Small-caliber non-spherical permanent magnet magnetorheological polishing processing machine tool

A magneto-rheological polishing and processing machine tool technology, which is applied in metal processing equipment, grinding machine parts, grinding/polishing equipment, etc., can solve the problems that cannot meet the shape and dimensional accuracy requirements of processed parts, and achieve shortened tool setting time, avoid interference, and improve the effect of tool setting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

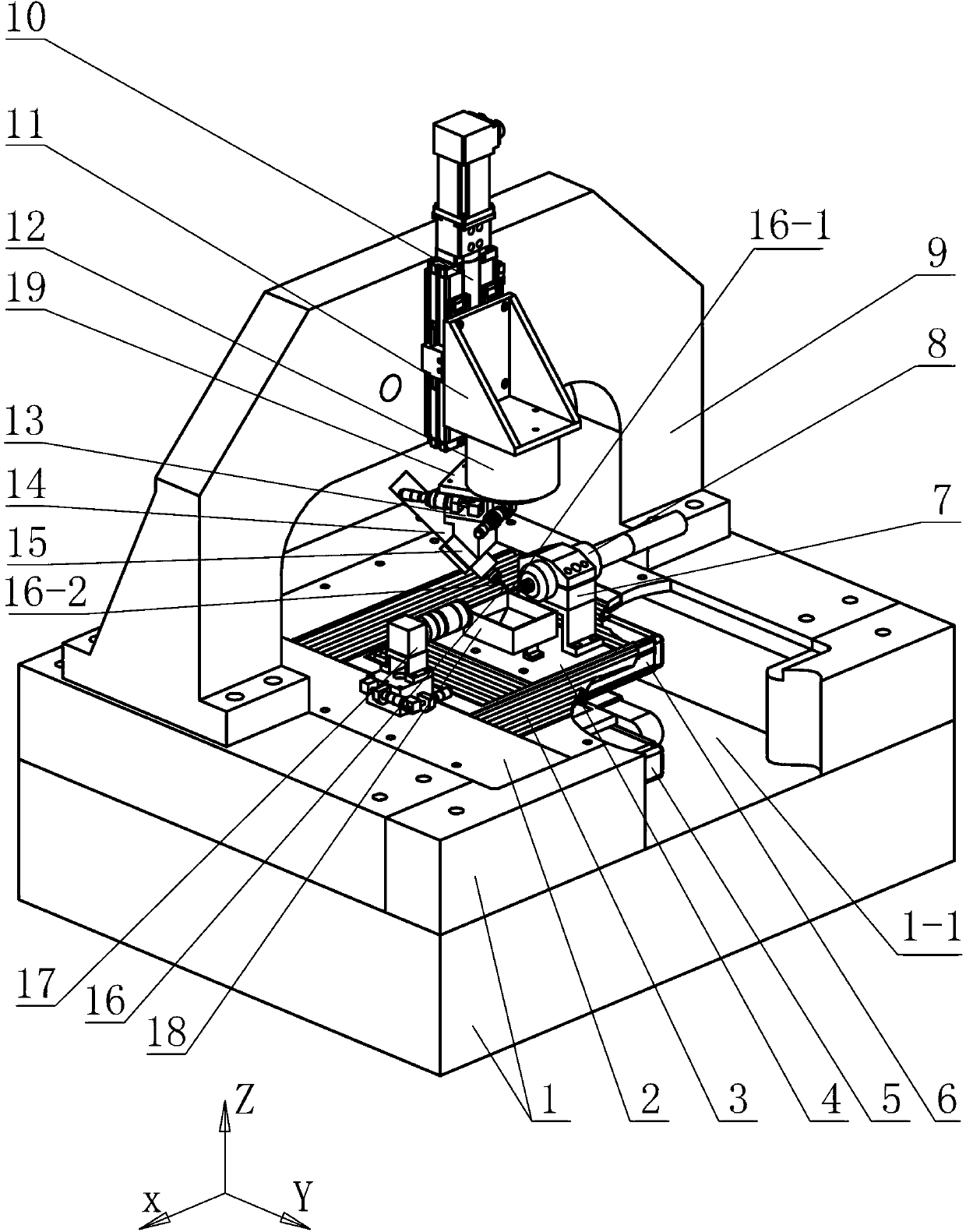

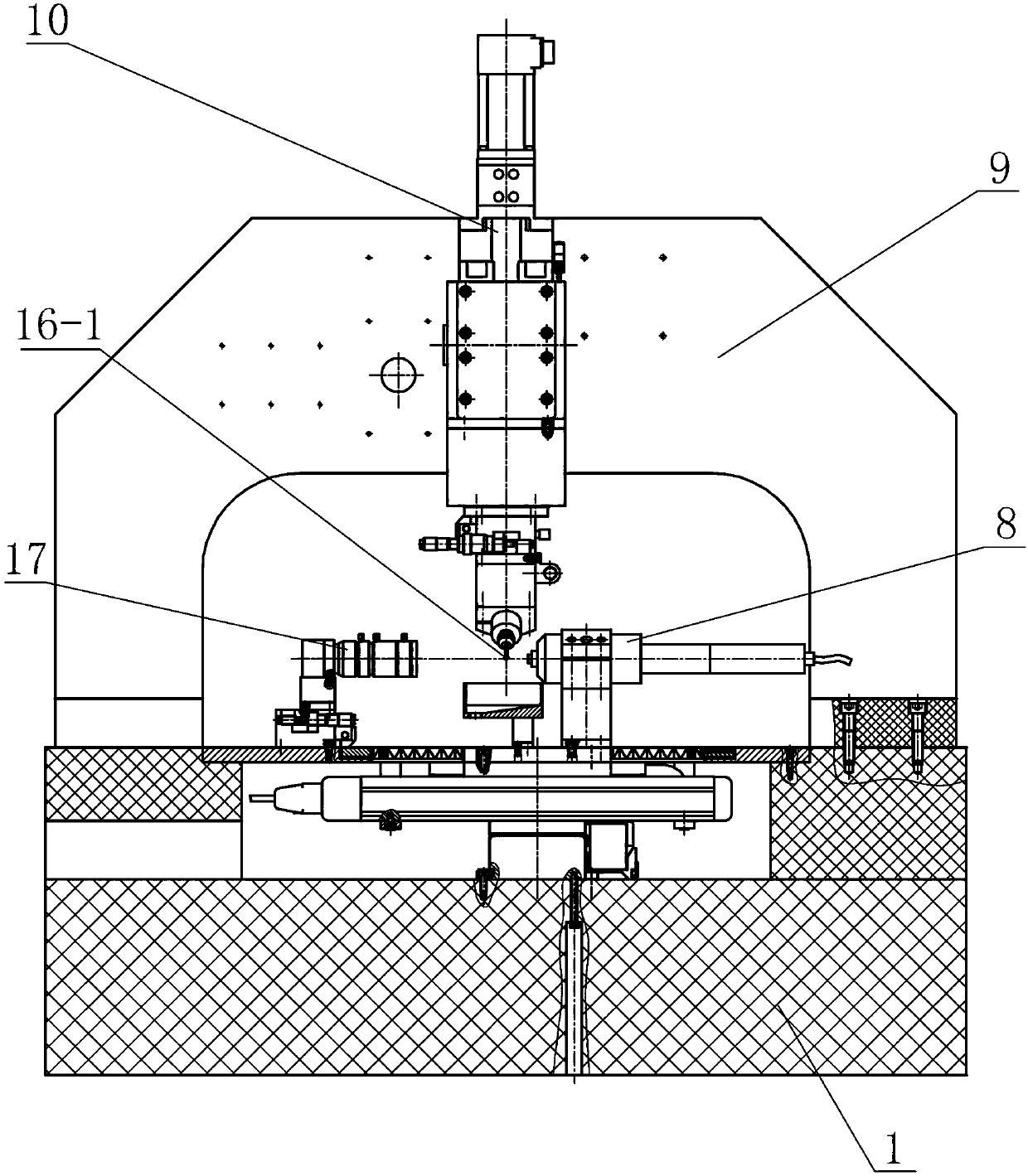

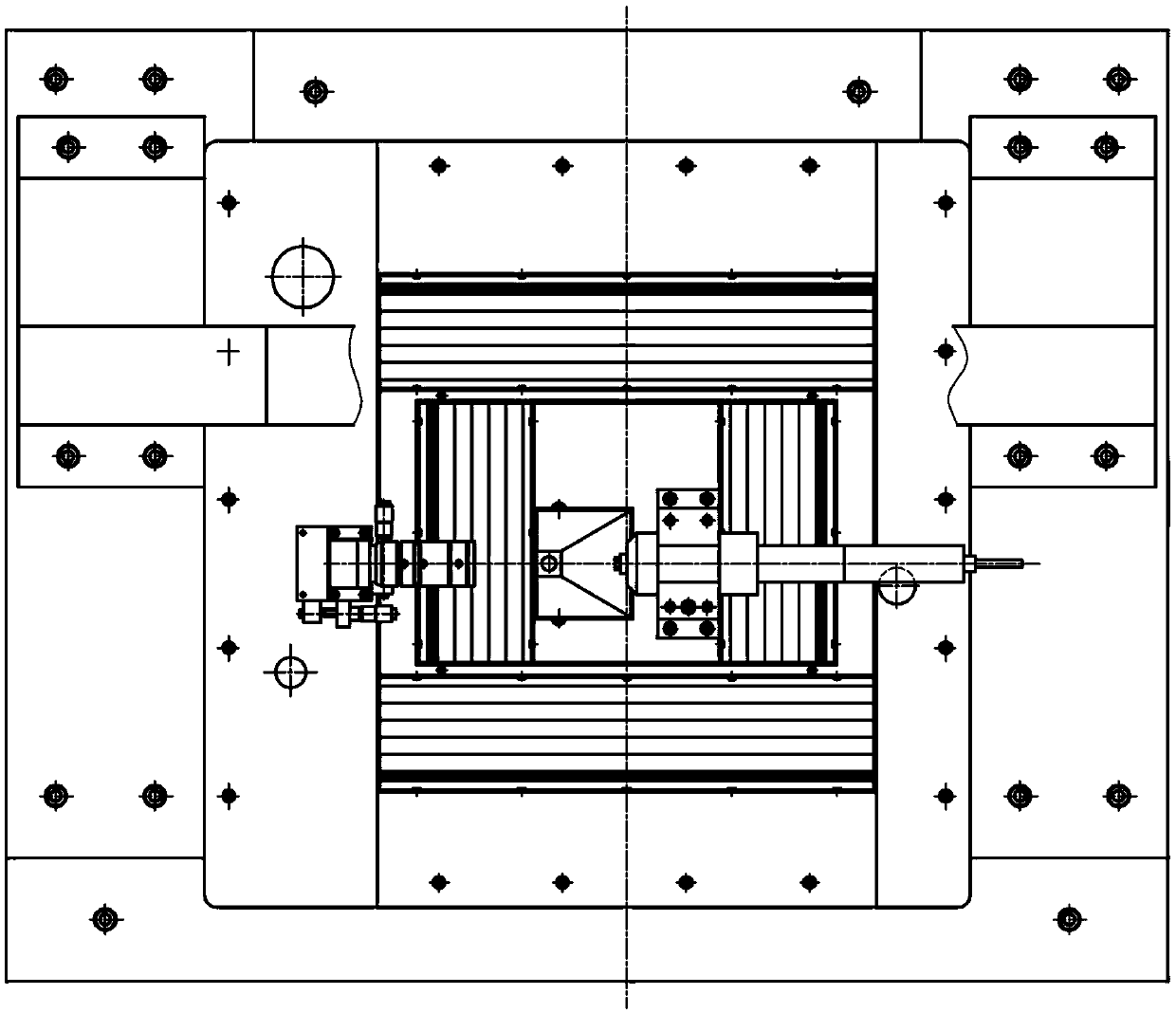

[0016] Specific implementation mode one: as Figure 1~4 As shown, a small-caliber aspheric permanent magnet magnetorheological polishing machine tool described in this embodiment includes a workpiece axis numerical control motion platform device for ultra-precision machining and a vertical axis turntable upside-down inclined-axis magnetorheological polishing device; The workpiece axis CNC motion platform device for ultra-precision machining includes XY precision mobile platform, machine base 1, cover plate 2, organ shield 3, workbench 4, workpiece spindle support 7, workpiece spindle 8, CCD tool setting device 17 and liquid return Groove 18; the XY precision mobile platform contains an X-axis linear unit 6 and a Y-axis linear unit 5, and the X-axis linear unit 6 is placed on the Y-axis linear unit 5; the machine base 1 is provided with a cavity 1 for accommodating the XY precision mobile platform -1, the XY precision mobile platform is placed in the cavity 1-1 of the machine t...

specific Embodiment approach 2

[0017] Specific implementation mode two: as Figure 1~4 As shown, the permanent magnet type polishing head 16-1 described in this embodiment is a small-diameter permanent magnet spherical polishing head, the diameter used at present is φ3.5mm~φ4mm, the shape accuracy is better than 0.02mm, and the surface magnetic field strength is 0.5~0.75 T. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: as Figure 1~4 As shown, the diameter range of the permanent magnet polishing head 16 - 1 in this embodiment can be extended to φ2 mm˜φ6 mm. Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface magnetic field strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com