Patents

Literature

1604 results about "Ultra precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

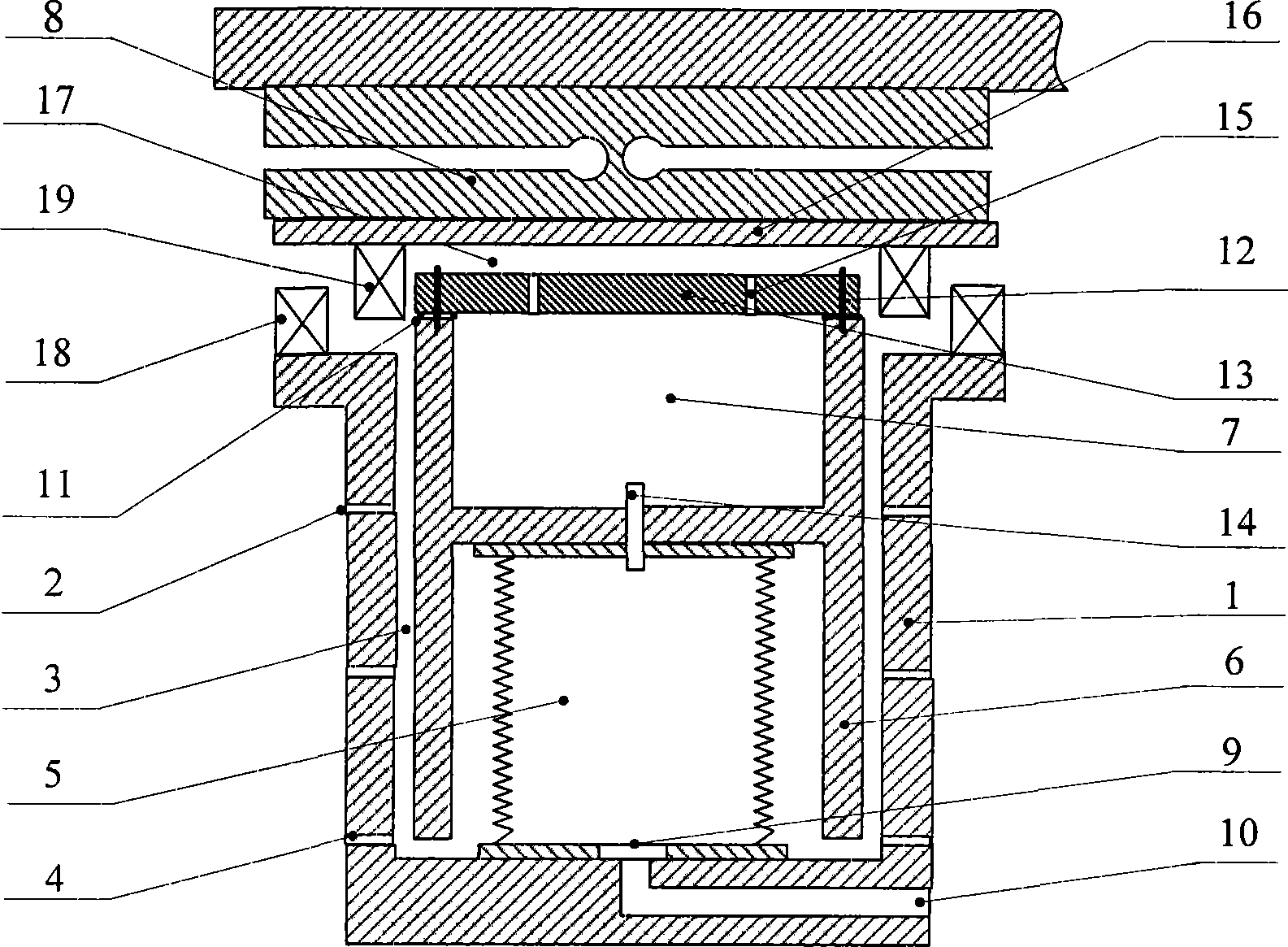

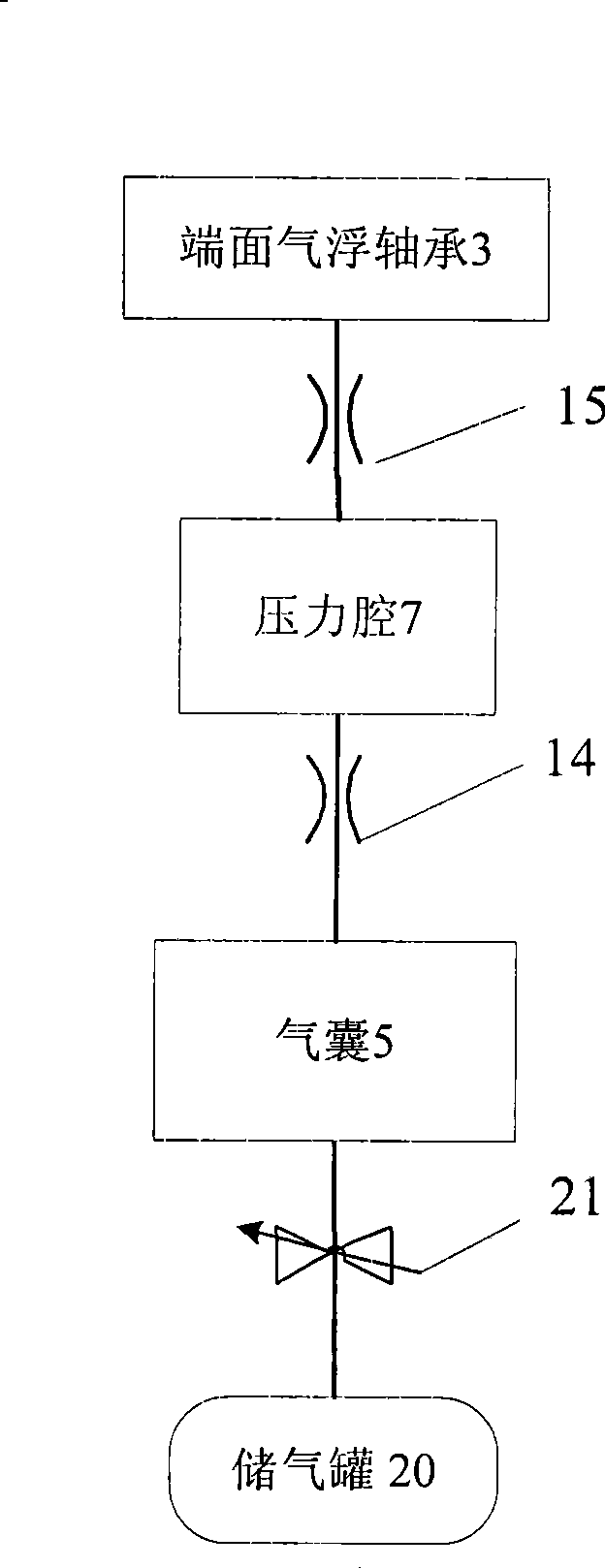

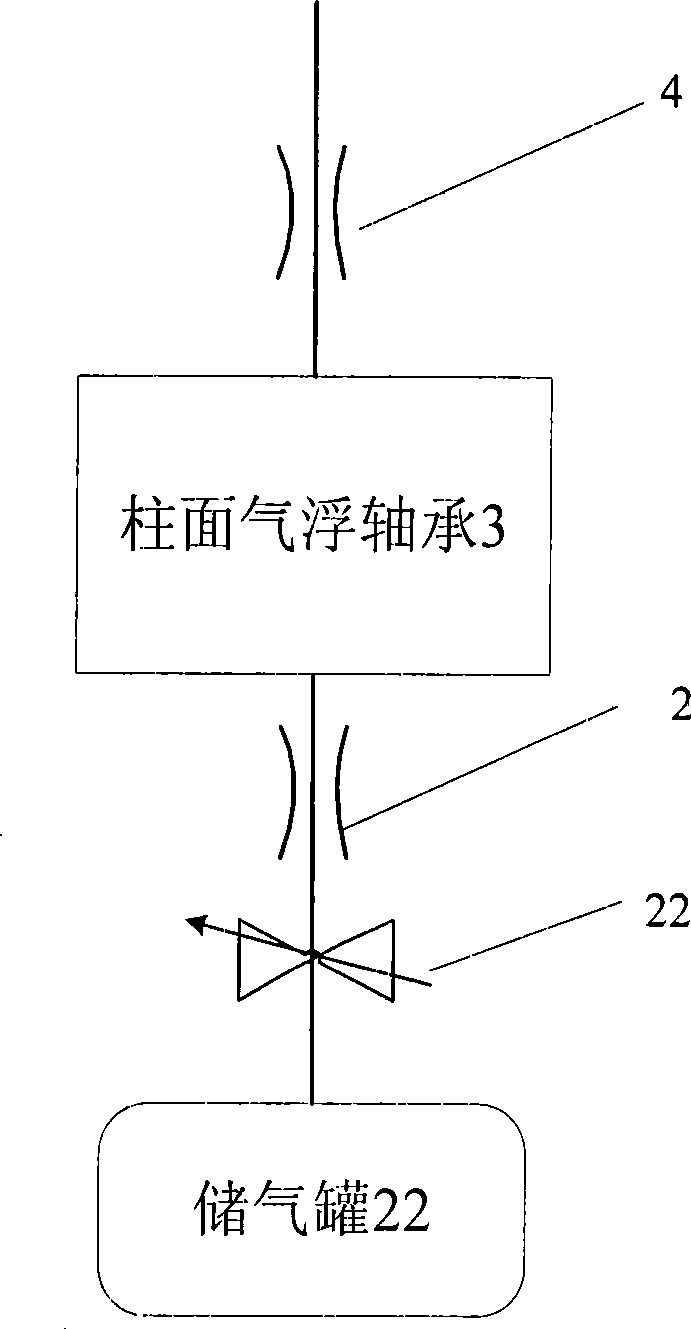

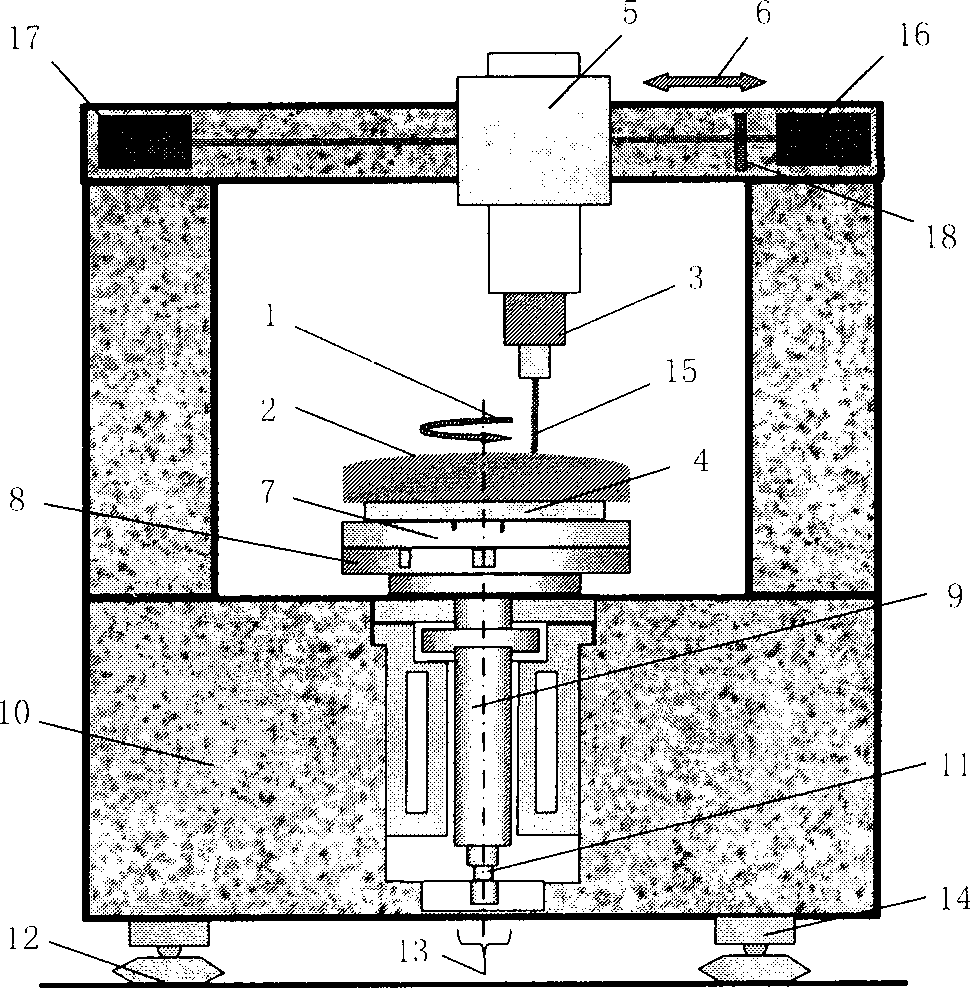

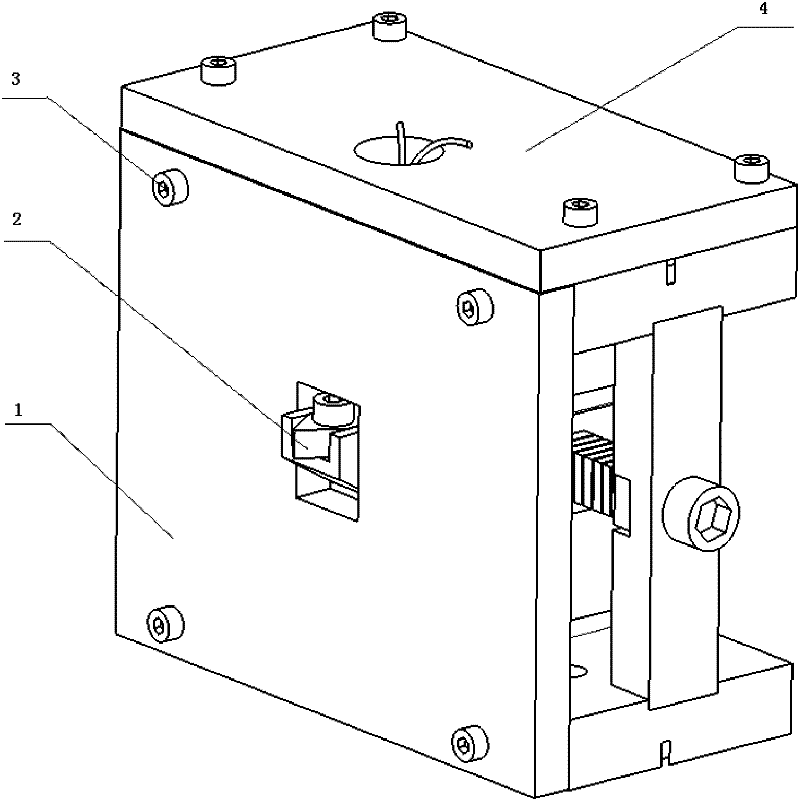

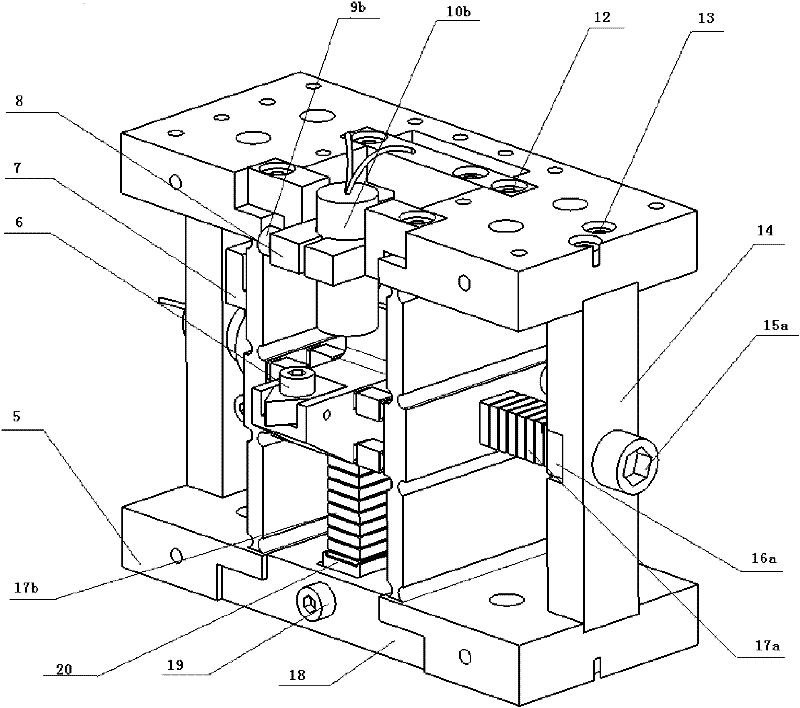

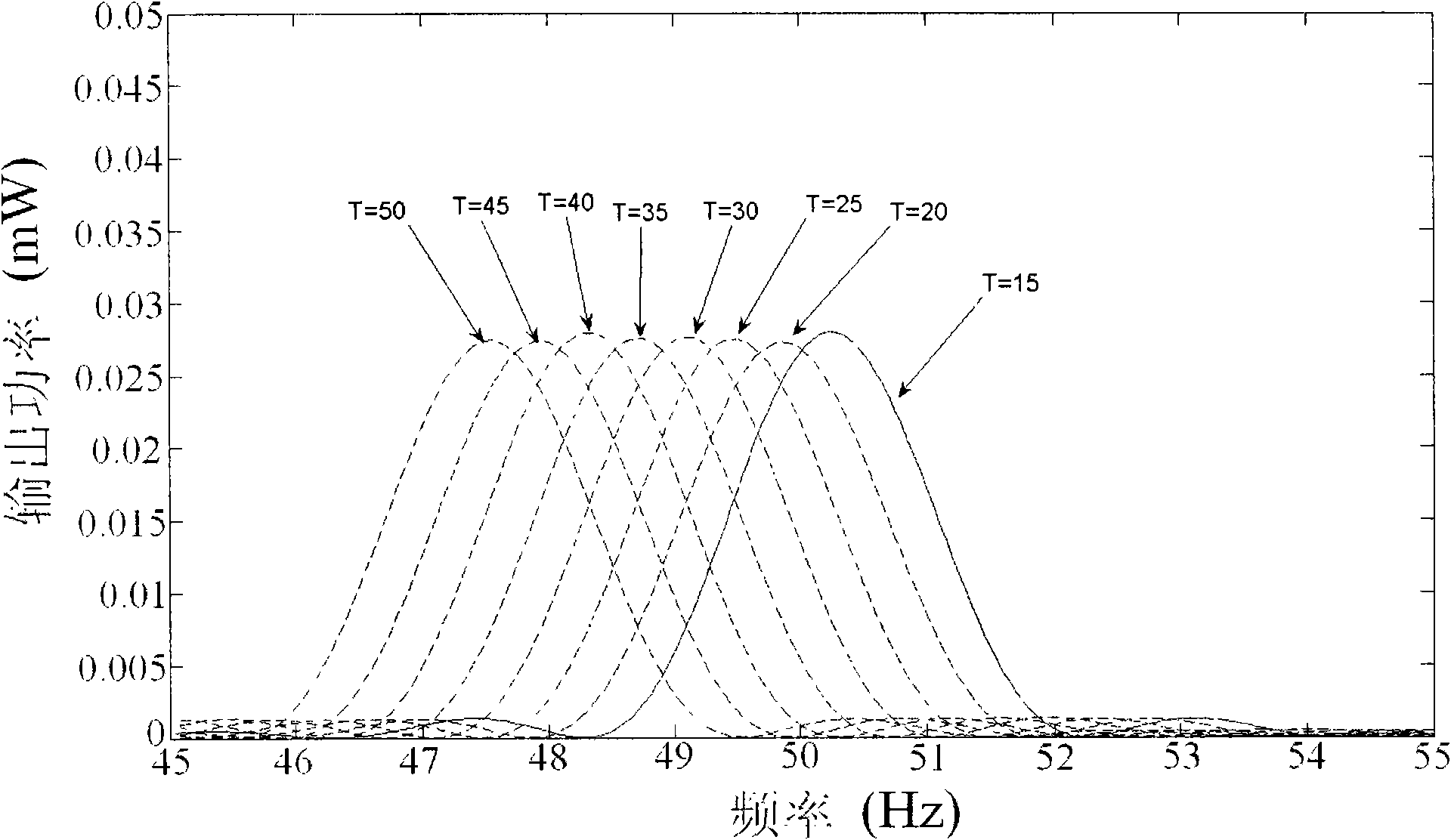

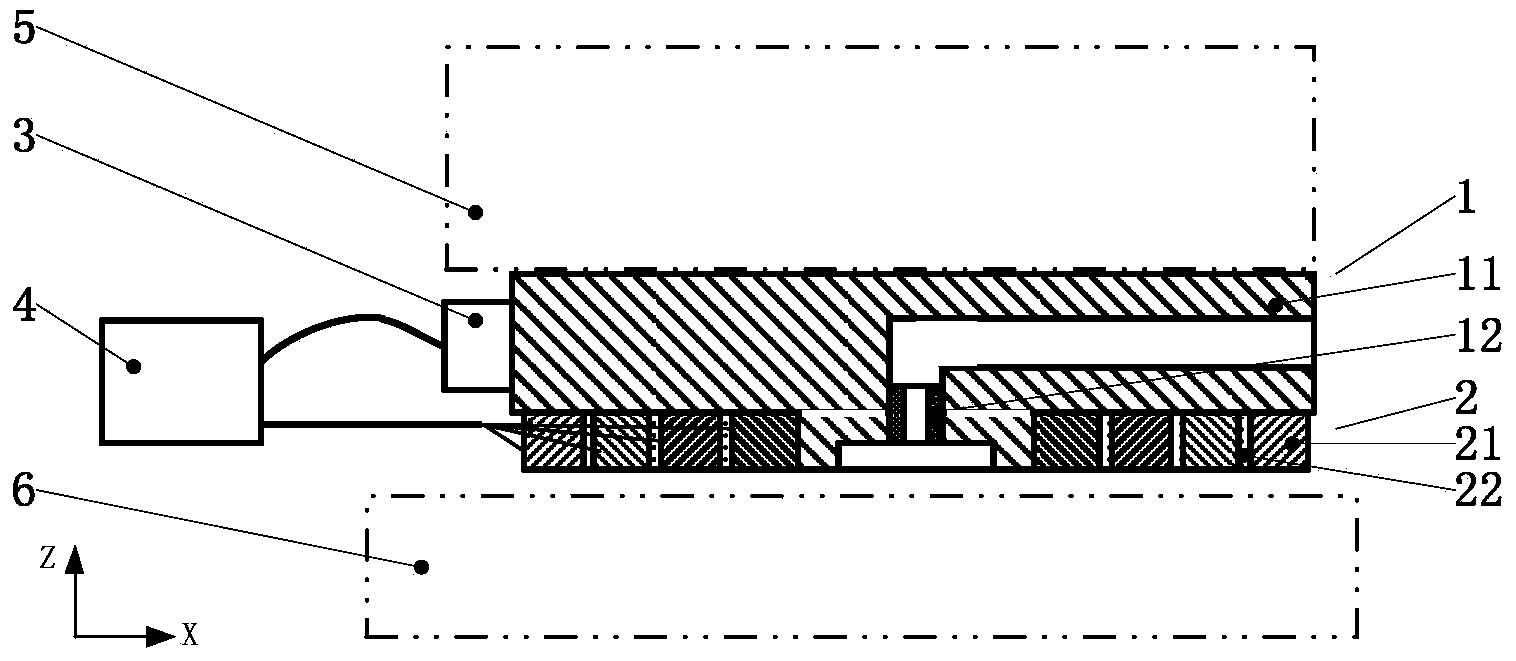

Precision vibration damping assembly and vibration damping platform composed of the assembly

InactiveCN101398636AAchieve precise positioningWith leveling and positioning functionPhotomechanical exposure apparatusMicrolithography exposure apparatusUltrasound attenuationDamping function

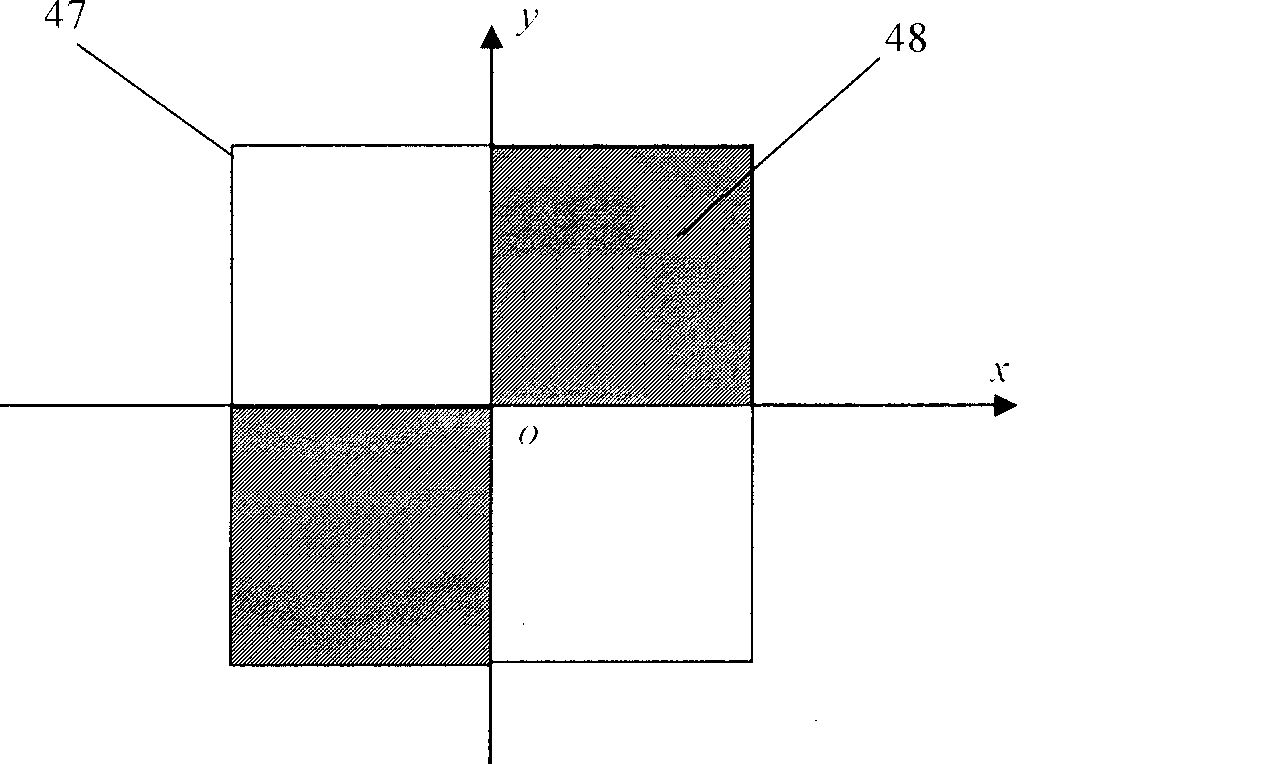

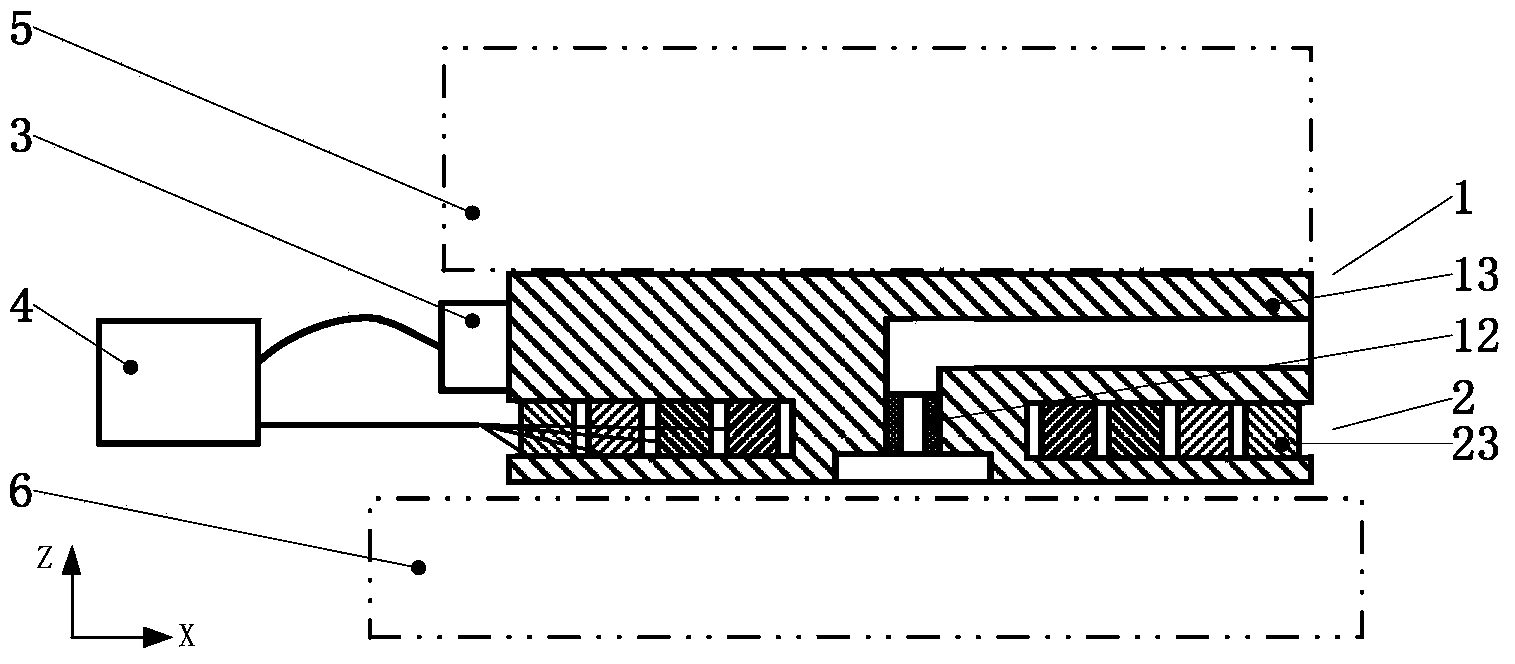

The invention discloses a precision damping component and a damping platform composed of the precision damping component, and the damping platform has damping function and positioning function along a Z direction. The precision damping component comprises a passive damping part, an active damping actuator and an external frame. The passive damping part is a piston rod with a structure of double cavities, an air pocket and a pressure cavity are respectively positioned in the two cavities, and the air pocket has larger longitudinal bracing power and lower rigidity, and can isolate the vibration of attenuation high frequency. The active damping actuator is a linear voice coil motor connected in parallel with the passive damping part, and applies acting force to a passive object according to the vibration condition and location information of the controlled object, so as to drive the controlled object to move to a designated position and compensate the vibration. The damping platform composed of at least three precision damping components has the functions of vibration damping with a plurality of degrees of freedom, accurately positioning along the Z direction, focusing and leveling. The precision damping component and the damping platform can be used in the apparatus with precision damping requirements such as mask aligners, ultra-precision numerically-controlled machine tools, biochip scanners and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

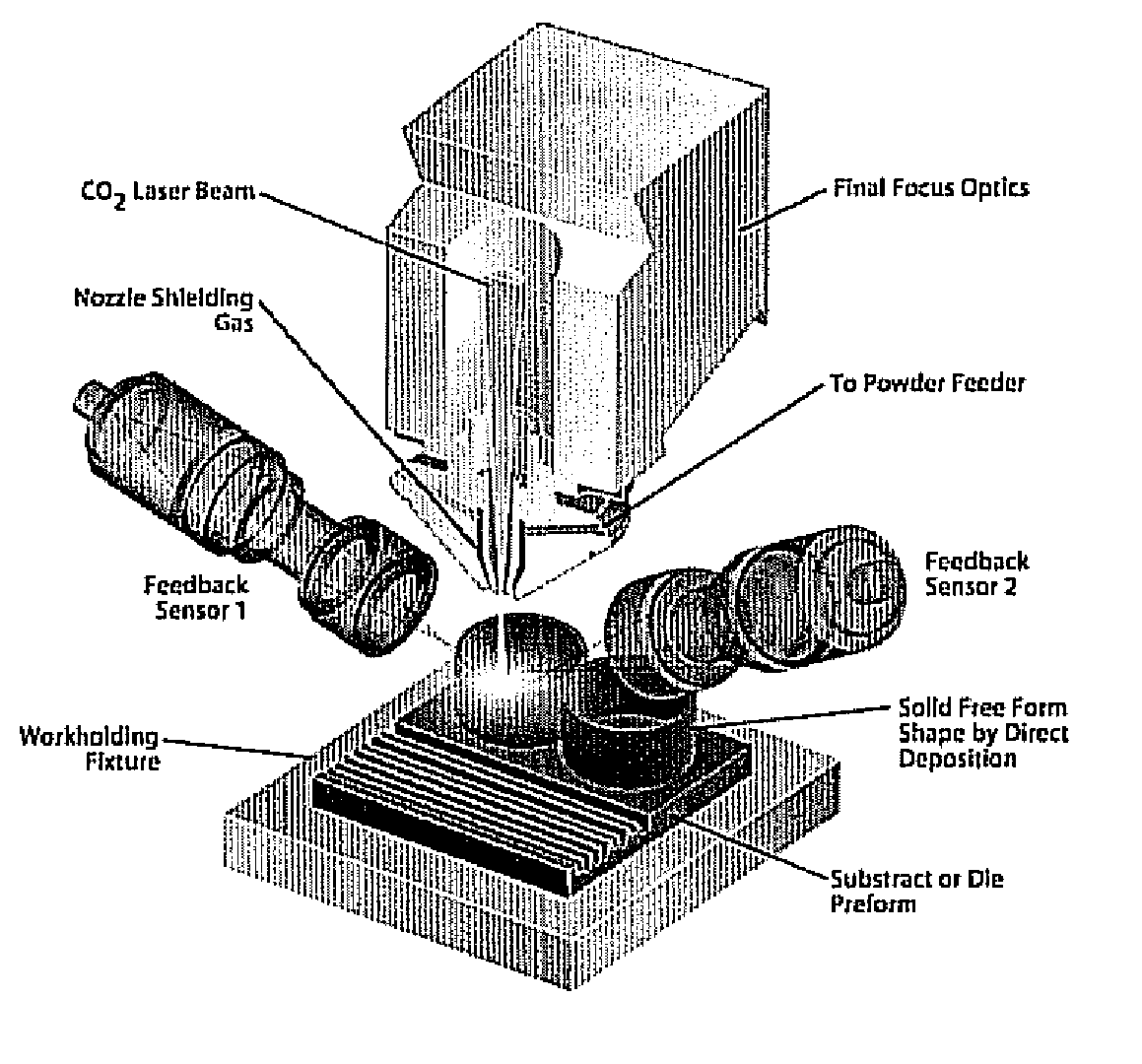

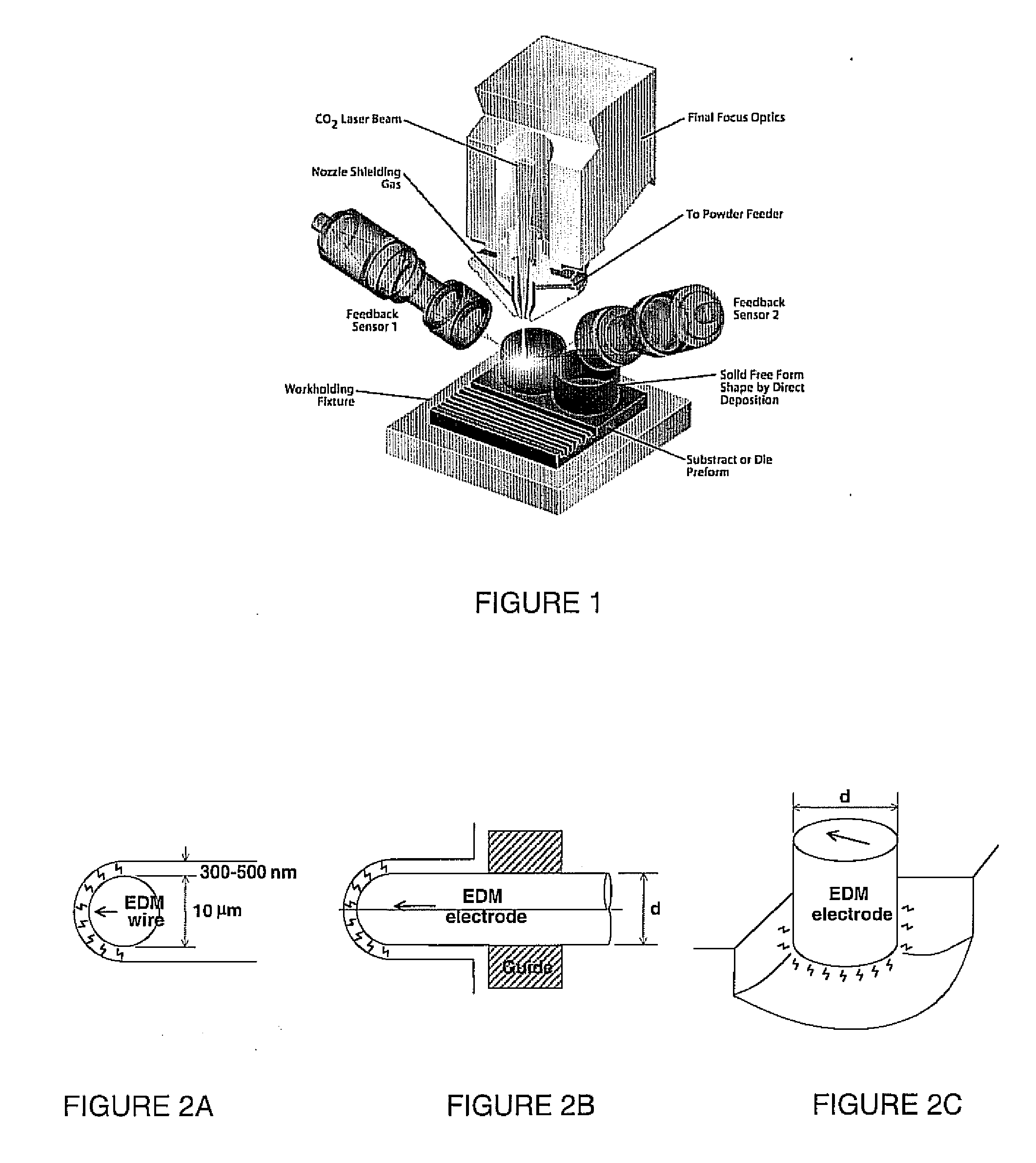

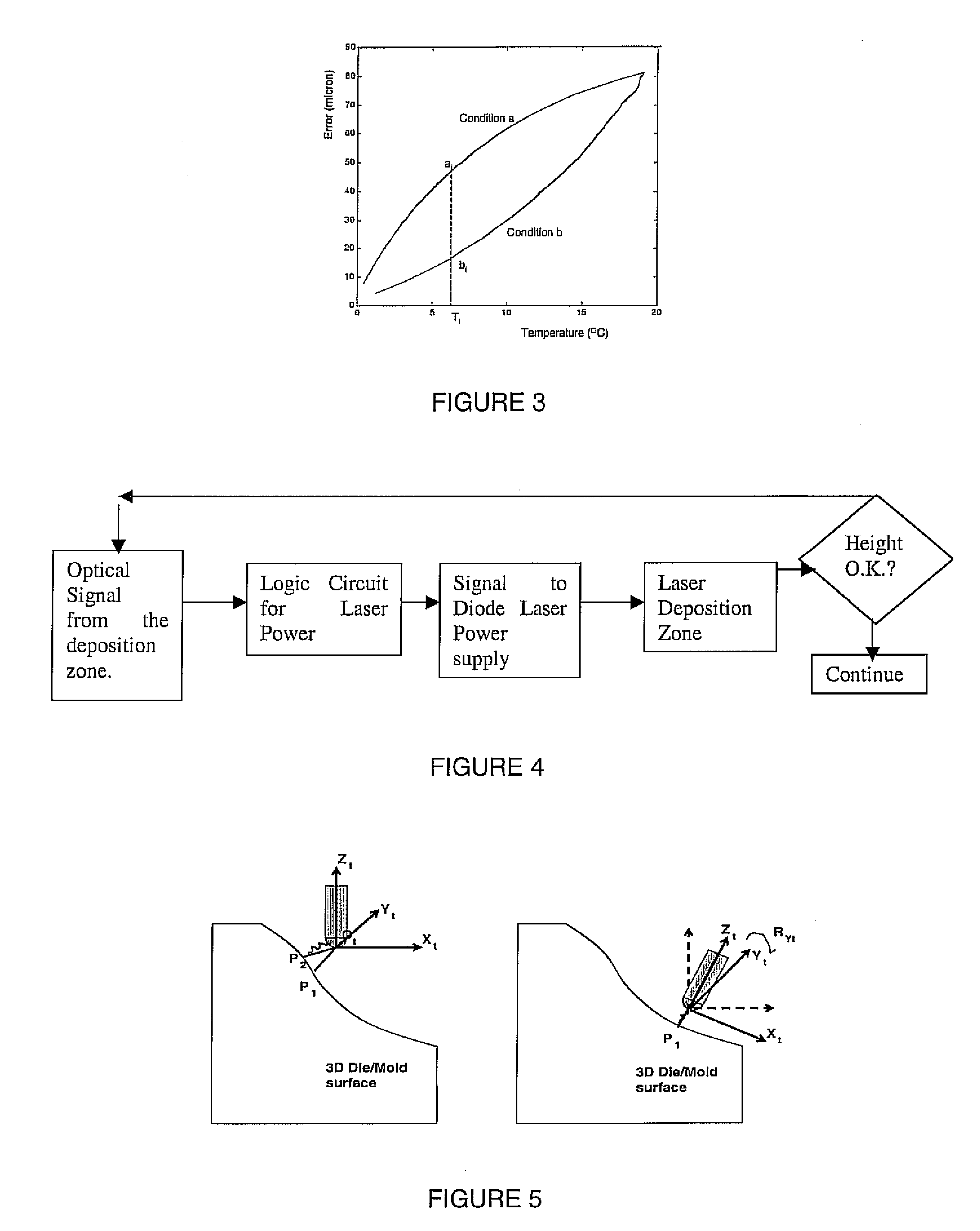

High-speed, ultra precision manufacturing station that combines direct metal deposition and edm

ActiveUS20070205184A1Fast transferImprove efficiencyAdditive manufacturing apparatusElectric discharge heatingEngineeringWorkstation

A direct-metal deposition (DMD) processing stage and a 5DOF (degree of freedom) dry micro-EDM (mEDM) stage are integrated to provide the submicron scale resolution necessary for the ultra-precision processing of work pieces. The DMD processing stage includes optical feedback for dimensional control utilizing a high-power, fiber-coupled diode laser with fast response time and small beam parameter product. The electrical discharge machining (EDM) stage is a dry EDM stage using an inert gas with appropriate dielectric properties to perform the surface finishing operations. The system further includes one or more surface treatment operations to obtain a desired level of surface hardness or wear resistance and / or to minimize the distortion induced in treating the surface.

Owner:DM3D TECH

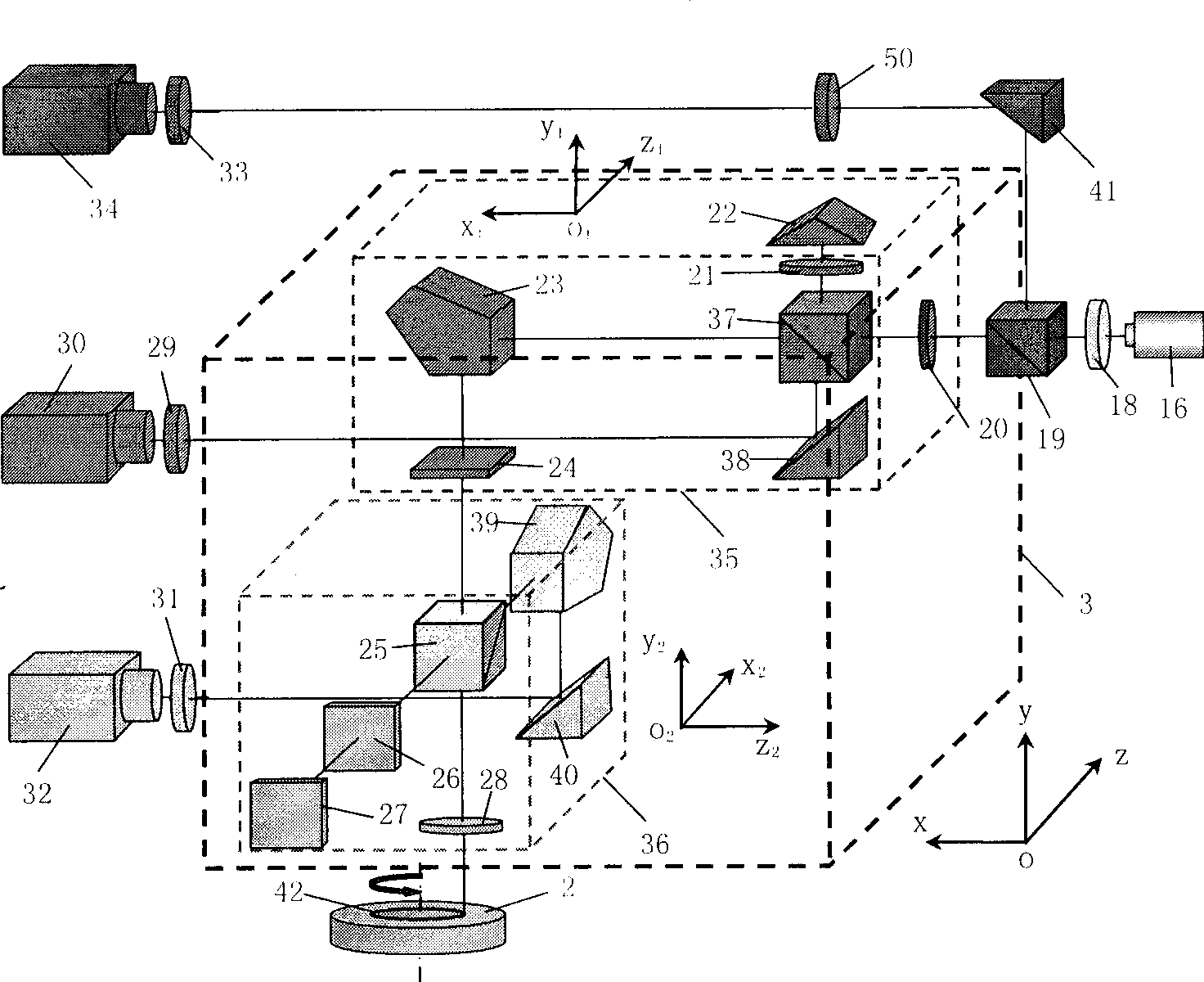

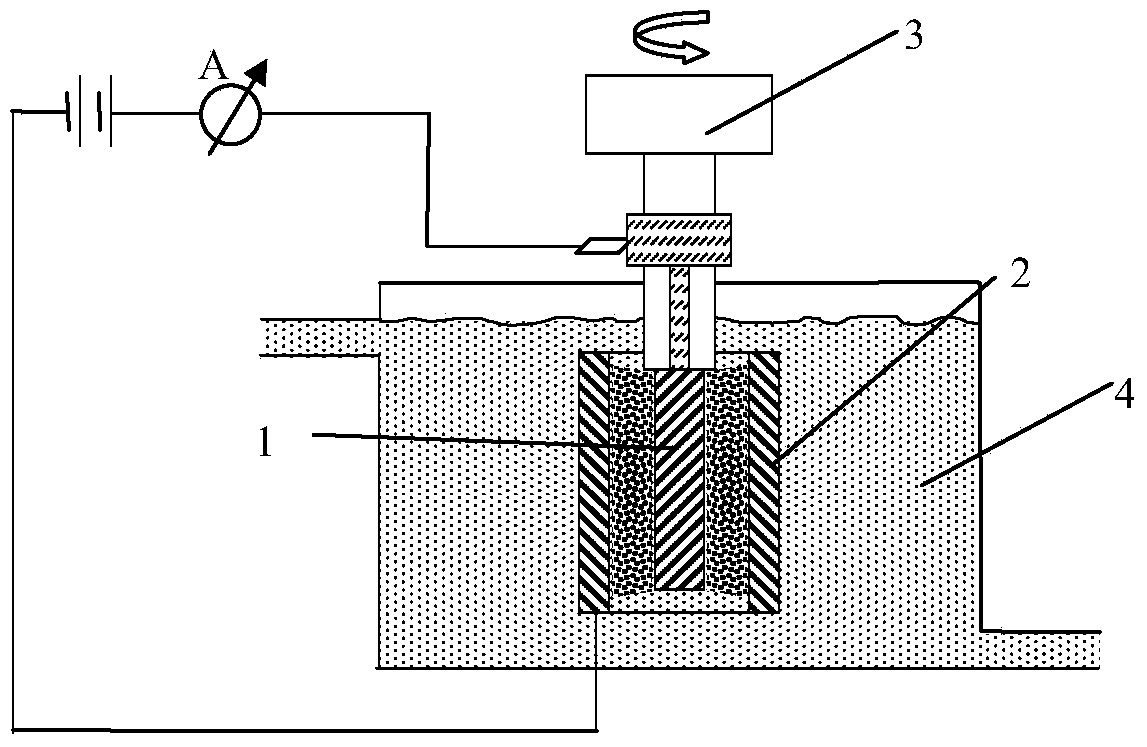

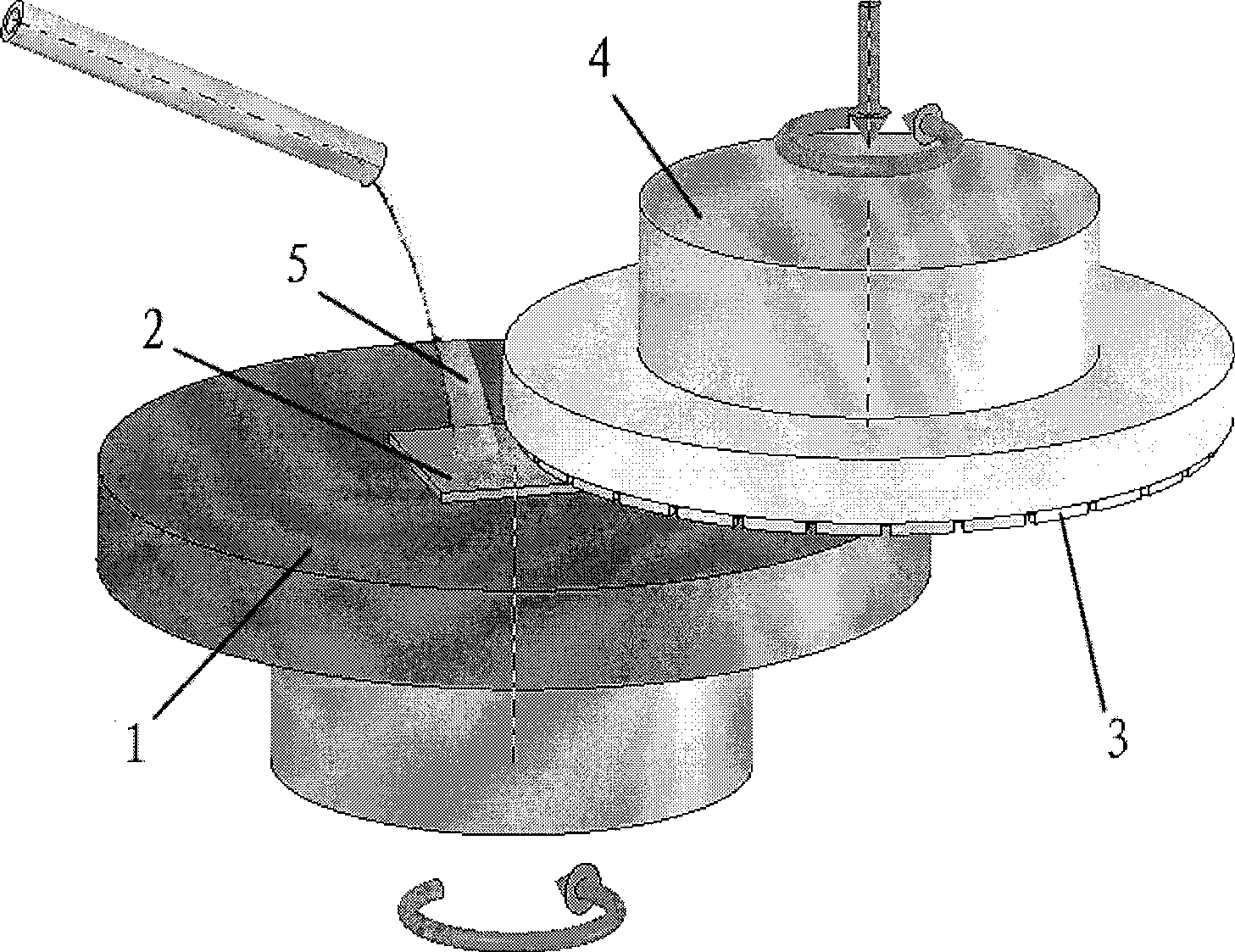

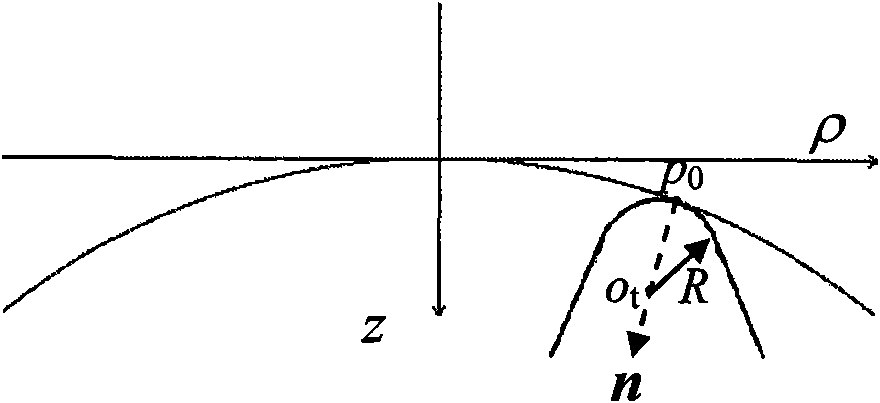

Large caliber aspheric surface measuring apparatus and method based on ultra-precise revolving scanning

InactiveCN101377410AGood effectRealize measurementUsing optical meansMeasurement deviceMacroscopic scale

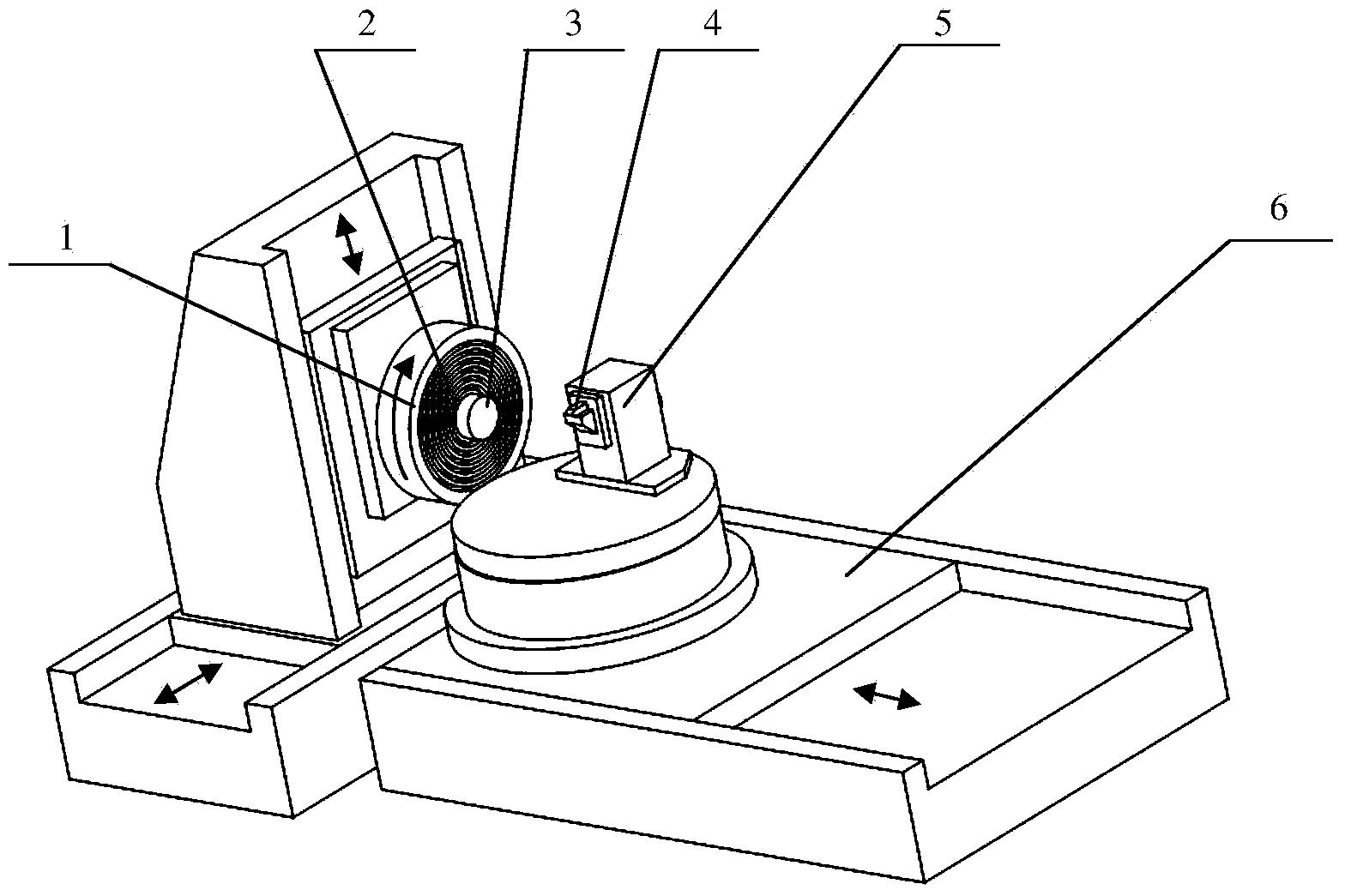

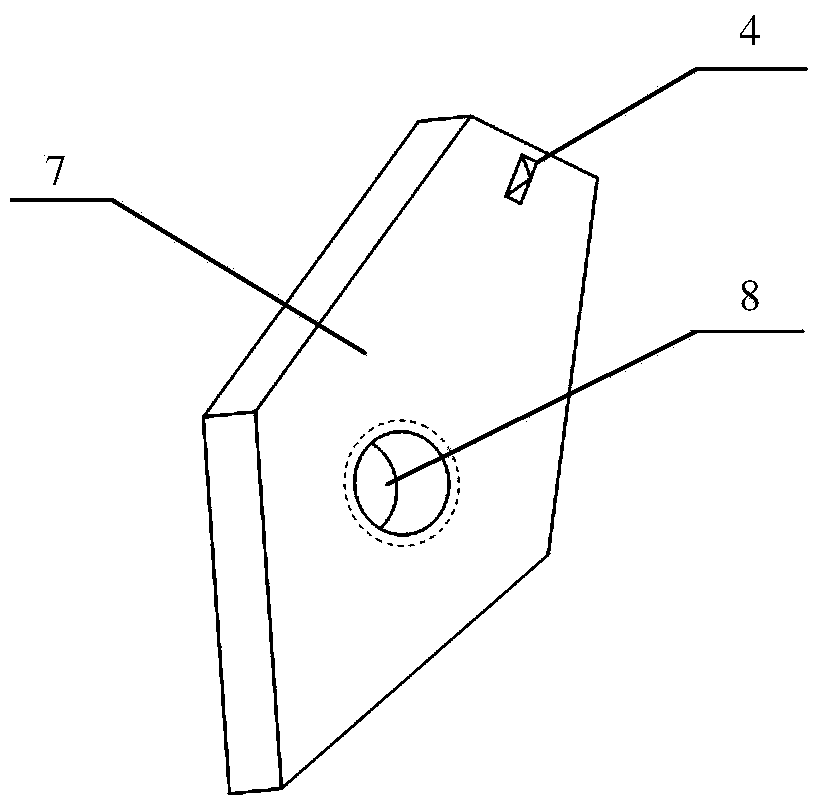

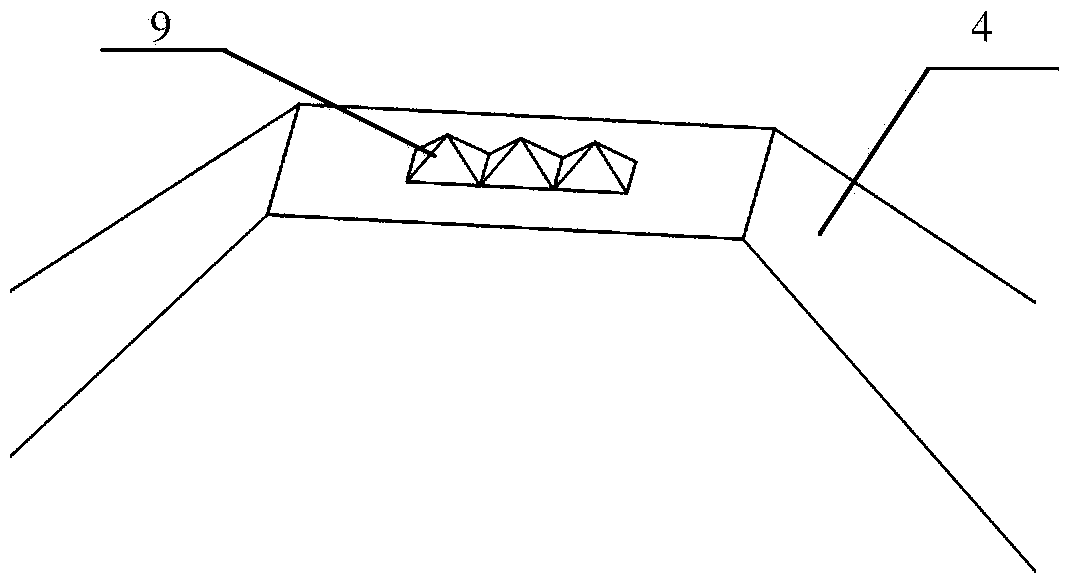

The invention provides a large diameter aspheric measuring device based on ultra-precision rotary scan and a method, belongs to the macroscopic measuring technology. The device comprises an ultra-precision air flotation turntable, a precision angle and angle measuring system, an ultra-precision linear air flotation guide, a length-measuring device and a gradient measurement system. The gradient measurement system comprises a linear polarization He-Ne laser or a semiconductor laser, a diffraction element, a scanning head and an image receiving unit. The linear polarization He-Ne laser or the semiconductor laser and the image receiving unit are separately fixed on the two sides of the base beam. The scanning head is fixed on the ultra-precision linear air flotation guide. The scanning head comprises a radial gradient measurement sub-scanning head and a tangential gradient measurement sub-scanning head, both of which comprise an error compensation light path. The working platforms of the two sub-scanning heads are orthogonal to each other. The invention discloses a large diameter aspheric measuring method based on ultra-precision rotary scan.

Owner:HARBIN INST OF TECH

High-purity nano diamond polishing liquid and preparing method thereof

InactiveCN101033374AEvenly dispersedImprove dispersion stabilityOther chemical processesPolishing compositions with abrasivesGranularitySlurry

The invention relates to a kind of high purity nano-scale diamond polishing slurry for ultra-precision processing and its preparation. The high-purity polishing slurry is prepared with nano-scale diamond, wetting agent, surface modification agent, dispersing agent, chemical additives and water, and the percentage of the raw materials by weight share are as follow: 0.05~10% of the nano-scale diamond, 0.01~2% of the wetting agent, 1~5% of the surface modification agent, 0.1~10% of the dispersing agent, 0.2~1% of the chemical additives, 88.69~98.64% of water. The amounts of all the materials are weighted as 100%. The amounts of the described wetting agent, surface modification agent, dispersing agent, and chemical additives are referred to solid content. The purity of the nano-scale diamond is 99.9% and the particle size of distribution is 10~200 nm.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

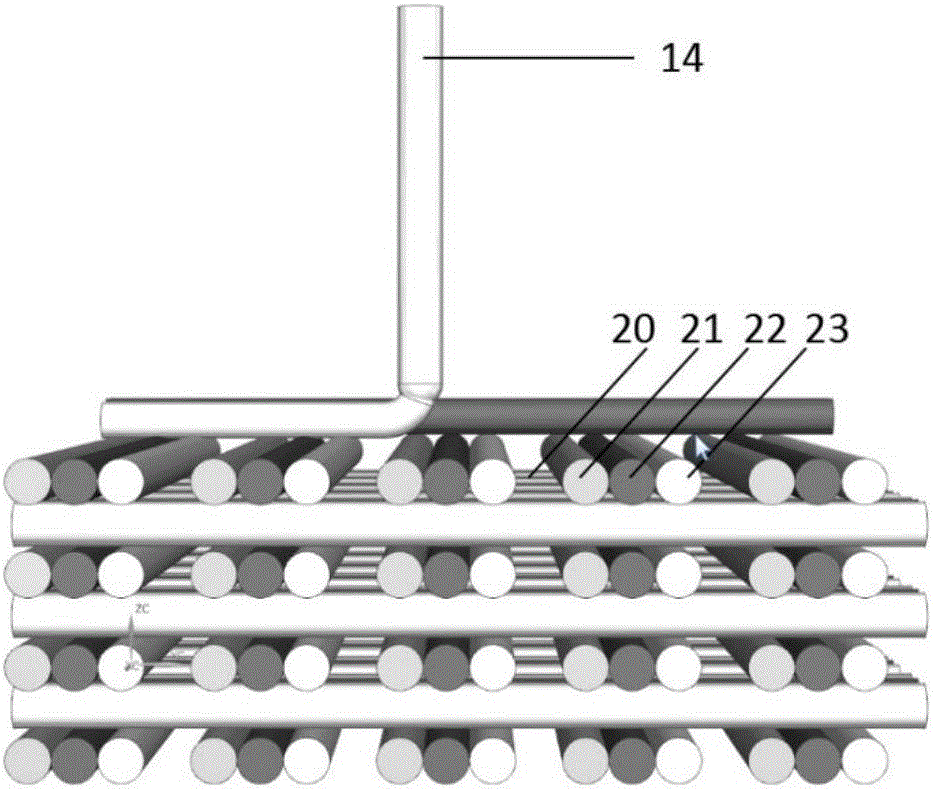

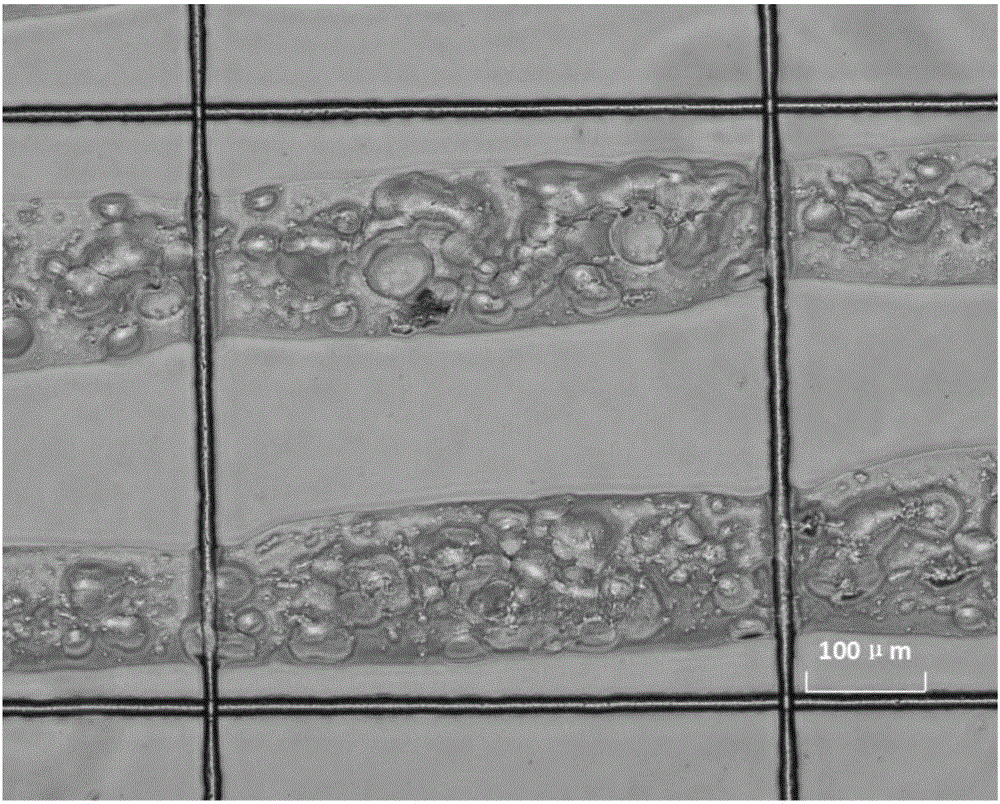

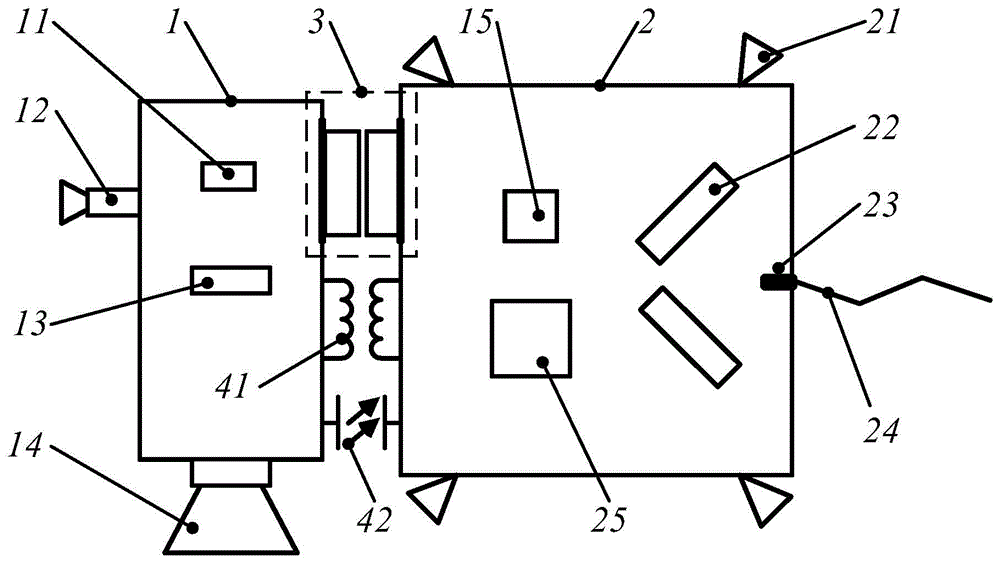

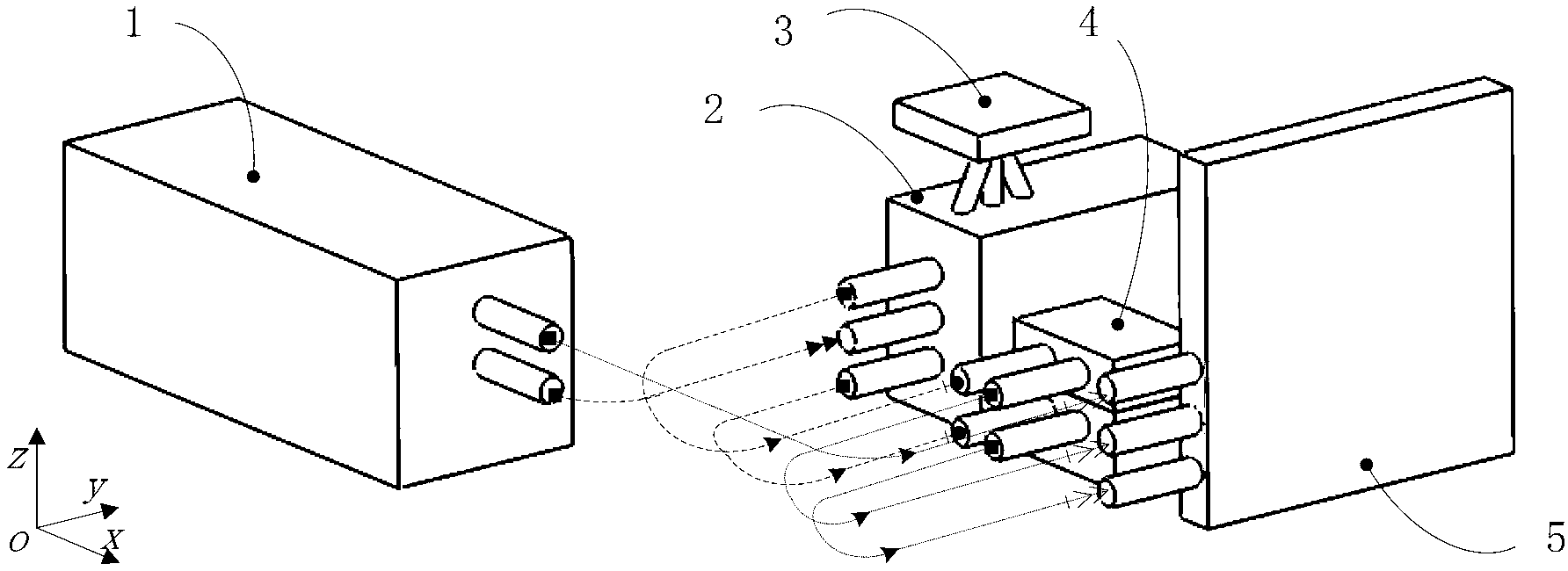

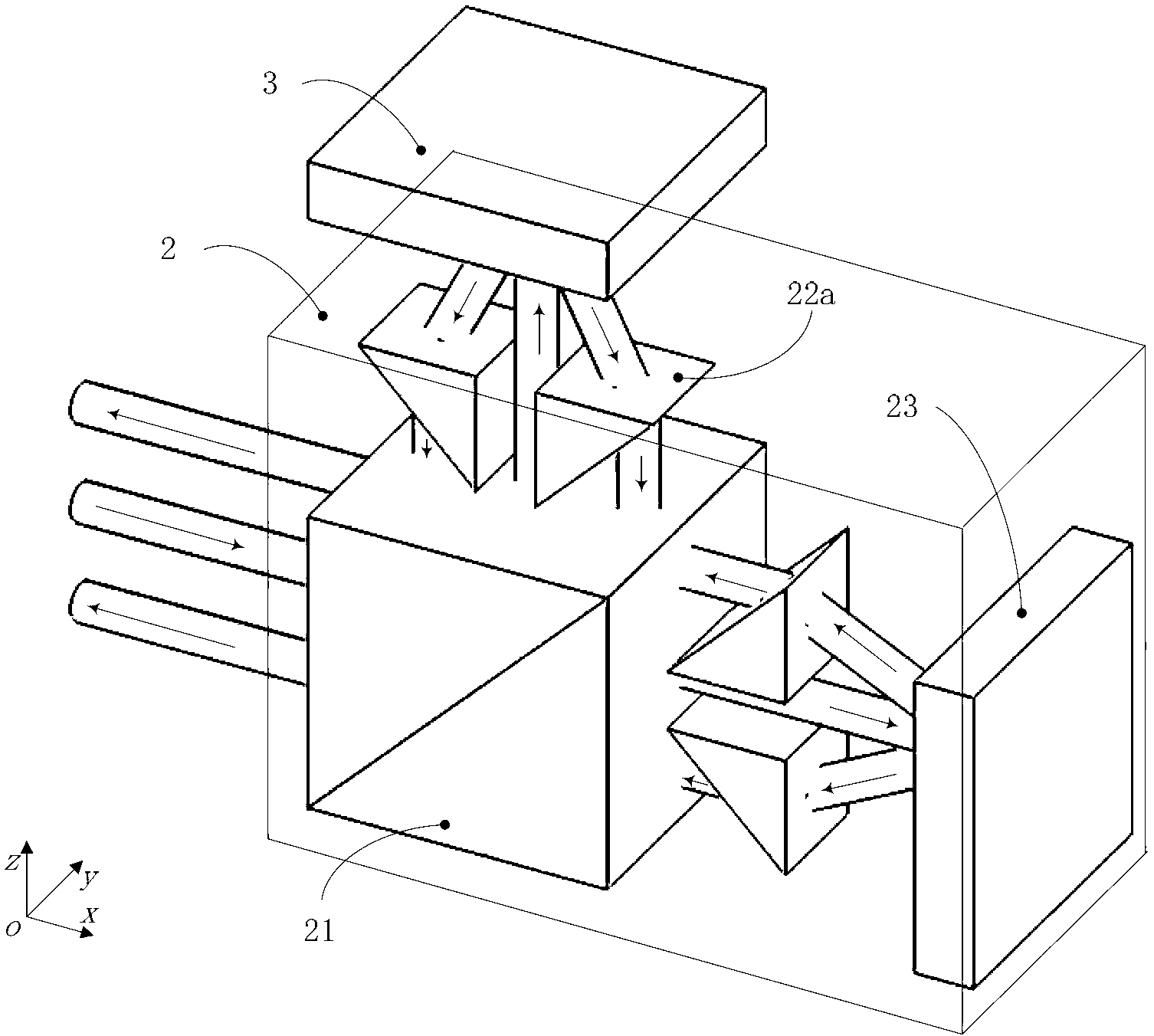

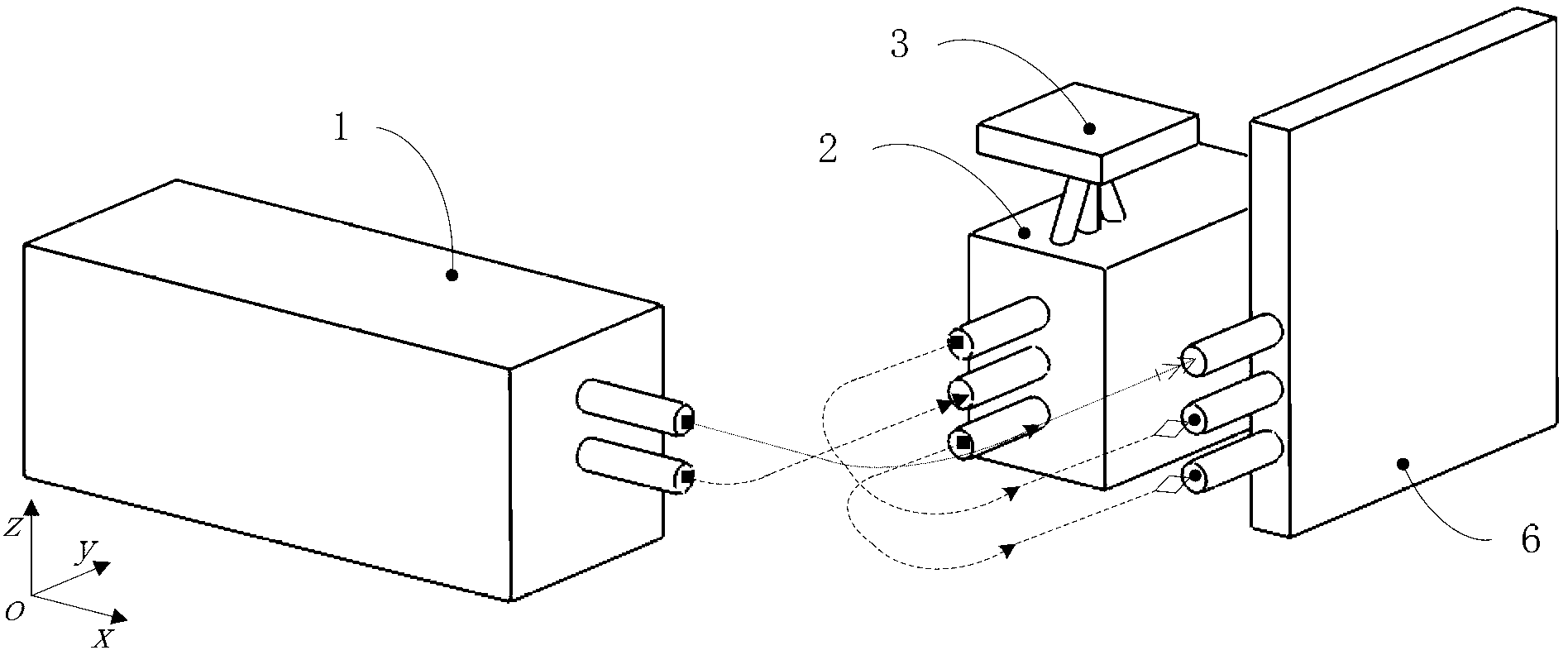

High-precision bio-compound 3D printing device and printing method

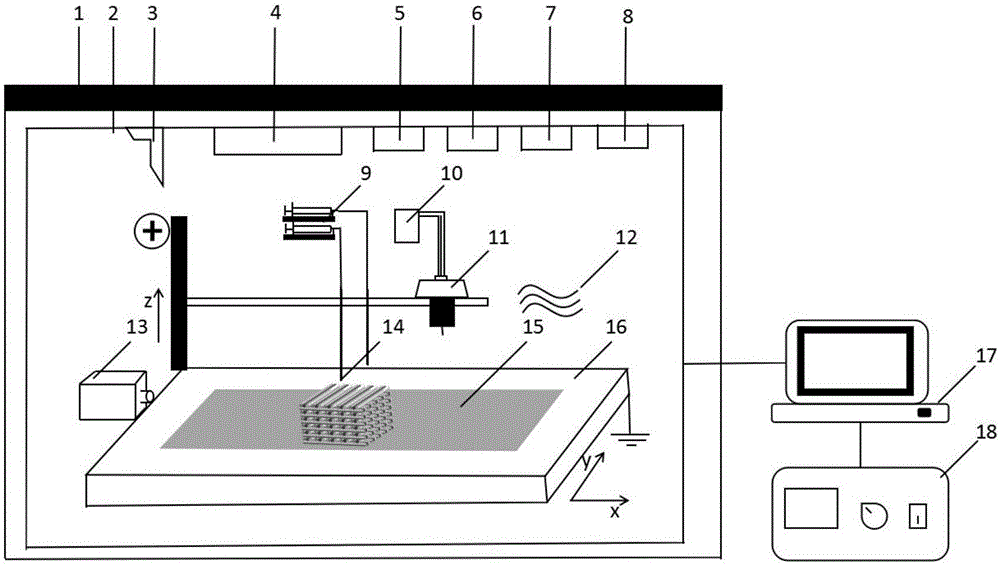

ActiveCN106222085AStable Composite PrintingHigh precisionAdditive manufacturing apparatusTissue/virus culture apparatusRefluxHigh-voltage direct current

The invention discloses a high-precision bio-compound 3D printing device and a printing method. The high-precision bio-compound 3D printing device comprises a cell printing spraying head and an electrostatic direct writing device which are arranged above a collection platform and are connected with a motion control module, wherein the cell printing spraying head is connected with an ultra-precision injection pump; the electrostatic direct writing device is connected with a reflux heating device; a main unit and a high-voltage direct current power supply are arranged outside an ultra-clean experiment table; the electrostatic direct writing device, the cell printing spraying head and the high-voltage direct current power supply are connected with the main unit. The printing method comprises the following steps: the main unit automatically switches the cell printing spraying head and the electrostatic direct writing device to print a cell-containing gel / biological scaffold / micro-channel compound structure; after the printing of one layer is completed, the cell printing spraying head and the electrostatic direct writing device move a distance equal to the thickness of one layer in the Z-axis direction for printing of the next layer, and repeating till all tissue organs to be printed are completed in printing. The high-precision bio-compound 3D printing device can stably and precisely print compounds of various cells and submicron or nano-level biological scaffolds.

Owner:XI AN JIAOTONG UNIV

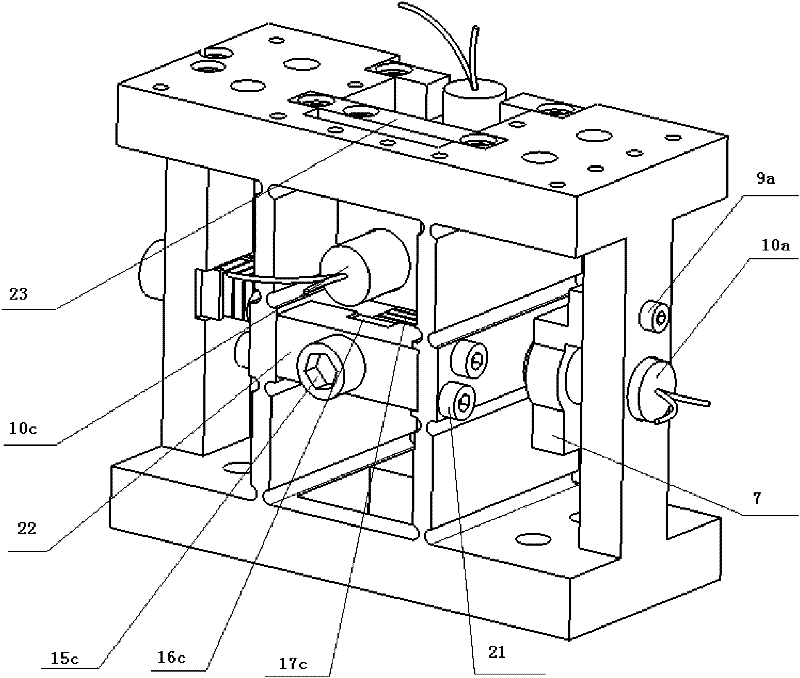

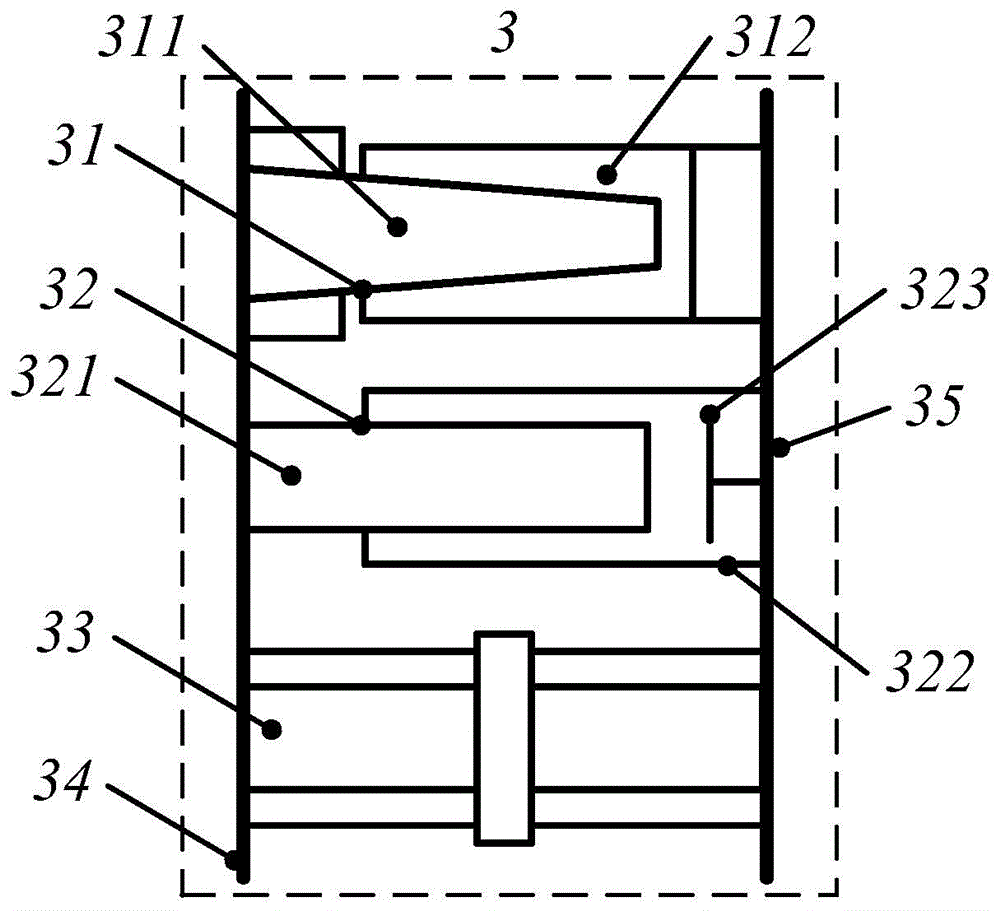

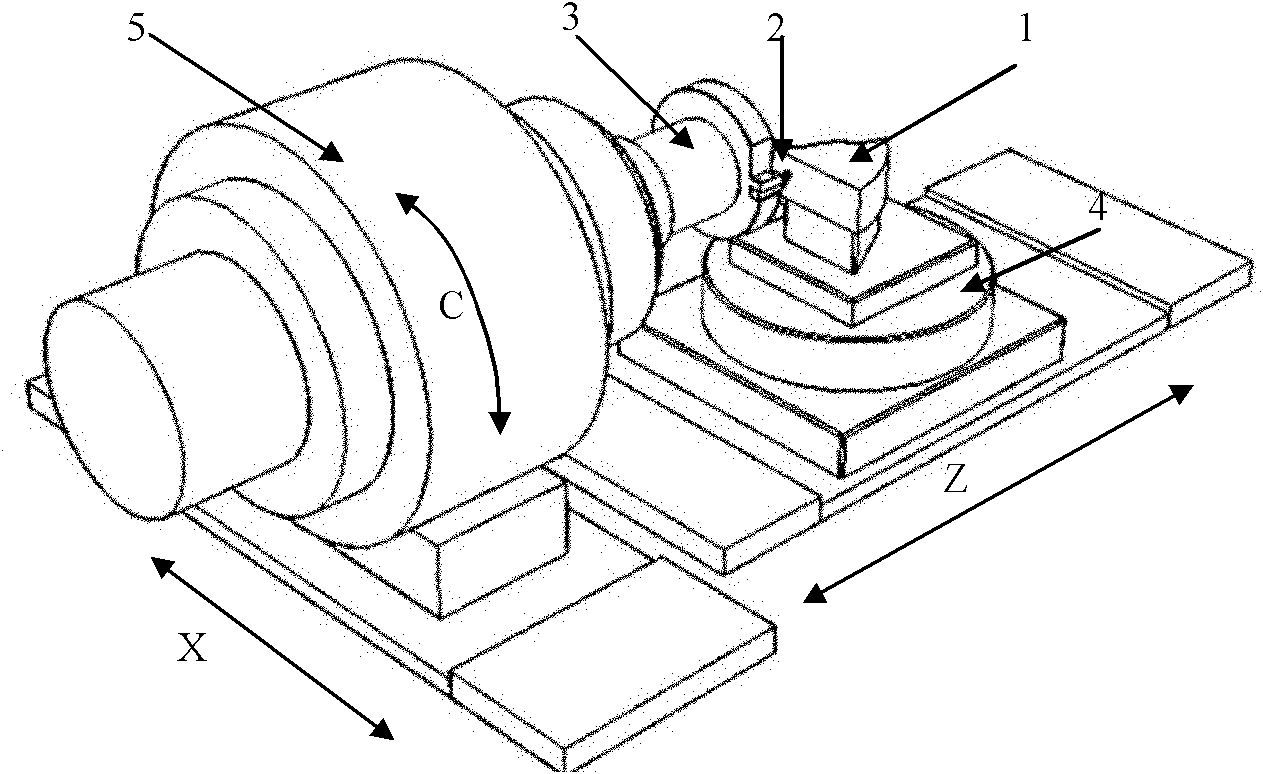

Three-dimensional elliptical vibration cutting device

ActiveCN102371359AImprove machinabilitySimplify the modeling processMeasurement/indication equipmentsTurning toolsLinear motionEllipse

The invention relates to a three-dimensional elliptical vibration cutting device, belonging to the field of cutting and ultra-precision cutting machining of materials which are difficult to machine. A diamond cutter is guided through flexible hinge mechanisms respectively along an X direction, a Y direction and a Z direction, and further, is driven by three piezoelectric stacks respectively alongthe X direction, the Y direction and the Z direction; the piezoelectric stacks of the X direction and the Z direction are preloaded by preloading screw bolts along respective axial direction; the piezoelectric stack of the Y direction is preloaded through a screw bolt screwing wedge; the preloading processes of the three directions are mutually independent; through regulating and matching the initial phase position and the amplitude of a driving signal for each of the three piezoelectric stacks, the projections of the cutter location point movements of the diamond cutter in an X-Y plane and aY-Z plane are elliptical motions, and the projection of the cutter location point movements of the diamond cutter in an X-Z plane is reciprocating elliptical motion or linear motion. The three-dimensional elliptical vibration cutting device has a novel and simple structure, is easy to implement, and is beneficial to obtaining the best cutting machinability of the diamond cutter.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

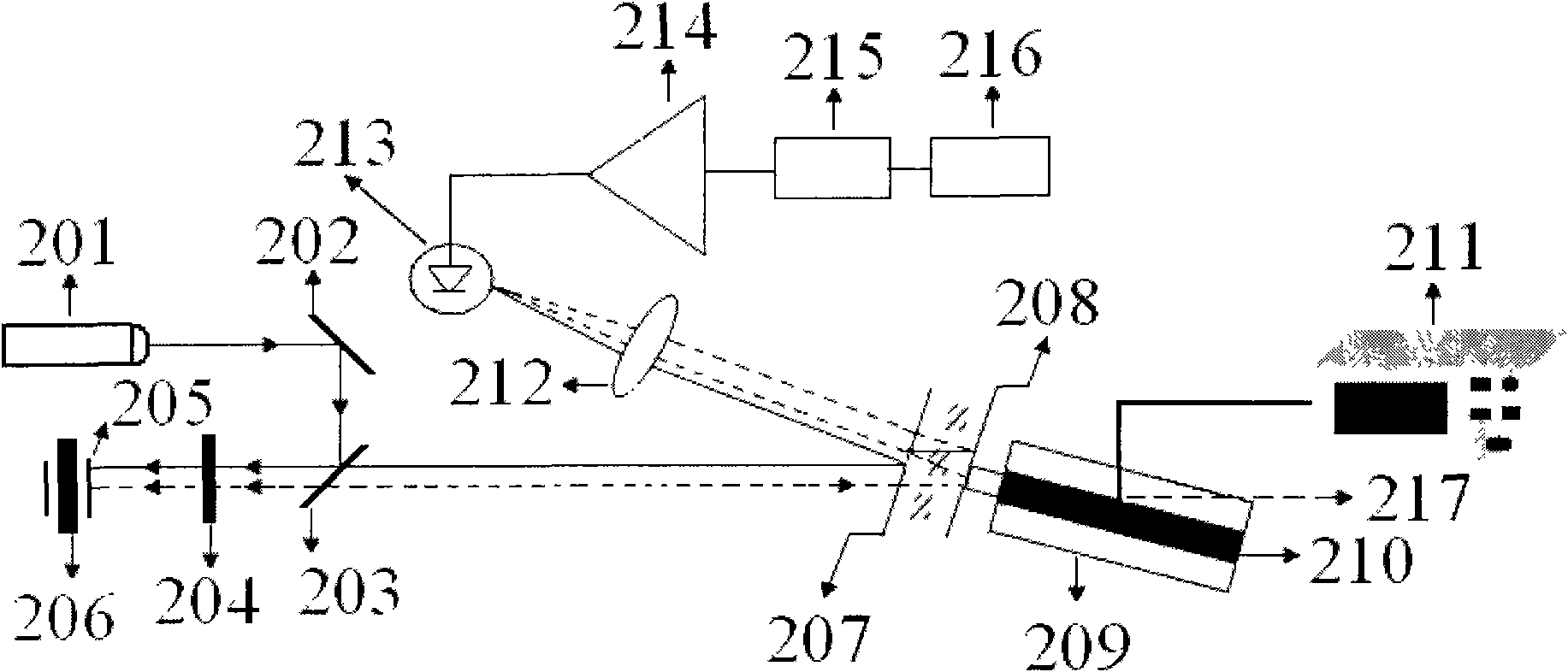

Device and method for high-accuracy measurement of expansion coefficients of metal wire

InactiveCN101825590AEasy to handleHigh precisionMaterial thermal coefficient of expansionUsing optical meansPhase differenceFrequency modulation

The invention discloses a device and a method for high-accuracy measurement of expansion coefficients of a metal wire. The method uses a PZT oscillating mirror system to perform frequency modulation on incident light at different times, can not only modulate parameter information to be measured to a phase difference, but also modulate the parameter information to be measured to in a frequency difference for the convenience of later signal treatments; and the device consists of an interference system, a high-speed PZT oscillating mirror system, a heating system and a signal processing system. Comparing the method with other measuring methods, a multi-beam laser heterodyne measuring method for measuring the expansion coefficients of the metal wire has the advantages of high space and time resolutions, high measurement accuracy, high linearity, quick dynamic response, large measuring range and the like, and simultaneously the method has the advantages of simple structure for an experimental apparatus, low power consumption, convenient operation, high repeatability, small experimental result error, high accuracy and the like. Because experimental phenomena are obvious and experimental data is reliable, the method and the device can be widely applied in the fields of engineering designs and the like, and have very high practical values in the field of laser ultra-precision measurements.

Owner:HARBIN INST OF TECH

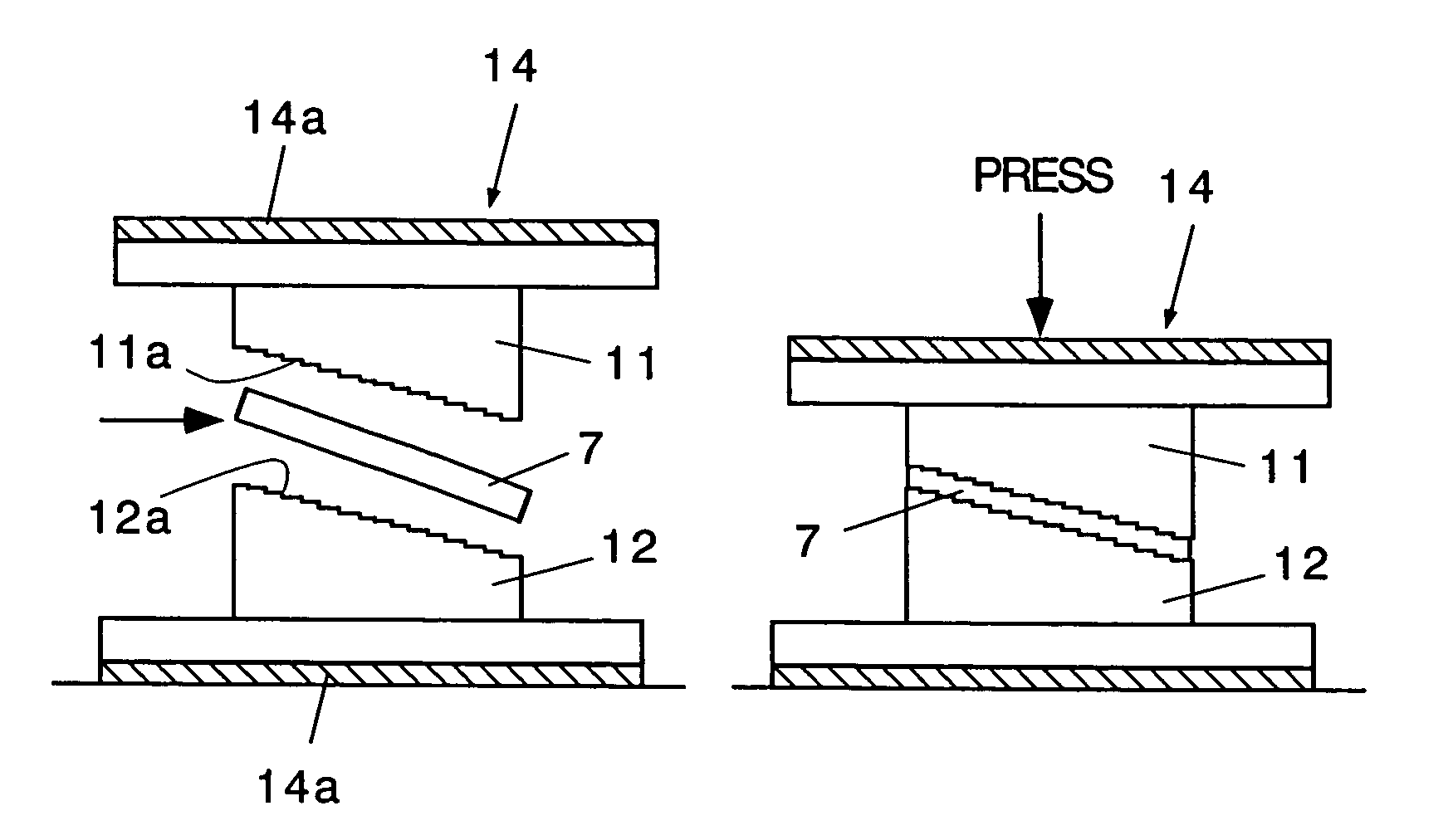

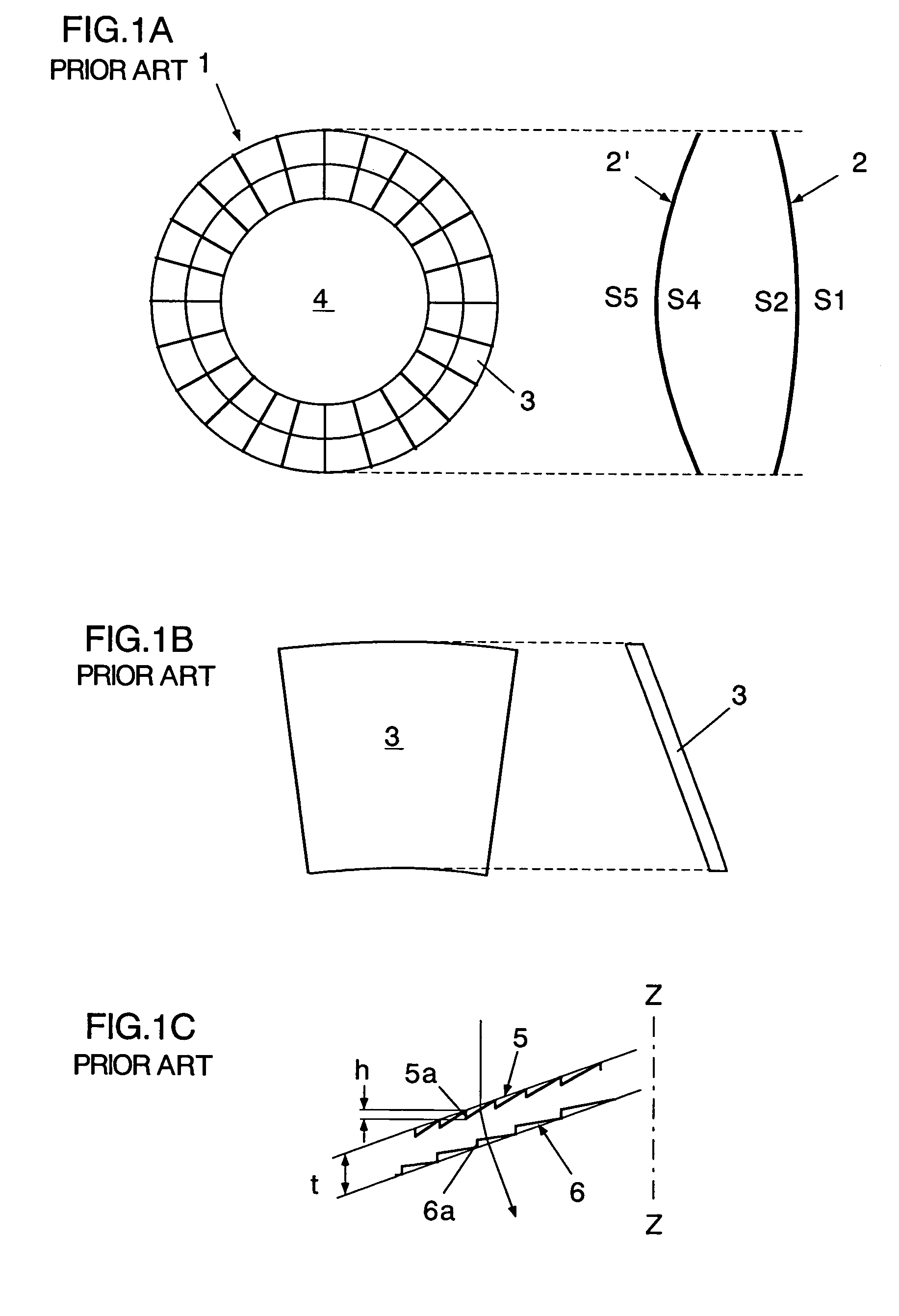

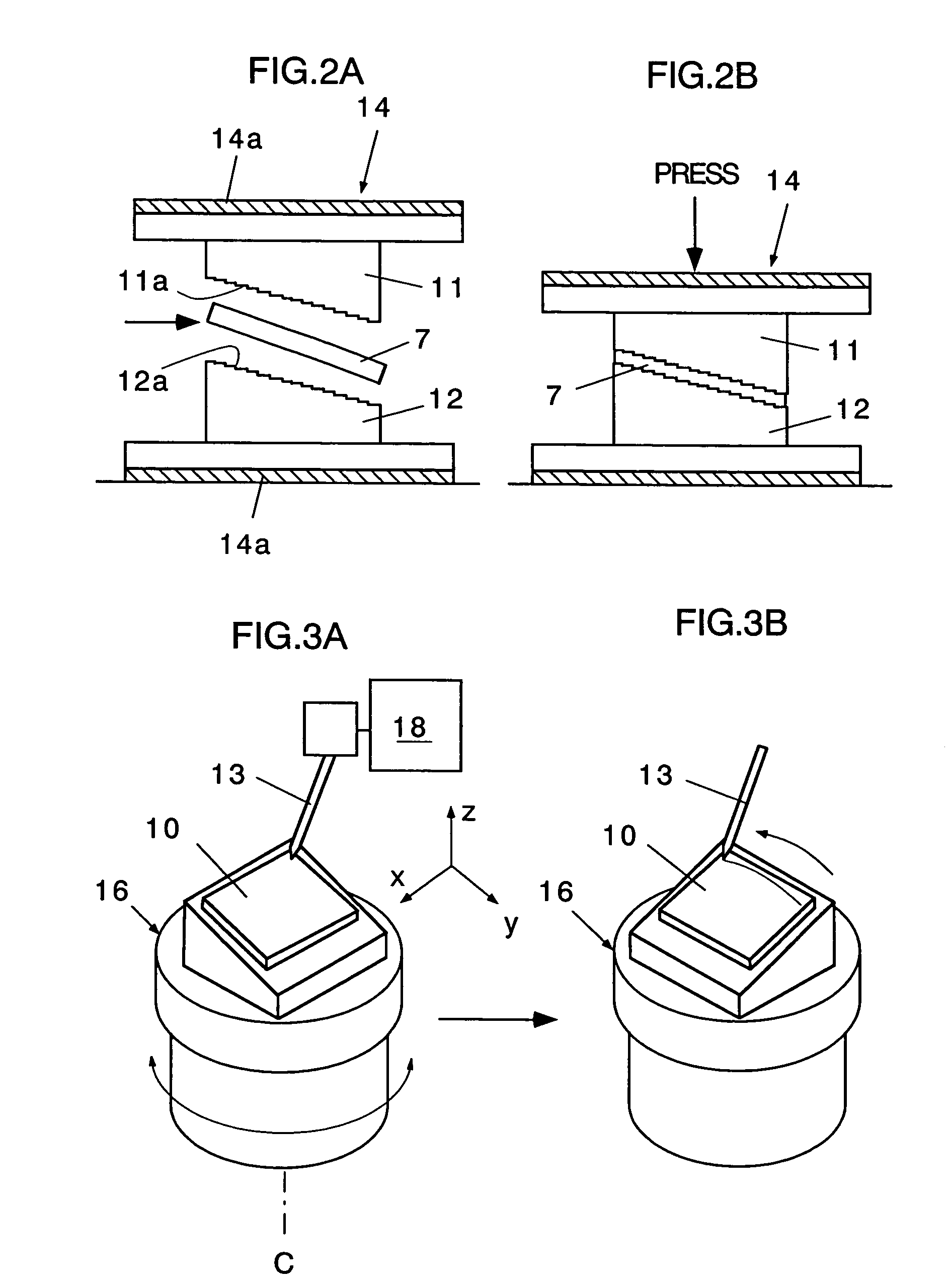

Method and apparatus for manufacturing large double-sided curved Fresnel lens

InactiveUS7106528B2Efficient preparationSmall roughnessOptical articlesCeramic shaping mandrelsFresnel lensShell molding

A method of manufacturing a large double-sided curved Fresnel lens. The method includes a machining step (A) of performing ultra-precise three-dimensional machining on an upper mold and a lower mold to each have an upper transfer surface and a lower transfer surface engaging an upper surface and a lower surface of a thermoplastic resin plate, respectively. Further, the method includes a hot press molding step (B) of pressing the thermoplastic resin plate between the upper and lower molds by a predetermined pressure with the resin plate being held at a temperature higher than a softening temperature thereof and lower than a melting temperature thereof so that the thermoplastic resin plate is curved, and both lens surfaces for the double-sided Fresnel lens are respectively transferred to an upper surface and a lower surface of the thermoplastic resin plate.

Owner:RIKEN

Method for preparing ultra-fine diamond grinding wheel of vitrified bond

InactiveCN101870091AReduce surface roughness valueReduce depthAbrasion apparatusGrinding devicesPotassiumUltra fine

Owner:DALIAN UNIV OF TECH

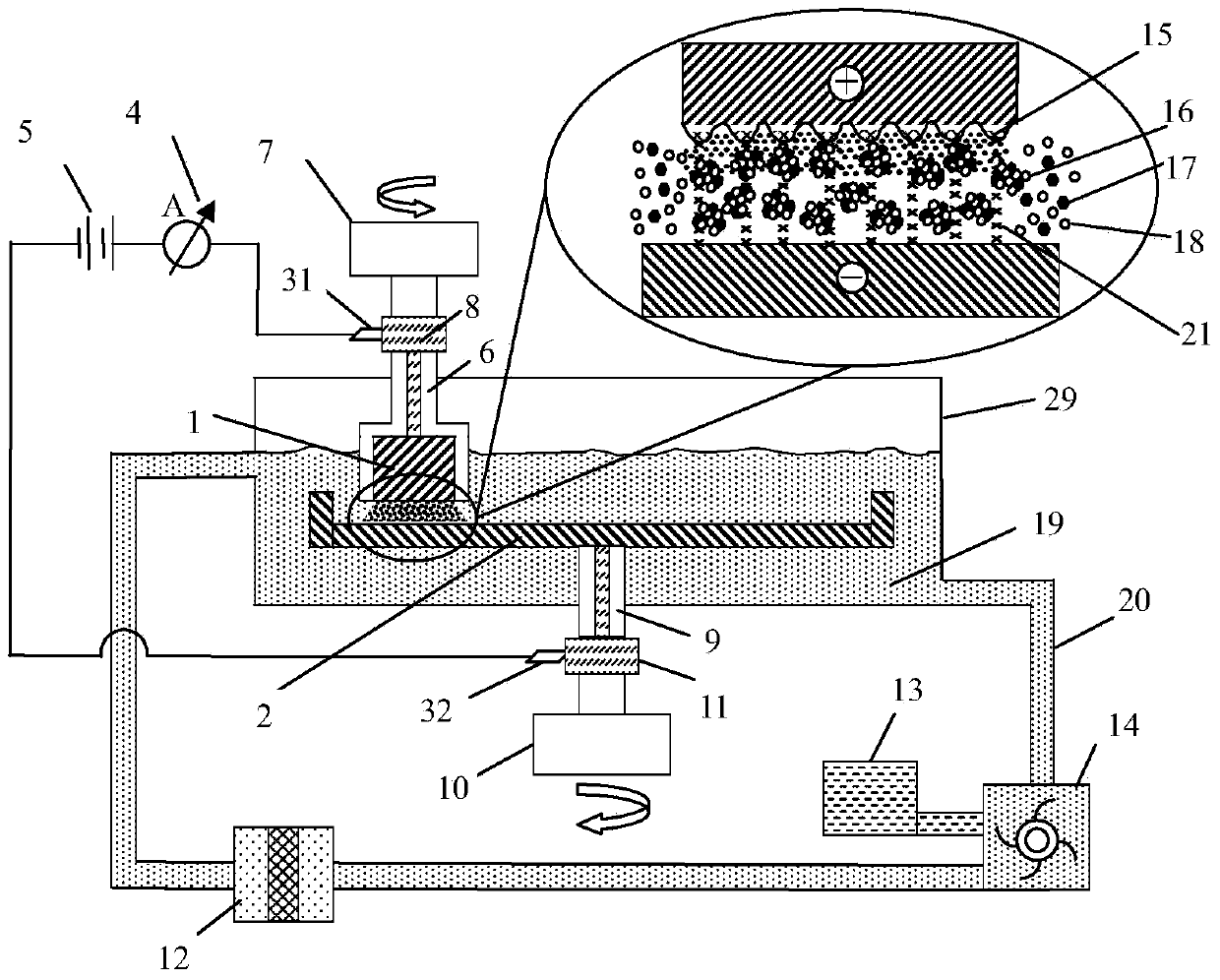

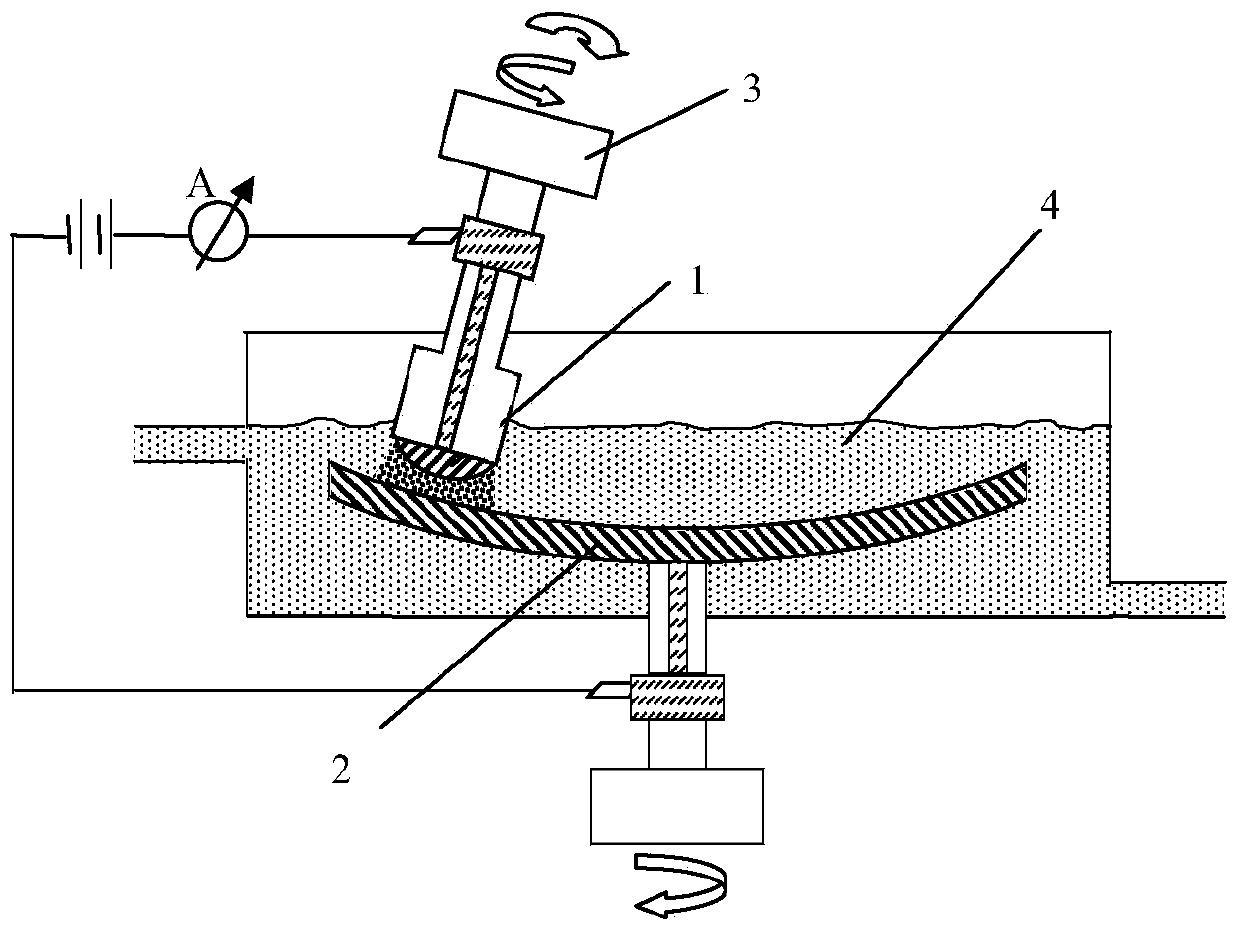

Ultra-precision machining device based on non-Newtonian fluid shear thickening and electrolysis composition effect

ActiveCN104191340AThe result is prone to the problem of spotsImprove processing efficiencyPolishing machinesPolishing compositions with abrasivesElectrolysisComponents of crude oil

An ultra-precision machining device based on non-Newtonian fluid shear thickening and an electrolysis composition effect comprises a polishing tool, a polishing tool clamp, a workpiece clamp and a polishing pool, wherein the polishing tool is located in the polishing pool, polishing liquid is contained in the polishing pool, a workpiece on the workpiece clamp is located in the polishing pool, and a gap is formed between the workpiece and the polishing tool; the workpiece clamp is connected with a workpiece driving mechanism, an electric conducing part of the polishing tool clamp is connected with a polishing tool driving mechanism, an electric conducting part of the workpiece clamp is connected with an anode of a power source, the polishing tool clamp is connected with a cathode of the power source, and abrasive particles or micro powder or electrolyte components are added into non-Newtonian fluid with the shear thickening effect to form the polishing solution. The ultra-precision machining device is wide in application range, high in efficiency and quality, low in cost, simple in device structure and easy to control.

Owner:ZHEJIANG UNIV OF TECH

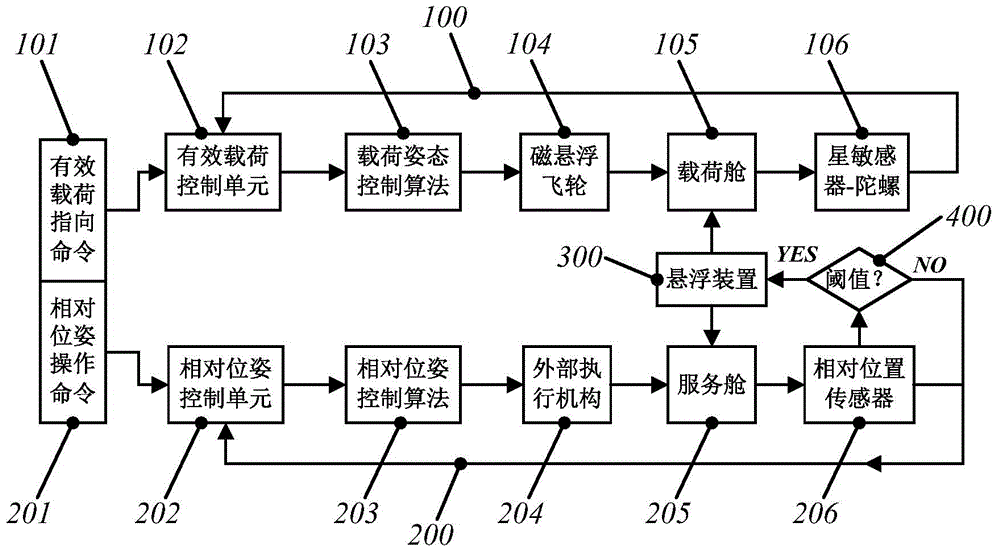

Follow-up tracking dynamic and static isolation type dual-super satellite platform and working mode implementation method thereof

ActiveCN104129509ASolve the problem of super precision and super stabilityTo achieve the purpose of keeping quiet while movingCosmonautic vehiclesCosmonautic partsDeep space explorationAstronomical telescopes

The invention discloses a follow-up tracking dynamic and static isolation type dual-super satellite platform and a working mode implementation method thereof. The follow-up tracking dynamic and static isolation type dual-super satellite platform is suitable for sensitive load spacecrafts with the ultra-precision and ultra-stability requirement. Dynamic and static isolation is used as the means, a satellite is divided into a load cabin and a service cabin, the load cabin can ensure that the effective load meets the expected ultra-precision and ultra-stability control requirement through a high-performance magnetic levitation flywheel arranged on the load cabin, the service cabin can resist environmental disturbance and track the load cabin in a follow-up mode through an external actuator mounted on the service cabin, and accordingly the two cabins can meet the expected relative pose requirement. The load cabin is connected with the service cabin through a suspension device in a non-contact mode, vibration disturbance of the service cabin can be effectively isolated, and the vibration isolation effect cannot be affected by the sensor performance. The satellite based on the dual-super satellite platform at least has the launching, ultra-precision and ultra-stability, anti-collision or mobility working mode. The dual-super satellite platform can be applied to high resolution sensitivity effective load spacecrafts such as a high resolution remote sensing satellite and a deep space exploration astronomical telescope.

Owner:SHANGHAI SATELLITE ENG INST

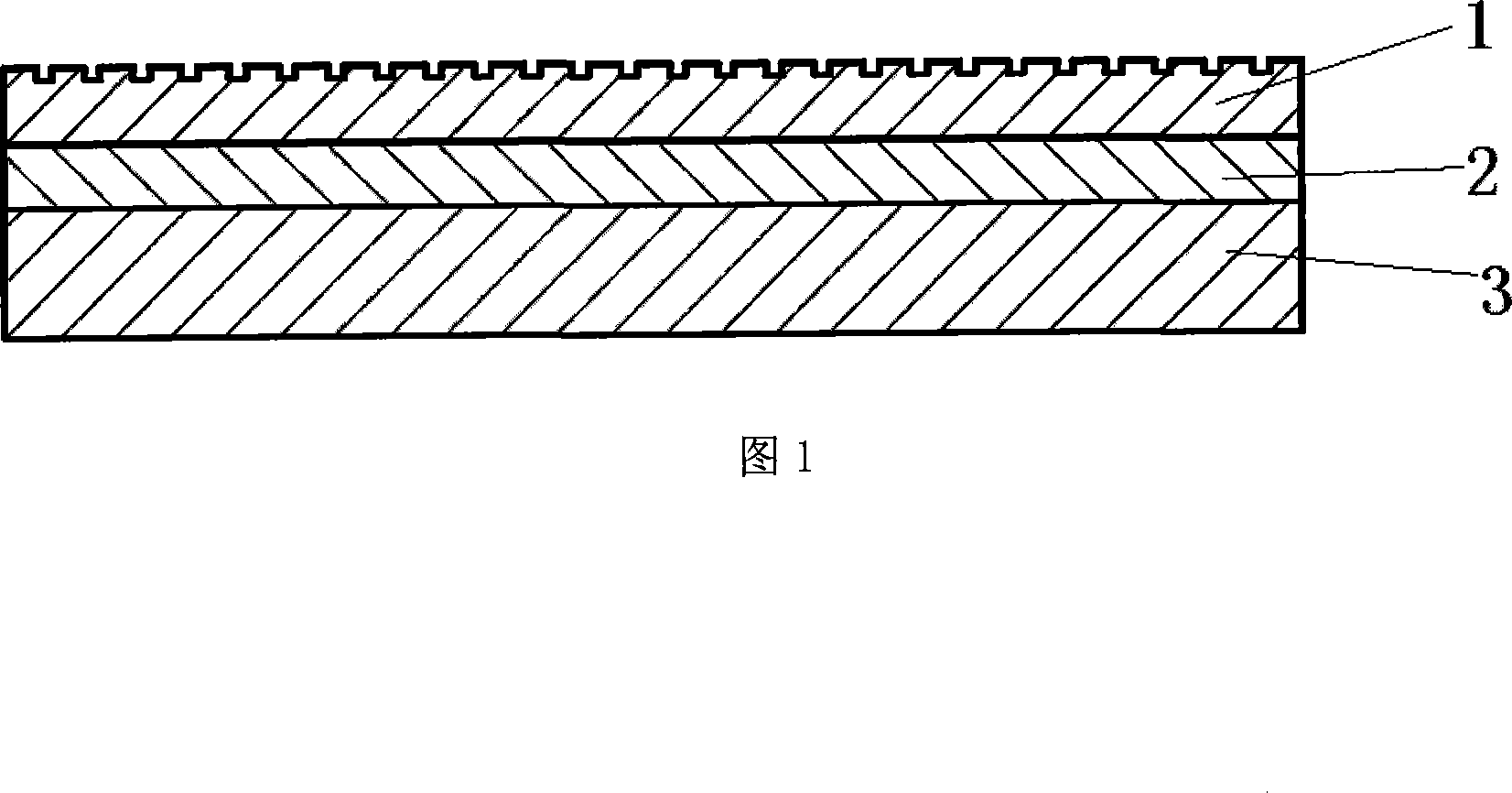

Solidified abrasive lapping polishing pad having self-modifying function and preparation method

InactiveCN101096080AReduce surface roughnessImprove flatnessAbrasion apparatusGrinding devicesCross-linkScreen printing

The invention relates to a grinding and polishing pad of consolidation abrasive with self-adjusting function and the preparation method, belonging to ultra-precision grinding and polishing machining technical field, which is characterized in that components of the abrasive layer (3)comprises 1-20% by wt of abrasive with granularity of 1-40 nanometer, 20-80% by wt of acrylic pre-polymer, 1-3% by wt of free radical photo initiator, 0-2% by wt of poly (dimethylsiloxane) / acrylic polymer, 0-20% by wt of adjustment additive with system cross-linking density performance, and 5-40% by wt of acrylic active diluent. The preparation process comprises (1)mixing stock fully and uniformly, (2)preparing rigid polymer matrix, (3)daubing uniformly by screen-printing, and (4)solidifying by ultraviolet cured machine. The invention is provided with stable grinding and polishing performance and self-adjustment performance. It is suitable for precision machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for grinding soft crisp functional crystal

InactiveCN101376228AAvoid scratchesPrevent embeddingSupport wheelsAqueous dispersionsHigh surfaceGrinding wheel

A soft brittle functional crystal grinding and machining method belongs to the technical field of soft brittle functional crystal machining, and particularly relates to a soft brittle functional crystal ultra-precision grinding and machining method for a semiconductor and a photoelectric crystal. The method is characterized in that a micro-powder diamond segmental variable speed feed and a soft abrasion grinding wheel chemical mechanical grinding method are adopted to machine the soft brittle function crystal. During the crude grinding period and the accurate grinding period, the feeding speed of the grinding wheel is firstly high and then low. A grinding fluid is de-ionized water. A soft abrasive agent grinding wheel is adopted to conduct the chemical mechanical grinding. The soft abrasive agent is a macromolecule polymer or waterproof resin. A filler is NaHCO3 or a refined naphthalene foaming agent. The chemical and mechanical grinding fluid is adopted as a reaction fluid and a cooling fluid. The grinding fluid mainly contains lactic acid, acetic acid and de-ionized water. The pH value of the grinding fluid is 2-4. The invention has the advantages of high grinding and machining efficiency, low machining cost and high surface precision. In addition, no surface / sub-surface damage is caused to the surface of a workpiece, such as small scratches, embedment of free abrasive agent, plastic deformation, residual stress, and the like.

Owner:DALIAN UNIV OF TECH

Active air-floatation support device

ActiveCN103836070AImprove dynamic stiffnessImprove dynamic stiffness characteristicsLinear bearingsGas cushion bearingsDynamic stiffnessControl signal

The invention discloses an active air-floatation support device which comprises an air-floatation support body, an air-film active adjustment unit, a support body detecting unit and a drive control unit, wherein the support body detecting unit measures the state of air-floatation support, the drive control unit generates a control signal according to a detection signal to drive and control the air-film active adjustment unit to generate an active role so as to dynamically adjust the air film form of an air-floatation support surface, thereby dynamically adjusting the pressure distribution of air film gaps of the air-floatation support device, and improving the dynamic stiffness characteristic of air-floatation support. According to the active air-floatation support device, the dynamic stiffness characteristic of air-floatation support can be significantly increased, and the purpose of stabilizing air-floatation support is achieved. In addition, the active air-floatation support device also has the characteristics of compact structure, convenience in control and high precision, thus being especially suitable for occasions of ultra-precision machining or with high-speed spindles with a high requirement on support dynamic stiffness.

Owner:HUAZHONG UNIV OF SCI & TECH

Method and device for determining grinding brittleness-ductility transformation critical cutting depth of hard and brittle material

InactiveCN103722467AImprove surface qualityHigh precisionGrinding feed controlGrinding machinesHigh surfaceRelative motion

The invention relates to the technical field of hard and brittle material ultra-precision machining. In order to achieve ductility domain grinding of the largest cutting depth, high surface quality of the hard and brittle material, and efficient and high-precision production machining, according to the technical scheme, a method and device for determining the grinding brittleness-ductility transformation critical cutting depth of the hard and brittle material comprises the following steps of (1) according to a grinding wheel used in ultra-precision grinding, determining the number, shape and distance of grains of a homemade multi-grain tool, (2) according to the grain shape, distance and front-angle parameters selected in the step (1), machining three or more grains on a grain base body, (3) controlling the multi-grain tool and a workpiece to generate relative motion, beginning to conduct scratching on the surface of the workpiece, meanwhile, controlling the multi-grain tool to conduct continuous feeding, enabling the depth of the scratch to continuously change, and observing and measuring the workpiece after scratching by utilizing a surface contourgraph and a confocal microscopy. The method is mainly applied to ultra-precision machining.

Owner:TIANJIN UNIV

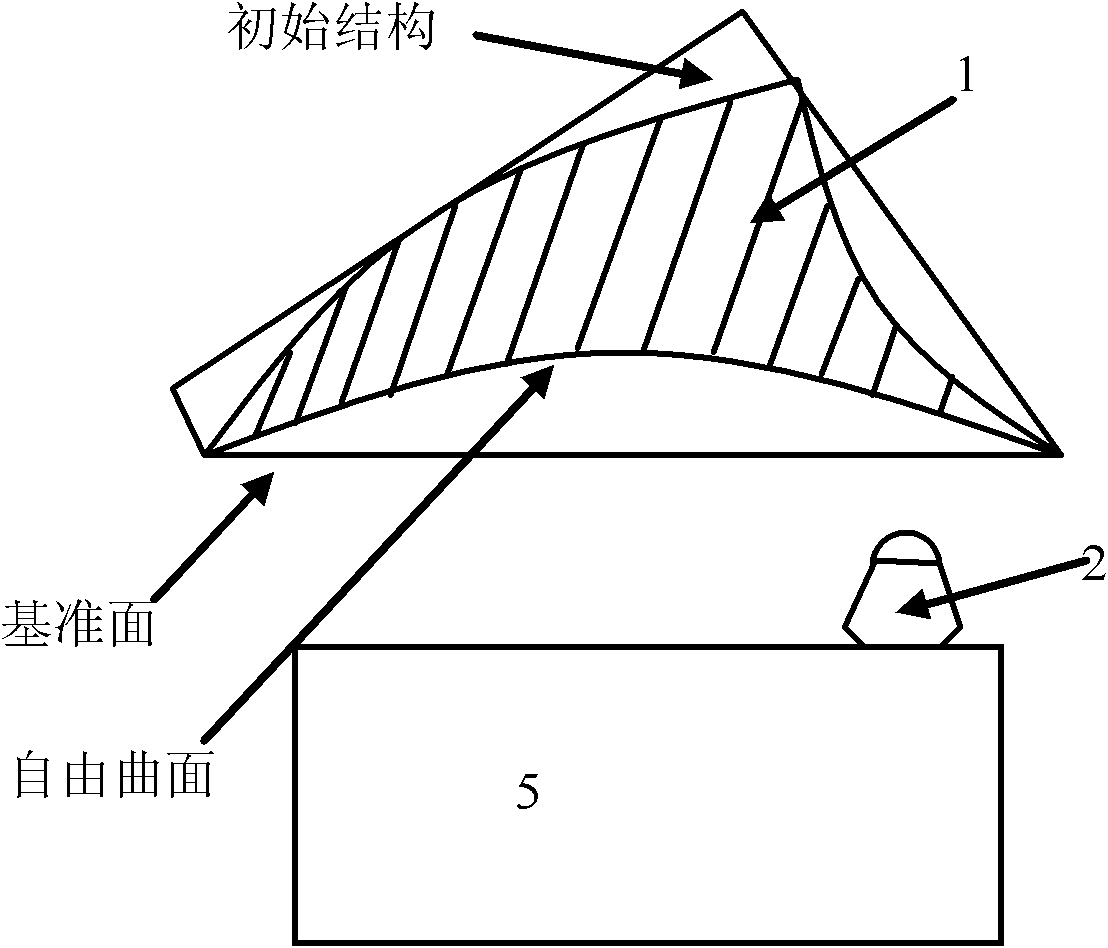

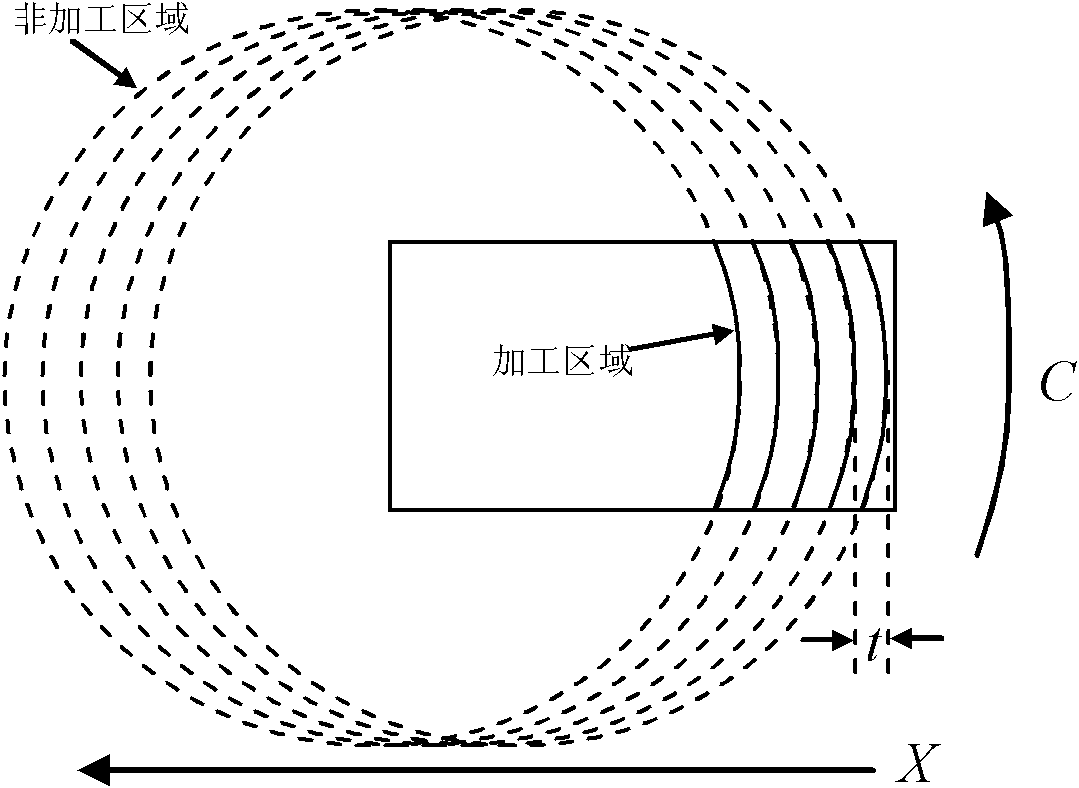

Method for processing free-form surface prism

The invention belongs to the technical fields of optical device manufacturing and ultra-precision processing and relates to a method for processing a free-form surface prism. The method comprises the following steps of: calculating an initiating structure according to the structure of the free-form surface prism to be processed, processing the initiating structure by utilizing a precise processing machine tool or a processing center and processing a side face to be processed to be a free-form surface to be a flat face; making a tool holder used for fixing a diamond cutter, wherein by means ofthe tool holder, the diamond cutter can be perpendicular to an end face of a main shaft and can rotate around the main shaft; arranging the diamond cutter and the tool holder on the main shaft of an ultra-precision machine tool and assembling a high-precision rotating table on a Z shaft of the machine tool to build a free-form surface prism ultra-precision processing system; fixing the free-form surface prism on the rotating table and regulating one flat face undergoing the initiating structure processing to be parallel to the end face of the processing main shaft; and designing a processing path. The method provided by the invention has the characteristics of high processing quality, simple structure, low cost and high efficiency.

Owner:TIANJIN UNIV

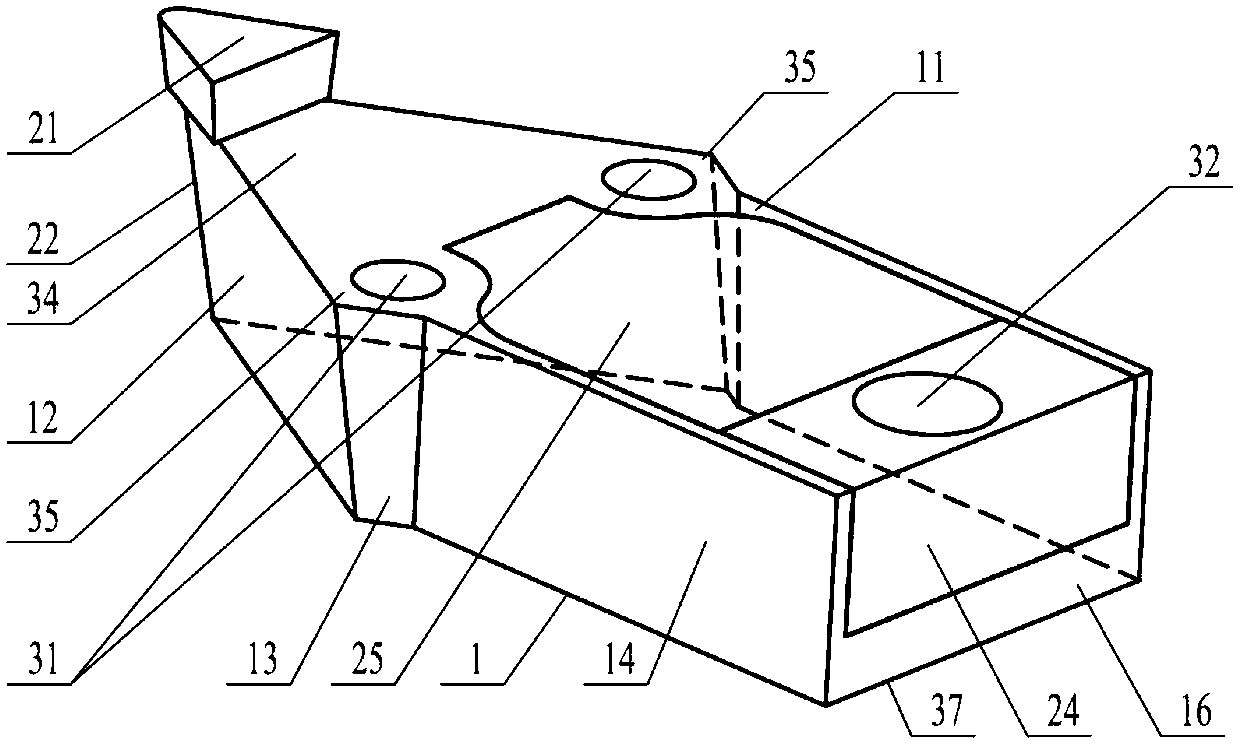

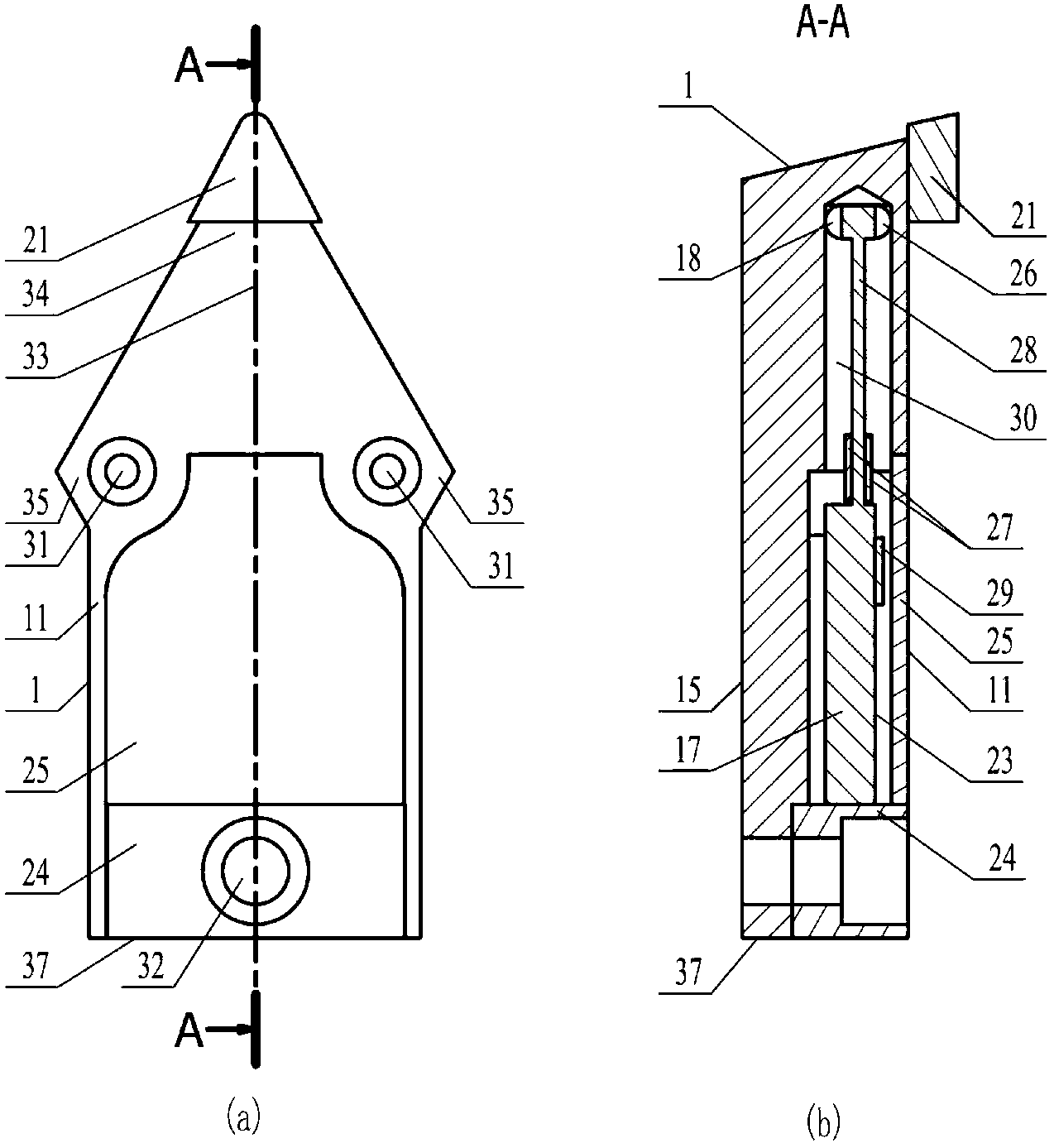

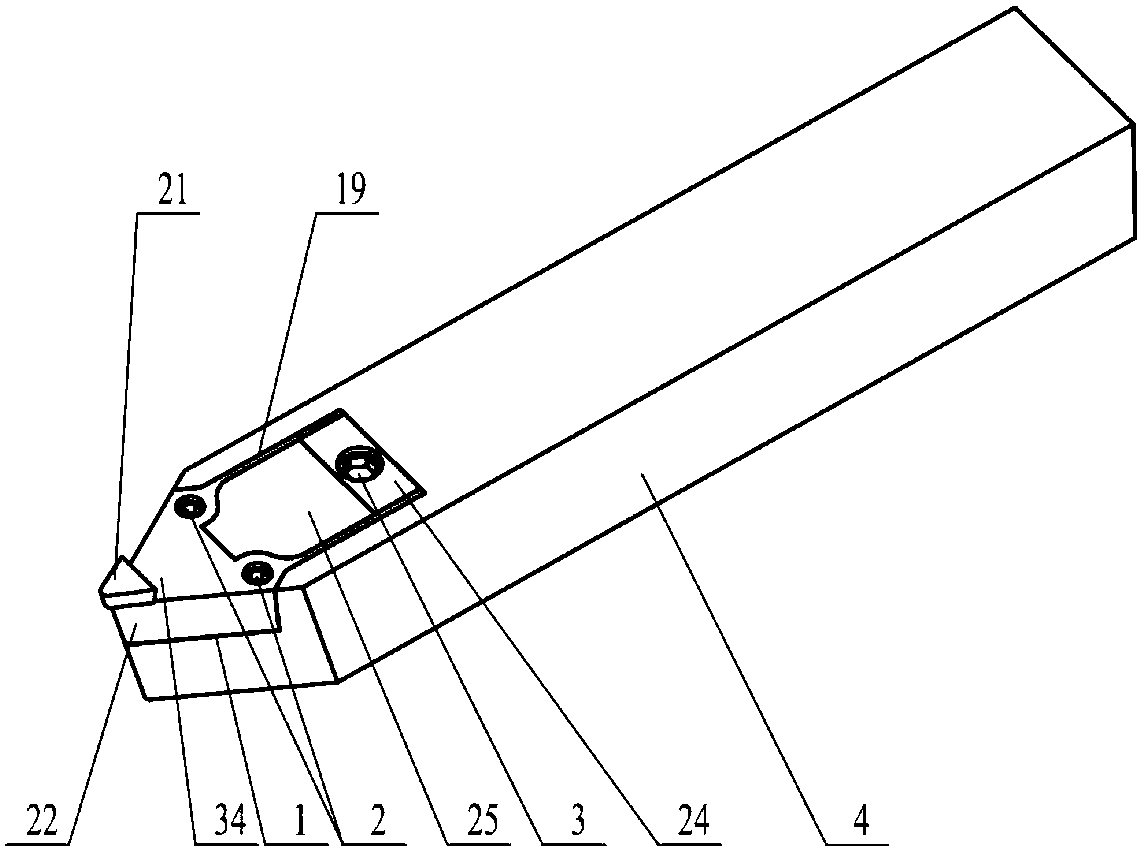

Intelligent diamond cutter with real-time sensing and monitoring system and cutter body matched with intelligent diamond cutter

InactiveCN102699362ARealize autonomous real-time monitoringRealize real-time monitoringMeasurement/indication equipmentsTurning toolsEngineeringCutting force

The invention discloses an intelligent diamond cutter with a real-time sensing and monitoring system and a cutter body matched with the intelligent diamond cutter, and belongs to the field of ultra-precision cutting machining and cutting state real-time monitoring. The requirements of real-time sensing and monitoring and adaptive machining of an ultra-precision machining process can be met. During the cutting machining of the intelligent diamond cutter, the cutting temperature, cutting force and vibration of the cutter are measured through a micro-electromechanical sensing system. The diamondcutter is fixedly connected to the front end of a cutter substrate. The micro-electromechanical sensing system is arranged in a cavity in the cutter substrate. A sensing and measurement long arm overhanging beam extended into an acute-angled cutter point area is arranged on the micro-electromechanical sensing system. A temperature sensor is arranged on the end part of the sensing and measurement long arm overhanging beam. Strain sensors are symmetrically arranged on the upper and lower surfaces of the root of the sensing and measurement long arm overhanging beam. An acceleration sensor and aninformation processing and wireless transmission module are integrated in the micro-electromechanical sensing system. A cavity is sealed by an upper sealing cover and a rear sealing gasket. The intelligent diamond cutter is arranged on a matched shank. The intelligent diamond cutter and the cutter body are used for the ultra-precision cutting machining and the real-time monitoring of the cutting machining process.

Owner:HARBIN INST OF TECH

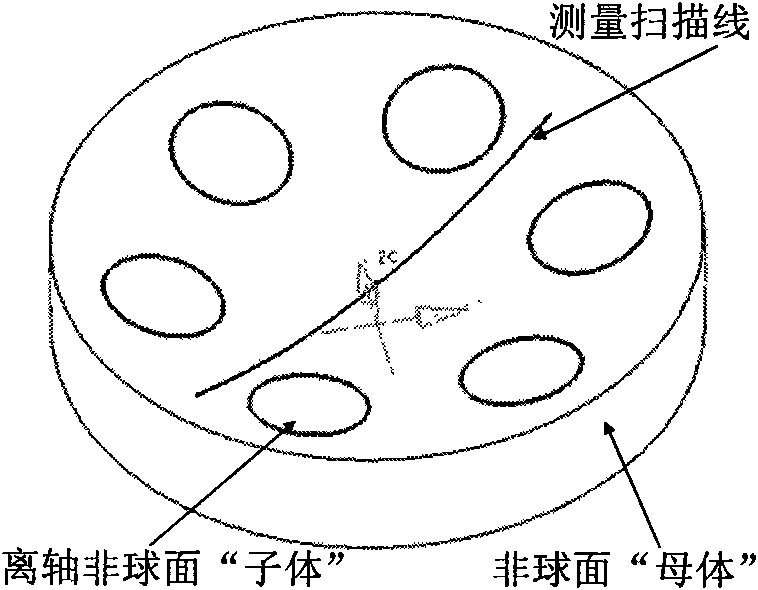

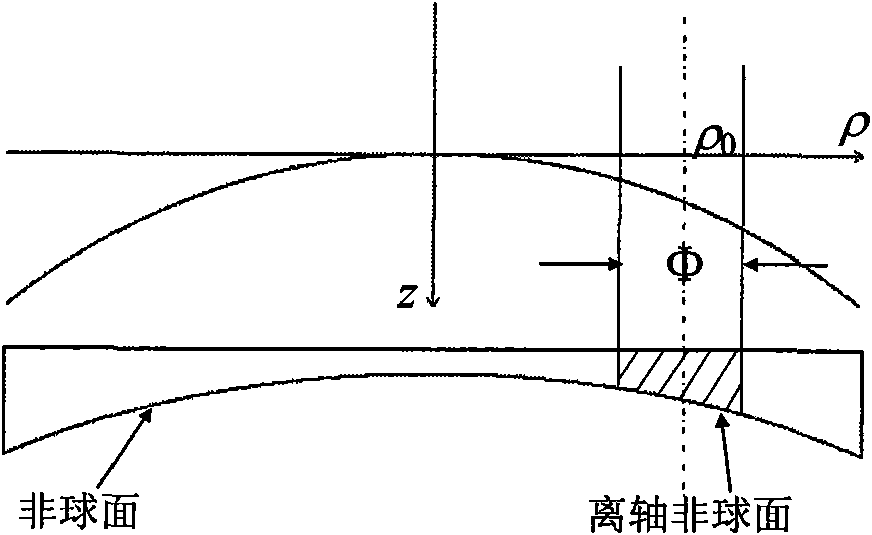

Method for improving shape accuracy and processing efficiency of off-axis aspheric mirror

InactiveCN101670442AEasy to processConsistent processabilityTurning machinesManufacturing technologyComputer science

The invention belongs to the technical field of optical device manufacturing and relates to a method for improving shape accuracy and processing efficiency of an off-axis aspheric mirror, comprising the following steps: (1) designing a rotary aspheric surface as well as a primary and secondary consubstantial structure for the primary body according to the size and the dimension of the off-axis aspheric mirror to be processed, i.e. a secondary body, and determining the amount of the off-axis aspheric secondary bodies to be processed at one time; (2) disposing through holes on a primary body blank piece; (3) placing all secondary body blank pieces into the through holes and fixing on a lathe after integrating into a cylindrical integrated work piece, and processing a spherical surface closest to the rotary aspheric surface on the integrated work piece; (4) generating a processing path of cutting tools based on the shape of the rotary aspheric surface, reprocessing the spherical surface by utilizing an ultra-precision lathe and carrying out form error analysis and compensating processing according to the measured integrated rotary aspheric surface shape. The provided method is simpleand easy to realize, has the advantages of high-efficiency, easy detachability and high shape accuracy and can realize high-efficient processing on an off-axis aspheric surface with high shape accuracy.

Owner:TIANJIN UNIV

Polishing liquid for polishing monocrystalline silicon piece chemical machine

InactiveCN101671528ANo surface defectsEfficient ultrafine chemical mechanical polishingPolishing compositions with abrasivesActive agentSurface roughness

The invention discloses a polishing liquid for polishing a monocrystalline silicon piece chemical machine, comprising the raw materials by mass percent: 0.1-20% of grinding material, 0.1-2% of chelating agent, 0.1-5% of dispersing agent, 0.1-5% of active agent, 0.01-10% of pH regulator and less than or equal to 90% of purified water; and the pH value is 9.0-12.0. The polishing liquid can obviouslyimprove the polishing speed (removing rate reaching 710nm), generates lower surface defect for a monocrystalline silicon piece, and reduces the surface roughness (reaching 0.18nm), thus realizing topolish the high-efficiency ultra-precision chemical machine of the monocrystalline silicon piece, and ensuring the fine quality of the surface of the monocrystalline silicon piece. The polishing liquid is alkaline, so as to be conveniently cleaned after polishing; furthermore, the polishing liquid does not corrode equipment, thus prolonging the service life of the equipment and reducing the processing cost.

Owner:DALIAN SANDAAOKE CHEM

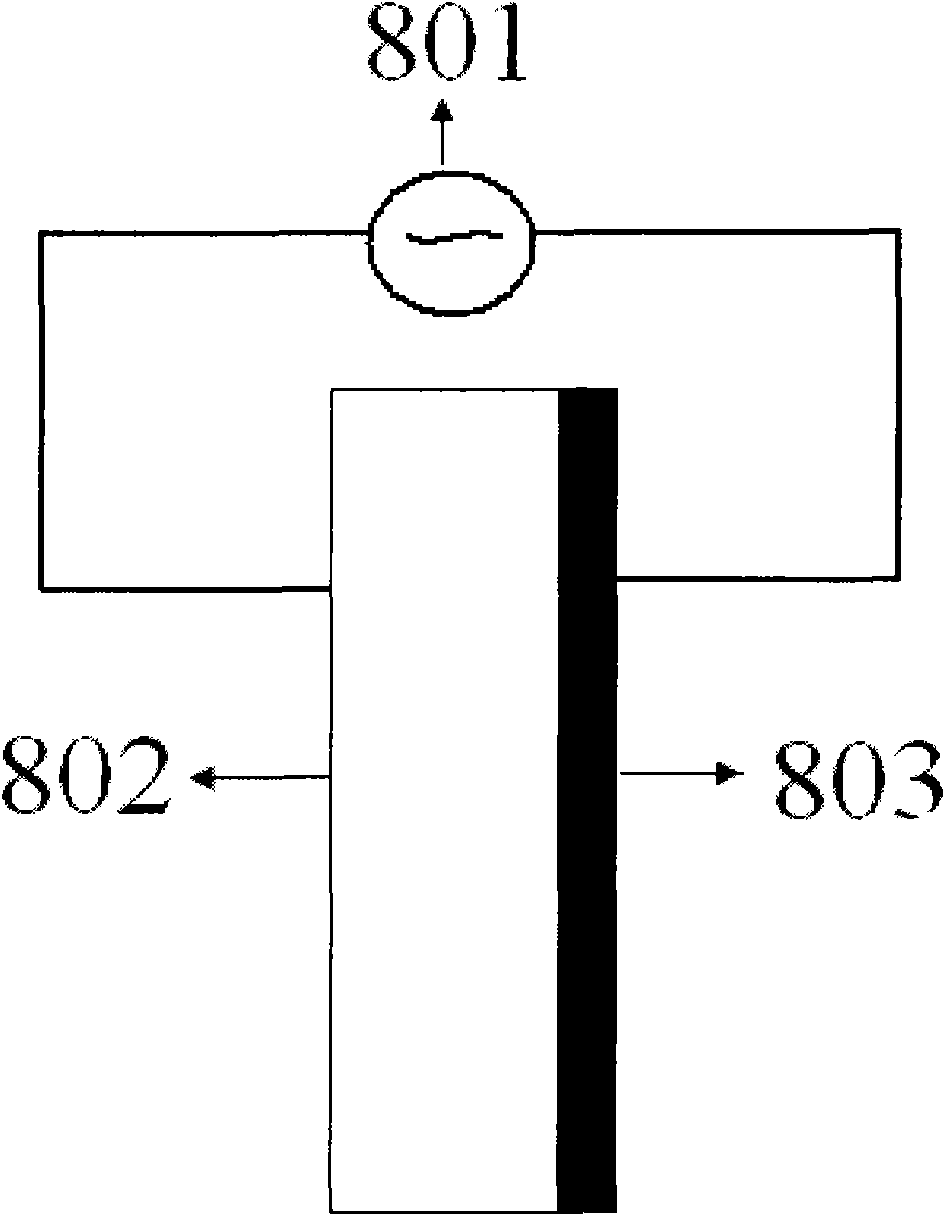

Two-DOF (degree of freedom) heterodyne grating interferometer displacement measurement system

ActiveCN103307986AMeasuring light path is shortLow environmental sensitivityInterferometersUsing optical meansGratingBeam splitter

A two-DOF (degree of freedom) heterodyne grating interferometer displacement measurement system comprises a two-frequency laser, a grating interferometer, a measuring grating, a receiver, and an electronic signal processing part. The grating interferometer comprises a polarizing beam splitter, a reference grating and a refraction element. The measurement system measures displacement according to optical grating diffraction, optical Doppler Effect and optical beat frequency principle. A two-frequency laser beam emitted by the two-frequency laser enter the grating interferometer and the measuring grating before two light signals are output to the receiver, and the signals are sent to the electronic signal processing part. When the grating interferometer is in two-DOF linear relative motion with the measuring grating, the system can output two linear displacements. The measurement system allows for sub-nano or higher resolution and precision, and can measure two linear displacements simultaneously. The measurement system has the advantages of insensitivity to environment, high measurement precision, small size, light weight and the like, and after the measurement system is used as a lithography machine ultra-precision workpiece bench position measurement system, comprehensive performances of a workpiece bench can be improved.

Owner:TSINGHUA UNIV +1

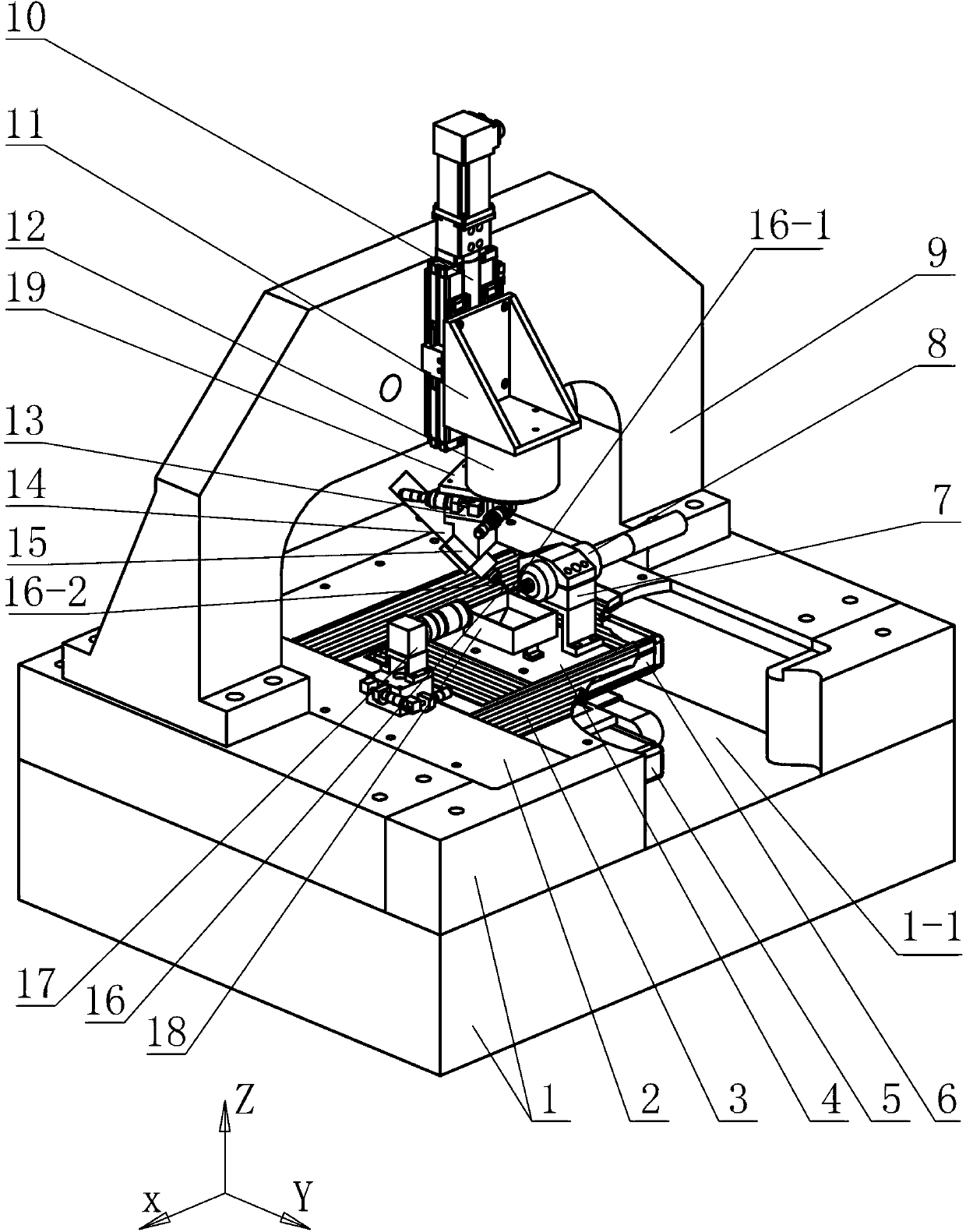

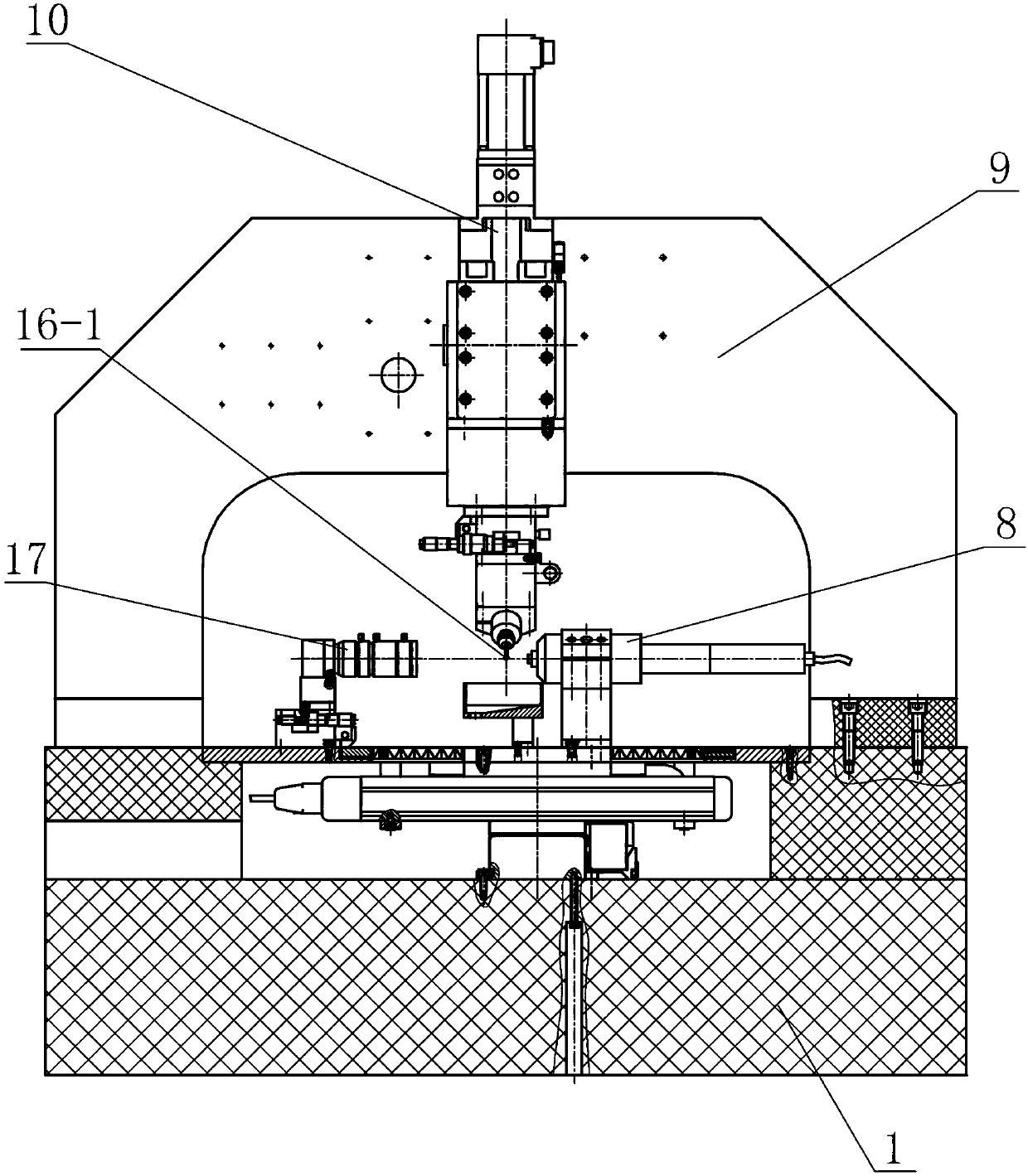

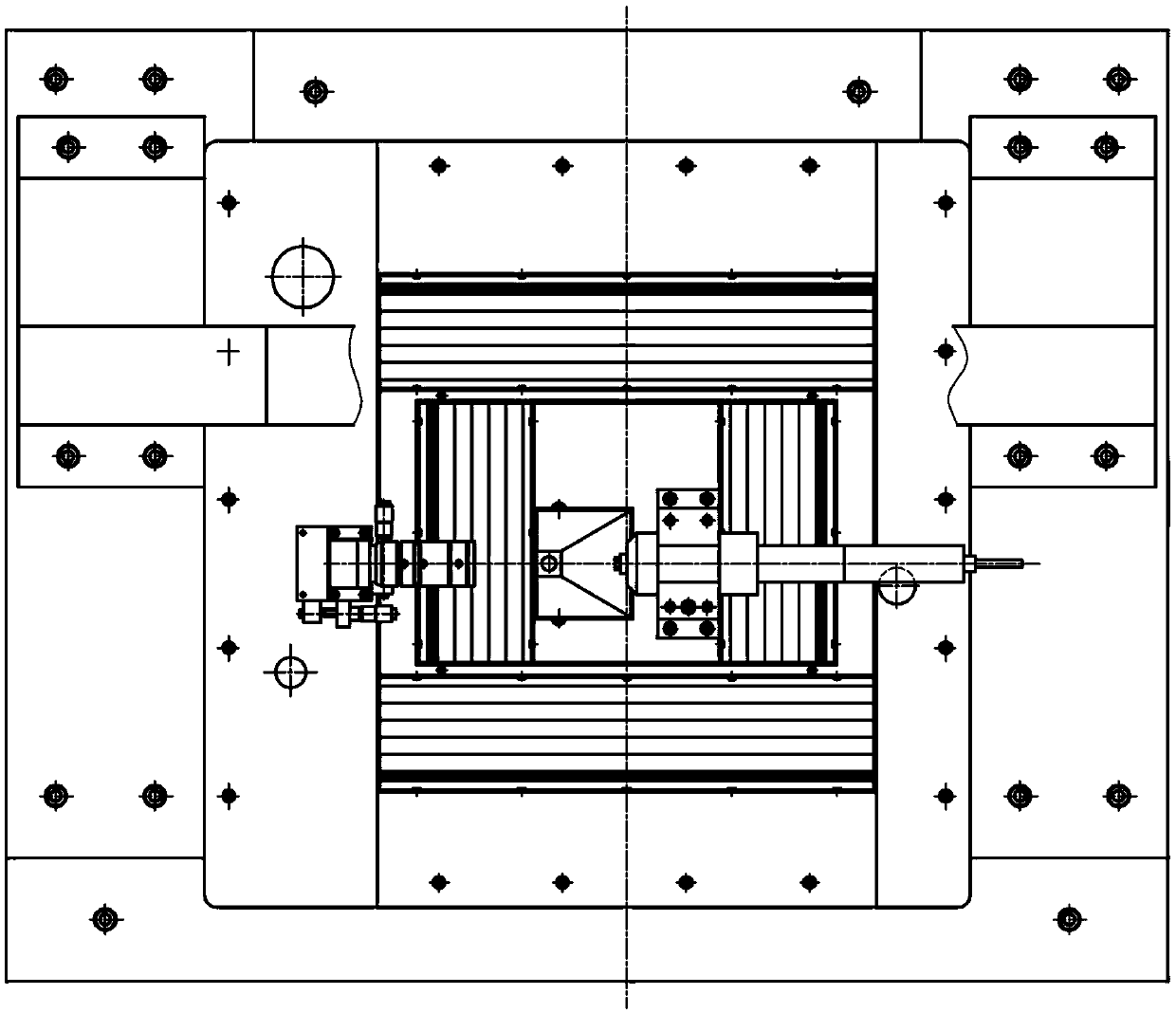

Small-caliber non-spherical permanent magnet magnetorheological polishing processing machine tool

ActiveCN103072047AIncrease contactAvoid interferenceGrinding machine componentsMachine toolComputer science

The invention discloses a small-caliber non-spherical permanent magnet magnetorheological polishing processing machine tool, which belongs to the technical field of grinding-polishing processing, and is used for solving the problem that the shape and size accuracy requirements of a processed part cannot be met since each position of a small-caliber non-spherical curved surface to be processed cannot be contacted during processing of workpieces with the conventional polishing processing equipment. A workbench is arranged on an X axis linear unit of an XY precision movable platform; an organ protection cover is arranged between the edge of the workbench and a cover plate; a workpiece main shaft is arranged on the workbench through a workpiece main shaft bracket; a Z axis linear unit is arranged on a portal frame; a revolving table is arranged on the Z axis linear unit through a right-angle connecting frame; the shaft end of a rotating shaft in the revolving table is connected with a polishing head main shaft bracket through a two-dimensional precision fine adjustment displacement table; and the polishing head main shaft bracket has a certain inclination angle, so that an included angle between a polishing head main shaft on the polishing head main shaft bracket and a horizontal plane is 40-45 degrees. The machine tool is suitable for ultra-precision polishing processing of high-accuracy small-caliber non-spherical parts.

Owner:HARBIN INST OF TECH

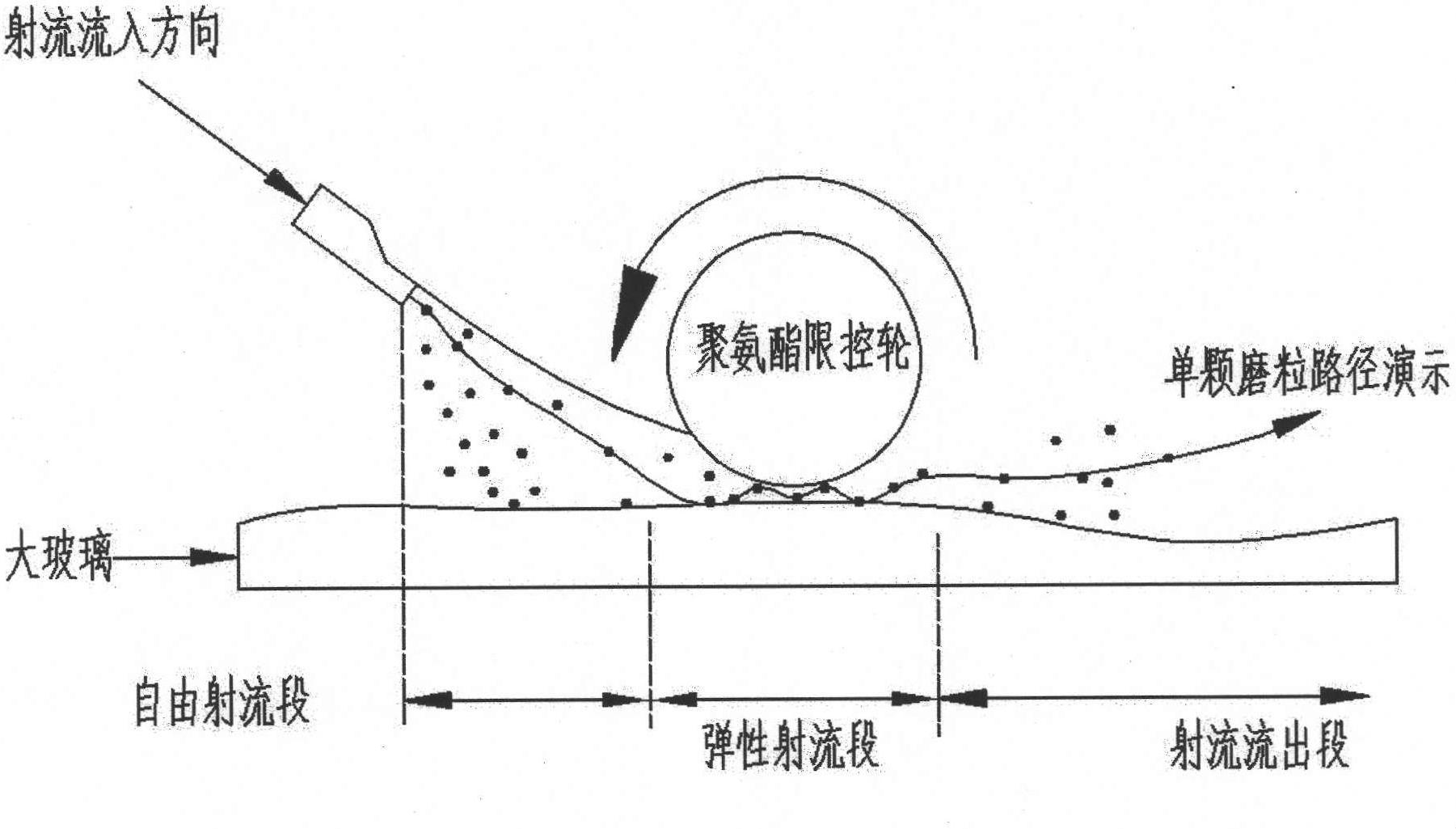

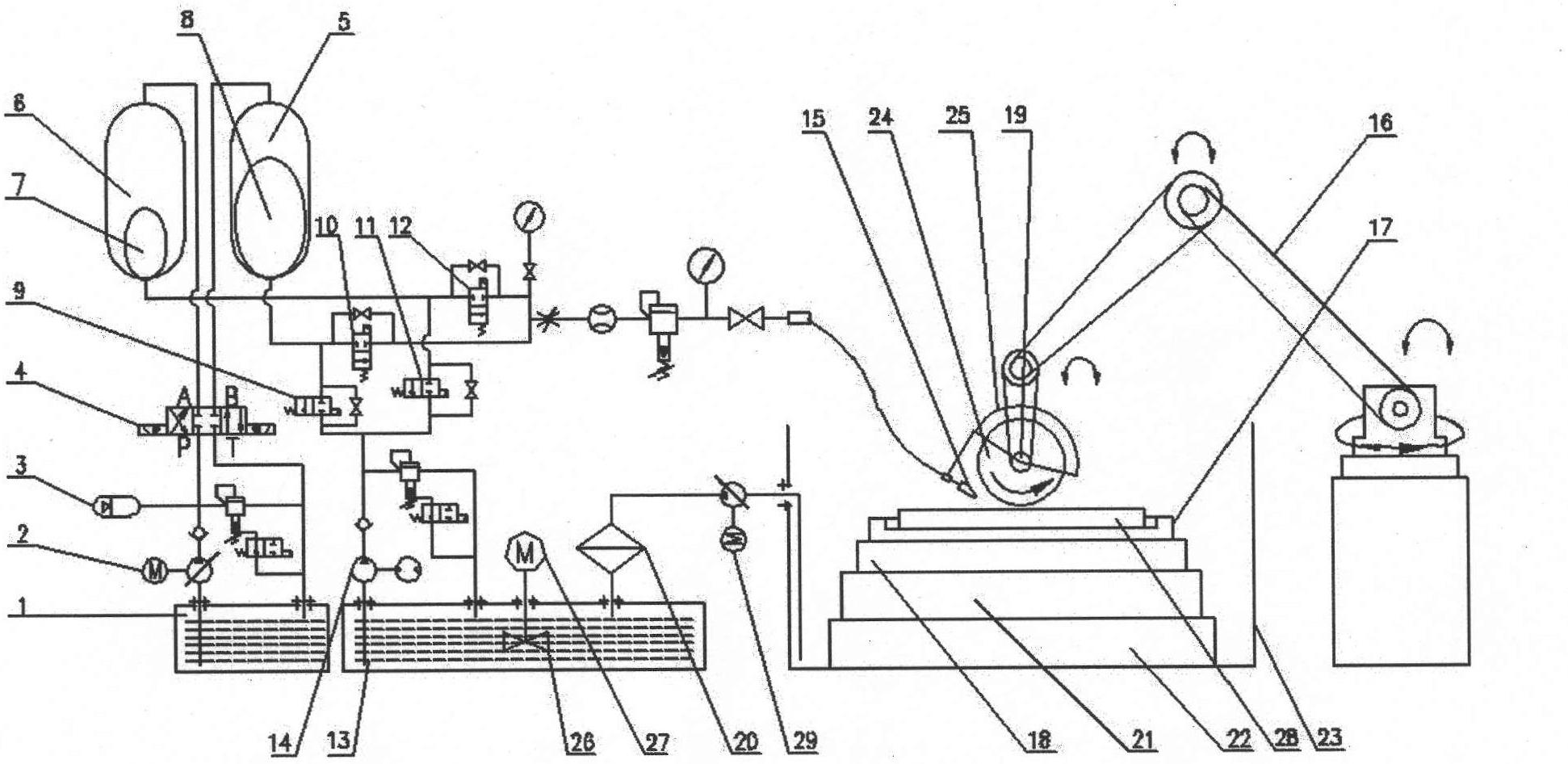

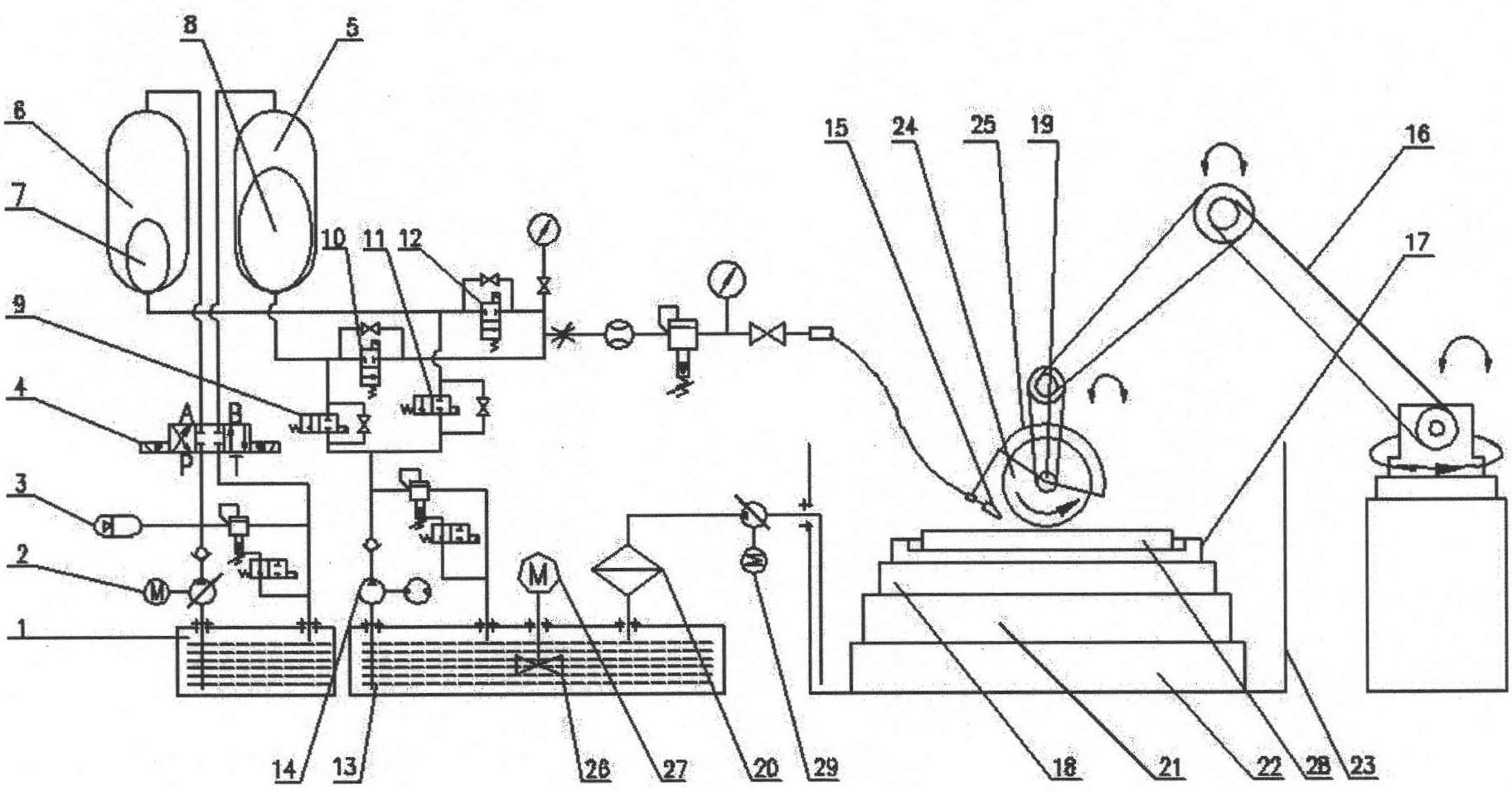

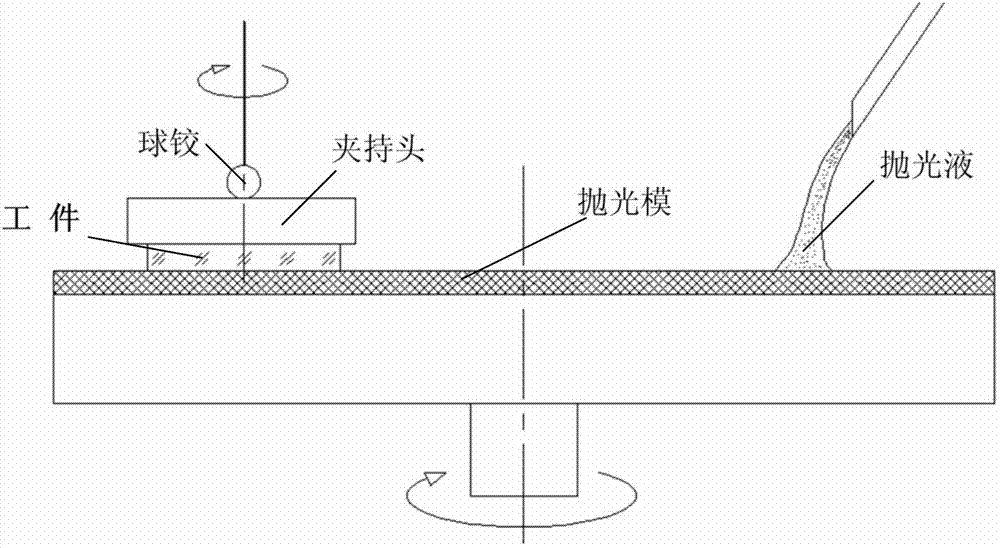

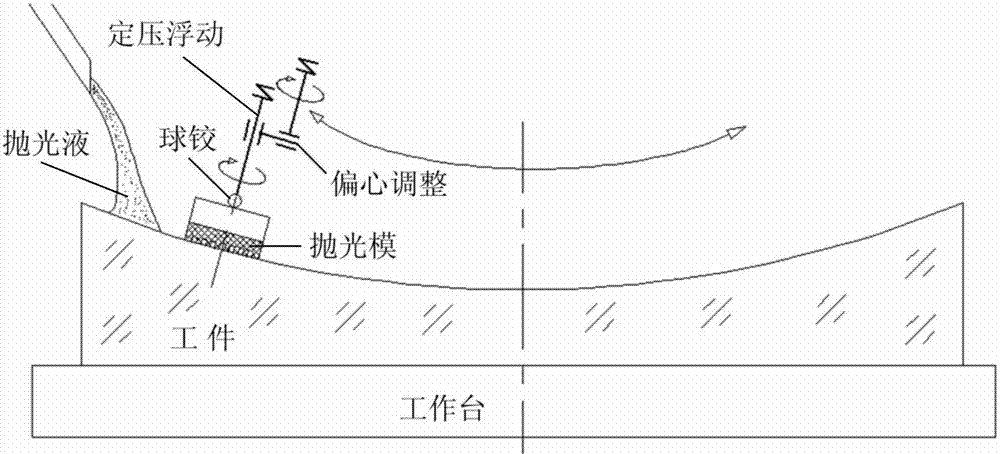

Controllable mix abrasive jet polishing equipment for large-scale ultra-precision optical glass

InactiveCN102689246AIncrease roughnessImprove polishing efficiencyPlane surface grinding machinesEngineeringOptical glass

The invention provides controllable mix abrasive jet polishing equipment for large-scale ultra-precision optical glass. The controllable mix abrasive jet polishing equipment is characterized by comprising a jet generating and transmission system and a robot controllable abrasive fluid polishing system. The equipment provided by the invention increases the machining precision and the machining efficiency, remarkably improves the shape precision and the roughness of large glass, eliminates subsurface damage and realizes machining of free surfaces.

Owner:DONGHUA UNIV

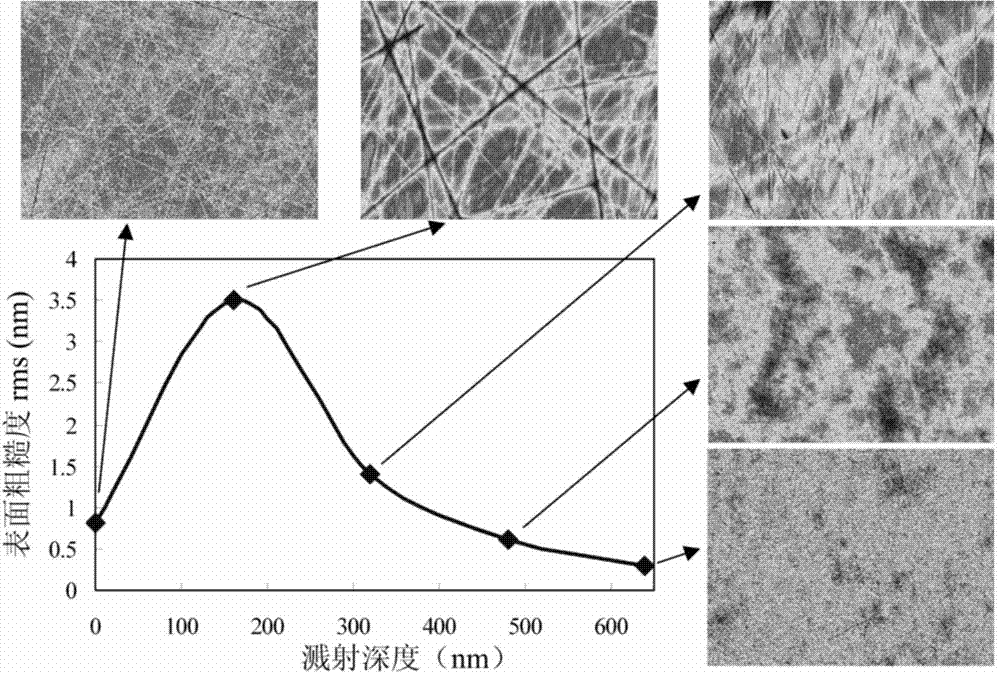

Calcium fluoride single crystal ultra-precision machining method based on chemico-mechanical polishing and ion beam polishing combined process

The invention disclose a calcium fluoride single crystal ultra-precision machining method based on a chemico-mechanical polishing and ion beam polishing combined process. The method comprises the following steps of: polishing a calcium fluoride single crystal by adopting a chemico-mechanical polishing, removing surface damages and sub-surface damages on a calcium fluoride surface, and exposing an ideal atom layer to obtain a super-smooth crystal surface; and improving the surface figure accuracy of the super-smooth crystal surface obtained in the previous step by adopting an ion beam polishing method to realize ultra-precision machining of a calcium fluoride single crystal with nano-grade or sub-nano-grade surface figure accuracy and a super-smooth surface. Due to the adoption of the machining method disclosed by the invention, respective technological advantages of chemico-mechanical polishing and ion beam polishing can be utilized fully; and moreover, the machining efficiency and the machining accuracy are high, and the product quality is good.

Owner:NAT UNIV OF DEFENSE TECH

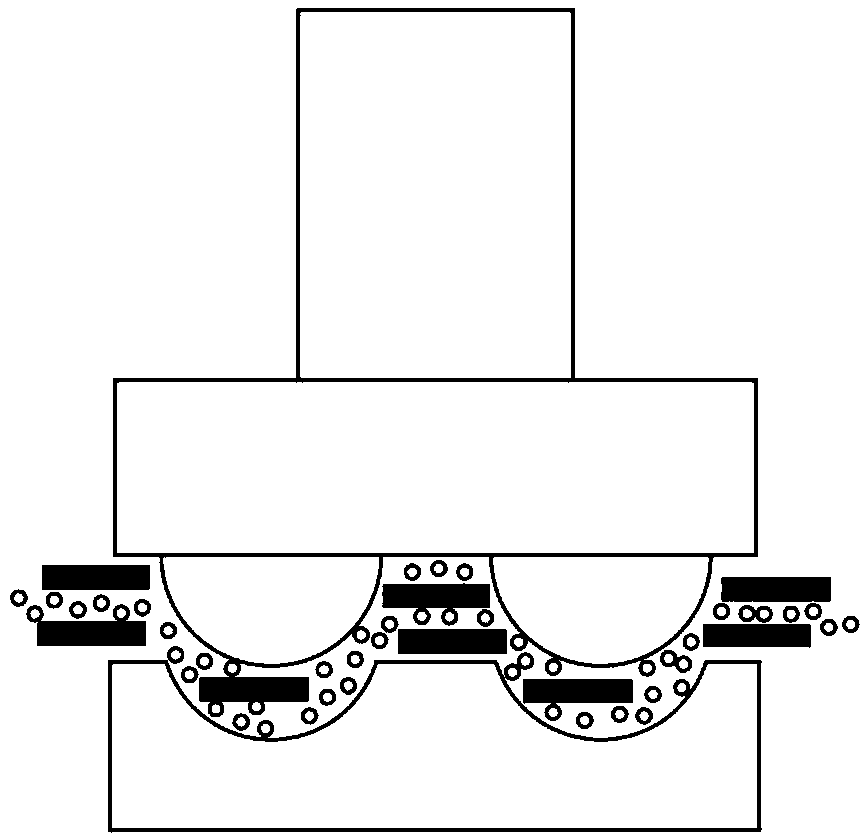

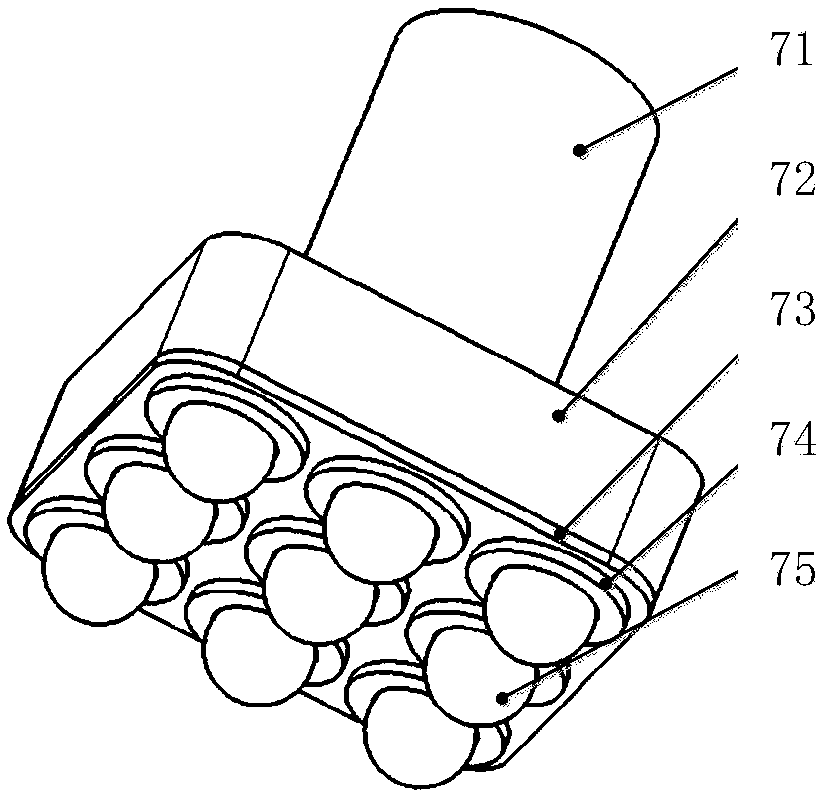

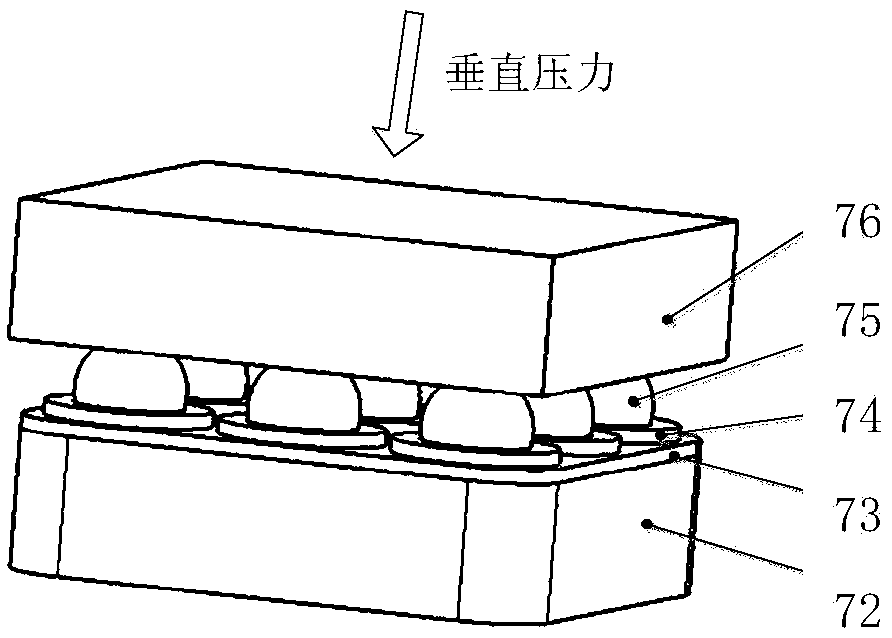

Micro semi-ring female die array-mode lapping and polishing method and device

ActiveCN105364641AImprove processing efficiencyEnsure consistencyLapping machinesLapping toolsMaterial removalGranularity

Disclosed is a micro semi-ring female die array-mode lapping and polishing method. The method includes the following steps that (1) a high-uniformity ultra-precise lapping and polishing die is manufactured, the upper end of a tool connecting rod is connected with a micro ultrasonic generator, the lower end of the tool connecting rod is connected with a positioning substrate, array apertures are formed in the positioning substrate, the size of the apertures is smaller than the diameter of precise spheres, spaces between the apertures and the precise spheres are filled with a binder, and part of the spheres is embedded into the apertures; and (2) the space between the high-uniformity ultra-precise lapping and polishing die and a substrate slice is filled with lapping and polishing liquid, the granularity of abrasive grains in the lapping and polishing liquid is nanoscale, the lapping and polishing die performs high-frequency micro ultrasonic vibration in the micro distance on the substrate slice, the ultrasonic vibration excites the abrasive grains in the lapping and polishing liquid to impact on the substrate slice at high speed, the lapping and polishing die performs feed movement downwards at set speed in the Z direction, and material removal of a micro semi-ring female die array is achieved. The invention further provides a micro semi-ring female die array-mode lapping and polishing device. The micro semi-ring female die array-mode lapping and polishing method and device can achieve the lapping and polishing effects of high efficiency, shape accuracy, shape uniformity and surface quality and low surface roughness.

Owner:ZHEJIANG UNIV OF TECH

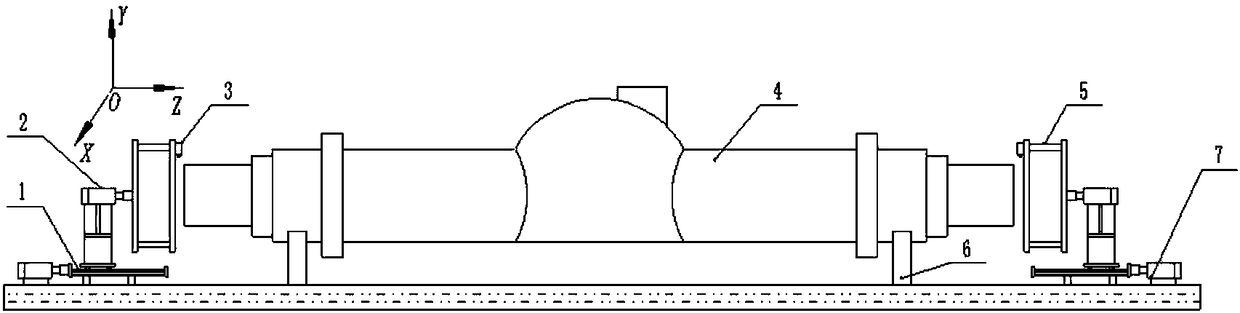

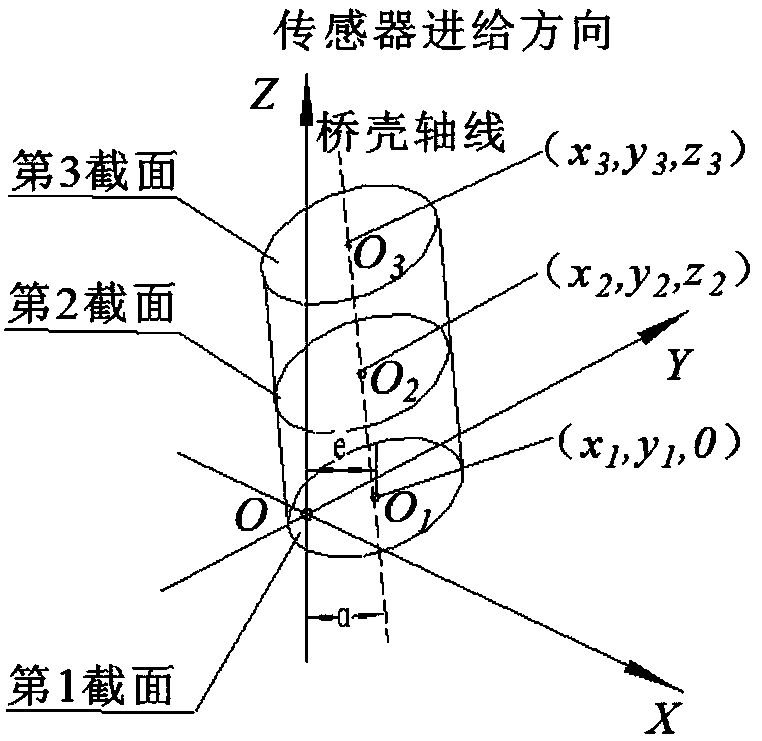

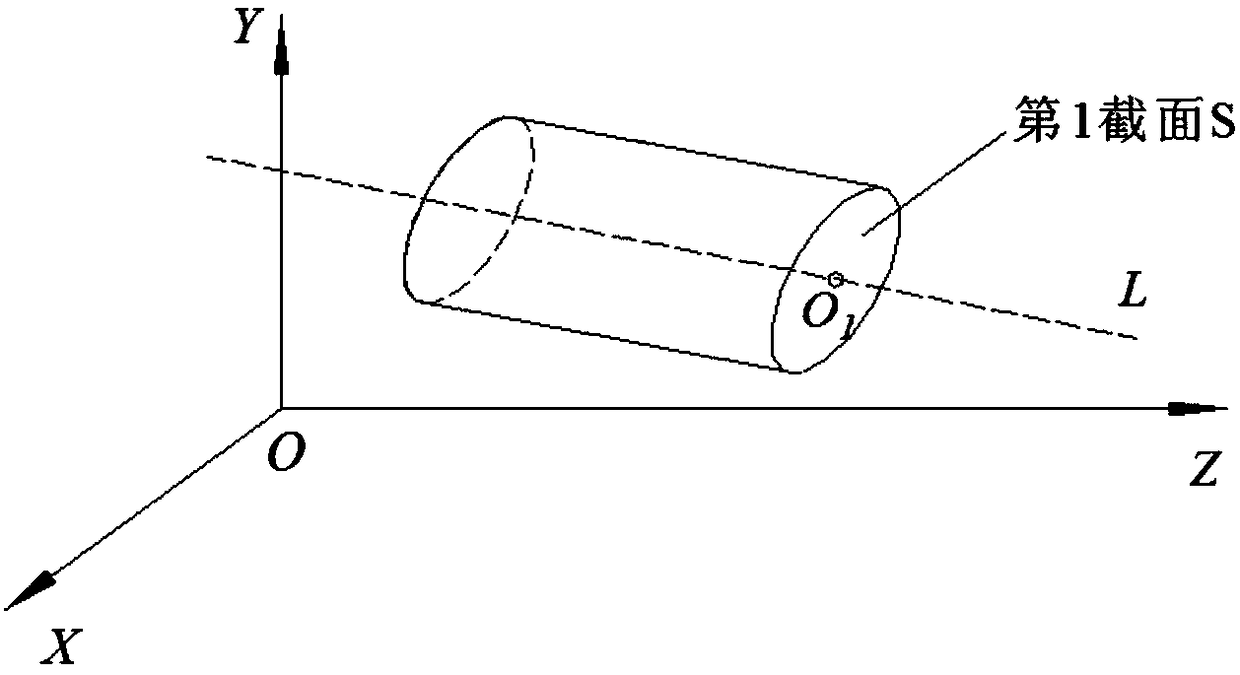

Workpiece axis positioning error compensation method for axle housing roundness and cylindricity detecting device

ActiveCN108253906AImprove detection accuracyAdapt to ultra-precision machining requirementsUsing optical meansEngineeringPosition error

The invention discloses a workpiece axis positioning error compensation method for an axle housing roundness and cylindricity detecting device and belongs to the field of detection. The method is characterized in that an axle housing positioning model is built, a first section, a second section and a third section are arranged on the model, and the second section and the third section are used tocorrect the first section step by step. The method specifically includes: a target section uses O as the benchmark to perform spatial translation on a circle contour where O1 is located, performing axis eccentricity compensation to obtain a section S1 after eccentricity correction, and an axis L and the section S1 are rotated a theta degree along a Z axis to obtain a section S2; the axis L and thesection S2 are rotated an alpha degree along a Y axis to allow the axis L to coincide with the Z axis so as to obtain a section S3; the section S3 and the axis L are reversely rotated theta degrees to obtain the section S4; error evaluation is performed on the section S4 to obtain real roundness errors with workpiece axis positioning eccentricity inclination errors being removed, and a constraintcondition beta is provided. The workpiece axis positioning error compensation method can compensate roundness errors and cylindricity errors caused by workpiece axis positioning eccentricity and workpiece axis positioning inclination, increase axle housing detection precision and meet ultra-precision machining requirements.

Owner:QILU UNIV OF TECH

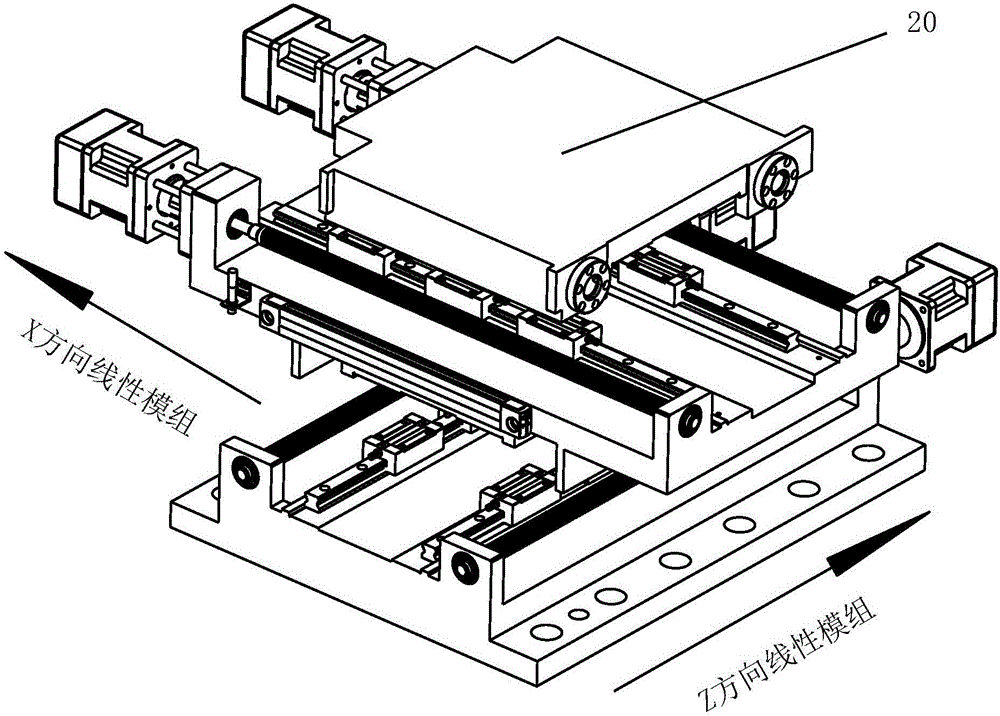

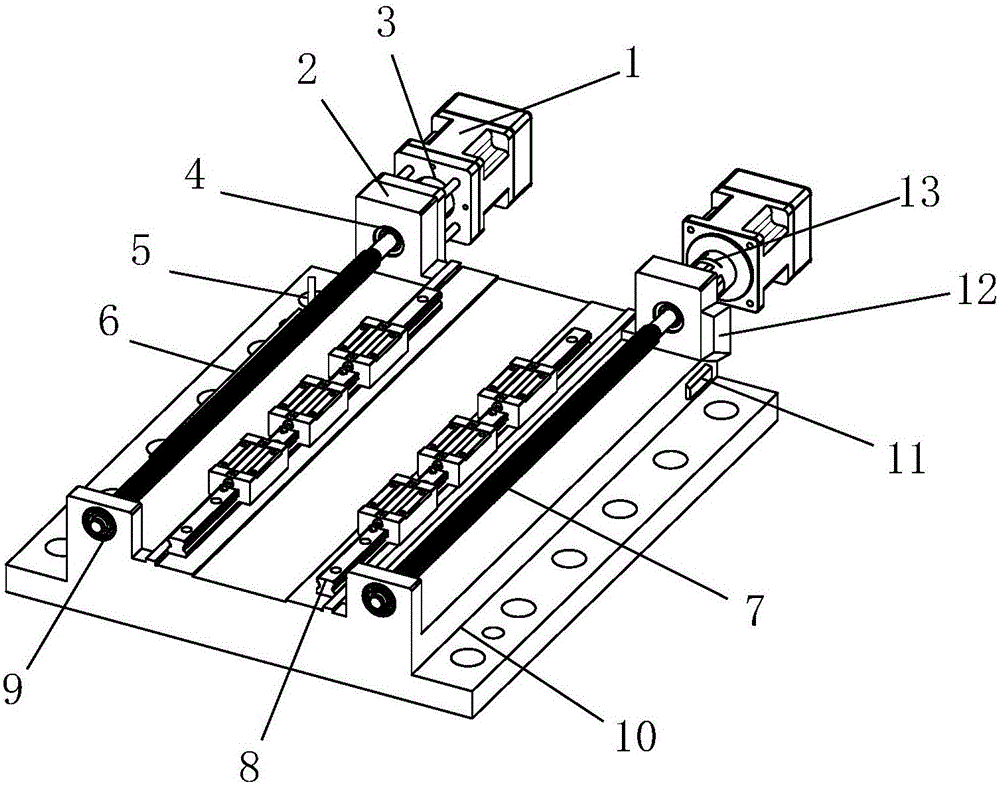

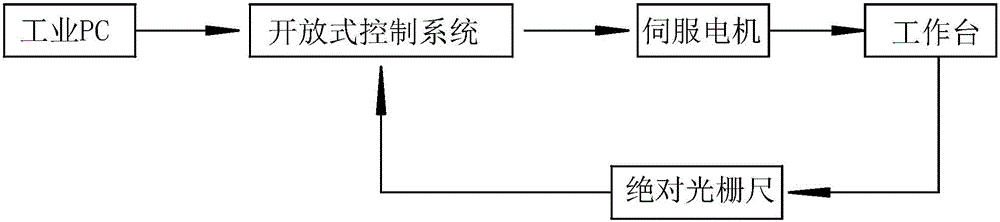

Precise linear two-dimensional double-drive workbench based on control of open numerical-control system

InactiveCN105729141AHigh precisionIncrease stiffnessMeasurement/indication equipmentsFeeding apparatusEngineeringMachine tool

The invention relates to the technical field of precision machining and ultra-precision machining of small-sized light-load machine tools, in particular to a precise linear two-dimensional double-drive workbench based on the control of an open numerical-control system. The precise linear two-dimensional double-drive workbench comprises a movable sliding table, an X-feeding-direction linear module, a Z-feeding-direction linear module, a base and the open numerical-control system. The movable sliding table is connected to the X-feeding-direction linear module through a flange with double screws and sliding blocks. The X-feeding-direction linear module is connected to the Z-feeding-direction linear module through a flange with double screws and sliding blocks. The X-feeding-direction linear module and the Z-feeding-direction linear module are arranged perpendicularly in an orthorhombic mode. The Z-feeding-direction linear module is arranged on the base. According to the precise linear two-dimensional double-drive workbench, by the adoption of the structure, the precise linear two-dimensional double-drive workbench has the characteristics of being high in accuracy, high in rigidity, free of gaps, and compact and attractive in appearance, and the precise linear two-dimensional double-drive workbench is suitable for precision machining and ultra-precision machining of small-sized and medium-sized light-load machine tools.

Owner:WUHAN UNIV OF TECH

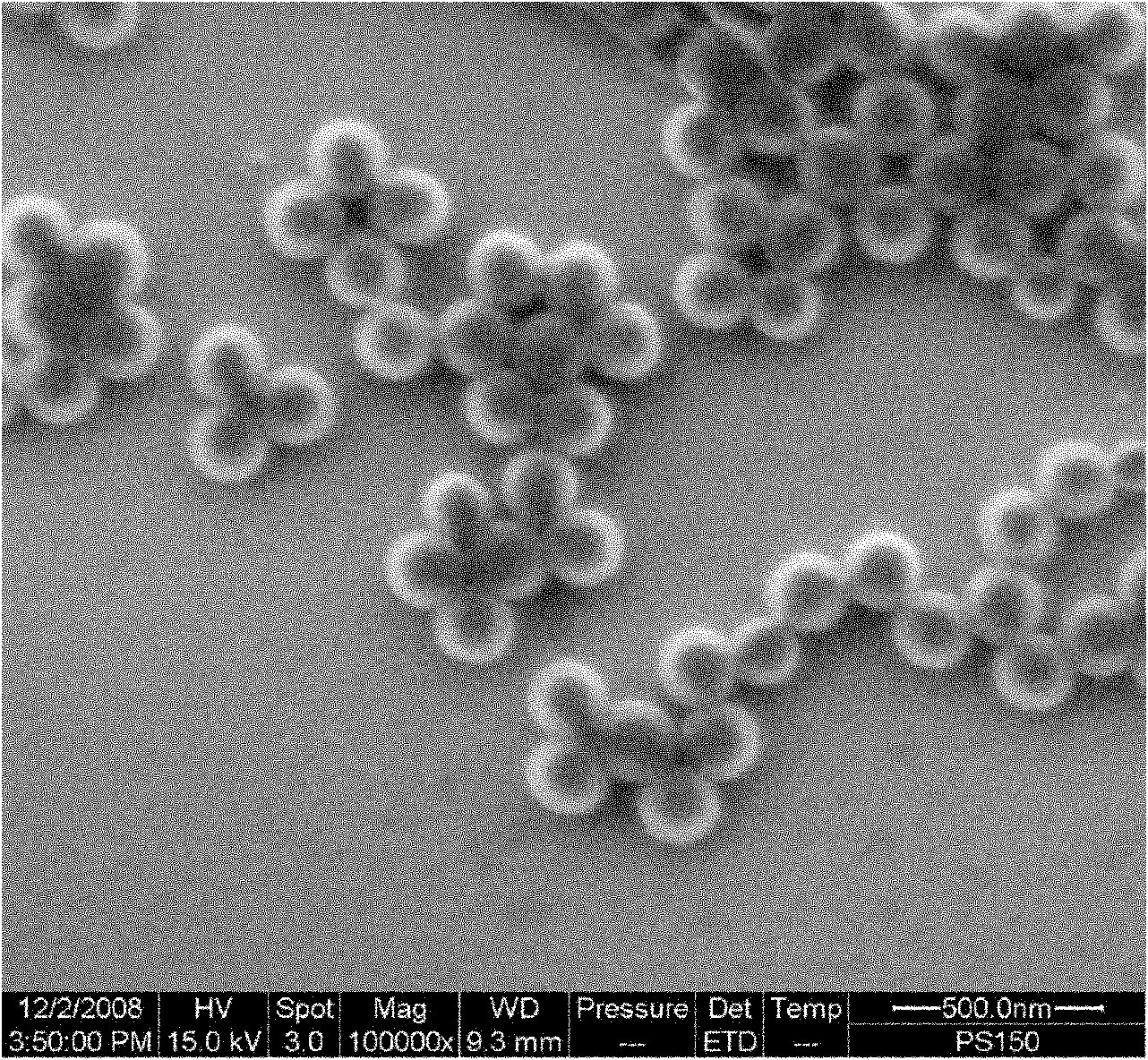

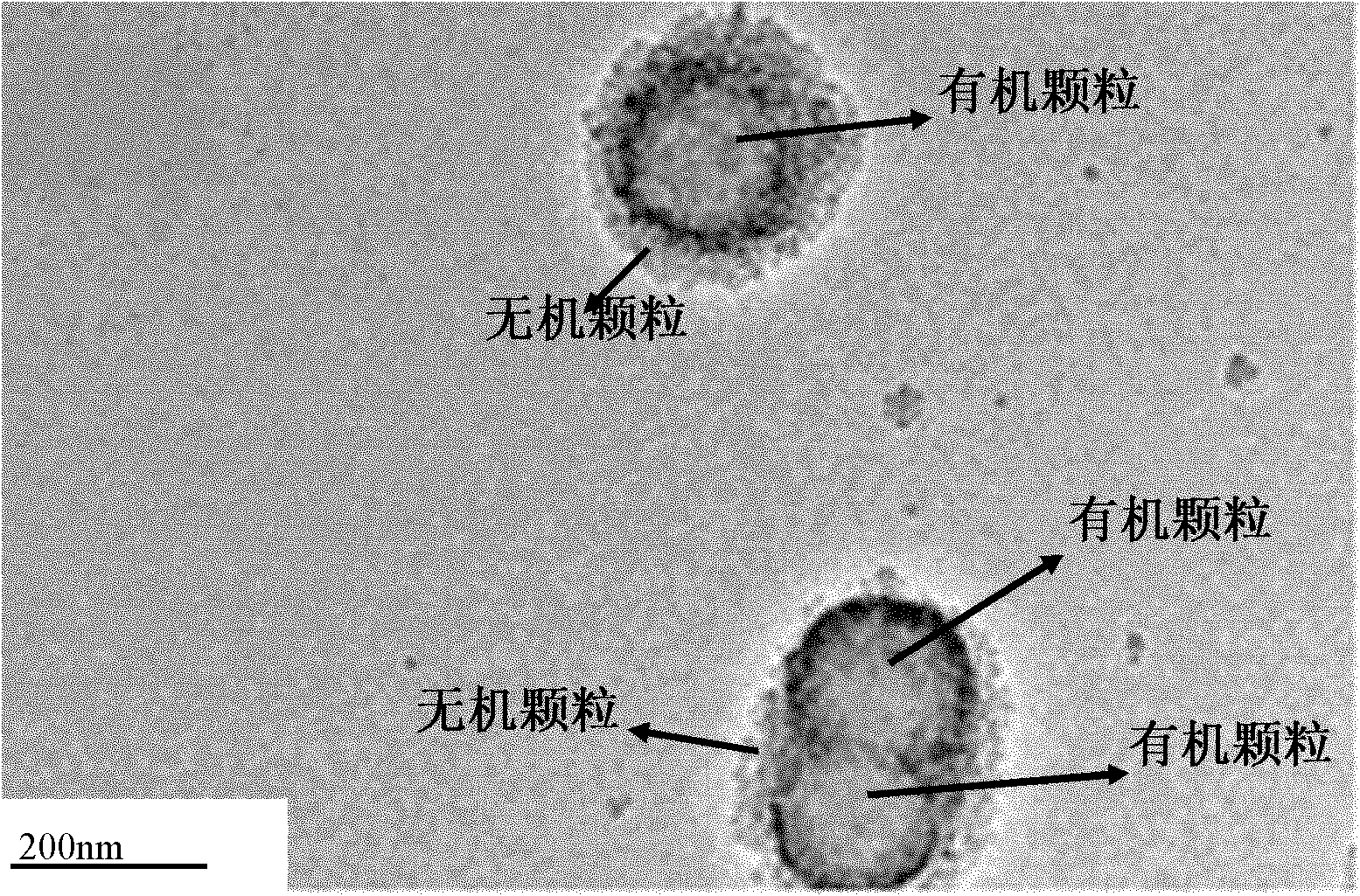

In-situ combination abrasive particle copper polishing composition

InactiveCN102140313AReduce scratchesReduce surface scratchesPolishing compositions with abrasivesHigh surfaceSurface-active agents

The invention discloses an in-situ combination abrasive particle copper polishing composition, belonging to the technical field of micro-electronic auxiliary materials and ultra-precision machining process. The composition comprises deionized water, organic-inorganic in-situ combination abrasive particles, an oxidizing agent, a complexing agent, a corrosion inhibitor, a PH conditioning agent, an interface reaction addition agent, a surface active agent, bactericide and a polishing accelerating agent, wherein the organic-inorganic in-situ combination abrasive particles are nuclear shell structure combination abrasive particles which are formed in situ and take organic particles as cores and inorganic particles as surface coating layer. The chemically mechanical polishing composition can form in situ the nuclear shell structure combination abrasive particles which take organic particles as cores and inorganic particles as surface coating layers under the synergistic effect of long rang and short range surface acting forces, and realizes the polishing process of high removal, low scratching and high surface accuracy of metal surfaces in the condition of grinding particles with lower concentration.

Owner:TSINGHUA UNIV +2

Copper chemical and mechanical polishing combination

InactiveCN102329572AReduce surface residueReduce surface corrosion defectsPolishing compositions with abrasivesCompound (substance)Copper

The invention discloses a copper chemical and mechanical polishing combination, which belongs to the technical field of microelectronic auxiliary materials and ultra-precision machining processes. The copper chemical and mechanical polishing combination comprises abrasive particles, an oxidant, a complexing agent, a polishing accelerating agent and a pH regulator. The copper chemical and mechanical polishing combination is characterized by further comprising a long chain corrosion inhibitor and a surface active agent. By using the polishing combination provided by the invention, surface residues, particularly surface granular residues, can be obviously decreased; surface corrosion defects can be obviously decreased; a higher removal speed rate is obtained; and the polishing combination provided by the invention further has the advantages of simple process, cheap price, low cost and the like.

Owner:SHENZHEN LEAGUER MATERIAL +2

Method for processing GaN epitaxial substrate

InactiveCN101378002AReduce processing costsImprove processing efficiencySemiconductor/solid-state device manufacturingWaferingCompound (substance)

The invention provides a processing method which is used for GaN epitaxial substrate, comprising the following steps of: carrying out grinding for a single crystal rod cut so as to remove the tool marks of the chip; (2) conducting chemical mechanical polishing to the chip grinded so as to remove a damage layer which is caused by grinding; (3) carrying out annealing to the chip after chemical mechanical polishing so as to remove the damage of near-surface atoms, with the annealing temperature from 500 DEG C to 1500 DEG C, and the temperature preserving time from 10 hours to20 hours; (4) cleaning the chip polished so as to remove residual particles and pollutants on the near-surface thereof. The invention can obtain required substrate by just conducting simple chemical mechanical polishing, does not conducting super-precision chemical mechanical polishing, reduces the processing cost of the substrate, and improves the processing efficiency. The method which is simple and feasible greatly improves the light extraction efficiency thereof as the stripes of the near-surface graphics of the single crystal substrate manufactured are irregular arbitrary scratches.

Owner:SHANDONG UNIV

Sapphire substrate ultraprecision machining method based on fixed abrasive pad

ActiveCN103252708AFast processingEfficient processingLapping machinesLapping toolsMachining timeUltra precision

The invention discloses a sapphire substrate ultra-precision machining method based on a fixed abrasive pad. The sapphire substrate ultra-precision machining method based on the fixed abrasive pad mainly relates to three steps of rough grinding, accurate grinding and polishing, namely, rough grinding is conducted on a cut sapphire substrate semi-finished product through a W75 nickel plated diamond FAP; then accurate grinding is conducted on a workpiece after rough grinding through a W28 nickel plated diamond FAP; last, polishing is conducted on the workpiece after accurate grind through a W5 diamond FAP, and grinding and polishing processes are finished. According to the sapphire substrate ultra-precision machining method based on the fixed abrasive pad, a sapphire substrate is machined, the time cost in the whole process is shortened within two hours, machining time of sapphire is greatly shortened, the sapphire substrate with the workpiece surface roughness (Ra) is smaller than 3nm can be finally obtained, surface defects such as pitting corrosion and scratches can be effectively removed, the damage of a subsurface is reduced and the quality of the surface is good. The sapphire substrate ultra-precision machining method based on the fixed abrasive pad improves machining efficiency of the substrate and the quality of the surface of the substrate, and is low in cost and pollution-free.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com