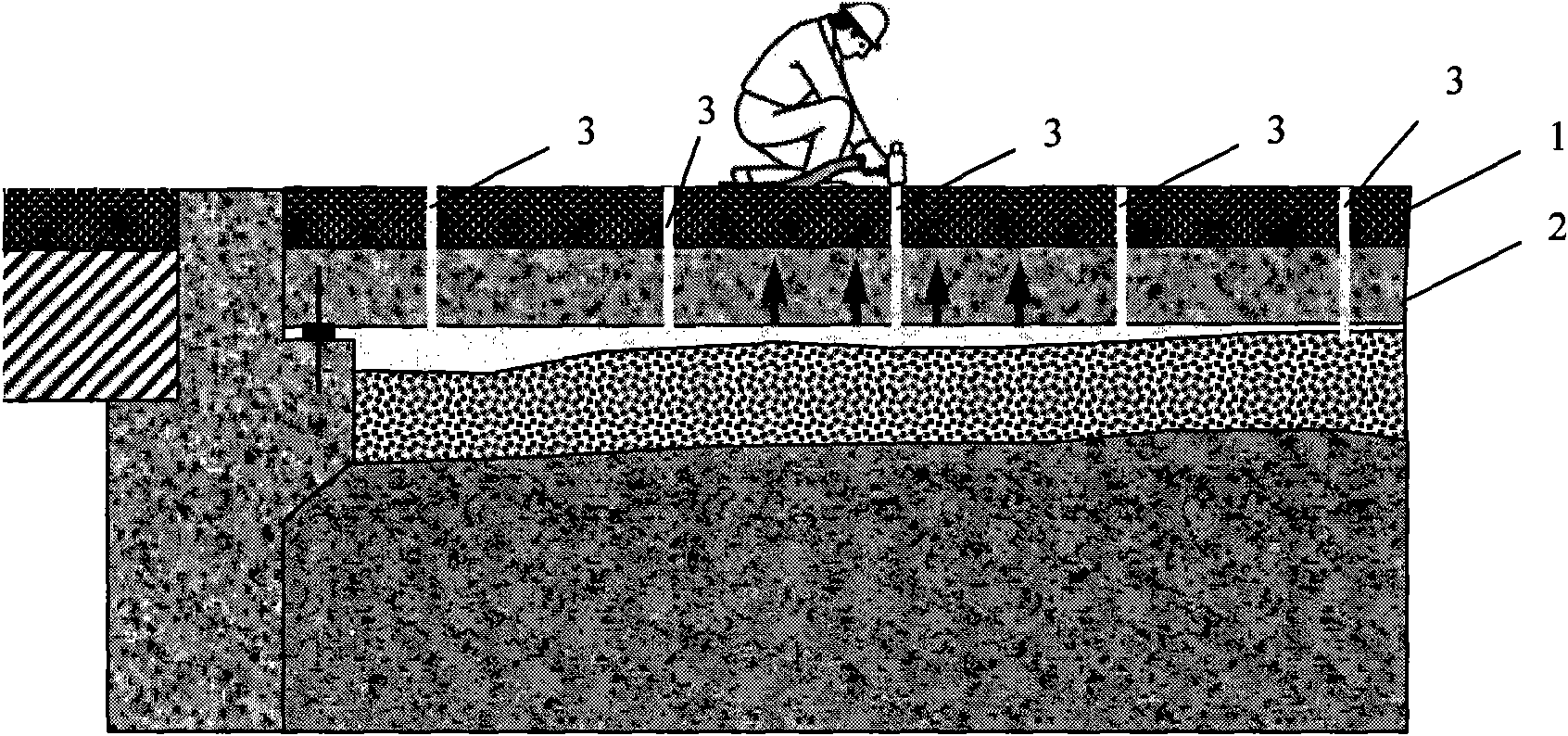

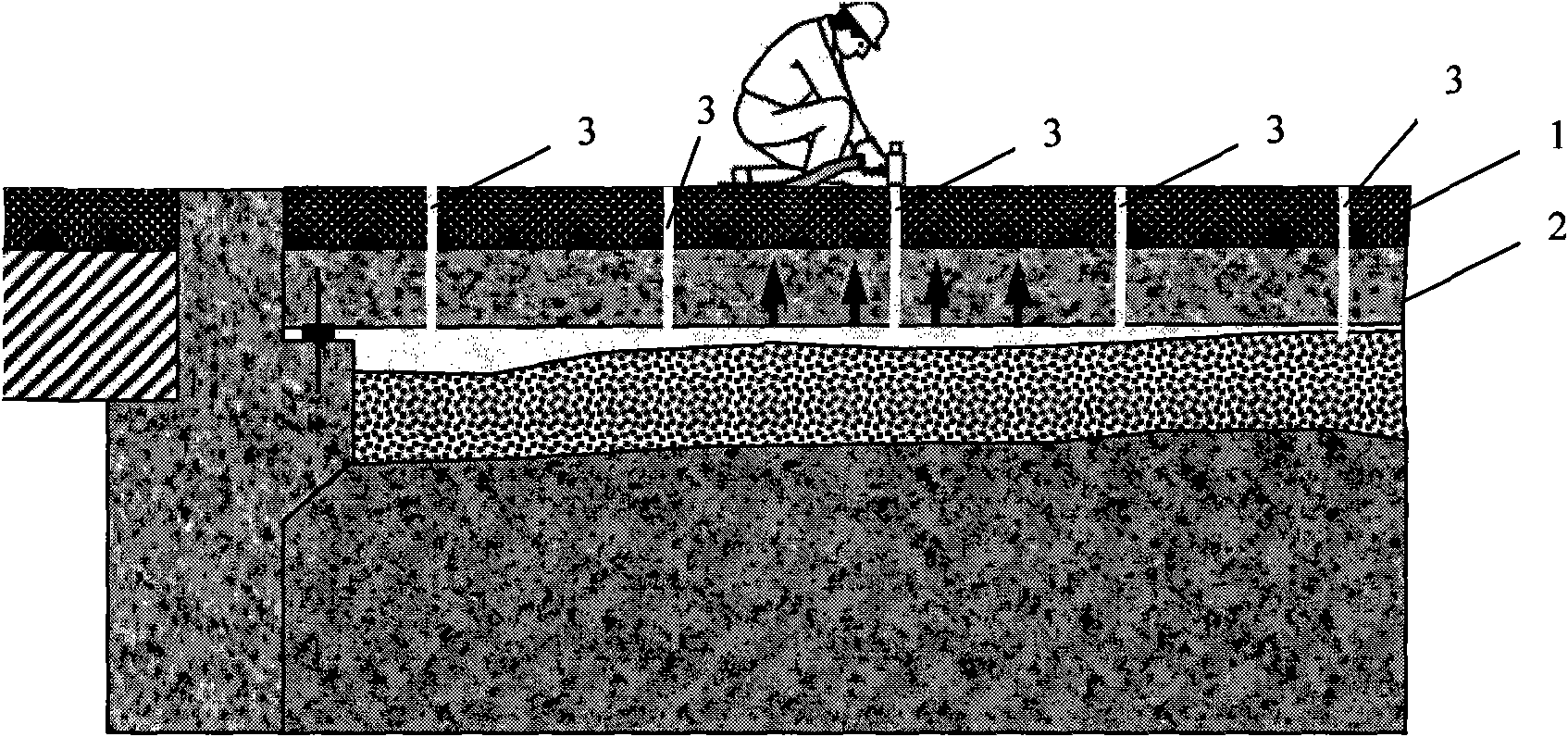

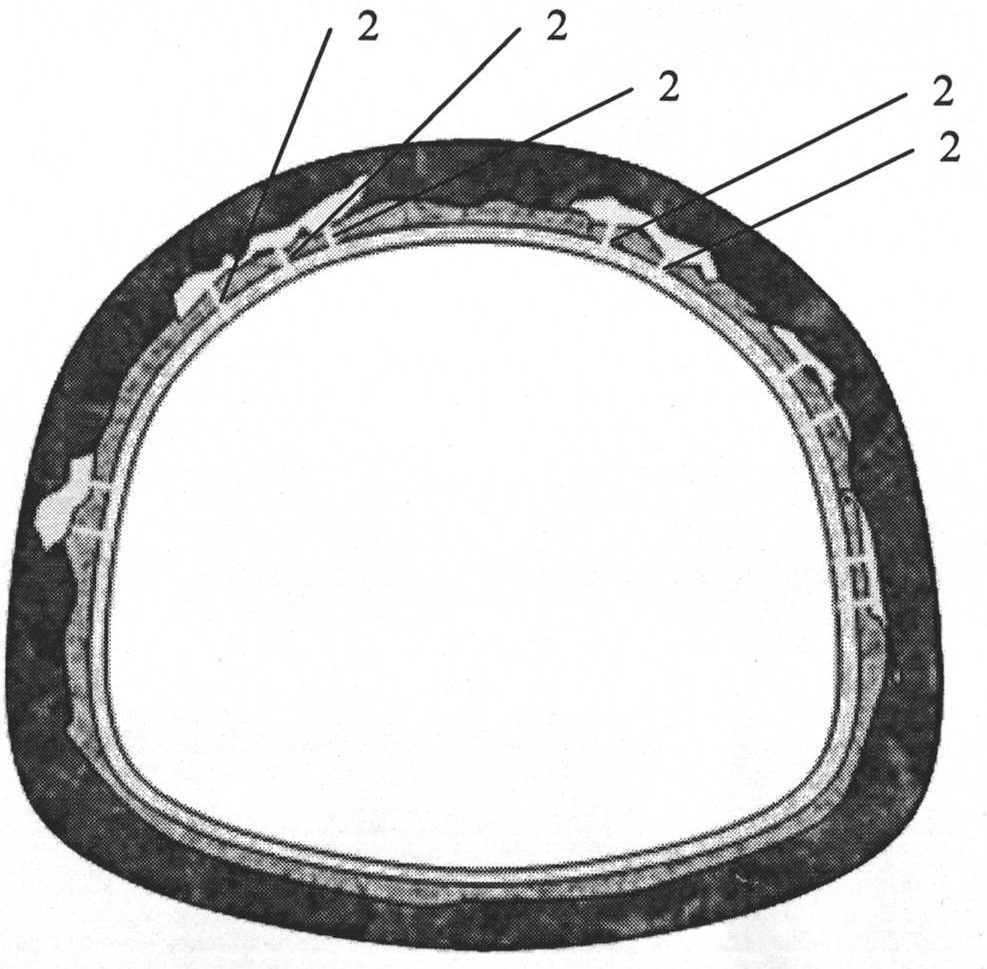

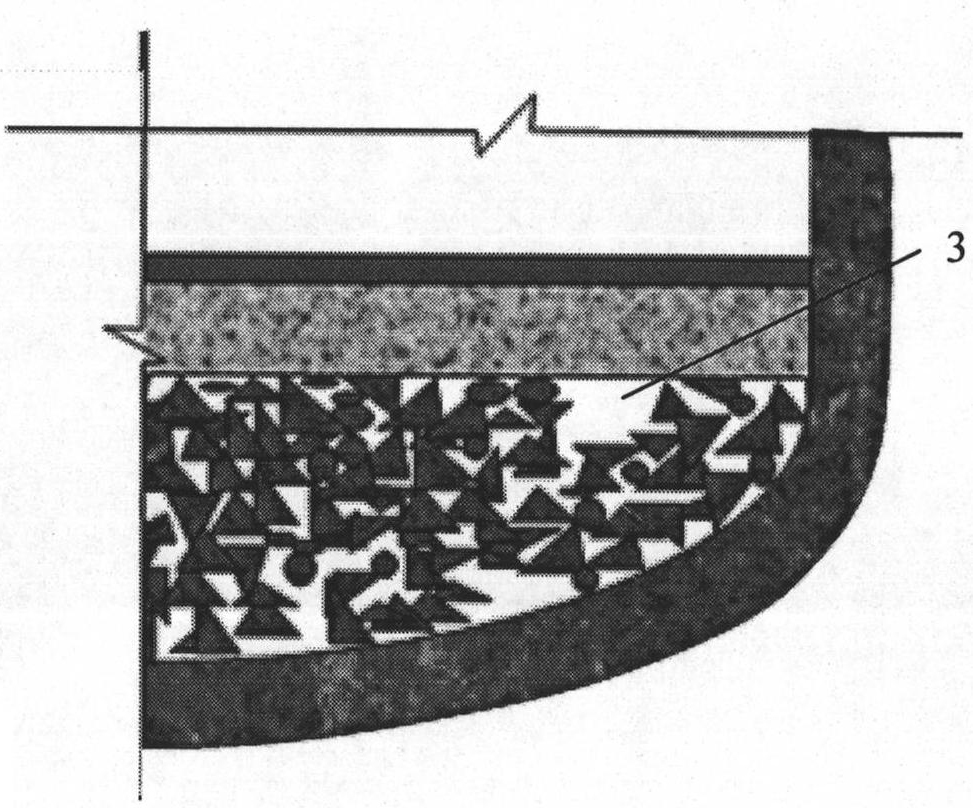

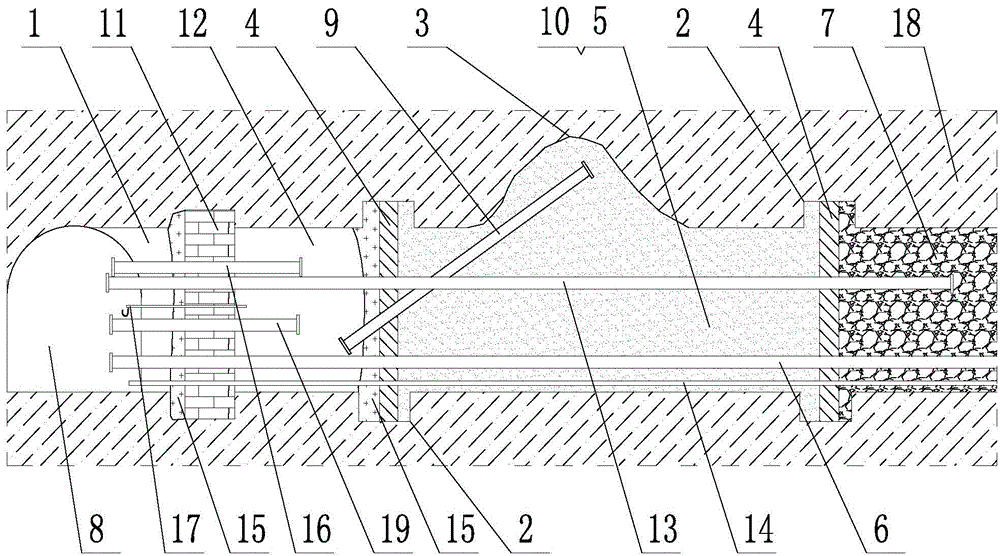

Bridgehead vehicle bump prevention and control high polymer grouting technique and construction method thereof

ActiveCN102051861AIncreased durabilityIncrease elasticityBridge erection/assemblyBridge strengtheningChemical reactionEngineering

The invention discloses a bridgehead vehicle bump prevention and control high polymer grouting technique and a construction method thereof. Aiming at the problems of bridgehead butt strap gapping and sinking problems, nondestructive detection systems of a ground penetrating radar (GPR), a falling weight deflectometer (FWD), a laser level and the like are comprehensively applied to detection and monitoring; and a high polymer material is injected to the bottom of a bridgehead butt strap or the bottom of a sleeper beam, the volume of the material is quickly expanded and the material is cured after chemical reaction, so that the gapped butt strap is quickly filled and raised, the roadbed is reinforced, and bridgehead vehicle bump is radically prevented and controlled. Compared with the conventional treatment method, the technique has obvious innovation on the aspects of technical principles and construction methods, has the characteristics of good durability, short construction period, strong pertinence and the like, and initiates a new advanced, efficient, economic and practical bridgehead bump prevention and control path.

Owner:王复明

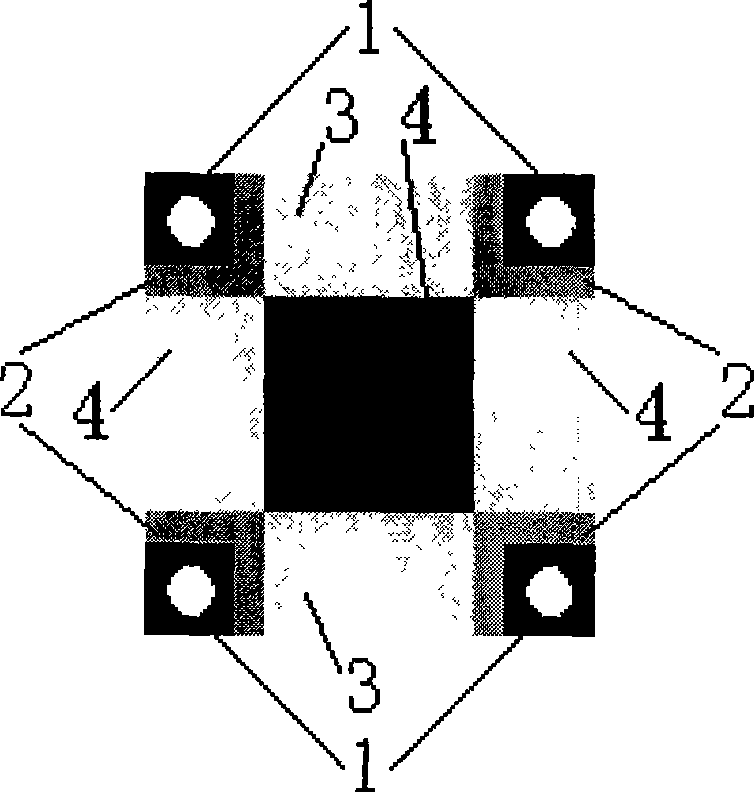

Two-dimension bar code system and its positioning method

ActiveCN101430768ASmall footprintLarge information capacityCharacter and pattern recognitionRecord carriers used with machinesPattern recognitionGraphics

The invention discloses a 2D bar code system and a locating method thereof. A code word is formed by arranged quadrate cell blocks, and a code word area is divided into a locating area, a spacer area, a data area and a pattern area. A sampled and preprocessed digital image signal is binarized by a maximum between-cluster variance algorithm; and a plurality of deep-color and light-color connected domains are obtained by a fast filling algorithm; a plurality of dead square deep-color and light-color connected domains are selected according to a shape factor and an area factor; then concentric selection is performed to obtain a plurality of candidate location graphs; in succession, square topologic selection is performed to determine an effective code word area, and finally, the space is sampled, thus achieving 2D code location.

Owner:成都市思博睿科技有限公司

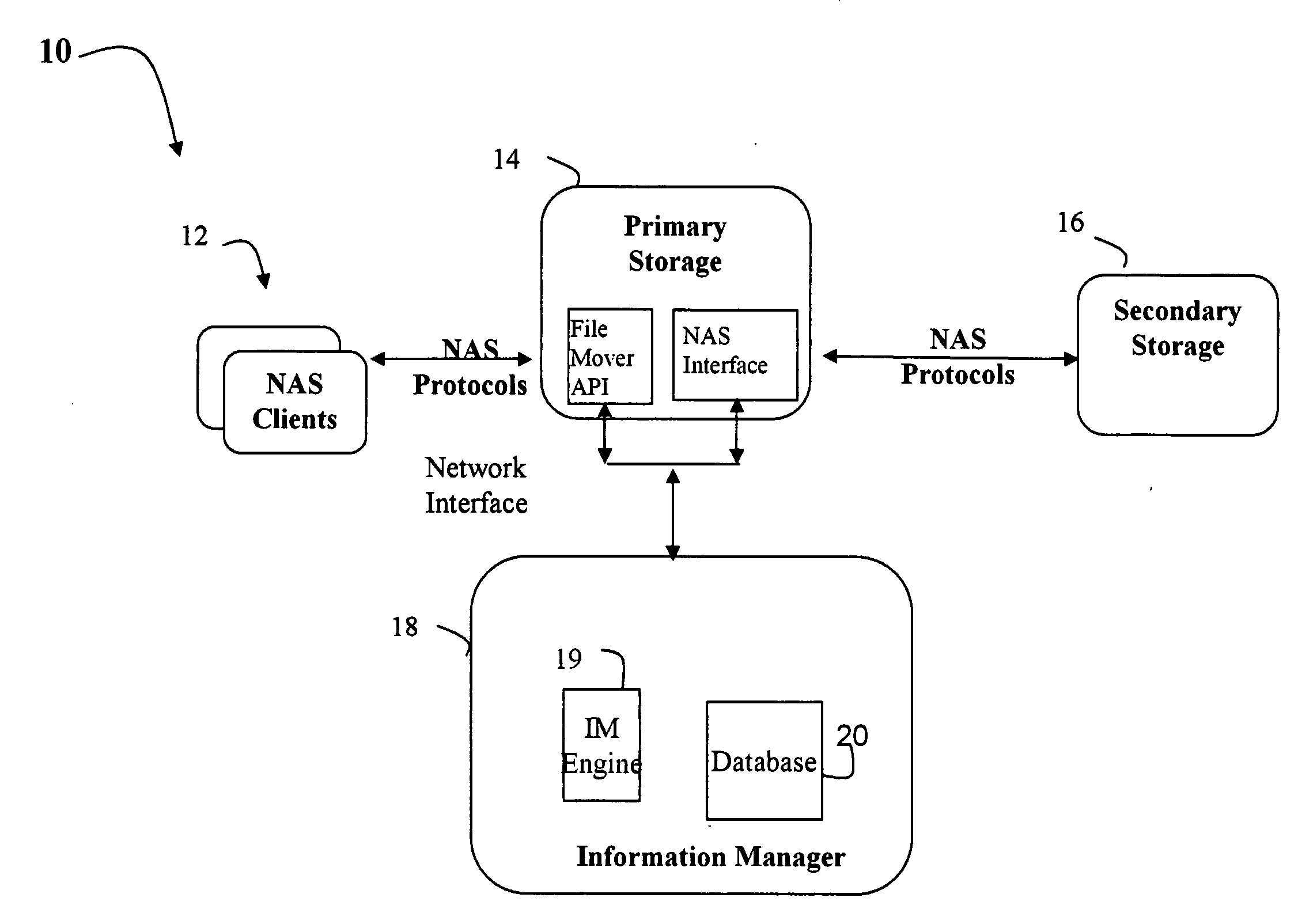

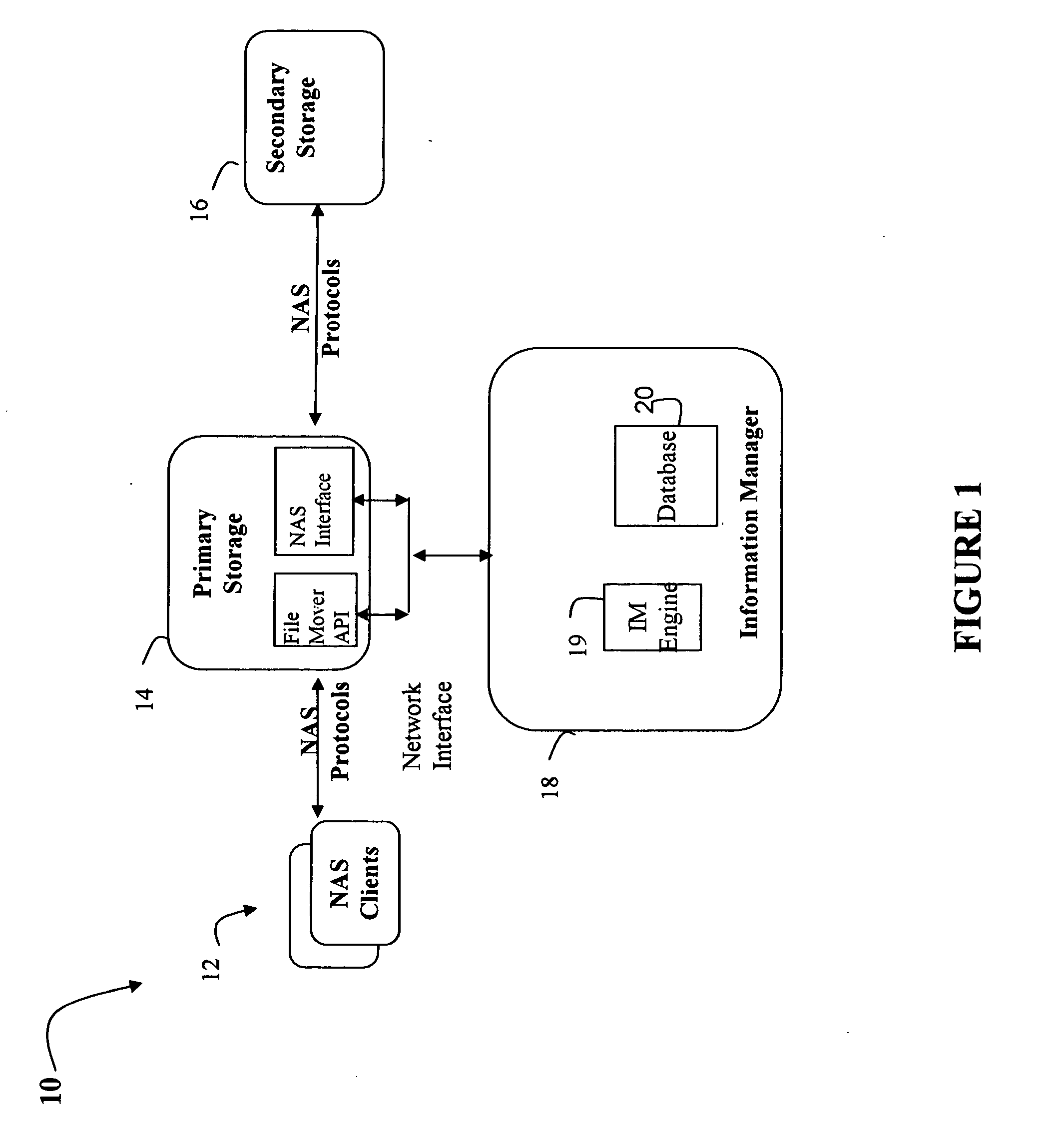

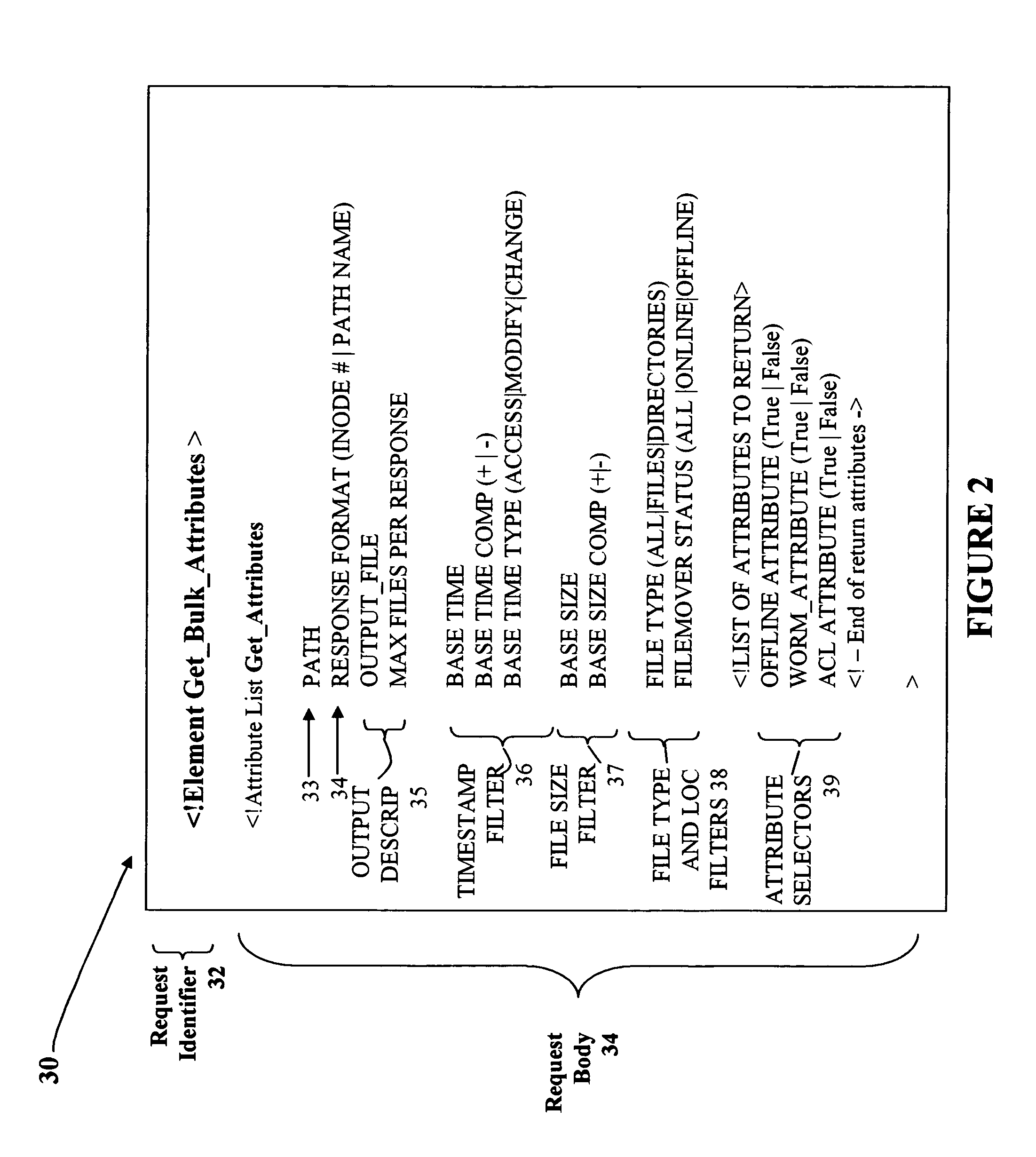

Method and apparatus for performing bulk file system attribute retrieval

ActiveUS20070179934A1Reduce the amount requiredNetwork resource utilization is minimizedDigital data information retrievalDigital data processing detailsFile systemFast filling

Accordingly a method and interface allows an attribute data base used by an Information Manager to be quickly populated and accurately maintained. A single Bulk Attribute Retrieval Request triggers the primary storage device to collect object attribute information. The method allows for selective collection of objects and attributes by providing filters and attribute lists in the Requests. The Request may be used to provide an incremental scan with appropriate time stamp filtering. In addition, the size of the results can be controlled by the IM by eliminating attributes that are not of interest to the IM. The Request is advantageously issued over a FileMover interface, which is an HTTP connection, and encoded in XML, allowing the IM to easily customize the Request as desired.

Owner:EMC IP HLDG CO LLC

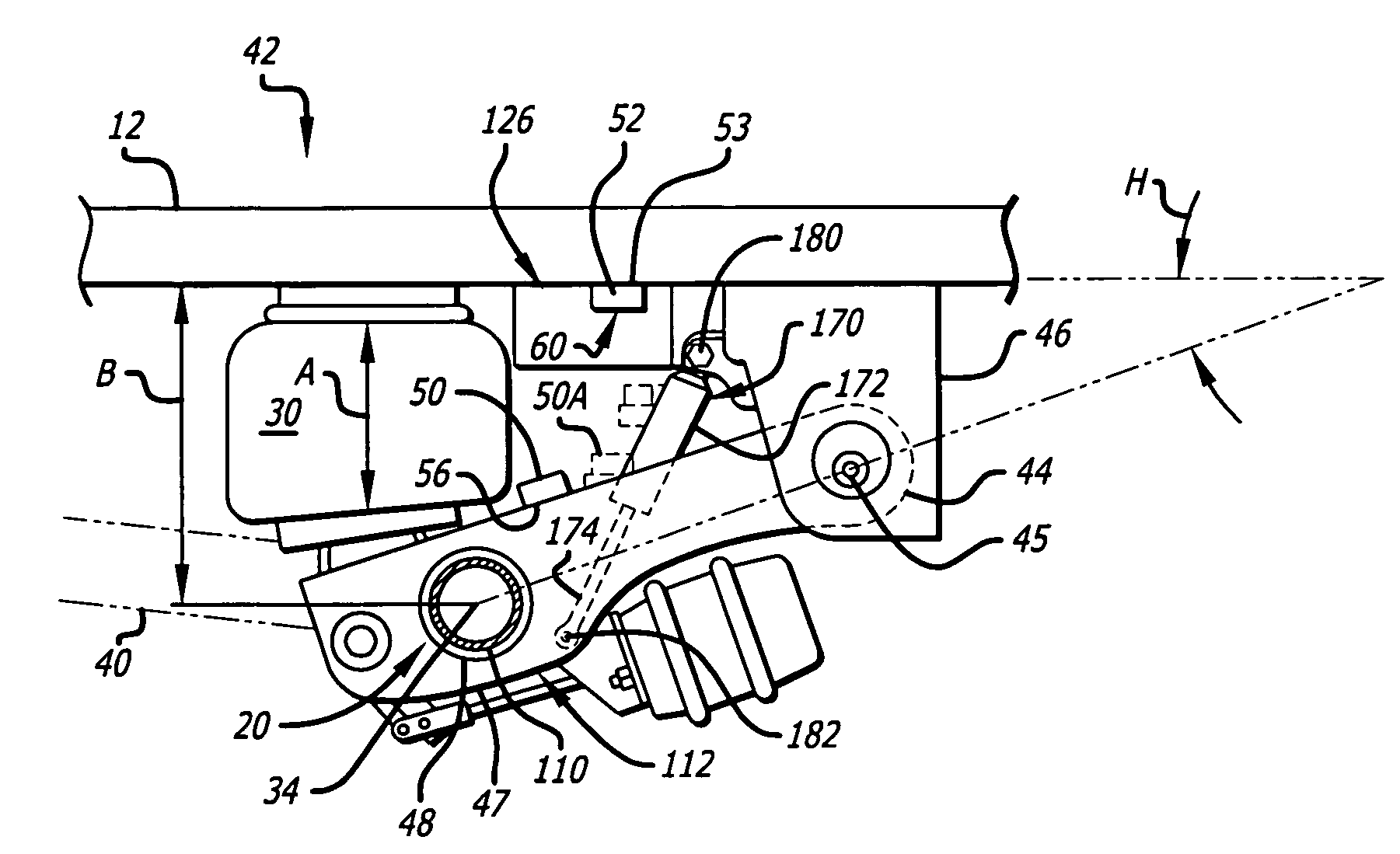

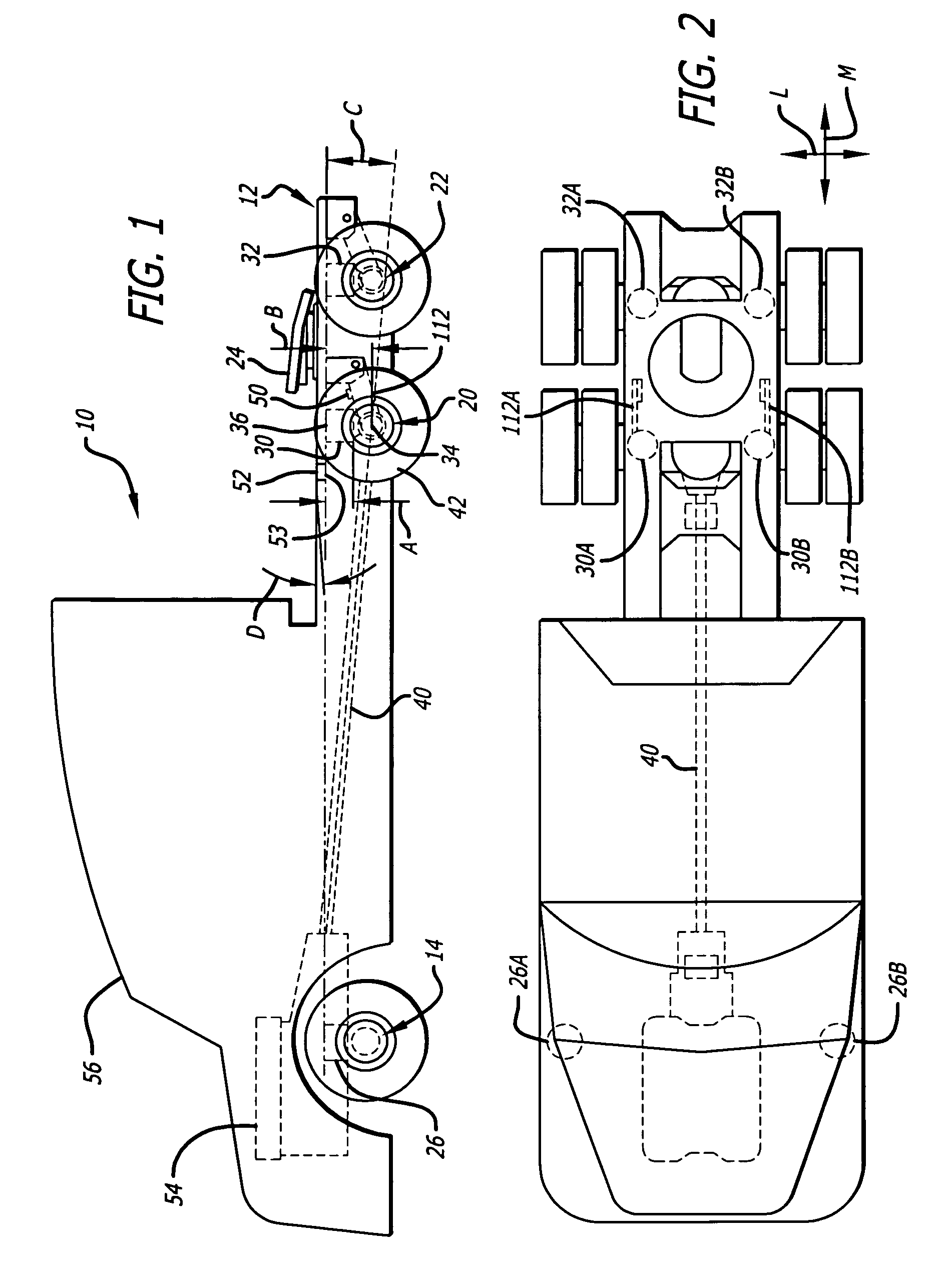

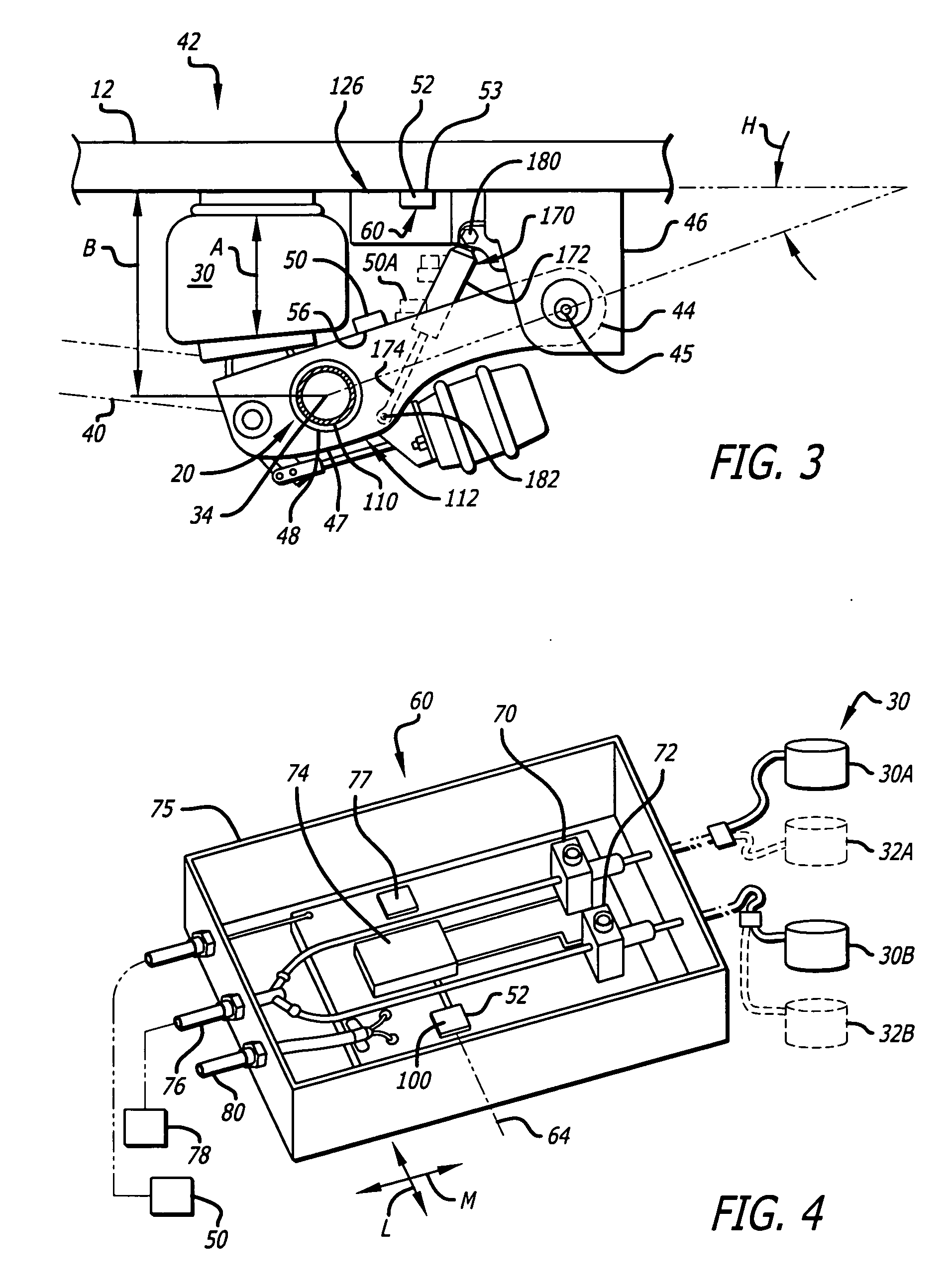

Electronic control of vehicle air suspension

InactiveUS20060267296A1Prolong lifeReduce the amount requiredSpringsResilient suspensionsMotion detectorVehicle frame

A system is provided for use on large vehicles of the type wherein the vehicle frame is supported on vehicle axle assemblies through air bags, and each air bag has a lower end coupled to the lower end of an arm such as a swing arm whose upper end is pivotally mounted on the frame. The height of the air bag is sensed by a pair of tilt sensors, sensing tilt of its location with respect to gravity, and the difference in tilt indicates air bag height. The output of the tilt sensors may be filtered, and a motion detector allows rapid filling or dumping of air bags independent of filtering of tilt sensor signals. Control of the vehicle air suspension can also be based upon inputs from one or more air bag pressure sensors.

Owner:BARKSDALE

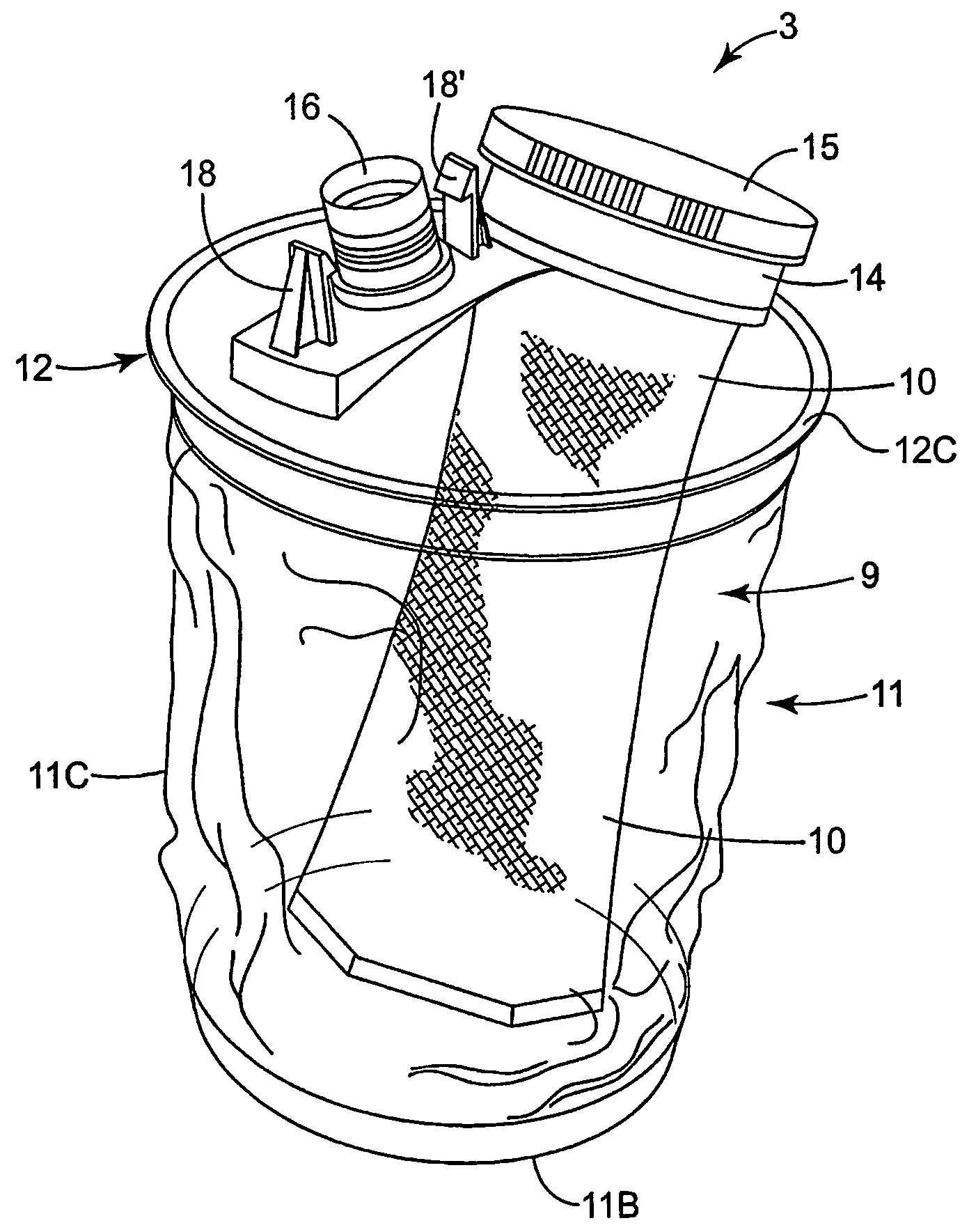

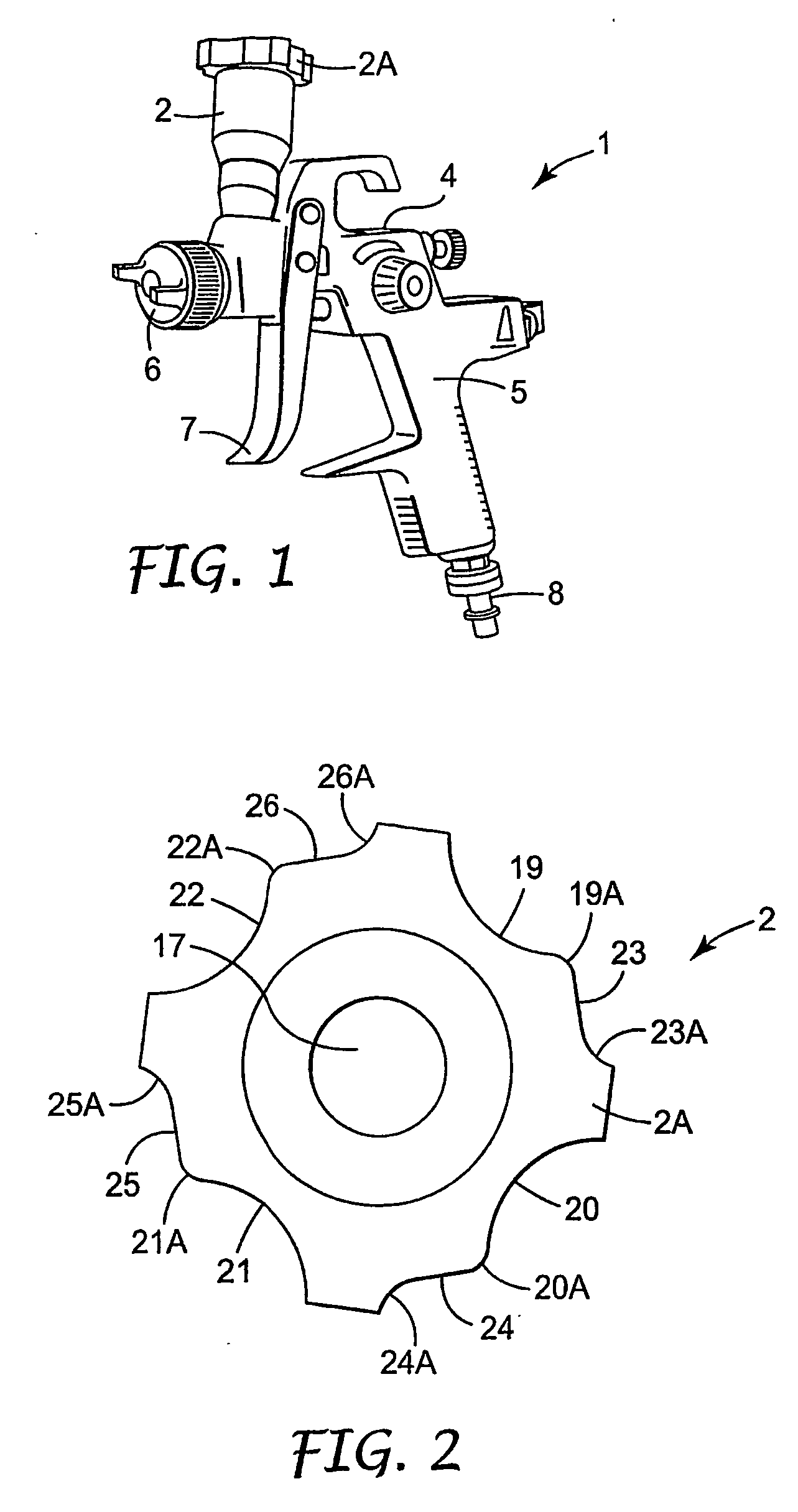

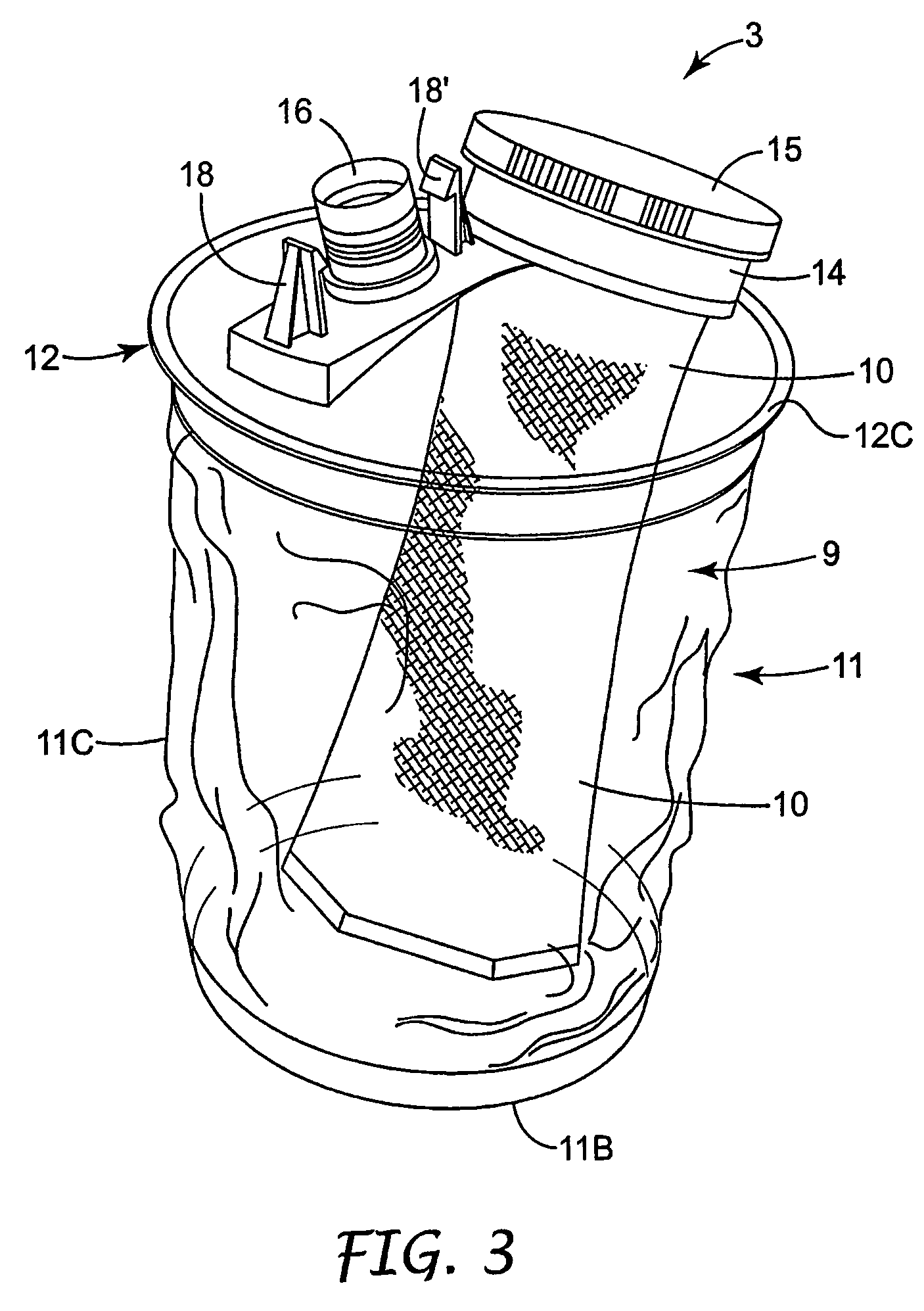

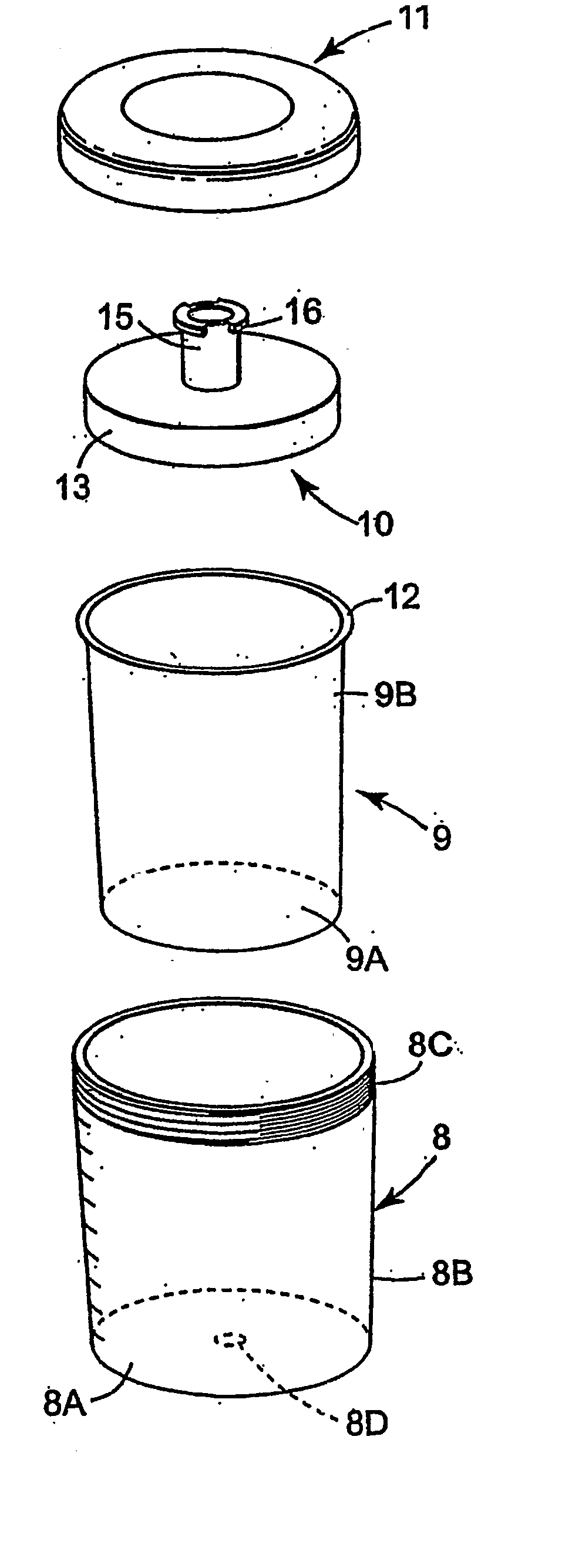

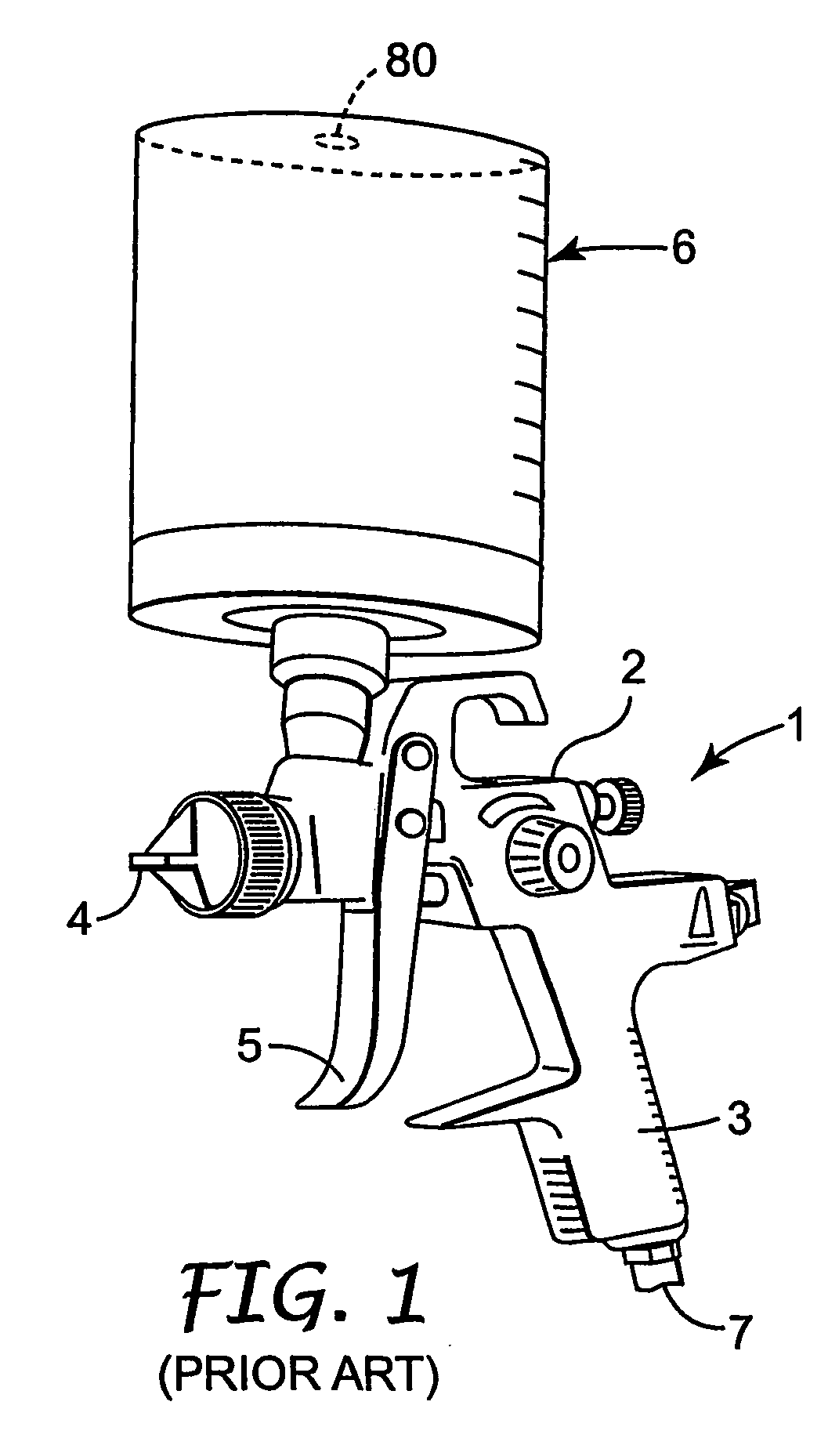

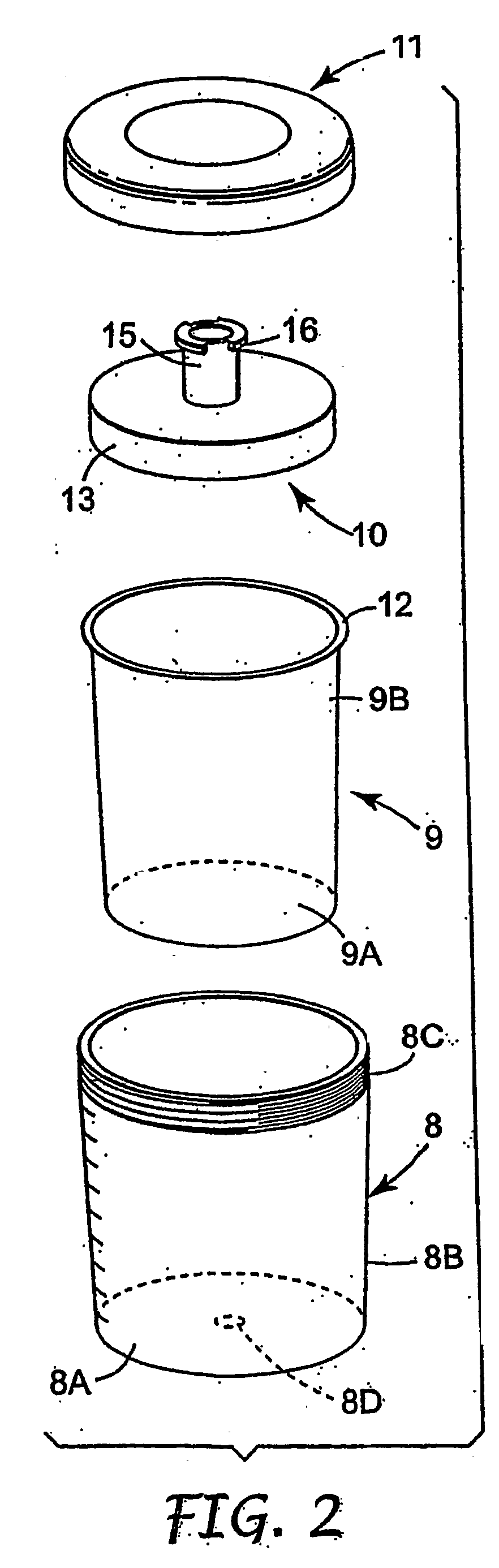

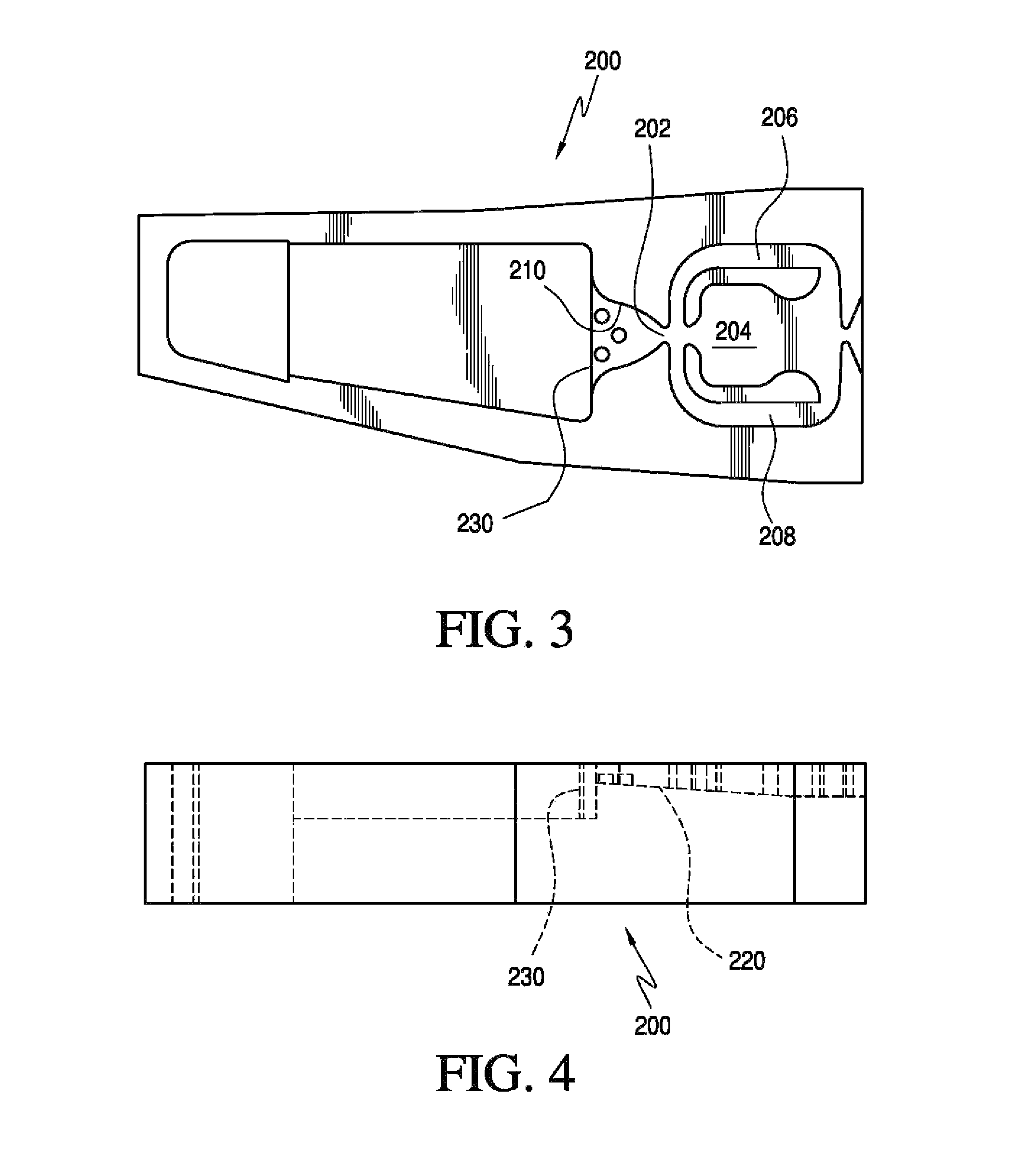

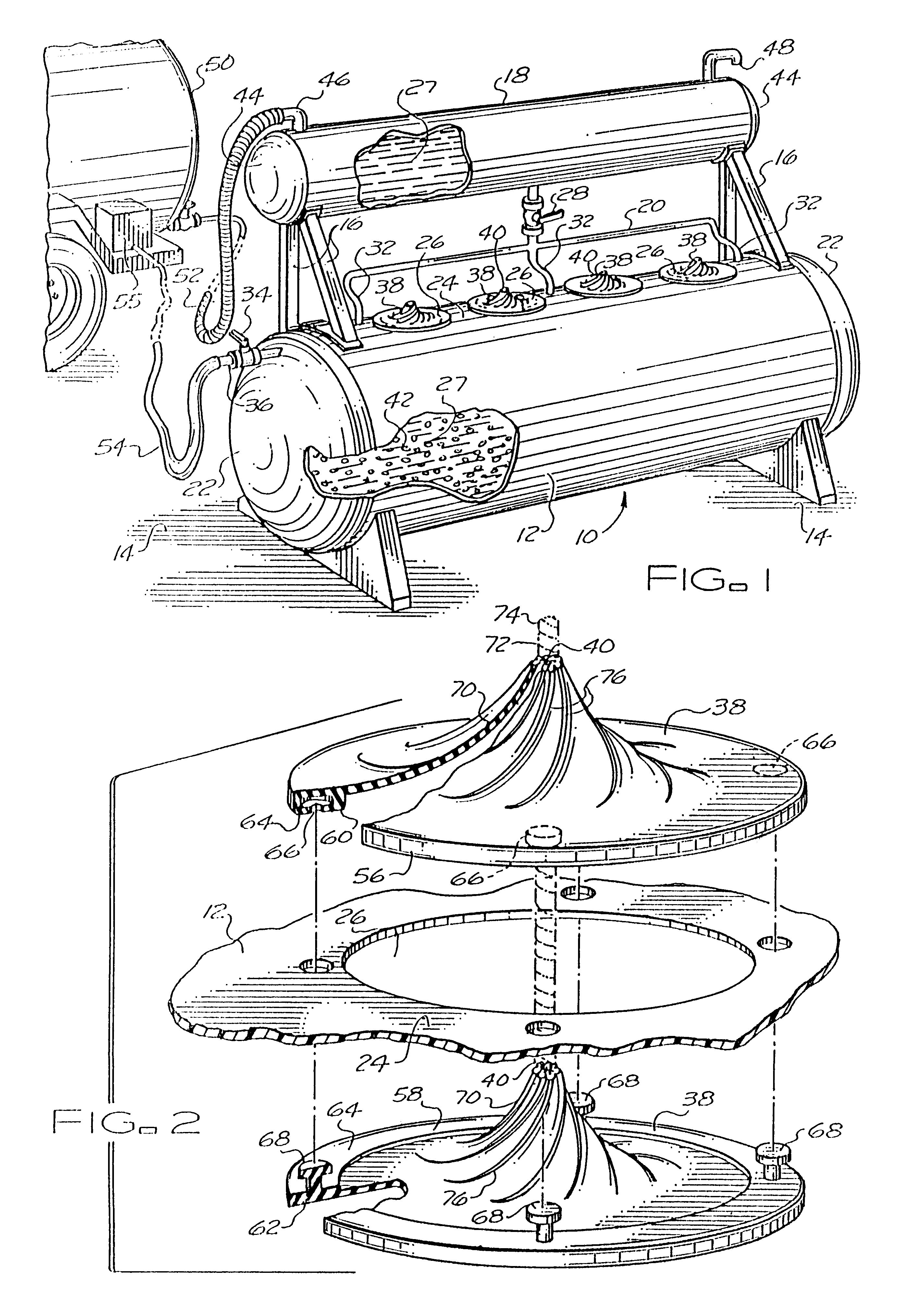

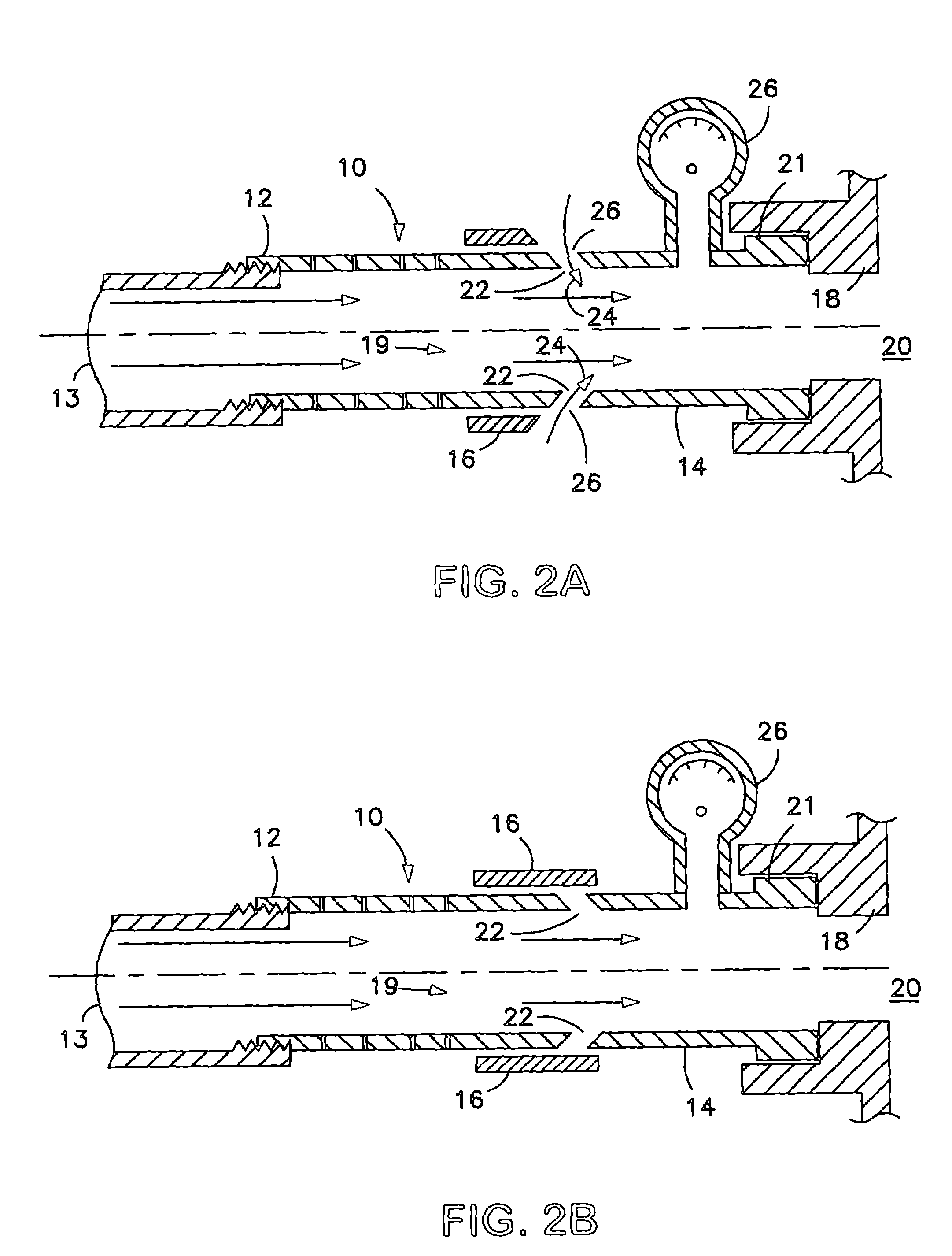

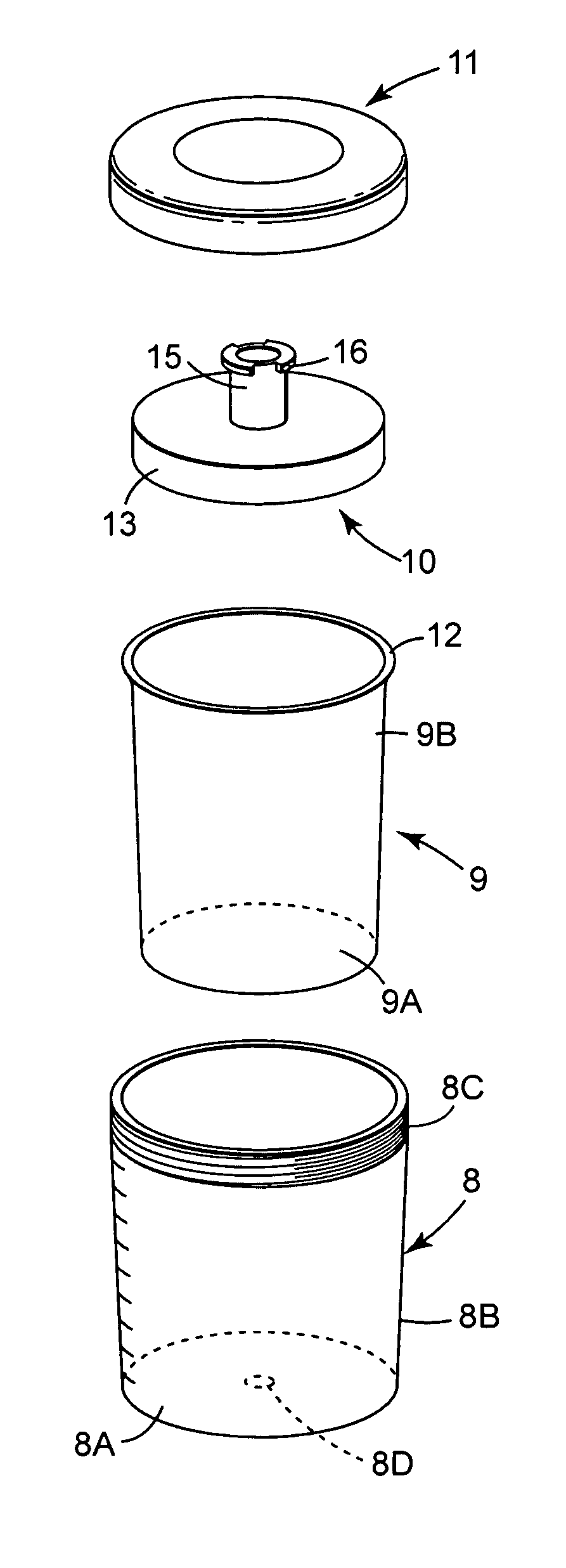

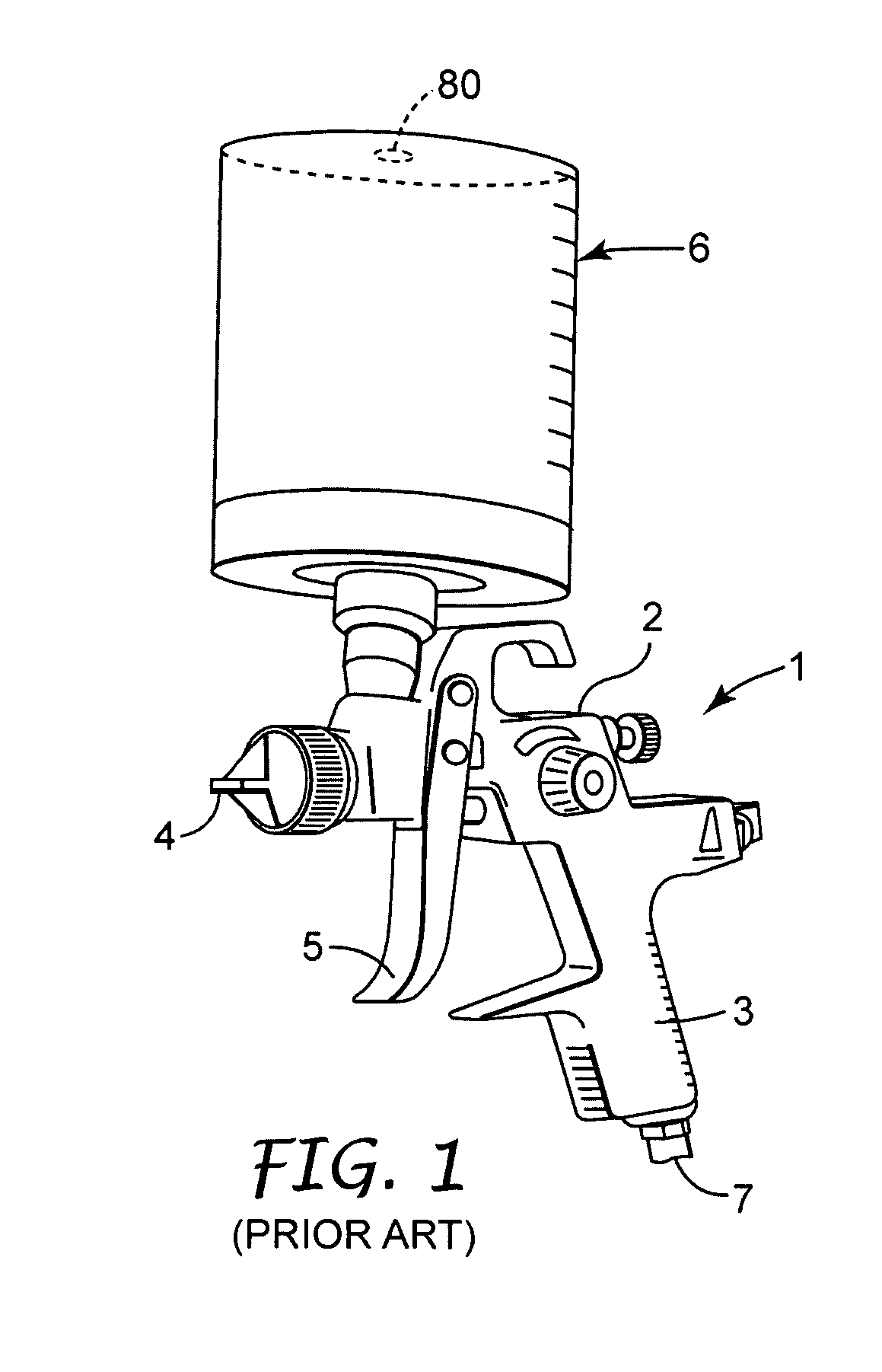

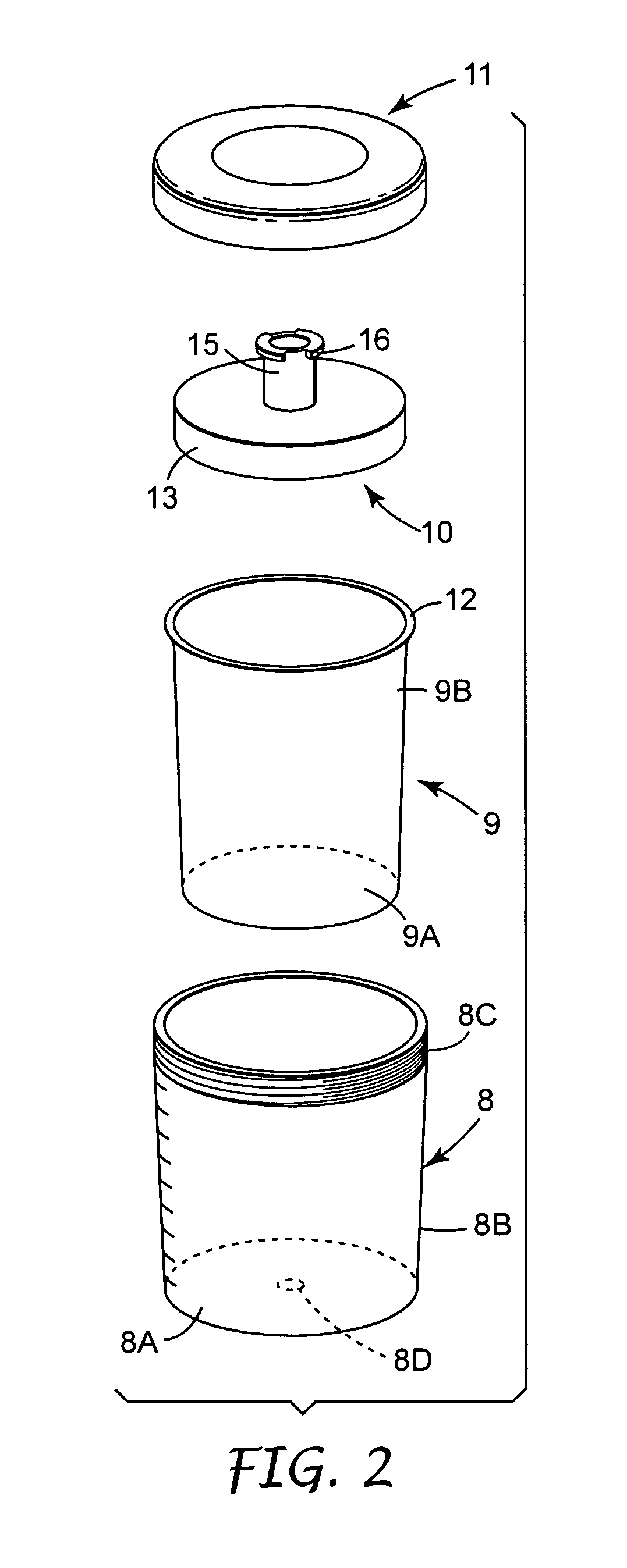

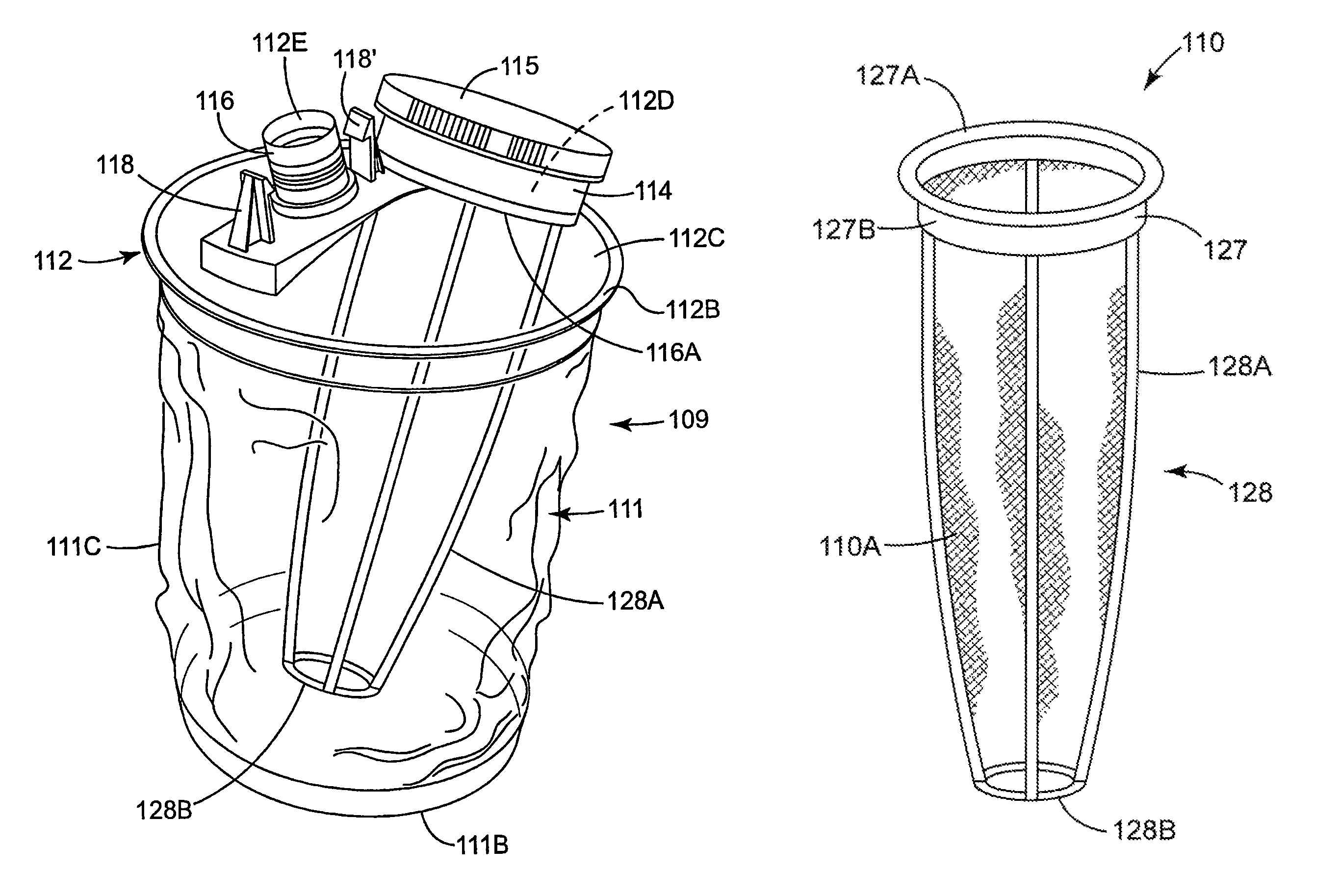

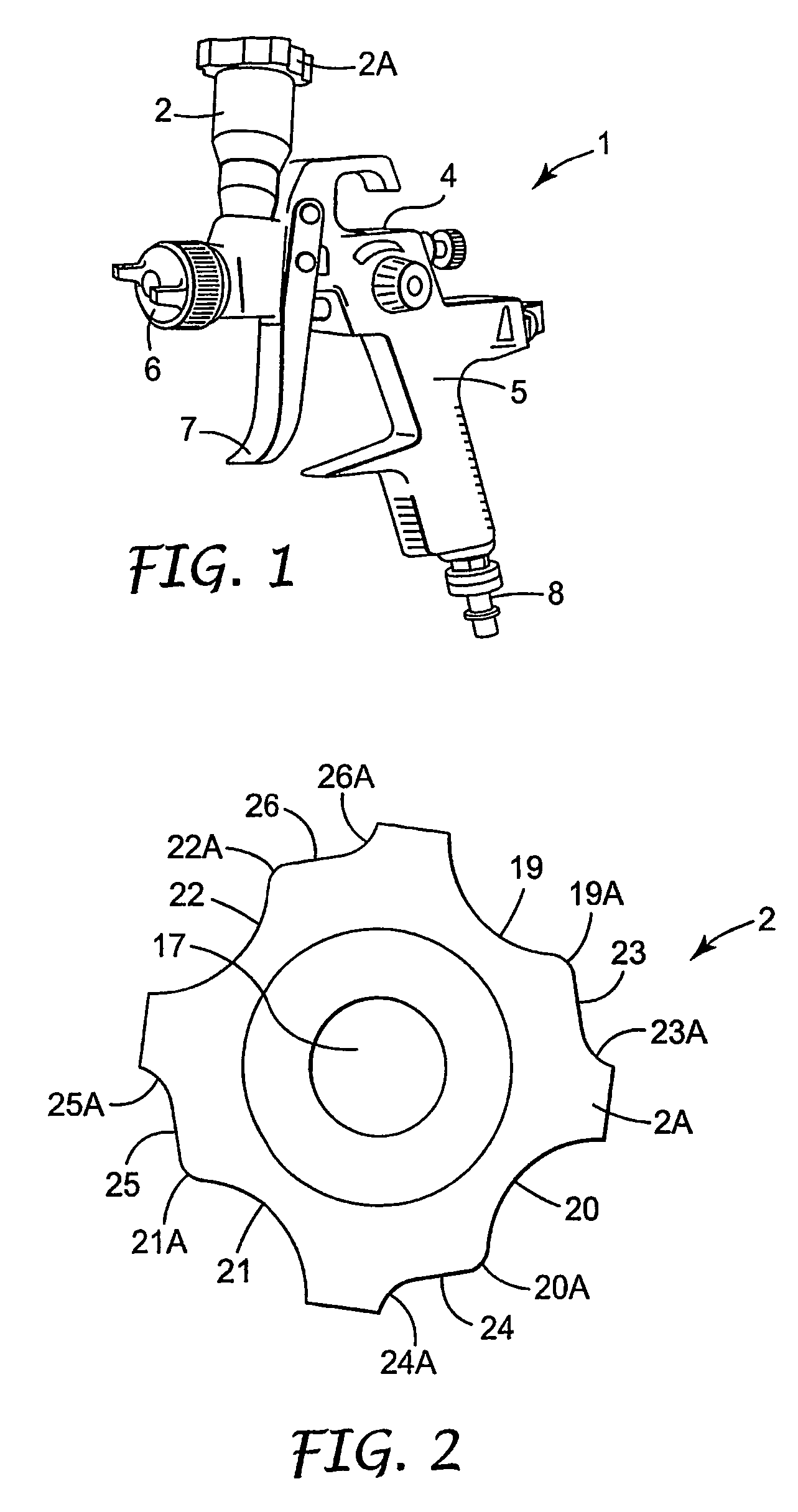

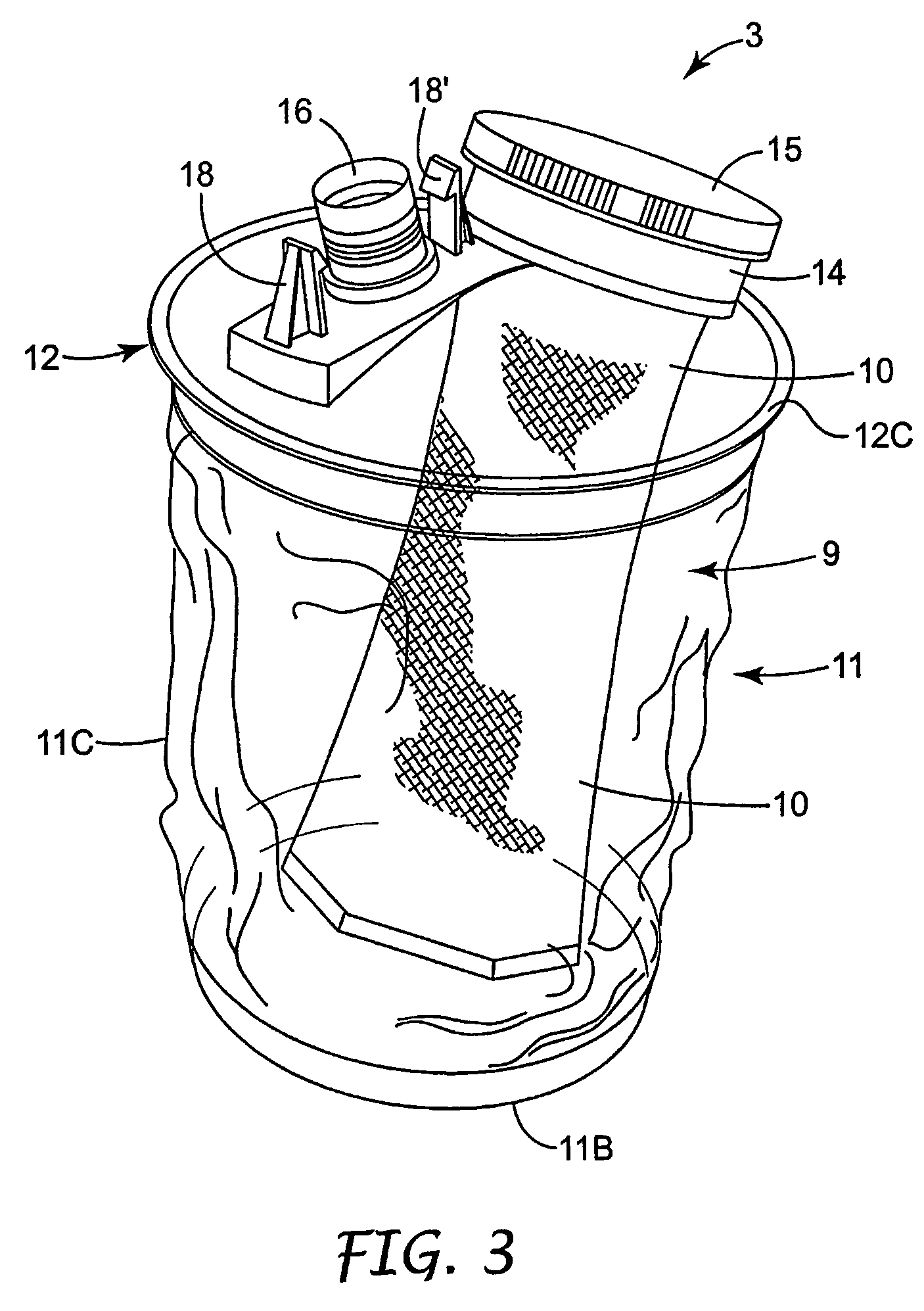

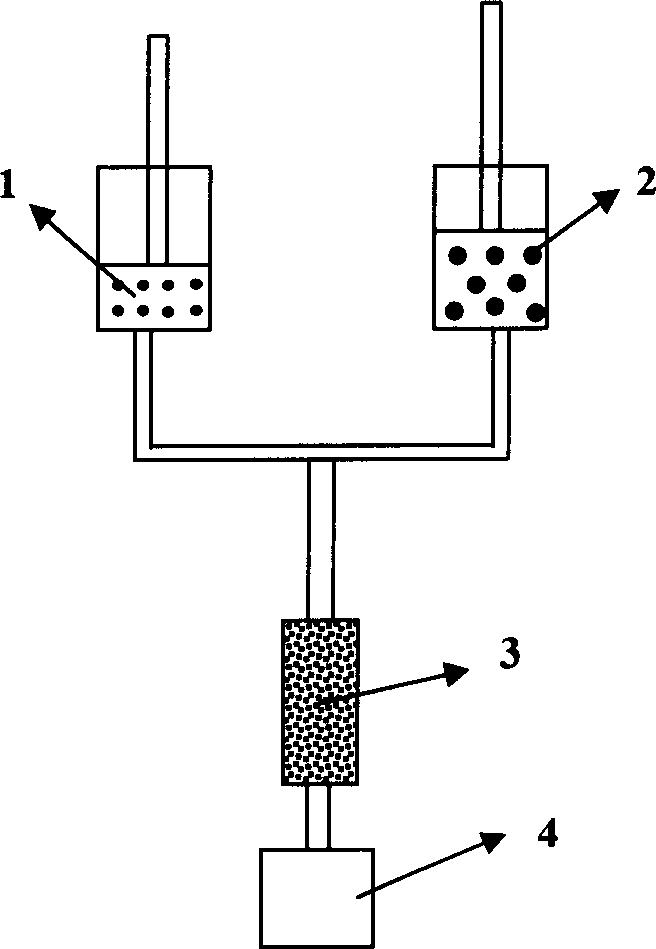

Drop-in filter for spray gun reservoir

InactiveUS20060065591A1Improve filtering effectFast fillLoose filtering material filtersCartridge filtersSolid particleEngineering

A liquid supply assembly for use with a spray gun (FIG. 1) comprises a reservoir 9 provided with a drop-in filter 10 for removing solid particles from liquid added to the reservoir 9. The reservoir 9 has a lid 12 with an outlet opening 12E connectable via a spout 16 to the spray gun and a separate inlet opening 12D in which a support collar 27 of the filter 10 is located. The filter 10 comprises a tubular mesh body 10A having an open end and a closed end. The open end is connected to the support collar 27 and the mesh body 10A extends away from the inlet opening 12D within the reservoir 9. The mesh body 10A is sized to pass through the filler opening 12D and has a high flow capacity to permit rapid filling of the reservoir 9. The filter 10 may be left in place when the reservoir 9 is connected to the spray gun and the reservoir 9 may be discarded together with the filter 10 after use.

Owner:3M INNOVATIVE PROPERTIES CO

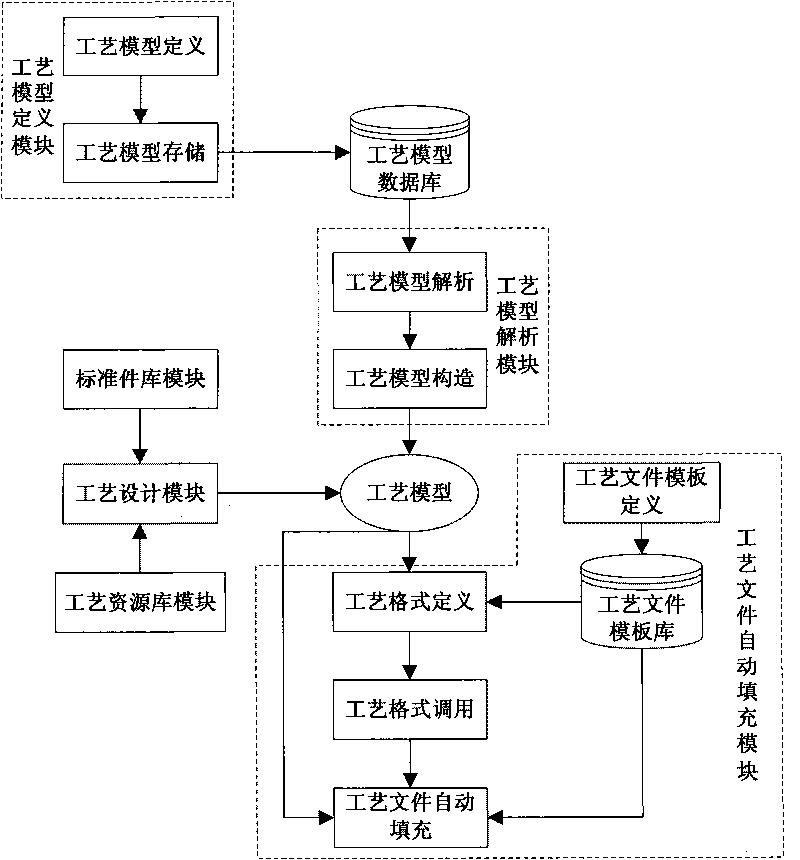

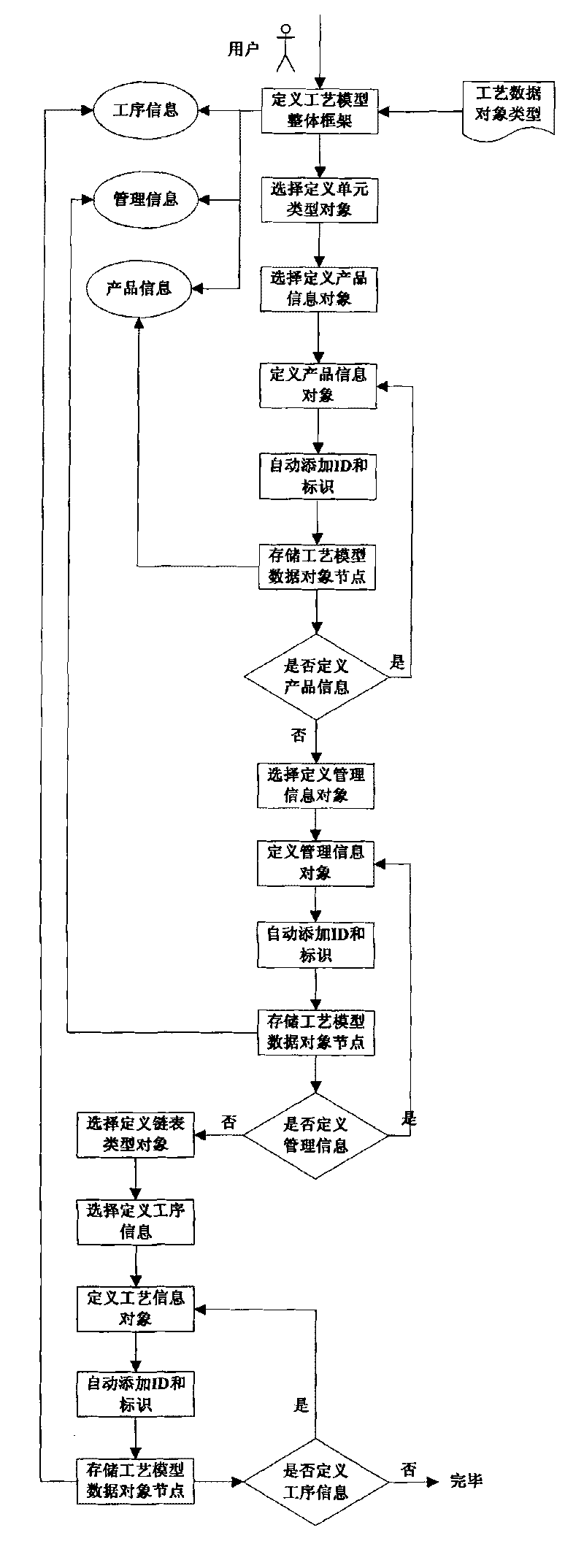

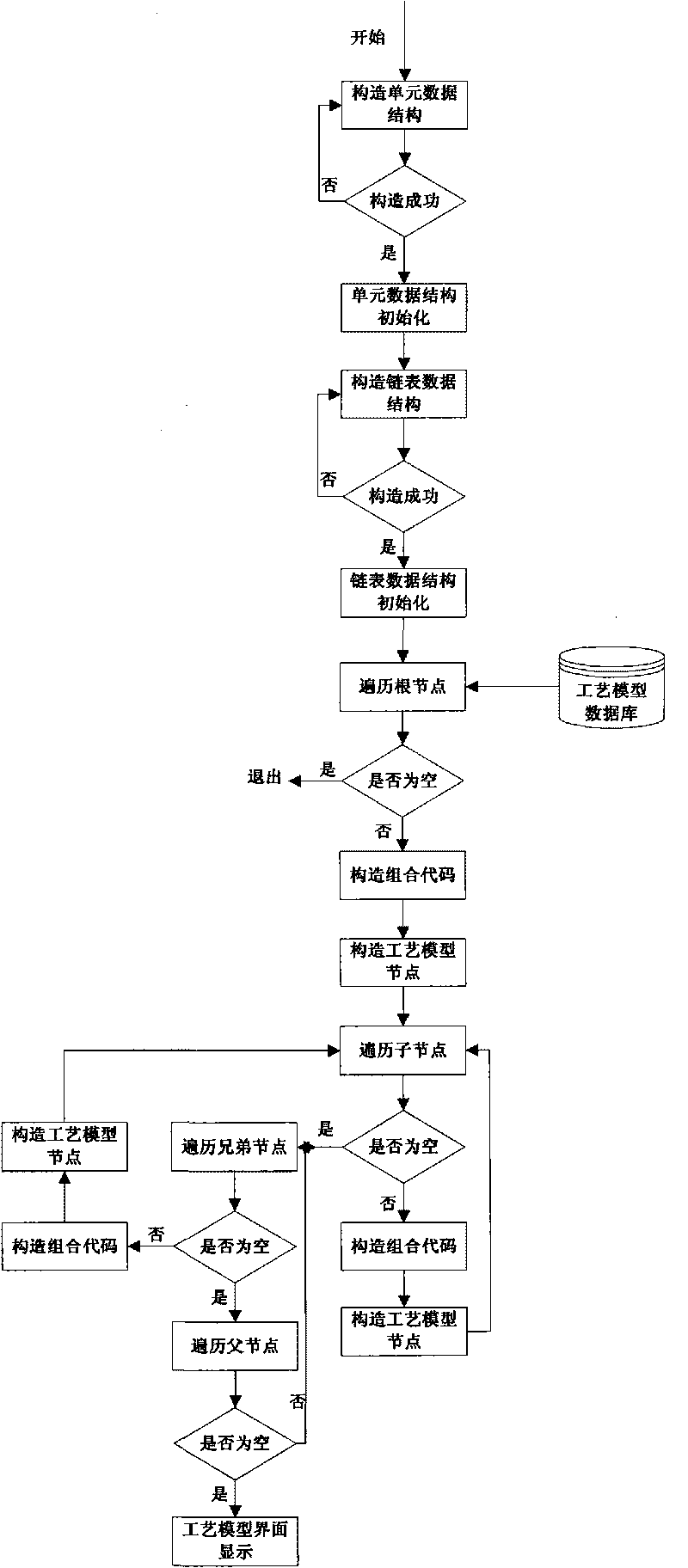

Numerical control machining process design system and method of aircraft complex components facing process object

InactiveCN101763064AImplement autofillRealize batch outputProgramme controlComputer controlNumerical controlFast filling

The invention discloses a numerical control machining process design system and a method of aircraft complex components facing a process object. The system consists of six modules, namely a process model definition module, a process model analysis module, a process design module, a process file automatic filling module, a standard part library module facing a process model and a process resource library module facing the process model. The method is realized by five processes, namely process model definition, process model analysis, process design facing the process model, process format definition and automatic filling of a process file by calling a process format. The system can define the process model in a way of facing the process object, and on the basis, process aided design and fast filling and generation of the process file can be carried out, and effective separation of process design data and the process file can be realized, thus liberating a process designer from process file compiling to ensure the process designer to concentrate on process method design.

Owner:SHENYANG AIRCRAFT CORP +1

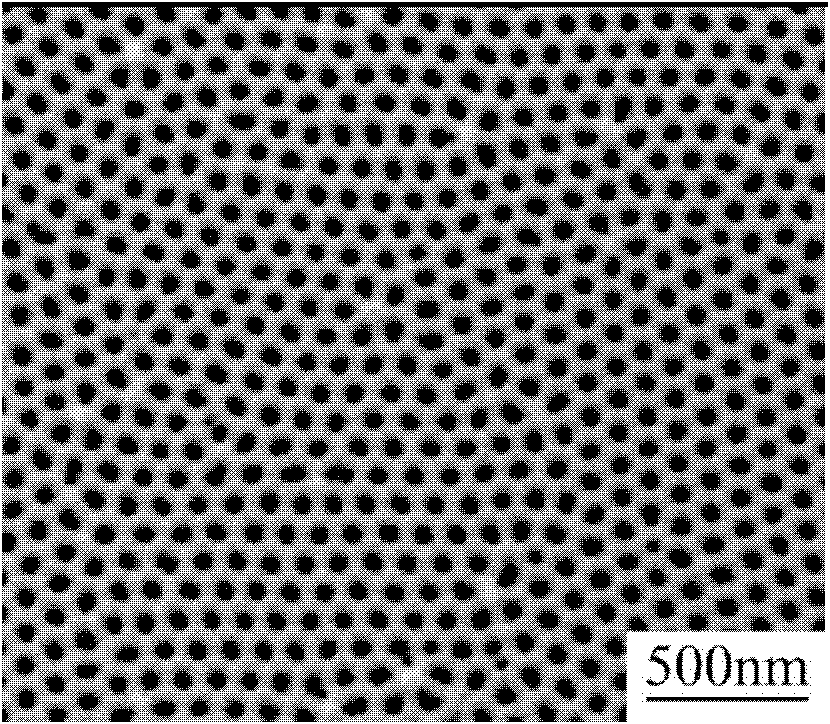

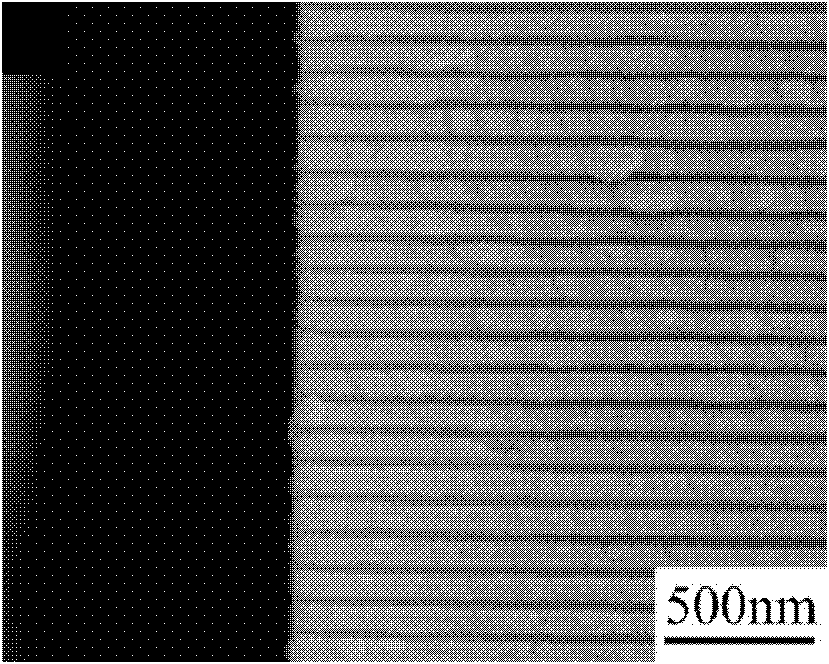

Method for preparing silver nanowire array in ordered porous alumina template

InactiveCN102251232AEasy to manufactureLow costSurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingMaterials preparationSilver bromide

The invention belongs to the field of nano material preparation, and discloses a method for preparing a silver nanowire array in an ordered porous alumina template. The method comprises the following steps: (1) sequentially carrying out annealing and ultrasonic cleaning on a high-purity aluminium sheet, removing a natural oxidation film of the high-purity aluminium sheet, sequentially carrying out electrochemical polishing and two-step anodic oxidation on the high-purity aluminium sheet, and removing an unoxidized aluminum substrate and unoxidized through holes of the high-purity aluminium sheet so as to prepare a two-way ordered porous alumina template; (2) filling silver bromide nanowires into the ordered porous alumina template by using a double-chamber chemical deposition method; and (3) irradiating the ordered porous alumina template filled with the silver bromide nanowires by using an ultraviolet lamp so as to carry out photodecomposition on silver bromides, then forming a silver nanowire array in the ordered porous alumina template. By using the method disclosed by the invention, the process for preparing a silver nanowire array is simplified; the method has low requirements on experimental equipment; and the method is simple in operation, low in cost, and favorable for the low-cost fast filling of a silver nanowire array in an ordered porous alumina template.

Owner:TONGJI UNIV

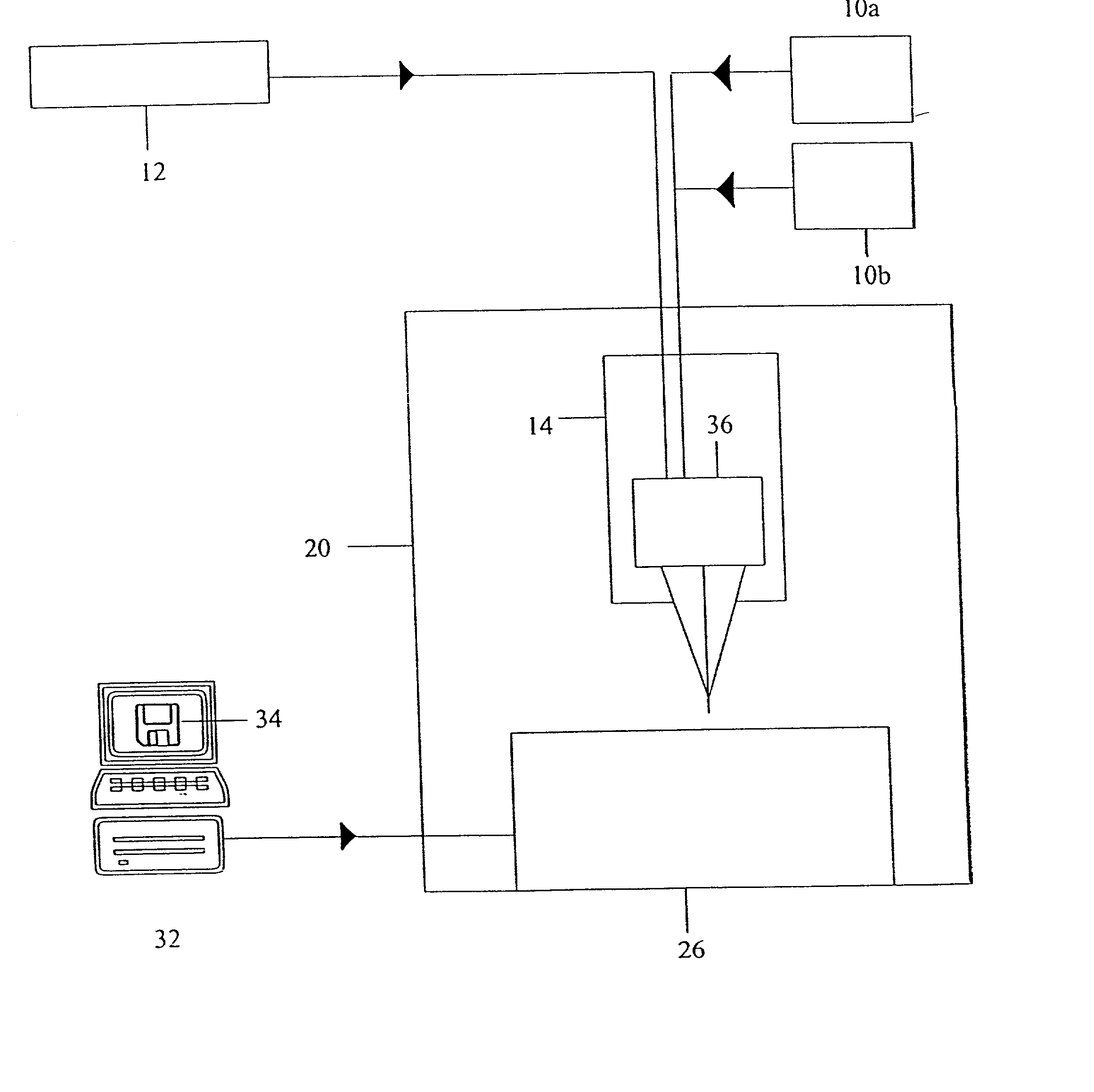

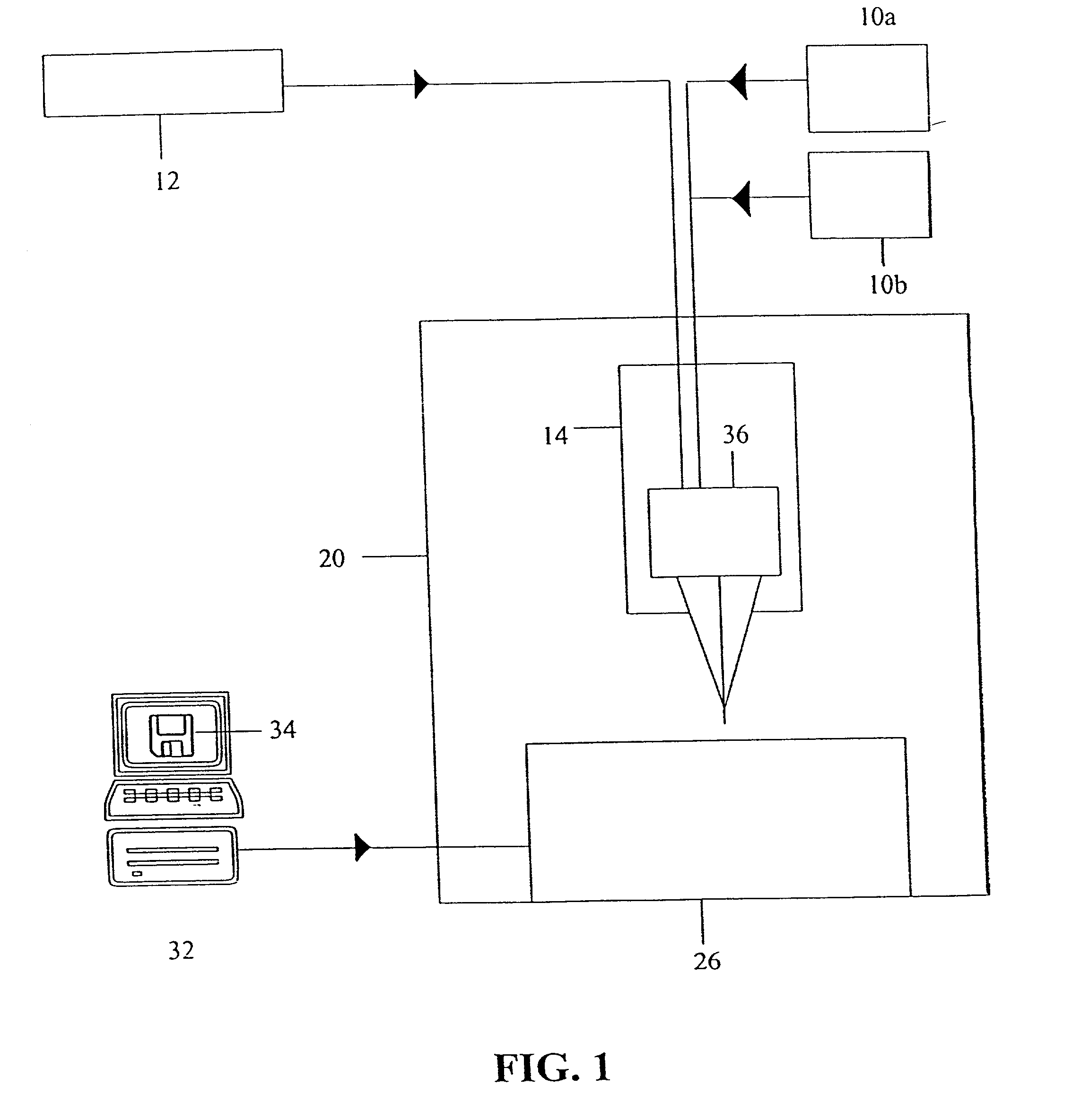

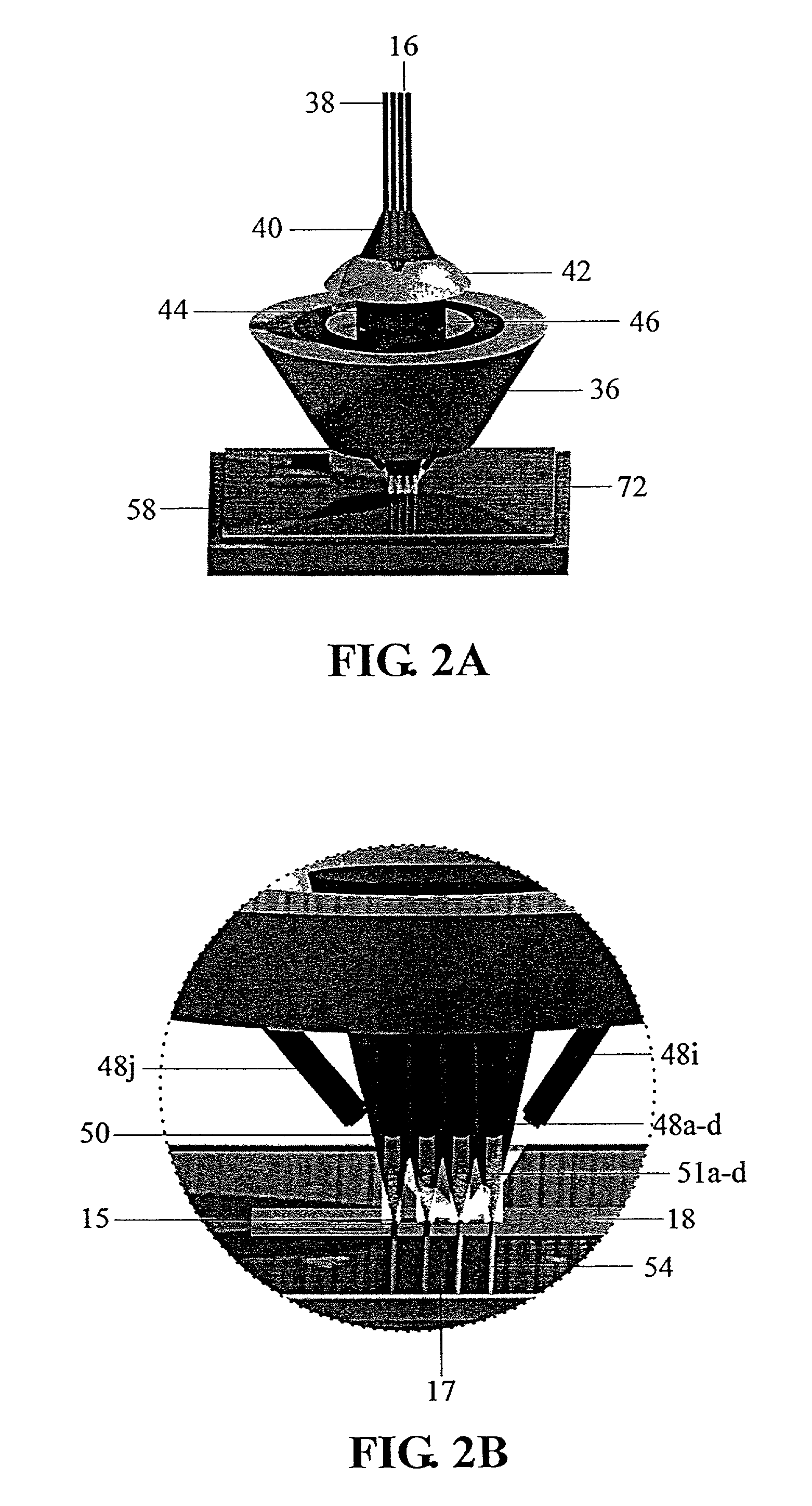

Multiple beams and nozzles to increase deposition rate

A method has been developed to exploit the desirable material and process characteristics provided by a low powered laser material deposition system, while overcoming the low material deposition rate imposed by the same process. One application of particular importance for this invention is direct fabrication of functional, solid objects from a CAD solid model This method of fabrication uses a software interpreter to electronically slice the CAD model into thin horizontal layers that are subsequently used to drive the deposition apparatus. The apparatus uses a single laser beam to outline the features of the solid object and then uses a series of equally spaced laser beams to quickly fill in the featureless regions. Using the lower powered laser provides the ability to create a part that is very accurate, with material properties that meet or exceed that of a conventionally processed and annealed specimen of similar composition. At the same time, using the multiple laser beams to fill in the featureless areas allows the fabrication process time to be significantly reduced.

Owner:OPTOMEC DESIGN CO

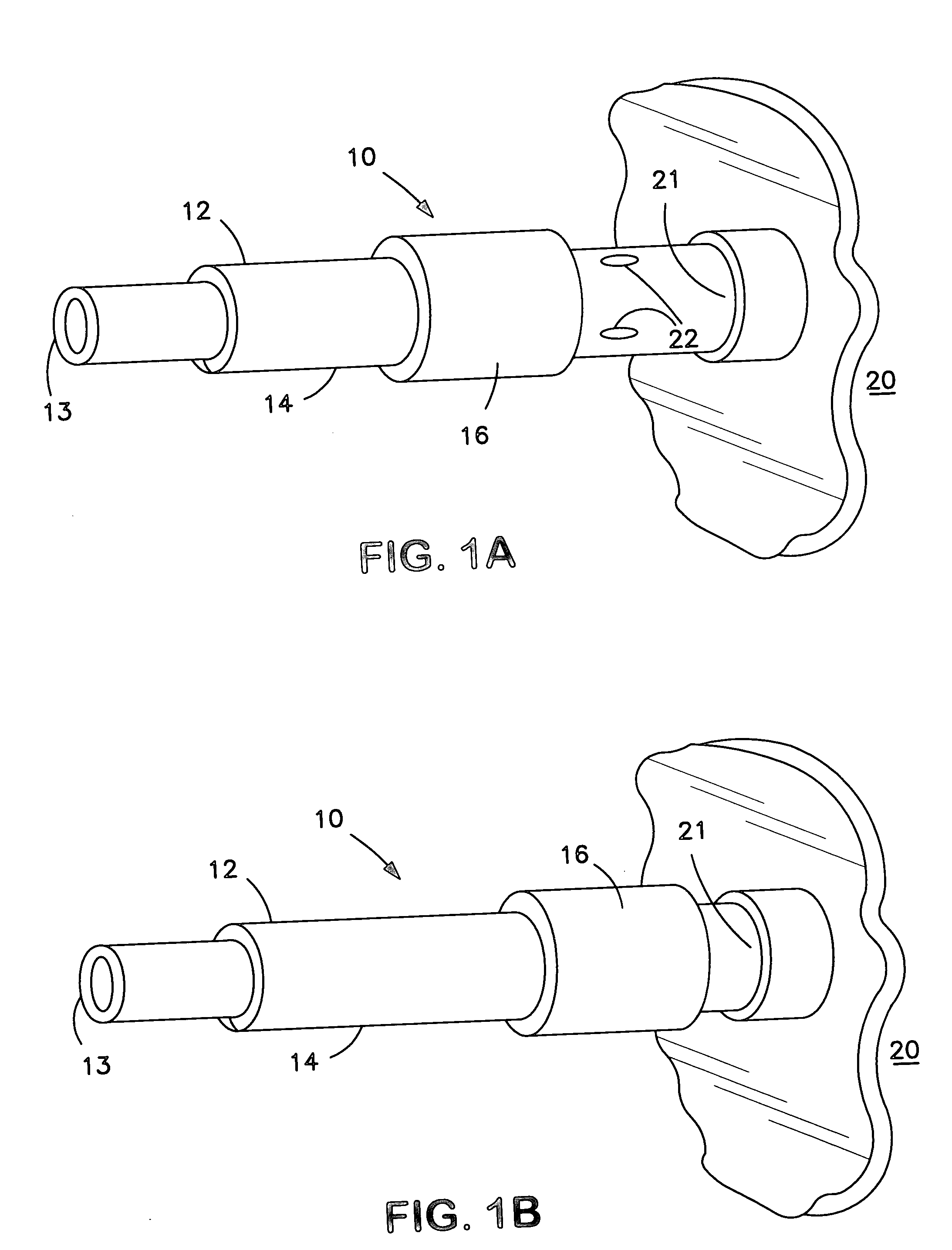

Spray gun reservoir with oversize, fast-fill opening

InactiveUS20060049277A1Improve further our existing systemSimple wayBurnersFunctional valve typesReduced sizeEngineering

A spray gun reservoir has an oversize central opening 130 at one end allowing liquid to be added to the reservoir for fast filling with reduced risk of spillage. A cap member 132 is connectable to the reservoir and has a spout 115 providing a fluid outlet of reduced size relative to the opening 130 for connection to the spray gun. The reservoir can be disconnected from the cap member 132 when it is desired to add liquid to the reservoir. In this way, the reservoir can be re-filled in use.

Owner:3M INNOVATIVE PROPERTIES CO

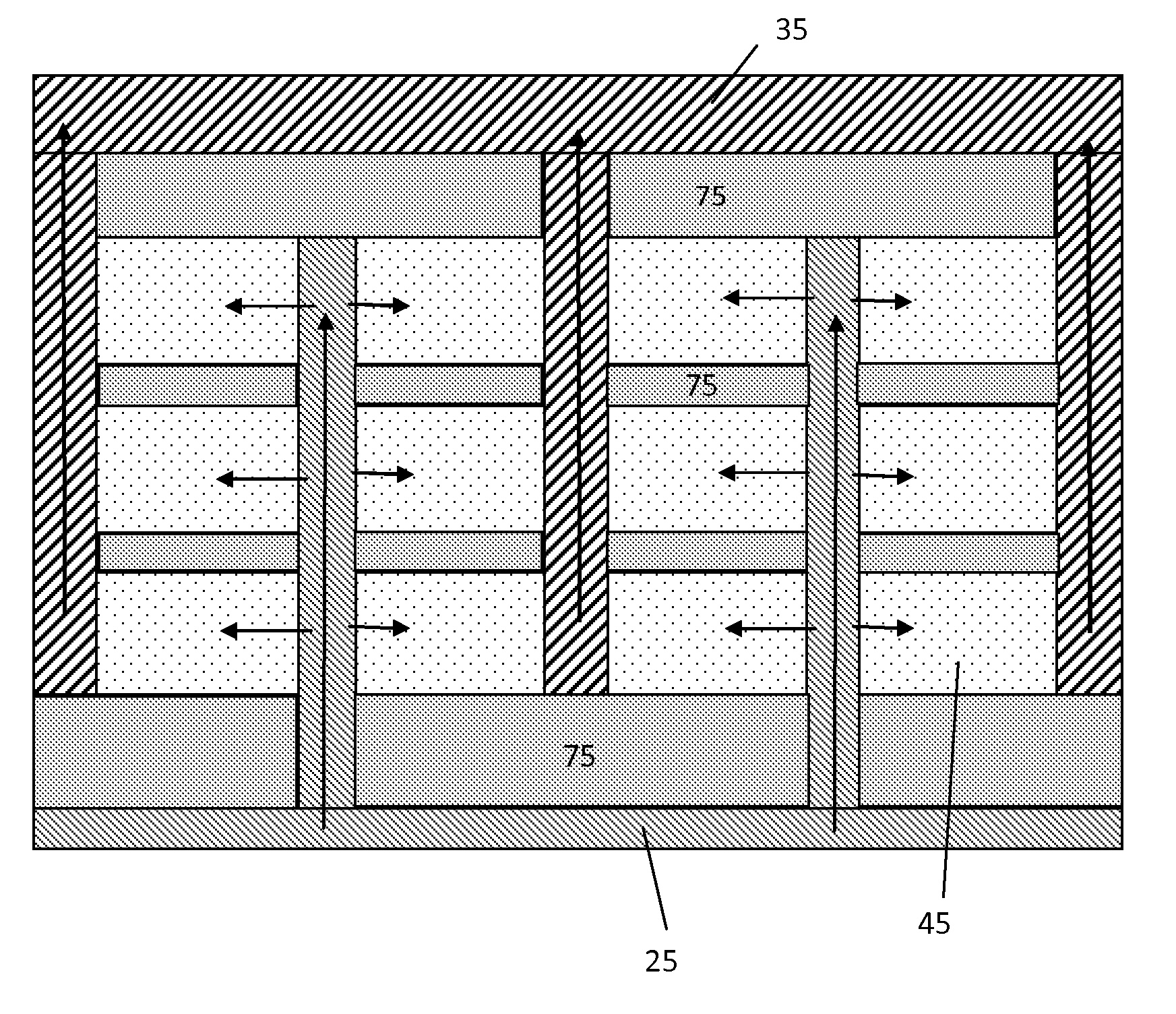

Preparation of thin layers of a fluid containing cells for analysis

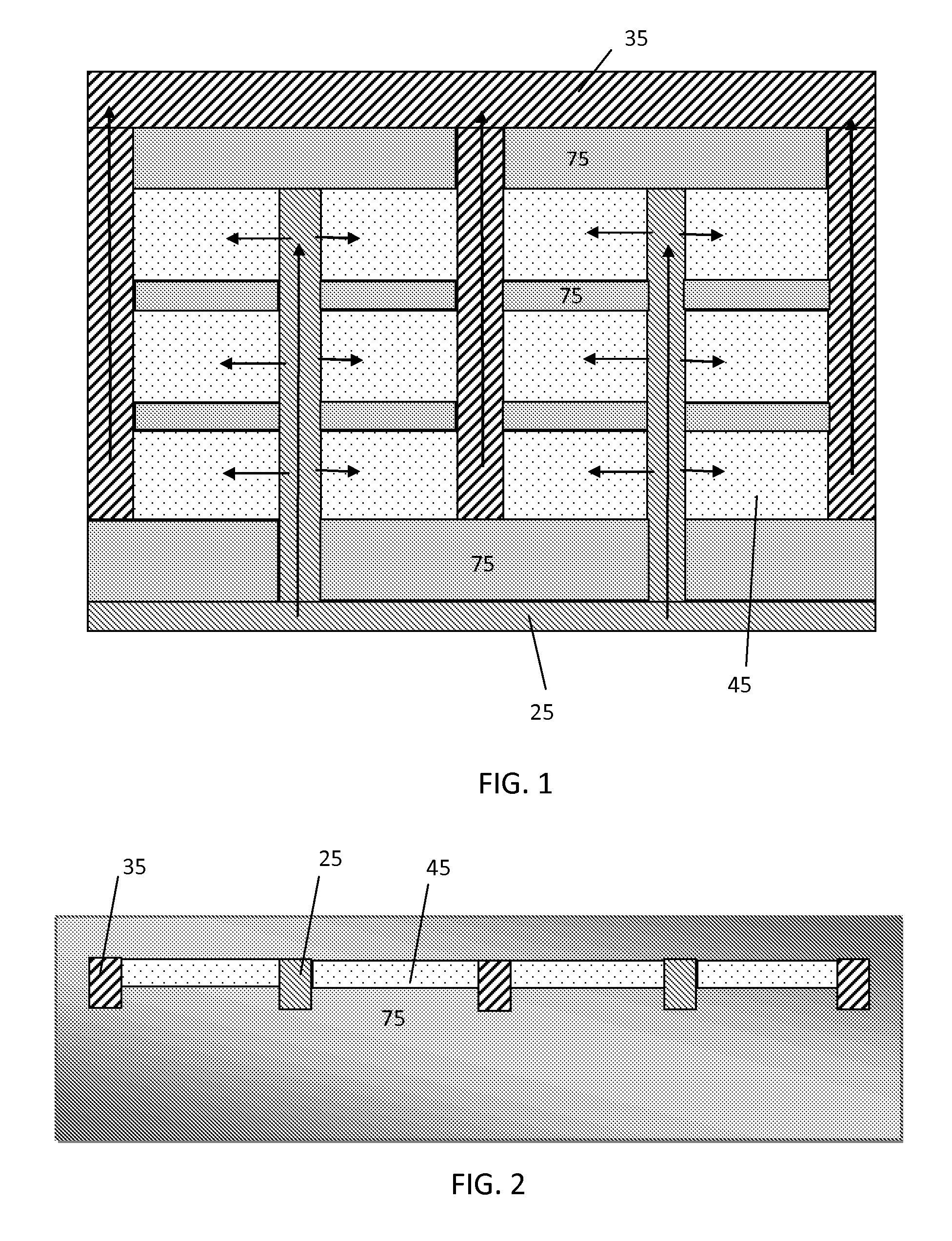

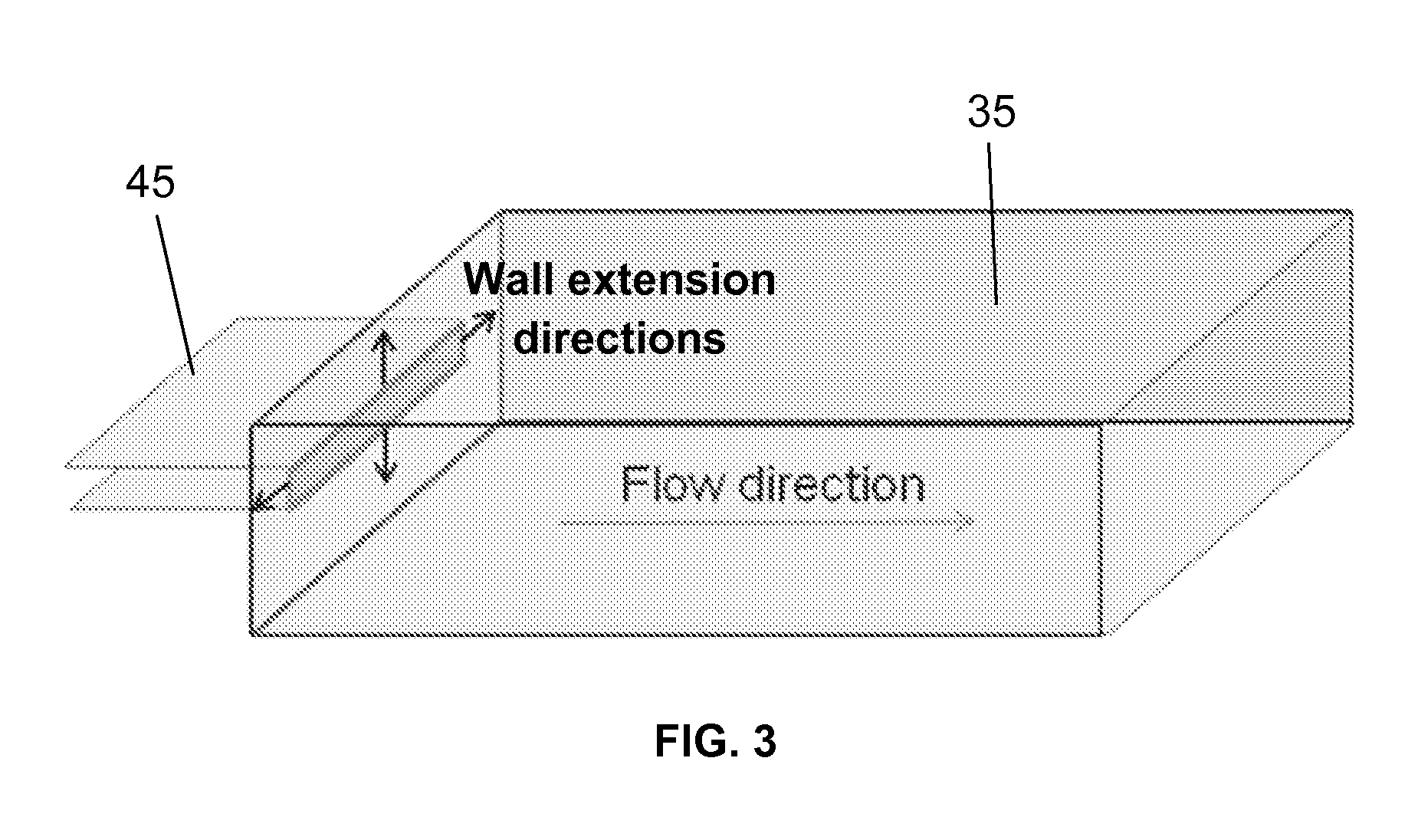

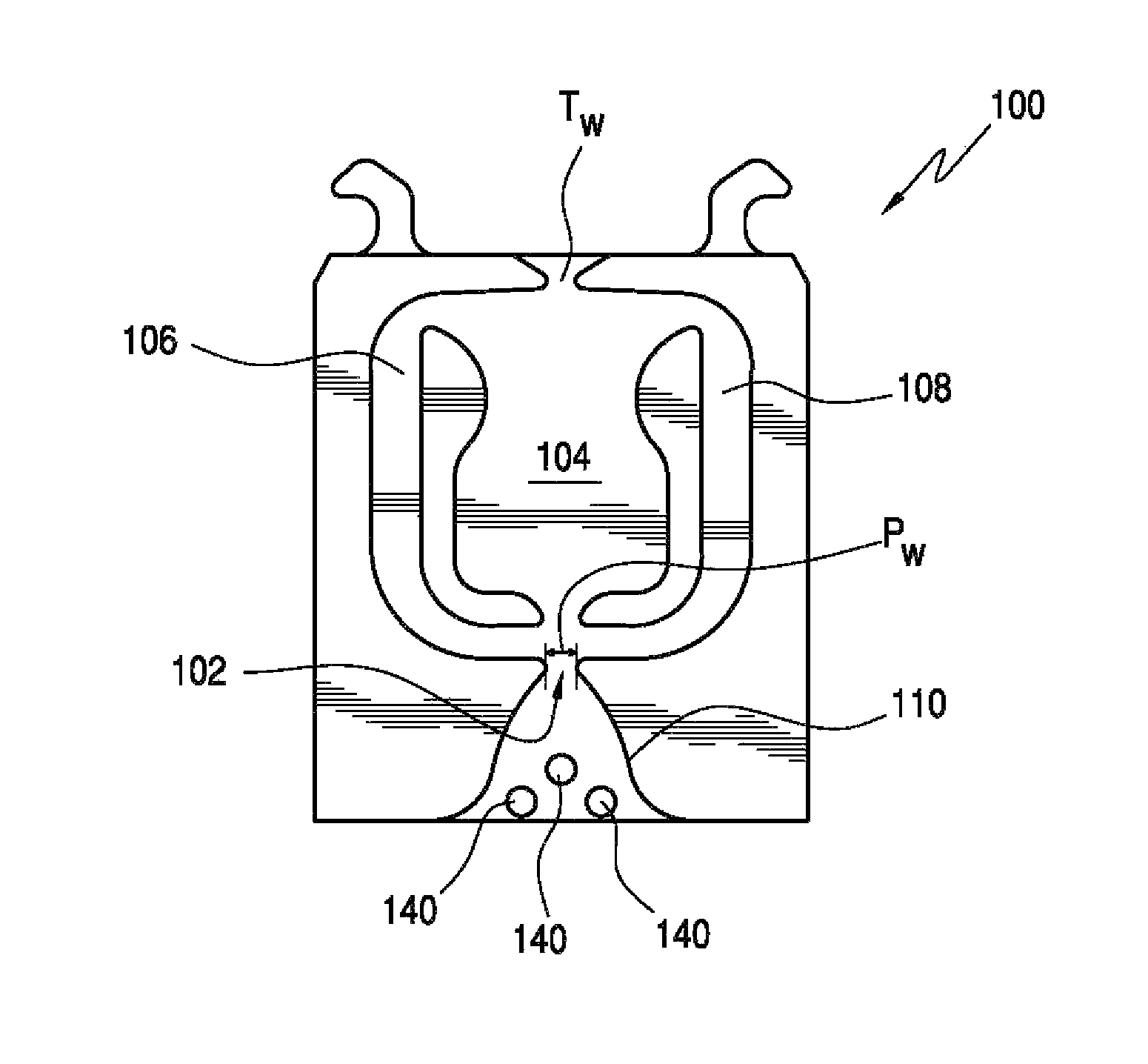

ActiveUS9470609B2Fast fillReduce variationBioreactor/fermenter combinationsBiological substance pretreatmentsFast fillingEngineering

Apparatus for producing thin layers of a fluid sample for analysis, has a two dimensional array of analysis chambers (45), and a branching pattern of entry channels (25) coupled to the array to enable the analysis chambers to be filled in parallel. The analysis chambers are planar with a height less than that of the entry channels so as to produce the thin layers when filled with the fluid sample. The array enables more spacers between chambers in a given area, so that variations in height of the chambers can be reduced, while still enabling fast filling of the chambers. The analysis chambers can be suitable for capillary filling by a specified fluid sample such as blood. A pattern of exit channels (35) can be coupled to the array. The entry and exit channels can form comb patterns, fingers of the comb patterns being interdigitated, and the analysis chambers being arranged between the interdigitated fingers of the comb patterns.

Owner:KONINK PHILIPS ELECTRONICS NV

Nozzle and fluidic circuit adapted for use with cold fluids, viscous fluids or fluids under light pressure

Owner:DLHBOWLES INC

Iron core tailing curing agent, iron core all-tailing cementing composition containing iron core tailing curing agent and application of iron core all-tailing cementing composition to gob of mine

The invention relates to an iron core tailing curing agent, an iron core all-tailing cementing composition containing the iron core tailing curing agent and an application of the iron core all-tailing cementing composition to a gob of a mine and belongs to the technical field of underground mining of metals and nonmetals. The tailing curing agent comprises the following components in parts by weight: 0.4-0.6 part of ground water-granulated blast furnace slag, 0.2-0.3 part of red mud, 0.2-0.4 part of active mineral admixture, 0.03-0.05 part of activity activator and 0.03-0.1 part of hydroxides of alkali metals or hydroxides of alkaline-earth metals. The iron core tailing curing agent provided by the embodiment of the invention is a high-efficiency novel environment-friendly cementing material with low cost and high early strength, can be used for realizing fast filling and fast curing of the gob, can be widely applied to the field of geotechnical engineering, such as mine mining and foundation treatment and has a very wide market prospect.

Owner:建研建材有限公司

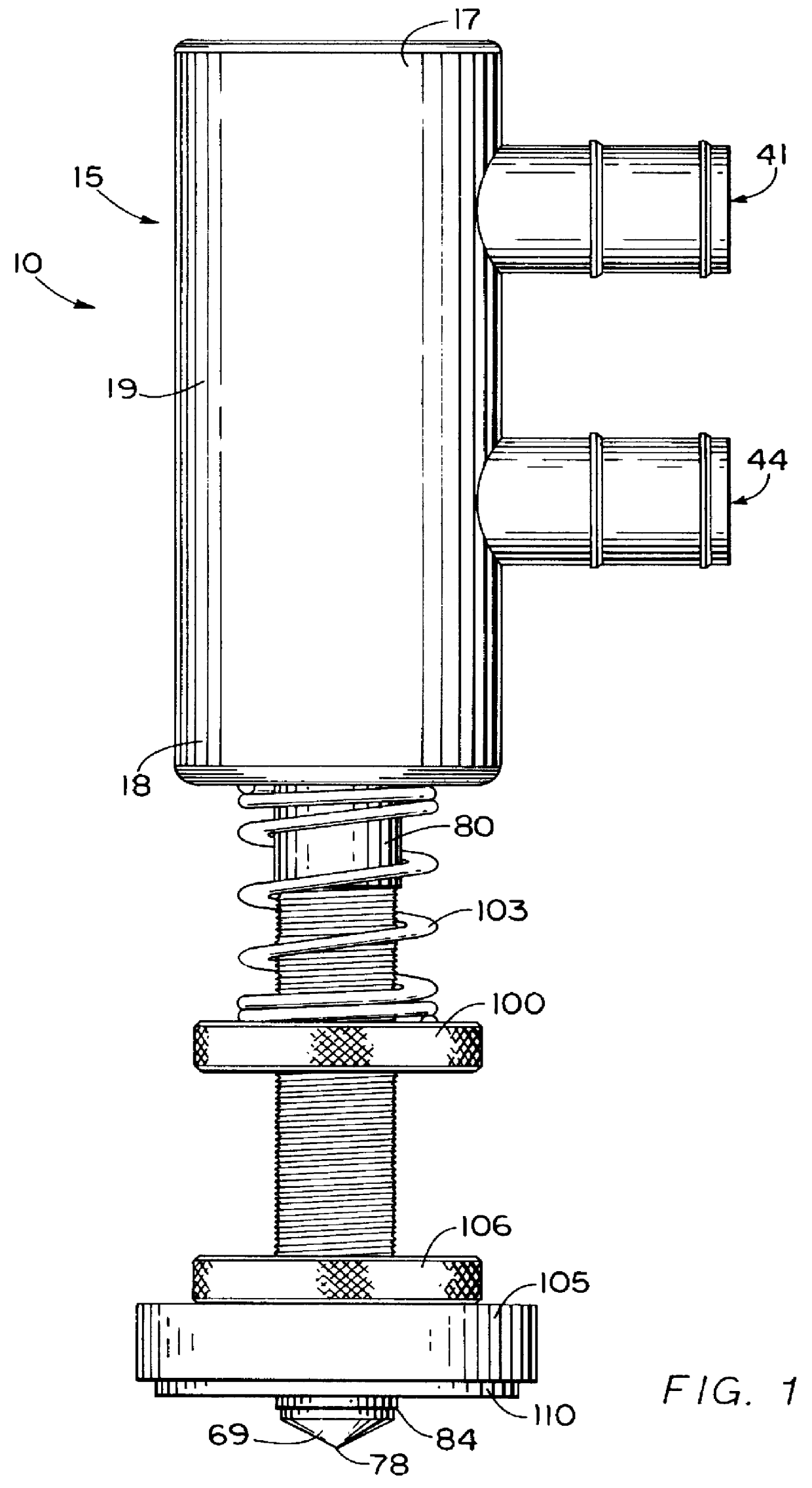

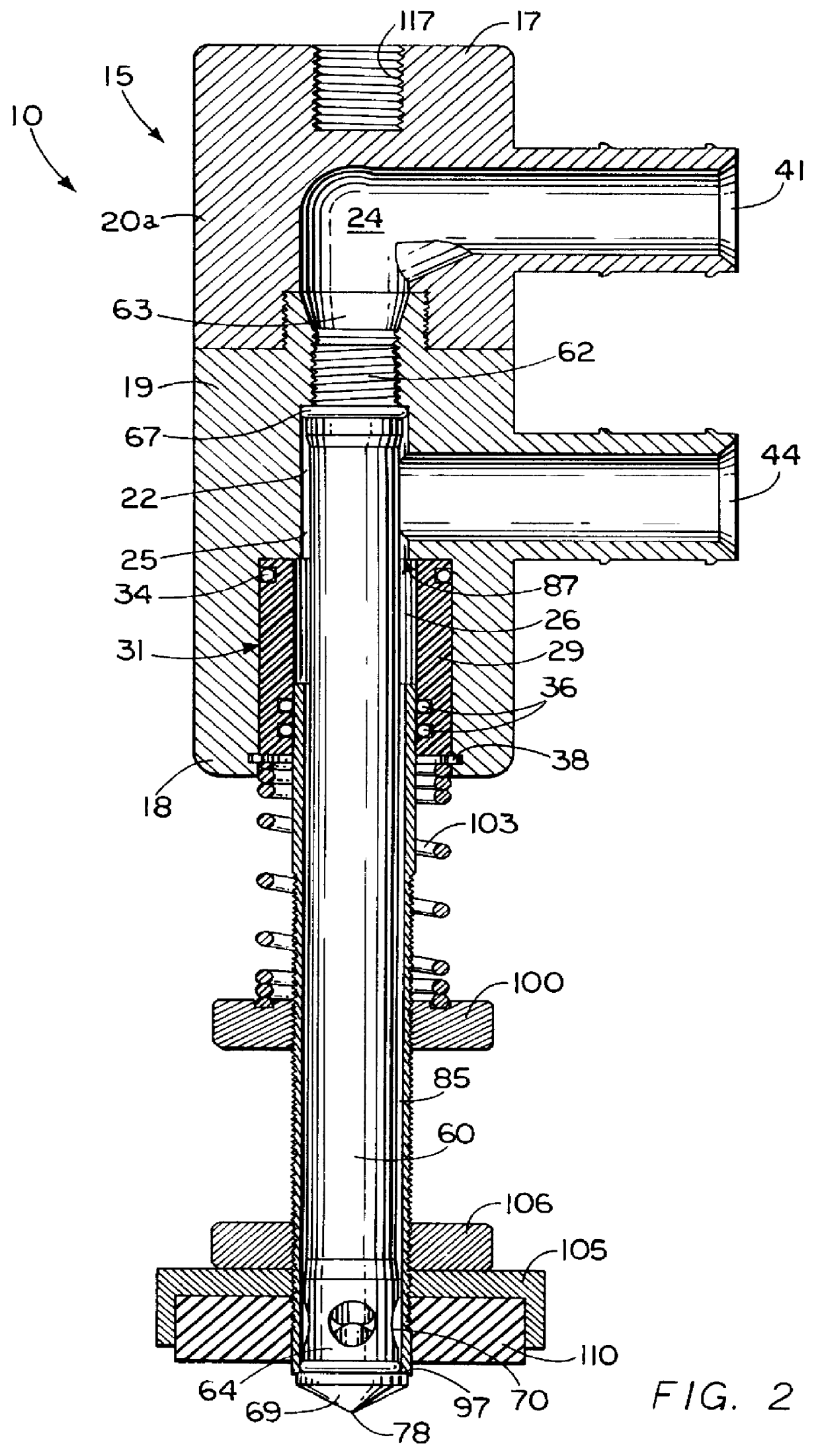

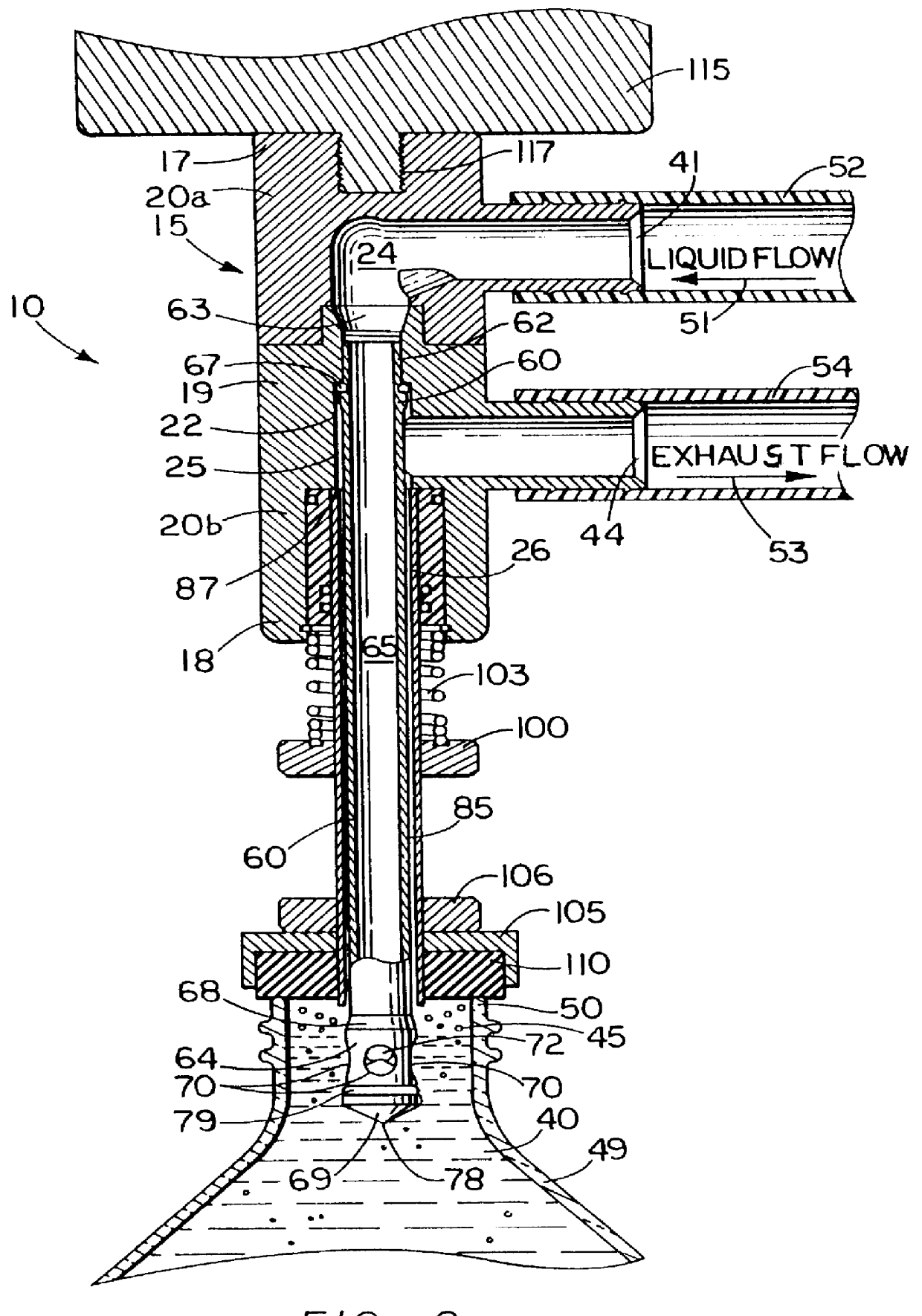

Method and apparatus for a filler valve

InactiveUS6135167AEasily employedIncrease flow rateLiquid fillingSolid materialEngineeringFast filling

An improved filling valve specially configured for attachment onto a conventional, high speed liquid filling machine that is typically utilized in food product container packaging lines to quickly fill large numbers of containers, such as bottle or cans. A filler valve has several improvements that result in greater reliability in operation, increased operational speed, and easier adjustment in operational parameters. The filler valve including a manifold that receives a manifold insert and a spring nut that abuts to a slider. The slider is the only moving part of the filler valve. A filler stem is received through the slider and attaches to the manifold. For filling, the top opening of a bottle is placed against a spanner nut and the manifold lowered, thereby compressing the slider into the manifold to insert the stem into the container. A liquid is then injected into the container, while displaced air is exhausted into the co-axial annular space between the stem and the slider. The stem also preferably contains four outlet ports.

Owner:KIHOLM INDS

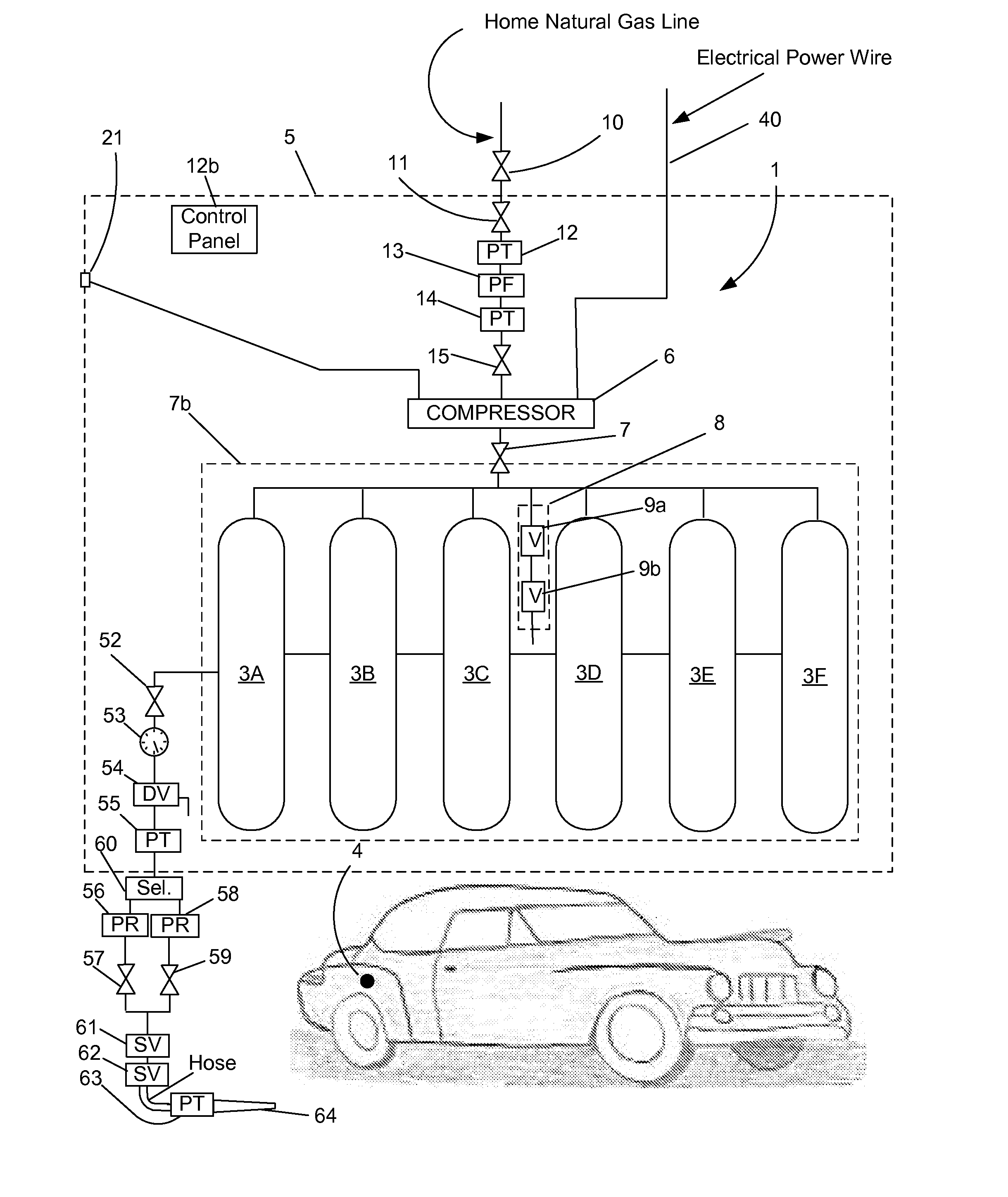

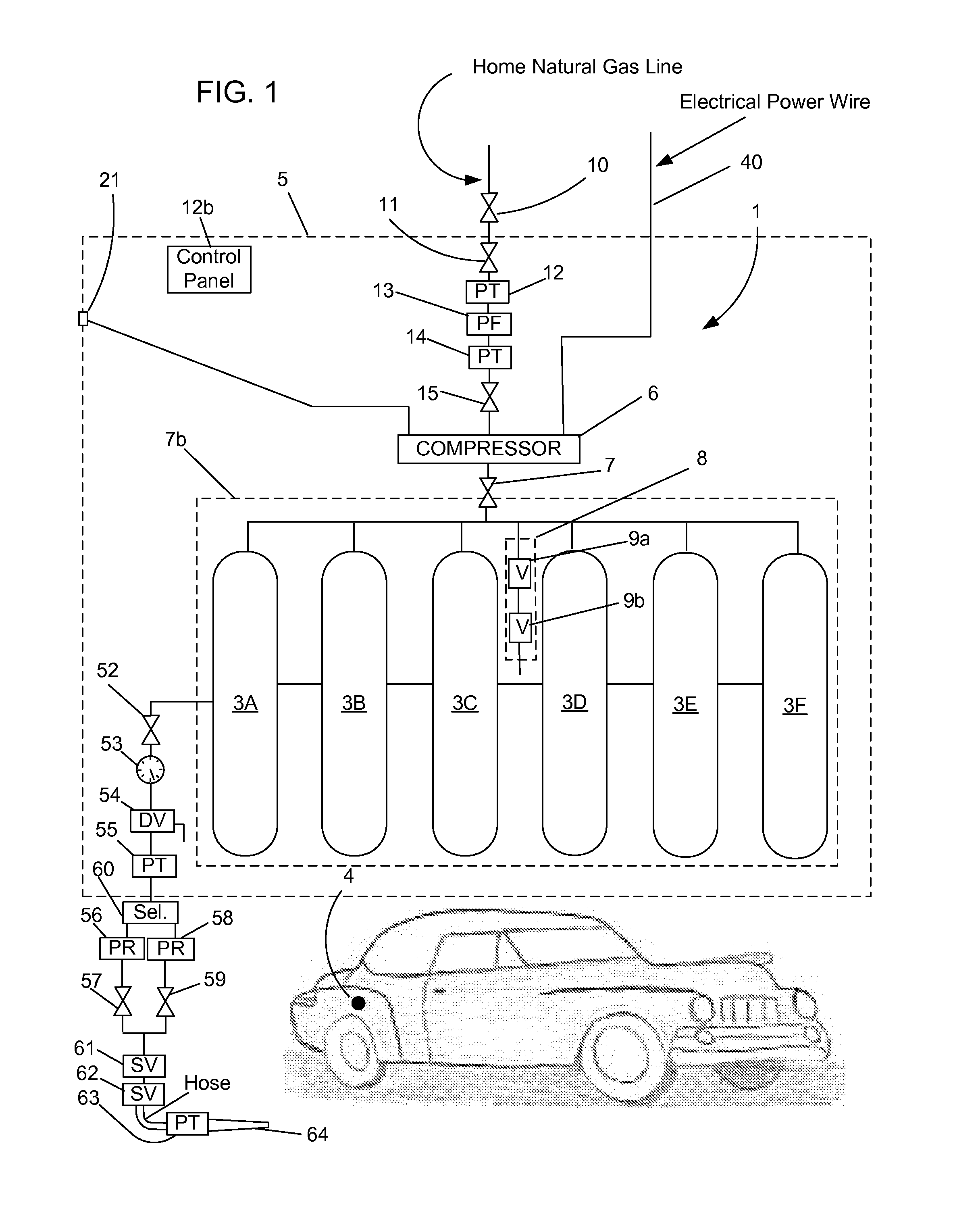

Natural gas home fast fill refueling station

InactiveUS20140130938A1Quick refuelingVessel mounting detailsVessel geometry/arrangement/sizeNatural gas storageProcess engineering

A home based fast-fill natural gas refueling station for providing natural gas fuel to a vehicle. A compressor is attached to the natural gas fill line. The compressor functions to pressurize a natural gas storage tank array. The storage tank array includes a plurality of natural gas storage tanks. A pressurized natural gas storage tank exit line is connected to a frontmost storage tank and a fill nozzle is connected to the storage tank exit line. During the refueling process the compressor is turned off. Also, during the refueling process as the pressure is depleted in the frontmost storage tank the frontmost storage tank is simultaneously and rapidly repressurized by other storage tanks in the storage tank array allowing for fast refueling of the vehicle.

Owner:LUPARELLO MICHAEL J

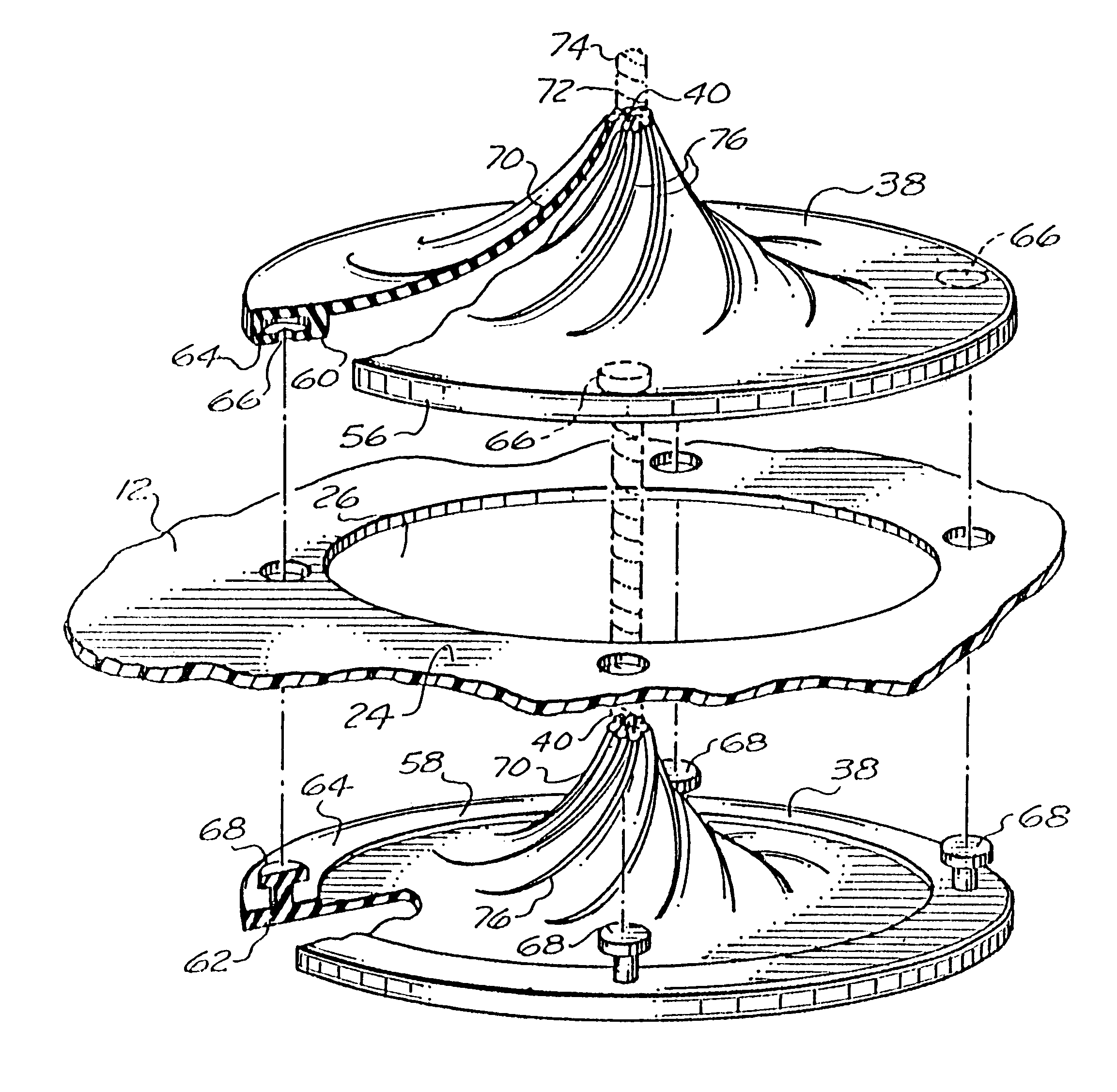

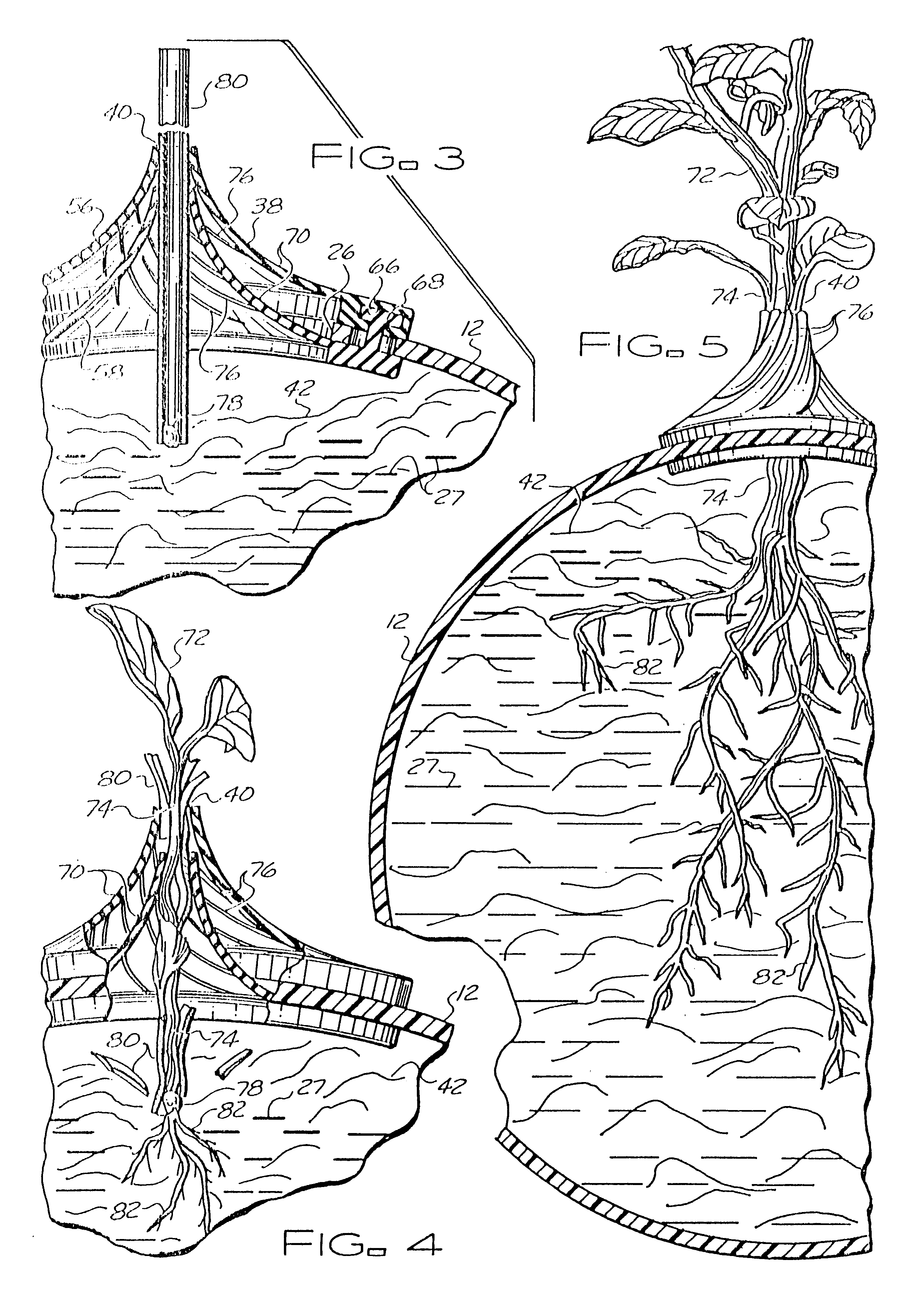

Hydroponic cultivation apparatus and method

InactiveUS6360483B1Reduce maintenanceReduce operating expensesAgriculture gas emission reductionCultivating equipmentsGrowth plantPlant stem

An apparatus which includes a growing container in which plants are hydroponically grown on a support medium is disclosed. The growing container includes a plurality of openings in which seals are installed. The seals include holes through which the plants grow. When seeds are planted, a hollow tube is placed through the seal hole to maintain the seed in position. After the seed germinates, it grows through the tube. As continued growth expands the plant's stem to the size of the tube, the tube breaks apart and does not constrain future plant growth. Moreover, as the plant grows further, the seal hole expands to accommodate the plant stem. The seal surrounds and contacts the plant stem to reduce evaporation of nutrient solution from the growing container and to keep insects and contamination out of the growing container. A holding container is positioned above the growing container and coupled to the growing container through a manifold arrangement. The holding container may be quickly filled with a single, measured nutrient solution charge for the growing container. Then, a valve is opened, and the manifold arrangement slowly distributes the nutrient solution to the growing container where it is substantially absorbed by the support medium and wicked to the vicinity of the plant within the growing container.

Owner:SHERFIELD CHARLES O

Valve for speed filling a dunnage bag

ActiveUS7455086B1Increase in flow through rateLiquid flow controllersLiquid transferring devicesDunnageFast filling

Owner:SIGNODE IND GRP

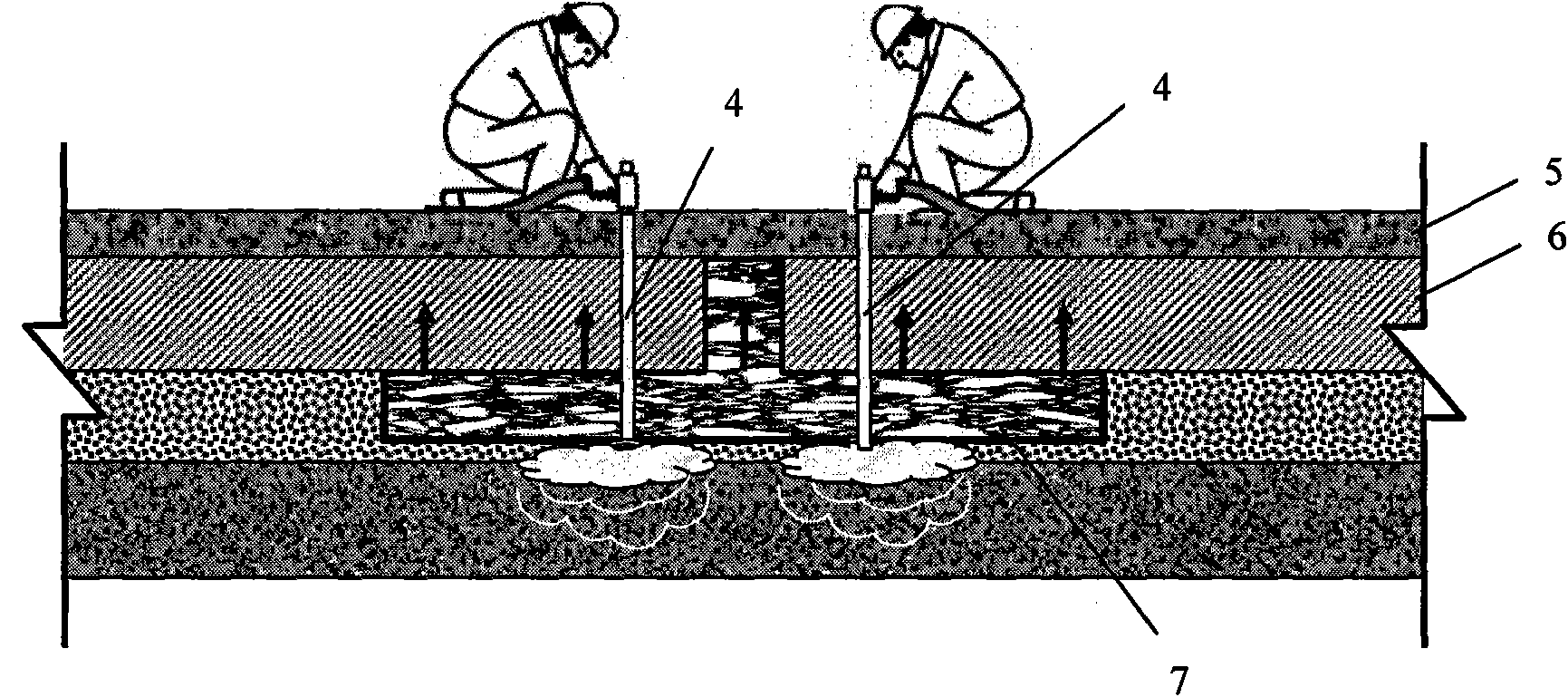

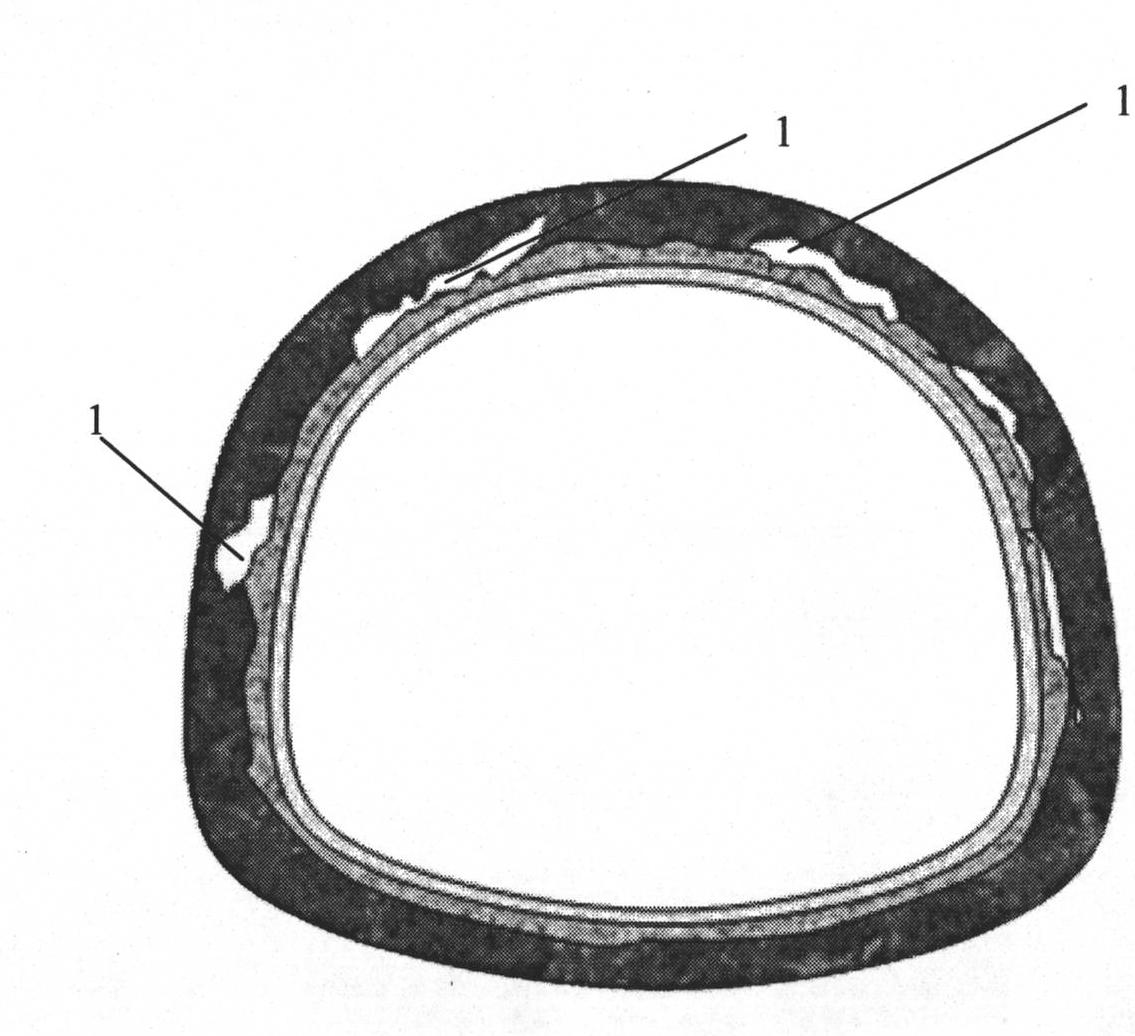

High polymer grouting technology for treating tunnel void and construction method thereof

InactiveCN102052081AIncreased durabilityIncrease elasticityUnderground chambersTunnel liningFast fillingTherapeutic effect

The invention discloses high polymer grouting technology for treating a tunnel void and a construction method thereof. The technology comprises the following steps of: detecting the tunnel void on the basis of a ground penetrating radar (GPR) or a falling weight deflectometer (FWD); and injecting a high polymer material to a void part according to the condition of the tunnel void, wherein after the material reacts, the volume is expanded quickly and the material is cured to quickly fill the void. The technology has the characteristics of good treatment effect, quick construction, no requirement on curing, obvious target, high controllability, cost conservation and the like. Compared with the traditional tunnel void treating method, the technology is innovative obviously in the aspects of technical principle and construction method and develops a new, quick, economical and practical way for maintaining a tunnel and enabling the tunnel to be durable.

Owner:ZHENGZHOU URETEK TECH

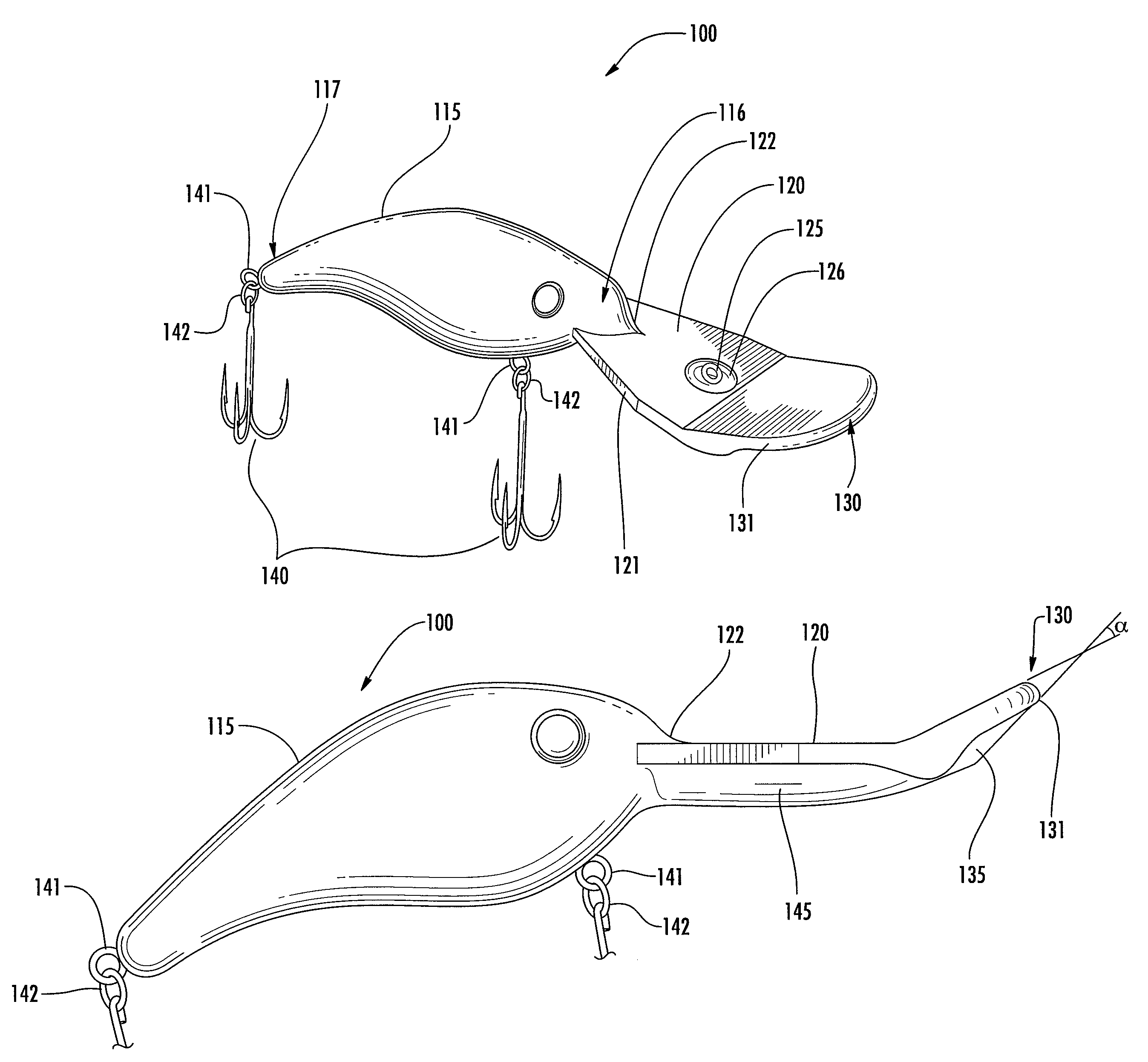

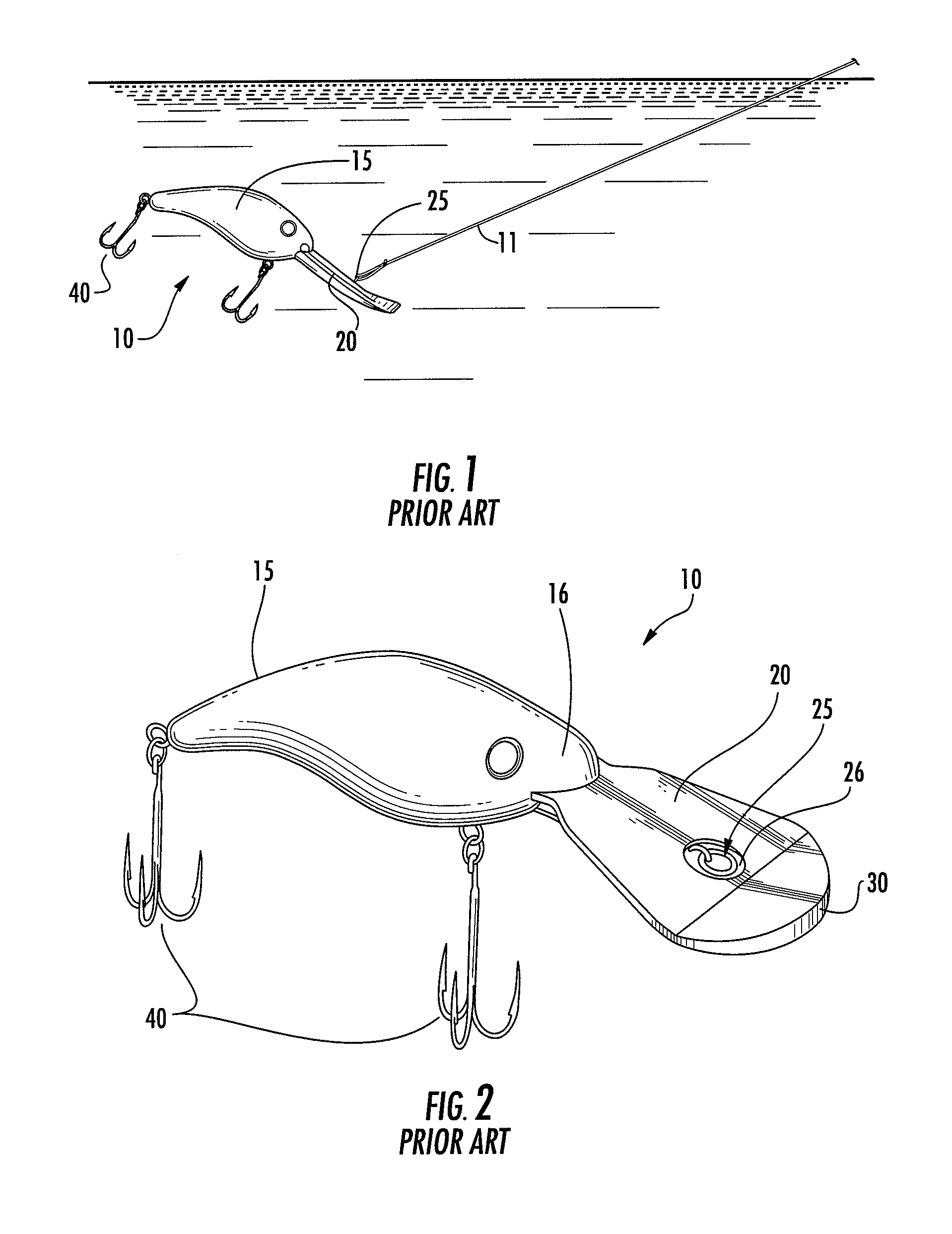

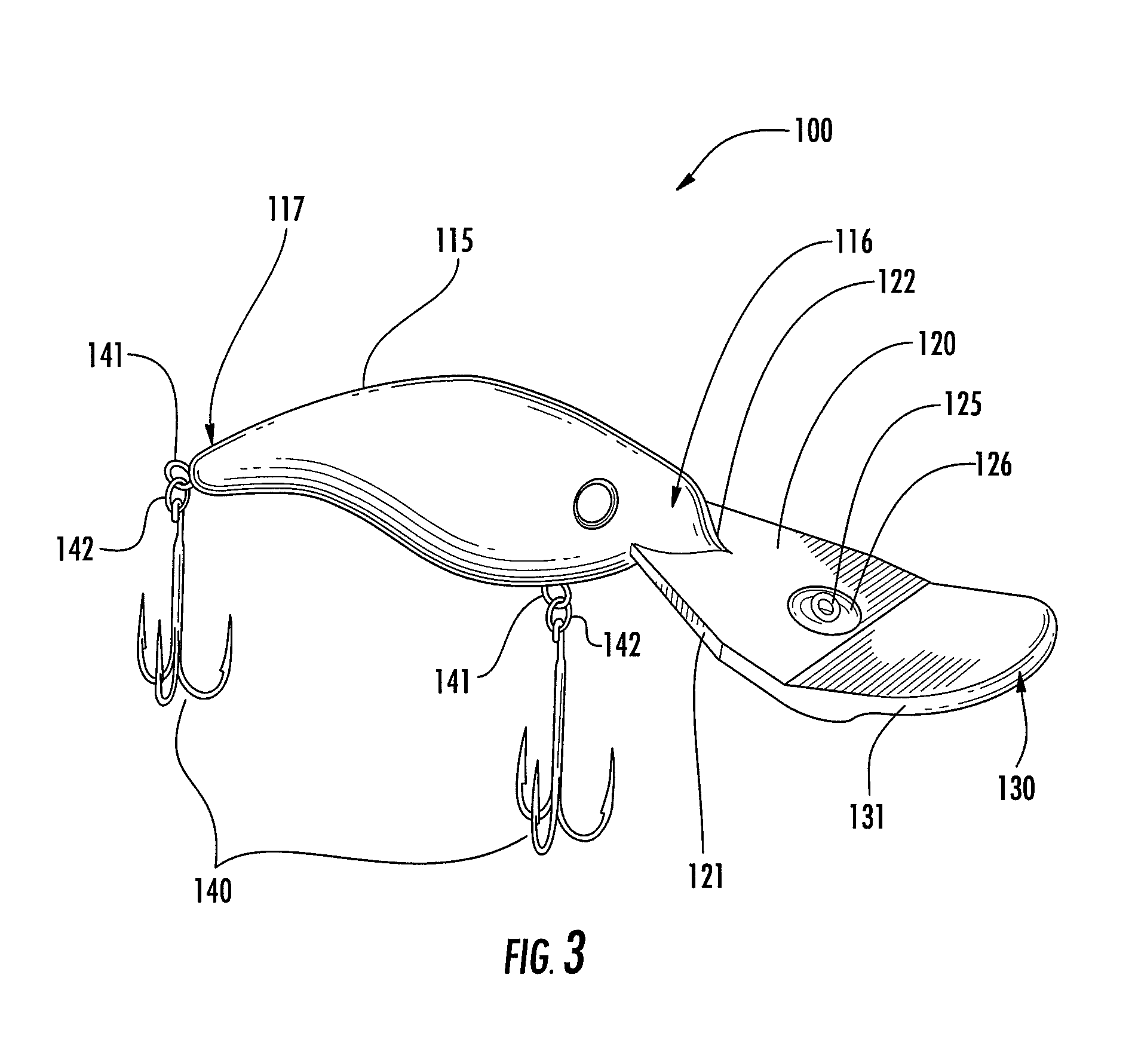

Diving fishing lures

The present invention provides an improved diving fishing lure having a more durable and stable design that is capable of assisting today's fishermen as they target fish at increasingly greater depths and at faster trolling or retrieval speeds. The fishing lure includes a lure body having first and second ends, at least one fish hook extending from the lure body, and a diving lip extending from the first end of the lure body. According to one embodiment, the fishing lure includes a connector mounted to the diving lip, wherein the diving lip defines a recessed surface at least partially around the connector having a sidewall with a radius of approximately 0.30 inches to approximately 0.40 inches.

Owner:MANNS BAIT

Coal mine gob area sealing method

ActiveCN104481588AFast fillWon't enterMining devicesGas removalSpontaneous combustionDifferential pressure

The invention discloses a coal mine gob area sealing method, and belongs to the technical field of coal mine gob area gas extraction. When retaining walls of a first sealing chamber or roadway surrounding rocks between the retaining walls are cracked, cracks can be rapidly filled by the aid of fine sand with flowability under the action of ground stress and mining dynamic stress, and tightness is ensured. By the aid of positive and negative differential pressure characteristics of a second sealing chamber, nitrogen pressure in the second sealing chamber is constantly higher than air pressure in a ventilating roadway, a gob area is separated from the ventilating roadway by the second sealing chamber, air in the ventilating roadway cannot enter the gob area, and gas in the gob area cannot permeate into the ventilating roadway. By double sealing of the first sealing chamber and the second sealing chamber, sealing reliability of the gob area is greatly improved, the probabilities of spontaneous combustion of float coal and gas explosion are minimized, and safety of nearby roadways or working faces is guaranteed.

Owner:LIAONING TECHNICAL UNIVERSITY

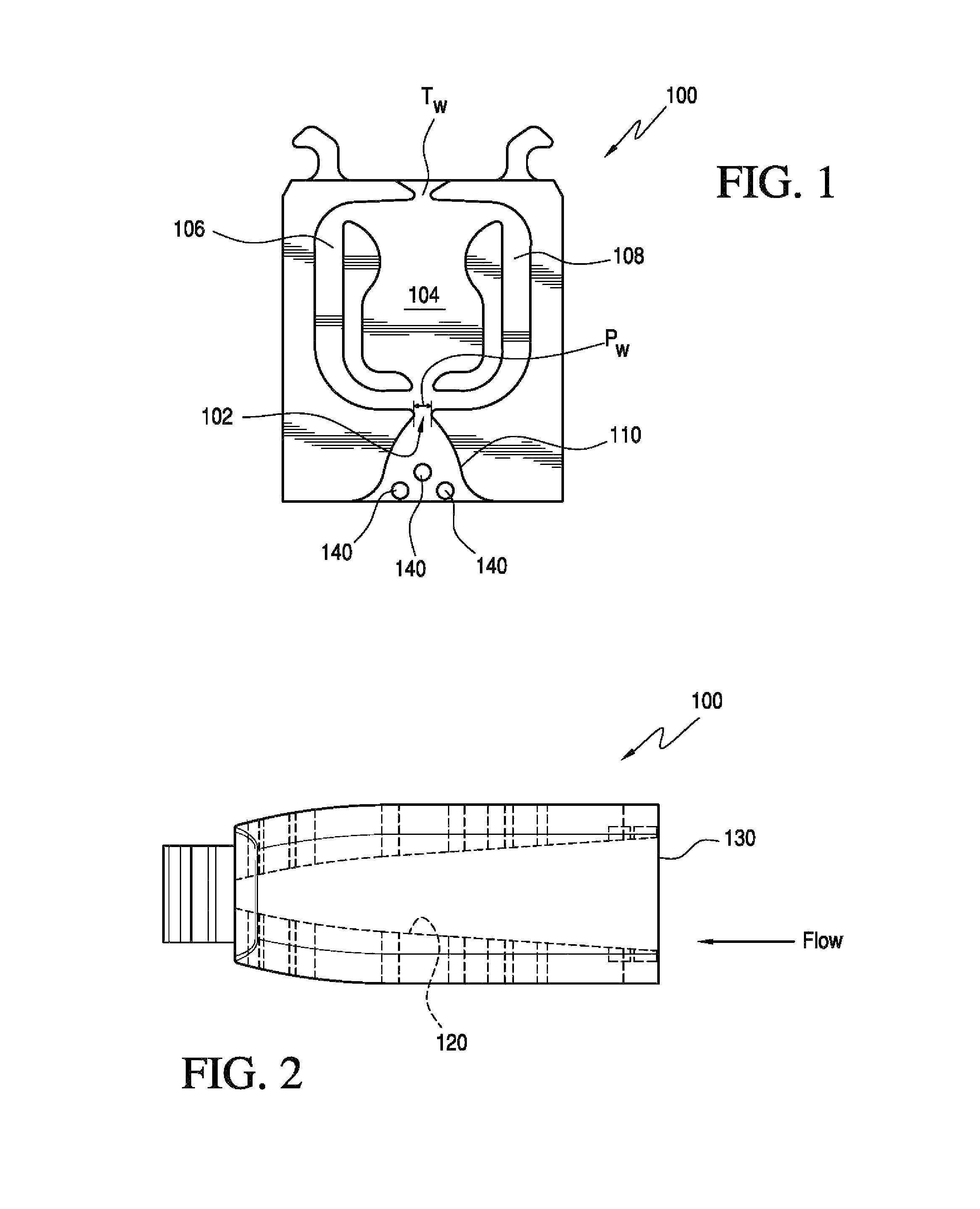

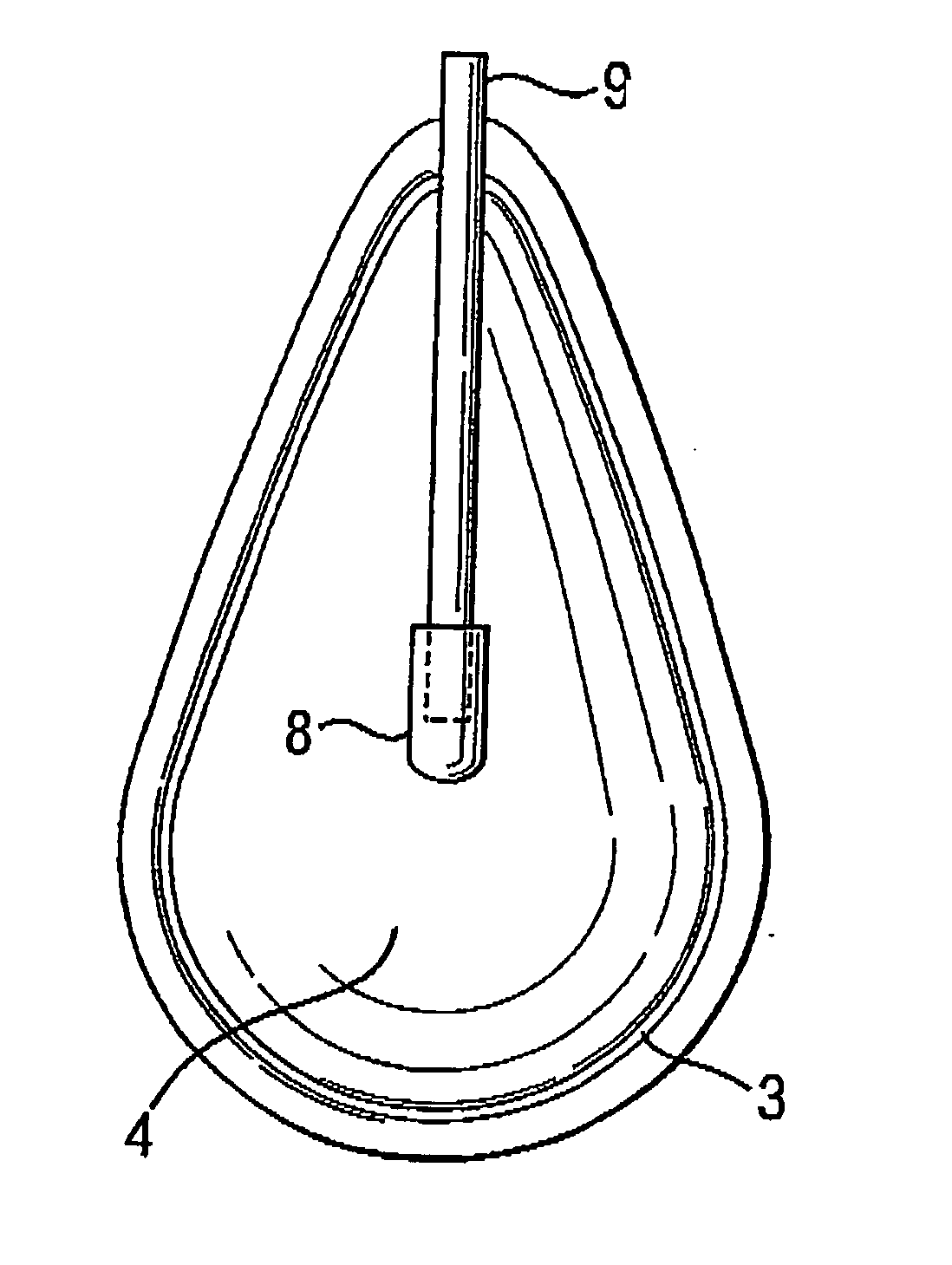

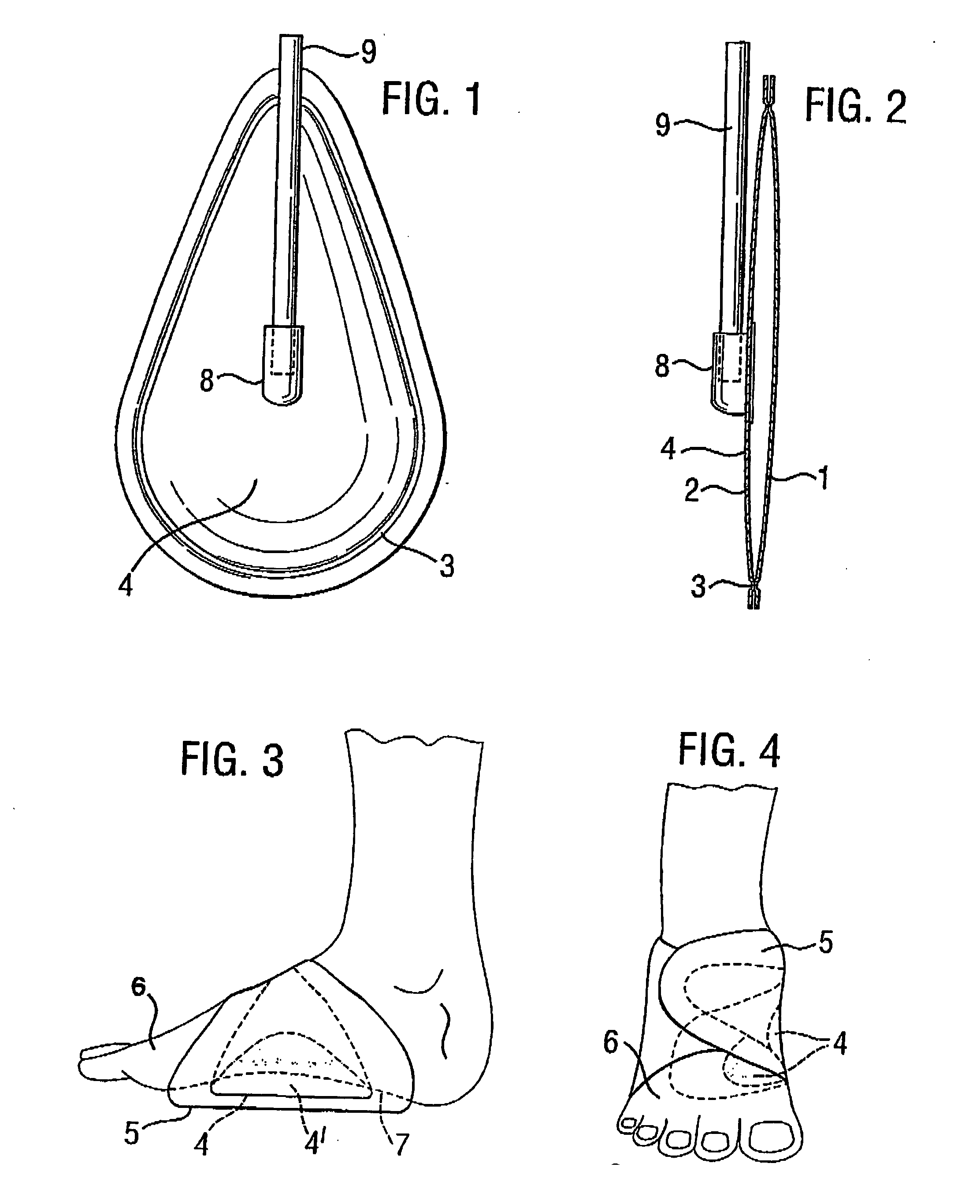

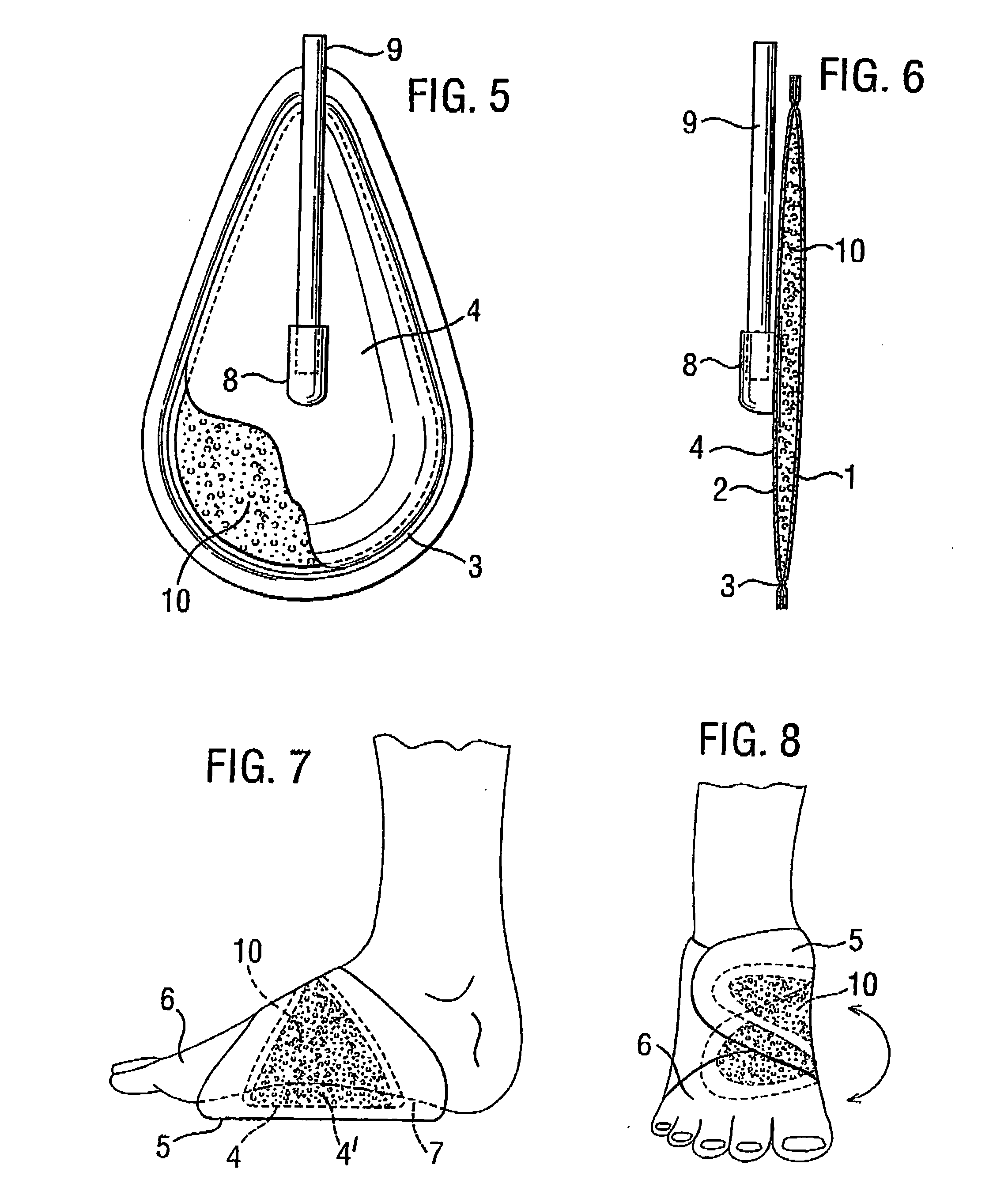

Inflatable device for use in impulse therapy

ActiveUS20060111655A1Low rate of fluid flowReduce noisePneumatic massageVibration massagePulse therapyMedicine

The invention relates to impulse therapy and particularly to a device for applying impulse pressure intermittently to a human foot to enhance blood circulation around the body. In the prior art impulse pressure is applied by means of an inflatable bladder applied to the foot. To be effective the bladder has to be filled rapidly and this produces unacceptable noise during operation. The bladder in accordance with invention is provided with internal means acting to dissipate fluid flow with accompanying reduction in fluid flow rates and consequent noise levels during the pressurisation process.

Owner:CARDINAL HEALTH IRELAND UNLTD

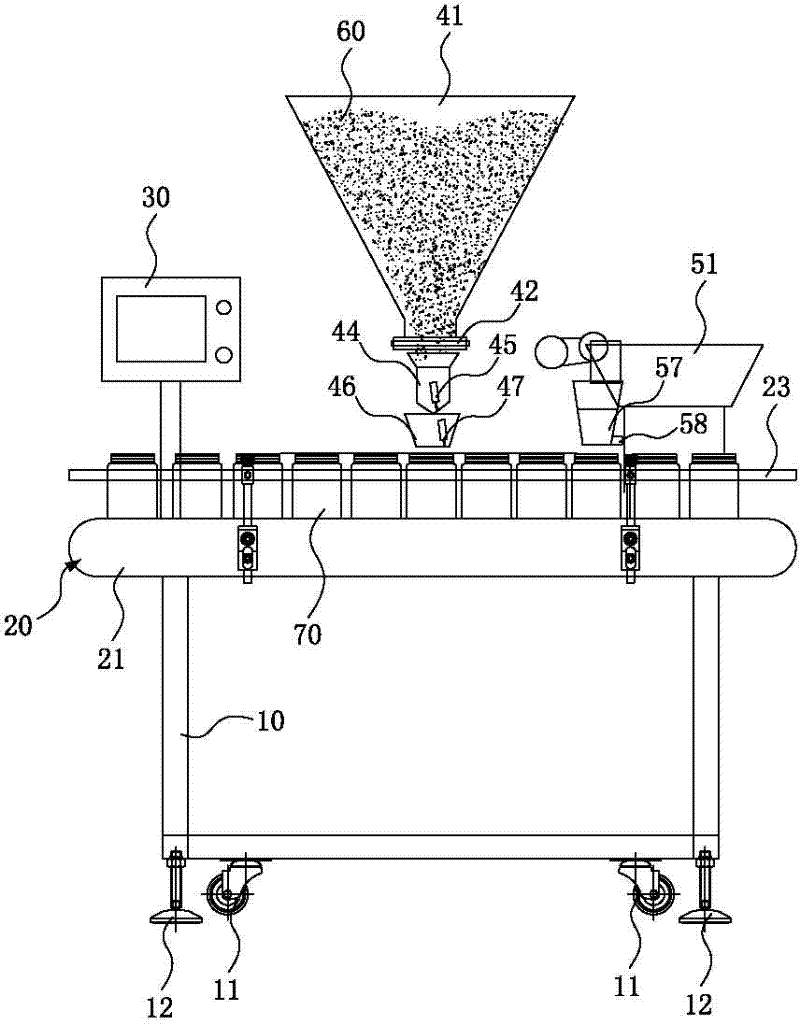

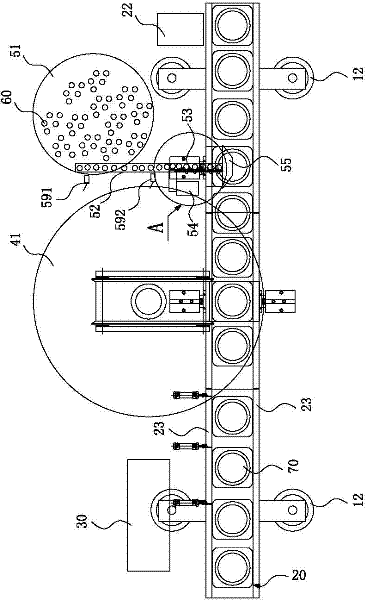

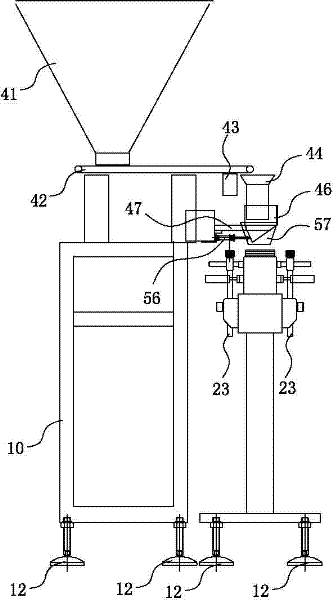

Regular particle material composition quantitative filling machine and filling method thereof

The invention discloses a regular particle material composition quantitative filling machine and a filling method thereof. The regular particle material composition quantitative filling machine comprises a coarse feeding device and a particle counting material complementing device which are sequentially arranged in the conveying direction of a conveying device, so the coarse feeding device is used for quantitative volume feeding and weighting filling on regular particle materials, then, the particle counting material complementing device is used for trace compensation baiting on a container in a particle counting mode, the filling standard can be perfectly met in the weight aspect, in addition, the whole filling process of the container adopts fully automatic and continuous operation, theautomation degree is high, and no gap retention time exists. Therefore, the filling process steps are simple and easy, the filling precision is high, the reliability is good, in addition, the fast filling can be realized, the production efficiency is improved, and the filling machine and the filling method are suitable for large-scale production.

Owner:GUANGZHOU V PACK IND CO LTD

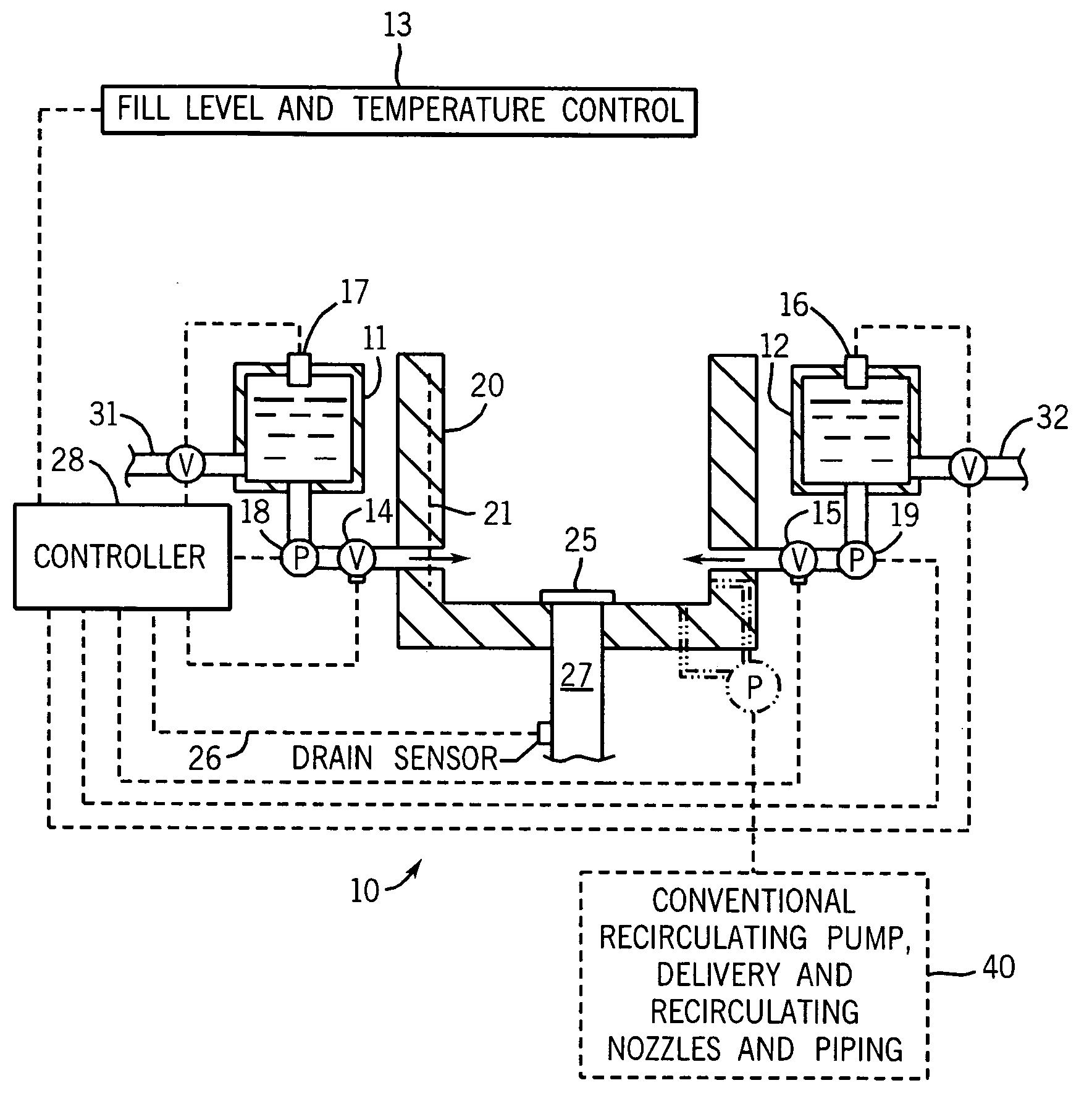

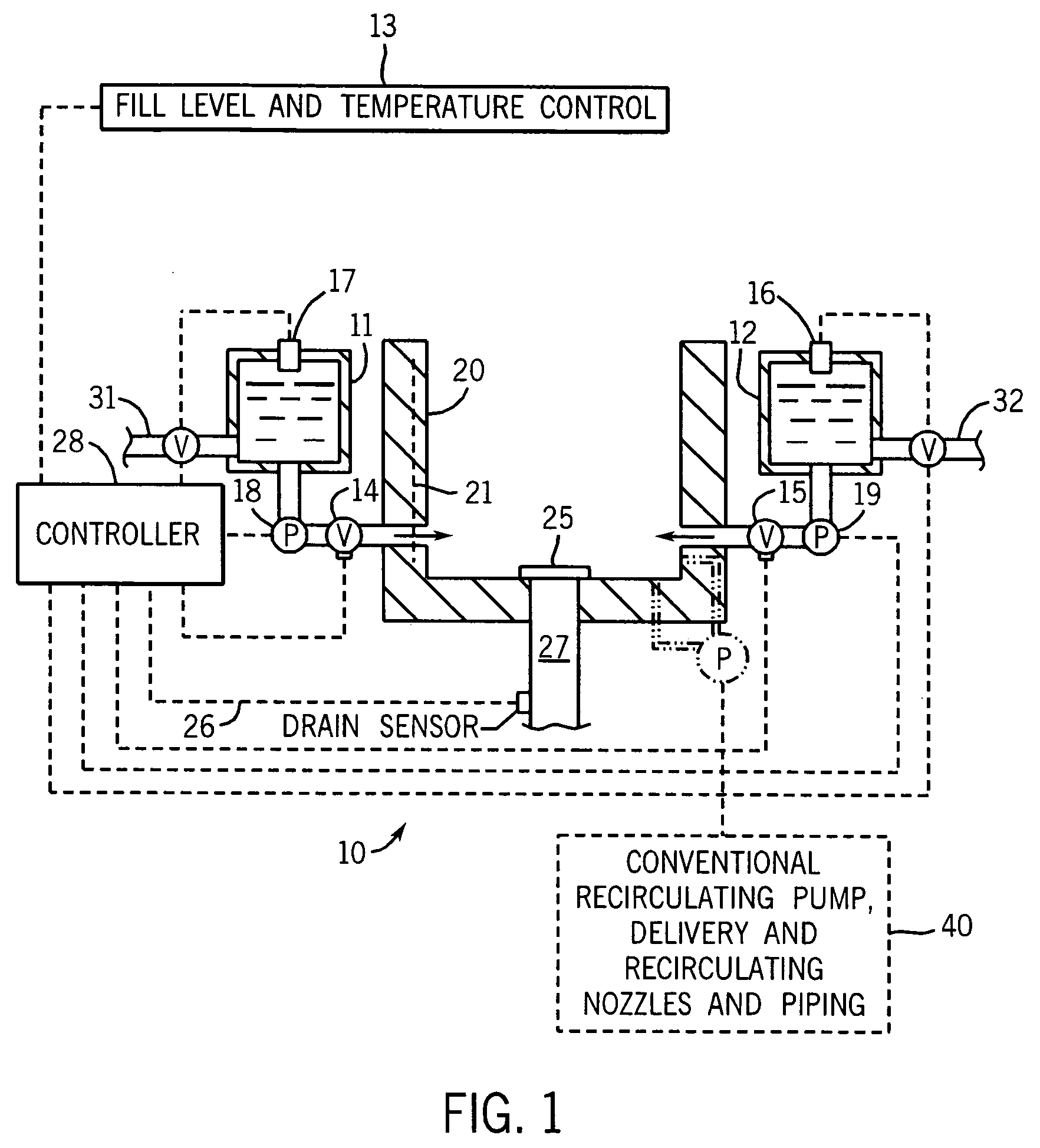

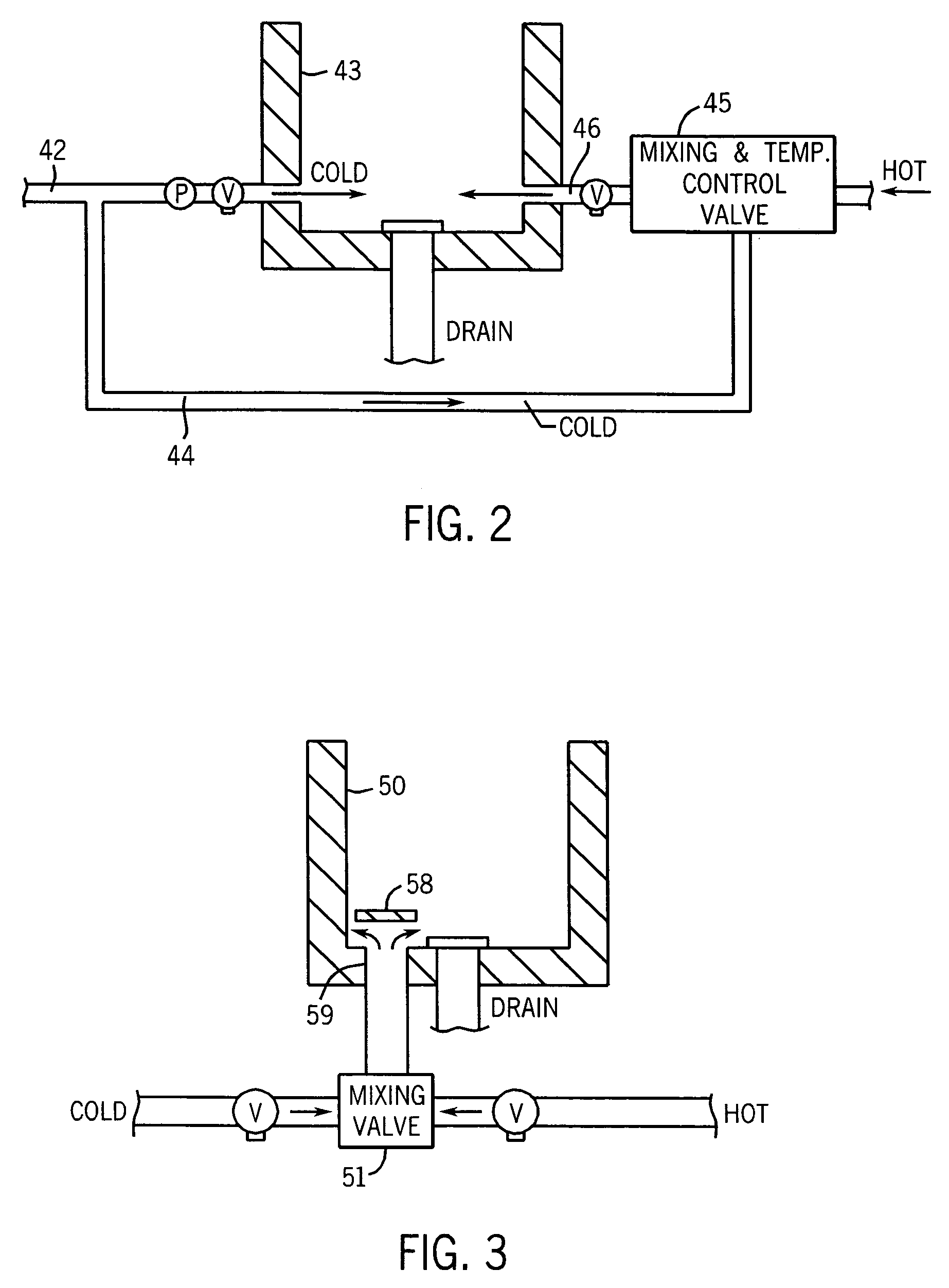

High flow rate water supply assembly

An assembly for rapidly filing bathtubs, whirlpools, spas, washing machine drums and the like includes a basin, water storage tank(s) (such as hot and cold water storage tanks), and a system for controlling the filling of the basin from the tank(s). When it is desired to supply water to the basin, this is expedited by placing the tank(s) above the basin, using connecting piping with extra large area, using a pressure pump, and / or providing extra large delivery ports. The tank(s) are dedicated to the assembly, and preferably are closely adjacent thereto. Controls are provided to avoid excess weight gathering adjacent the basin.

Owner:KOHLER CO

Spray gun reservoir with oversize, fast-fill opening

InactiveUS7845582B2Improve further our existing systemSimple wayBurnersFunctional valve typesReduced sizeEngineering

A spray gun reservoir has an oversize central opening 130 at one end allowing liquid to be added to the reservoir for fast filling with reduced risk of spillage. A cap member 132 is connectable to the reservoir and has a spout 115 providing a fluid outlet of reduced size relative to the opening 130 for connection to the spray gun. The reservoir can be disconnected from the cap member 132 when it is desired to add liquid to the reservoir. In this way, the reservoir can be re-filled in use.

Owner:3M INNOVATIVE PROPERTIES CO

Drop-in filter for spray gun reservoir

InactiveUS7832567B2Improve filtering effectFast fillLoose filtering material filtersCartridge filtersEngineeringSolid particle

Owner:3M INNOVATIVE PROPERTIES CO

Method for preparing ceramic with pore gradient

InactiveCN1830902AImprove performanceEasy to operateCeramicwareClaywaresTetramethylammonium hydroxidePorosity

A process for preparing the porosity-gradient ceramic includes such steps as adding deionized water to ceramic powder and disperser, ball grinding to obtain slurry A, adding deionized water to solidifying organic substance (starch or modified starch), ultrasonic dispersing or ball grinding to obtain slurry B, vacuum mixing, fast filling the mixture in mould, solidifying, drying and sintering. Said ceramic powder is chosen from alumina powder, SiC powder and Si3N4 powder. Said disperser is chosen from ammonium citrate and ammonium tetramethyl hydroxide.

Owner:TSINGHUA UNIV

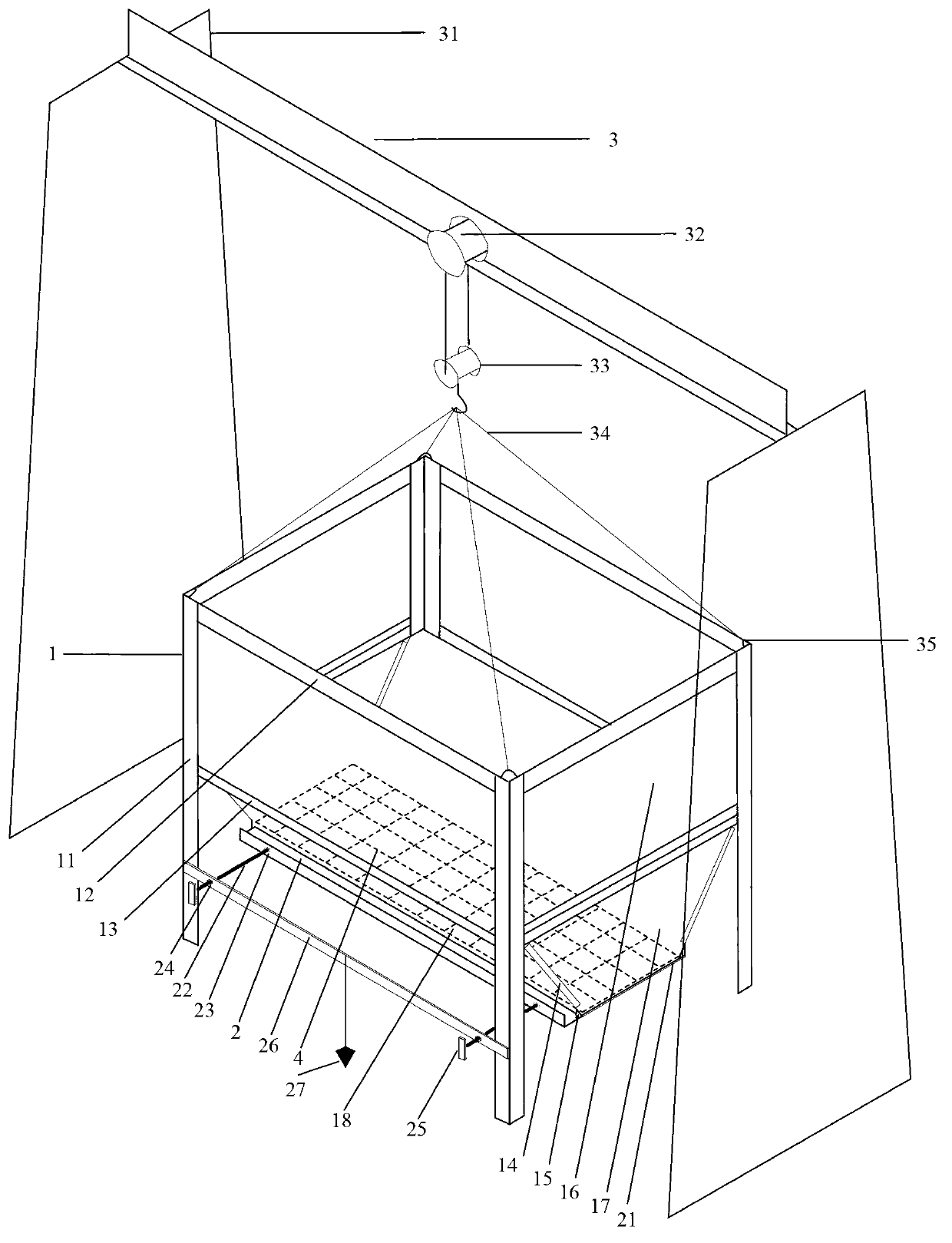

Sand rain-type filling device for geotechnical engineering model test

ActiveCN103278612APrecise control of filling speedPrecise height controlEarth material testingFilling rateFast filling

The invention provides a sand rain-type filling device for a geotechnical engineering model test. The sand rain-type filling device comprises a hopper, a control panel, a hoisting and translation device, and a screen mesh. The screen mesh is arranged in the hopper. Sand for a geotechnical engineering model test is filled on the screen mesh. The bottom of the hopper is provided with the control panel for accurately controlling a sand filling rate and sand filling height. The top of the hopper is connected to the hoisting and translation device. The sand rain-type filling device is convenient for operation, has a low investment cost and a large one-step filling amount, effectively saves labor, has high integral strength, is sturdy and durable, and provides an accurate and efficient equipment basis for a sand filling process in a geotechnical engineering model test.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com