Patents

Literature

292results about How to "Avoid plugging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fuel additives for treating internal deposits of fuel injectors

InactiveUS20130074794A1Reduce the amount requiredAvoid cloggingNon-fuel substance addition to fuelInternal combustion piston enginesHydrogenDicarboxylic acid

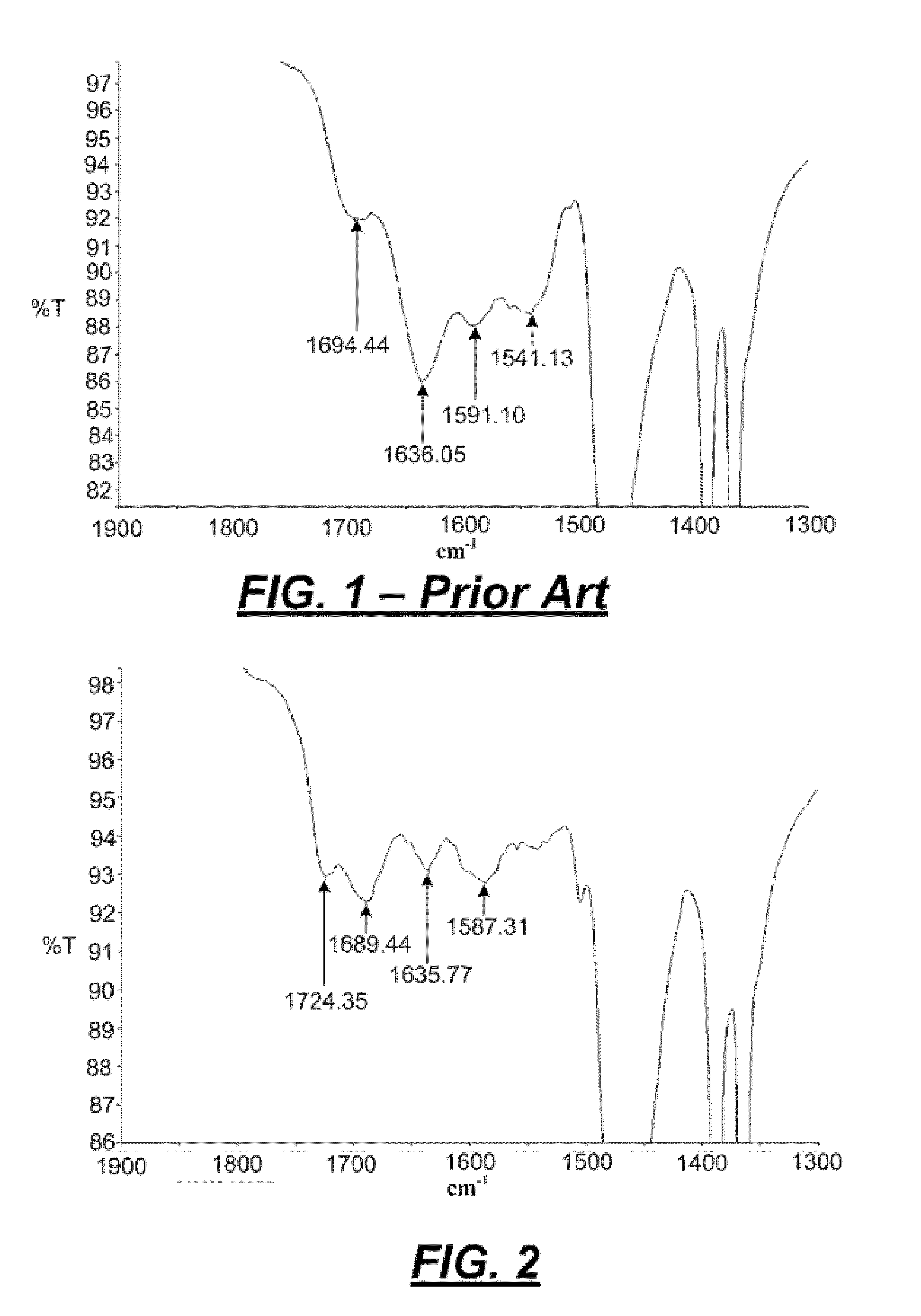

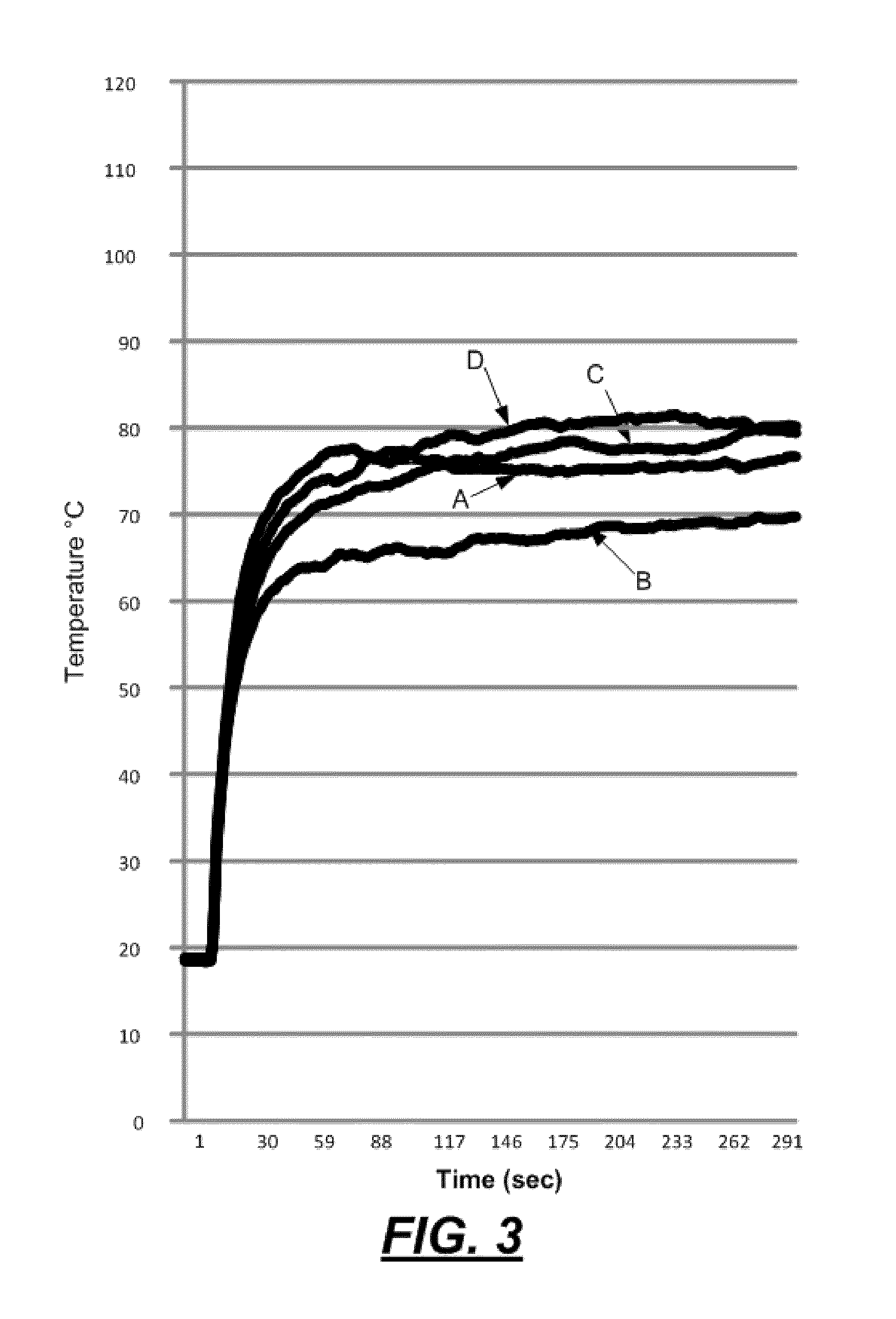

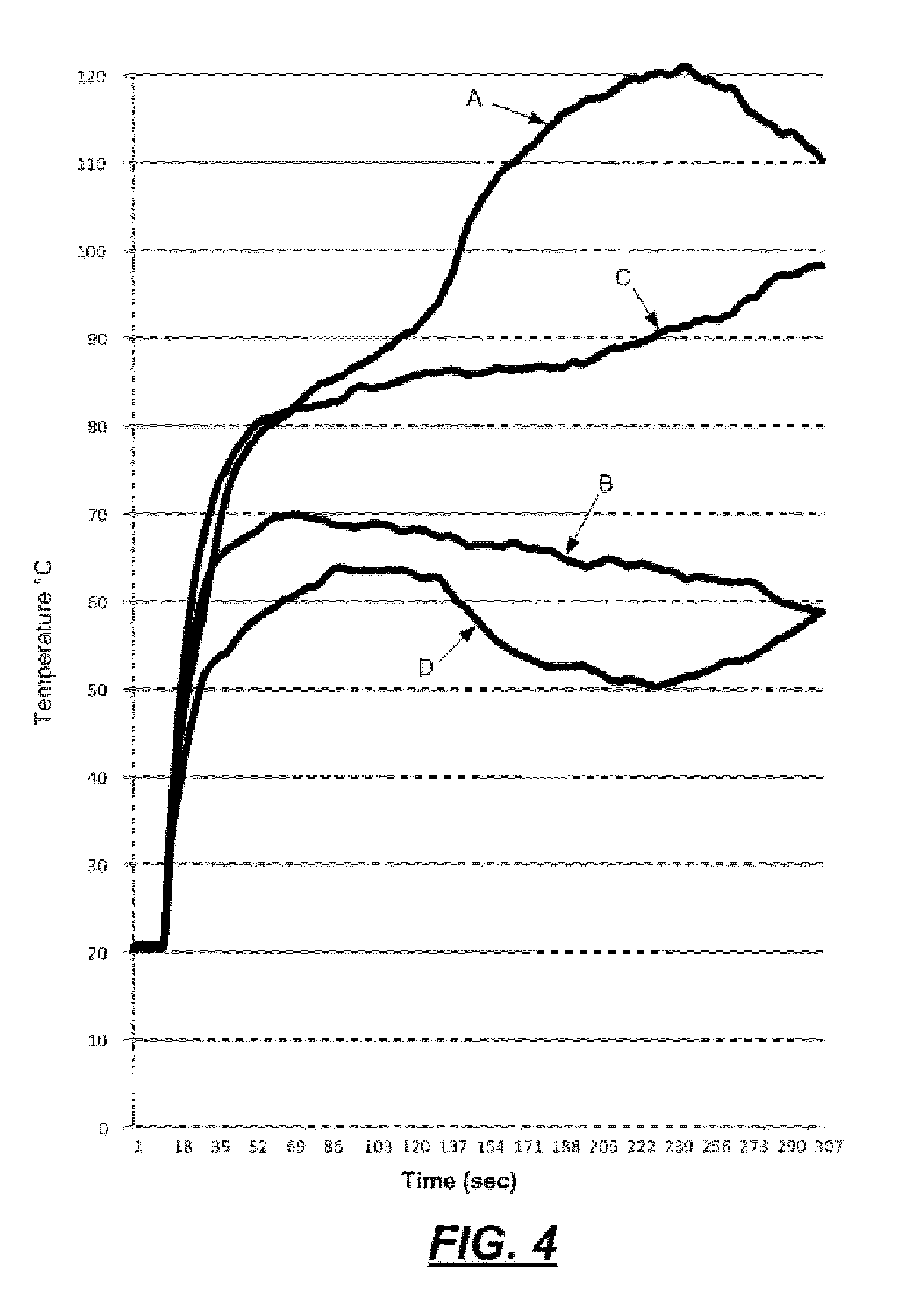

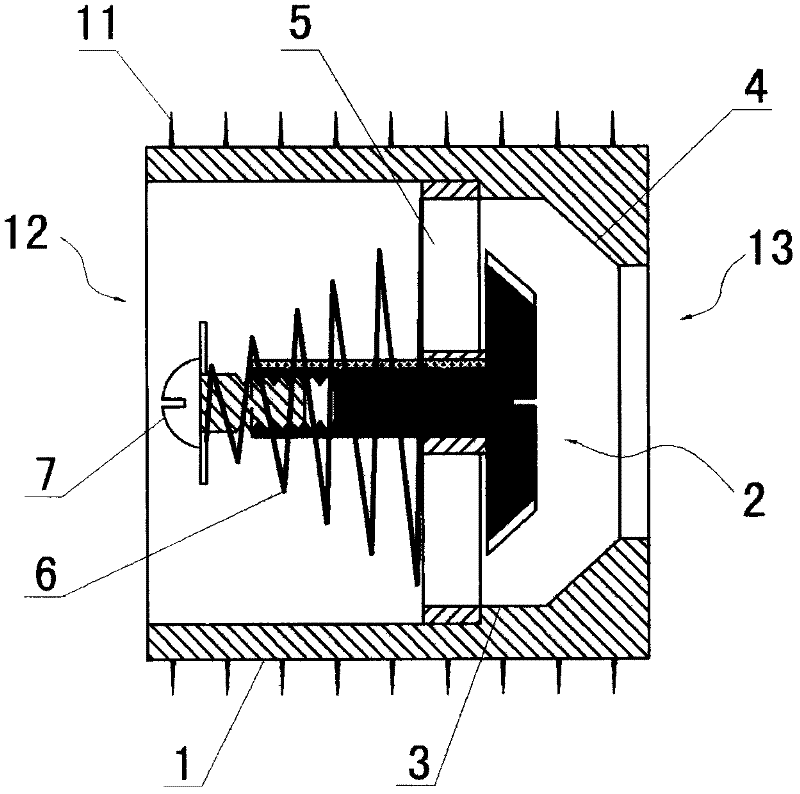

A method cleaning up internal components of a fuel injector for a diesel engine. The method includes operating a fuel injected diesel engine on a fuel composition that includes a major amount of diesel fuel and from about 5 to about 500 ppm by weight of a reaction product derived from (a) a hydrocarbyl substituted dicarboxylic acid, anhydride, or ester and (b) an amine compound or salt thereof of the formulawherein R is selected from the group consisting of hydrogen and a hydrocarbyl group containing from about 1 to about 15 carbon atoms, and R1 is selected from the group consisting of hydrogen and a hydrocarbyl group containing from about 1 to about 20 carbon atoms. The reaction product is characterized by a particular FTIR spectrum.

Owner:AFTON CHEMICAL

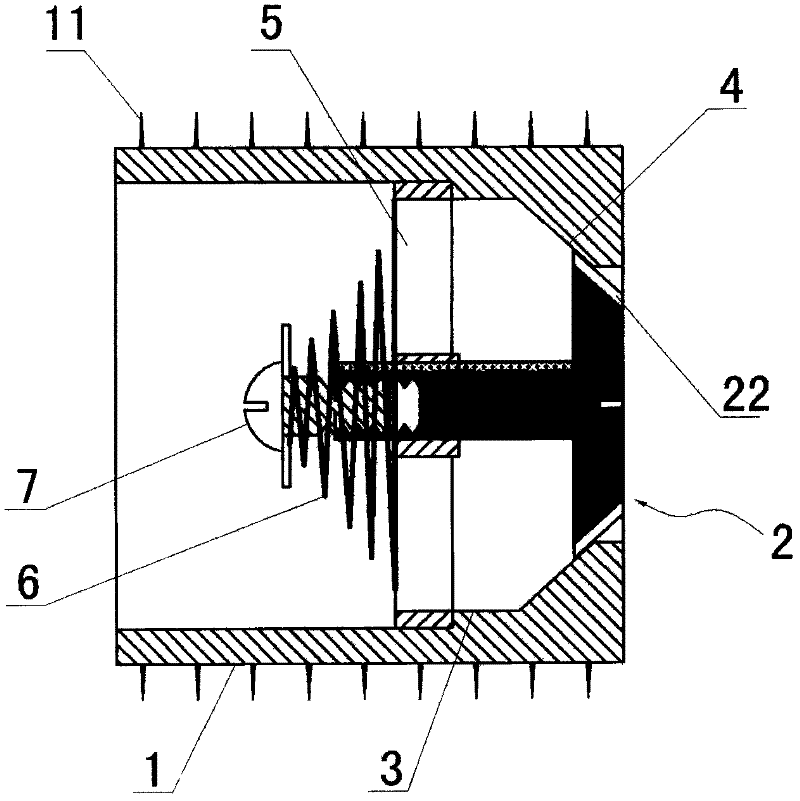

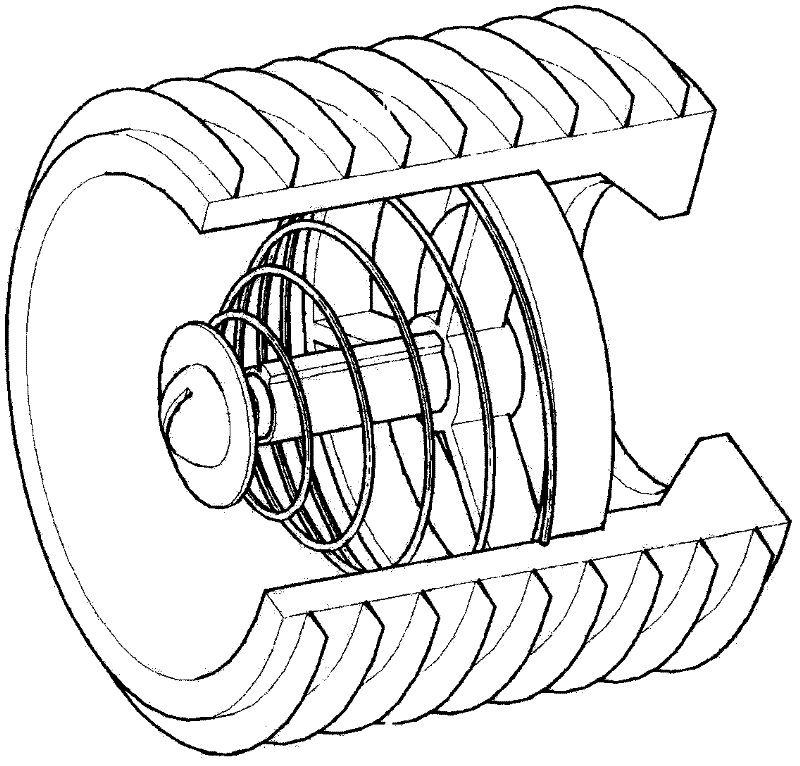

Pressure regulator

InactiveCN102287561APlay the role of voltage regulation and flow controlImprove sealingEqualizing valvesSafety valvesWrinkle skinEngineering

The pressure regulator is mainly composed of a body, a throttle valve, a limit platform, a conical platform, a positioning seat, a spring, and screws. The body is made of plastic, and the outer surface is provided with sealing folds, which can adapt to the pipes produced by different manufacturers. , The tolerance of the inner diameter of the joint plays a very good sealing role; there is a protrusion on the throttle valve, when the pressure is too large, the cone is embedded in the outlet end, and the liquid or gas flows out from the gap between the outlet end and the protrusion. It can play the role of voltage regulation and flow control.

Owner:李耀强

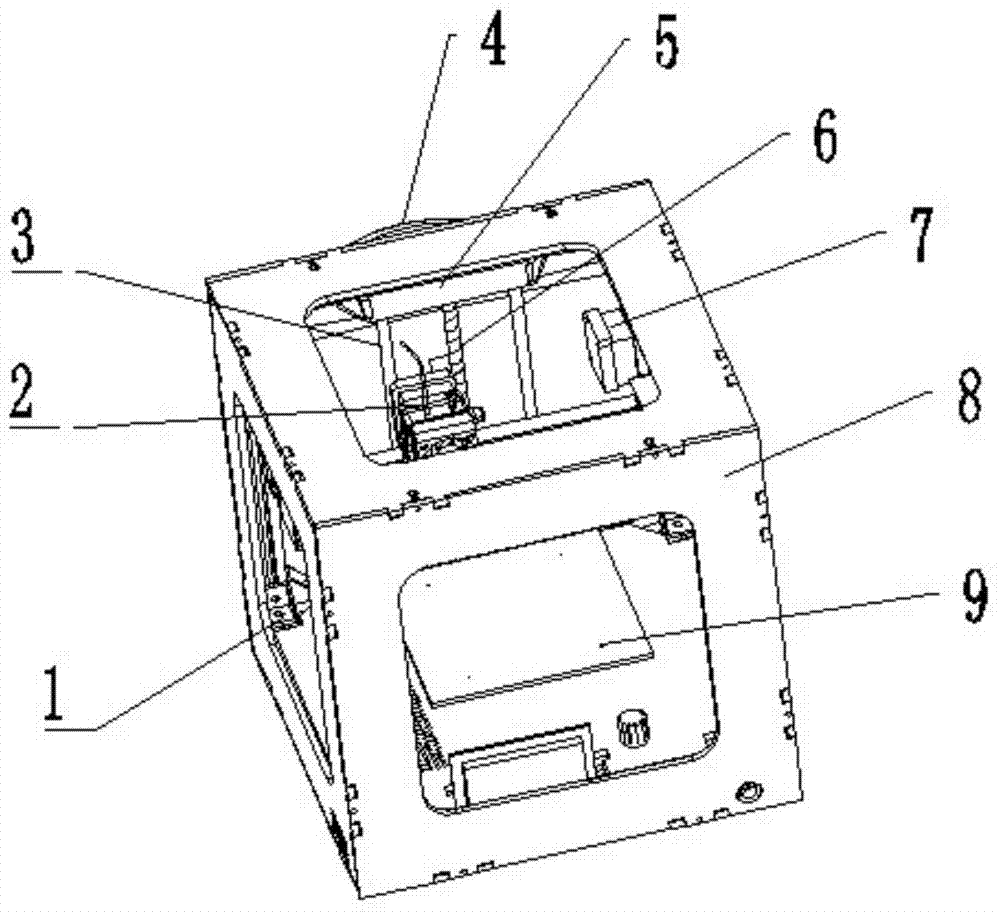

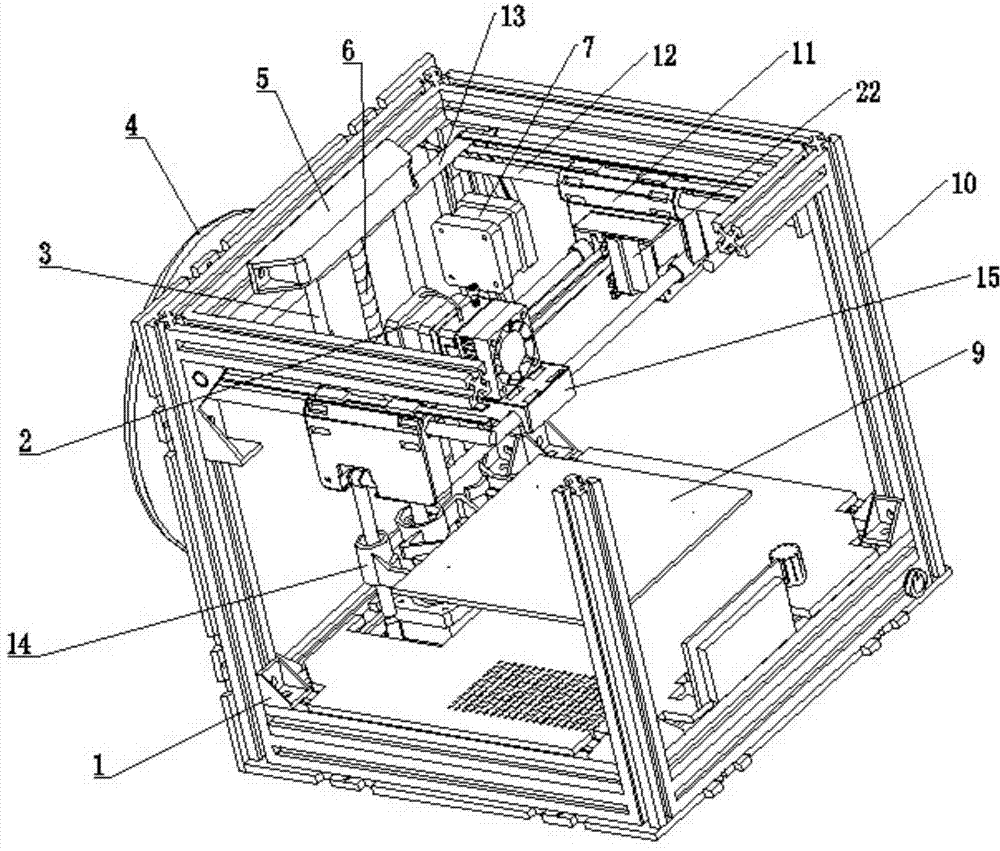

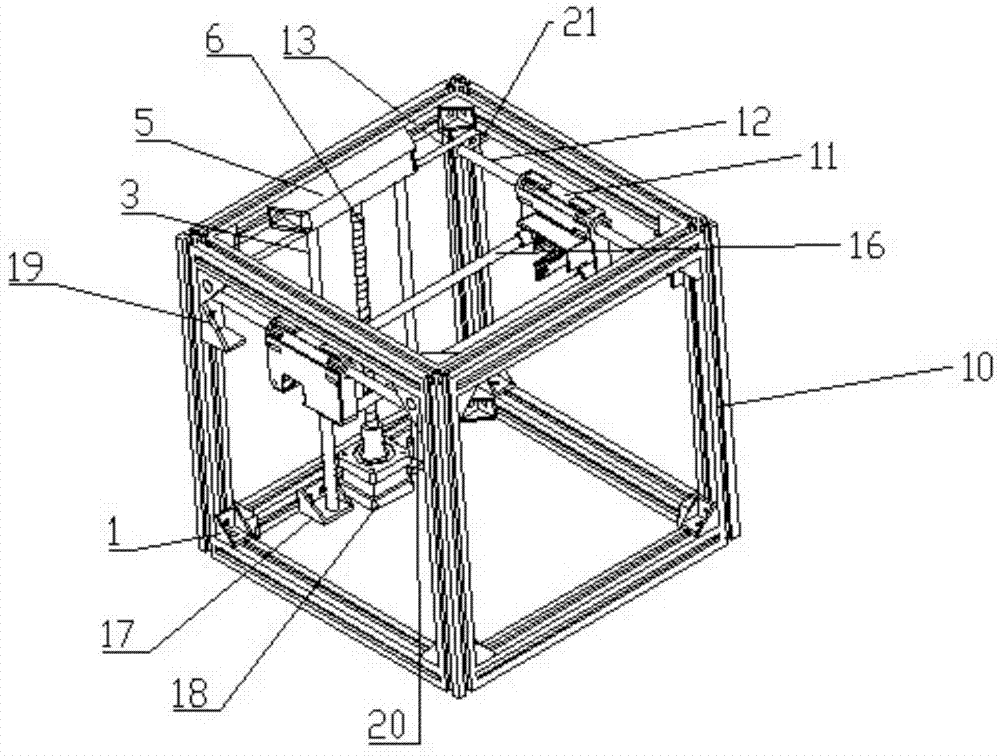

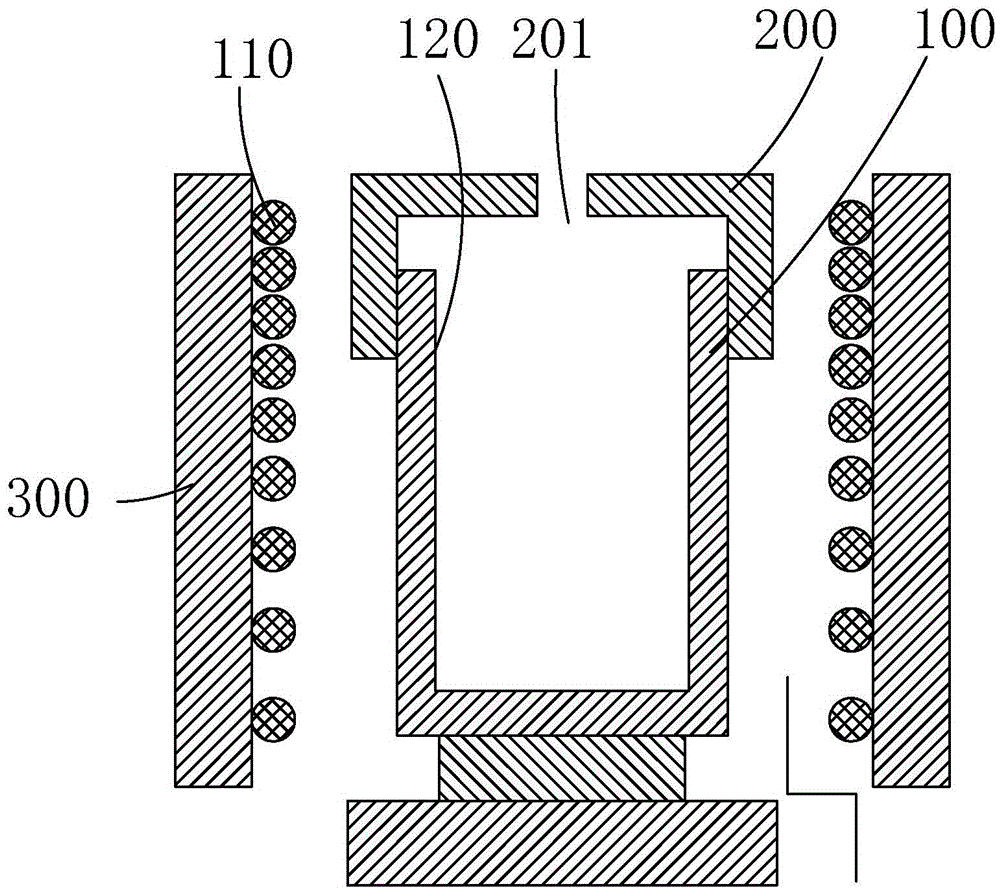

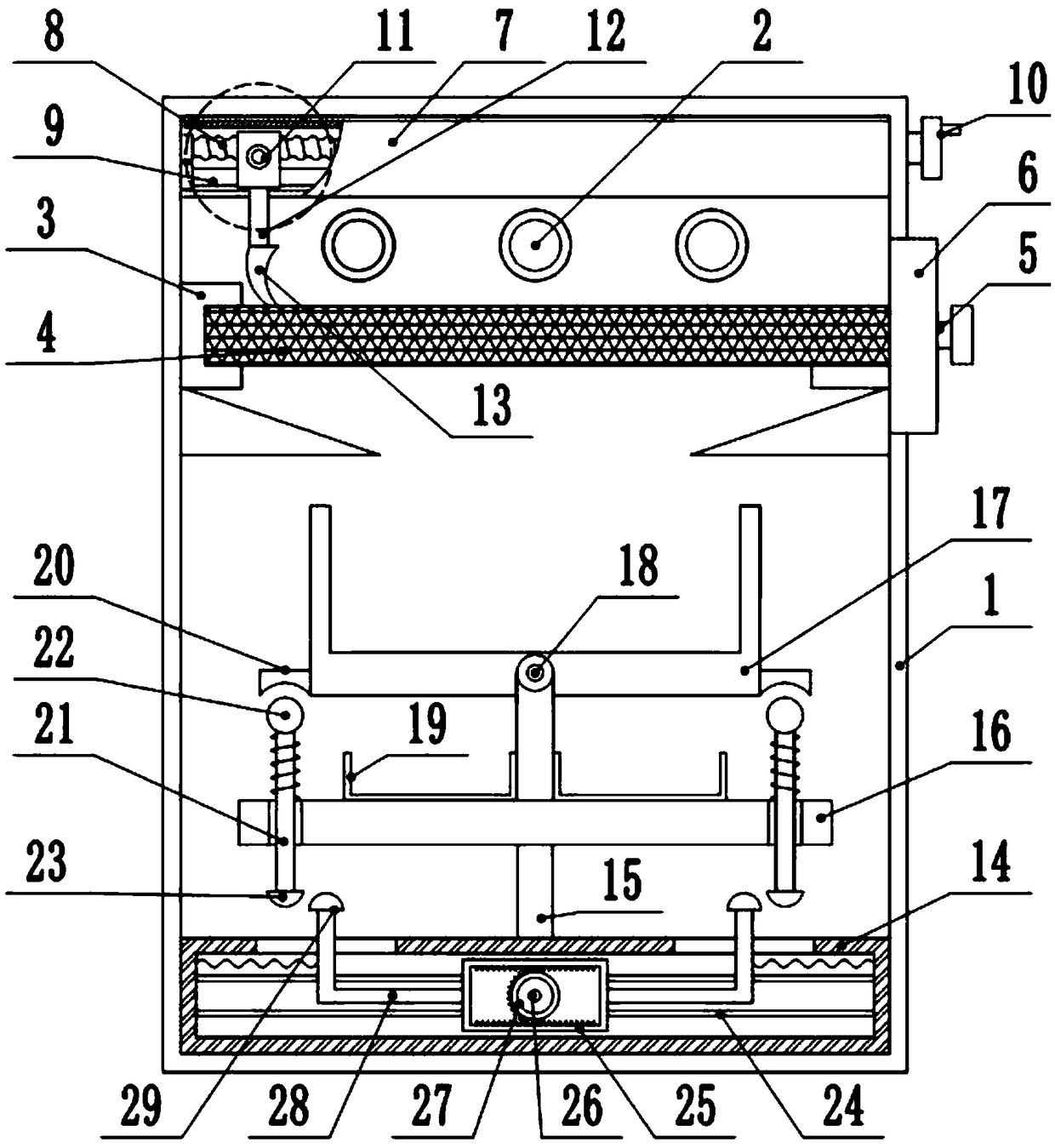

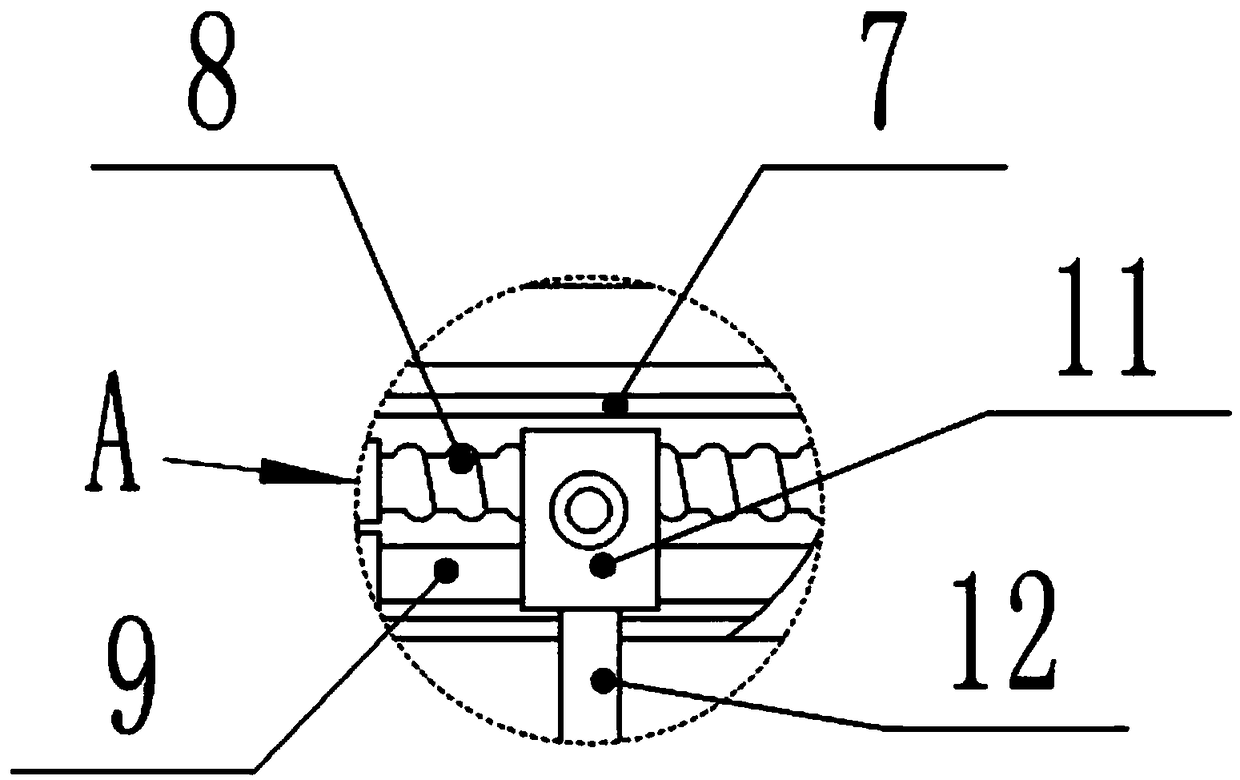

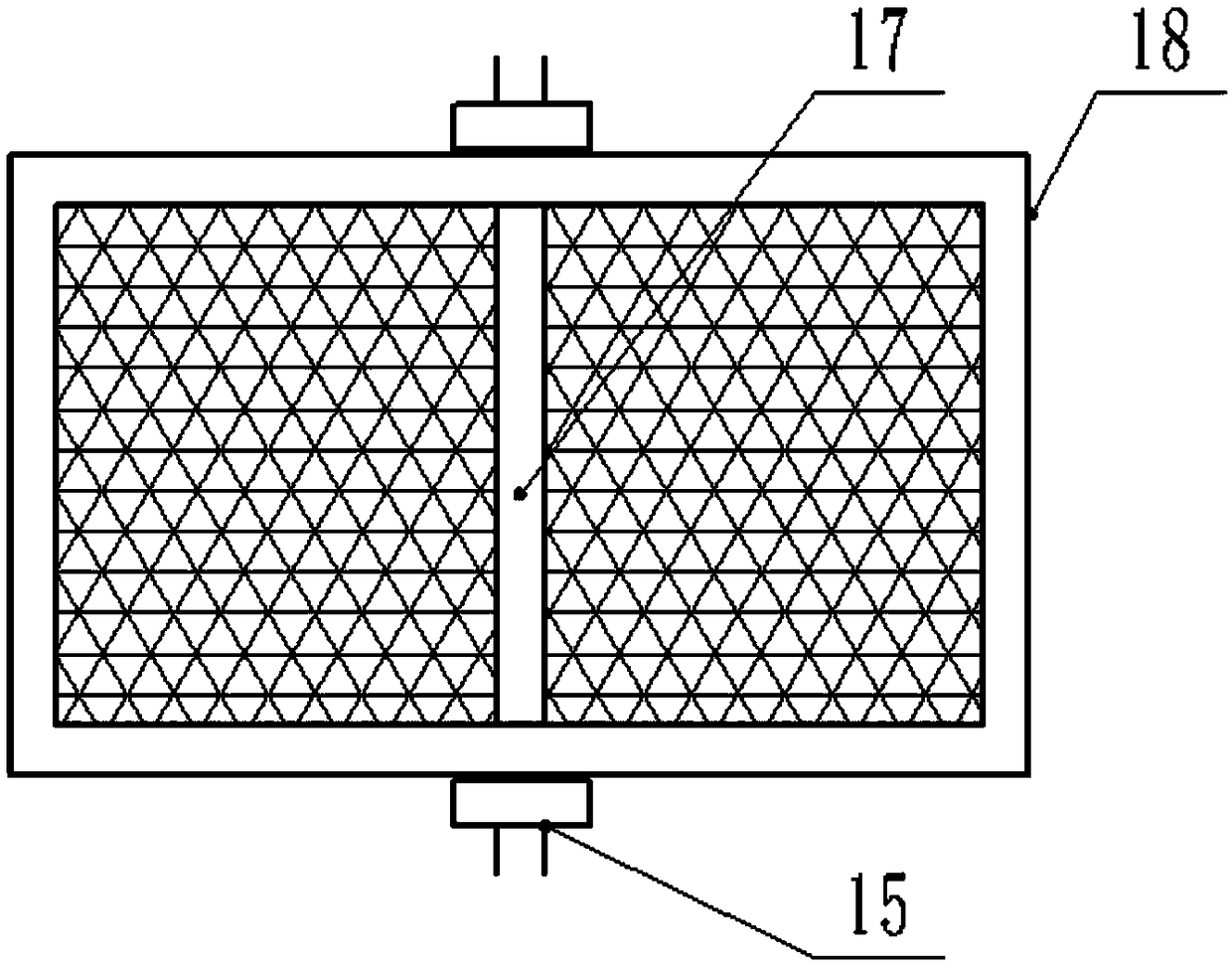

3D (three-dimensional) printer

The invention belongs to the technical field of 3D (three-dimensional) printers, and relates to a small desktop 3D printer which can reduce resonance. The 3D printer comprises a case, a machine frame, a printing unit, a drive device and a consumable mounting box, wherein the drive device comprises an X-axis drive motor, a Y-axis drive motor and a Z-axis drive motor; the drive device is fixed to the machine frame; the printing unit comprises a consumable extrusion device, a motor bracket, a printing platform and a platform bracket; the consumable extrusion device is fixedly mounted on the motor bracket; the printing platform is fixed to the platform bracket; the consumable mounting box is fixedly mounted on the case. The 3D printer has the beneficial effects that the overall structure is simple and attractive; consumables are convenient to replace; a phenomenon of wire blocking in a wire feed throat pipe is effectively avoided; the vibration generated when the 3D printer works is reduced; the printing quality of a product is improved; the internal space utilization rate of the 3D printer is improved; the printing range is large; the 3D printer is simple in structure and convenient to assemble.

Owner:青岛天智清华电子科技发展有限公司

Method for preventing bottom holes of circuit board from being blocked in copper plating

InactiveCN103298273AEffective chip removalAvoid pluggingMultilayer circuit manufacturePrinted element electric connection formationCopper platingCopper wire

The invention discloses a method for preventing bottom holes of a circuit board from being blocked in copper plating. After holes are formed in the circuit board in a drilling mode, electroless copper plating and full-plate flash plating are carried out, so the thickness of copper in each hole reaches 5-7um, then a segmentation drilling mode is adopted, drilling is carried out according to the back drilling depth ratio of 1:2:3:4, and a drill bit is taken out after drilling is carried out each time, so formed copper wires and glue residues are taken out from the holes. Due to the segmentation drilling mode, scraps in back drilling holes can be effectively removed, and the problem of hole blocking caused by the fact that the copper wires and the glue residues are difficult to remove is avoided, and quality of products is improved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

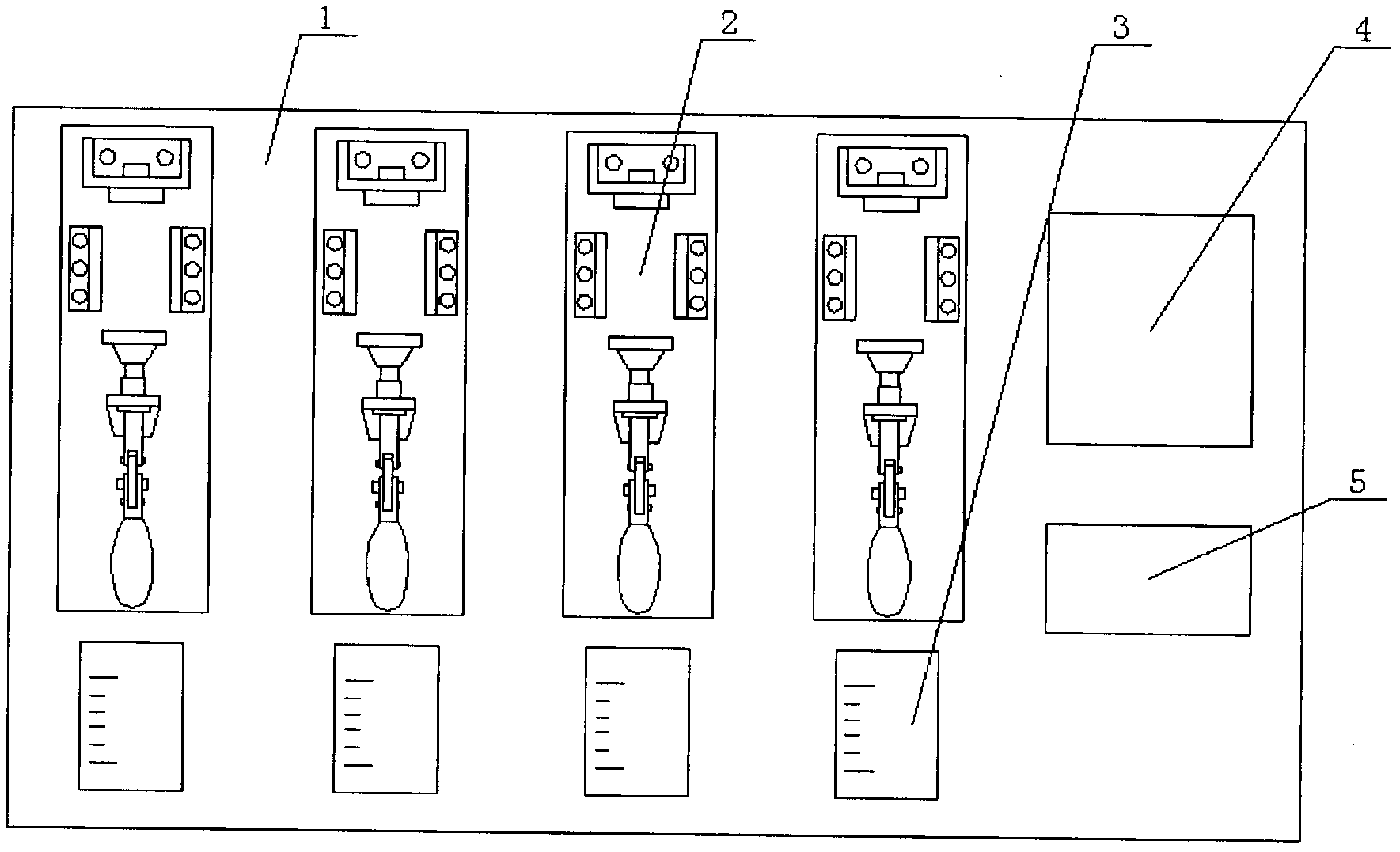

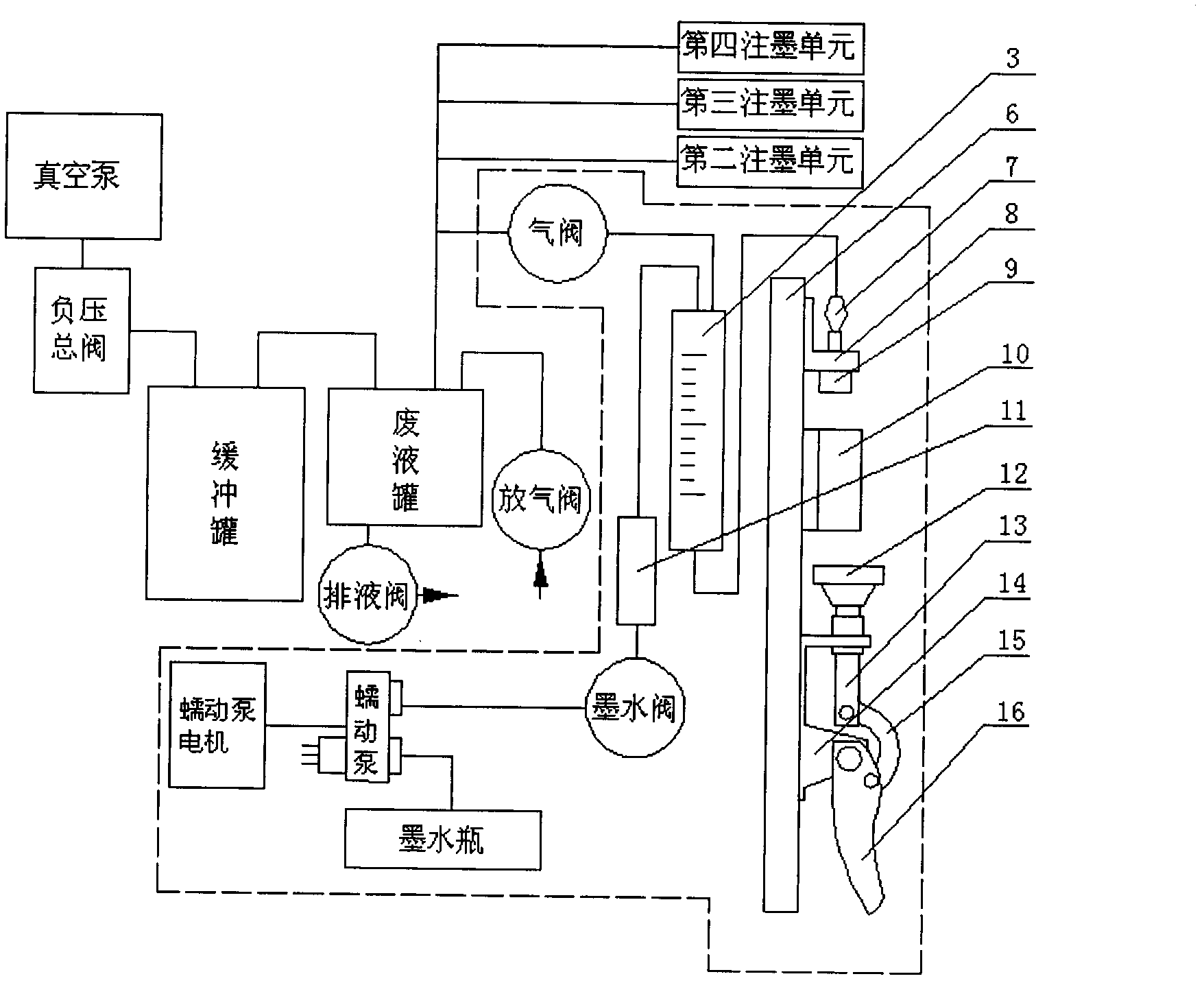

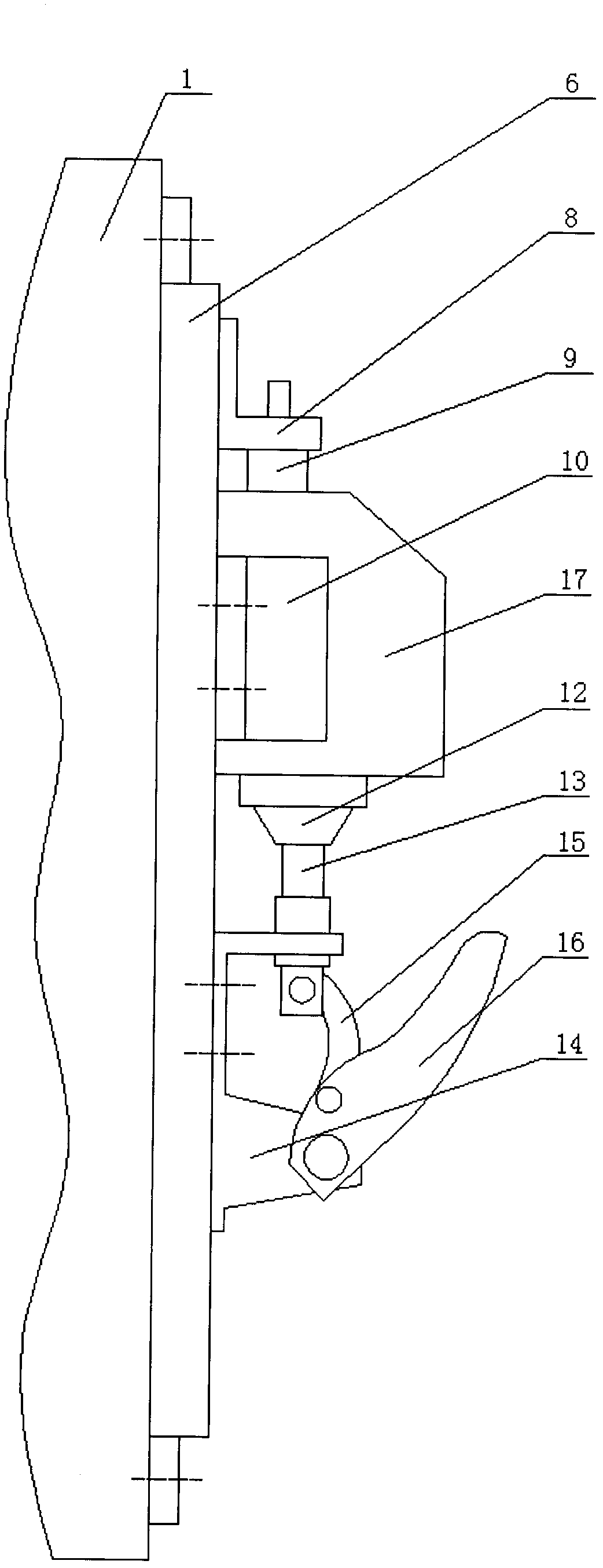

Accurately-metering automatic ink injection machine

The invention relates to an accurately-metering nondestructive automatic ink injection machine. The ink injection machine comprises a shell, a vacuum pump arranged in the shell, a negative pressure main valve, a waste liquid tank, a control module, and at least one set of ink injection units, wherein the vacuum pump is connected with the waste liquid tank through the negative pressure main valve; and the waste liquid tank is connected with each set of ink injection units. The automatic ink injection machine is suitable for injecting ink to various ink boxes with a structure such as an ink box and sprayer head integrated structure, an ink box and sprayer head separated structure, an in-box sponge structure, an in-box non-sponge structure, and the like, which means the automatic ink injection machine can inject ink to all most ink boxes on the market; thus, the automatic ink injection machine has a wide application range. When the ink is injected, the sponge structure is protected from being damaged and the sprayer heat from being worn, and the regeneration times of the ink box can be increased to a maximum extent to save the cost of a user. When the ink injection is finished, the ink can be fully filled to an ink spray nozzle, the automatic ink injection machine can be directly arranged on a printer for use and the ink does not need to be absorbed to the ink spray nozzle from the sprayer head with negative pressure.

Owner:陈换芳

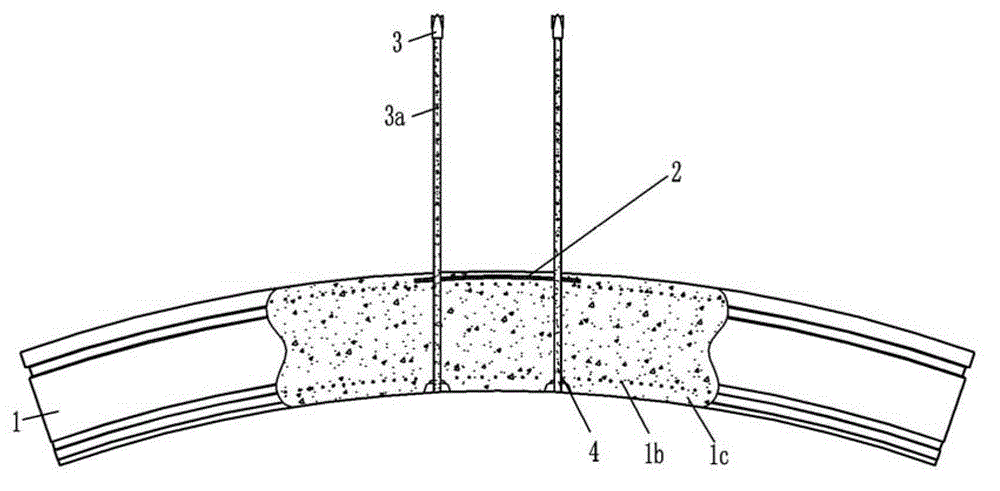

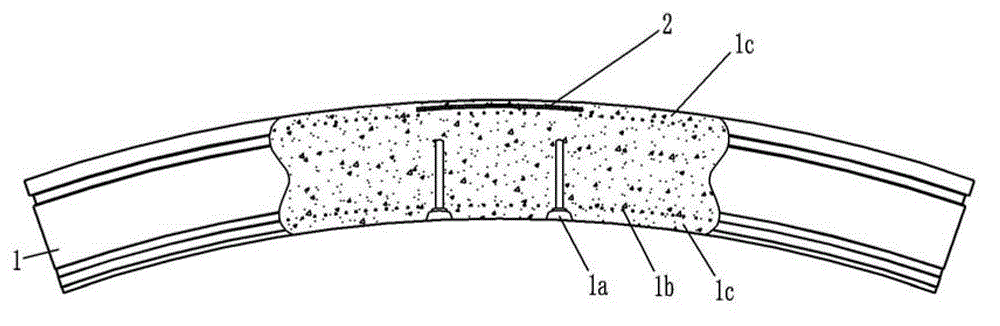

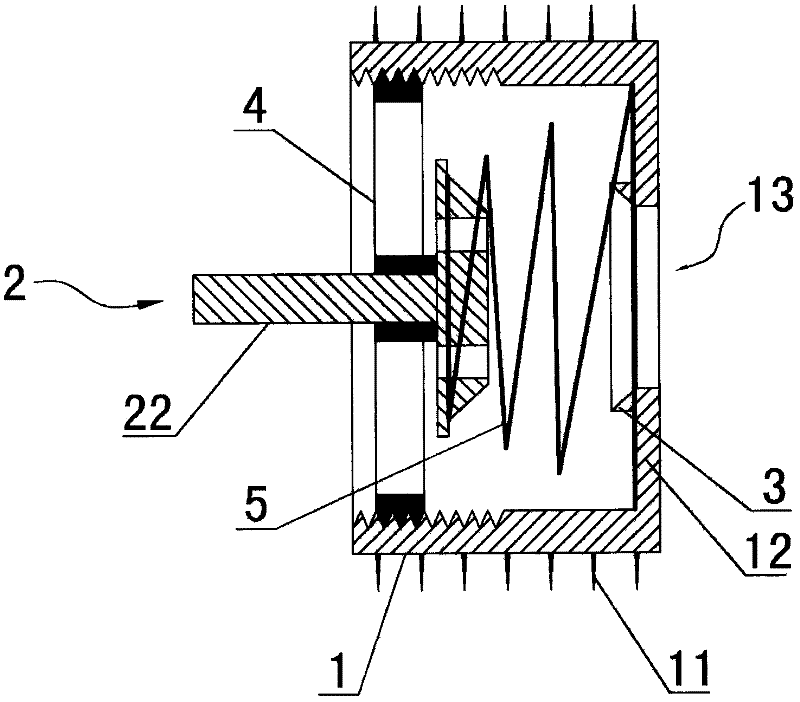

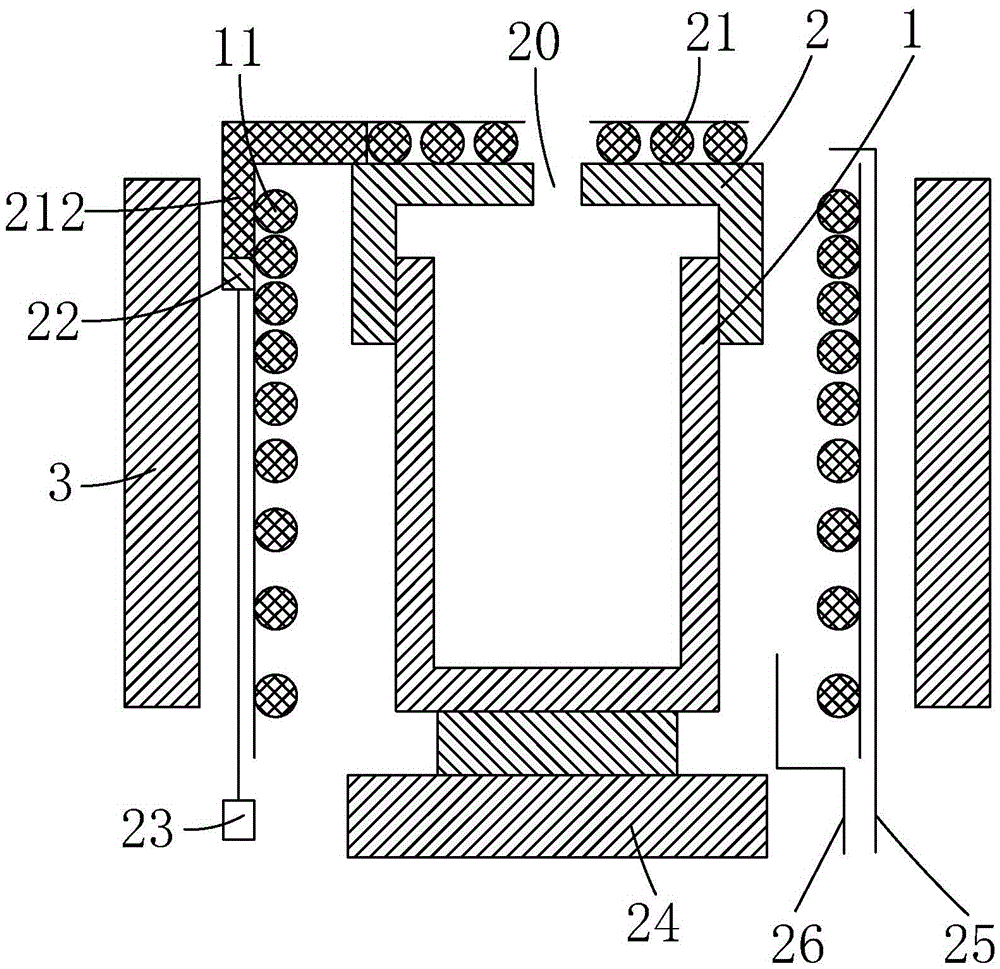

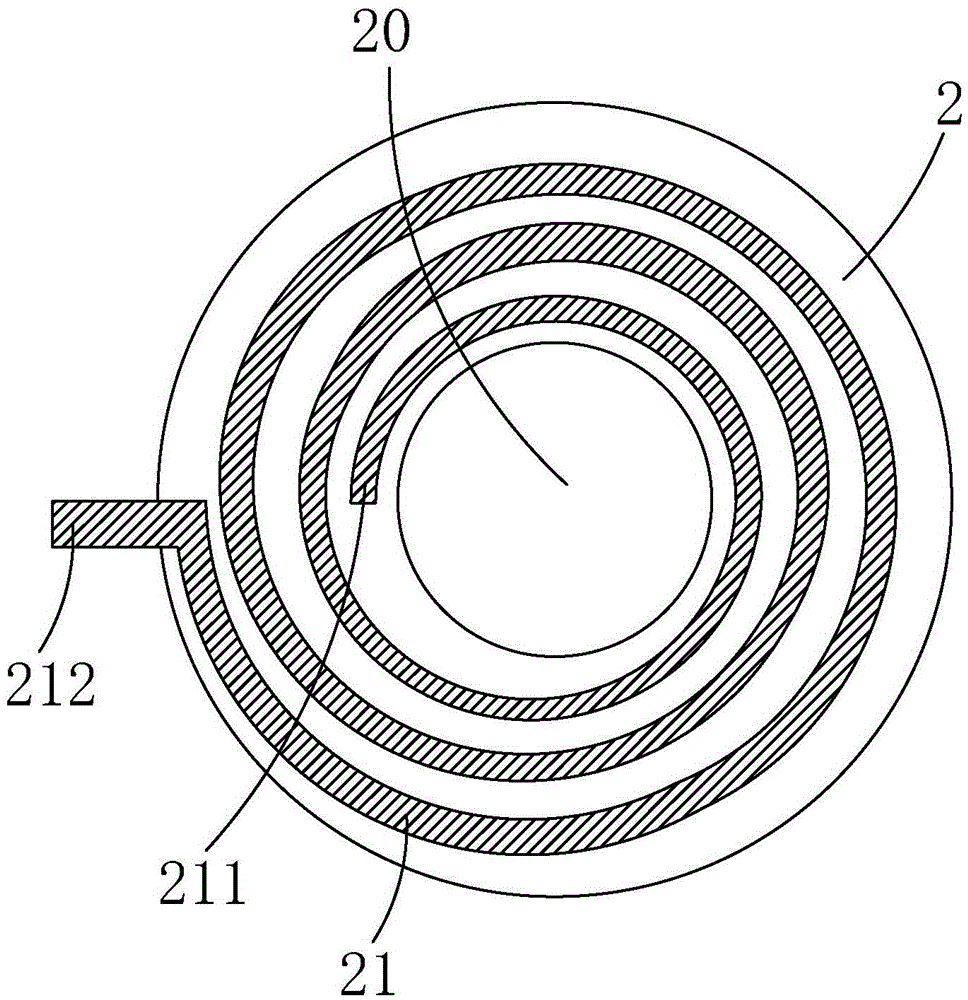

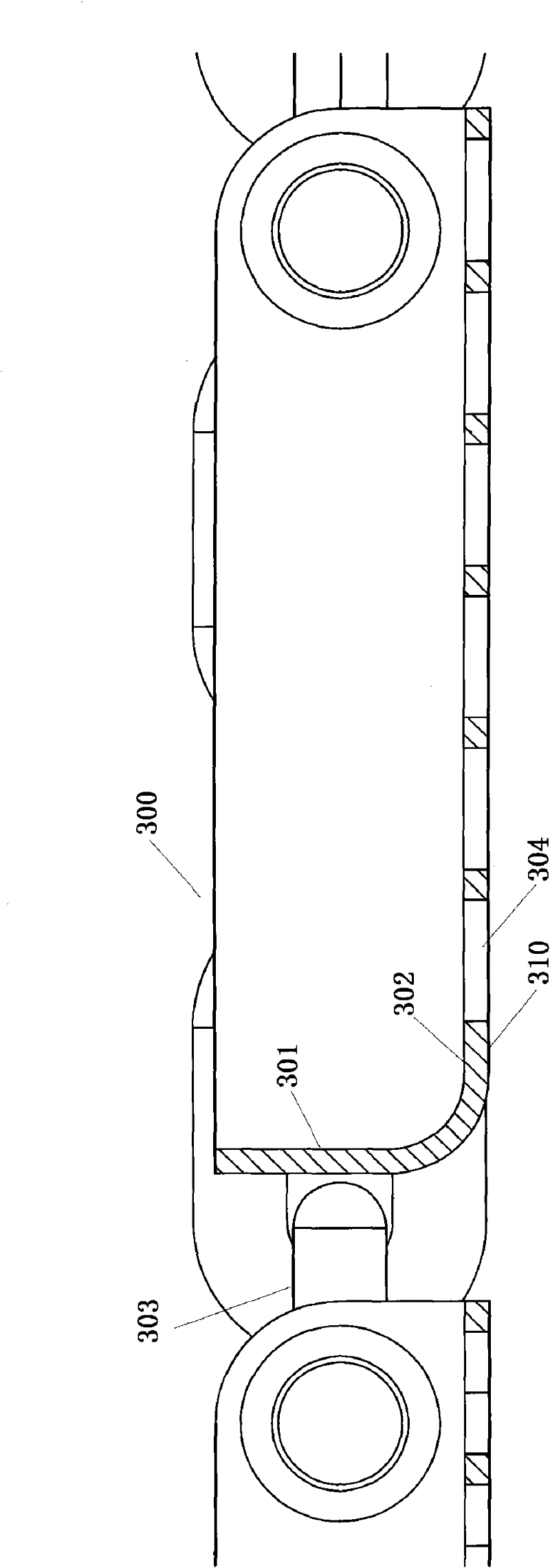

Drain-type pipe piece for tunnel lining

ActiveCN102979535ANo need to increase intensityEnsure safetyUnderground chambersDrainageReinforced concreteSlurry

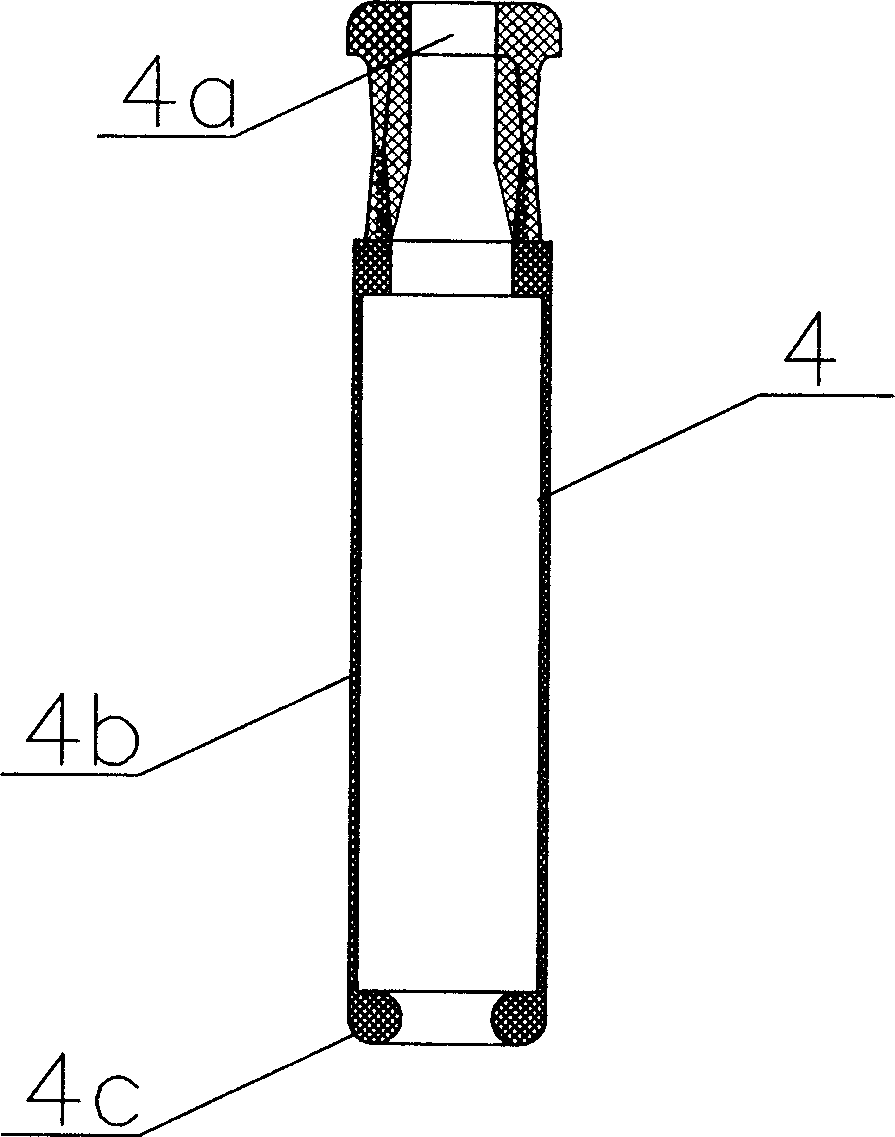

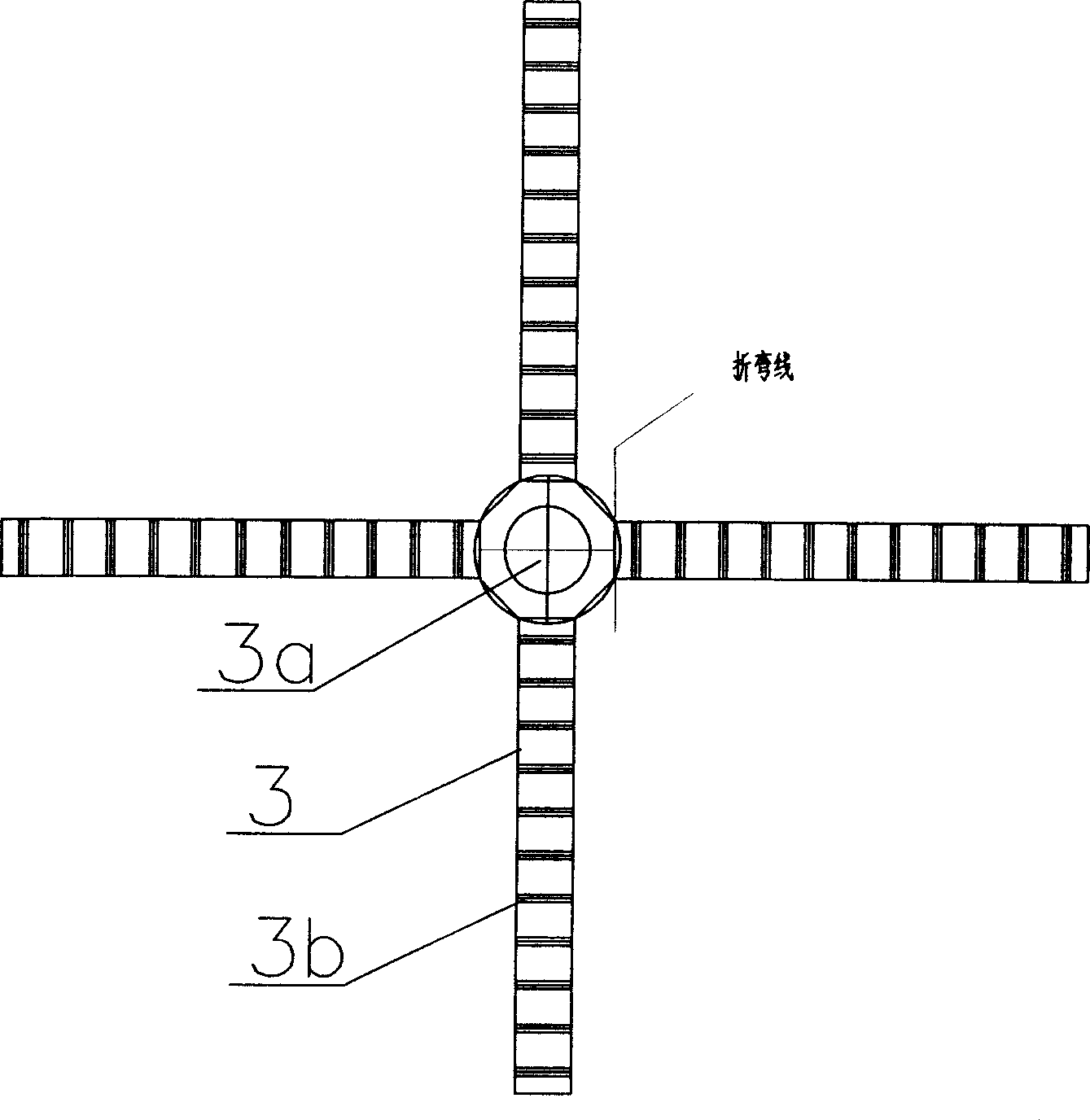

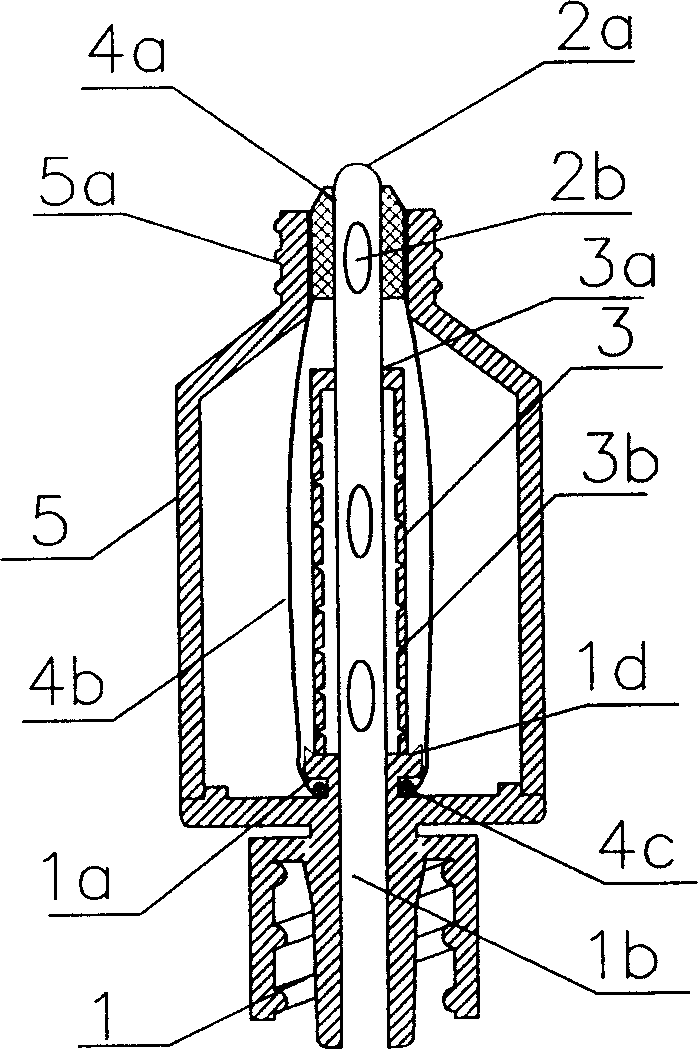

The invention discloses a drain-type pipe piece for tunnel lining. The drain-type pipe piece comprises a reinforced concrete pipe piece (1), a slurry injection hole (or a hoist hole) (1a) in the pipe piece (1), a load bearing steel bar (1b), and a concrete protective layer (1c) on the outer side; a water stop rubber block (2) capable of being expanded when being in contact with water is preburied in the concrete protective layer (1c) right opposite to one or two slurry injection holes (1a) of the pipe piece (1); a self-advancing type hollow anchor rod (3) is inserted in the slurry injection holes (or the hoist hole) (1a) of the pipe piece (1), then penetrates the water stop rubber block (2), and shoots out of the concrete protective layer (1c); and drain holes (3a) are formed in the rod wall of the outer end of the self-advancing type hollow anchor rod (3), and a filter column (4) used for filtering sand is plugged in the inner cavity of the self-advancing type hollow anchor rod (3). Lining built with the pipe pieces has a reliable drain function, and can reduce water pressure around the structure to ensure tunnel safety; and construction is convenient, small damage is caused to the pipe piece lining structure, and construction cost of the pipe piece lining is low.

Owner:SOUTHWEST JIAOTONG UNIV

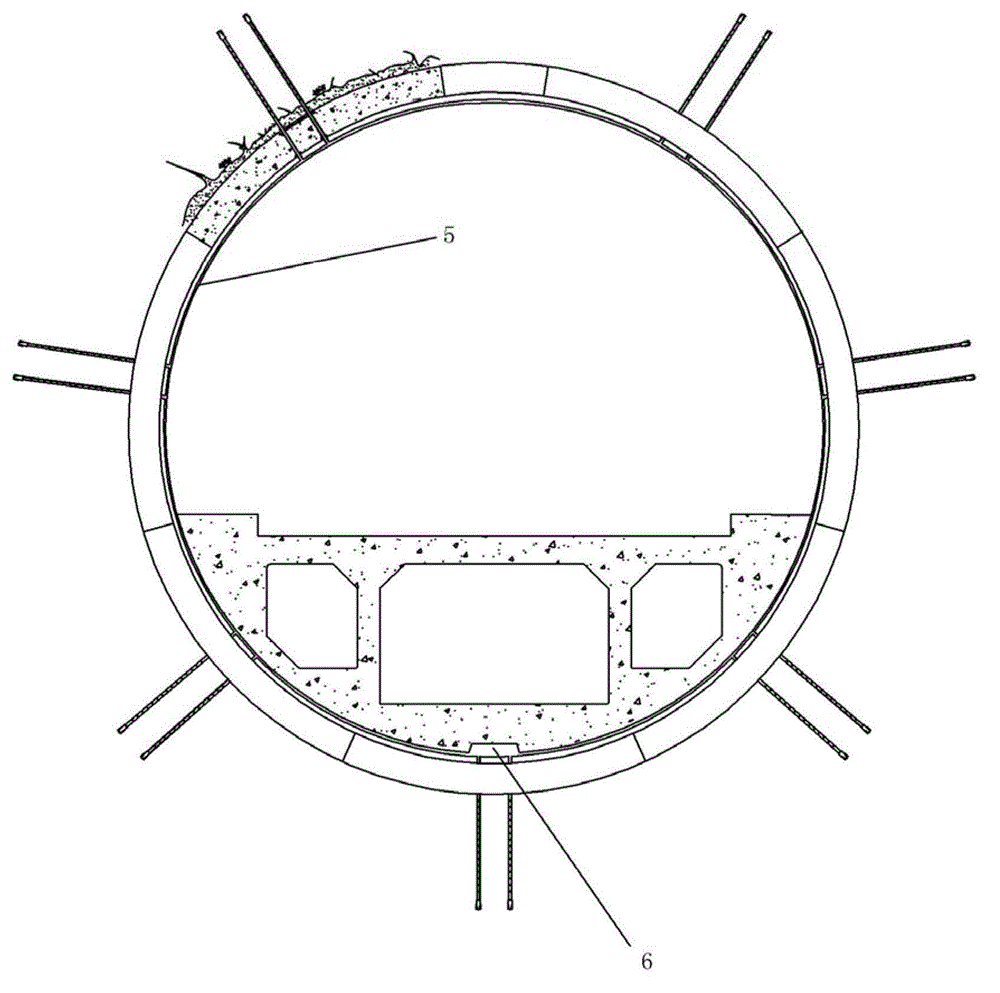

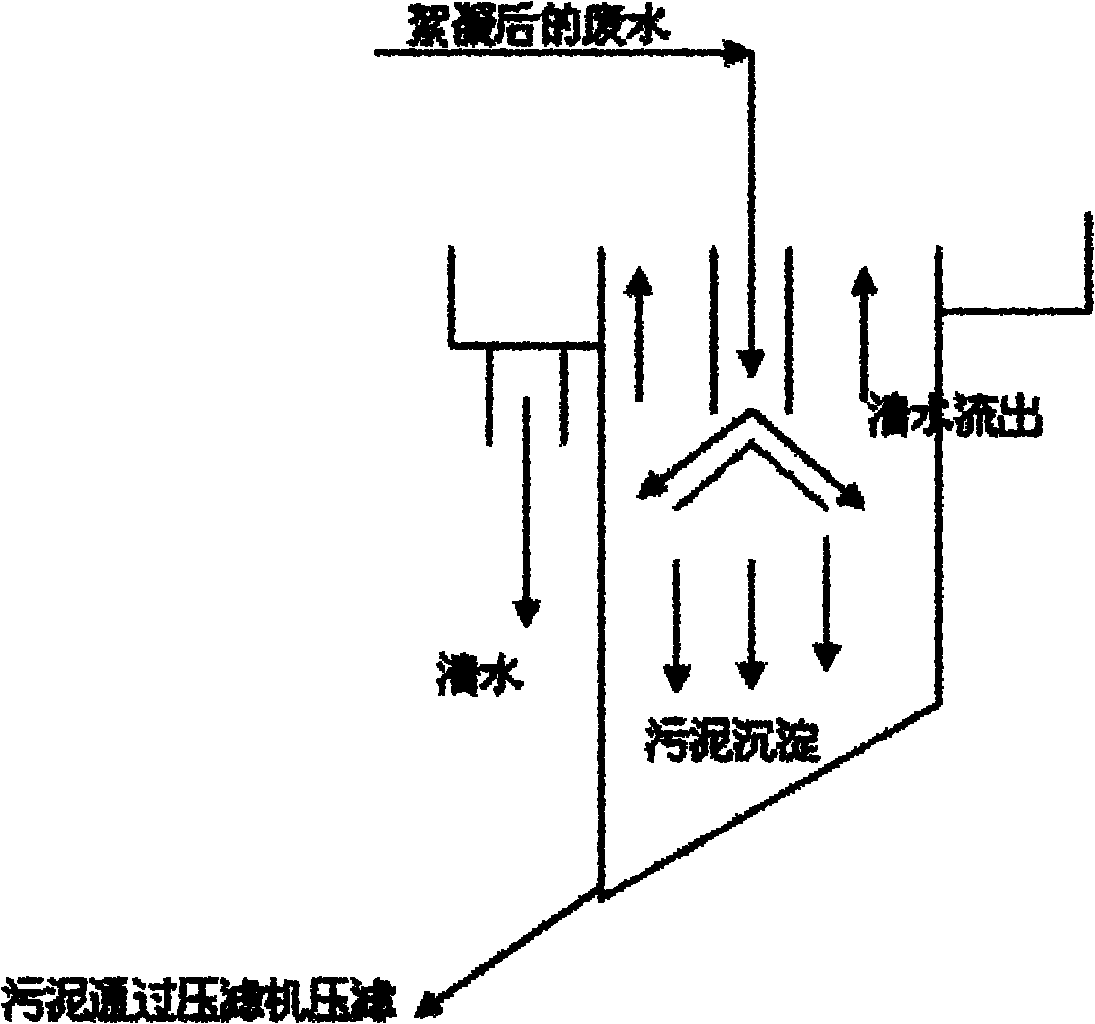

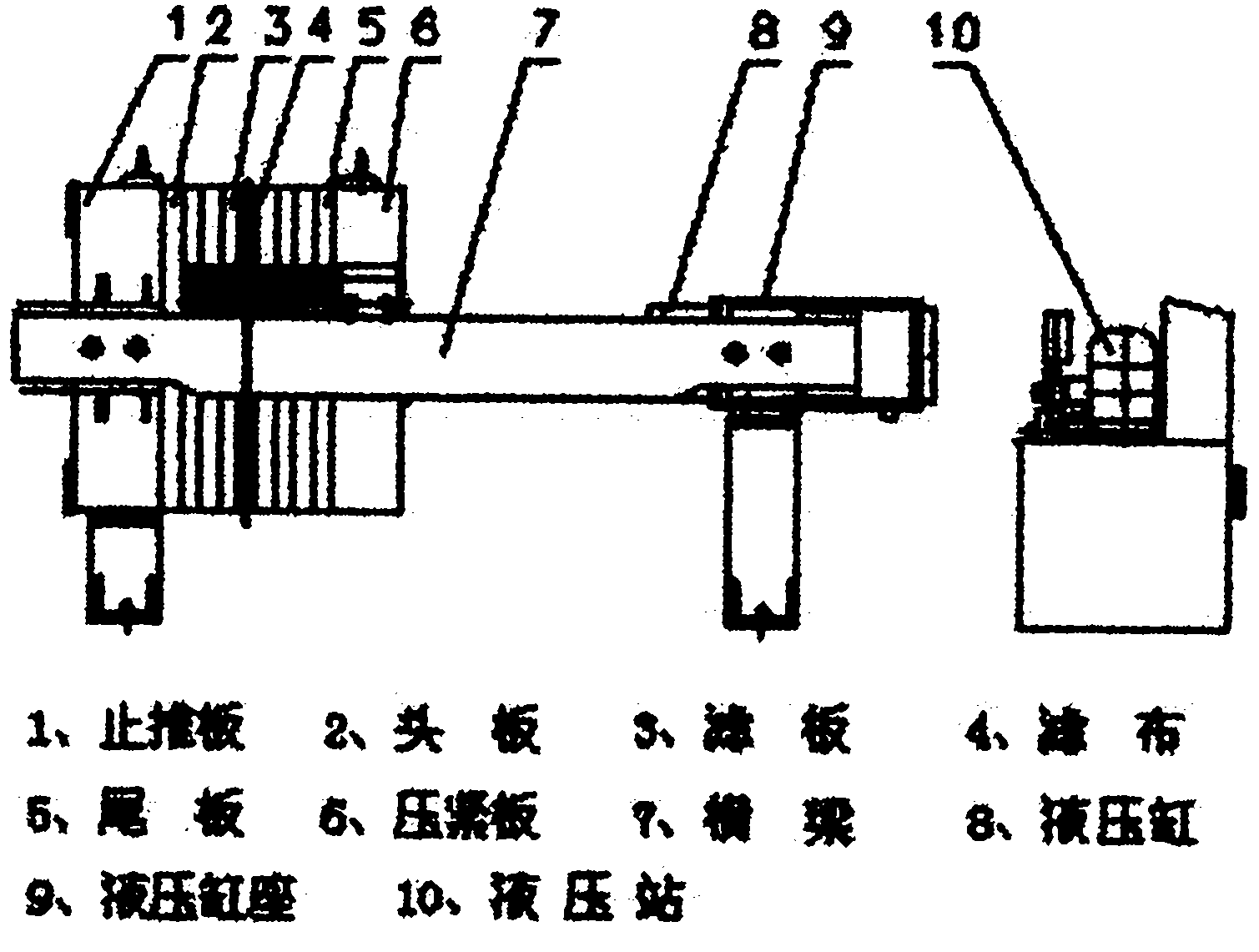

Treatment method of waste water discharged by silicon carbide micro powder production device

InactiveCN102092876AReduce in quantityReduce manufacturing costSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentAcid washingEconomic benefits

The invention discloses a treatment method of waste water discharged by a silicon carbide micro powder production device, which belongs to multi-stage treatment of the waste water. The method is characterized by comprising the following steps of: (1) collecting waste water discharged at an acid washing section and waste water discharged at an alkali washing section respectively for pH adjustment during waste water treatment; and (2) neutralizing, flocculating, performing filter pressing, separating and precipitating with a composite flocculating agent prepared from an inorganic flocculating agent A and an organic flocculating agent B, and recycling or discharged qualified waste water. Suspended matters in treated waste water reach a discharge standard. Silicon carbide micro powder is recycled from the waste water discharged by the silicon carbide micro powder production device and is sold as a byproduct, so that wastes are made profitable, the environment is protected, the economic benefits of enterprises are enhanced, and production cost is lowered.

Owner:临沂市凯祥硅粉有限公司

Bamboo charcoal profiled fiber and preparation method thereof

InactiveCN102154715AGuaranteed to meltGuaranteed compressionHollow filament manufactureFilament/thread formingYarnPolyester

The invention discloses bamboo charcoal profiled fiber with good product quality and low production cost, and a preparation method thereof. The fiber comprises the following components in percentage by weight: 94-99 percent of melt-spun slices, 1-6 percent of bamboo charcoal fine particles, 0.05-0.5 percent of surfactant and 0.1-1 percent of antioxidant, wherein the melt-spun slices are polyester, polyamide, polypropylene, polyethylene and modified polymers of polyester, polyamide, polypropylene and polyethylene; and the bamboo charcoal fine particles are black bamboo charcoal or white bamboo charcoal with the particle sizes of less than 2 mum. The preparation method comprises the following steps of: (1) preparing the bamboo charcoal fine particles according to a certain proportion, adding the surfactant and the antioxidant into a double-screw machine in a mixed conveying way, and directly putting the dried melt-spun slices into the hybrid double-screw machine; (2) melting and extruding the melt-spun slices in the double-screw machine, uniformly mixing the melt-spun slices with the bamboo charcoal fine particles and an aid, and conveying the mixture into a spinning box for direct spinning, by means of connection of a flange bent pipe; (3) spinning a blend melt with a spinning component from a spinneret plate, cooling, blowing and winding to obtain bamboo charcoal profiled nascent fibers; and (4) performing stretching twice and heat setting according to a continuous yarn or short yarn post-processing procedure. The invention is suitable for the bamboo charcoal profiled fiber and preparation thereof.

Owner:浙江三马锦纶科技股份有限公司

constant voltage regulator

InactiveCN102297279ATo achieve the purpose of voltage regulation and flow controlPrevent pluggingEqualizing valvesSafety valvesEngineeringTower

The constant pressure current stabilizer is mainly composed of a base, a throttle valve, a conical platform, a positioning seat, and a spring. The outlet end of the base is provided with a platform, and a hole is provided in the center of the platform; the spring It adopts a tower structure, the large-diameter end is placed on the platform in the base, the small-diameter end is sleeved on the outer edge of the cone and pressed on the flange; the center hole of the positioning seat is sleeved on the valve stem, and the positioning seat The outer wall is provided with a thread that matches the inner wall of the base, and the positioning seat is screwed on the inner wall of the base, and the prestressed pressure of the spring can be adjusted by adjusting the position of the positioning seat on the inner wall of the base, so as to achieve the purpose of stabilizing the voltage and controlling the flow .

Owner:李耀强

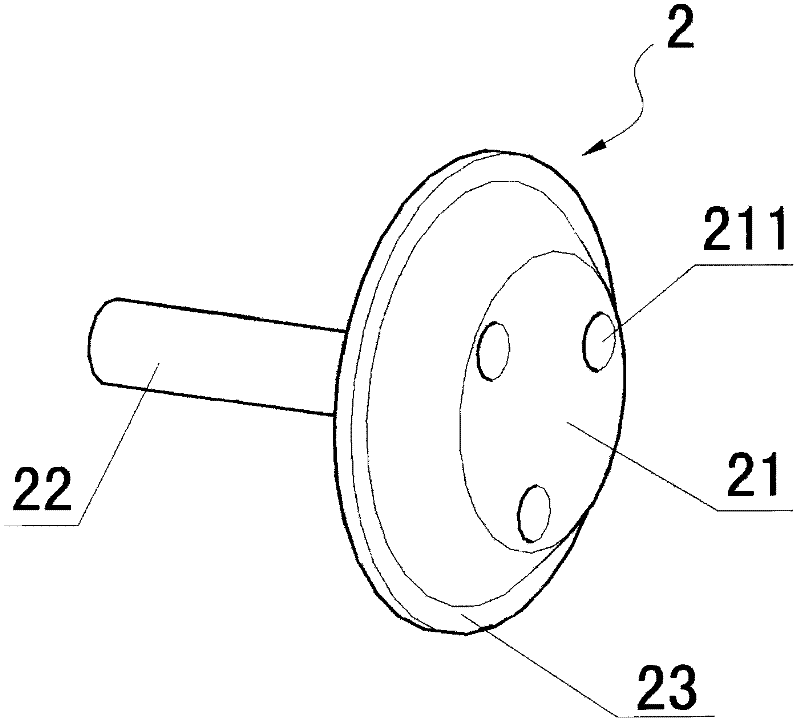

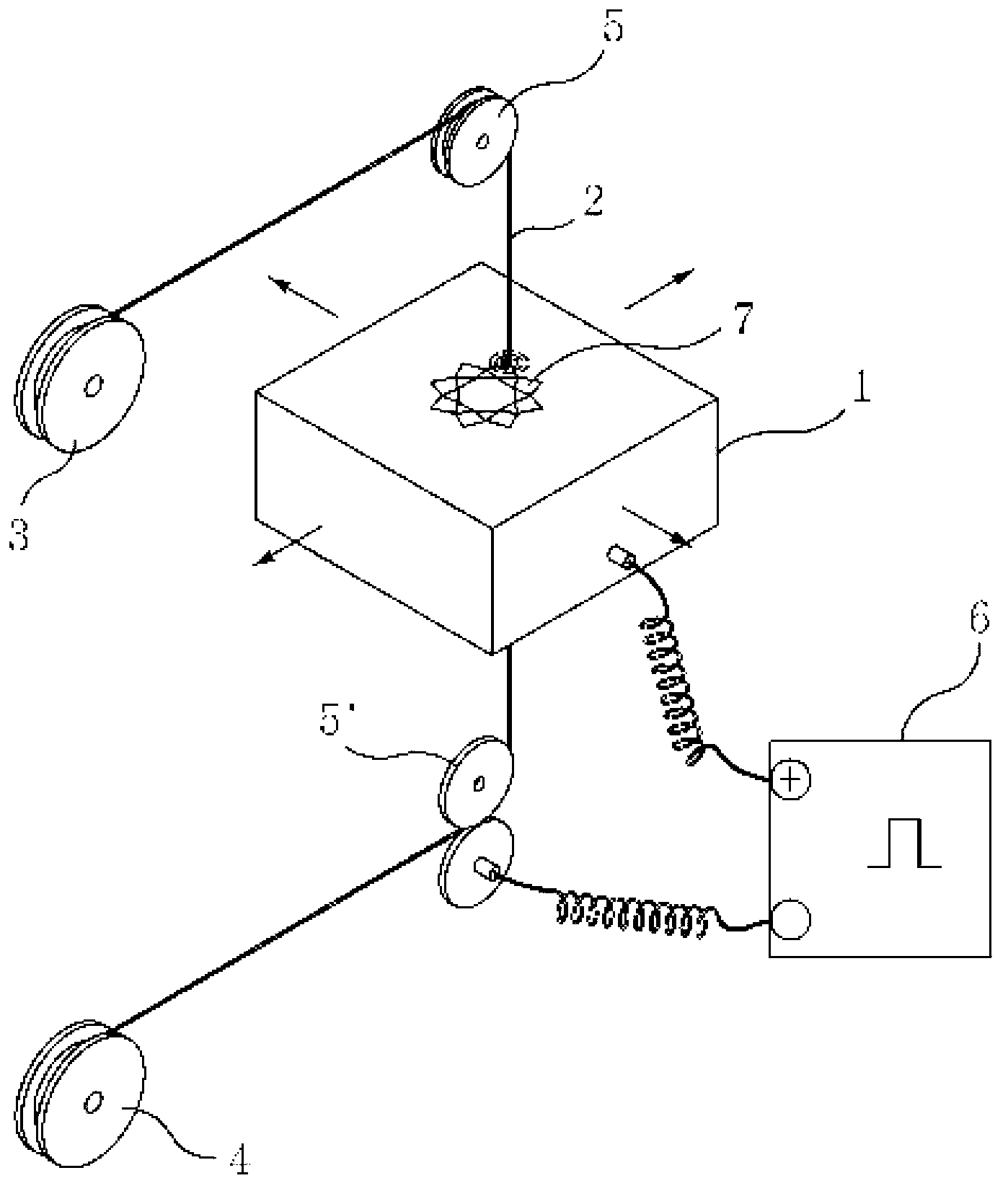

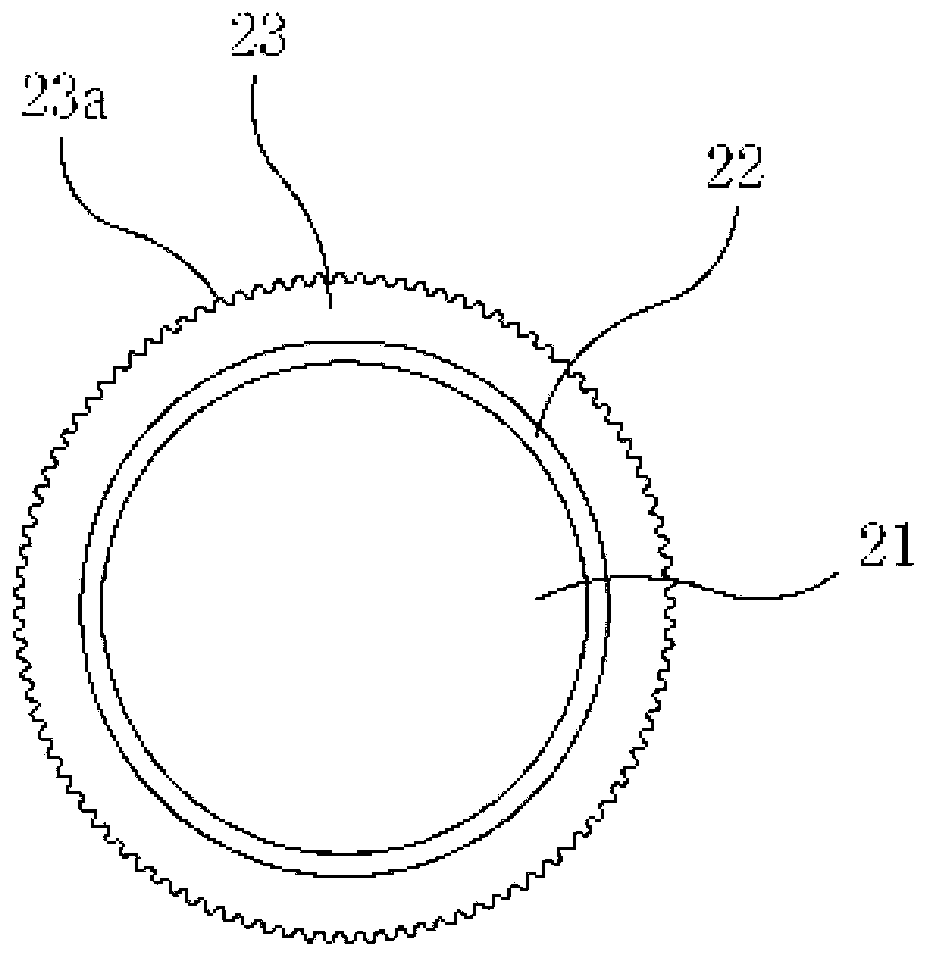

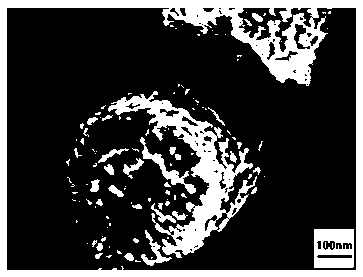

Electrode wire for electro-discharge machining and method for manufacturing the same

ActiveCN102922065ANo crackStop sheddingElectrical-based machining electrodesSuperimposed coating processSurface roughnessAlloy

Disclosed are an electrode wire (2) for electro-discharge machining and a method for manufacturing the same, which reduce micro-particles generated when an electrode wire is subject to the electro-discharge machining and improving the machining speed and the surface roughness of a workpiece. The method includes preparing a wire rod, which includes a first metal (21) and has a first diameter, as a core wire, plating a second metal (23) on the core wire, performing a fine wire process for the core wire plated with the second metal so that the core wire has a second diameter, while forming a corrugation (23a, 24a) having a predetermined pattern on a surface of the core wire having a second diameter, and performing a heat treatment process to form a first alloy layer at a boundary surface between the core wire and the second metal through a mutual diffusion between the core wire and the second metal, and to form a second alloy layer at an outer portion of the first alloy layer through diffusion of the first metal toward the second metal.

Owner:欧佩克梅德美国有限责任公司

Needleless seal transfusion joint

The sealed needle-less transfusion joint includes one casing, one liquid outlet joint with central hole adhered to the casing, one four claw elastic tab outside the needle tube, and one rubber tube outside the elastic tab matched with the liquid outlet joint and the needle tube wall. When the sealed needle-less transfusion joint is in use, the injector nipple compresses the rubber tube and the elastic tab to make the rubber tube form one saccule so that medicine liquid can enter to the saccule and further enter through the side hole to the needle tube, the liquid outlet joint and the retained vein needle. After finishing transfusion, the injector nipple is withdrawn, and the liquid is jetted fast through the liquid outlet joint owing to the resilience of the rubber tube, so as to rinse the vein needle and to avoid blood solidification.

Owner:张亚平

Manufacturing method of function module used for absorbing fog drops and VOC (volatile organic compounds) in airflows

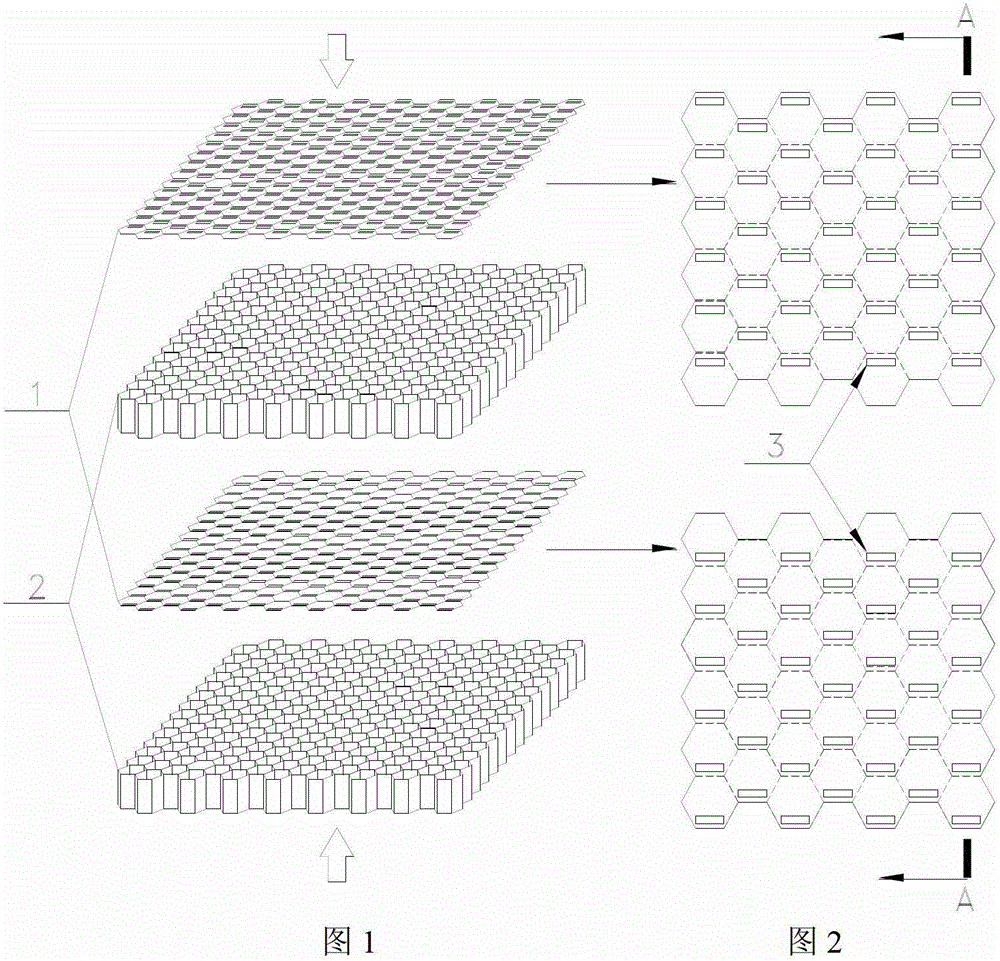

ActiveCN102908860AImprove adsorption capacityGive full play to the adsorptionDispersed particle separationAir quality improvementMaterials preparationHoneycomb

The invention relates to a manufacturing method of a function module used for absorbing fog drops and VOC (volatile organic compounds) in airflows and belongs to technical field of material preparation and environmental protection. The manufacturing method includes utilizing honeycomb paper as a base material, drilling holes at different positions of two adjacent partition layers, impregnating the honeycomb paper in pulp containing absorbent powder, taking the honeycomb paper out and drying to obtain the function module for absorbing fog drops and VOC in the airflows. The airflows pass in a baffling manner in the function module, the fog drops and the VOC are captured by absorbent on the inner wall of the honeycomb paper and the surface of a partition layer, so that the function module can efficiently remove the fog drops and the VOC in the airflows under the condition of lower pressure drop, and is more applicable to purification and treatment of catering waste gas.

Owner:中科新环(北京)环境工程有限公司

Method for preparing composite carbon material with high specific surface area

The invention relates to a method for preparing a composite carbon material with a high specific surface area, which comprises the following steps of: after active carbon is impregnated into saturated aqueous solution of soluble metal salt, carrying out decompression and impregnation for 15 to 60 minutes in a sealed container; filtering and drying the obtained solution; processing the obtained product for 1 to 3 hours under the protection of nitrogen at a temperature of 400 to 600 DEG C and repeating the operation for 2 to 5 times to obtain an active carbon hole blocking material; carrying out impregnation coating of metal salt on the active carbon hole blocking material by solution of VIIIB metal salt; filtering and drying to obtain active carbon coated with a metal catalyst; carrying out vapor phase deposition on the active carbon coated with the metal catalyst to obtain a discharge material; immersing the discharge material in hydrochloric acid solution to remove the catalyst and a hole protective agent in a reaction product; in case of necessity, carrying out stirring or ultrasonic processing; filtering; washing the product into neutrality by de-ionized water; and drying to obtain the composite carbon material. The composite carbon material has the advantages of high specific surface area and high electrical conductivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

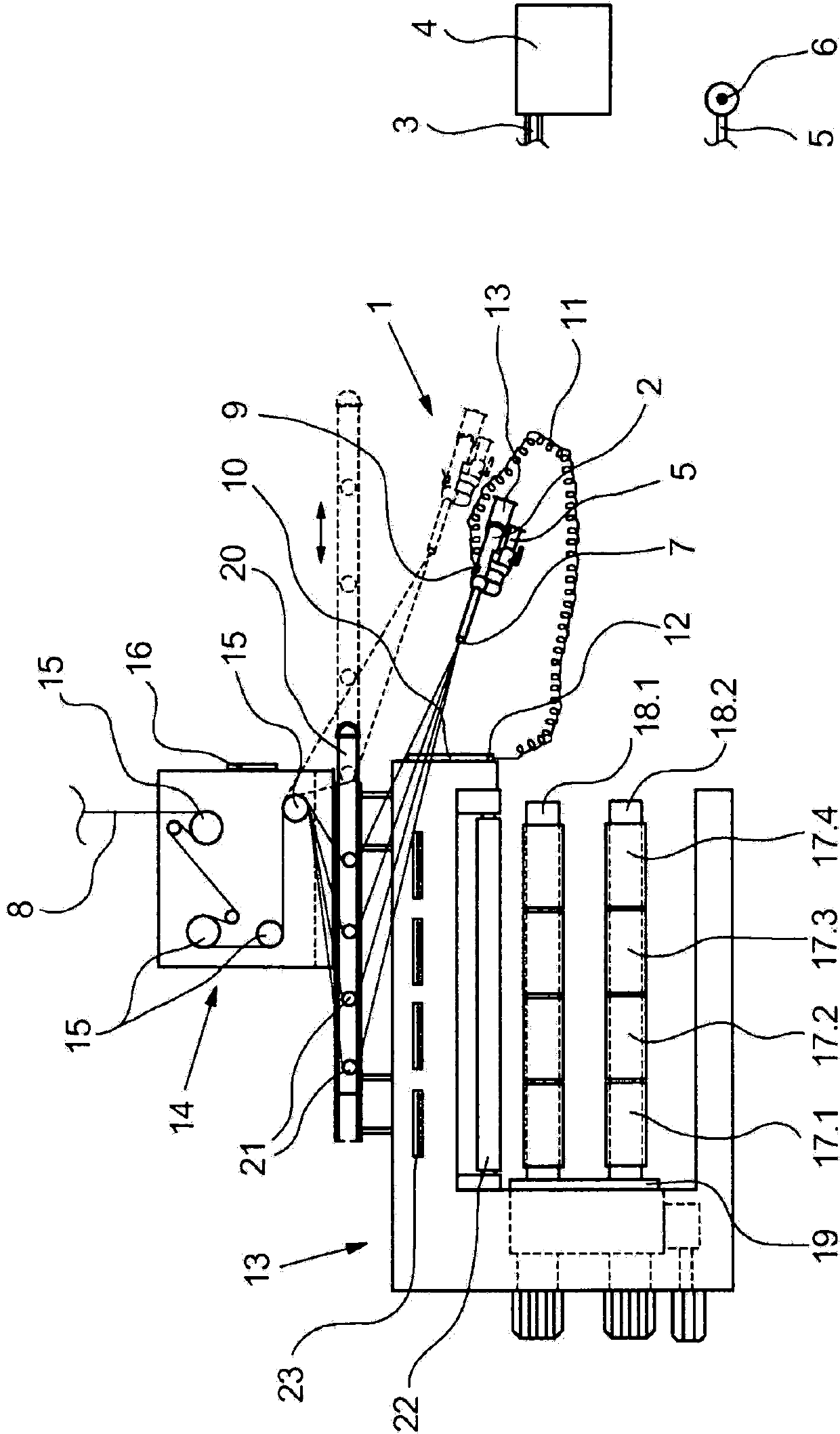

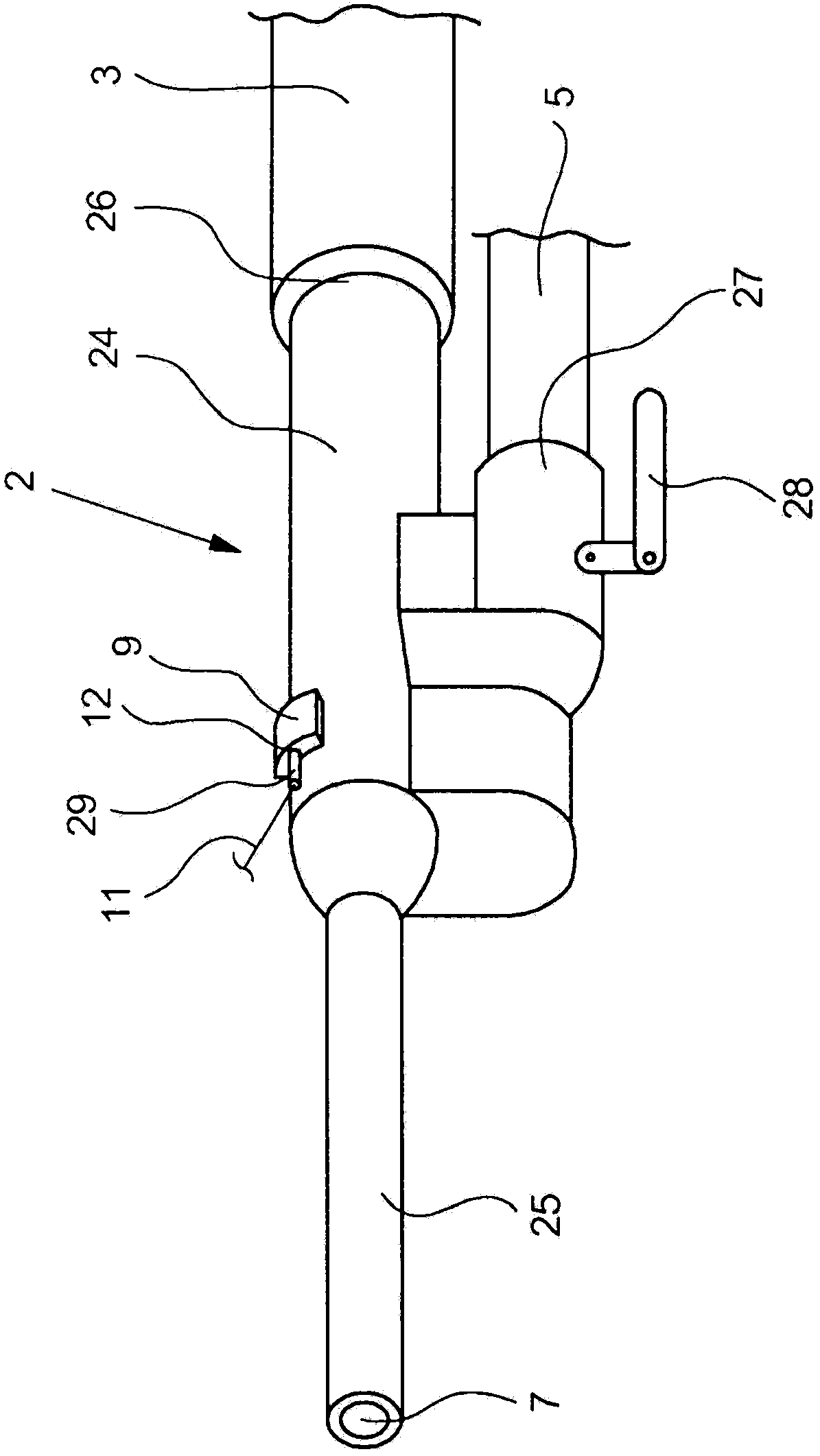

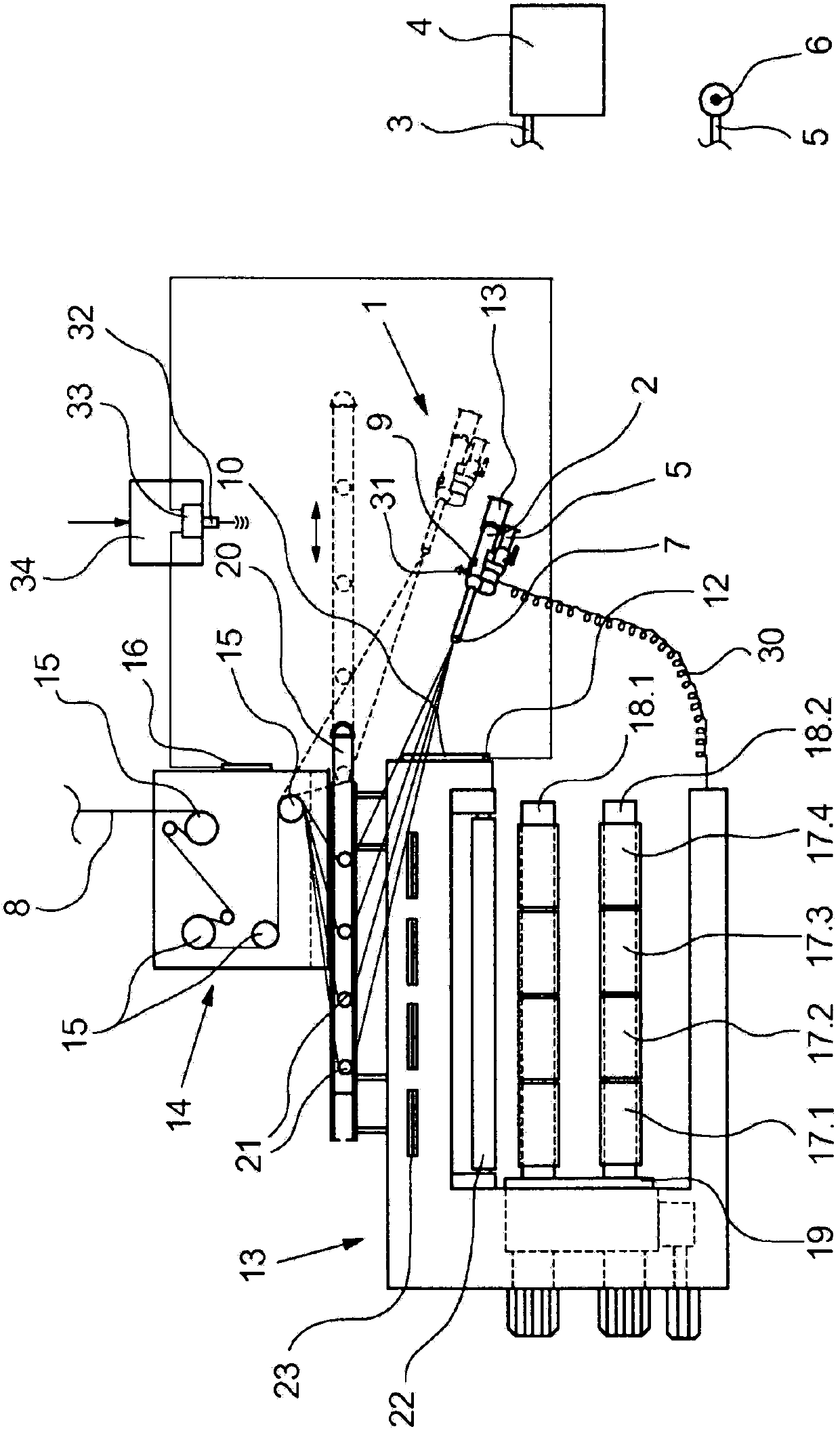

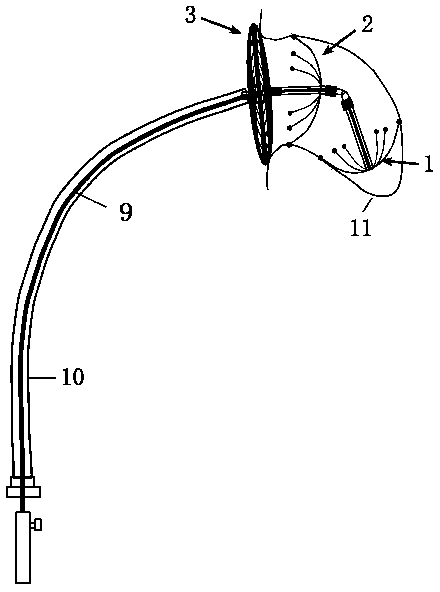

Auxiliary apparatus for the manual guidance of moving threads

InactiveCN103476692AAvoid uncontrolled discharge processAvoid distanceFilament handlingFormation startingKey pressingElectricity

The invention relates to an auxiliary apparatus for the manual guidance of moving threads in a thread-production and / or thread-handling process. The auxiliary apparatus has a hand injector (2), which is connected to a compressed-air line (5) and to a waste line (3), which is coupled to a waste-collecting location (4), wherein the hand injector, at a free end, has a suction opening for accommodating the threads. In order for an operator to realize quick operating sequences in the case of complex threading and feeding operations, according to the invention the hand injector has at least one manually operable control button (9) which interacts, via a signal connection (11, 31, 32), with a control unit (10, 16, 34) of a machine (13) and / or a machine component (14). For this purpose, use is advantageously made of a hand injector with a grip component (24), which is assigned at least one manually operable control button for triggering electrical button signals.

Owner:OERLIKON TEXTILE GMBH & CO KG

Method for preparing electrode materials with hollow carbon fibers coated with manganese dioxide

ActiveCN105513822AMild preparation conditionsMultiple load areasHybrid capacitor electrodesHybrid/EDL manufactureFiberCarbon fibers

The invention discloses a method for preparing electrode materials with hollow carbon fibers coated with manganese dioxide, and relates to the technical field of preparation of electrode materials. The method includes the steps that metal-oxide nanorods inside carbon fibers are washed away through acid, and the hollow carbon fibers are obtained; the surfaces of the carbon fibers are loaded with MnO2 with the hydrothermal method; polytetrafluoroethylene serves as a binding agent, acetylene black serves as an electric conduction assistant agent, foamed nickel serves as a current collector, and the HCNF@MnO2 electrode materials are prepared. According to the preparing process, the condition is mild, and the environment is friendly; economically, as cheap metal oxide is used, technology cost is reduced; the method is suitable for mass production.

Owner:YANGZHOU UNIV

Vacuum evaporation heating device

ActiveCN105603365AAvoid pluggingEasy to placeVacuum evaporation coatingSputtering coatingCrucibleEngineering

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

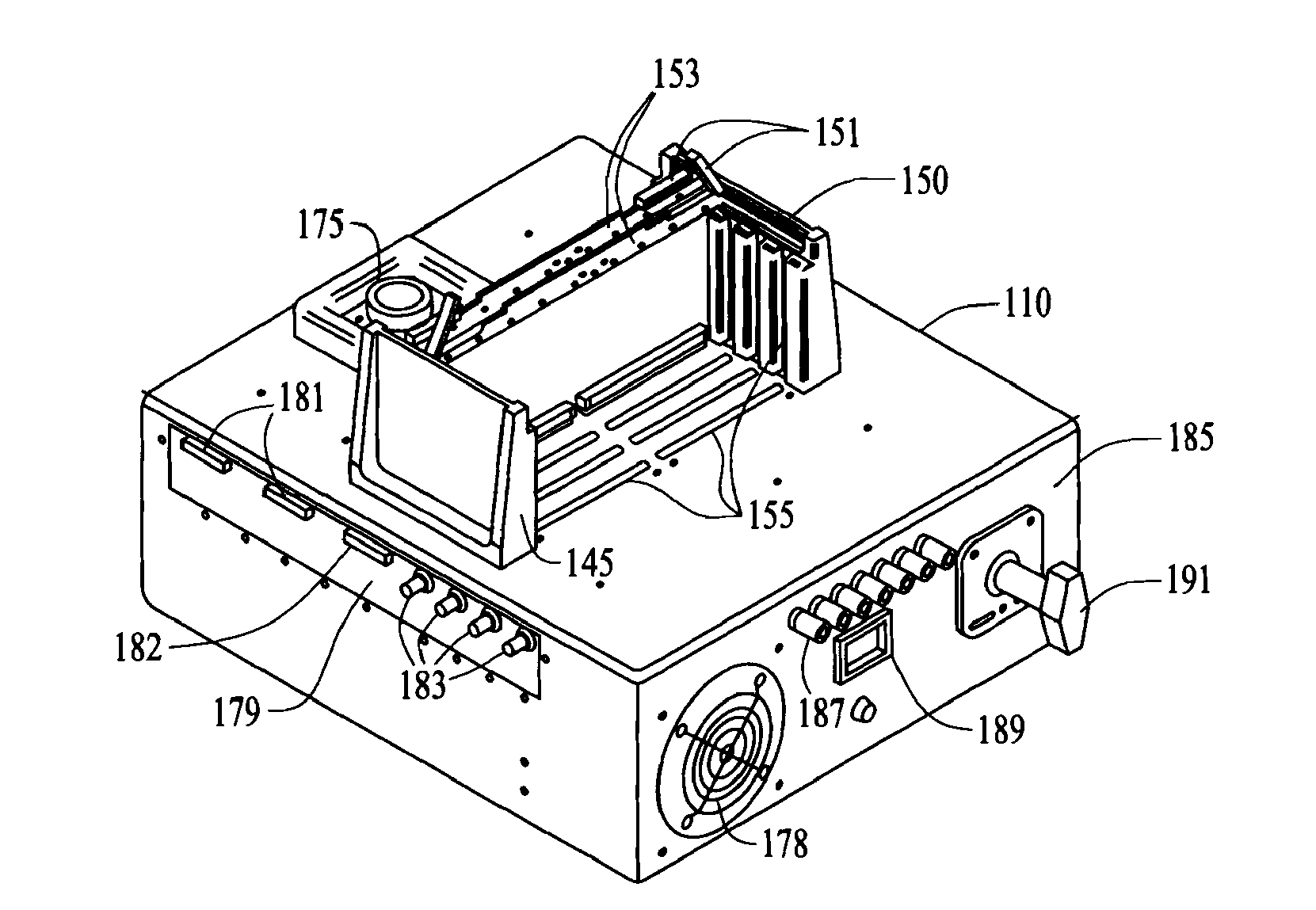

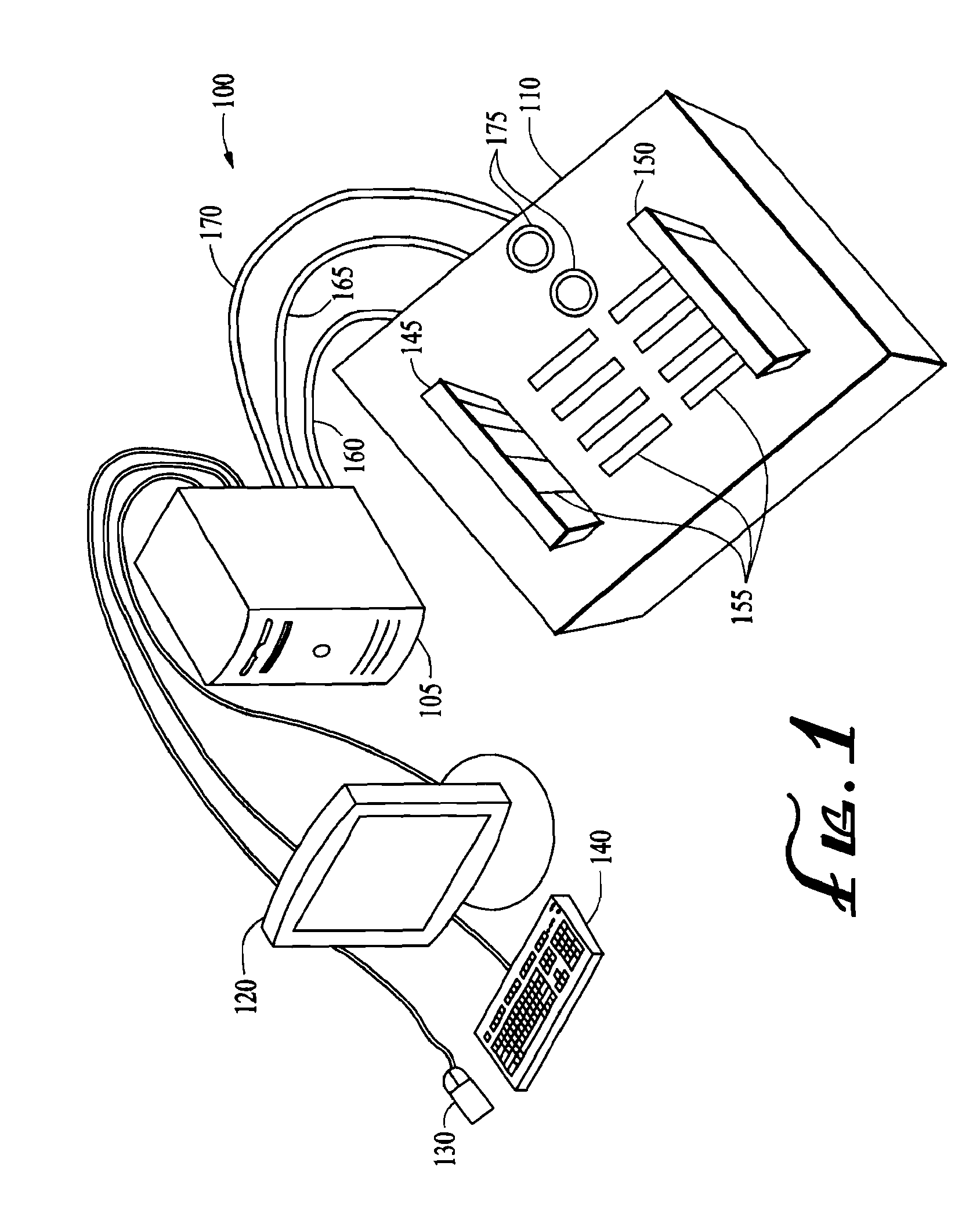

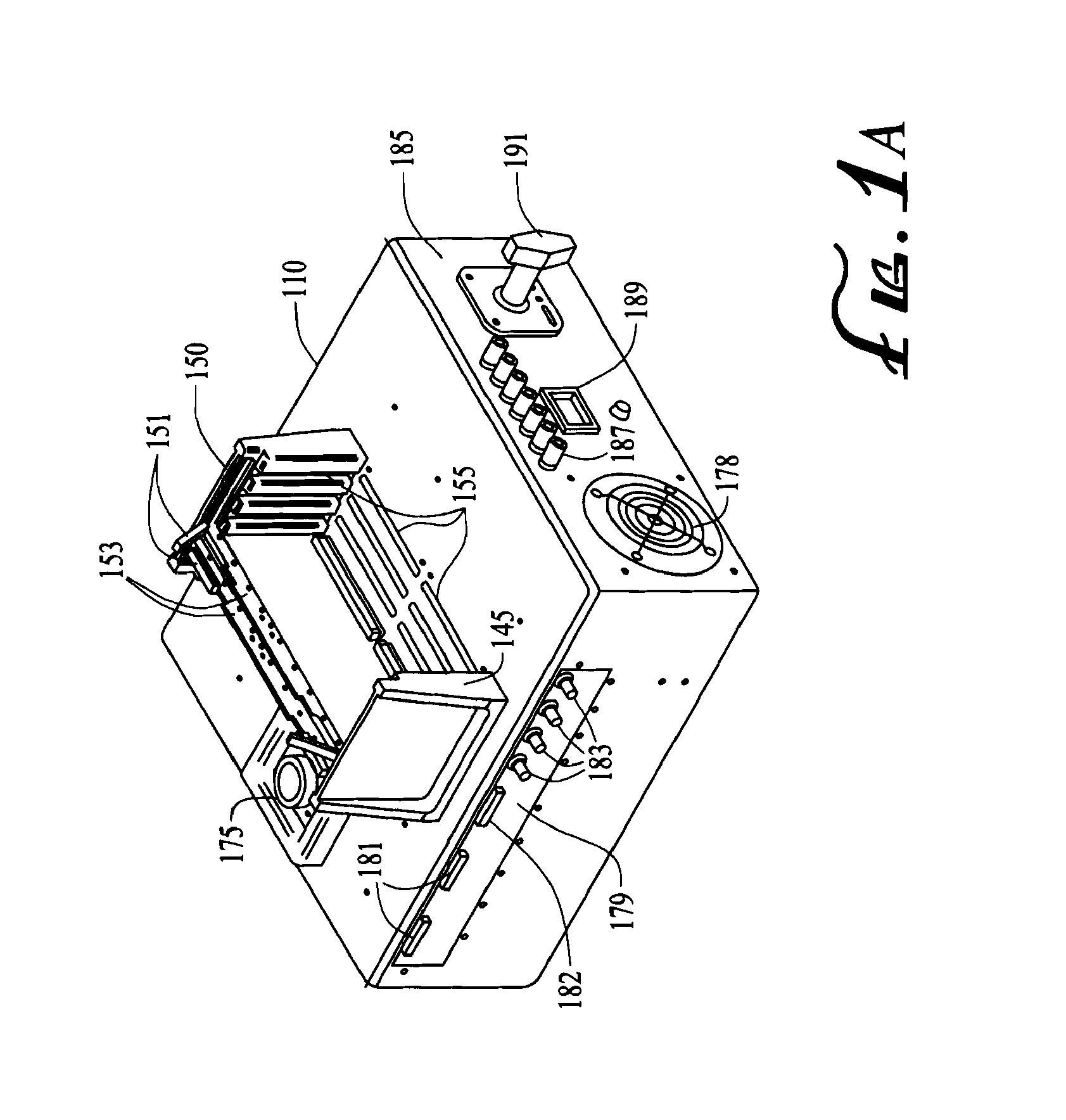

Circuit card assembly testing system for a missile and launcher test set

InactiveUS20090299677A1Avoid pluggingResistance/reactance/impedenceNuclear monitoringMissilePull off test

The invention generally relates to a circuit card assembly testing system for testing and troubleshooting new and failed circuit card assemblies. Specifically, circuit card assemblies that are part of a guided missile and launcher test set are tested using a board testing system (BTS), the preferred embodiment, to isolate faults or to verify final assembly. The BTS is used for testing and troubleshooting a wide variety of circuit card assemblies at the end of final assembly and upon their return as a failed item from the field. The BTS is designed to rapidly isolate faults in failed circuit card assemblies that have been returned to a maintenance facility by providing an improved means of fault isolation. The BTS is designed to aid in the production of circuit card assemblies by providing an improved means of rapidly verifying the proper operation of circuit boards after final assembly.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

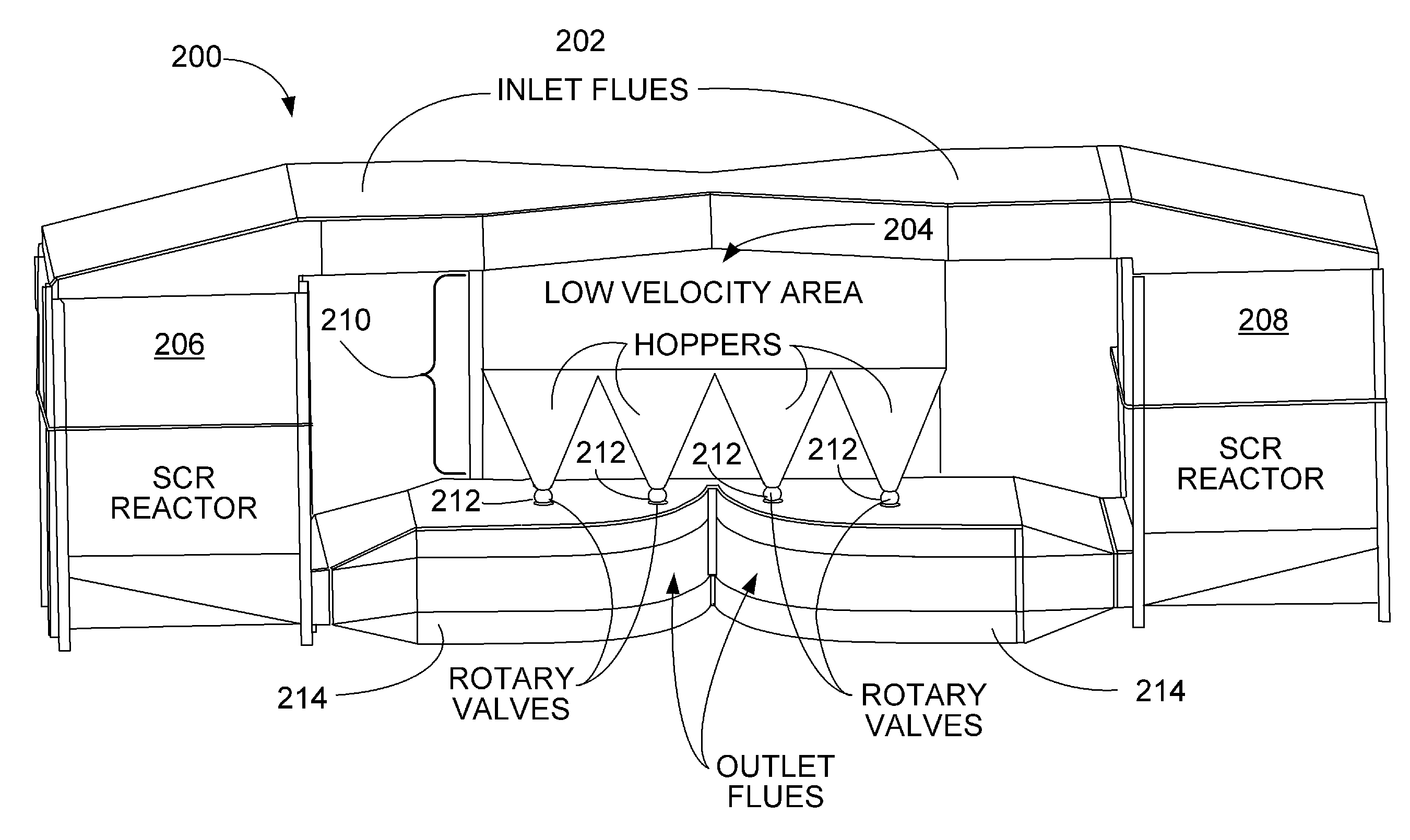

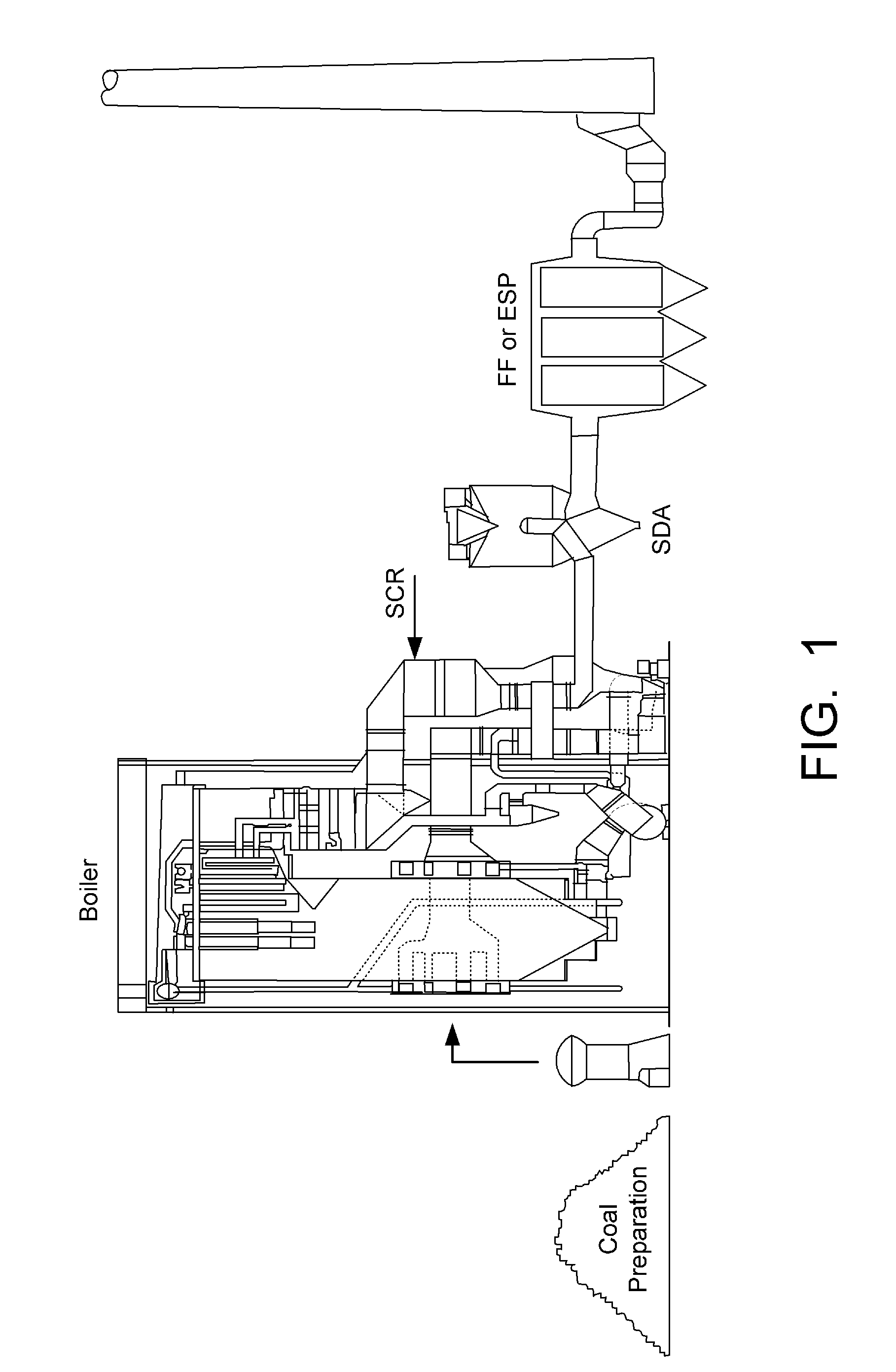

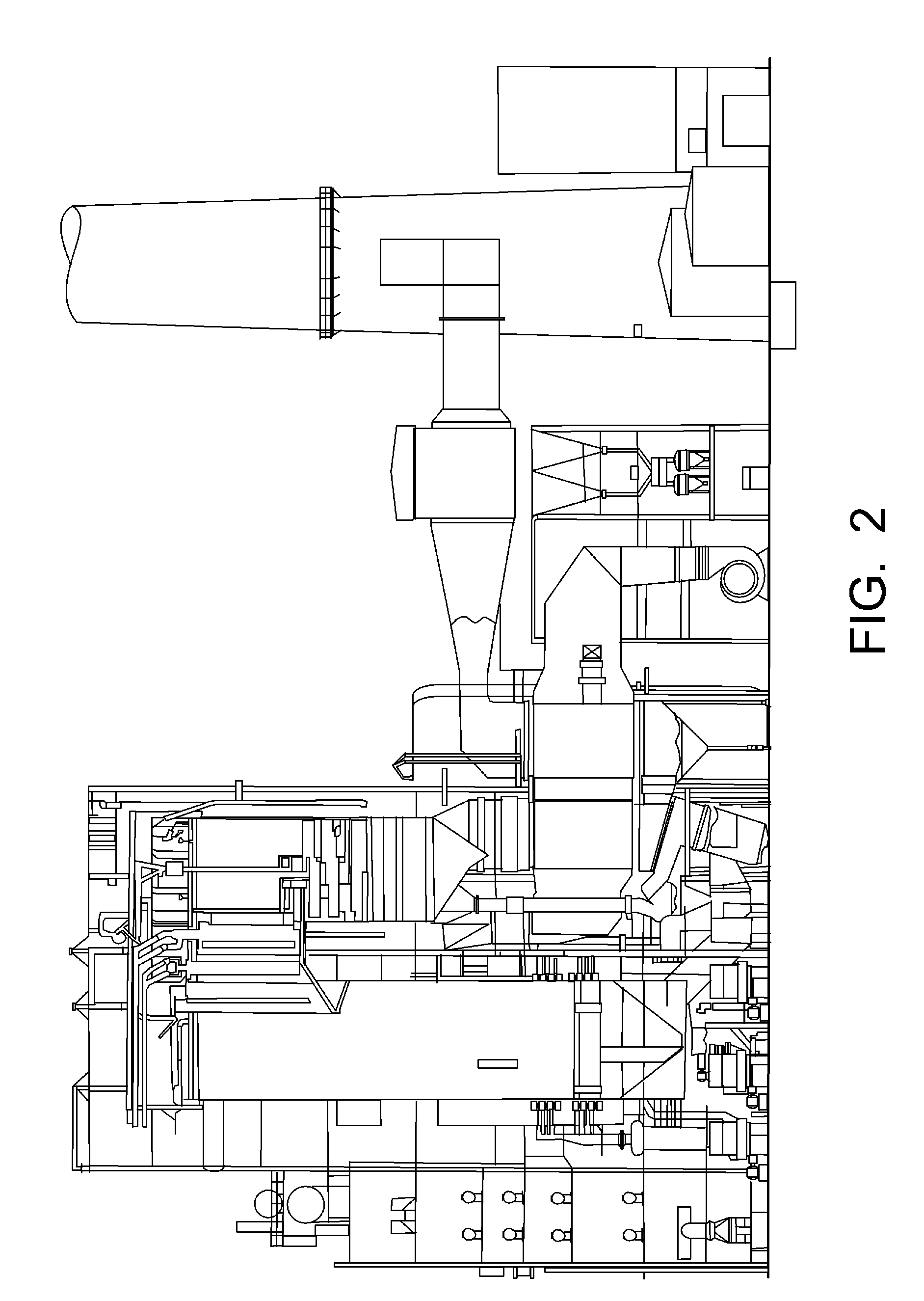

System and method for protection of scr catalyst

InactiveUS20110048234A1Avoid pluggingAvoid blockageCombination devicesGas treatmentCombustionPower station

The present invention relates generally to the field of emission control equipment for boilers, heaters, kilns, or other flue gas-, or combustion gas-, generating devices (e.g., those located at power plants, processing plants, etc.) and, in particular to a new and useful method and apparatus for preventing the plugging, blockage and / or contamination of an SCR catalyst. In another embodiment, the method and apparatus of the present invention is designed to protect an SCR catalyst from plugging and / or blockage from large particle ash that may be generated during combustion.

Owner:THE BABCOCK & WILCOX CO

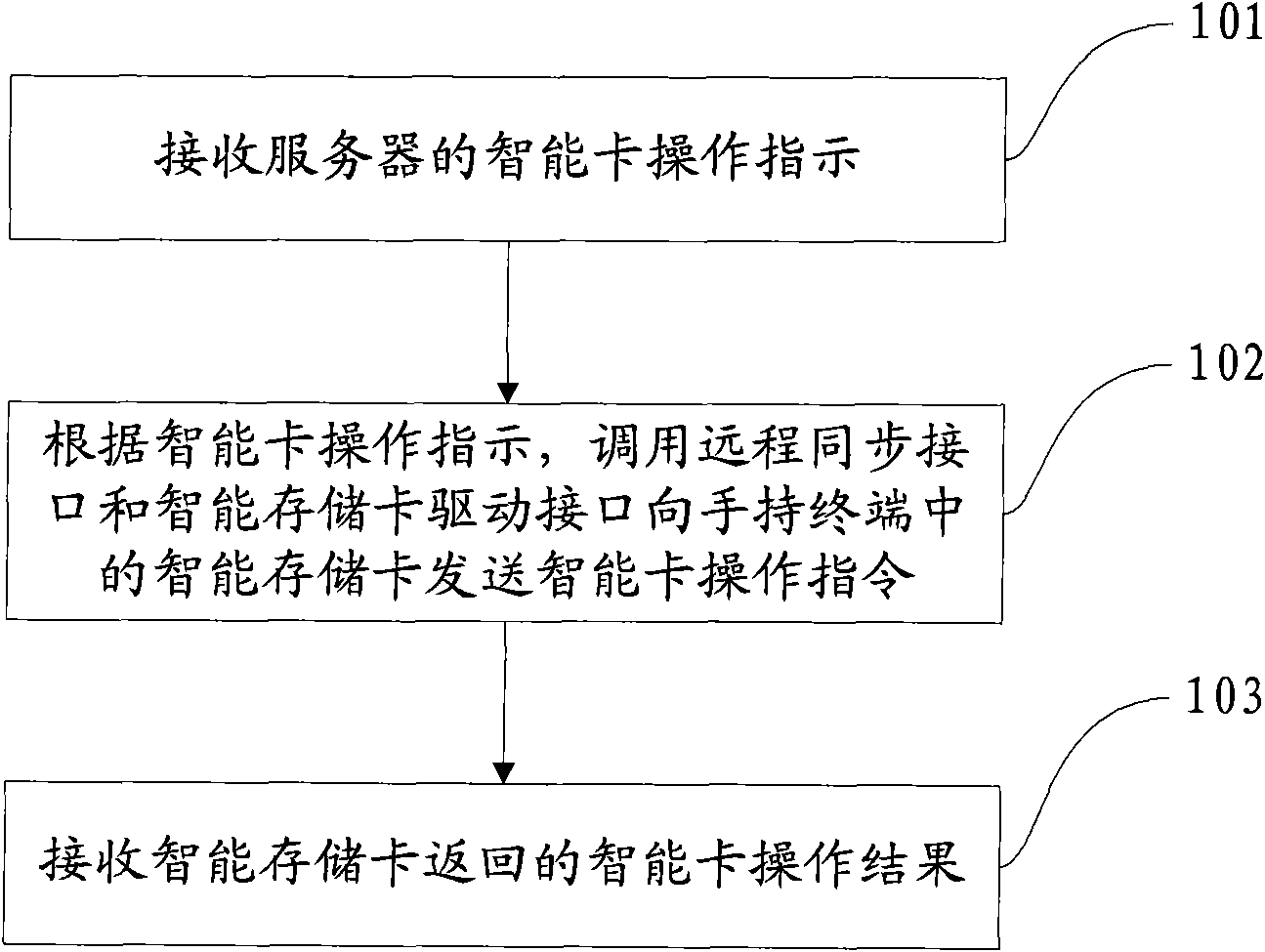

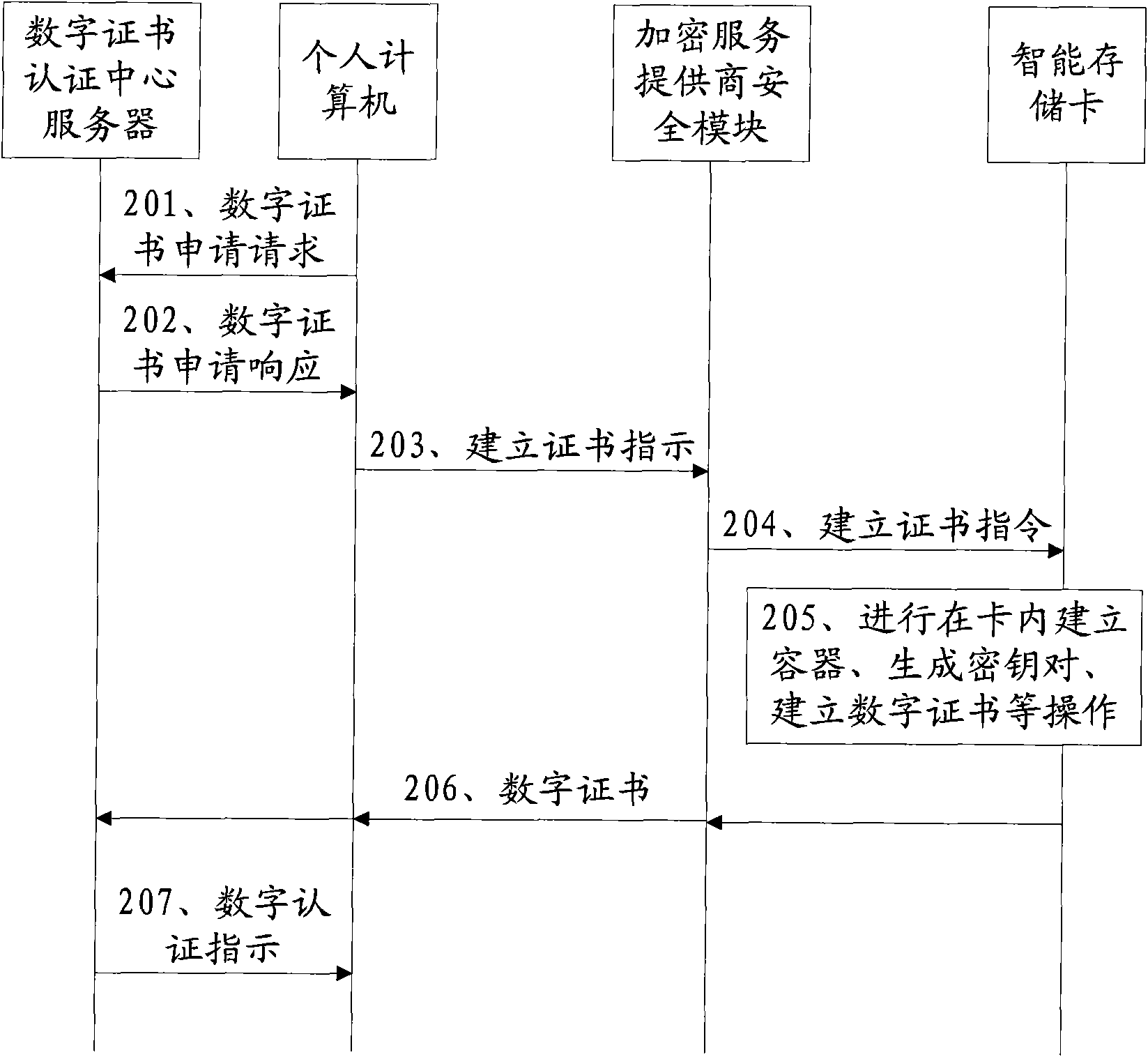

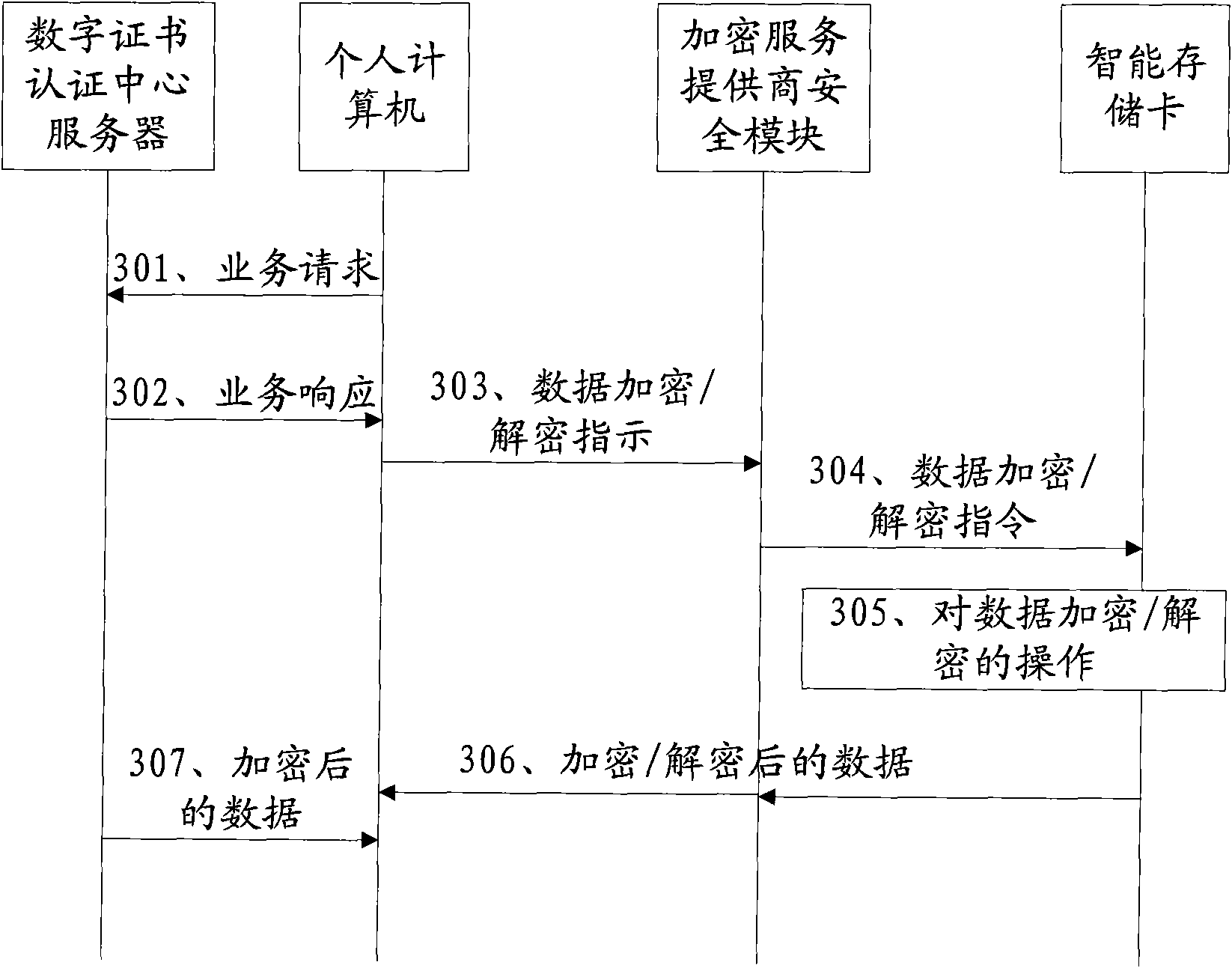

Operation method and device for intelligent storing card

InactiveCN101587458AReduce user costsAvoid pluggingCo-operative working arrangementsSpecific program execution arrangementsOperating instructionSmart card

The embodiment of the invention embodiment an operation method and device for an intelligent storing card, relating to the communications field. for realizing that the PC machine executes the smart card operation for the storing card inserted a handhold terminal directly, the embodiment of the invention has the technical scheme that the method includes: receiving the smart card operation indication of a server by a PC machine; calling a remote synchronous interface and an intelligent storing card drive interface to transmit the operating instruction of a smart card to the intelligent storing card in the handhold terminal according to the smart card operation indication; the smart card operating instruction being used for indicating the intelligent storing card to execute the smart card operation; receiving the smart card operation result returned by the intelligent storing card. The embodiment of the invention is suitable for the storing card operation.

Owner:BEIJING WATCH DATA SYST

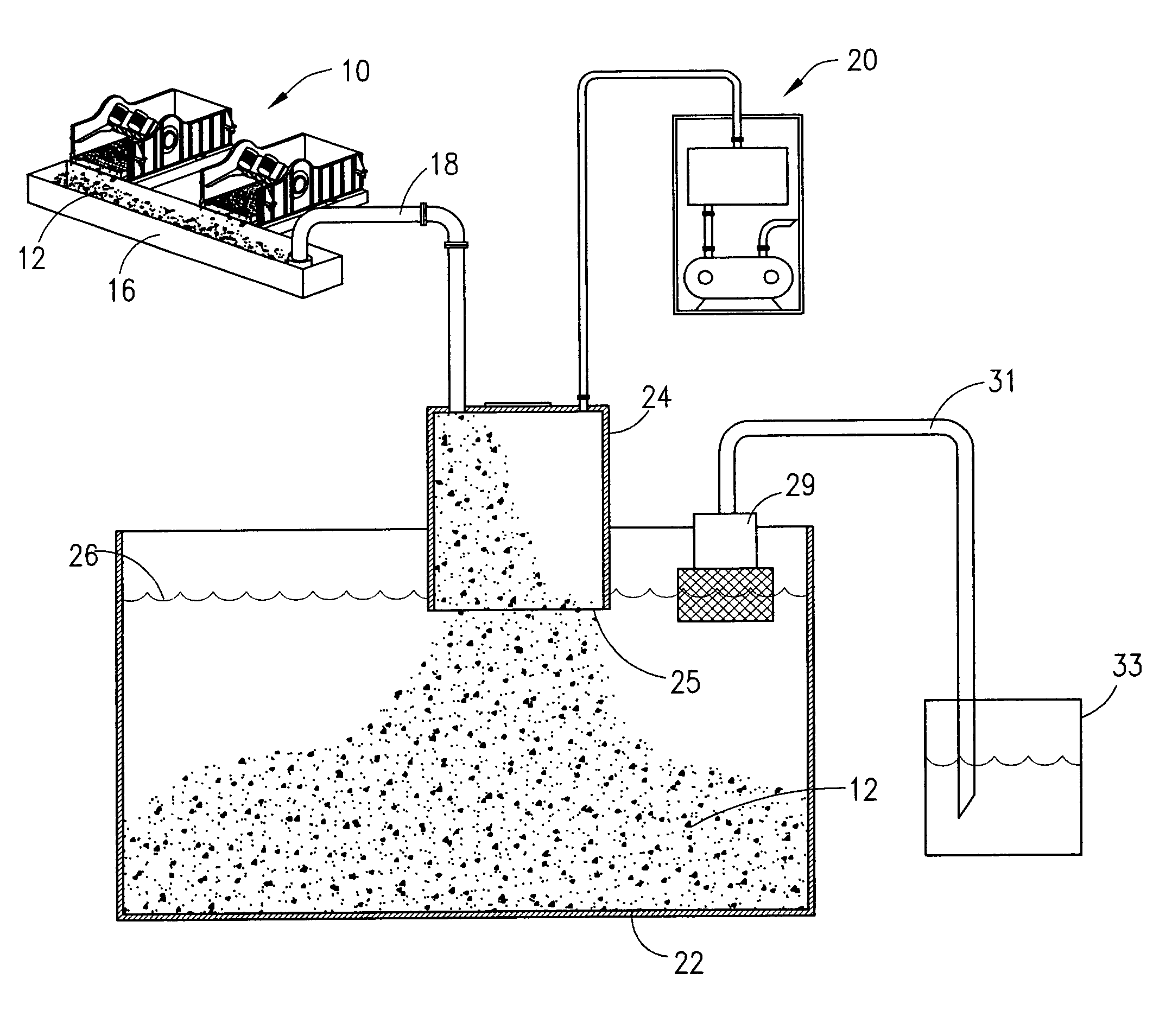

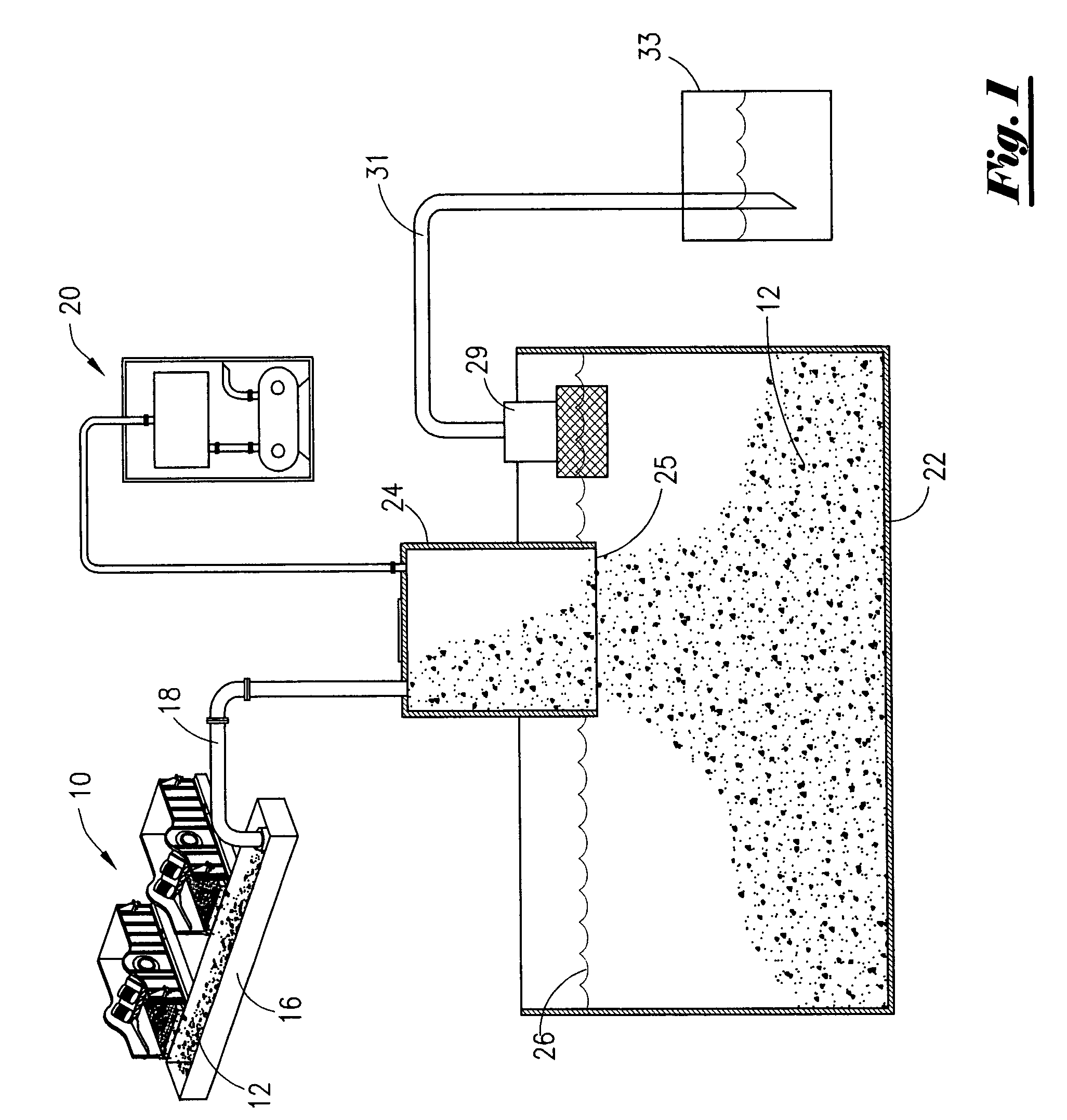

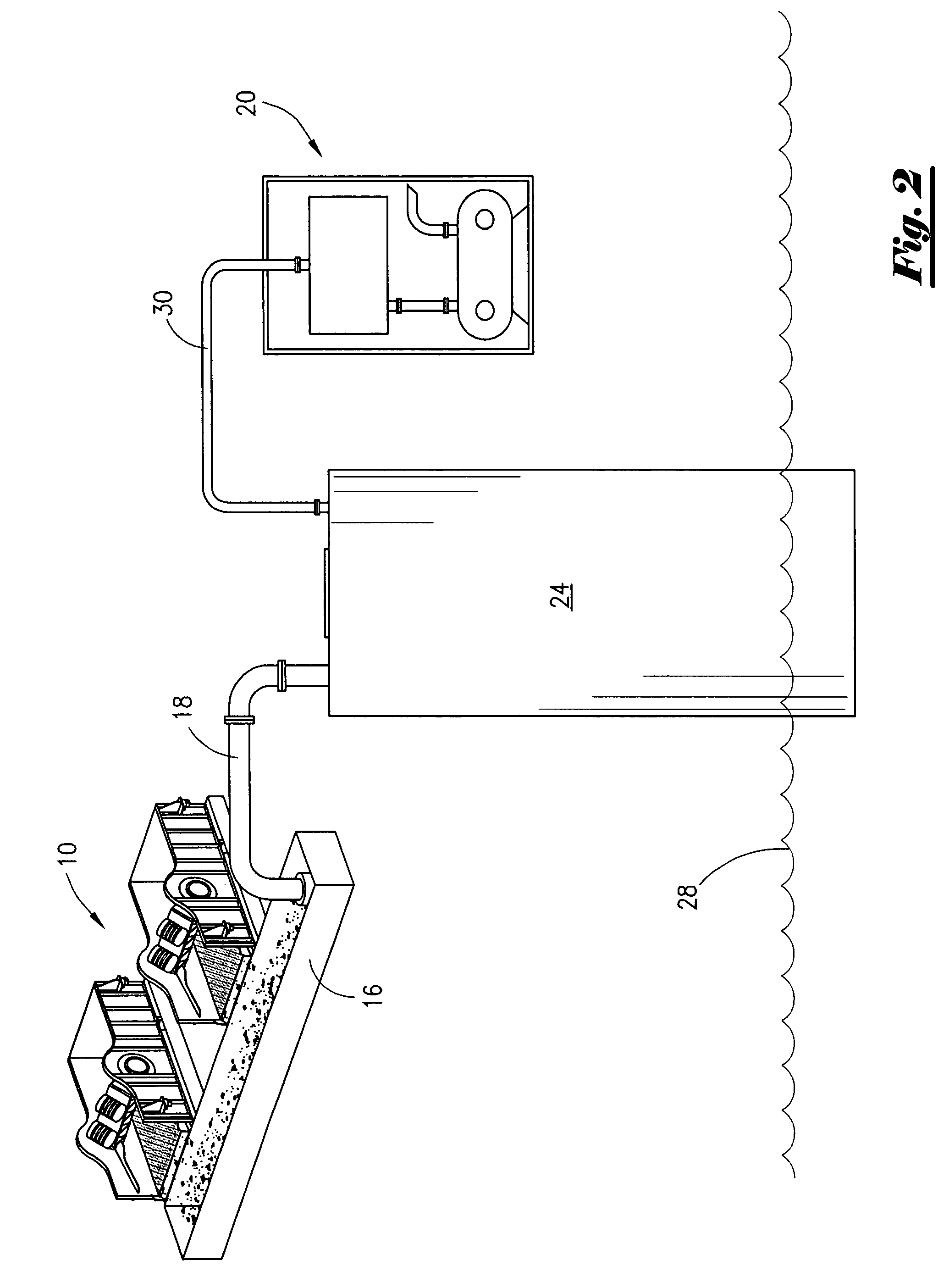

Method and apparatus for vacuum collecting and gravity depositing drill cuttings

InactiveUS7753126B2Eliminate bottlenecksPrevent overloadFluid removalUnderwater drillingEngineeringDrill cuttings

Owner:REDDOCH SR JEFFREY A

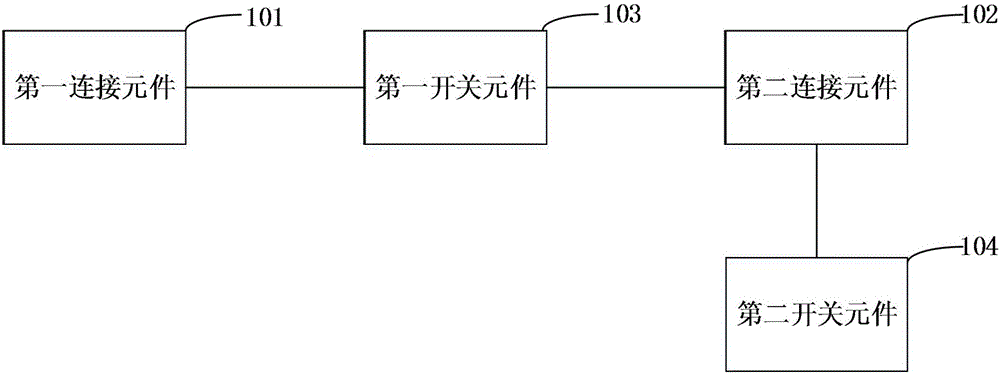

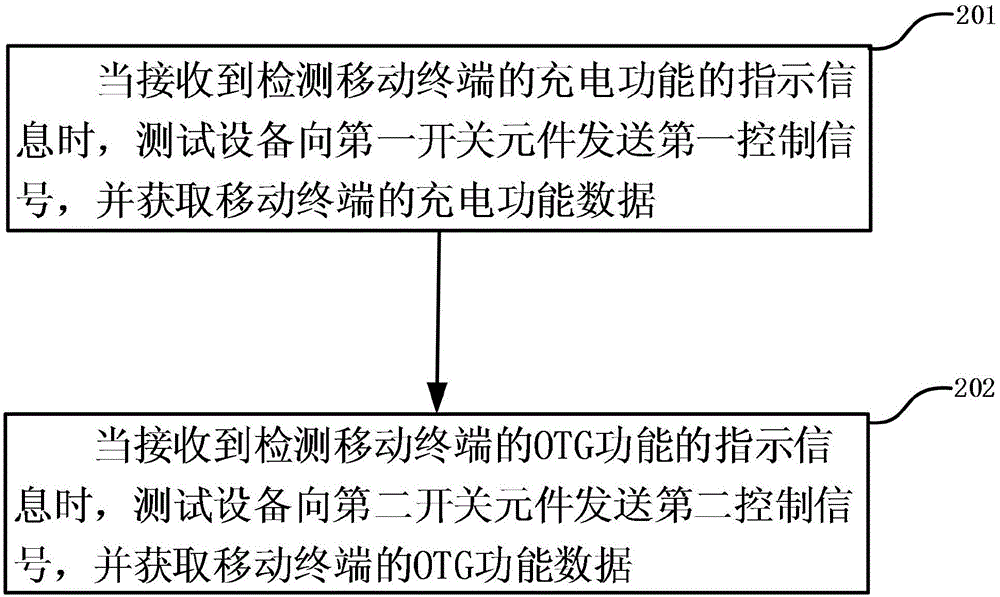

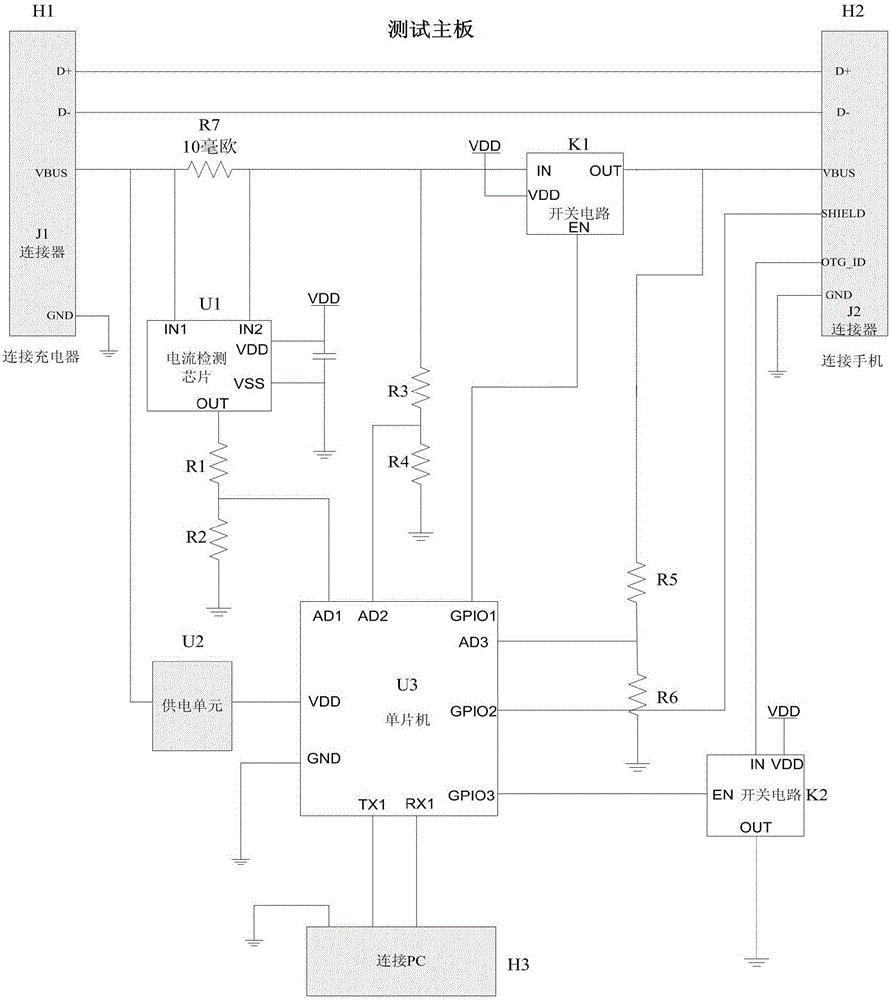

Test device and test method

ActiveCN106597143AReduced risk of scratchesAvoid repeated cable plugging and unplugging processElectrical testingTest efficiencyMobile phone

The invention provides a test device which comprises a first connecting element, a second connecting element, a first switch element and a second switch element, wherein the first connecting element is used for connecting with a charging device; the second connecting element is used for connecting with a mobile terminal; the first switch element is respectively connected with the first connecting element and the second connecting element and is used for charging the mobile terminal by the charging device when the first switch element is switched on, so that the test device can acquire a charging function data of the mobile terminal; the second switch element and the second connecting element are connected and grounded and are used for grounding an OTG control port of the mobile terminal when the second switch element and the second connecting element are switched on, so that the test device can acquire the OTG function data of the mobile terminal. Thus, the test for the charging function and the OTG function can be completed by only connecting the mobile terminal with the test device, so that the repeated processes of plugging and pulling the connecting wire can be avoided, the test efficiency is increased and the risk of scratching the mobile phone shell can be reduced.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

Denitrating coal economizer high-temperature bypass device

InactiveCN105716100ASuppress generationGuaranteed denitrification efficiencyEmission preventionDispersed particle separationAir preheaterGrating

The invention discloses a denitrating coal economizer coal economizer high-temperature bypass device which comprises a coal economizer and a coal economizer bypass flue, wherein the inlet end of the coal economizer bypass flue is connected with one side of the coal economizer; an electrically operated baffle door is arranged at the inlet end of the coal economizer bypass flue; a coal economizer inlet is formed in the top of the coal economizer; a coal economizer outlet is formed in one side of the bottom of the coal economizer; a coal economizer ash hopper is arranged at the bottom of the coal economizer; the coal economizer outlet and the outlet end of the coal economizer bypass flue are connected with a vertical flue; an ammonia spraying grating is arranged on the vertical flue; a first horizontal flue is connected with the top of a denitrating reactor; a denitrating reactor inlet ash hopper is arranged at the bottom of a second horizontal flue; the bottom of the denitrating reactor is connected with a denitrating reactor outlet flue; and the denitrating reactor outlet flue is connected with an air preheater. The denitrating coal economizer coal economizer high-temperature bypass device provided by the invention has the beneficial effects that the necessary denitrating efficiency can be guaranteed, and the generation of sulfate and ammonium hydrogen sulfate can be inhibited; and large-grain ash slag in smoke can be removed, so as to avoid obvious hole blockage and erosion to a catalyst.

Owner:DATANG ENVIRONMENT IND GRP

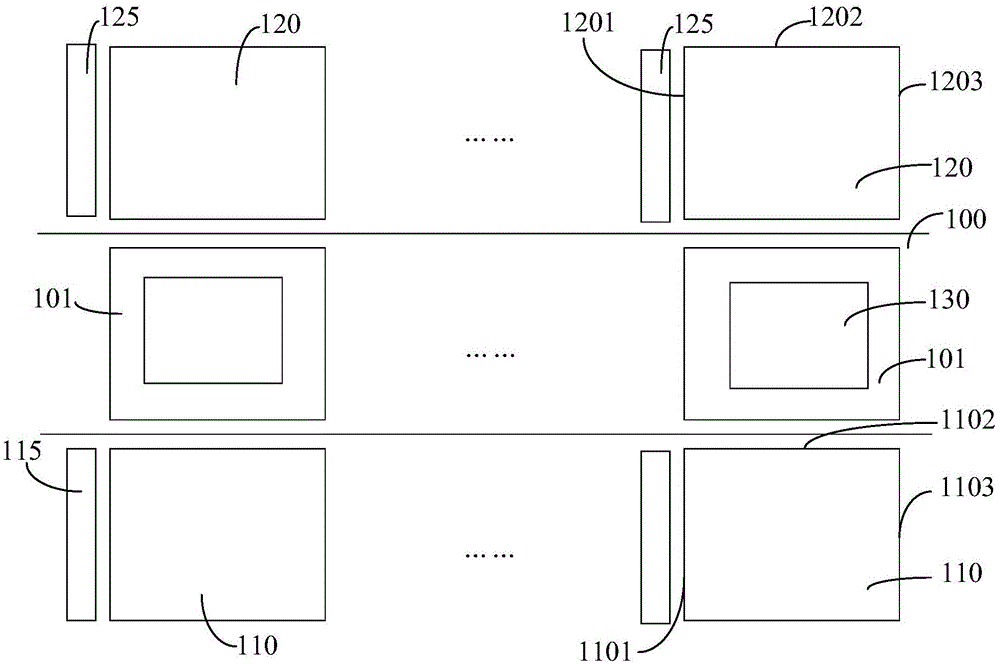

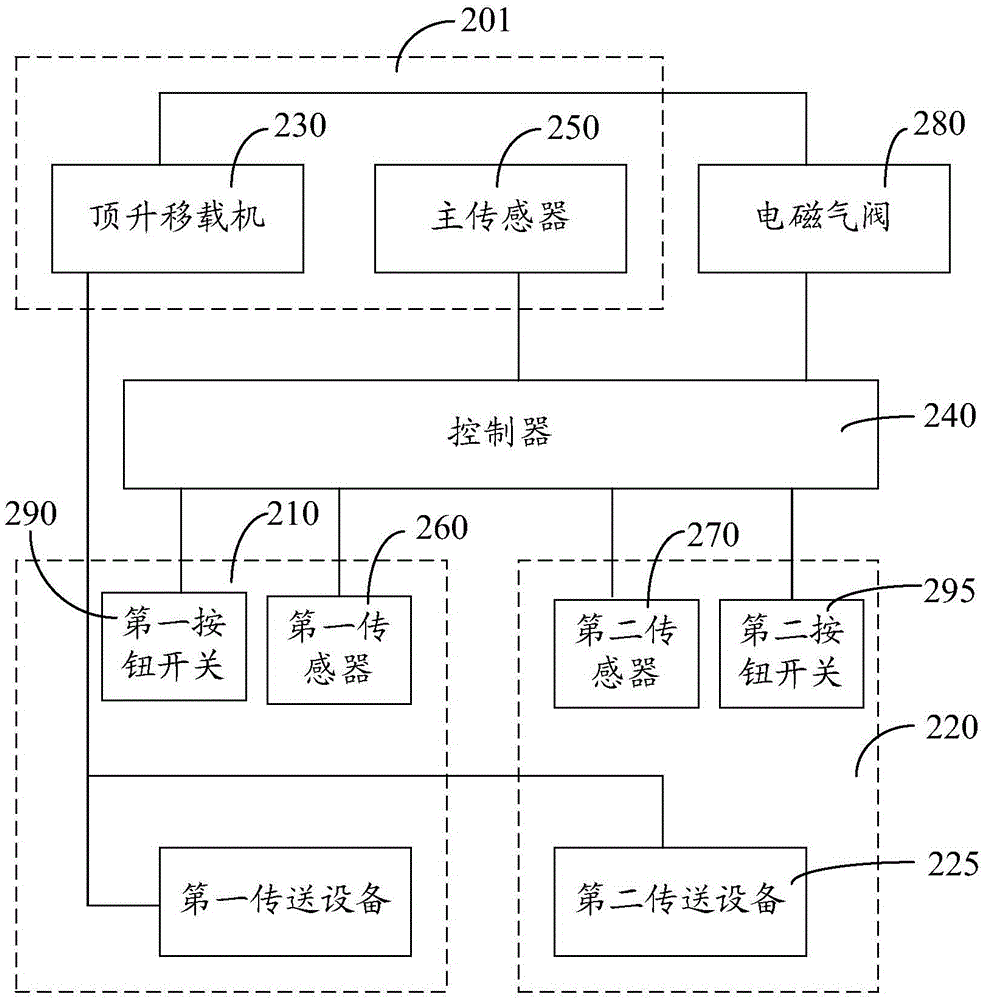

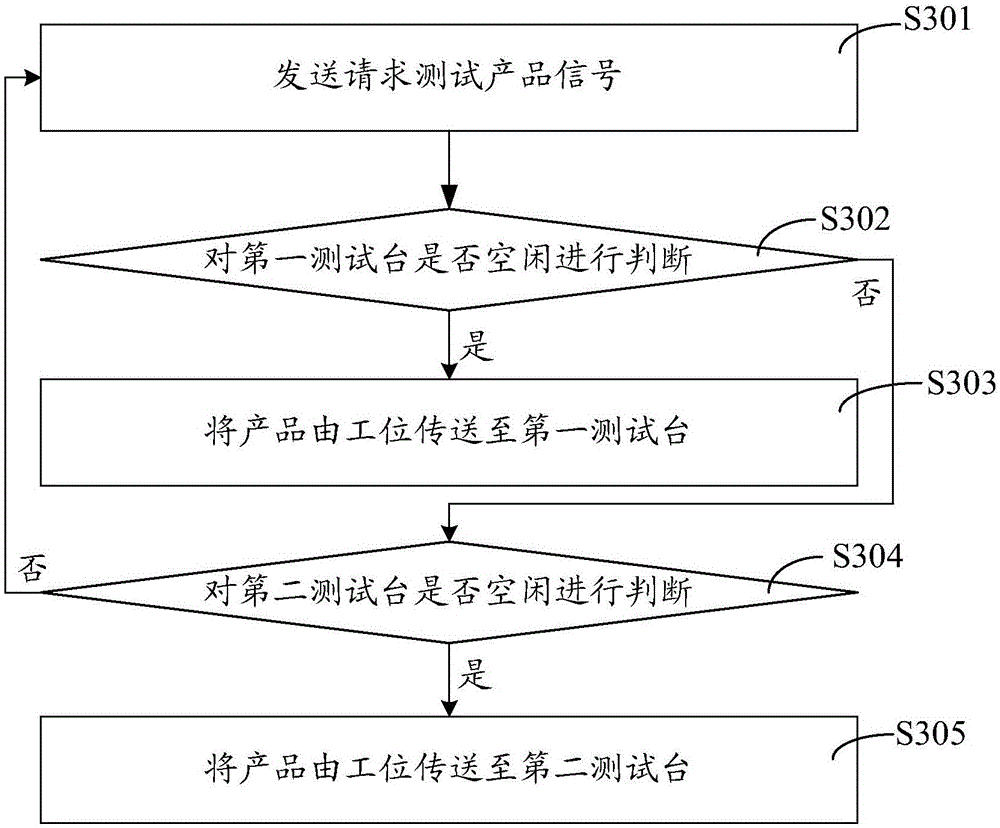

Automatic assembly line device and control method

ActiveCN105109951AAvoid pluggingControl devices for conveyorsProgramme control in sequence/logic controllersEngineeringAssembly line

The invention relates to an automatic assembly line device and a control method. The automatic assembly line device comprises an assembly main line with multiple stations, first test tables, second test tables, first conveying devices and second conveying devices. Each first test table and the corresponding second test table are located on the two sides of the corresponding station respectively. Each first test table, the corresponding second test table and the corresponding station are located on the same straight line. The first conveying devices are arranged on the side faces of the first test tables and used for conveying products between the stations and the first test tables. The second conveying devices are arranged on the side faces of the second test tables and used for conveying the products between the stations and the second test tables. Each station is correspondingly provided with the two corresponding test tables. When the first test tables are busy, the products can be conveyed to the second test tables to be tested, and the products can be effectively prevented from blocking the line.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

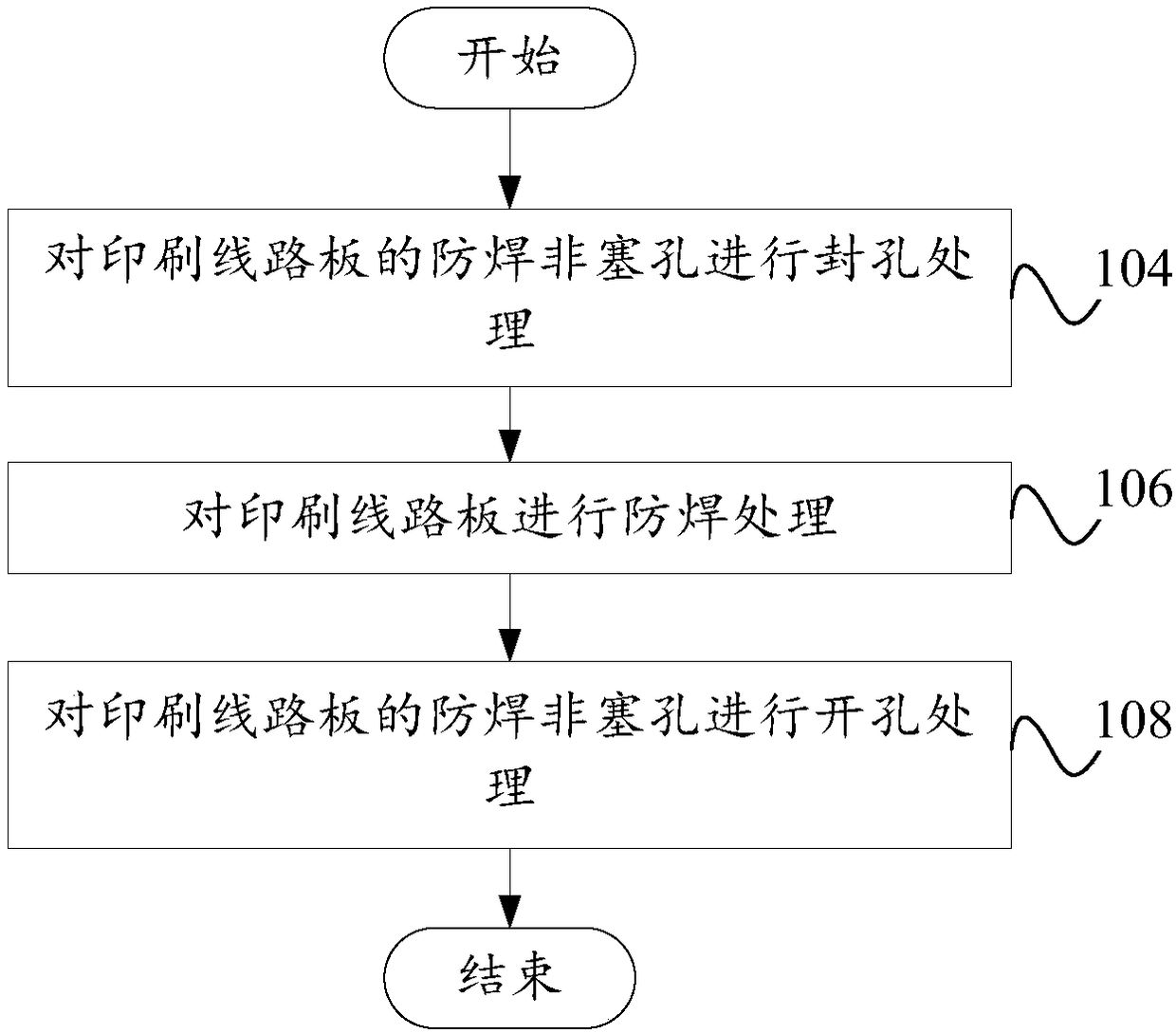

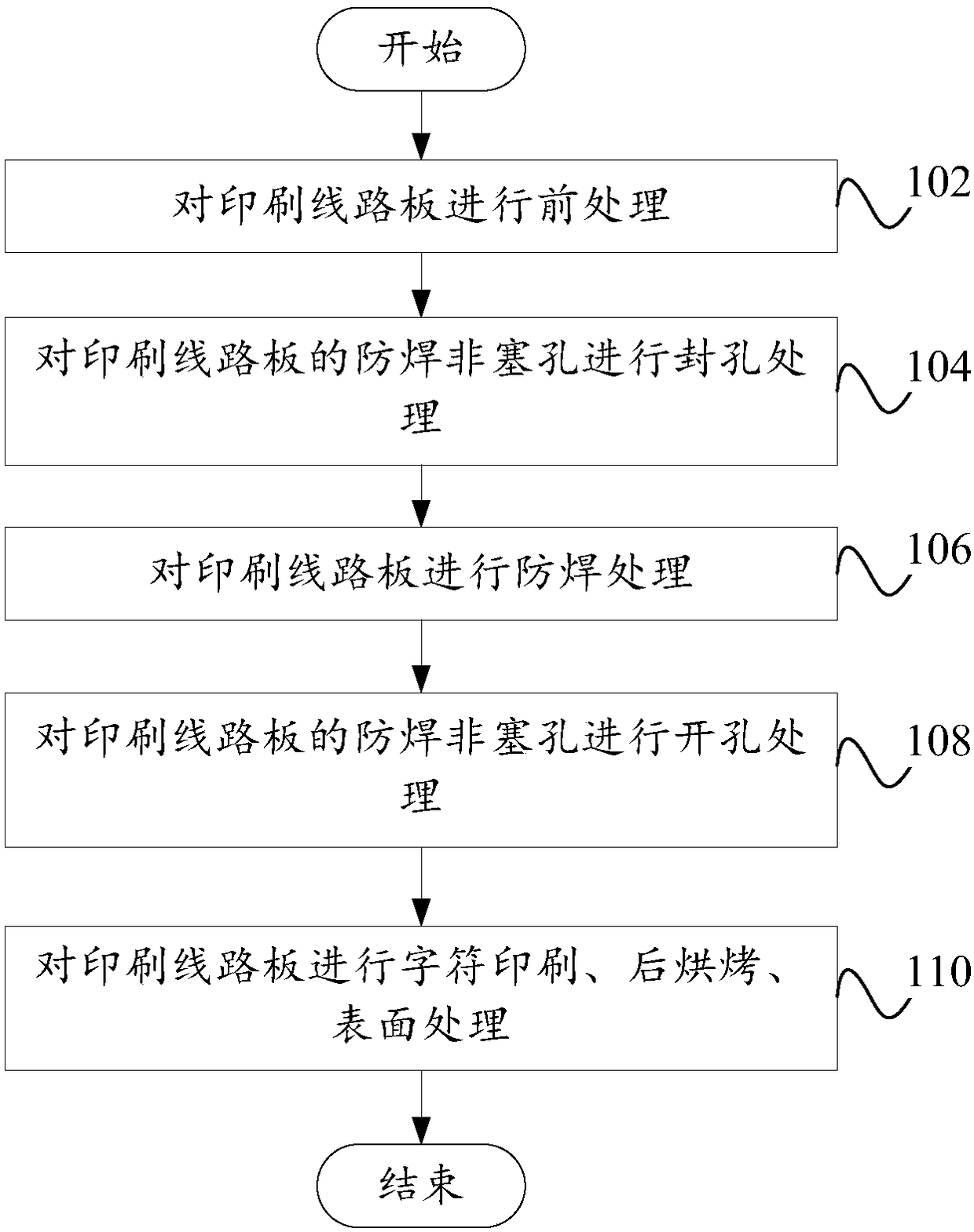

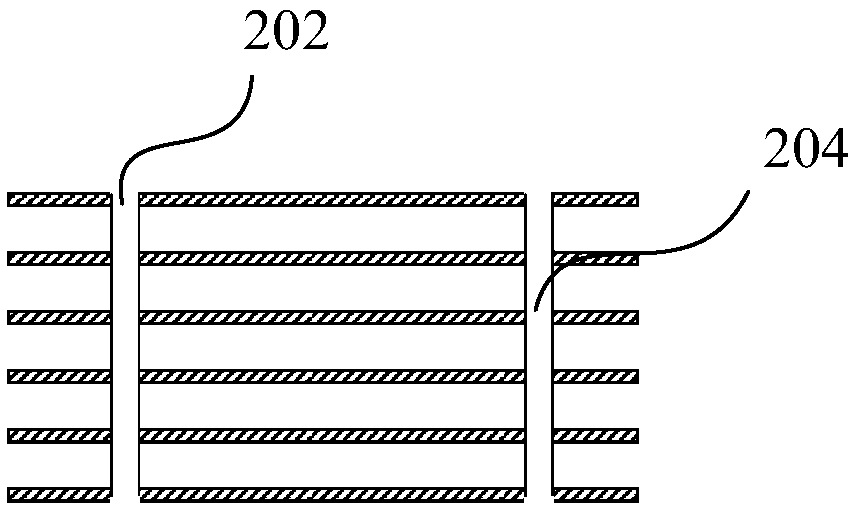

Method for preventing solder mask ink from plugging hole, printed circuit board and computer device

InactiveCN108934128AAvoid incomplete ink printingAvoid pluggingNon-metallic protective coating applicationSolder maskEngineering

The invention provides a method for preventing solder mask ink from plugging a hole, a printed circuit board, a computer device and a computer readable storage medium. The method for preventing the solder mask ink from plugging the hole comprises the following steps: a solder mask non-plugging hole of the printed circuit board is subjected to hole sealing operation; solder masking operation is performed on the printed circuit board; the solder mask non-plugging hole of the printed circuit board is subjected to hole opening operation. The method disclosed in the present invention can help prevent the non-plugging hole from being plugged by ink, the method can help prevent a problem of printed circuit board and blocking point net expansion and shrinkage that occurs when block point net ink is used and a problem of alignment precision, scrapping of the printed circuit board which is caused when the hole is plugged by ink can be reduced, and high reliability and high efficiency can be realized.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

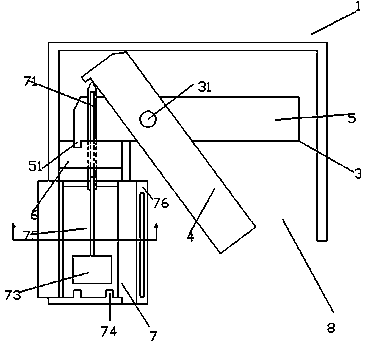

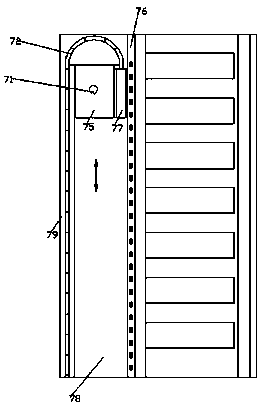

Circuit board control cabinet for automation equipment

InactiveCN104270906AAvoid pluggingAvoid shockRack/frame constructionComponent plug-in assemblagesEngineeringElectrical and Electronics engineering

The invention provides a circuit board control cabinet for automation equipment. The circuit board control cabinet comprises a cabinet case (1), a circuit board installing assembly (3), a fixing frame (6) and a lifting circuit board opening part (7), wherein the cabinet case (1) is used for containing the circuit board installing assembly (3), the fixing frame (6) and the lifting circuit board opening part (7) and provided with a doorway area (8). The doorway area (8) is used by a user for operating and maintaining the circuit board control cabinet. The circuit board installing assembly (3) is provided with a stand column shaft (31). A plurality of circuit boards (4 and 5) are installed on the stand column shaft (31) in a pivoting mode from top to bottom. Each circuit board can independently pivot relative to the stand column shaft (31). The fixing frame (6) is vertically and fixedly arranged in the cabinet case (1).

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

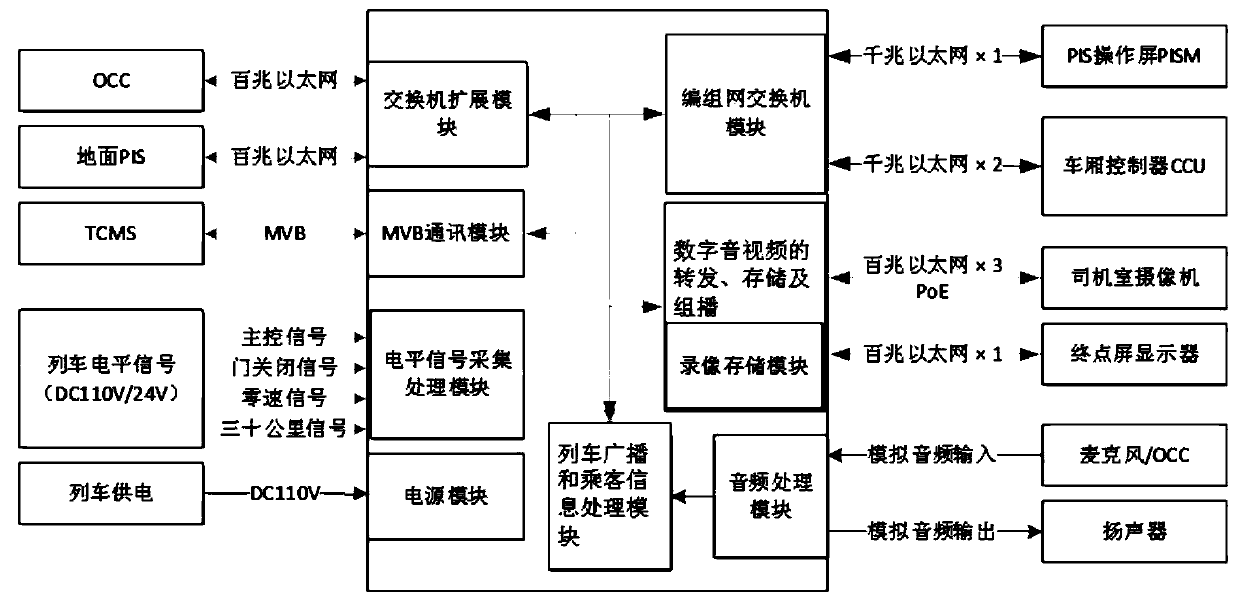

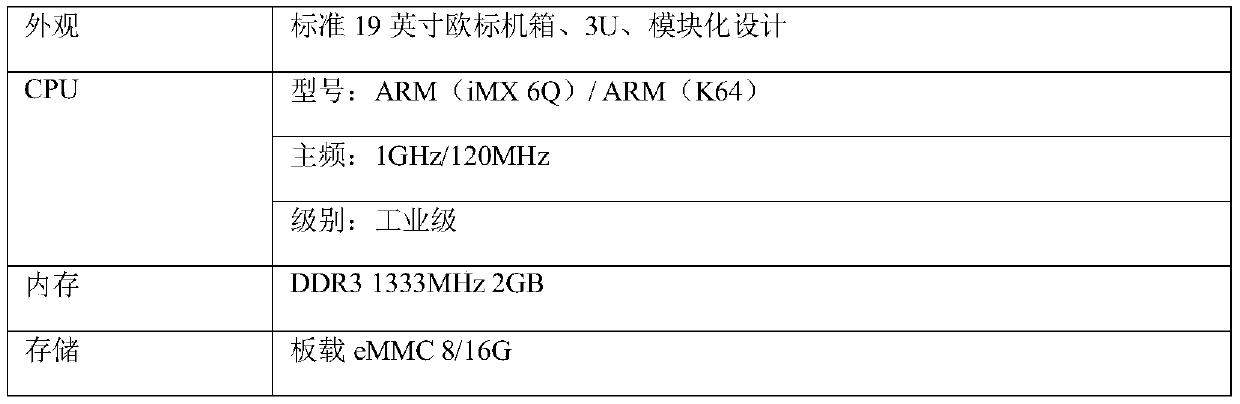

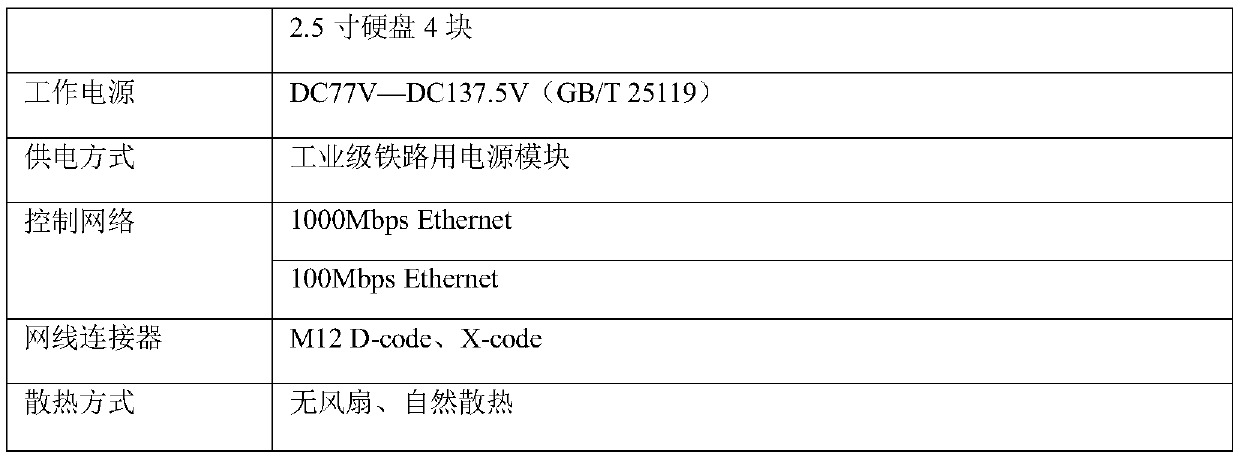

Networked train broadcasting system and implementation method

PendingCN111082886ASimple structureReal-time online monitoringError preventionBroadcast specific applicationsIp addressEngineering

The invention discloses a networked train broadcasting system and an implementation method, and belongs to the technical field of urban rail transit vehicles and motor train units. A full Ethernet topology is adopted and is matched with a digital multimedia terminal. The POE power supply IEEE 802.3 af / at technology is adopted for the low-power-consumption terminal device. The switch adopts a dynamic host configuration protocol DHCP to automatically allocate the IP address of the terminal device. A VoIP technology is adopted to realize visual digital intercom. Based on a gigabit Ethernet communication technology, an embedded processor is used as a core, a full Ethernet topology, a digital multimedia terminal and an integrated control host are adopted, three subsystems are integrated with the Ethernet, and terminal device uses a POE power supply and DHCP technology.

Owner:北京华高世纪科技股份有限公司

Water-based paint filtering device with self-cleaning function

InactiveCN108837585ASpeed up filteringImprove liquidityMoving filtering element filtersWater basedEngineering

The invention discloses a water-based paint filtering device with a self-cleaning function. The device comprises a paint filtering tank, a filter plate impurity scarper and a swinging filtering tank,wherein a casing is further horizontally arranged in the paint filtering tank; a hollow structure is formed inside the inner casing; a threaded screw rod and a guide column are horizontally arranged inside the inner casing; a threaded sliding block is mounted on the threaded screw rod through threads; a connecting rod is mounted on the lower side of the threaded sliding block through threads; an impurity scarper is fixedly welded with the lower end of the connecting rod. When a filtering plate is daily cleaned, impurities on the upper surface of the filtering plate are scrapped to the rightmost side of the filtering plate through indirectly driving the impurity scarper to move rightward, and then an impurity opening is opened, so that the impurities can be removed, the filtering plate is not required to be completely shifted out to be cleaned, and the filtering device is very effective on small-scale cleaning, can further reduce the amount of labor, and is simple and convenient; for periodic cleaning of the filtering plate, as the filtering plate adopts a detachable structure, the filtering plate can be integrally taken out to be cleaned, and is more thorough to clean.

Owner:何晓燕

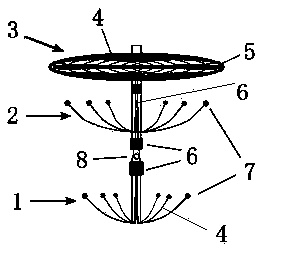

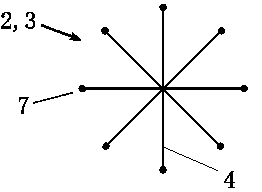

Double umbrella type left auricle sealing device

A double umbrella type left auricle sealing device is characterized by comprising a first fixed umbrella, a second fixed umbrella and a sealing disc. The section of the first fixed umbrella and the section of the second fixed umbrella are in an umbrella rib shape and formed by a plurality of expanded shape memory nitinol wires, an umbrella handle of the first fixed umbrella is crookedly connected with an umbrella top of the second fixed umbrella, an umbrella handle of the second fixed umbrella is connected with one side of the sealing disc, and the other side of the sealing disc is movably connected with one end of an operating rod of a release device. The whole sealing device is loaded into a catheter through the top of the sealing disc to be conveyed; after the sealing device leaves the catheter, first the first fixed umbrella is automatically formed, then the second fixed umbrella is automatically formed and can be automatically bent to the adjust the angle along with the ear canal of the left auricle, finally the sealing disc is automatically expanded to recover to be in a disc shape, and the left auricle is sealed. The double umbrella type left auricle sealing device is convenient to operate and can reduce operation risk, shorten operation time and improve operation success rate.

Owner:孙伟 +2

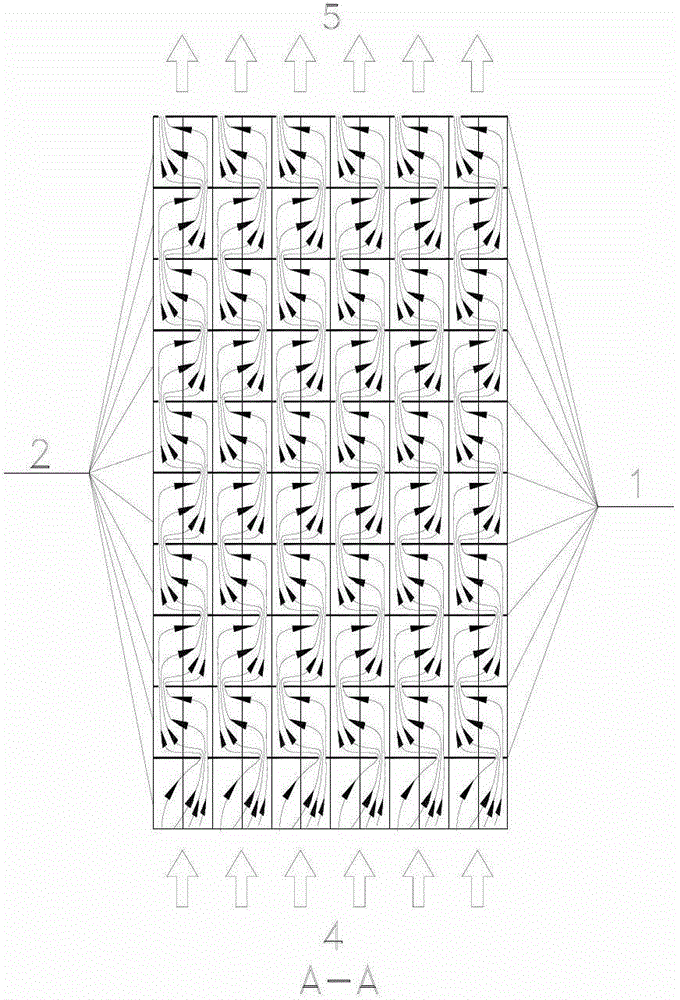

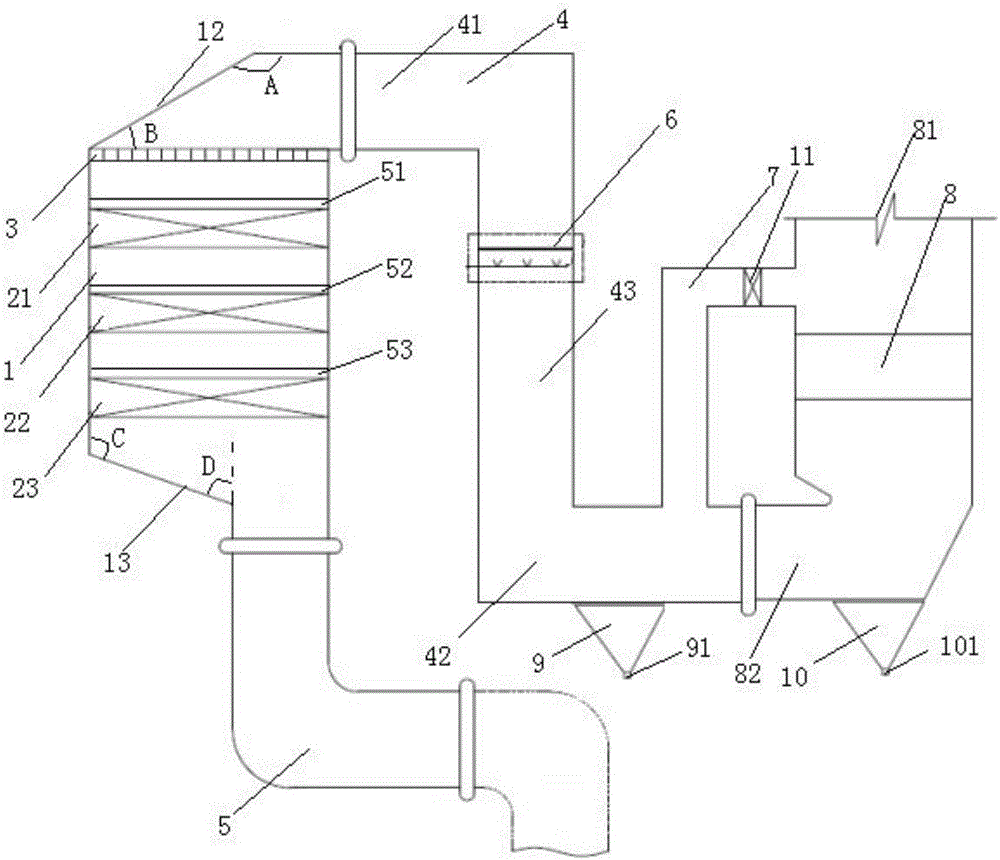

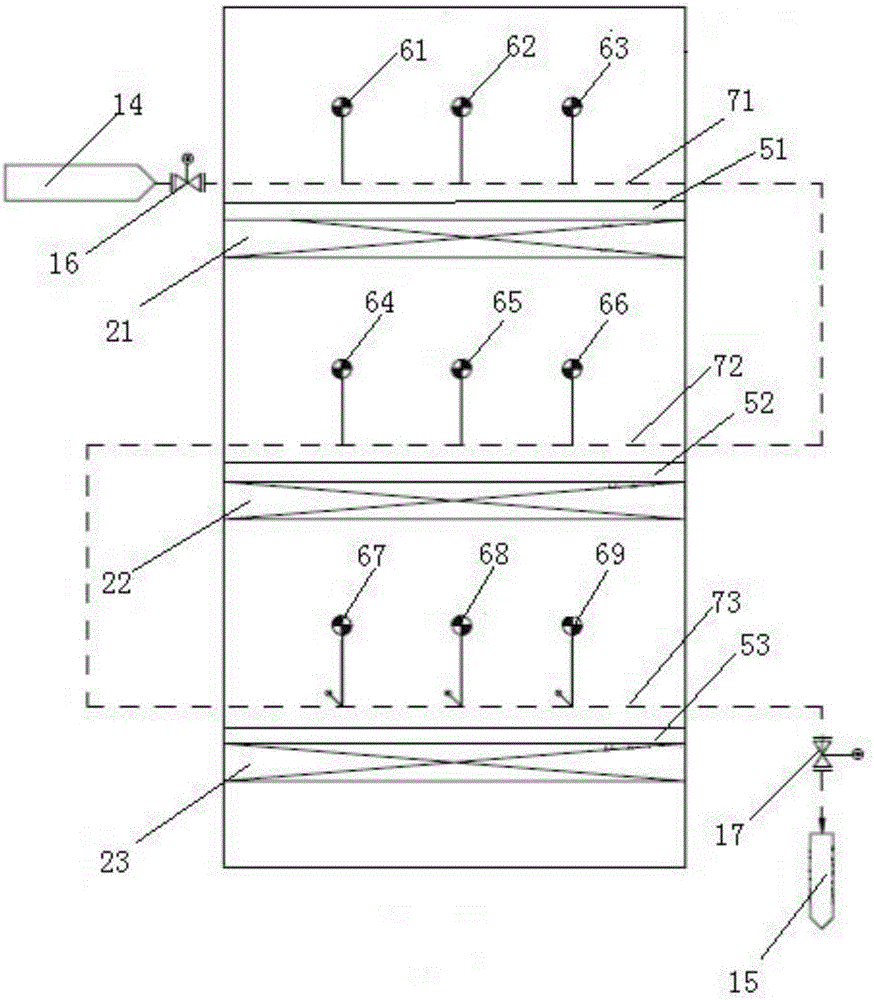

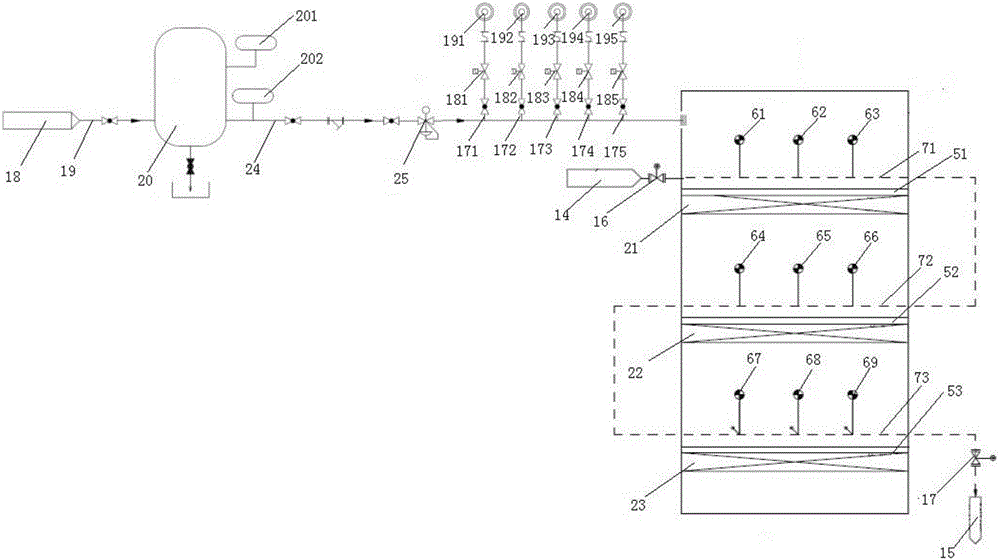

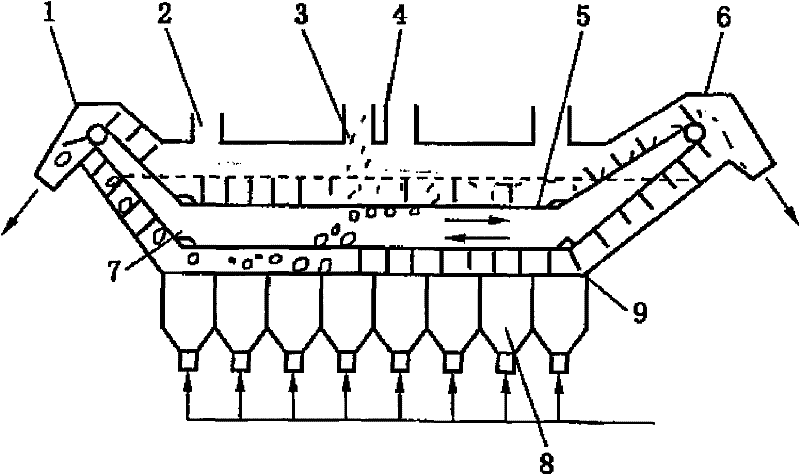

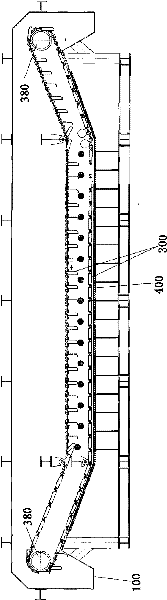

Air dense medium dry separation device

InactiveCN102049350AAvoid pluggingAvoid uniformityGas current separationGradingEngineeringElectrical and Electronics engineering

The invention discloses an air dense medium dry separation device, comprising: a box body, a supporting plate device and an air distribution device, wherein the box body is used for providing a space for forming a separation fluidized bed and is further used for installing the supporting plate device and the air distribution device; the air distribution device is arranged at a lower part of the box body; the supporting plate device is used for conveying floats and sediments, the floats and sediments are formed in a process when materials pass through the separation fluidized bed and the air distribution device, the supporting plate device is located over the air distribution device and comprises a plurality of linked supporting plates or screens circularly operating around two rotation shafts, each supporting plate or screen comprises a baffle part which is vertical to a bed layer surface of the separation fluidized bed, and a flat plate part which is connected with the baffle part and is parallel to the bed layer surface, and the flat plate part comprises through holes or meshes. According to the device disclosed in the invention, a problem of failure in fluidization and separation caused by blockage of air holes is effectively avoided.

Owner:孙刚

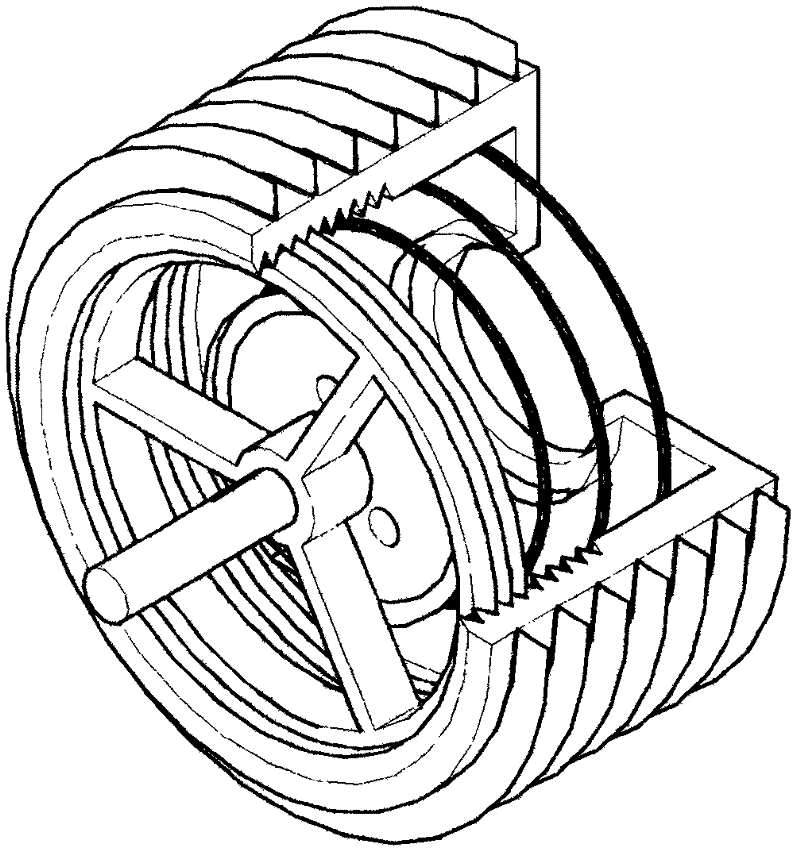

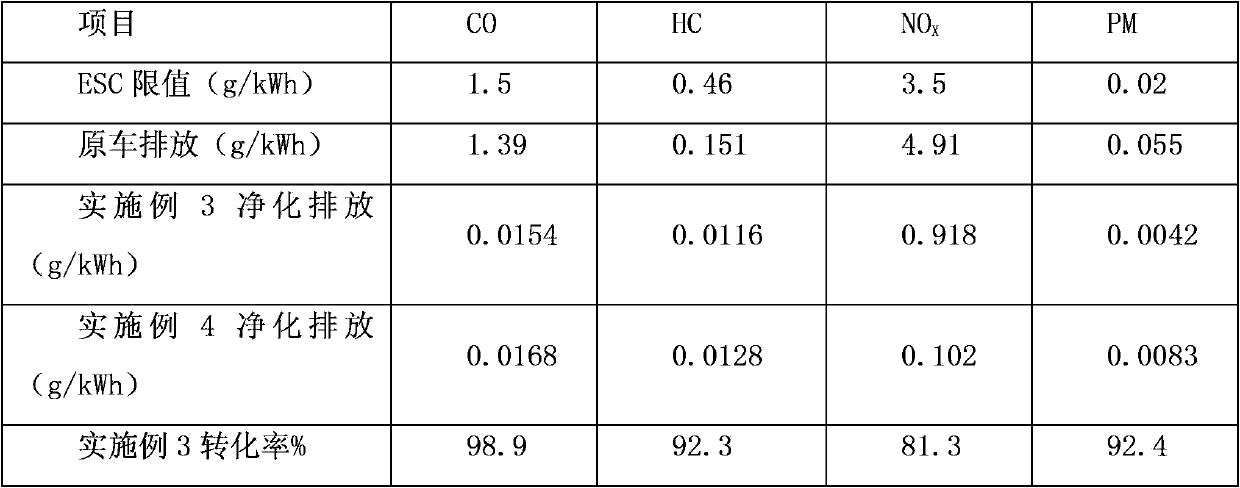

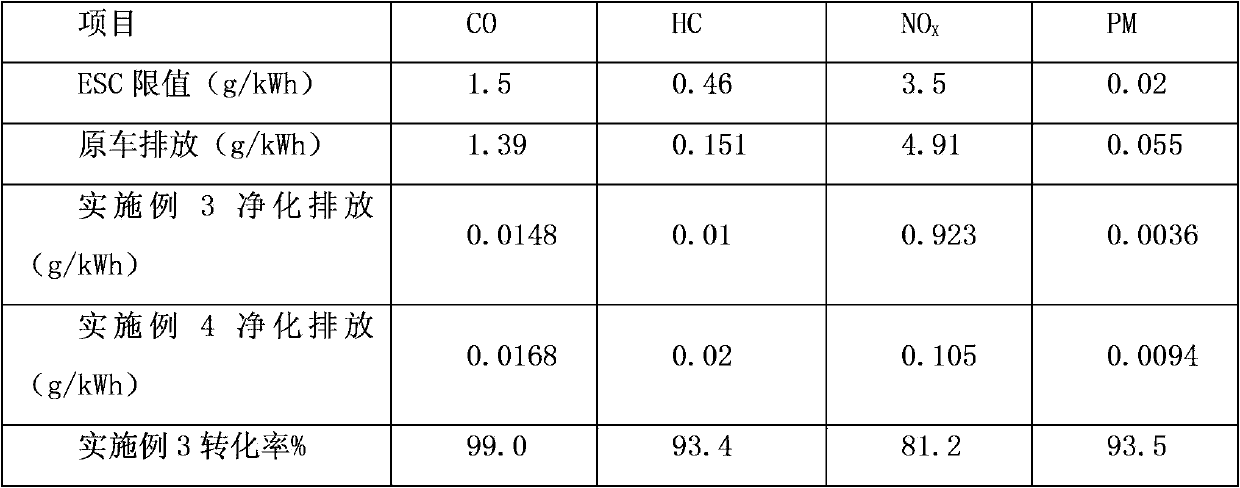

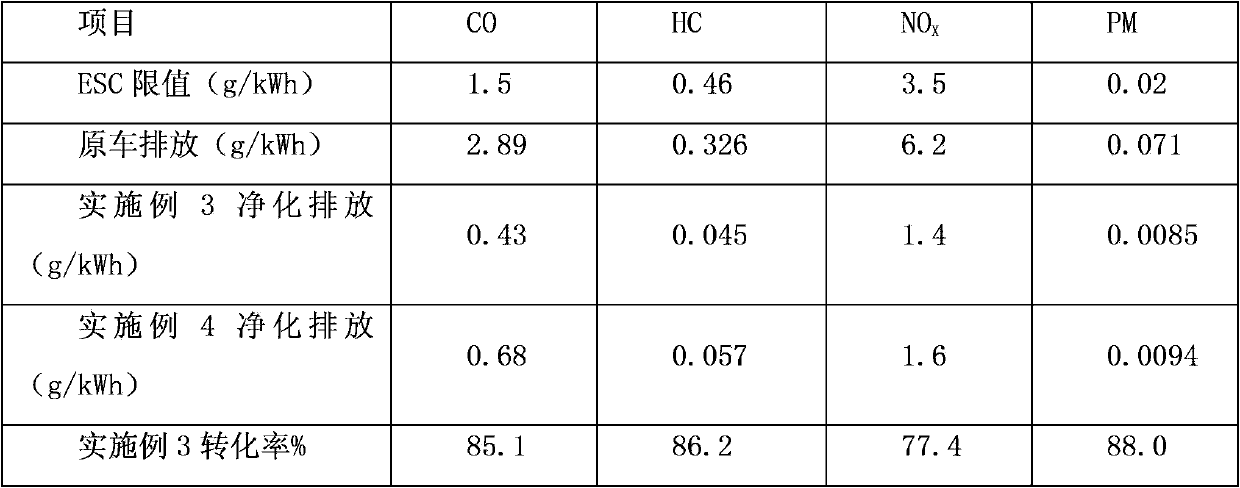

Catalyst used for diesel engine tail gas soot collection catalysis

InactiveCN103861612ALower combustion temperatureImprove purification efficiencyCatalyst carriersDispersed particle separationEngineeringSoot

The invention provides a catalyst used for diesel engine tail gas soot collection catalysis. The catalyst is prepared via following processing on stainless steel meshes: the stainless steel meshes are subjected to bluing liquid treatment, electroplating, and pressure wave treatment, are cut into strips, are rolled, and then are delivered into stainless steel pipes for encapsulation brazing. The catalyst can be used for diesel engine tail gas soot collection catalysis; pressure reduction is less; and catalysis performance is excellent.

Owner:SHANGHAI LANGT AUTOCATALYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com