Fuel gas concentration self-adaptive control method for fuel gas generating set

An adaptive control and generator set technology, which is applied in engine control, electrical control, combustion engine, etc., can solve the problems of gas generator set wear, low precision, and inability to adapt to rapid changes in gas components, so as to prevent knocking, Achieving Precisely Controlled Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below with reference to the drawings and embodiments.

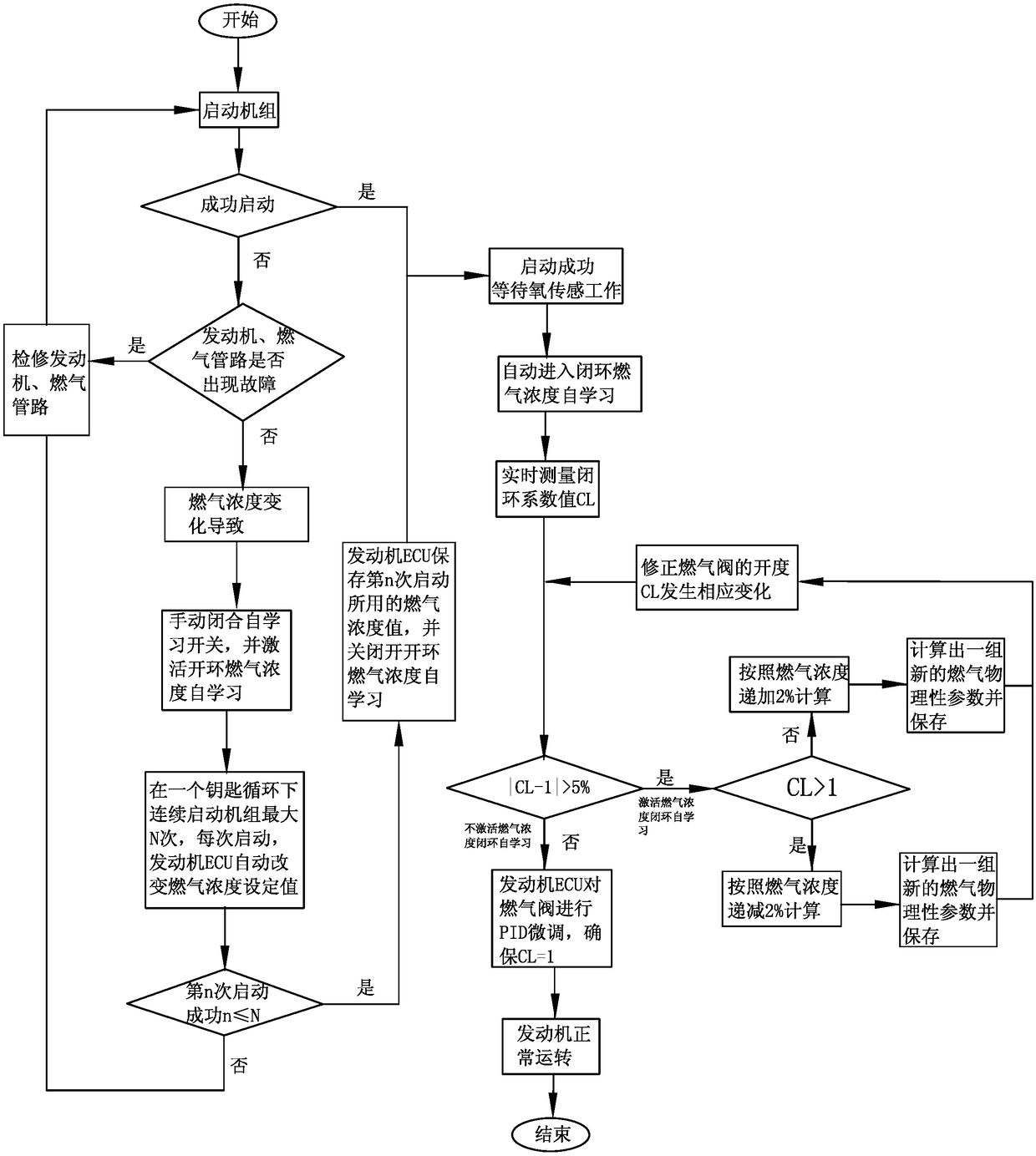

[0044] Such as figure 1 The flow chart shown is an adaptive control method for gas concentration of a gas generator set, where the gas concentration is the methane concentration in the gas. The control method mainly includes two major steps:

[0045] The open-loop gas concentration self-learning start-up control procedure performed when the gas generator set is not successfully started;

[0046] The closed-loop gas concentration self-learning control procedure performed when the gas generator set is successfully started.

[0047] Among them: when the gas generator set is not successfully started, the open loop gas concentration self-learning startup control steps include:

[0048] (a1) When the gas generator set is not successfully started, check and judge whether the engine and gas pipeline in the gas generator set are malfunctioning (we have to judge by ourselves to check w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com