Small-sized metallic oxide nano-cluster/mesoporous SiO2 nanocomposite and preparation method thereof

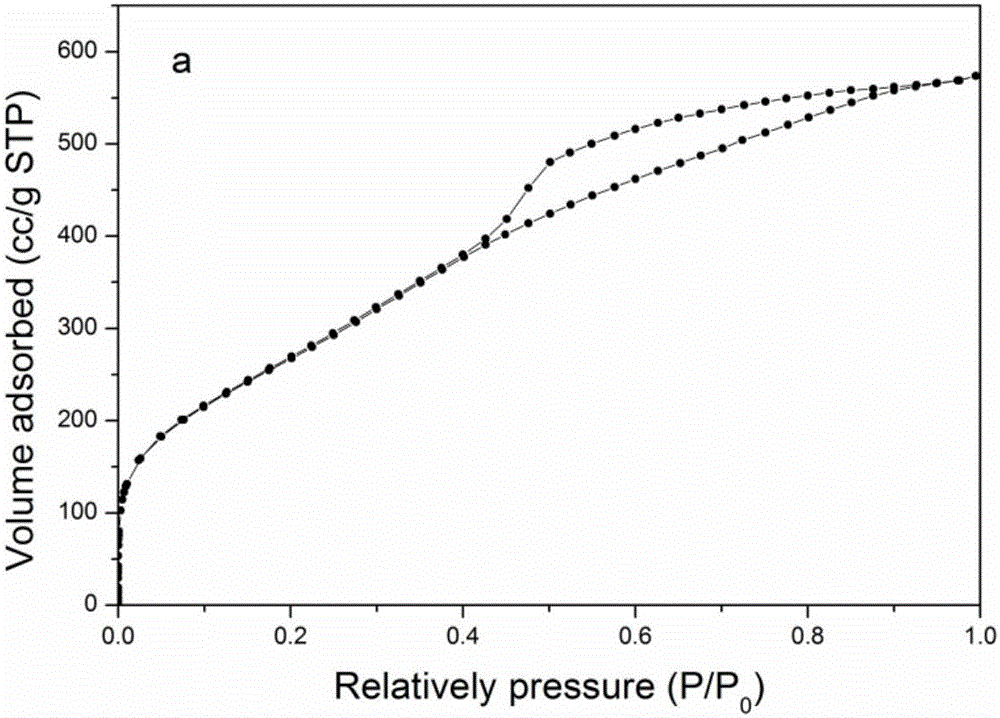

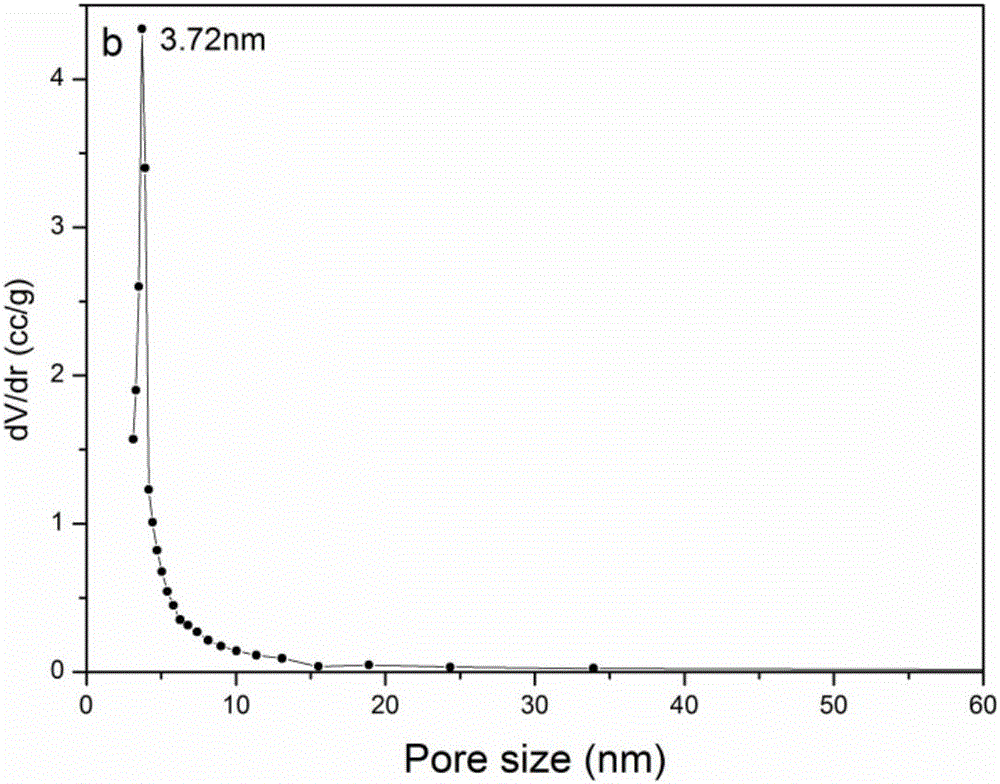

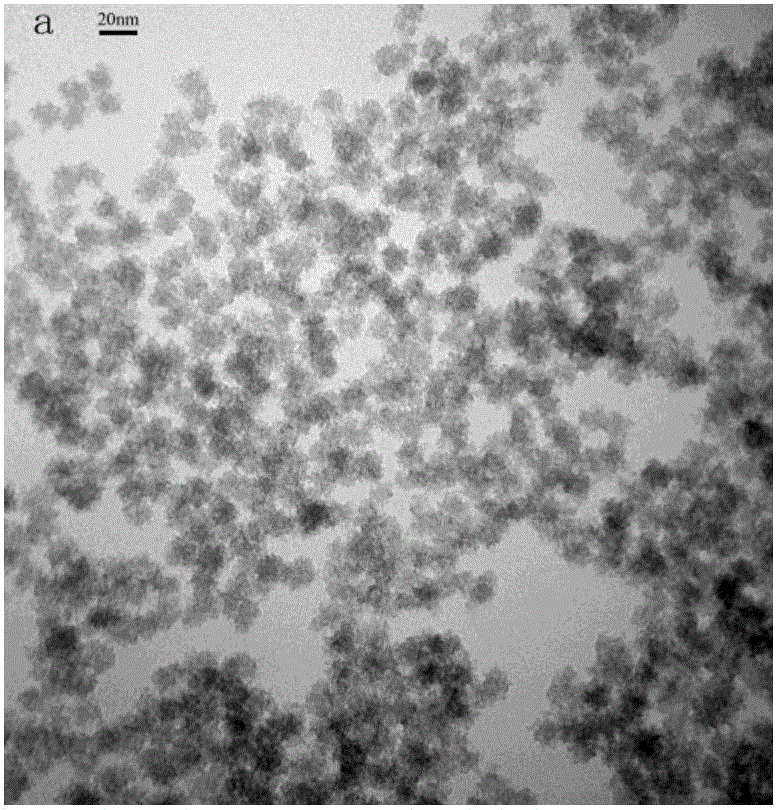

A nano-composite material and oxide technology, which is applied in the field of nano-material preparation and heterogeneous catalysis, can solve the problems of long reaction time and complicated process, and achieve the effect of small size, relatively large pore size and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]Add 0.01mol of cationic surfactant cetyltrimethylammonium chloride into the flask, then add 11mL of cyclohexane, 3mL of n-butanol, and 0.6mL of ammonia water into the flask, stir at 25°C for 3min, and then Add 50 μL ammonium molybdate (0.05 mol / L ammonium molybdate aqueous solution) and continue stirring for 40 min. Measure 0.08 mL of ethyl orthosilicate, add octadecyltrimethoxysilane, make the molar ratio of octadecyltrimethoxysilane: ethyl orthosilicate to be 1:4, and react for 2 hours. After the reaction is finished, isopropanol is added, and then undergoes ultrasonication, centrifugation, washing, roasting, and natural cooling to obtain the target product. The roasting process is as follows: during the whole roasting process, air with a flow rate of 20mL / min is introduced, and the temperature is programmed from room temperature to 250 °C at a rate of 5 °C / min, and then roasted for 30 minutes, and then the temperature is programmed to rise to 300 °C at a rate of 2 °C / ...

Embodiment 2

[0031] 0.01 mol of cationic surfactant cetyltrimethylammonium bromide was added to the flask, and then 17 mL of cyclohexane, 5 mL of n-butanol and 0.8 mL of ammonia water were added to the flask. Stir at 35°C for 3 min, then add 50 μL ammonium molybdate (0.1 mol / L ammonium molybdate aqueous solution) and continue stirring for 40 min. Measure 1.8mL tetraethyl orthosilicate, add octadecyltrimethoxysilane, make C 18 The molar ratio of TMS to TEOS was 1:4, and the reaction was 2h. After the reaction is finished, isopropanol is added, and then undergoes ultrasonication, centrifugation, washing, roasting, and natural cooling to obtain the target product. The roasting process is as follows: during the entire roasting process, air with a flow rate of 30mL / min is introduced, and the temperature is programmed from room temperature to 250 °C at a rate of 10 °C / min, and the temperature is programmed to rise to 500 °C at a rate of 5 °C / min. Calcined for 2 hours to get MoO 3 Nanocluster / ...

Embodiment 3

[0034] Take 0.01mol of cationic surfactant cetyltrimethylammonium chloride and add it into the flask, then add 19mL of cyclohexane, 5.5mL of n-butanol, and 1mL of ammonia water into the flask, stir at 45°C for 3min, and then Add 50 μL ammonium molybdate (0.2 mol / L ammonium molybdate aqueous solution) and continue stirring for 40 min. Measure 6 mL of ethyl orthosilicate, add octadecyltrimethoxysilane to make the molar ratio of octadecyltrimethoxysilane: ethyl orthosilicate is 1:40, and react for 2 hours. After the reaction is finished, isopropanol is added, and then undergoes ultrasonication, centrifugation, washing, roasting, and natural cooling to obtain the target product. The roasting process is as follows: during the whole roasting process, air with a flow rate of 40mL / min is introduced, and the temperature is programmed from room temperature to 250 °C at a rate of 2 °C / min, and then roasted for 50 minutes, and then the temperature is programmed to rise to 380 °C at a rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com