Catalyst used for diesel engine tail gas soot collection catalysis

A catalyst and diesel engine technology, applied in the direction of physical/chemical process catalysts, catalyst carriers, catalyst activation/preparation, etc., can solve the problems of increasing the cost of diesel engine exhaust treatment, cumbersome catalyst devices, and high cost, so as to improve the anti-sulfur performance and improve Anti-corrosion performance, the effect of improving the anti-sulfur performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

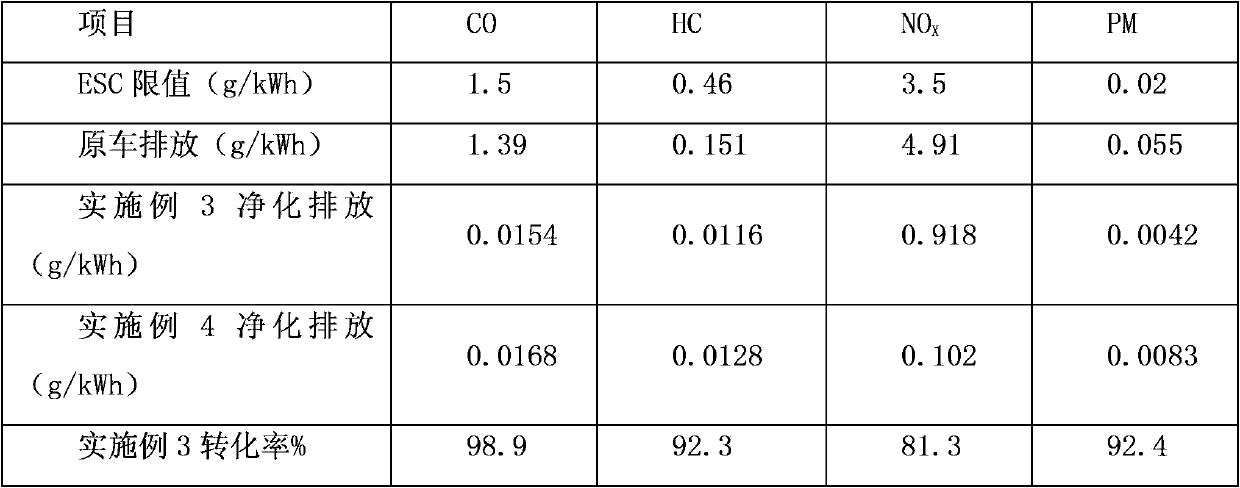

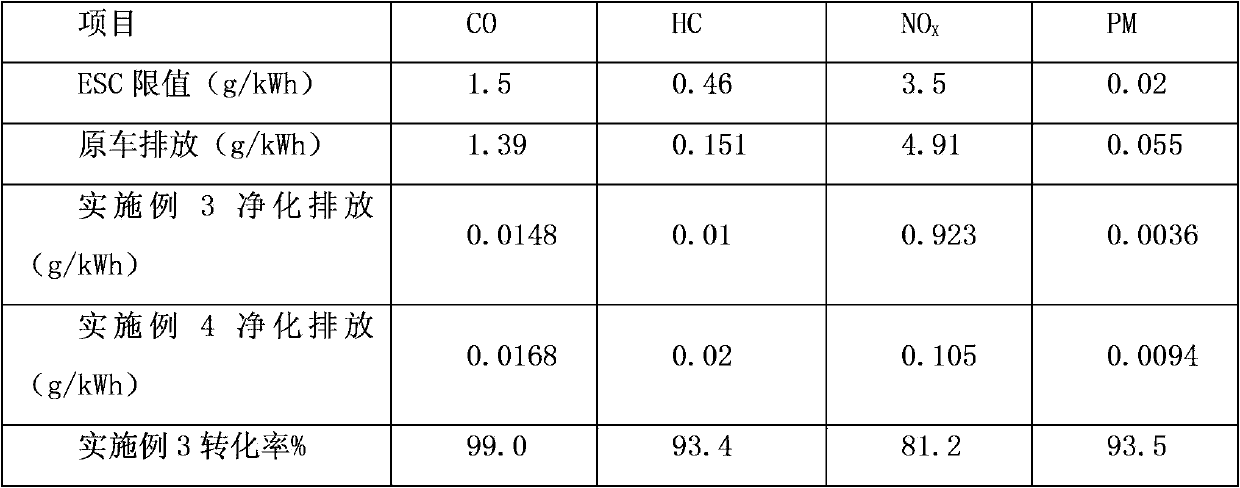

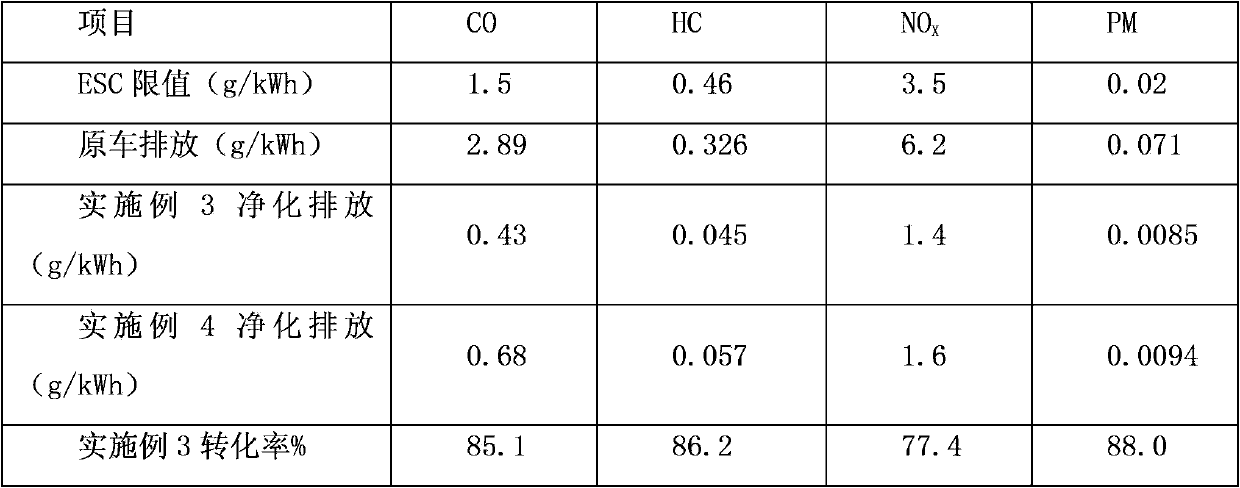

Examples

Embodiment 1

[0050] Embodiment 1 prepares blue liquid

[0051] Mix sodium nitrite, sodium nitrate, sodium hydroxide, sodium carbonate, and water glass in a mass ratio of 5:15:5:5:1, and then add water. The water content accounts for 90% of the weight of the final bluish liquid.

Embodiment 2

[0052] Embodiment 2 prepares blue liquid

[0053] Mix sodium nitrite, sodium nitrate, sodium hydroxide, sodium carbonate, and water glass in a mass ratio of 3:10:3:8:2, and then add water. The water content accounts for 85% of the weight of the final bluish liquid.

Embodiment 3

[0054] Embodiment 3 prepares stainless steel mesh catalyst according to following steps successively

[0055] 1. adopt the blue liquid of embodiment 1;

[0056] 2. Select a stainless steel screen with an aperture of 0.2mm, a chemical composition of 6% aluminum, 20% chromium and 84% iron, and the wire diameter of the screen is 0.1mm;

[0057] 3. Treat the stainless steel screen with the bluing liquid: put the stainless steel screen in the bluing liquid and heat and boil for 15 minutes at a heating temperature of 90°C;

[0058] 4. Preparation of rare earth solution: Ce 2 (SO 4 ) 3 and H 2 o 2 Mix according to the ratio of 20:1, then add water, and finally the mass concentration of the rare earth solution is 30%;

[0059] 5. Preparation of titanium liquid: Titanium sulfate, nickel sulfate, nickel chloride, boric acid, sodium lauryl sulfate and saccharin are mixed according to the mass ratio of 76:7:7:3:5:2 to obtain titanium liquid;

[0060] 6. Prepare precious metal solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com