Processing method for corroding titanium or titanium alloy by burning and exploding under electric spark induction effect

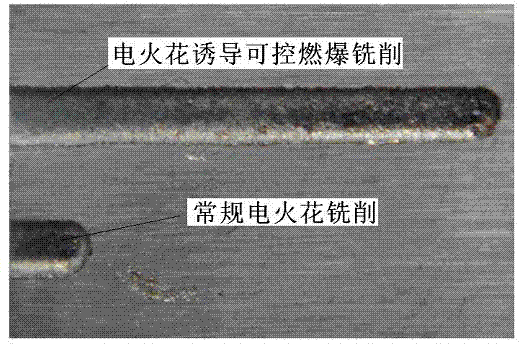

A processing method and technology for titanium alloys are applied in the field of electric spark-induced controllable detonation processing of titanium or titanium alloys. The effect of surface quality and precision, material removal rate improvement, and energy increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] A kind of titanium alloy TC4 electric spark induces controllable detonation detonation and removes processing method, it comprises the following steps:

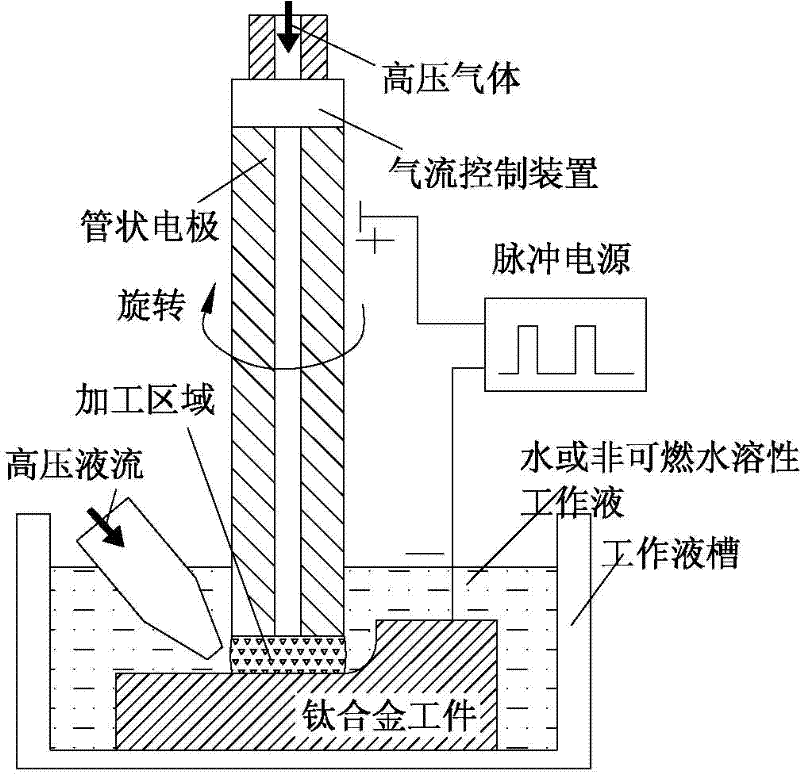

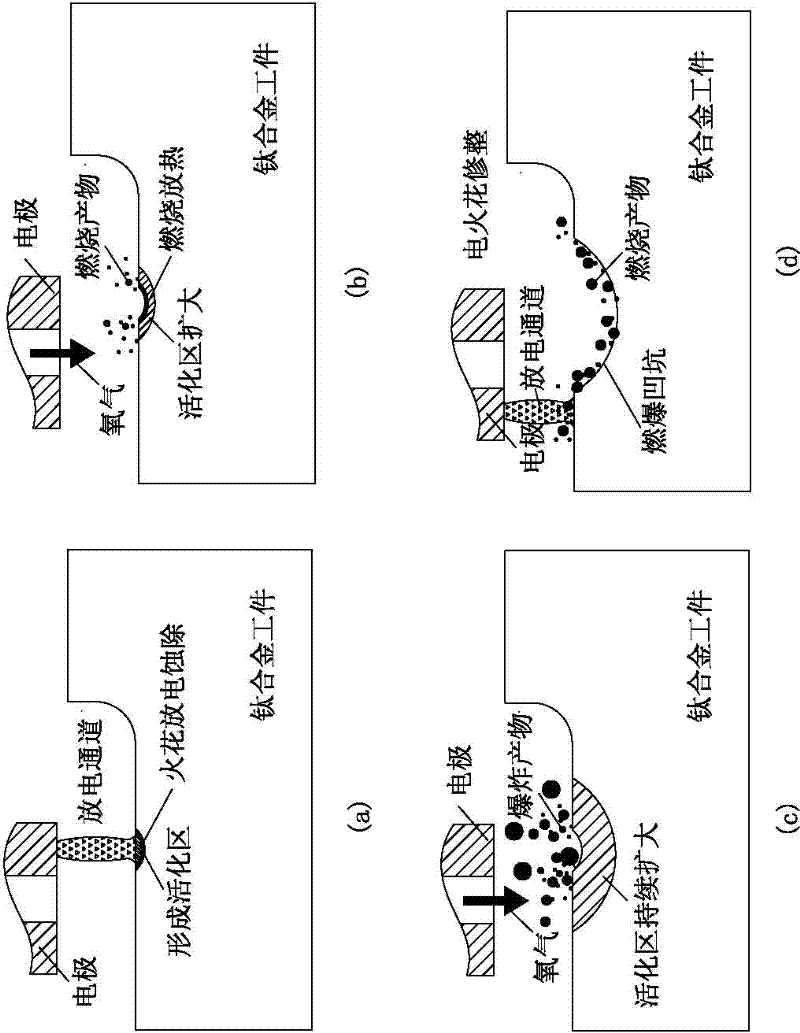

[0039] The first step is to build a processing system. Such as figure 1 As shown, the gas is connected to the tubular electrode through the gas flow control device, the electrode can rotate relative to the gas flow control device, and the gas flow control device can convert high-pressure oxygen into an intermittently adjustable intermittent oxygen flow. The tool electrode is connected to the positive pole of the pulse power supply, and the titanium alloy is connected to the negative pole of the pulse power supply (negative polarity processing) to form an electric spark discharge; the workpiece is immersed in the liquid working medium, and the liquid surface is more than 20mm away from the processing area to compress the combustion area; The method of liquid acts on the processing area, strengthens the deflagration eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com