Method for preparing ceramic with pore gradient

A gradient and ceramic technology, applied in the field of ceramic materials, can solve the problems of porosity gradient ceramics that have not been reported, and achieve the effects of easy control of porosity and pore size, good performance, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

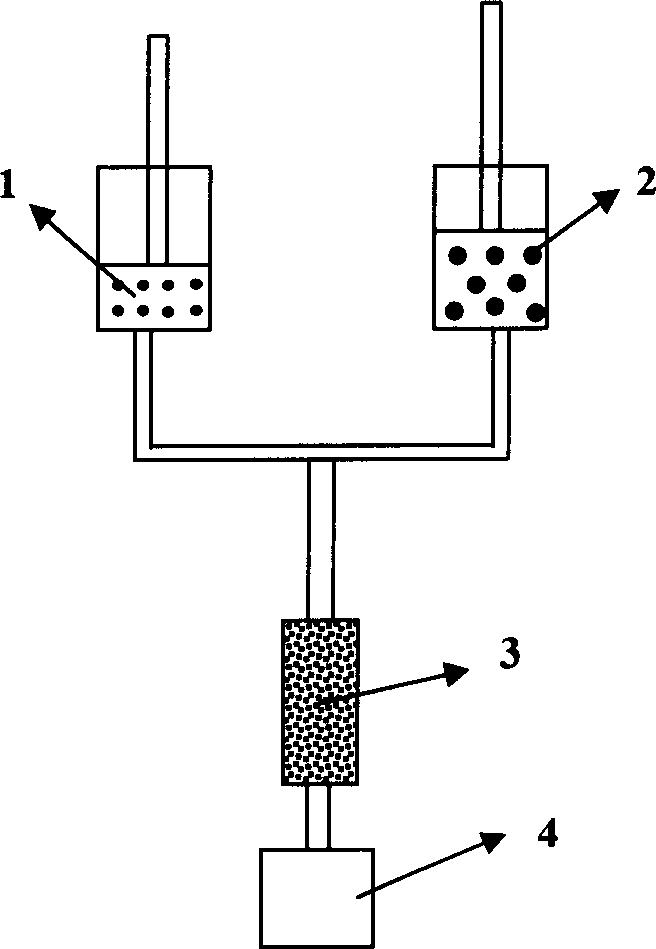

Embodiment 1

[0027] Use 196g of alumina powder, add 60ml of deionized water, 0.2g of ammonium citrate as a dispersant, ball mill and mix for 24 hours to prepare a slurry with good fluidity; use 60g of potato starch, add 60ml of deionized water, and prepare a fluidity slurry by ultrasonic dispersion Good slurry; the two kinds of slurry are placed in two storage tanks respectively, and the flow rate of the two kinds of slurry is controlled in a timely manner. The slurry is quickly mixed in a vacuum static mixer, injected into a glass mold with a diameter of 50mm, and the mold Seal and place in a constant temperature oven at 55°C for 30 minutes. After the slurry is solidified and sealed with the mold, place it at room temperature for 48 hours before demoulding. After demoulding, place it in an oven at 80°C and dry for 48 hours to obtain a starch content transition from 10% to 40%. After removing starch by heat preservation at 200-550°C and sintering at 1450°C for two hours in an air atmosphere...

Embodiment 2

[0029] Use 120g of SiC powder, add 25ml of deionized water and 2g of tetramethylammonium hydroxide as a dispersant, ball mill and mix for 48 hours to prepare a slurry with good fluidity; use 90g of cornstarch, add 40ml of deionized water, and prepare a fluidity slurry by ultrasonic dispersion Good slurry, the two kinds of slurry are placed in two storage tanks, and the flow rate of the two kinds of slurry is controlled in time. The slurry is quickly mixed in a vacuum static mixer, and injected into a steel mold with a size of 30mm×20mm×10mm , put the mold seal in a constant temperature oven at 75°C for two hours, dry the slurry together with the mold seal in a constant temperature oven at 40°C for 24 hours, and then remove the mold, and dry it in an oven at 100°C for 24 hours after demoulding. Prepare the green body with the starch content transitioning from 5% to 30%; remove the starch by heat preservation at 200-550°C, and sinter at 1850°C for two hours in a vacuum atmosphere...

Embodiment 3

[0031] Using 200gSi 3 N 4 powder, add 16ml of deionized water and 16g of gum arabic as dispersant, ball mill and mix for 36h to prepare a slurry with good fluidity; use 120g of wheat starch, add 20ml of deionized water, and prepare a slurry with good fluidity through ball milling, two kinds The slurry is placed in two storage tanks respectively, and the flow rate of the two kinds of slurry is controlled in a timely manner. The slurry is quickly mixed in a vacuum static mixer, injected into a steel mold with a size of 30mm×20mm×10mm, and the mold is sealed in a Put it in a constant temperature oven at 90°C for five hours. After the slurry is cured, seal the mold and place it in a constant temperature oven at 60°C for 12 hours before demoulding. After demoulding, place it in a 110°C oven and dry for 12 hours. The starch content can be prepared from 5%. to 30% green body; after heat preservation at 200-550 °C to remove starch, heat preservation at 1800 °C in nitrogen atmosphere ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com