Electronic control diesel-methanol dual-fuel engine control system and method based on EGR technology

A dual-fuel engine and control system technology, applied in engine control, fuel injection control, electrical control, etc., can solve the problems of reduced combustion efficiency, instability, and unstable switching of combustion modes of dual-fuel engines, so as to avoid knocking The effect of reducing the occurrence of power fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

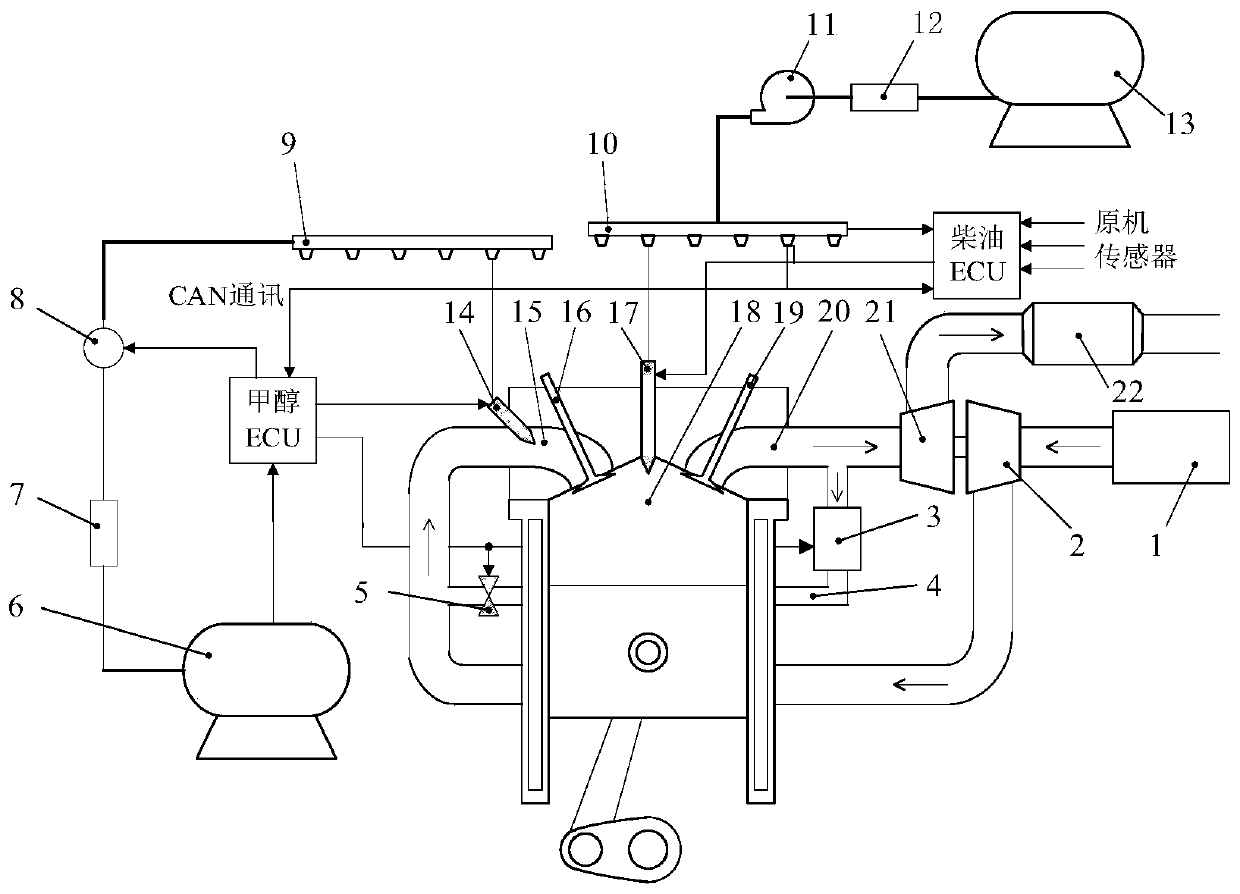

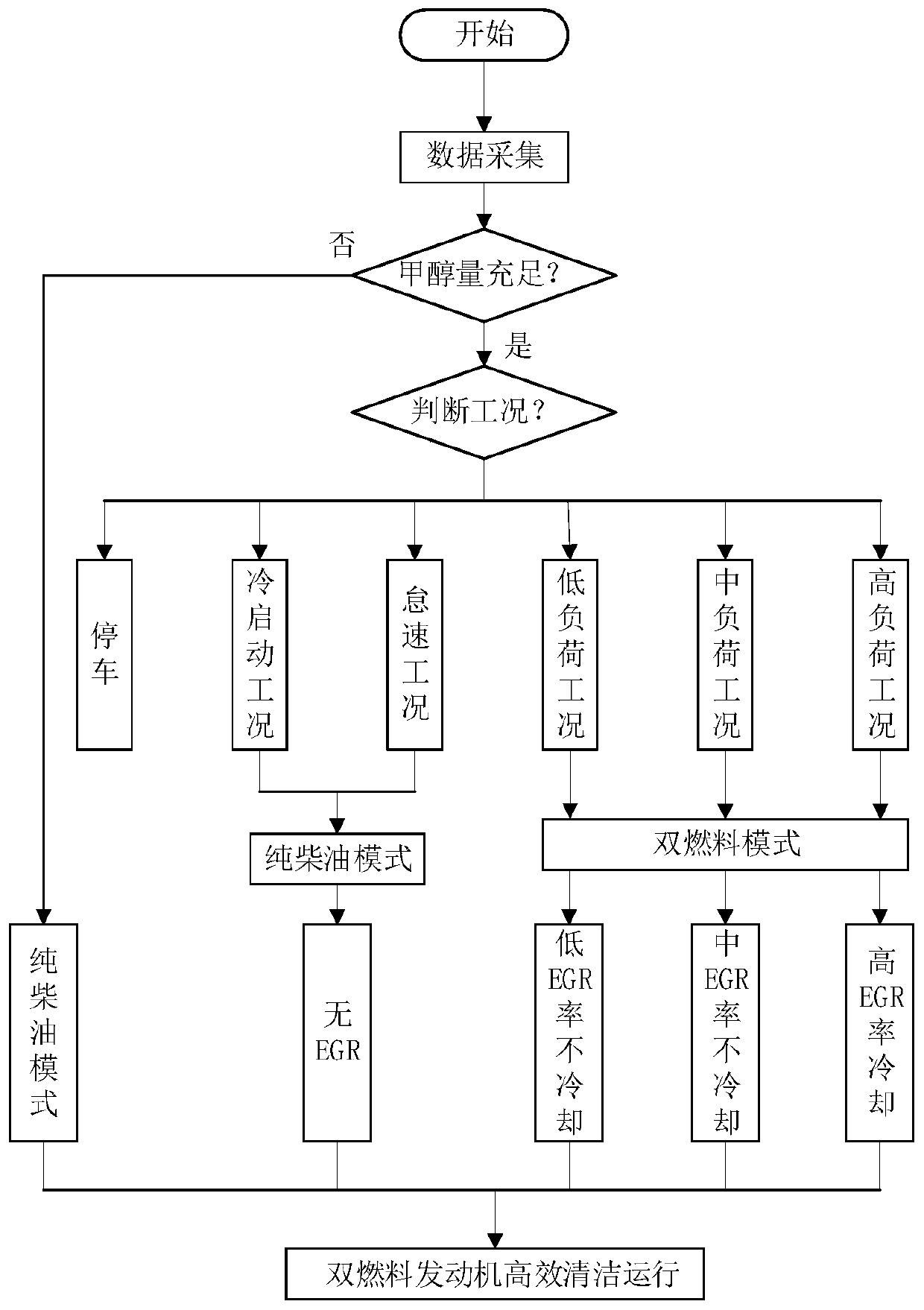

[0055] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

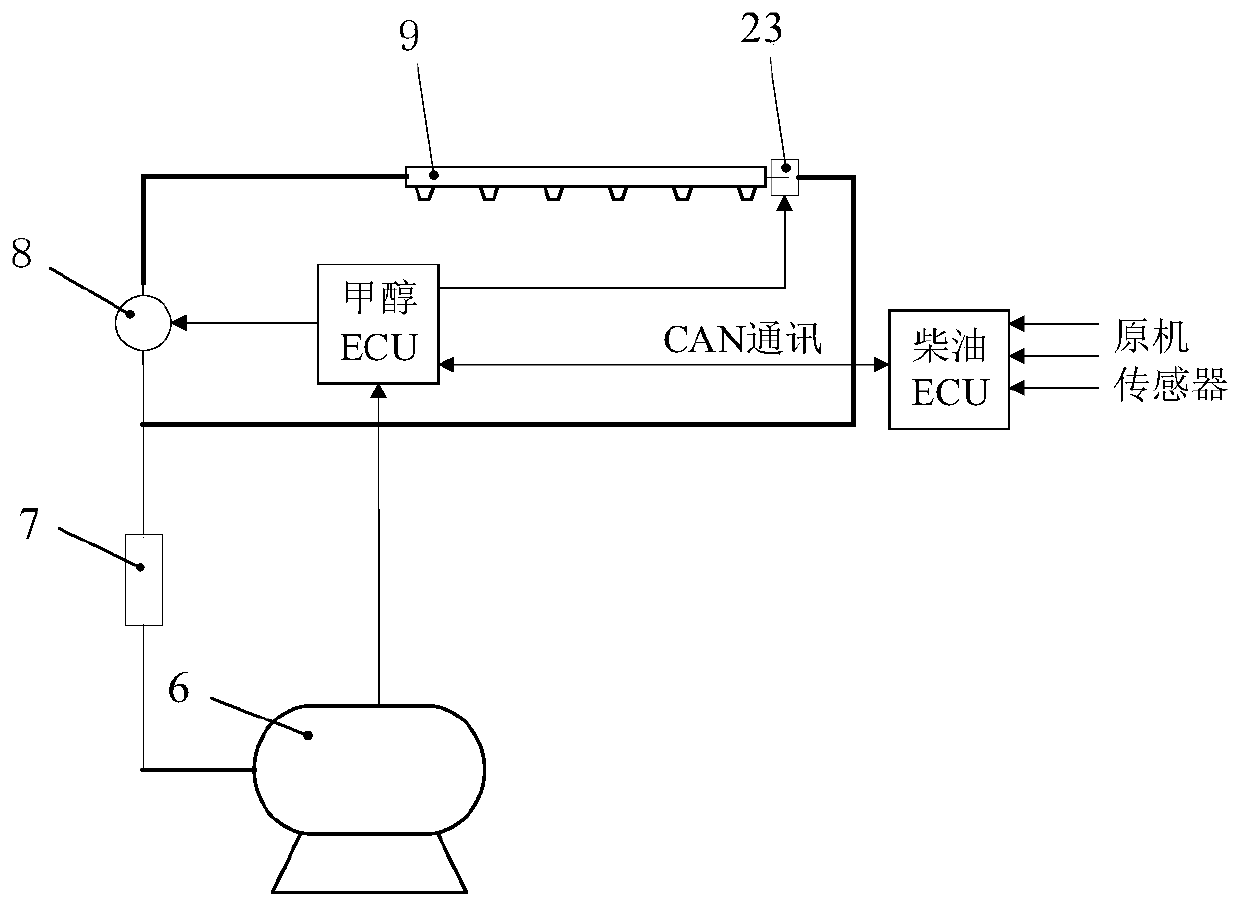

[0056] attached figure 2 Shown is the schematic diagram of the methanol supply system of the present invention, the methanol supply system comprises a methanol tank 6, a methanol filter 7, a methanol pump 8, a methanol rail 9, a methanol nozzle 14 and a methanol rail pressure regulating valve 23; the methanol nozzle 14 Installed on the intake manifold 15 after the entrance of the EGR pipeline 4, the high-temperature gas in the EGR pipeline 4 is fully utilized to heat the methanol injected into the intake manifold 15 through the methanol nozzle 14 in dual-fuel mode.

[0057] attached Figure 4 It is a schematic diagram of the overall structure of the control system of the present invention, and the control system is composed of diesel ECU, methanol ECU, sensors and CAN c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com