Method for processing free-form surface prism

A technology of a curved prism and a processing method, which is applied in the field of optical device manufacturing and ultra-precision processing, can solve the problems of complex structure of a free-form prism, and achieves the effects of simple structure, high processing quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

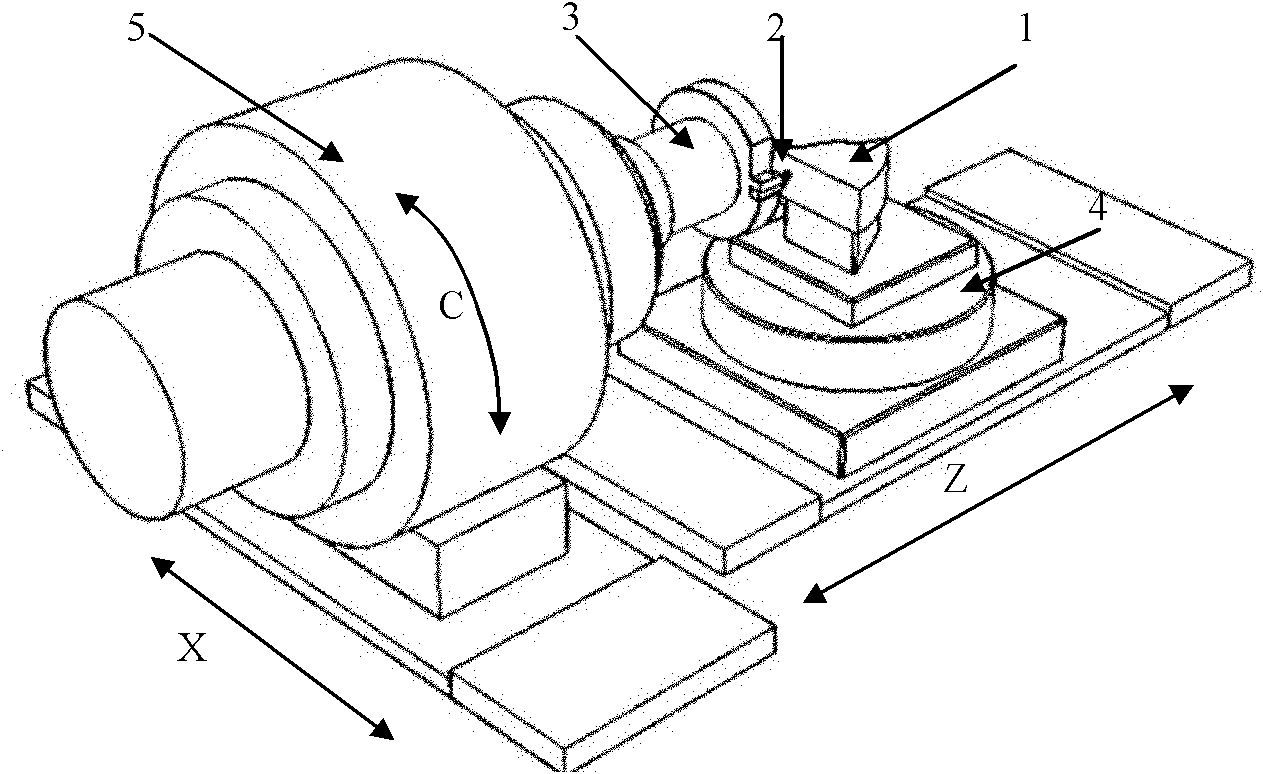

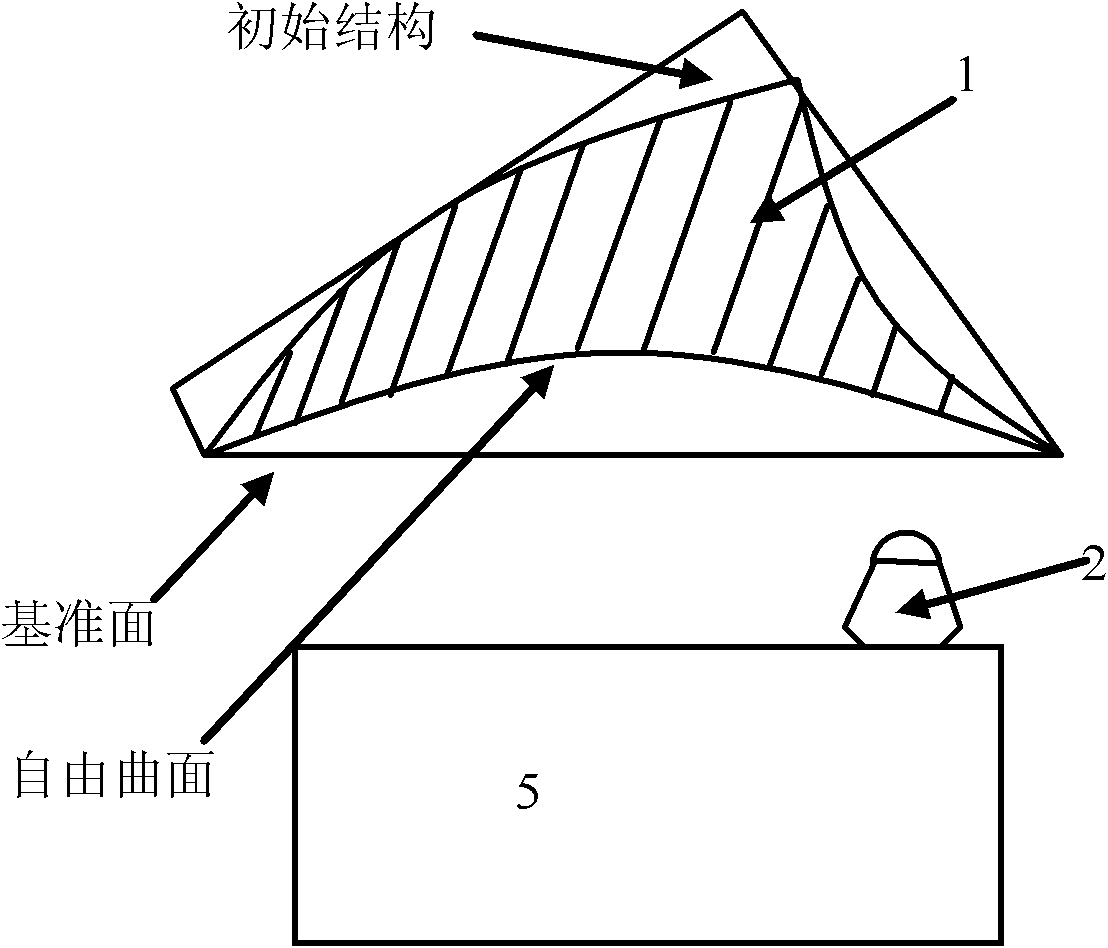

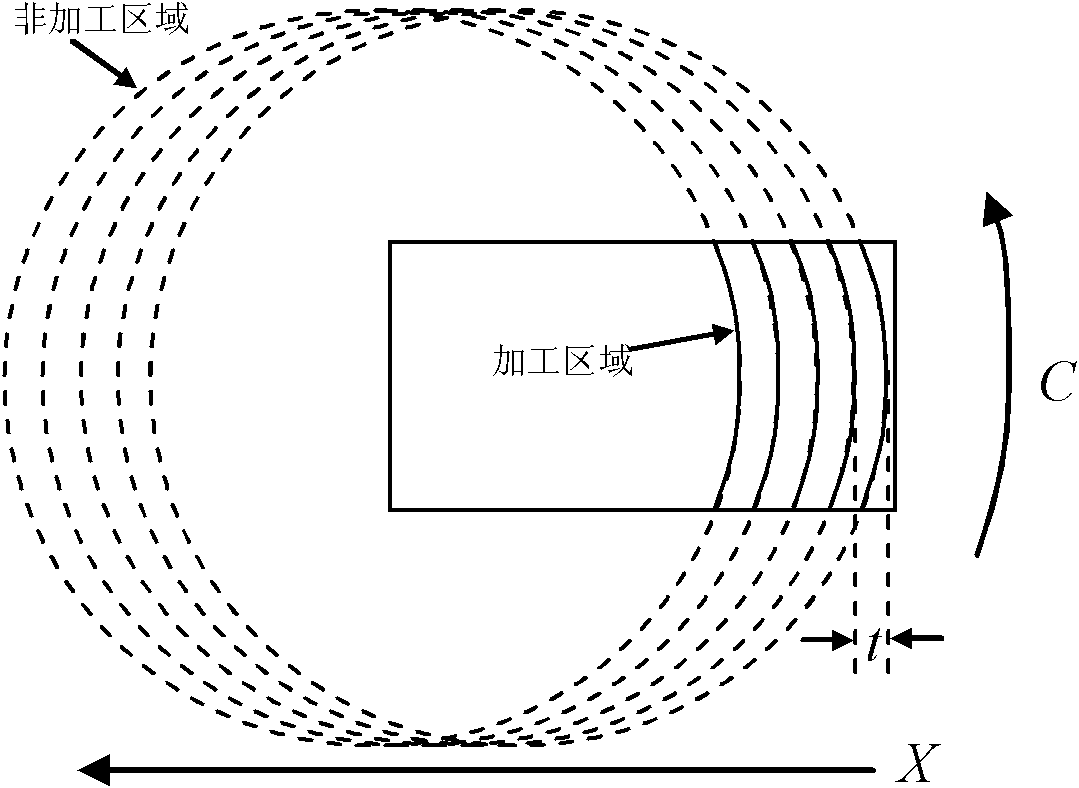

[0020] figure 1 It is a schematic diagram of the processing method of the present invention, which adopts an ultra-precision lathe system with slow-tool servo control, that is, the lathe has linear motion axes X, Z and a turning spindle C with angular positioning. When the C-axis rotates to a certain angle, the X and Z-axis can be controlled to vibrate at a higher speed and with a small stroke, so as to realize the slow tool servo control. The traditional slow-tool servo processing method is to fix the workpiece on the rotating shaft for C-axis rotation, and the tool 2 feeds in the X direction and slightly vibrates in the Z direction. In the present invention, the diamond tool 2 is fixed on the turning spindle 4 through the tool holder 3, and is perpendicular to the end face of the spindle 4. As the turning spindle C rotates, it is controlled by the slow tool servo system to free the workpiece parallel to the end face of the spindle 4 Continuous cutting of curved surfaces, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com