Sapphire substrate ultraprecision machining method based on fixed abrasive pad

A sapphire substrate, ultra-precision machining technology, applied in grinding tools, metal processing equipment, grinding devices, etc., can solve the problems of difficult to guarantee accuracy, low processing efficiency, and large environmental pollution, and achieve high processing efficiency and utilization rate. High, high surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

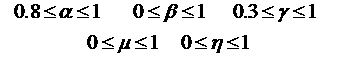

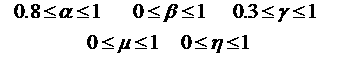

[0034] Set the laboratory temperature at 15°C and keep the laboratory at a constant temperature. W75 (grain size 60-75 microns) and W28 (grain size 20-28 microns) nickel-plated diamond abrasives and W5 used for rough grinding, fine grinding and polishing (The particle size is 3.5-5 microns) The fixed abrasive grinding and polishing pad of diamond (not nickel-plated) is pasted on three polishing discs respectively, and is installed on the polishing equipment, and the fixed abrasive grinding and polishing pad is trimmed before the experiment, so as to Ensure that the diamonds on the surface of the fixed abrasive polishing pad are exposed. The fixed abrasive grinding and polishing pad is prepared by uniformly mixing and solidifying resin and diamond abrasive, in which nickel-plated diamond is a layer of nickel oxide electroplated on the surface of diamond powder particles (the same below). The quality of nickel-plated diamond should be guaranteed to increase to 110%~200% of the o...

example 2

[0040] Set the laboratory temperature at 25°C and keep the laboratory at a constant temperature. W75 (grain size 60-75 microns) and W28 (grain size 20-28 microns) nickel-plated diamond abrasives and W5 used for rough grinding, fine grinding and polishing (with a particle size of 3.5-5 microns) diamond (non-nickel-plated) fixed abrasive polishing pads were respectively pasted on three polishing discs. Before the experiment, the fixed abrasive grinding and polishing pads were trimmed to ensure that the diamonds on the surface of the polishing pads were exposed. .

[0041] The pressure during rough grinding is 0.3Mpa, the flow rate of the polishing liquid is 300ml / min, the rotational speed of the workbench is 100r / min, and the rough grinding time is 6min. The content of each component of the polishing liquid during rough grinding is expressed as follows: , the highest volume fraction A of deionized water in the polishing liquid is 90%, the highest volume fraction B of triethanol...

example 3

[0046] Set the laboratory temperature at 30°C and keep the laboratory at a constant temperature. W75 (grain size 60-75 microns) and W28 (grain size 20-28 microns) nickel-plated diamond abrasives and W5 used for rough grinding, fine grinding and polishing (with a particle size of 3.5-5 microns) diamond (non-nickel-plated) fixed abrasive polishing pads were respectively pasted on three polishing discs. Before the experiment, the fixed abrasive grinding and polishing pads were trimmed to ensure that the diamonds on the surface of the polishing pads were exposed. .

[0047] The pressure during rough grinding is 0.2Mpa, the flow rate of polishing liquid is 250ml / min, the rotational speed of the workbench is 125r / min, and the rough grinding time is 7min. The content of each component of the polishing liquid during rough grinding is expressed as follows: , the highest volume fraction A of deionized water in the polishing liquid is 90%, the highest volume fraction B of triethanolamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com