Fixed abrasive grinding polishing pad and method of manufacturing the same

A technology of bonding abrasives and polishing pads, applied in grinding/polishing equipment, abrasives, grinding devices, etc., can solve problems affecting processing efficiency and accuracy, pollution, etc., achieve high processing efficiency, good workpiece flatness, improve Effect of Surface Quality and Machining Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

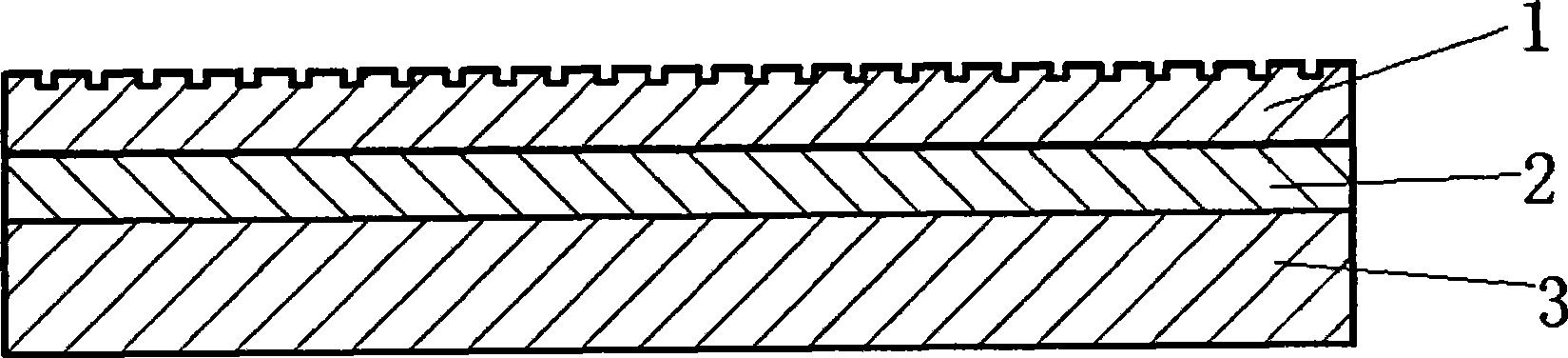

[0044] Such as figure 1 shown.

[0045] A kind of fixed abrasive polishing pad, is made up of abrasive material layer 1, rigid layer 2 and elastic layer 3, and it is made by following method:

[0046] 1. First, take the following components fully and evenly for later use:

[0047] (1) Diamond (or silicon dioxide, ceria, aluminum oxide, silicon carbide, boron carbide, zirconia, or any two or more of them with a particle size of 1 nanometer to 40 microns, when combined, each The components can be prepared in equal parts, or can be prepared according to the performance of the workpiece) 20 grams;

[0048] (2) Bisphenol A epoxy acrylate (or novolac epoxy acrylate and amine-modified epoxy acrylate, chain-modified long aliphatic epoxy acrylate with oleic acid and linoleic acid, polyurethane acrylate, polyester One or several combinations of ester acrylate, polyether acrylate, and acrylated polyacrylate. When combining, each component can be prepared in equal parts, or it can be p...

Embodiment 2

[0060] A kind of fixed abrasive polishing pad, is made up of abrasive material layer 1, rigid layer 2 and elastic layer 3, and it is made by following method:

[0061] 1. First, take the following components fully and evenly for later use:

[0062] (1) Diamond (or silicon dioxide, ceria, aluminum oxide, silicon carbide, boron carbide, zirconia, or any two or more of them with a particle size of 1 nanometer to 40 microns, when combined, each The components can be prepared in equal parts, or can be prepared according to the performance of the workpiece) 40 grams;

[0063] (2) Bisphenol A epoxy acrylate (or novolac epoxy acrylate and amine-modified epoxy acrylate, chain-modified long aliphatic epoxy acrylate with oleic acid and linoleic acid, polyurethane acrylate, polyester One or several combinations of ester acrylate, polyether acrylate, and acrylated polyacrylate, each component can be prepared in equal parts, or it can be prepared as appropriate according to the performance...

Embodiment 3

[0075] A kind of fixed abrasive polishing pad, is made up of abrasive material layer 1, rigid layer 2 and elastic layer 3, and it is made by following method:

[0076] 1. First, take the following components fully and evenly for later use:

[0077] (1) Diamond (or silicon dioxide, ceria, aluminum oxide, silicon carbide, boron carbide, zirconia, or any two or more of them with a particle size of 1 nanometer to 40 microns, when combined, each The components can be prepared in equal parts, or can be prepared according to the performance of the workpiece) 40 grams;

[0078] (2) Bisphenol A epoxy acrylate (or novolac epoxy acrylate and amine-modified epoxy acrylate, chain-modified long aliphatic epoxy acrylate with oleic acid and linoleic acid, polyurethane acrylate, polyester One or several combinations of ester acrylate, polyether acrylate, and acrylated polyacrylate, each component can be prepared in equal parts, or it can be prepared as appropriate according to the performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com