A splitter valve

A shunt valve and stream flow technology, which is applied in the air flow field of household cogeneration systems, can solve problems such as equipment damage, increased blade drive failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

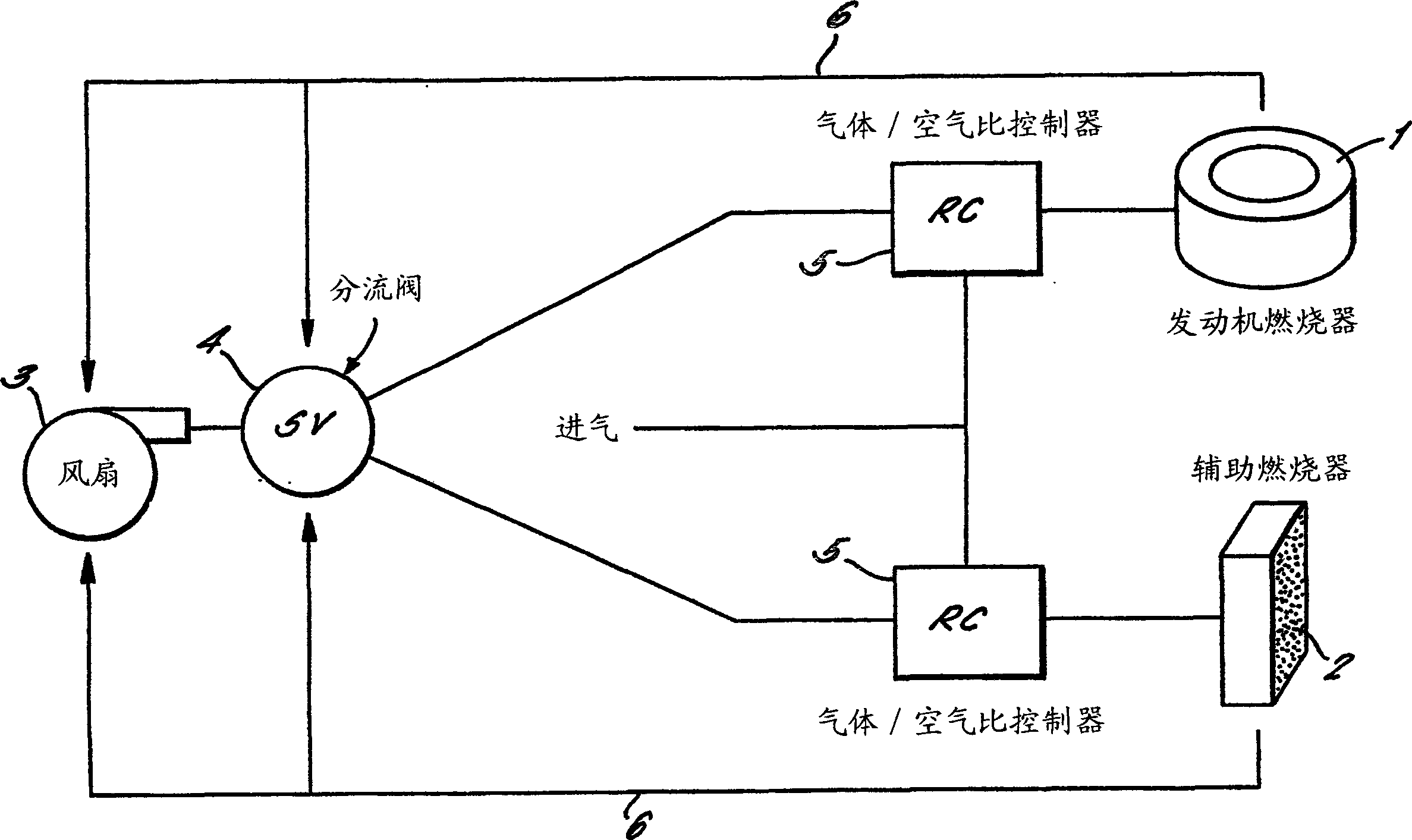

[0020] figure 1 A gas system for a domestic cogeneration system based on a linear free-piston Stirling engine is shown in .

[0021] The arrangement comprises two burners, Stirling engine burner 1 and auxiliary burner 2 . Stirling engine burners 1 are ignited according to domestic heat demand. This will also generate electricity as a by-product. However, in order to ensure sufficient capacity for all domestic heat loads, an auxiliary burner 2 is provided. Therefore, the two burners are adjusted according to the domestic heating needs. Air is supplied to both burners by a single fan 3 . This flow is diverted in a diverter valve 4 which will be described in more detail below. Fuel gas is added to each air stream under the control of the gas / air ratio controller 5 . The demand information of the burners 1 and 2 is fed back to the fan 3 and the diverter valve 4 along the control line 6 . The rotational speed of the fan 3 and the position of the diverter valve 4 are thus con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com