Patents

Literature

307results about How to "For precise control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

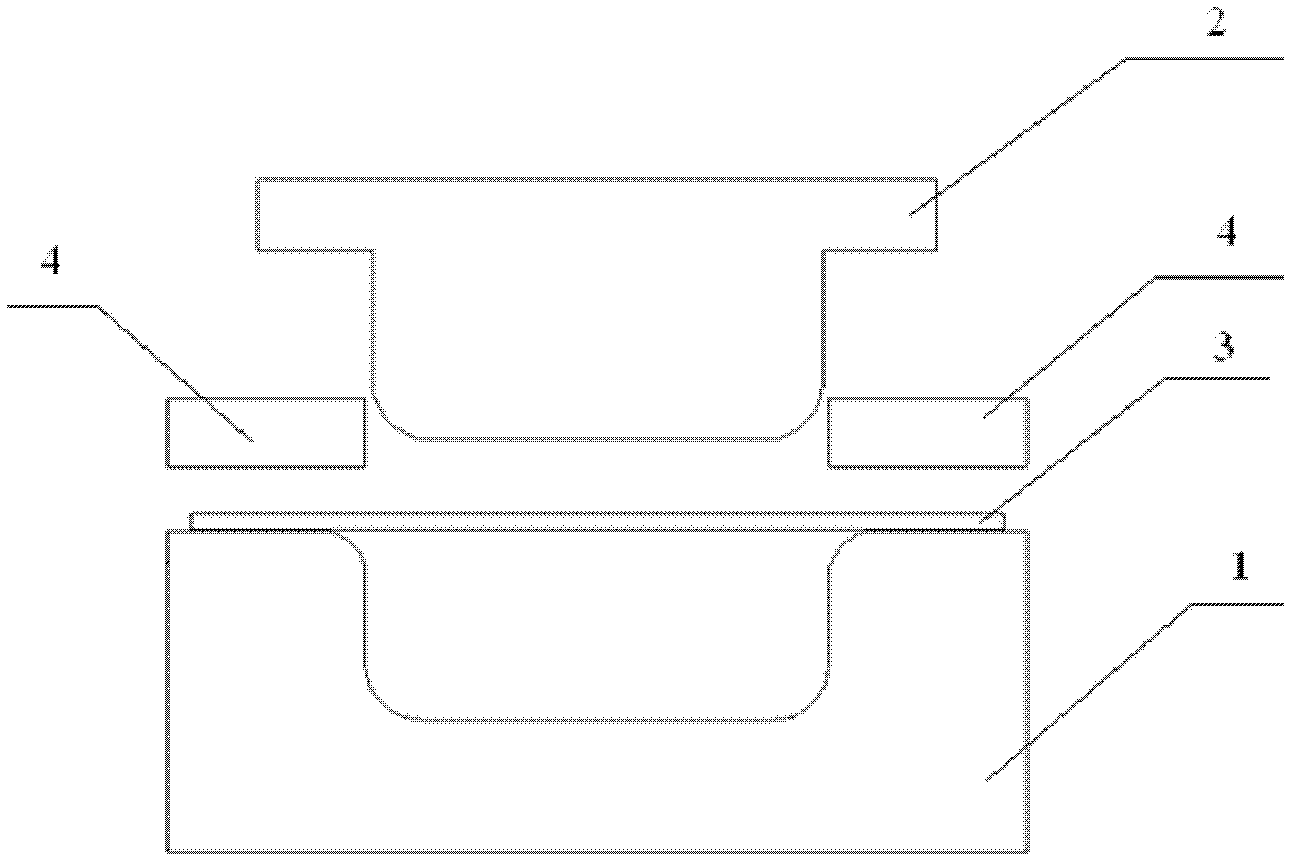

Cold-hot compound die molding method for aluminum alloy sheet metal component

ActiveCN102615201ADimensionally stableDimensional change, shape stability can be obtained directly through one-time formingShaping toolsMetalAluminium alloy

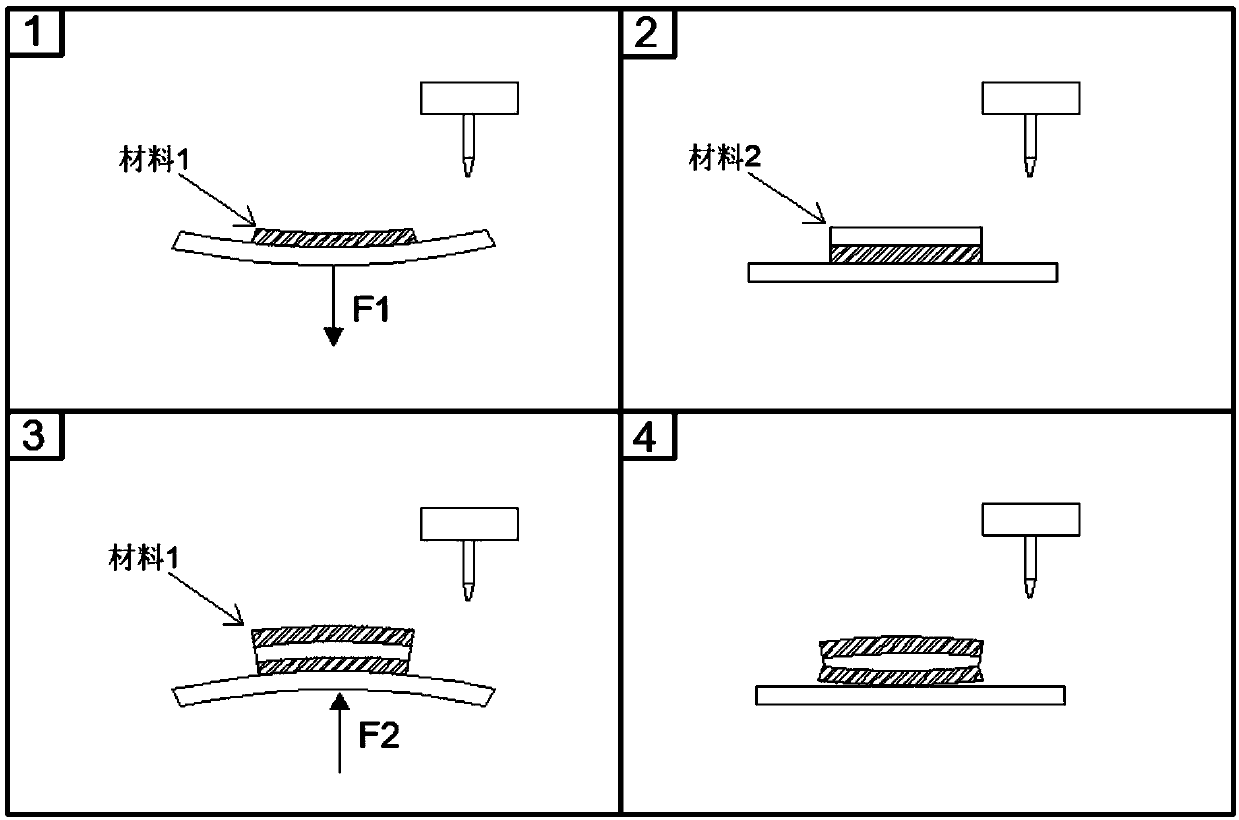

The invention discloses a cold-hot compound die molding method for an aluminum alloy sheet metal component, and relates to a molding method for a sheet metal component. The invention aims to solve the technical problems that the conventional hot-state molding method for the aluminum alloy sheet metal component is low in molding efficiency and can easily cause local crinkles and fractures, and provides the cold-hot compound die molding method for the aluminum alloy sheet metal component. The cold-hot compound die molding method comprises the following steps of: 1, heating a lower die to a temperature of between 200 and 900 DEG C; 2, placing an aluminum alloy plate blank on the lower die and heating the aluminum alloy plate blank to the deformation temperature of the aluminum alloy plate blank; 3, closing the die to press the aluminum alloy plate blank into the aluminum alloy sheet metal component; 4, separating the aluminum alloy sheet metal component, an upper die and a blank holder from the lower die; and 5, cooling the upper die and the blank holder, keeping the temperature for a certain period of time, and taking the aluminum alloy sheet metal component down to finish the cold-hot compound die molding of the aluminum alloy sheet metal component. According to the method, a cold-hot compound die in which the upper die is in a cold state and the lower die is in a hot state is adopted to mold the aluminum alloy sheet metal component. The cold-hot compound die molding method is suitable for making the aluminum alloy sheet metal component.

Owner:天津哈工永兴科技有限公司

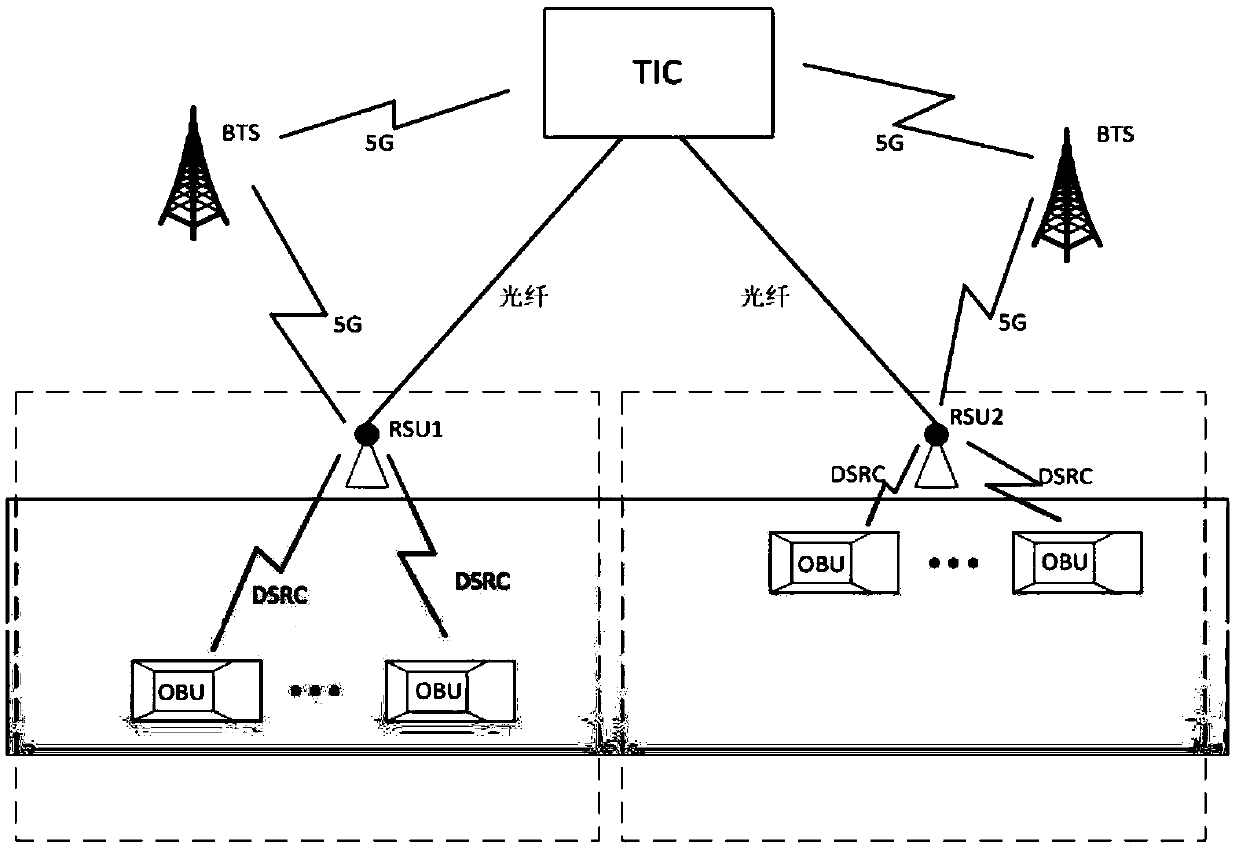

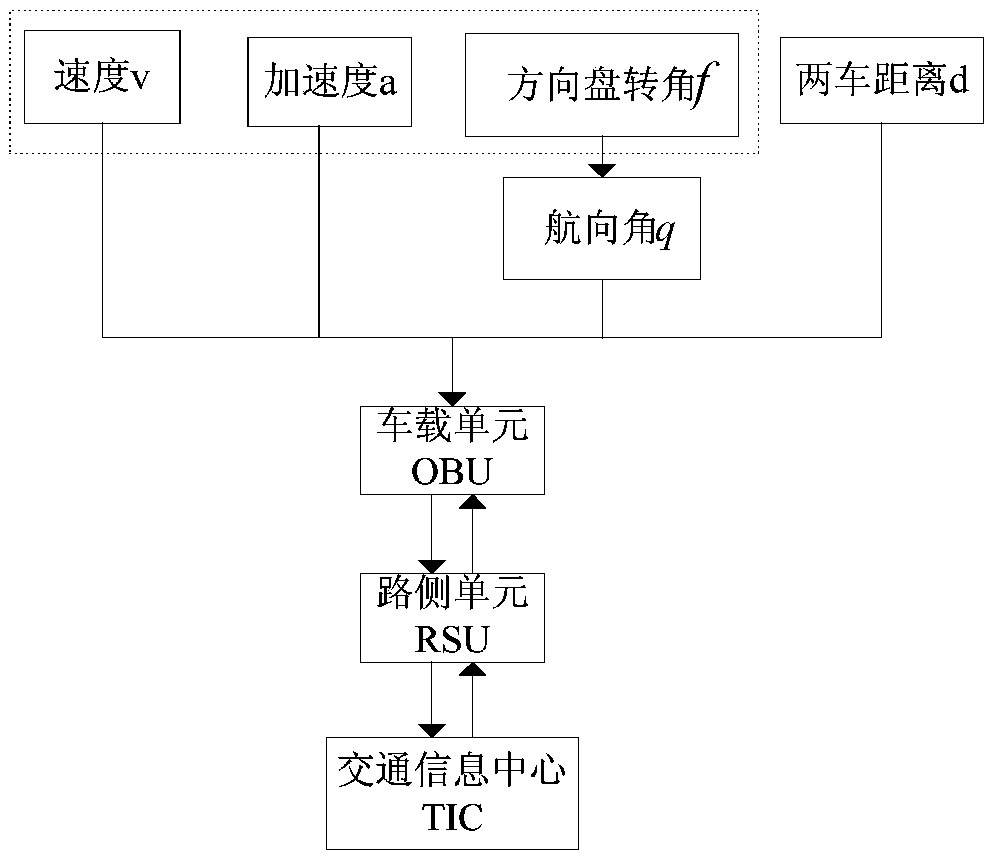

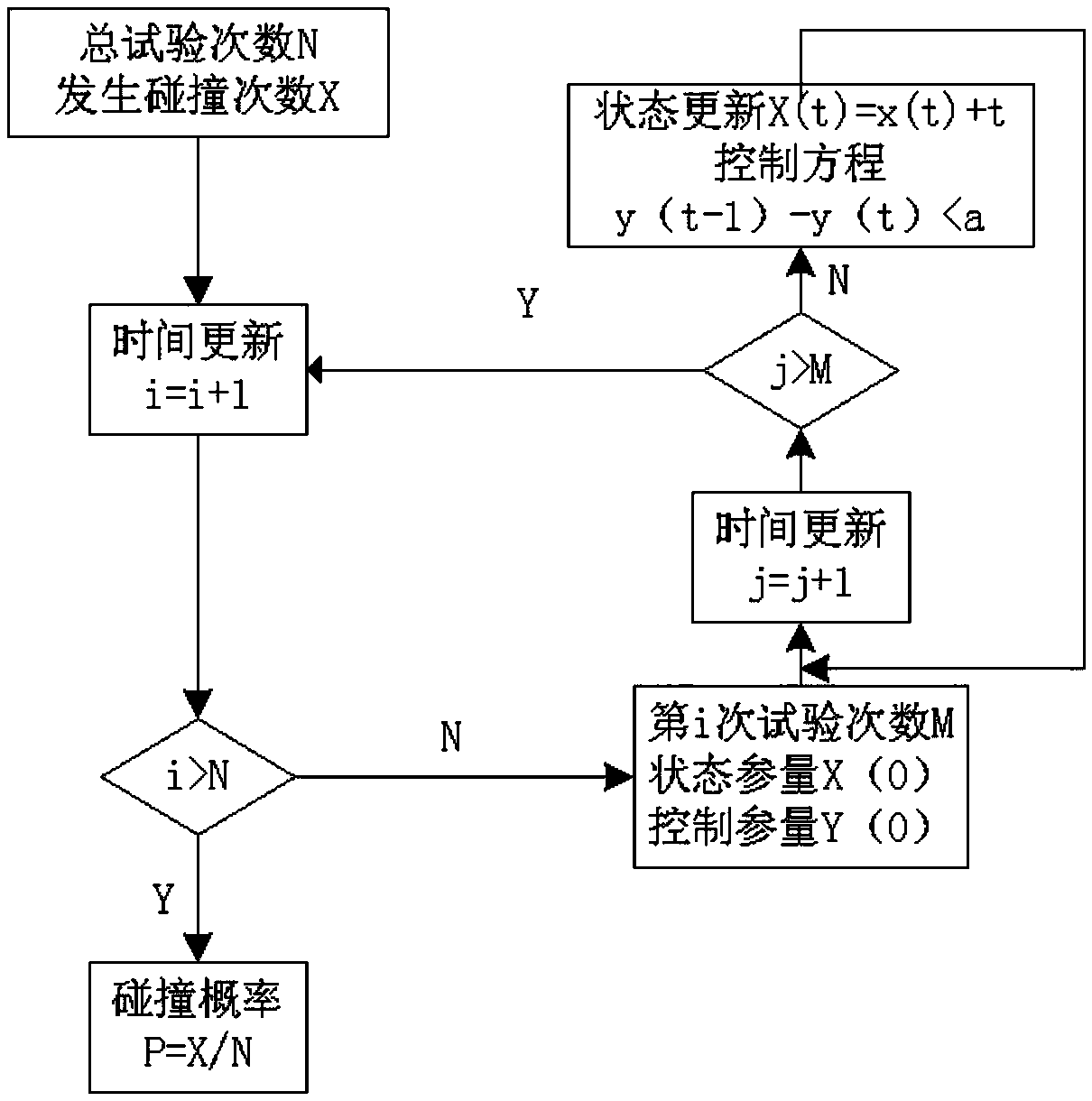

Vehicle collision risk algorithm and accident pre-warning method

ActiveCN105513425AImprove confidentialityFor precise controlAnti-collision systemsTraffic crashOn board

The invention discloses a vehicle collision risk algorithm and accident pre-warning method, which comprise an on-board unit (OBU), a road side unit (RSU), a traffic information center (TIC) and an information communication unit (ICU). The OBU is used for acquiring vehicle speed, accelerated speed, a steering wheel angle and other parameters, and combining with a road traffic system to acquire a track angle of a vehicle and a real-time distance between two vehicles; the OBU transmits the parameters to the belonged RSU through a DSRC (Dedicated Short Range Communication) technology; the RSU transmits the vehicle parameters in an area to the TIC for risk calculation through an optical fiber / 5G technology; the result is forwarded to the OBU for pre-warning through the RSU. According to the vehicle collision risk algorithm and accident pre-warning method, traffic accidents can be prevented and controlled accurately, and thus the traffic jam and the frequent accidents can be effectively avoided.

Owner:JIANGSU UNIV

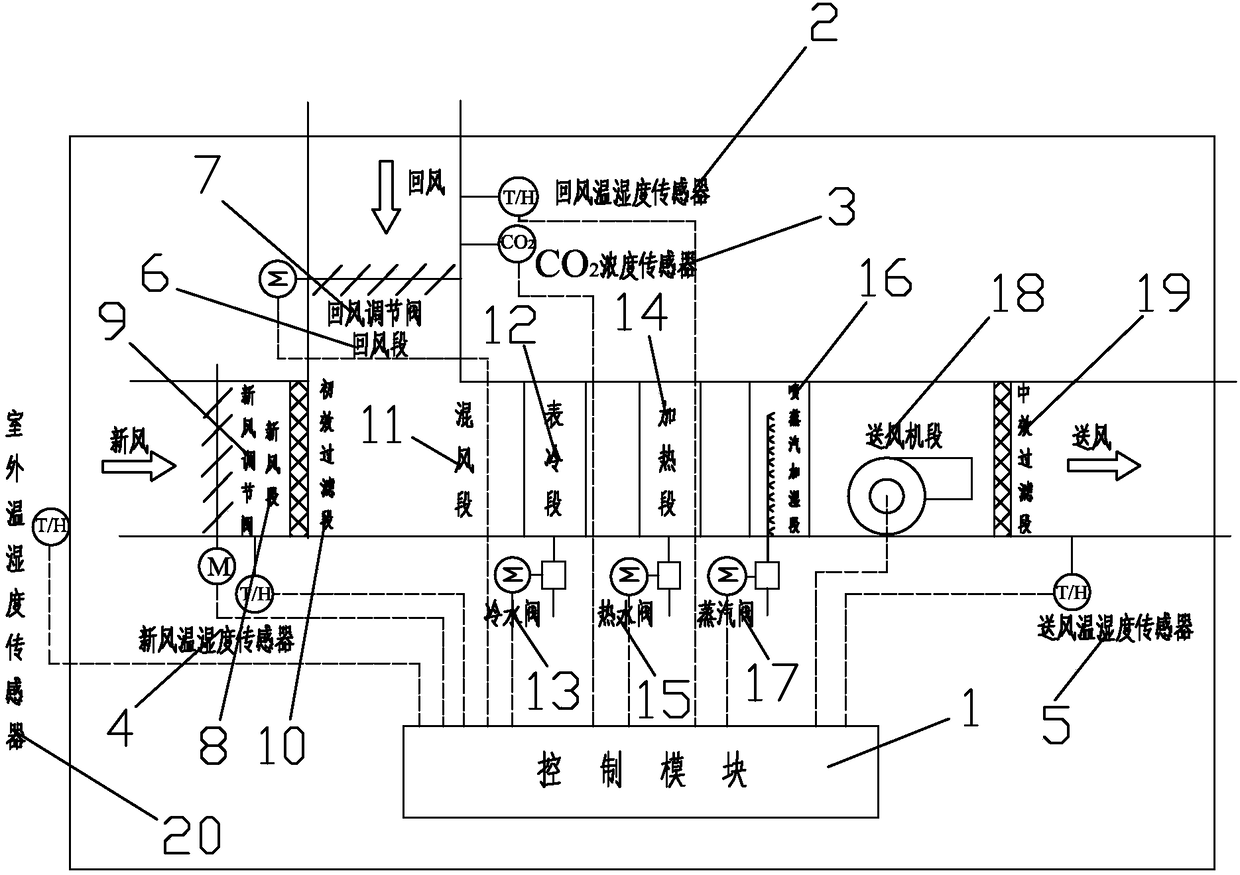

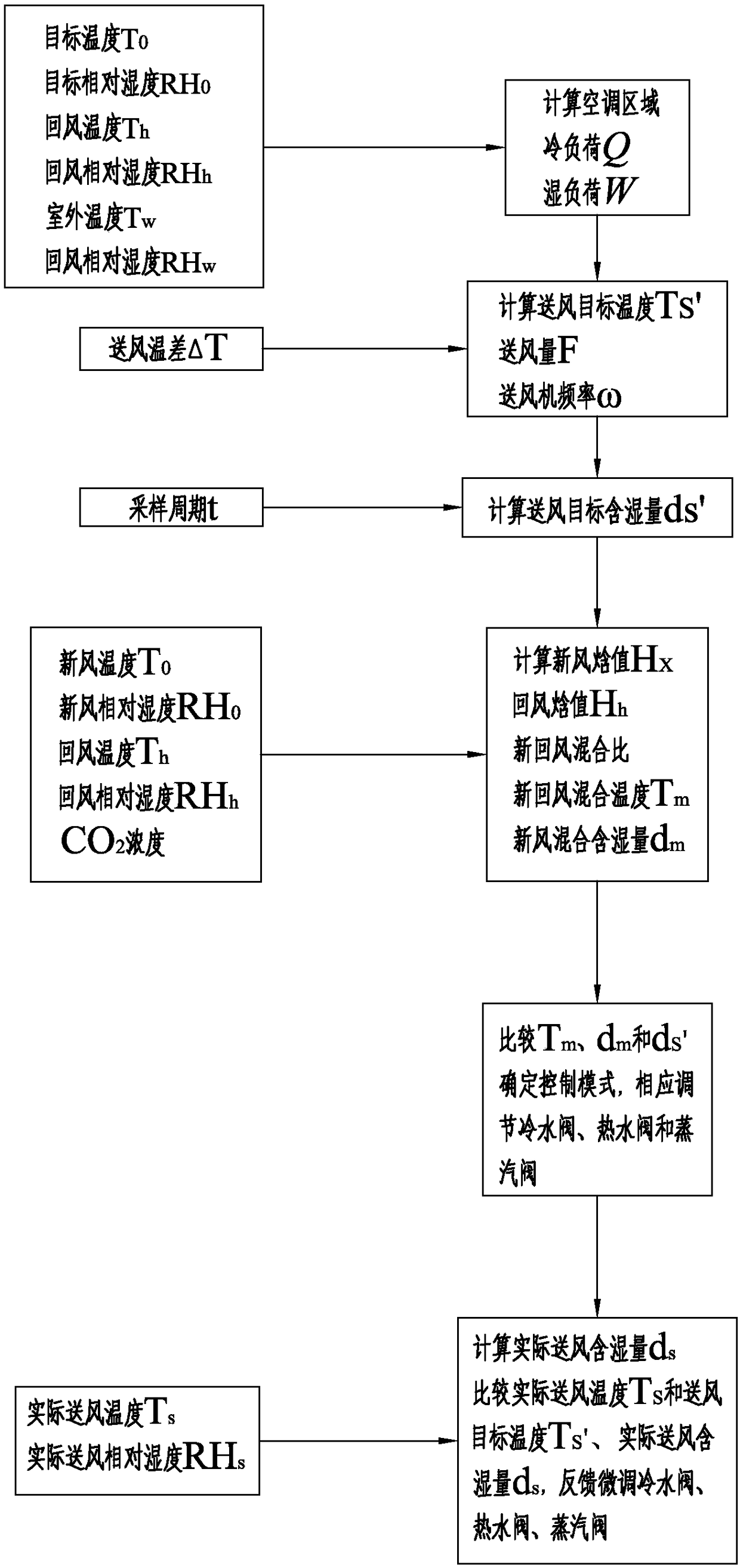

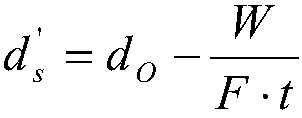

Precision control system and method for air supply temperature and humidity of combined air handling unit

InactiveCN108518764AFor precise controlReasonable structural designMechanical apparatusSpace heating and ventilation safety systemsAir volumeControl system

The invention discloses a precision control system for an air supply temperature and humidity of a combined air handling unit. The system comprises the combined air handling unit, a control module, areturn air temperature and humidity sensor, a CO2 concentration sensor, a fresh air temperature and humidity sensor, an air supply temperature and humidity sensor and an outdoor temperature and humidity sensor. A control method comprises the following steps of a, calculating the cold load Q and the wet load W of an air conditioner area; b, determining the air supply capacity F and the frequency ofan air supplier omega; c, determining the air supply target moisture content ds'; d, determining the mixing ratio and mixing parameters of fresh air and return air; e, determining a control mode; andf, determining a control mode. As the fewer sensors are installed at the position where measurement accuracy can be ensured, the air handling process of the combined air handling unit is accurately calculated according to a controller built-in algorithm, and accurate control over the air supply temperature and humidity of the combined air handling unit and energy-saving running are achieved.

Owner:浙江盾安自控科技有限公司

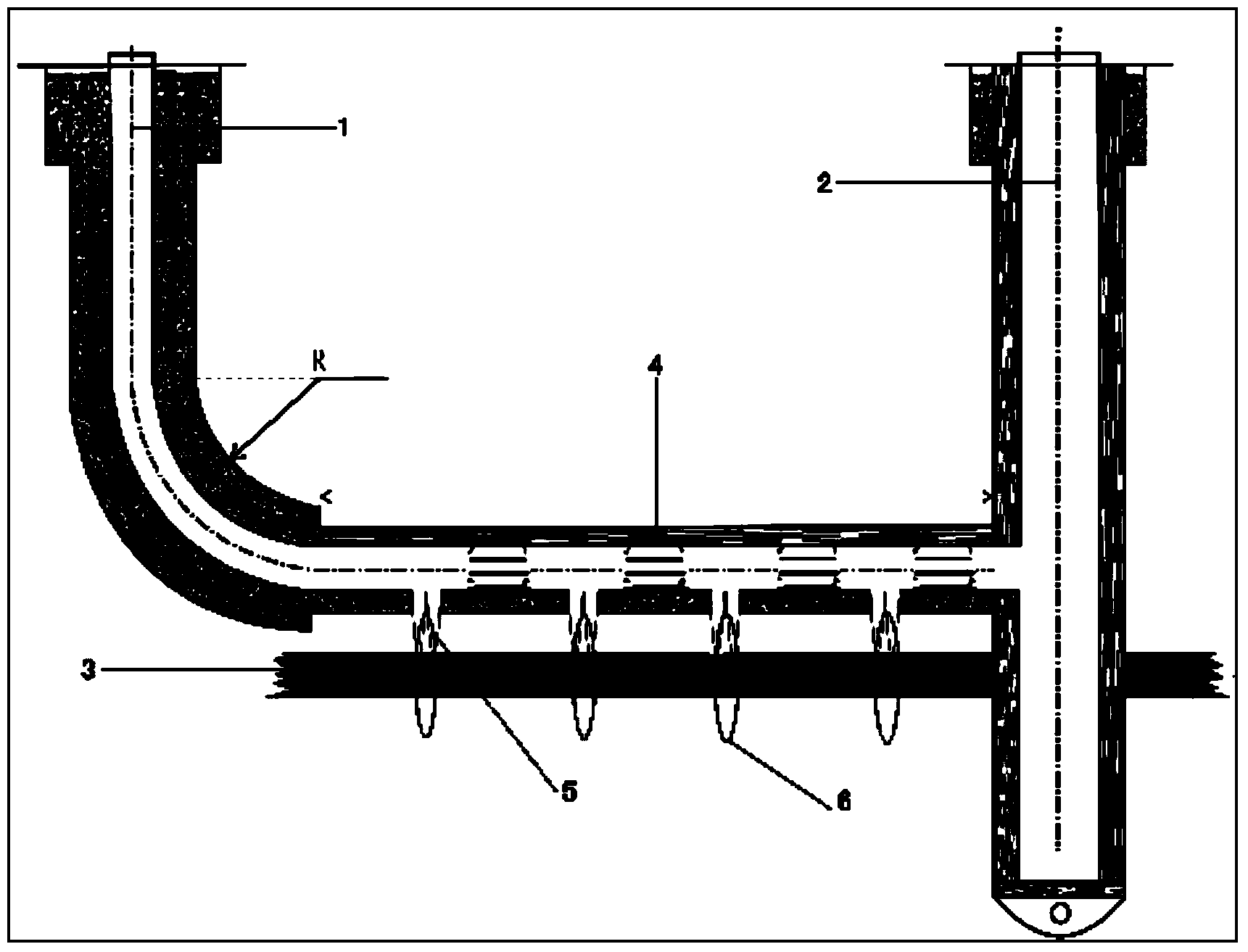

Horizontal well forced gas drainage method with coal bed gas subjected to staged fracturing

ActiveCN103967472AFor precise controlSolving the Difficulties of Directional DrillingFluid removalSoil scienceDrill

The invention relates to a horizontal well forced gas drainage method with coal bed gas subjected to staged fracturing. In order to solve the problems that hole forming performance of horizontal drilling in a coal bed is poor and buried drill accidents can happen easily and to achieve the forced gas drainage effect on tectonic soft coal, the well track of a horizontal well is controlled in mudstone or sand stone with a certain range above a coal bed top boundary, and the horizontal well is docked with a drainage vertical well at a far end. An ultra deep penetration perforating technology is used, according to the requirement for certain hole density and orientation, orientated perforating is conducted downwards on the horizontal well section in a segmented mode, a steel sleeve, a well cementation cement ring and a mudstone top plate are penetrated, and the horizontal well is communicated with a target coal layer below. Then, a clear water sand carrying fracturing technology is used, staged fracturing is conducted on the target coal bed according to the requirements for large discharge capacity, large liquid amount, high prepad fluid ratio, large sand amount and middle sand ratio, and the purpose of increasing production is achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

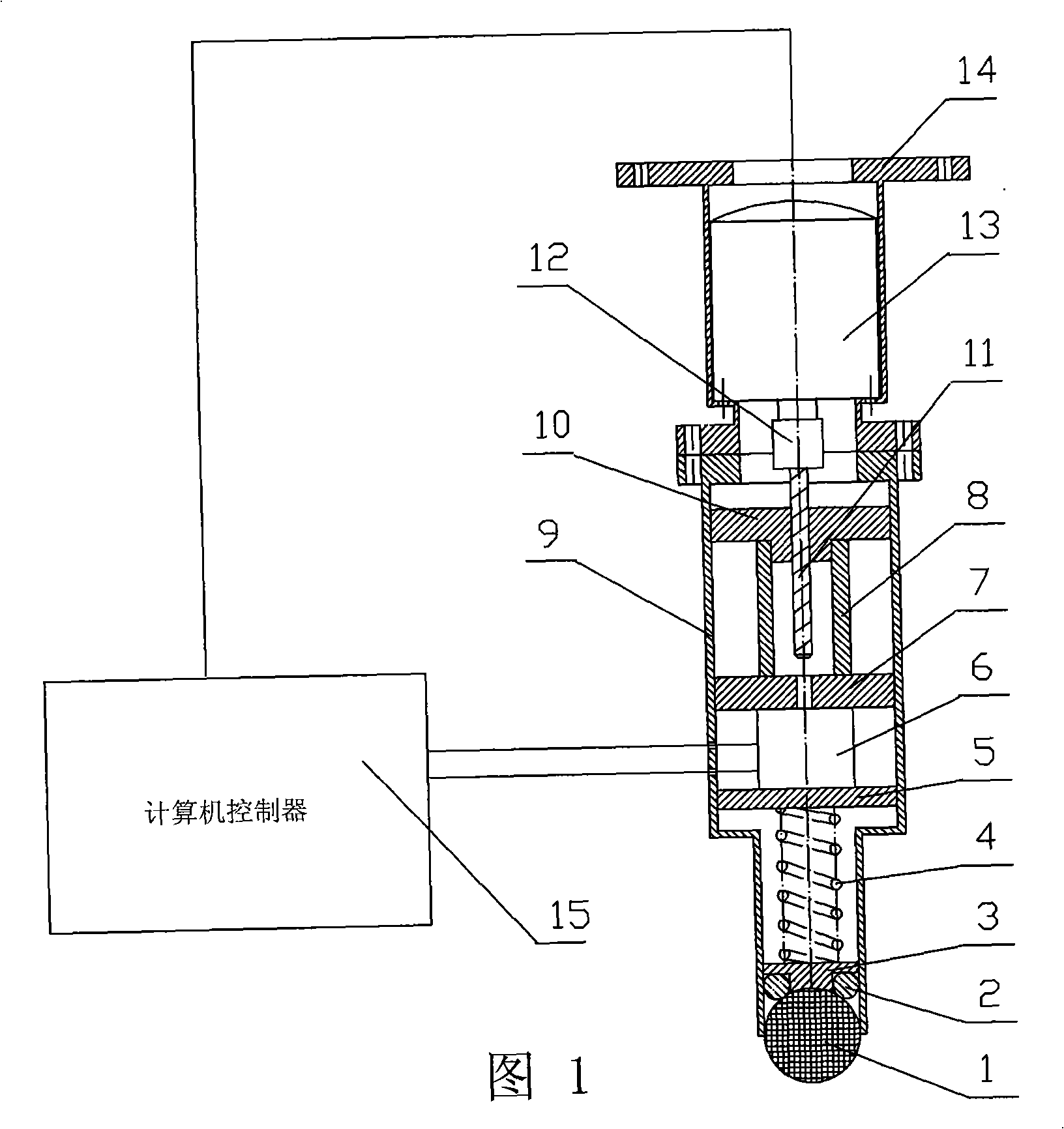

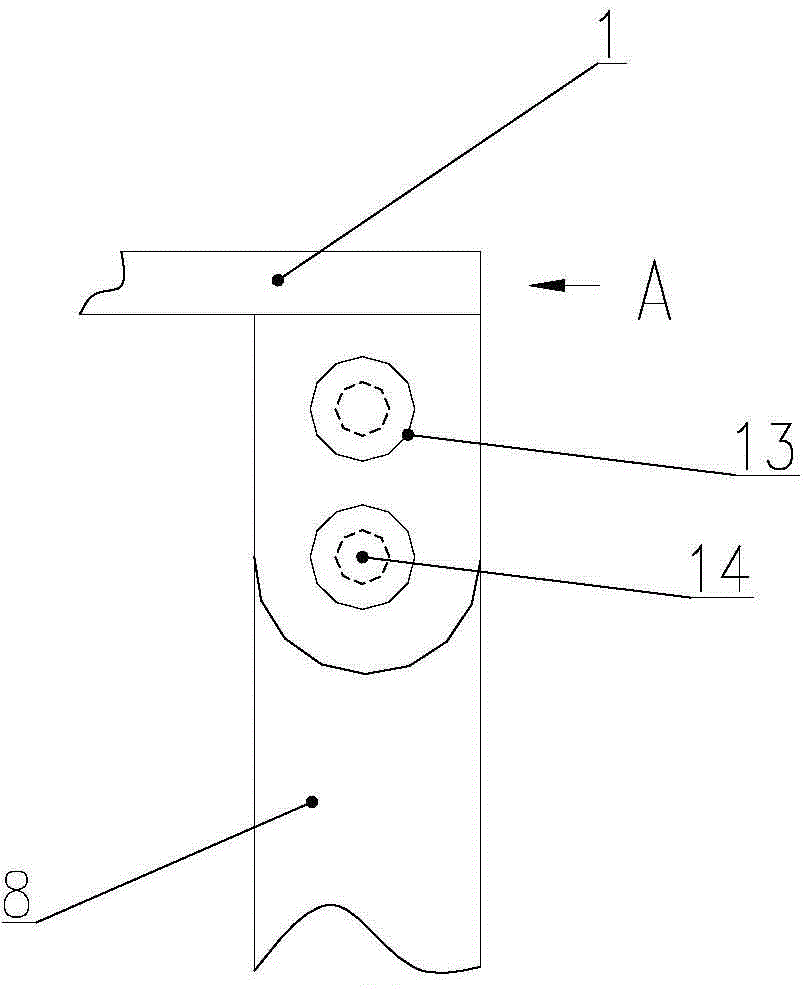

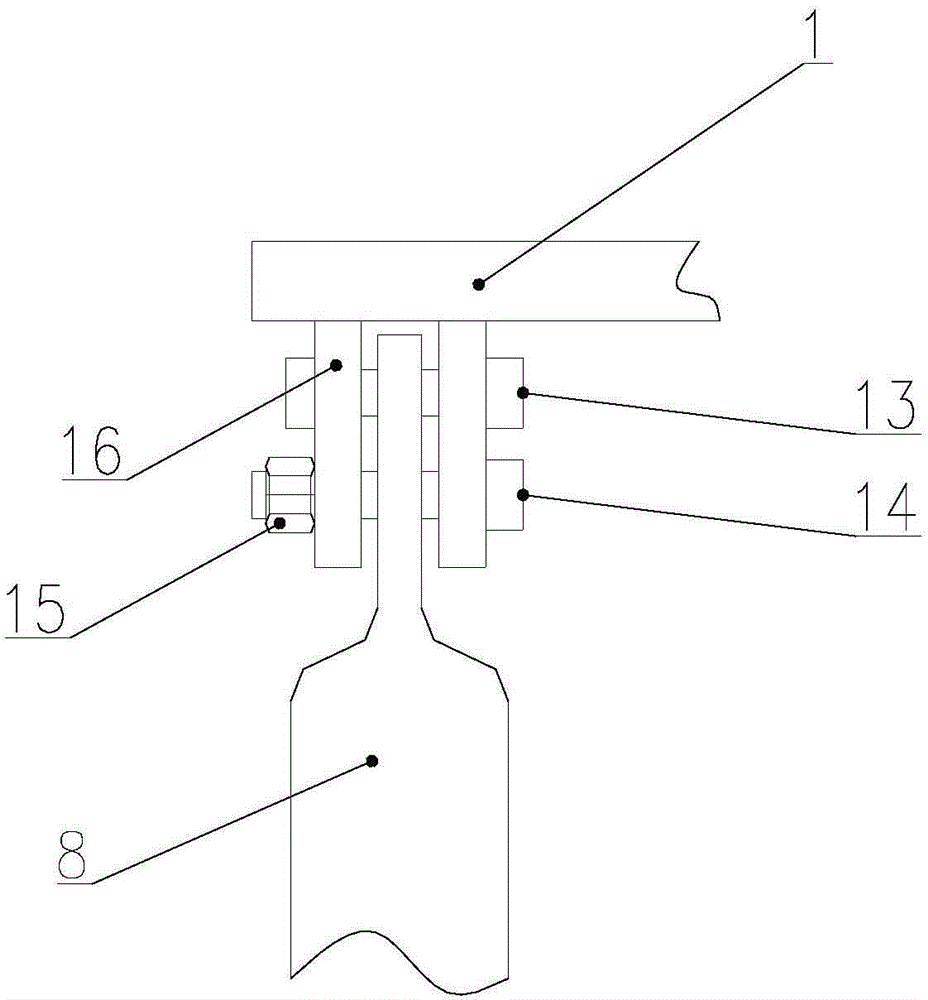

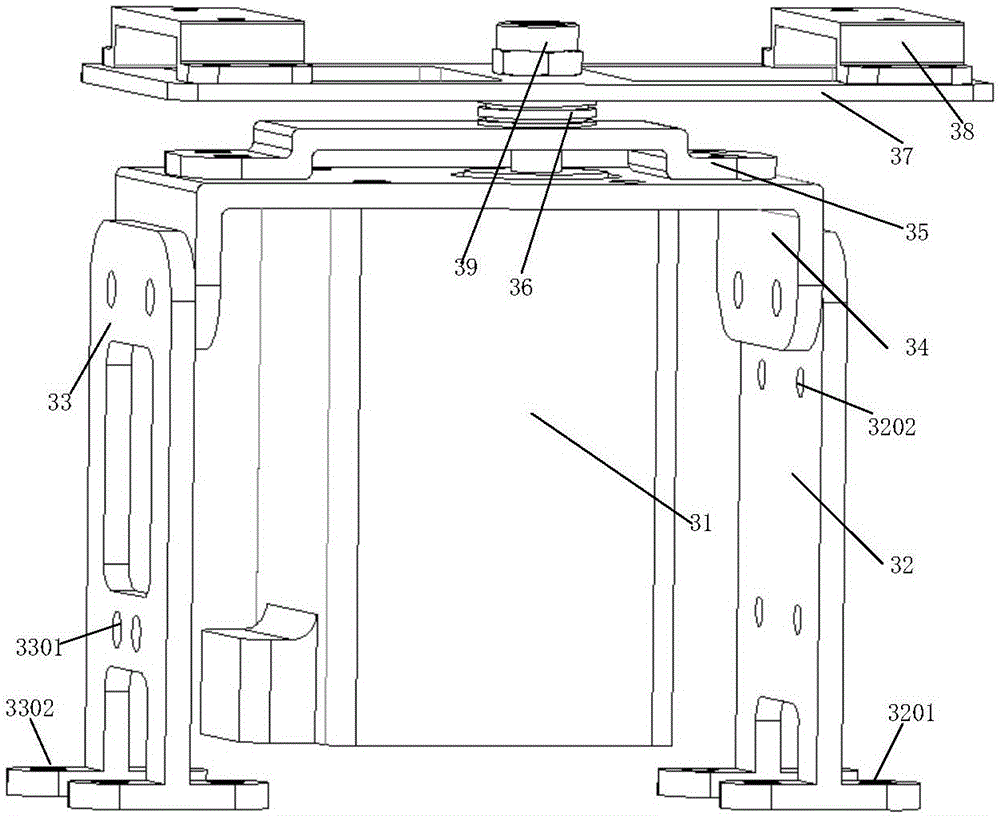

Pressure-tunable plate gradual shaping pressure head and shaping device thereof

The invention discloses an incremental forming indenter for sheet material with an adjustable pressure. The indenter comprises a forming indenter cylinder body, wherein a forming motor is fixedly mounted at the upper end of the cylindrical forming indenter cylinder body; a forming ball head is moveably arranged at the lower end of the forming indenter cylinder body via a ball cup, and the forming ball head is provided with an overhang ball cap part which extends out of the lower end of the forming indenter cylinder body; a transmission pair composed of a screw rod and a screw nut, and a pressure sensor are sequentially arranged from top to bottom in an inner cavity of the forming indenter cylinder body, and the pressure sensor is positioned between an upper backing plate and a lower backing plate; the screw rod is connected with an output shaft of the forming motor, and the screw nut is supported on the upper backing plate; and a ball head spring is supported between the lower backing plate and the ball cup. Based on the principle of 'layered manufacture', a thin-shell piece with a required shape is produced by adopting the layered incremental forming, therefore, the indenter is characterized by high machining accuracy, good surface quality, accurate and stable forming, adjustable and controllable pressure, etc., and is widely applicable to the forming processes of various complex curved shapes and various trial-manufacture stamping parts in small amount.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Portable dust preventive lifting platform for UAV (unmanned aerial vehicle) in mountainous region

ActiveCN104527991APlay the role of double protectionFor precise controlGround installationsUncrewed vehicleEngineering

Owner:MAINTENANCE BRANCH STATE GRID LIAONING ELECTRIC POWER +2

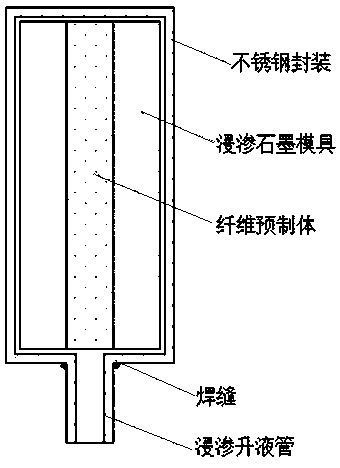

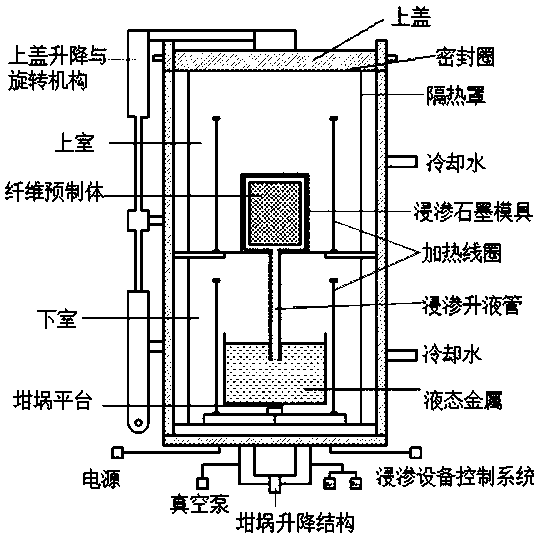

Near-net forming method of 3D braided fiber reinforced metal-based composite material

The invention discloses a near-net forming method of the 3D braided fiber reinforced metal-based composite material, and belongs to the technical field of advanced composite materials. The method is characterized in that a vacuum air pressure infiltration preparation technology based on a liquid binder is adopted to assist in accurately controlling the shape and the size of a 3D braided fiber preform structure; in the 3D weaving process of the fiber preform, a liquid binder is adopted to accurately fix and shape the 3D braided fiber preform, then the size precision of the 3D braided fiber reinforced metal-based composite material is accurately controlled through the impregnated graphite mold of the embedded fiber preform, and deformation and local fiber polarization of the 3D braided fiberpreform in the infiltration process are prevented. The prepared 3D braided fiber reinforced metal-based composite material has high dimensional accuracy and excellent mechanical properties, the near-net forming of the 3D braided fiber reinforced metal-based composite material is realized, batch industrial production can be realized, the near-net forming method has a wide application prospect in the fields of aerospace, national defense, military and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

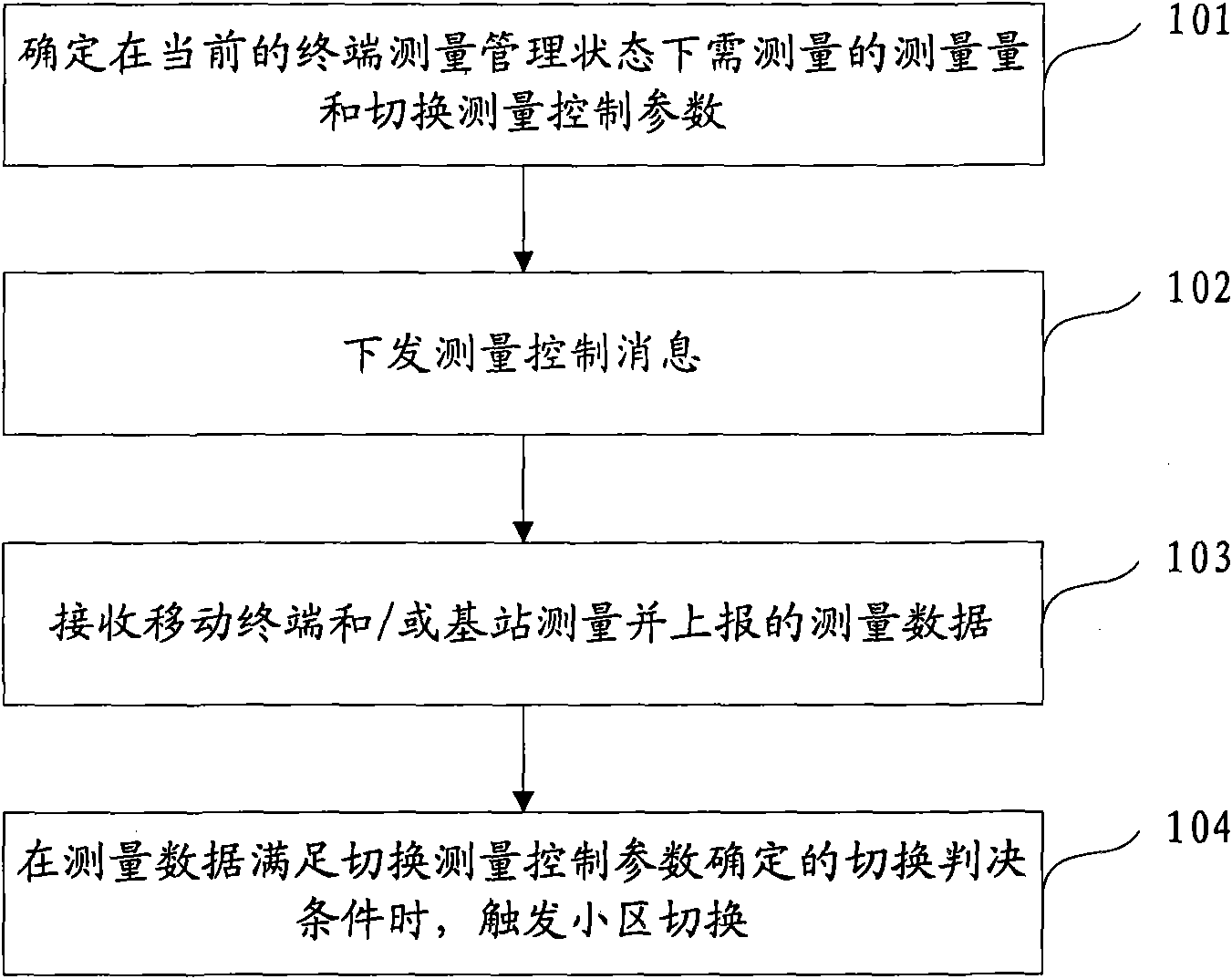

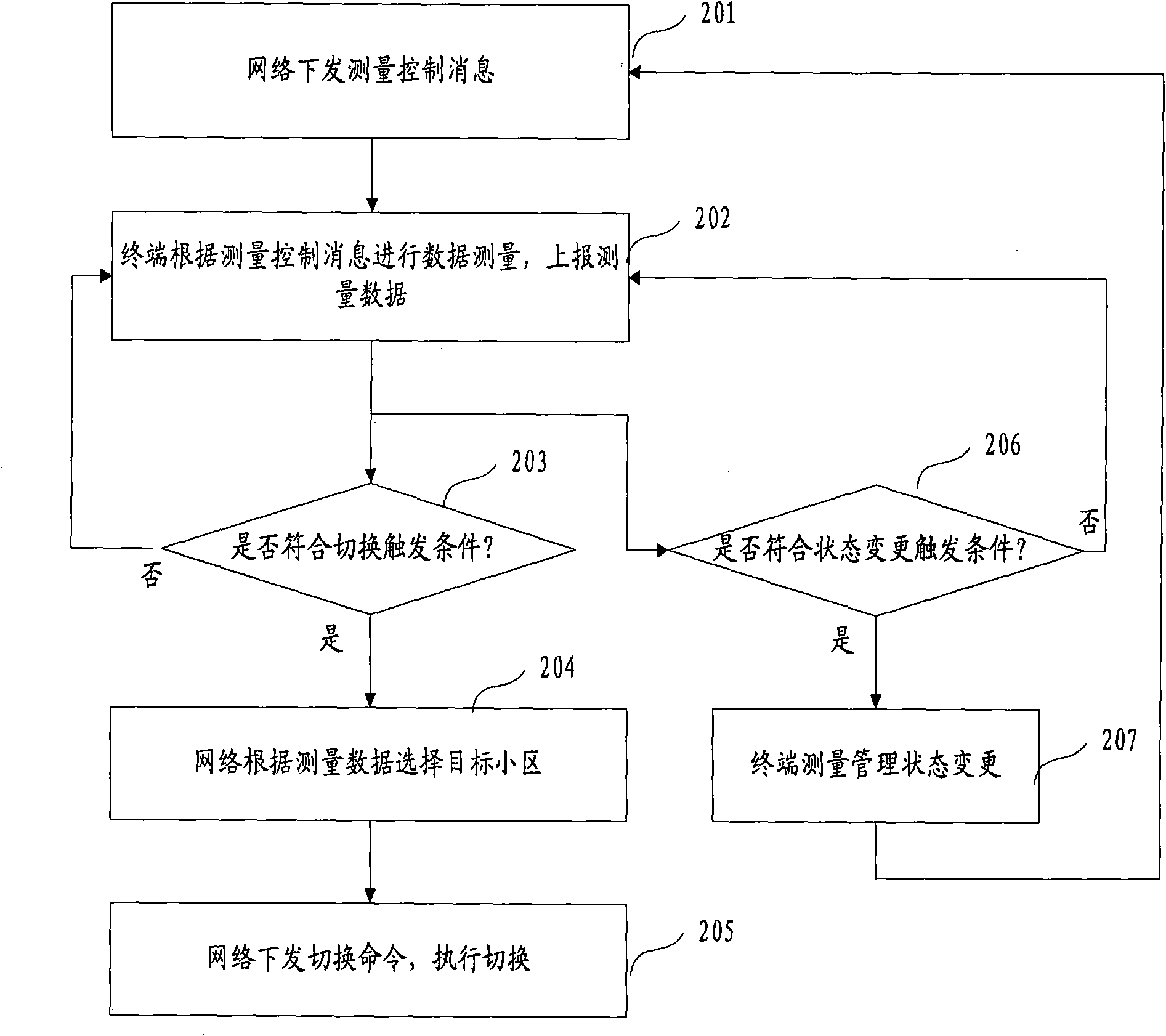

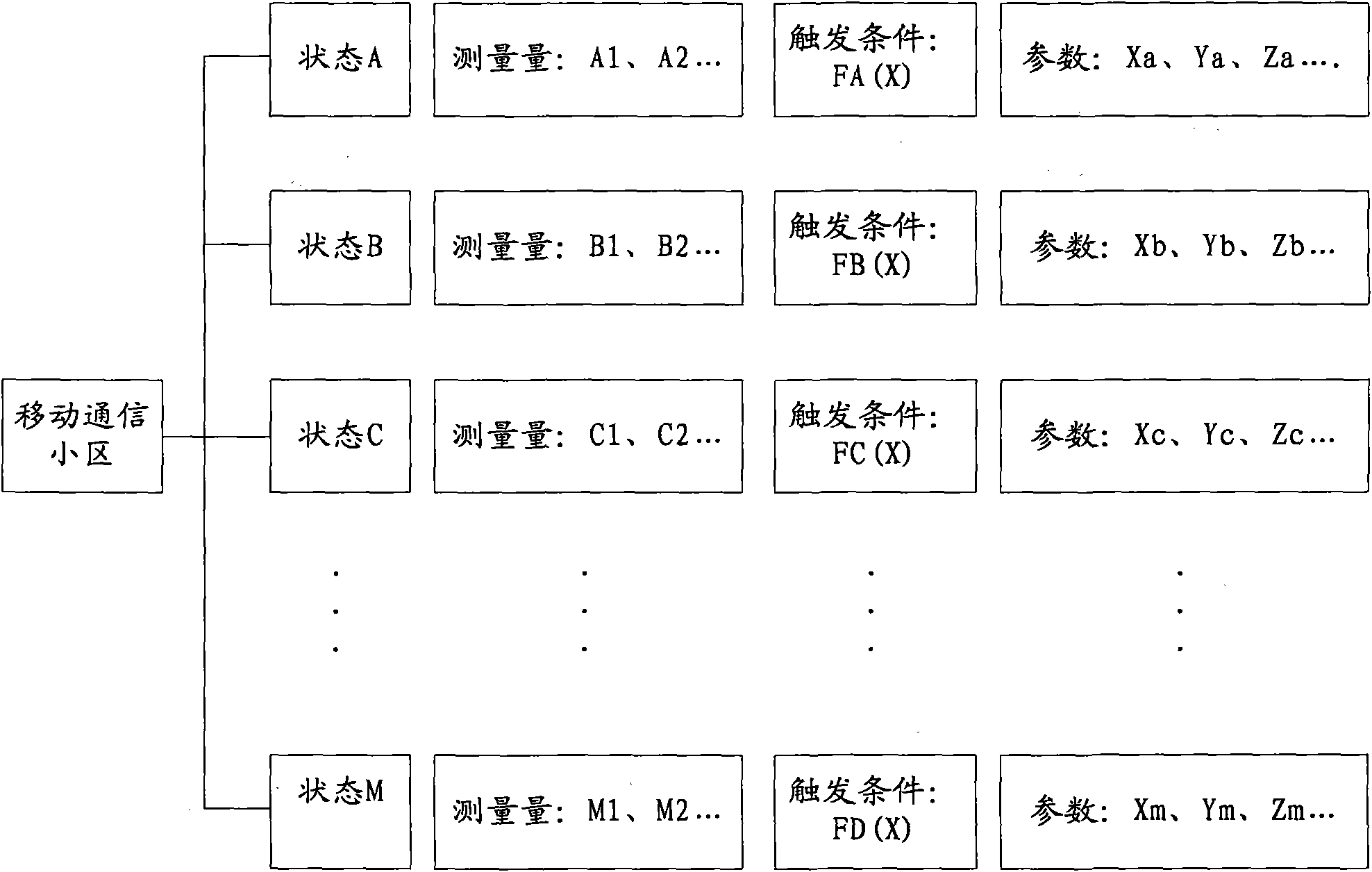

Switching controlling method in mobile communication system and wireless network controller

InactiveCN102083159AFor precise controlQuality improvementWireless communicationControl parametersEngineering

The invention provides a switching controlling method in a mobile communication system and a wireless network controller. The method comprises the following steps of: (A) determining a measurement quantity needed to be measured and a switching measurement control parameter under the current terminal measurement managing state by the wireless network controller according to the corresponding relation of a preset terminal measurement management status, the measurement quantity needed to be measured and the switching measurement control parameter; (B) issuing a measurement control message to a mobile terminal and / or a base station by the wireless network controller, wherein the measurement control message includes the determined measurement quantity needed to be measured; (C) receiving measurement data which are measured and reported by the mobile terminal and / or the base station according to the measurement quantity needed to be measured, included in the measurement control messageby the wireless network controller; and (D) triggering cell switching by the wireless network controller when the measurement data meet a switching judgment condition confirmed by the switching measurement control parameter. By adopting the technical scheme, more accurate switching control can be realized, and thus the network quality is improved.

Owner:CHINA MOBILE GRP BEIJING

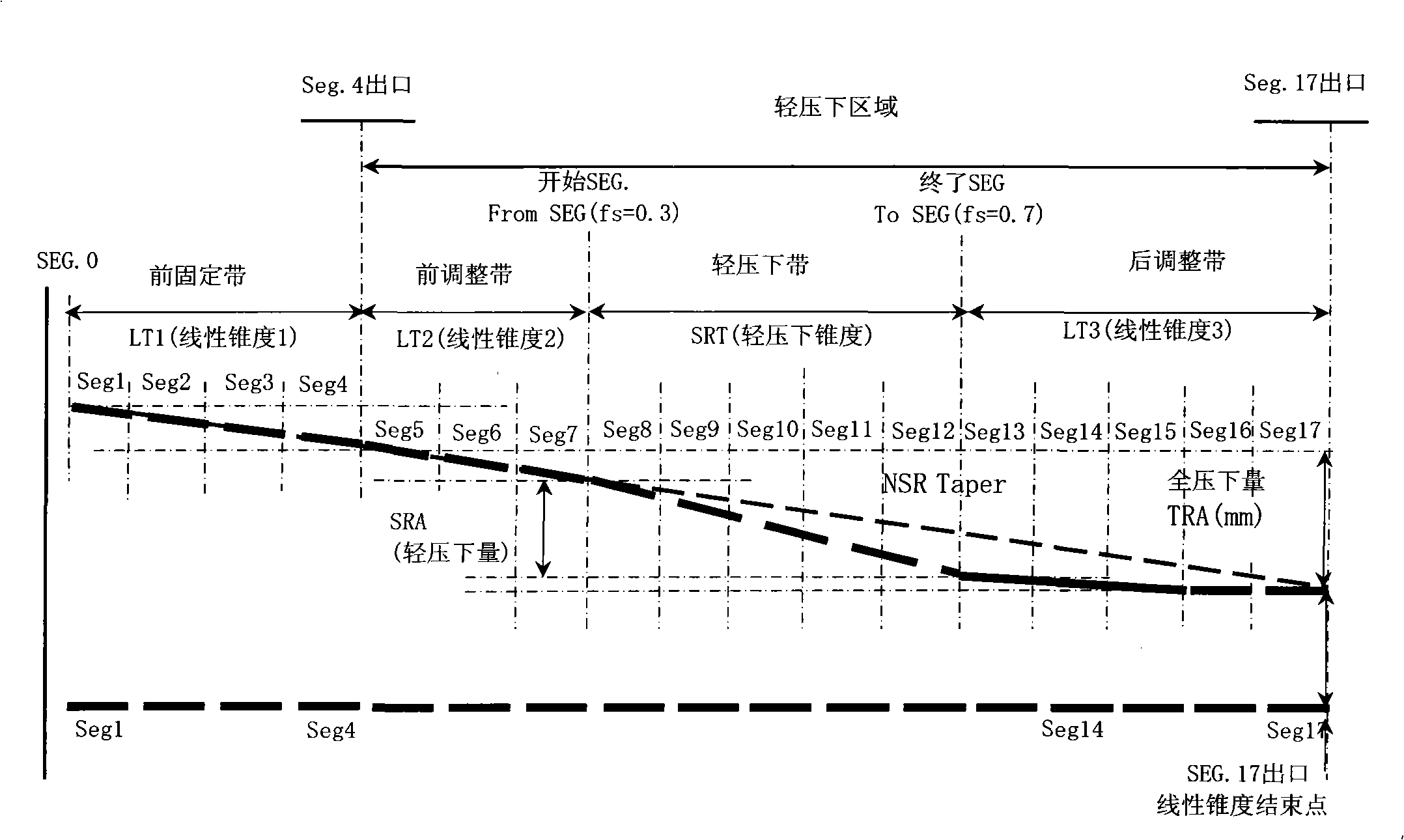

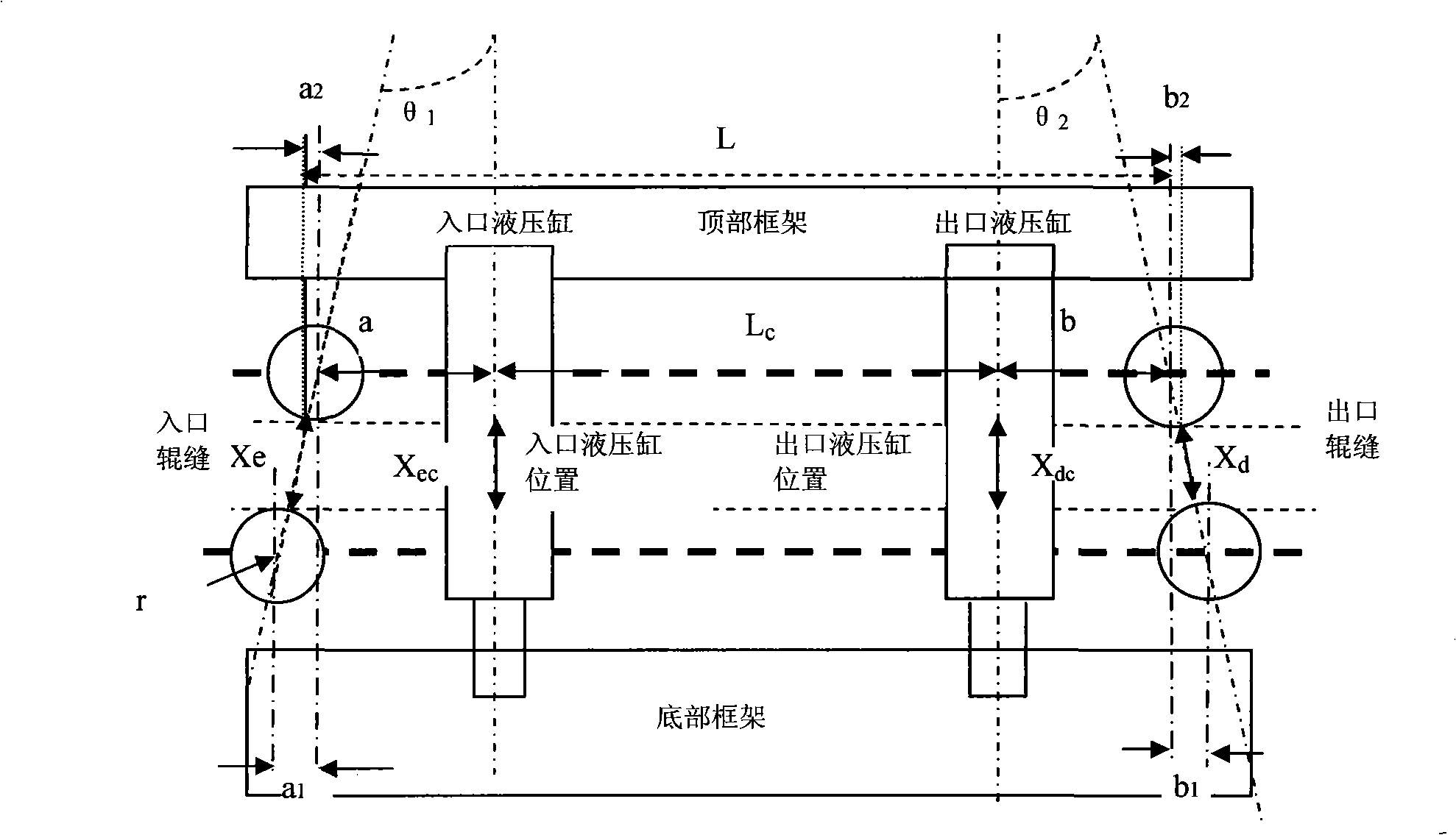

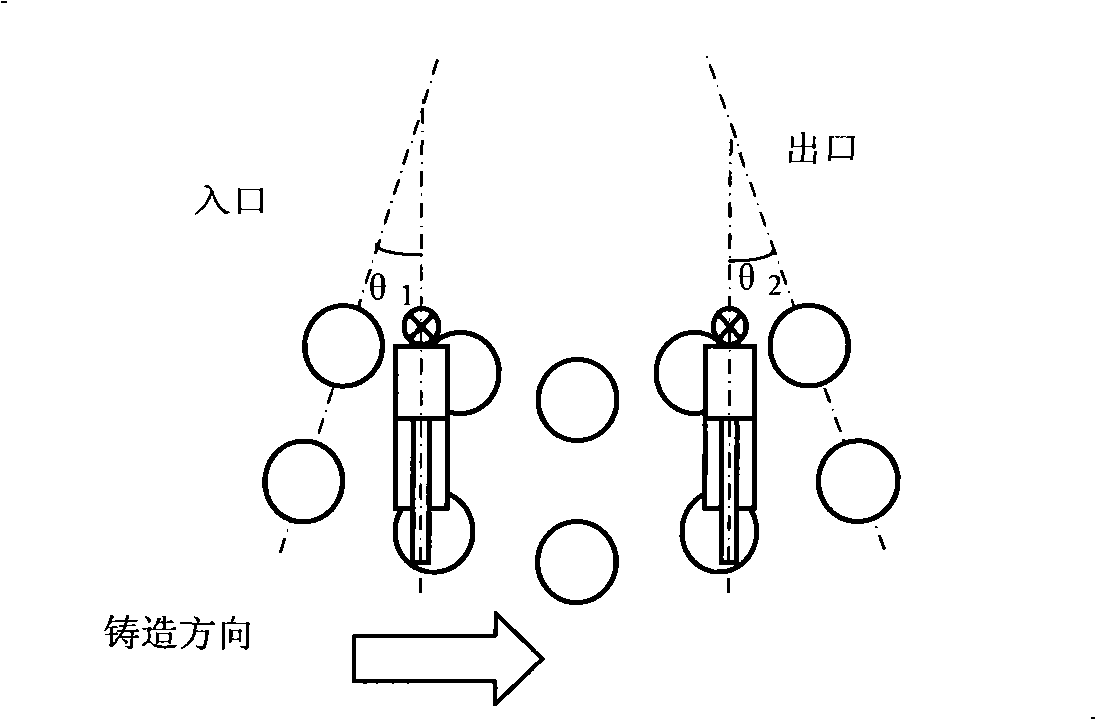

Method for controlling roll gap of roller in segment soft reduction control technology

InactiveCN101327516AFor precise controlMeet the general requirementsMetal rolling arrangementsHydraulic cylinderPunching

The invention discloses a control method of roll gap punching in sector segment slight press control technique, which includes the following steps: (1) the target gap values of the rolls at the inlet and the outlet sides of the sector segment are set; (2) the target roll gap values are converted into target hydraulic cylinder position values and transferred to a hydraulic system, wherein, the calculation formula of converting the target roll gap values into target hydraulic cylinder position values is: Xec = {[L-(a+a2)] / L}.Xe.costhelta1+[(a+a2) / L].Xd.costhelta2 Xdc = [(b+b2) / L].Xe.costhelta1+{[L-(b+b2)] / L}.Xd.costhelta2; (3) after receiving the target hydraulic cylinder position values, the hydraulic system controls the stroke of the hydraulic cylinder piston to move the hydraulic cylinder piston to the position indicated by the target hydraulic cylinder position values; (4) the movement of the hydraulic cylinder piston drives the roll to move to achieve the set target roll gap target values, thus achieving the control of the roll gaps. The invention is capable of achieving the precise control of the roll gaps via the hydraulic system.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

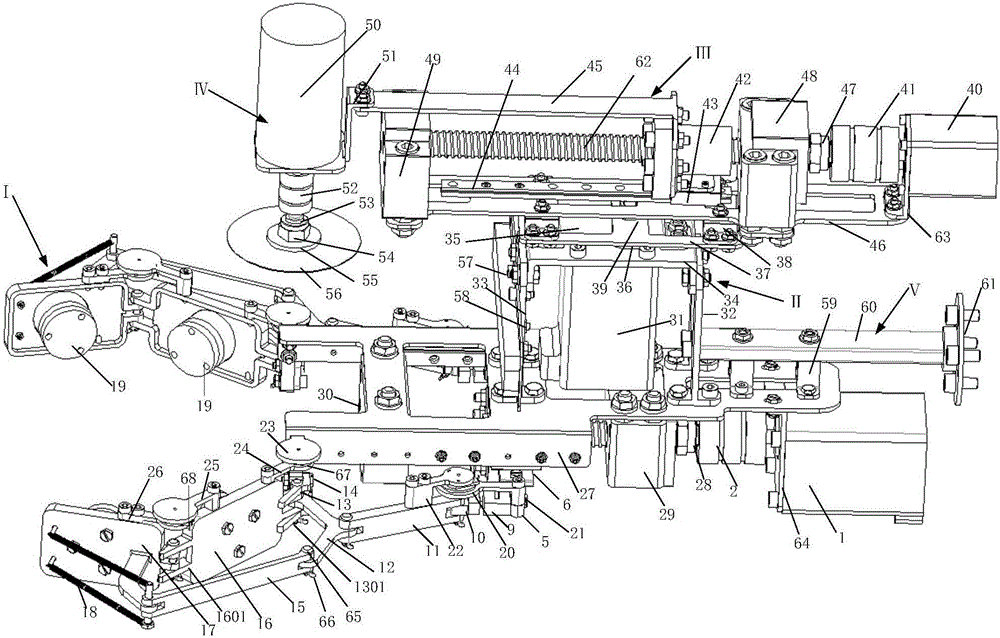

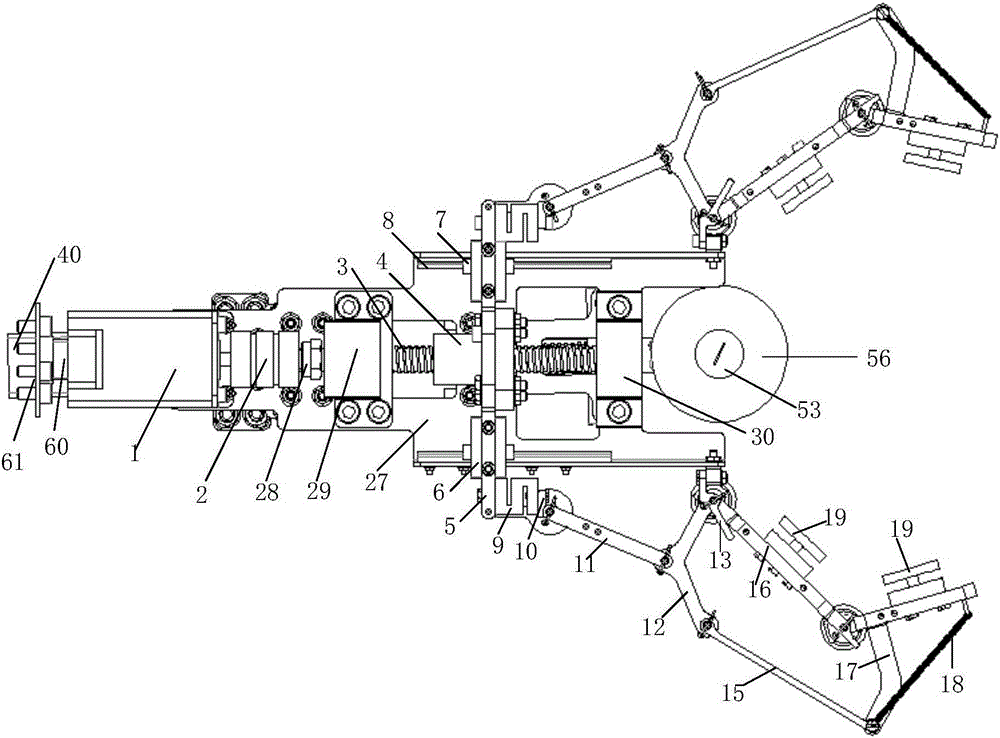

Clamping rotary cutting type underactuated two-finger grape picking device

ActiveCN106342484AWith envelope grabbing functionImprove stabilityPicking devicesCircular discClosed loop

The invention provides a clamping rotary cutting type underactuated two-finger grape picking device, which mainly comprises underactuated finger mechanisms, a rotation mechanism, a pushing mechanism, a rotary cutting mechanism, a wrist connecting mechanism, a main support plate and a binocular camera, wherein the underactuated finger mechanisms are distributed at two sides of the main support plate; the wrist connecting mechanism is connected with the rotation mechanism; the rotation mechanism is connected with the main support plate; the pushing mechanism is connected with the rotation mechanism; the rotary cutting mechanism is connected with the pushing mechanism; the wrist connecting mechanism is connected with the waist of a mechanical arm; a motor A drives the underactuated finger mechanisms to move; through the effects of an S-shaped pressure sensor, a potentiometer, a flat plate pressure sensor and a tension spring, the flexible target object gripping and the closed loop real-time control on the underactuated finger mechanisms by a controller are realized; the rotary cutting mechanism controls a circular disc cutter blade to realize rotary cutting action on target fruit stems through a direct current motor. The grape picking device has the advantages that the structure is ingenious; the flexibility is high; the finger pose work space is large; high picking success rate can be obtained; the mechanical damage to plants and fruits can be reduced; the picking on clustered fruits such as grapes can be realized; the characteristics of self-adaption capability to the fruit shape and contact force controllability are realized.

Owner:JIANGSU UNIV

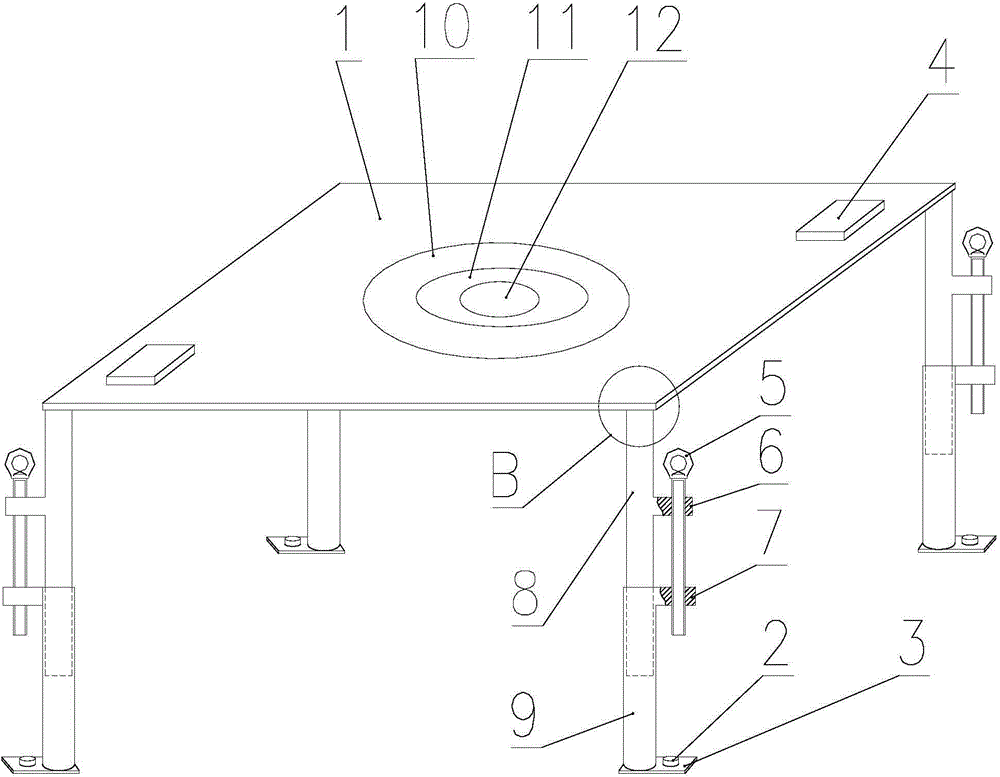

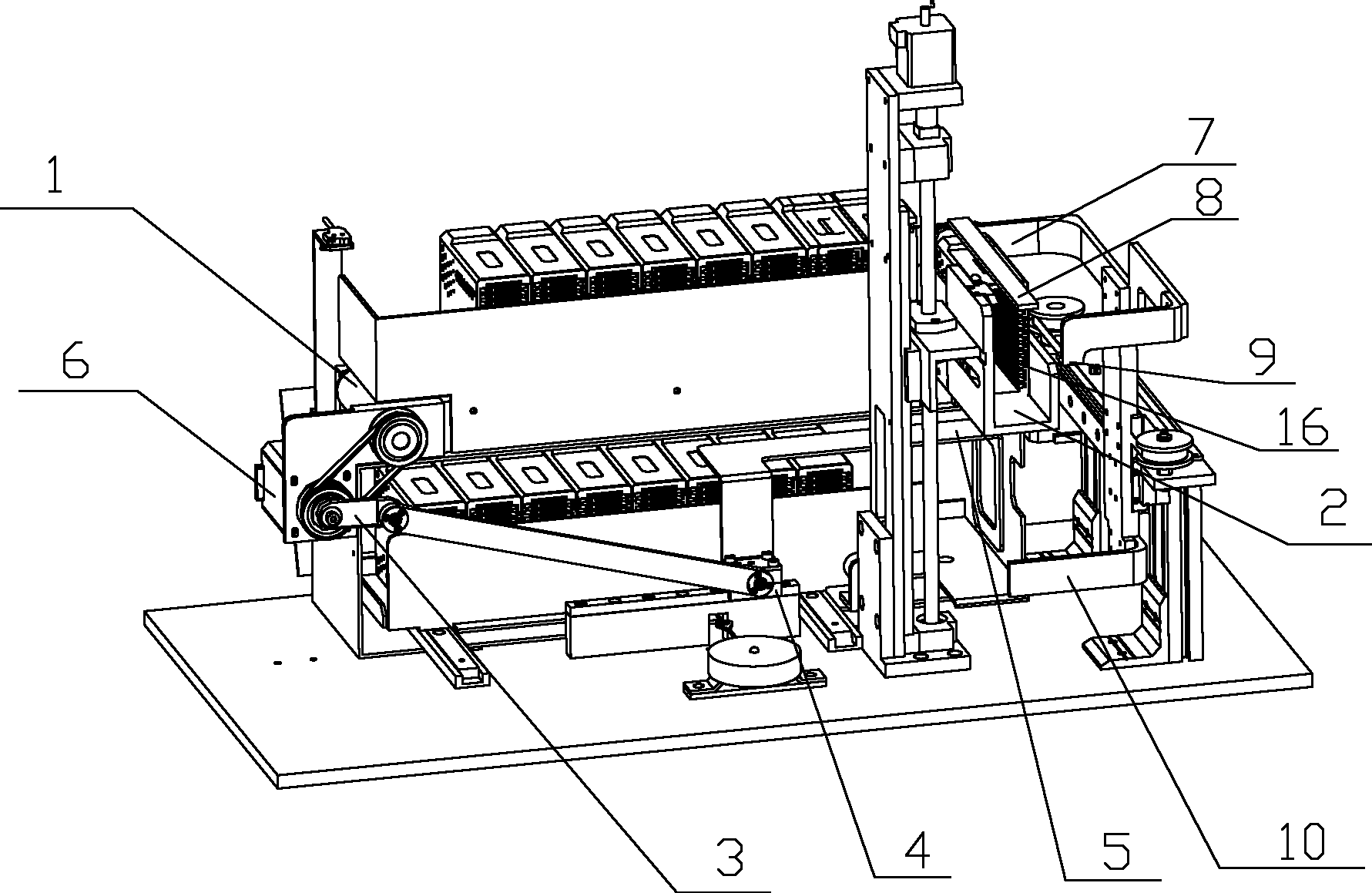

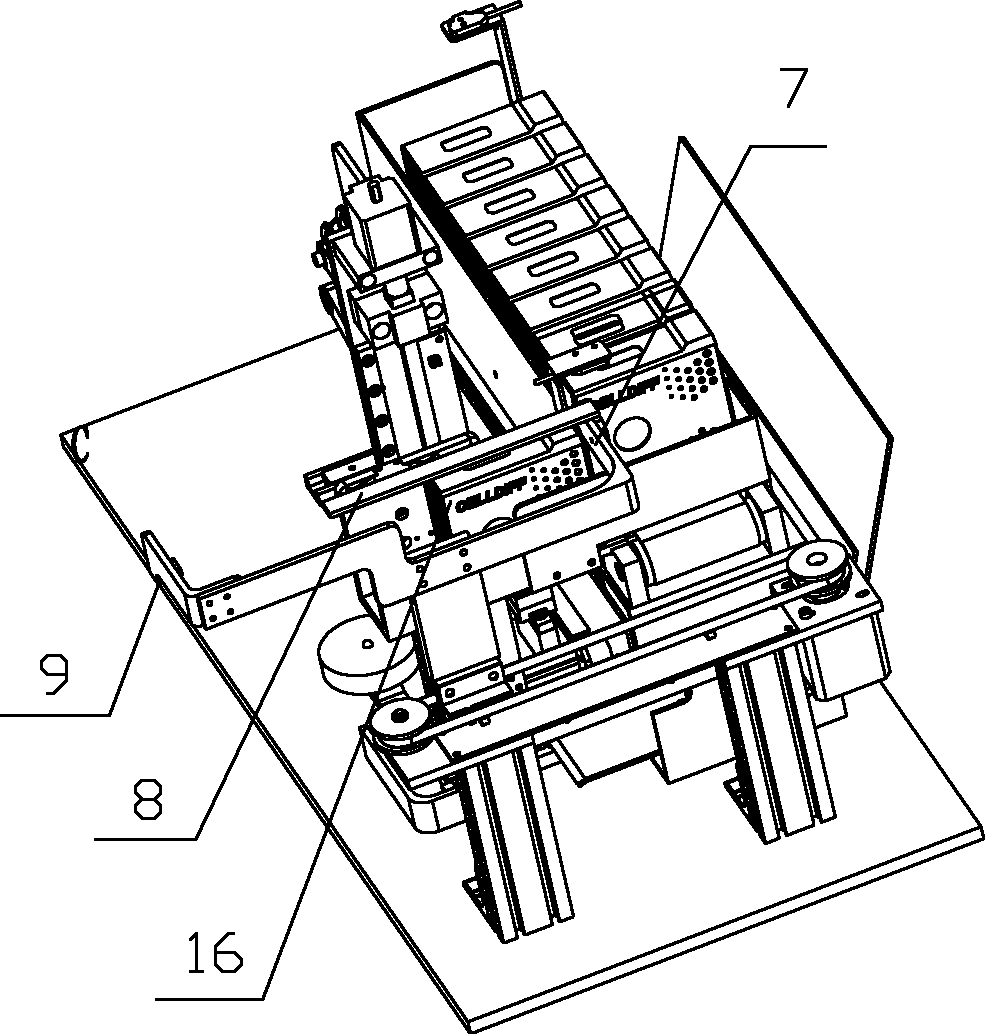

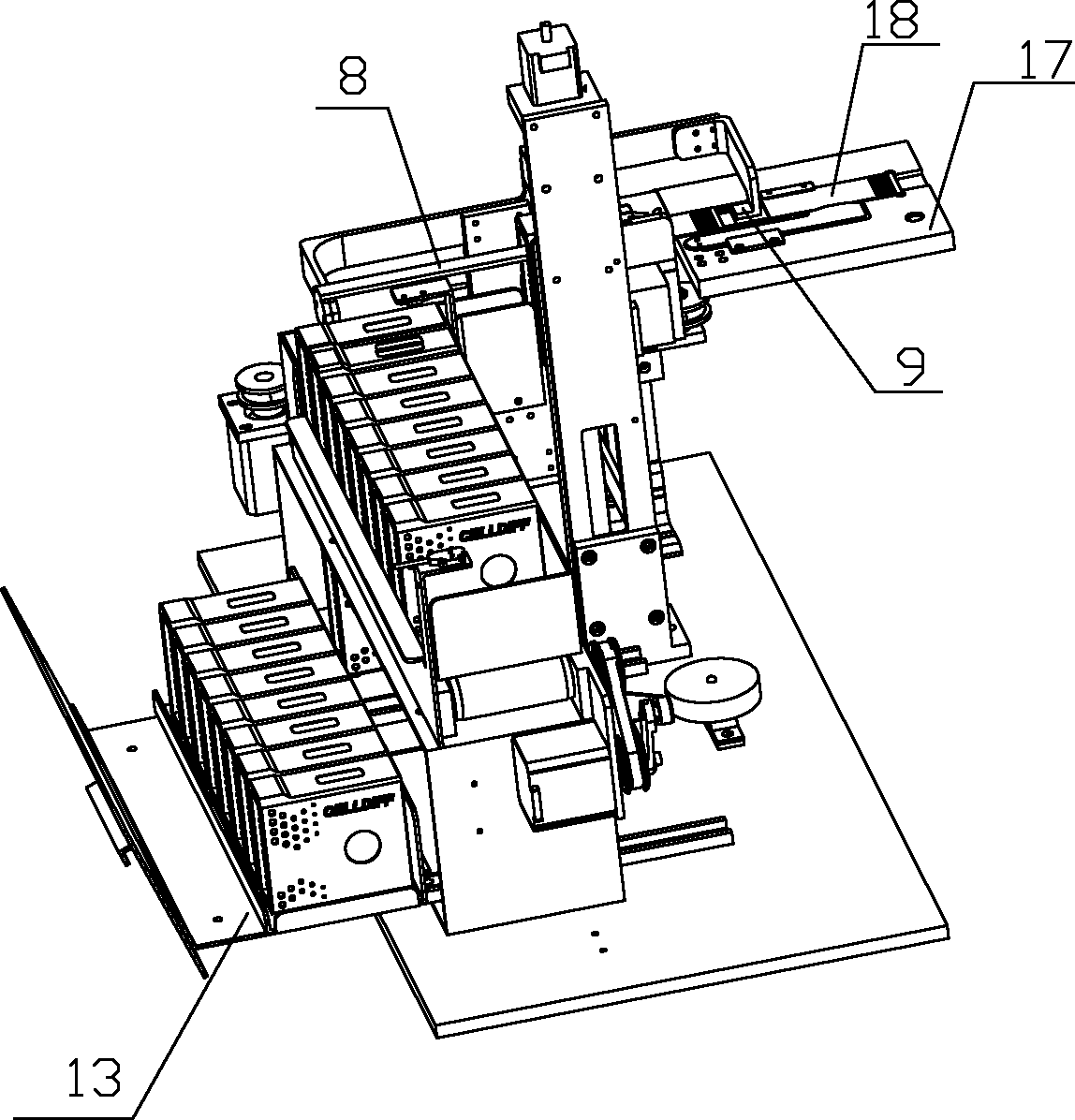

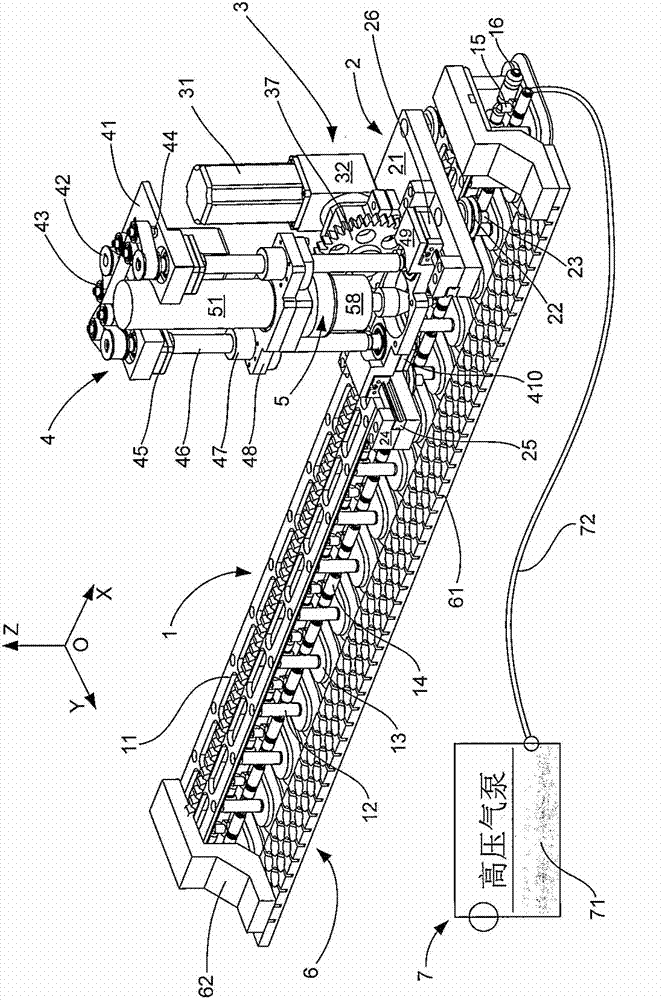

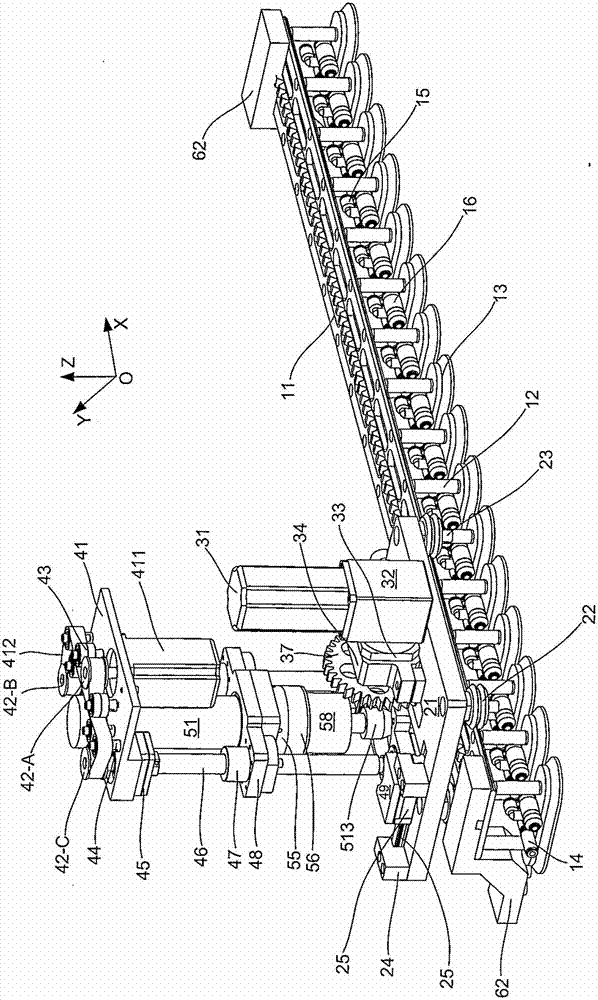

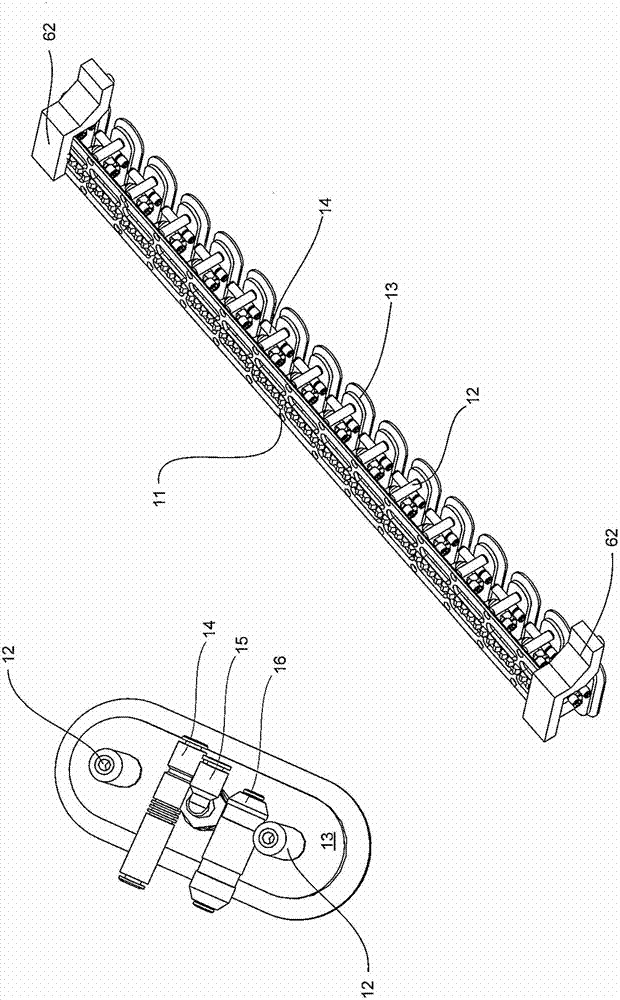

Full automatic conveying device suitable for batch microscopic examination of glass slides

ActiveCN102338807AClosely connectedFit closelyMaterial analysis by optical meansAutomatic controlMicroscopic exam

The invention provides a full automatic conveying device suitable for batch microscopic examination of glass slides. The full automatic conveying device consists of the following sub-systems: a vertical conveying system, a synchronous belt piece-pushing and box-pushing system, a crank sliding block conveying hook box system and a slide box in-out bin system. Three stepping motors are used for providing motive power, wherein the crank sliding block conveying hook box system and the slide box in-out bin system share one stepping motor. A variety of transmission modes such as a synchronous belt mode, a feed screw nut mode and a crank sliding block mechanism mode are used. The structures of all parts of the full automatic conveying device suitable for the batch microscopic examination of the glass slides are closely linked and matched with one another to ensure that the automatic control of the device is very convenient and accurate, and the working efficiency is improved.

Owner:NANJING LIVINGCHIP BIOTECHNOLOGY CO LTD

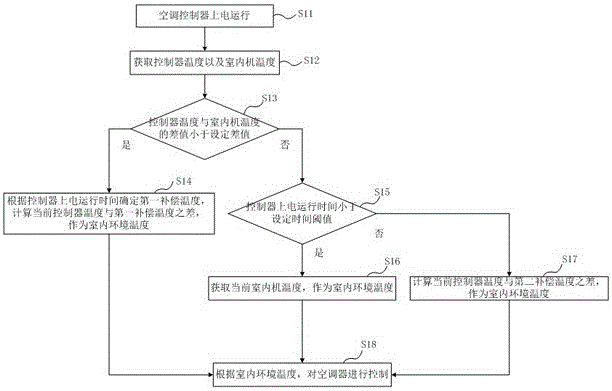

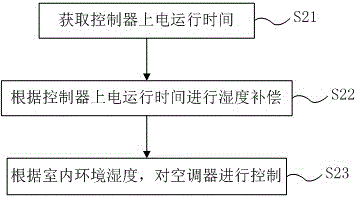

Air conditioner indoor environment temperature and humidity compensation method

ActiveCN106524398AImprove user experienceFor precise controlMechanical apparatusSpace heating and ventilation safety systemsElectricitySetting time

The invention discloses an air conditioner indoor environment temperature and humidity compensation method. The method comprises the steps that an air conditioner controller is powered on to run, and the controller temperature and the indoor unit temperature are obtained; whether the difference value of the controller temperature and the indoor unit temperature is smaller than a set difference value or not is judged; if yes, the first compensation temperature is determined according to the controller powered-on running time, and the difference of the current controller temperature and the first compensation temperature is calculated as the indoor environment temperature; if not, whether the controller powered-on running time is smaller than a set time threshold value or not is judged; if yes, the current indoor unit temperature is obtained as the indoor environment temperature; and if not, the difference of the current controller temperature and the second compensation temperature is calculated as the indoor environment temperature. According to the air conditioner indoor environment temperature and humidity compensation method, by means of compensation for the temperature and the humidity, the accuracy of the obtained indoor environment temperature and indoor environment humidity is improved, so that an air conditioner is accurately controlled, user experience is improved, and the market competitiveness of the air conditioner is improved.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD

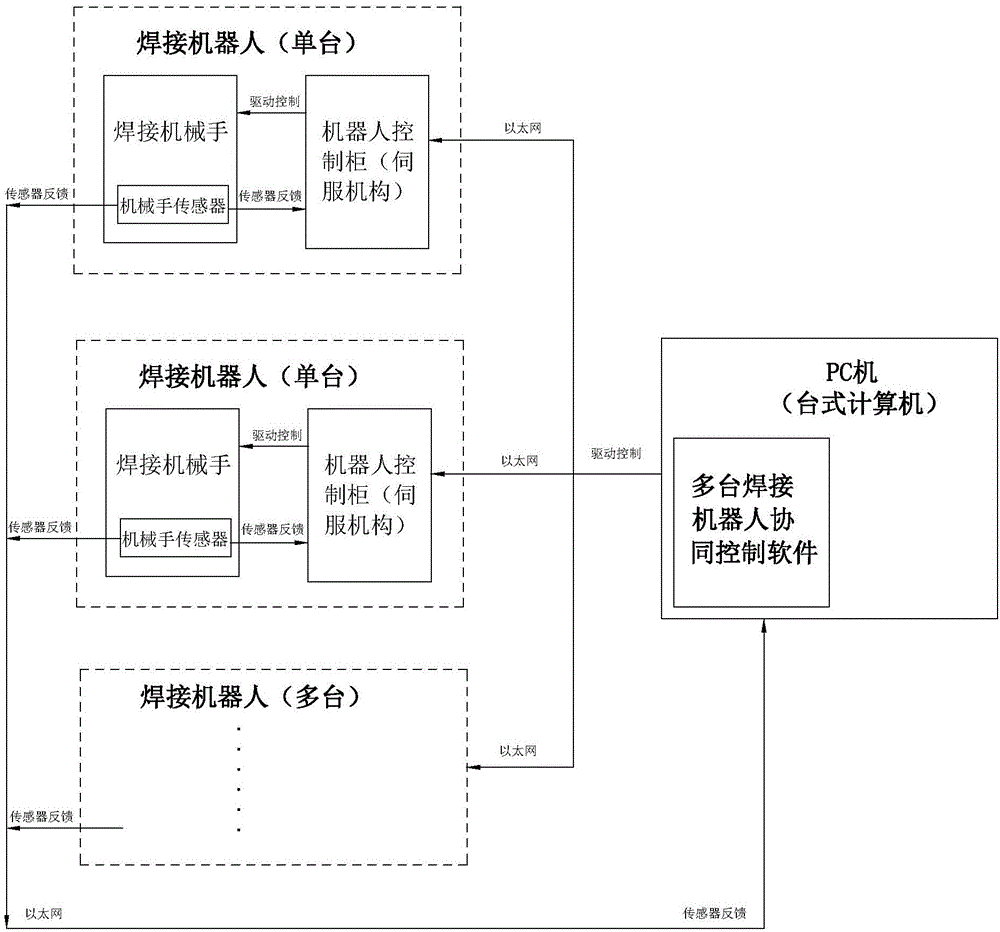

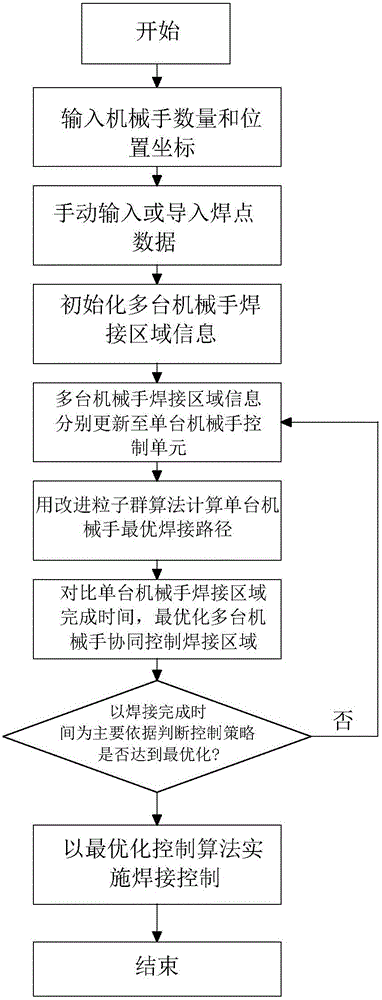

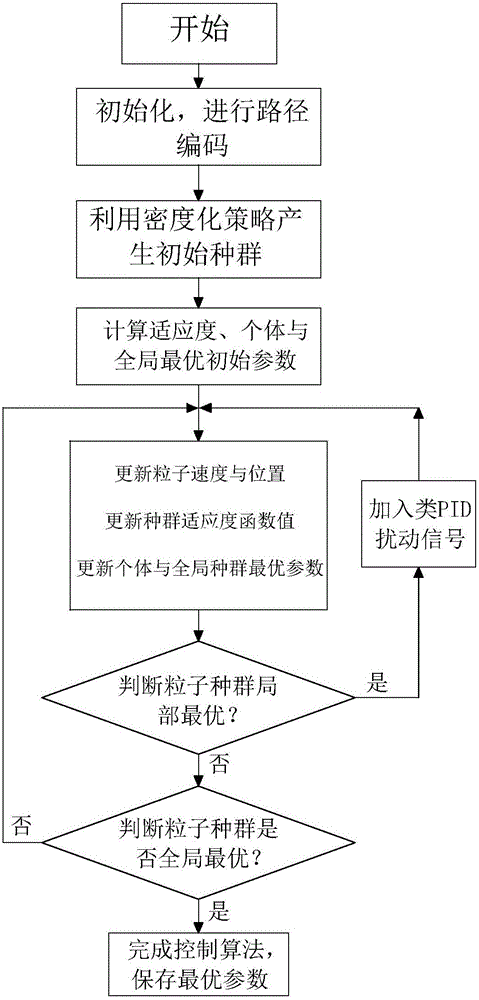

Cooperative control system for multiple welding robots based on improved particle swarm algorithm

ActiveCN105033520AAchieve continuous controlRealize regulationWelding/cutting auxillary devicesAuxillary welding devicesControl systemClosed loop

The invention discloses a cooperative control system for multiple welding robots based on an improved particle swarm algorithm, and relates to the technical field of automatic welding control over robots. The cooperative control system comprises a PC with cooperative control software installed and the multiple welding robots. Each welding robot comprises a manipulator for welding and a robot control cabinet used for driving the manipulator to work, wherein the manipulator is provided with a manipulator sensor used for sensing the position of the manipulator. The output end of the PC is connected with the robot control cabinet of each welding robot through the Ethernet. The manipulator sensor of each welding robot is connected with the corresponding robot control cabinet through a signal cable and further connected with the input end of the PC through the Ethernet. The welding robots adopt a double-closed-loop control strategy, and the welding motions and positions of the manipulators are fed back to a welding robot controller and the PC simultaneously through the sensors, so that the correctness of position information and the best welding route planning control are realized.

Owner:广西翰林辅教育管理有限公司

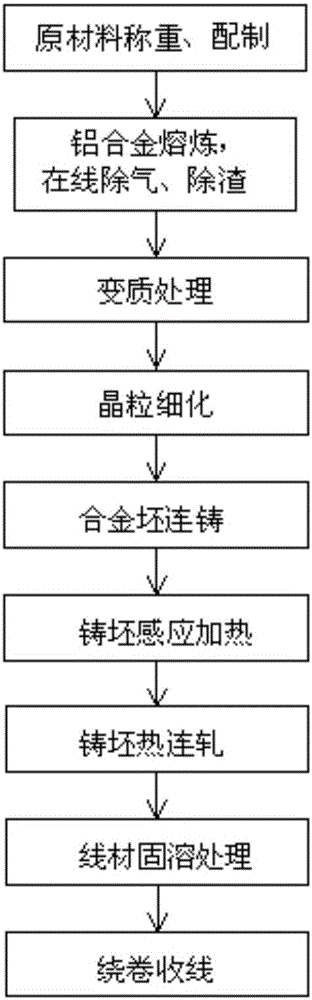

Continuous casting and rolling method for ZL114A welding wire rods

InactiveCN106244861AEasy to detectFor precise controlMetal rolling arrangementsWire rodSolution treatment

The invention belongs to the field of technical processes for cast aluminium alloys, and specifically relates to a continuous casting and rolling method for ZL114A welding wire rods. The method comprises the following steps: raw material weighing and preparation; aluminium alloy smelting, and online degassing and deslagging; modification treatment; grain refinement, alloy blank continuous casting; casting blank induction heating; casting blank hot-continuous rolling; wire solution treatment; and wire winding. The method disclosed by the invention overcomes the shortages of the prior art; online detection and accurate control can be realized for the chemical components of the produced aluminium alloy wire blanks; the alloy has a low hydrogen content inside and less inclusion, and is almost free from segregation; welding wires are good in welding manufacturability, and free from splashing and chip falling during a use process; welding arcs are stable; and welded joints have high interior quality and mechanical property.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

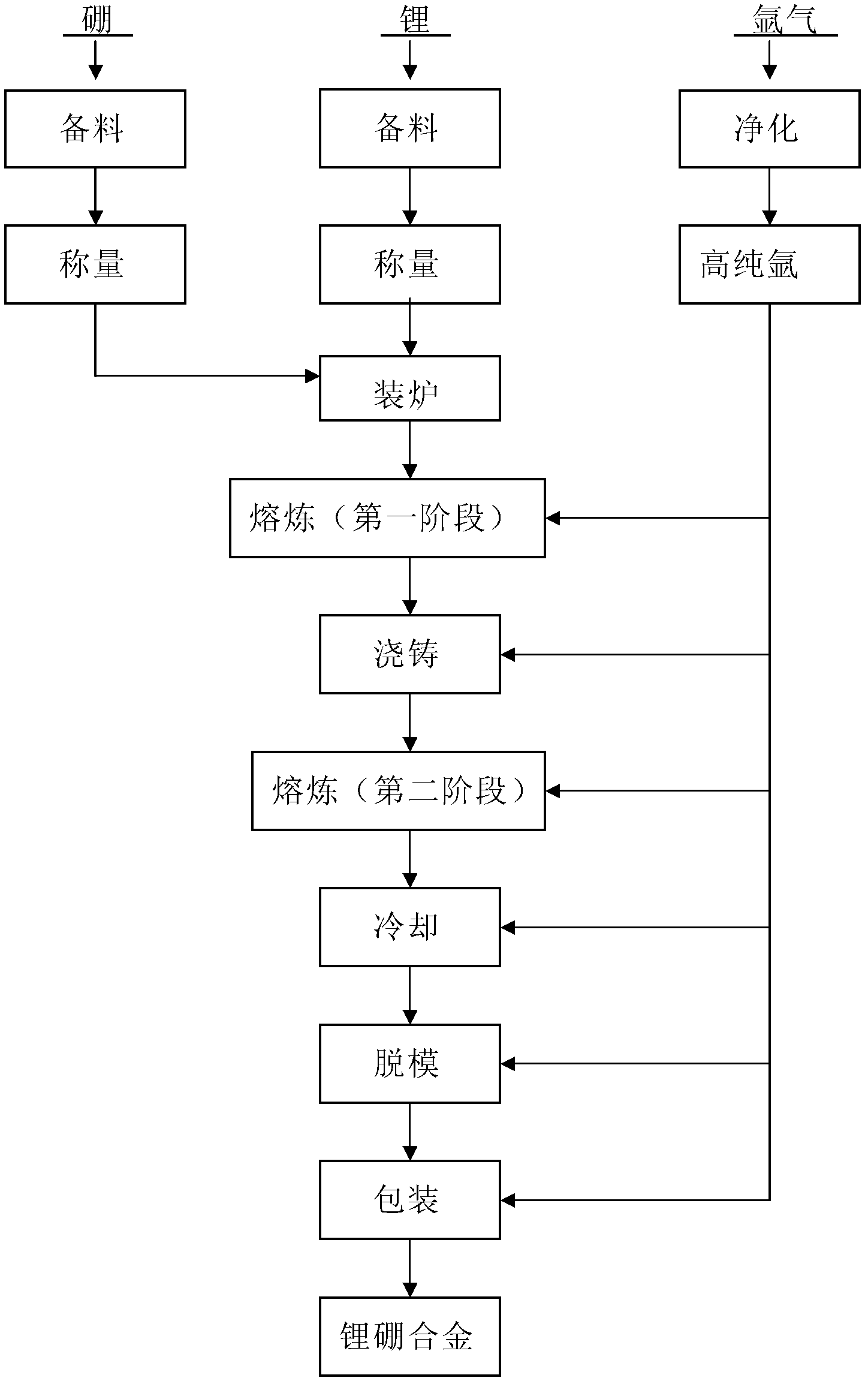

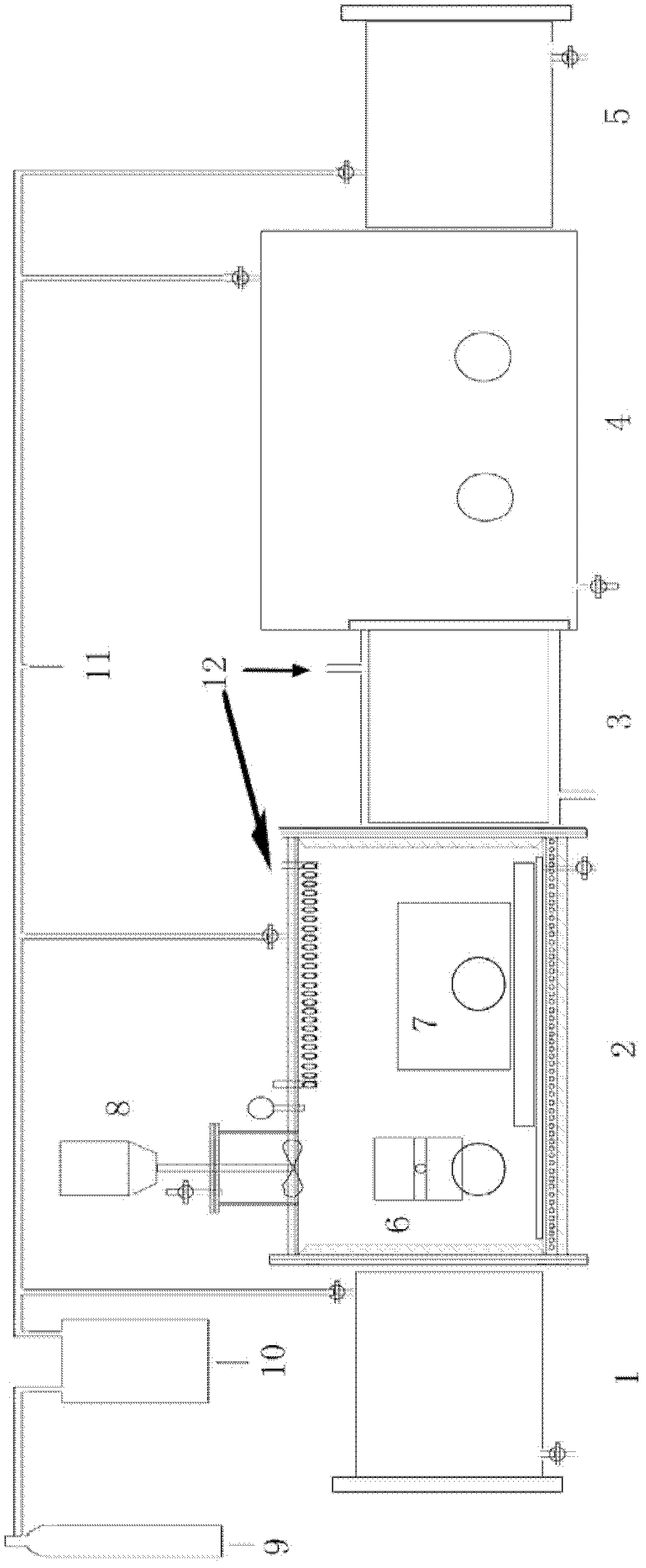

Lithium boron alloy production process, and device thereof

Provided are a lithium boron alloy production process, and device thereof. The process includes mixing lithium and boron, heating to 400 DEG C. under high-purity argon gas atmosphere, stirring and reacting for 2h, heating to 450 DEG C. to form molten alloy, casting into a mold, continuously heating to 650 DEG C., and reacting for 1h till to hardening; and cooling to the alloy billet to room temperature, demolding, and packaging. The device includes a first transition bin, a synthesis box body, a cold well, a glove box and a second transition bin; two adjacent units are in sealed connection and spaced via a sealed bin gate, and each unit is connected with an argon gas purification device, respectively; the synthesis box body is provided with a first heating region and a second heating region, the first heating region is provided with a stirring device, and the heating body thereof can be turned over. By adopting innovative double-heating region staged reaction and synthesis, casting and transport under the protective atmosphere, the process prevents generation of various defects in the synthesis process of the lithium boron alloy, reduces the difficulty of the product subsequent processing and realizes energy saving and yield increase as well.

Owner:北京得瑞科技有限公司

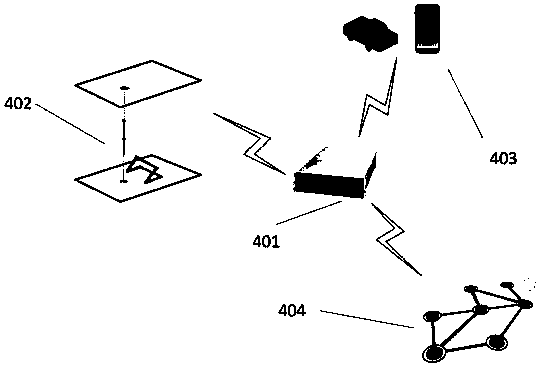

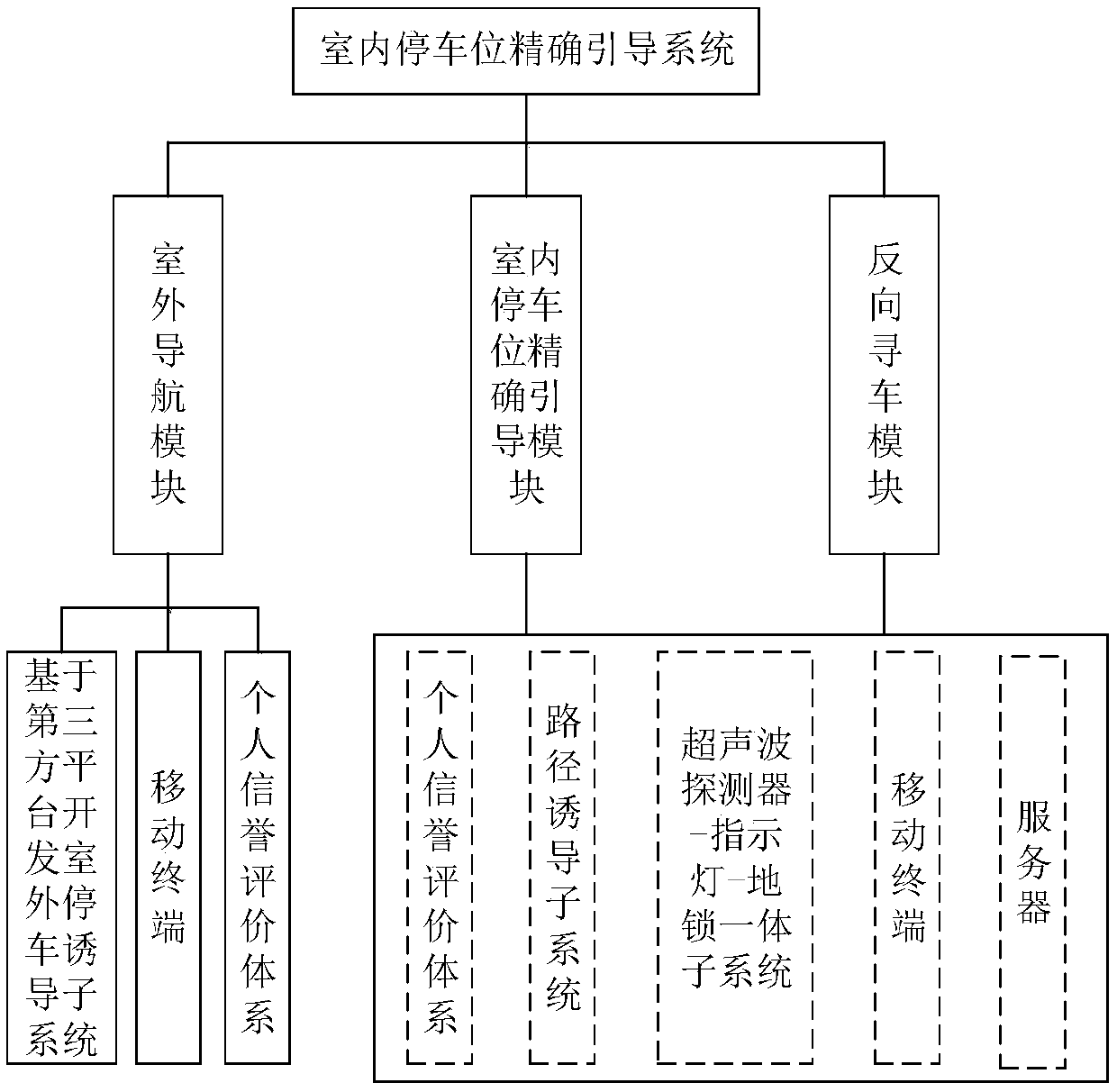

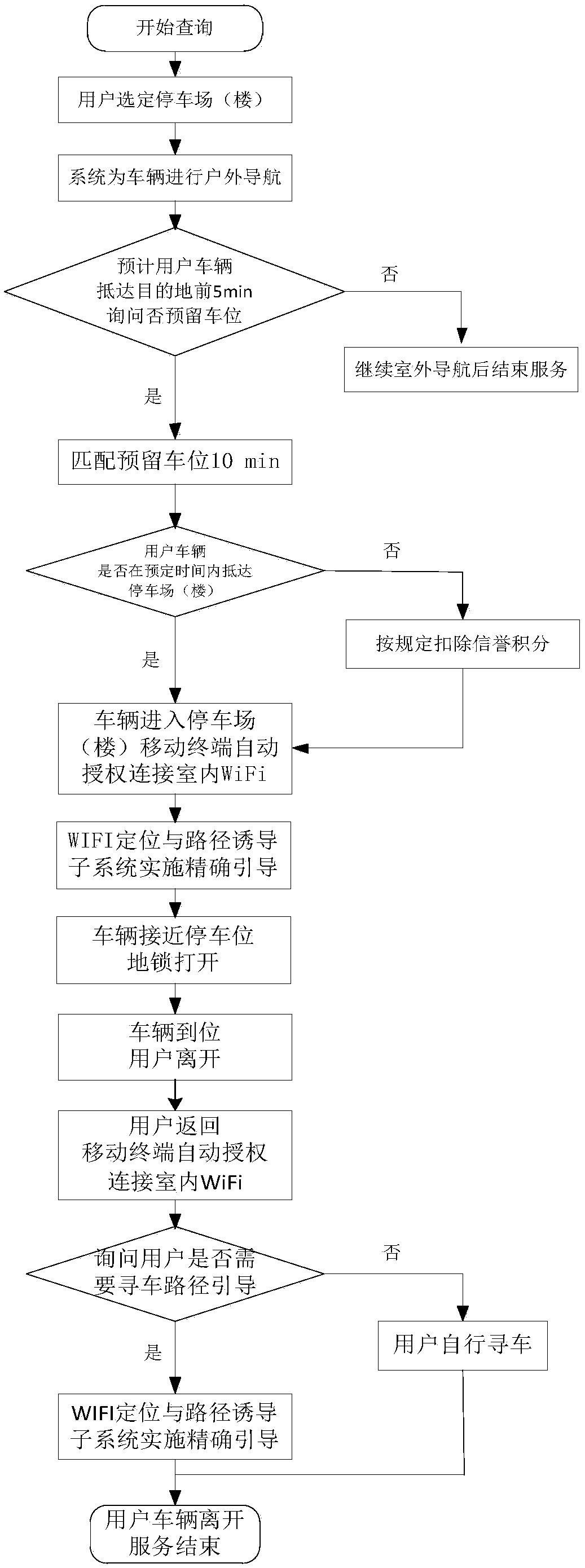

Indoor parking stall accurate guidance system and method based on WiFi

InactiveCN107798911ARealize real-time monitoringFor precise controlIndication of parksing free spacesGuidance systemThird party

The present invention discloses an indoor parking stall accurate guidance system and method based on the WiFi. The system concretely comprises three parts consisting of an outdoor navigation module, an indoor parking stall accurate guidance module and a reverse vehicle tracking module. The outdoor navigation module is achieved mainly based on development of an outdoor parking guidance subsystem and a mobile communication terminal by employing a third-party platform, and a personal reputation evaluation system is added in the system; and the indoor parking stall accurate guidance module and thereverse vehicle tracking module achieve indoor parking stall accurate guidance of a vehicle and reverse vehicle tracking guidance of a user indoor parking stall by mainly employing WIFI location, a route guidance subsystem, an ultrasonic wave-indicating lamp-parking lock integration subsystem, the mobile communication terminal and a server. The indoor parking stall accurate guidance system and method based on the WiFi combine outdoor navigation and indoor parking stall accurate guidance, and therefore, the management level of parking facilities is improved and full utilization of parking resources is promoted to facilitate alleviate road traffic congestion.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

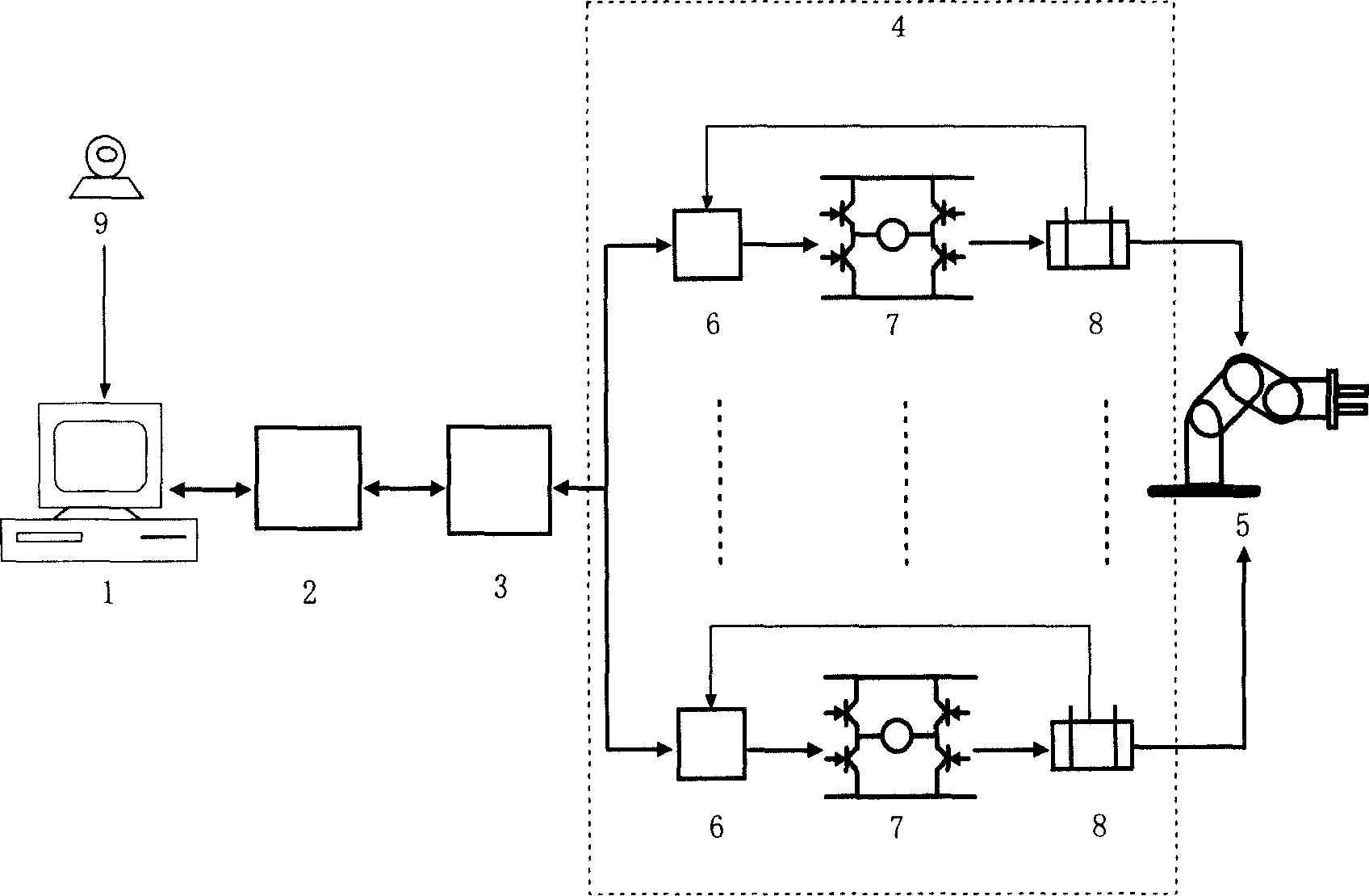

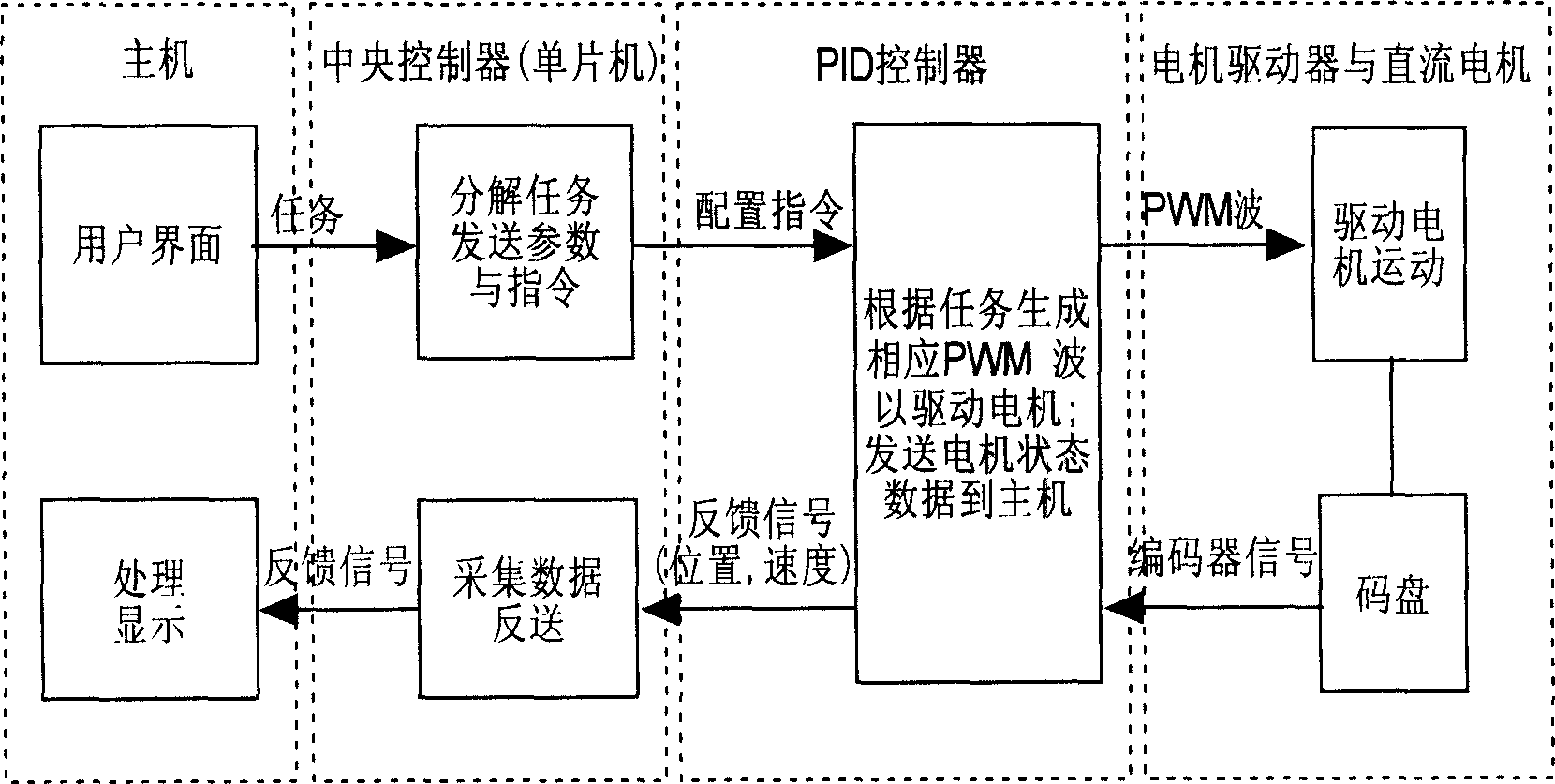

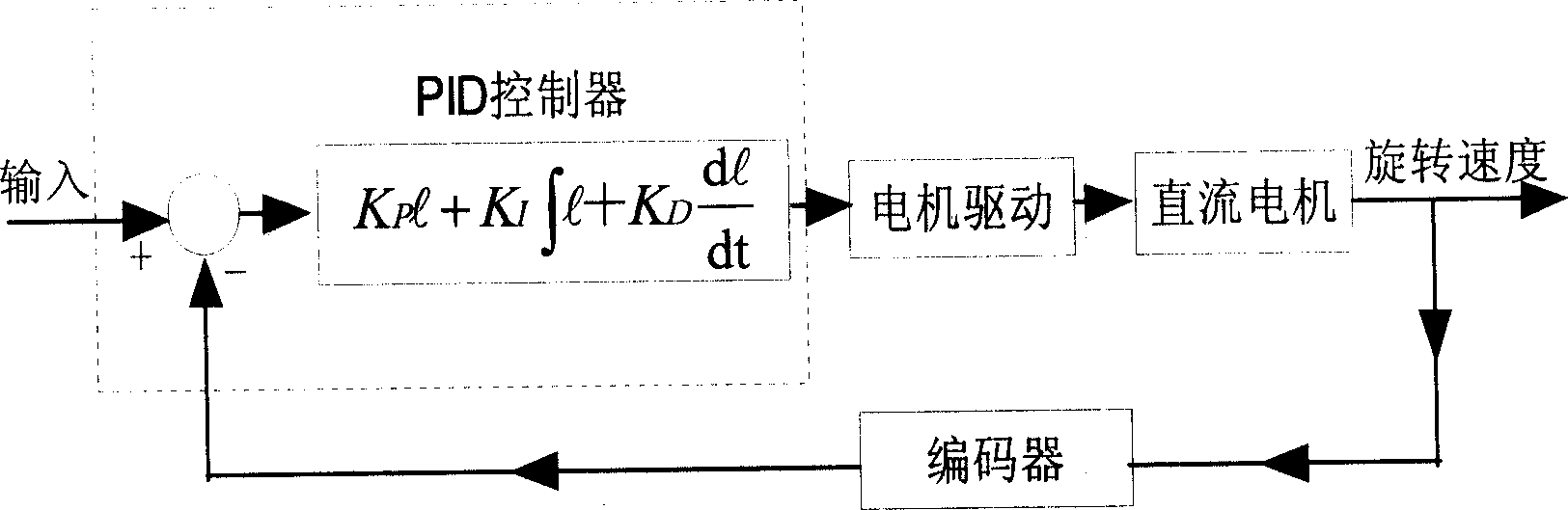

Plug-and-play mechanical arm system based on distributive control

The plug-and-play mechanical arm system based on distributive control in robotic technology includes system unit, USB interface module, central controller, internal distributive control system and mechanical arm. The system unit is connected via a USB cable with USB interface module, and the central controller is located between the USB interface module and the internal distributive control system, which are connected to the central controller via parallel bus. The internal distributive control system consists of several parallel subsystems with the same functions, and each of the subsystems includes one PID controller, one DC motor driver and one DC motor with feedback; and connected via control lines to the mechanical arm. The present invention provides complete interface and control scheme for the popular future robot.

Owner:SHANGHAI JIAO TONG UNIV

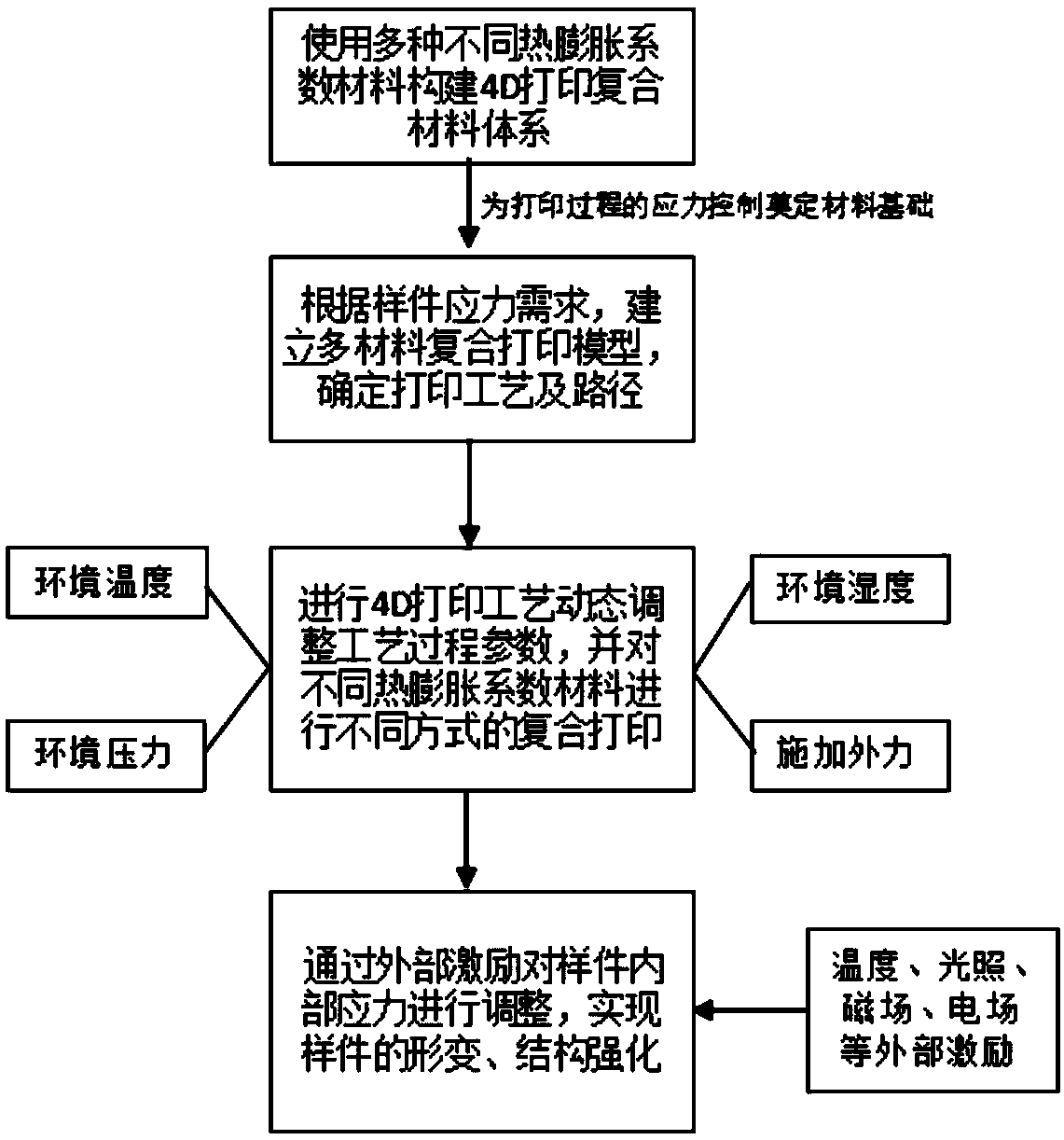

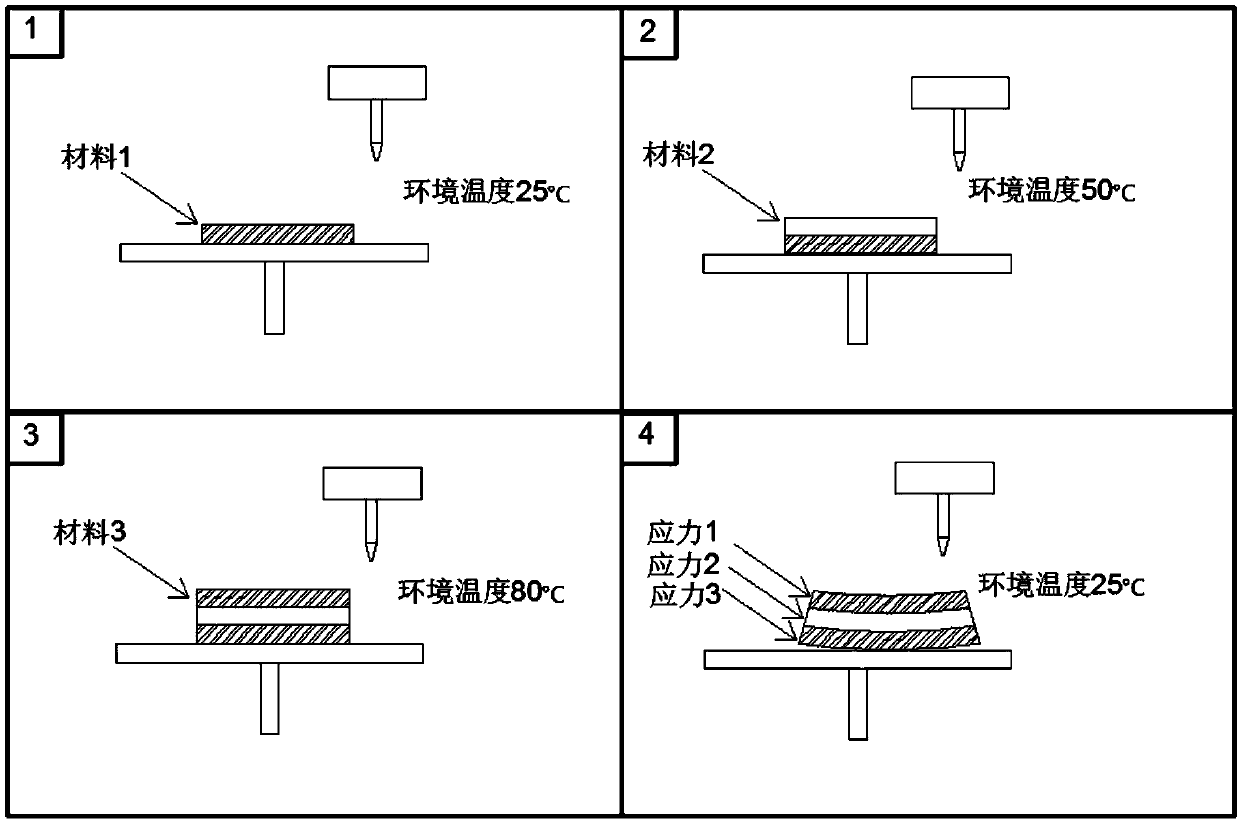

4D printing process method capable of presetting internal stress

ActiveCN109094004ARealize energy accumulationAchieve stressAdditive manufacturing apparatusAdditive manufacturing processesDistribution controlThermal expansion

The invention discloses a 4D printing process method capable of presetting internal stress. Different grades of thermal expansion coefficient materials are used to construct a composite system, so that different thermal expansion coefficient materials change with temperature environment and the like during processing to produce different degrees of strain an stress; a 3D printed additive manufacturing process or a 3D printing process and traditional processing manner mixed process is used for preparing samples; energy accumulation and internal stress distribution control of different spatial position materials are realized through ordered and controllable change of material composition manner, external environment and printing process parameters. The 4D printed composite system constructedthrough composition printing of multiple materials lays a material foundation for stress control during printing, and accurate control of stress, strain and deformation of samples during printing arerealized under the control of multiple factors such as material distribution, process parameters and environment parameters in the printing process.

Owner:XI AN JIAOTONG UNIV

Hard alloy, and preparation method and application thereof

The invention provides a hard alloy which comprises 6.0-13.2 wt% of cobalt and 86.3-93.5 wt% of tungsten carbide (WC). The average grain size of the hard alloy is 0.6-1.0 mu m, the structure is uniform, the hardness is HRA91.5-93.0, the bending strength is 3000-4500 MPa, and the fracture toughness value is 9-15 Mpam<1 / 2>. The invention also provides a preparation method of the hard alloy, which comprises the following steps: carrying out ball milling on the raw material WC / Co composite powder for 13-20 hours while stirring to obtain a mixture, pressing, dewaxing and sintering under low pressure. The invention also provides application of the hard alloy in the field of high-pressure and wear-resistant parts, preferably application in the field of synthesis of artificial diamonds.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Single side soft absorption type automatic drilling robot

ActiveCN102765088ARealize processingAchieve protectionManipulatorDrill jigsEngineeringUltrasonic vibration

The invention provides a single side soft absorption type automatic drilling robot which is applicable to operation such as hold drilling, reaming, dimpling and the like at wings and fuselage parts, and the machining for materials which are hard to machine such as titanium alloy (Ti) and composite materials (CPRF) is realized. The robot is fixed at an expected machining area by using a gas source provided by a vacuum generator and by using a vacuum chuck; and a soft track can adapt to different machining curves according to different curvature. The positioning of a drilled hole and the adjustment of the verticality of a drill bit are realized according to a drill plate. A pneumatic main shaft is adopted as the main shaft of the robot; and in combination of an ultrasonic vibration machining technology, the quality and efficiency of the machining are improved; the machining difficulty is reduced; the current detection at a feeding direction can be carried out in real time during the hole making process; and the protection and precise control for the machining process are realized.

Owner:SHANGHAI AIRCRAFT MFG +1

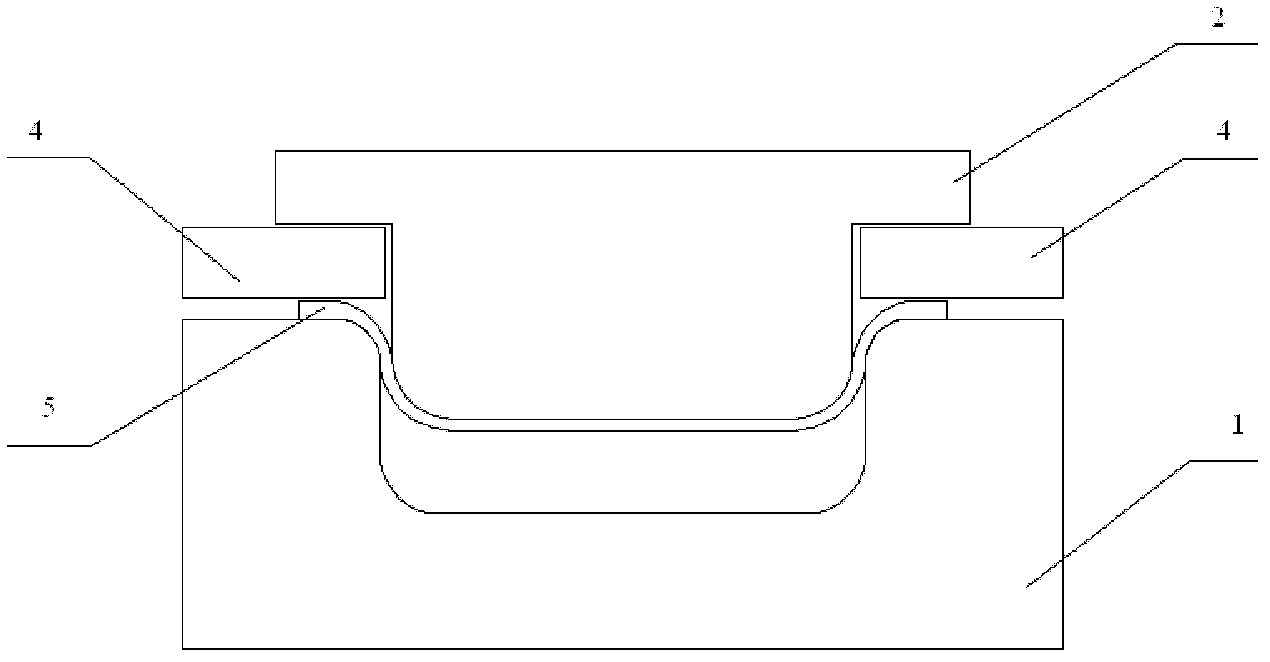

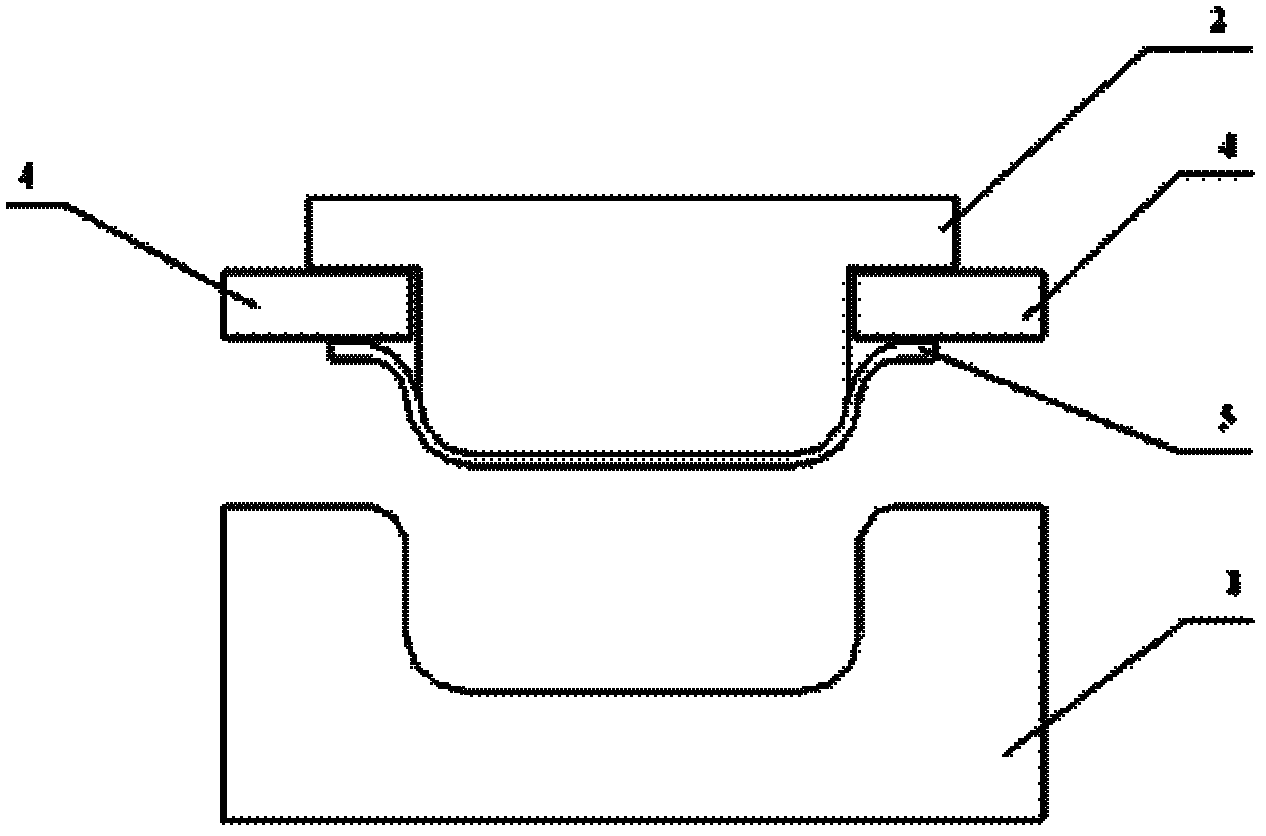

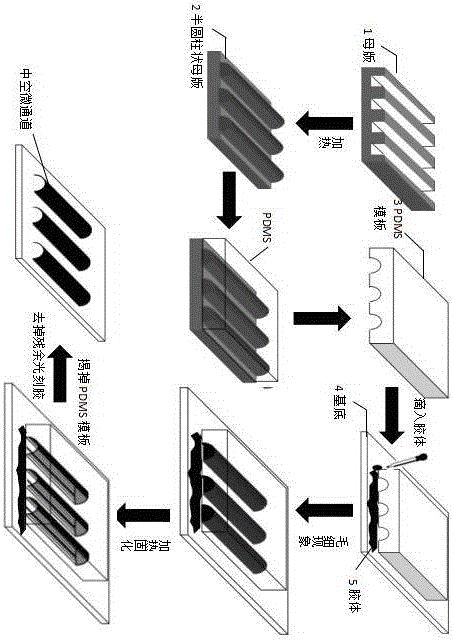

Preparation method of hollow micro-channel structure

ActiveCN107176588AEasy to operateFor precise controlDecorative surface effectsChemical vapor deposition coatingMicro fluidicMicrofluidic chip

The invention discloses a preparation method of a hollow micro-channel structure, and specifically relates to the field of micro machining. The method comprises the following steps: making a micron-sized micro-channel master mask by a photoetching technology and a hot reflux technology; making a PDMS (Polydimethylsiloxane) flexible template by using the master mask, wherein the obtained flexible substrate has a pattern structure complementary to the micro-channel master mask; tightly attaching the PDMS flexible template to the surface of a chip to form a micro-channel cavity; dripping S1813 photoresist on one side; filling the micro-channel cavity with the photoresist under the action of capillary force; heating after filling for a long time, wherein the photoresist in the micro-channel cavity reflows, so that the photoresist in contact with an inner wall of the micro-channel cavity is attached to the inner wall; cooling, curing and removing the PDMS flexible template to obtain the hollow micro-channel structure on the surface of the chip. Compared with other methods for preparing a hollow micro-channel, the preparation method disclosed by the invention has the advantages of low cost, simple process and the like. The preparation method is suitable for the application fields of micro machining, micro-fluidic chips, biomedicine and the like.

Owner:LUDONG UNIVERSITY

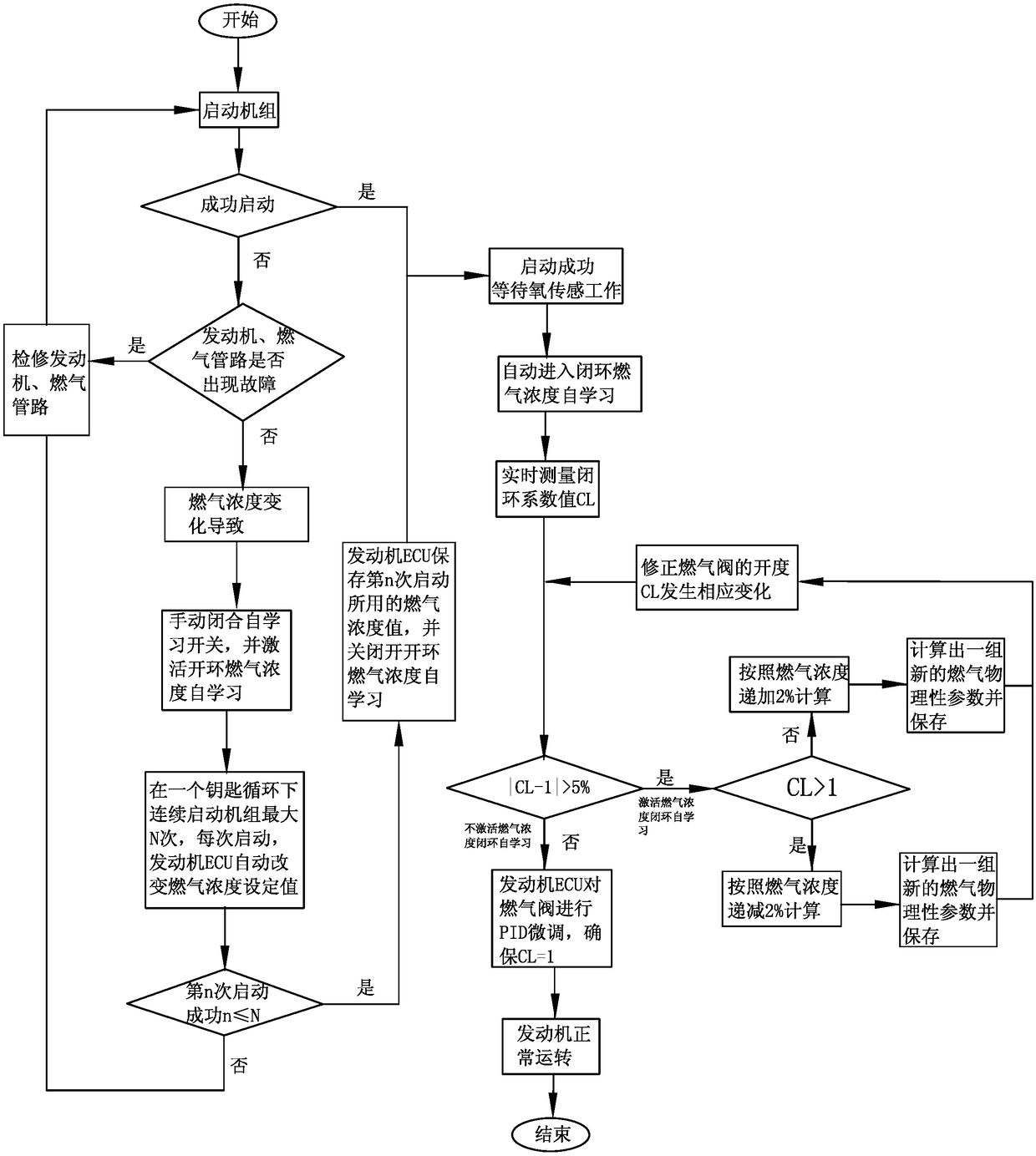

Fuel gas concentration self-adaptive control method for fuel gas generating set

ActiveCN108757194AFor precise controlPrevent knockingElectrical controlInternal combustion piston enginesAutomotive engineeringBiomass

The invention discloses a fuel gas concentration self-adaptive control method for a fuel gas generating set. The fuel gas concentration is the concentration of methane in fuel gas. The method comprises an open-loop fuel gas concentration self-learning starting control step carried out when the fuel gas generating set is not successfully started, wherein an engine ECU performs internal logic fuel gas concentration self-learning to reach the changed fuel gas concentration value, so that the set can be started smoothly; and the method further comprises a closed-loop fuel gas concentration self-learning control step, wherein the engine ECU continuously and finely adjusts the fuel gas methane concentration value repeatedly according to closed-loop data of an oxygen sensor, and finally performsaccurate self-learning to reach the changed fuel gas methane concentration value so that the fuel gas generating set can easily respond to the change of the concentration of the methane in the fuel gas. According to the method, the fuel gas generator set can accurately control the injection amount of a fuel gas valve and the air-fuel ratio better under the condition of fuel gas such as biogas, gasand biomass gas with the methane concentration variable, so that safe and stable operation is realized.

Owner:WEICHAI XIGANG NEW ENERGY POWER

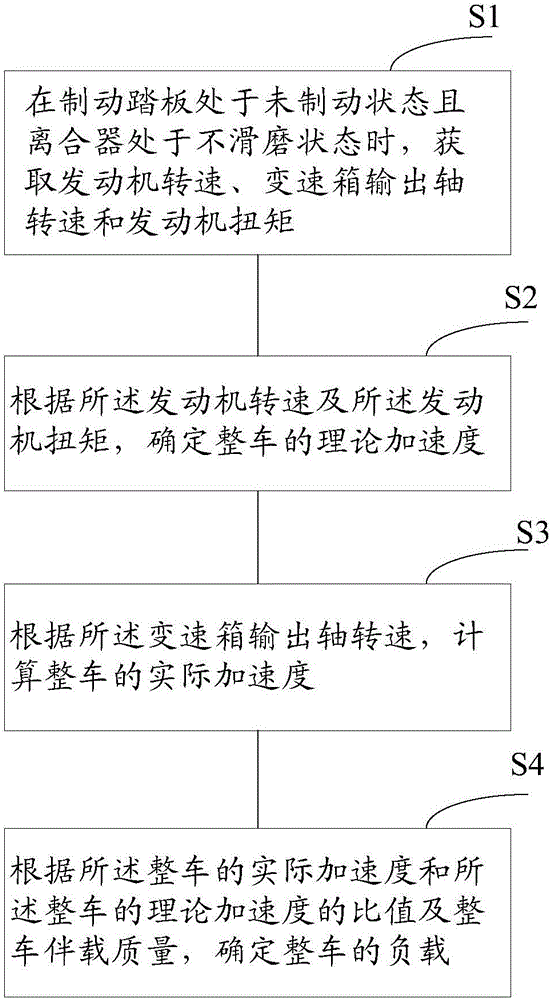

Control method and control system for integral vehicle load computation

ActiveCN106476811AFor precise controlImprove powerGearing controlControl devicesControl systemPower performance

The invention relates to a control method and a control system for integral vehicle load computation. The control method includes: acquiring an engine speed, a rotating speed of an output shaft of a gearbox and engine torque when a brake pedal is not in a braking state and a clutch is in a slipping friction state; determining a theoretical acceleration speed of an integral vehicle according to the engine speed and the engine torque; computing an actual acceleration speed of the integral vehicle according to the rotating speed of the output shaft of the gearbox; determining the load of the integral vehicle according to a ratio of the actual acceleration speed and the theoretical acceleration speed of the integral vehicle and an accompanying mass of the integral vehicle. The control method and the control system solve the problem of inaccuracy in integral vehicle control and are capable of reducing energy waste and improving power performance and economic performance of the integral vehicle.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

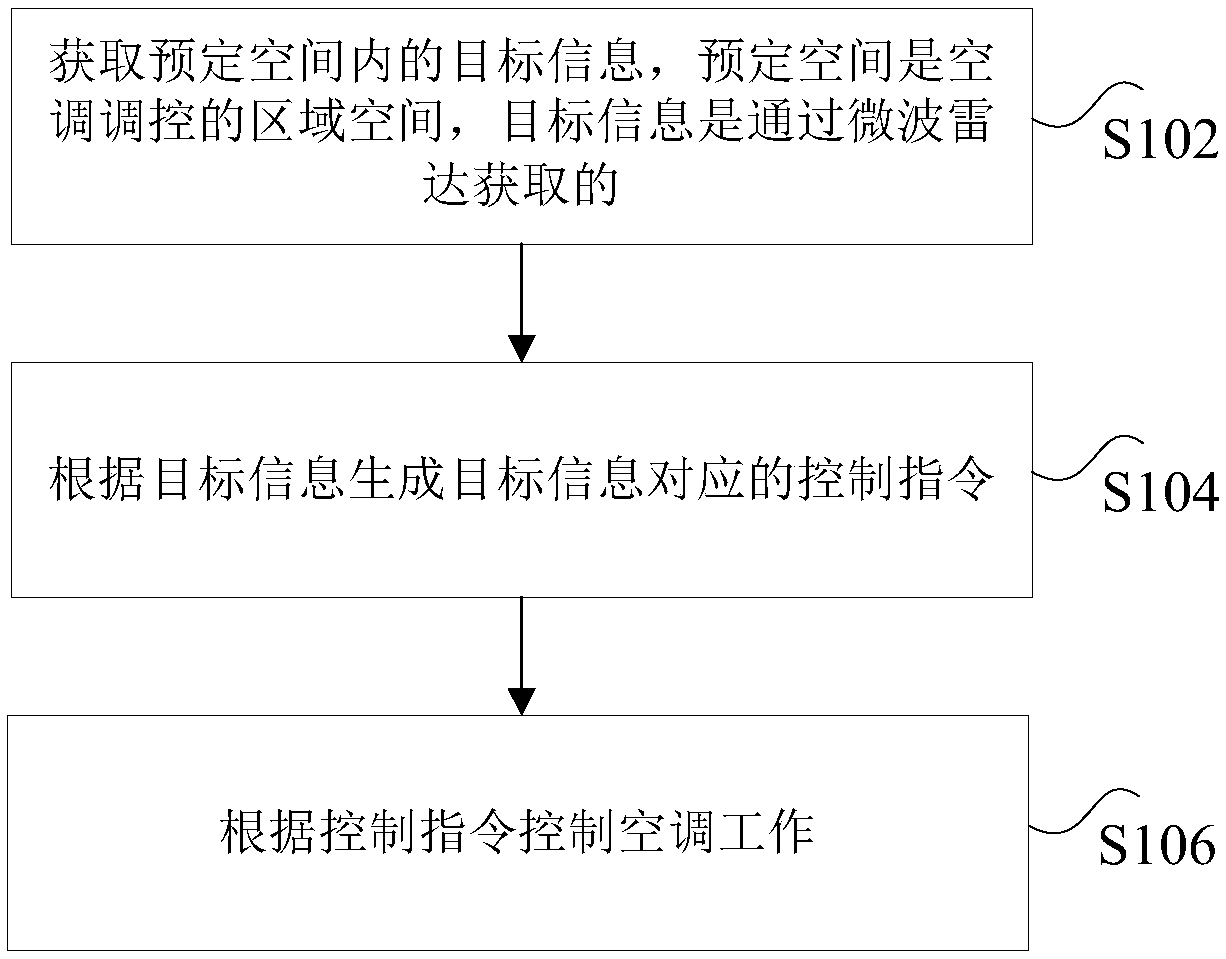

Air conditioner control method and device, storage medium and processor

InactiveCN109631245ARealize intelligent control and precise controlImprove the ability to adapt to complex working environmentsSpace heating and ventilation safety systemsLighting and heating apparatusMicrowave radarUser control

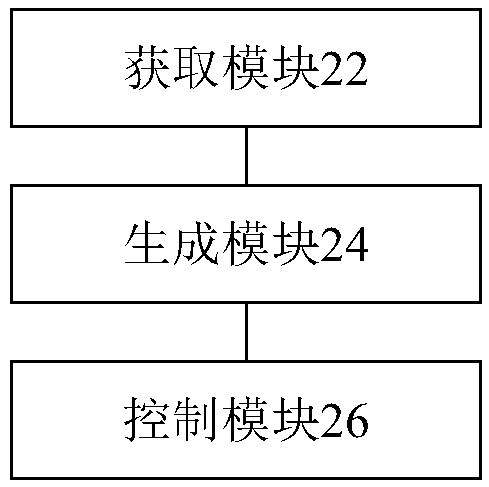

The invention discloses an air conditioner control method and device, a storage medium and a processor. The method comprises the steps that target information in a preset space is acquired, the user preset space is a regional space controlled by an air conditioner, and the user target information is acquired through a microwave radar; a control instruction corresponding to the user target information is generated according to the user target information; and the air conditioner is controlled to work according to the user control instruction. Therefore, the technical problem that in the relatedtechnology, the air conditioner is difficult to adapt to changes of the working environment due to the fact that the air conditioner is manually controlled.

Owner:GREE ELECTRIC APPLIANCES INC

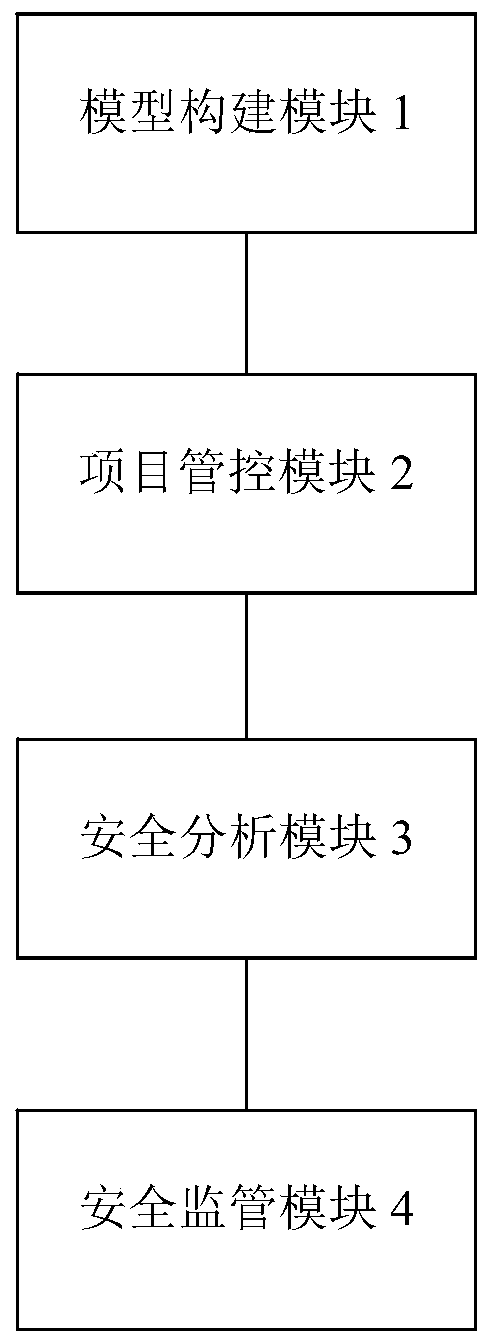

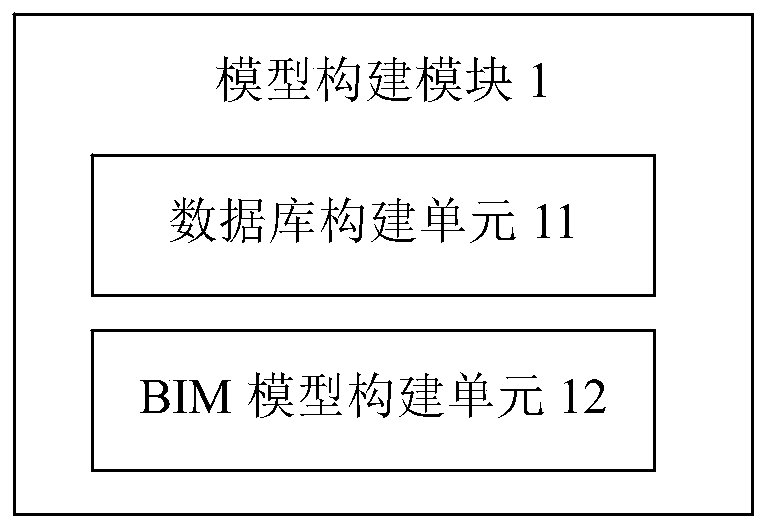

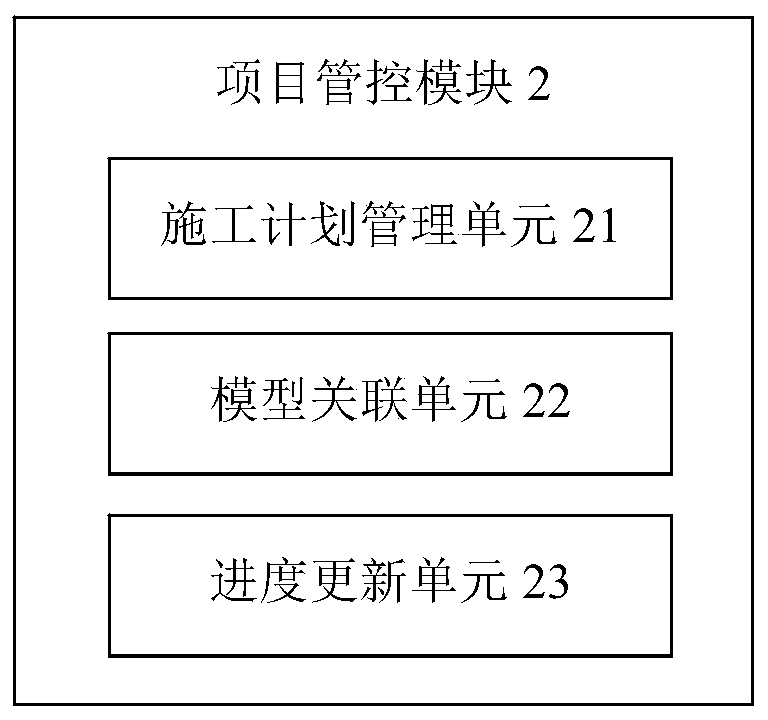

Engineering project intelligent dynamic safety supervision system based on BIM

ActiveCN111507595AImprove the intelligent level of safety risk managementRealize unified managementCharacter and pattern recognitionOffice automationControl systemMarking out

The invention provides an engineering project intelligent dynamic safety supervision system based on BIM, and the system comprises: a model building module which is used for building an engineering project BIM model according to the basic information of an engineering project; a project management and control module which is used for associating the construction progress of the engineering projectwith an engineering project BIM model to form an engineering project 4D BIM model; a safety analysis module which is used for analyzing dangerous large projects in the engineering project 4D BIM model according to the engineering project 4D BIM model and marking corresponding dangerous large project information in the engineering project 4D BIM model; and a safety supervision module which is usedfor monitoring the on-site construction process of the dangerous large project, acquiring on-site safety management information, and performing safety risk assessment and safety risk management according to the on-site safety management information. The intelligent dynamic safety management and control system is helpful for acquiring basic information of a project, analyzing dangerous large projects in the project by combining with the support of a database, and carrying out key safety supervision, analysis and management and control on the dangerous large projects, so that the efficiency ofengineering project safety supervision is improved.

Owner:广州高新工程顾问有限公司

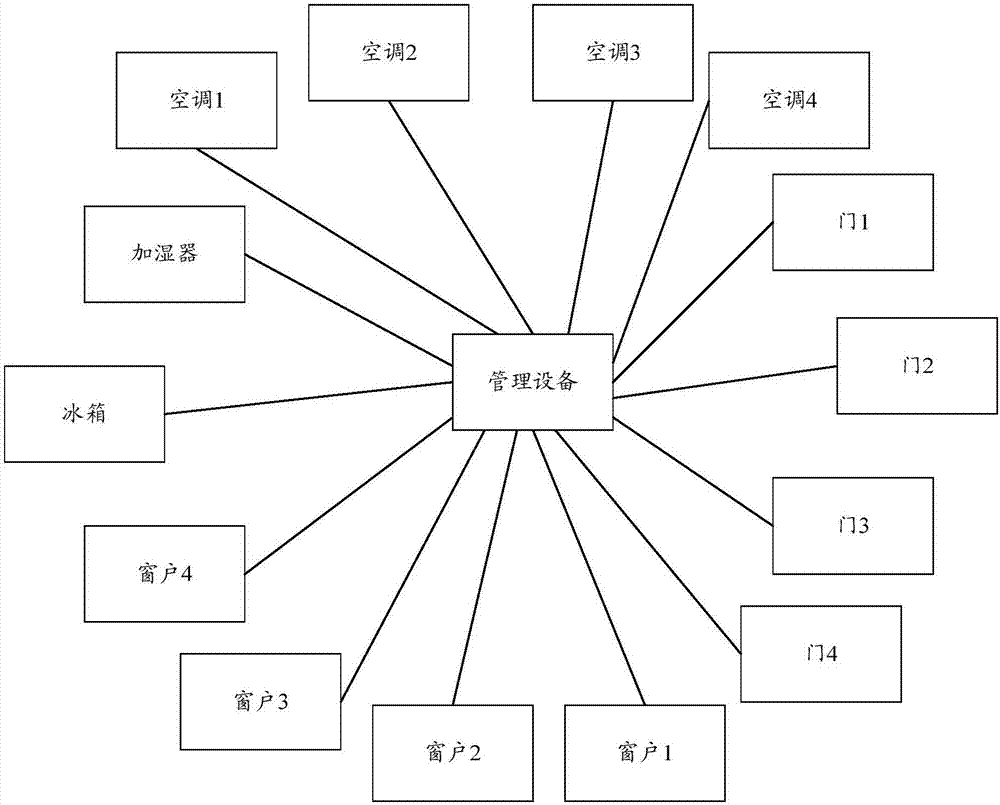

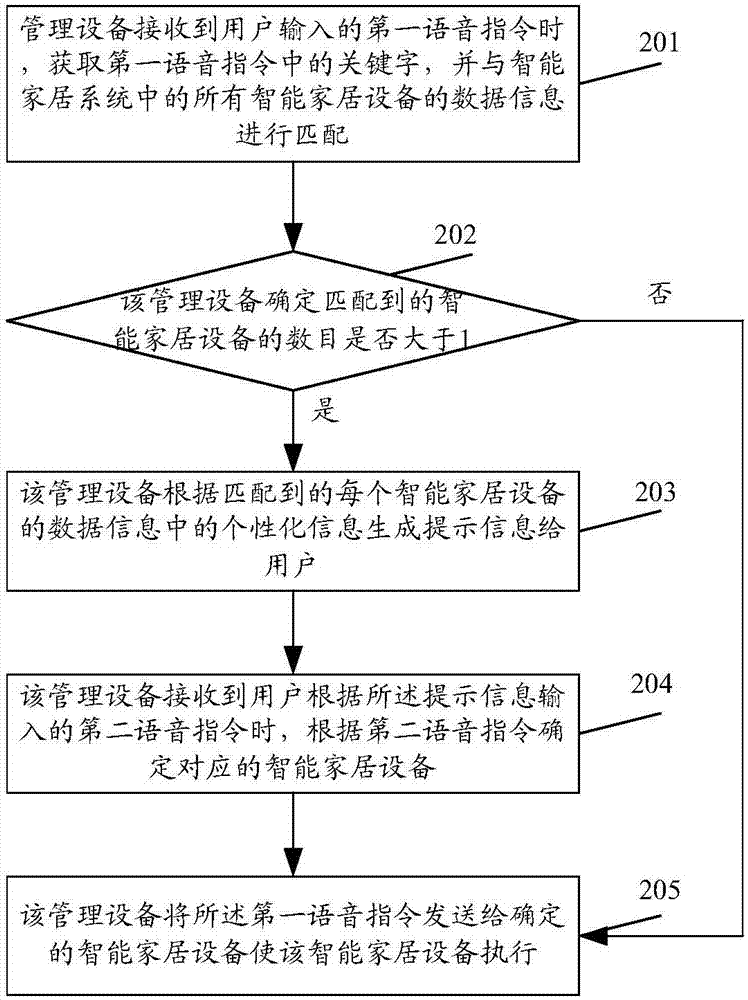

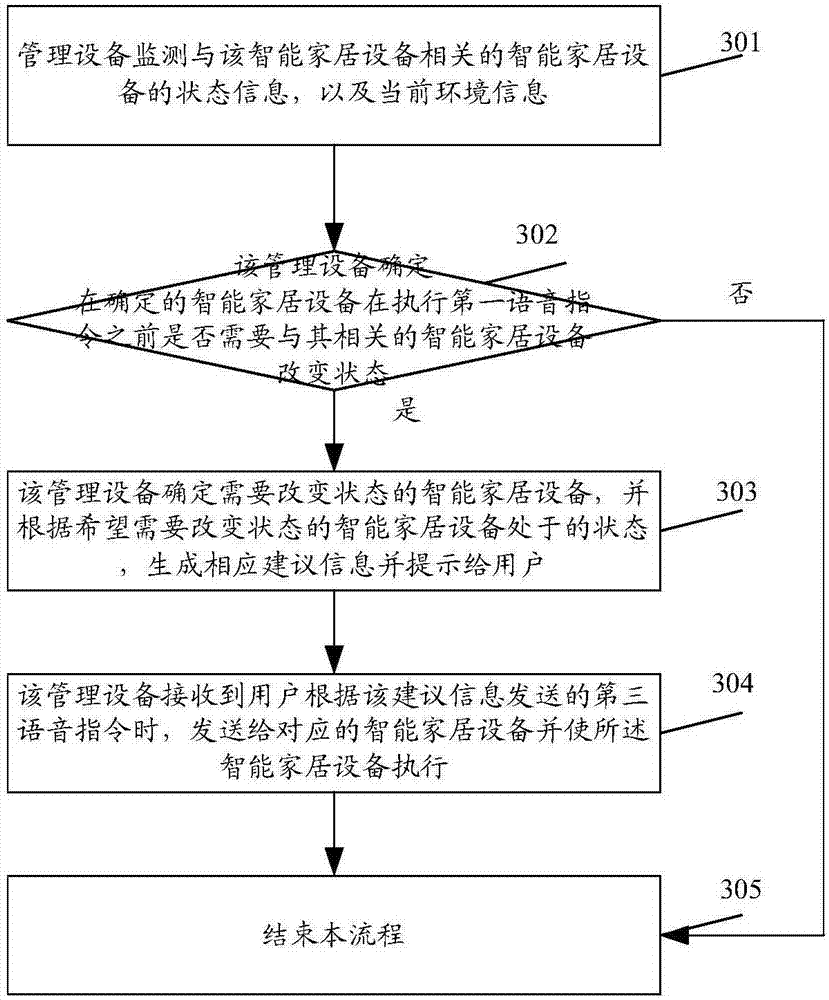

Smart interactive method and device

InactiveCN107290974AFor precise controlReduce difficultyComputer controlProgramme total factory controlSpeech controlData information

The invention provides a smart home interactive method, and the method comprises the steps: when a first voice command inputted by a user is received, key words in the first voice command are acquired and matched with data information of all smart home equipment in a smart home system, if the number of matched smart home equipment is greater than 1, a prompt message is generated to the user according to the personalized information in the data information of each matched smart home equipment; when a second voice command inputted by the user according to the prompt message is received, the corresponding smart home equipment is determined according to the second voice command, and the first voice command is transmitted to the smart home equipment to enable the smart home equipment to execute. Based on the same inventive concept, the invention also provides a smart home interactive device, the difficulty for voice controlling the smart home can be reduced, and the operation and user experience are improved.

Owner:SAMSUNG ELECTRONICS CHINA R&D CENT +1

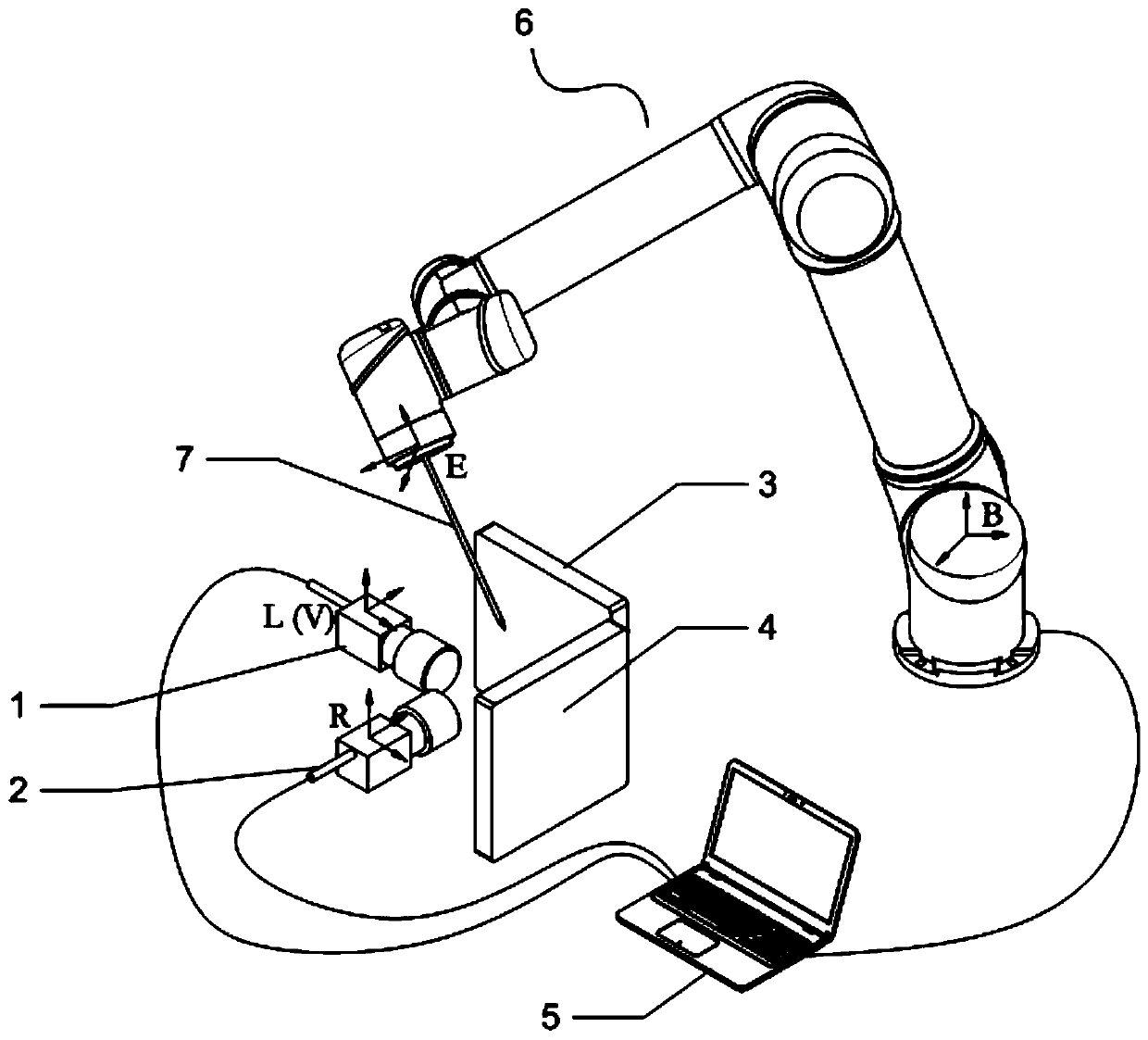

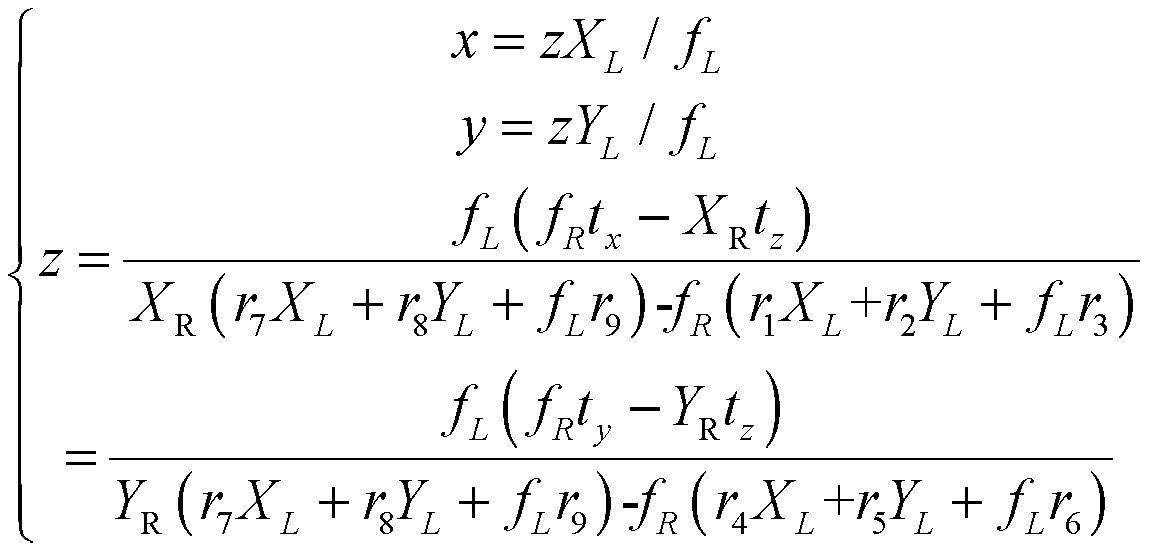

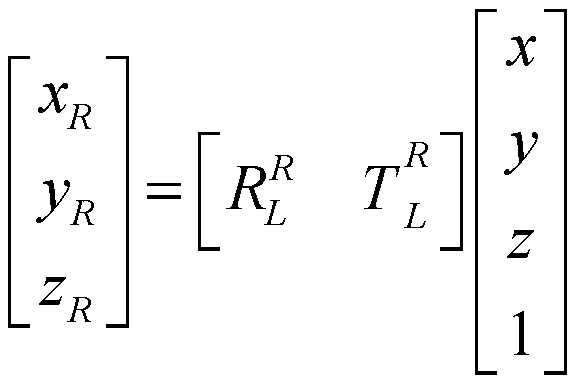

Robot-assisted puncture operation end tool center calibration method based on stereoscopic vision

ActiveCN111012506AFor precise controlAchieve punctureDiagnosticsSurgical needlesRobot controlEngineering

The invention discloses a robot-assisted puncture operation end tool center calibration method based on stereoscopic vision, which belongs to the field of robot control, and aims to realize accurate control of a robot on a needle tip. The method comprises the following steps: performing monocular vision calibration on two cameras, performing binocular system vision calibration, and establishing avision measurement space coordinate system; wherein a puncture needle performs single translational motion and rotary translational motion respectively in a visual measurement space range; processingan image acquired in the moving operation to generate a closed area and a minimum enclosing rectangle of the closed area; circularly detecting an intersection point of the short edge of the minimum enclosing rectangle and the closed area, and obtaining the position change description of a needle tip in the visual measurement space coordinate system in the single translational motion process and the position change description of the needle tip in the visual measurement space coordinate system in the rotary translational motion process; obtaining an attitude rotation relationship between the visual measurement space coordinate system and a robot base coordinate system; obtaining position description of the needle tip relative to the tail end of the mechanical arm, and completing position calibration of the needle tip.

Owner:HARBIN INST OF TECH

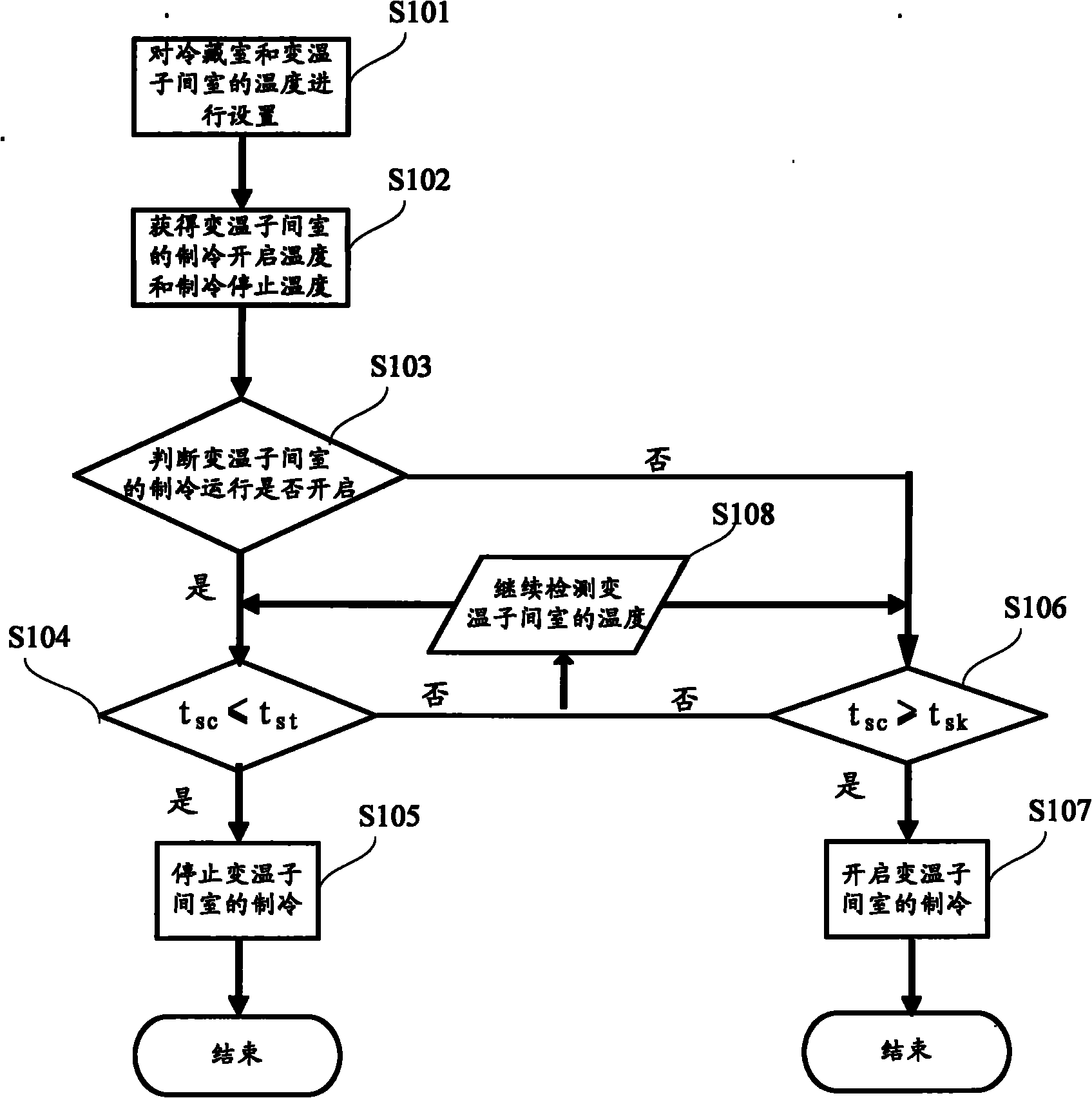

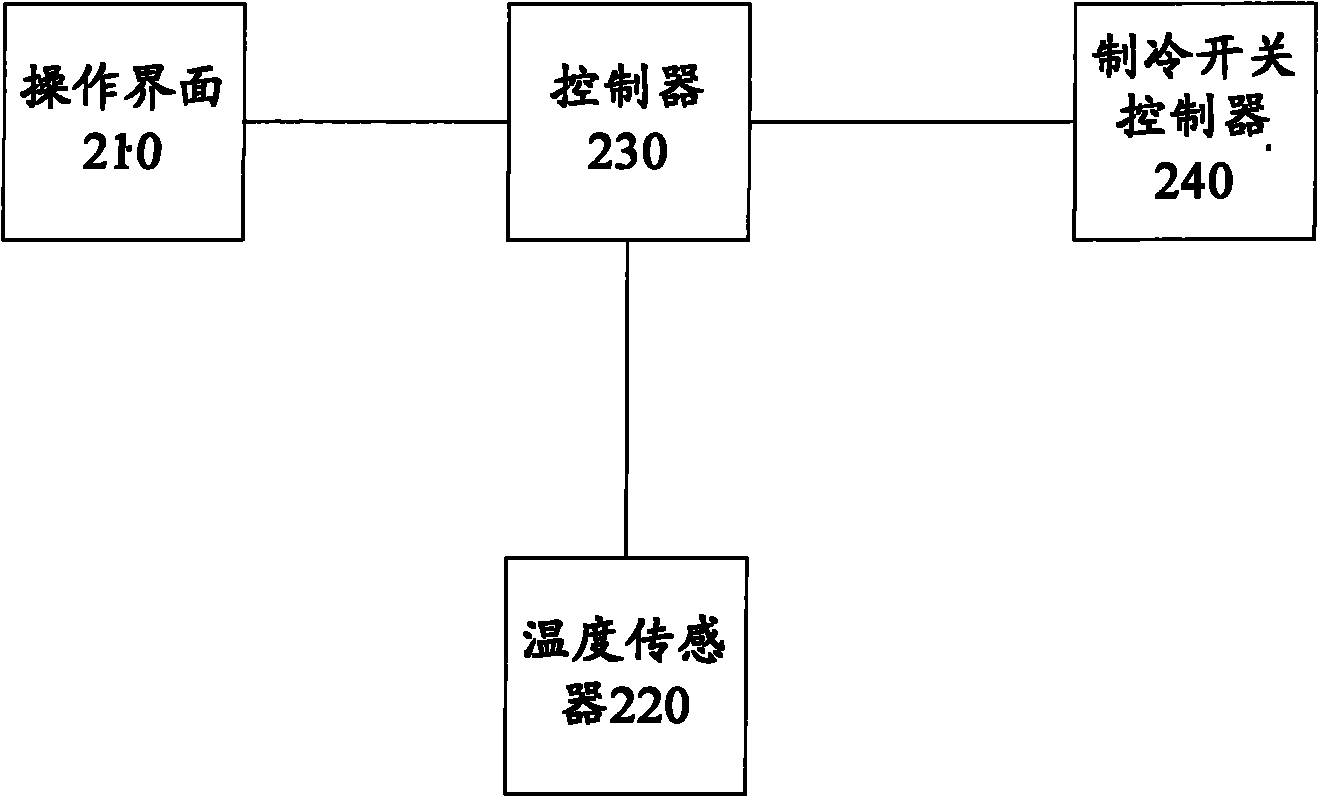

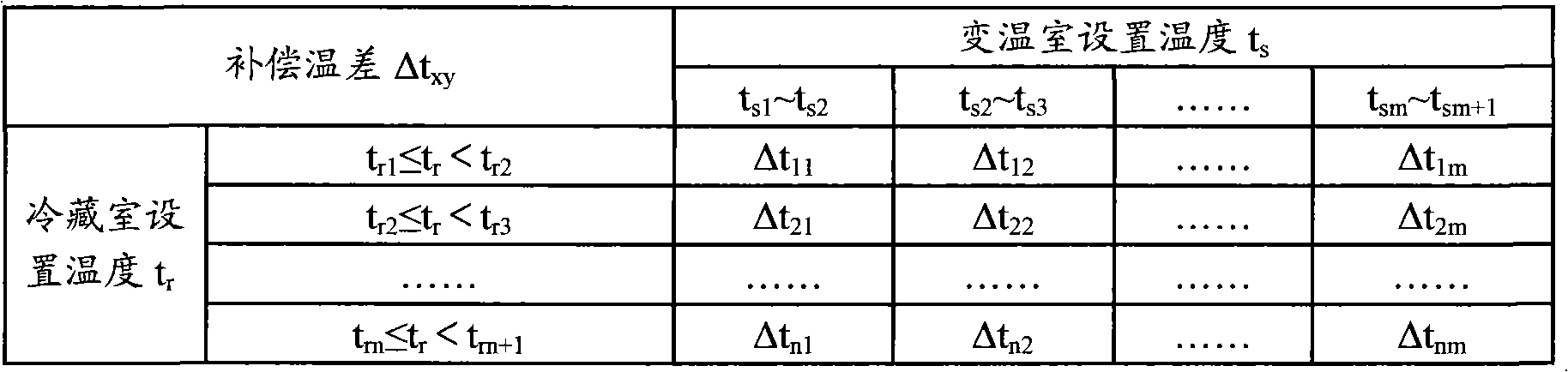

Temperature control method and device of temperature changing subchamber and refrigerator with same

ActiveCN101968663AWide temperature rangeAchieve freshnessDomestic cooling apparatusLighting and heating apparatusEngineeringTemperature control

The invention provides a temperature control method of a temperature changing subchamber, which comprises the following steps of: setting temperatures of a refrigerating chamber and a temperature changing subchamber; obtaining a refrigerating start temperature and a refrigerating suspension temperature of the temperature changing subchamber according to a temperature setting value of the refrigerating chamber, a temperature setting value of the temperature changing subchamber and a sectioning compensation temperature difference table; and detecting the current temperature of the temperature changing subchamber and controlling the refrigeration of the temperature changing subchamber according to the current temperature value, the refrigerating start temperature and the refrigerating suspension temperature. The invention carries out accurate control on the temperature of a temperature changing chamber by a principle of the temperature control sectioning compensation of the temperature changing chamber, thereby more favorably realizing all functions of freshness retaining, freezing point temperature and soft freezing of the temperature changing chamber.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

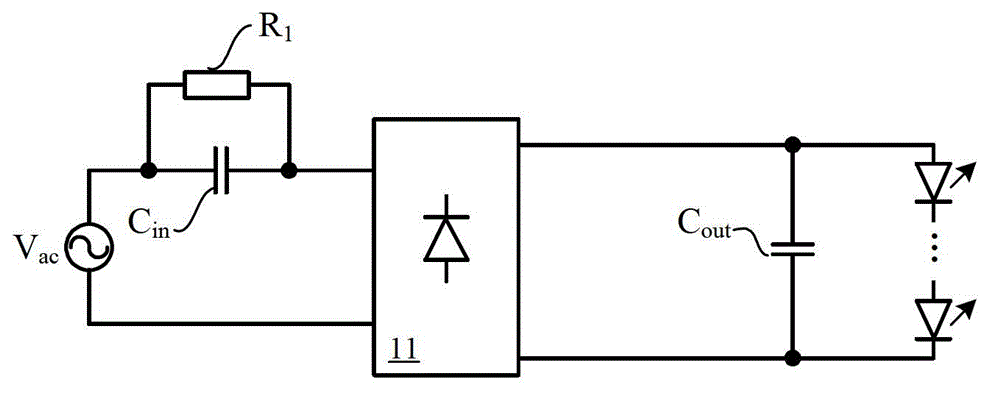

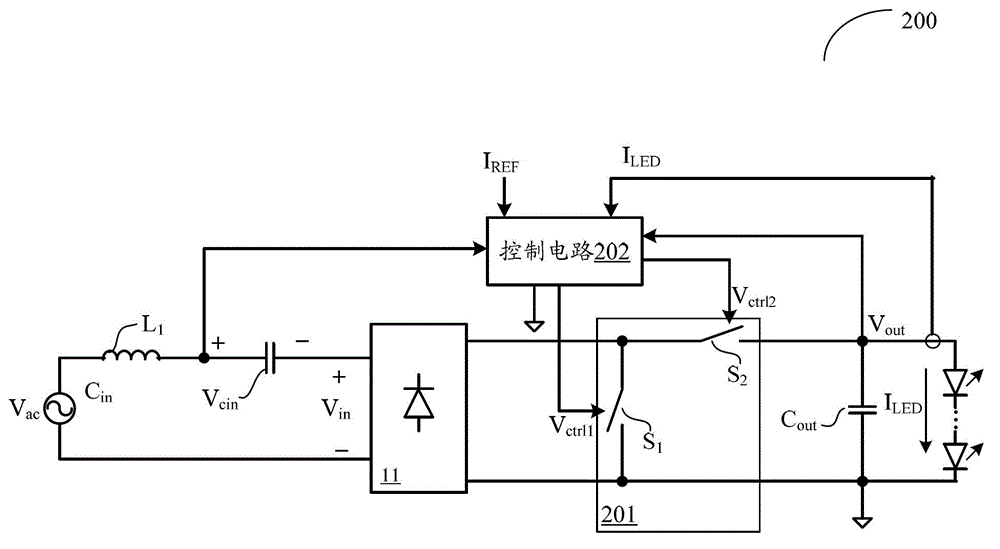

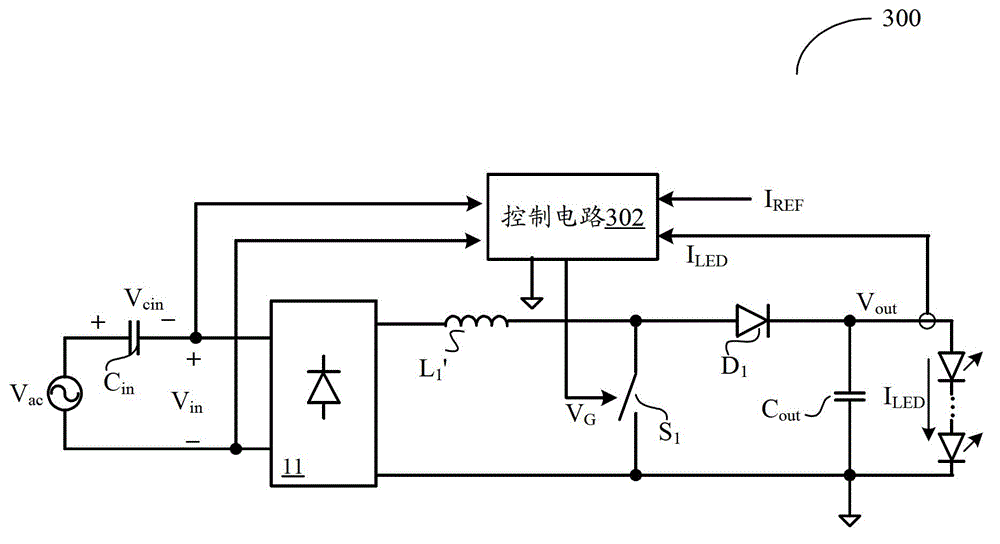

Capacitance buck type light emitting diode (LED) driver and capacitance buck type LED driving method

InactiveCN103152949AFor precise controlReduce power consumptionElectrical apparatusElectroluminescent light sourcesLed driverCapacitance

The invention relates to a capacitance buck type light emitting diode (LED) driver and a capacitance buck type LED driving method. The capacitance buck type LED driver comprises a control circuit and a switching circuit, wherein the control circuit controls a switching state of the switching circuit according to output current and the output voltage of the capacitance buck type LED driver so as to control energy transferred from an input side to an output side; in a first working state, the switching circuit controls the input side not to transfer the energy to the output side; and in a second working state, the switching circuit controls the input side to transfer the energy to the output side so as to keep the output current and expected driving circuit consistent.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

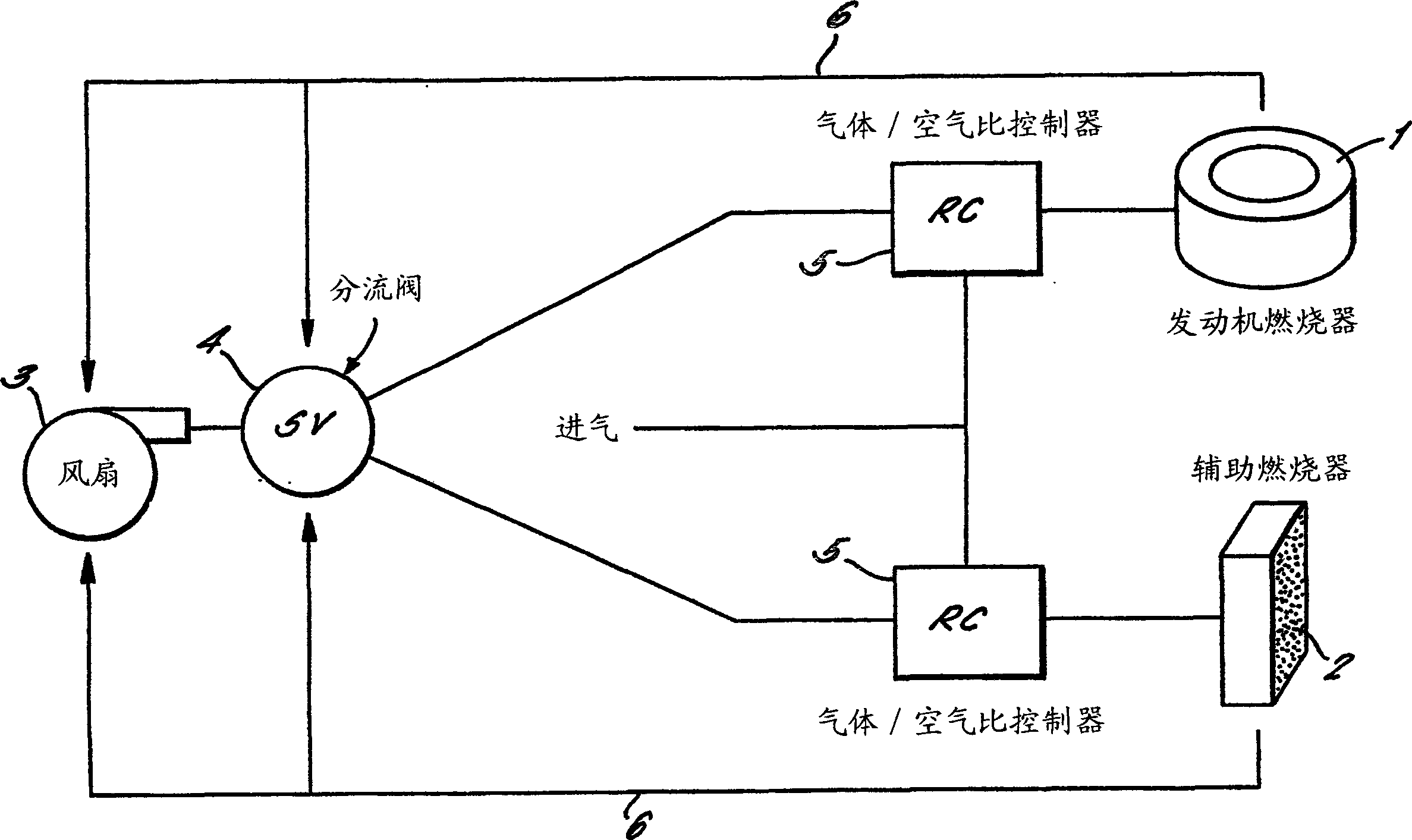

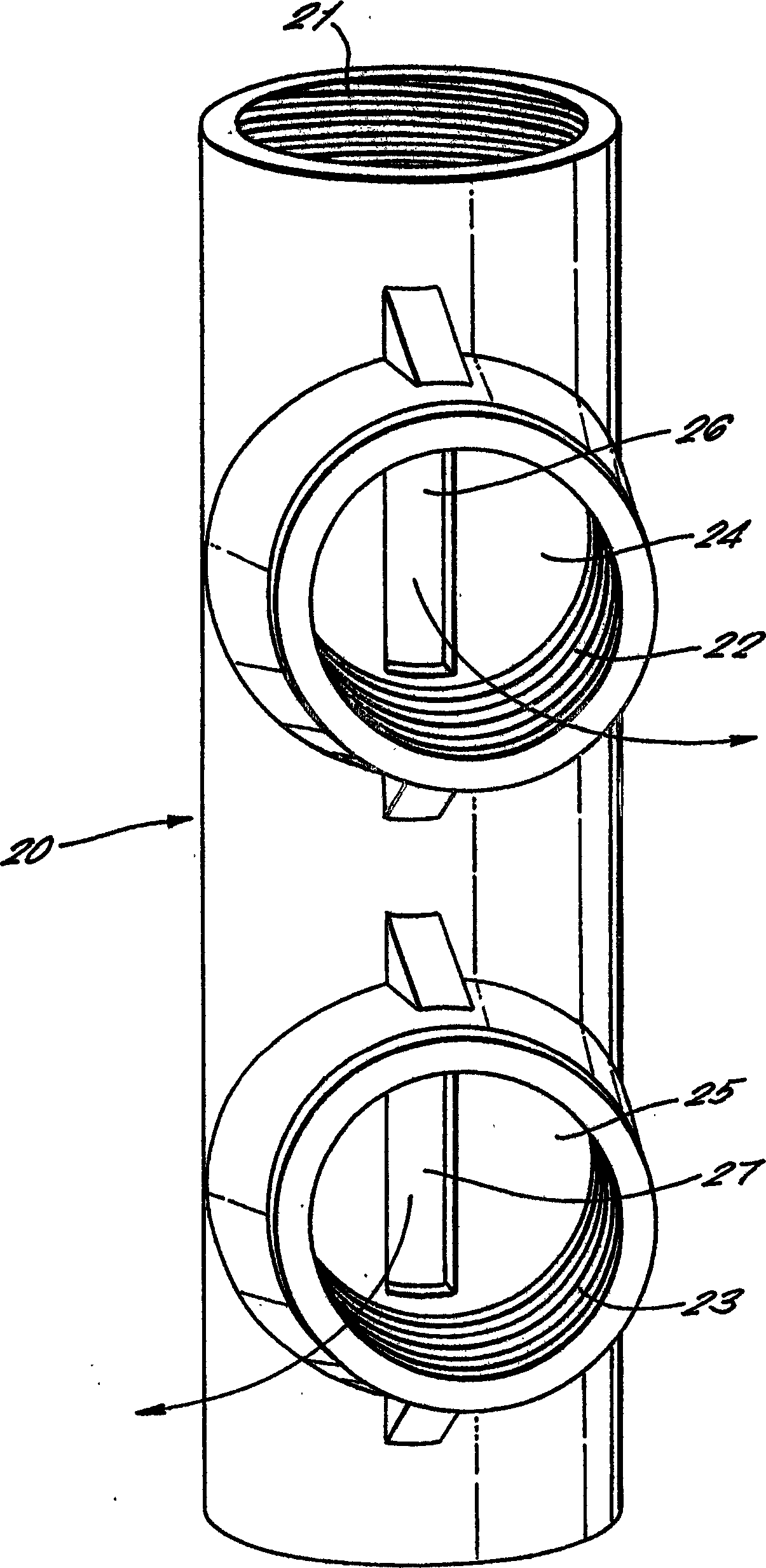

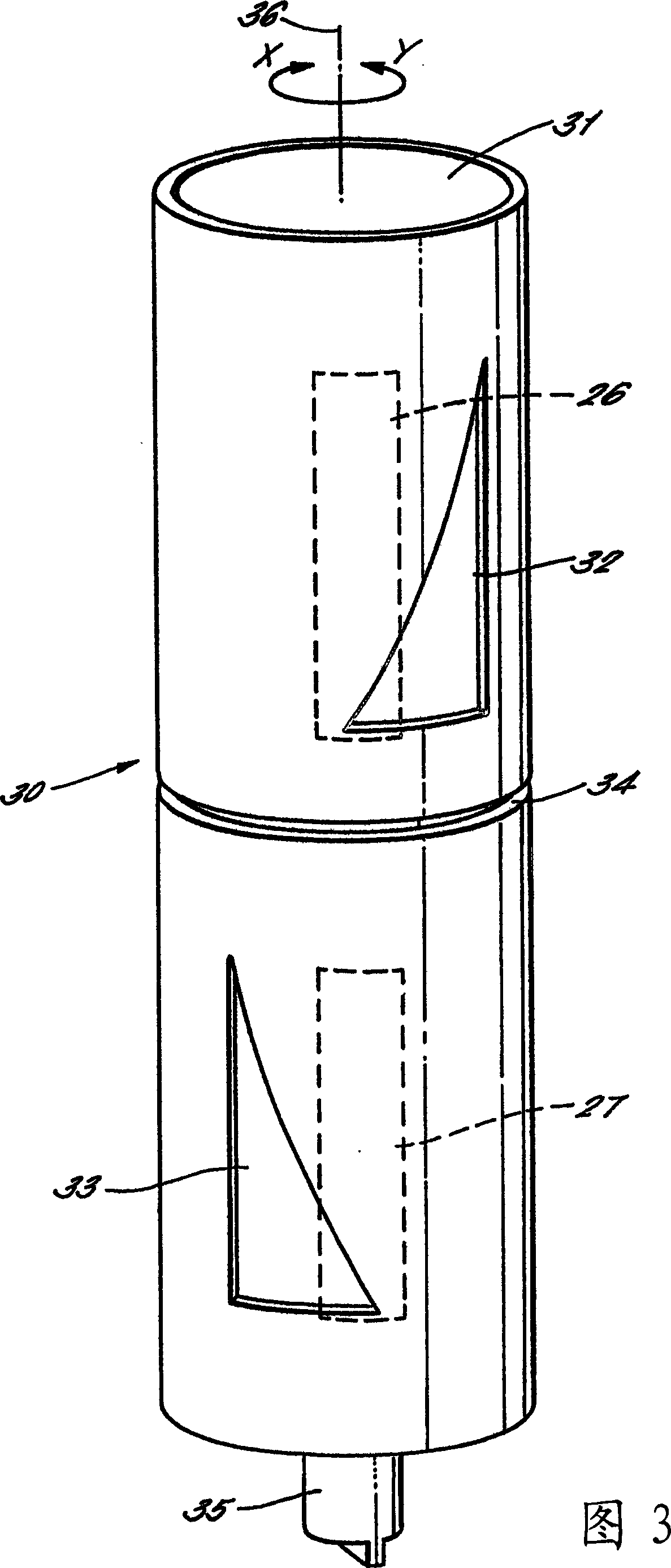

A splitter valve

InactiveCN1761829AStable structureFor precise controlInternal combustion piston enginesMultiple way valvesRelative scaleEngineering

A splitter valve for splitting an inlet stream into a plurality of outlet streams. The valve comprising an inlet (31) and a plurality of outlets, one for each outlet stream. An outer sleeve (20) has a plurality of first outlet orifices (32, 33), one for each stream. An inner element (30) is moveably retained within the outer sleeve and has an inlet and a plurality of second outlet orifices (32, 33), one for each stream. The relative proportion of the inlet stream fed to each outlet is determined by the relative position of the inner element and outer sleeve. The first and second outlet orifices are shaped such that the flow through each outlet varies substantially linearly with the relative position of the inner element and outer sleeve.

Owner:MICROGEN ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com