Method for recycling silicon cutting waste mortar

A waste mortar, silicon cutting technology, applied in chemical instruments and methods, silicon carbide, silicon compounds, etc., to achieve the effects of improving appearance quality, improving conversion rate, and high dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

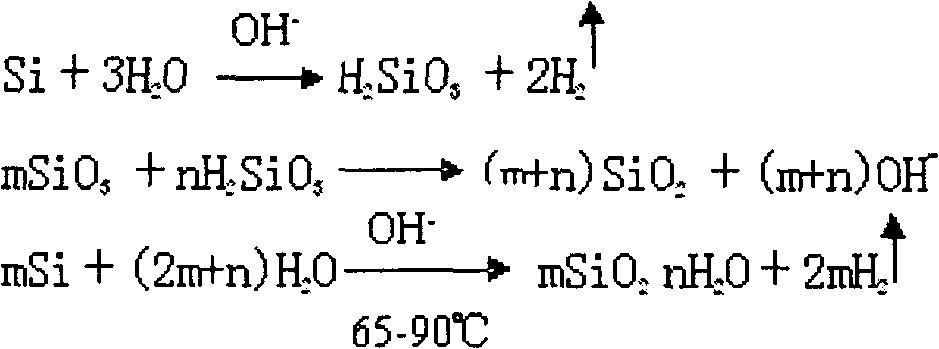

Method used

Image

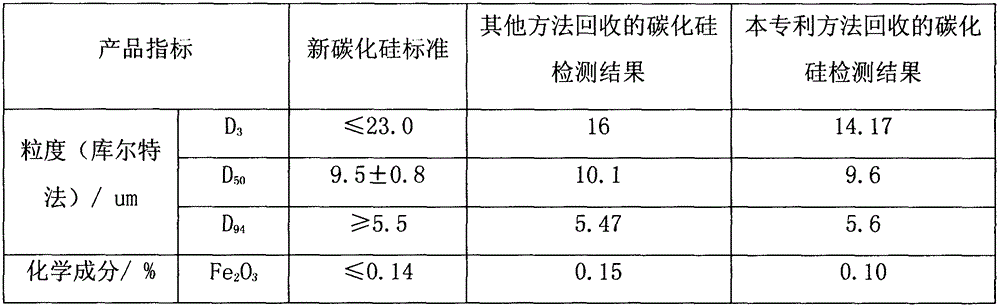

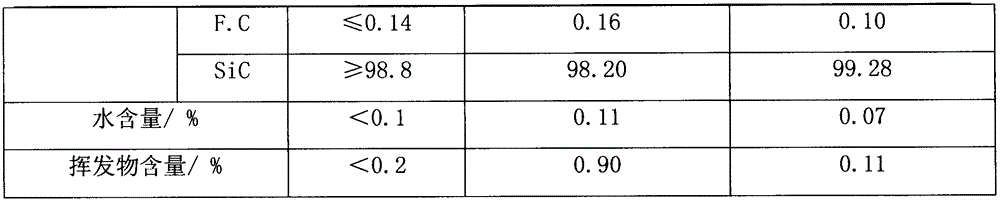

Examples

Embodiment 1

[0052] Step (1): Weigh 2000g of silicon cutting waste mortar, stir evenly, add to a cyclone separator, and separate to obtain 1350g of solid flow and 650g of liquid flow;

[0053] Step (2): wash the separated solid flow with 1000g of water, vacuum filter, dry the obtained solid phase filter cake at a temperature of 110°C and weigh 1200g (silicon carbide content 94%; silicon component ( Si+SiO2) content 5.3%, wherein silicon content 5%, silicon dioxide content 0.3%);

[0054] Step (3): Dissolving 1200 g of the filter cake in 2400 g of deionized water, stirring evenly and fully to obtain a mixed suspension, stirring and activating the reaction at a temperature of 30°C for 40 minutes to remove the inert film on the surface of the silicon powder;

[0055] Step (4): After the activation reaction, add water glass at a temperature of 30°C (water glass is a solution of sodium silicate, the experiment specifically uses sodium silicate nonahydrate, and the density is 0.85g / cm 3 , the s...

Embodiment 2

[0067] Step (1): Weigh 2000g of silicon cutting waste mortar, stir evenly, add into a cyclone separator, and separate to obtain 1355g of solid flow and 645g of liquid flow;

[0068] Step (2): wash the separated solid flow with 2000g of water, vacuum filter, dry the obtained solid-phase filter cake at a temperature of 110°C and weigh 1200g (silicon carbide content 93.9%; silicon component ( Si+SiO 2 ) content of 5.2%, of which silicon content is 4.9%, silicon dioxide content is 0.3%);

[0069] Step (3): Dissolving 1200 g of the filter cake in 600 g of deionized water, stirring evenly and thoroughly to obtain a mixed suspension, stirring and activating the reaction at 30° C. for 30 minutes to remove the inert film on the surface of the silicon powder;

[0070] Step (4): After the activation reaction, add water glass at a temperature of 30°C, the quality of the water glass is 48g, i.e. 4% of the filter cake quality, stir evenly and let stand for 20 minutes;

[0071] Step (5): T...

Embodiment 3

[0082] Step (1): Weigh 4000g of silicon cutting waste mortar, stir evenly, add to a cyclone separator, and separate to obtain 2700g of solid flow and 1300g of liquid flow;

[0083] Step (2): wash the separated solid flow with 4000g of water, vacuum filter, and dry the obtained solid phase filter cake at a temperature of 110°C to obtain a mass of 2400g (silicon carbide content 94.3%; silicon component ( Si+SiO 2 ) content of 5.3%, including 5% silicon content and 0.3% silicon dioxide content);

[0084] Step (3): Dissolving 2400 g of the filter cake in 1200 g of deionized water, stirring evenly and thoroughly to obtain a mixed suspension, stirring and activating at a temperature of 50°C for 35 minutes to remove the inert film on the surface of the silicon powder;

[0085] Step (4): After the activation reaction, add water glass at a temperature of 50°C, the quality of the water glass is 48g, i.e. 2% of the filter cake quality, stir evenly and let stand for 60 minutes;

[0086]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com