Circuit board control cabinet for automation equipment

A technology for automation equipment and circuit boards, applied in the direction of circuit layout on support structures, electrical equipment enclosures/cabinets/drawers, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

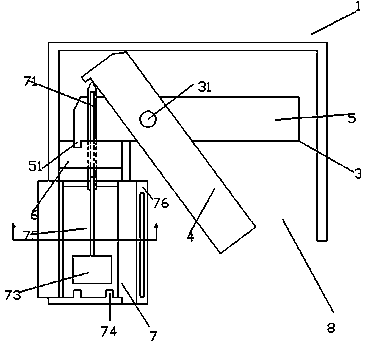

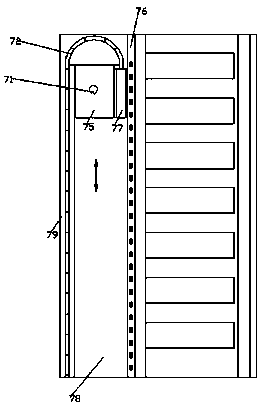

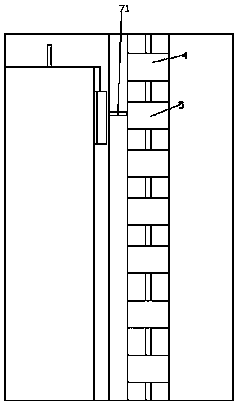

[0016] Combine below Figure 1-5 The present invention will be described in detail.

[0017] A circuit board control cabinet for automation equipment, including a cabinet housing 1, a circuit board placement assembly 3, a fixing frame 6, and a lifting type circuit board opening part 7, wherein the cabinet housing 1 is used to accommodate the circuit board placement assembly 3 , a fixed frame 6 and a lifting type circuit board opening part 7 and has a doorway area 8, which is used for the user to operate and maintain the circuit board control cabinet, and the circuit board placement assembly 3 is provided with a column shaft 31, where A plurality of circuit boards 4, 5 are pivotally mounted on the column shaft 31 from top to bottom, and each of the circuit boards can pivot independently of each other relative to the column shaft 31; Fixedly arranged in the cabinet housing 1; the lifting type circuit board opening part 7 can move up and down, and can drive the selected circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com