Solidified abrasive lapping polishing pad having self-modifying function and preparation method

A fixed abrasive, self-correcting technology, applied in grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of abrasive splashing, uneven grinding cutting amount, abrasive waste processing efficiency, etc., to reduce surface roughness , Improve the mechanical properties, the effect of good workpiece flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

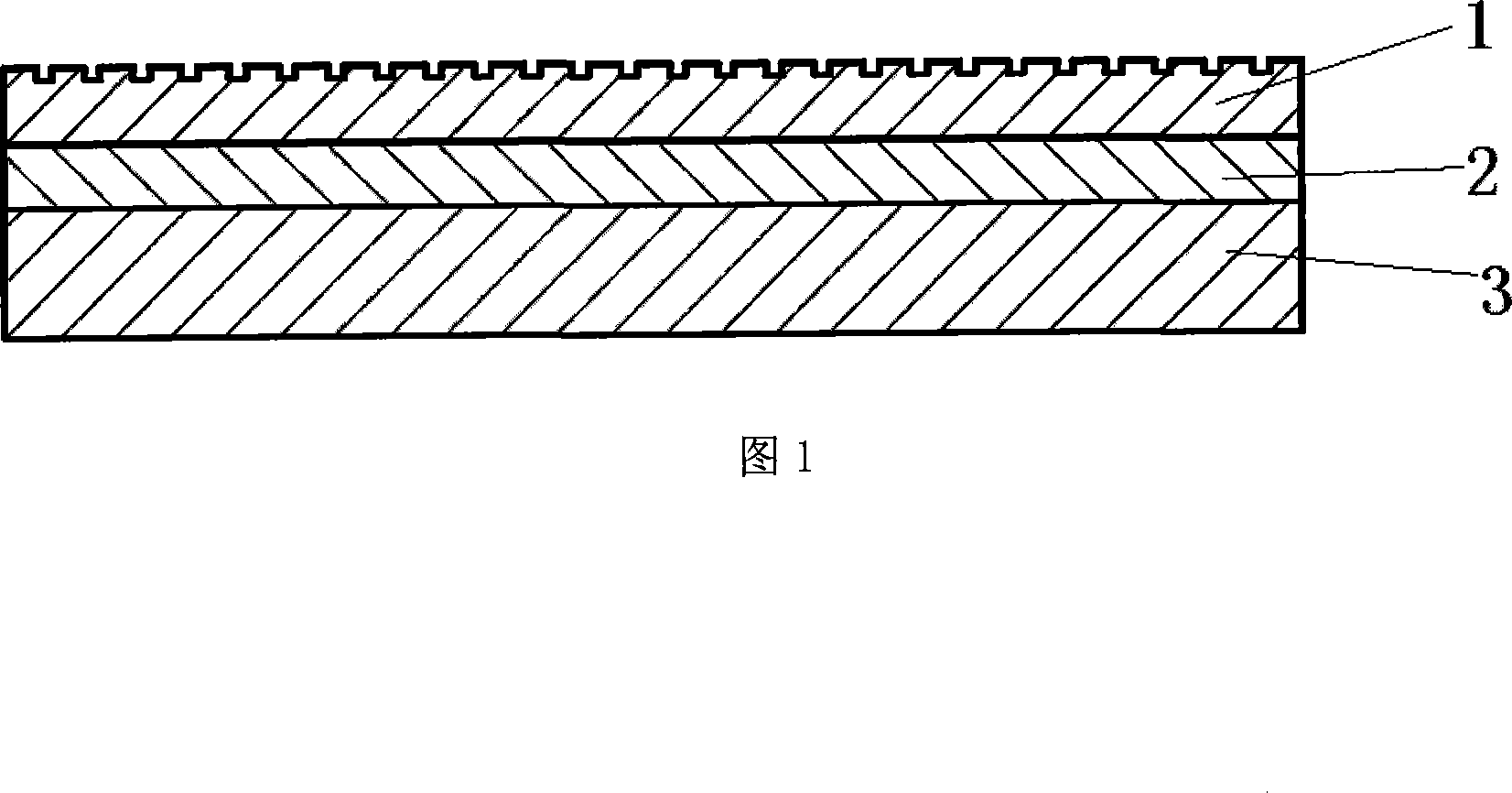

Image

Examples

Embodiment 1

[0029] Surface-modify the nano-cerium oxide abrasive with an average particle size of 20 nanometers with a silane coupling agent, weigh 2.5 grams of the above-mentioned surface-modified nano-cerium oxide, weigh 10 grams of polyurethane acrylate and 35 grams of polyether acrylate For the prepolymer formed, take 15 grams of performance regulator polyethylene glycol as the performance regulator, weigh 1 gram of free radical photoinitiator α-hydroxyalkyl phenone, and weigh 1 gram of polyethylene glycol dimethyl Acrylate: trimethylolpropane triacrylate is 36.5 grams of reactive diluent mixture of 1: 1, first mix other materials except photoinitiator evenly, then add photoinitiator, and stir again, make it uniform, Prepare a cleaned polycarbonate polymer substrate with a thickness of 1 mm, and apply the above-mentioned mixture evenly on the rigid polymer substrate by screen printing; pass through a UV curing machine at a speed of 2m / min to make the above-mentioned mixture solidified...

Embodiment 2

[0034] The diamond synthesized by the static pressure method is crushed and made into nano-diamonds with an average particle diameter of 100 nanometers, and 2 grams of the above-mentioned nano-diamonds are weighed, and the prepolymer composed of 28 grams of polyester acrylate and 50 grams of polyether acrylate is weighed. Take 10 grams of performance regulator polyethylene glycol as performance regulator, weigh photoinitiator α, α-dimethoxyl-α phenylacetophenone 2, g, bis (2,4,6-trimethyl Base benzoyl) phenyl phosphorus oxide 1 gram, take by weighing 5 grams of active diluent mixture with triethylene glycol bismethacrylate: trimethylolpropane trimethacrylate as 1: 1 in advance, in addition , weigh 2 grams of polydimethylsiloxane, first mix other substances except the photoinitiator evenly, then add the photoinitiator, and stir again to make it uniform, and prepare a clean polycarbonate polymer For the substrate, apply the above mixture evenly on the rigid polymer substrate by ...

Embodiment 3

[0039] Surface-modify the cerium oxide abrasive with an average particle size of 1.5 microns with a silane coupling agent, weigh 20 grams of the above-mentioned surface-modified cerium oxide, weigh 15 grams of bisphenol A epoxy acrylate and 20 grams of polyether The prepolymer composed of acrylate, weighed 1.5 grams of free radical photoinitiator α-hydroxyalkyl phenone, 0.5 grams of benzophenone, weighed in advance with neopentyl glycol diethoxy dimethacrylate: Trimethylolpropane triacrylate is 39.5 grams of a 1:1 reactive diluent mixture. First, mix other substances except the photoinitiator evenly, then add the photoinitiator, and stir again to make it uniform, and prepare a piece of processing A clean polycarbonate polymer substrate with a thickness of 1 mm, the above-mentioned mixture is evenly applied to the rigid polymer substrate by screen printing; the above-mentioned mixture is cured by a UV curing machine at a speed of 1m / min, and the obtained Fixed abrasive polishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com