Patents

Literature

89 results about "Photosensitive glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

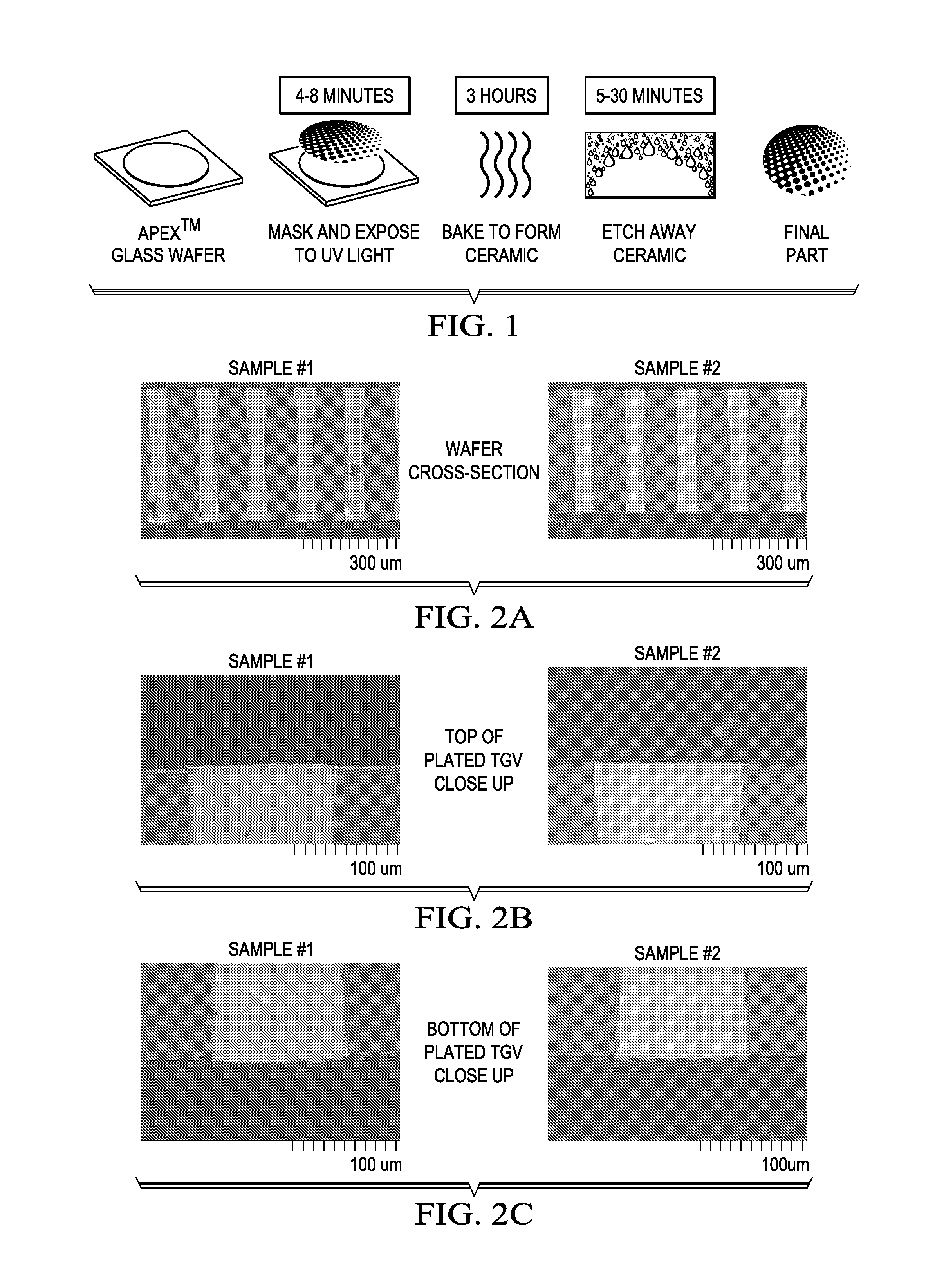

Photosensitive glass, also known as photostructurable glass (PSG), or photomachinable glass, is a crystal-clear glass that belongs to the lithium-silicate family of glasses, in which an image of a mask can be captured by microscopic metallic particles in the glass when it is exposed to short wave radiations such as ultraviolet light. Photosensitive glass was first discovered by S. Donald Stookey in 1937.

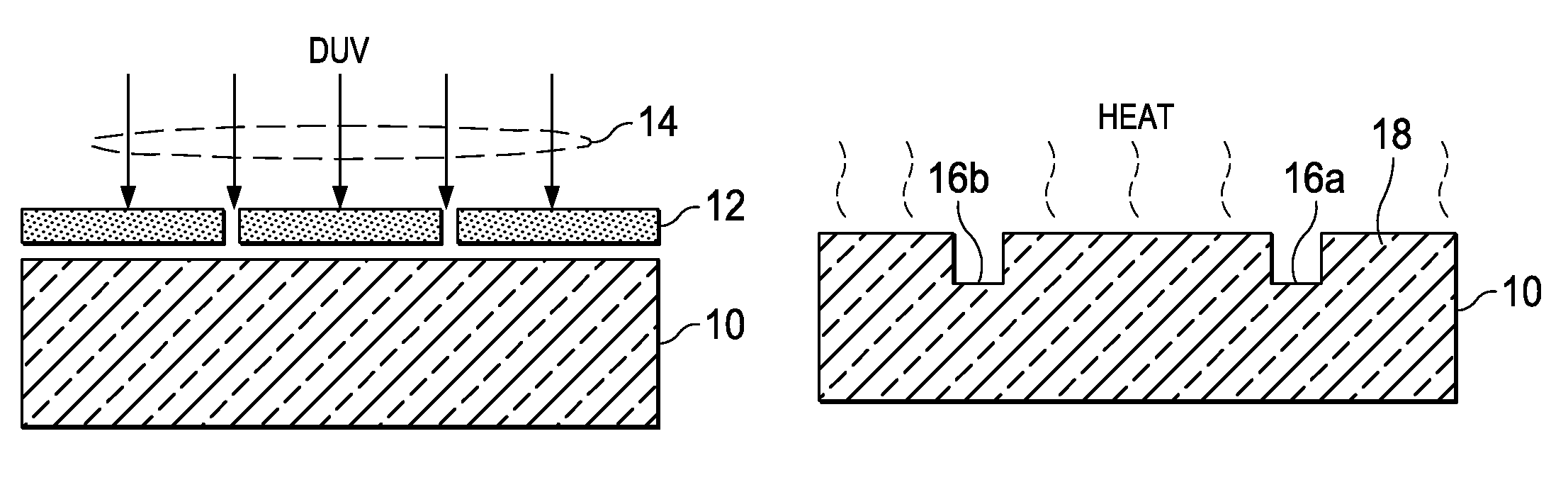

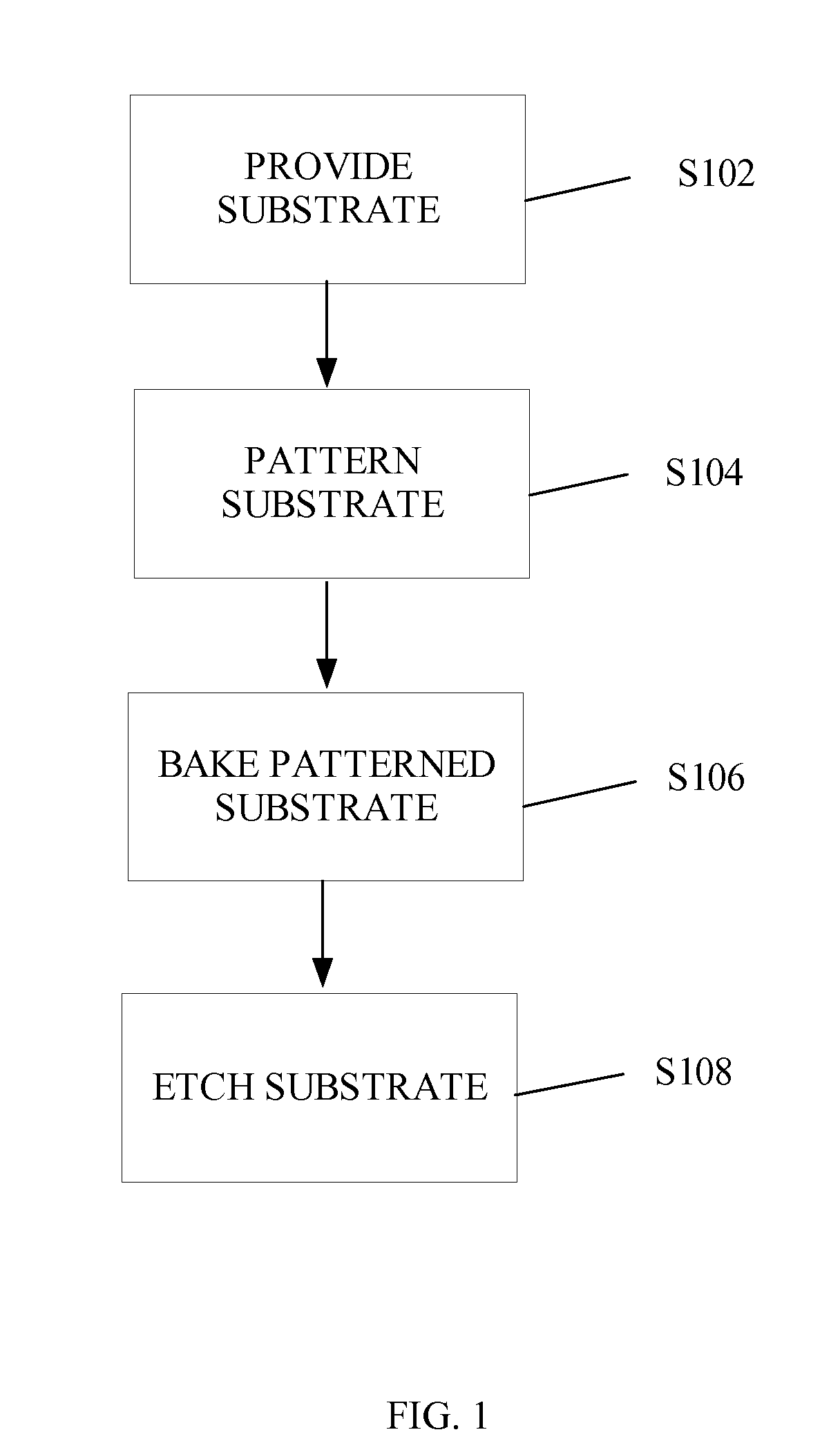

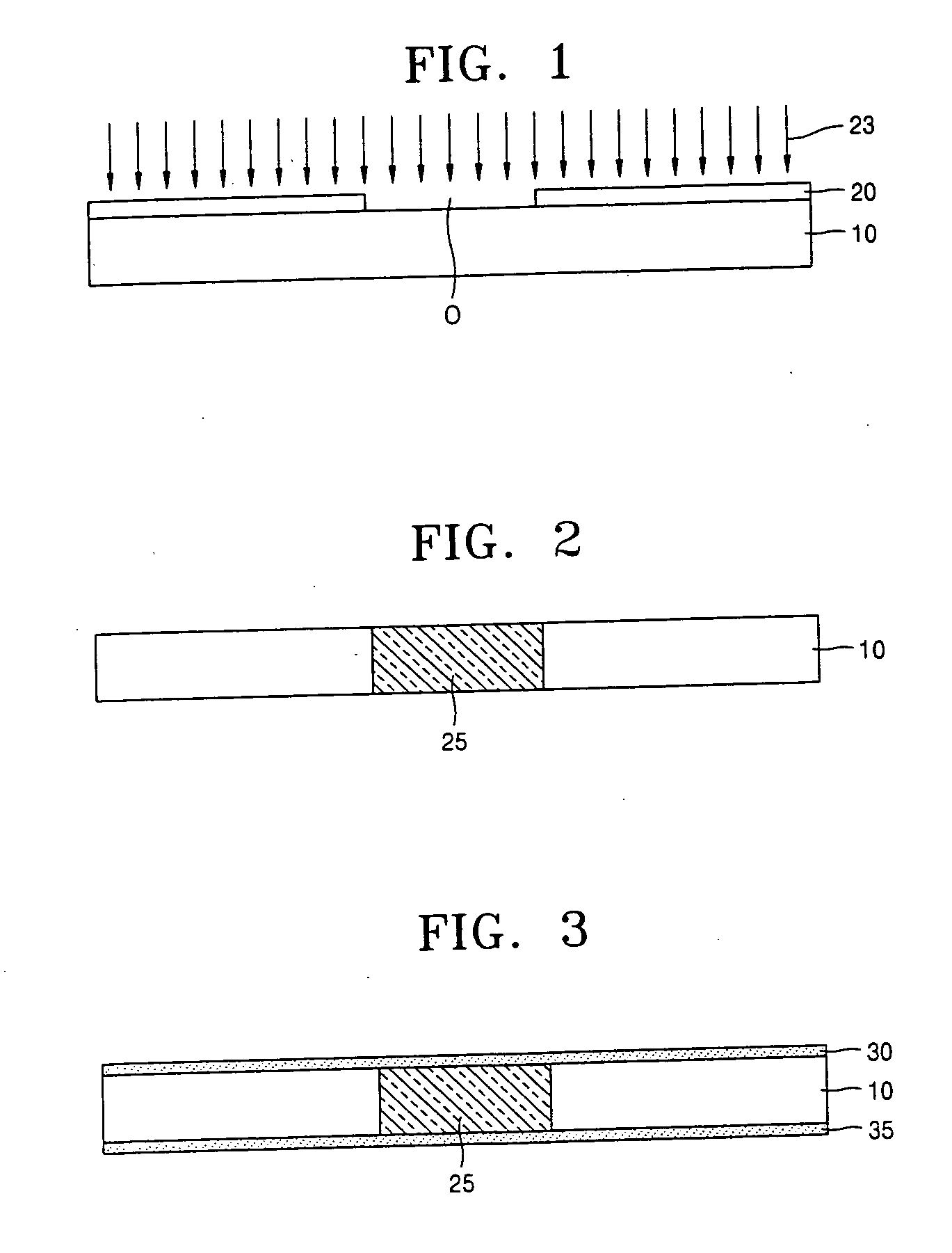

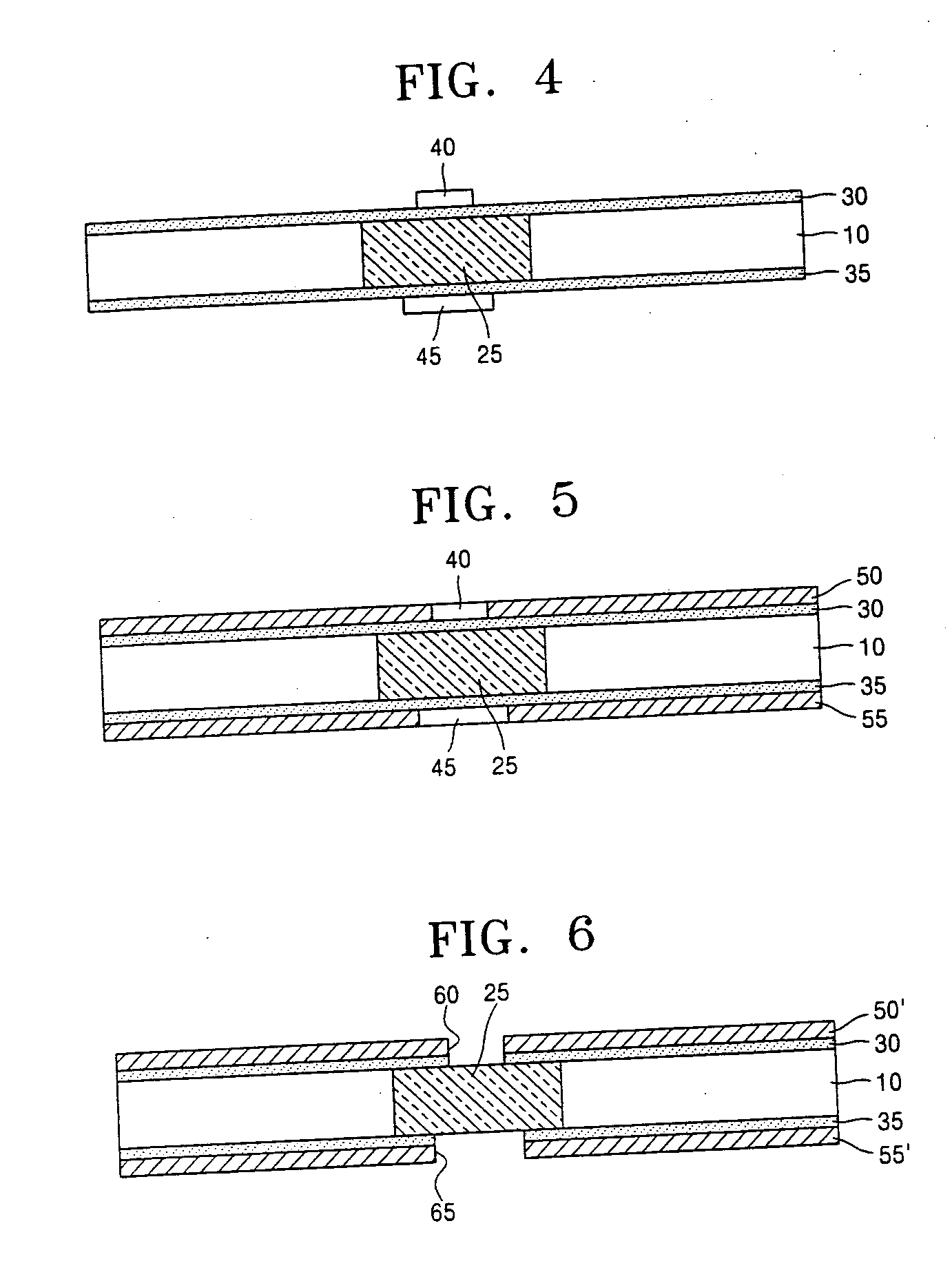

Methods to fabricate a photoactive substrate suitable for microfabrication

ActiveUS20110195360A1Solid-state devicesSemiconductor/solid-state device manufacturingLithium oxideGlass transition

Owner:3D GLASS SOLUTIONS INC

Methods to fabricate a photoactive substrate suitable for microfabrication

InactiveUS20110217657A1Improve performanceSmall layer thicknessContact member manufacturingPhotosensitive materialsLithium oxideSilicon dioxide

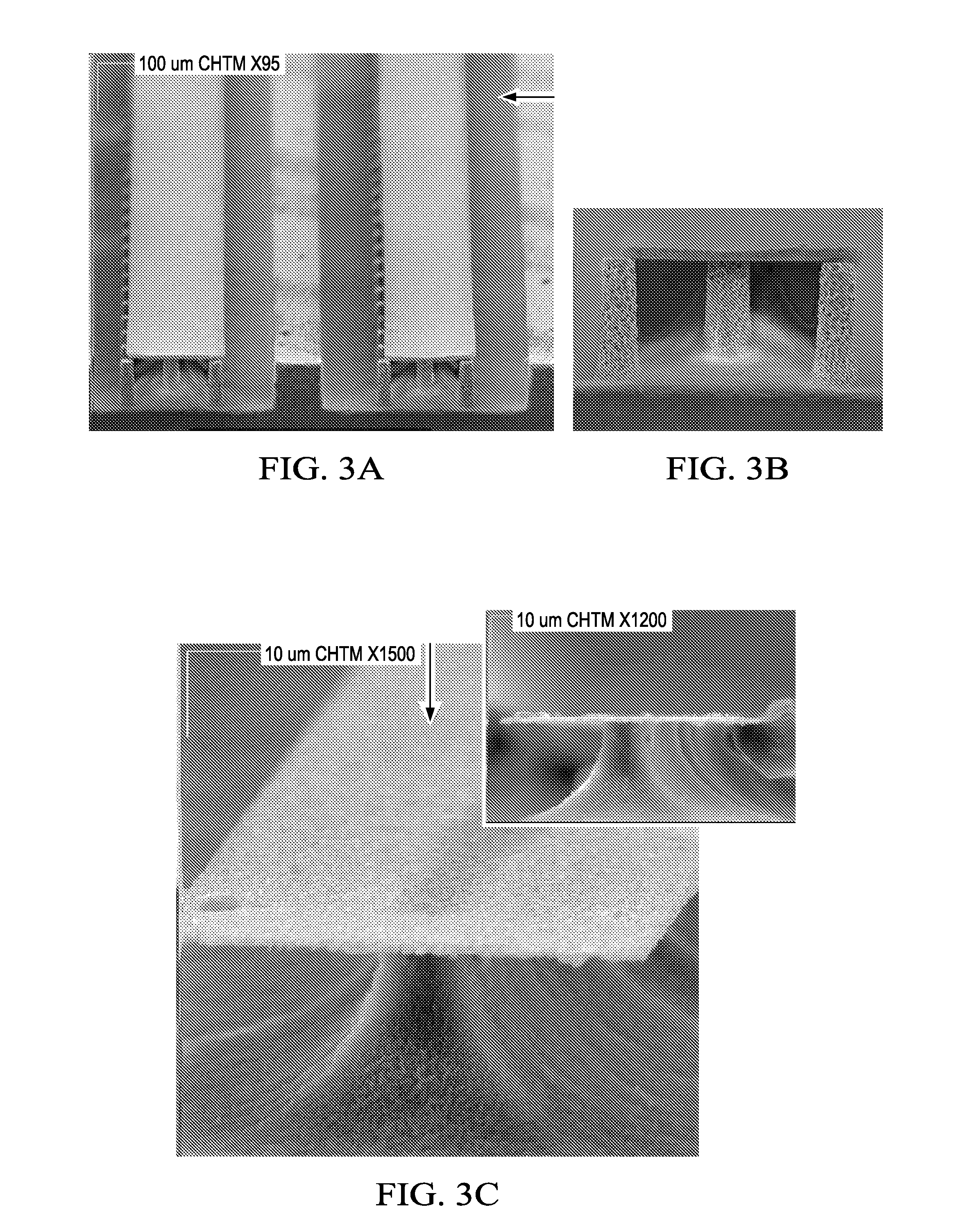

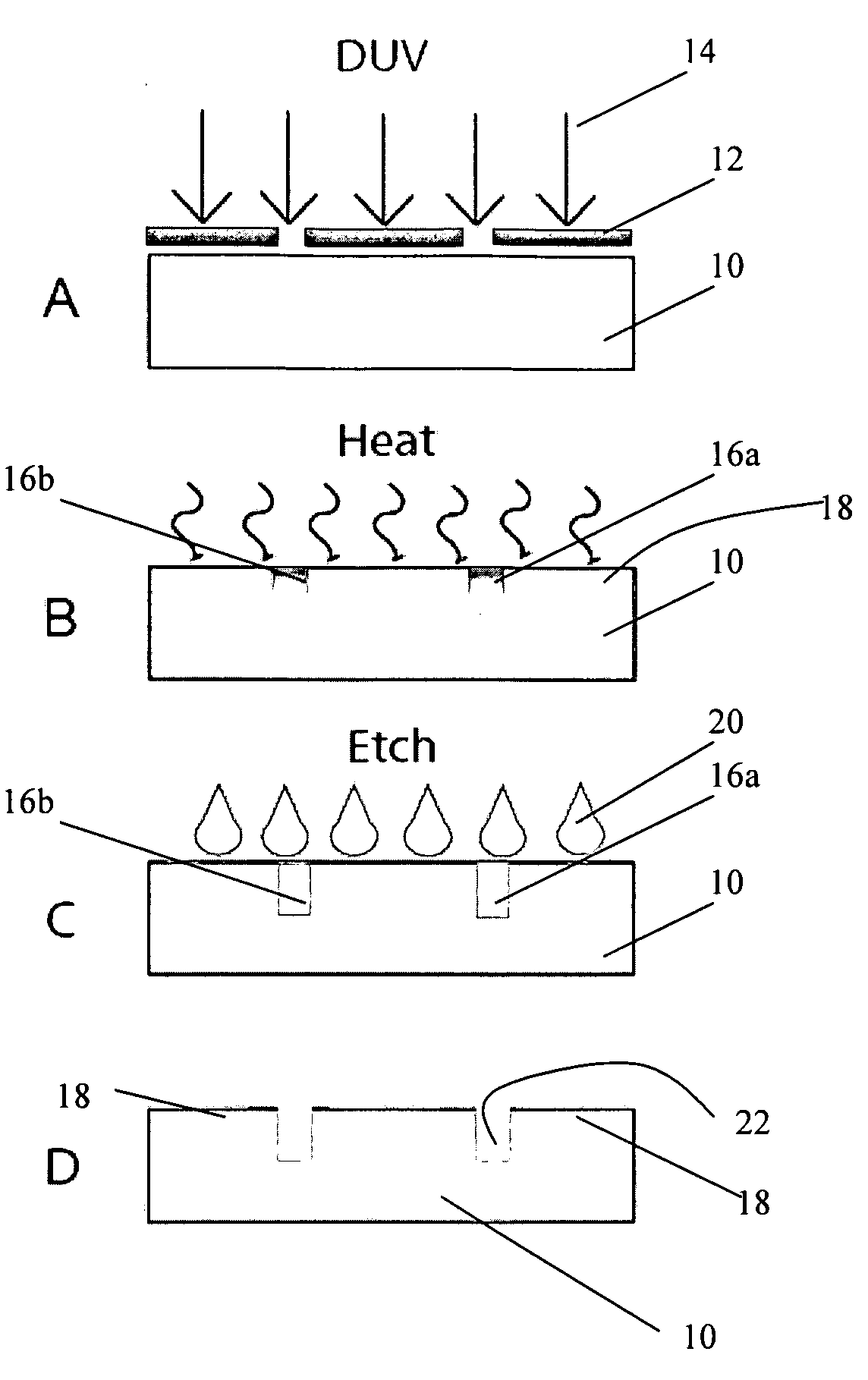

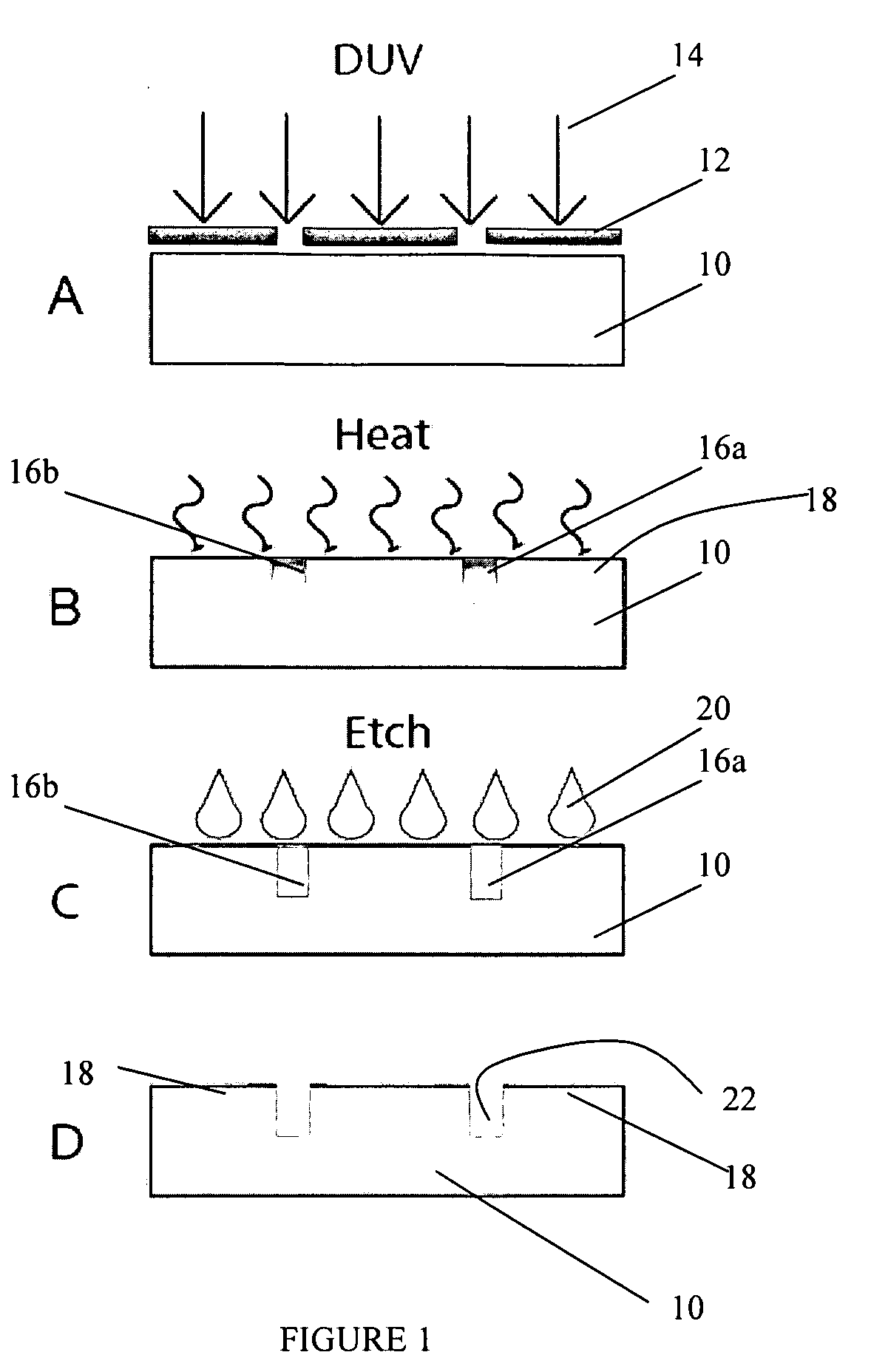

A method of fabrication and device with holes for electrical conduction made by preparing a photosensitive glass substrate comprising at least silica, lithium oxide, aluminum oxide, and cerium oxide, masking a design layout comprising one or more holes to form one or more electrical conduction paths on the photosensitive glass substrate, exposing at least one portion of the photosensitive glass substrate to an activating energy source, exposing the photosensitive glass substrate to a heating phase of at least ten minutes above its glass transition temperature, cooling the photosensitive glass substrate to transform at least part of the exposed glass to a crystalline material to form a glass-crystalline substrate and etching the glass-crystalline substrate with an etchant solution to form the one or more depressions or through holes for electrical conduction in the device.

Owner:LIFE BIOSCI

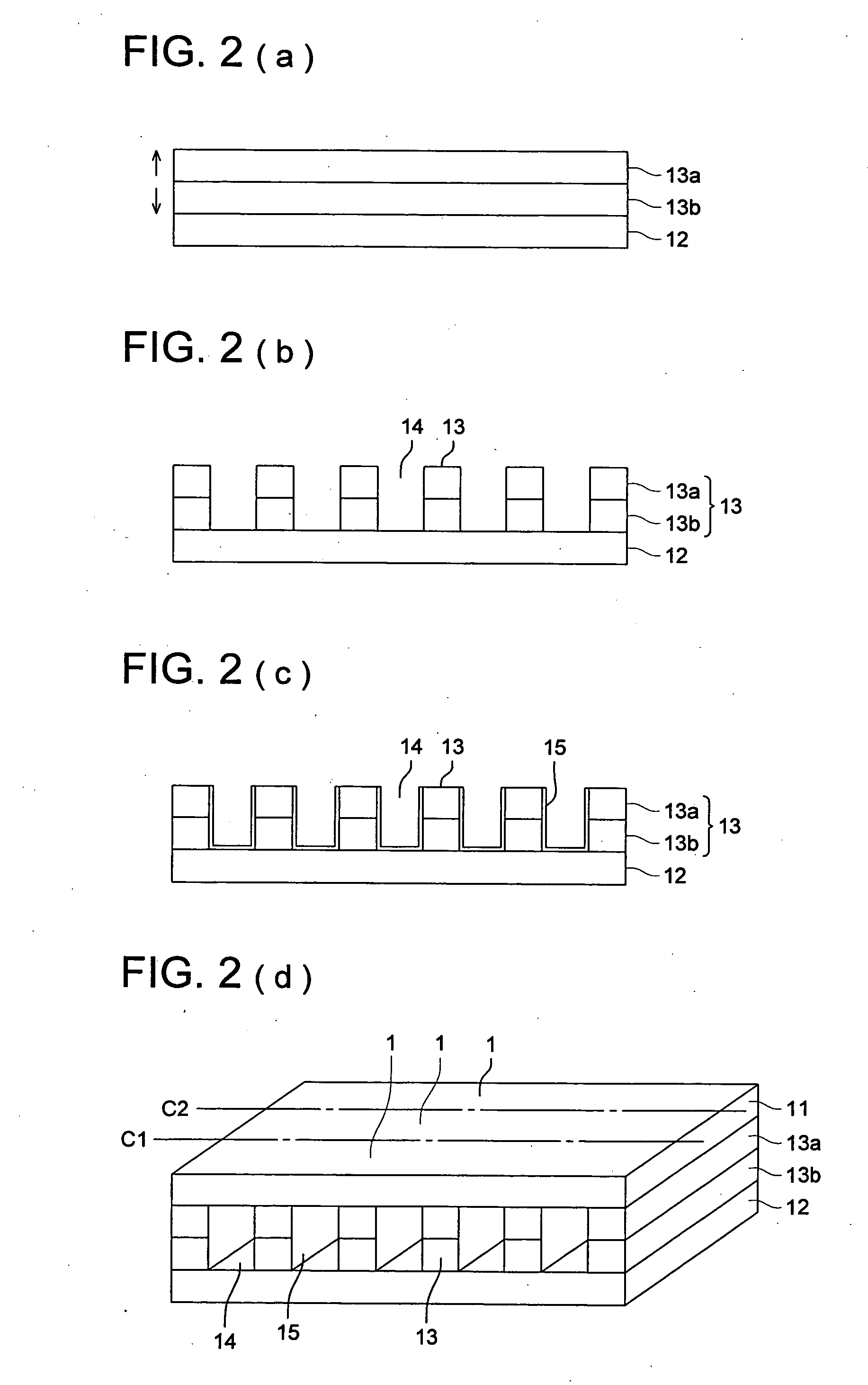

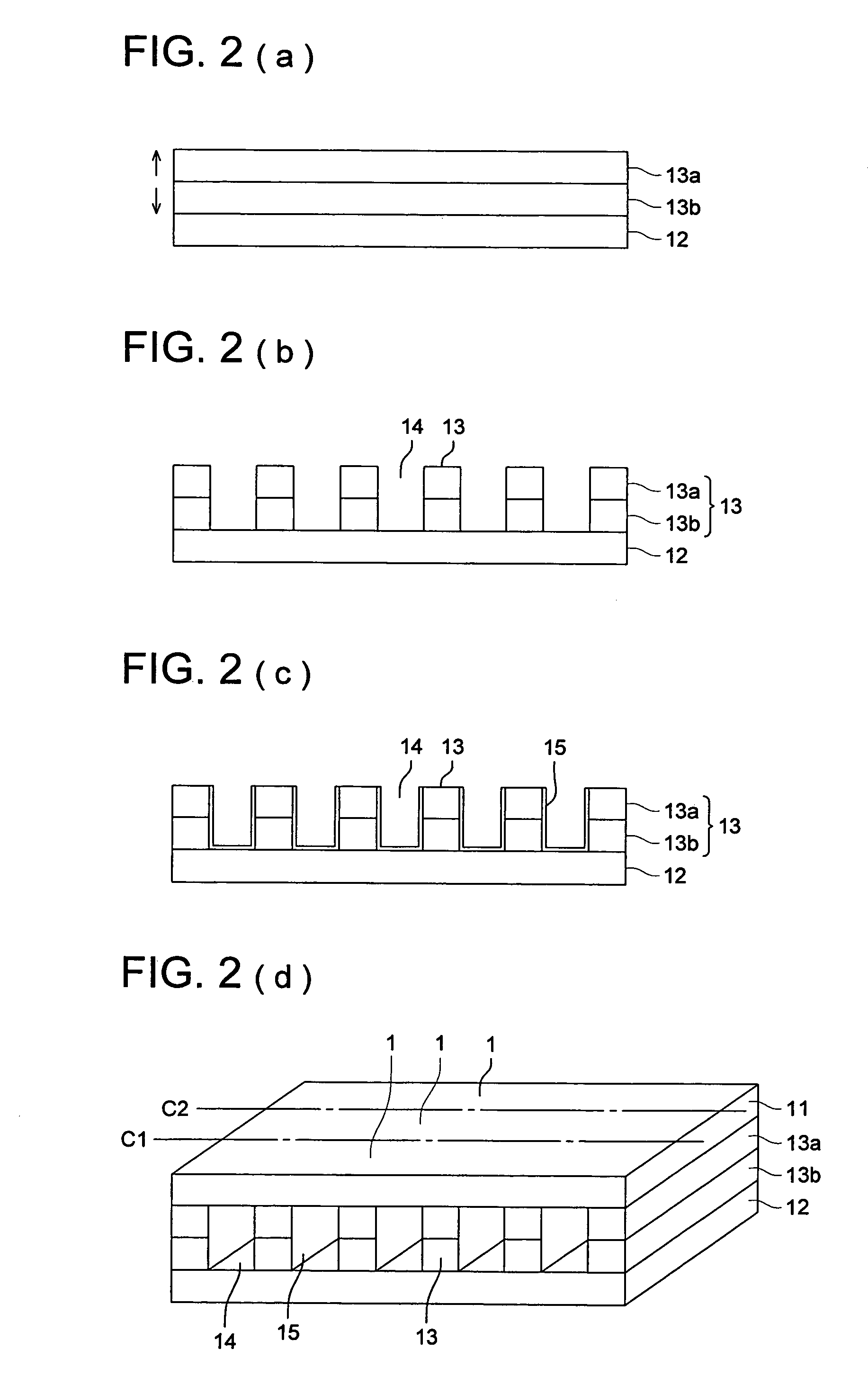

Method for producing an optical component, optical component produced according to the method and devices comprising such components

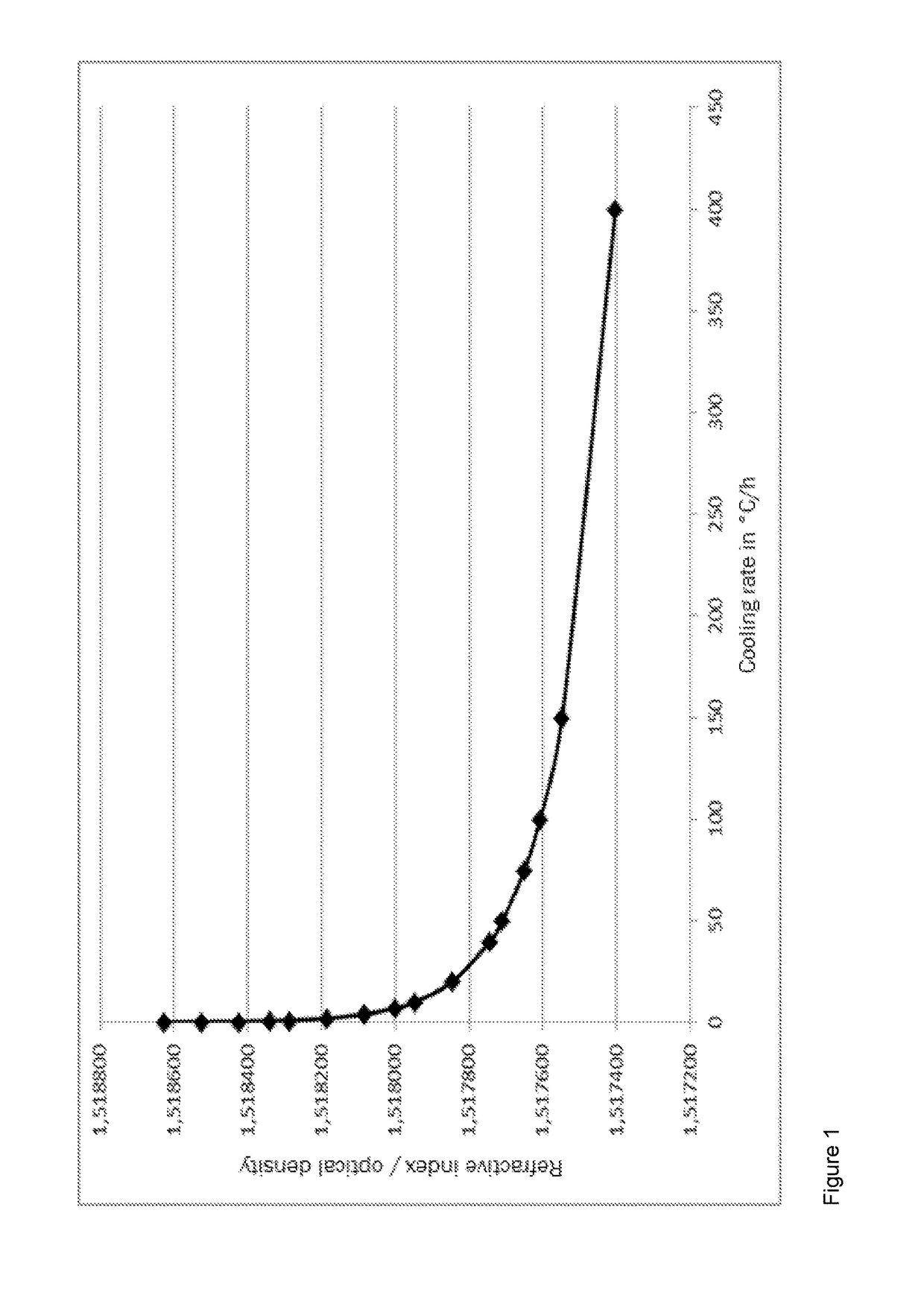

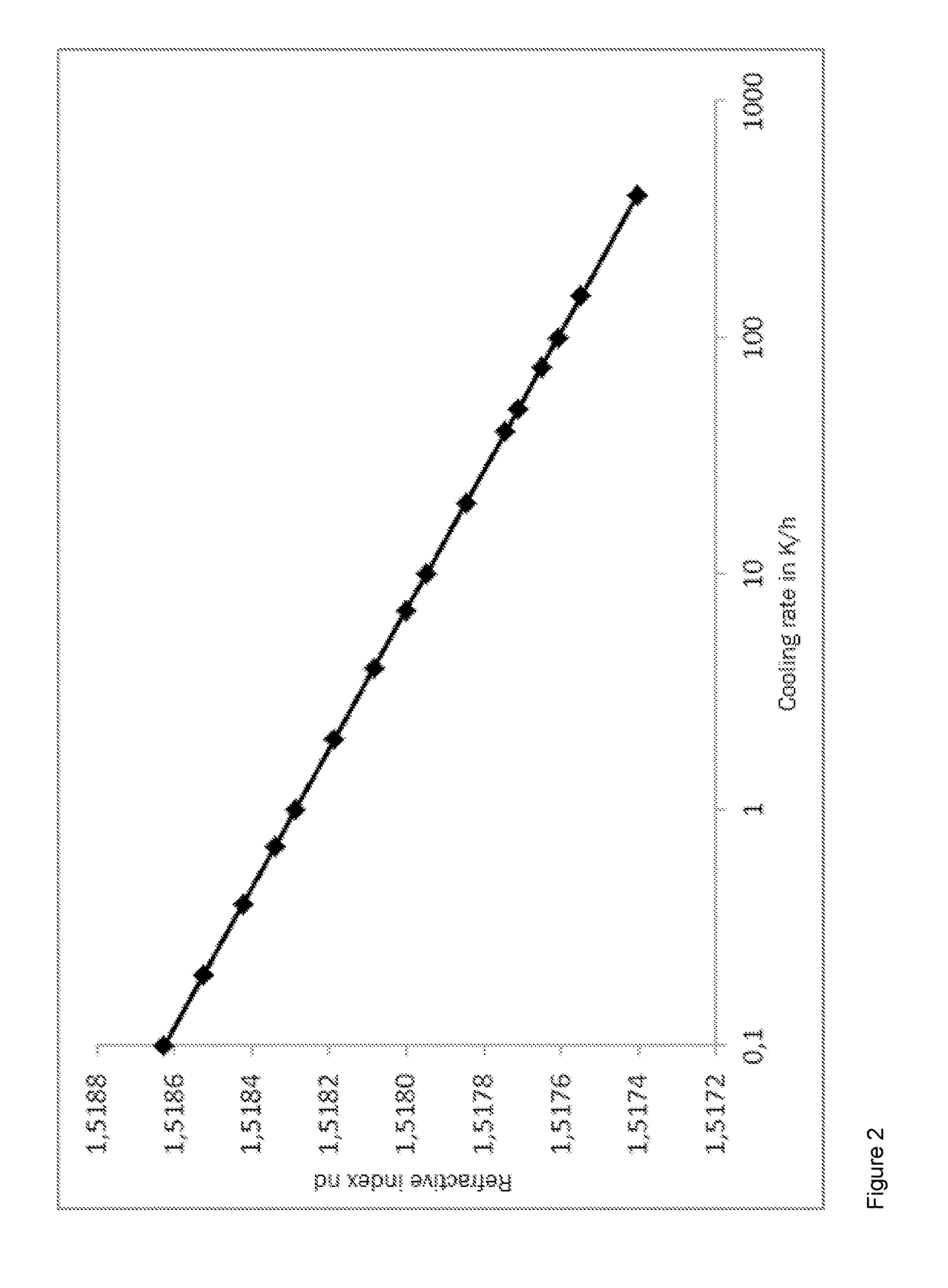

ActiveUS8062753B2Good optical performanceCost-effectivePhotomechanical apparatusOptical articlesInfluence propagationCeramic

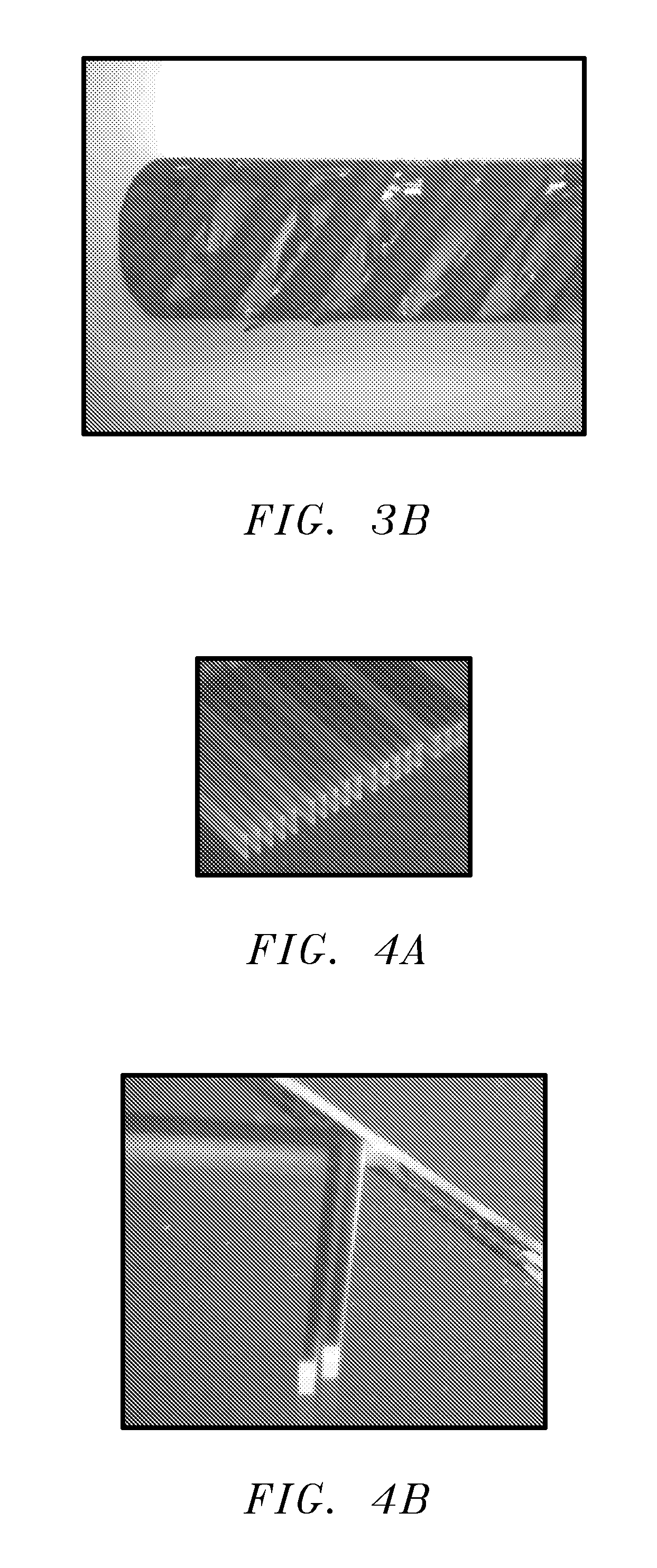

An optical component having a diffractive element and / or refractive element is provided. The optical component includes a photosensitive glass and / or a photosensitive glass ceramic and a plurality of structures influencing propagation of light in at least a part of the photosensitive glass and / or a photosensitive glass ceramic.

Owner:SCHOTT AG

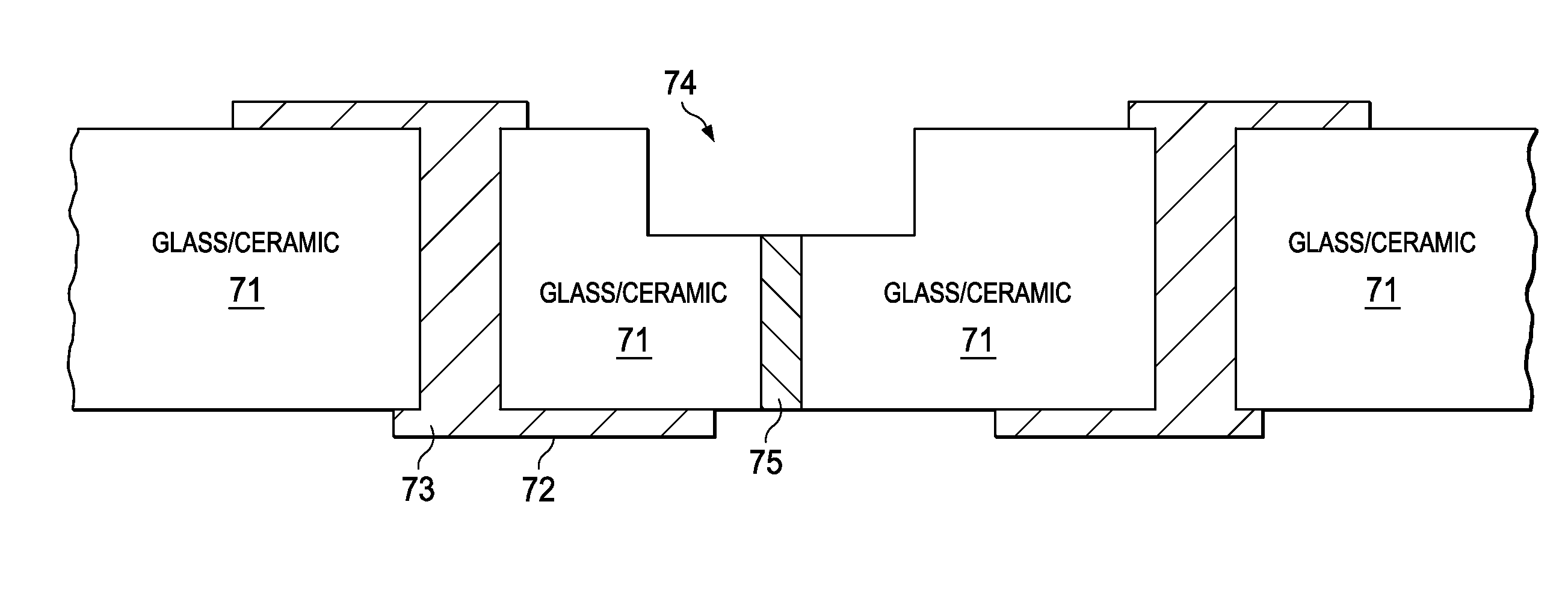

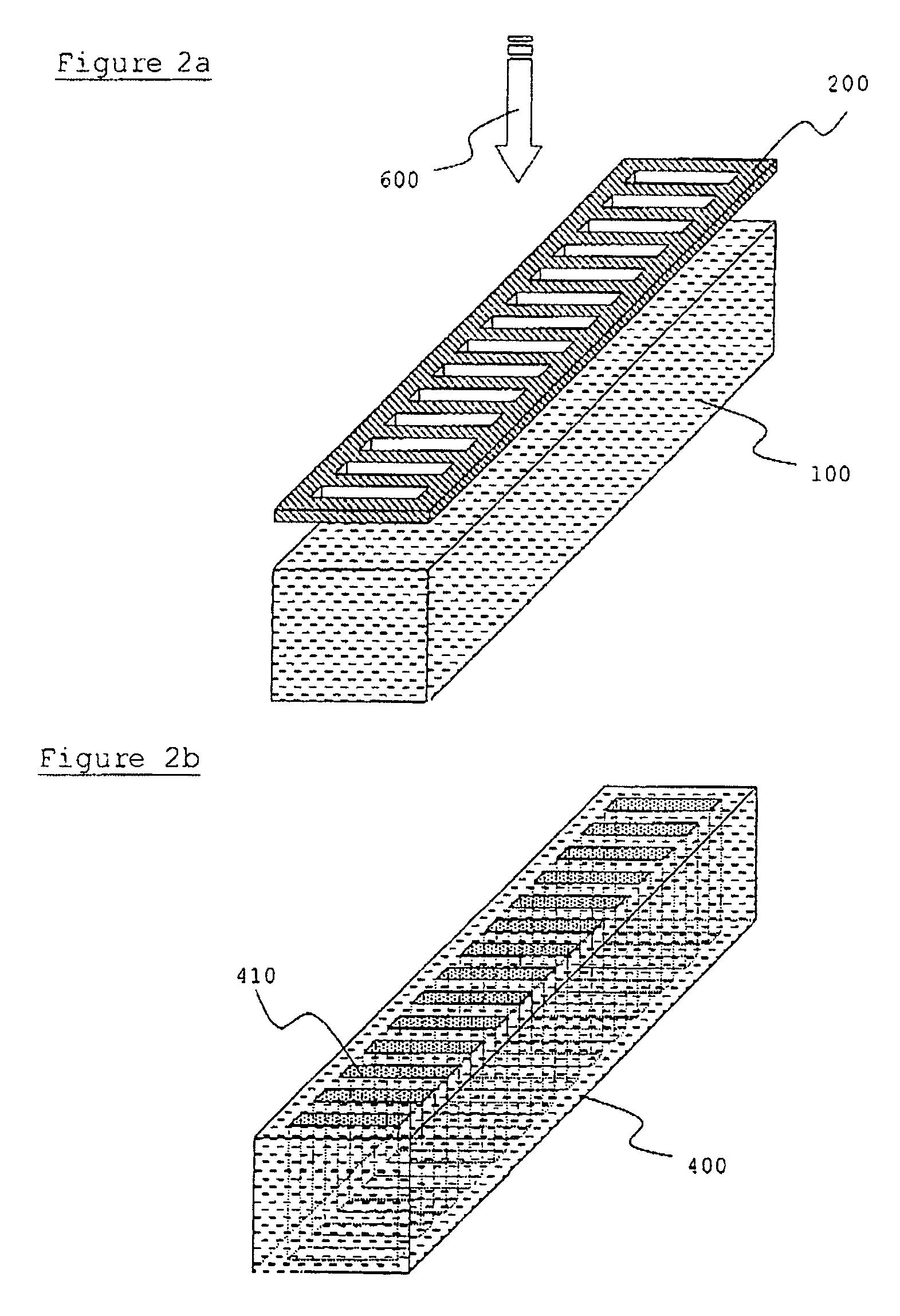

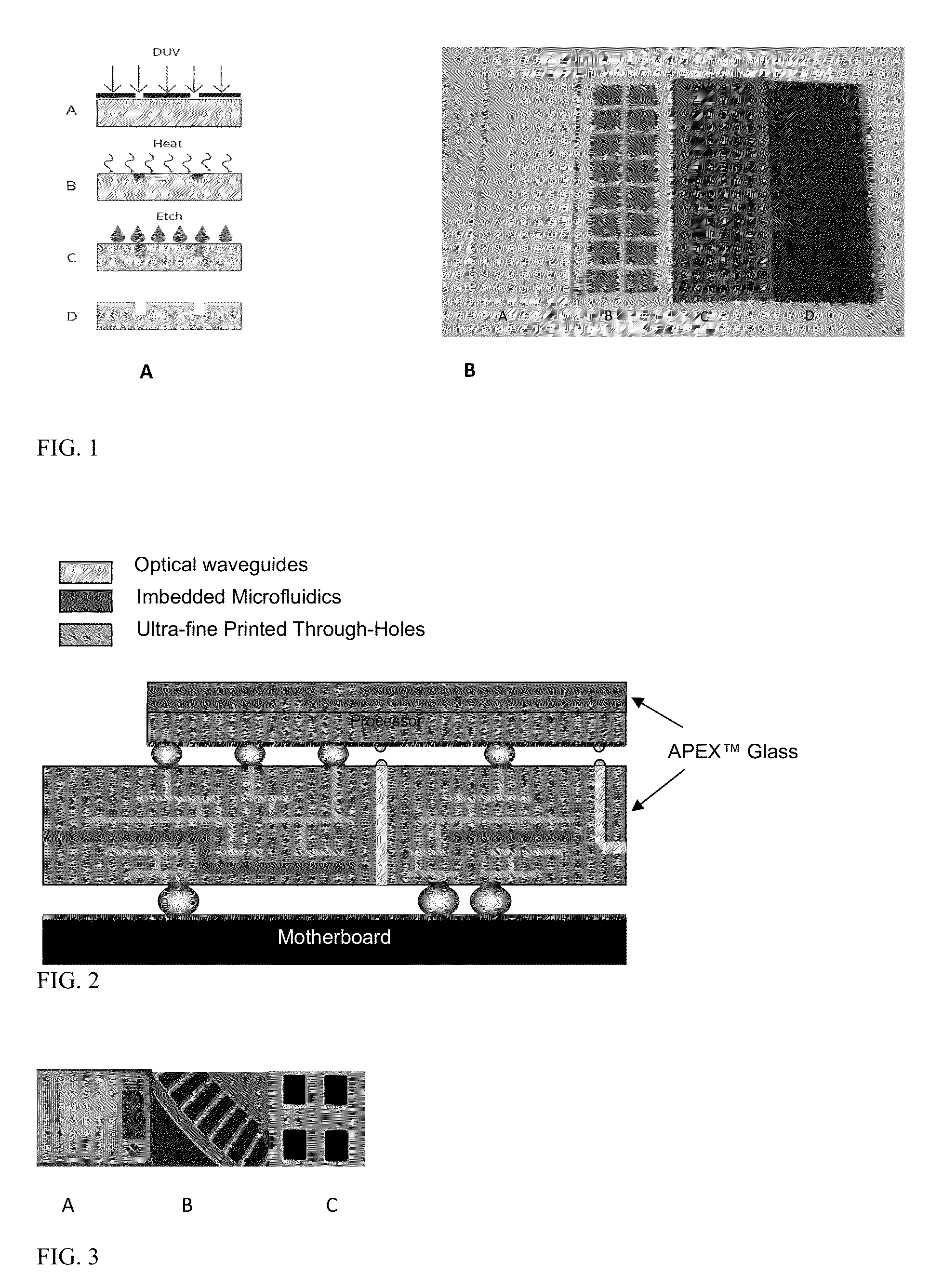

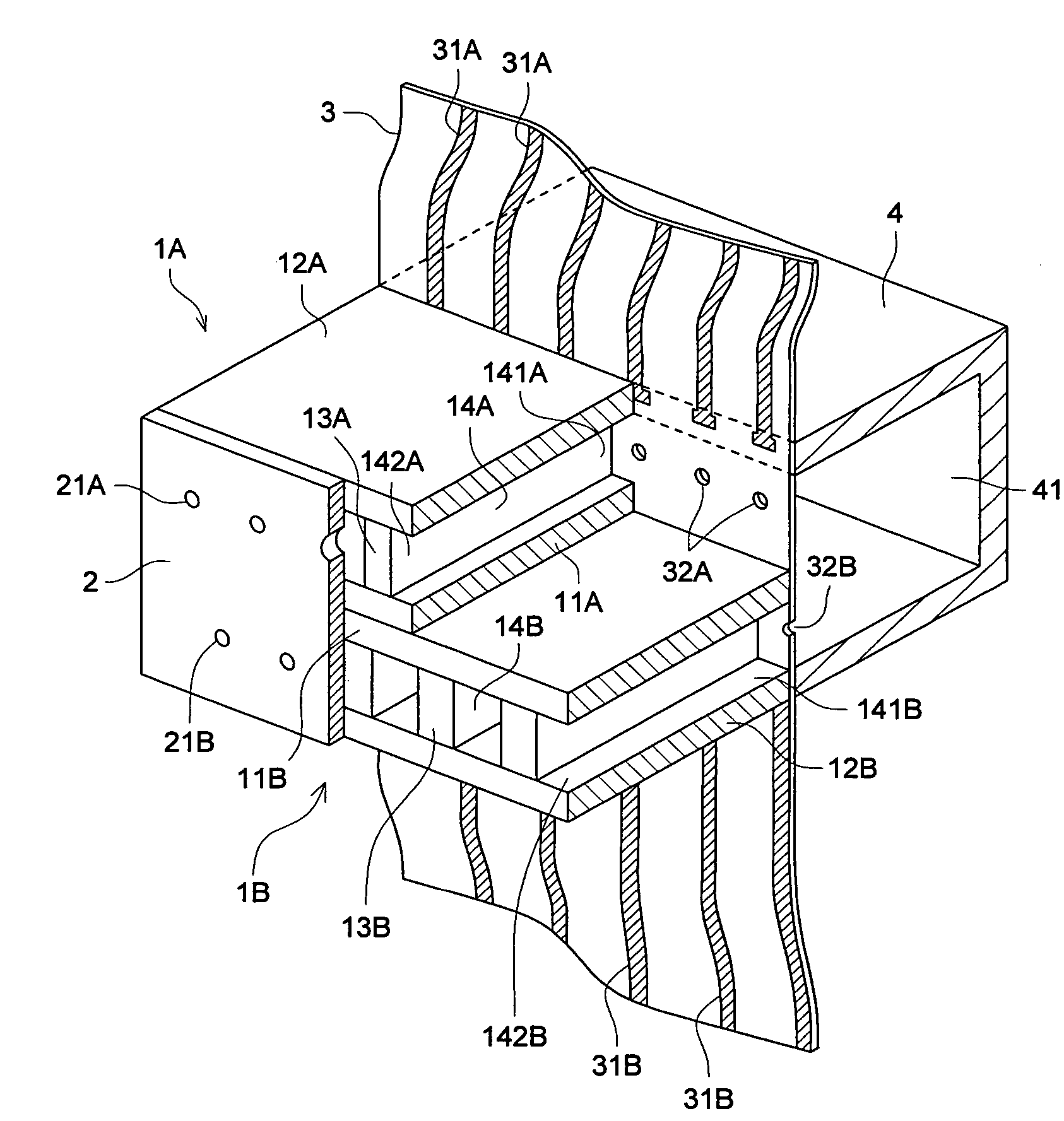

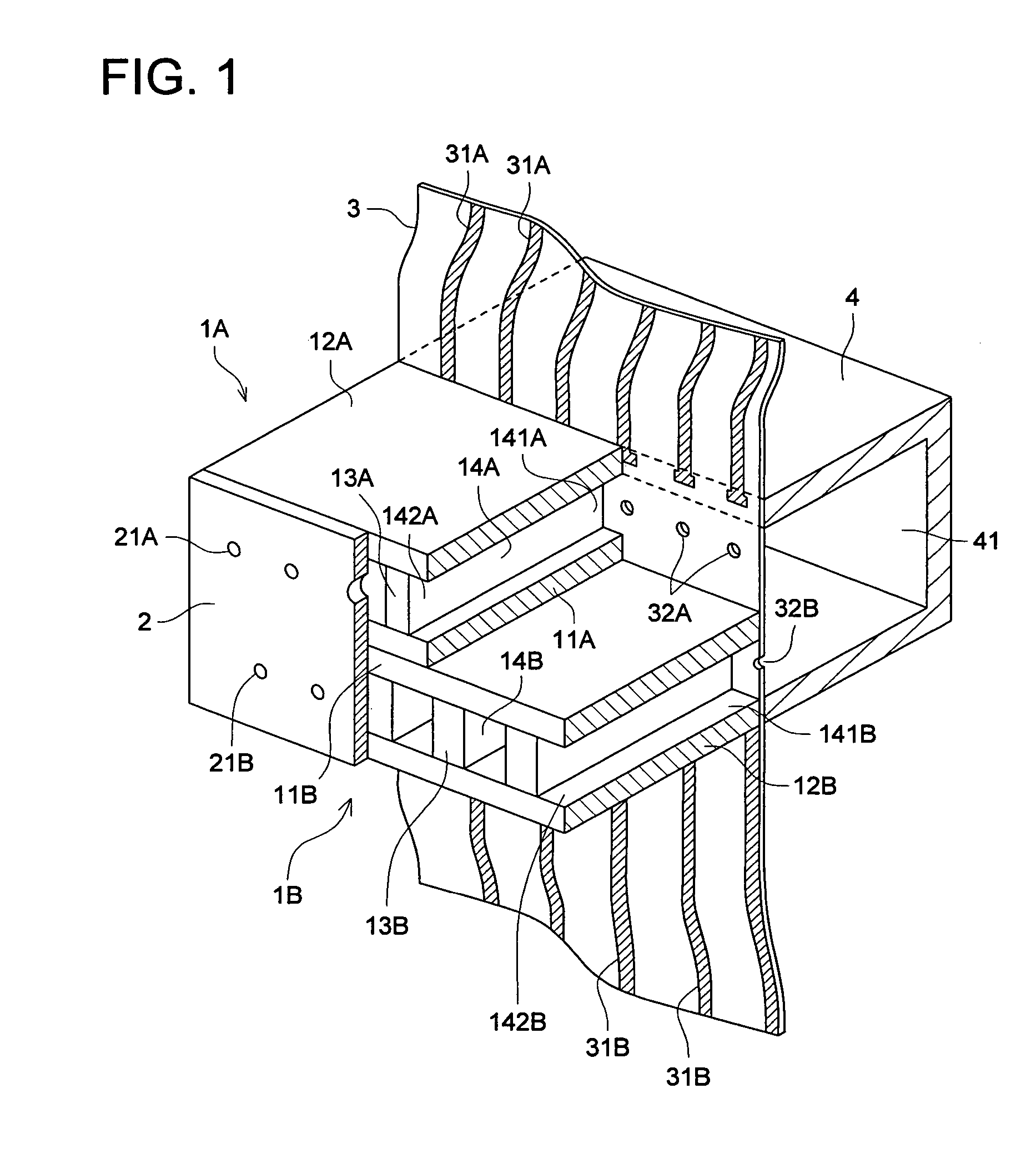

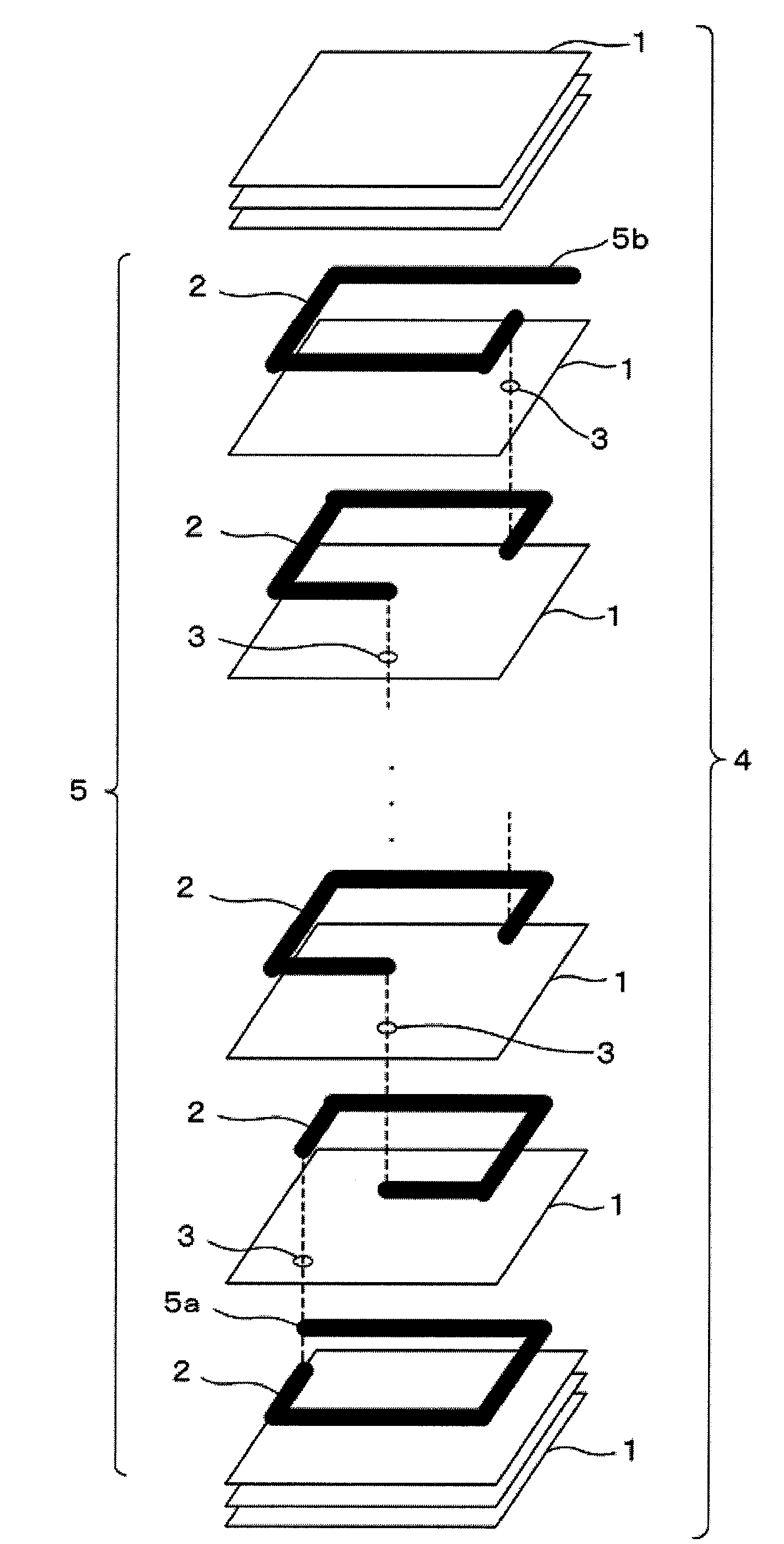

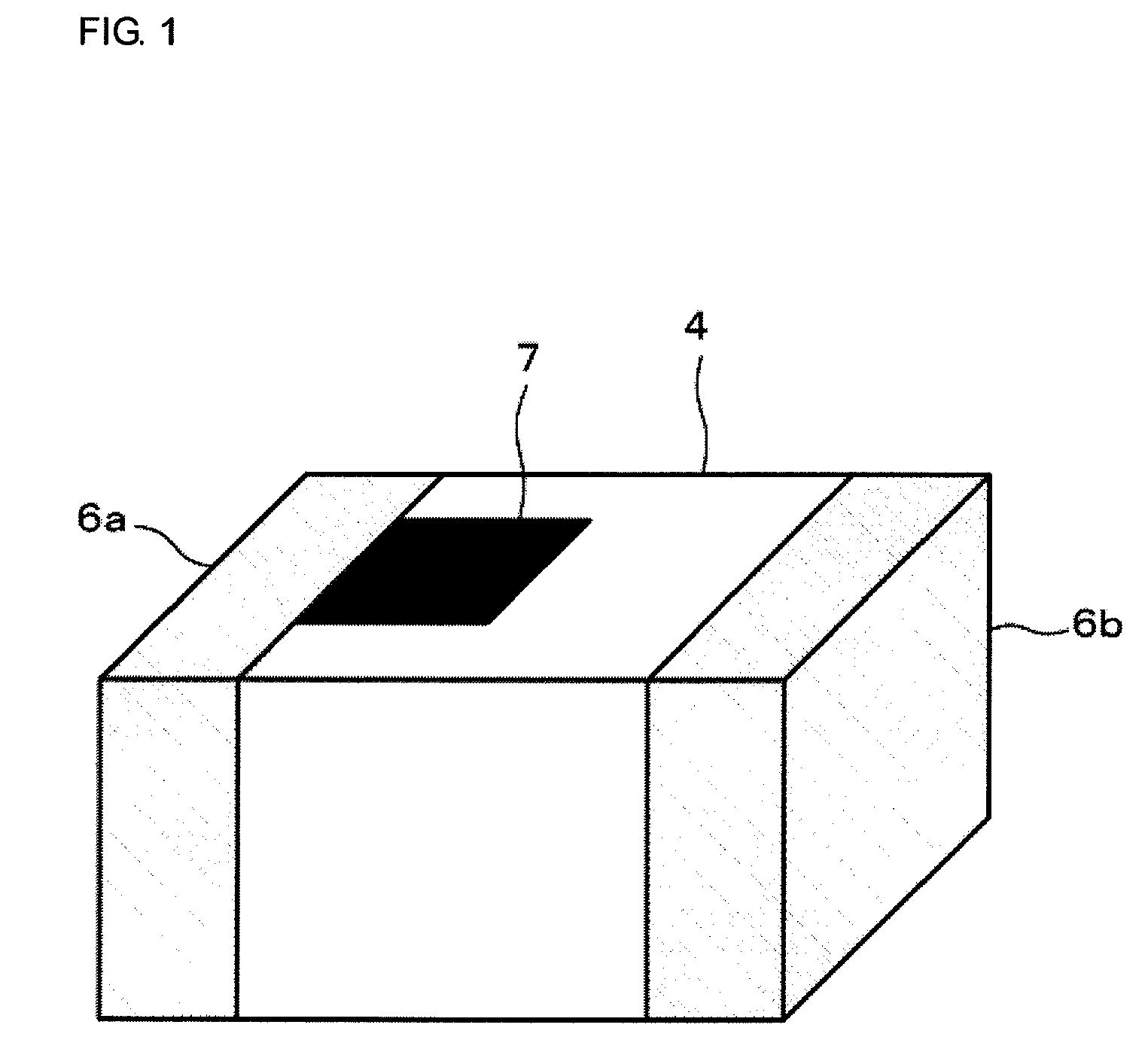

2D and 3D inductors antenna and trausformers fabricating photoactive substrates

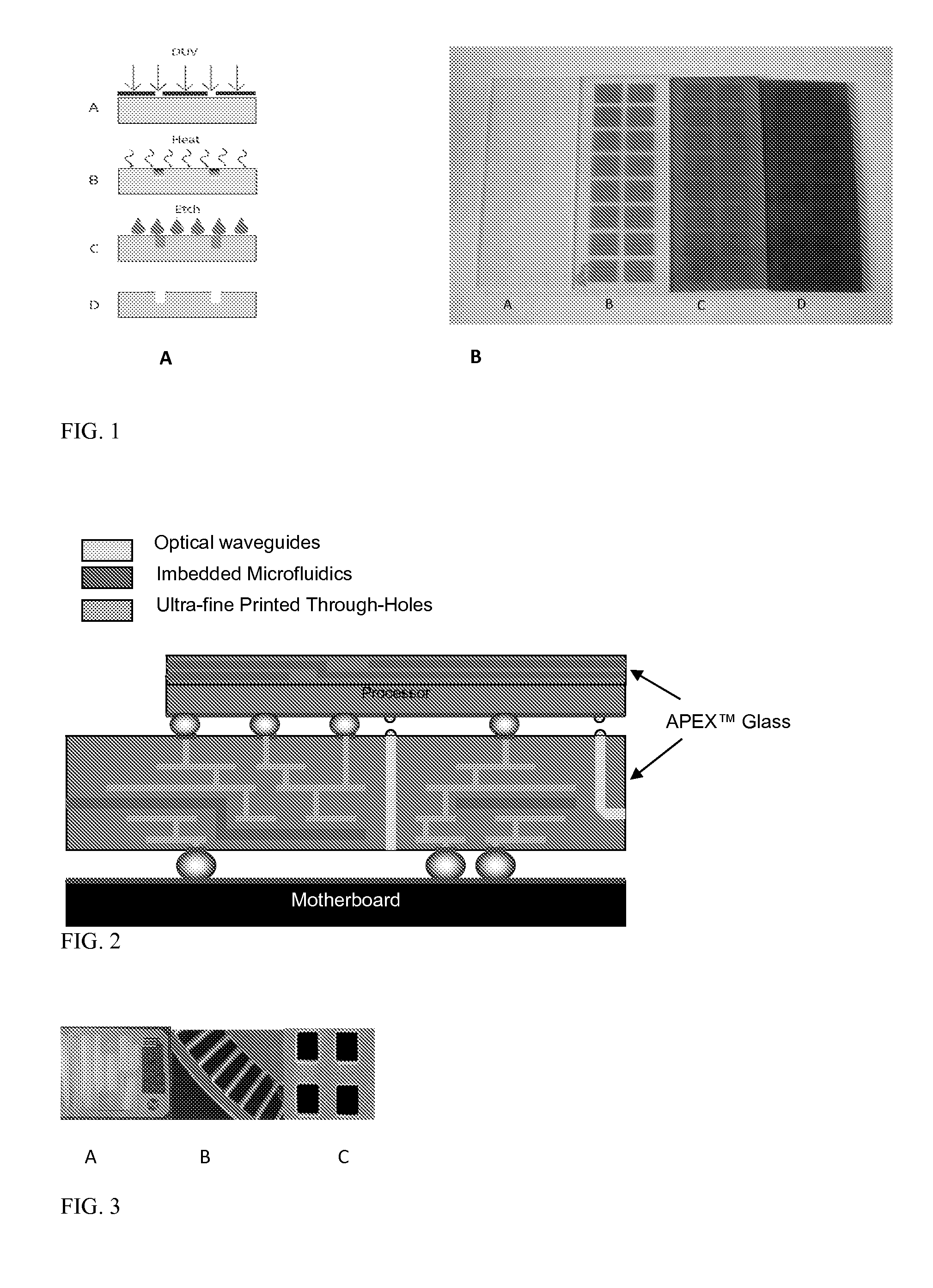

ActiveUS20170098501A1Semiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsLithium oxideCrystalline materials

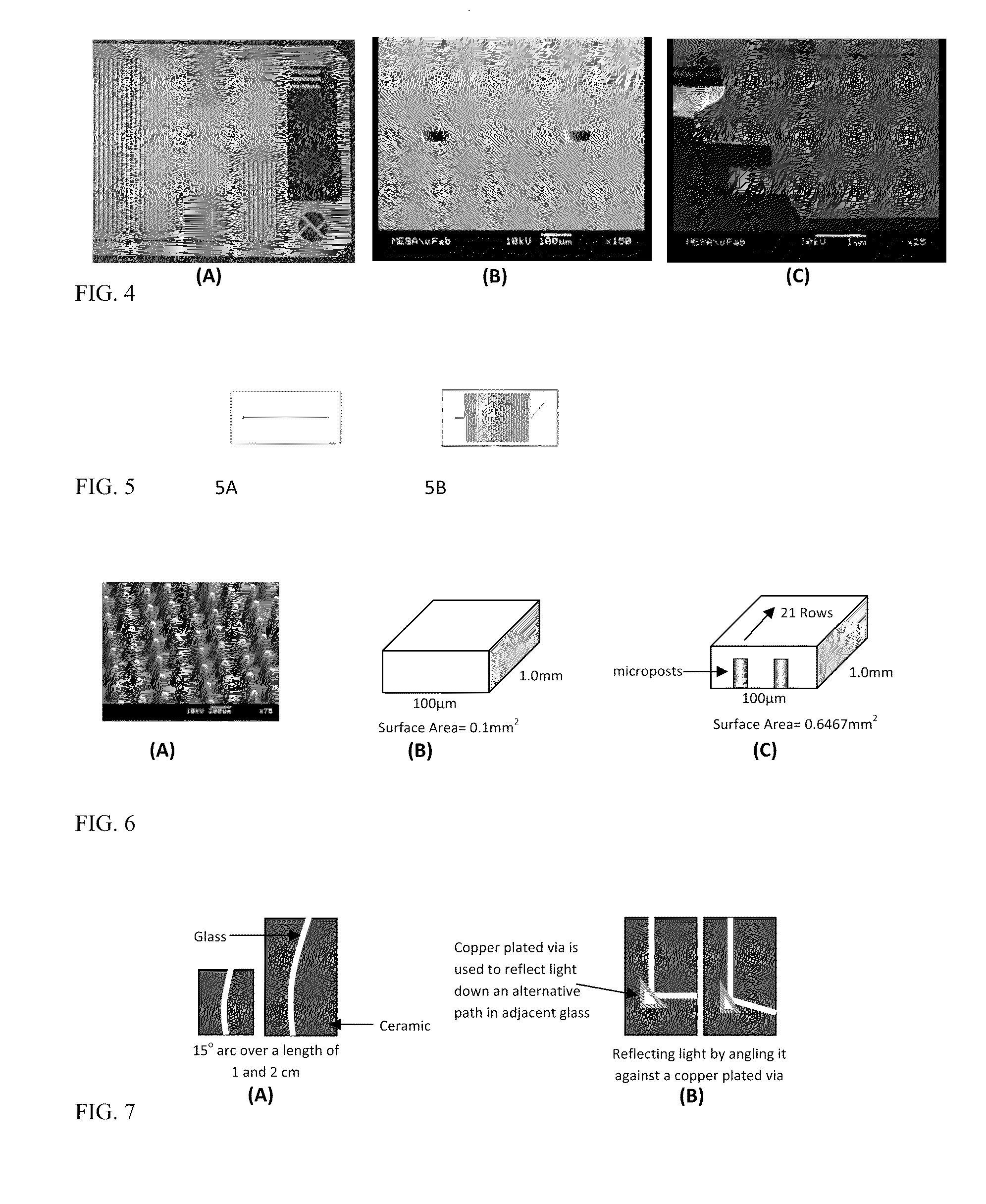

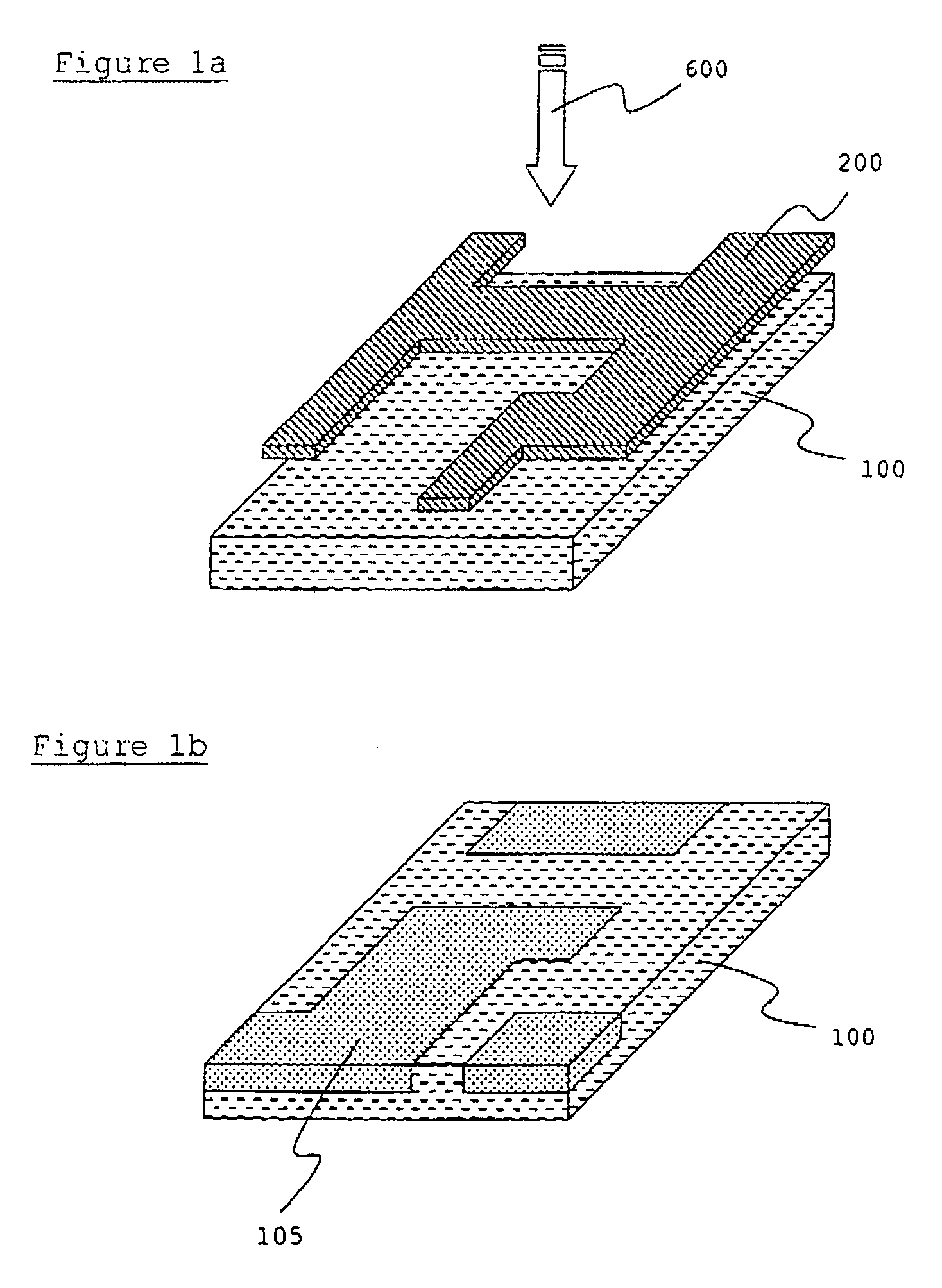

A method of fabrication and device made by preparing a photosensitive glass substrate comprising at least silica, lithium oxide, aluminum oxide, and cerium oxide, masking a design layout comprising one or more holes to form one or more electrical conduction paths on the photosensitive glass substrate, exposing at least one portion of the photosensitive glass substrate to an activating energy source, exposing the photosensitive glass substrate to a heating phase of at least ten minutes above its glass transition temperature, cooling the photosensitive glass substrate to transform at least part of the exposed glass to a crystalline material to form a glass-crystalline substrate and etching the glass-crystalline substrate with an etchant solution to form one or more angled channels that are then coated.

Owner:3D GLASS SOLUTIONS INC

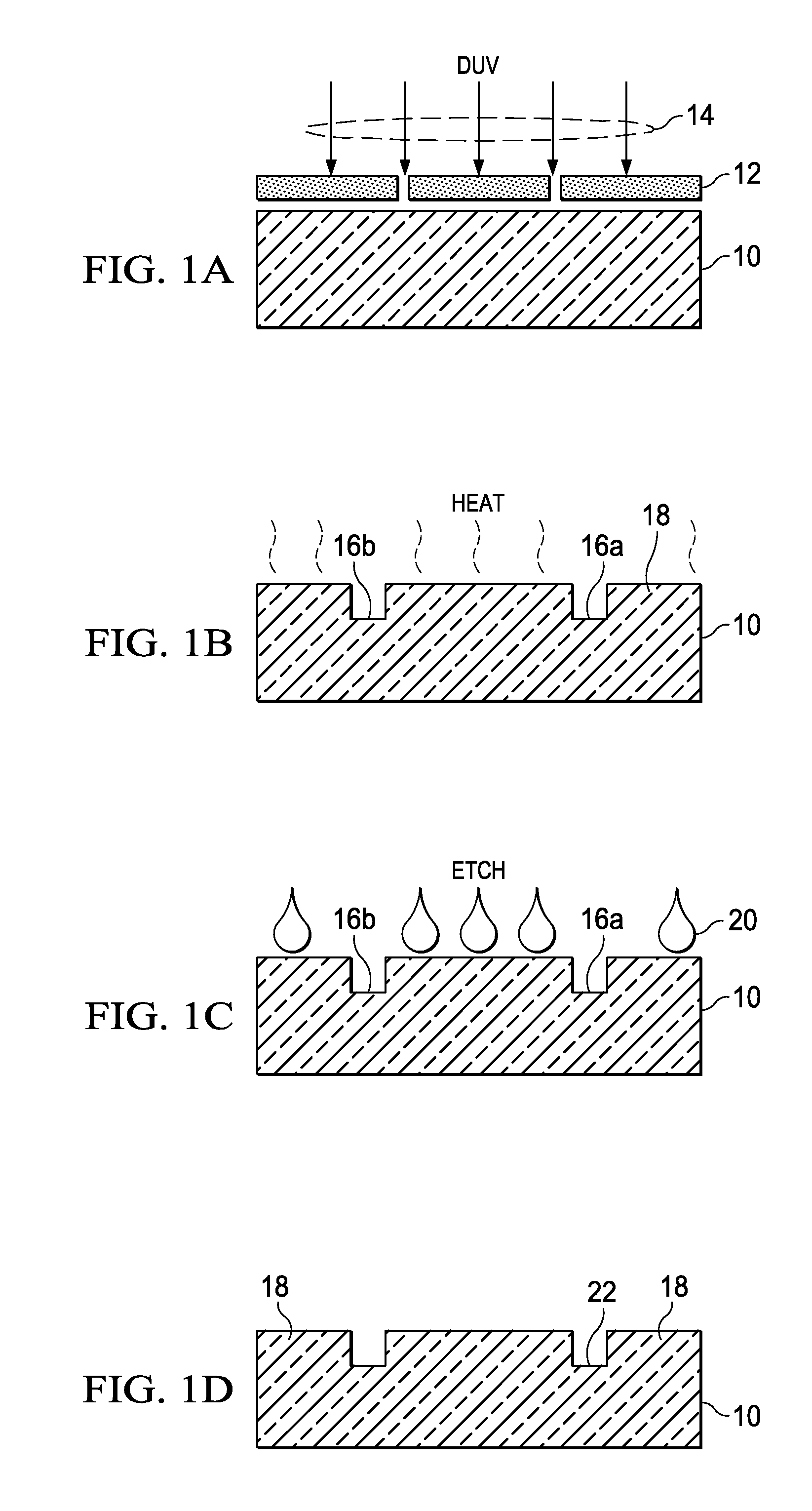

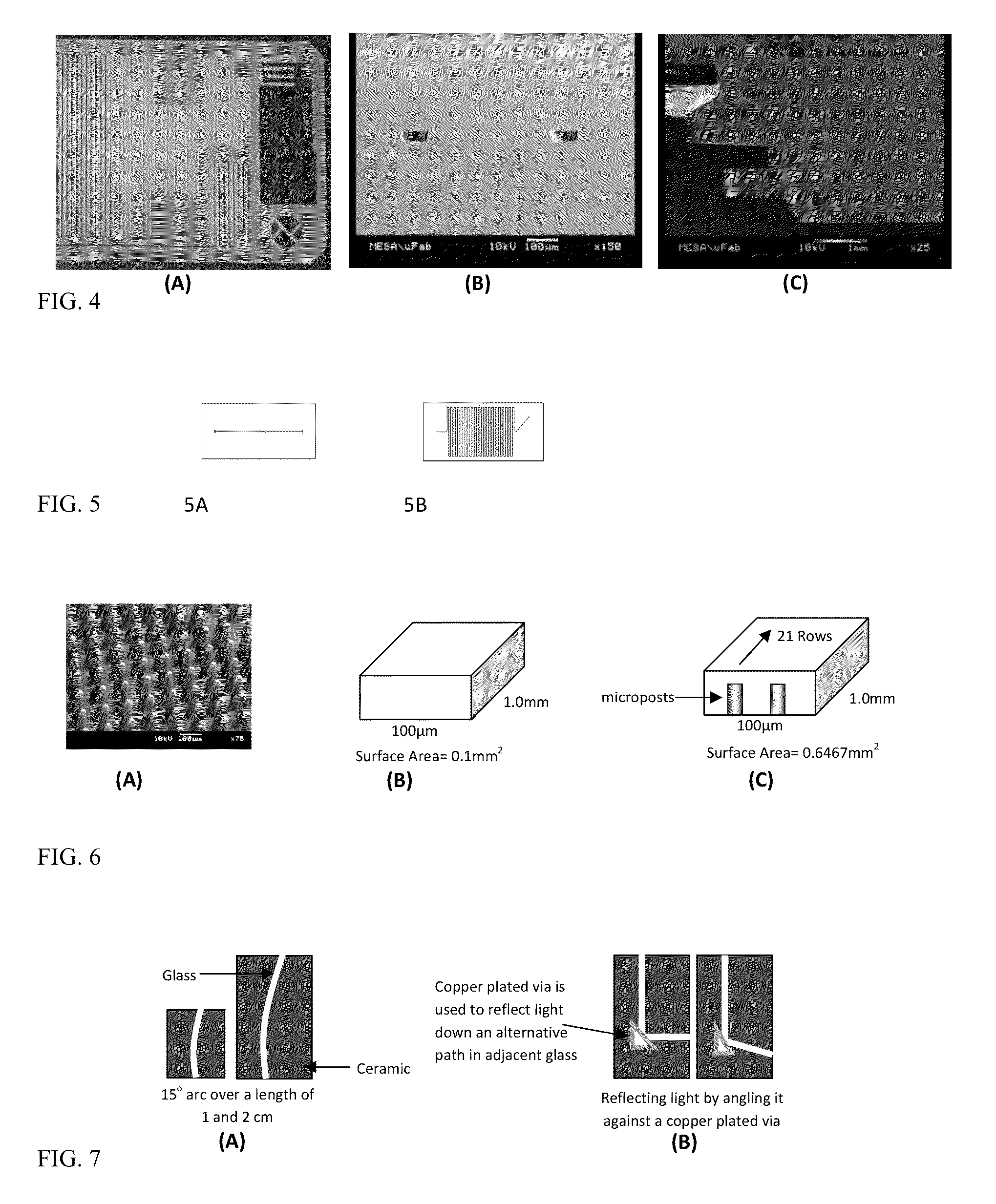

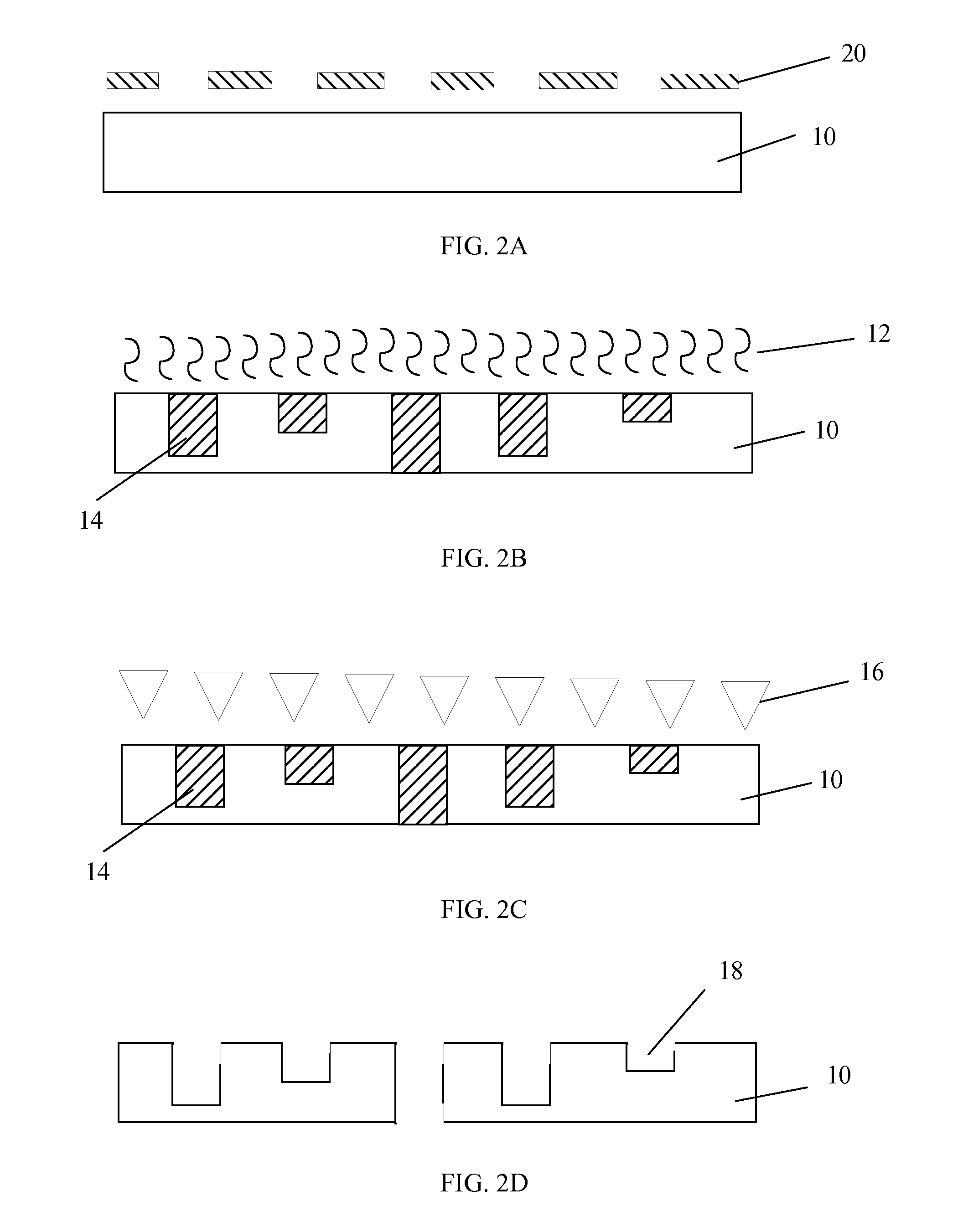

Methods to fabricate a photoactive substrate suitable for shaped glass structures

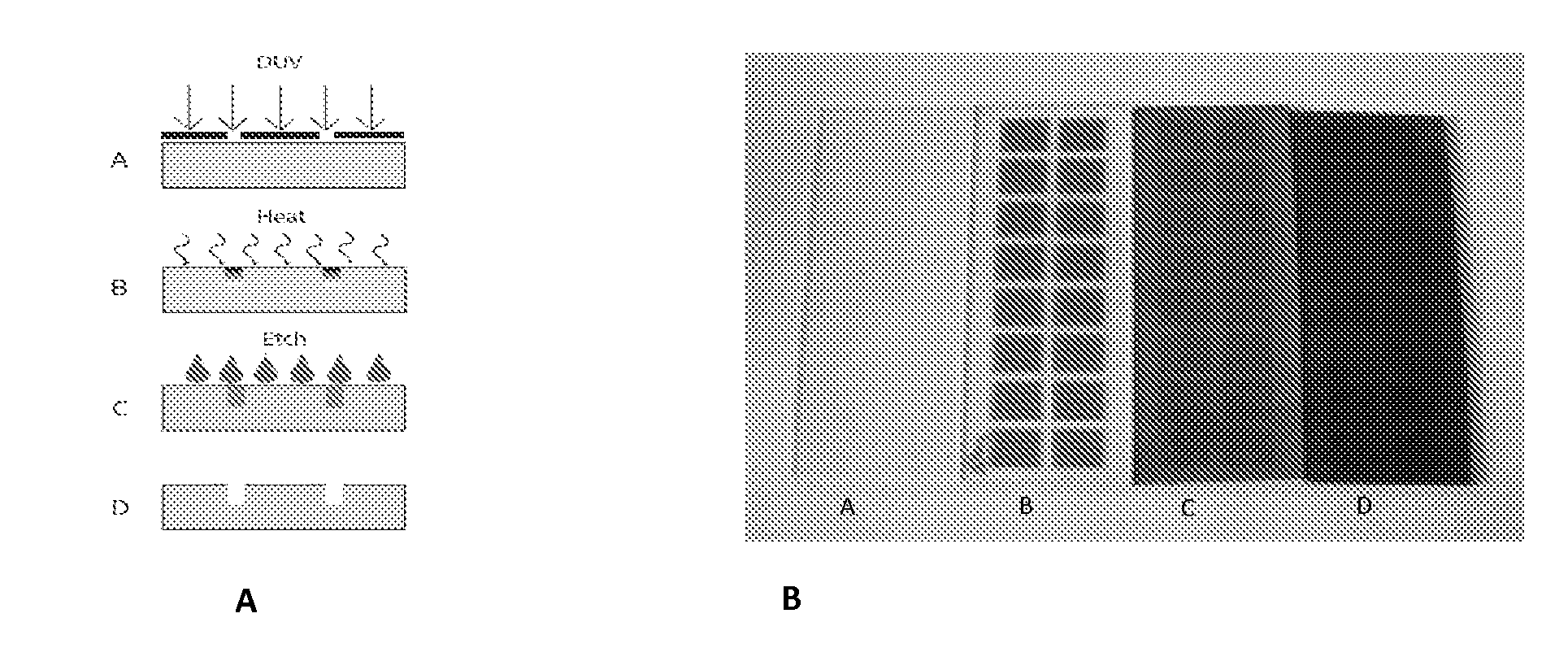

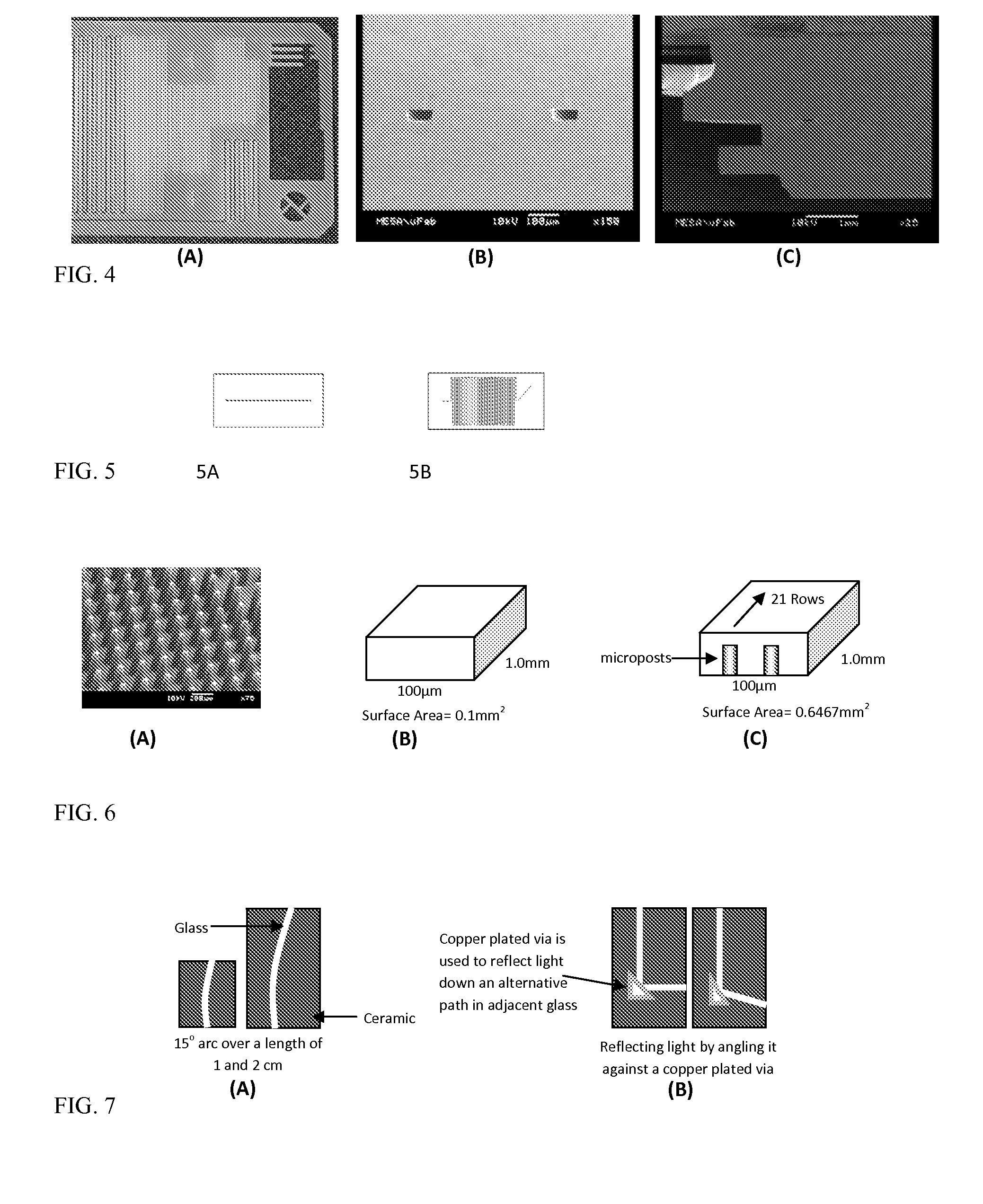

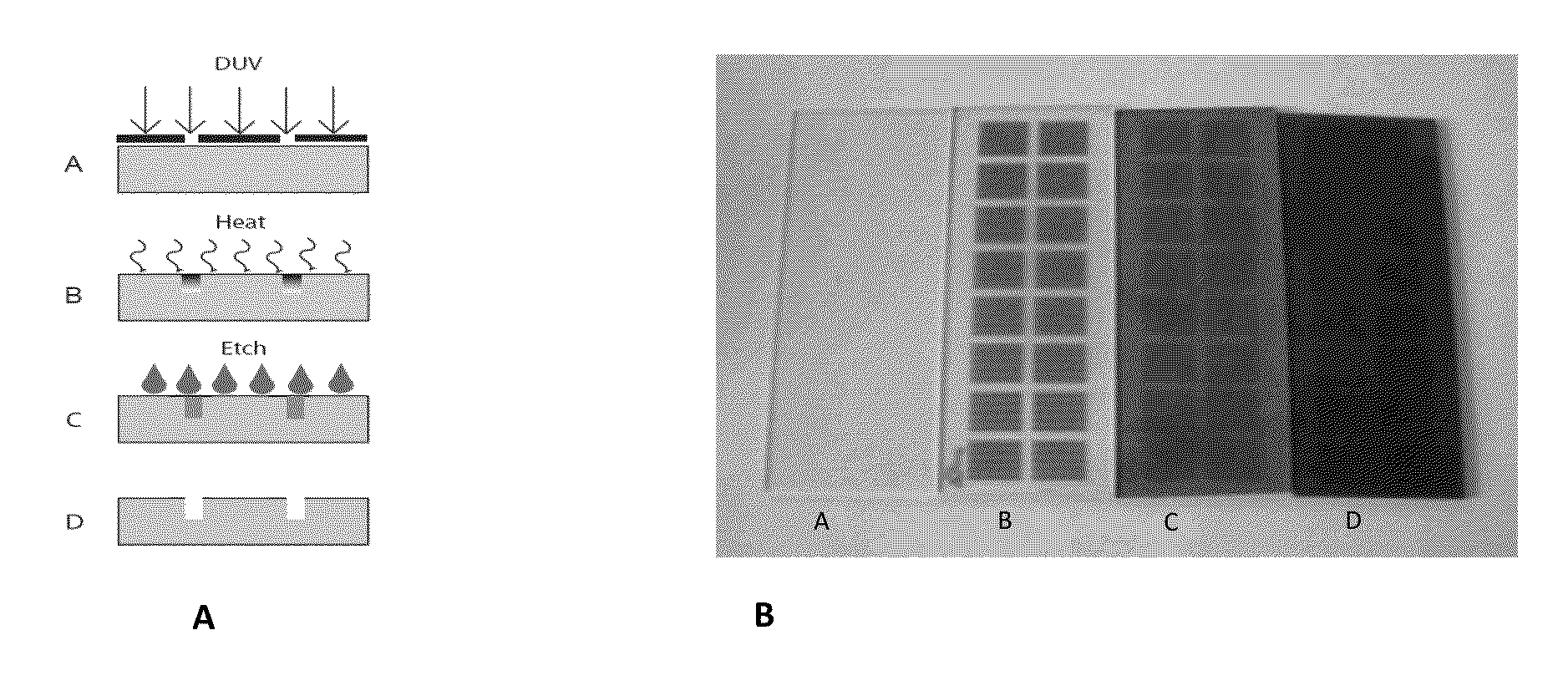

ActiveUS8096147B2Low wall slopeReduce the overall diameterLayered productsCoatingsAnisotropic etchingGlass structure

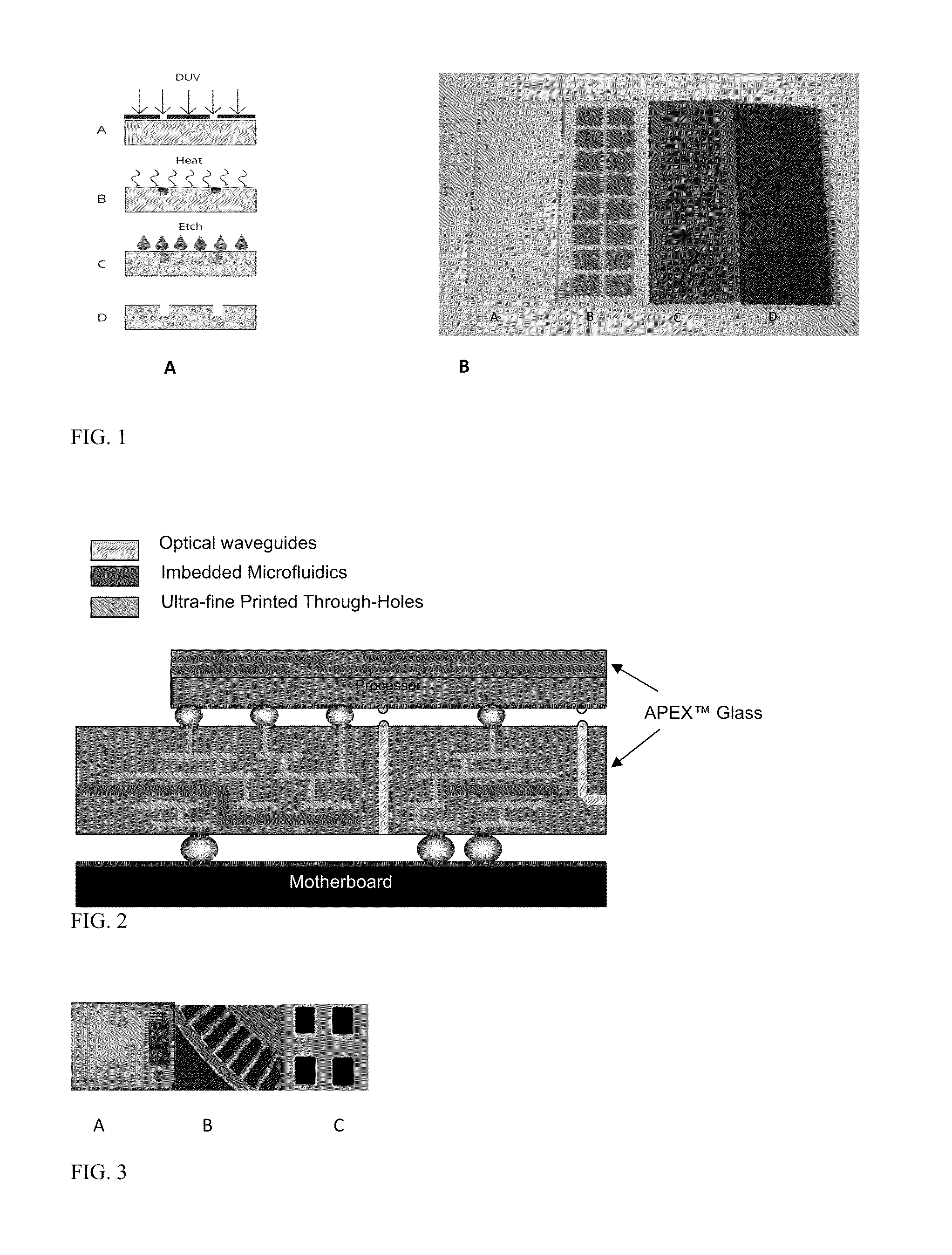

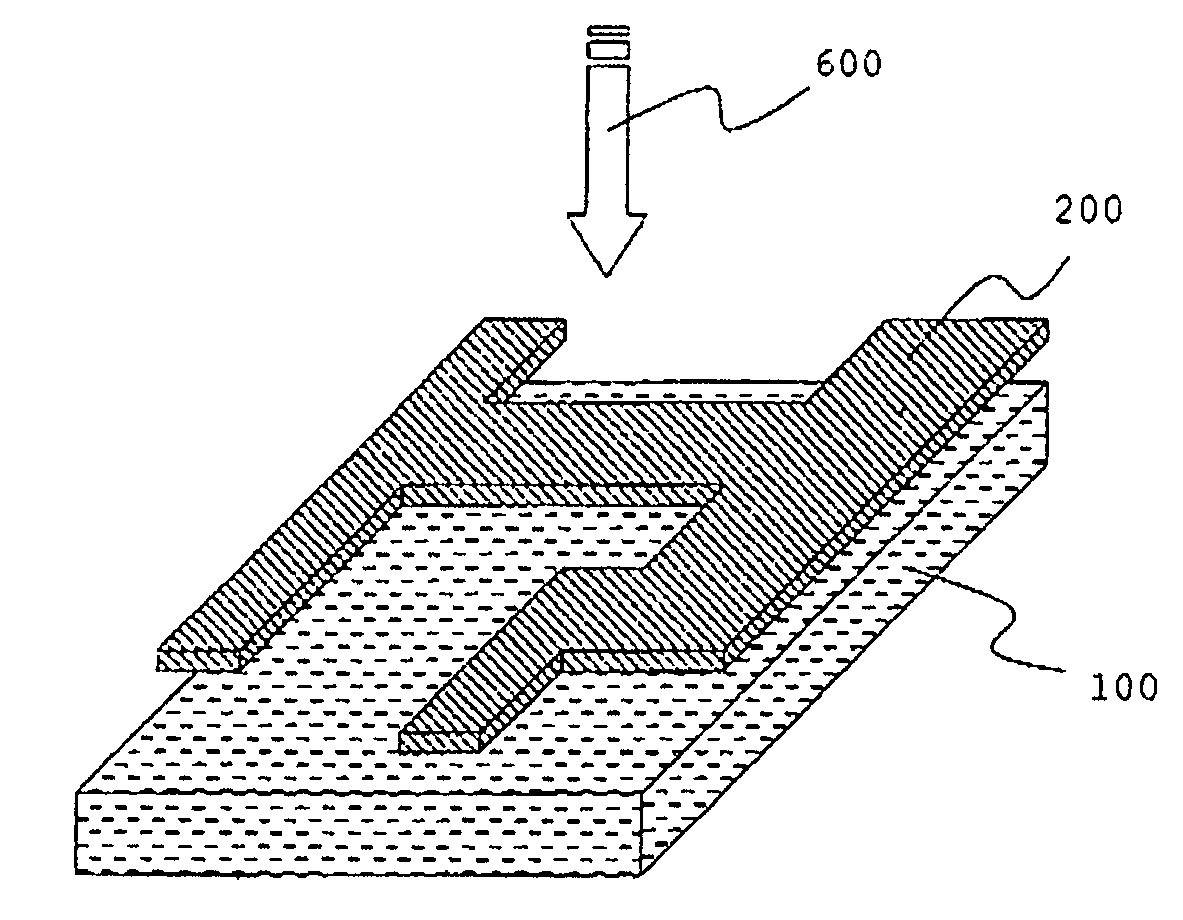

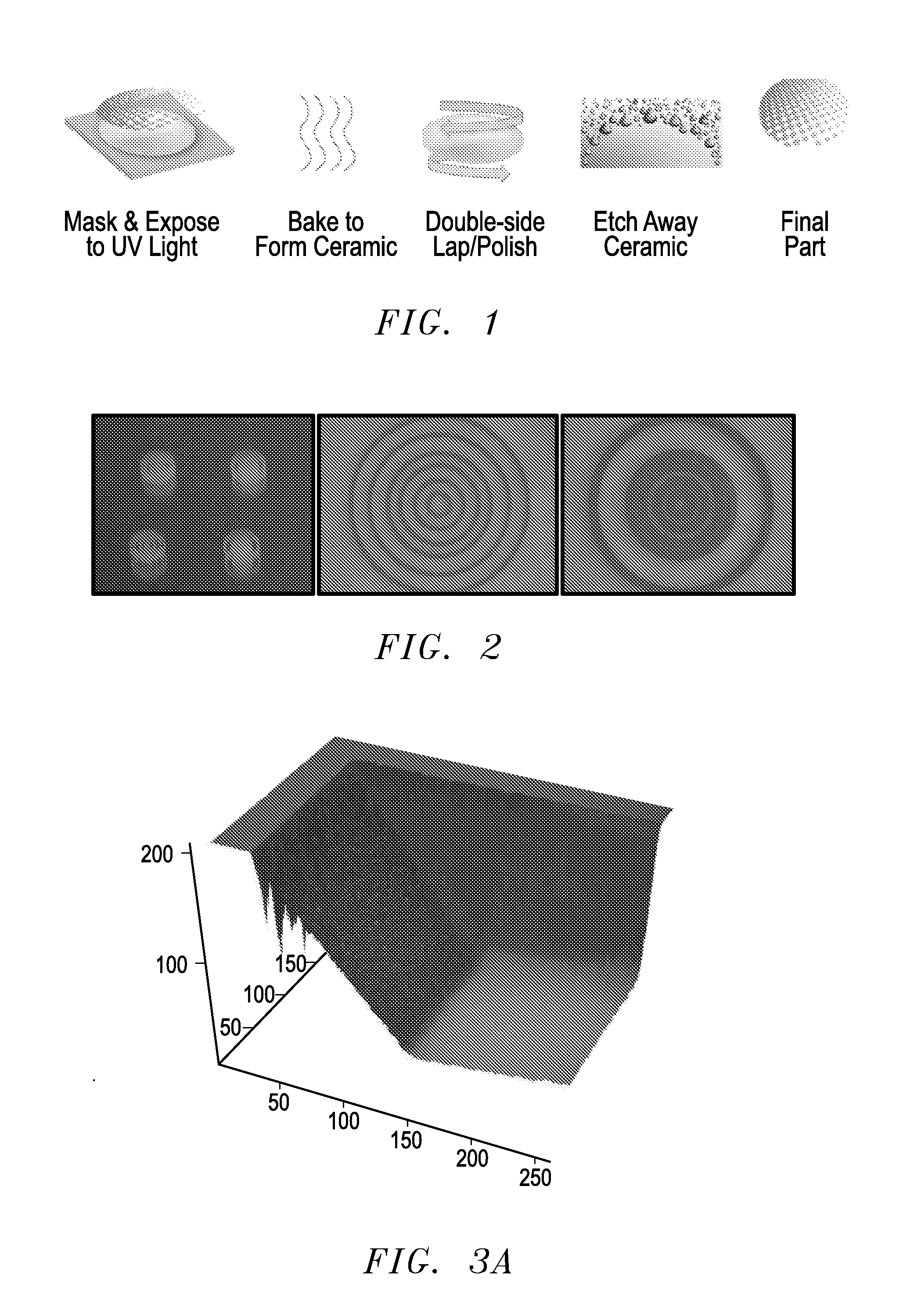

This invention provides an inexpensive and rapid method for fabricating a high-anisotropic-etch ratio, shaped glass structures using a novel photosensitive glass composition. Structures of the photosensitive glass may include micro-channels, micro-optics, microposts, or arrays of hollow micro-needles. Furthermore, such shaped glass structures can be used to form a negative mold for casting the shape in other materials.

Owner:3D GLASS SOLUTIONS INC

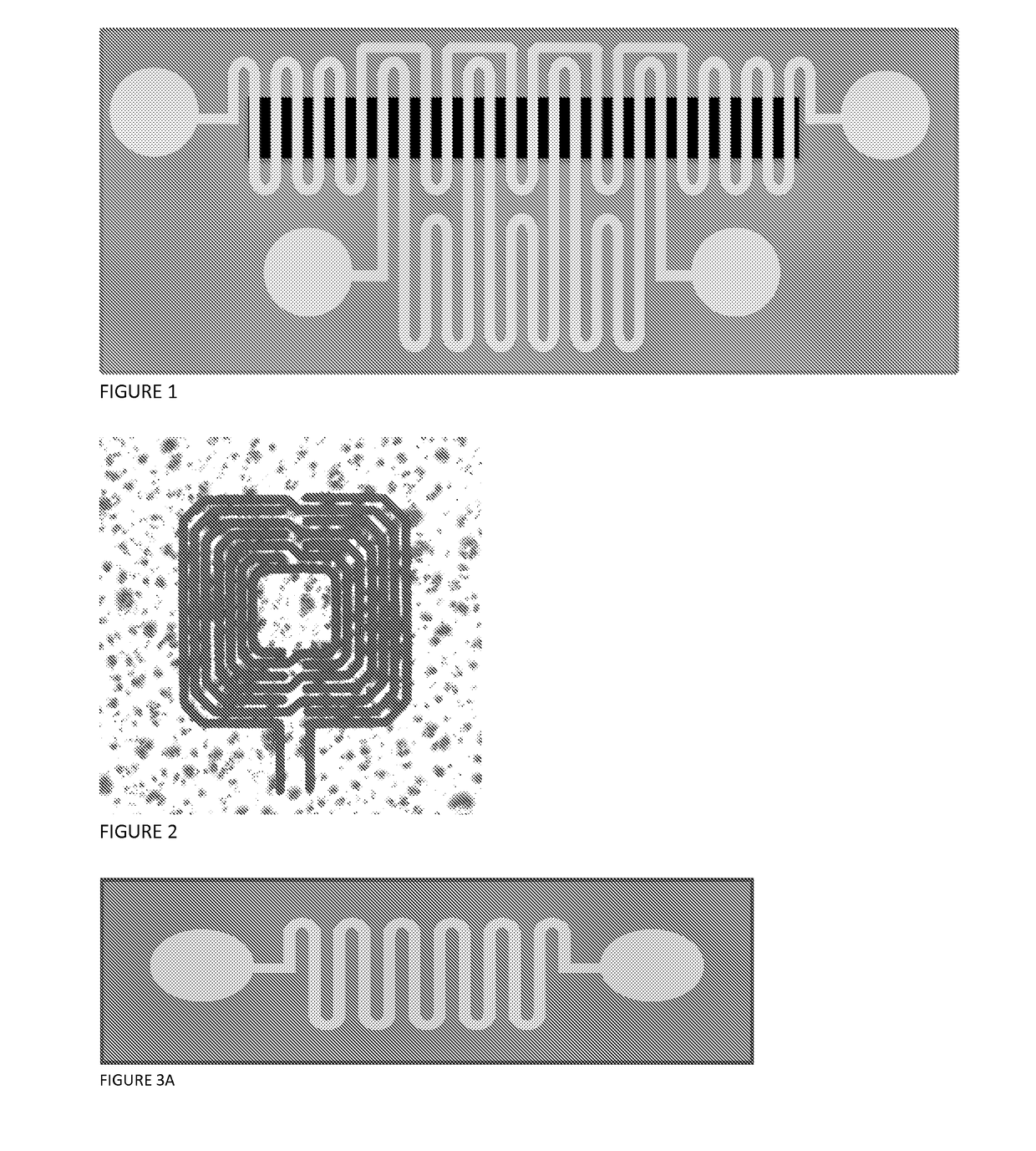

Methods of fabricating photoactive substrates suitable for electromagnetic transmission and filtering applications

InactiveUS20150277047A1Solid-state devicesPhotomechanical apparatusLithium oxideCrystalline materials

A method of fabrication and device made by preparing a photosensitive glass substrate comprising at least silica, lithium oxide, aluminum oxide, and cerium oxide, masking a design layout comprising one or more holes to form one or more electrical conduction paths on the photosensitive glass substrate, exposing at least one portion of the photosensitive glass substrate to an activating energy source, exposing the photosensitive glass substrate to a heating phase of at least ten minutes above its glass transition temperature, cooling the photosensitive glass substrate to transform at least part of the exposed glass to a crystalline material to form a glass-crystalline substrate and etching the glass-crystalline substrate with an etchant solution to form one or more angled channels that are then coated.

Owner:3D GLASS SOLUTIONS INC

Methods to fabricate a photoactive substrate suitable for shaped glass structures

ActiveUS20080245109A1Decrease in overall micropost diameterImprove accuracyLayered productsCoatingsPhotosensitive glassGlass structure

This invention provides an inexpensive and rapid method for fabricating a high-anisotropic-etch ratio, shaped glass structures using a novel photosensitive glass composition. Structures of the photosensitive glass may include micro-channels, micro-optics, microposts, or arrays of hollow micro-needles. Furthermore, such shaped glass structures can be used to form a negative mold for casting the shape in other materials.

Owner:3D GLASS SOLUTIONS INC

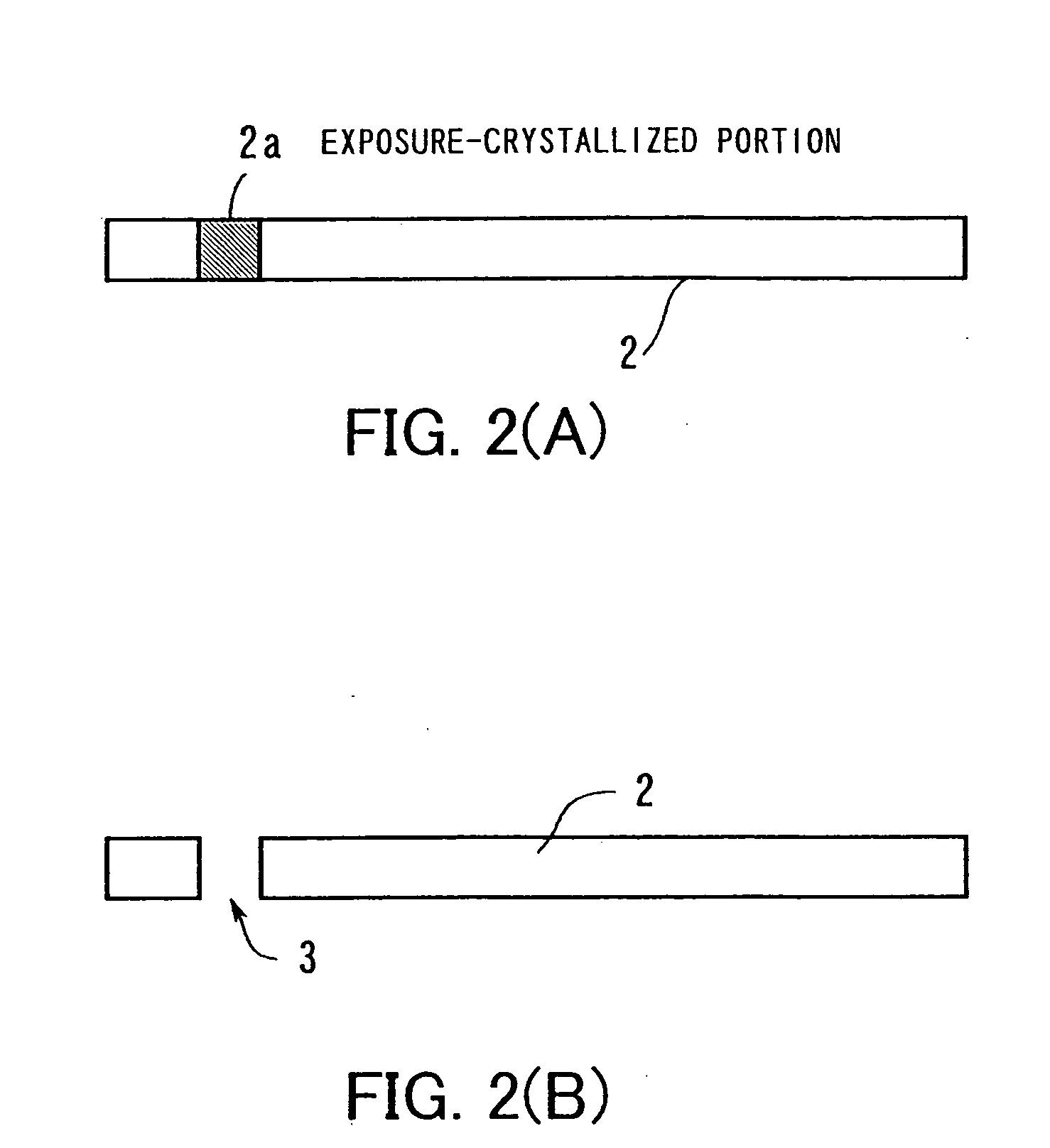

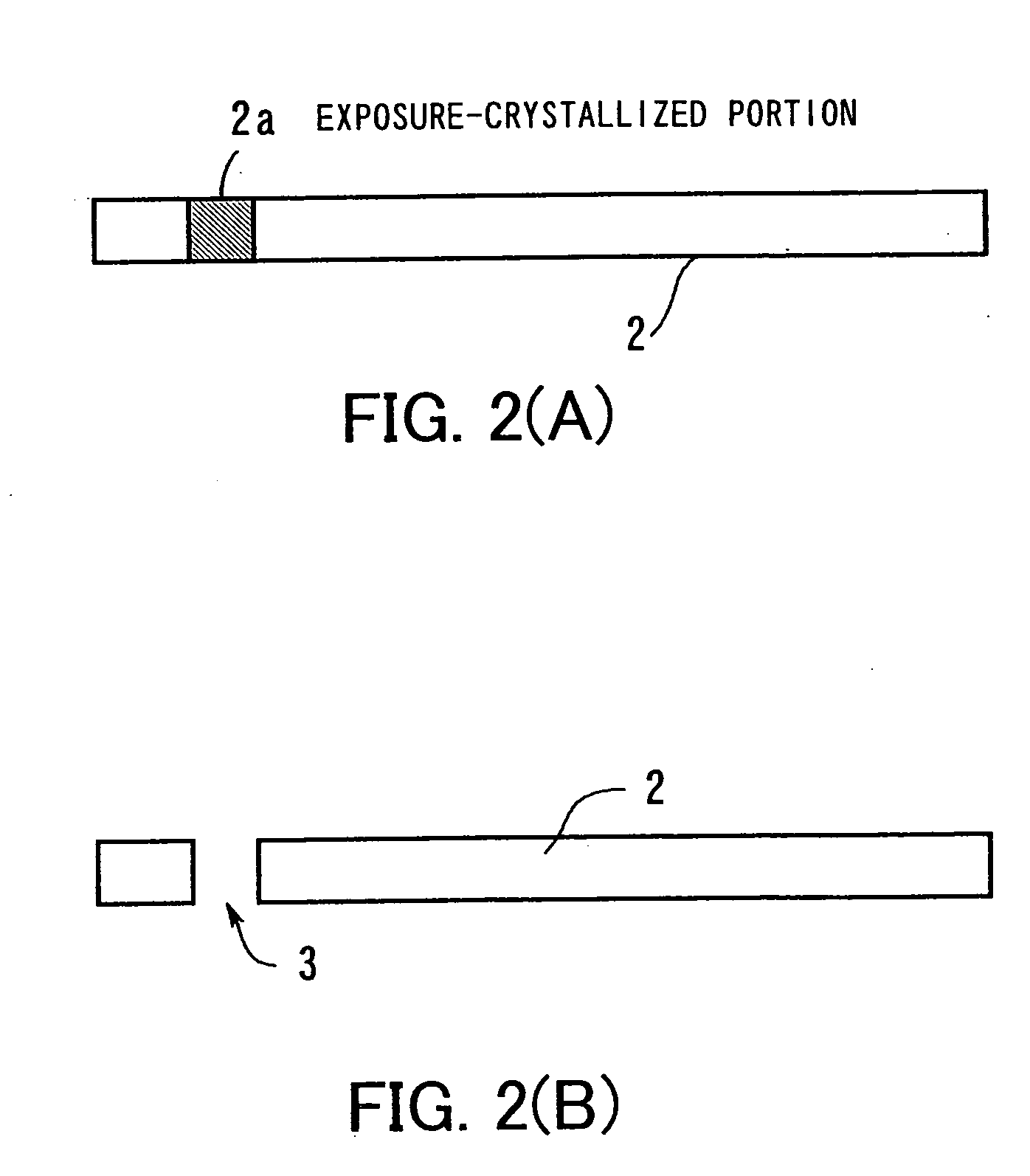

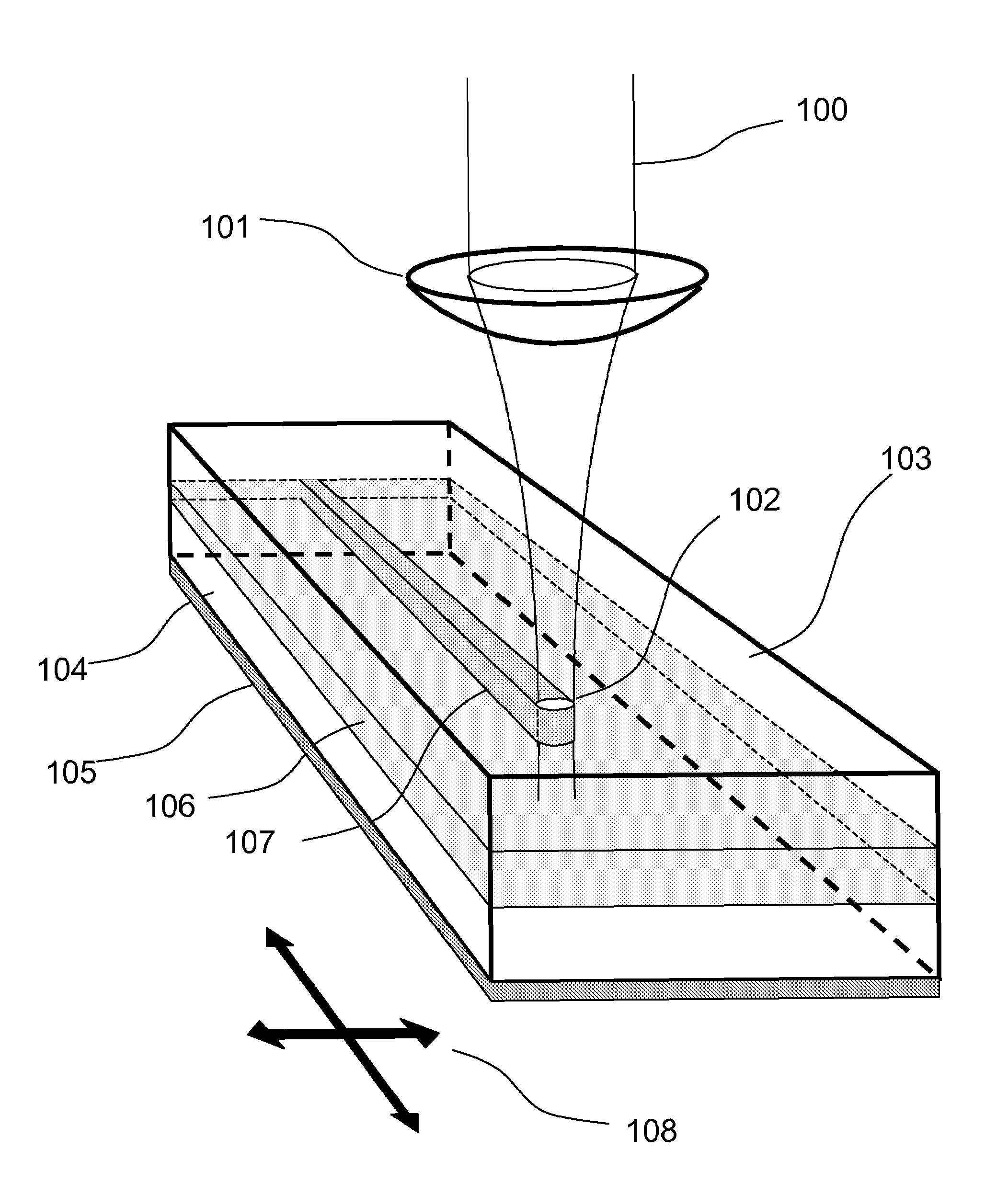

Method and system for manufacturing microstructure in photosensitive glass substrate

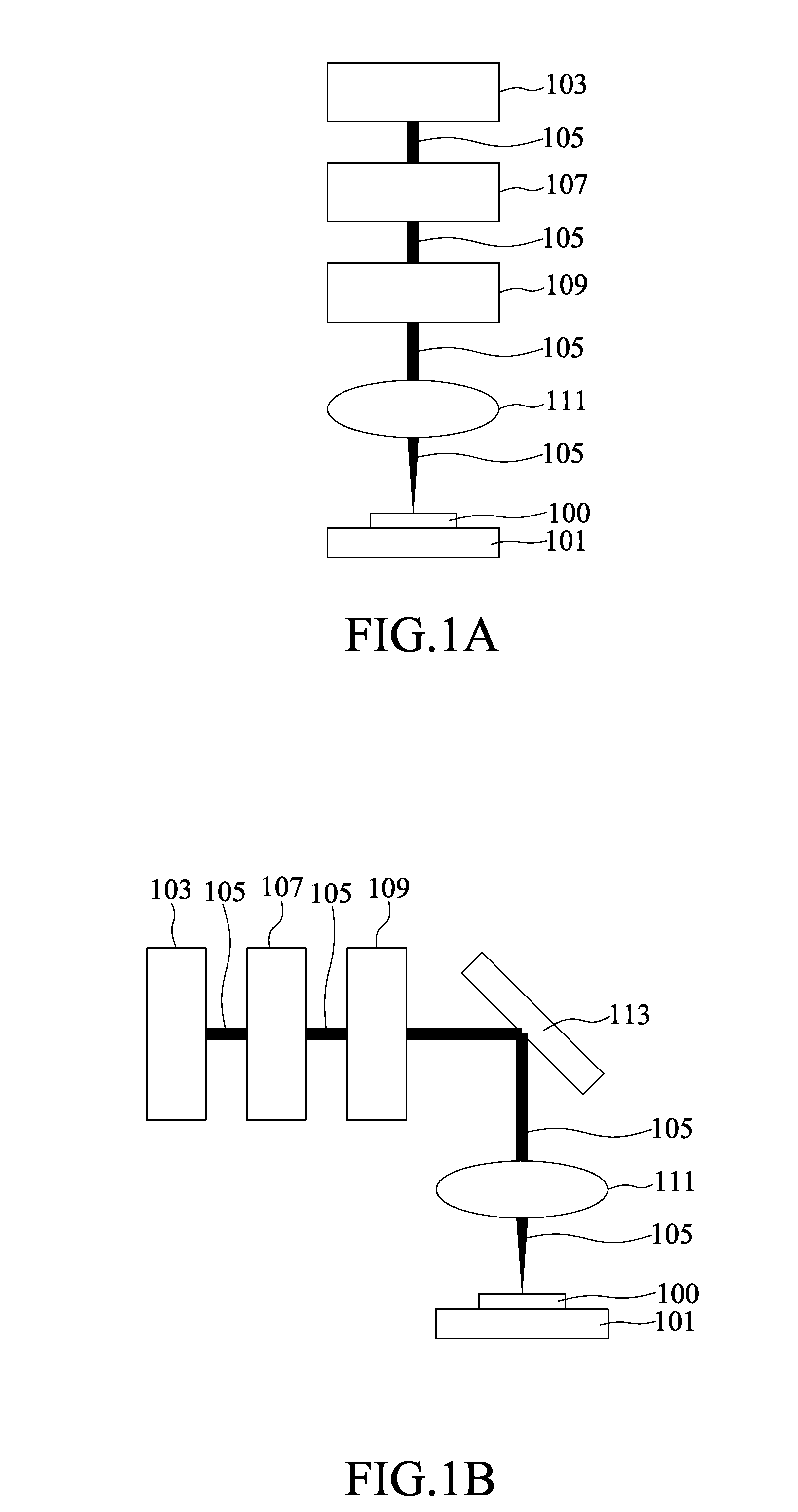

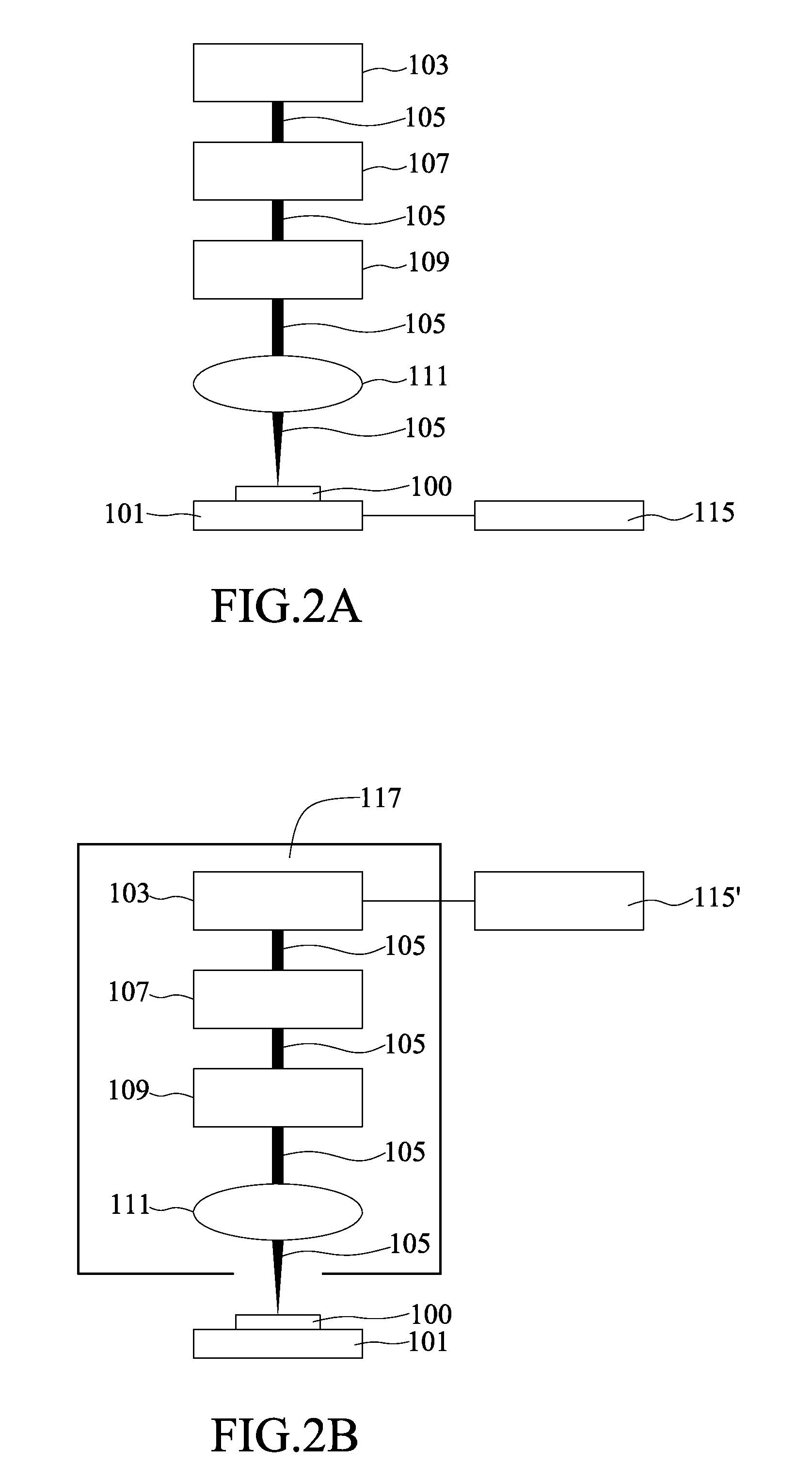

InactiveUS20110108525A1Reduce stepsShorten the timePolycrystalline material growthDecorative surface effectsLaser sourceCrystallization

The present invention provides a method and system for manufacturing a microstructure in a photosensitive glass substrate, which include the steps of generating first femtosecond laser pulses by a femtosecond laser source and focusing the first femtosecond laser pulses on a surface or an interior of the photosensitive glass substrate by a focus lens to define a modified region; generating second femtosecond laser pulses by the femtosecond laser source, adjusting a frequency of the second femtosecond laser pulses to be higher than that of the first femtosecond laser pulses by a frequency adjustment unit and an energy adjustment unit; focusing the adjusted second femtosecond laser pulses on the modified region of the photosensitive glass substrate to crystallize a substance of the modified region; and, after crystallization, etching off the crystallized region to obtain the microstructure in the photosensitive glass substrate.

Owner:IND TECH RES INST

Methods to fabricate a photoactive substrate suitable for microfabrication

ActiveUS8709702B2Solid-state devicesSemiconductor/solid-state device manufacturingLithium oxideMicrofabrication

A method of fabrication and device with holes for electrical conduction made by preparing a photosensitive glass substrate comprising at least silica, lithium oxide, aluminum oxide, and cerium oxide, masking a design layout comprising one or more holes to form one or more electrical conduction paths on the photosensitive glass substrate, exposing at least one portion of the photosensitive glass substrate to an activating energy source, exposing the photosensitive glass substrate to a heating phase of at least ten minutes above its glass transition temperature, cooling the photosensitive glass substrate to transform at least part of the exposed glass to a crystalline material to form a glass-crystalline substrate and etching the glass-crystalline substrate with an etchant solution to form the one or more depressions or through holes for electrical conduction in the device.

Owner:3D GLASS SOLUTIONS INC

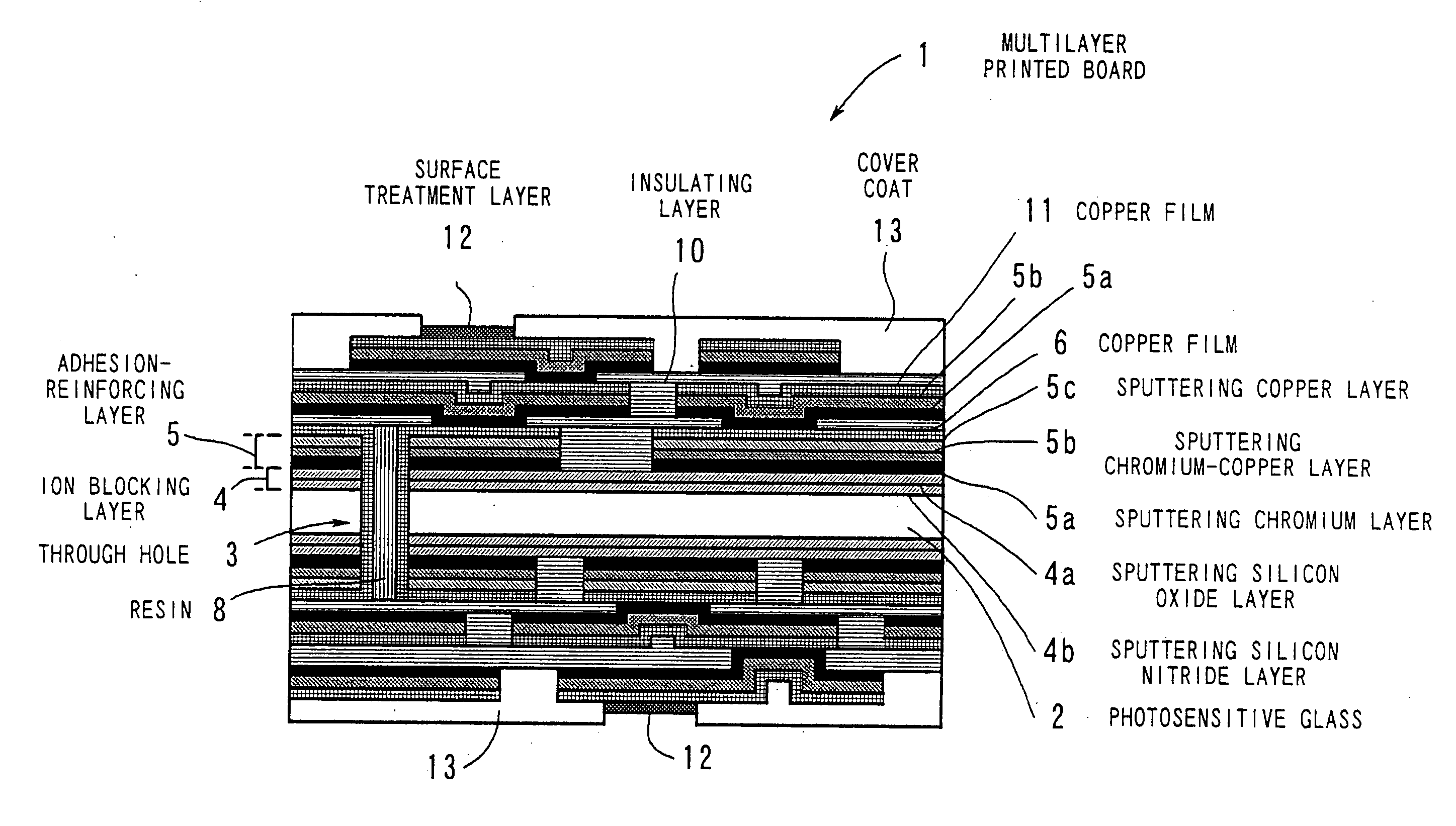

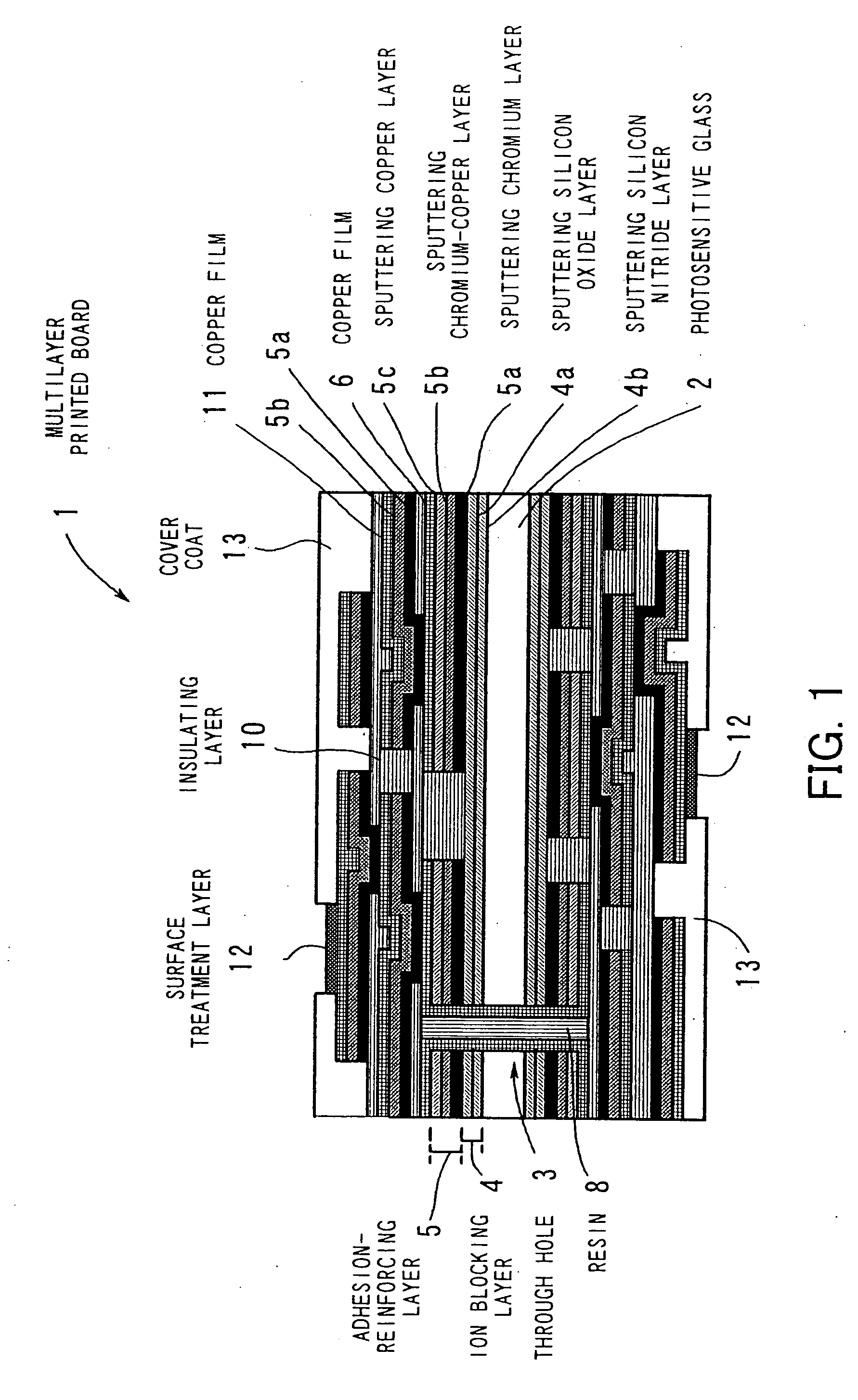

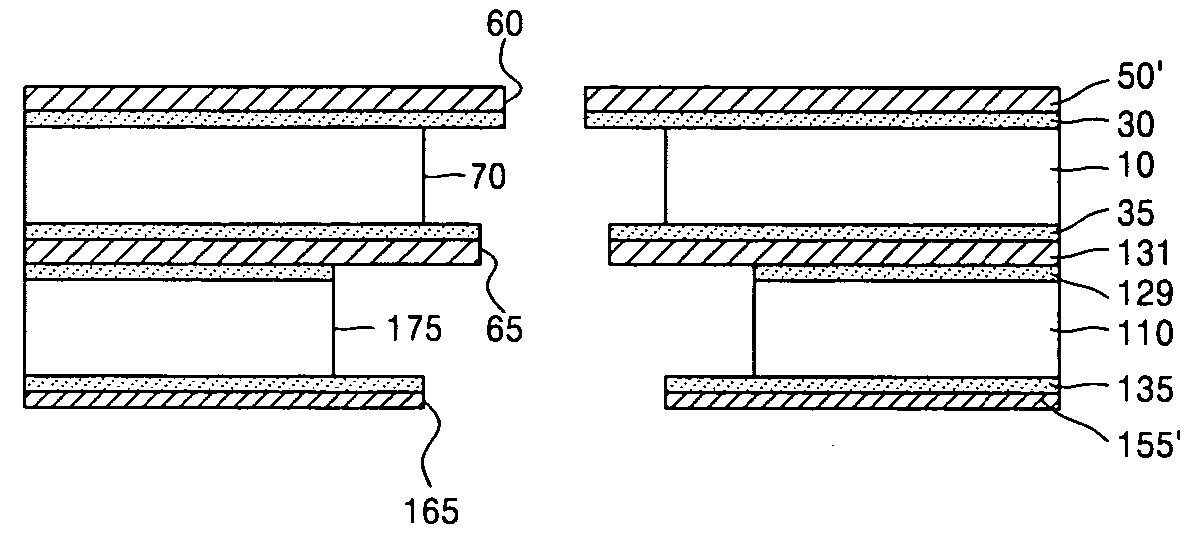

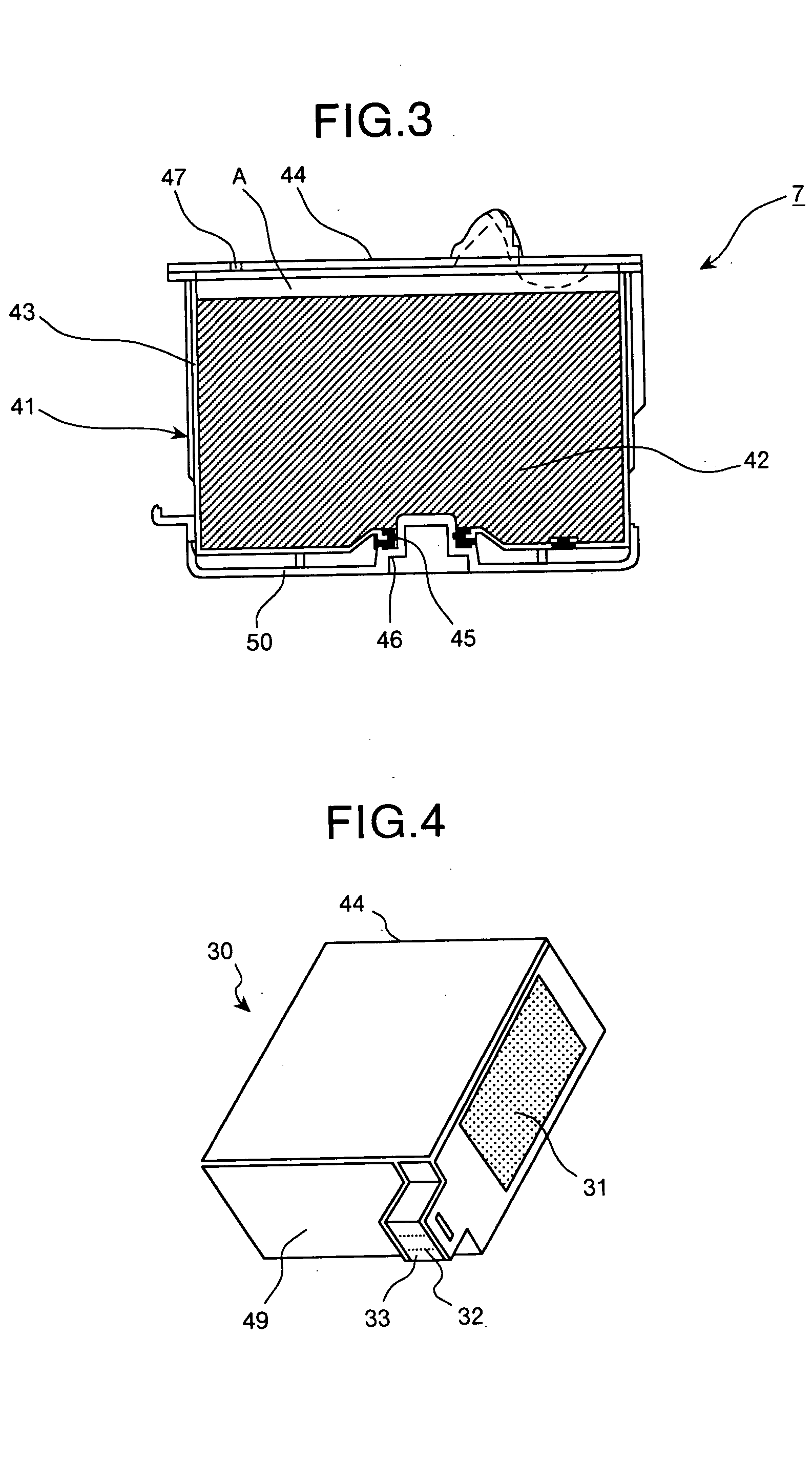

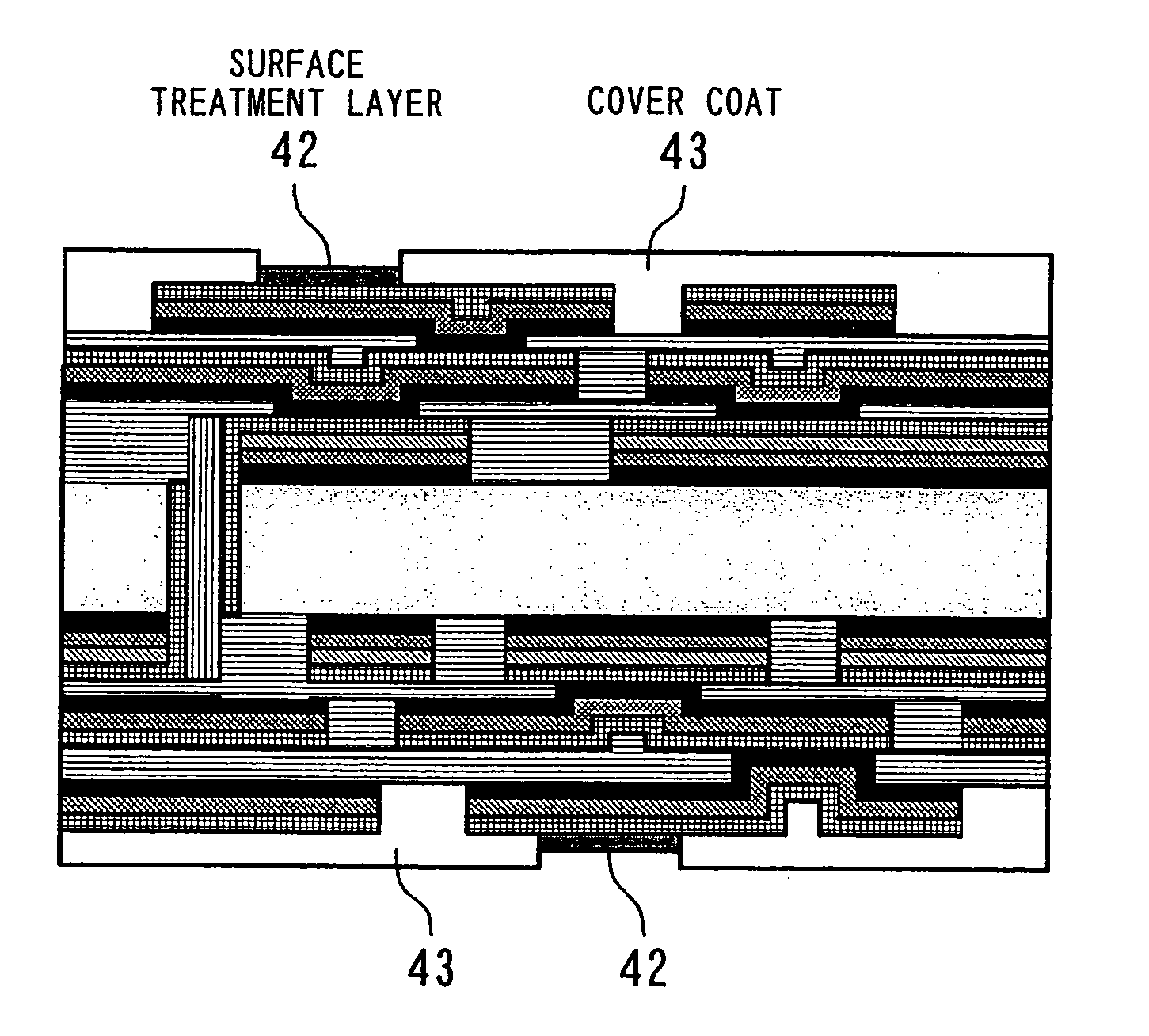

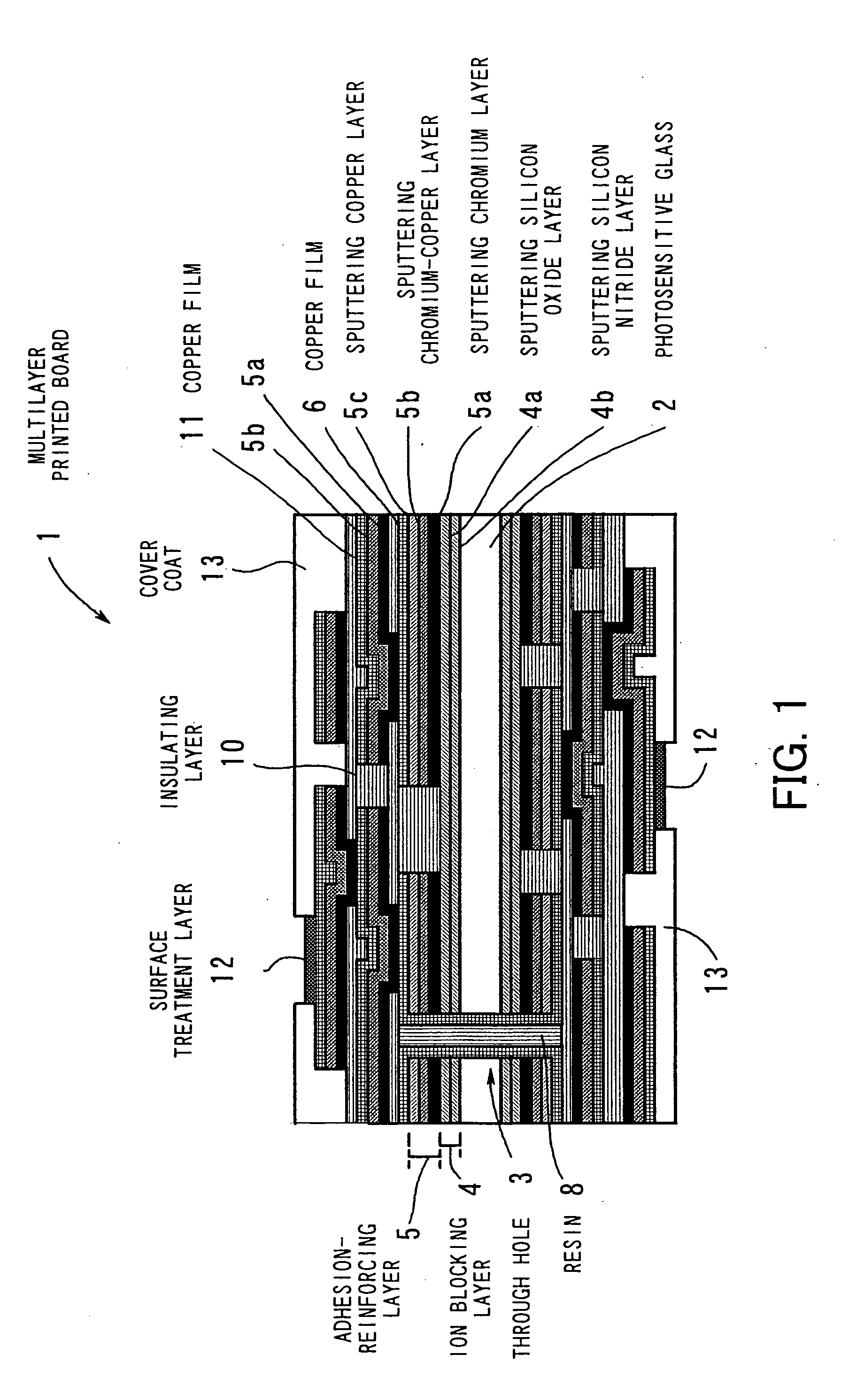

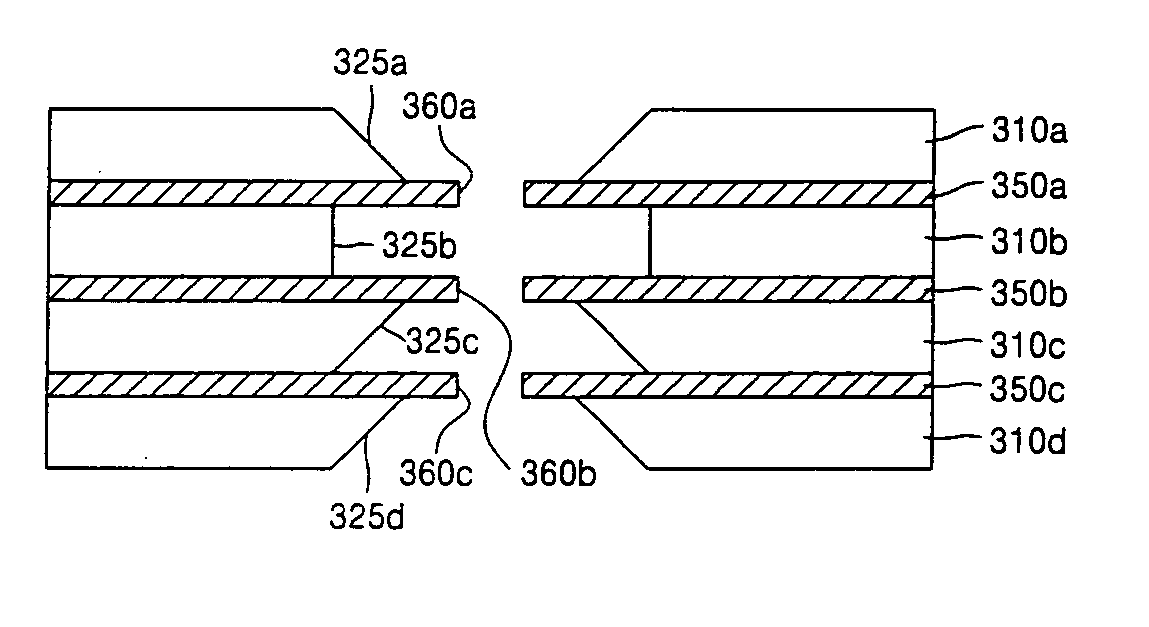

Multilayer printed wiring board and a process of producing same

InactiveUS20060191710A1High densitySemiconductor/solid-state device detailsSolid-state devicesSputteringSilicon oxide

Owner:HOYA CORP

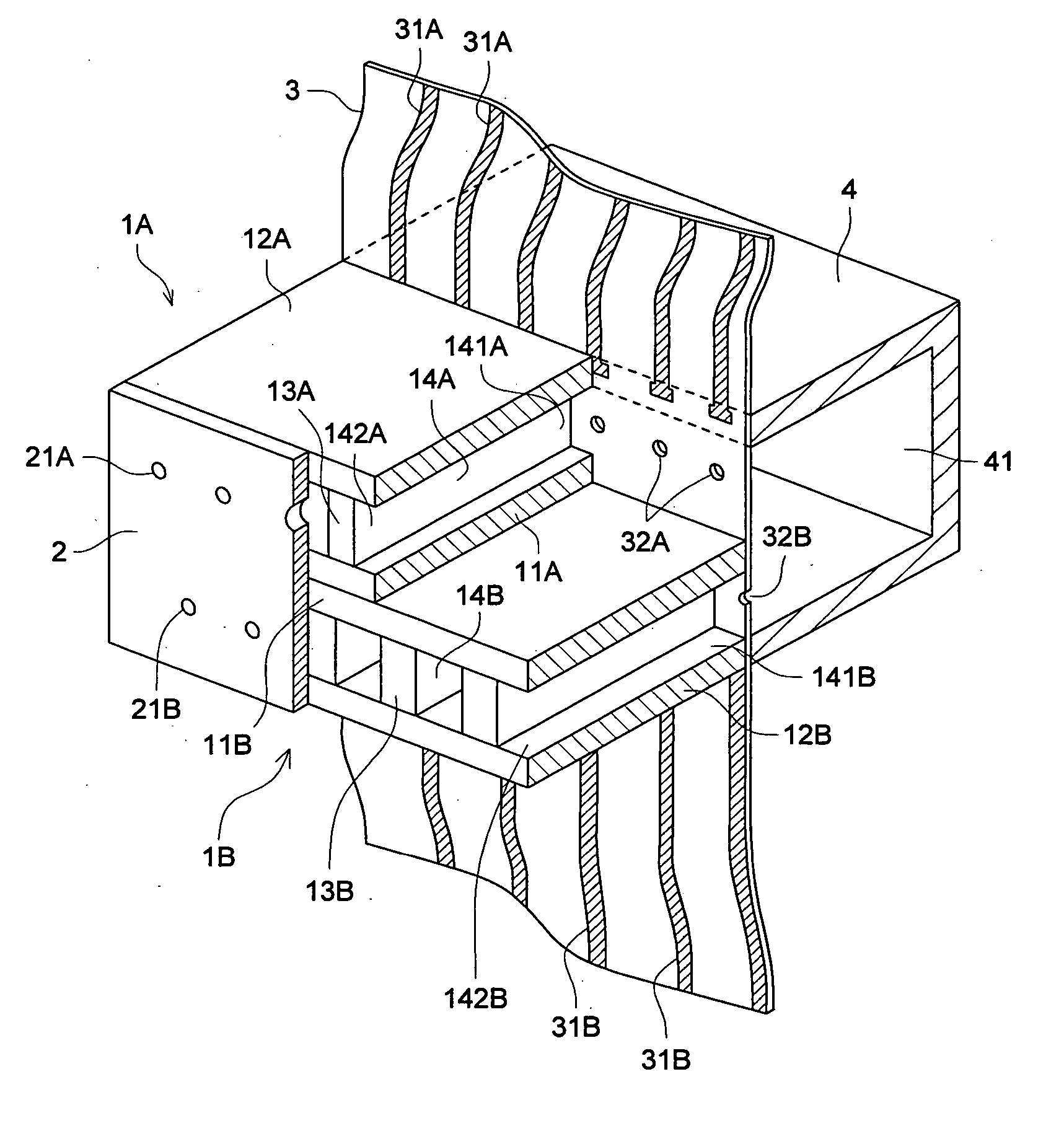

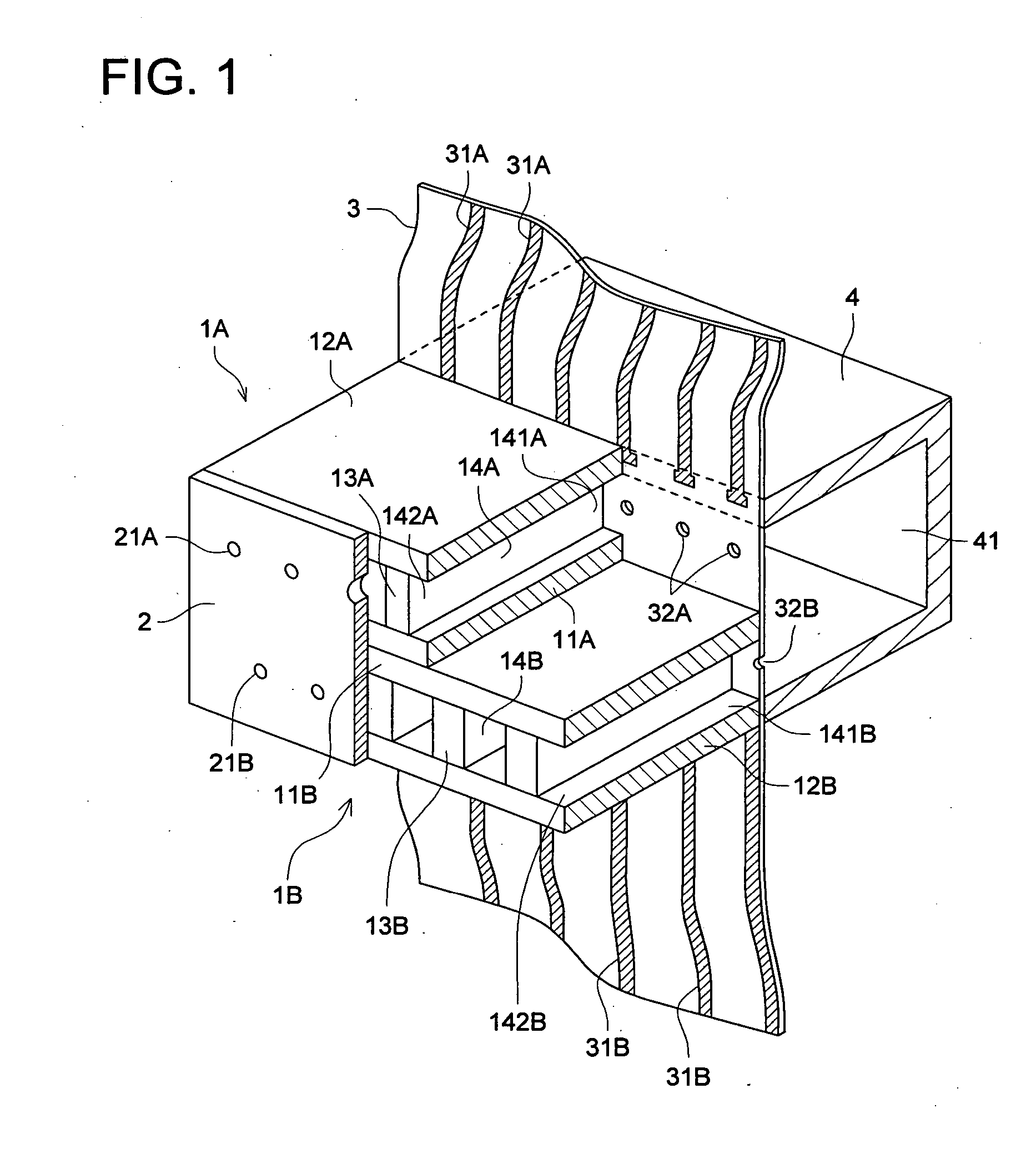

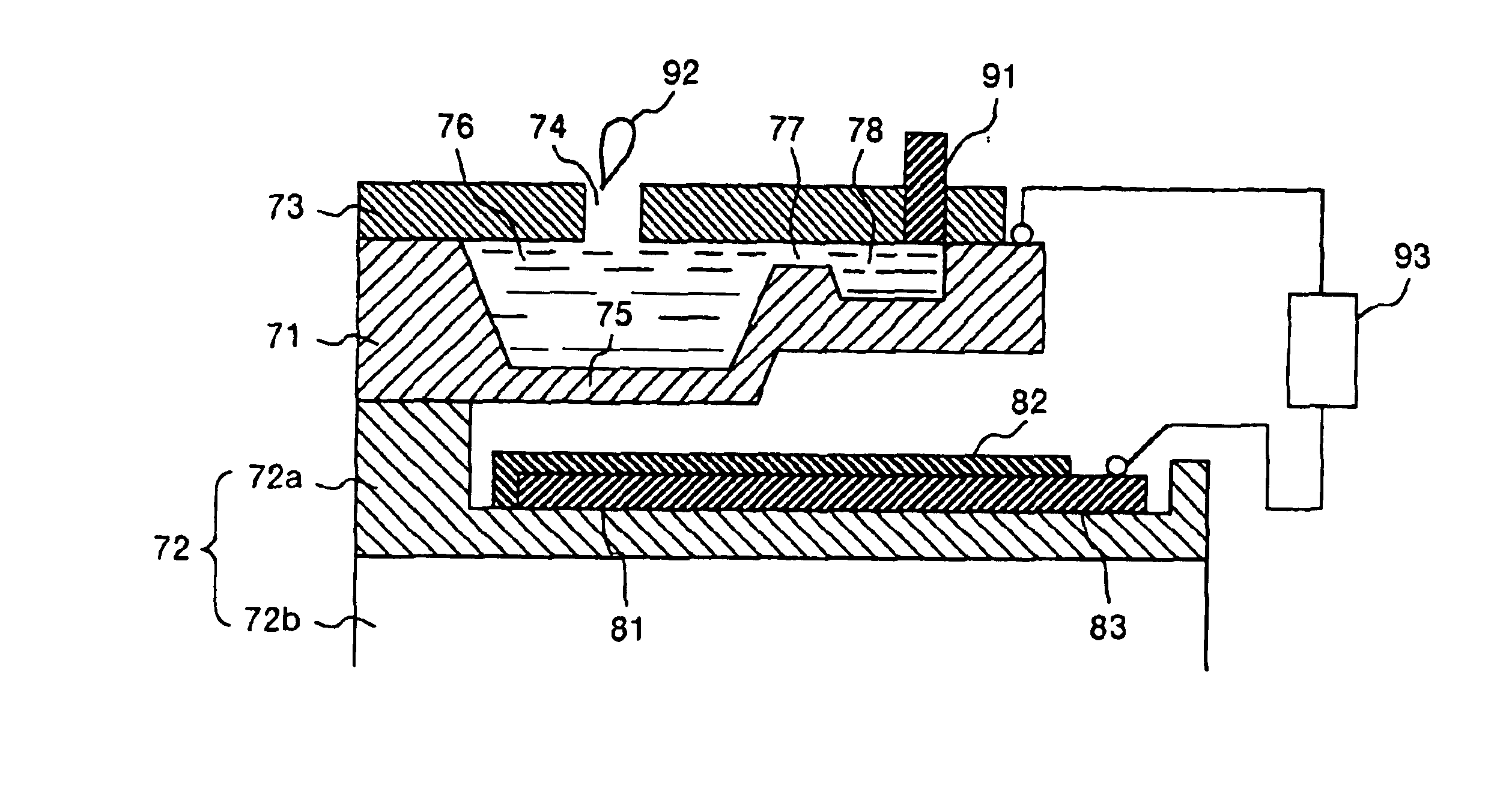

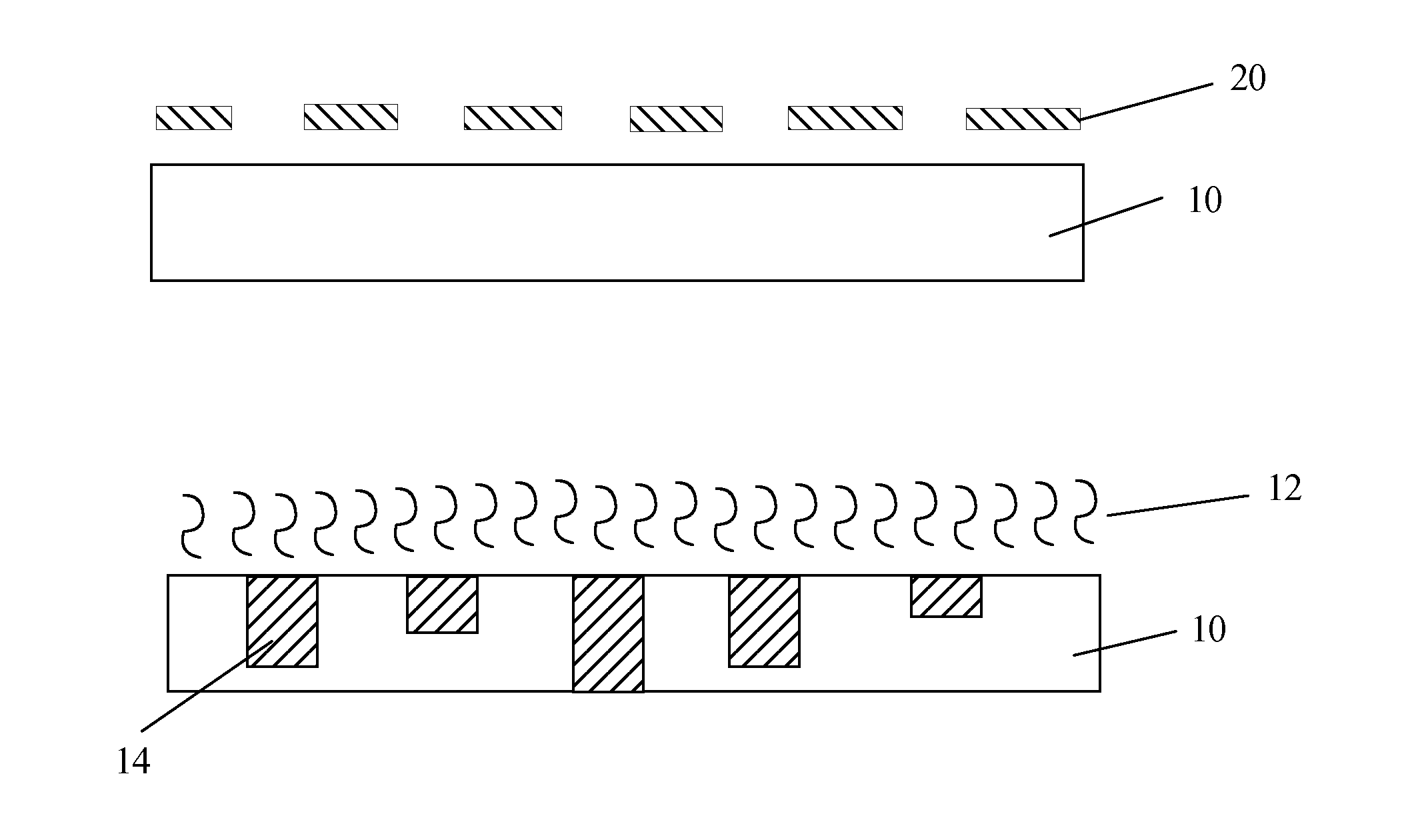

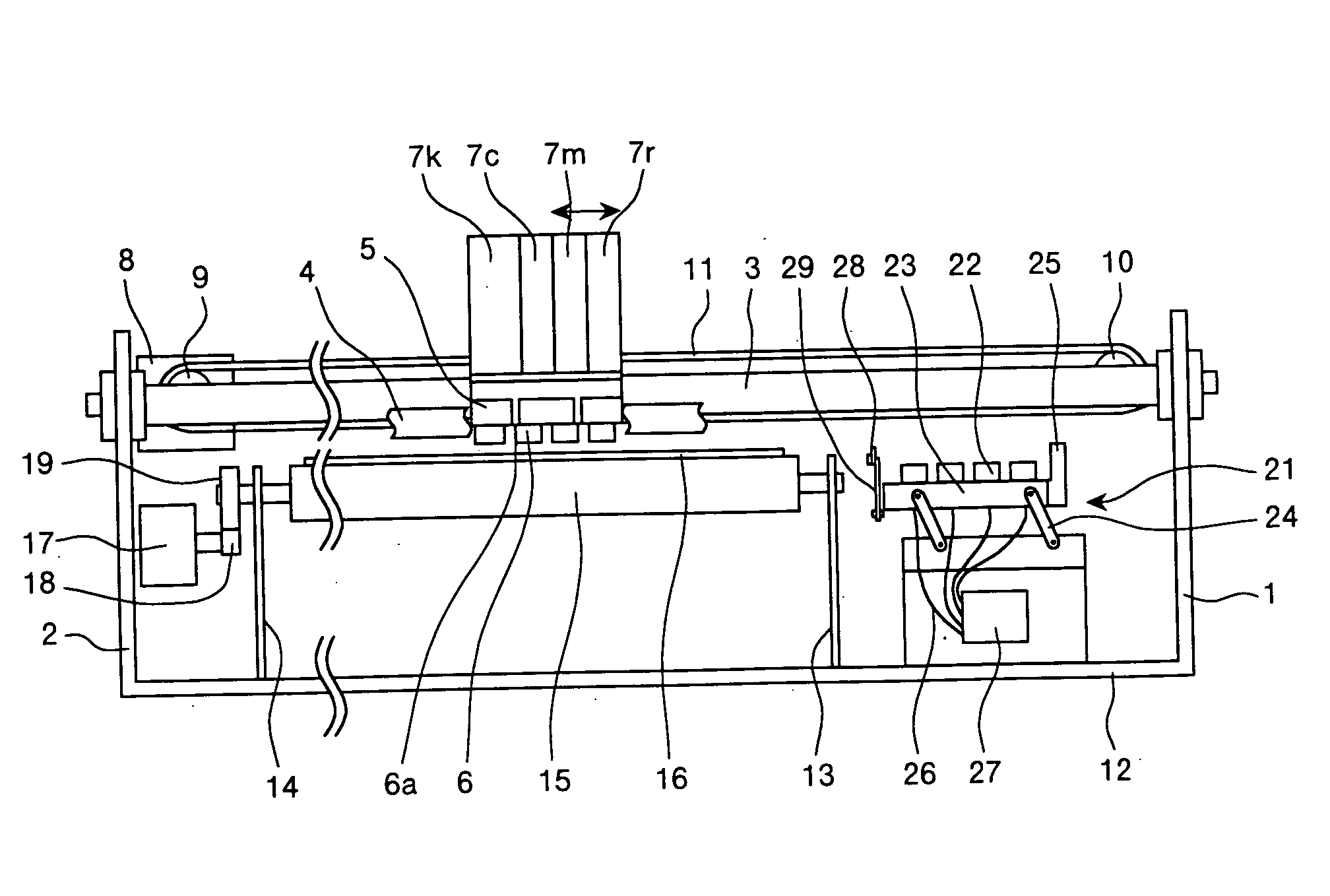

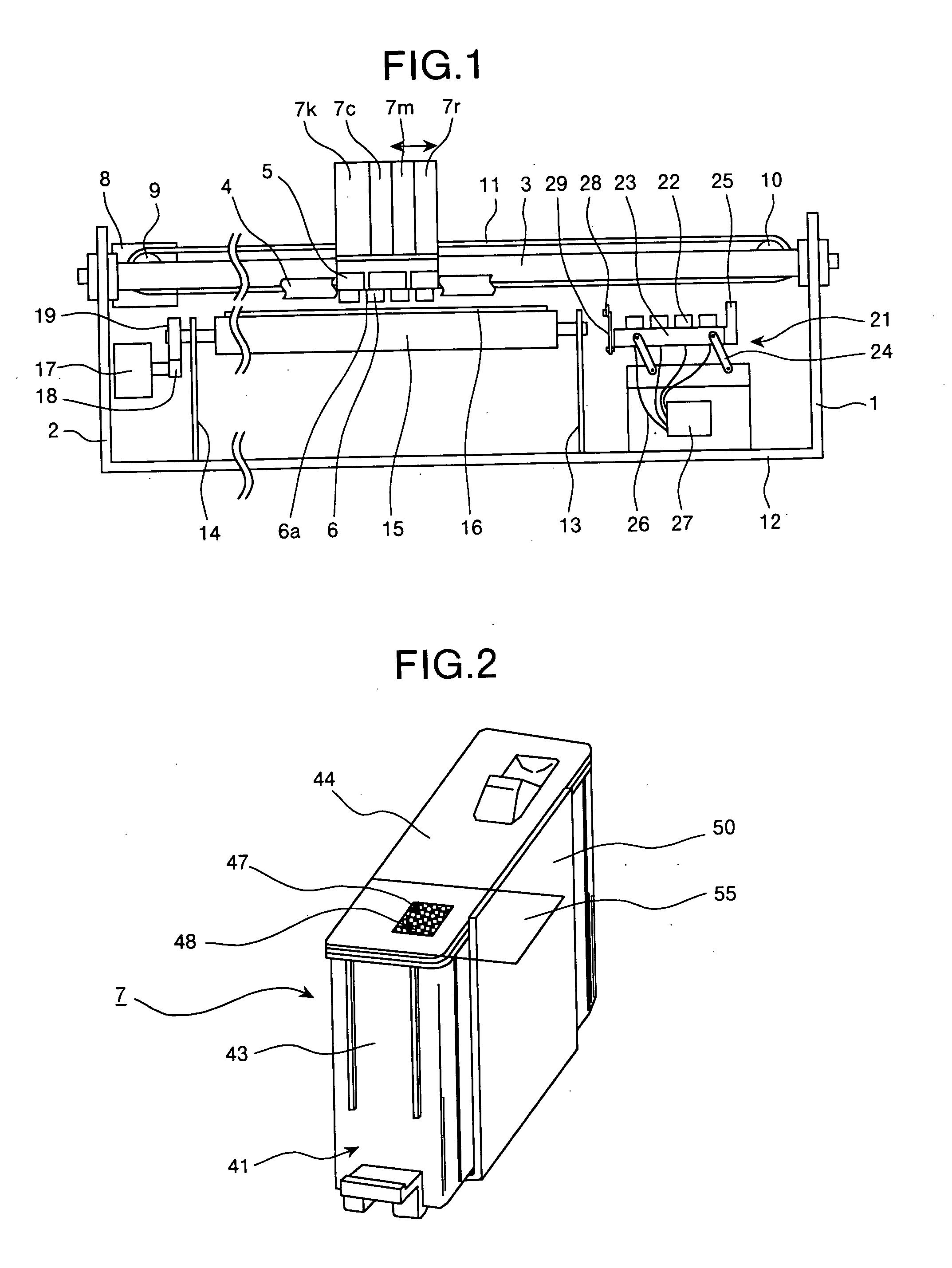

Inkjet print head and manufacturing method thereof

InactiveUS20060017778A1Improved versionSimplifies electrical connectionsInking apparatusElectrical and Electronics engineeringPhotosensitive glass

an inkjet print head wherein the surface (front surface) for ejecting ink droplets coming from an ink channel partitioned by a drive wall composed of a piezoelectric device is arranged opposite to the surface (back surface) for supplying ink coming to the ink channel. The connection electrode for driving the piezoelectric device is pulled out to the back surface, and the back surface is a photosensitive glass substrate wherein the ink feed apertures manufactured by exposure and etching process, and the drive wires electrically connected with the connection electrode are formed.

Owner:KONICA MINOLTA INC

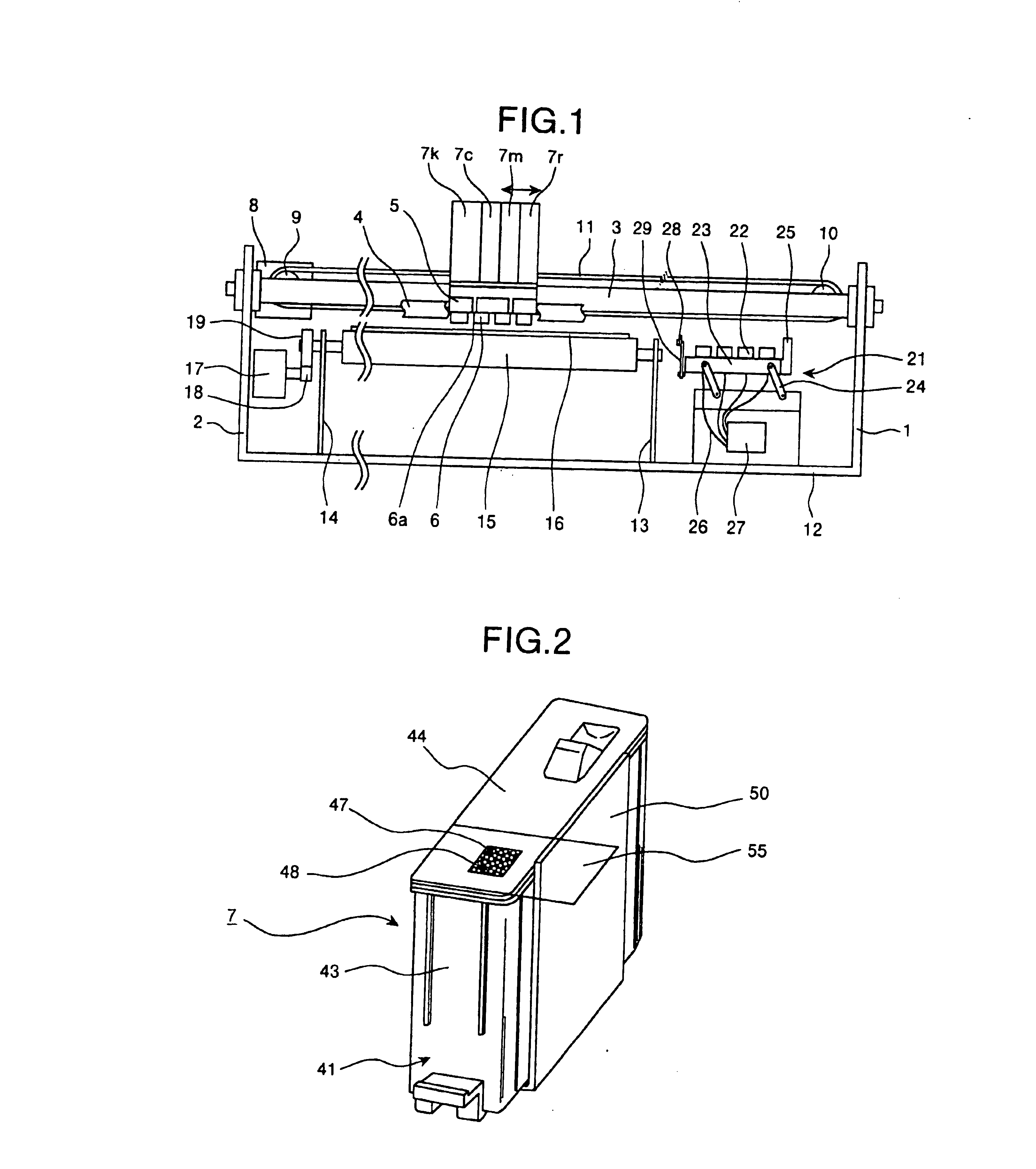

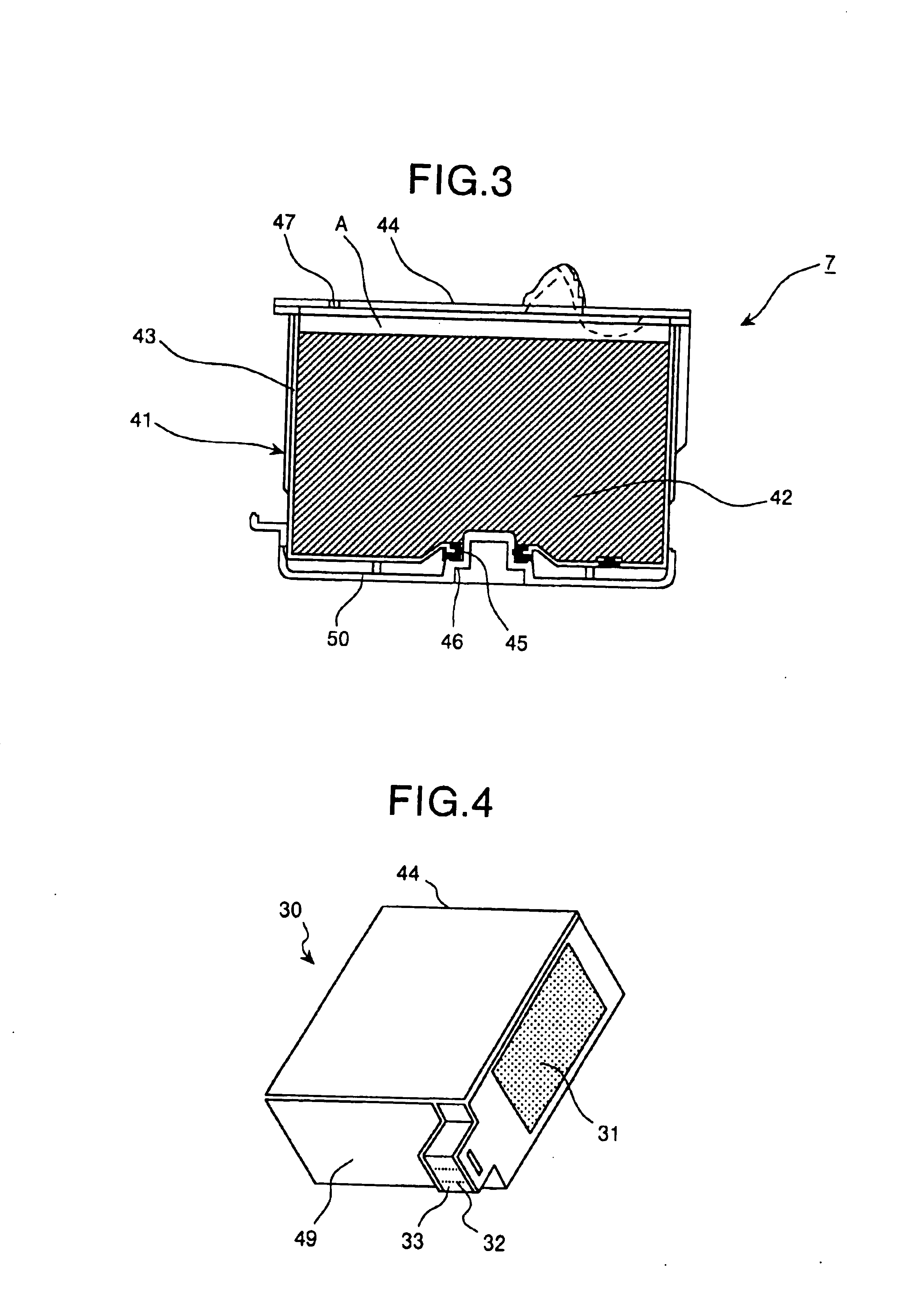

Ink for ink jet recording, ink jet recording method, ink cartridge and ink jet recording apparatus

InactiveUS6899751B2Good dispersibilityImprove stabilityMeasurement apparatus componentsInksPhosphoniumTitanium nitride

An ink for ink jet recording which is used for an ink jet printer in which at least a portion of a member being in contact with the ink is formed by any one of a borosilicate glass, a soda lime glass, a photosensitive glass, single crystal silicon, polysilicon, a silicon oxide film, a titanium nitride film, a zirconium film, a titanium oxide film, and a silicon nitride film, wherein a corrosion inhibitor is contained, and a phosphonium ion represented by the general formula (Formula 1) described below is contained: (wherein in Formula 1, Ra, Rb, Rc and Rd represent a linear, branched, or cyclic alkyl group having 1 to 4 carbon atoms, a hydroxyalkyl group, a halogenated alkyl group and a substituted or non substituted phenyl group, and X− represents a counter ion) is provided.

Owner:RICOH KK

Ink jet print head

Owner:KONICA MINOLTA INC

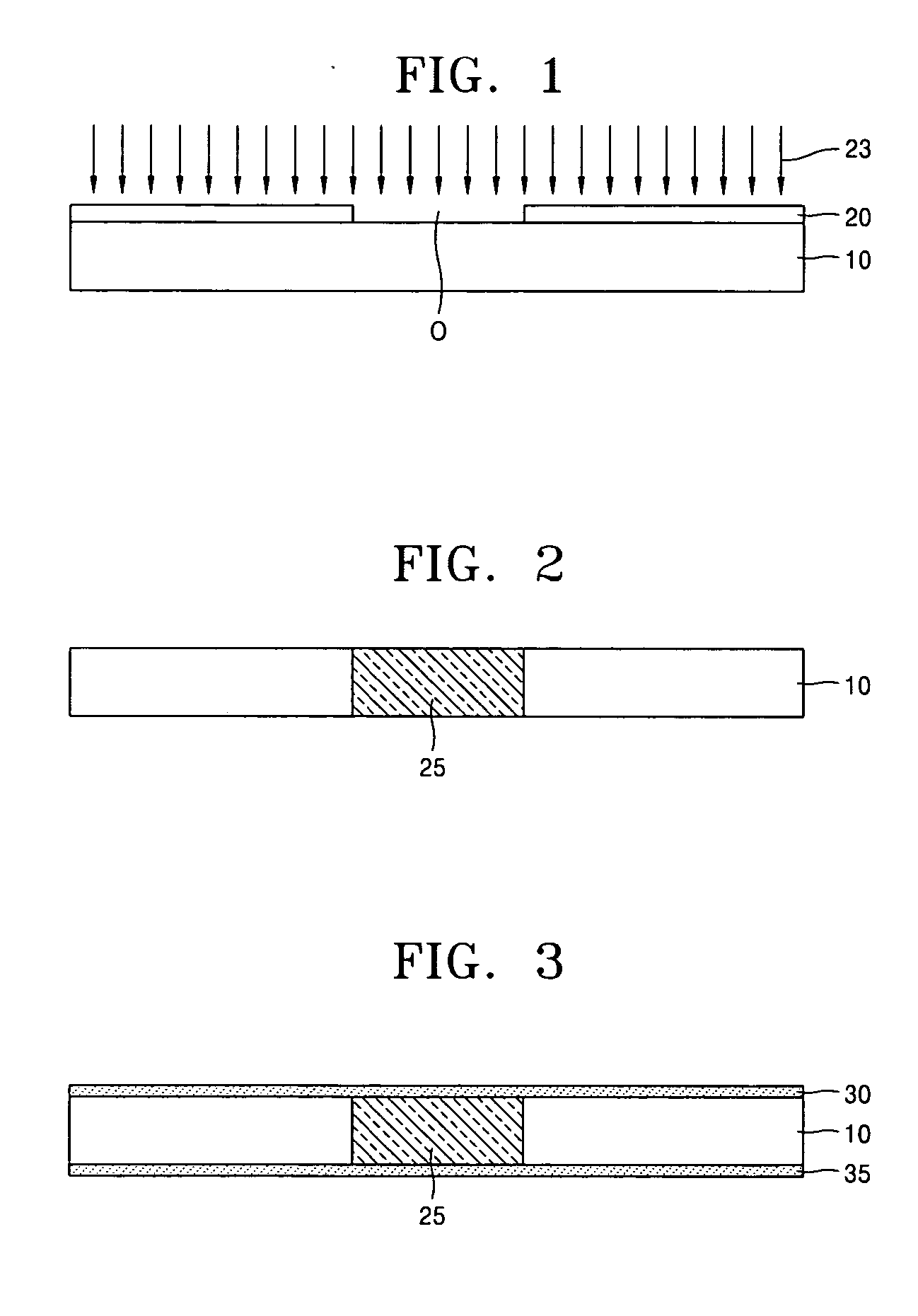

Grayscale lithography of photo definable glass

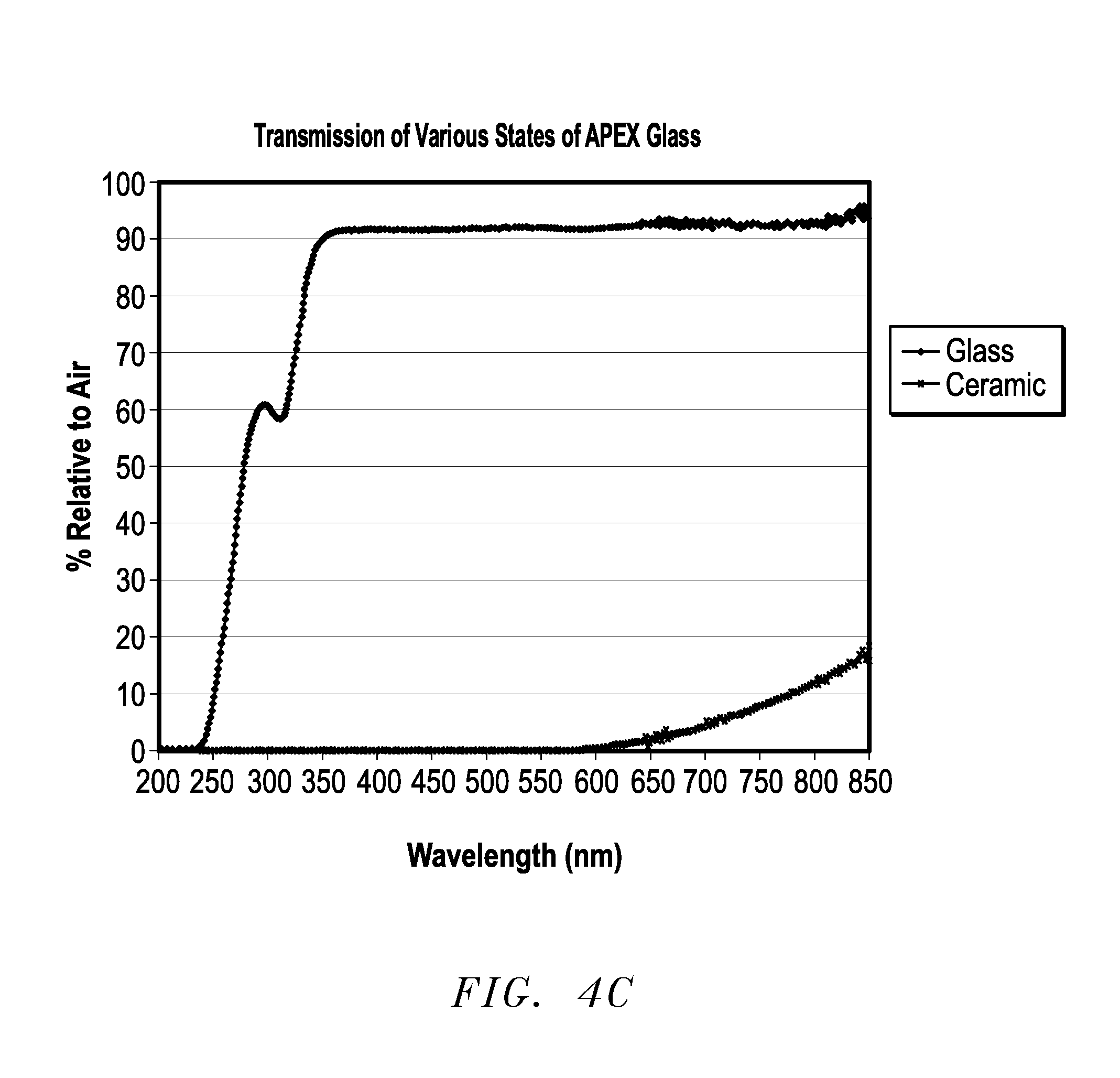

InactiveUS20140272688A1Increased autofluorescenceBiofuelsPhotomechanical exposure apparatusThree dimensional microstructureContinuous tone

A method for forming a three-dimensional microstructure includes providing a photosensitive glass substrate; exposing the photosensitive glass substrate to energy through a continuous tone, variable transmission photomask so as to form opaque portions in the photosensitive glass substrate, each of the opaque portions having one of a variety of depths extending through the entire thickness of the photosensitive glass substrate; and removing the opaque portions so as to form three-dimensional features in the photosensitive glass substrate.

Owner:PHOTRONICS INC

Electron beam lens for micro-column electron beam apparatus and method of fabricating the same

InactiveUS20050087696A1Improve performanceStability-of-path spectrometersLine/current collector detailsThin metalMicro column

Provided is an electron beam lens for a micro-column electron beam apparatus and a method of manufacturing the same. A photosensitive glass substrate is used as a base isolation substrate and a thin metal film is grown by a plating method. Holes through which electron beam passes are formed by a lift off method after forming a resist pattern shaped as a hole on a seed metal layer and plating the thin metal film.

Owner:ELECTRONICS & TELECOMM RES INST

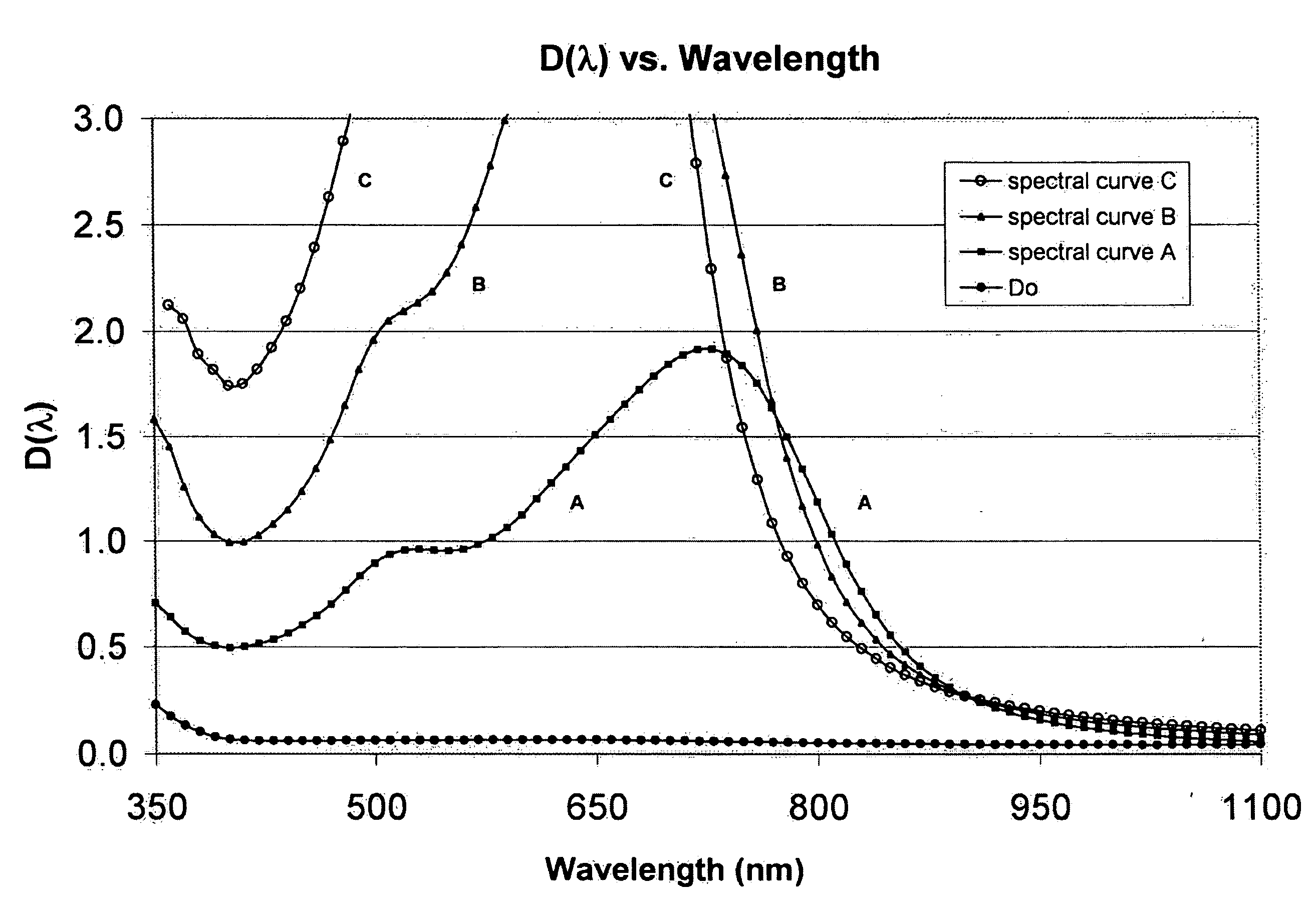

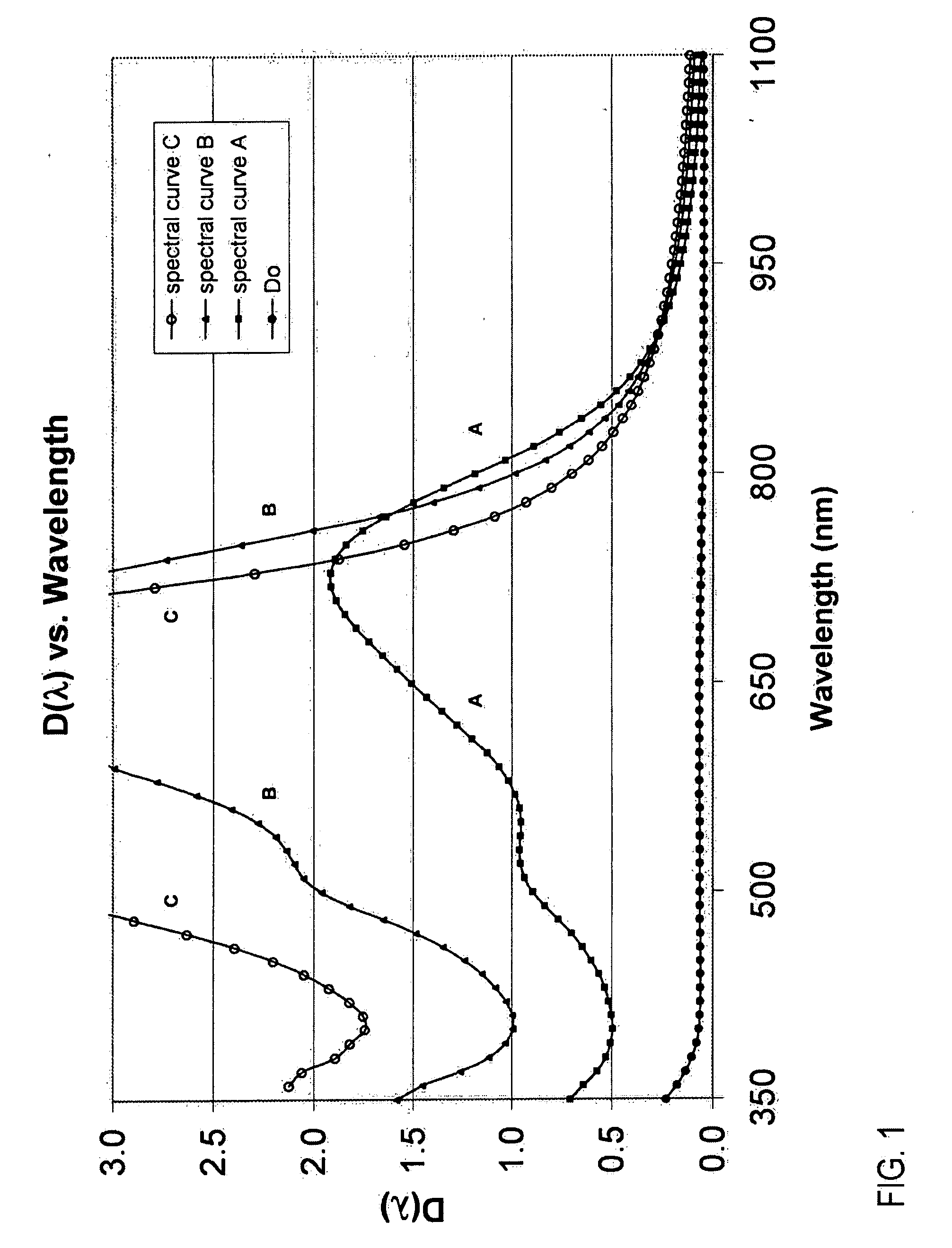

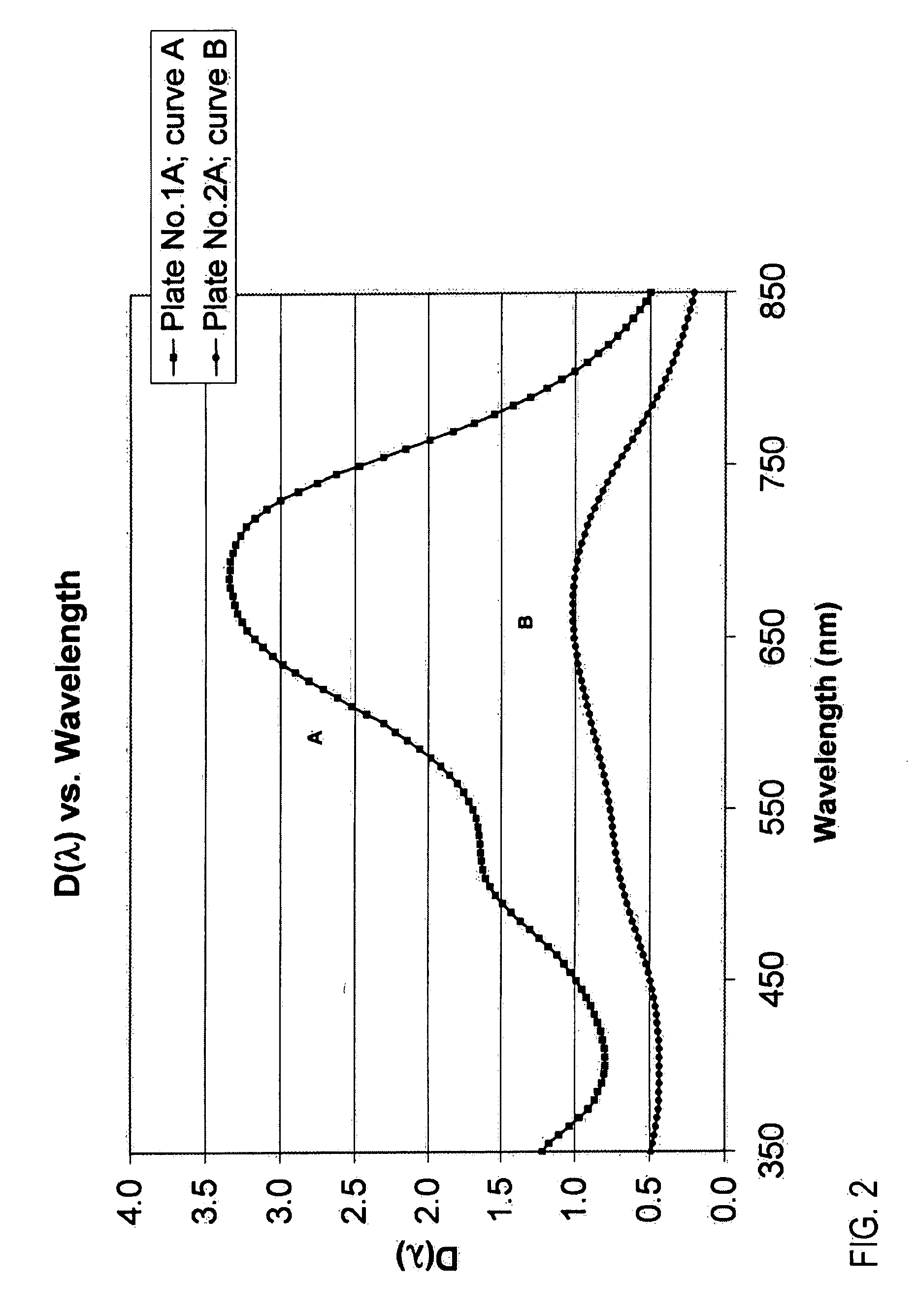

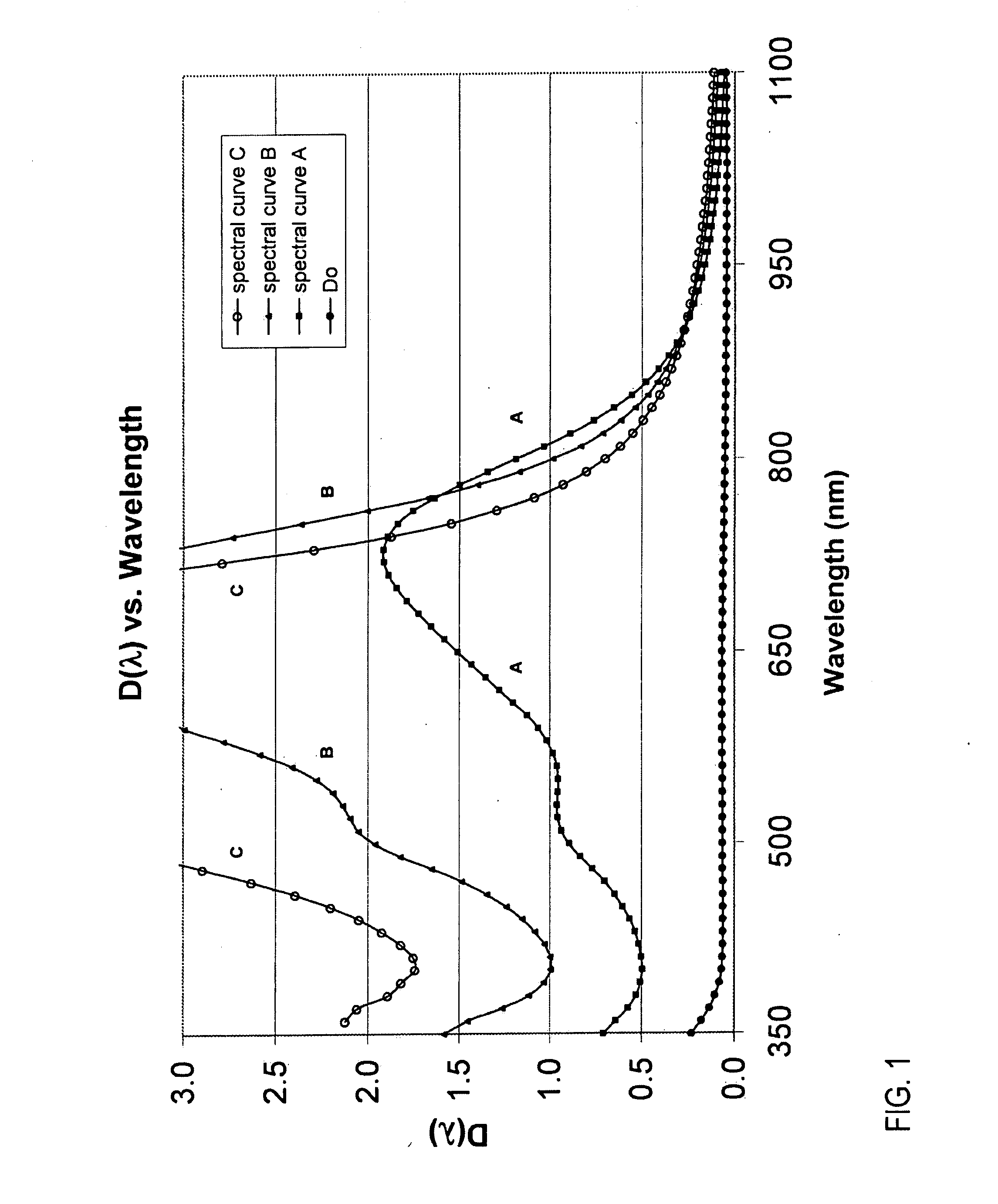

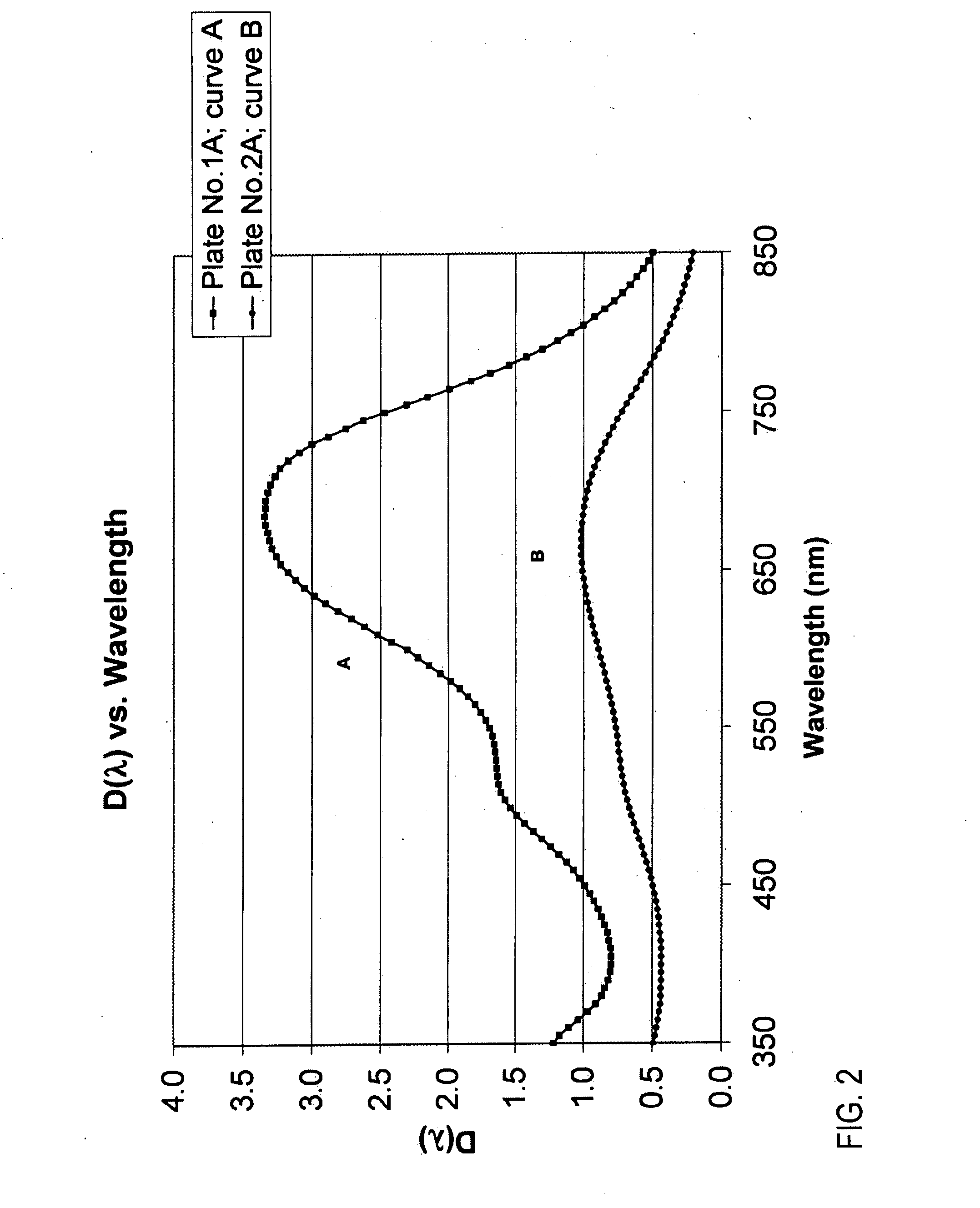

PDR and PBR glasses for holographic data storage and/or computer generated holograms

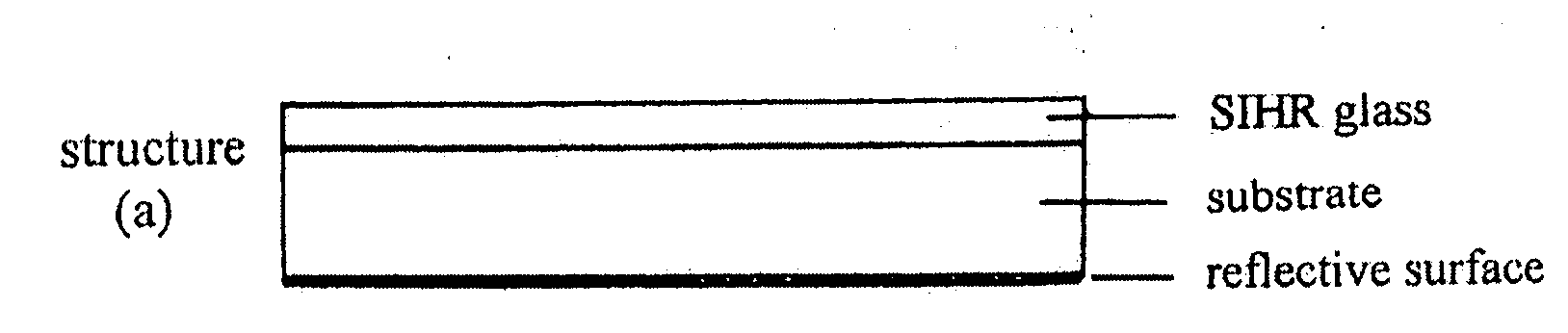

InactiveUS20080254372A1Change the refractive indexPhotomechanical apparatusDigital storageIon exchangeRefractive index

Silicate glasses for storing holographic data and for producing computer-generated holograms, including photo-darkenable-refractive (PDR) and photo-bleachable-refractive (PBR) glasses. In one embodiment, a PBR glass plate contains a photosensitive glass layer of a silver ion-exchanged holographic recording (SIHR) glass, with a base glass composition that has been ion-exchanged in an aqueous ion-exchange solution containing silver ions. The SIHR glass is uniformly darkened with darkening-light radiation, causing a refractive index change in the photosensitive glass layer upon exposure to bleaching-light radiation without any post-exposure steps. In another embodiment, an optical information recording medium includes a PDR glass plate containing SIHR glass optimized for multiplex recording and for reproducing information, which utilizes holography with darkening-light radiation as recording beams. In still another embodiment, an optical information recording medium includes a PBR glass plate containing SIHR glass optimized for multiplex recording and for reproducing information, which utilizes holography with bleaching-light radiation as recording beams.

Owner:CANYON MATERIALS

Methods of Fabricating Photoactive Substrates for Micro-lenses and Arrays

A method of fabrication and device made by preparing a photosensitive glass substrate comprising at least silica, lithium oxide, aluminum oxide, and cerium oxide, masking a design layout comprising form one or more micro lens on the photosensitive glass substrate, exposing at least one portion of the photosensitive glass substrate to an activating energy source, exposing the photosensitive glass substrate to a heating phase of at least ten minutes above its glass transition temperature, cooling the photo sensitive glass substrate to transform at least part of the exposed glass to a crystalline material to form a glass-crystalline substrate and etching the glass-crystalline substrate with an etchant solution to form one or more a micro lens.

Owner:3D GLASS SOLUTIONS INC

Method of making PDR and PBR glasses for holographic data storage and/or computer generated holograms

Methods of making volume phase holograms and / or making computer-generated holograms using silver ion-exchanged silicate glass articles that include a photo-darkenable-refractive (PDR) glass plate and / or a photo-bleachable-refractive (PBR) glass plate. In one embodiment, a method of forming a volume phase hologram includes the steps of making a PBR glass plate that has at least one photosensitive glass layer of a silver ion-exchanged holographic recording (SIHR) glass, and of exposing the photosensitive glass layer to the bleaching-light radiation of laser write beams, causing the volume phase hologram to form in the photosensitive glass layer of the PBR glass plate. The base glass composition of the SIHR glass has been ion-exchanged in an aqueous ion-exchange solution containing silver ions. The SIHR glass is then uniformly darkened with darkening-light radiation. This process causes the photosensitive glass layer of the PBR glass plate to show a change in refractive index upon exposure to the bleaching-light radiation without any post-exposure treatment.

Owner:CANYON MATERIALS

Ink for ink jet recording, ink jet recording method, ink cartridge and ink jet recording apparatus

InactiveUS20050168552A1Good dispersibilityImprove stabilityMeasurement apparatus componentsInksPhosphoniumTitanium nitride

An ink for ink jet recording which is used for an ink jet printer in which at least a portion of a member being in contact with the ink is formed by any one of a borosilicate glass, a soda lime glass, a photosensitive glass, single crystal silicon, polysilicon, a silicon oxide film, a titanium nitride film, a zirconium film, a titanium oxide film, and a silicon nitride film, wherein a corrosion inhibitor is contained, and a phosphonium ion represented by the general formula (Formula 1) described below is contained: (wherein in Formula 1, Ra, Rb, Rc and Rd represent a linear, branched, or cyclic alkyl group having 1 to 4 carbon atoms, a hydroxyalkyl group, a halogenated alkyl group and a substituted or non substituted phenyl group, and X− represents a counter ion) is provided.

Owner:RICOH KK

Multilayer printed wiring board and a process of producing same

InactiveUS20060000640A1High densityInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsSputteringSilicon oxide

A multilayer printed wiring board which permits the formation of fine wiring patterns, thereby increasing the density of wiring patterns. Using photosensitive glass having a coefficient of thermal expansion close to that of a copper film as a core substrate, a through hole is formed in the photosensitive glass by photolithography, a sputtering silicon oxide layer and a sputtering silicon nitride layer are formed to prevent leak of alkali metal ions from the photosensitive glass, a sputtering chromium layer, a sputtering chromium-copper layer and a sputtering copper layer are formed to enhance the adhesion strength between the copper film and the sputtering silicon oxide layer, and a copper film of 1 to 20 μm thick is formed. With resin filled into the interior of the through hole, a wiring layer is patterned by etching, an insulating layer is formed, and the surface is covered with a surface treatment layer and a cover coat.

Owner:HOYA CORP

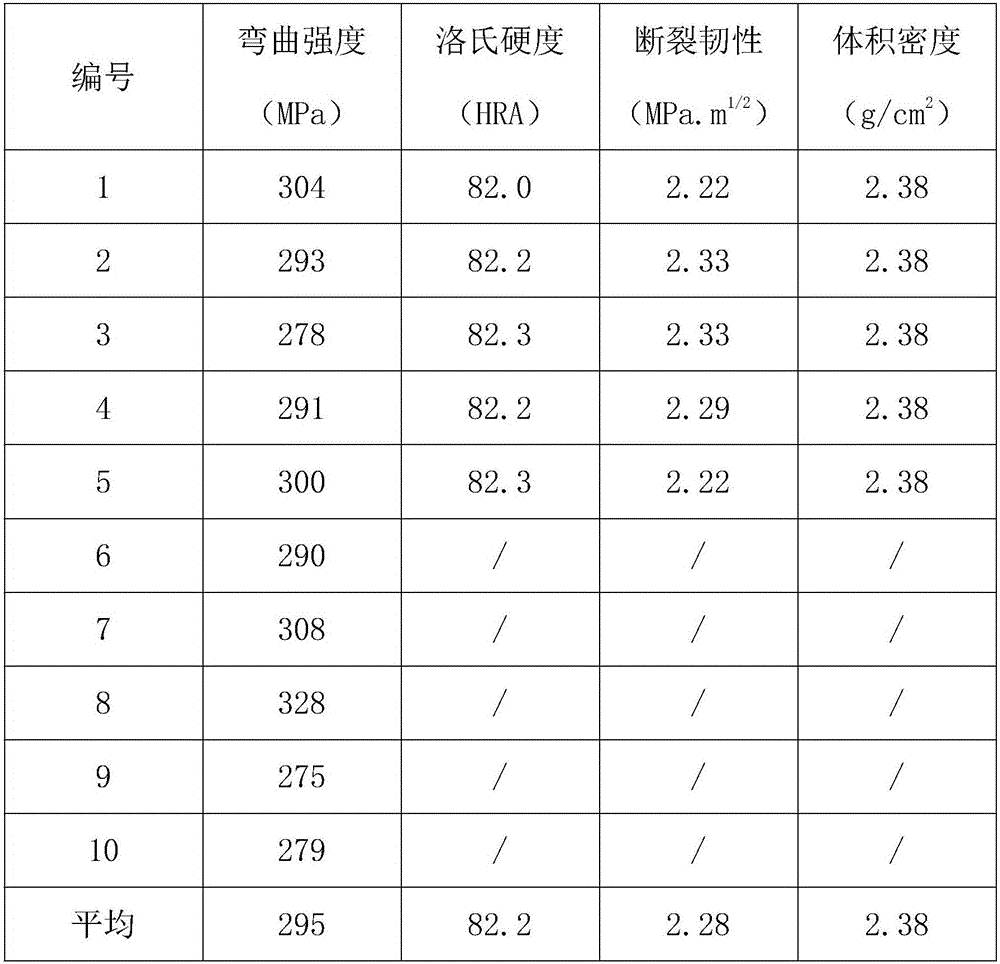

Low-dielectric loss sensitized photosensitive glass and production method

The invention discloses low-dielectric loss sensitized photosensitive glass and a production method belonging to the technical field of glass production. The photosensitive glass is prepared from the following chemical components in percentage by weight: 63-72wt% of SiO2, 6-12wt% of Li2O, 1-5wt% of Na2O, 3-9wt% of K2O, 2-5wt% of Al2O3, 1-4wt% of ZnO, 0.5-0.9wt% of Sb2O3, 0.02-0.06wt% of Ce2O3, 0.09-0.16wt% of Ag2O, 2-5wt% of B2O3, 0.5-2wt% of BaO and / or 0.5-3wt% of CaO and 1-5wt% of MgO. The production method comprises the steps of material preparation, primary preparation of a mixture, ball-mill mixing, melting, molding and annealing treatment. According to the photosensitive glass, the dielectric coefficient at a room temperature or above 1MHz is 4.2-5.6 and the dielectric loss is 2*10<-3> to 4*10<-3>. The low-dielectric loss sensitized photosensitive glass has the characteristics that the strength and the photochemical stability of a glass body of the un-sensitized part are high, the dielectric coefficient and the dielectric loss during high-frequency working are low, the stability during working is high, the etching depth-to-width ratio of the sensitized glass is high and the production process is simple and convenient.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

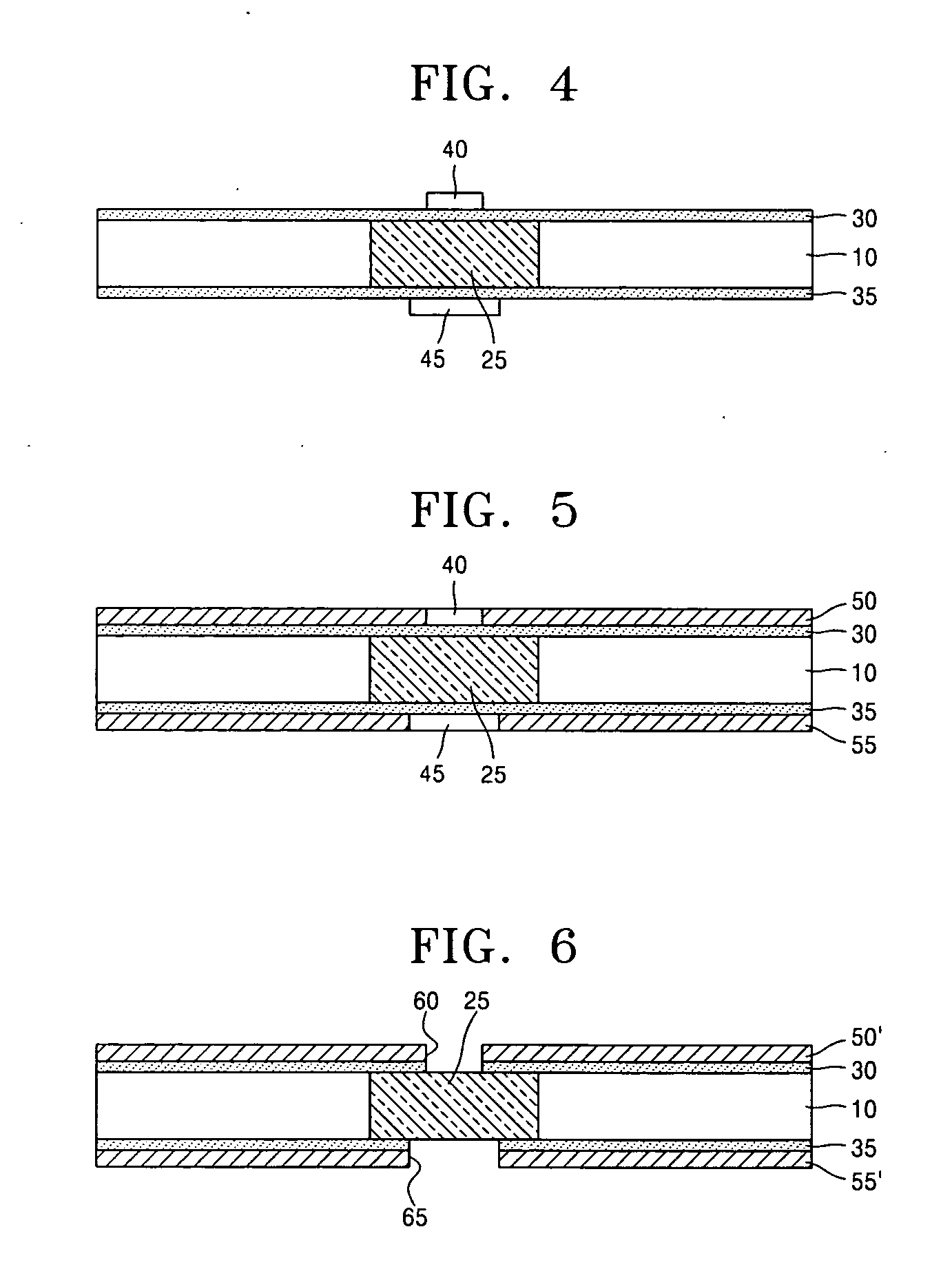

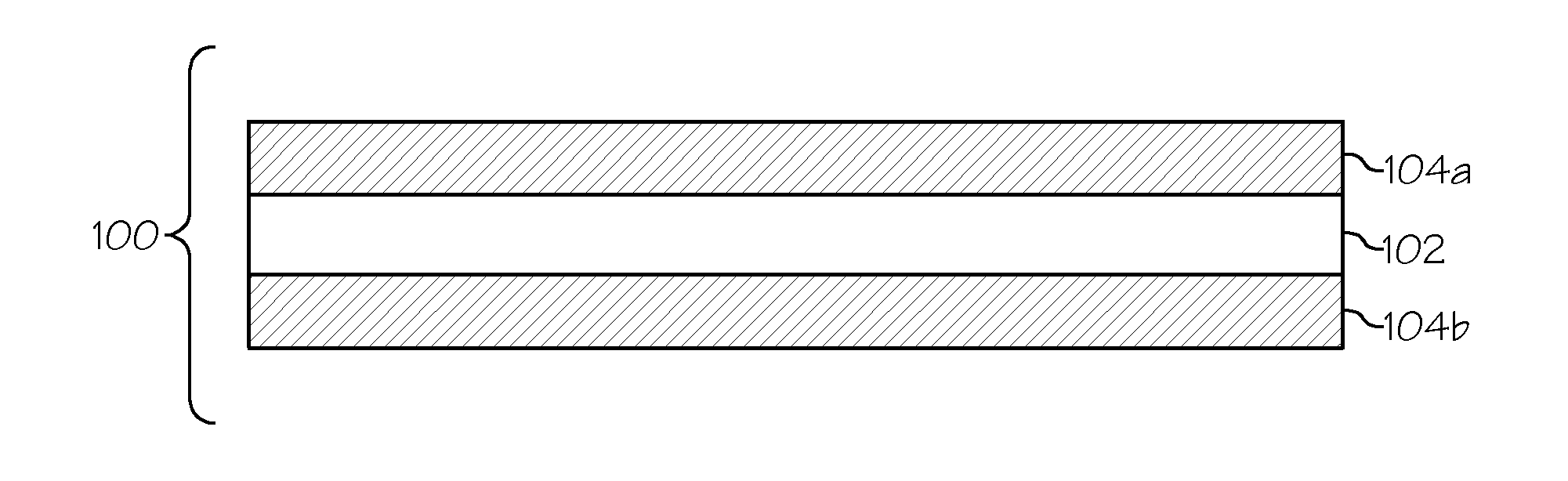

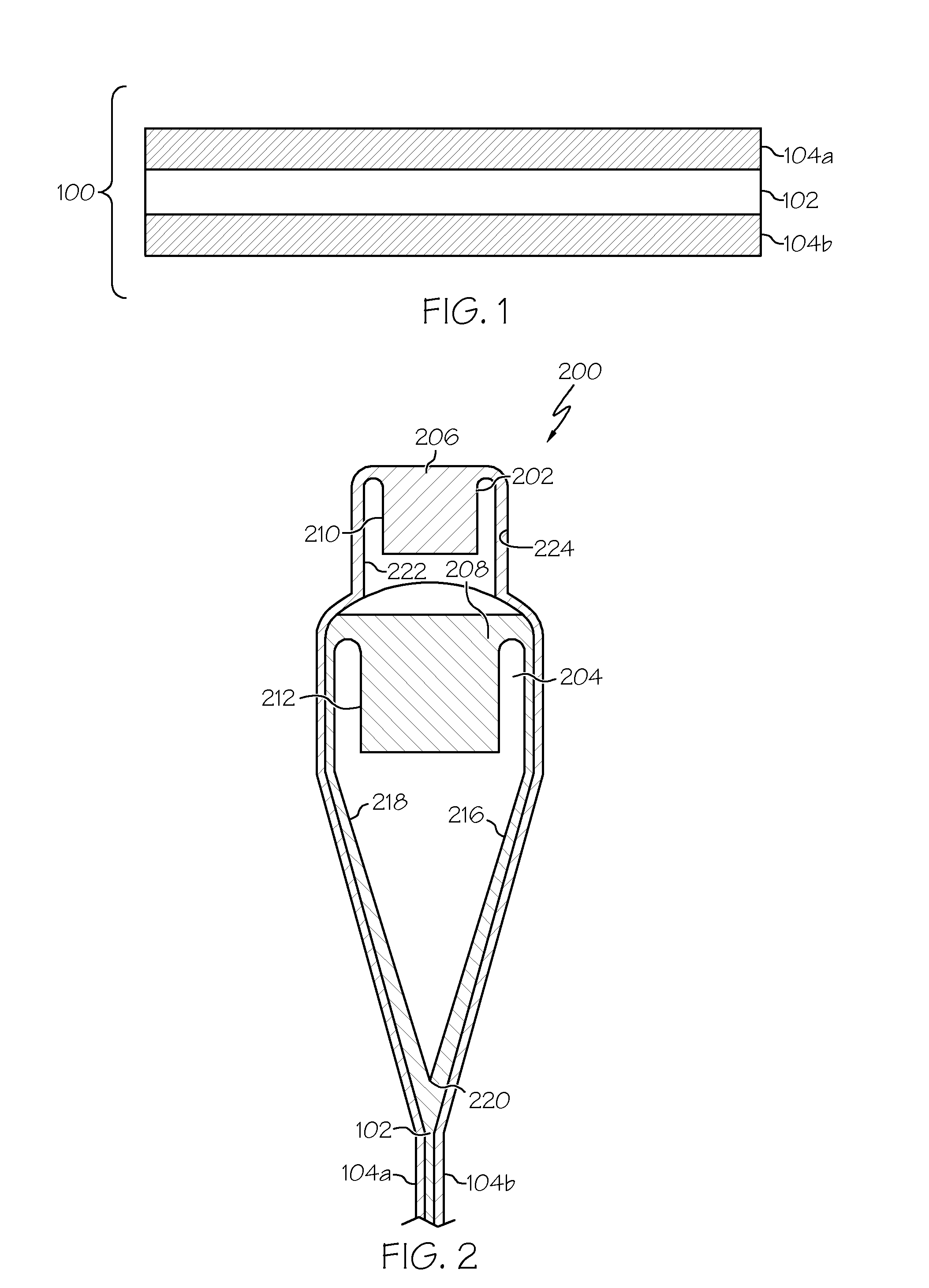

Compressively stressed laminated glass article via photosensitive glass and method of making the article

ActiveUS20150291468A1Simple structureGlass forming apparatusGlass/slag layered productsPhotosensitive glassLaminated glass

Laminated articles comprised of glass core and clad layers, more specifically, to compressively stressed laminated articles comprising a glass core sandwiched between first and second clad layers, the clad layers being formed from photosensitive glass.

Owner:CORNING INC

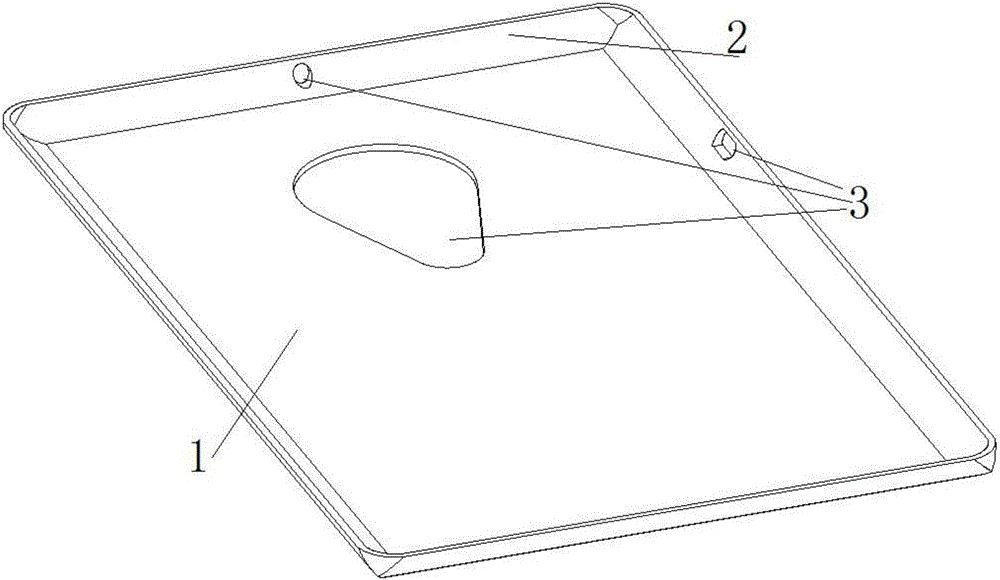

Method for preparing photosensitive glass-ceramics mobile phone shell

PendingCN106830678AImprove performanceLess investmentGlass reforming apparatusTelephone set constructionsWire cuttingSilicon dioxide

The invention discloses a method for preparing a photosensitive glass-ceramics mobile phone shell and relates to application of photosensitive glass-ceramics. The method disclosed by the invention comprises the following steps: configuring silicon dioxide, lithium carbonate, potassium nitrate, alumina, calcium oxide and zirconium serving as raw materials, and placing the raw materials in a melting furnace to be molten into a solution; performing cast molding on the solution, immediately feeding the solution into an annealing furnace, performing annealing treatment on the solution to become a preform body; performing specification slicing on the preform body by using a commercially available wire cutting machine; performing rough polishing on the slices, and performing punching treatment to obtain rectangular standard slices; performing preset data hot-bending shaping on four edges of the rectangular standard slices on a hot press so as to obtain a four-fold crude product; performing illumination treatment on the crude product; performing crystallization treatment on the illuminated crude product in a calcining furnace; performing fine polishing, thereby obtaining the finished mobile phone shell. According to the method disclosed by the invention, the utilization range is wide, the thickness can reach 0.15 mm, and the mobile phone shell is wear / corrosion-resistant, high in electric conductivity and high in heat conductivity coefficient, and has enough strength to be prevented from being smashed to pieces. In addition to the mobile phone shells, the technology disclosed by the invention can be further applied to circuit boards, aerospace engineering and military defense projects.

Owner:王月辉

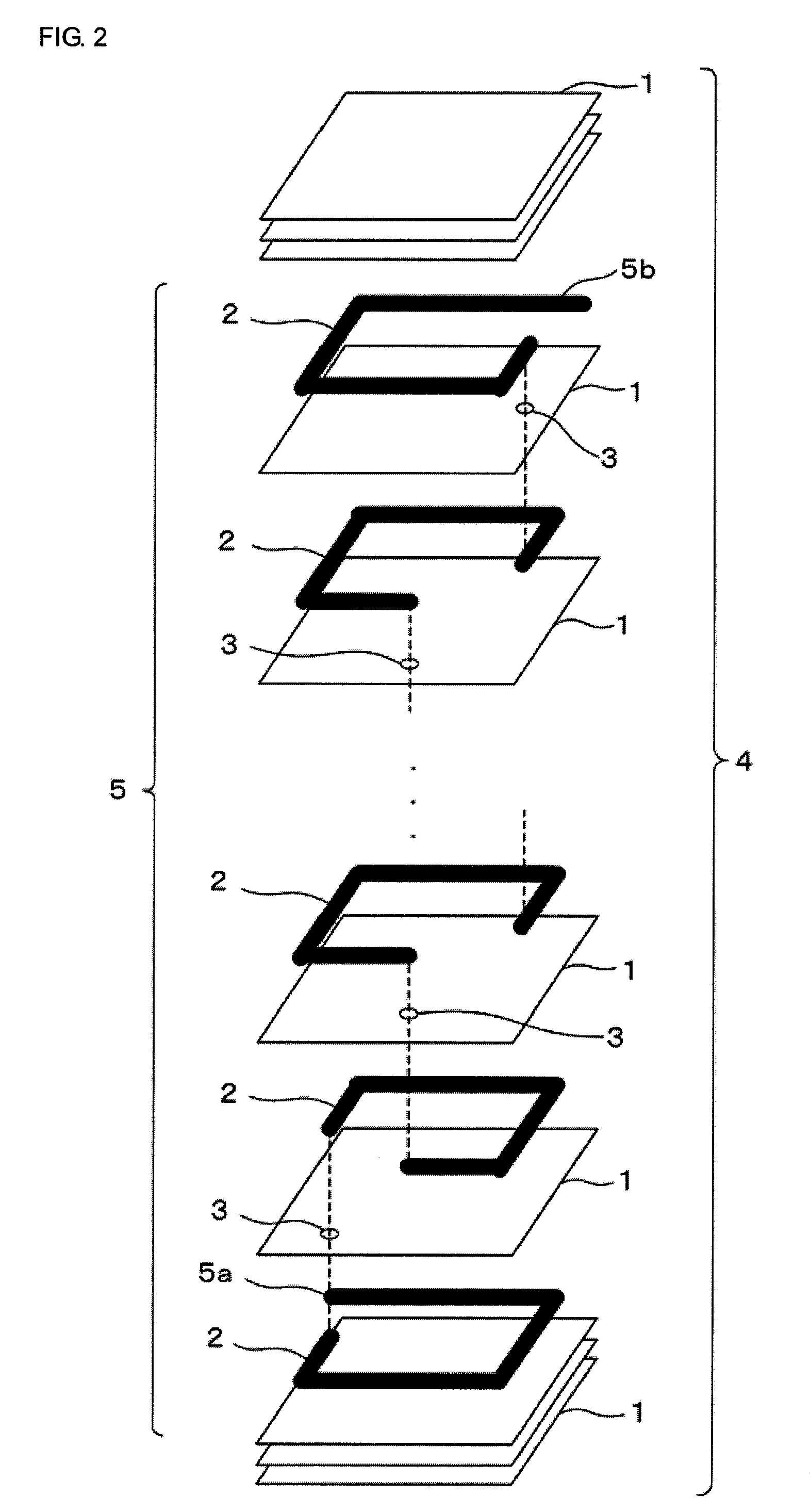

Photosensitive glass paste and multilayer wiring chip component

ActiveUS20090283306A1Suppress generationImprove wettabilitySemiconductor/solid-state device detailsSolid-state devicesMetallurgyMaterials science

A photosensitive glass paste that can be fired at a low temperature for a short period of time and that can suppress generation of voids and diffusion of Ag in glass layers formed by firing, and a high-performance multilayer wiring chip component manufactured by using the above photosensitive glass paste are provided. As a sintering aid glass which is combined with a ceramic aggregate and a primary glass, a glass having a contact angle to the ceramic aggregate smaller than that of the primary glass to the ceramic aggregate is used, and the content of the sintering aid glass is set to 5 to 10 percent by volume of the inorganic component. As the sintering aid glass, a glass containing SiO2, B2O3, CaO, Li2O, and ZnO at a predetermined ratio is preferably used. As the primary glass, a glass containing 70 to 90 percent by weight of SiO2, 15 to 20 percent by weight of B2O3, and 1 to 5 percent by weight of K2O can be used.

Owner:MURATA MFG CO LTD

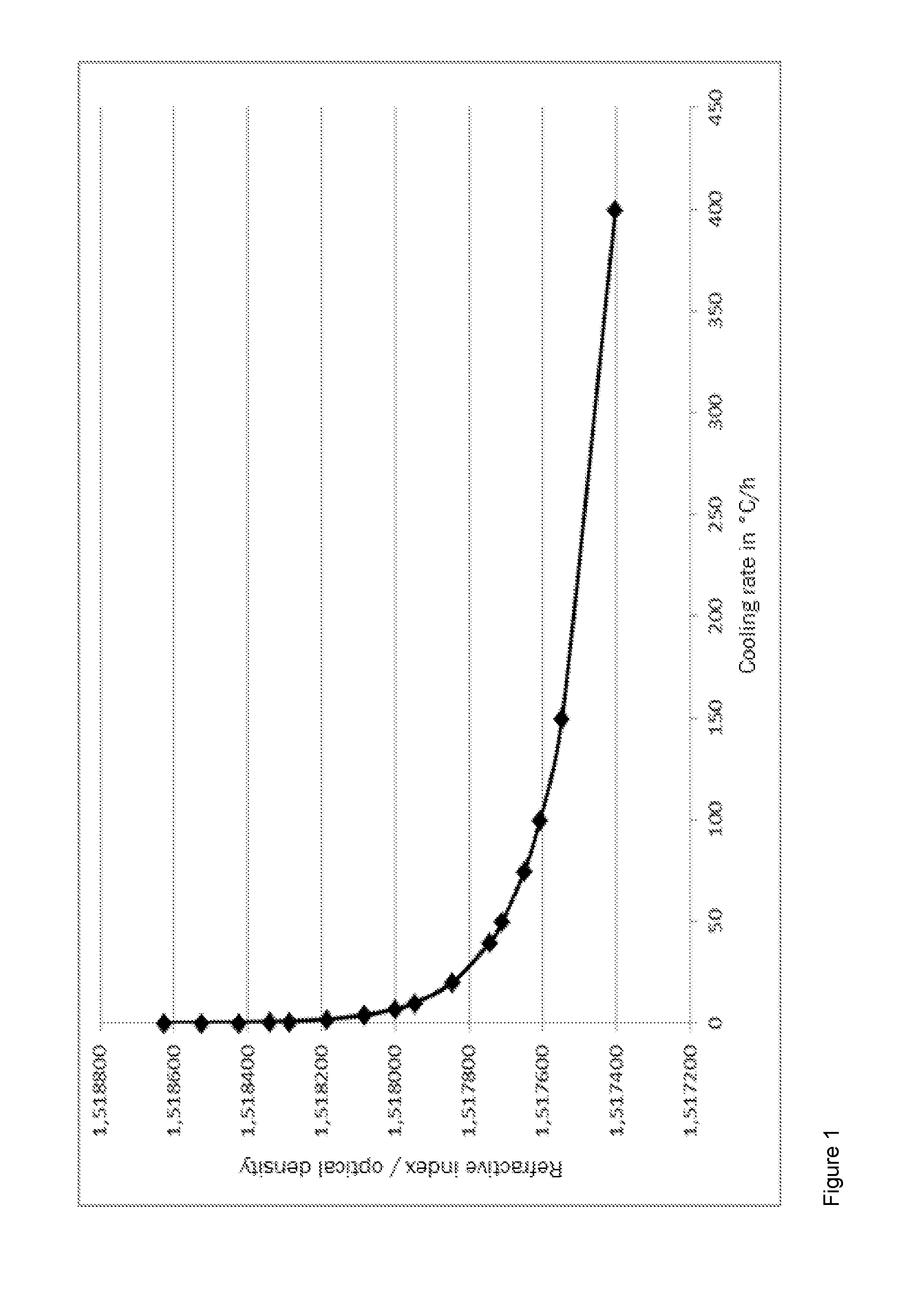

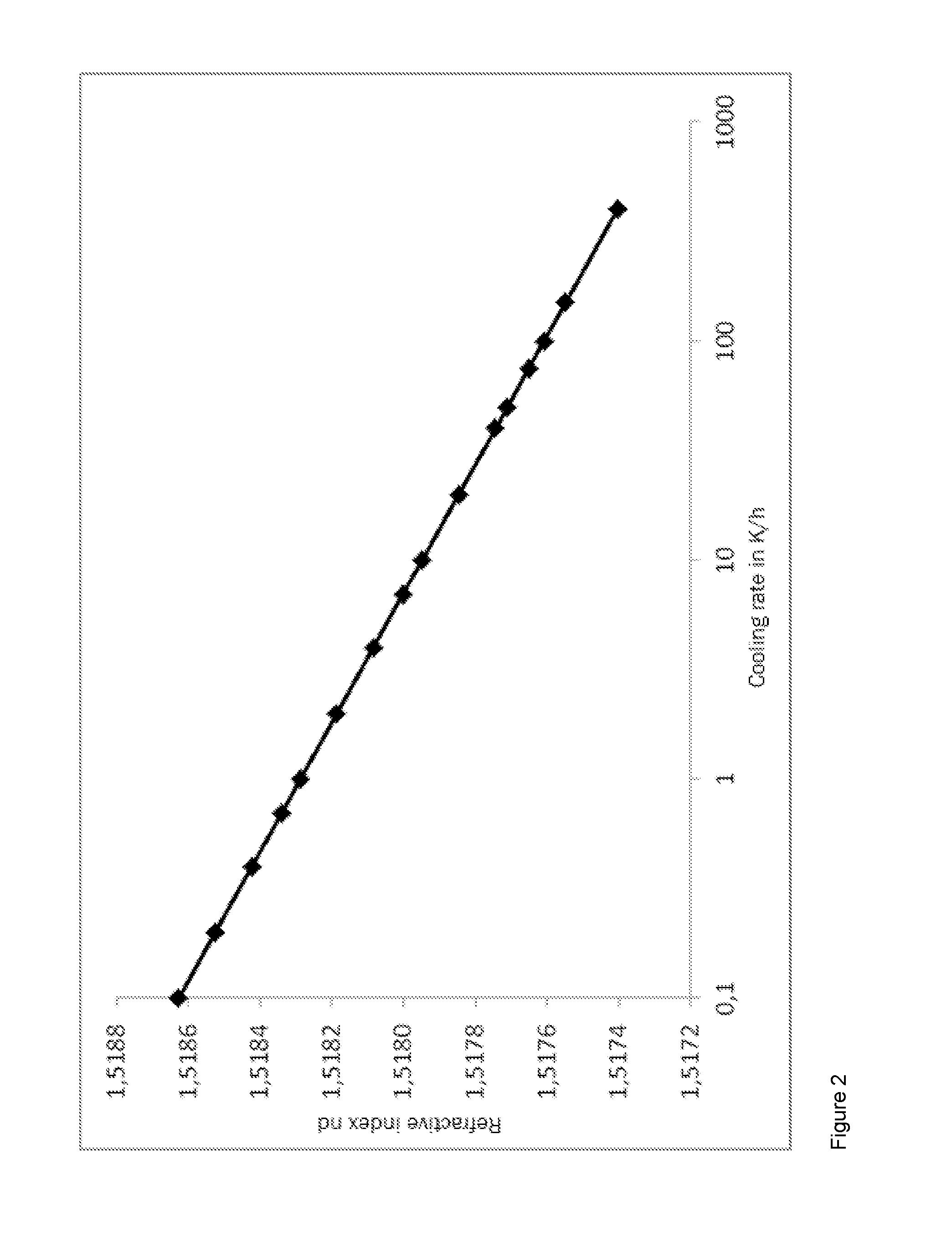

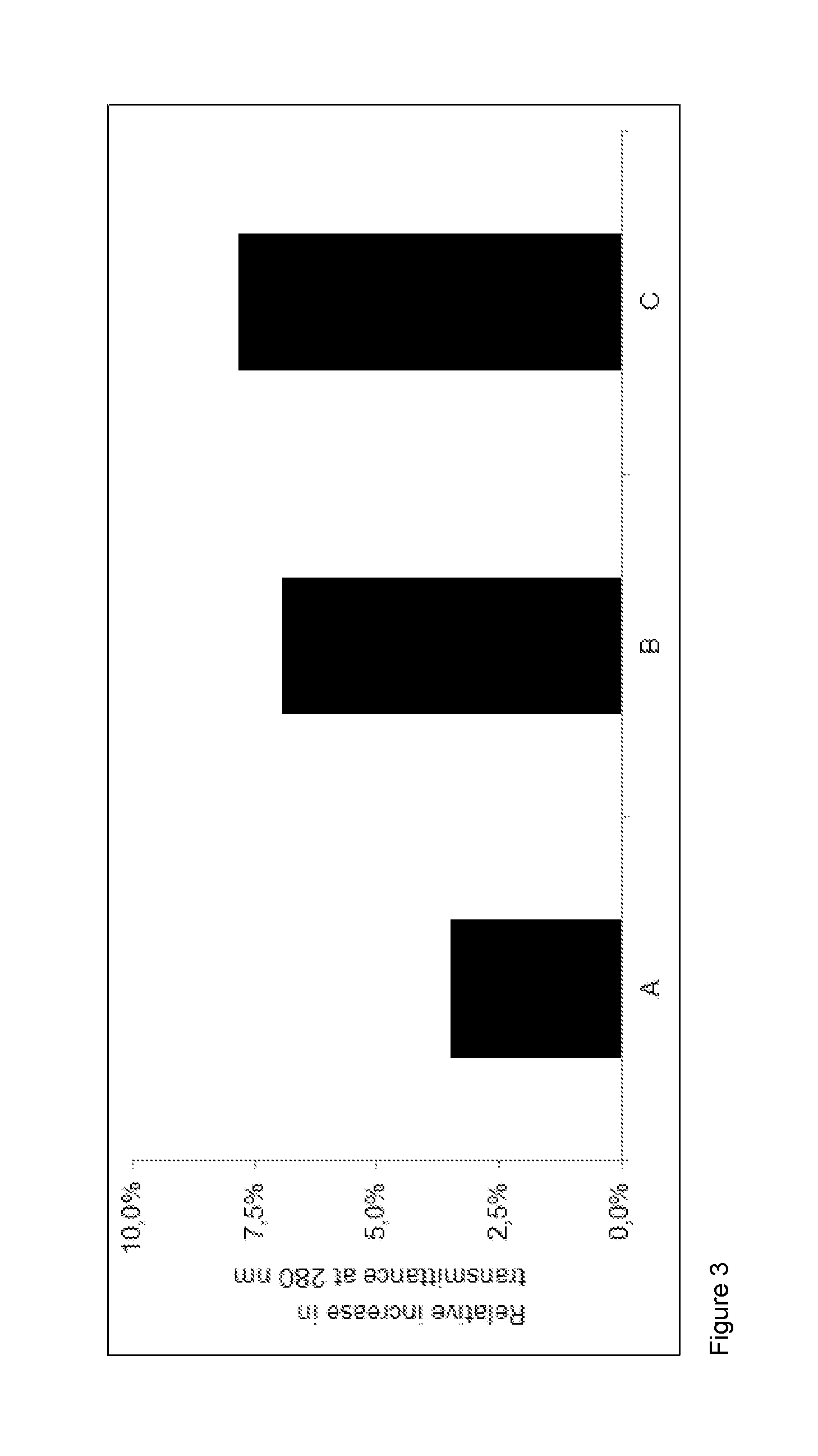

Sensitized, photo-sensitive glass and its production

ActiveUS9914660B2Improve homogeneityGlass transportation apparatusGlass forming apparatusBiotechnologyUltraviolet

Owner:SCHOTT AG

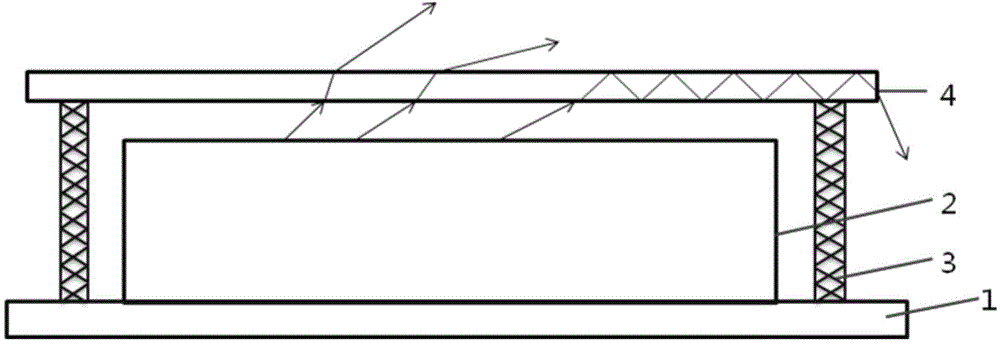

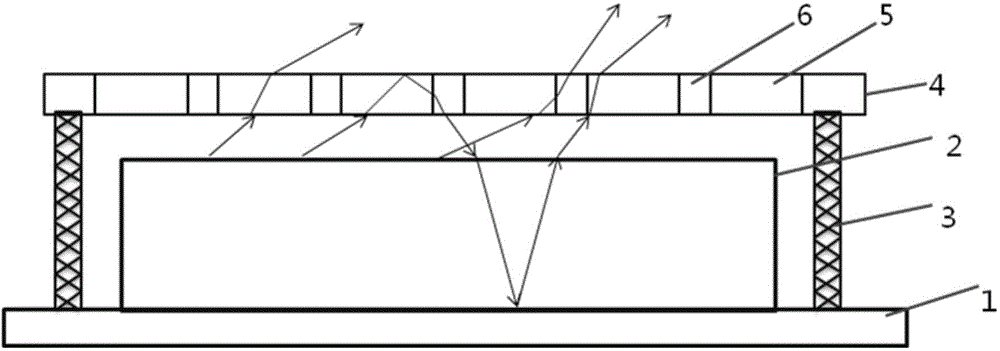

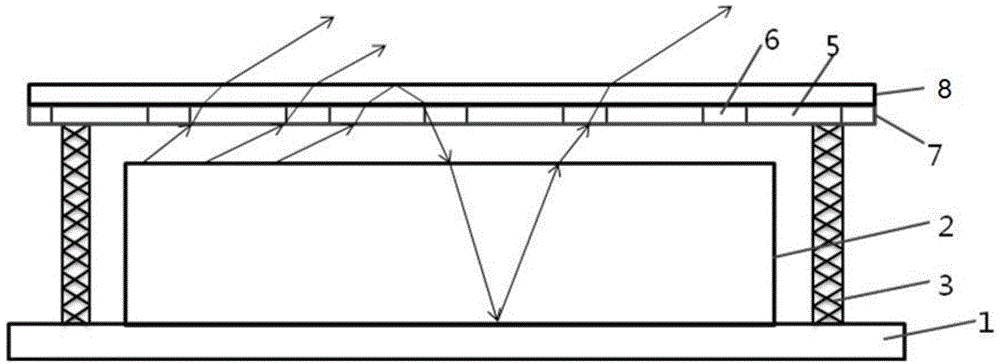

Encapsulating cover plate and application thereof in organic electroluminescence device

ActiveCN104409657AImprove exit efficiencyImprove viewing angleOLED manufacture/treatment processesSolid-state devicesRefractive indexEngineering

The invention belongs to the technical field of panel display, and discloses an encapsulating cover plate and application thereof in an organic electroluminescence device. The encapsulating cover plate uses a piece of photosensitive glass with photoinduced refractive index change or a transparent substrate provided with a transparent photosensitive material, interference pattern irradiation enables the photosensitive glass with photoinduced refractive index change or the transparent substrate provided with the transparent photosensitive material to present blended distribution of high and low refractive indexes, an original total reflection structure of the photosensitive glass or the transparent substrate is destroyed, and the light originally lost because of total reflection is reused after the light is reflected on the encapsulating cover plate, so that the dispersion effect of emergent light is improved, the emergent efficiency of the light and the angle of view are improved, and meanwhile, an effect of antireflection is achieved on the light in the external environment to a certain degree.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

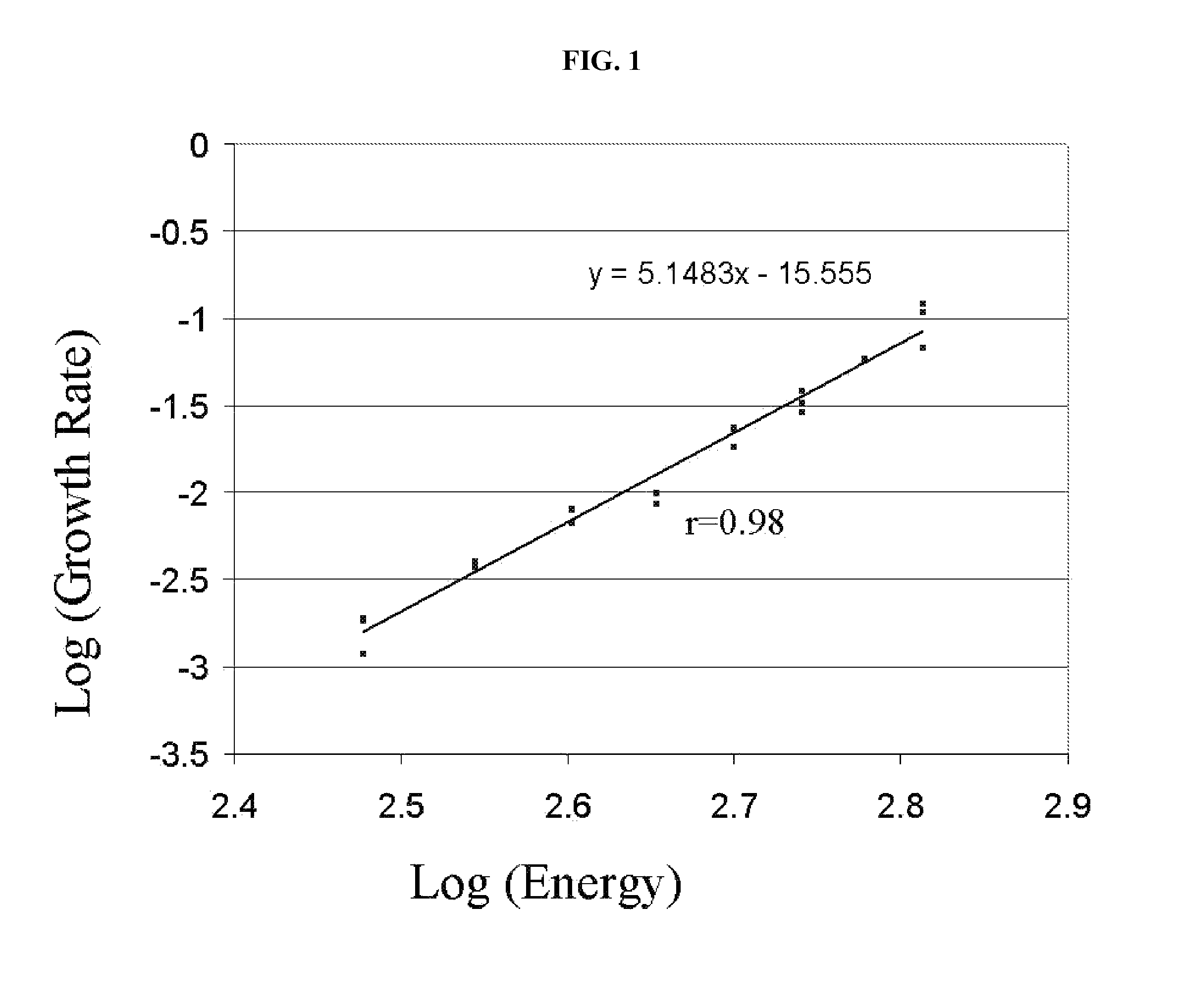

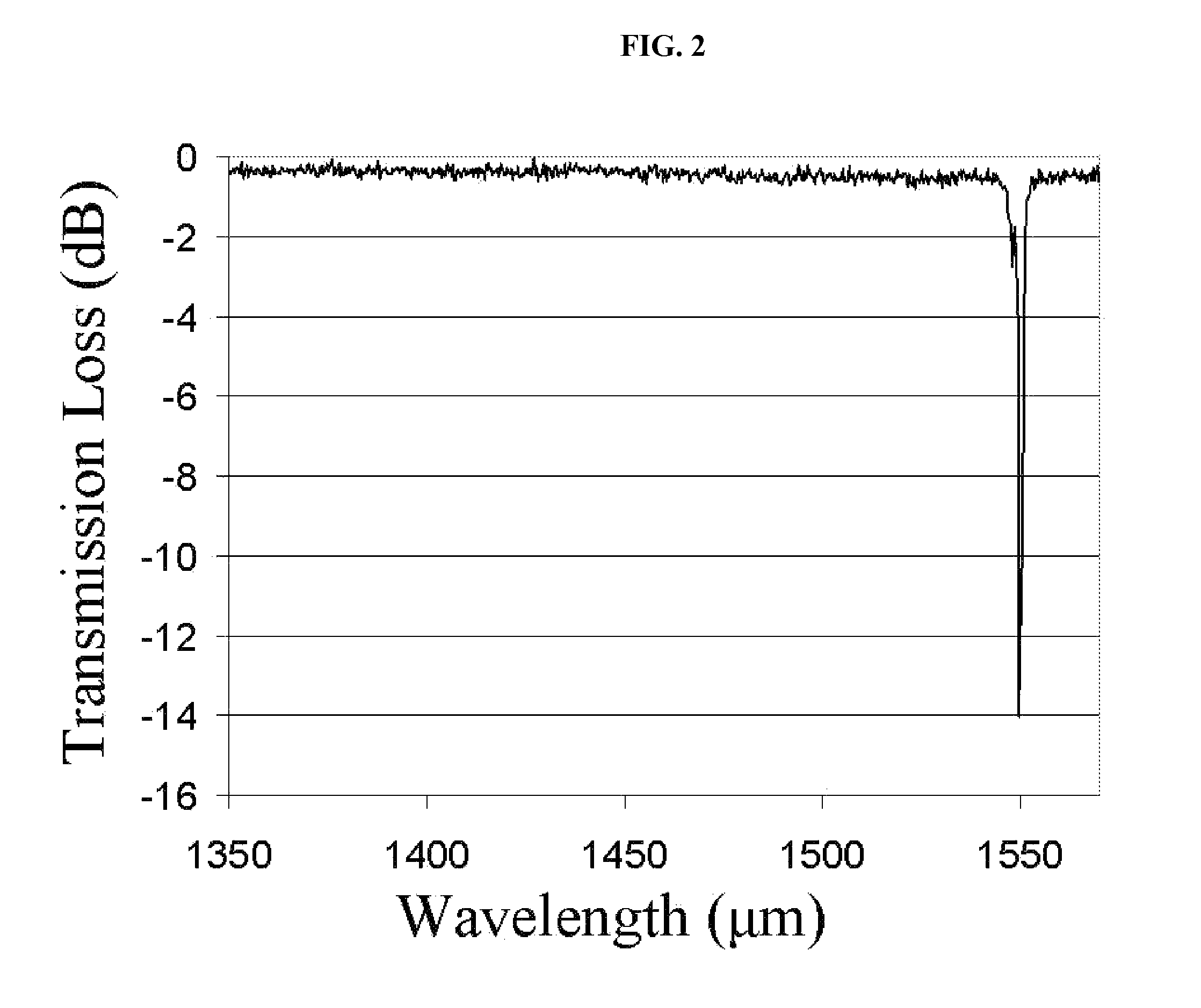

Method of increasing photosensitivity of glasses to ultrafast infrared laser radiation using hydrogen or deuterium

InactiveUS7515792B2Coupling light guidesOptical waveguide light guideRefractive indexPhotosensitivity

A method of increasing the refractive index in a photosensitive glass is disclosed so as to induce an refractive index change of at least 10−5 within a region of the glass. The method includes the step of providing a hydrogen or deuterium loaded doped glass material wherein a dopant within the glass is photosensitive to infrared radiation in the presence of hydrogen or deuterium. The hydrogen or deuterium loaded doped glass is subsequently irradiated with femtosecond pulses of infrared light having an intensity of at least 109 W / cm2 and less than 5×1013 W / cm2.

Owner:NAT RES COUNCIL OF CANADA

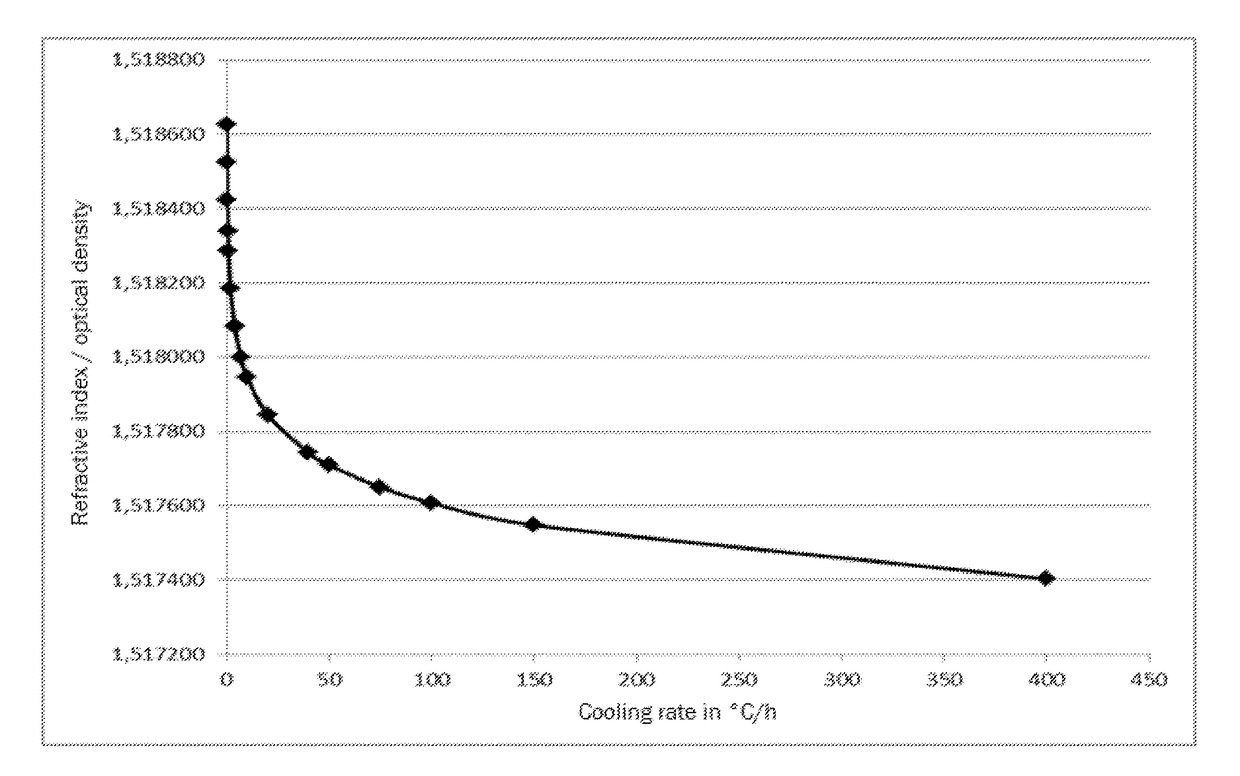

Sensitized, photo-sensitive glass and its production

ActiveUS20160340228A1Improve homogeneityGlass transportation apparatusGlass forming apparatusBiotechnologyUltraviolet

A sensitized, photo-structurable glasses and methods for producing are provided. The glasses includes Si4+, one or more crystal-agonist, one or more crystal-antagonist, and one or more pair of nucleating agents. The glasses are sensitized in that the glass reacts more sensitive to irradiation with UV-light and can be crystallized easier and with higher aspect ratios than a non-sensitized glass with equal composition. Furthermore, the sensitized glasses of this invention have smaller crystal sizes after irradiation and tempering than a non-sensitized glass with equal composition. The invention also relates to a structured glass product. Such product can be obtained by submitting the crystallized glass product to a subsequent etching step. The structured product can be used in components or as component for the application fields micro-technology, micro-reaction-technology, electronic packaging, micro-fluidics, FED spacer, bio-technology, interposer, and / or three-dimensional structured antennae.

Owner:SCHOTT AG

Continuous production of photo-sensitive glass bodies

A method for continuous production of photo-sensitive glass bodies, glass bodies, and structured glass articles are provided. The method comprises steps of a. providing a mixture, b,melting the mixture, c transferring a melted body to a mold, d suppressing the glass in the mold into a glass body, wherein the melted body has temperature higher than 1000 DEG in the mold where the melted body is transferred, wherein the glass bodies include glass having temperature higher than 1000 DEG, the melted body is cooled down in the mold in such mode from 990 DEG to 600 DEG in less than 15 minutes. The glass includes Si4+, at least one crystal-agonist, at least one crystal-antagonist, and at least one pair of nucleating agents. The glass may be used in a method for structuring of glass. The glass bodies may be structured and / or unstructured and used in different applications such as in components or as components in micro-technology, in micro-reaction-technology, in electronic packaging, for micro-fluidic components, in or as FED spacer, for bio-technology (for example titer plates), as interposer, and in or as three-dimensional structure antennae.

Owner:SCHOTT AG +1

Electron beam lens for micro-column electron beam apparatus and method of fabricating the same

InactiveUS20050263712A1Improve performanceStability-of-path spectrometersLine/current collector detailsThin metalMicro column

Owner:ELECTRONICS & TELECOMM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com