Multilayer printed wiring board and a process of producing same

a printing process and wiring board technology, applied in the direction of printing element electric connection formation, insulating substrate metal adhesion improvement, transportation and packaging, etc., can solve the problems of difficult to form a small diameter through hole, difficult to enhance and difficult to form a high-density wiring pattern, etc., to achieve the effect of increasing the density of the wiring pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

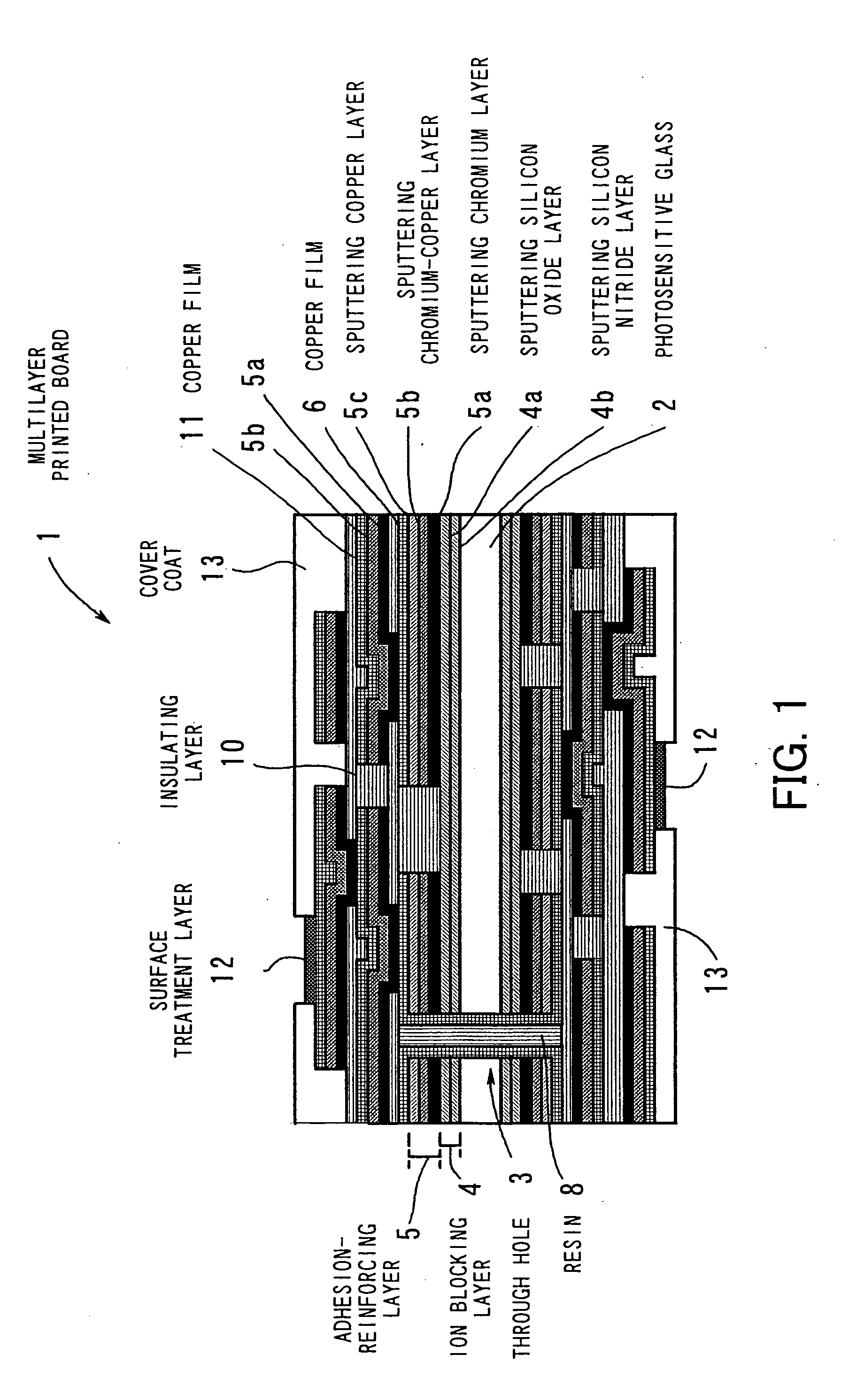

example 1

[0089] An example according to the first embodiment will be now described.

[0090] In this example, a photosensitive glass (trade name: PEG3, manufactured by HOYA CORPORATION) having the composition stated below was used as the glass substrate.

(wt %)SiO278.0%Li2O10.0%Al2O3 6.0%K2O 4.0%Na2O 1.0%ZnO 1.0%Au0.003% Ag0.08%CeO20.08%

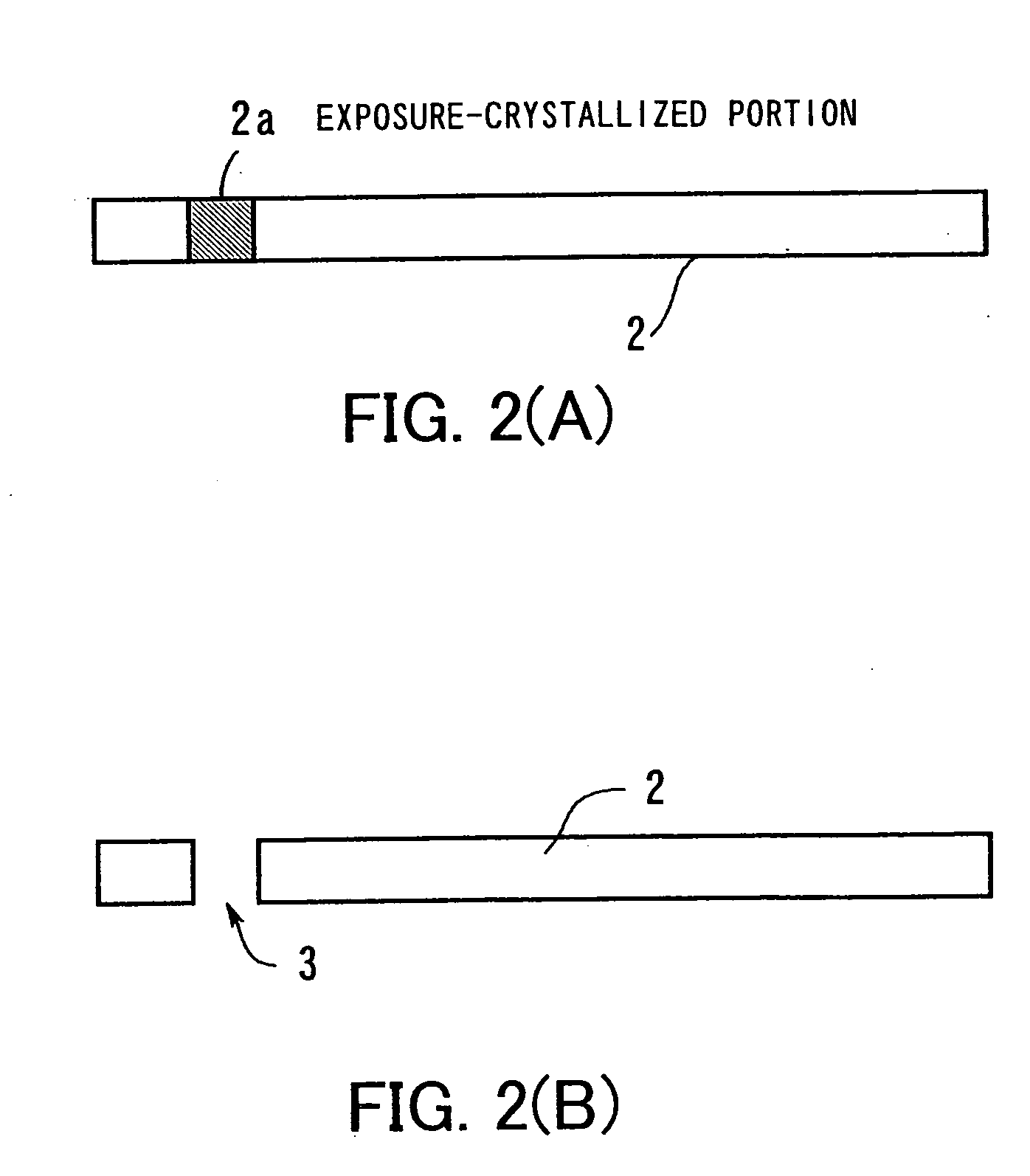

(Through Hole Formation Step)

[0091] 1) With a mask held in close contact with the photosensitive glass, UV light was irradiated onto a through hole portion of the glass through the mask, thereby forming a latent image corresponding to the exposed portion. The mask used was made of silica glass patterned using chromium / chromium oxide. Subsequently, the photosensitive glass was heat-treated at 400° C. to crystallize only the exposed portion.

[0092] 2) Dilute hydrofluoric acid (10% solution) was sprayed on both surfaces of the photosensitive glass to remove the crystallized through hole portion by dissolution, thereby forming a through hole with a diameter φ of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com