Horizontal well forced gas drainage method with coal bed gas subjected to staged fracturing

A technology for staged fracturing and horizontal wells, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., which can solve the problem of difficult to achieve structural soft coal coalbed methane content, difficult to achieve the effect of enhanced coalbed methane extraction, problems such as high construction risks, to achieve the effects of low production and operation costs, less land occupation, and rapid reduction of gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

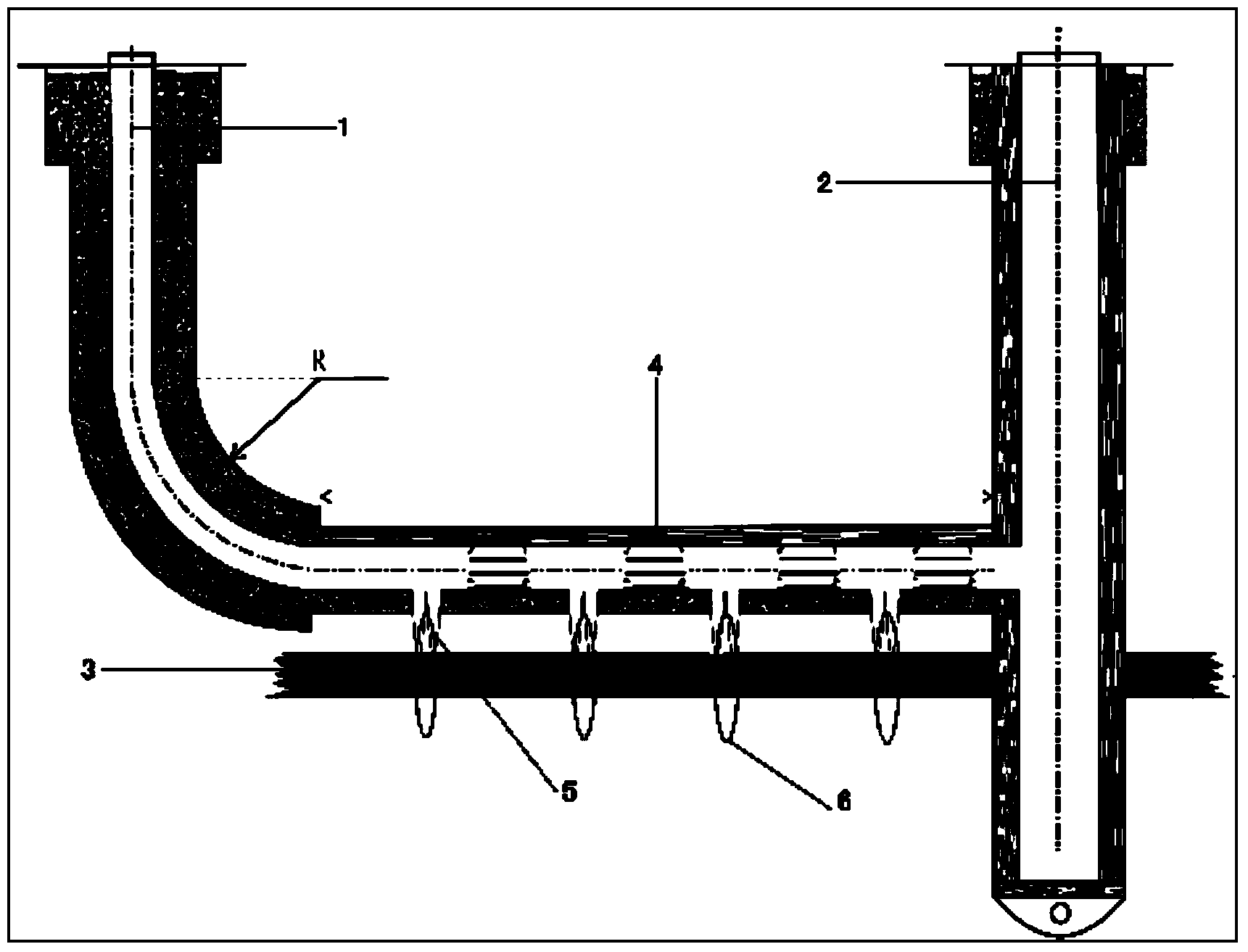

[0021] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0022] 1) Drill a drainage and production vertical well 2 first, and drill to 60 meters below the target coal seam to complete the drilling, which will be used for later drainage; then build a cave with a radius of 0.5m at the coal seam section and the roof position to facilitate the smooth docking of the horizontal well 1 .

[0023] 2) Then connect the horizontal well 1 with the construction, and use the boundary detector technology to control the wellbore trajectory of the horizontal well to be located at a position 0.5-1.5m above the target coal seam section, so that the subsequent ultra-deep penetration perforation can smoothly communicate with the target coal seam; The mining vertical well is connected at the location where the hole is created, and then casing cementing is performed.

[0024] 3) After cementing, use staged fracturing method to car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com