Efficient machining method of controllable ablation metallic material based on electric-spark induction

A metal material and cutting technology, applied in the field of high-efficiency cutting of metal materials induced by electric spark induced controllable ablation, can solve problems such as low processing efficiency of difficult-to-machine metal materials, and achieve low processing efficiency, prolong service life, and rigidity. The effect of request reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

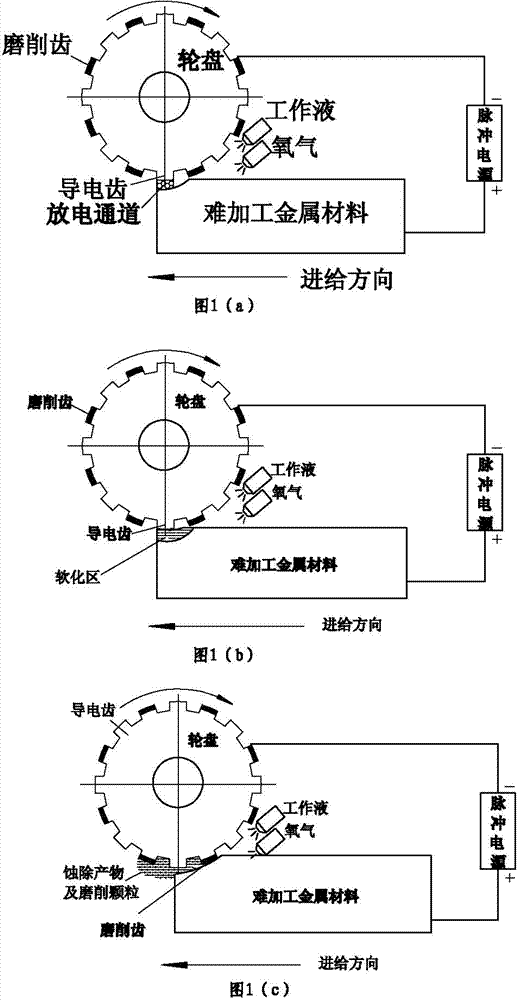

[0044] Such as figure 1 shown.

[0045] A new method for processing difficult-to-machine metal materials based on electric spark induced controlled ablation and electric discharge grinding, which includes the following steps:

[0046] First, make the grinding wheel with mechanical cutting effect conductive and rotate; the conductive grinding wheel can be circular or slotted intermittently, and the combustion-supporting gas can be input from the grinding wheel body to the processing area or from the grinding wheel body to the processing area;

[0047] Secondly, under the action of DC or pulse power supply, spark discharge is generated between the conductive part of the grinding wheel and difficult-to-machine metal materials (such as titanium alloys, high-temperature alloys, high-strength steel or stainless steel materials), and the use of electric spark discharges makes difficult-to-machine The surface of the metal material reaches the ignition point temperature and is in an a...

Embodiment 2

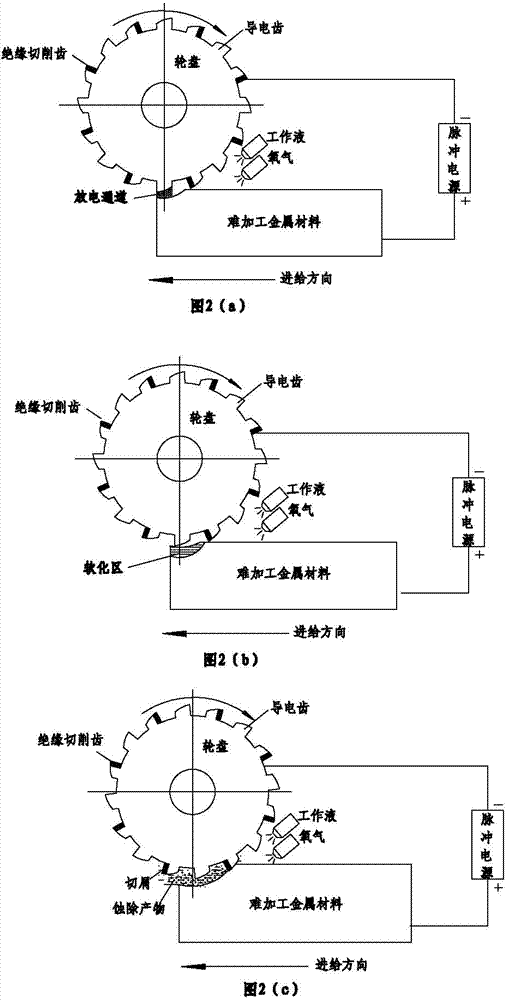

[0057] Such as figure 2 shown.

[0058] A new method for processing difficult-to-machine metal materials based on electric spark induced controlled ablation and milling, which includes the following steps:

[0059] First of all, the milling cutter with mechanical cutting function is made conductive and rotates; the milling cutter can be composed of conductive teeth, insulating cutting teeth and wheel discs, and the insulating teeth can be made of diamond, cubic boron nitride or ceramics, through electroplating, It is fixed on the wheel by clamping or welding, and the combustion-supporting gas can be input from the wheel to the processing area or from the outside of the wheel to the processing area;

[0060] Secondly, under the action of DC or pulse power supply, spark discharge is generated between the conductive part of the milling cutter and difficult-to-machine metal materials (such as titanium alloys, high-temperature alloys, high-strength steel or stainless steel materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com