Patents

Literature

119results about How to "Craft economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste salt resourceful treatment system and application

PendingCN110201975ARealize resourcesAchieve emission standardsSolid waste disposalTransportation and packagingSlagEvaporation

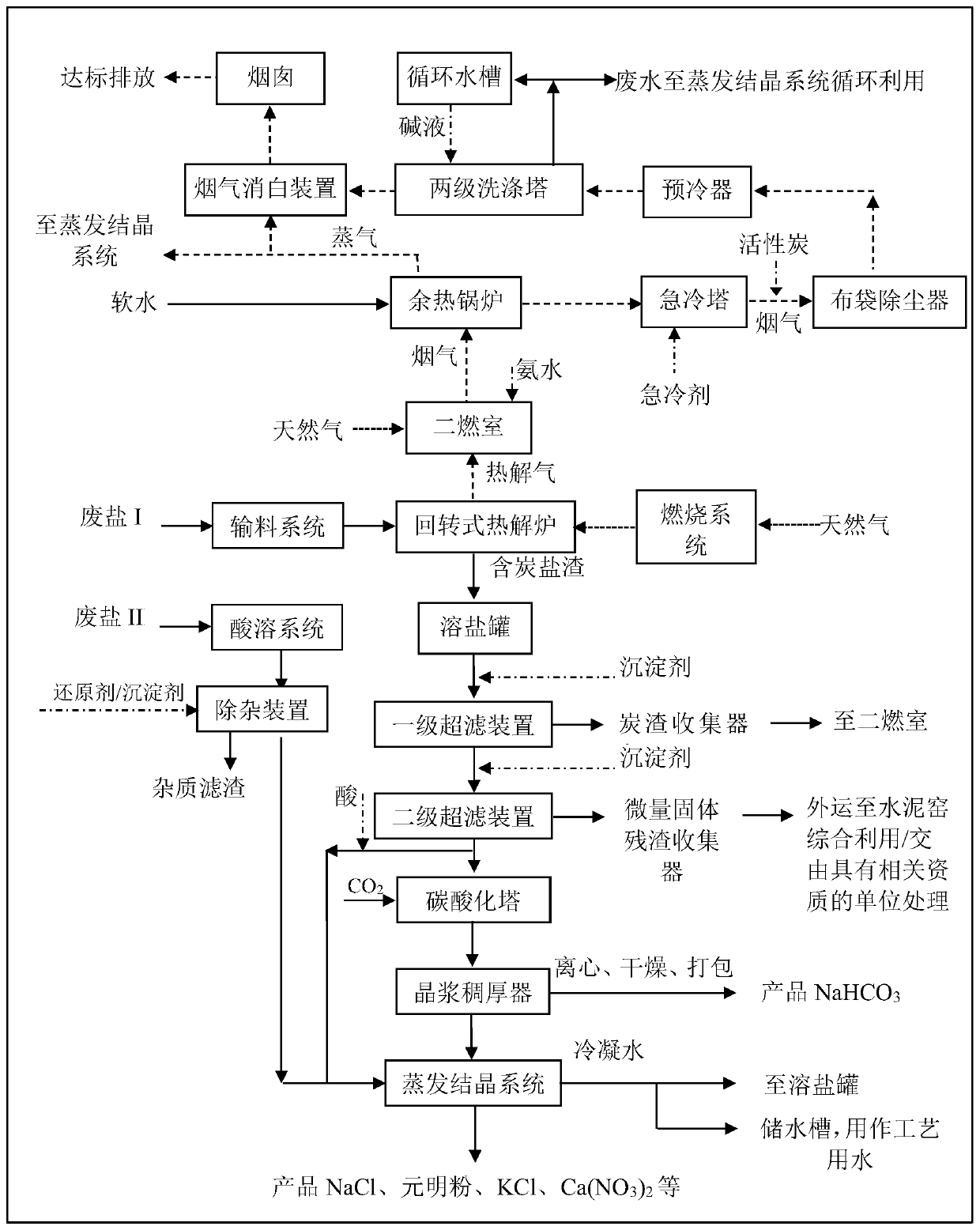

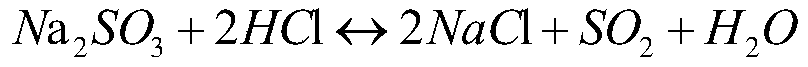

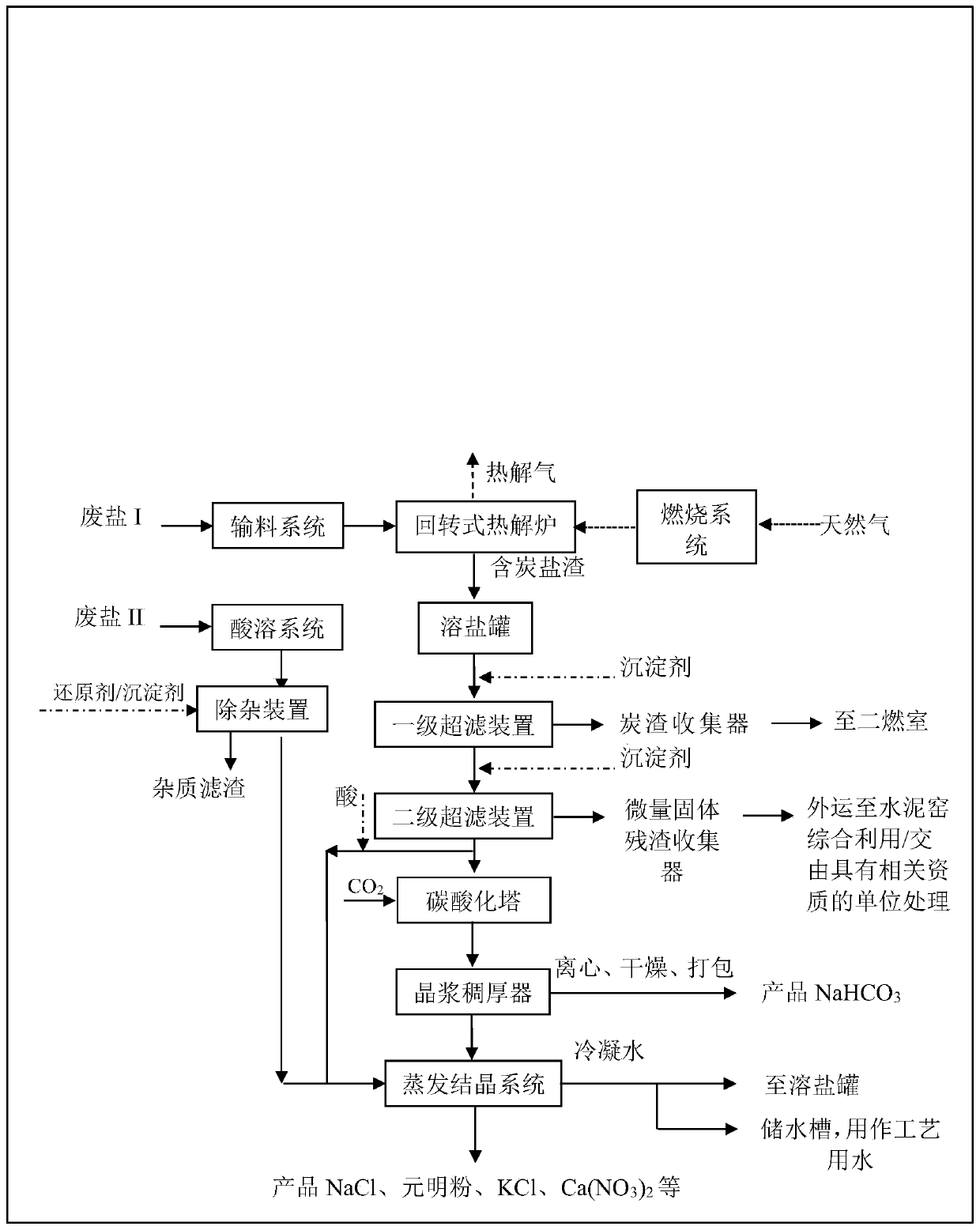

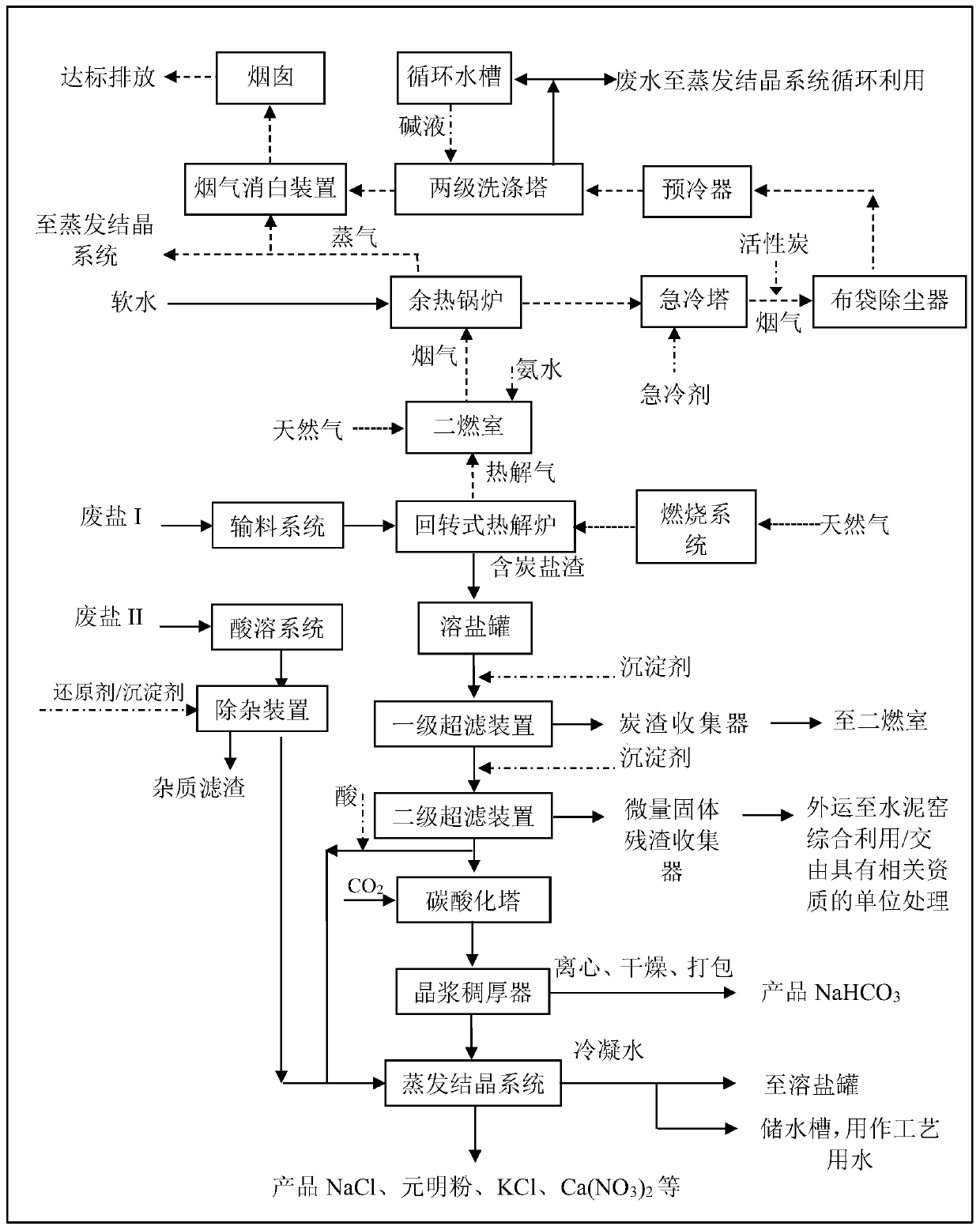

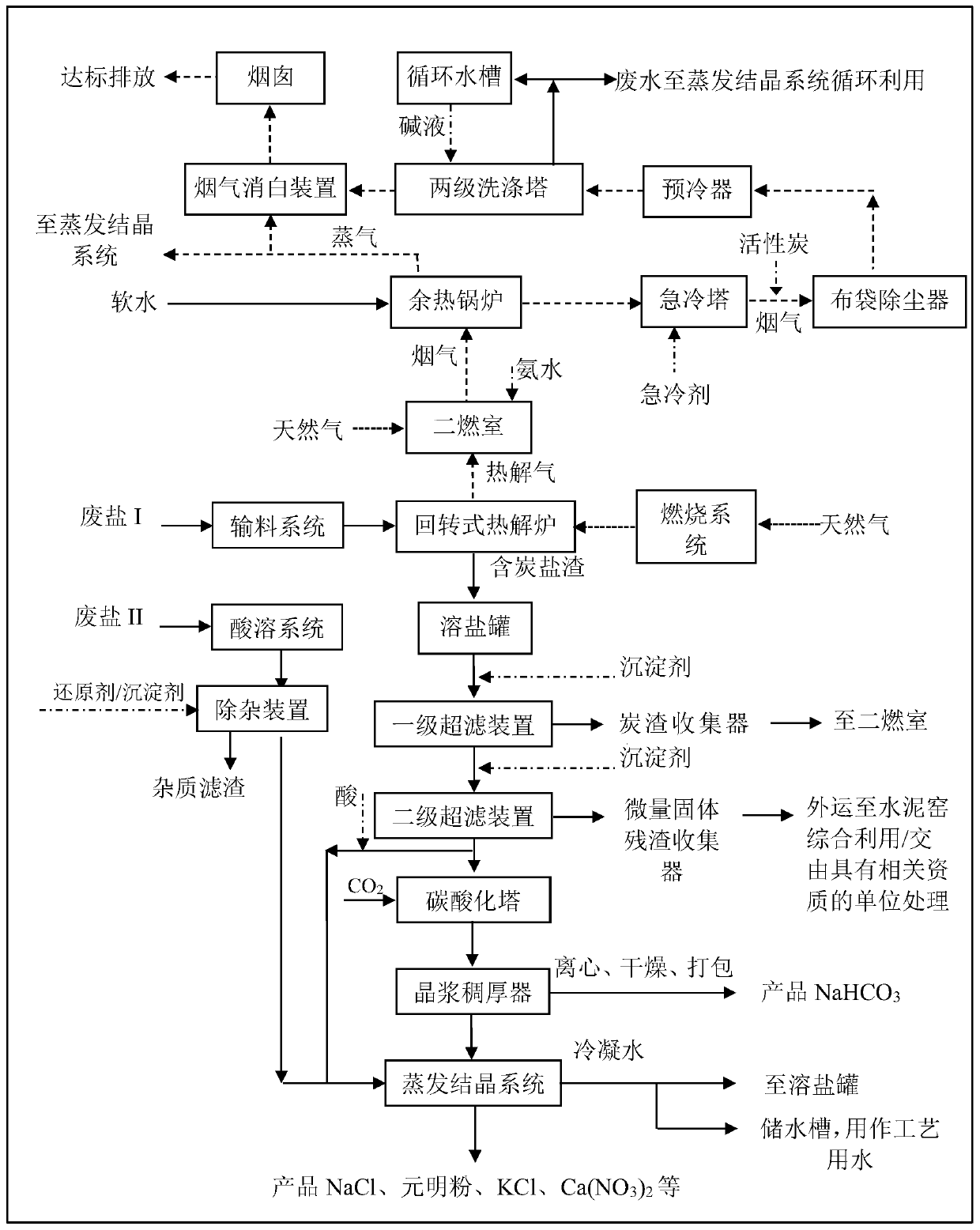

The invention relates to a waste salt resourceful treatment system which comprises a waste salt carbonization and pyrolysis system, a carbon-containing salt slag dissolving and filtering system and anevaporating and salt separating system in sequential connection, wherein the waste salt carbonization and pyrolysis system can carry out carbonization and pyrolysis treatment on waste salt I composedof sodium chloride, and sodium sulfate monomer salt or mixed waste salt and also can treat tail gas; the carbon-containing salt slag dissolving and filtering system can dissolve and filter the carbon-containing salt slag treated by the waste salt carbonization and pyrolysis system; and the evaporating and salt separating system can carry out evaporation and concentration, fractional crystallization and drying treatment on the strong brine treated by the carbon-containing salt slag dissolving and filtering system to obtain product salt. The waste salt resourceful treatment system takes industrial waste salt as the raw material, removes organic pollutant from waste salt and separates mixed inorganic salt to finally obtain an industrial second-grade salt product, so that recycling of waste salt is realized, and the flue gas generated during the production process is discharged after reaching the standard.

Owner:北京航天环境工程有限公司

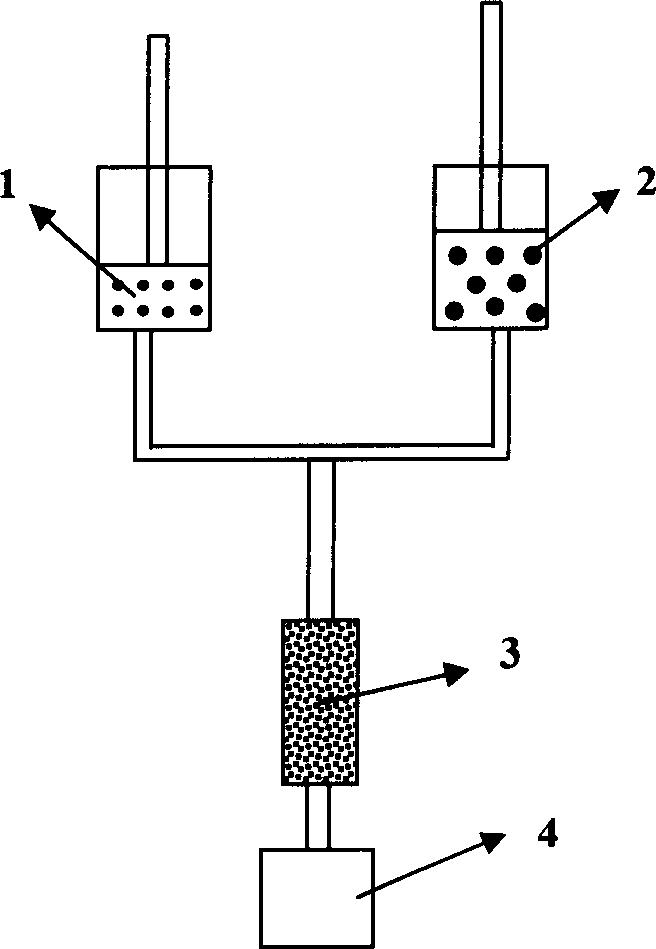

Preliminary dexidation-anaerobism-oxygen deficit-multistage aerobic/anaerobic biological N and P removing method and device

InactiveCN101723510ASmall volumeImprove the effect of nitrogen and phosphorus removalTreatment with aerobic and anaerobic processesRefluxAeration system

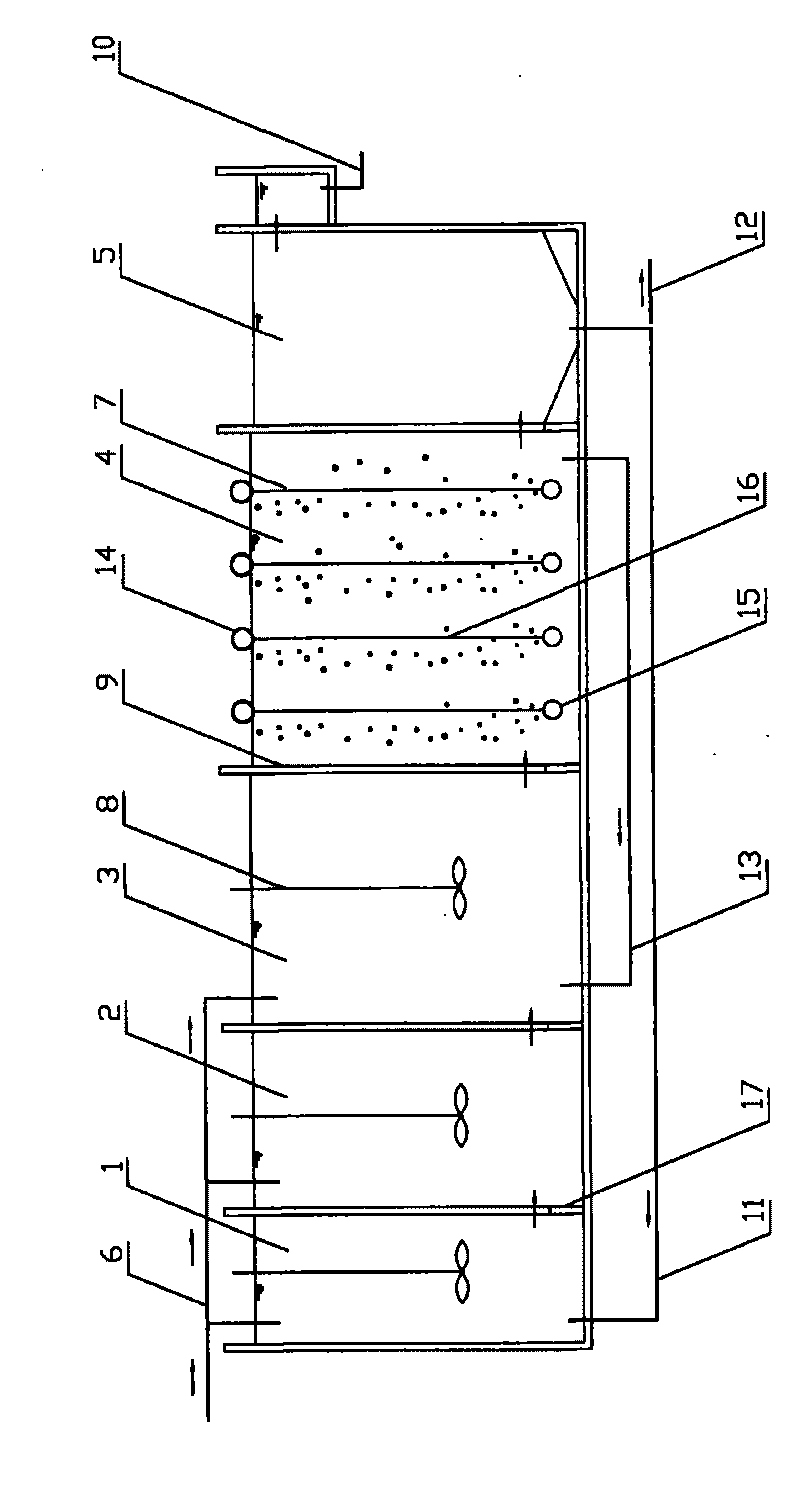

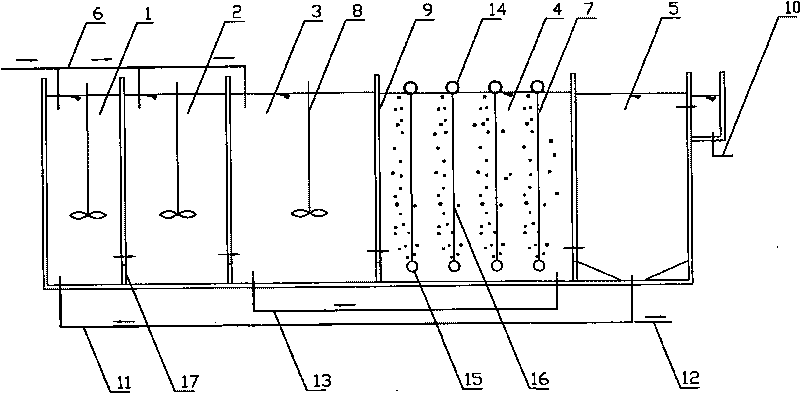

The invention relates to a preliminary dexidation-anaerobism-oxygen deficit-multistage aerobic / anaerobic biological N and P removing technology, including the steps: a) deoxygenation denitrification is carried out on returned sludge and part of sewage; b) anaerobic phosphorus releasing is carried out on the mixed liquid and part of sewage treated by the step a; c) denitrification is carried out on the mixed liquid and part of sewage treated by the step b and returned nitrification liquid; d) synchronous nitrification denitrification and decarbonising phosphorous absorption is carried out on the mixed liquid treated by the step c; e) nitrification liquid treated by the step d is returned to the step c; f) nitrification liquid treated by the step d is precipitated, part of sludge is returned to the step a, excess sludge is discharged, clean water is discharge or recycled after reaching standards. The device comprises a preliminary dexidation tank, an anearobism tank, an anaerobic tank, a multistage aerobic / anaerobic tank and a secondary sedimentation tank which are sequentially communicated; wherein the multistage aerobic / anaerobic tank is internally provided with a suspension chain aeration system, an inflow water distributing pipeline is connected with the preliminary dexidation tank, the anaerobism tank and the anaerobic tank, and sludge reflux quantity and nitrification liquid reflux quantity can all be regulated by a refluxing device.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

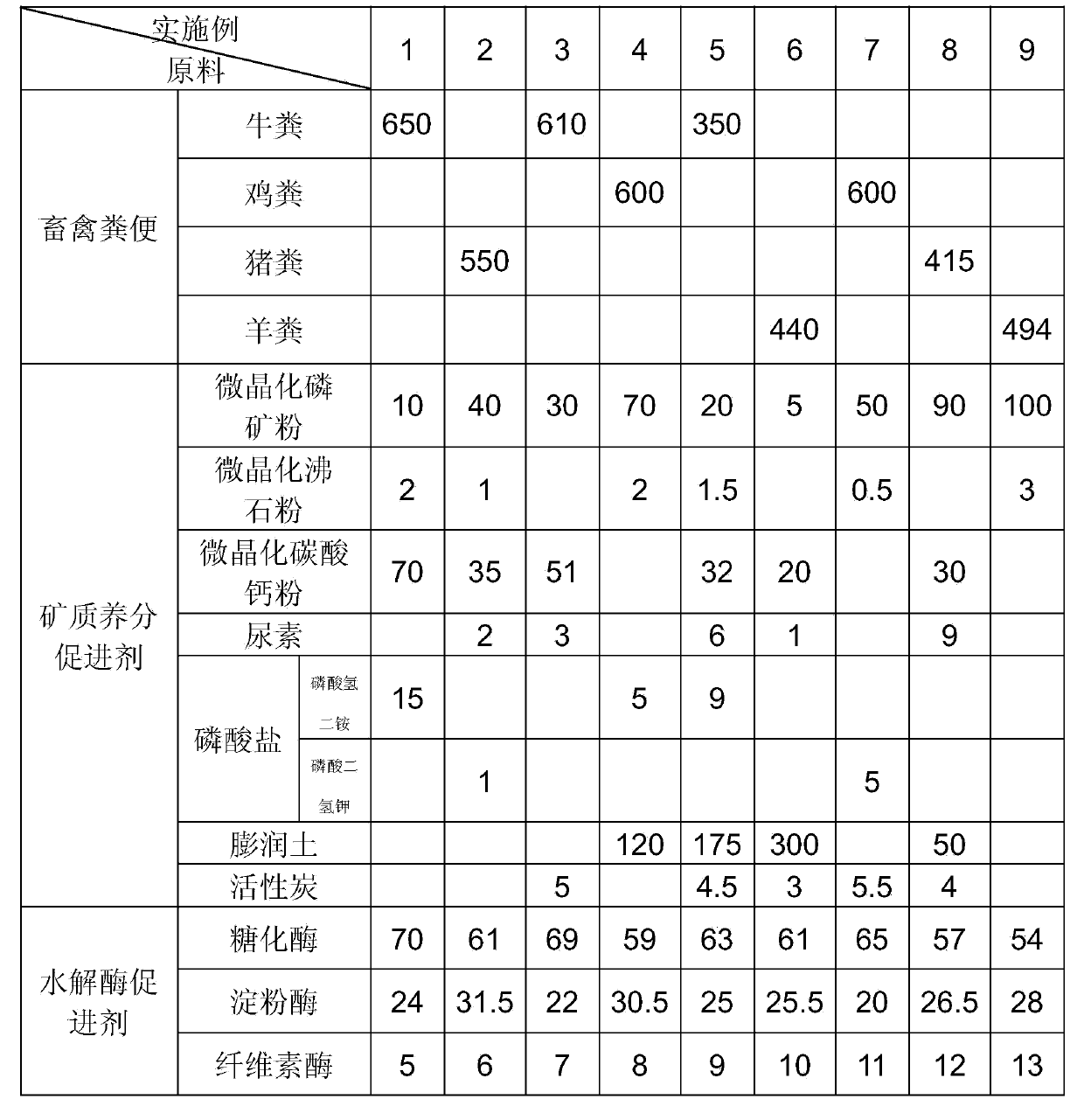

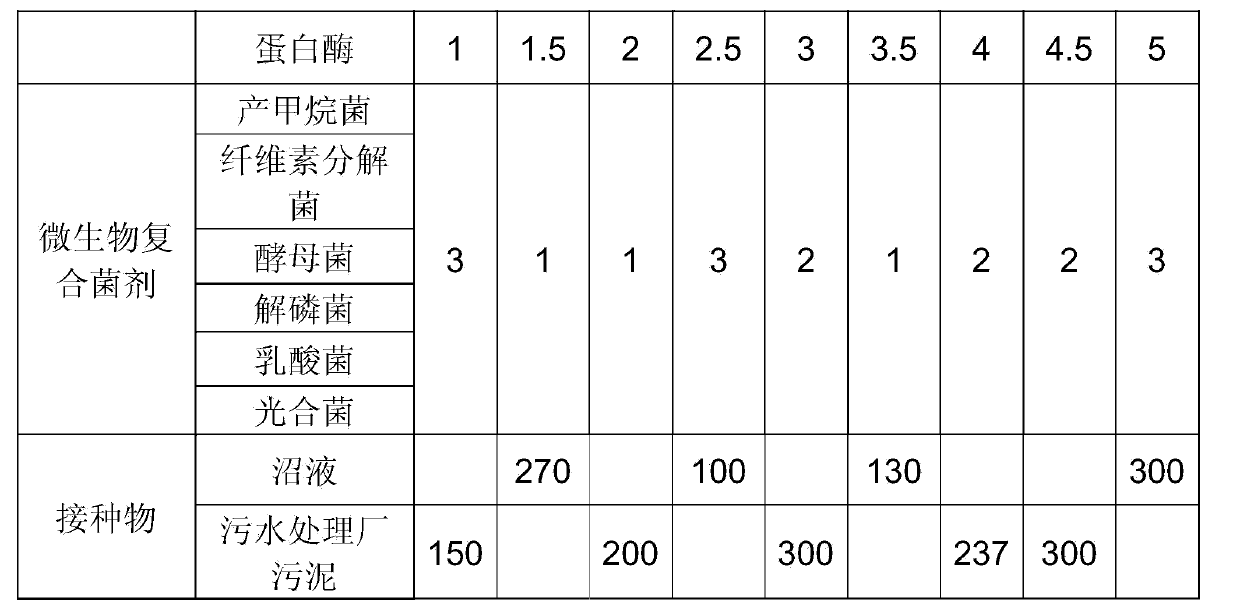

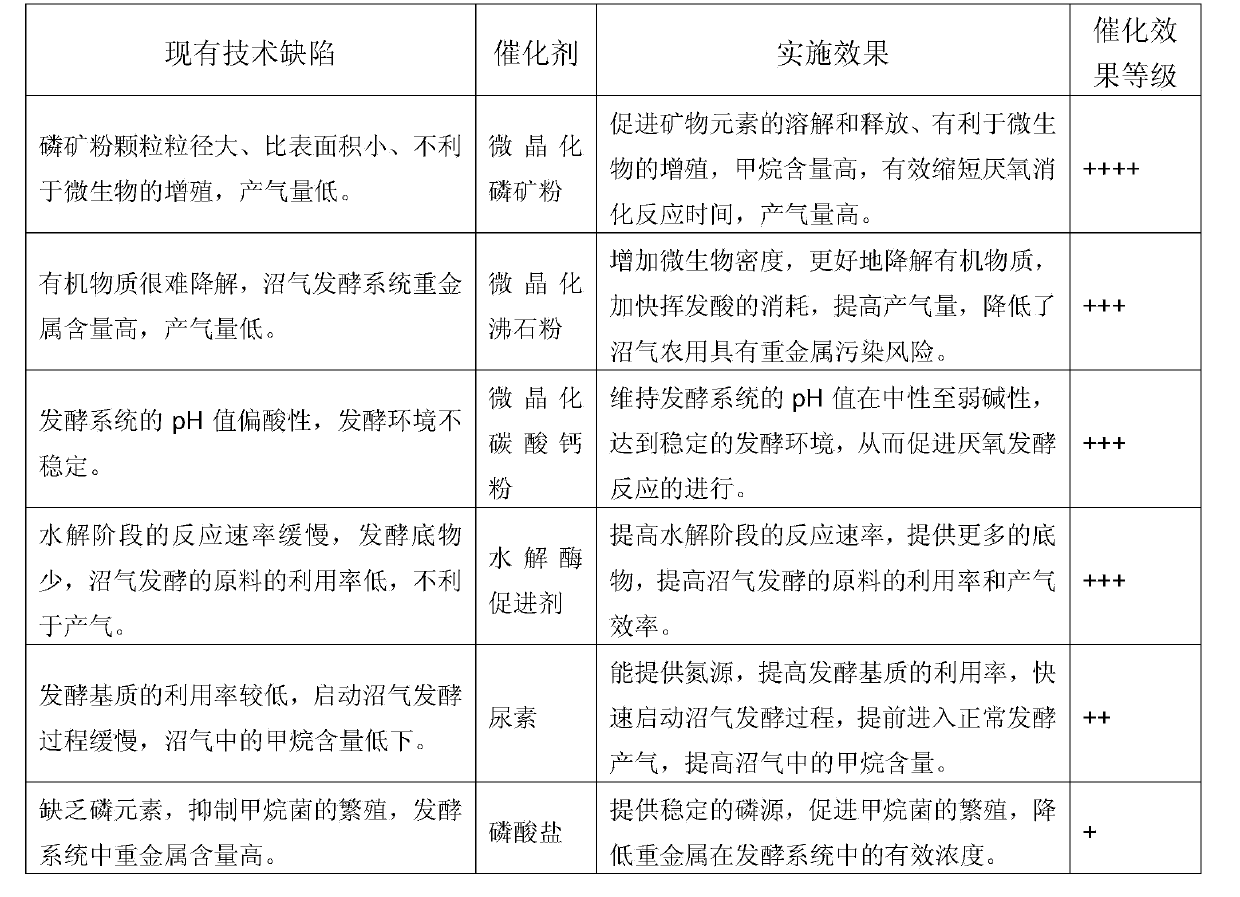

Functional biocatalyst for biogas fermentation and method for fermenting using catalyst

ActiveCN103740764ANo dischargeMethanogenic effect is stableWaste based fuelFermentationFiltrationSorbent

The invention discloses a functional biocatalyst for biogas fermentation and a method for fermenting using the catalyst. The catalyst comprises 1-3 parts of a microbial composite bacterial agent, 100 parts of hydrolase accelerant and 61-329 parts of mineral nutrient accelerant, wherein the mineral nutrient accelerant is one or more of microcrystalline ground phosphate rock, microcrystalline zeolite powder, microcrystalline calcium carbonate powder, urea, phosphate, bentonite and active carbon. The biogas fermentation method comprises the following steps: performing biogas fermentation by using 350-650 parts of poultry excrement, 100-300 parts of inoculum and 163-430 parts of functional biocatalyst while controlling the moisture content of the poultry excrement at 75-85%; and stirring and mixing for fermentation, wherein the concentration of the whole original feed liquid is 7-12%. In the invention, apart from the supplement of the nutritive elements for biogas fermentation, the effects of deodorization and inhibition of pathogenic microorganisms are realized through the functional complementation effect among the adsorption of an adsorbent, ion exchange, biodegradation and membrane filtration so that the biocatalyst is harmless; and moreover, the preparation technology has the advantages of simple process, easiness in operation, good effect, low investment, no pollution and wide application value.

Owner:INNER MONGOLIA HUAMENG KECHUANG ENVIRONMENTAL PROTECTION TECH ENG CO LTD

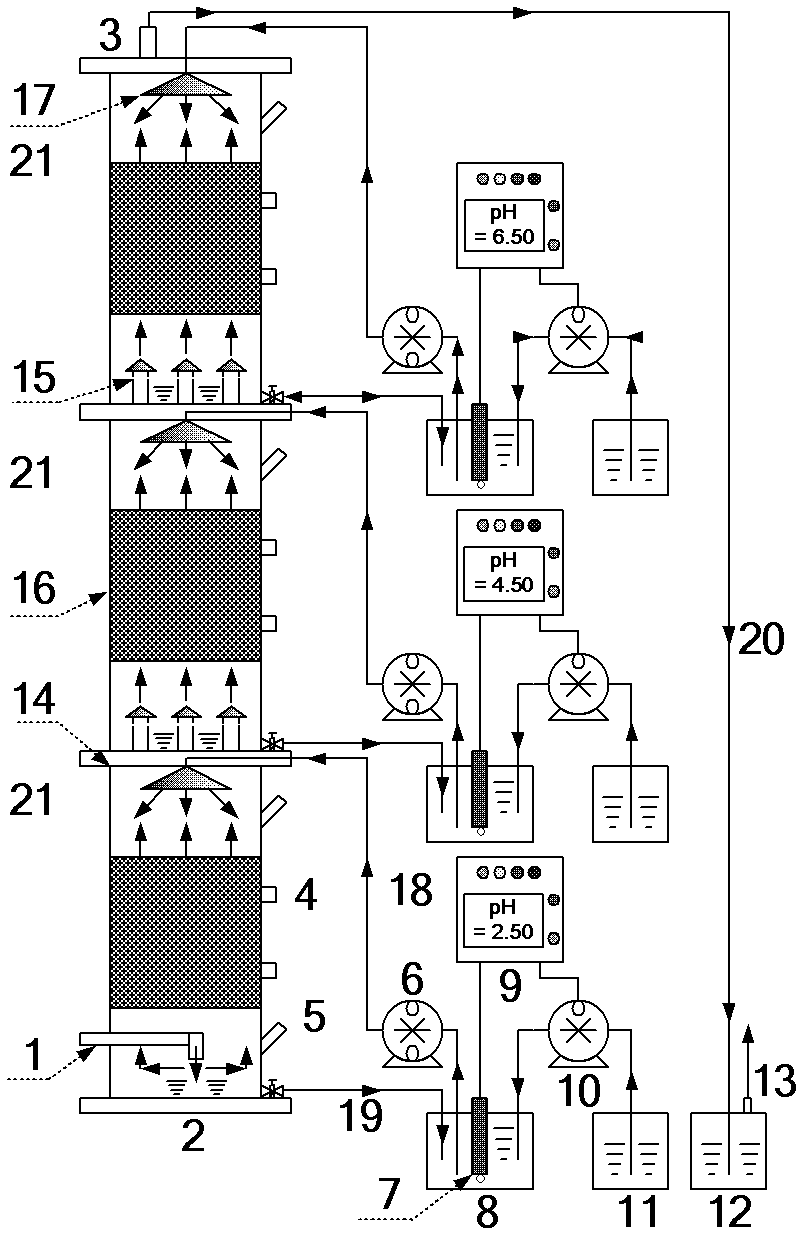

A method for treating waste gas with a biological trickling filter tower and its special device

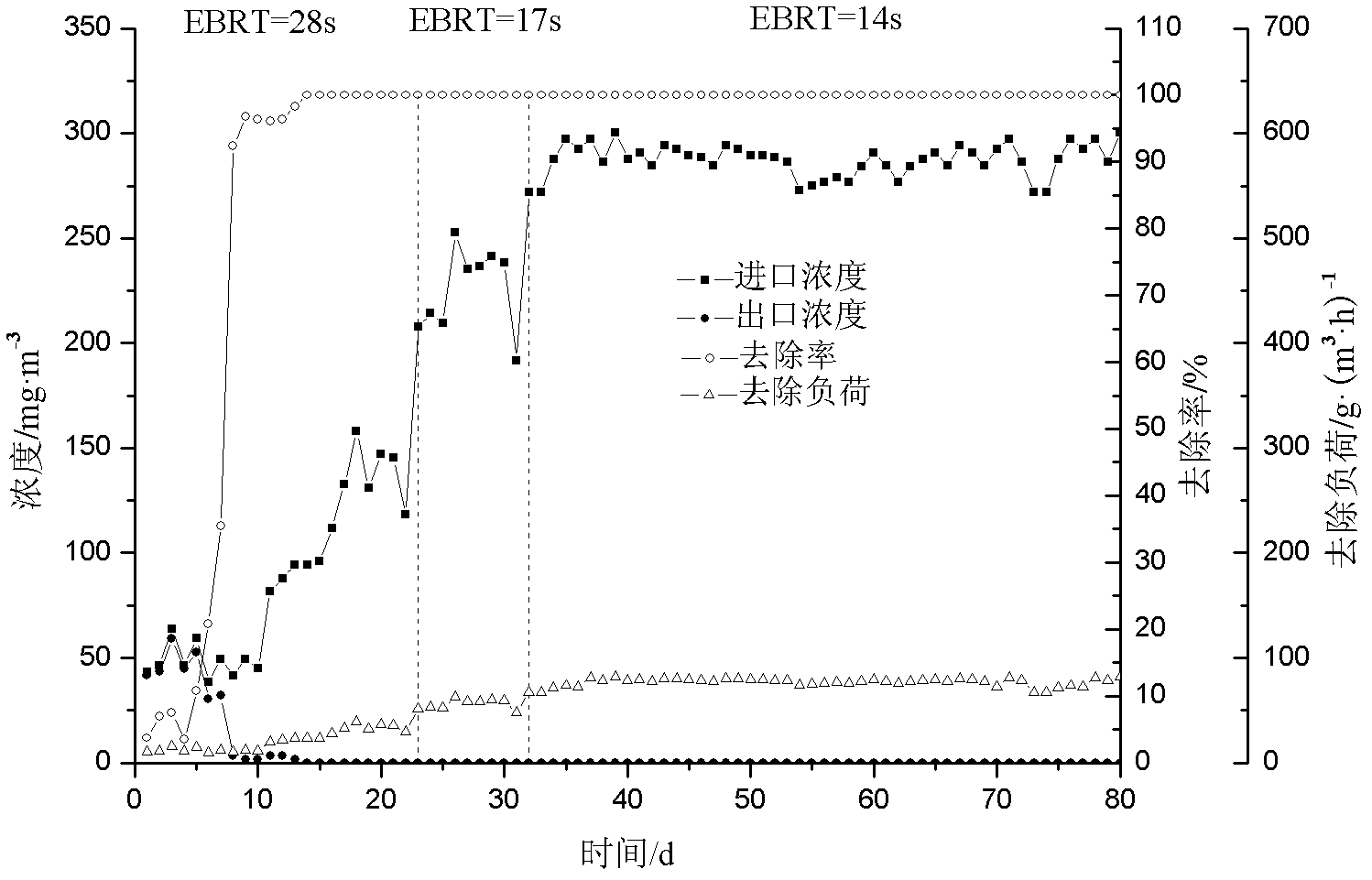

InactiveCN102284245AImprove blockageEven contactDispersed particle separationAir quality improvementTemperature controlTrickling filter

The invention discloses a method for treating waste gas with a biological trickling filter tower: the waste gas is passed through the bottom of the biological trickling filter tower, treated by the biological trickling filter tower, and the treated waste gas is discharged from the top, and the biological trickling filter tower is composed of The bottom of the tower with exhaust gas inlet, the tower body, and the top of the tower equipped with exhaust gas outlet are composed. The tower body is composed of several biological treatment units stacked from bottom to top, and the biological treatment units on adjacent layers are arranged There is a liquid interlayer, and the air vents for the adjacent layers are arranged on the liquid interlayer, and each layer of biological treatment units is independently equipped with a nutrient solution spray system and a temperature control device from top to bottom. Biological packing layer and nutrient solution receiving pool; the invention increases the processing load of the unit packing; improves the plugging problem of the packing layer, avoids the occurrence of channeling phenomenon, and has uniform and sufficient gas-liquid contact; packing replacement and backwashing are more convenient; the process Economical, suitable for the purification treatment of complex volatile organic mixed pollutants.

Owner:ZHEJIANG UNIV OF TECH

Processing technology for recovering and utilizing mother solution of glyphosate as resource

ActiveCN101659673AImprove throughputReduce flux decay speedGroup 5/15 element organic compoundsWater/sewage treatment bu osmosis/dialysisFiltrationCatalytic oxidation

The invention relates to a processing technology for recovering and utilizing the mother solution of glyphosate as a resource, which comprises the following concrete steps: firstly, preprocessing themother solution of glyphosate, and then, separating, concentrating and recovering the glyphosate by a membrane combination technique; returning the concentrated solution to a crystallization working section in the production process of the glyphosate after membrane filtration, thereby effectively recovering and utilizing the glyphosate resource; adsorbing the diluted solution with high efficiency,and further recovering and utilizing the glyphosate; and processing the adsorbed solution by catalytic oxidation with high efficiency to recover the sodium chloride resource with higher purity. The invention achieves the purposes of recovering and utilizing the glyphosate in the mother solution as a resource to the maximum extent and efficiency separating, recovering and utilizing the sodium chloride as a resource, has the advantages of economical technology, high efficiency, good system stability, high safety, easy operation, convenient industrial amplification, and the like, solves the problems of the soil salinization caused by applying water agents with high content of sodium chloride, the processing and disposal of solid wastes of the sodium chloride and the environment pollution, and effectively recovers and utilizes the resources of the glyphosate and the sodium chloride in the mother solution of the glyphosate.

Owner:NANJING UNIV OF TECH

Treatment system for waste salt recycling treatment and application thereof

PendingCN110201976ARealize resourcesReduce dosageSolid waste disposalTransportation and packagingSodium bicarbonateSlag

The invention relates to a treatment system for waste salt recycling treatment. The treatment system comprises a waste salt carbonization pyrolysis system, a coke-containing salt slag dissolving and filtering system and an evaporation and desalination system which are sequentially connected with one another, wherein the waste salt carbonization pyrolysis system can be used for carrying out carbonization pyrolysis treatment on waste salt I composed of sodium chloride monomer salt, sodium sulfate monomer salt or the mixed waste salt; the coke-containing salt slag dissolving and filtering systemcan be used for carrying out the dissolution and filtration operation on the coke-containing salt slag obtained after the treatment by the waste salt carbonization pyrolysis system; and the evaporation and desalination system can be used for carrying out the evaporation and concentration, fractional crystallization and drying treatment on strong brine obtained after the treatment by the coke-containing salt slag dissolving and filtering system, so that salt products are obtained. According to the treatment system, with the industrial waste salt as a raw material, organic pollutants are removedfrom the waste salt, desalination treatment is carried out on mixed inorganic salt, and finally the industrial secondary salt products are produced, such as anhydrous sodium sulfates, sodium chlorides, sodium bicarbonate and other finished salt, so that the recycling of the waste salt can be realized; and the system can be applied to the waste salt recycling treatment.

Owner:北京航天环境工程有限公司

Method for extracting low-pesticide-residue ginsenoside from ginsengs

The invention relates to a method for extracting low-pesticide-residue ginsenoside from ginsengs. The method comprises the following steps of leaching the ginsengs for 3-4 times in cold water, wherein each leaching lasts for 8-12 hours; combining leaching liquids, carrying out concentration, solvent extraction and concentration, enabling the leaching liquids to pass through a macroporous resin column, and flushing by utilizing water; carrying out ethanol elution, collecting the eluted liquid, and drying to obtain the low-pesticide-residue ginsenoside. The production method of the ginsenoside comprises two purification processes, the preliminary purification is extraction, and the resin is highly purified; partial impurities are removed in the extraction process, so that the high purification efficiency is improved.

Owner:HUNAN NUSTREETCARAX

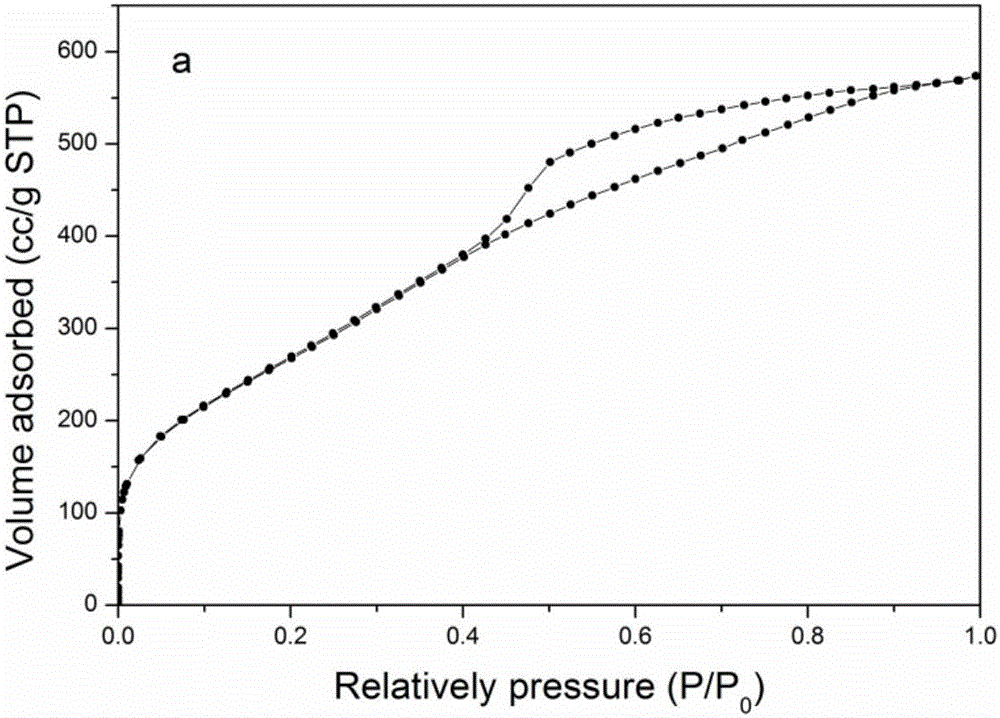

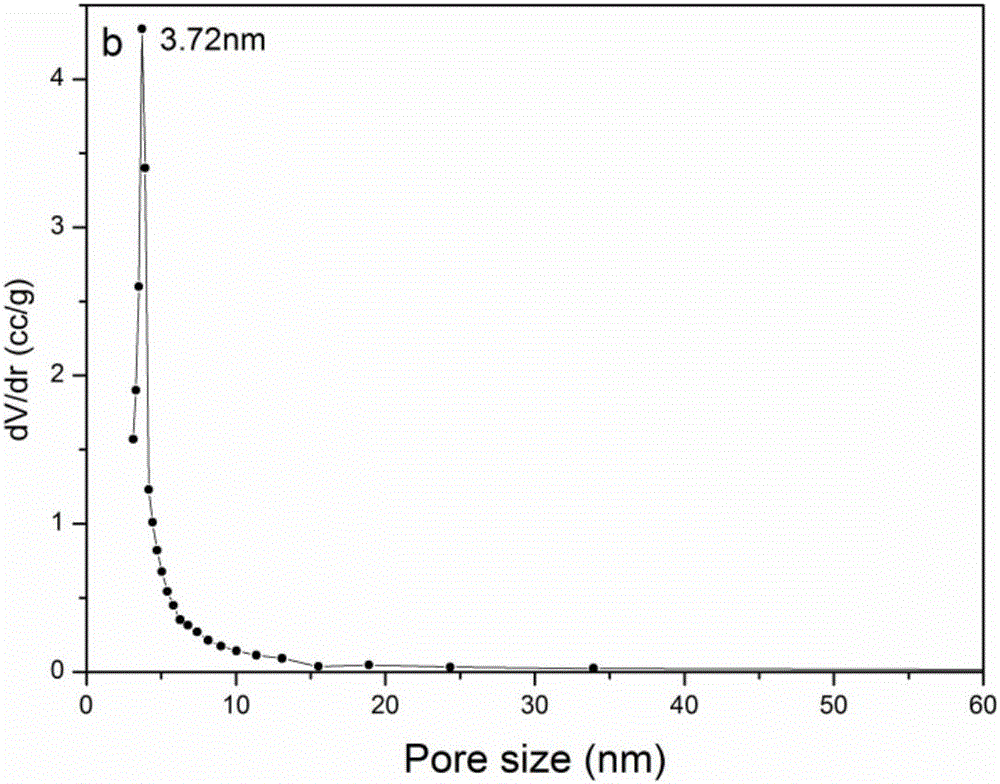

Small-sized metallic oxide nano-cluster/mesoporous SiO2 nanocomposite and preparation method thereof

ActiveCN106000391ASimple processSmall sizeMaterial nanotechnologyHydrocarbon oils refiningNano clustersPore diameter

The invention belongs to the field of nanometer material preparation and particularly relates to a small-sized metallic oxide nano-cluster / mesoporous SiO2 nanocomposite and a preparation method thereof. The particle size and the pore diameter of every mesoporous SiO2 nanosphere carrier are 5-30 nm and 2-5 nm respectively; every metallic oxide nano-cluster refers to MoO3 or WO3 and 0.1-2 nm in particle size. A reversed-phase microemulsion method is adopted for synthesis. The preparation method of the small-sized metallic oxide nano-cluster / mesoporous SiO2 nanocomposite is simple in technology, economic and safe; the metallic oxide nano-clusters are highly dispersed on the mesoporous SiO2 carrier, the metallic oxide nano-clusters and the mesoporous SiO2 carrier are controllable in both size and shape, and accordingly the small-sized metallic oxide nano-cluster / mesoporous SiO2 nanocomposite is excellent in catalytic performance.

Owner:DALIAN UNIV OF TECH

Method for preparing ceramic with pore gradient

InactiveCN1830902AImprove performanceEasy to operateCeramicwareClaywaresTetramethylammonium hydroxidePorosity

A process for preparing the porosity-gradient ceramic includes such steps as adding deionized water to ceramic powder and disperser, ball grinding to obtain slurry A, adding deionized water to solidifying organic substance (starch or modified starch), ultrasonic dispersing or ball grinding to obtain slurry B, vacuum mixing, fast filling the mixture in mould, solidifying, drying and sintering. Said ceramic powder is chosen from alumina powder, SiC powder and Si3N4 powder. Said disperser is chosen from ammonium citrate and ammonium tetramethyl hydroxide.

Owner:TSINGHUA UNIV

Method for extracting tea oil by demulsification based on aqueous enzymatic method

InactiveCN104928012AFully formedIncrease the degree of emulsificationFatty-oils/fats productionWater bathsEnzymatic hydrolysis

The invention discloses a method for extracting tea oil by demulsification based on an aqueous enzymatic method. The method comprises the following steps: processing tea seed powder by microwaves for 60 to 120 seconds; adding distilled water at a material-liquid mass ratio of 1:4 to 1:8, pulping, and collecting upper-layer emulsified liquid; pulping the residual water phase and residues again, and collecting upper-layer emulsified liquid; combining the collected emulsified liquid; adding 0.5-6% of composite enzymatic hydrolysis liquid based on the total mass of the emulsified liquid, performing water bath enzymolysis, centrifuging, and taking upper-layer tea oil; adding an ethanol solution into the residual emulsified liquid, performing water bath treatment, centrifuging, and collecting upper-layer tea oil; combining the collected tea oil, an drying in vacuum. According to the method, the emulsified liquid is high in oil content, and the process is simple, novel and practical; the emulsified liquid is subjected to composite enzyme hydrolysis and ethanol demulsification, so that the enzymatic hydrolysis volume is greatly reduced, the enzyme consumption is greatly reduced, and the process is economic and efficient; microwaves, enzymatic hydrolysis and ethanol are adopted for assisting in oil extraction, so that natural active ingredients of the tea oil are better preserved, and the oil extraction process is safe and nutritive.

Owner:NANCHANG UNIV

Melt spinning method for high-strength high-modulus polyvinyl alcohol fiber

InactiveCN102797050AMeet toughnessMeet the needs of crack resistanceArtificial filament washing/dryingArtificial filament heat treatmentHot air ovenPolyvinyl alcohol

The invention relates to a melt spinning method for a high-strength high-modulus polyvinyl alcohol fiber, comprising the following steps: uniformly mixing polyvinyl alcohol, water and an amide compound, and then, sufficiently swelling; adding the sufficiently swelled polyvinyl alcohol into a twin screw extruder, sufficiently melting, then extruding, and cooling the melt trickle through air blowing to form a nascent fiber; and drying the prepared nascent fiber through a hot-air oven, and then carrying out multistage stretching and tension heat setting to form the polyvinyl alcohol fiber. By using the preparation method of the polyvinyl alcohol fiber provided by the invention, melt spinning and high stretching of the polyvinyl alcohol are realized through hydrogen bond compounding among molecules of the water, the amide compound and the polyvinyl alcohol, and the prepared polyvinyl alcohol fiber has excellent mechanical property; and the melt spinning method is simple in production process, little in environment pollution and low in production cost; and the polyvinyl alcohol fiber prepared by using the method has the advantages of controllable fineness, high strength and high modulus so as to be widely applied to the field of civil engineering concrete.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

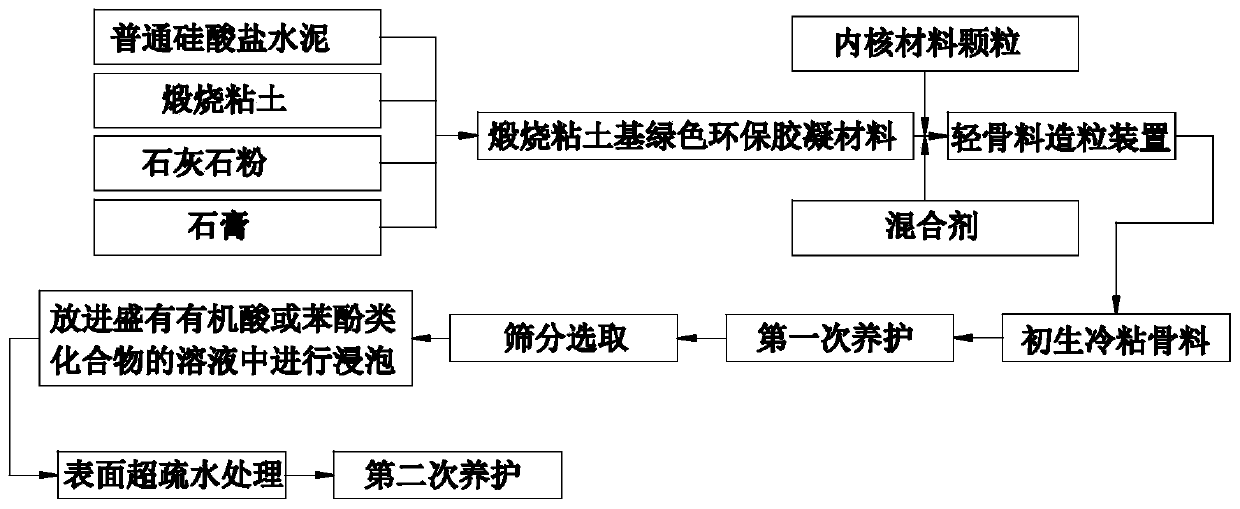

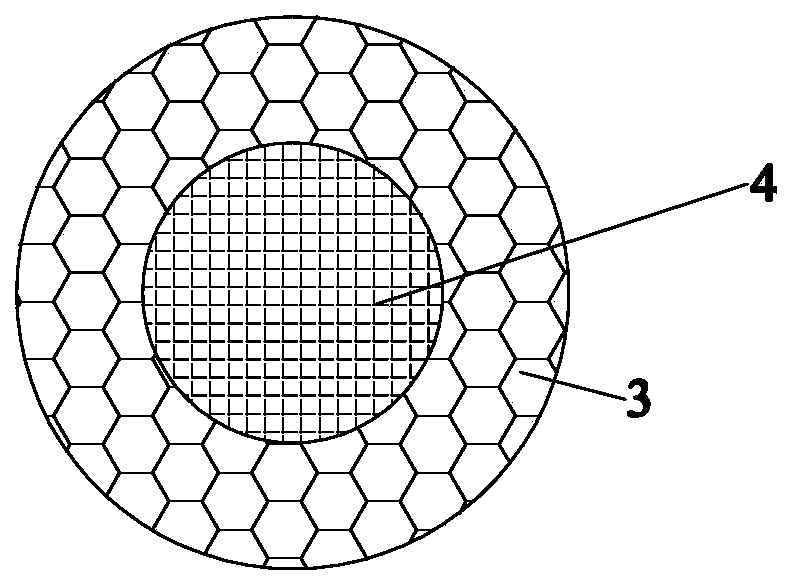

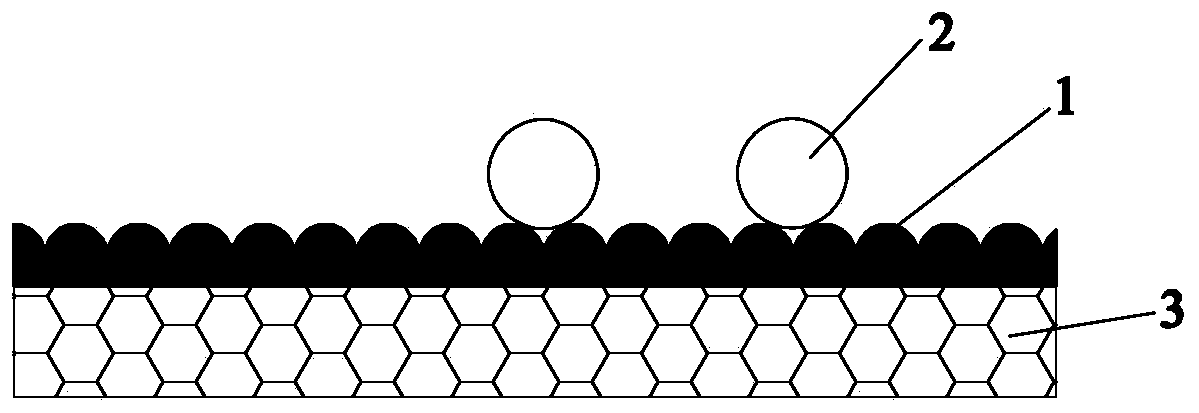

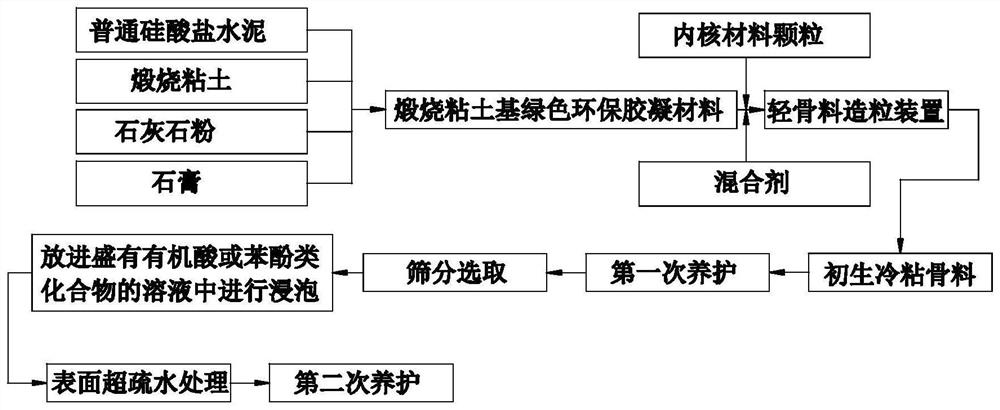

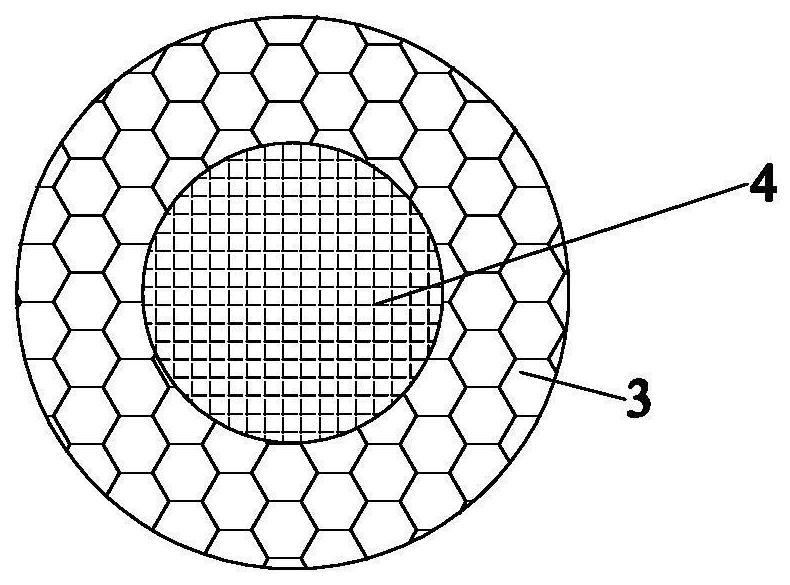

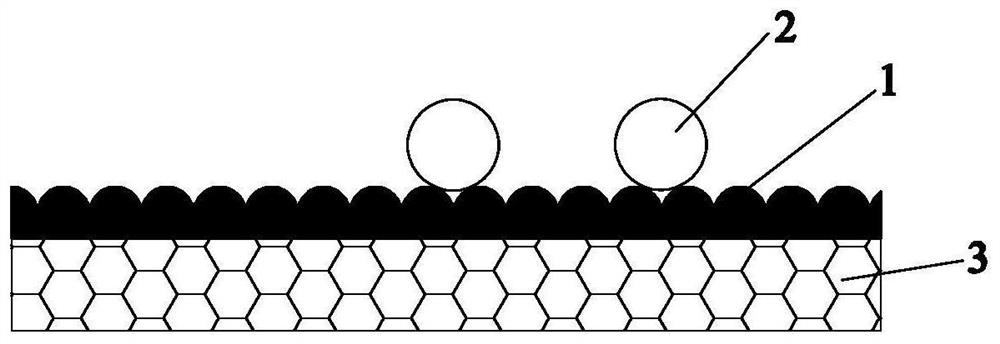

Core-shell-structure lightweight aggregate prepared by cold bonding method and preparation method thereof

The invention discloses a core-shell-structure lightweight aggregate prepared by a cold bonding method and a preparation method thereof. The preparation method comprises the following steps: preparinga calcined clay-based environment-friendly cementing material from ordinary Portland cement, calcined clay, limestone powder and gypsum in proportion; putting core material particles into a lightweight aggregate granulation device, then adding the calcined clay-based environment-friendly cementing material, and uniformly spraying a mixture for granulation to form primary cold-bonded aggregate; carrying out primary maintenance on the primarily-generated cold-bonded aggregate, soaking the primarily-generated cold-bonded aggregate in a solution containing organic acid or phenol compounds, takingout the primarily-generated cold-bonded aggregate, airing, and repeatedly spraying a calcium hydroxide aqueous solution on the surface of the aggregate to form aggregate with a super-hydrophobic surface; and subjecting the aggregate with the super-hydrophobic surface to water for secondary maintenance to produce the super-hydrophobic high-strength lightweight aggregate. According to the core-shell structure lightweight aggregate and the preparation method thereof, energy is saved, consumption is low, the processing flow is simplified, solid waste recycling can be achieved, the water absorption rate is low, and the single bearing capacity is high.

Owner:SHENZHEN UNIV

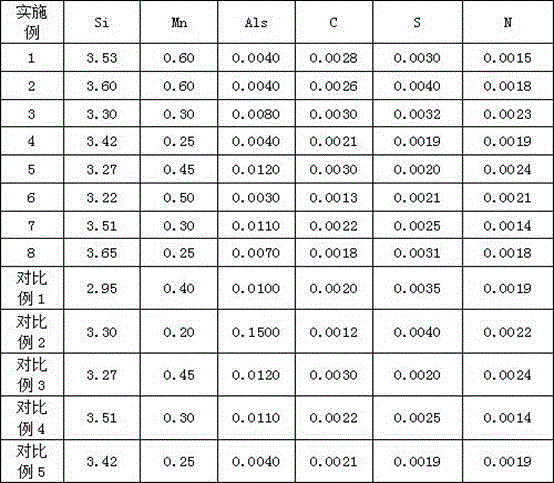

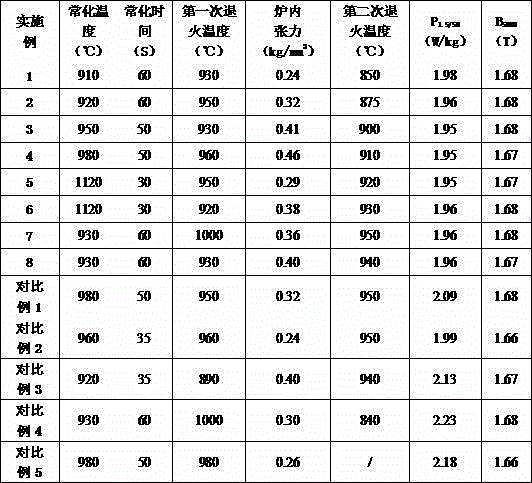

Cold-rolled non-oriented silicon steel low in iron loss and production method

The invention discloses cold-rolled non-oriented silicon steel low in iron loss. The cold-rolled non-oriented silicon steel low in iron loss is composed of, by weight, Si of 3.0-3.7%, Als smaller than or equal to 0.15%, C smaller than or equal to 0.004%, Mn of 0.15-0.80%, P smaller than or equal to 0.02%, S smaller than or equal to 0.005% and N smaller than or equal to 0.002%. The invention further discloses a production method of the cold-rolled non-oriented silicon steel low in iron loss. The production method comprises the production steps of steel making and blank casting; cast blank heating; hot rolling; normalizing; cold rolling after conventional acid pickling; annealing of primary finished products; annealing of final finished products; cooling, coating and finishing. According to the cold-rolled non-oriented silicon steel low in iron loss and the production method, by lowering the content of Als, the iron loss is further lowered; by annealing the finished products twice, the cold-rolled non-oriented silicon steel with the thickness being 0.35 mm, the iron loss P1.5 / 50 smaller than or equal to 2.0 W / kg and the magnetic inductivity B5000 greater than or equal to 1.67 T can be obtained, the rate of the finished products is high, and the cost is low.

Owner:武汉钢铁有限公司

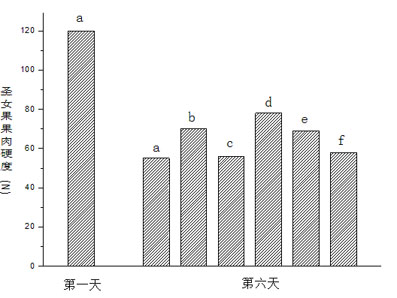

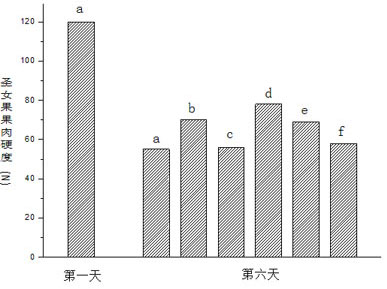

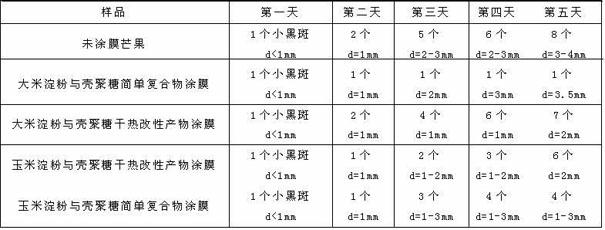

Edible coating taking starch and polysaccharide compound modified product as matrixes and preparation method thereof

InactiveCN101921515ASimple processCraft economyStarch coatingsFruits/vegetable preservation by coatingBiological macromoleculeChemistry

The invention provides an edible coating taking a starch and polysaccharide compound modified product as matrixes and a preparation method thereof, belonging to the field of food technology. The edible coating of the invention is prepared by the compound modification (dry-heat modification or formulation synergia) of the starch and the polysaccharide as well as the addition of components such as a plasticizer and the like. The obtained edible coating integrates the functional characteristics of the starch and the polysaccharide. Being applied to fruit refreshment, the edible coating can effectively control the change of the total acidity during the fruit storage period, reduce the rot rate, decrease the water and Vc (vitamin C) losses, keep the color, the brightness and the pulp quality of the fruit, and prolong the refresh period. The main components of the coating are edible large biological molecules (the starch and the polysaccharide), so that the coating can be directly eaten together with the fruit. Compared with the traditional non-edible refreshment material, the invention is simple in preparation, convenient in use, green and environment-friendly.

Owner:JIANGNAN UNIV

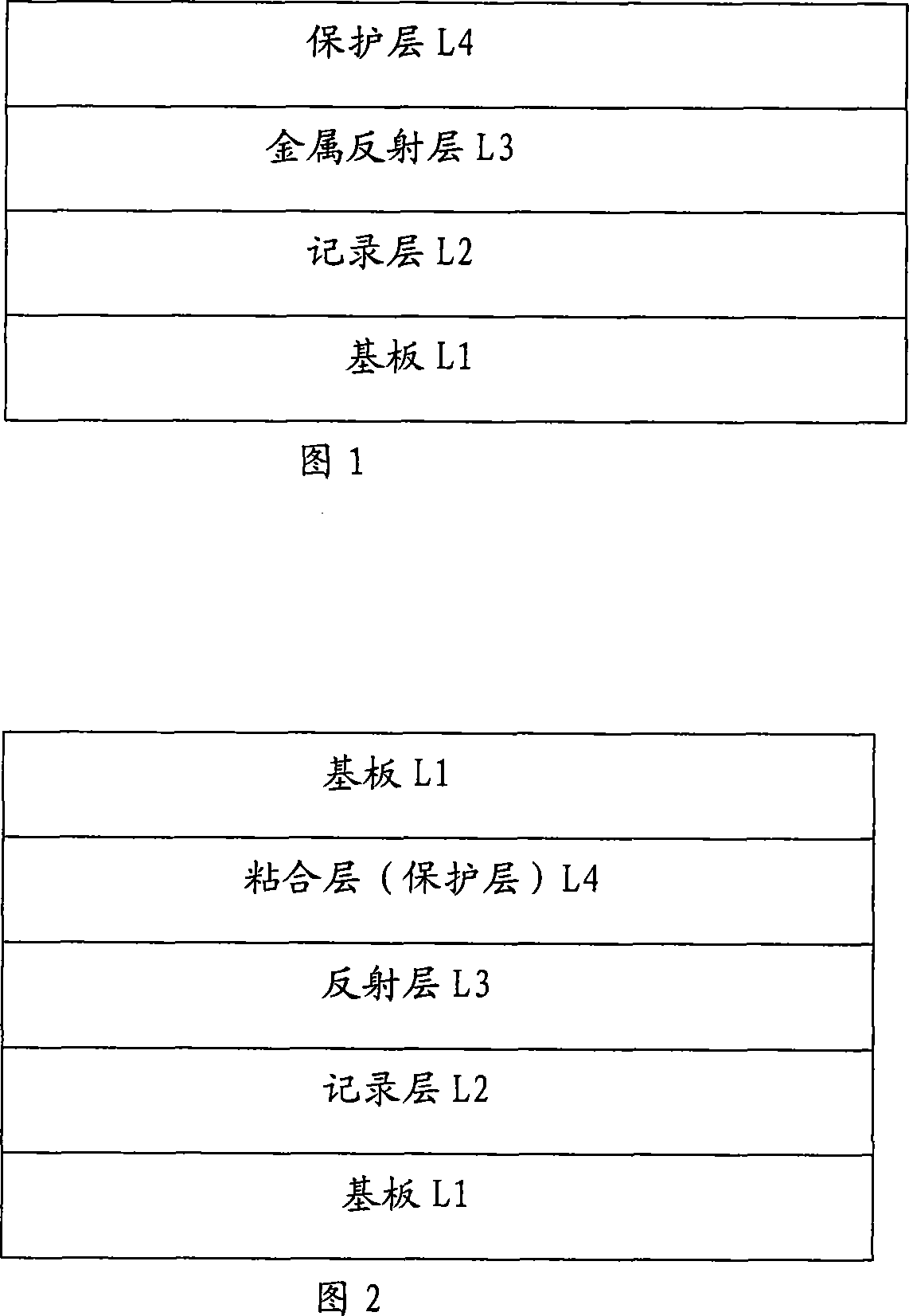

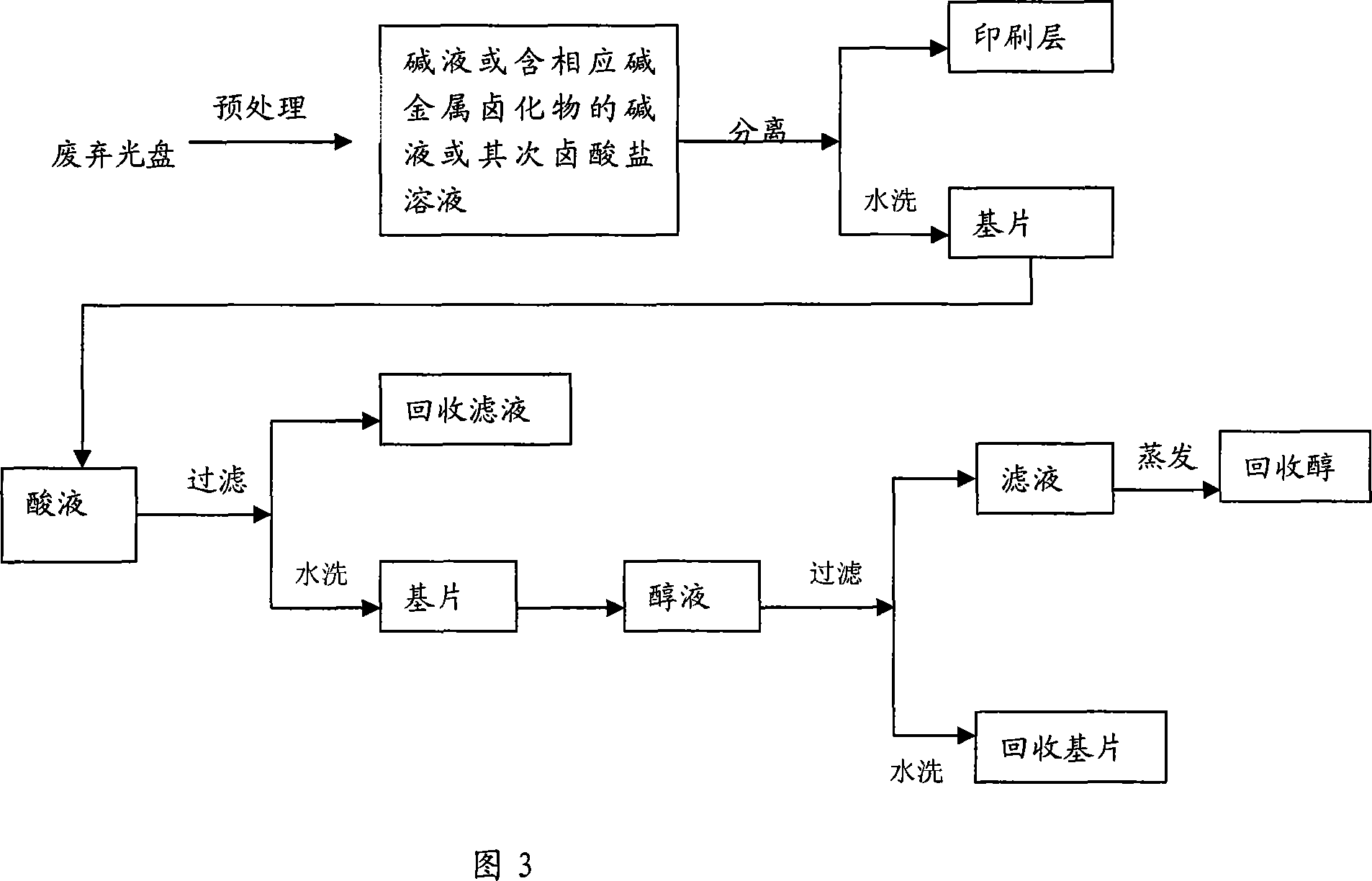

Method for reclaiming optical disk substrate from abandon optical disk

InactiveCN101157257AProcess environmental protectionCraft economyRecord carriersSolid waste disposalSaline waterHalogen

A method of recycling a compact disk substrate from waste discs pertains to the field of the electronic waste recycling technology. The invention has the following techniques: stripping treatment: the disc is put in alkali solution, alkaline salt solution, alkali solution including corresponding halide, or hypo-halogen acid salt solution one by one to isolate a printing layer and an aluminum layer from the CD. After being washed, other metals of the CD can be further separated by pouring acid liquor, and the CD is washed again and then put into the ethanol solution to strip the dye layer; separation and recovery: The CD substrate is taken out of the ethanol solution, and is washed in water to recycle plastic substrate. In the end, the ethanol is evaporated and recovered. The method has the advantages of realizing the recycle and the utilization of resources while reducing the environmental pollution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

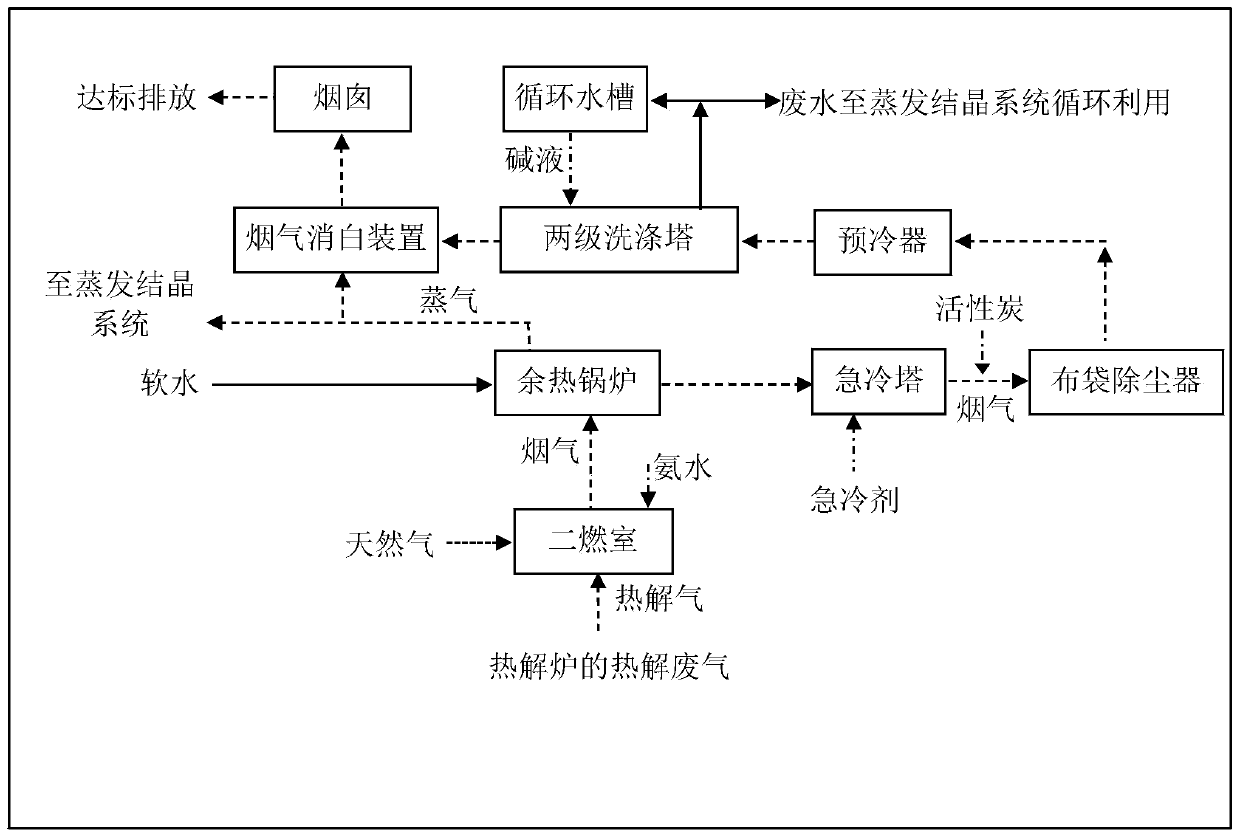

Tail gas treatment system for waste salt recycling treatment and application of tail gas treatment system

PendingCN110201514ASimple structural connectionEasy to useCombination devicesIncinerator apparatusCombustion chamberEmission standard

The invention relates to a tail gas treatment system for waste salt recycling treatment. The tail gas treatment system comprises a two-time combustion chamber, a waste heat boiler, a quench tower, a bag dust collector, a precooler, a two-stage washing tower, a white flue gas elimination device, a chimney and a circulating water tank, wherein the two-time combustion chamber comprises an input end and a flue gas output end, the input end of the two-time combustion chamber comprises a natural gas input end, a pyrolysis gas input end and an ammonium hydroxide input end, the natural gas input end is connected with natural gas, the natural gas can be input into the two-time combustion chamber through the natural gas input end, the pyrolysis gas input end of the two-time combustion chamber is connected with pyrolysis waste gas of a pyrolyzing furnace, the ammonium hydroxide input end is connected with ammonium hydroxide, and the ammonium hydroxide can be input into the two-time combustion chamber through the ammonium hydroxide input end. The tail gas treatment system for the waste salt recycling treatment has the advantages that the connection of the structure is simple, the use is convenient, after the pyrolysis waste gas in the pyrolyzing furnace is treated, pollutants in flue gas can completely meet emission standards, the cost is low, the effect is good, and the system can be applied in the waste salt recycling treatment.

Owner:北京航天环境工程有限公司

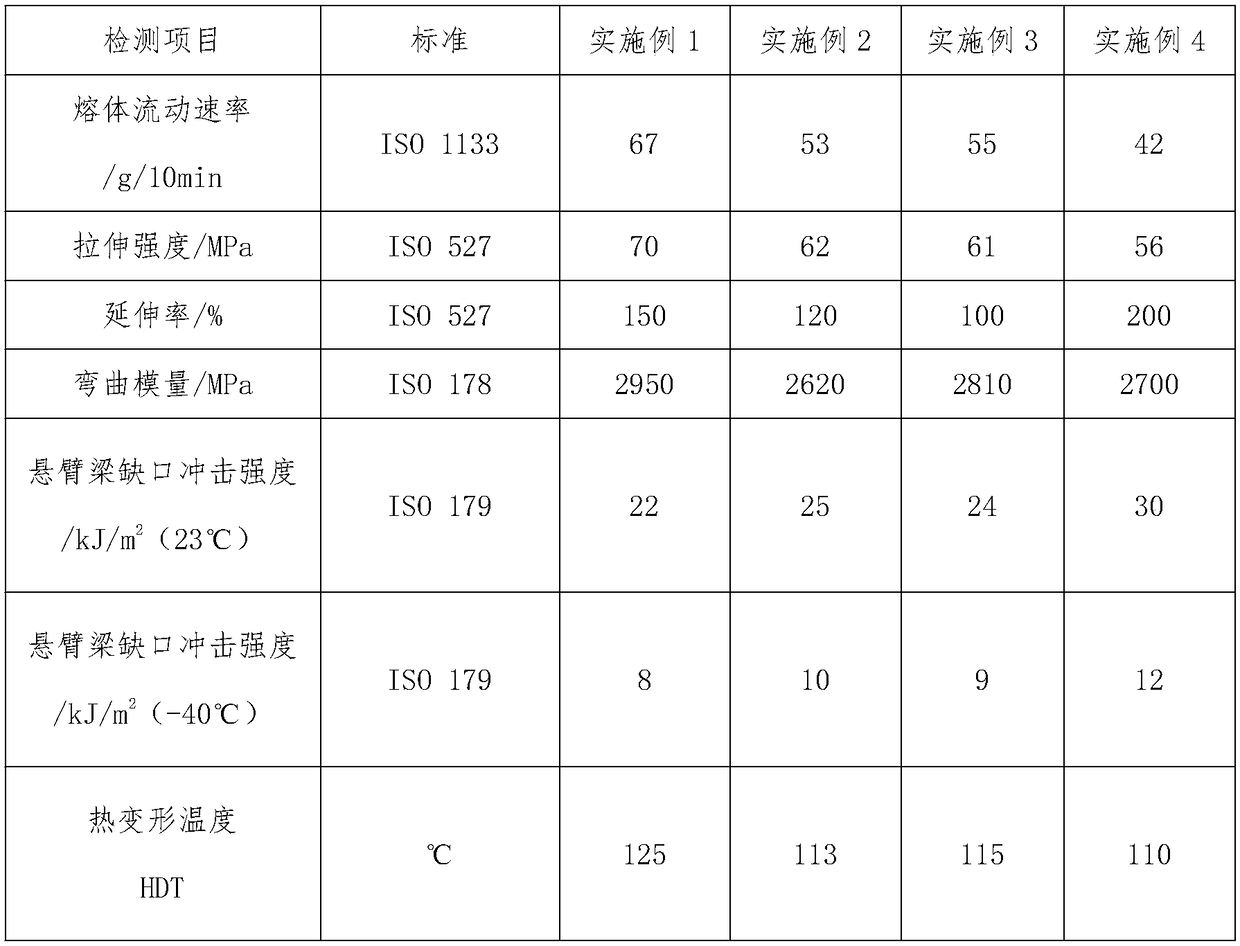

Degradable cable tie material and preparation method thereof

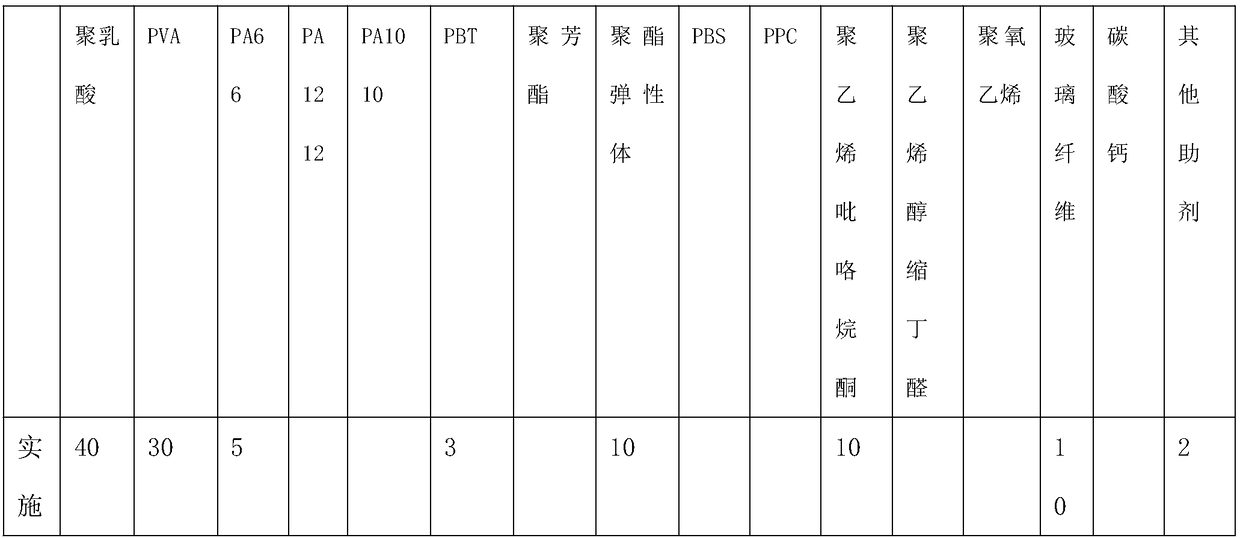

The invention relates to a cable tie material and a preparation method thereof, and in particular discloses a degradable cable tie material and a preparation method thereof. The material comprises thefollowing components in parts by weight: 40-60 parts of polylactic acid, 30-50 parts of polyvinyl alcohol, 5-20 parts of aliphatic polyamide, 1-10 parts of polyester, 5-15 parts of toughener, 5-10 parts of filler, 1-10 parts of degradation synergist and 1-3 parts of other additives. The material has the characteristics of high strength, high elongation, excellent high and low temperature performance, etc., and satisfies requirements of normal use of cable ties at high temperature heat resistance to 85 DEG C, and no fracture at low temperature of extreme weathers of Xinjiang, Heilongjiang, etc.; meanwhile, the material has the advantages of natural easy degradation, good biocompatibility and direct degradation or composting treatment after use, is natural and environmentally friendly, is pollution-free, and meets environmental friendliness requirements; and moreover, the material also has good hydrophilicity and anti-static property, and can meet anti-static requirements of wire harness cable ties of electronic industry.

Owner:NANJING JULONG SCI&TECH CO LTD

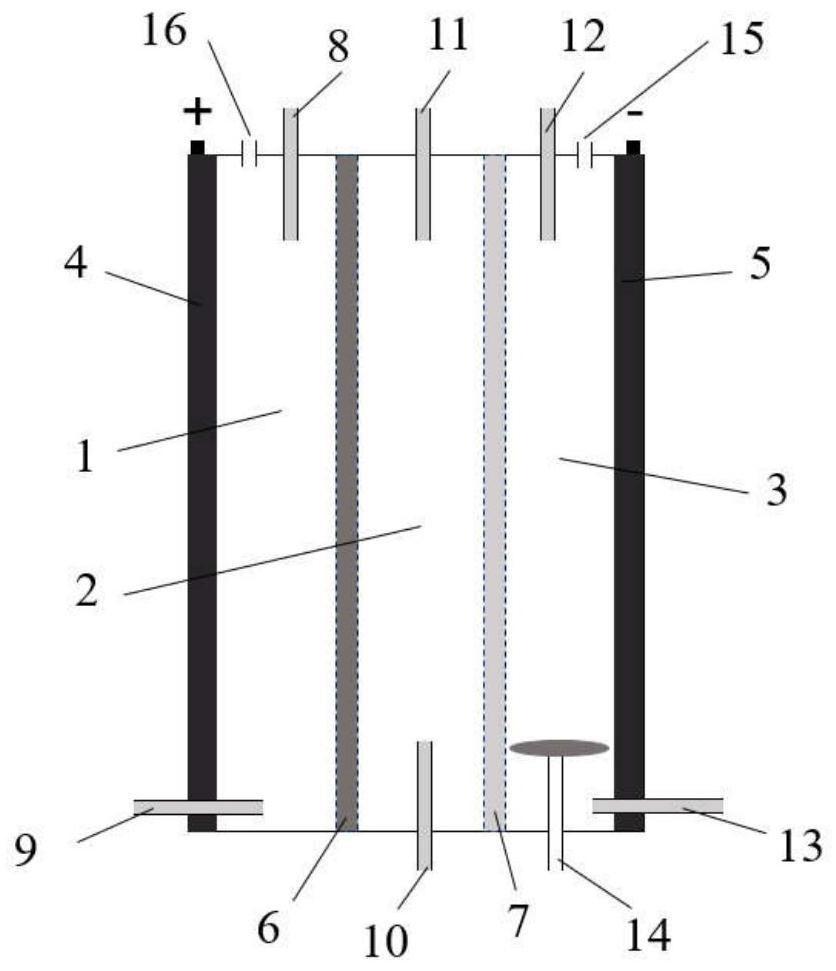

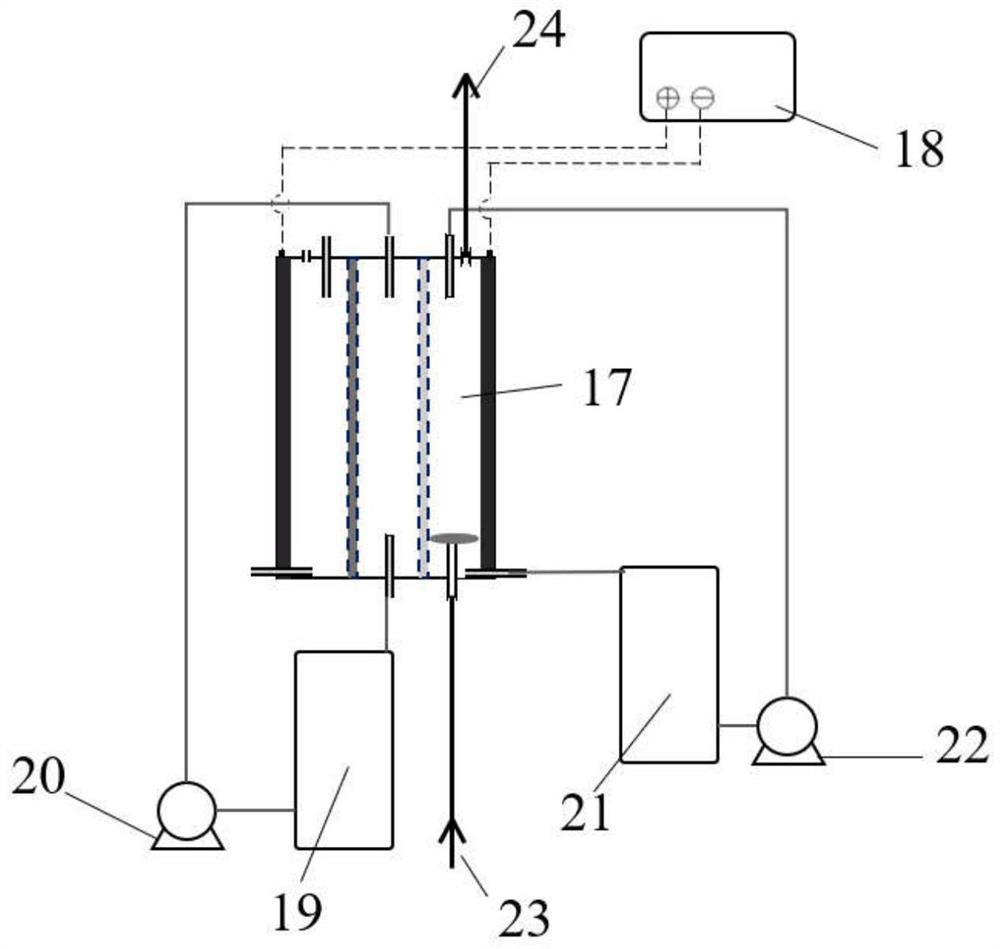

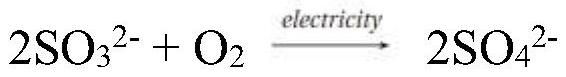

Method and device for capturing carbon dioxide and simultaneously producing sulfuric acid by sodium bisulfate

The invention belongs to the field of flue gas purification, and discloses a method and a device for capturing carbon dioxide and simultaneously producing sulfuric acid by using sodium bisulfate. According to the method, a desulfurization byproduct (NaHSO4) is converted into H2SO4 by using a three-grid electrodialysis device, and CO2 in flue gas is captured in a cathode chamber. Under the action of electric field driving and an ion exchange membrane, HSO4<-> enters an anode chamber to generate H2SO4 and is concentrated, and Na<+> enters the cathode chamber to generate NaOH; and CO2 containinggas to be treated is introduced from the cathode chamber and is absorbed and captured by NaOH. The technology is simple, green and economical, carbon dioxide in the flue gas is captured in the comprehensive utilization process of the sodium bisulfate solution, good environmental benefits are achieved, updating and upgrading of the flue gas treatment technology in China are promoted, and the treatment pressure of desulfurized gypsum is relieved.

Owner:PINGXIANG HUAXING ENVIRONMENTAL PROTECTION ENG TECH CO LTD

Core-shell structure lightweight aggregate prepared by cold bonding method and preparation method thereof

The invention discloses a core-shell structure lightweight aggregate prepared by a cold bonding method and a preparation method thereof. The method comprises the steps: preparing a calcined clay-basedgreen environment-friendly cementing material from ordinary Portland cement, calcined clay, limestone powder and gypsum in proportion; putting core material particles into a lightweight aggregate granulation device, then putting the calcined clay-based green environment-friendly cementing material, and uniformly spraying a mixture for granulation to form primarily-generated cold-bonded aggregate;carrying out primary maintenance on the primarily-generated cold-bonded aggregate, soaking the primarily-generated cold-bonded aggregate in a solution containing organic acid or phenol compounds, taking out the primarily-generated cold-bonded aggregate, airing the primarily-generated cold-bonded aggregate, and repeatedly spraying a calcium hydroxide aqueous solution on the surface of the aggregate to form aggregate with a super-hydrophobic surface; and continuously putting the aggregate with the super-hydrophobic surface into water for secondary maintenance, and thus producing the super-hydrophobic high-strength lightweight aggregate. According to the core-shell structure lightweight aggregate and the preparation method thereof, energy is saved, consumption is low, the processing flow issimplified, solid waste recycling can be achieved, the water absorption rate is low, and the single bearing capacity is high.

Owner:SHENZHEN UNIV

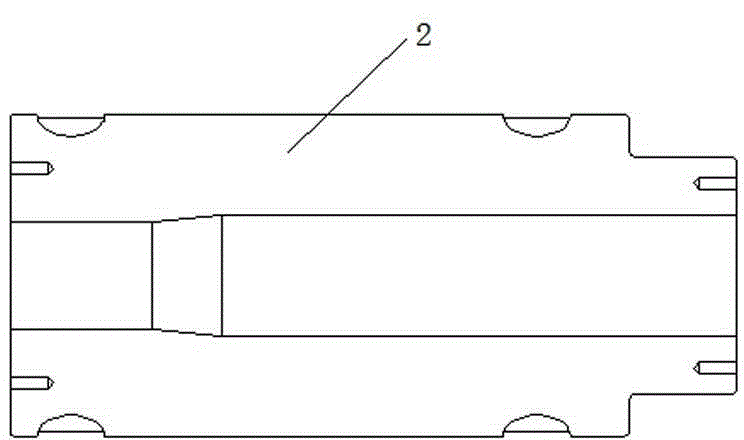

Multi-pass thickening molding integrated heavy weight drill pipe manufacturing method

The invention relates to the technical field of petroleum drill pipe processing and manufacturing, in particular to a multi-pass thickening molding integrated heavy weight drill pipe manufacturing method. The method specifically comprises the following steps of (1) selecting a large-wall thickness seamless steel tube containing high-molybdenum and high-chromium alloy as a raw material; (2) adopting an intermediate frequency furnace to carry out intermediate frequency heating on the end part of the seamless steel tube, wherein the heating temperature is 1190-1210 DEG C. According to the method, firstly, the seamless steel tube containing the high-molybdenum and high-chromium alloy is adopted as a tube body; secondly, the seamless steel tube containing the high-molybdenum and high-chromium alloy is subjected to upsetting thickening molding by adopting an integrated upsetting heavy weight drill pipe technology; finally, the subsequent processing is carried out to enable a finished product to reach the standards of 980 Mpa yield strength, 1105 Mpa tensile strength, 16% ductility, and (-20) 75 J ballistic work. The production technology is capable of solving the problems that in the traditional technology production process, too much raw materials are used, the cost of the whole thermal processing is overhigh, the yield of central deep hole drilling is over low, and the like.

Owner:NANTONG YONGDA PIPE IND

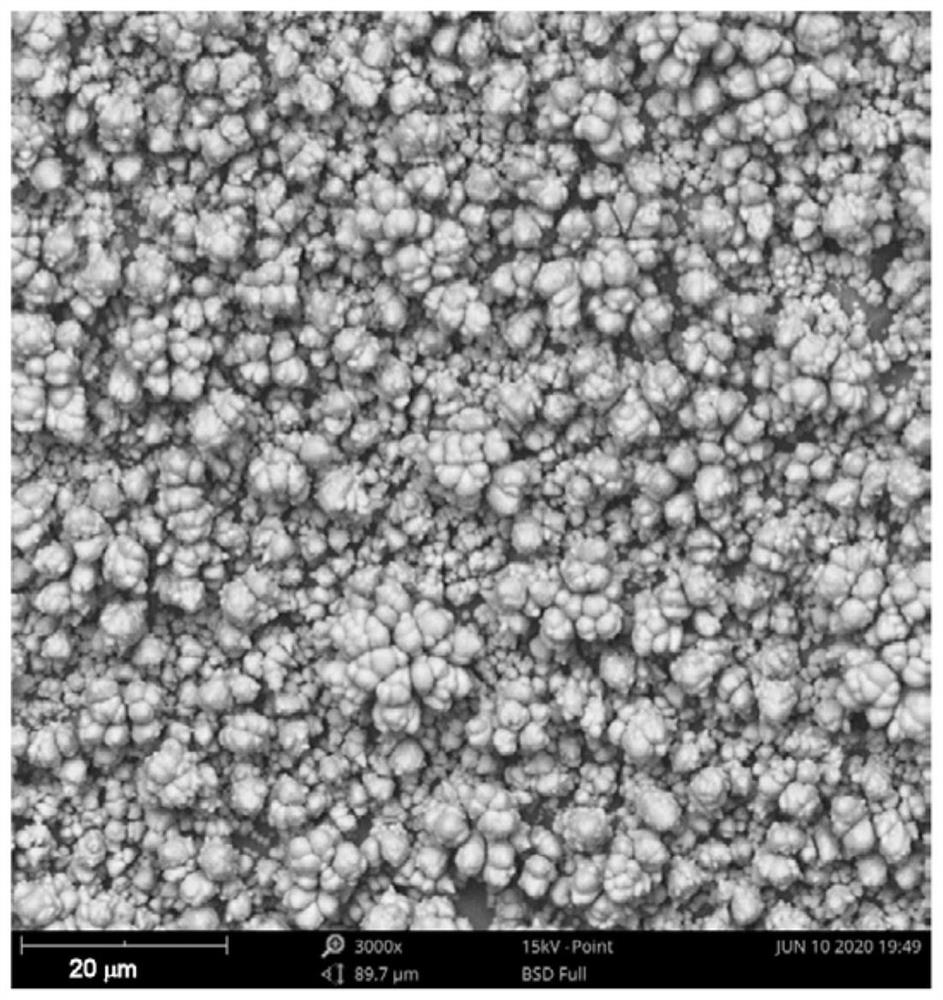

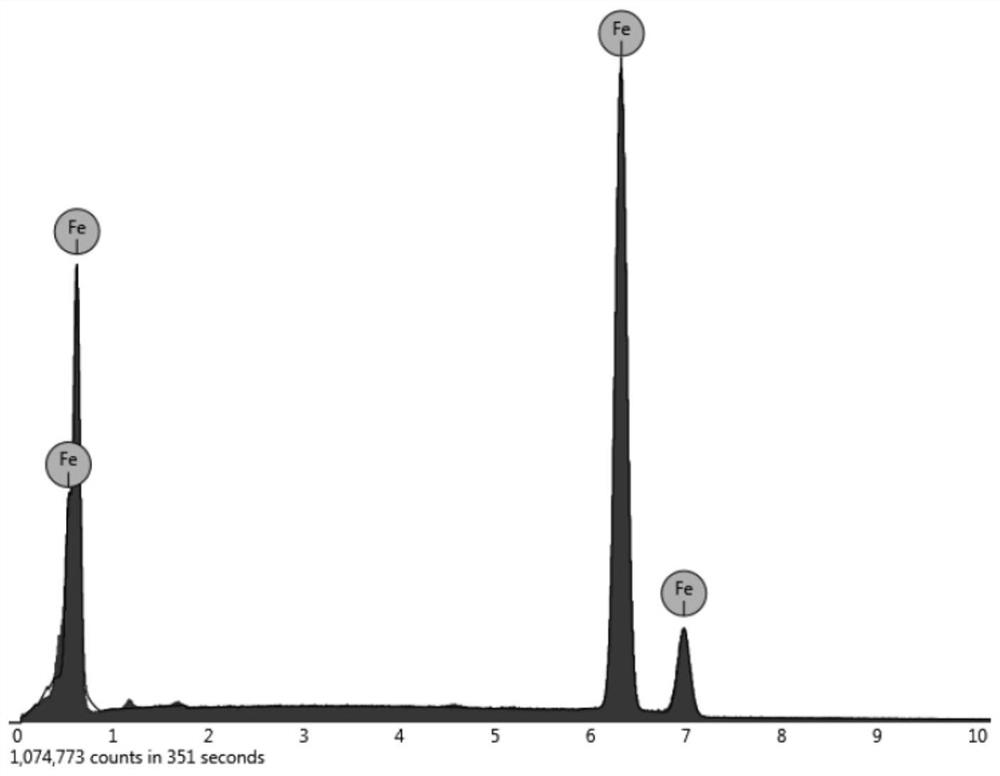

Electroplating solution for directly electrodepositing iron on surface of magnesium alloy and electroplating process thereof

The invention belongs to the technical field of surface engineering and surface treatment, and discloses an electroplating solution for directly electrodepositing iron on the surface of a magnesium alloy and an electroplating process thereof. The electroplating solution comprises the following components in concentration of 1-300 g / L of water soluble iron / ferrous salt, 1-1000 g / L of citric acid and / or citrate, 1-50 g / L of sodium fluoride, 0.01-200 g / L of a surfactant, 0.1-500 g / L of a co-complexing agent and 1-1000 mL / L of ammonia, and water is used as a solvent. The electroplating solution can be used for electrodepositing the iron on the surface of the magnesium alloy in a one-step method, and a prepared pure iron coating is compact, uniform, good in binding force, good in biocompatibility, degradable and stable in effect, can provide effective corrosion protection for a magnesium alloy matrix, and can also realize controllable preparation of coating morphology, grain size and thickness and the like. The electroplating solution and the electroplating process thereof have the advantages of low cost, simple operation and easiness in large-scale production.

Owner:JINAN UNIVERSITY

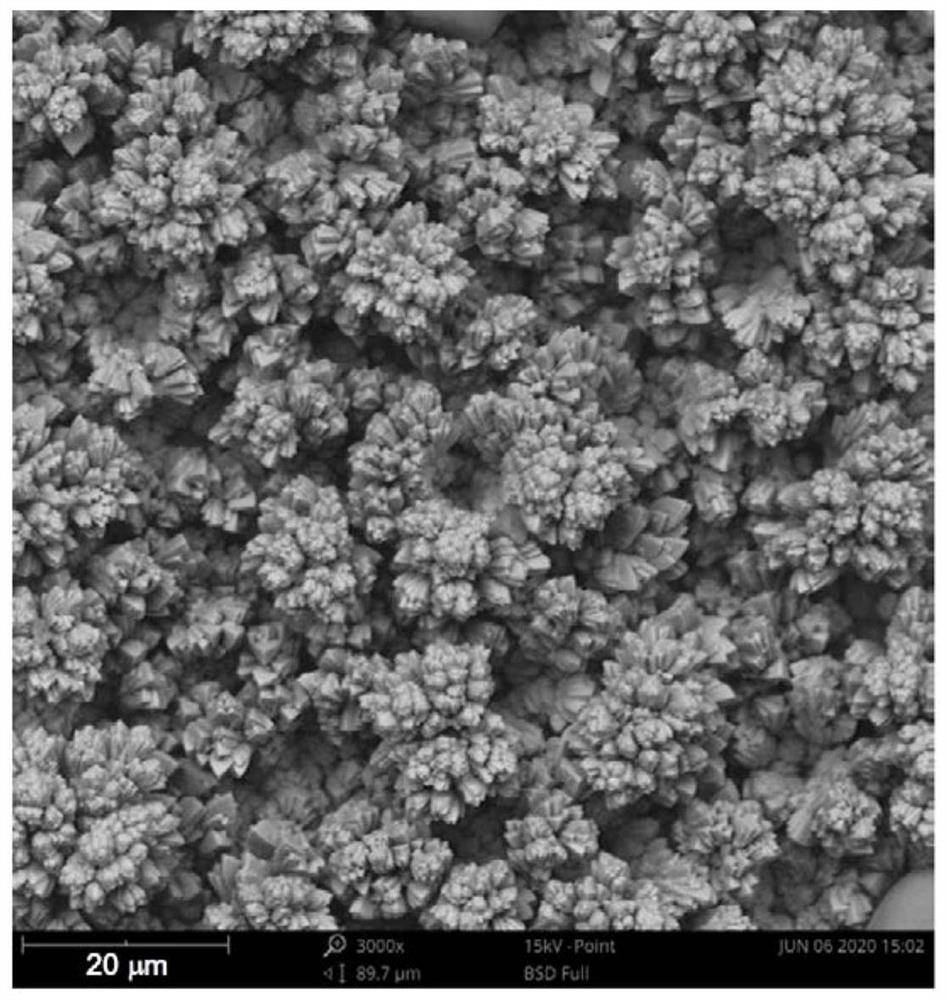

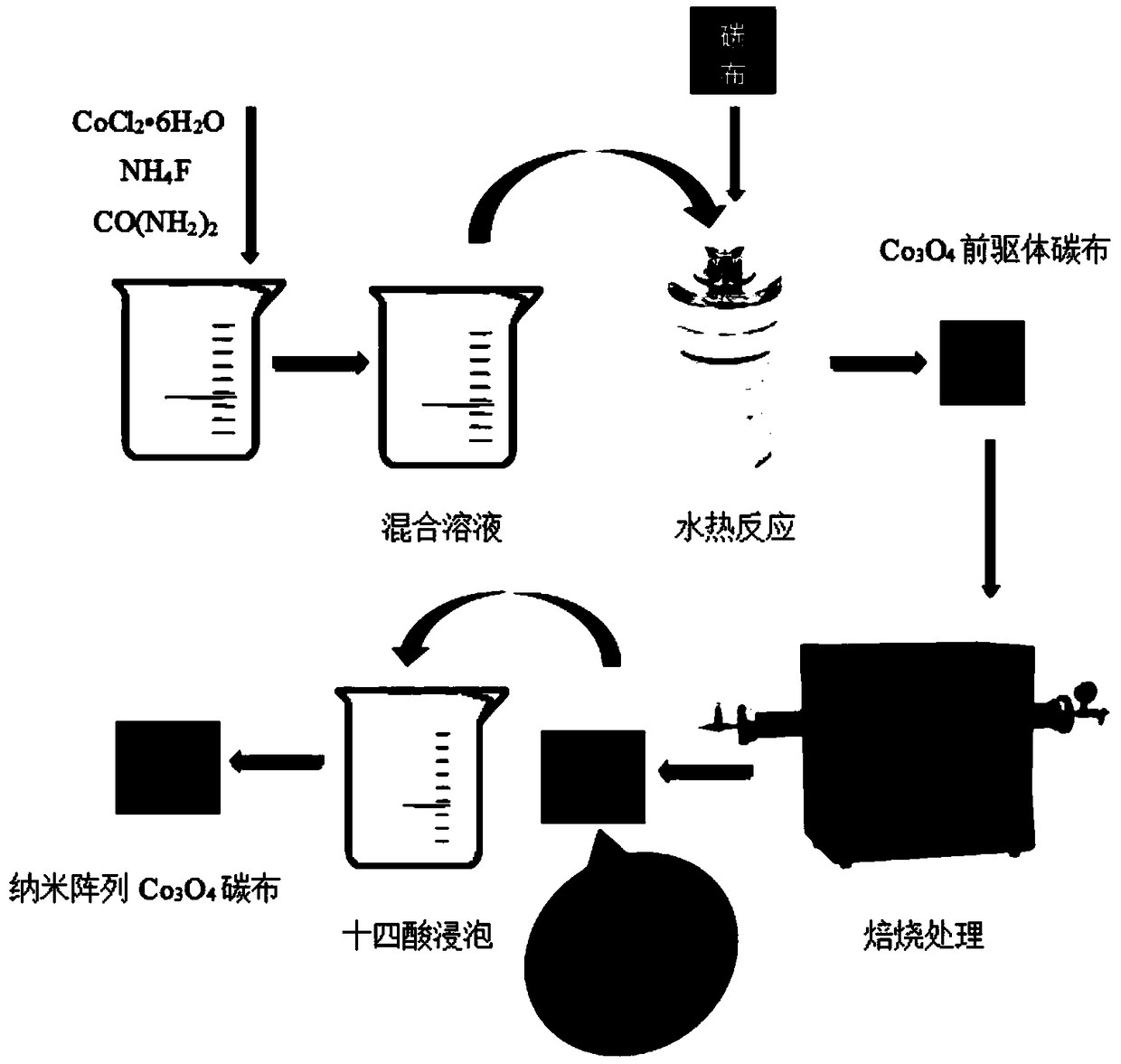

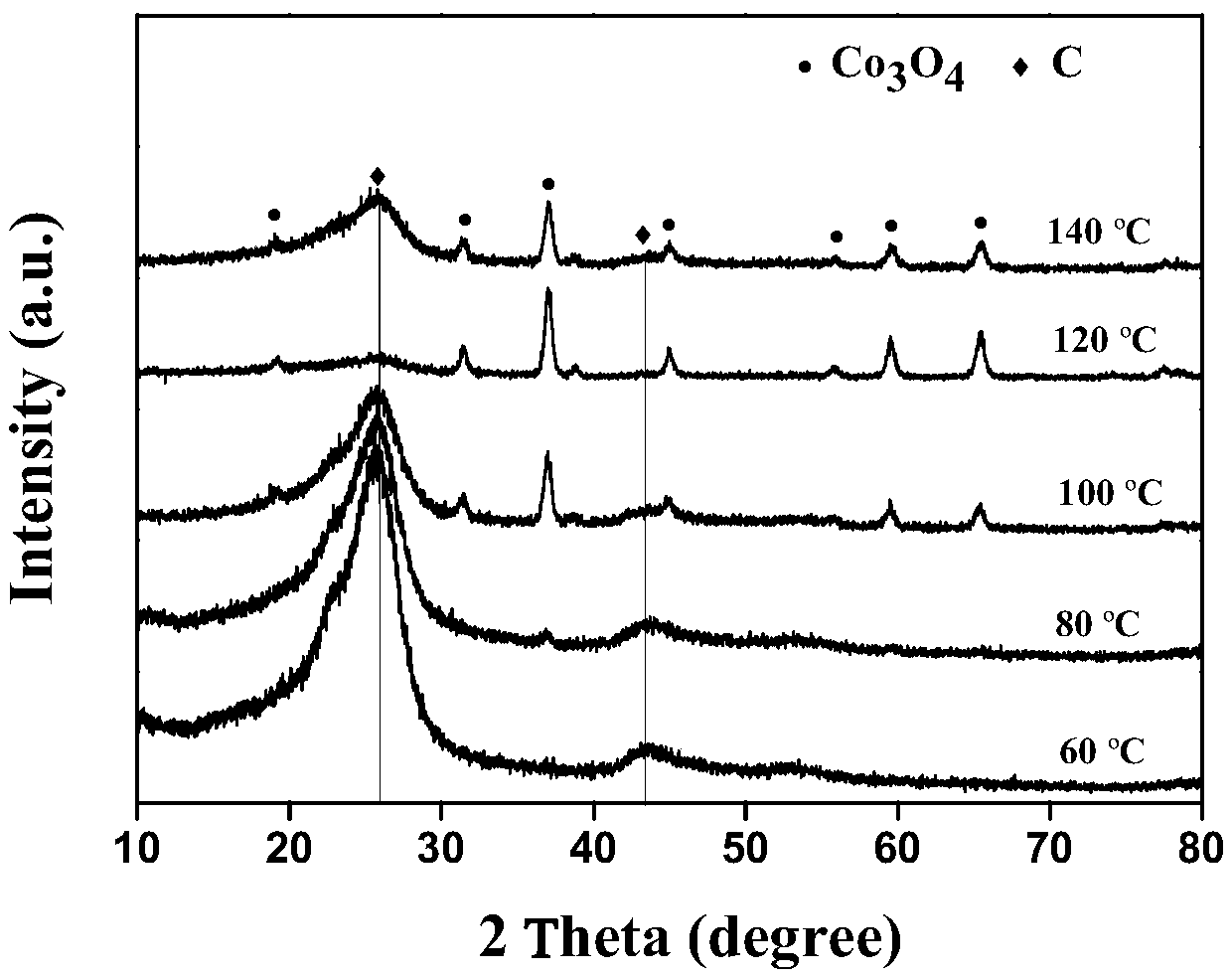

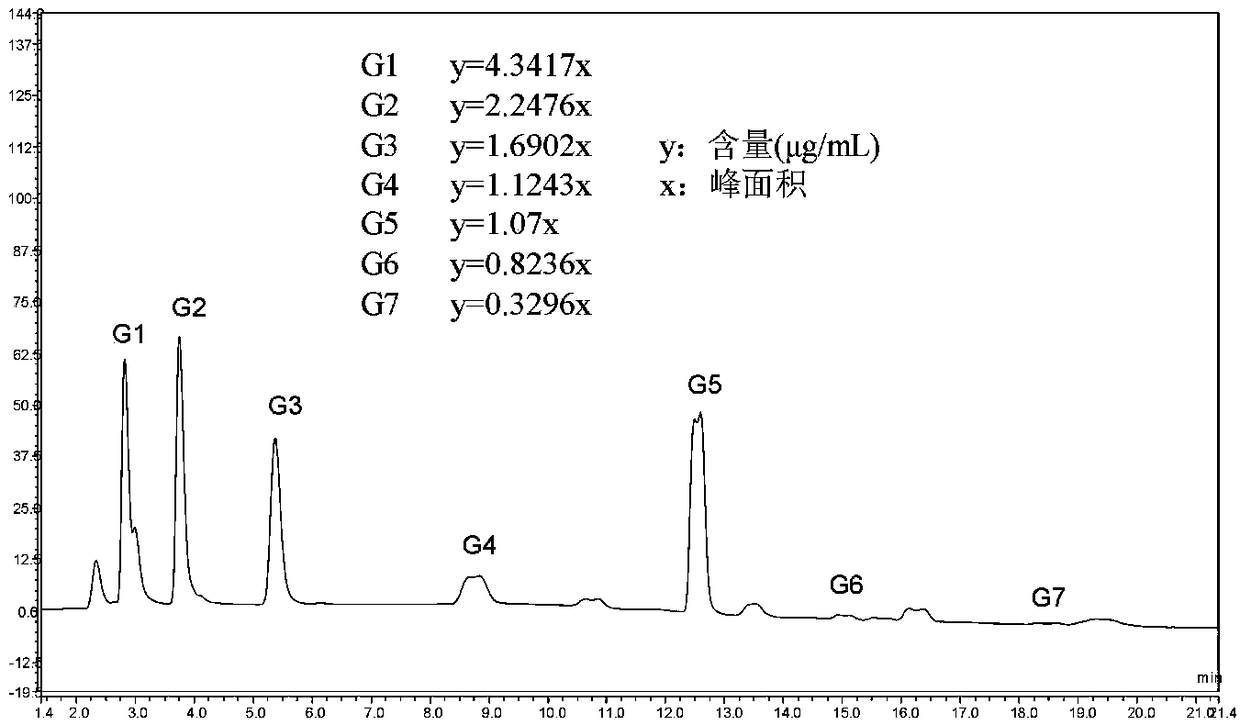

Co3O4 nanometer array super-hydrophobic material coating and preparation method thereof

ActiveCN109505115AEconomical and easy to operateSolve the harsh preparation conditionsCarbon fibresLiquid repellent fibresNanometreCobalt(II,III) oxide

The invention discloses a Co3O4 nanometer array super-hydrophobic material coating and a preparation method thereof. The preparation method is characterized by comprising the following steps of synthesis of a cobaltosic oxide nanometer array and synthesis of a hydrophobic material on a carbon cloth substrate. The preparation method has the beneficial effects that the preparation method of the Co3O4 nanometer array super-hydrophobic material coating is economical in technology and easy to operate and solves the problems of rigorous condition, tedious step and high cost of preparation of the hydrophobic material to a certain degree; and in addition, the prepared Co3O4 nanometer array super-hydrophobic material coating has super-hydrophobicity, is wide in applicability, can be attached to other substances and the like.

Owner:NORTHWEST UNIV

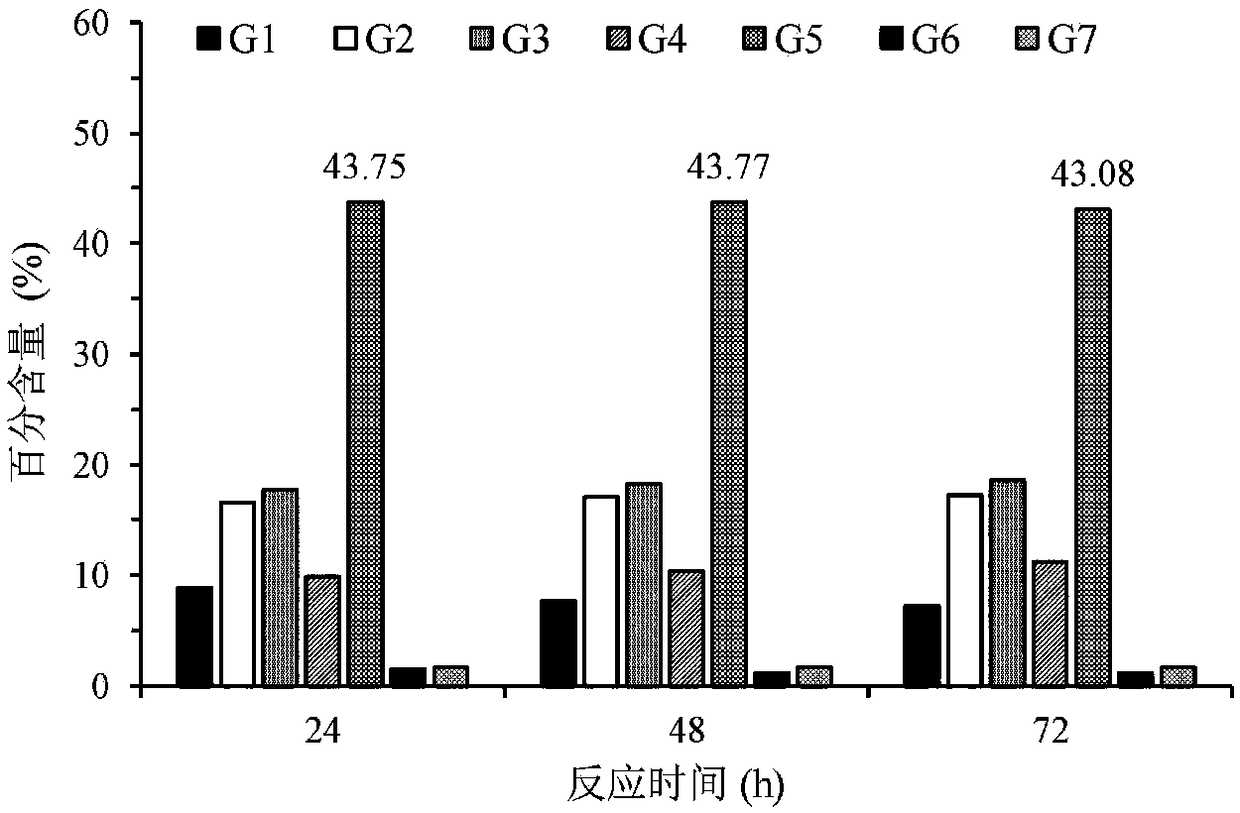

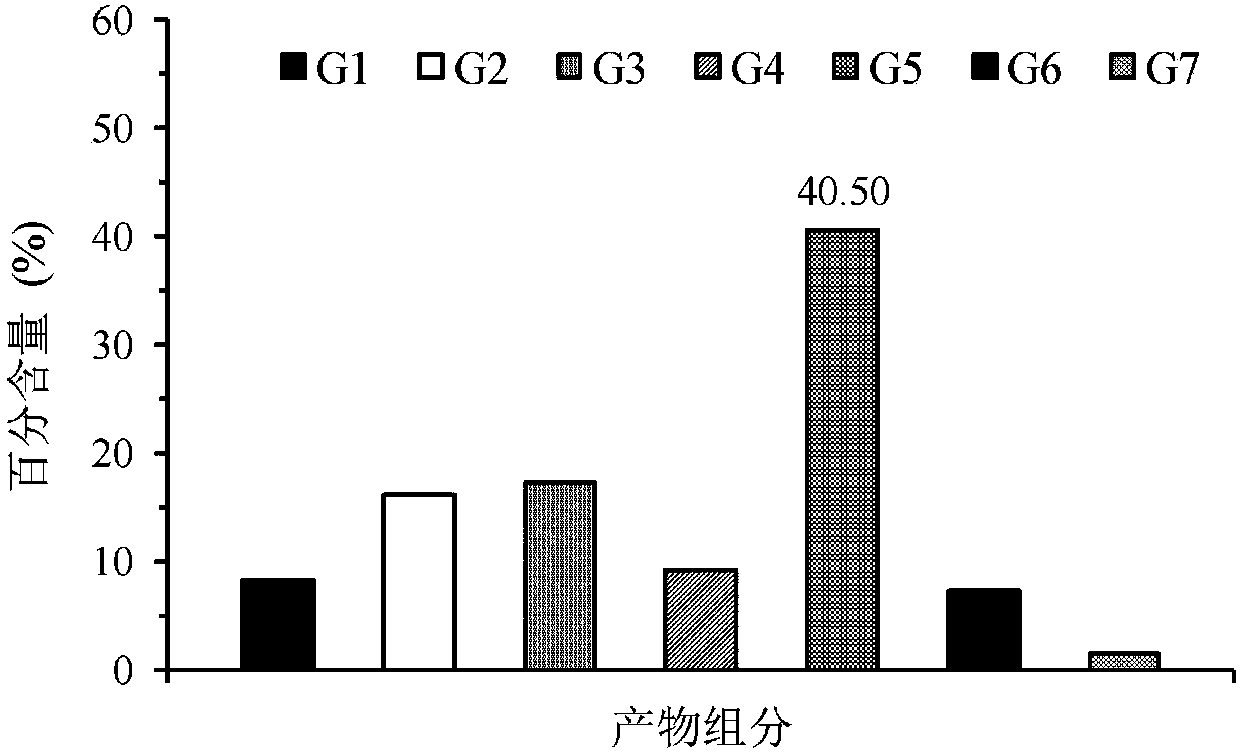

Method for preparing straight-chain maltopentaose by using double-enzyme method

ActiveCN108300749AImprove thermal stabilityIncreased specific enzyme activityOrganic active ingredientsMetabolism disorderReaction temperaturePullulanase

The invention relates to a method for preparing straight-chain maltopentaose by using a double-enzyme method, and belongs to the technical field of the production of functional sugar. The number, in the GenBank, of the amino acid sequence of a used straight-chain maltooligosaccharide producing enzyme is AIV43245.1; the used pullulanase is purchased from the Japanese Amano Enzyme Inc.. The method comprises the following steps of preparing starch or maltodextrin solution with the pH (potential of Hydrogen) of 5.5 to 6.5 as a substrate, adding the straight-chain maltooligosaccharide producing enzyme according to an enzyme addition amount of 50U / g to 100U / g, adding the pullulanase according to an enzyme addition amount of 2U / g to 5U / g, and reacting for 24 to 72 hours at 60 to 70 DEG C to subsequently obtain straight-chain maltooligosaccharide syrup, wherein a conversion ratio (measured according to glucose to straight-chain maltoheptaose) reaches 90 percent or above; a main product is thestraight-chain maltopentaose; the percent of the main product can reach 40 percent or above. Two types of enzymes used by the method can be simultaneously added; the reaction temperature or the pH does not need to be regulated midway; the alpha-amylase is also not needed to liquefy the substrate; a calcium ion does not need to be added, and the method is simple in production process, is safe and further economical, and has higher application value.

Owner:JIANGNAN UNIV

Freeze-thawing demulsification based method for extracting tea oil

A freeze-thawing demulsification based method for extracting tea oil is as follows: (1) artificially removing shells in tea-oil tree seed, drying and crushing; (2) weighing the tea seed powder obtained in the step (1), adding distilled water according to the mass ratio of solid to liquid being 1: 3-1: 8, beating by a colloid mill for 10-15 min, centrifuging at 3000-10000 r / min for 10-30 min, repeating 3-5 times, and collecting the upper layer emulsion; (3) beating the remaining aqueous phase and the residue from the step (2) by a colloid mill again for 5-10 min, allowing to stand, centrifuging at 3000-10000 r / min for 10-30 min, repeating 3-5 times, and collecting the upper layer emulsion; (4) combining the emulsion collected in step (3) and step (4); (5) freezing the emulsion under conditions of -20 to -80 DEG C for 12-24 h, taking out, thawing in warm water at 40-60 DEG C, centrifuging at 2000-5000 r / min, separating the upper supernatant oil layer, and repeating 3-5 times; and (6) merging the collected clear oil into and drying under vacuum. The emulsion of the present invention has oil content rate of 60-70%; freeze-thawing demulsification process is simple and does not use any chemicals; and the extracted tea oil is economic, efficient, safe and nutritious.

Owner:NANCHANG UNIV

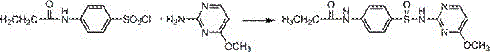

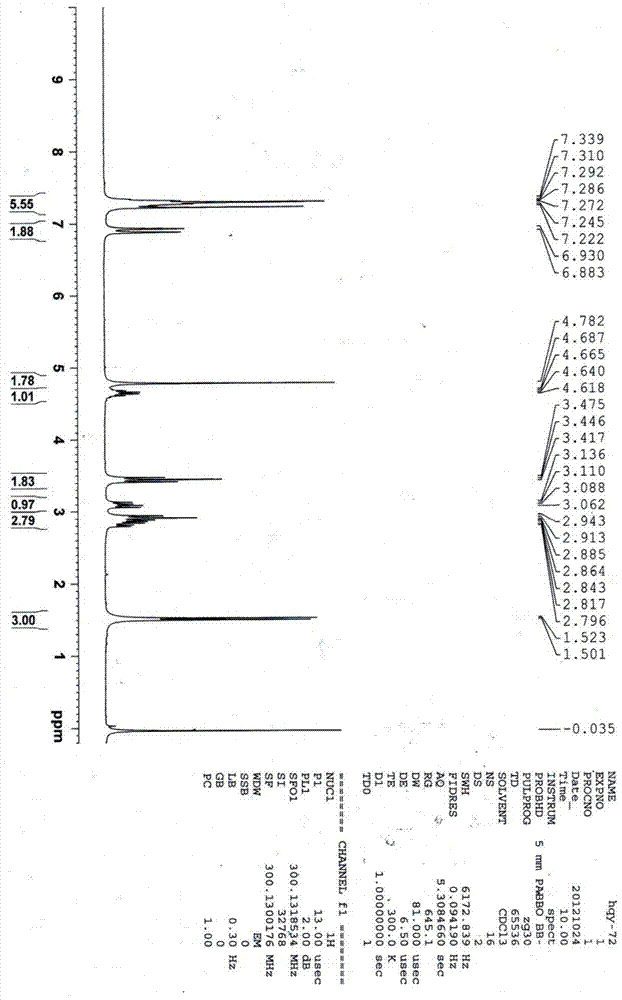

Preparation method of antibacterial veterinary drug sulfamonomethoxine sodium

InactiveCN106565616AEliminate large-scale water removal operationsImprove reaction efficiencyOrganic chemistrySulfonyl chlorideSulfamonomethoxine

The invention relates to preparation of a veterinary drug, namely, sulfamonomethoxine sodium used for treating animal diseases caused by sensitive bacteria. An anhydrous lewis acid catalyst, namely, anhydrous calcium chloride is introduced into a condensation reaction step, and 4-methoxy group-2-aminopyrimidine serves as a reaction raw material; in organic alkaline solvent, the 4-methoxy group-2-aminopyrimidine and the catalyst are added in the first place, and then p-acetamidobenzene sulfonyl chloride is added in batches; the effect that moisture in a reaction system is controlled to be always in a low level can be achieved, and meanwhile a reaction substrate can also be effectively activated, so that an intermediate product with the purity being more than 98% can be obtained in short time at a high temperature through a condensation reaction, and the yield can reach more than 95%; and then after hydrolysis, decoloration and crystallization operation in specific mixed crystallization solvent, a target product, namely, the sulfamonomethoxine sodium with the purity reaching more than 99% can be obtained, and the situation of requirements for animal antibacterial veterinary drugs in the prior art is relieved.

Owner:杭州洪晟生物技术股份有限公司

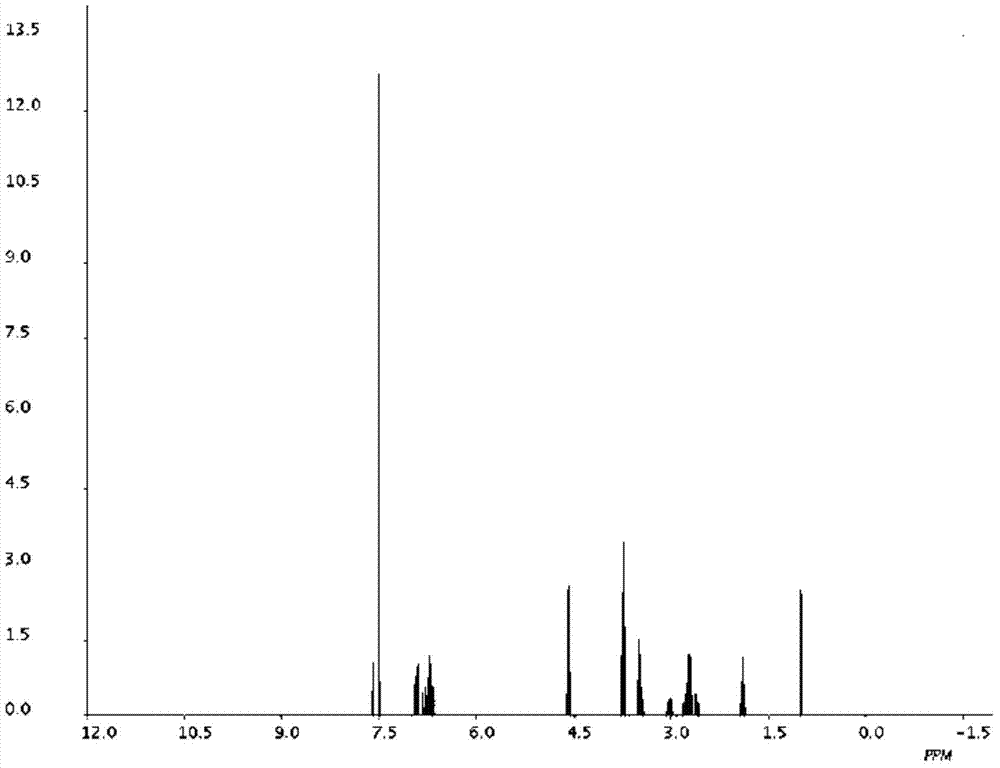

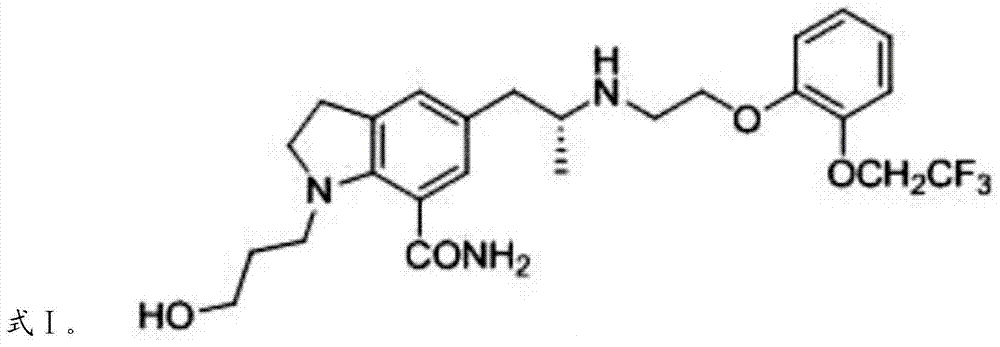

Silodosin intermediate, preparation method of silodosin intermediate and method for preparing silodosin from silodosin intermediate

The invention relates to the field of compound synthesis and especially relates to a silodosin intermediate, a preparation method of the silodosin intermediate, and a method for preparing silodosin from the silodosin intermediate. The method for preparing silodosin from the silodosin intermediate has the characteristics of economy, safety, high purity and high yield and is suitable for large-scale industrial production.

Owner:ANHUI QINGYUN PHARMA & CHEM

Method for synergically removing simple substance mercury and hydrogen sulfide from hot coal gas

InactiveCN102226114ASynergistic removalEfficient and Stabilized TreatmentGas purification by catalytic conversionGas purification with selectively adsorptive solidsSorbentPhysical chemistry

The invention relates to a method for synergically removing simple substance mercury and hydrogen sulfide from hot coal gas, which comprises the following steps: charging oxygen into unpurified coal gas with 50-300 DEG C so that the weight of oxygen is 0.8-1.7 times of that of hydrogen sulfide in the coal gas; and introducing the coal gas into an adsorber filled with adsorbent at volume space velocity of 1000-3000h<-1>, and adsorbing for 2.5-3 hours. The invention has the advantages of low cost and no secondary pollution.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for comprehensively extracting active substances from asparagus scraps based on multi-stage membrane separation

InactiveCN102532333AEasy extractionImplement extractionSugar derivativesSugar derivatives preparationUltrafiltrationSeparation technology

The invention relates to a method for comprehensively extracting active substances from asparagus scraps based on multi-stage membrane separation, which comprises the following steps that: the asparagus scraps are used as a raw material, are extracted with hot water of PH = 7-9 to obtain an extract, and then the extract is subjected to sedimentation centrifugation and 100-800-mesh bag filtering; the extract is subjected to an ultrafiltration membrane with interception molecular weight of 5000-15000Da to obtain a concentrated solution and a filtrate, the concentrated solution is precipitated with 75-95% alcohol to obtain an asparagus polysaccharide precipitate, and the asparagus polysaccharide precipitate is separated and dried to obtain asparagus polysaccharide with the content of 50%; the obtained filtrate is concentrated with a nanofiltration membrane with the molecular weight of 100-500Da to obtain a concentrated solution, the pH value of the concentrated solution is adjusted to 3-4, the concentrated solution is precipitated and dried to obtain rutin; and finally, a dialysate is pumped back to an extraction tank to be used as water for extraction. The residues are crushed to be used for feed. The process adopts an advanced membrane separation technology, improves the preparation efficiency of asparagus polysaccharide and rutin, realizes clean production and no waste water and residue emission, turns waste into wealth and realizes comprehensive utilization of resources. The method has the advantages of advanced process, stable product quality, high purity, clear target and easiness in industrial production.

Owner:FUJIAN HUIZE BIOTECH

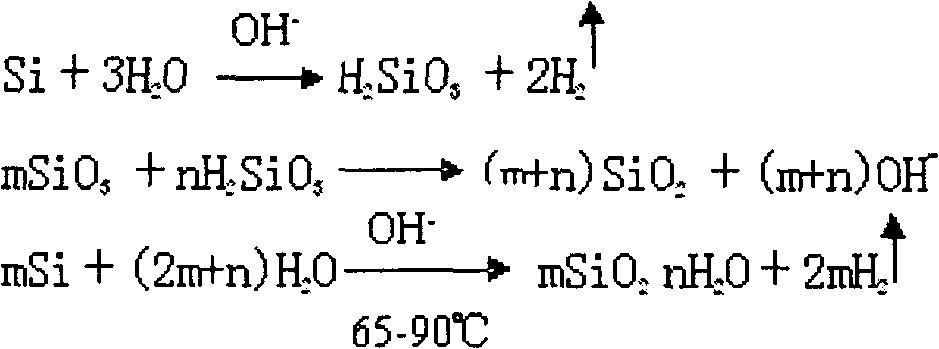

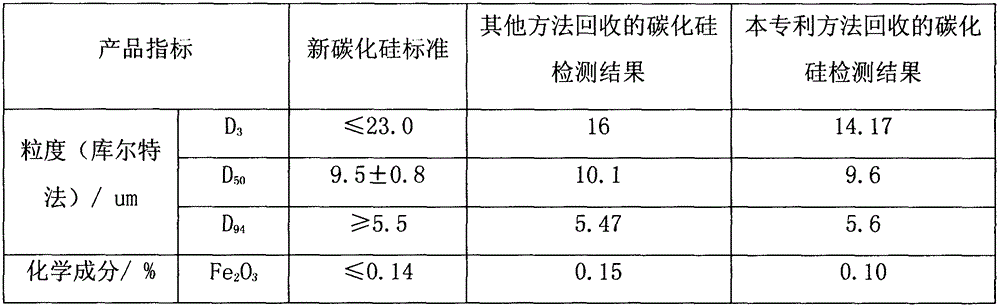

Method for recycling silicon cutting waste mortar

ActiveCN102746935AReduce dosageReduce cost investmentSilicon carbideSilicon compoundsDistillationPolyethylene glycol

Disclosed is a method for recycling silicon cutting waste mortar. The method comprises the steps of performing solid-liquid separation of the waste mortar; performing solid flow washing and vacuum filtration; drying the obtained filter cake, mixing with deionized water and performing activation reaction; adding water glass and sodium hydroxide successively and performing heating reaction, performing solid-liquid separation of the obtained product, performing ion exchange resin decolorization and distillation of the liquid phase to obtain silica sol, and performing solid phase washing and drying to obtain a silicon carbide raw material; and performing ultra precision filter of obtained liquid phase after solid-liquid separation of the waste mortar, adding a decoloring agent a filter aid to perform solid-liquid separation, reducing the conductivity, and heating and evaporating water to obtain finished polyethylene glycol cutting liquid. According to the technical scheme of the method, the flow line production is achieved, the silicon cutting waste mortar is recycled, the silica sol is prepared effectively, and the environmental pollution is reduced.

Owner:山东网金资源再利用发展有限公司

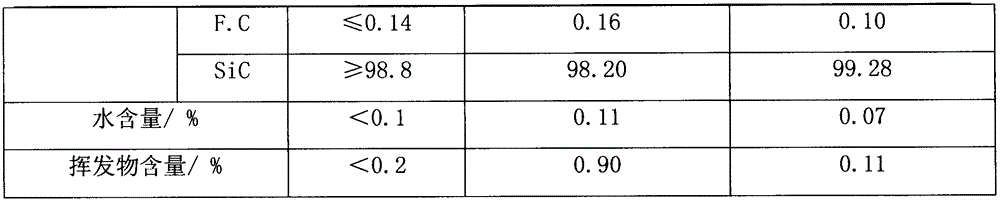

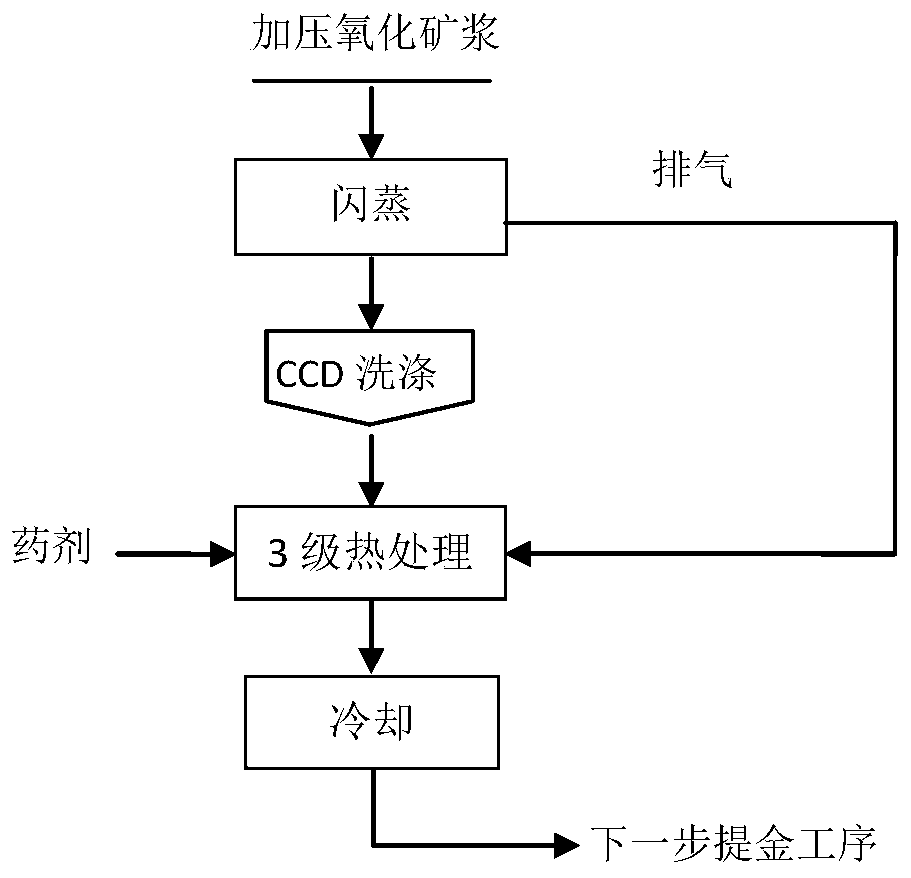

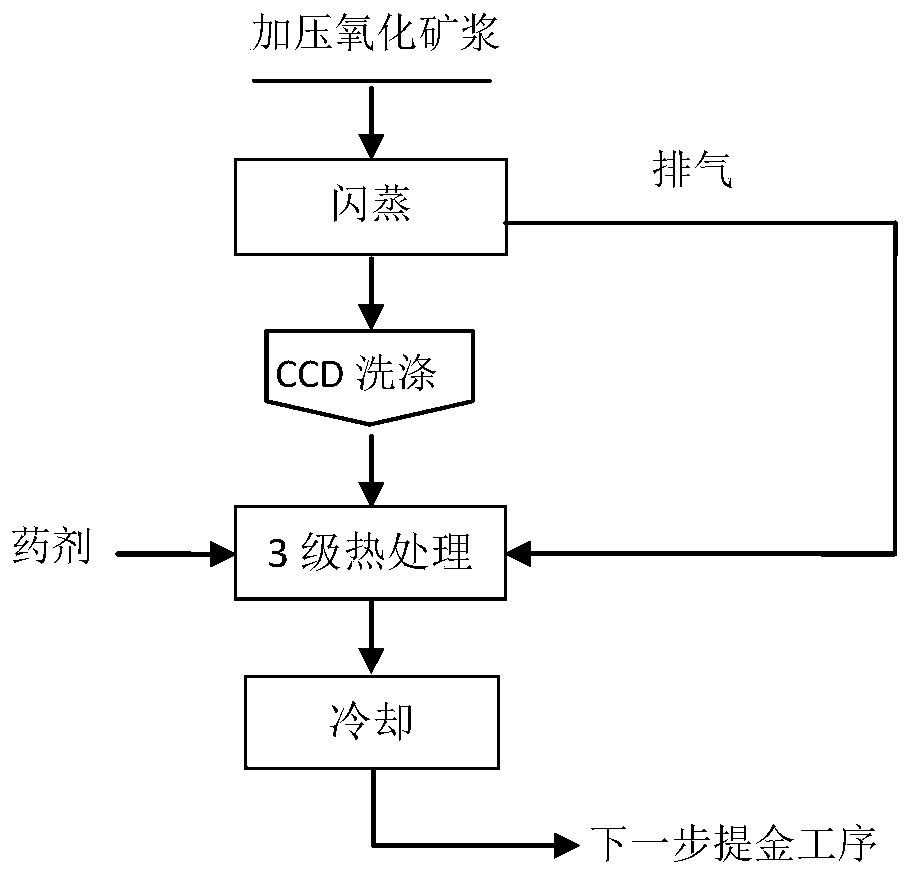

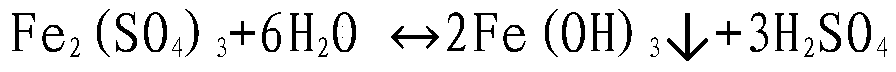

Method for improving leaching efficiency of gold in pressurized oxidizing slag of gold concentrate

InactiveCN109957652AHigh recovery rateImprove adaptabilityProcess efficiency improvementSlagResource utilization

The invention discloses a method for improving the leaching efficiency of gold in pressurized oxidizing slag of gold concentrate. The technology characteristics of a pressurizing oxidizing slag are combined, waste heat of flashing is recycled, washed oxidizing ore pulp of the gold concentrate is introduced, an reagent breaking wrapping of vitriol class and gypsum is added in a serial reaction tank, temperature and reaction parameters on different stages are controlled, thus reaction is completed under the condition of low dosage of the reagent, and treated oxidizing ore pulp enters a gold extraction system again after being cooled. According to the method, dissociation gold wrapped with the vitriol class and gypsum class can be opened, the waste heat of a flashing system is used, treatmentcan be completed only by using reaction of traditional reagents and a stirring tank, thus the high recovery rate of gold is achieved in the gold extraction process, the technology is simple, convenient and economic, meanwhile adaptability of the pressurizing technology is also improved, the application range of the method is broadened, the resource utilization rate is improved, and the effect isobvious.

Owner:厦门紫金矿冶技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com