Method for completing network transformer coil wiring by using pin winding machine

A network transformer and pin-wound technology, applied in fixed transformer or mutual inductance, inductance/transformer/magnet manufacturing, coil manufacturing, etc., can solve problems such as low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

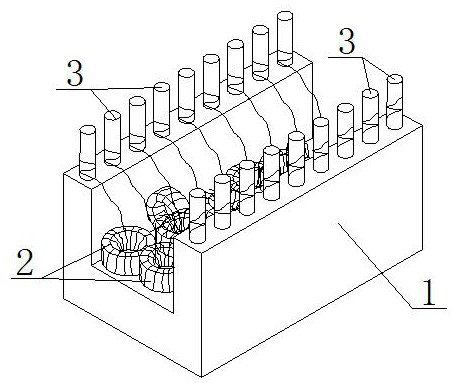

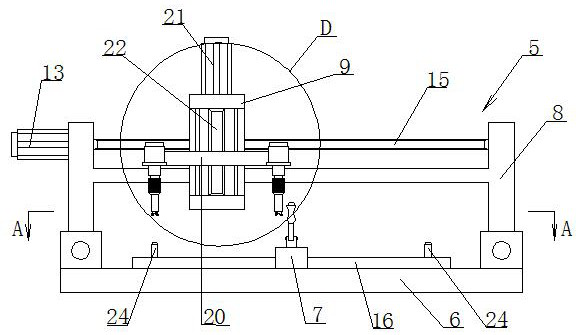

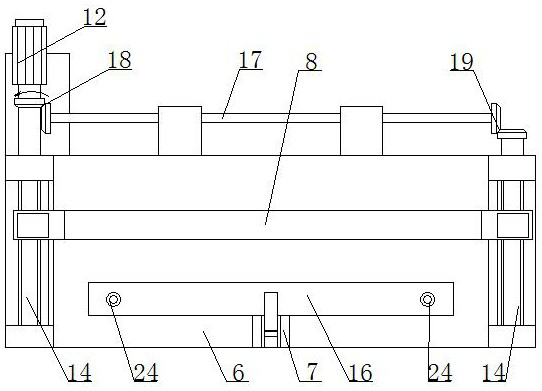

[0040] The foot wrapping machine includes a positioning fixture 4 and a foot wrapping device 5 . The foot wrapping device 5 includes a bottom plate 6, a horizontal clamp 7, a vertical movement bracket 8, a transverse movement slide seat 9, a rotating motor 10, a rotary needle 11, a transverse movement motor 13, a transverse screw rod 15 and a positioning base plate 16 (refer to the instruction manual attached figure 2 with 3 ).

[0041] The bottom plate 6 is slidably installed with a vertical movement bracket 8 through the longitudinal slide rail; when working, it can only move longitudinally along it under the guidance of the longitudinal slide rail, so as to avoid the occurrence of “derailment” and The "off track" problem.

[0042] The longitudinal movement drive mechanism is housed on the base plate 6 (referring to instruction manual appendix image 3 ); the longitudinal movement drive mechanism includes a longitudinal movement motor 12, a longitudinal screw mandrel 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com