Air dense medium dry separation device

An air heavy mediating and sorting technology, which is used in wet separation, grading, and separation of solids from solids by air flow. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

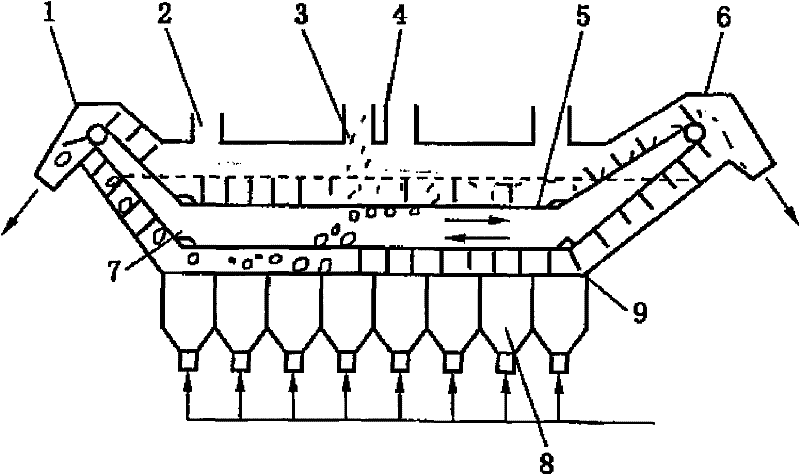

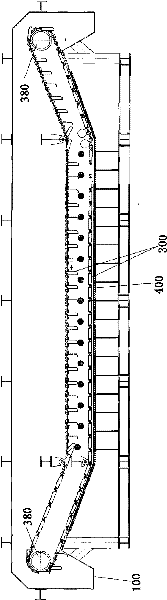

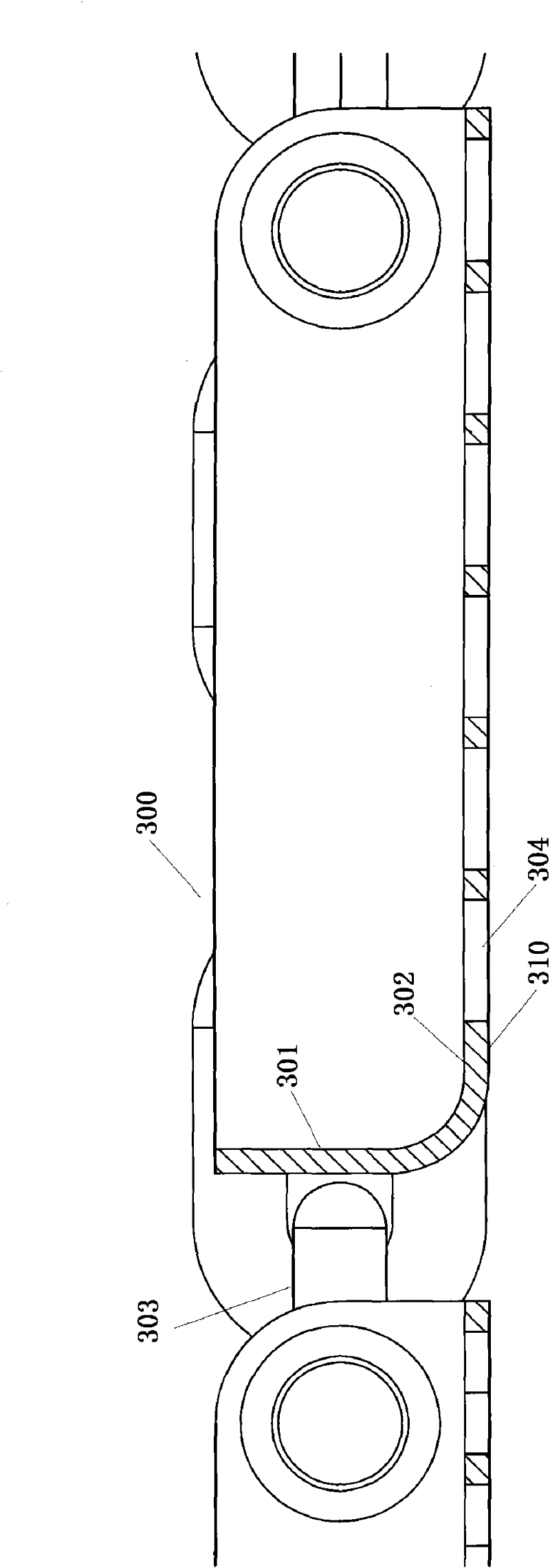

[0022] Such as figure 2 , 3 , 4, the air dense medium dry separation equipment of the present invention includes: a box 100, a pallet device 300, and an air distribution device 400. The box body 100 is used for providing a space for forming a sorting fluidized bed and for installing a pallet device and an air distribution device. The sorting fluidized bed is a laminar fluid formed when air, heavy medium and other substances pass through the air distribution device 400 . The air distribution device 400 is located at the lower part of the box body. The supporting plate device 300 is used to transport floating and sinking objects, which are formed when the materials to be sorted pass through the sorting fluidized bed and the air distribution device, and the supporting plate device is located above the air distribution device. The pallet device includes a plurality of pallets or screens that are linked, and the multiple pallets or screens that are linked circulate around two r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com