Patents

Literature

34results about How to "Solve the problem of low processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

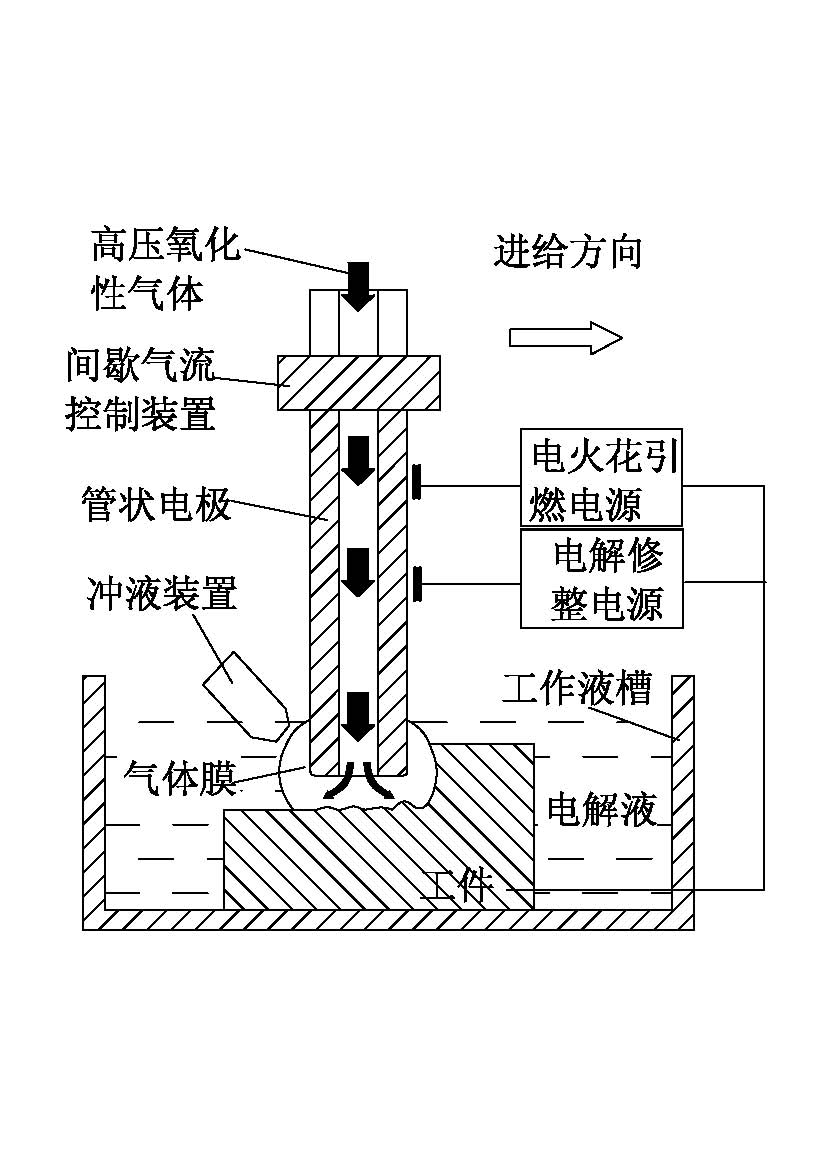

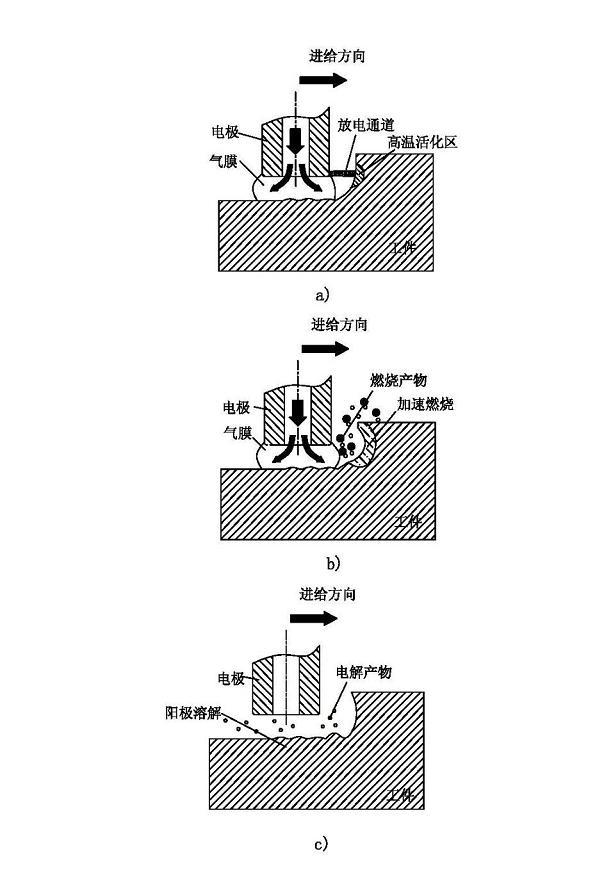

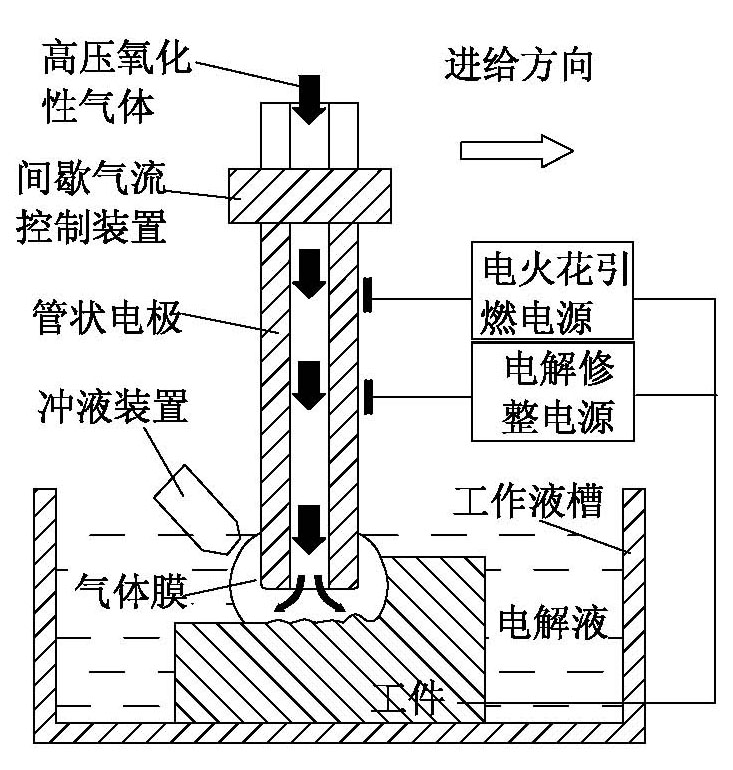

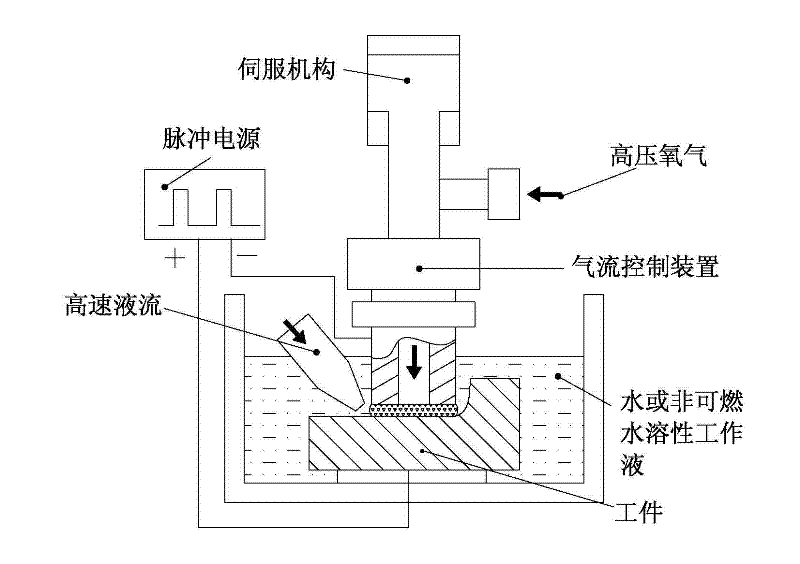

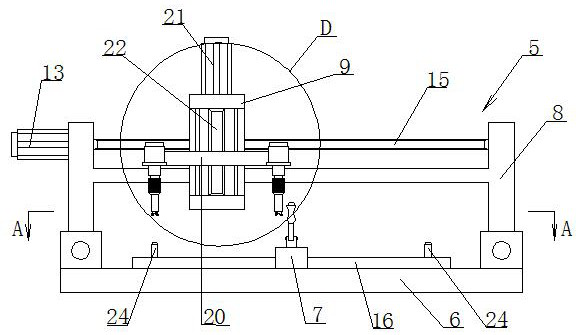

Electric spark induction controllable erosion and electrolysis compound efficient machining method

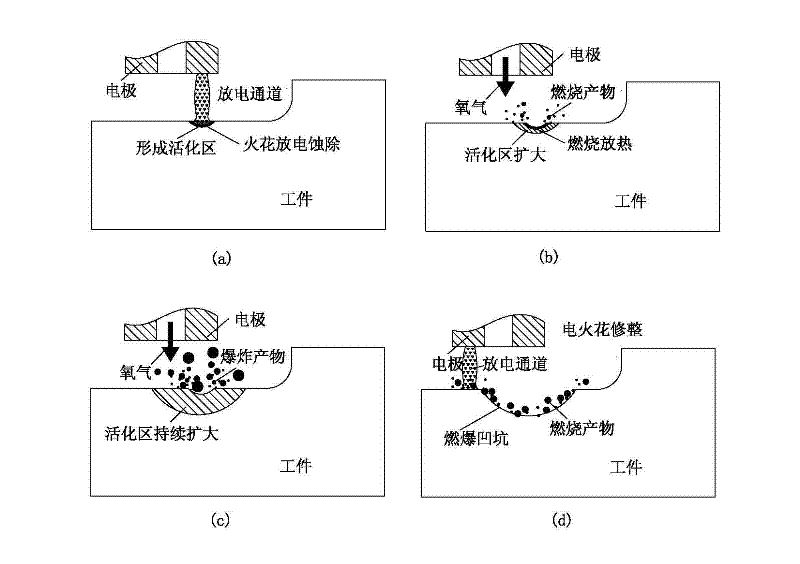

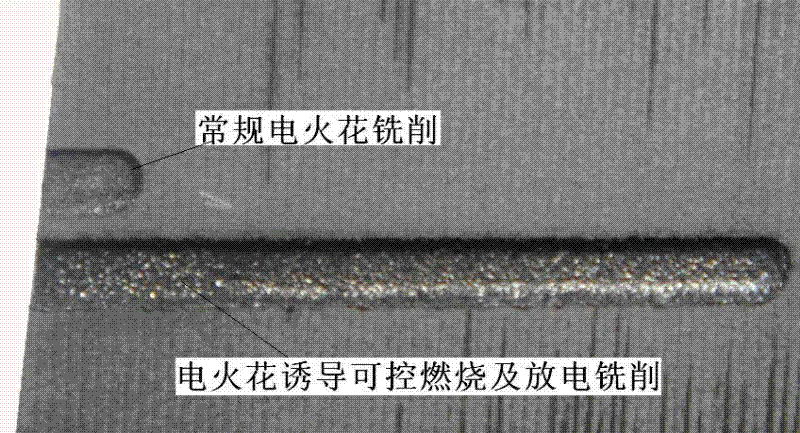

The invention discloses an electric spark induction controllable erosion and electrolysis compound efficient machining method which is characterized by comprising the steps of: with electrolyte as a working medium, immersing one end of a to-be-machined workpiece electrode and a tool electrode in the working medium, intermittently introducing air to a machining area and forming an air film between the to-be-machined workpiece electrode and the tool electrode; generating electric spark discharge between the to-be-machined workpiece electrode and the tool electrode under the action of an electric spark power supply to ensure that the to-be-machined workpiece generates an oxidation exothermic reaction with the introduced air under the action of electric spark discharge ignition and forms a burning effect so that efficient ablation is realized; in an air closed stage, carrying out electrochemical machining and surface dressing on the ablation surface under the action of an electrolysis power supply; and alternating to start an electric spark ignition pulse power supply and an electrolysis eroding power supply and moving the tool electrode until machining is finished. The invention has the advantages of high material eroding efficiency up to be several times, even tens of times of that of the conventional electric spark machining and also be higher than that of the conventional electrolysis machining under the same electrical parameters on the premise of ensuring machining quality and precision, good surface quality, precision and controllability and capability of eliminating surface residual stress.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

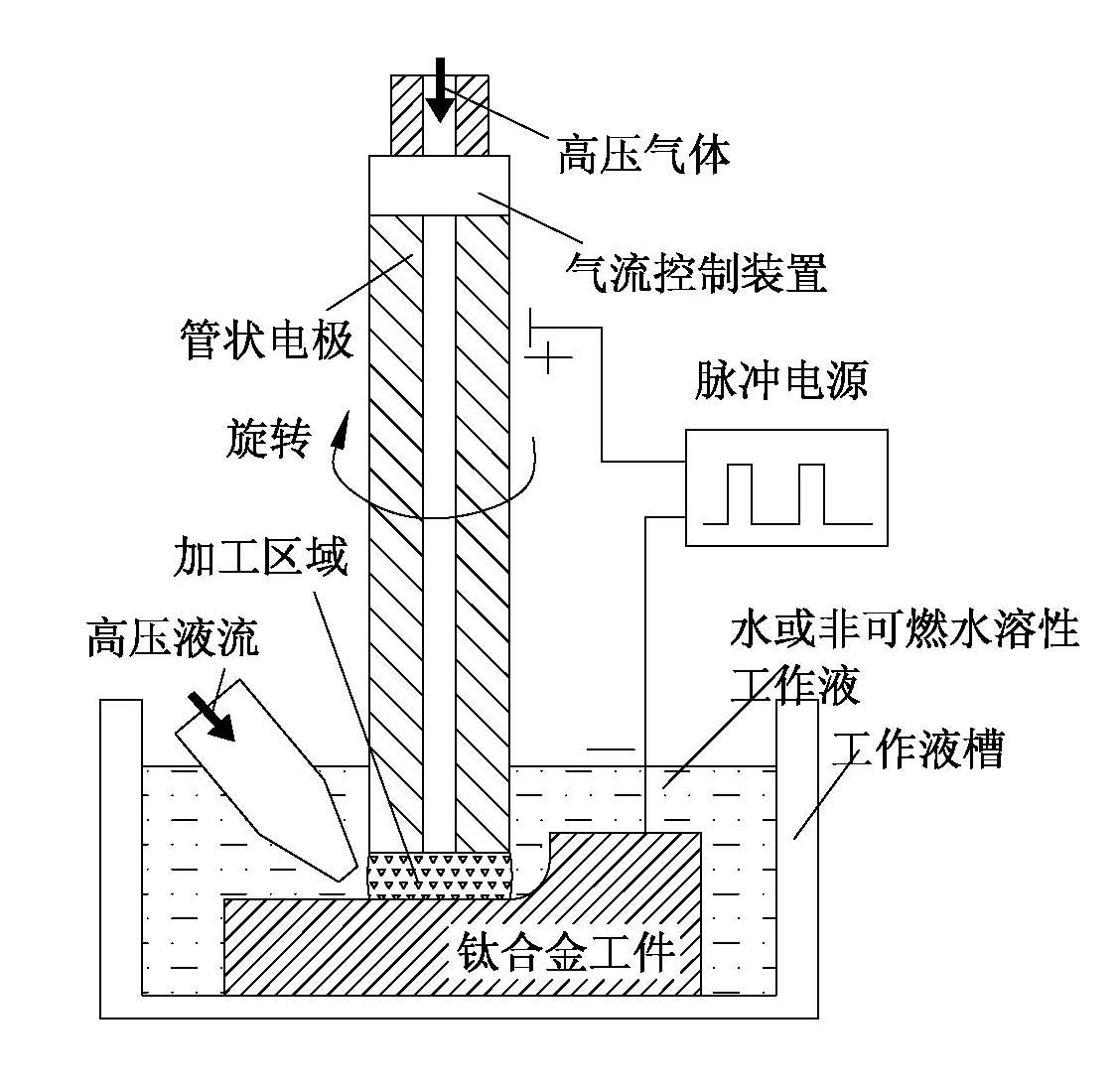

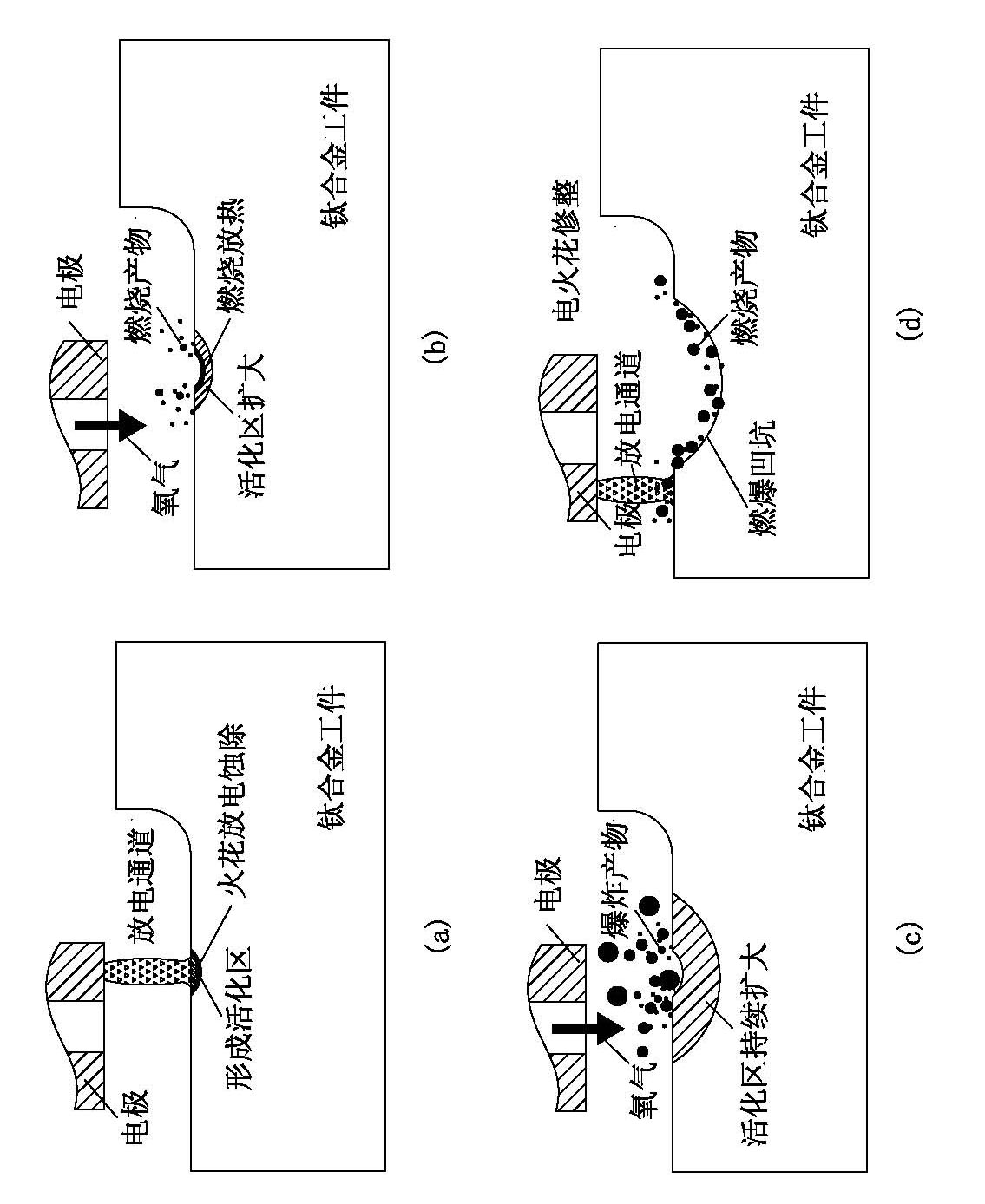

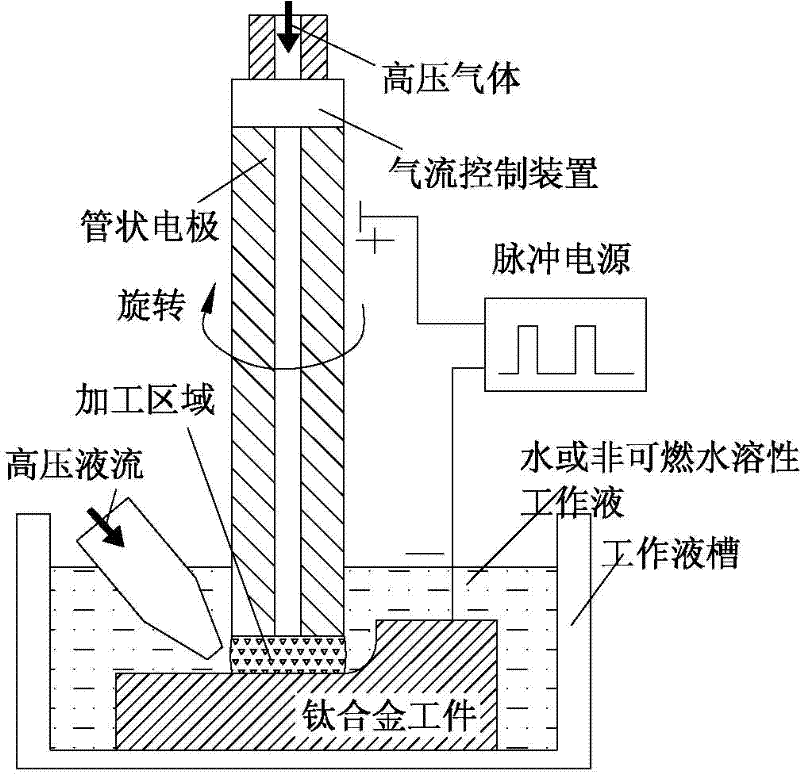

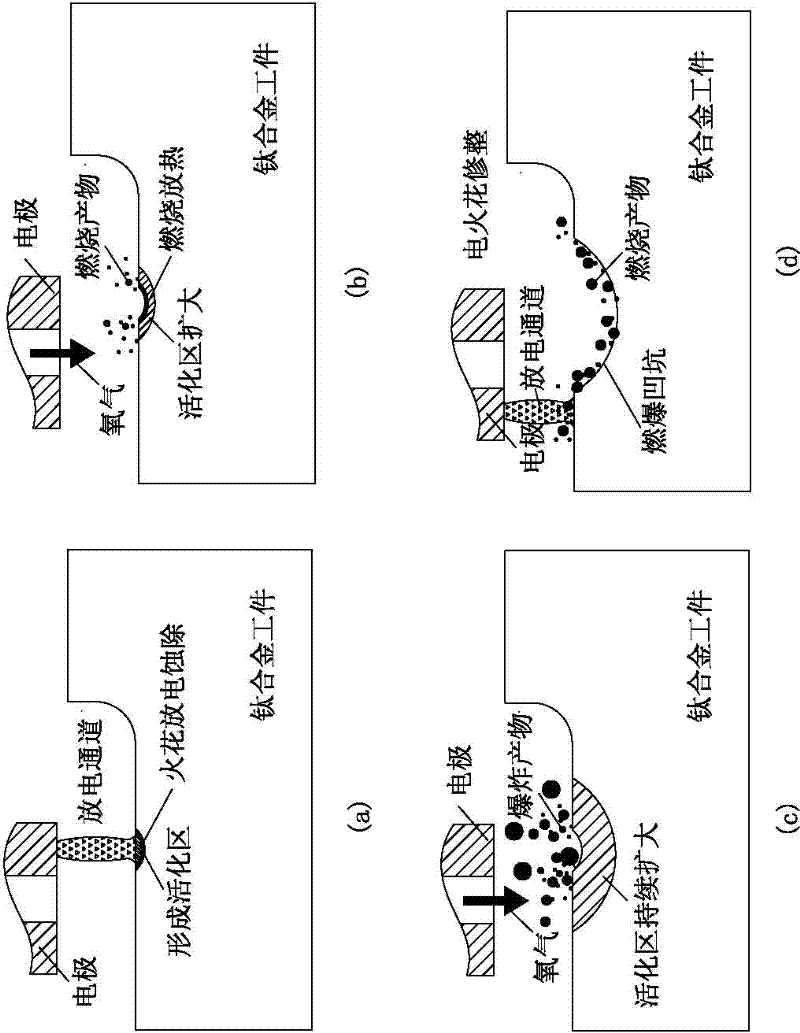

Processing method for corroding titanium or titanium alloy by burning and exploding under electric spark induction effect

The invention relates to a processing method for corroding titanium or a titanium alloy by burning and exploding under the electric spark induction effect, which is characterized in that a gas which can generate vigorous exothermic oxidation and burning and exploding effects with a titanium or titanium alloy materal to be processed is introduced in a processing area intermittently in the conventional process for processing the titanium or titanium alloy under the electric spark induction effect so that the titanium or titanium alloy of which the surface is activated under the electric spark induction effect and the introduced gas are subjected to burning and exploding reactions and a new activated layer can be exposed, and the process is carried out repeatedly so that the surfaces of titanium or titanium alloy substrate materials can be corroded rapidly and continuously in large quantities. Compared with the conventional method for corroding the titanium or titanium alloy under the electric spark induction effect, the invention can improve the material corroding rate by dozens of times or even hundreds of times. The invention can be used for processing through the relative motion of small-scale equipment on a large-scale structural component, can solve the problems on the size, the rigidity and the like of a large-scale structural component processing machine tool and has the advantages of high efficiency, low loss, low cost, safety and no pollution.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Sapphire substrate ultraprecision machining method based on fixed abrasive pad

ActiveCN103252708AFast processingEfficient processingLapping machinesLapping toolsMachining timeUltra precision

The invention discloses a sapphire substrate ultra-precision machining method based on a fixed abrasive pad. The sapphire substrate ultra-precision machining method based on the fixed abrasive pad mainly relates to three steps of rough grinding, accurate grinding and polishing, namely, rough grinding is conducted on a cut sapphire substrate semi-finished product through a W75 nickel plated diamond FAP; then accurate grinding is conducted on a workpiece after rough grinding through a W28 nickel plated diamond FAP; last, polishing is conducted on the workpiece after accurate grind through a W5 diamond FAP, and grinding and polishing processes are finished. According to the sapphire substrate ultra-precision machining method based on the fixed abrasive pad, a sapphire substrate is machined, the time cost in the whole process is shortened within two hours, machining time of sapphire is greatly shortened, the sapphire substrate with the workpiece surface roughness (Ra) is smaller than 3nm can be finally obtained, surface defects such as pitting corrosion and scratches can be effectively removed, the damage of a subsurface is reduced and the quality of the surface is good. The sapphire substrate ultra-precision machining method based on the fixed abrasive pad improves machining efficiency of the substrate and the quality of the surface of the substrate, and is low in cost and pollution-free.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

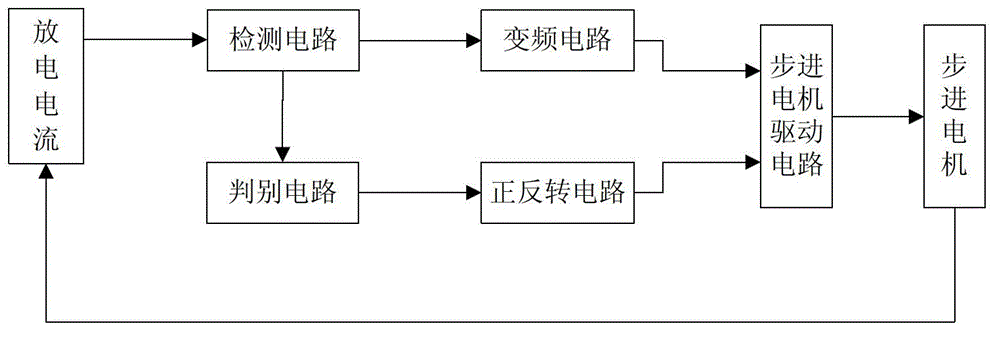

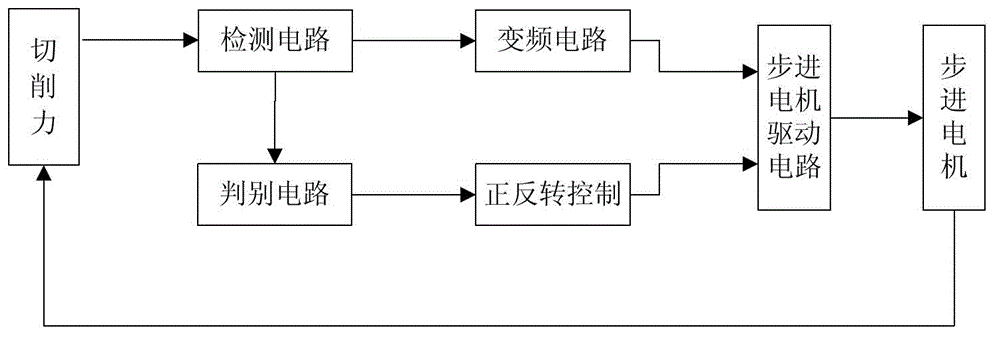

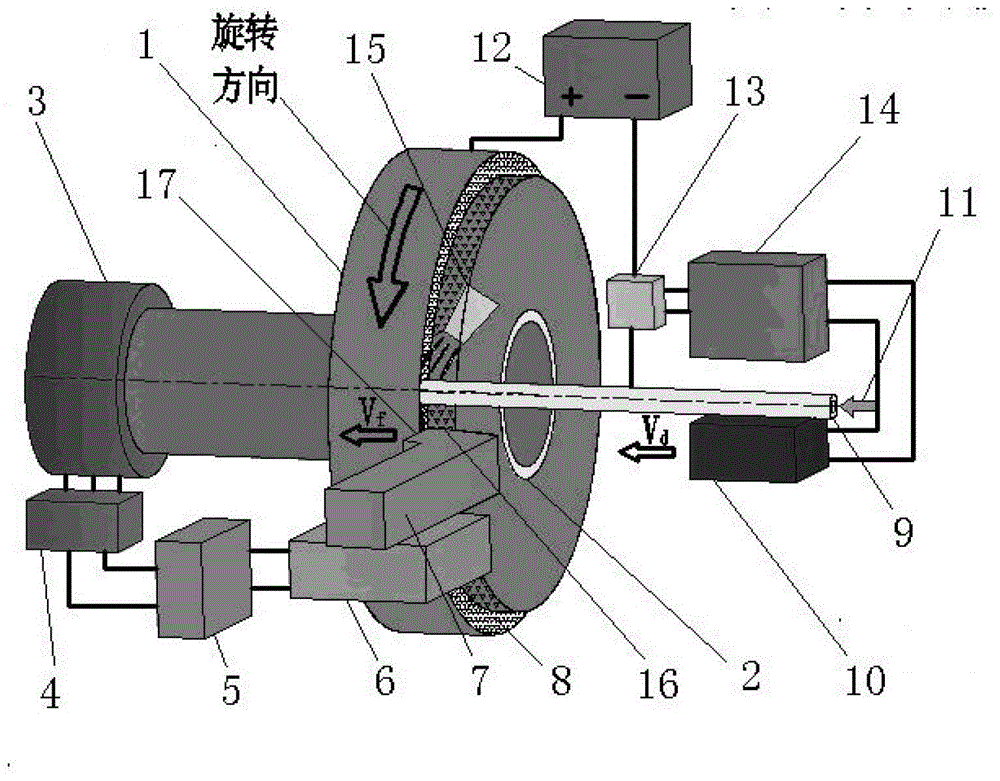

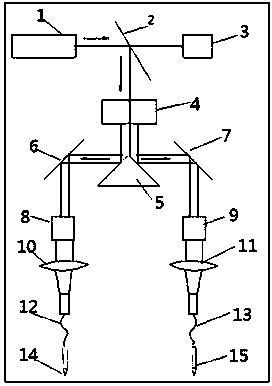

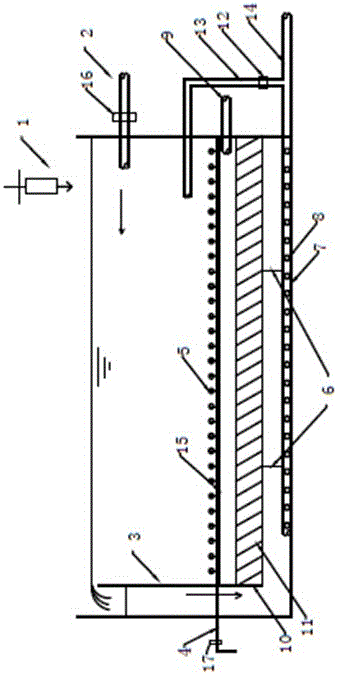

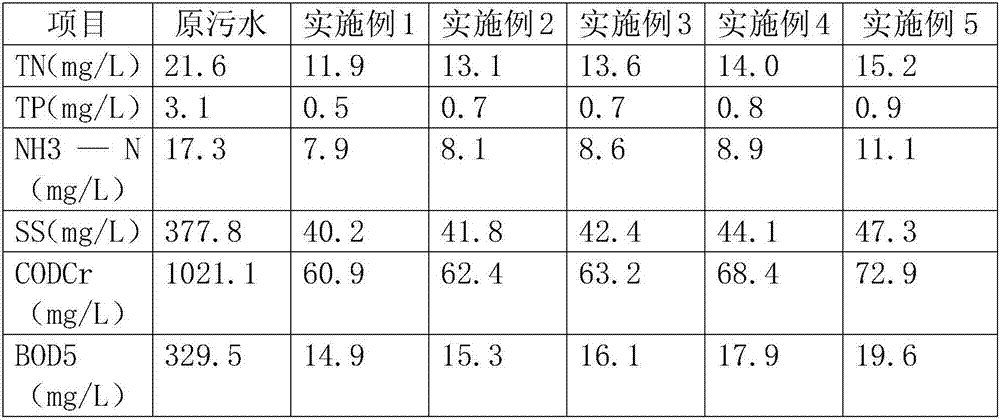

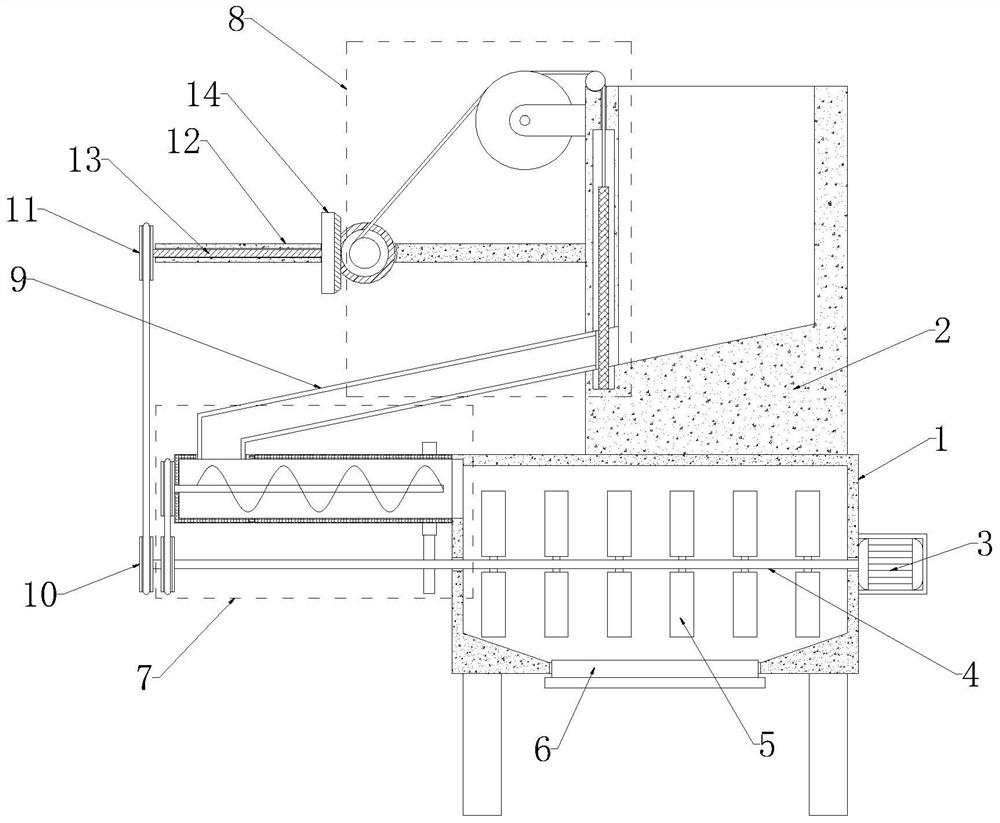

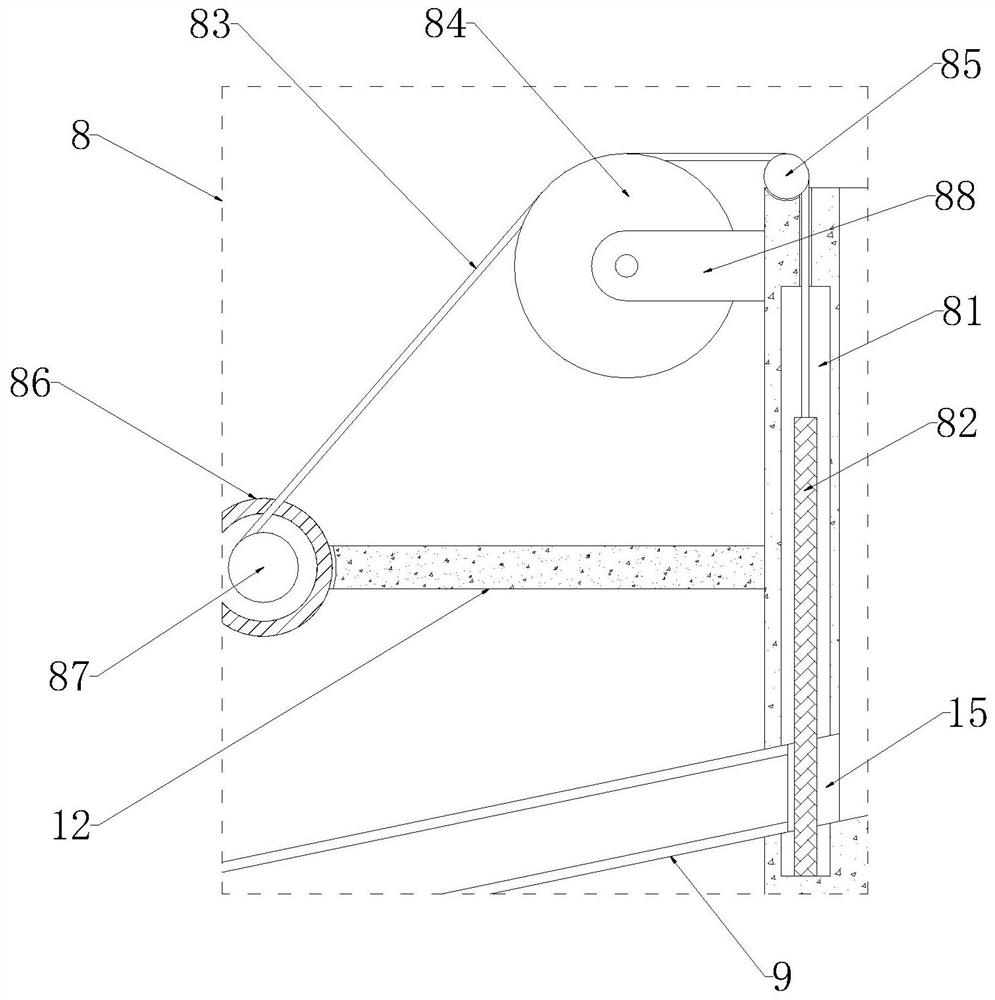

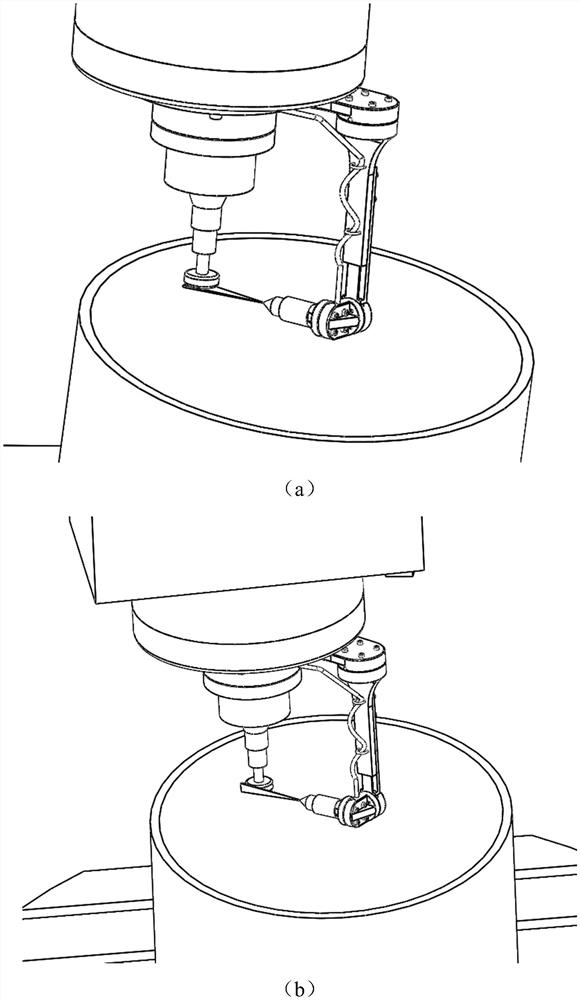

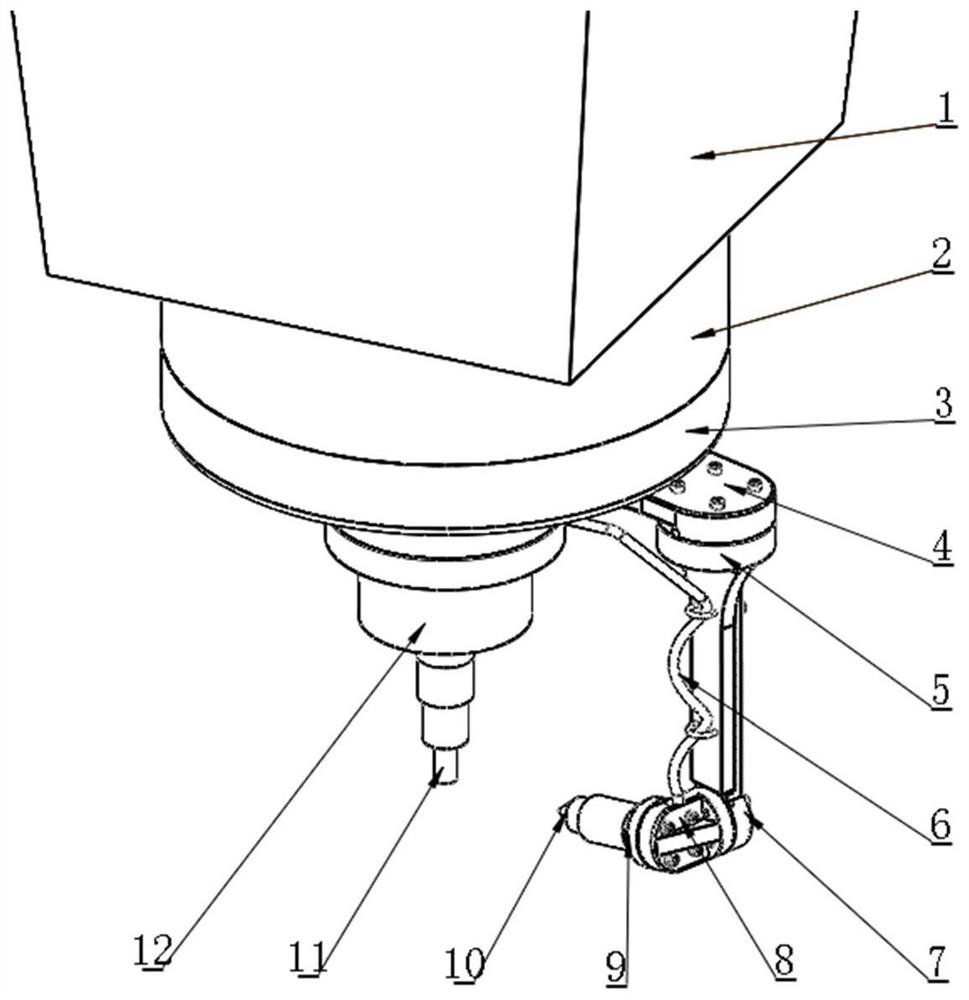

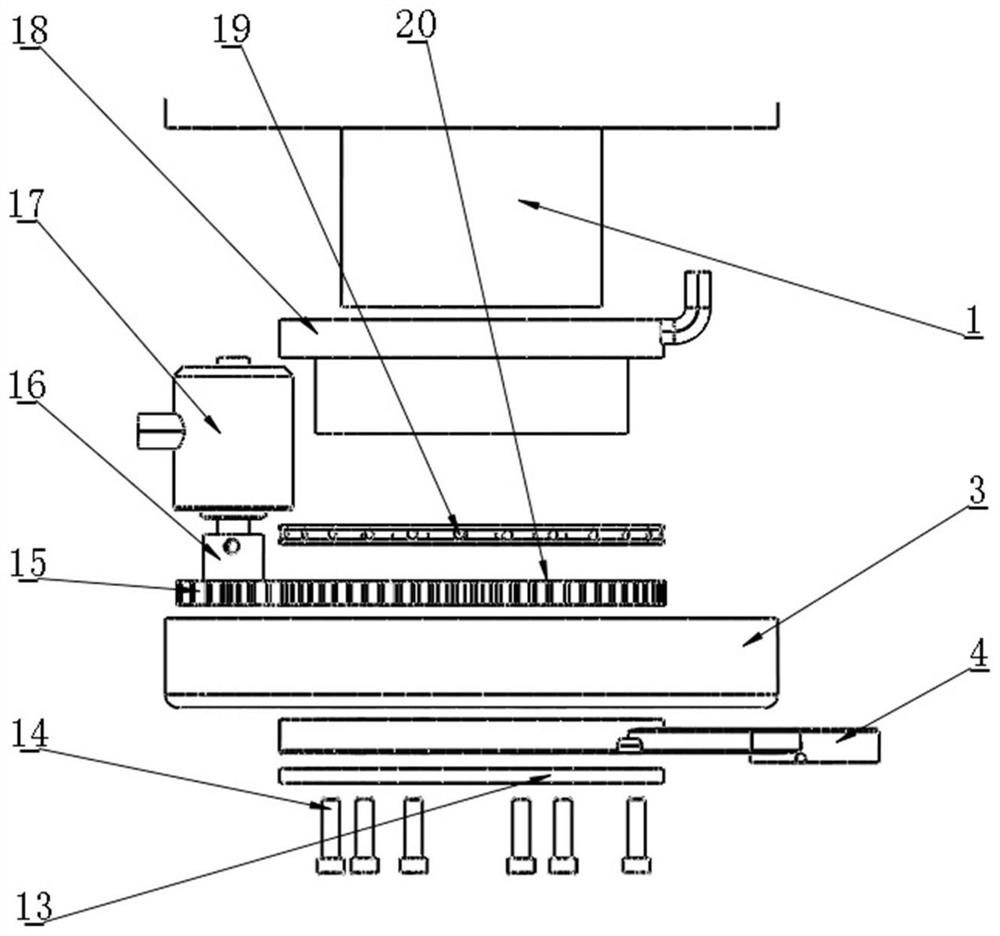

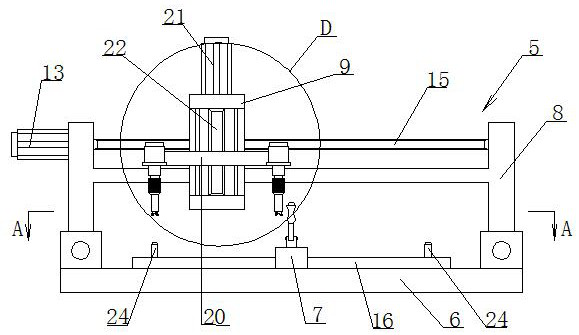

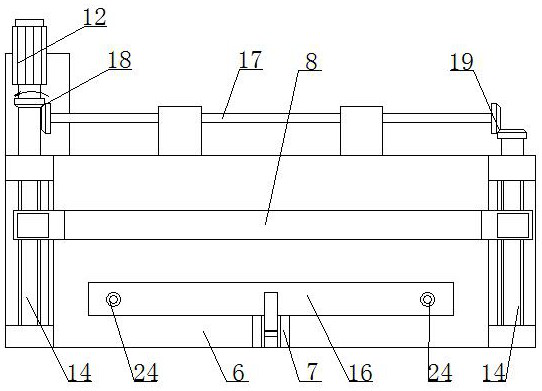

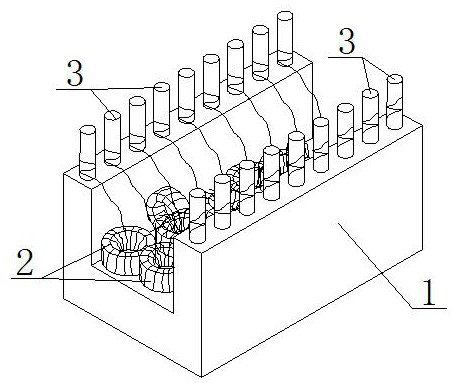

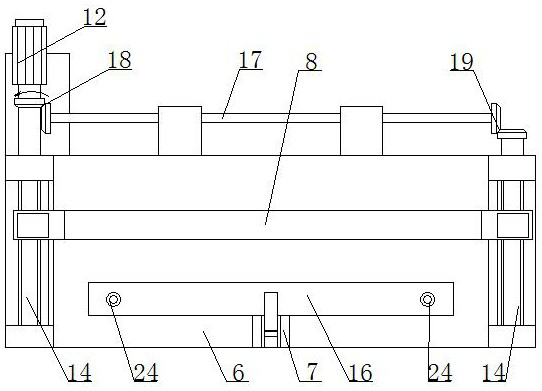

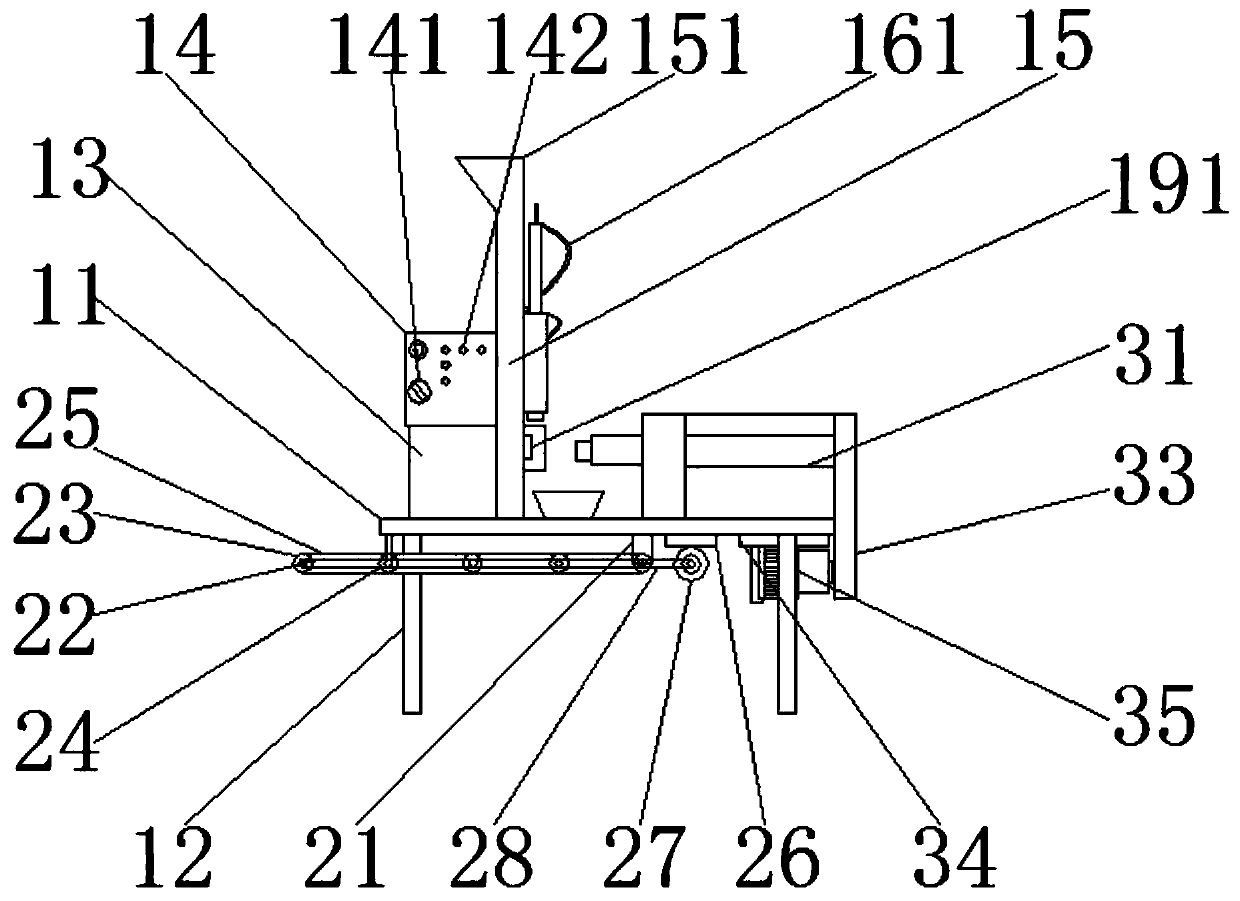

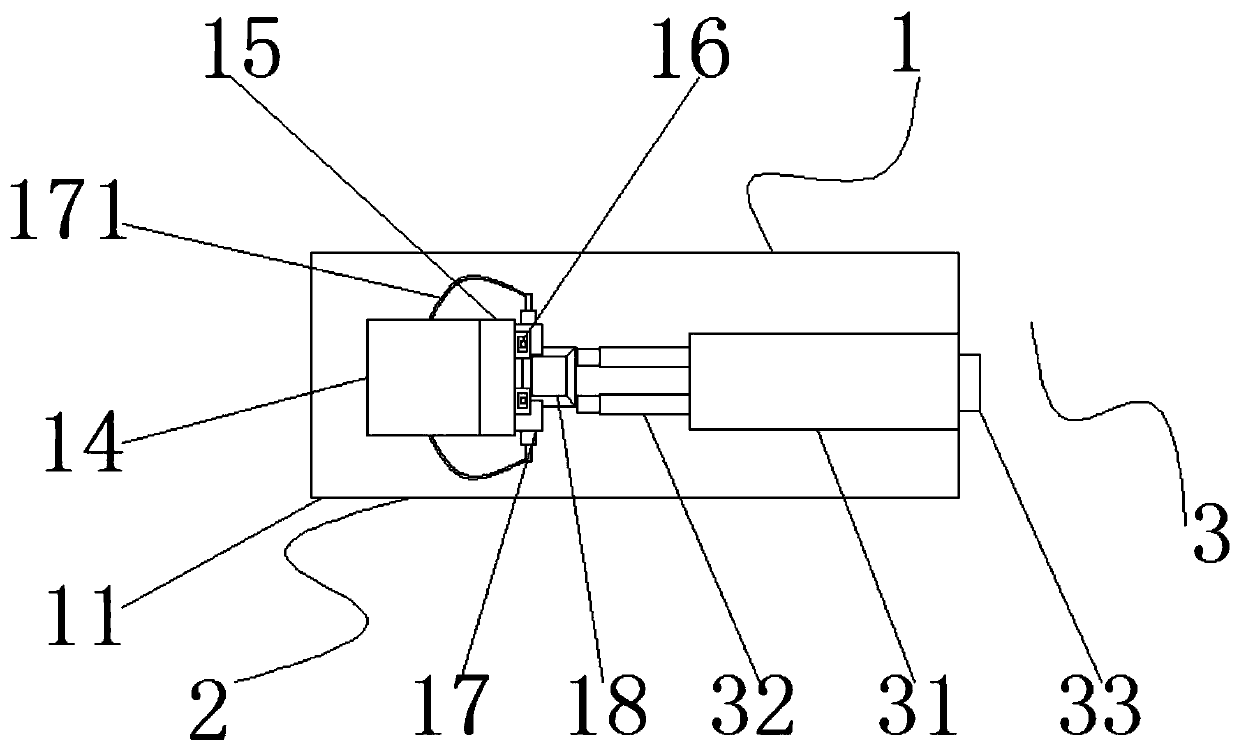

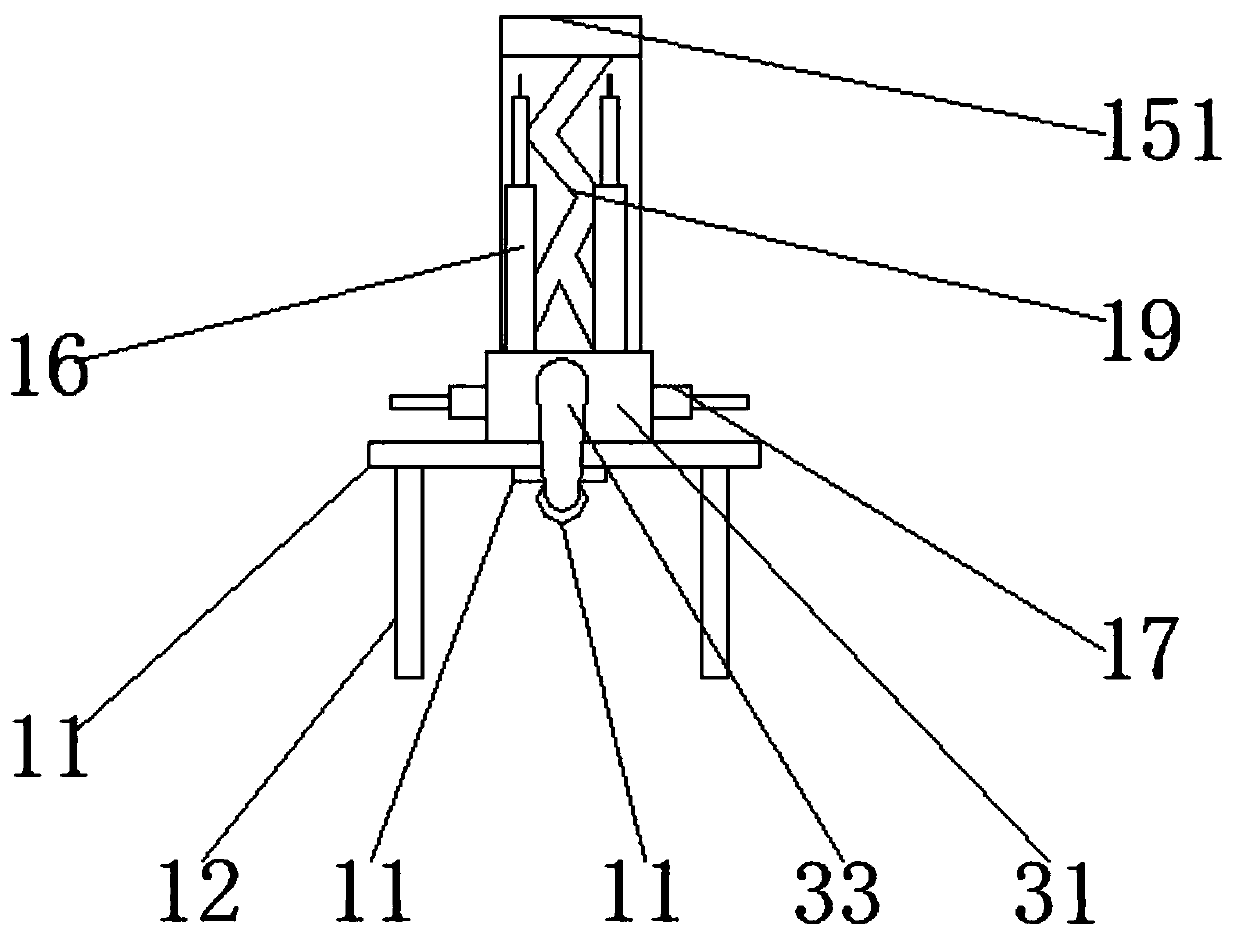

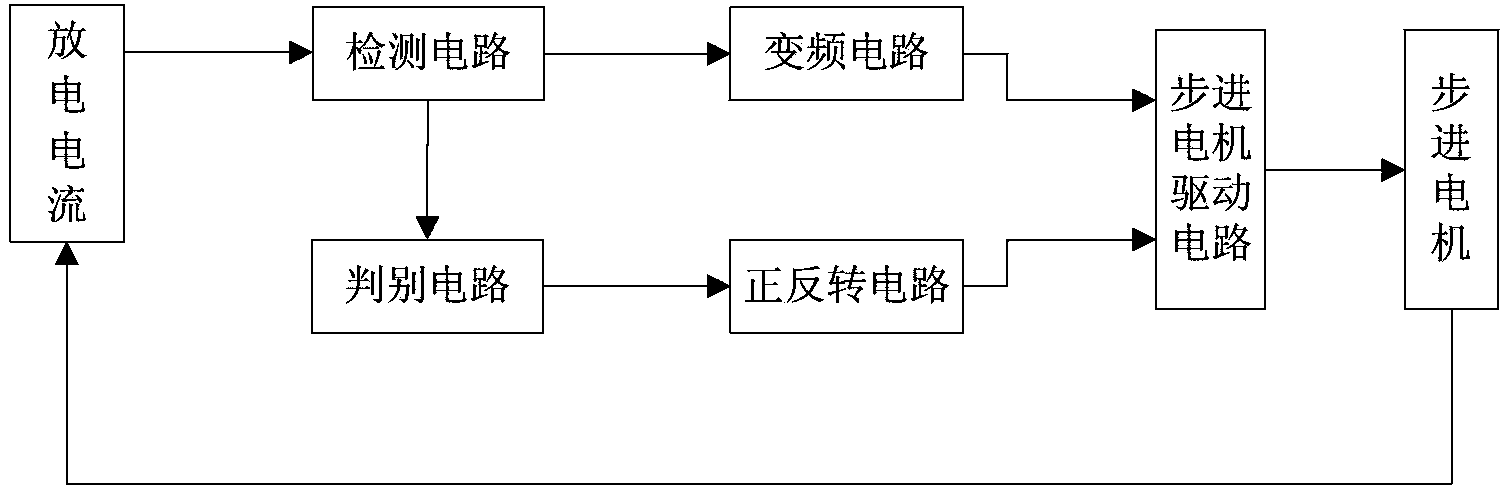

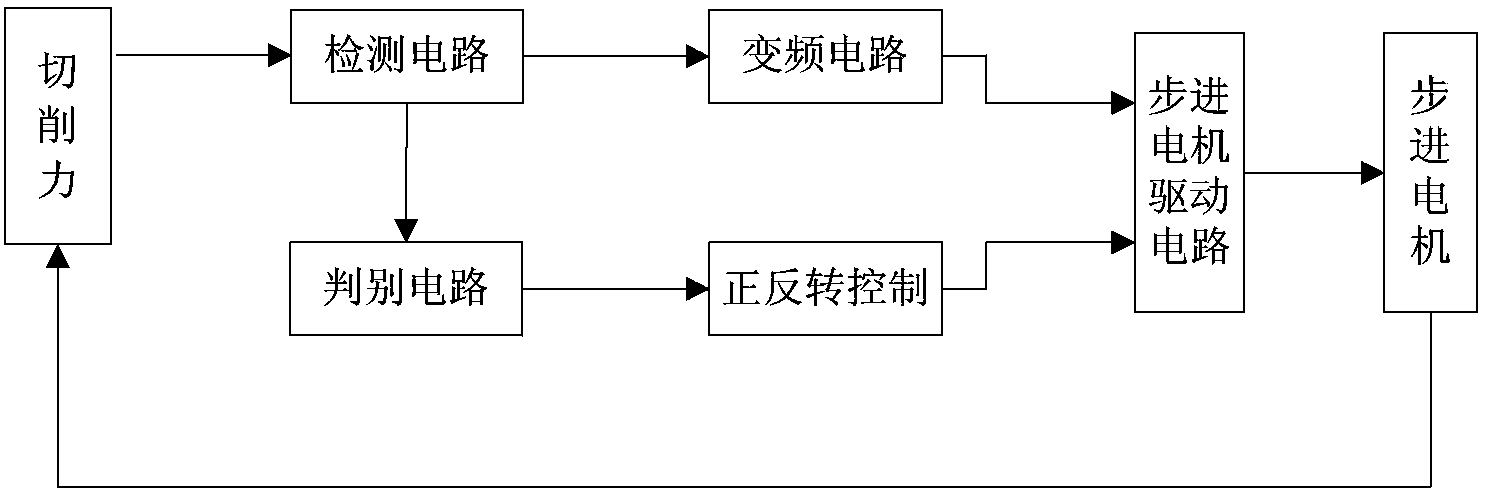

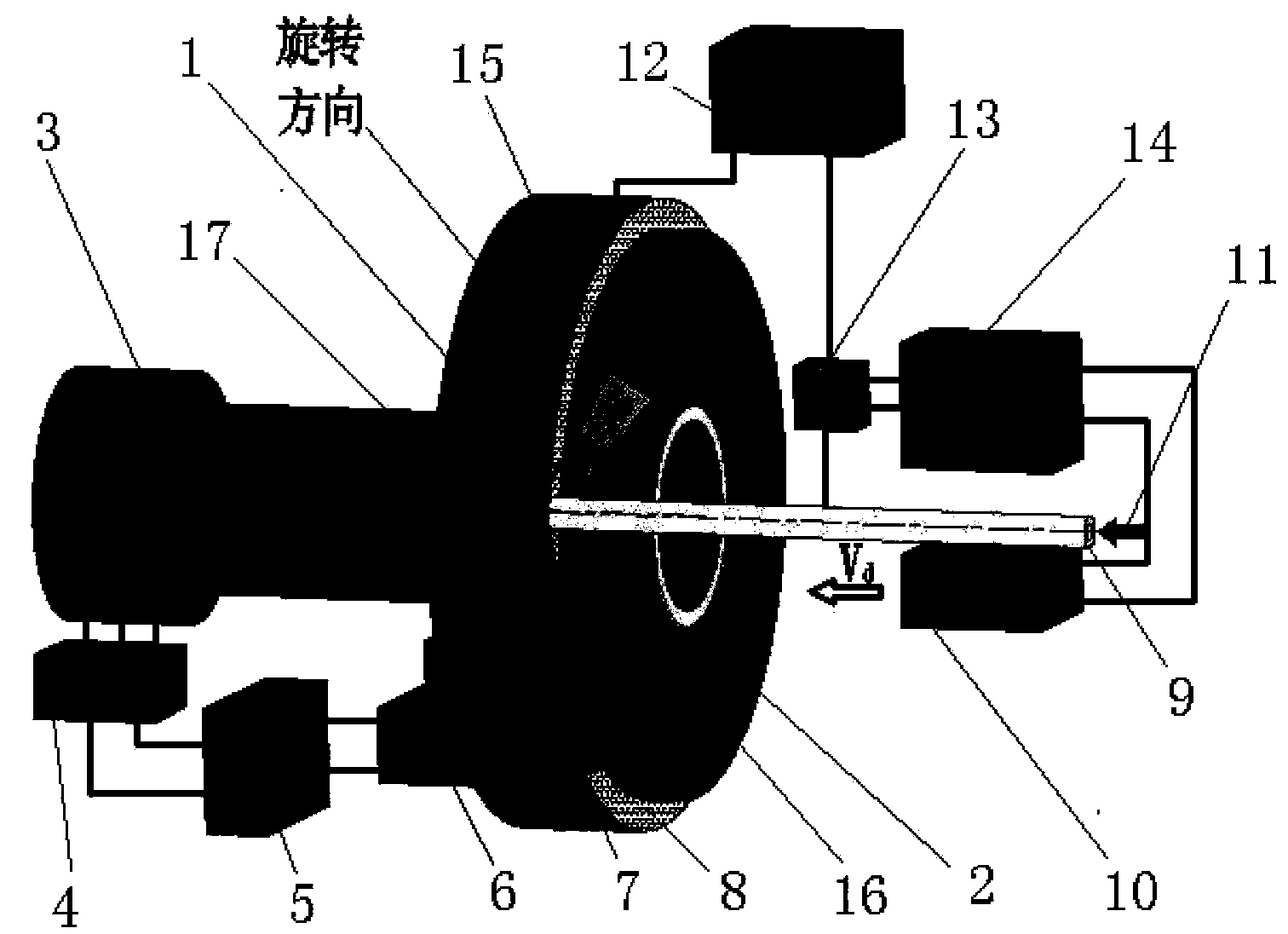

Electric spark induction controllable erosion and mechanical finishing compound cutting dual-servo feeding processing system

ActiveCN102974902AHigh removal rateSolve the problem of low processing efficiencyControl systemCutting force

The invention discloses an electric spark induction controllable erosion and mechanical finishing compound cutting dual-servo feeding processing system which is characterized by comprising an electric spark induction erosion electrode servo feeding control system (1) using an erosion state as a sampling basis and a mechanical finishing tool automatic feeding regulating system (2) using a cutting force as a sampling basis, wherein the electric spark induction erosion electrode servo feeding control system controls the feeding of an induction erosion electrode, ensures that the electric spark induction erosion in a machining region is controllably, efficiently and stably carried out, and forms an erosion product and a softened layer through controllable erosion; and the mechanical finishing tool automatic feeding regulating system ensures that the erosion product and the softened layer which are generated by erosion are cut and removed without cutting a base body material, so that the tool loss is reduced, the finished surface quality is ensured and the processing efficiency is increased. According to the invention, the processing efficiency of a metal material difficult in processing can be remarkably increased, the finished surface quality is increased, and the finished surface is final mechanized surface due to the mechanical finishing function of a tool.

Owner:南京航浦机械科技有限公司

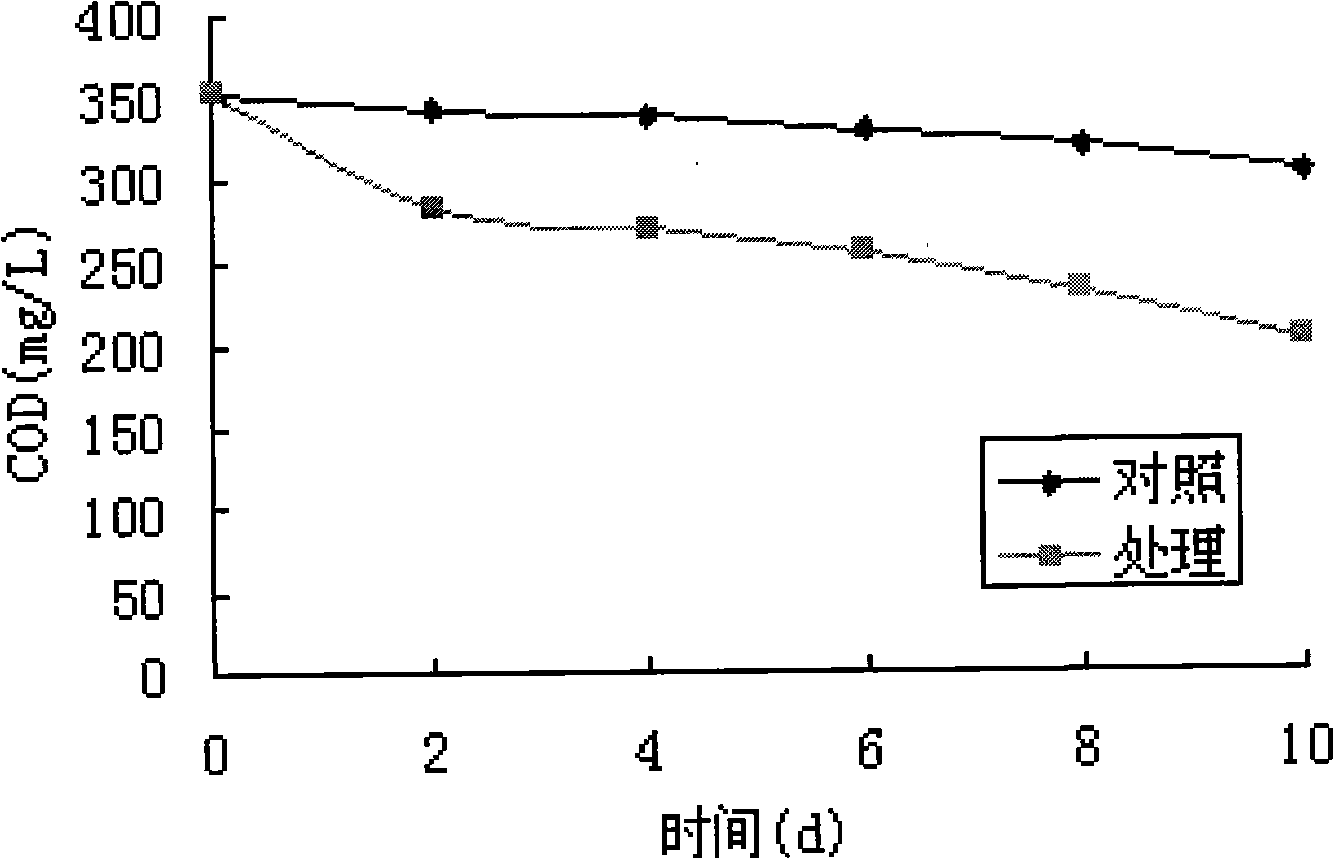

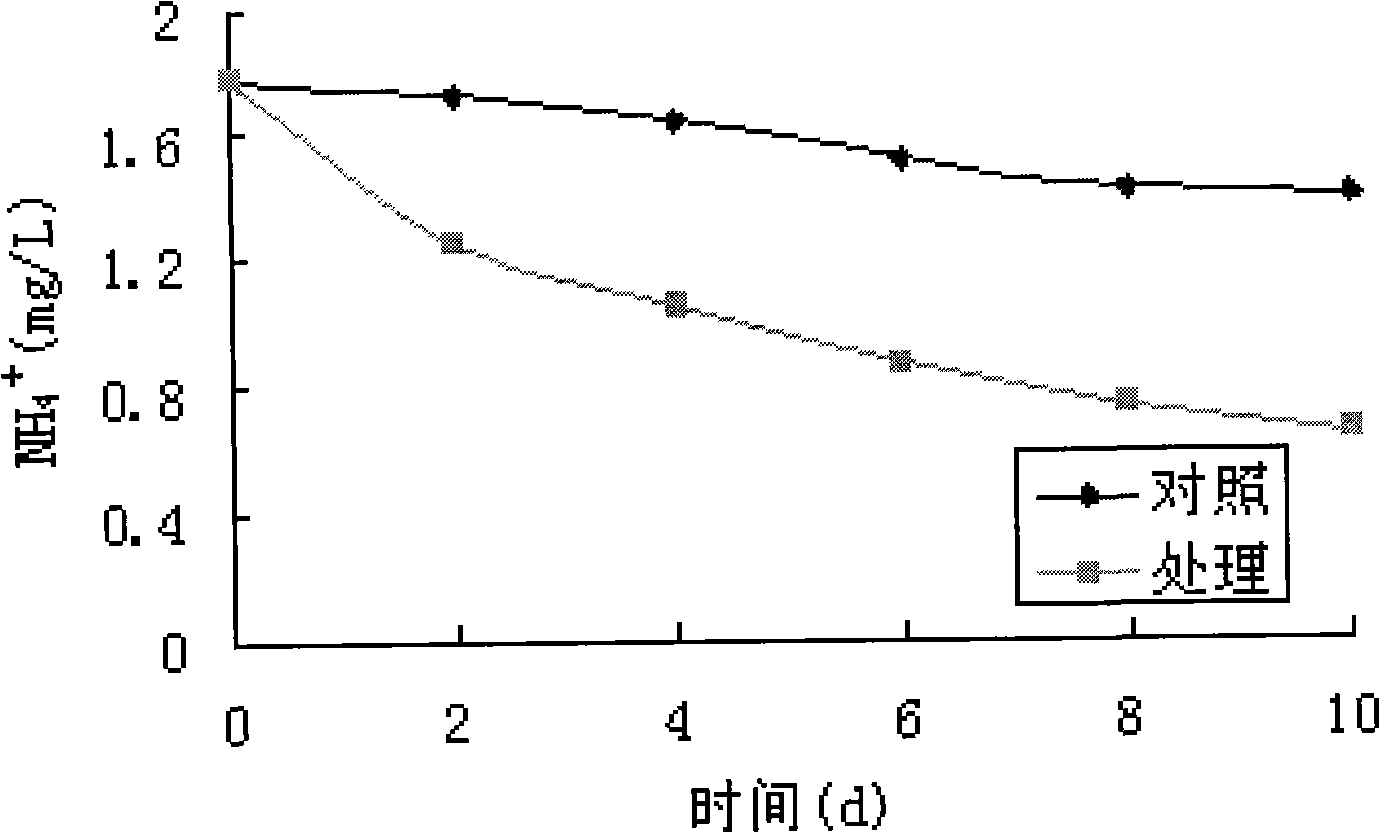

Microorganism water purifying assistant, and preparation and use thereof

InactiveCN101328463APromote decompositionImprove water treatment efficiencyFungiMicroorganism based processesChemistryDecomposition

The invention provides a microbe water purifying additive and a preparation method thereof and an application thereof. The preparation of the microbe water purifying additive is as follows: aspergillus niger CCAM080003 is subject to activation, expansion and fermentation culture, and the culture materials collected are dried and crushed, and the additive is prepared. The microbe water purifying additive of the invention contains hydrolase such as hot activity cellulase, xylanase, dextranase, prolease and lipase, etc., and can accelerate the decomposition of organic matters in the sewage and improve the water treatment efficiency, so the microbe water purifying additive is applied to the water purification treatment in ponds, sewage treatment plants and scenic water, etc. The microbe water purifying additive of the invention can be joined with the microbe purifying agent to purify water; compared with the independent use of the microbe purifying agent, the addition of the water purifying additive can greatly improve the speed of purifying the water and obviously improving the purifying effect.

Owner:东莞市华中生物科技有限公司

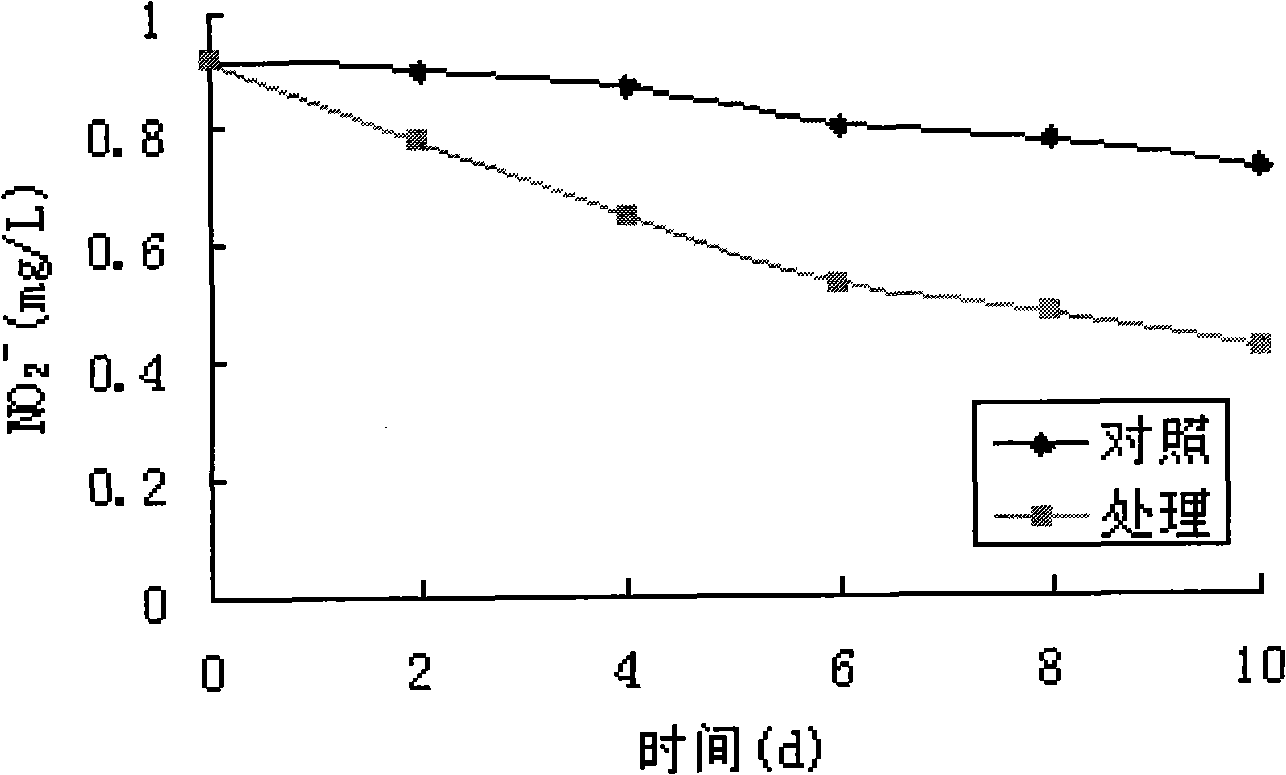

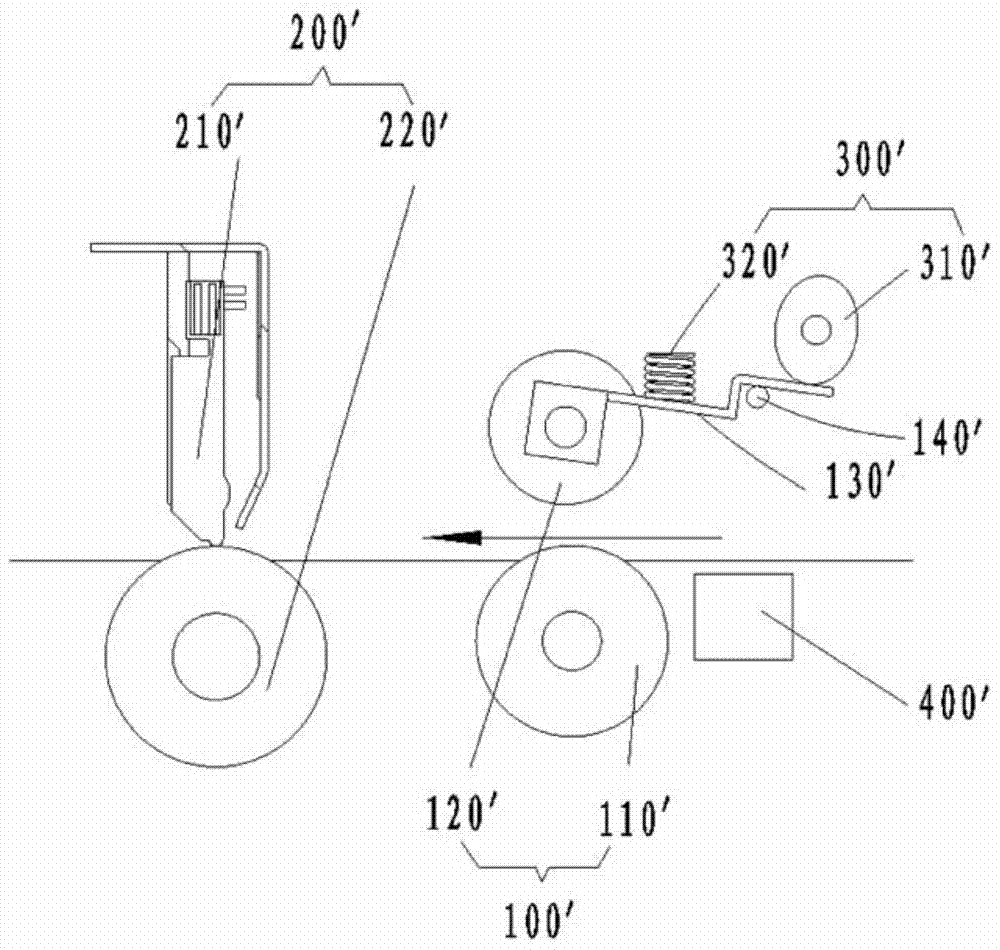

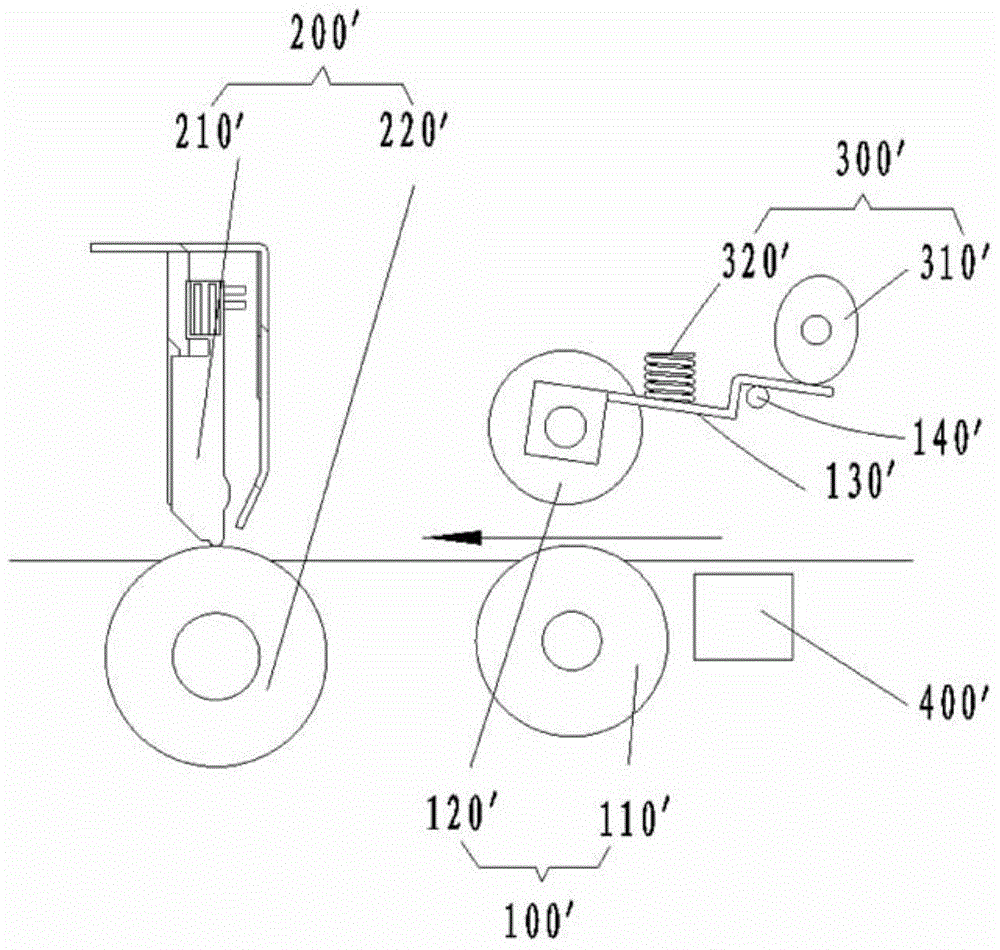

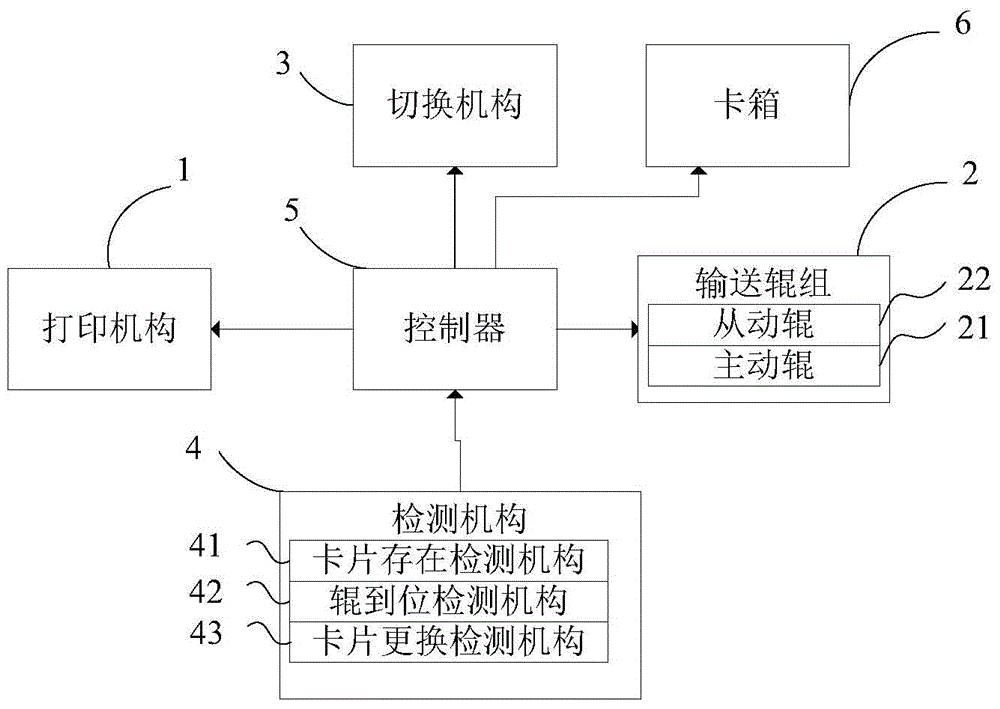

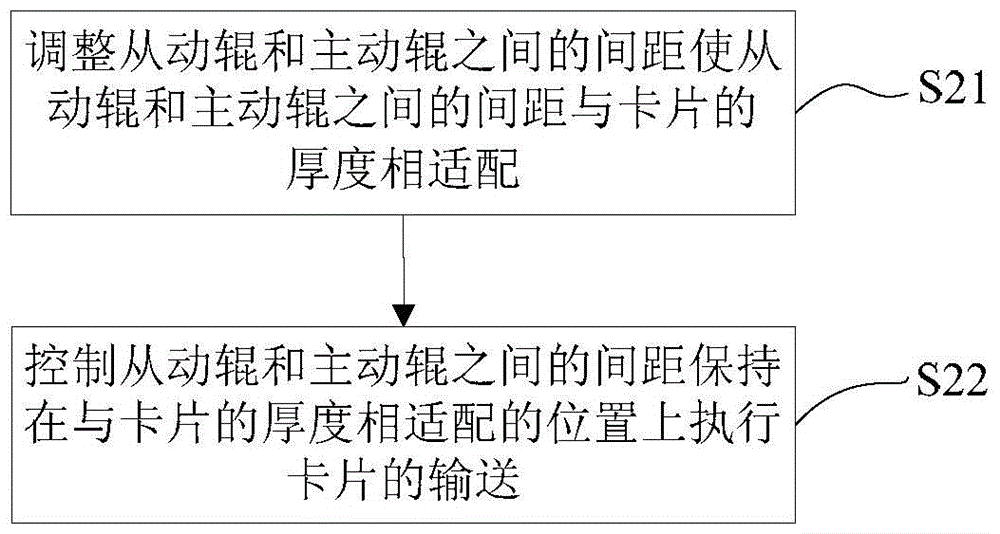

Card printer and conveying roller control method of same

ActiveCN104723694AImprove processing efficiencySolve the problem of low processing efficiencyTypewritersOther printing apparatusEngineeringMechanical engineering

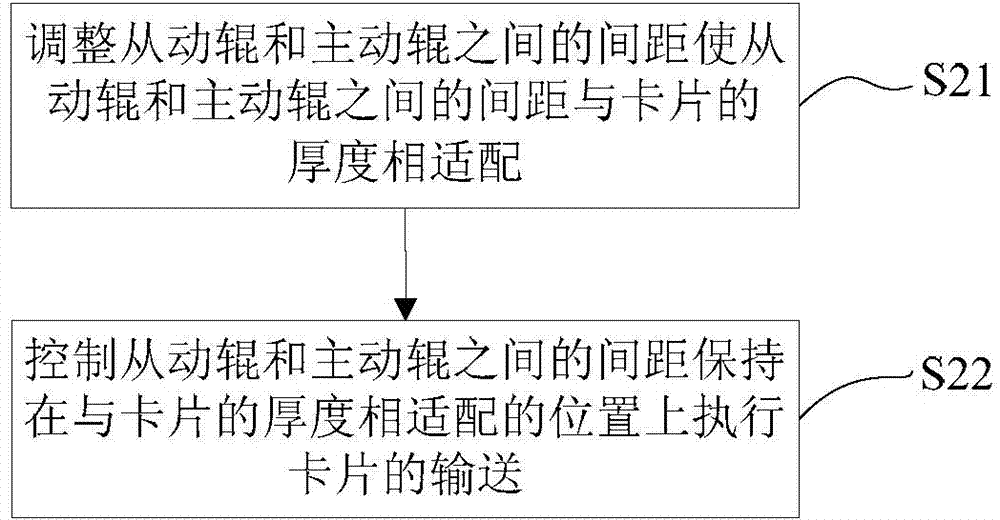

The invention discloses a card printer and a conveying roller control method of the card printer. The card printer comprises a printing mechanism, a conveying roller set, a switching mechanism and a controller, wherein the printing mechanism is used for conducting printing on the surface of a card; the conveying roller set is used for conveying the card to the printing mechanism and comprises a drive roller and a driven roller which are opposite to each other; the switching mechanism is used for adjusting the interval between the driven roller and the drive roller; the controller is used for controlling the switching mechanism to adjust the interval between the driven roller and the drive roller so as to make the interval between the driven roller and the drive roller be matched with the thickness of the card, controlling the interval between the driven roller and the drive roller to enable the conveying roller set to be kept at the position matched with the thickness of the card and convey the card. By means of the card printer and the conveying roller control method of the card printer, the card processing efficiency of the card printer can be improved.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

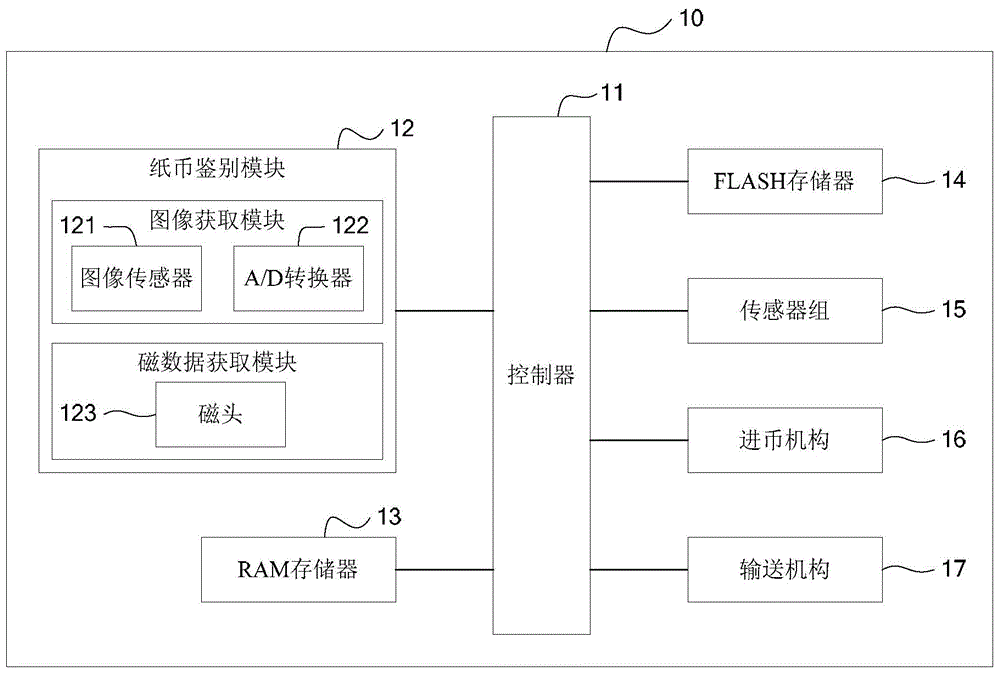

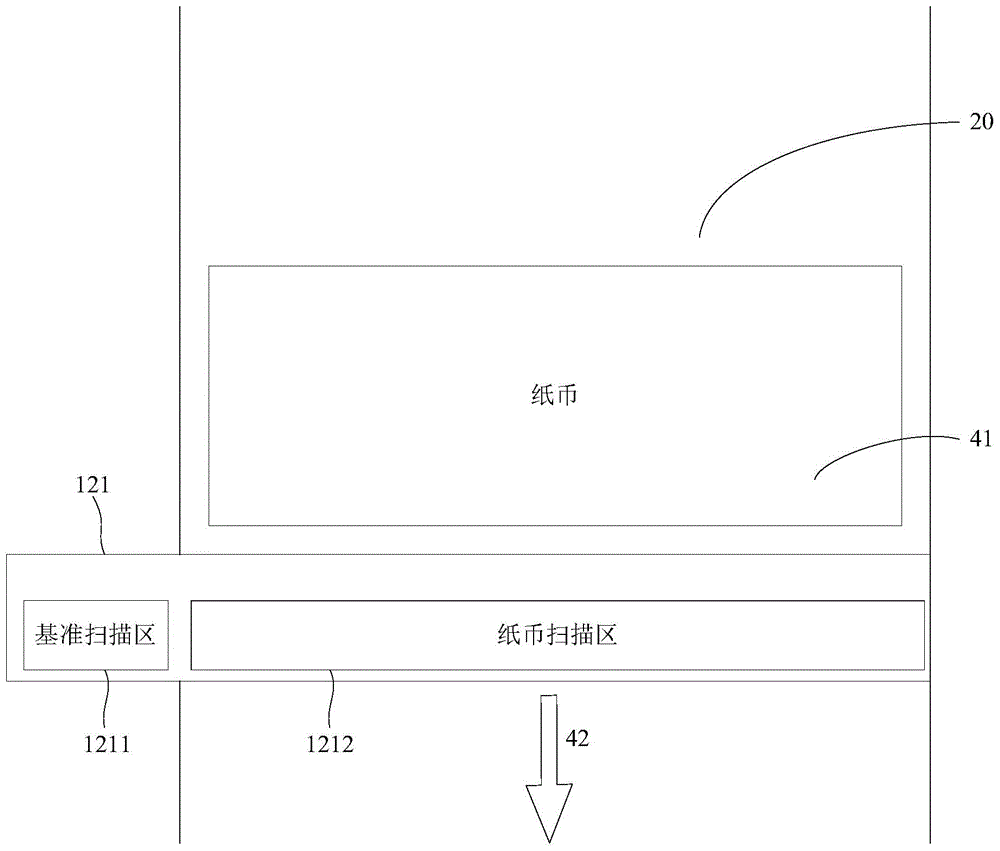

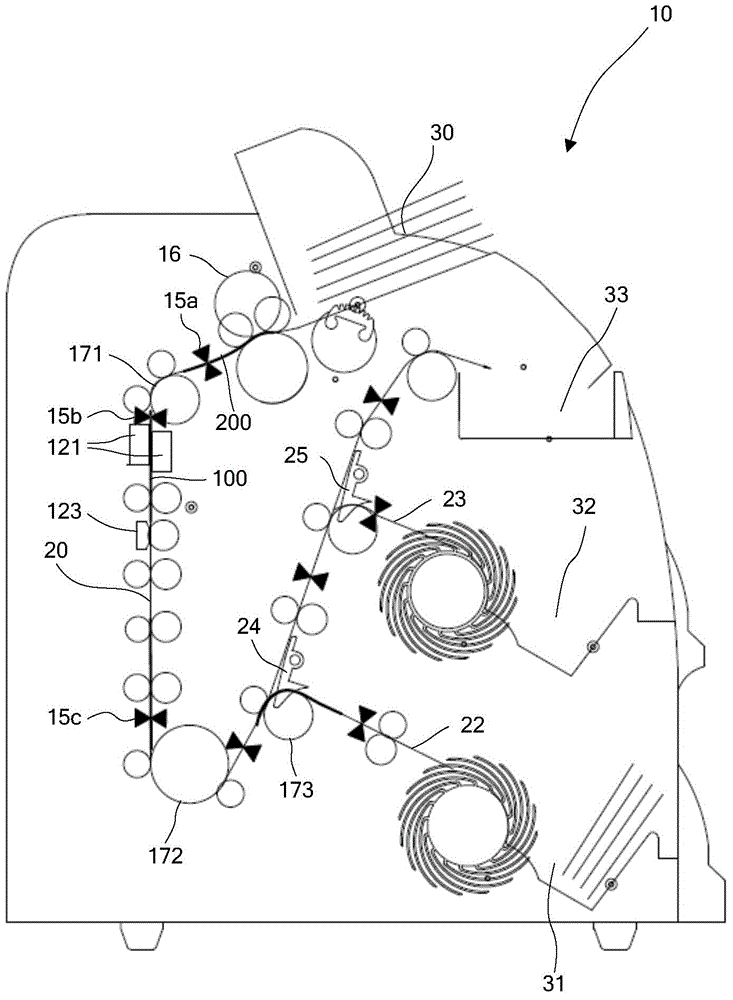

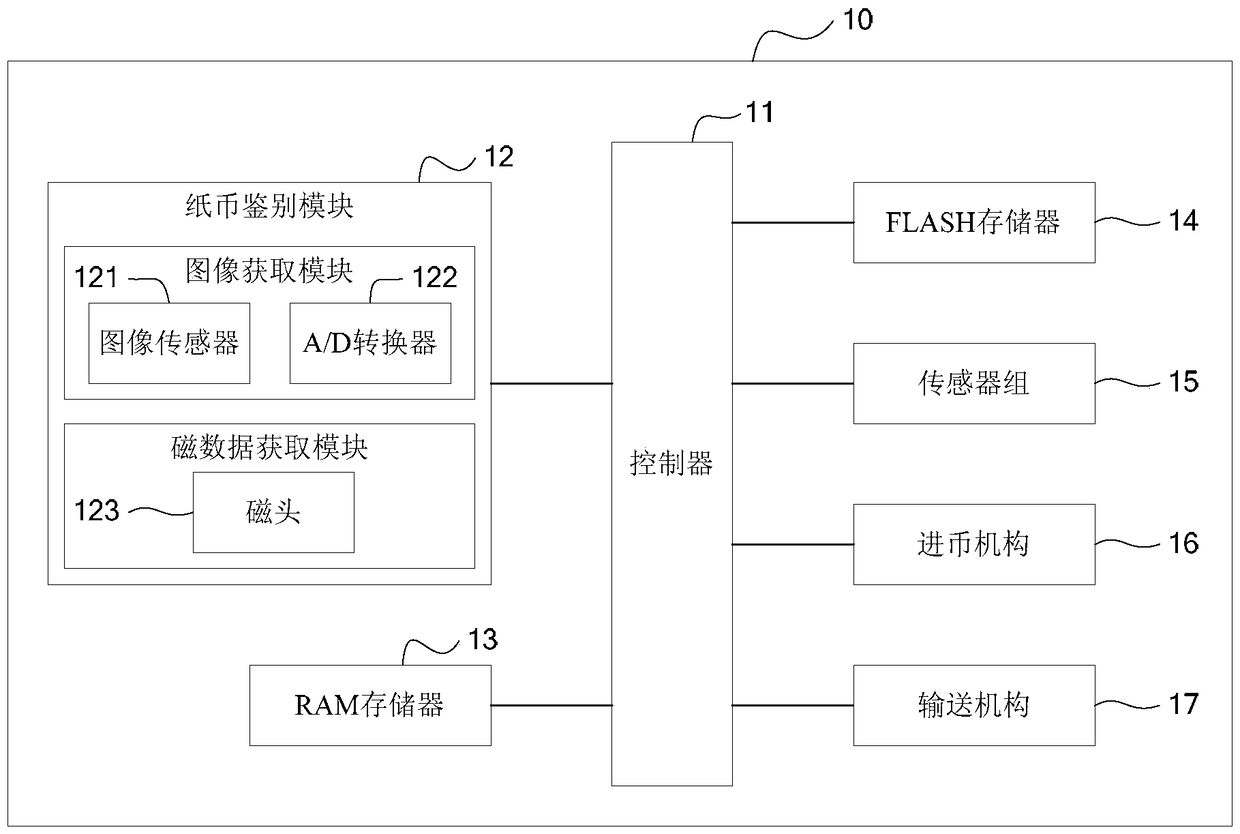

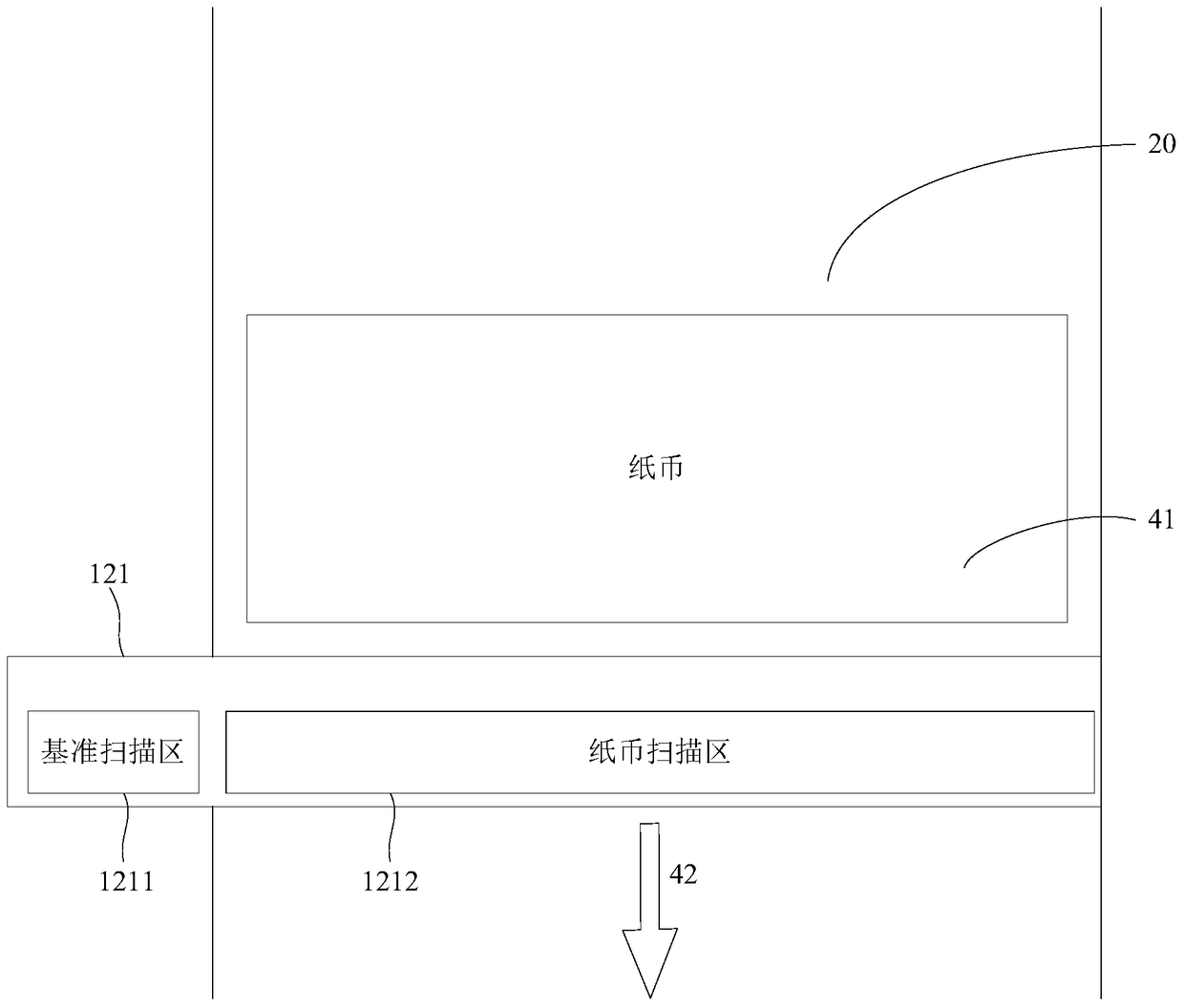

Banknote processing method and banknote processing device

ActiveCN105654608ASolve the problem of low processing efficiencyImprove work efficiencyPaper-money testing devicesCharacter and pattern recognitionImaging dataImage acquisition

The invention discloses a banknote processing method and a banknote processing device. The banknote processing method comprises the following steps: while acquiring banknote image data through an image acquisition module, scanning a substrate through the image acquisition module to get substrate image data; acquiring the characteristic value of the substrate image data; calculating the change value of the characteristic value of the substrate image data relative to a reference characteristic value; judging whether the change value is greater than a preset threshold; and configuring the parameters of the image acquisition module if judging that the change value is greater than the threshold. According to the invention, the work efficiency of the banknote processing device is improved.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

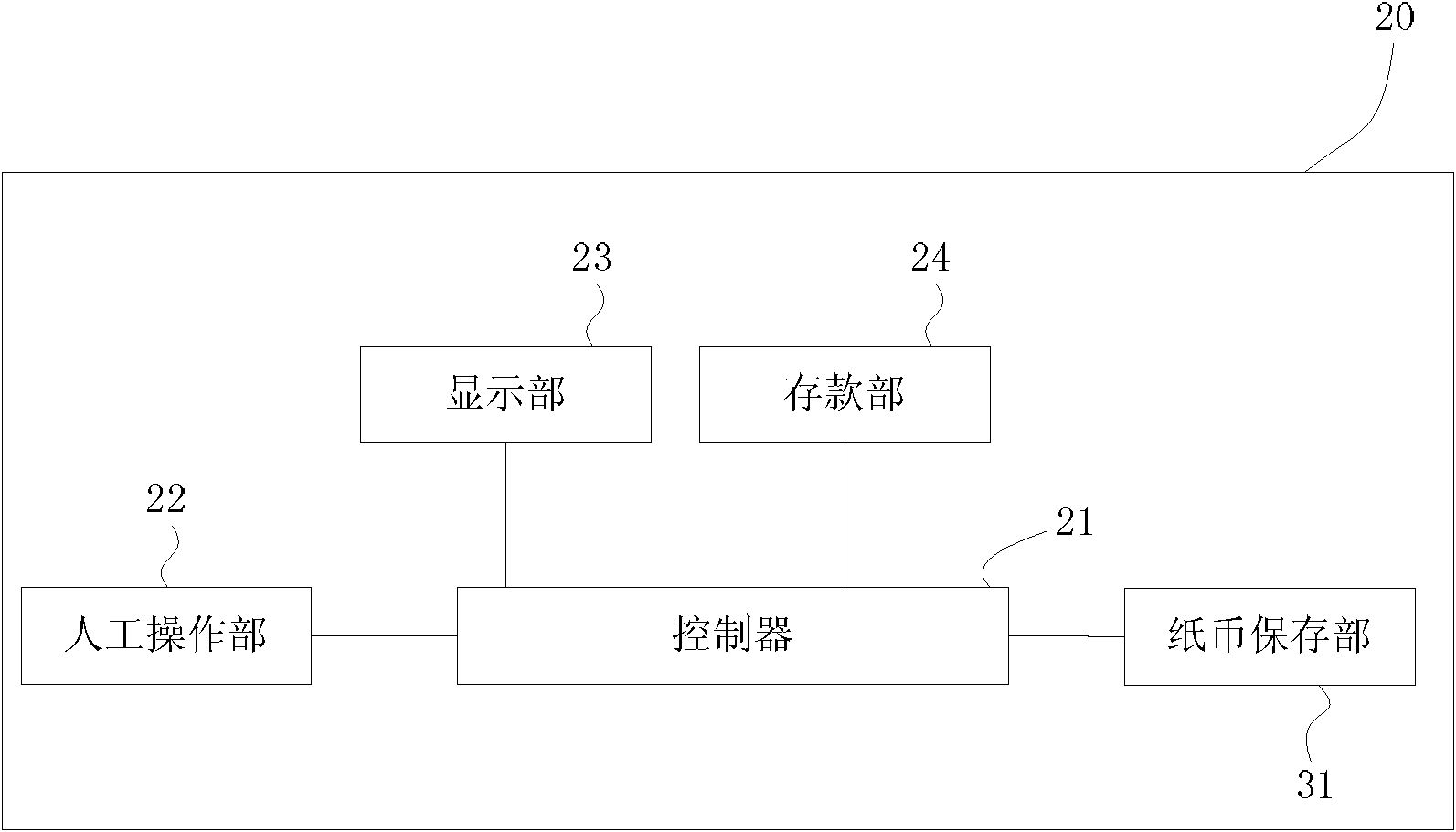

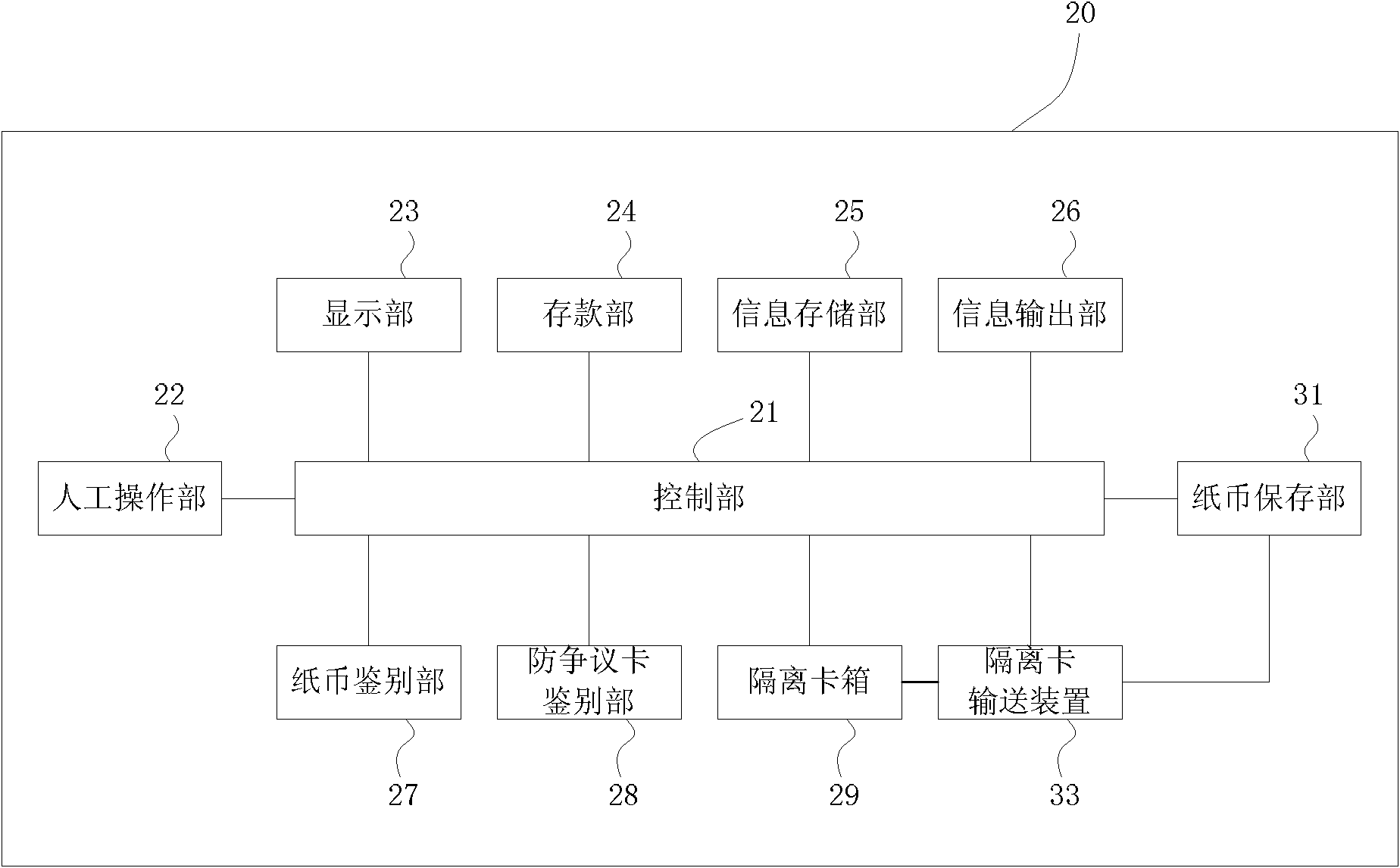

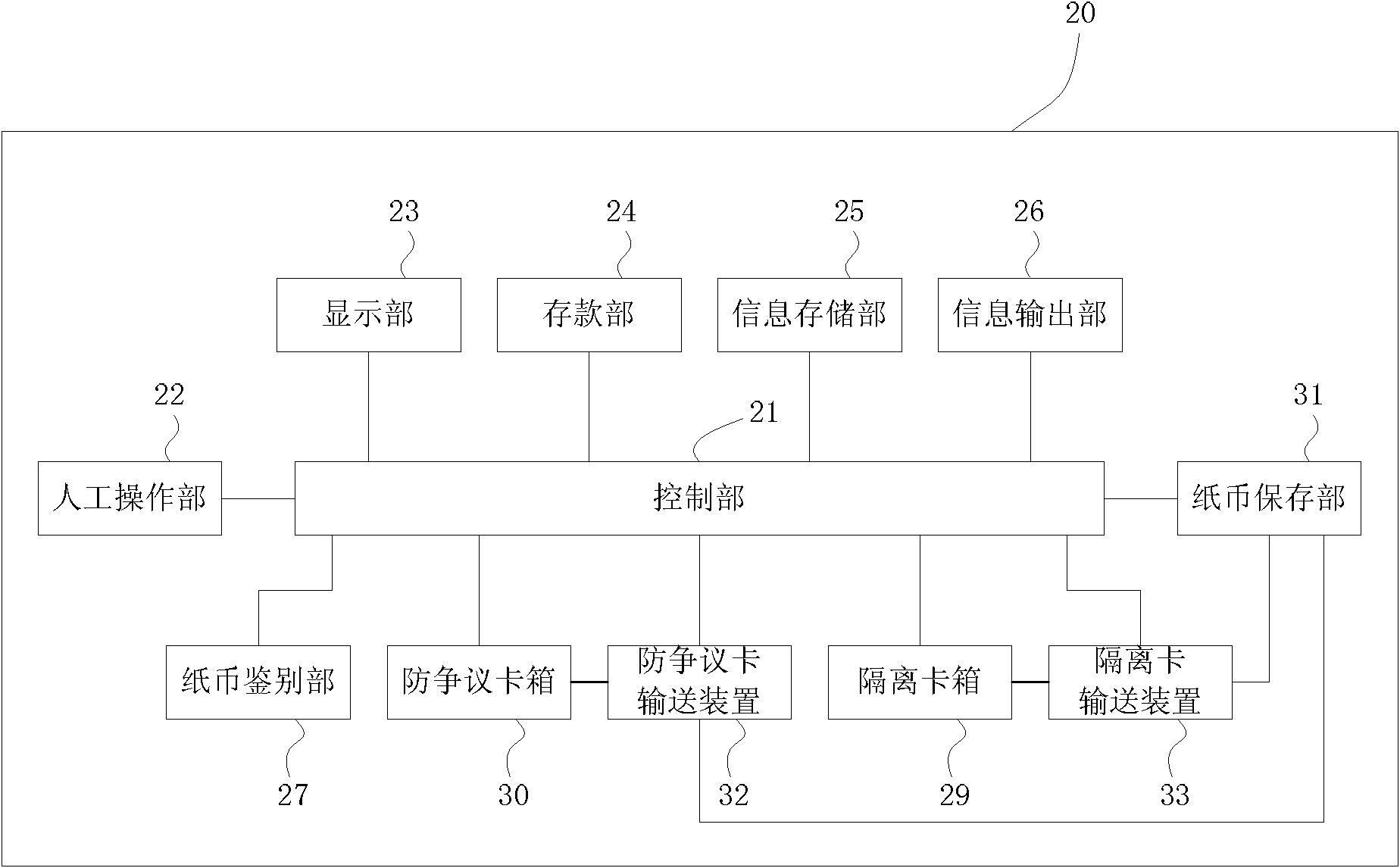

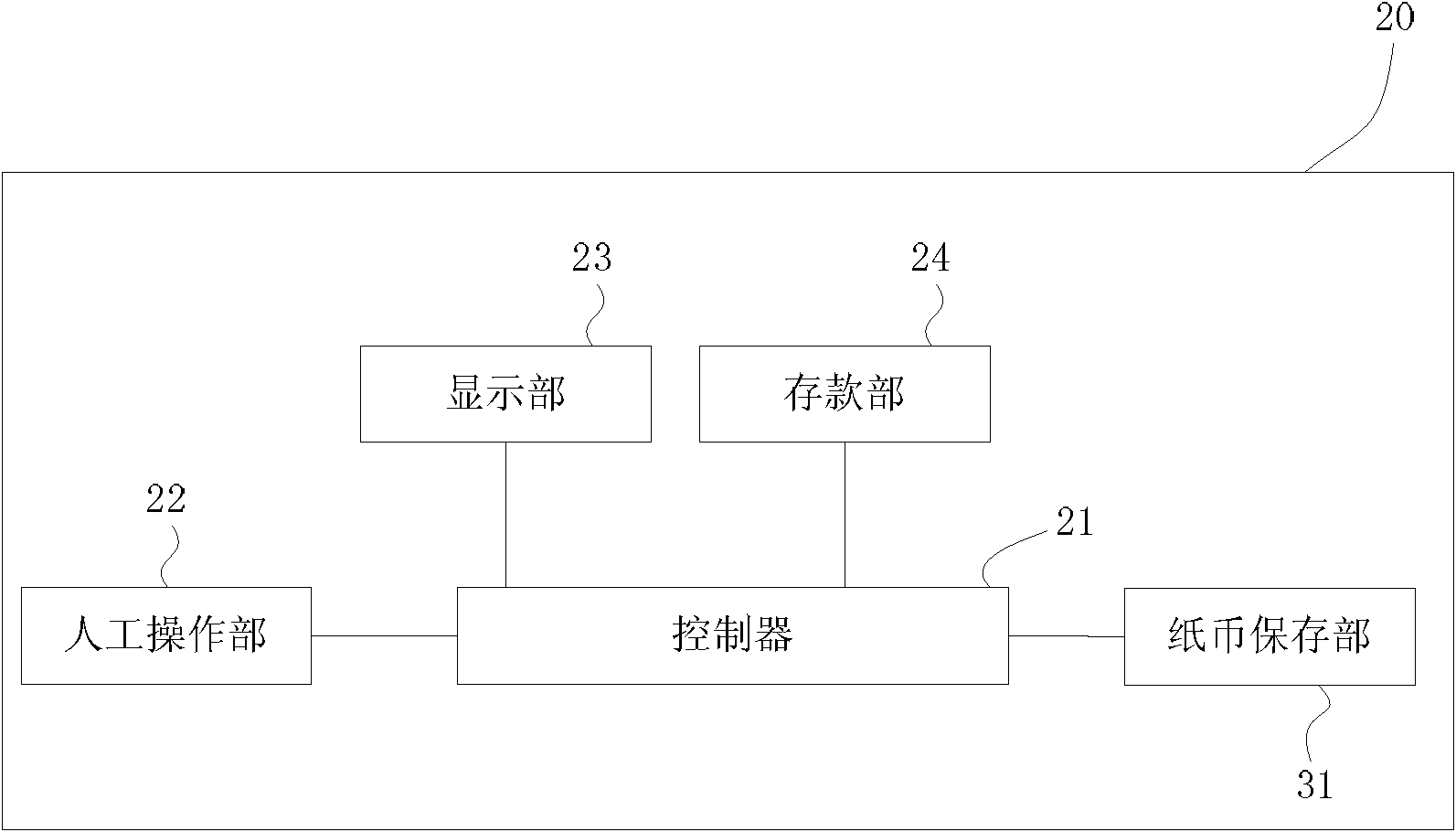

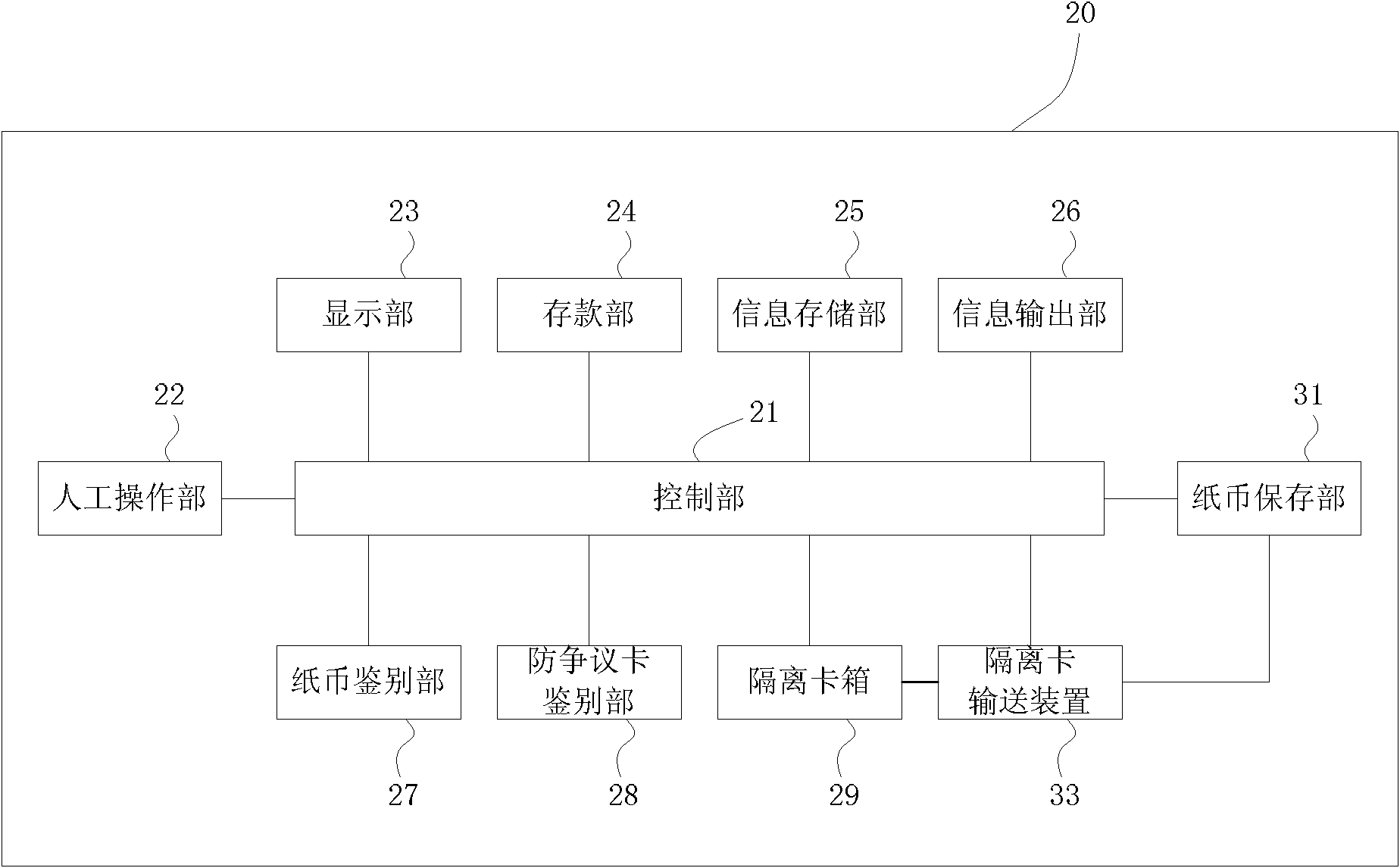

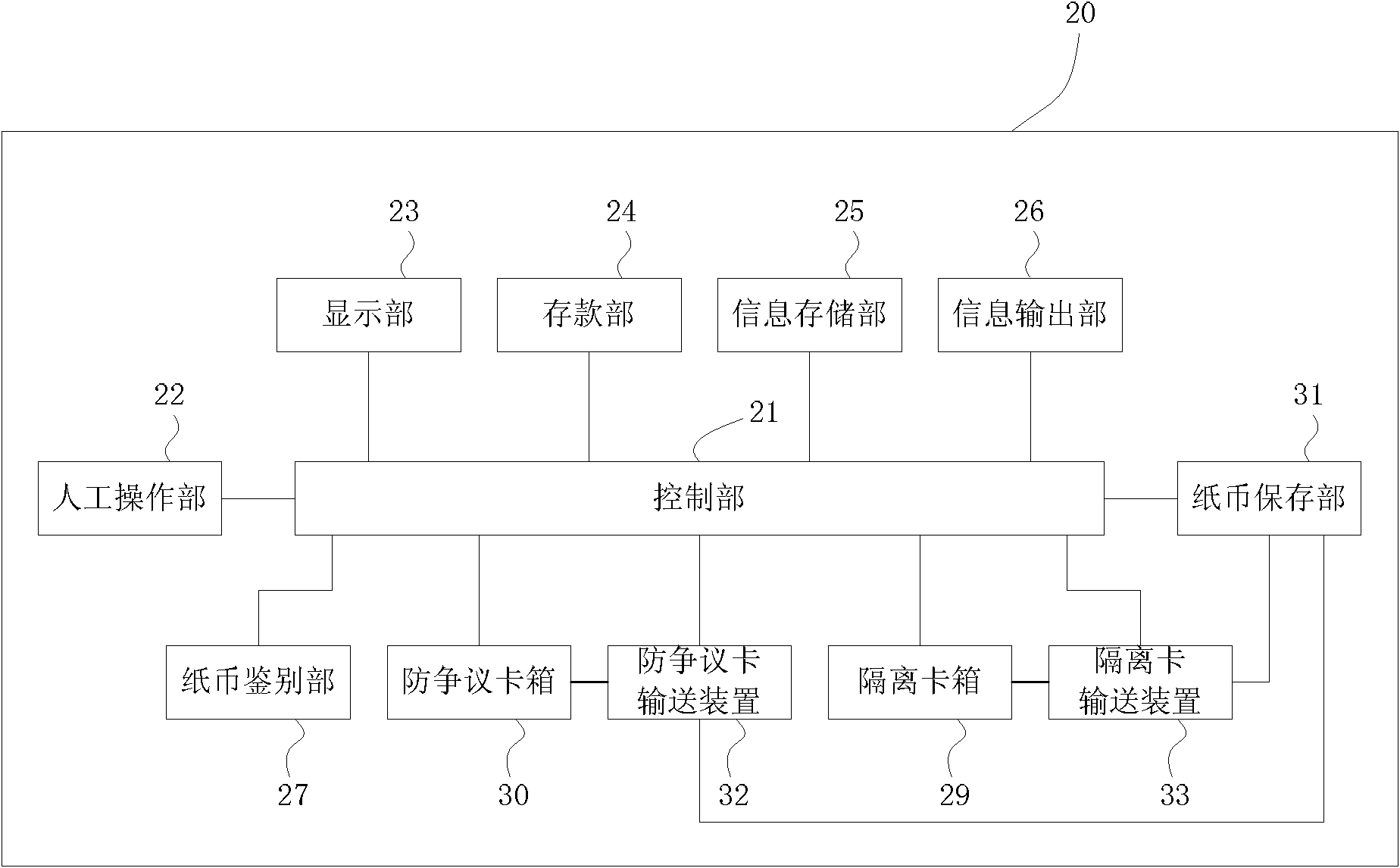

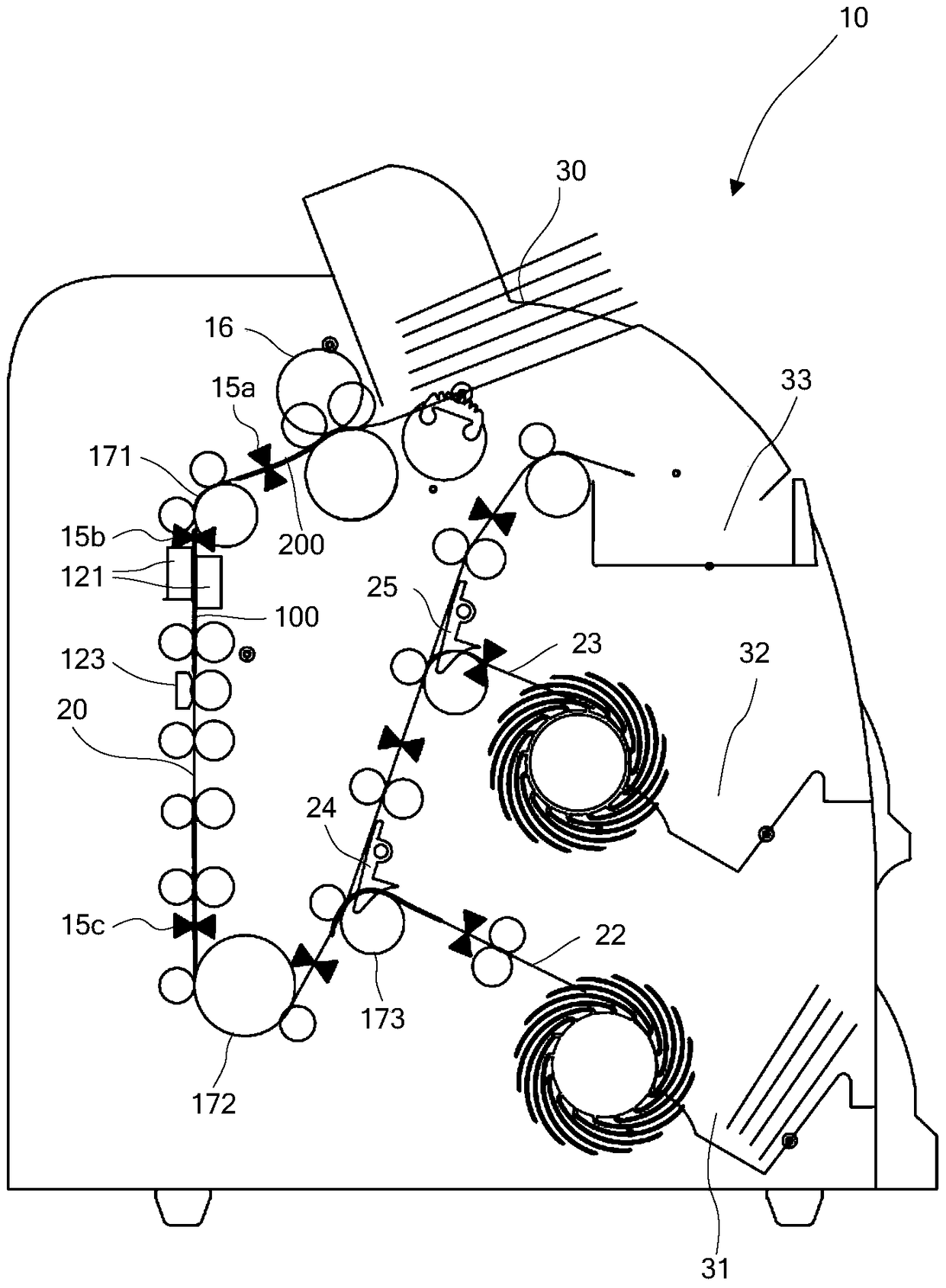

Note treatment device and note treatment method thereof

ActiveCN102693577ASolve the problem of low processing efficiencyImprove processing efficiencyCoin/currency accepting devicesComputer science

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

A method for manufacturing a metal silenced honeycomb structure

InactiveCN109204845AAvoid pluggingImprove hole making efficiencyAircraft power plant componentsFuselage insulationBeam splitterOptoelectronics

The invention relates to a method for manufacturing a metal silenced honeycomb structure. The metal honeycomb structure obtained by brazing the panel and the honeycomb core body adopts the laser to drill the metal silencing hole, and adopts a single-stage or multi-stage beam splitter system to separate the single beam laser light source into a plurality of laser beam streams when the laser drillsthe hole, so as to simultaneously drill the metal silencing hole by the plurality of laser beam streams. On the basis of avoiding hole blocking in the brazing process of metal muffler honeycomb and ensuring the muffler performance, the method solves the problem of low machining efficiency when drilling holes one by one with single laser beam, and improves the drilling efficiency of metal muffler honeycomb.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

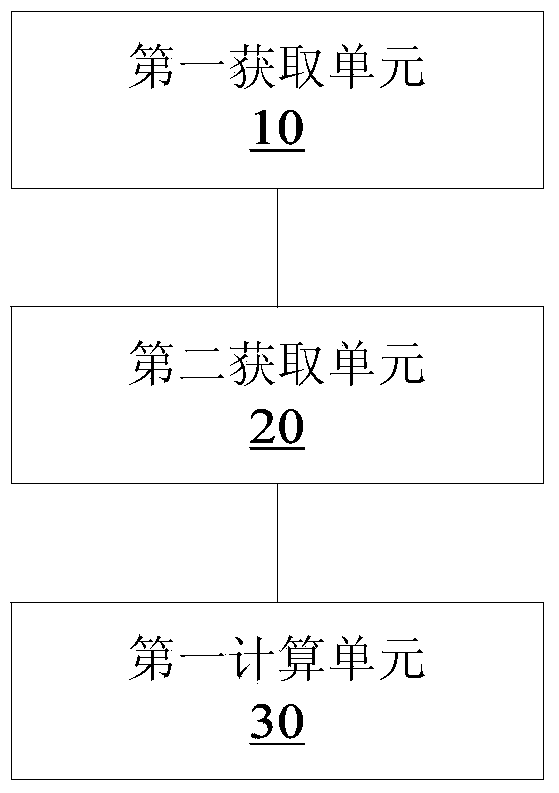

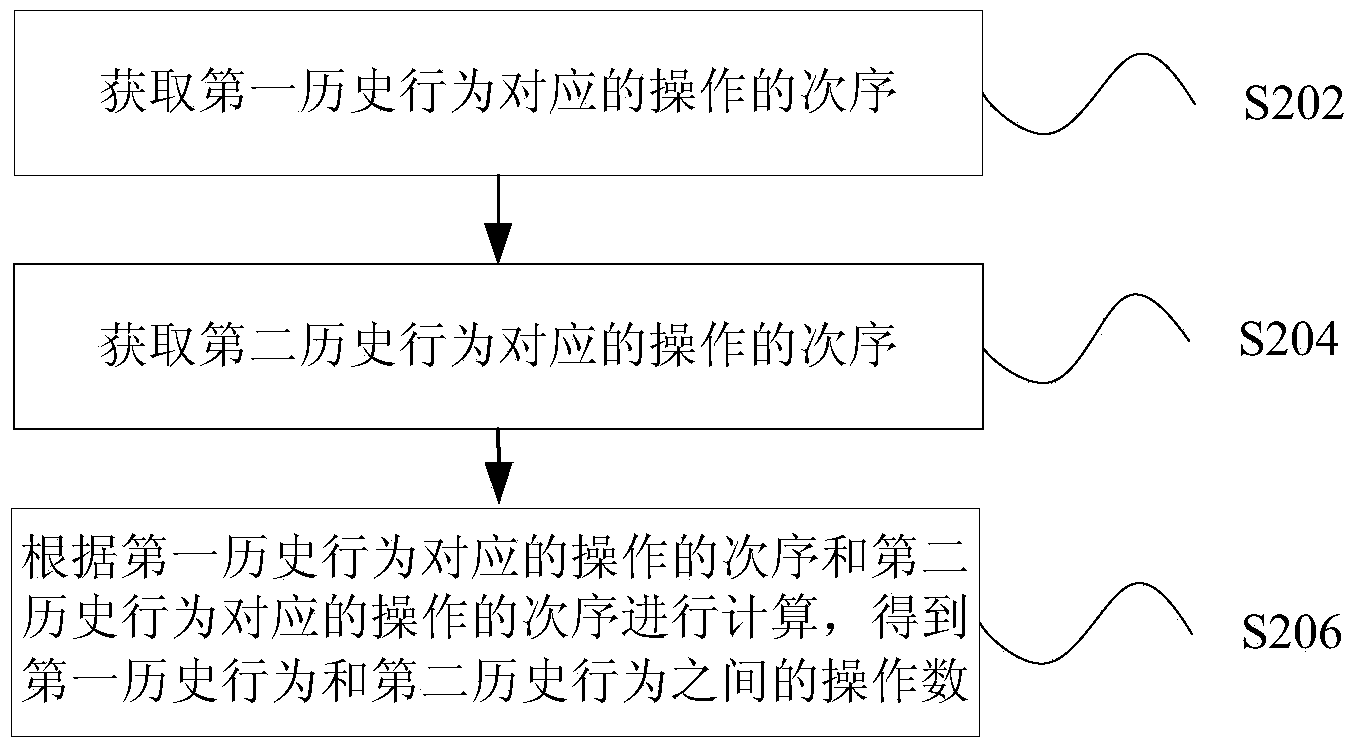

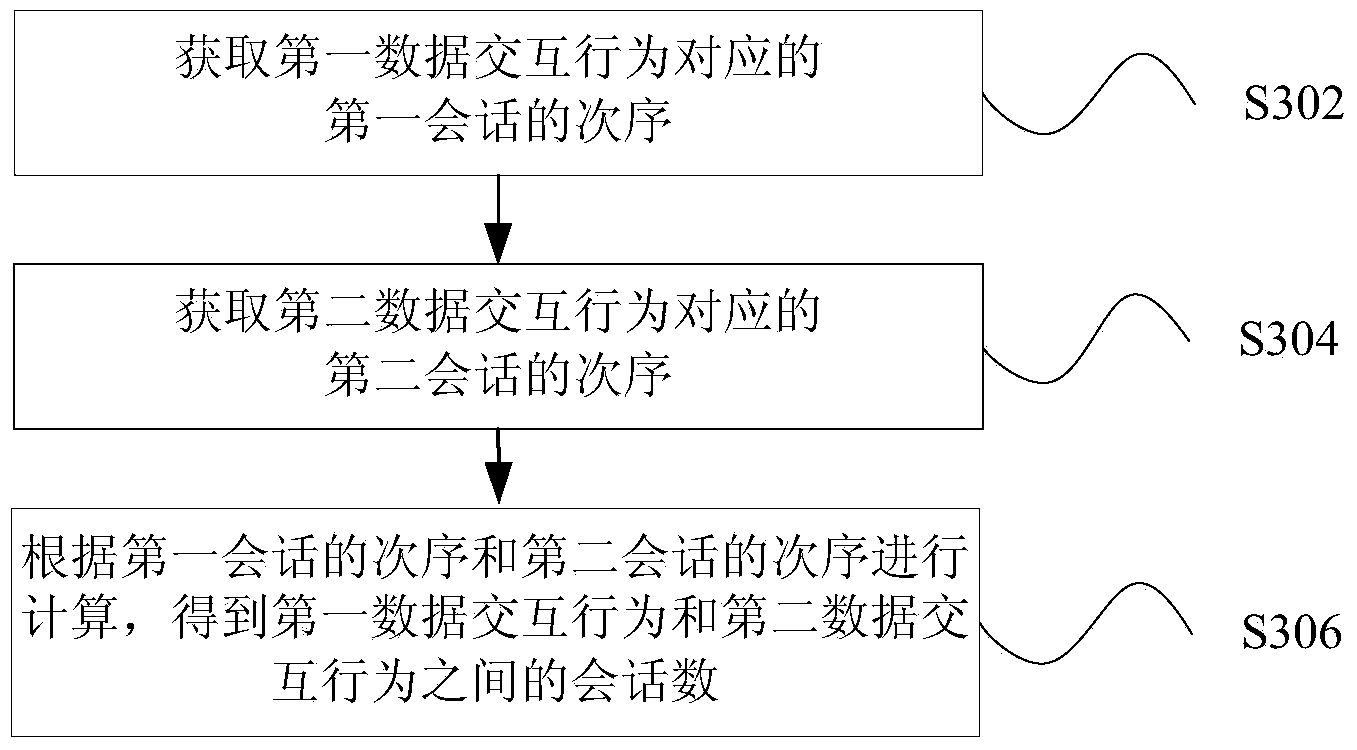

Data processing method and device for computer historical behavior analysis

ActiveCN103823891ASolve the problem of low processing efficiencyQuick analysisError detection/correctionSpecial data processing applicationsComputer engineeringData processing

The invention discloses a data processing method and device for computer historical behavior analysis. The data processing method for the computer historical behavior analysis comprises the steps of obtaining the sequence of operations corresponding to a first historical behavior; obtaining the sequence of operation corresponding to a second historical behavior; calculating according to the sequence of the operations corresponding to the first historical behavior and the sequence of the operations corresponding to the second historical behavior to obtain the operation number between the first historical behavior and the second historical behavior, wherein the computer historical behaviors comprise the first historical behavior and the second historical behavior corresponding to different time. By the invention, the problem of lower processing efficiency of data processing on historical behavior analysis in related technologies is solved.

Owner:BEIJING GRIDSUM TECH CO LTD

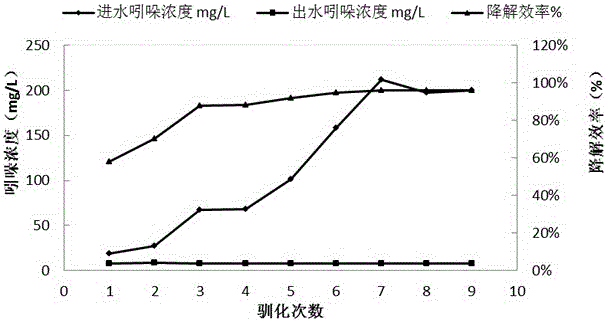

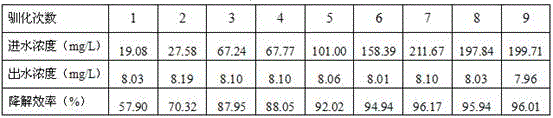

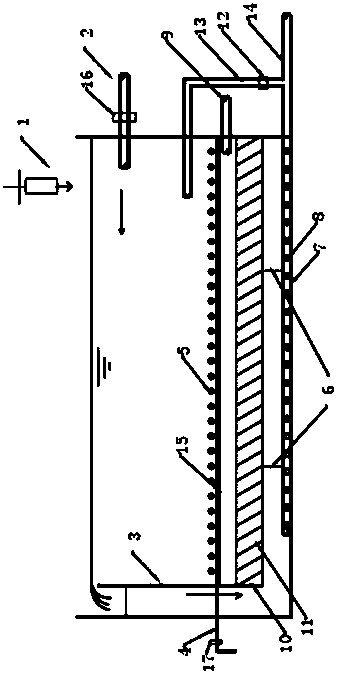

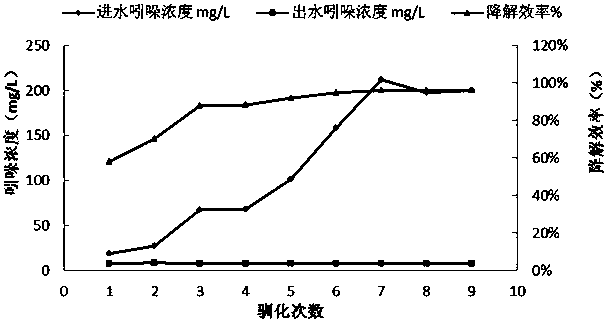

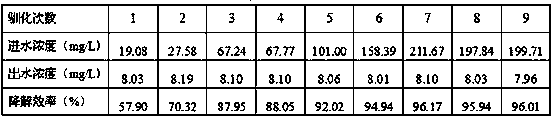

Indole-degrading compound bacterial agent and reaction device thereof

ActiveCN106011016APracticalHigh efficiency in degrading pollutantsBacteriaWater contaminantsChemistryOrganism Strain

The invention discloses an indole-degrading compound bacterial agent and a reaction device thereof. The compound bacterial agent is prepared from three indole-degrading microbial strains including pseudomonas monteilii QM, bacillus L1 and Tolumonas G1. The reaction device comprises an aeration mixing reaction area, an aeration device, a bacterial agent feeder with the indole-degrading compound bacterial agent, an overflow area, an inclined-plate precipitation area, a residual sludge discharge pipe and a sludge backflow device. The indole-degrading compound bacterial agent disclosed by the invention has strong practicability; under the joint effect with the compound bacterial agent, the pollutant degrading efficiency of aerobic active sludge is high; the compound bacterial agent can adapt to the environment within short time so as to culture and acclimatize an efficient flora suitable for indole wastewater; the indole and COD detected in the water both can reach the standard; and the problems of limitation of existing methods in treating nitrogen heterocyclic ring organic matter indole and low treatment efficiency of existing bacterial agents are solved.

Owner:HARBIN INST OF TECH

Papermaking sewage treatment agent and preparation method thereof

InactiveCN107445275AEffective coagulationImprove adsorption capacityOther chemical processesWaste water treatment from plant processingSodium BentoniteZincite

The invention belongs to the field of sewage treatment and in particular relates to a papermaking sewage treatment agent. The papermaking sewage treatment agent is prepared from the following raw materials in parts by weight: 60 to 70 parts of shell powder, 8 to 10 parts of zinc chloride, 10 to 15 parts of polyaluminum chloride, 10 to 15 parts of polyacrylamide, 3 to 5 parts of bentonite, 5 to 7 parts of zincite powder and 5 to 8 parts of trioctylamine; a preparation method of the treatment agent comprises the following steps: weighing all the raw materials in parts by weight according to the requirement; after the shell powder is subjected to pre-treatment including curing and the like, putting the shell powder and the other raw materials into a reaction kettle together; pre-heating, mixing and stirring for 2h to 3h under the condition that the temperature is 65 DEG C to 75 DEG C; then raising the temperature to 100 DEG C to 110 DEG C, and standing and keeping heat for 1h to 2h; then discharging a product, naturally cooling and sealing and packaging. A processing method of the papermaking sewage treatment agent disclosed by the invention is simple; suspended matters, inorganic salt and organic matters in papermaking sewage can be effectively coagulated and adsorbed and the treatment efficiency of the sewage is improved.

Owner:ANHUI XUANTONG IND DESIGN CO LTD

Processing device for traditional Chinese medicine decoction pieces

PendingCN112294653ASolve the problem of low processing efficiencyImprove processing efficiencyPharmaceutical product form changeLoading/unloadingElectric machineryDrive motor

The invention discloses a processing device for traditional Chinese medicine decoction pieces, relates to the field of traditional Chinese medicine processing, and aims to solve the problem that the processing efficiency is low due to the fact that raw materials are directly poured into the processing device in existing traditional Chinese medicine decoction piece processing. According to the scheme, the processing device comprises a processing box and a material supply box, wherein the material supply box is fixedly installed at the top end of the processing box; a driving motor is fixedly installed on one side of the processing box; an output shaft of the driving motor is fixedly connected with a rotating rod; and the rotating rod penetrates through the processing box and extends to theexterior of the other side of the processing box. The processing device is novel in structure; the traditional Chinese medicine raw materials are automatically and discontinuously fed into the processing box by the device; the processing efficiency of the processing device to the traditional Chinese medicine raw materials can be effectively improved through cooperation of the traditional Chinese medicine raw materials and a turning plate in the processing box; a material conveying device and a material conveying box of the material conveying device are arranged in a net cylinder shape, so thatimpurities attached to the traditional Chinese medicine raw materials can be effectively removed, and the cleanliness of the traditional Chinese medicine raw materials is improved; and the device issuitable for application and popularization.

Owner:湖北世友中药饮片有限公司

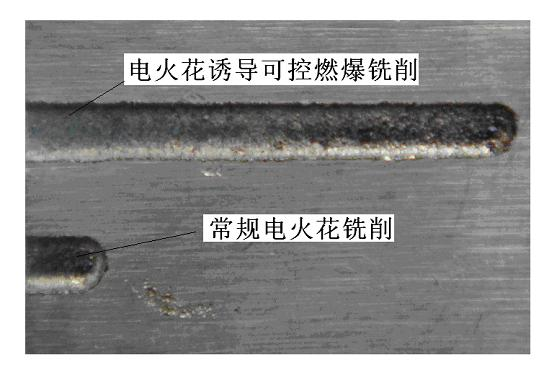

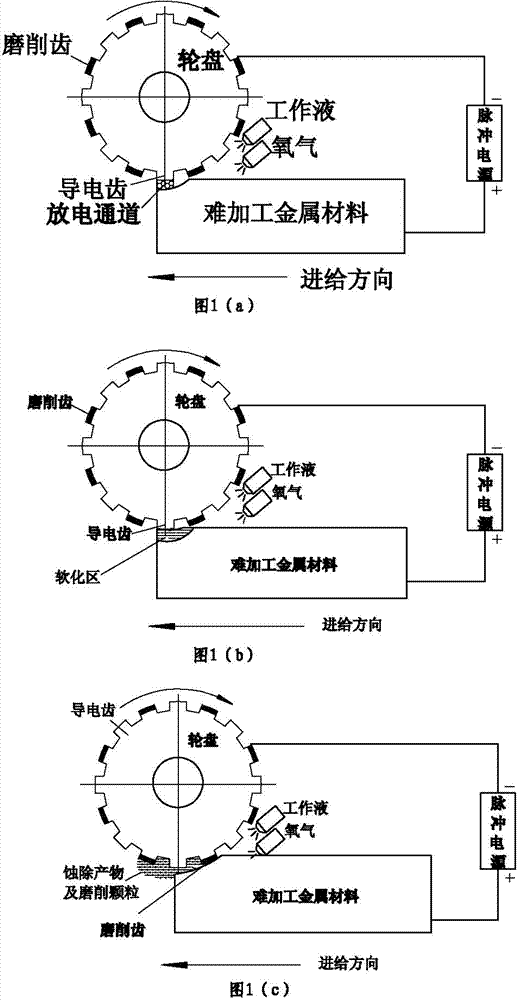

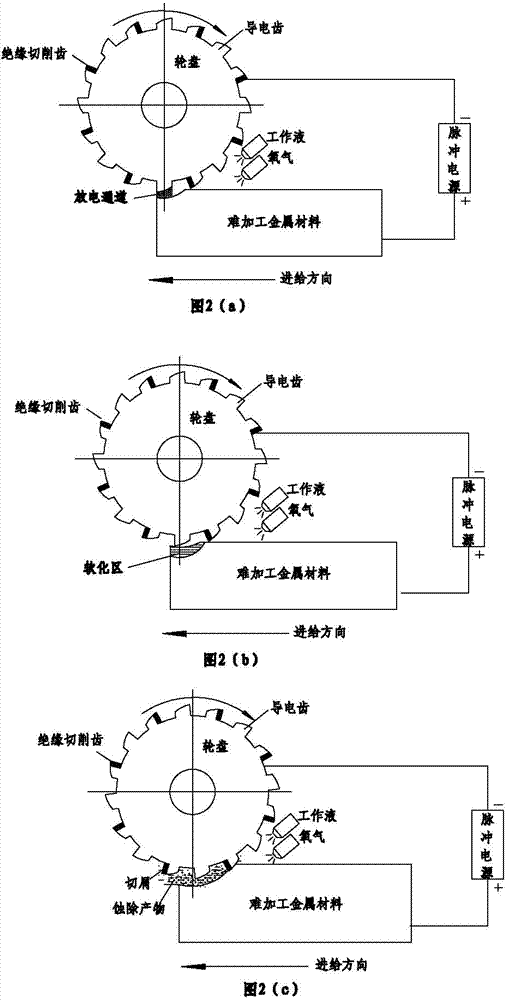

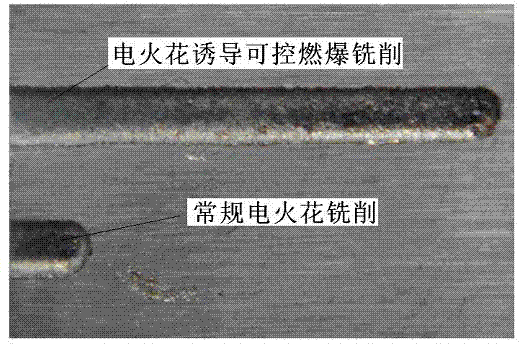

Efficient machining method of controllable ablation metallic material based on electric-spark induction

Efficient machining method of controllable ablation unmanageable metallic material based on electric-spark induction is characterized by comprising the following steps of: rotating a conductive roulette at a high speed, producing spark discharge between conductive teeth of the conductive wheel disc and the unmanageable metallic material under the action of a direct-current power supply or pulse power supply, meanwhile continuously or periodically introducing combustion-supporting gas which can produce combustion heat release effect through reacting with the unmanageable metallic material intoa processing area so that the processing area of the unmanageable metallic material is in states of discharging induced by electric spark, ablating and softening and machining. Based on the discharging function of the electric spark, the surface of metallic material has a temperature higher than ignition temperature and in state of activation, has an ablation reaction with combustion-supporting gas to generate an ablation product and release a large quantity of heat; the heat acts on the material base in the processed area so that the unmanageable metallic material is heated, softened and even in a molten state; the ablation product and softened or even molten metallic material is removed through abrasive particles on the wheel disc or mechanical cutting function of the cutting tooth. Themethod has advantages of high processing efficiency, low power consumption, environmental friendliness and high safety, and is especially suitable for machining of the unmanageable metallic material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

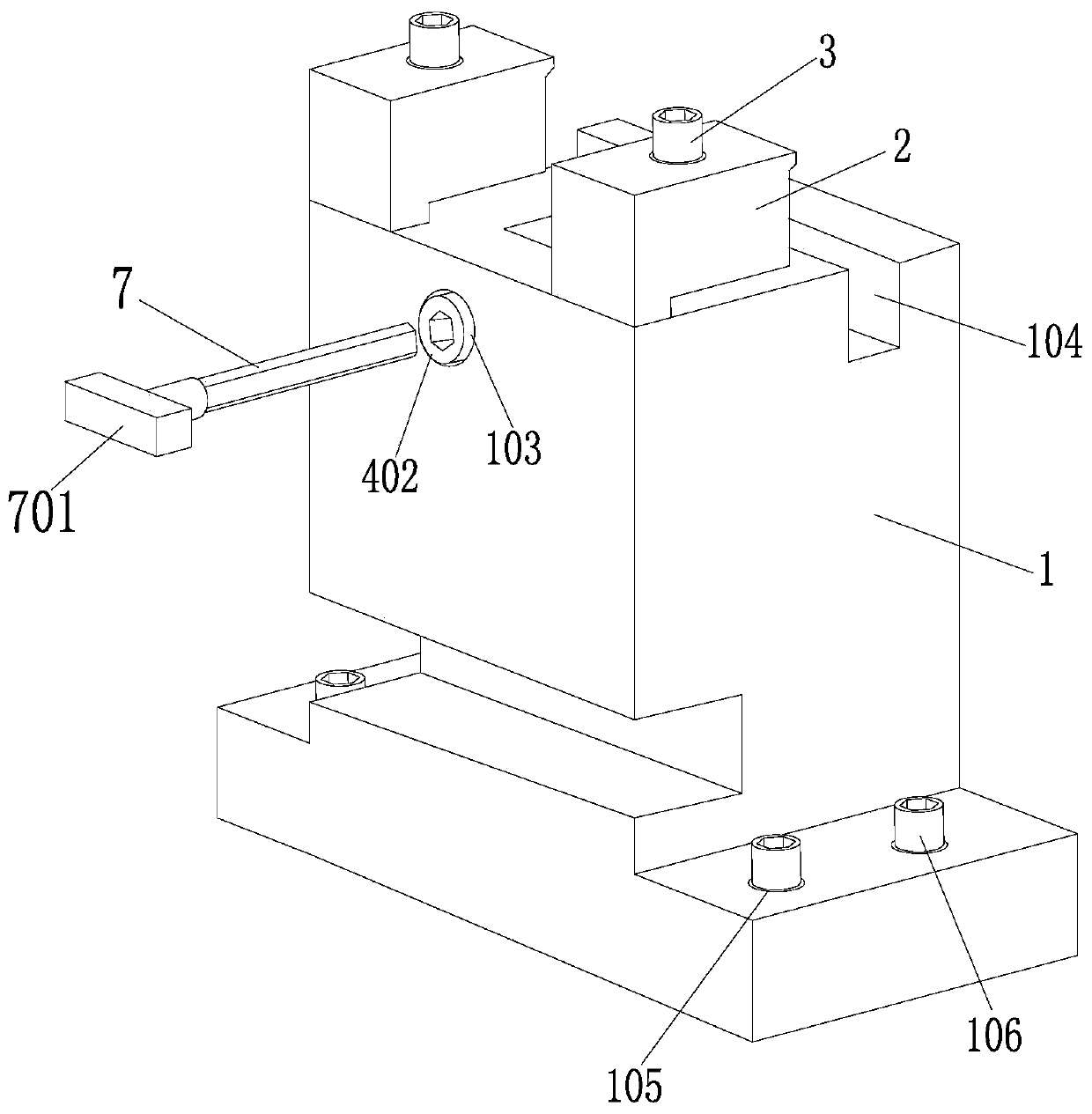

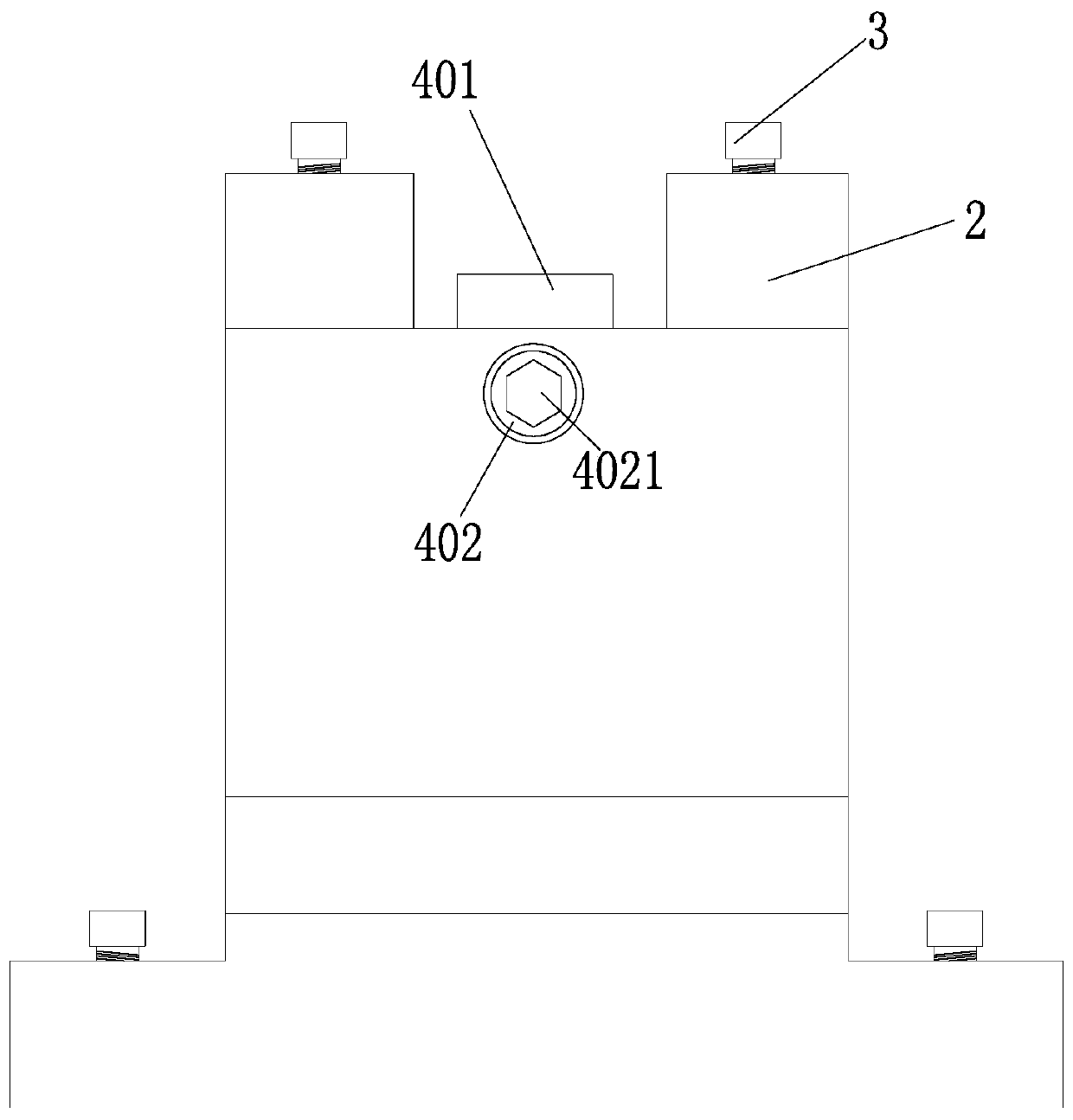

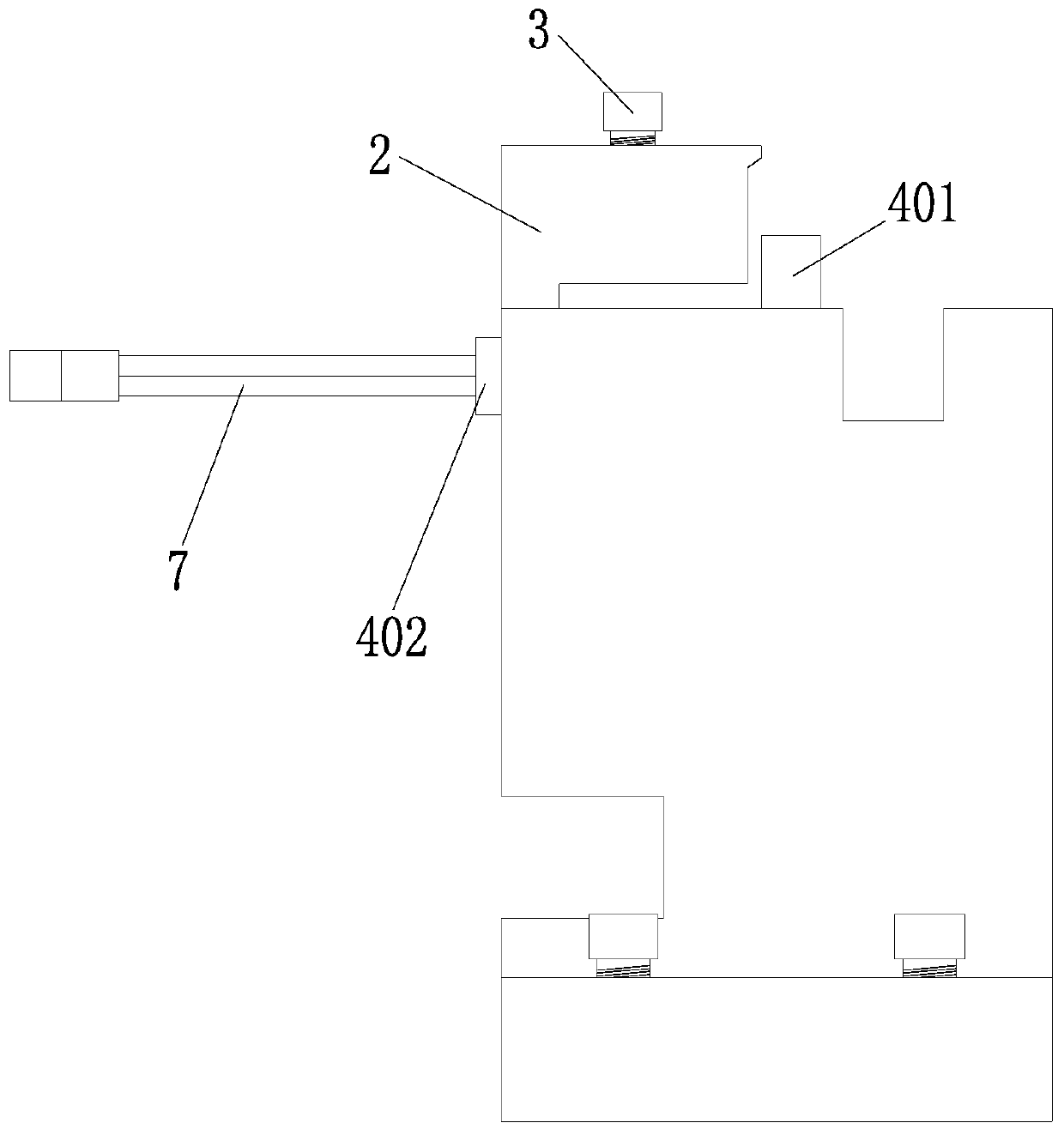

Improved multifunctional movable saddle clamping device

The invention provides an improved multifunctional movable saddle clamping device, and relates to the field of machining and fixing. The improved multifunctional movable saddle clamping device structurally comprises a base, a pressing block detachably connected with the upper end of the base, a locking piece for fixing the pressing block and the base and a positioning mechanism. According to the saddle clamping device, the pressing block is fixedly connected with the base through the locking piece, so that the pressing block fixes a saddle. Compared with a traditional saddle fixing device, theimproved multifunctional movable saddle clamping device has the advantages that after the saddle is fixed, a fixing device on the inner side or the outer side of the processed saddle does not need tobe disassembled for fixing again, the improved multifunctional movable saddle clamping device is convenient to use, and the problem that a saddle fixing device in the prior art is complicated in locking process, inaccurate in positioning and low in saddle processing efficiency is solved effectively.

Owner:漳州市永良针纺机械有限公司

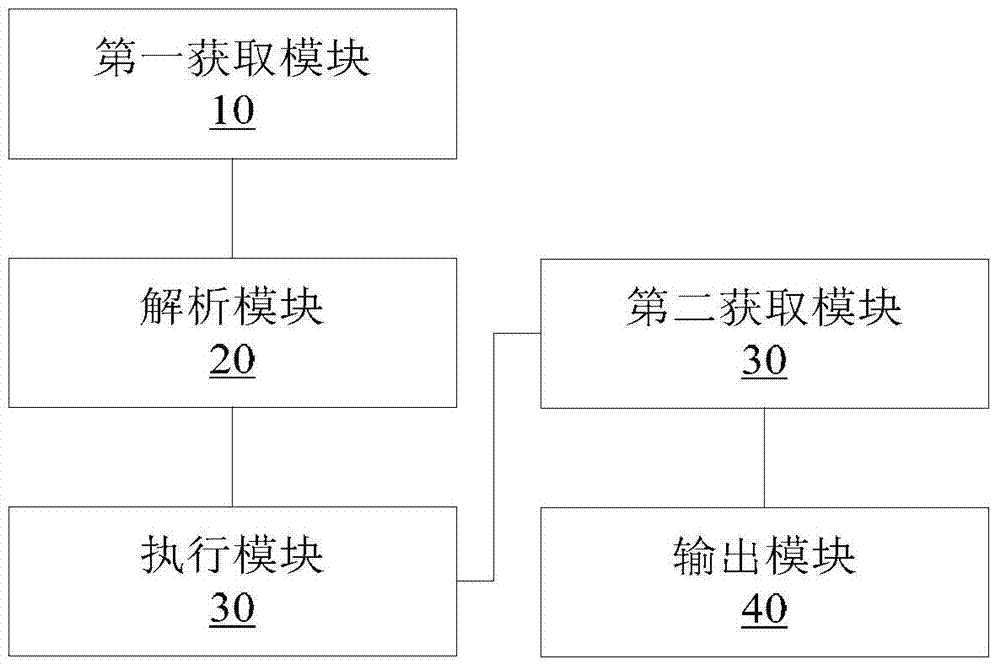

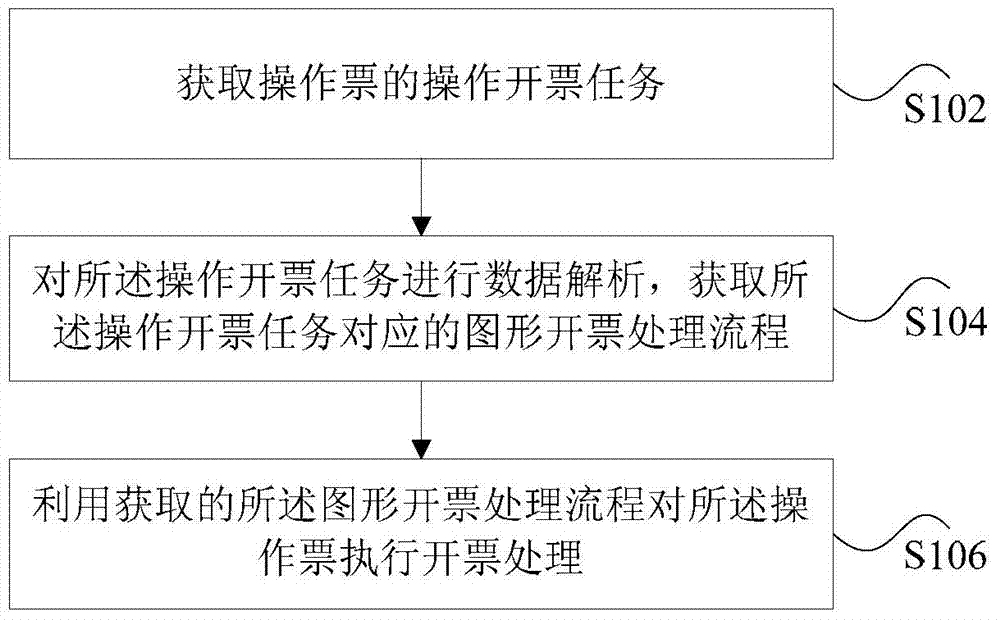

Data processing method and device for operation ticket

The invention discloses a data processing method and device for an operation ticket. The data processing method for the operation ticket comprises the steps that an operation billing task of the operation ticket is obtained; the operation billing task is subjected to data analysis, and a graph billing processing procedure corresponding to the operation billing task is obtained; and through the obtained graph billing processing procedure, the operation ticket is subjected to billing processing. According to the data processing method and device for the operation ticket, the problem that in a related technology, the processing efficiency on the operation ticket is low is solved.

Owner:STATE GRID CORP OF CHINA +1

Laser composite ultrasonic auxiliary grinding machining unit and method suitable for curved surface component

PendingCN114850877ASolve the problem of low processing efficiencyHighly integratedOther manufacturing equipments/toolsLaser beam welding apparatusEngineeringUltrasonic vibration

The invention provides a laser composite ultrasonic auxiliary grinding machining unit and method suitable for a curved surface component. According to the milling and grinding machining device and the laser auxiliary system integrated on the outer side of the machining main shaft, the main shaft of the milling and grinding machining device is provided with the optical fiber rolling ring module rotationally connected to the main shaft, the laser auxiliary system is connected to the optical fiber rolling ring module, the optical fiber rolling ring module can rotate by 360 degrees around the main shaft, and the laser auxiliary system is used for outputting laser spots. Preset laser treatment is carried out on a machined material in the feeding direction before machining is carried out on the milling and grinding machining device, the position and the rotation angle of the laser auxiliary system are adjustable, and an optical fiber and an electric wire for a posture adjusting system of the laser auxiliary system are arranged in the optical fiber rolling ring module. Laser synchronous composite ultrasonic vibration machining of the complex curved surface component can be achieved, and the limitation that in the prior art, synchronous composite machining of the curved surface component cannot be achieved or asynchronous auxiliary machining cannot be achieved is overcome.

Owner:DALIAN UNIV OF TECH

A kind of composite bacterial agent for degrading indole and its reaction device

ActiveCN106011016BHigh efficiency in degrading pollutantsPracticalBacteriaWater contaminantsBiotechnologyTolumonas

The invention discloses an indole-degrading compound bacterial agent and a reaction device thereof. The compound bacterial agent is prepared from three indole-degrading microbial strains including pseudomonas monteilii QM, bacillus L1 and Tolumonas G1. The reaction device comprises an aeration mixing reaction area, an aeration device, a bacterial agent feeder with the indole-degrading compound bacterial agent, an overflow area, an inclined-plate precipitation area, a residual sludge discharge pipe and a sludge backflow device. The indole-degrading compound bacterial agent disclosed by the invention has strong practicability; under the joint effect with the compound bacterial agent, the pollutant degrading efficiency of aerobic active sludge is high; the compound bacterial agent can adapt to the environment within short time so as to culture and acclimatize an efficient flora suitable for indole wastewater; the indole and COD detected in the water both can reach the standard; and the problems of limitation of existing methods in treating nitrogen heterocyclic ring organic matter indole and low treatment efficiency of existing bacterial agents are solved.

Owner:HARBIN INST OF TECH

Note treatment device and note treatment method thereof

ActiveCN102693577BSolve the problem of low processing efficiencyImprove processing efficiencyCoin/currency accepting devicesComputer science

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

Electric spark induced controlled combustion and discharge machining corrosion removing method

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Card printer and conveying roller control method of card printer

ActiveCN104723694BSolve the problem of low processing efficiencyImprove processing efficiencyTypewritersOther printing apparatusMechanical engineeringEngineering

The invention discloses a card printer and a conveying roller control method of the card printer. The card printer comprises a printing mechanism, a conveying roller set, a switching mechanism and a controller, wherein the printing mechanism is used for conducting printing on the surface of a card; the conveying roller set is used for conveying the card to the printing mechanism and comprises a drive roller and a driven roller which are opposite to each other; the switching mechanism is used for adjusting the interval between the driven roller and the drive roller; the controller is used for controlling the switching mechanism to adjust the interval between the driven roller and the drive roller so as to make the interval between the driven roller and the drive roller be matched with the thickness of the card, controlling the interval between the driven roller and the drive roller to enable the conveying roller set to be kept at the position matched with the thickness of the card and convey the card. By means of the card printer and the conveying roller control method of the card printer, the card processing efficiency of the card printer can be improved.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

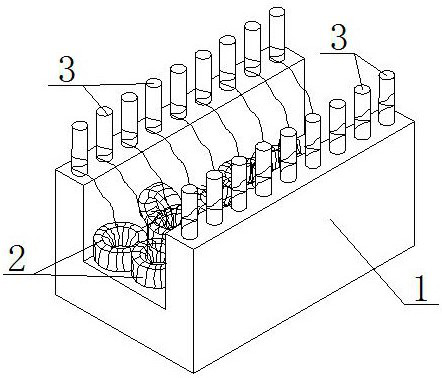

A method of using a foot winding machine to complete the wiring of network transformer wire wrap

ActiveCN112349512BSolve the problem of "low processing efficiency"Meet the needs of useFixed transformers or mutual inductancesCoils manufactureWinding machineElectric machine

The invention relates to a method for using a foot-winding machine to complete wire wrap wiring of a network transformer, and belongs to the technical field of network transformer production equipment. The foot winding machine in the method of using the foot winding machine to complete the wire wrapping of the network transformer includes a positioning fixture and a foot winding device: the foot winding device includes a base plate, a horizontal clamp, a longitudinal moving bracket, a lateral sliding seat, a rotating motor, Rotating needle, traverse motor, transverse screw rod and positioning substrate; the bottom plate is slidably installed with a longitudinal movement bracket through a longitudinal slide rail; the bottom plate is equipped with a longitudinal movement driving mechanism; the longitudinal movement driving mechanism is connected with the longitudinal movement support; the longitudinal movement A transverse slide seat is slidably installed on the support through a transverse slide rail. The method of using the foot-winding machine to complete the wiring of the network transformer wire wrap can use the foot-winding machine to mechanize the work of winding the network transformer, thereby solving the problem of "low processing efficiency" existing in the existing network transformer foot winding method, It meets the needs of efficient production of enterprises.

Owner:湖北磁创电子科技有限公司

Banknote handling method and device

ActiveCN105654608BSolve the problem of low processing efficiencyImprove work efficiencyPaper-money testing devicesCharacter and pattern recognitionComputer scienceImaging data

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

Processing method for corroding titanium or titanium alloy by burning and exploding under electric spark induction effect

The invention relates to a processing method for corroding titanium or a titanium alloy by burning and exploding under the electric spark induction effect, which is characterized in that a gas which can generate vigorous exothermic oxidation and burning and exploding effects with a titanium or titanium alloy materal to be processed is introduced in a processing area intermittently in the conventional process for processing the titanium or titanium alloy under the electric spark induction effect so that the titanium or titanium alloy of which the surface is activated under the electric spark induction effect and the introduced gas are subjected to burning and exploding reactions and a new activated layer can be exposed, and the process is carried out repeatedly so that the surfaces of titanium or titanium alloy substrate materials can be corroded rapidly and continuously in large quantities. Compared with the conventional method for corroding the titanium or titanium alloy under the electric spark induction effect, the invention can improve the material corroding rate by dozens of times or even hundreds of times. The invention can be used for processing through the relative motion of small-scale equipment on a large-scale structural component, can solve the problems on the size, the rigidity and the like of a large-scale structural component processing machine tool and has the advantages of high efficiency, low loss, low cost, safety and no pollution.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for completing network transformer coil wiring by using pin winding machine

ActiveCN112349512ASolve the problem of "low processing efficiency"Meet the needs of useFixed transformers or mutual inductancesCoils manufactureWinding machineElectric machine

The invention relates to a method for completing network transformer coil wiring by using a pin winding machine, and belongs to the technical field of network transformer production equipment. According to the method for completing network transformer coil wiring by using the pin winding machine, the pin winding machine comprises a positioning clamp and a pin winding device; the pin winding devicecomprises a bottom plate, a horizontal clamping device, a longitudinal moving bracket, a transverse moving sliding seat, a rotating motor, a rotating needle, a transverse moving motor, a transverse screw rod and a positioning base plate; a longitudinal moving support is installed on the bottom plate in a sliding mode through a longitudinal sliding rail; a longitudinal movement driving mechanism is arranged on the bottom plate; the longitudinal movement driving mechanism is connected with the longitudinal movement bracket; and the transverse moving sliding seat is mounted on the longitudinal moving bracket through the transverse sliding rail in a sliding manner. According to the method for completing network transformer coil wiring by using the pin winding machine, the pin winding work ofthe network transformer can be completed mechanically by using the pin winding machine, so that the problem of low processing efficiency existing in an existing network transformer pin winding mode issolved, and the use requirements of efficient production of enterprises are met.

Owner:湖北磁创电子科技有限公司

A round cap automatic processing equipment

ActiveCN109261841BSolve the problem of low processing efficiencySolve the dangerShaping safety devicesClosure capsMachineMaterials processing

Owner:芜湖立新清洁用品有限公司

Ultra-precision Machining Method of Sapphire Substrate Based on Consolidated Abrasive Polishing Pad

ActiveCN103252708BFast processingEfficient processingLapping machinesLapping toolsPolishingMachining time

The invention discloses an ultra-precision processing method for a sapphire substrate based on a fixed abrasive polishing pad, which mainly includes three steps of rough grinding, fine grinding and polishing: first, a W75 nickel-plated diamond fixed abrasive grinding polishing pad ( FAP) to roughly grind the cut sapphire blank, secondly, use W28 nickel-plated diamond FAP to fine-grind the rough-grinded workpiece, and finally, use W5 diamond FAP to polish the fine-grinded workpiece, that is, to complete the grinding and polishing process. The invention processes the sapphire substrate, shortens the whole process to less than 2 hours, greatly shortens the processing time of sapphire, and finally can obtain the sapphire substrate with the workpiece surface roughness Ra less than 3nm, and can effectively remove pitting, scratches and other surface defects , and the subsurface damage is low, and the surface quality is excellent. The invention improves the processing efficiency and surface quality of the sapphire substrate, and has low cost and no pollution.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Electric spark induction controllable erosion and mechanical finishing compound cutting dual-servo feeding processing system

ActiveCN102974902BHigh removal rateSolve the problem of low processing efficiencyControl systemEngineering

The invention discloses an electric spark induction controllable erosion and mechanical finishing compound cutting dual-servo feeding processing system which is characterized by comprising an electric spark induction erosion electrode servo feeding control system (1) using an erosion state as a sampling basis and a mechanical finishing tool automatic feeding regulating system (2) using a cutting force as a sampling basis, wherein the electric spark induction erosion electrode servo feeding control system controls the feeding of an induction erosion electrode, ensures that the electric spark induction erosion in a machining region is controllably, efficiently and stably carried out, and forms an erosion product and a softened layer through controllable erosion; and the mechanical finishing tool automatic feeding regulating system ensures that the erosion product and the softened layer which are generated by erosion are cut and removed without cutting a base body material, so that the tool loss is reduced, the finished surface quality is ensured and the processing efficiency is increased. According to the invention, the processing efficiency of a metal material difficult in processing can be remarkably increased, the finished surface quality is increased, and the finished surface is final mechanized surface due to the mechanical finishing function of a tool.

Owner:南京航浦机械科技有限公司

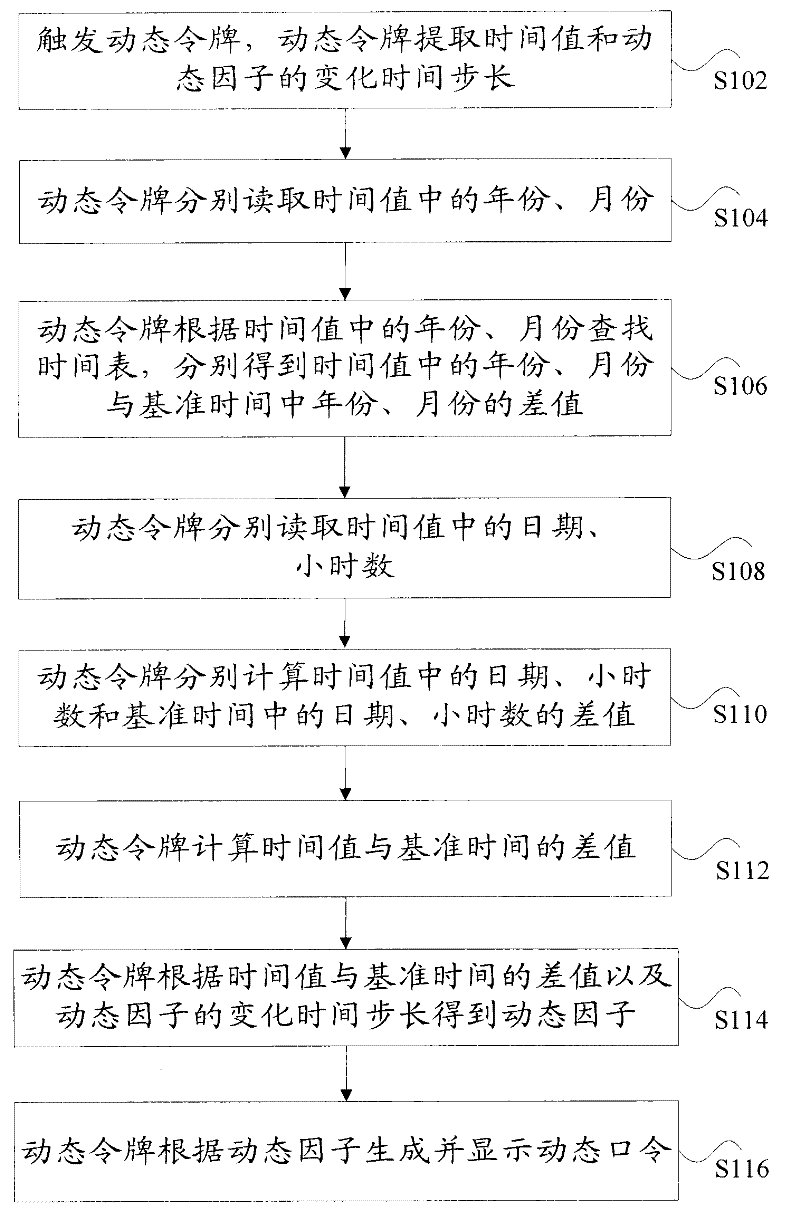

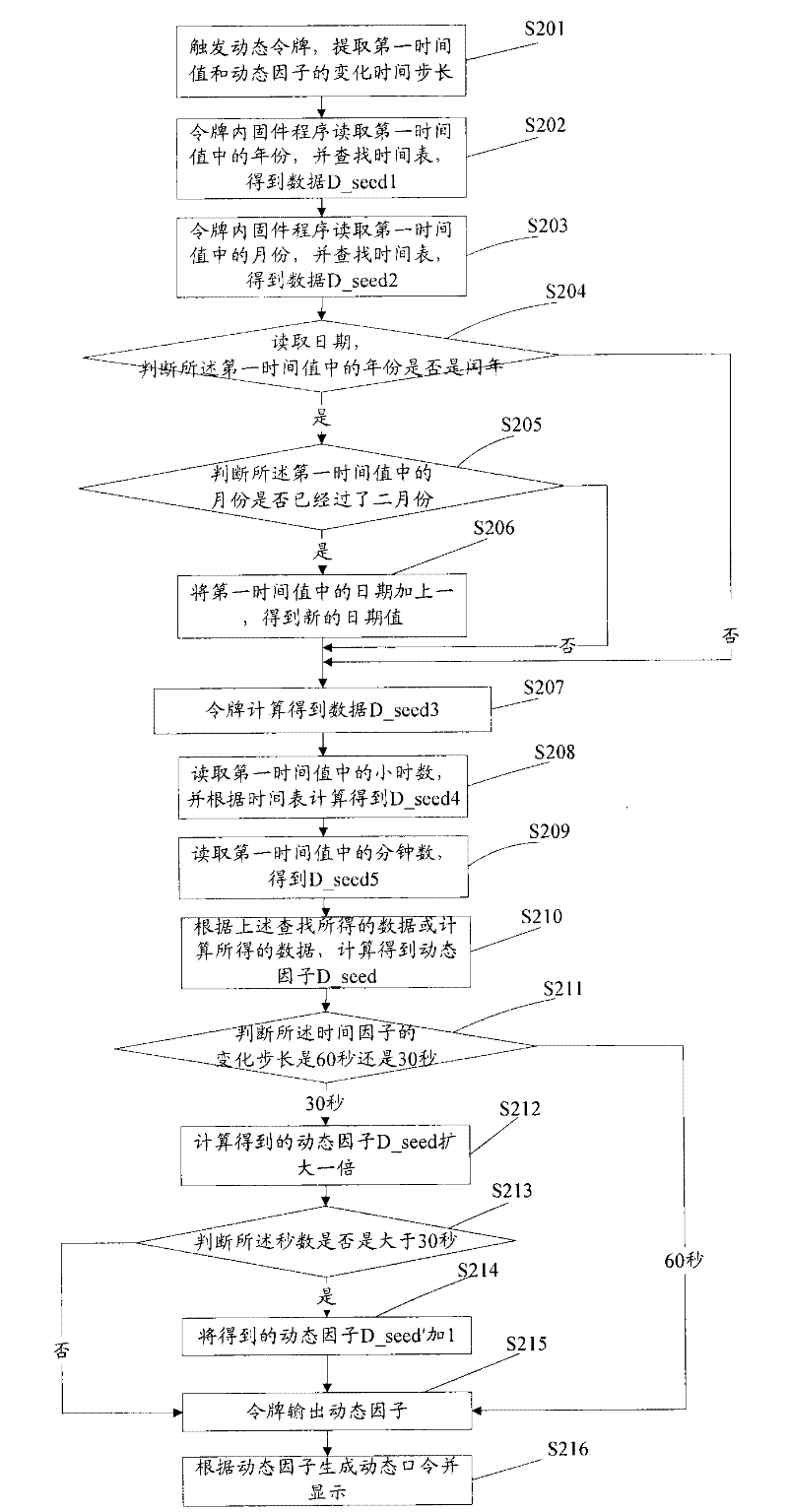

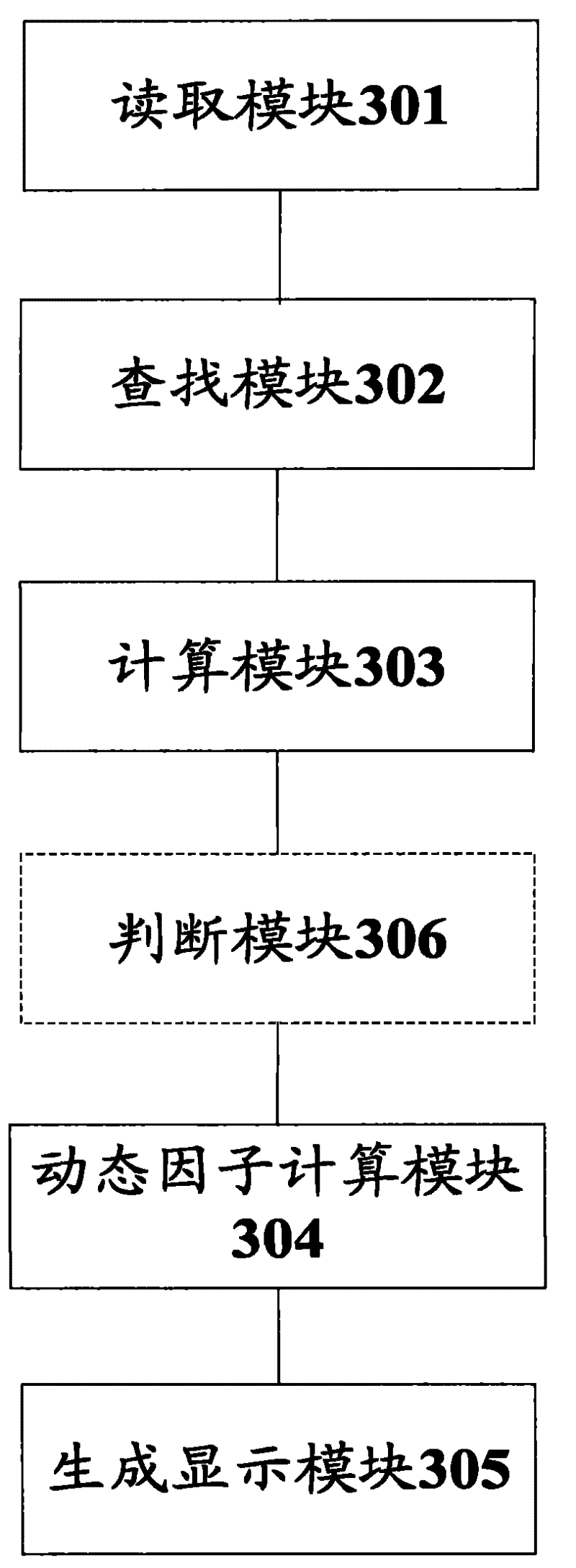

Method for processing time information and dynamic token

ActiveCN101800643BSolve the problem of low processing efficiencyImprove processing efficiencyUser identity/authority verificationTime informationPassword

The invention discloses a method for processing time information and a dynamic token. The method comprises that: the dynamic token respectively reads the year and month in a time value; the dynamic token searches a time table according to the year and month in the time value to respectively acquire a difference value of the year in the time value and the year in a reference time, and a differencevalue of the month in the time value and the month in the reference time; the dynamic token respectively reads the date and hour in the time value and respectively calculates a difference value between the date in the time value and the date in the reference time and a difference value between the hour in the time value and the hour in the reference time; the dynamic token calculates a differencevalue between the time value and the reference value; and the dynamic token acquires a dynamic factor according to the difference value between the time value and the reference time and variable timestep of the dynamic factor and generates and displays a dynamic password according to the dynamic factor. The method can improve the efficiency of processing time information.

Owner:FEITIAN TECHNOLOGIES

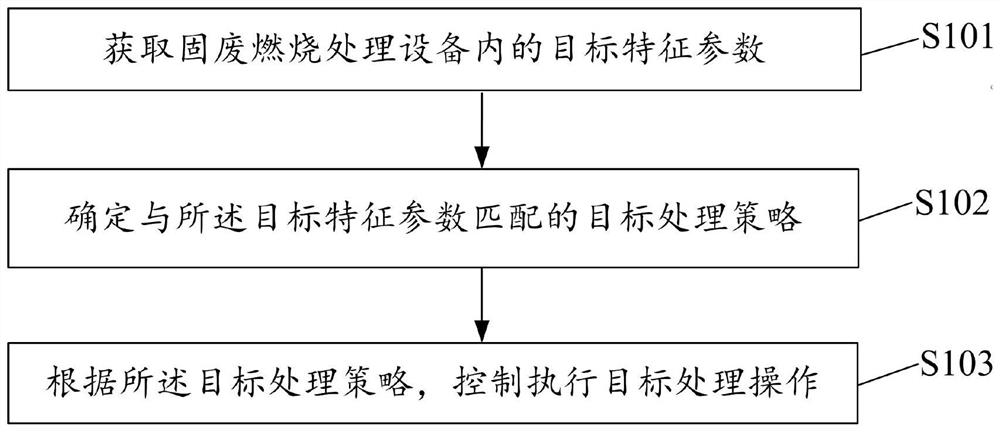

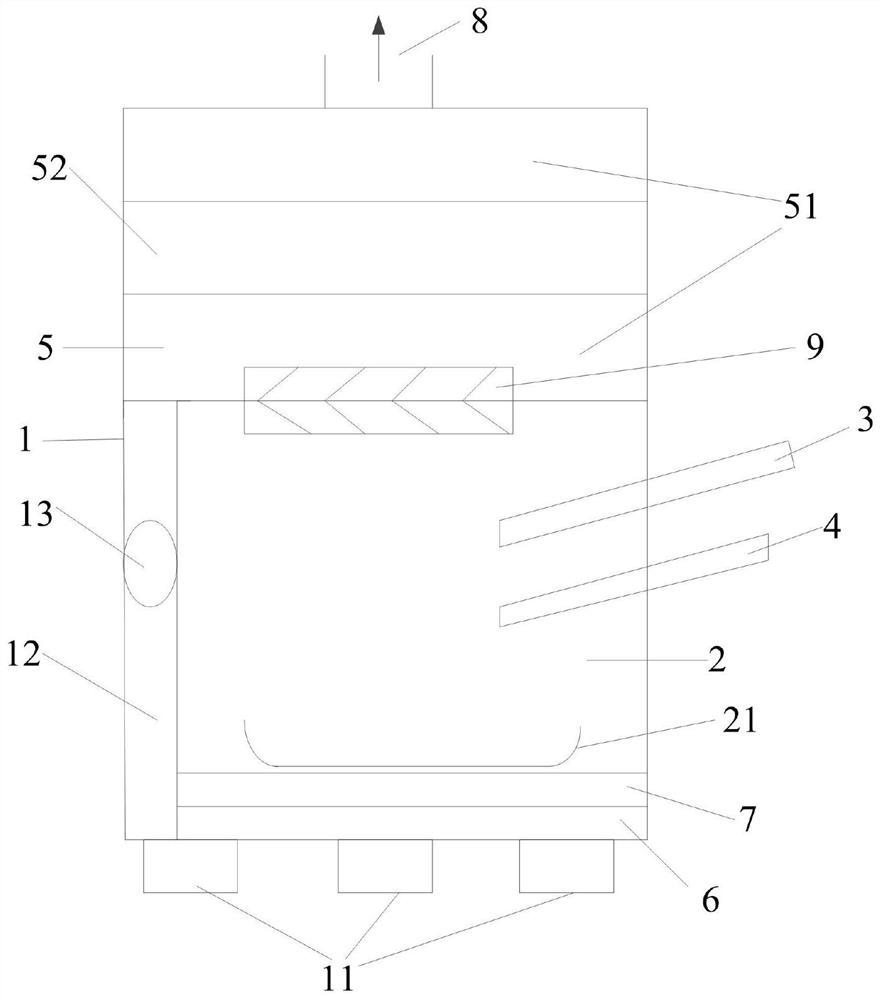

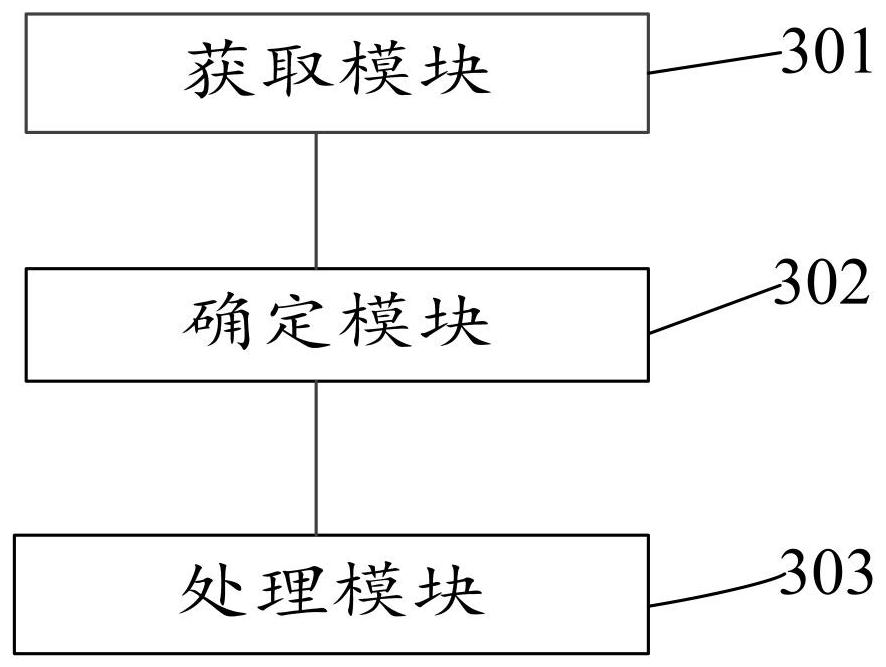

Solid waste combustion treatment method and control system thereof

PendingCN113483329ASolve the problem of low processing efficiencyEasy to handleIncinerator apparatusFlue gasControl system

The invention provides a solid waste combustion treatment method and a control system thereof, and belongs to the field of solid waste harmless treatment.The method comprises the steps: obtaining target characteristic parameters in solid waste combustion treatment equipment, wherein the target characteristic parameters comprise a current temperature in a furnace body, a first current concentration of organic waste gas molecules in the current gas at the gas outlet and a second current concentration of organic impurities in the current gas; determining a target processing strategy matched with the target characteristic parameters; and controlling to execute a target processing operation according to the target processing strategy. Namely, according to the current temperature in the furnace body, the first current concentration of organic waste gas molecules in the current gas at the gas outlet and the second current concentration of organic matter impurities in the current gas, the purpose of efficiently and rapidly treating flue gas generated by solid waste combustion can be achieved, the solid waste treatment efficiency is greatly improved, the energy consumption is reduced, and the energy conservation and emission reduction effects are achieved, and therefore, the service life of the solid waste combustion treatment equipment is prolonged.

Owner:陕西青朗万城环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com