Method for preparing photosensitive glass-ceramics mobile phone shell

A technology of glass-ceramic and mobile phone case, which is applied in the field of preparation of photosensitive glass-ceramic mobile phone case, can solve the problems of low yield rate of zirconia mobile phone case, perfect fit of photosensitive glass-ceramic, easy damage to zirconia body, etc. The effect of high added value, beautiful appearance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention describes a method for preparing a photosensitive glass-ceramic mobile phone case, which is characterized in that it comprises the following steps:

[0026] (1) Configure silicon dioxide, lithium carbonate, potassium nitrate, aluminum oxide, calcium oxide, and zirconium as raw materials. After the mixing is completed, the raw materials are placed in a melting furnace to be melted into a solution;

[0027] (2) Immediately send the solution to the annealing furnace for annealing treatment after casting the solution to be a billet;

[0028] (3) Carry out specification slicing with blank utilizing commercially available wire cutting machine;

[0029] (4) Roughly polishing and punching the slices into rectangular standard slices;

[0030] (5) The four edges of the rectangular standard sheet are processed into a four-fold rough product by pre-setting data heat bending on the hot press;

[0031] (6) Carry out light treatment to crude product;

[0032] (7) Carr...

Embodiment

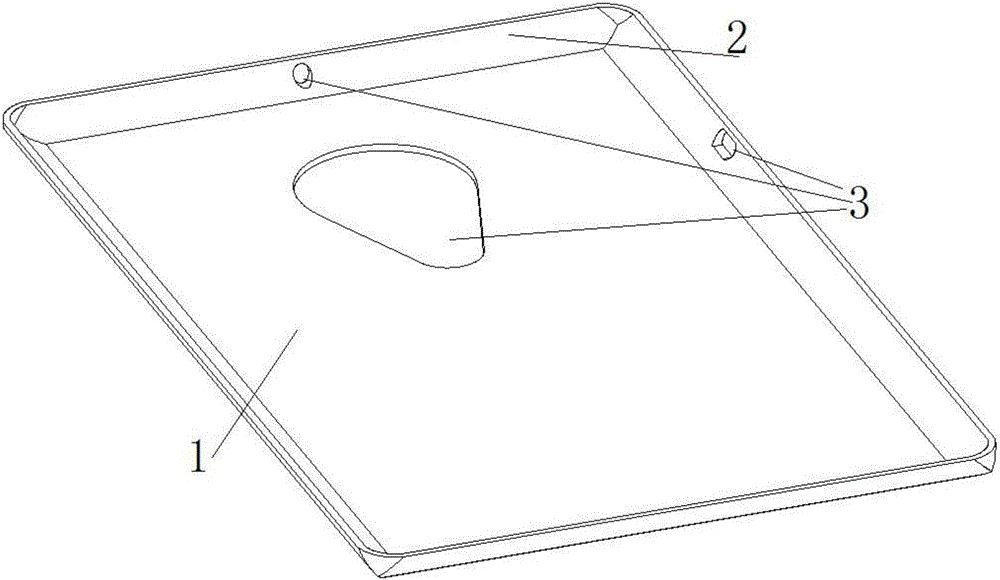

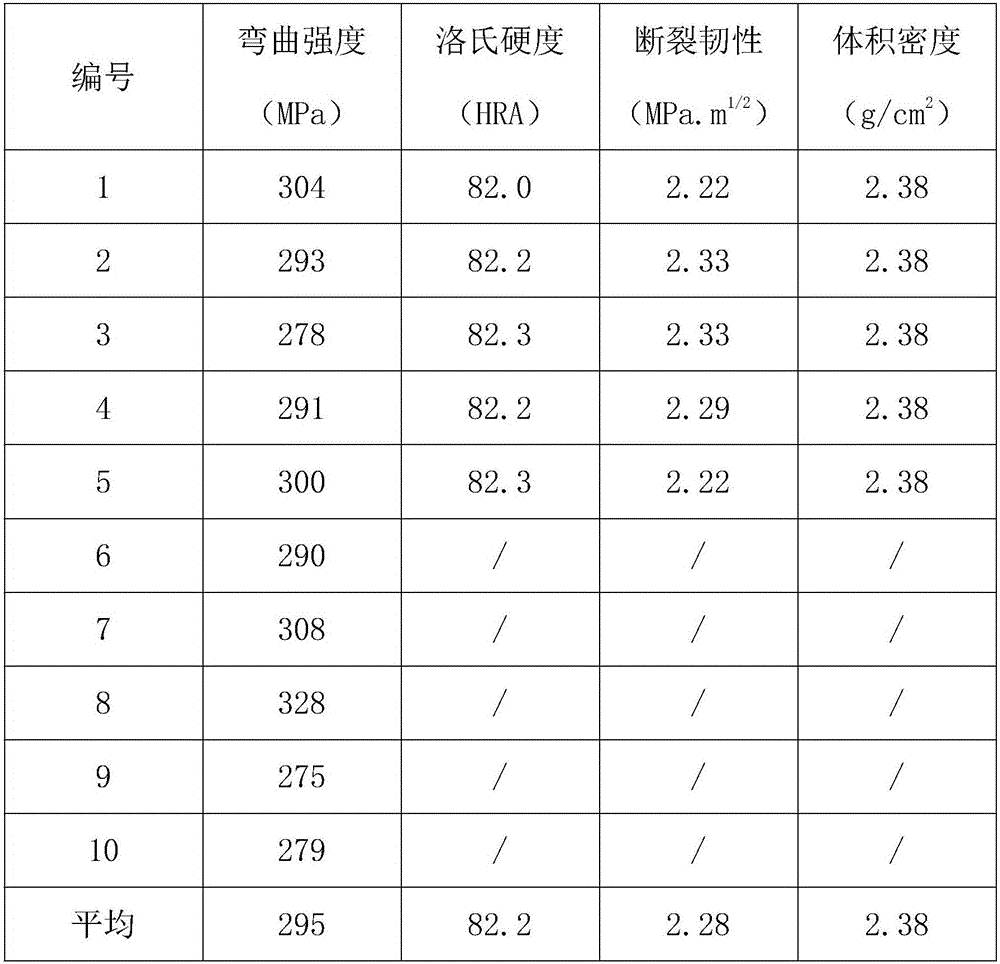

[0040] Example, using 50 parts of silicon dioxide, 32 parts of lithium carbonate, 10 parts of potassium nitrate, 4.5 parts of aluminum oxide, 0.5 parts of calcium oxide, and 3 parts of zirconium as raw materials, the photosensitive glass mobile phone case was prepared according to the above steps, and a total of 10 parts were prepared. individual such as figure 1 For the samples shown, each sample is tested for experimental mechanical properties, using equipment: INSTRON-5566 universal material testing machine Vickers / microhardness tester; the test results are as follows:

[0041]

[0042] Implementing the technology of the present invention does not require special equipment, only common industrial ceramic production equipment, such as melting furnaces, wire cutting machines, hot presses, firing furnaces, etc., can be produced. It has the advantages of low equipment investment, no pollution in the production process, high added value of products, energy saving and environm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com