Patents

Literature

852results about How to "Reduce production and operation costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

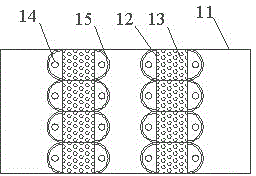

Preparation method of layer-by-layer self-assembled hollow fiber forward osmosis membrane

ActiveCN108325400ALess materialSimple production processSemi-permeable membranesGeneral water supply conservationHollow fibreFiber

The invention discloses a preparation method of a layer-by-layer self-assembled hollow fiber forward osmosis membrane. The preparation method comprises the steps of: preparing hollow fiber forward osmosis base film, modifying hollow fiber ultrafiltration base film, repeating layer-by-layer assembly of polycation and polyanion layers, performing interface cross-linking polymerization for preparinga selective functional layer, conducting moisturizing, and carrying out treatment and storage so as to prepare the layer-by-layer self-assembled hollow fiber forward osmosis membrane. The surface of the hollow fiber self-support base film which is prepared by using a phase conversion method is activated firstly, layer-by-layer assembly of polycation and polyanion is repeated on the surface of thefilm so as to form an functional polarization layer for an electrolyte solution, and the polyamide selective layer is prepared through interfacial chemical cross-linking polymerization. The prepared hollow fiber forward osmosis membrane has a controllable thickness and an internal polarization layer with a high charge capacity, and the internal concentration polarization phenomenon can be alleviated effectively during the forward osmosis process; therefore, the hollow fiber forward osmosis membrane can simultaneously obtain high flux and low reverse salt flux, has high filtration separation efficiency, easy cleaning and a long service life, and can be widely applied to seawater desalination and concentration and desalination of brine.

Owner:西安金藏膜环保科技有限公司

Deep treatment process of oily wastewater

ActiveCN102060350ASolving Deep Processing ChallengesImplement deep processingFatty/oily/floating substances removal devicesCombustible gas purificationActivated carbonSorbent

The invention relates to a deep treatment process of oily wastewater, which is characterized in that an absorption system and a regeneration system are provided in the process, wherein the absorption system is formed by a series of absorption tower groups with columns in series used for realizing parallel operation, the absorption tower groups are used for alternately performing deep treatment on oily yielding water with a low concentration of 30-50 mg / L of a traditional process, the absorption operation is carried out at normal temperature, the oil content in the yielding water is controlled to be lower than 1 mg / L through the treatment of a group of the absorption towers with columns in series, and an absorbing agent is made of modified fly ash, activated carbon and an expanded graphite absorbing material; when the yielding water in a group of the absorption towers exceeds a treatment requirement, the group of the absorption towers is switched to a biological regeneration system, and other absorption tower groups are simultaneously switched to the absorption system for continuous absorption; and saturated absorption towers are used for performing in-situ regeneration on the saturated absorbing agent by utilizing degradation ability of high temperature-resistant and efficient petroleum hydrocarbon for degrading bacteria.

Owner:CHINA NAT OFFSHORE OIL CORP +2

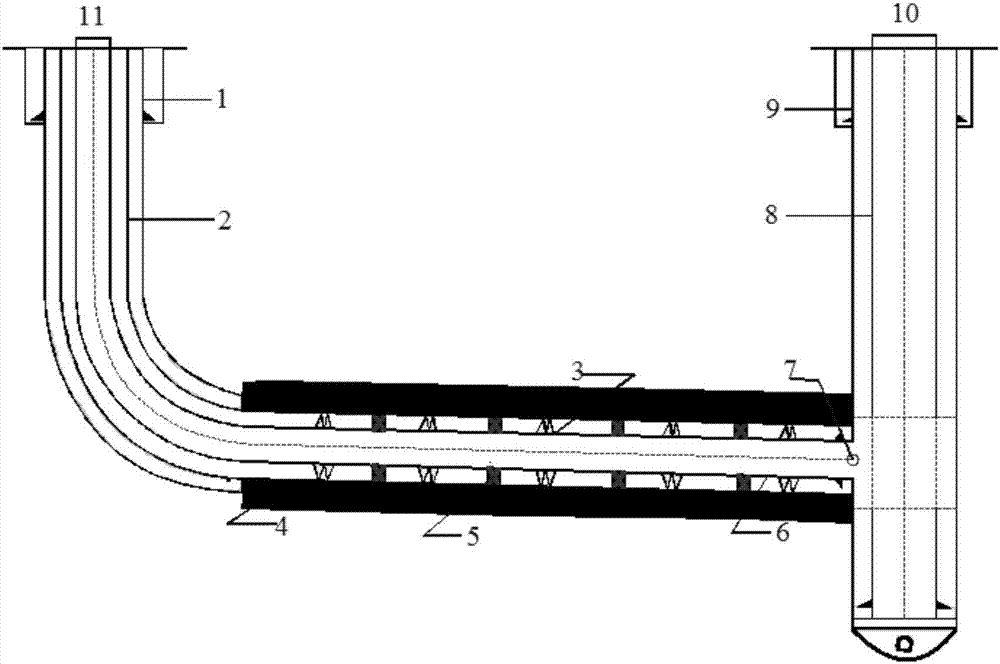

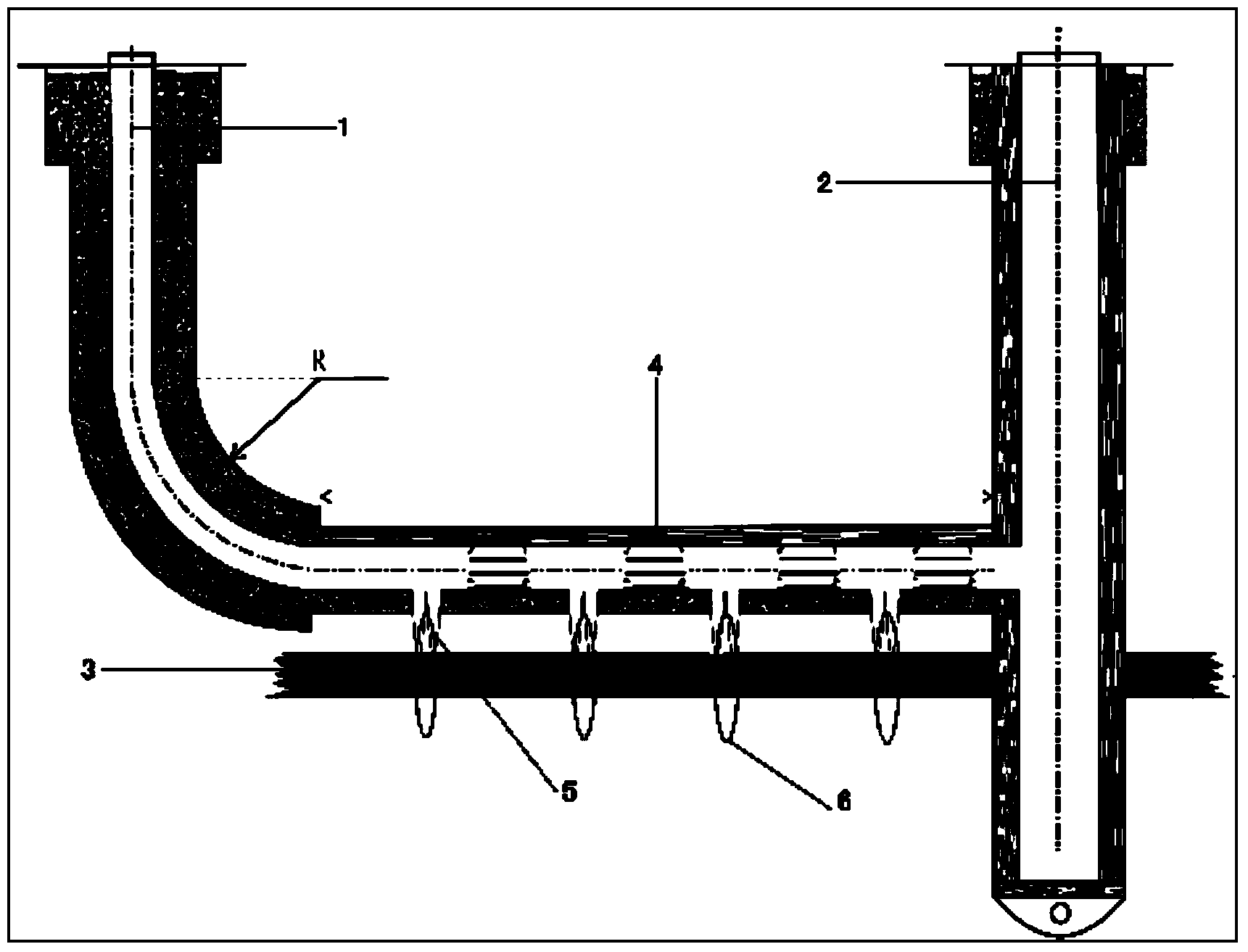

Drainage method of non-cell-cementation cased-hole-completion coal bed gas horizontal well

ActiveCN107387034AAvoid pollutionImprove fracturing effectFluid removalSand blastingProduction effect

The invention discloses a drainage method of a non-cell-cementation cased-hole-completion coal bed gas horizontal well. The method includes: a U-shaped butted well is used, the horizontal section of the horizontal well is deployed along the declination direction of a coal bed and a direction parallel to the minimum main stress of the coal bed, and well completion is performed by using casing running and an external self-expansion casing packer in a non-cell-cementation manner; the setting section, perforation and fracturing section of the external casing packer of the horizontal well are optimized; perforation is performed in a large-displacement and fixed-direction hydraulic abrasive perforation manner, and slug insertion type sand-carrying fracturing is performed on the horizontal well section by section in a large-displacement, large-scale, high-prepad-fluid-ratio and medium-sand-ratio manner; draining is performed at the wellhead of a drainage vertical well, and gas production is performed at the wellhead of the horizontal well. The drainage method has the advantages that pollution of a coal reservoir and production and operation costs can be lowered, the fracturing transformation effect and draining and gas production effect of the non-cell-cementation cased-hole-completion horizontal well are improved, the drainage efficiency and effect of the horizontal well are increased, the coal bed gas content of soft, broken and low-permeability coal beds can be lowered in a large-range and fast manner, and intensified coal bed gas drainage is achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

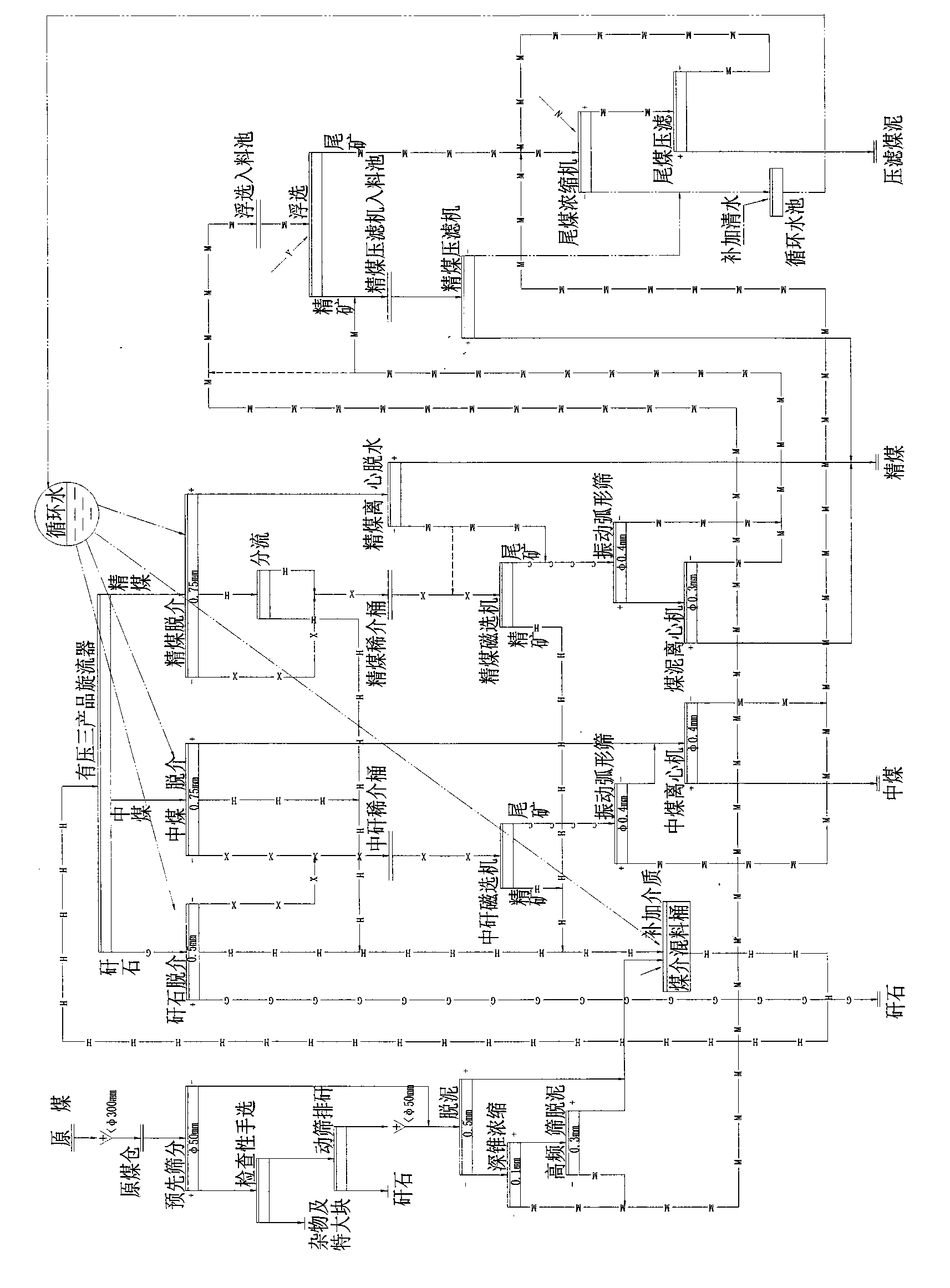

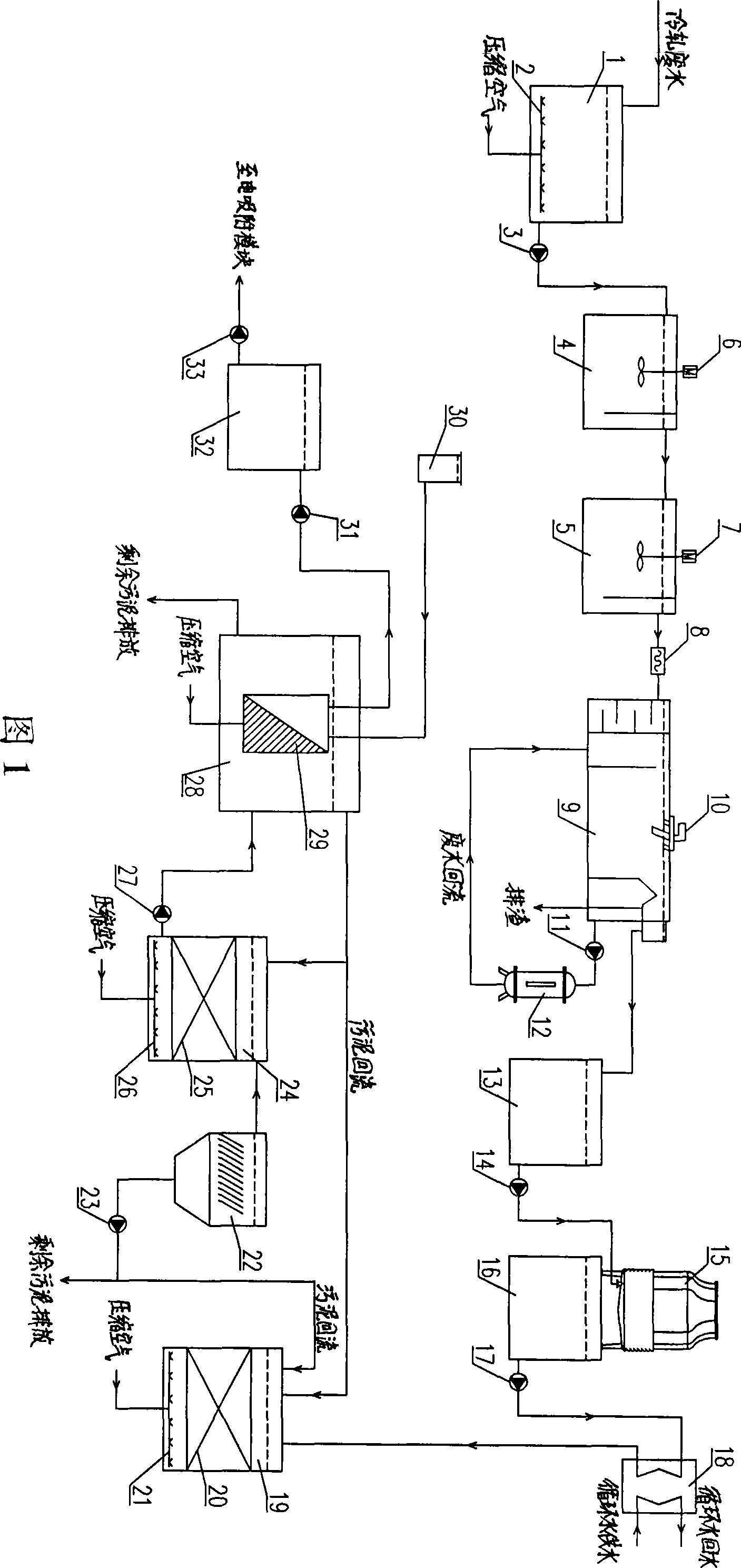

Classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process

InactiveCN103350027AImprove sorting efficiencyFlexible structureWet separationThermodynamicsMagnetic separator

Provided is a classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process. The process comprises the steps that wet classification and primary desliming are carried out on raw coal after prescreening, gangue predischarging and breaking are carried out on the raw coal, secondary desliming is carried out on the screen underflow of the raw coal after the screen underflow is concentrated, the oversize products of the secondary desliming and the screen underflow of the primary desliming are together fed in a pressurized three-product cyclone, three products are obtained after separation, and clean coal, middle coal and gangue are obtained after medium separation and dehydration are carried out on the three products. Part of qualified suspension liquid and dilute suspension liquid are obtained when the medium separation is carried out on the three products, magnetic concentrate is obtained after the dilute suspension liquid is recovered by a magnetic separator, and the magnetic concentrate and the qualified suspension liquid are directly fed in a medium blending barrel. The magnetic tailings of the dilute suspension liquid and the undersize mixtures of pre-desliming, the overflow of concentration classifying equipment and a secondary desliming screen enter a coal slime recovery processing system together. The process is high in separation efficiency, flexible in product structure, low in producing and operating cost and prone to achieving the large-scale single system, the modularization and the integrating intellectualization of plant layout.

Owner:煤炭科学研究总院唐山研究院

Method for separating and recovering nickel, cobalt, magnesium, iron and silicon from nickel-bearing laterite

InactiveCN101525690AImprove leaching rateHigh dissolution rateProcess efficiency improvementSlagLaterite

A method for separating and recovering nickel, cobalt, magnesium, iron and silicon from nickel-bearing laterite is disclosed; nickel, cobalt, magnesium and iron therein are leached out by using high-temperature peracid, leachate is pre-neutralized via serpentine powder, after the pre-neutralization, the leachate is neutralized by magnesite powder for de-ironing, and the scum is delivered for ironmaking after being dewatered by smoke gases in a fluidized bed furnace for making sulfuric acid, the de-ironed clear nickel liquid uses magnesite powder to precipitate nickel carbonate, and the precipitated liquid is concentrated and crystallized to obtain magnesium sulfate heptahydrate. The leached slag mainly contains silicon and can be used for making white carbon black. The invention can sufficiently recover and utilize nickel, cobalt, magnesium, iron and silicon in the nickel-bearing laterite, and the invention is simple in technology, low in energy consumption and pollution-free on environment.

Owner:广西冶金研究院有限公司 +1

A treating method of waste cathode charcoal blocks

InactiveCN106166560ARealize harmless treatmentEliminate pollutionSolid waste disposalSolid fuelsElectrolysisSlag

A treating method of waste cathode charcoal blocks is provided. The waste cathode charcoal blocks are from electrolytic tank heavy maintenance slag of an electrolytic aluminium factory. The method includes treating the electrolytic tank heavy maintenance slag to obtain powdered waste cathode charcoal blocks, subjecting the powdered waste cathode charcoal blocks to water leaching to obtain a leachate and cathode charcoal blocks after leaching, performing solid liquid separation after the leachate and a fluorine removal agent are subjected to a curing reaction, returning the filtrate to the leaching step for circulated use, and stacking filter cakes or adopting the filter cakes as a raw material for preparing calcium fluoride. The method adopts a manner of a plurality of times of leaching, thus achieving innocent treatment of the waste cathode charcoal blocks. The filtrate and the filter cakes after leachate treatment can be reused, and the cathode charcoal blocks after leaching can be adopted as fuel for producing alumina. The method overcomes a series of problems caused by stacking of a large amount of the waste cathode charcoal blocks, achieves efficient utilization of the waste cathode charcoal blocks, and is obvious in economic benefit and suitable for industrial production.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

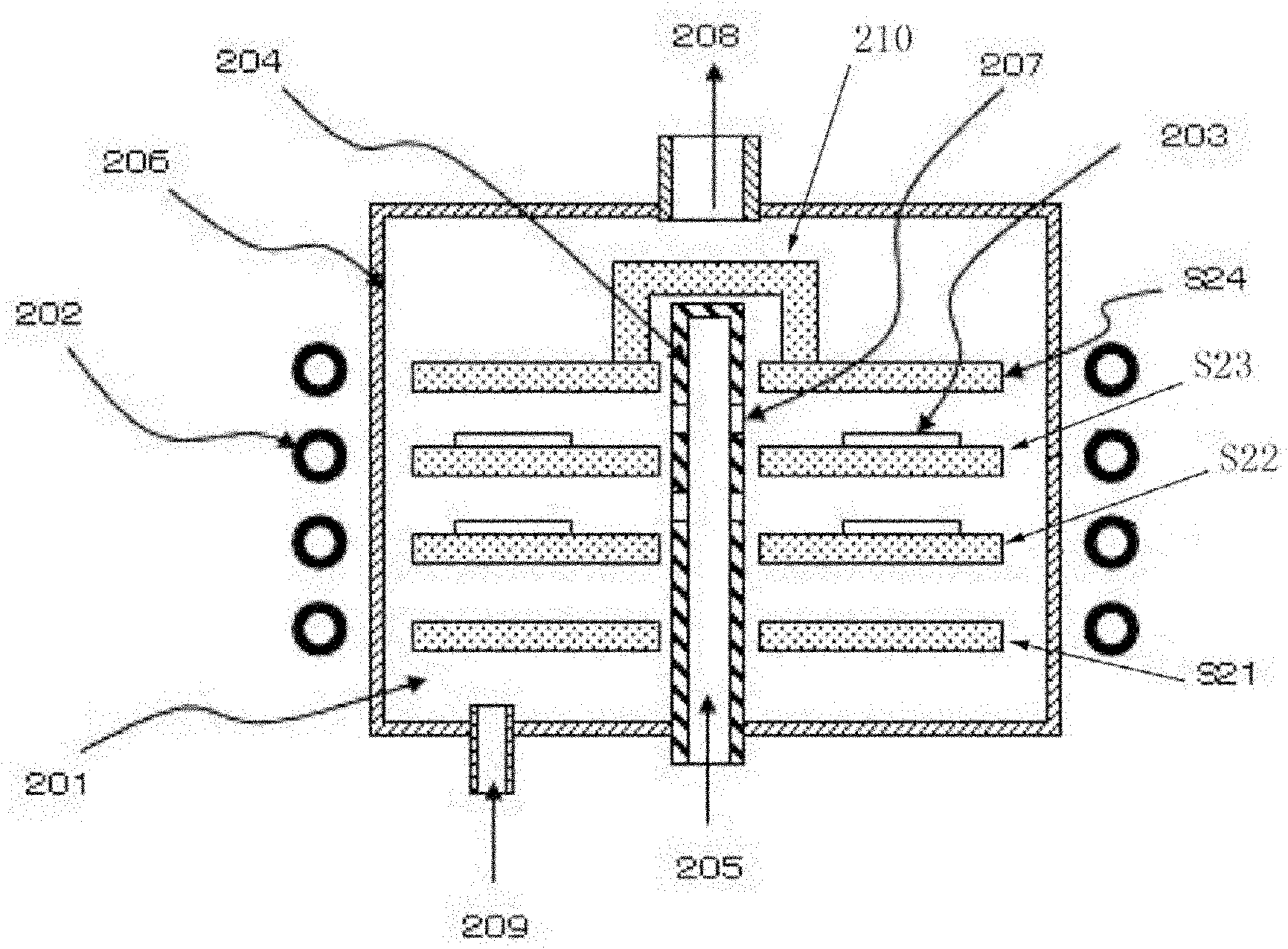

Pallet device and crystallized film growth device

ActiveCN102485953AIncrease production capacityIncrease profitSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringProduct gas

The invention, belonging to the technical field of crystallized film growth, particularly provides a pallet device for bearing processed substrates. The ballet device comprises a plurality of pallets arranged laminatedly along with a length wise direction, and certain space exists between adjacent pallets. In addition, the invention further provides a crystallized film growth device, comprising a process cavity, a process gas conveying system and an exhaust system, wherein the process cavity is provided with the pallet device for bearing the substrates in the process. The pallet device and the crystallized film growth device having the pallet device can increase the number of the substrates processed by the process at every time with low cost and increase the productivity.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

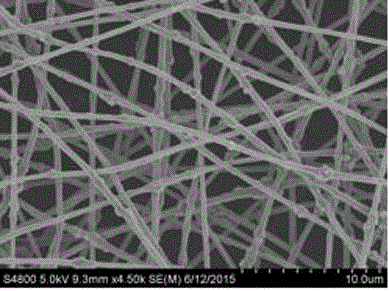

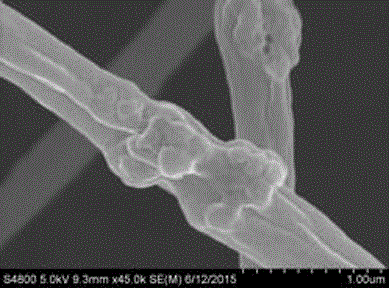

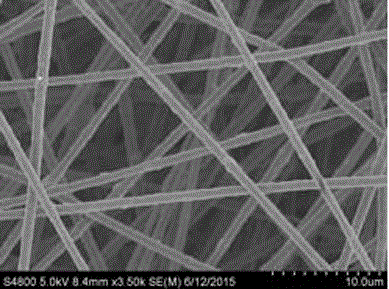

Filter membrane as well as preparation method and application

ActiveCN105536574AImprove filtering effectHEPASemi-permeable membranesDispersed particle filtrationPorosityFiltration membrane

The invention relates to a filter membrane, which is formed by a metal organic framework material and a polymer. The invention also provides a method for preparing the filter membrane which is formed by the metal organic framework material and the polymer. The method comprises the following steps: the metal organic framework material and the polymer are contacted, and the filter membrane is formed by spinning or dip-coating. The invention also relates to an application of the filter membrane to filtering of PM2.5 and volatile organic compounds. The filter membrane has the advantages of high specific surface area, abundant surface function groups, high amount of porosity, light transmission, ventilation, etc., and the filter membrane is used for realizing high-efficiency filtering of PM2.5 and volatile organic compounds.

Owner:理工清科(北京)科技有限公司

Horizontal well forced gas drainage method with coal bed gas subjected to staged fracturing

ActiveCN103967472AFor precise controlSolving the Difficulties of Directional DrillingFluid removalSoil scienceDrill

The invention relates to a horizontal well forced gas drainage method with coal bed gas subjected to staged fracturing. In order to solve the problems that hole forming performance of horizontal drilling in a coal bed is poor and buried drill accidents can happen easily and to achieve the forced gas drainage effect on tectonic soft coal, the well track of a horizontal well is controlled in mudstone or sand stone with a certain range above a coal bed top boundary, and the horizontal well is docked with a drainage vertical well at a far end. An ultra deep penetration perforating technology is used, according to the requirement for certain hole density and orientation, orientated perforating is conducted downwards on the horizontal well section in a segmented mode, a steel sleeve, a well cementation cement ring and a mudstone top plate are penetrated, and the horizontal well is communicated with a target coal layer below. Then, a clear water sand carrying fracturing technology is used, staged fracturing is conducted on the target coal bed according to the requirements for large discharge capacity, large liquid amount, high prepad fluid ratio, large sand amount and middle sand ratio, and the purpose of increasing production is achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

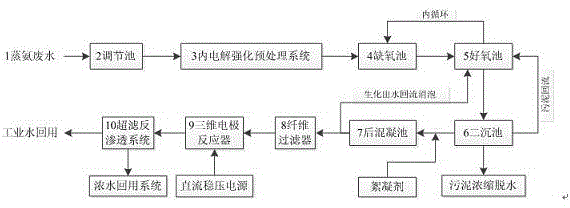

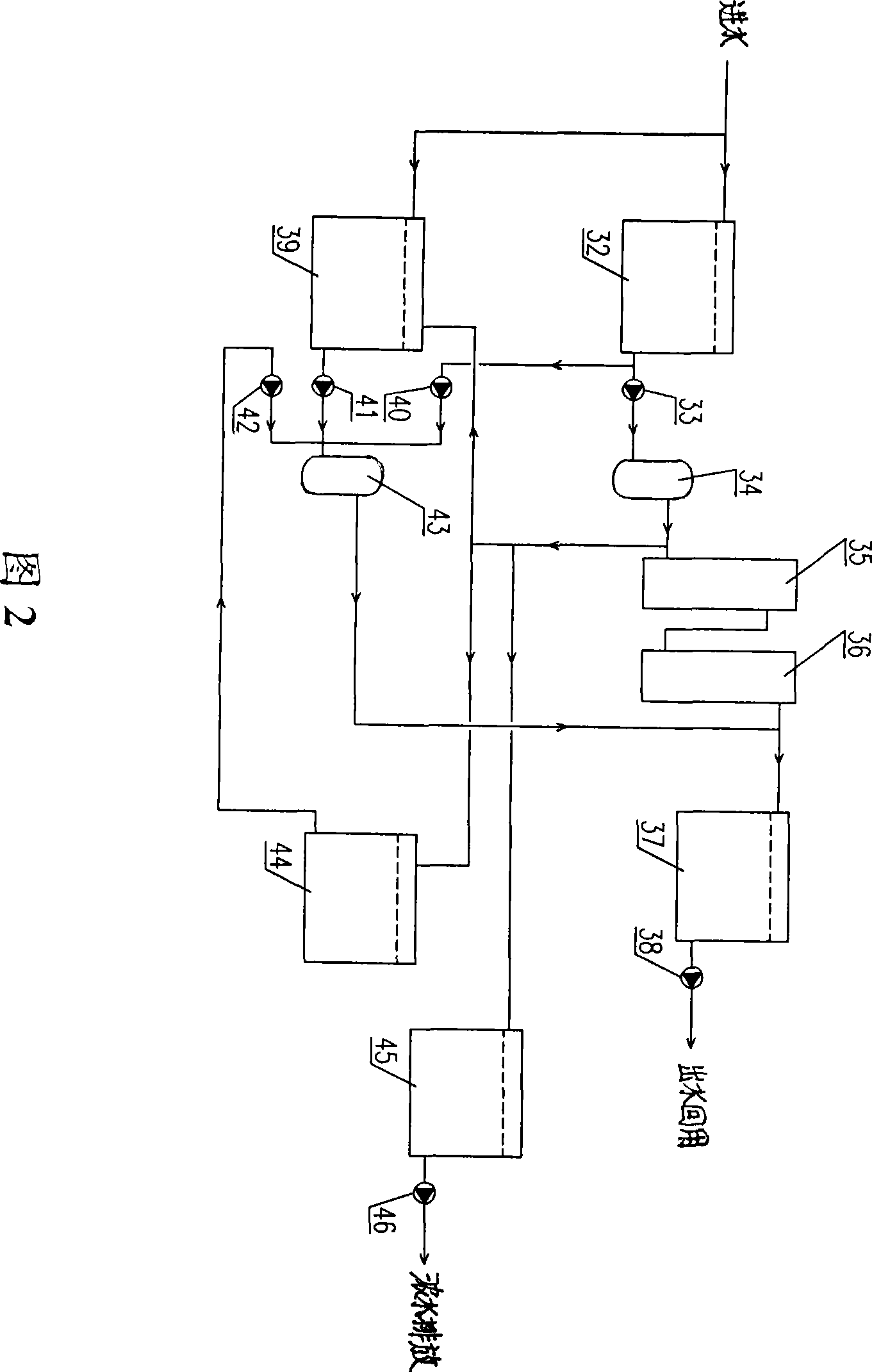

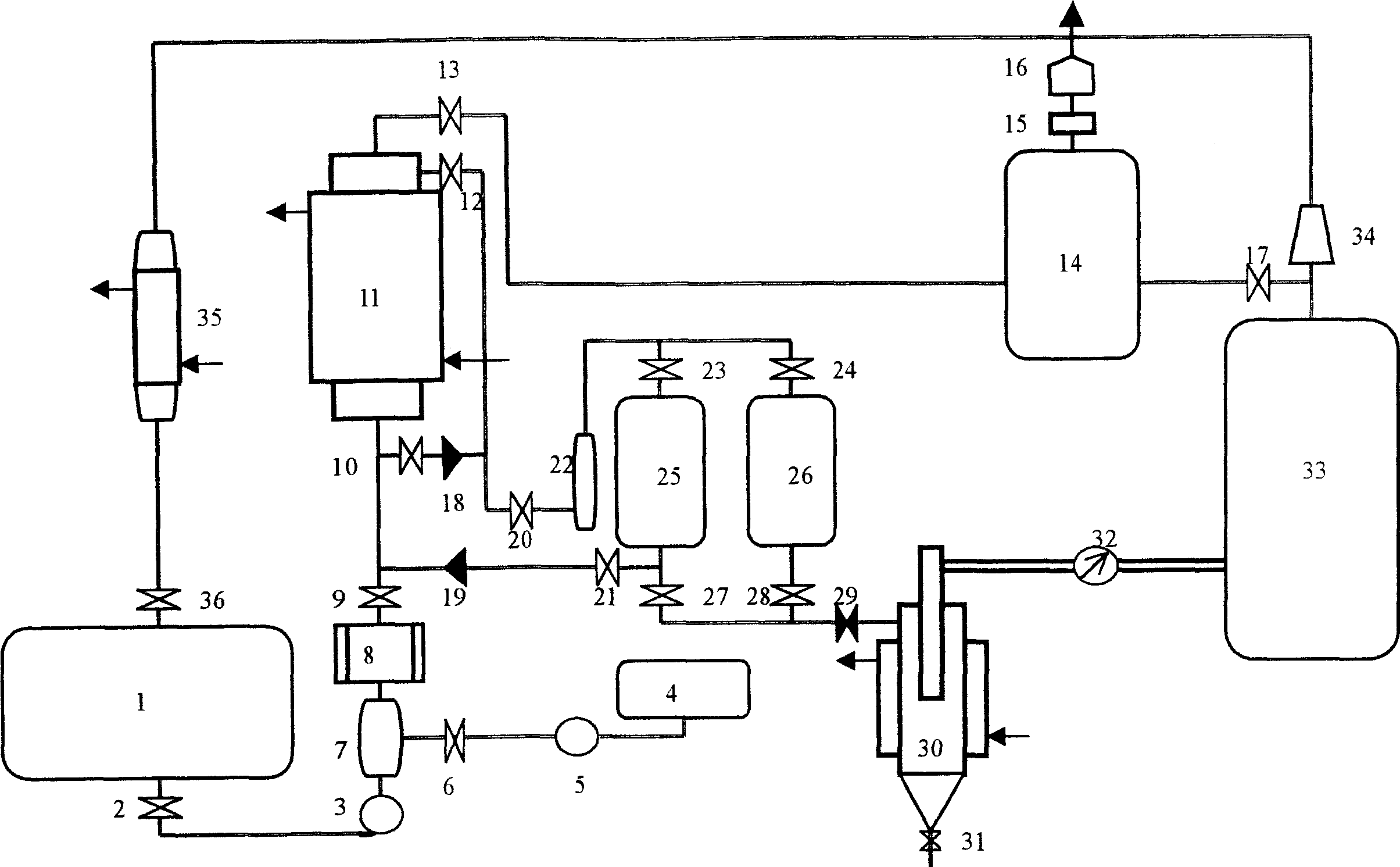

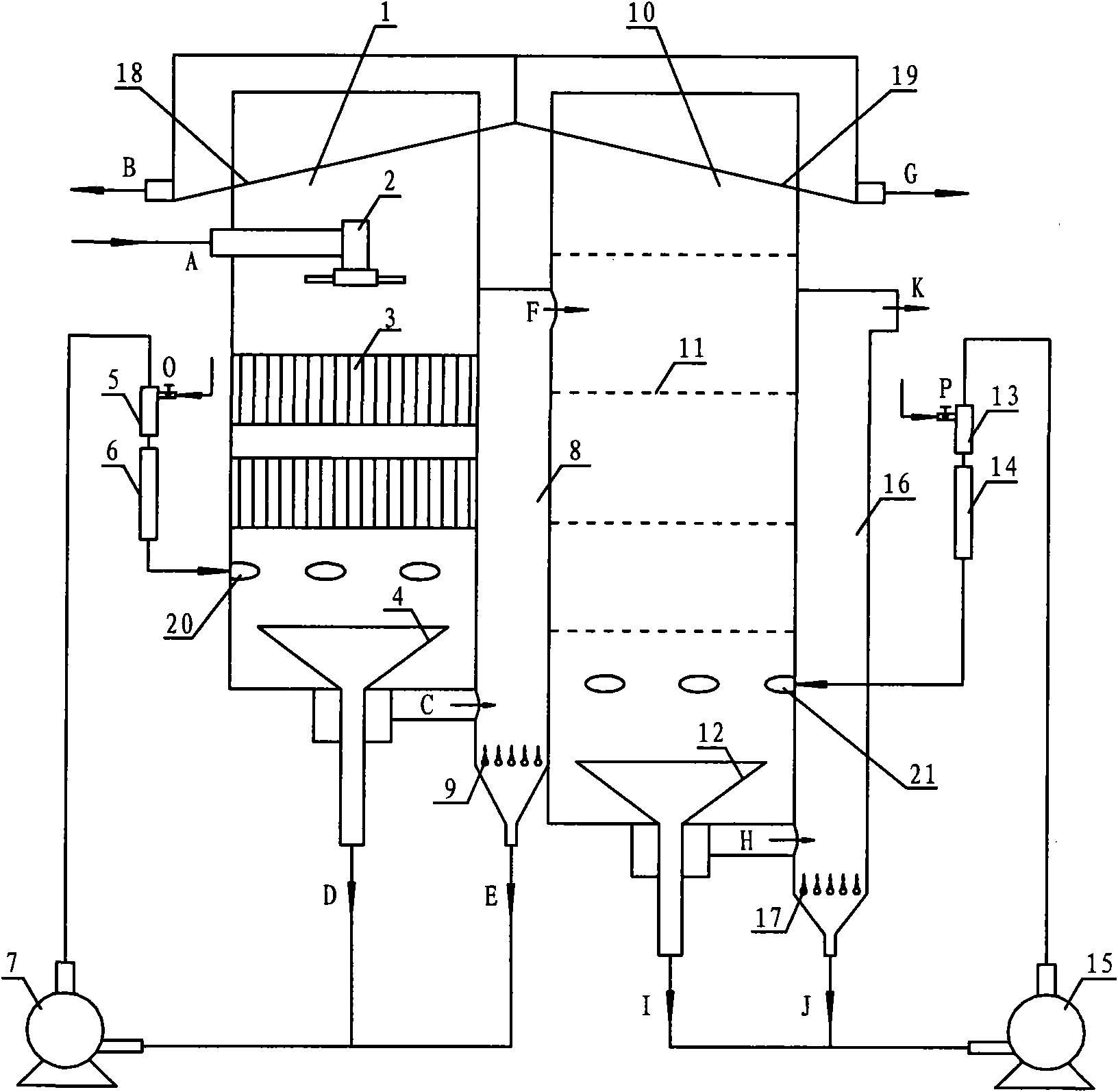

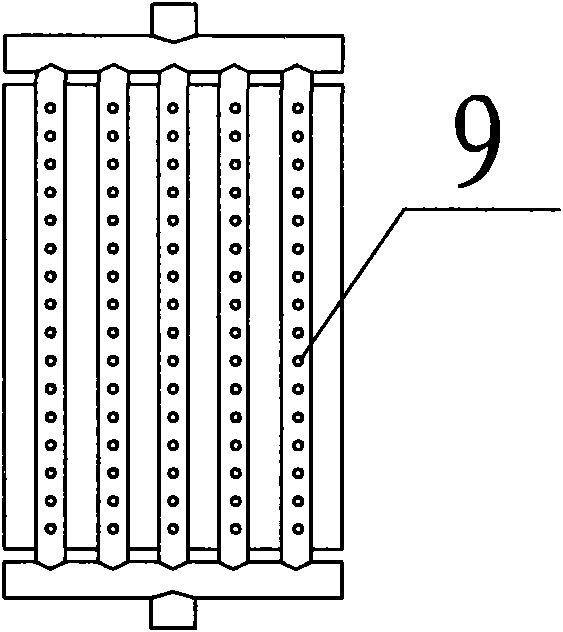

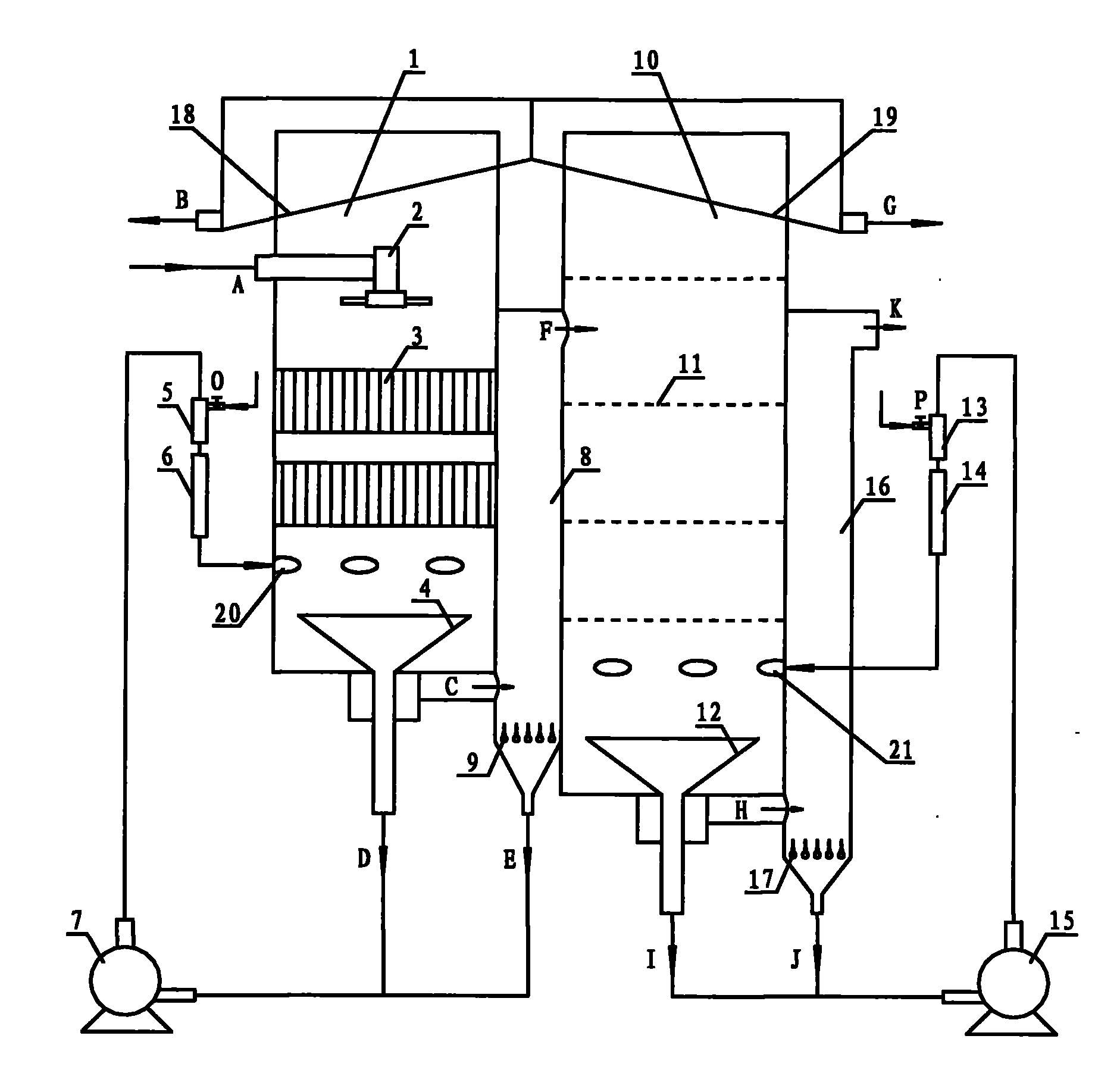

Advanced treatment and zero emission process for coking wastewater

ActiveCN104016547AReduce processingImprove BOD/COD valueMultistage water/sewage treatmentElectrolysisUltrafiltration

The invention relates to an advanced treatment and zero emission process for coking wastewater. The process comprises the following steps: performing ammonia stilling and dephenolizing on the coking wastewater, allowing the treated coking wastewater to enter a regulation pond, conveying the wastewater to an inner electrolysis intensified pretreatment system by using a pump, wherein the inner electrolysis intensified pretreatment system forms an anaerobic biofilter through iron carbon inner electrolysis fillers, and carrying out an iron carbon inner electrolysis reaction and a biological anaerobic reaction; and allowing the wastewater to sequentially enter an anoxic pool and an aerobic pool for carrying out an A / O biological reaction, then allowing the wastewater to enter a secondary sedimentation tank and a later coagulating basin, and further performing advanced treatment on the wastewater in a three-dimensional electrode reactor and an ultrafiltration reverse osmosis treatment system. The coked reverse osmosis concentrated water is treated in a concentrated water recycling system, and zero emission of the coking wastewater is achieved. The process has the aims that dilution water is not added in the conventional coking wastewater treatment process, the coking wastewater subjected to biochemical treatment is subjected to advanced treatment for recycling, and reduction, harmlessness and recycling of the coking wastewater are realized.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

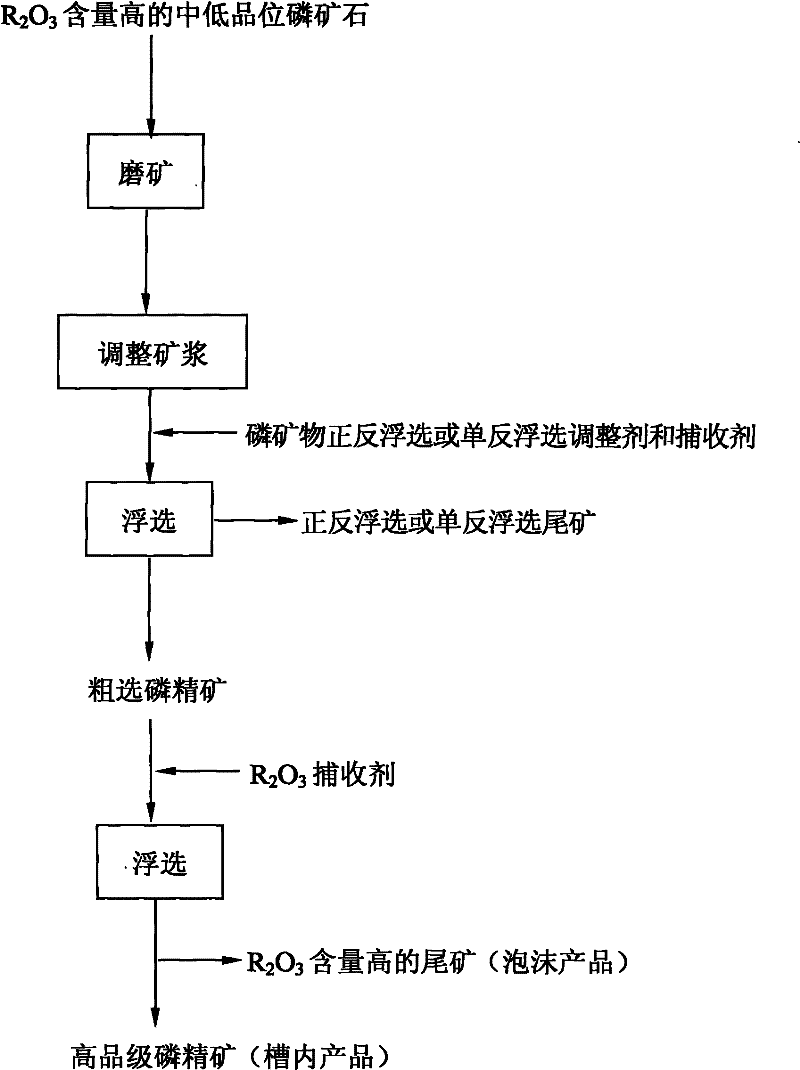

Oredressing method for removing sesquioxide of iron and aluminum

The invention relates to an oredressing method for pertinently reducing content of sesquioxide of iron and aluminum (R2O3) in the collophanite floatation process in advance. The process comprises the following steps of: (1) levigating raw collophanite until grains with the grain size of 0.038mm are more than or equal to 76 weight percent, and controlling the pulp mixing concentration to be 25-40 weight percent; (2) introducing ore pulp into a mineralizing agitation tank of a floatation machine, adding an agent for floating conventional mid-low grade collophanite for pneumatic flotation, ensuring that a spindle speed of the floatation machine is 1,800-2,100r / min, the floating aeration quantity is 0.05-0.10m<3> / h and the floating scraper speed is 20-30r / min, and obtaining phosphate concentrate subjected to rough concentration; and (3) controlling the pH of the phosphate concentrate subjected to rough concentration to be 4.5-5.5, adding a collector for removing R2O3, performing pneumatic flotation for 4 to 8 minutes, removing an impurity of R2O3 from foam, and obtaining base flow, namely a high grade phosphate concentrate product. By the method, the R2O3 content in the concentrate can be obviously reduced, the quality of the phosphate concentrate is improved, and production processes, flows and cost during purification in the subsequent acid making process can be reduced.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

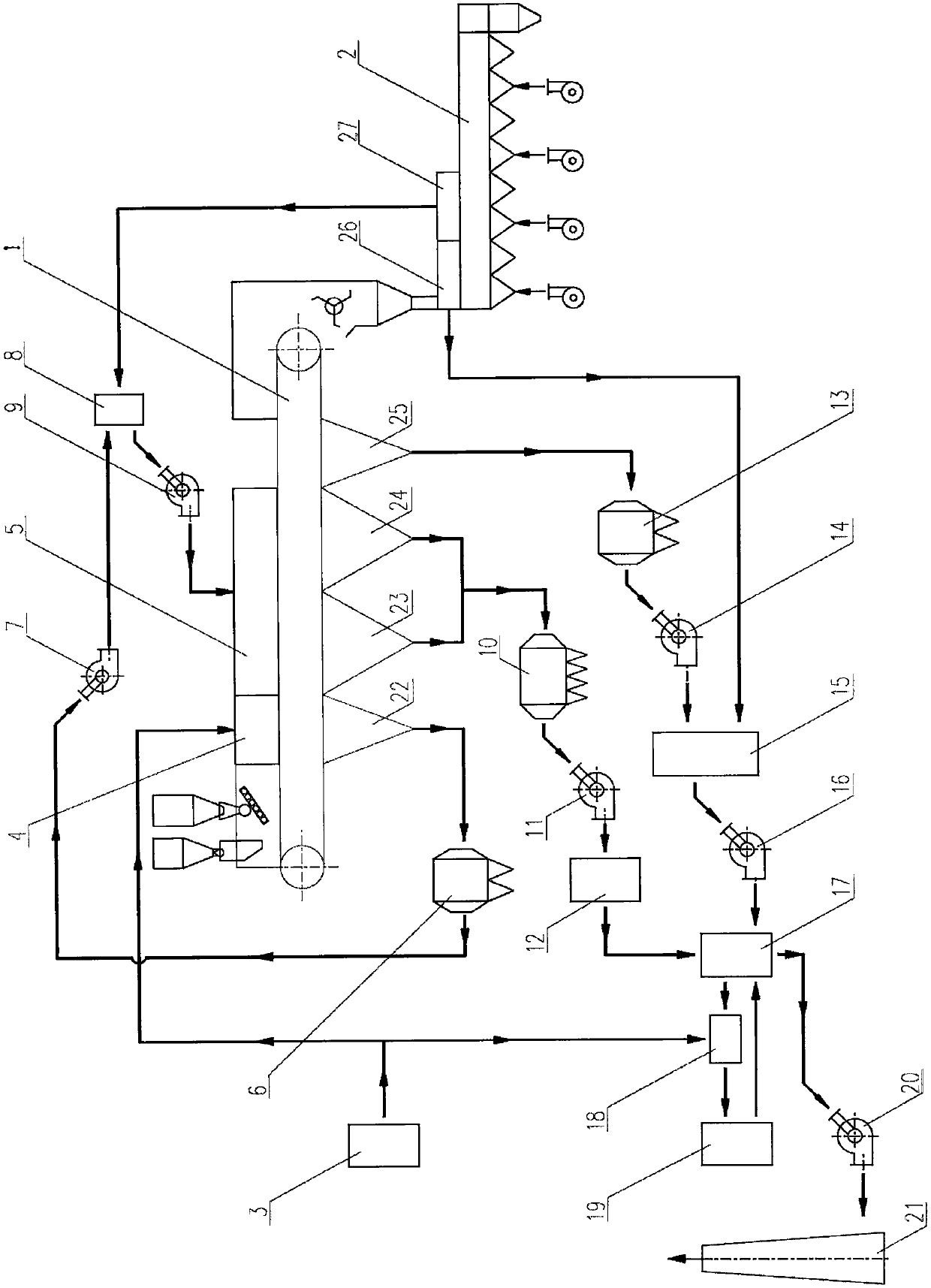

Environmental-protection and energy-conservation treatment technology of sintering flue gas

ActiveCN105509491AIncrease concentrationLow investment costGas treatmentDispersed particle separationCombustionMetallurgy

The invention discloses an environmental-protection and energy-conservation treatment technology of sintering flue gas, and belongs to the technical field of energy conservation and environmental protection. Flue gas having high SO2 concentration and very low NOx concentration at a sintering head is subjected to dust removal, and is mixed with hot flue gas in a flue gas hood at a second cooling section of a cooling machine to form circulating hot flue gas, and then flue gas circulating sintering is carried out; flue gas having high SO2 concentration and high NOx concentration at a sintering middle part is subjected to the dust removal and then flue gas desulfurization, the desulfurized flue gas is sintered and cooled by a flue gas heat exchanger, undergoes preheating temperature-rising, then undergoes pipeline complementary combustion temperature-rising to meet the requirement on SCR (Selective Catalytic Reduction) denitration temperature, flue gas denitration is carried out, and the denitrified flue gas is discharged; flue gas having low SO2 concentration and low NOx concentration at a sintering tail is subjected to the dust removal, and is mixed with hot flue gas in the flue gas hood at a first cooling section of the cooling machine to form high-temperature mixed flue gas, the high-temperature mixed flue gas is subjected to heat exchange by the flue gas heat exchanger, the flue gas after being subjected to heat exchange and cooled is directly discharged. According to the treatment technology, the effects of sectional desulfurization and denitration of sintering flue gas, and reduction in flue gas emission are realized; waste heat of the flue gas is used, so that the denitrified flue gas heating consumption is reduced; the construction investment and production running cost are reduced integrally; and the treatment technology corresponds with the running mode of energy conservation, environmental protection, emission reduction, consumption reduction, effect increasing and circular economy.

Owner:安庆沐尔环保科技有限公司

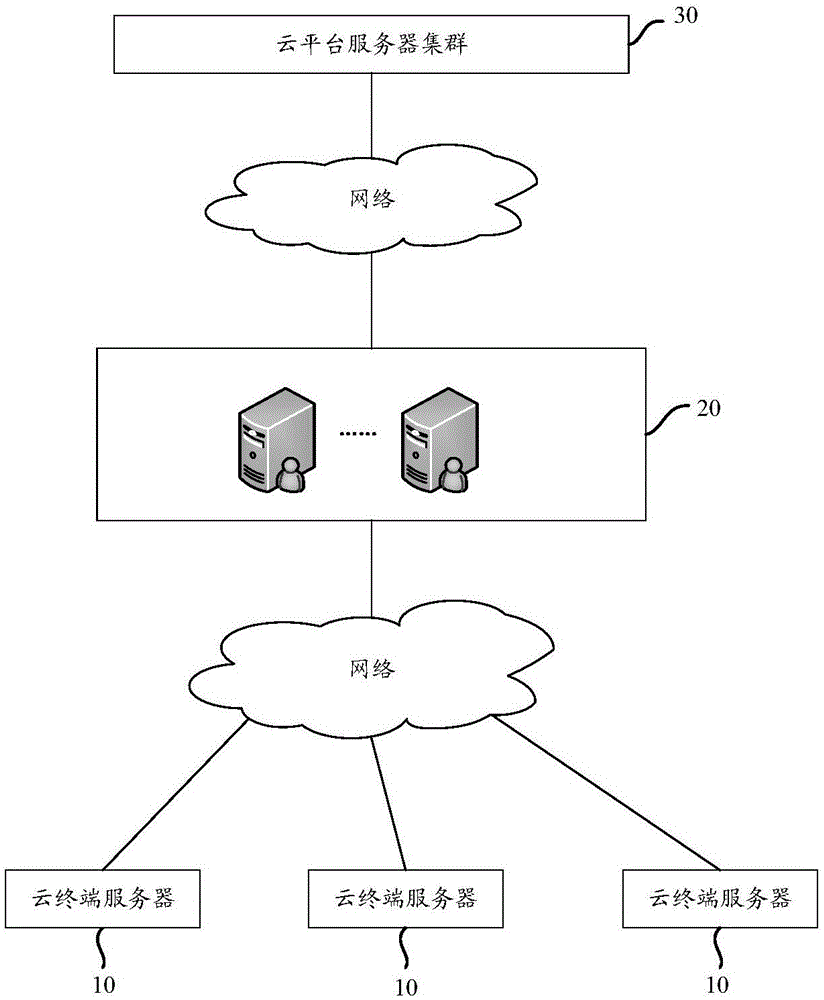

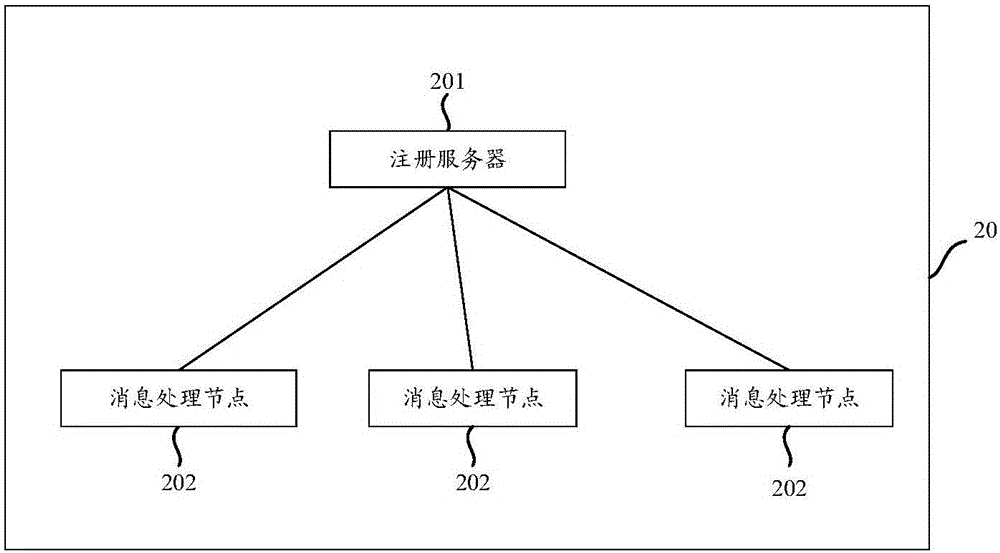

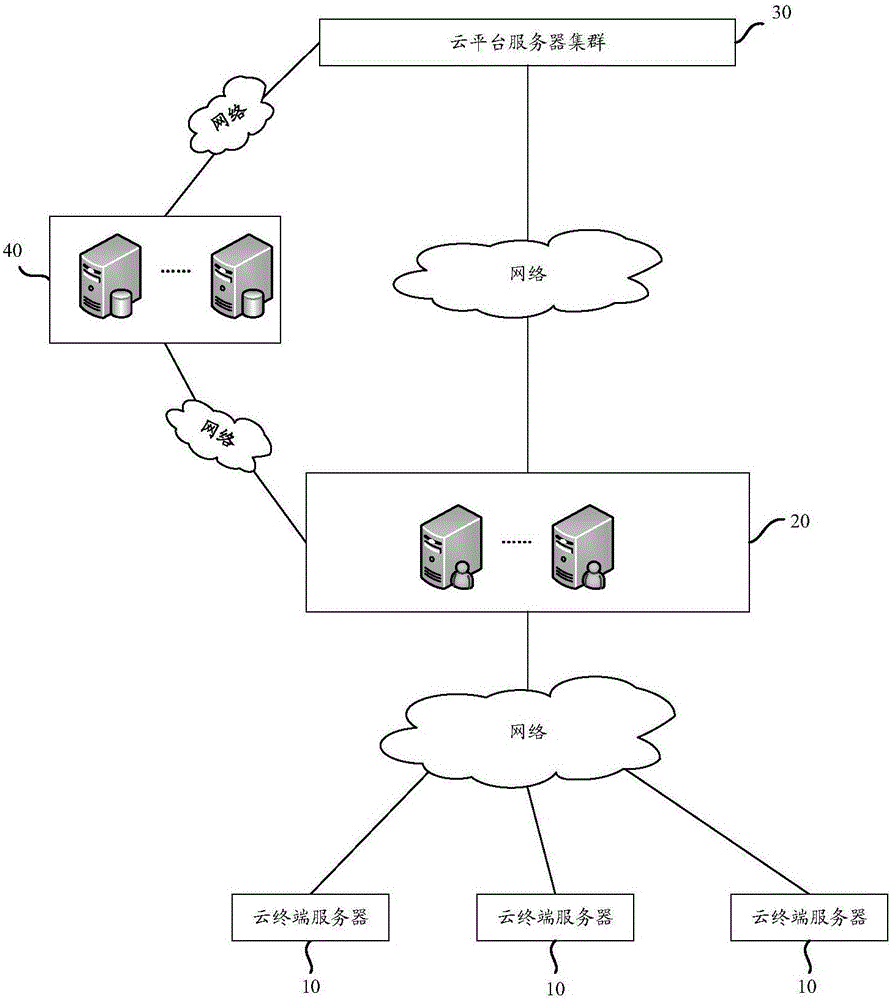

Energy cloud service system and communication method thereof

ActiveCN106412113AReduce production and operation costsImprove usabilityTransmissionEnergy technologyTerminal server

The embodiment of the invention relates to the technical field of energy, and particularly relates to an energy cloud service system and a communication method thereof. The communication method comprises the steps that a plurality of cloud terminal servers collect data information of field equipment on site actively or passively, the plurality of cloud terminal servers convert the data information into data information with a uniform format and send the data information to a message server cluster, the message server cluster stores the data information into storage spaces corresponding to the plurality of cloud terminal servers, and the data information is acquired by a cloud platform server cluster. Therefore, the field equipment perform asynchronous decoupling and load balancing and ensure reliable delivery of information through network communication between the cloud terminal servers and the cloud platform server cluster, and the cloud platform server cluster can perform remote asynchronous communication management on the subordinate field equipment of the cloud terminal servers through a network. In addition, the energy cloud service system can also provide a higher data load and communication load capacity under the same hardware resource condition, and thus the production, operation and maintenance cost of enterprises can be reduced.

Owner:上海东土远景工业科技有限公司

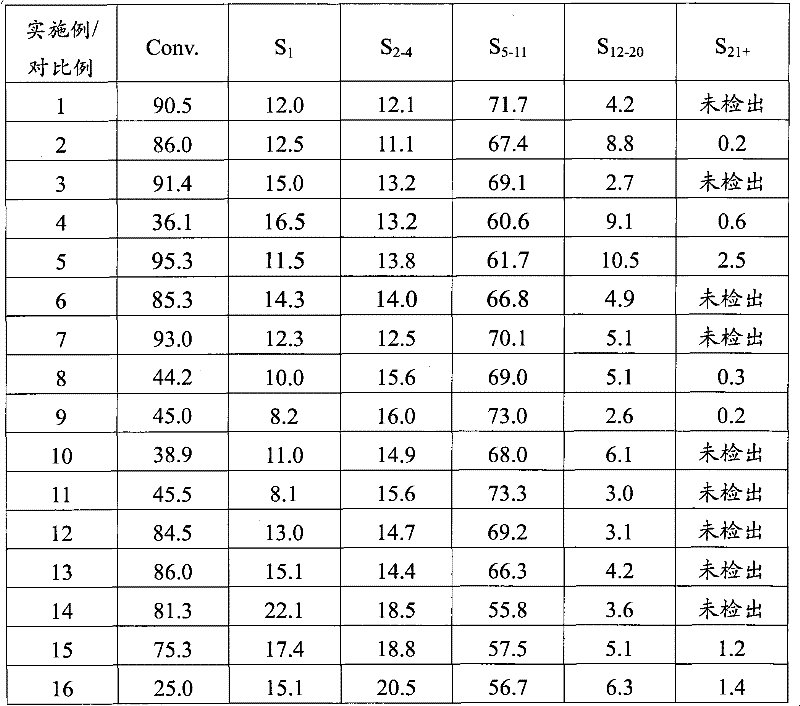

Catalyst for preparing high-quality gasoline fraction by virtue of syngas high selectivity and preparation method thereof

InactiveCN102211034AReduce stickingReduce pipe blockage and other problemsMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneMolecular sieve

The invention provides a catalyst for preparing a high-quality gasoline fraction by virtue of syngas high selectivity and a preparation method thereof. The catalyst comprises the following components in percentage by weight: 1-30% of metallic cobalt, 0.01-5% of assistant elements and the balance of molecular sieve. The catalyst has good selectivity to isoparaffin with 5-11 carbon atoms and quite low selectivity to the waxy hydrocarbons with more than 20 carbon atoms, so that the catalyst can be used for preparing high-quality gasoline fuels, and the catalyst carbon deposition can be avoided or obviously reduced. In addition, the invention further provides the preparation method of the catalyst.

Owner:WANHUA IND GRP

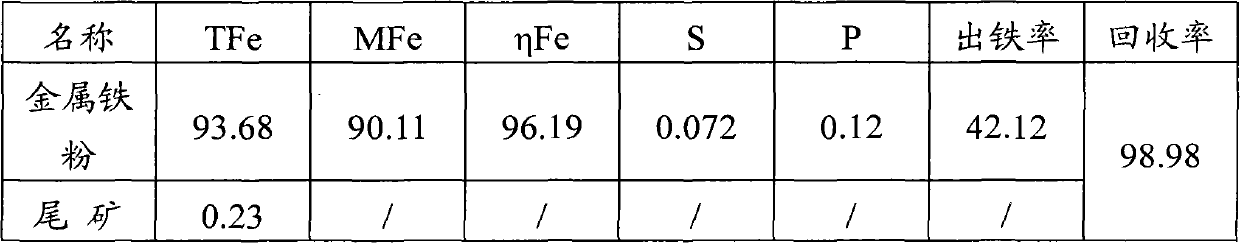

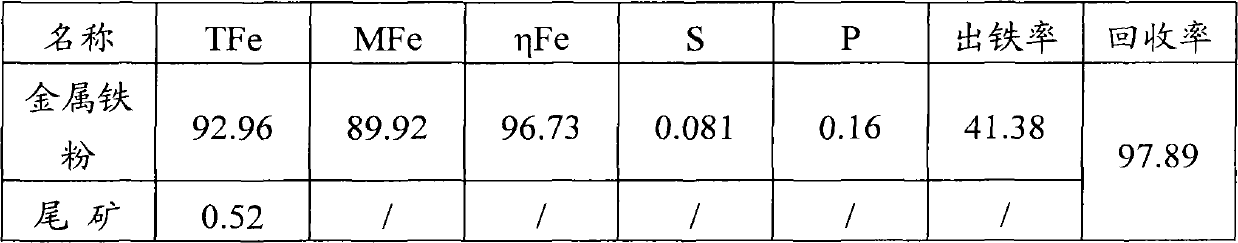

Preparing method for direct reduced iron using low grade high phosphorus iron ore as raw materials

Disclosed is a preparing method for direct reduced iron using low grade difficult-to-reduce high phosphorus iron ore as raw materials. The preparing method includes crushing ferric oxide iron ore to a granularity of 0-1mm so as to produce iron ore fines; mixing the iron ore fines, pulverized coals and auxiliaries sufficiently in a ratio of (80-84): (6-9) : (8-12) by mass percentage, to produce a pellet with a diameter of about 8-16mm, placing the pellet in a reduction kiln, subjecting the pellet to a reducing reaction in a reducing atmosphere at a temperature ranging from 1180 DEG C to 1350 DEG C for 3-8 hours to produce a metallized pellet, and performing crushing, magnetic separation and separation. By means of the preparing method, not only the direct reduced iron with low sulphur and phosphorus indexes can be obtained, but also various high-sulfur iron ore and low-poor-dull-phosphorus iron ore with a total Ferrum (TFe) <=40% can be used effectively, and production operating cost can be remarkably reduced.

Owner:辽宁瑞凡冶金科技有限公司

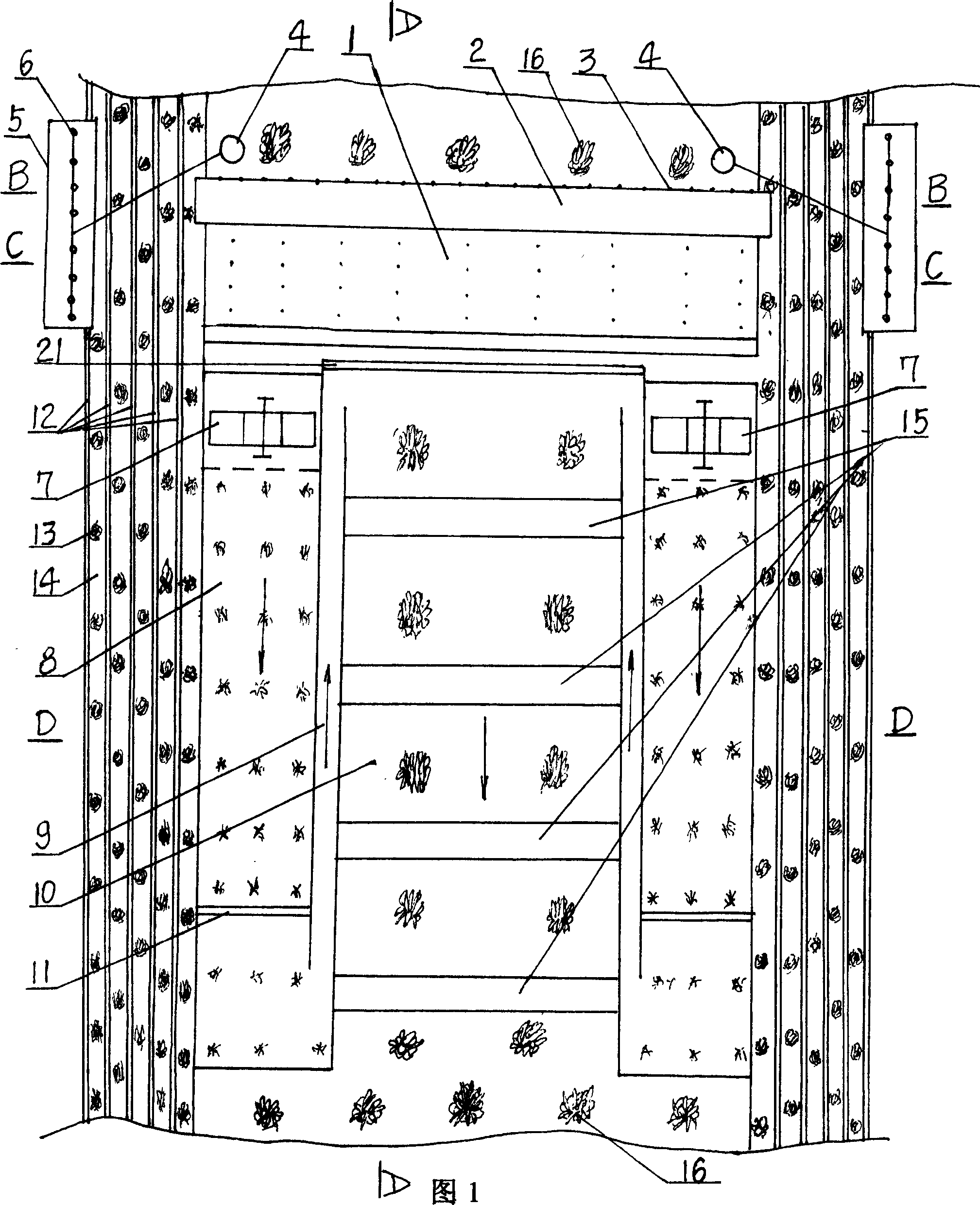

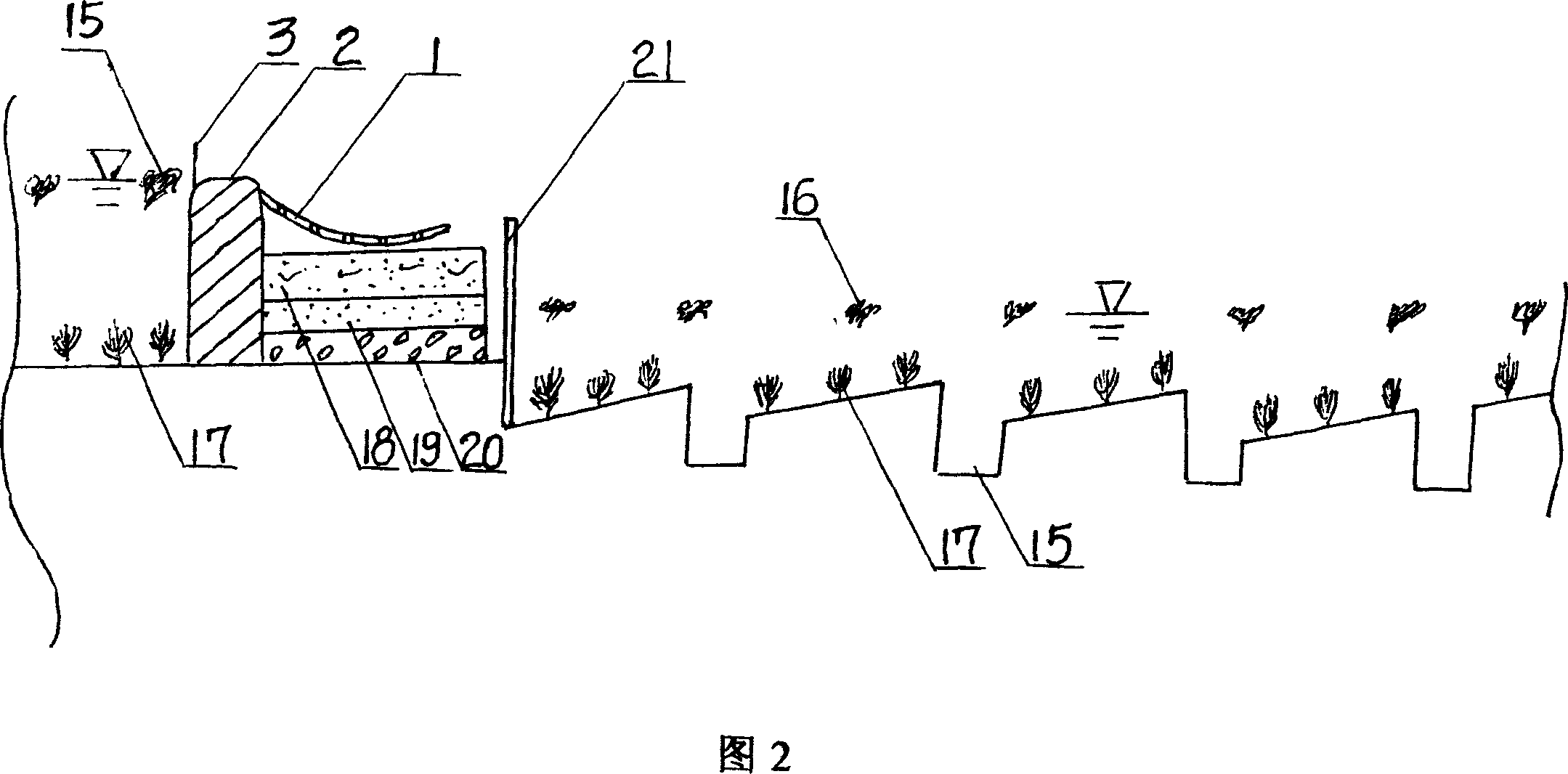

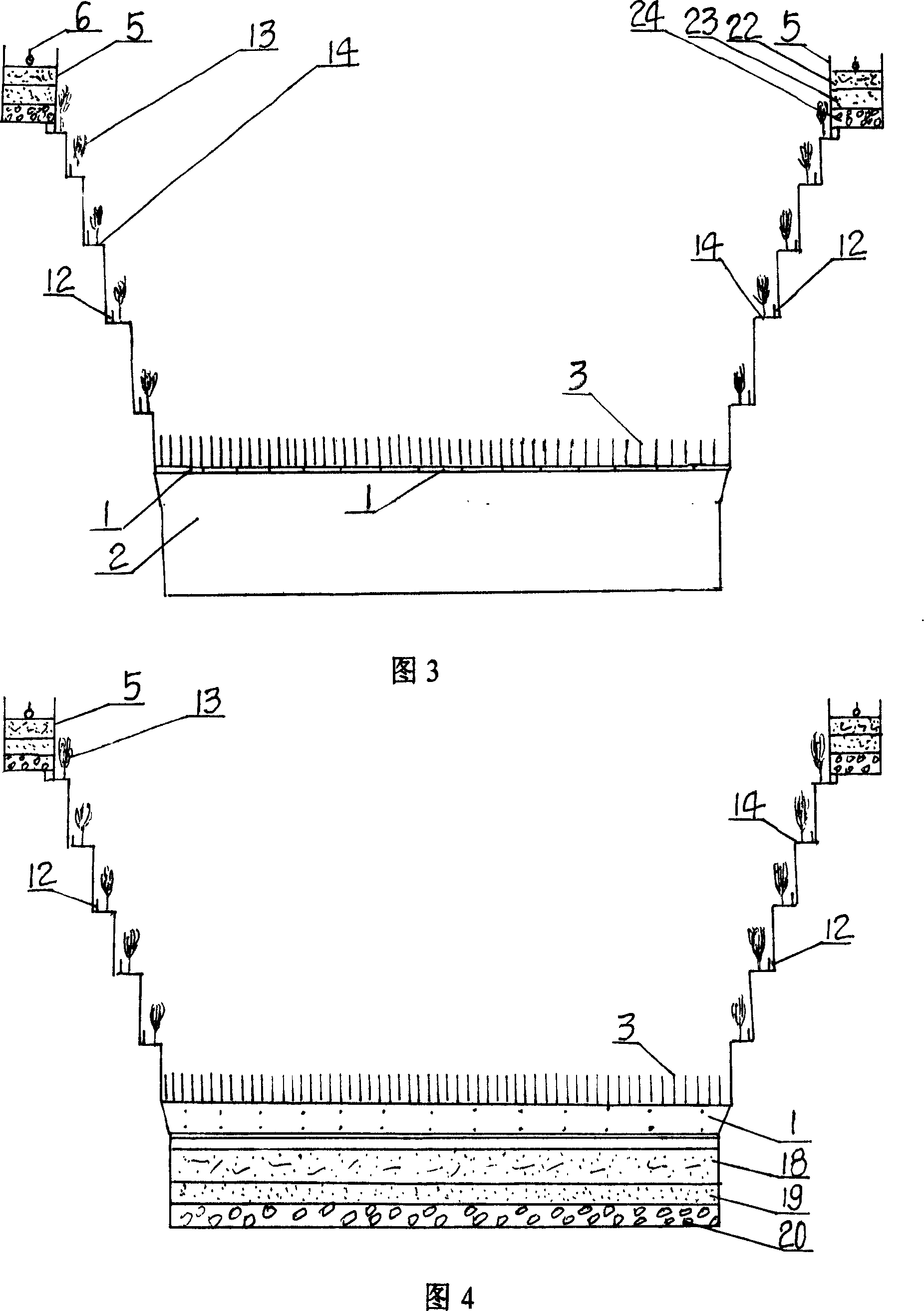

City ditch polluted water in situ ecological purifying processing device

InactiveCN101007674ARestoring ecological functionsReduce consumptionTreatment using aerobic processesSustainable biological treatmentWater wheelEngineering

The invention discloses an ecological purifying device of urban effluent, which comprises the following parts: biological earthworm reactor, biological rack, hydraulic aerating distributor, biological water-wheel type rotary disc, ecological purifying functional area and aeration filter purifying system, wherein the hydraulic aerating distributor connects biological earthworm reactor through overflow distributing board, which interconnects emergent aquatic plant area of ecological purifying functional area; the biological water-wheel type rotary disc is set in the outlet channel of biological earthworm reactor.

Owner:HEBEI AGRICULTURAL UNIV.

System for advanced treatment and recycle of cold rolling wastewater

ActiveCN101428939AEfficient removalAchieve the goal of energy saving and emission reductionDispersed particle separationWaste water treatment from metallurgical processCooling towerEngineering

The invention relates to a cold rolling waste water advanced treatment reuse system, which comprises a pretreatment process, a biological two-stage treatment process and an electric adsorption desalting treatment process. The pretreatment process comprises a uniformly-adjusting tank, a two-stage pH adjusting groove, a dissolved-air float, a middle pond, a cooling tower, a cooling pond, a plate type heat exchanger and the like. The biological two-stage treatment process comprises a biological contact oxidation pond, an inclined plate settling tank, a membrane biological reaction tank, a reactor, a cleaning box, a suction pump and the like. The electric adsorption desalting treatment process comprises an electric adsorption raw water pool, an electric adsorption moudle, a clean water tank, a reuse water pump, a regeneration pump, a sewage drain pump, an electric adsorption enriched water tank and the like. The cold rolling waste water undergoes the pre-treatment process comprising the uniform aeration adjustment, the two-stage pH adjustment and the dissolved-air flotation, the biological two-stage treatment step provided with the membrane biological reactor for contact oxidation and the electric adsorption deep desalting treatment process, thereby effectively removing pollutants in the cold rolling waste water, reutilizing the cold rolling waste water and achieving the aim of energy conservation and emission reduction.

Owner:宝武水务科技有限公司

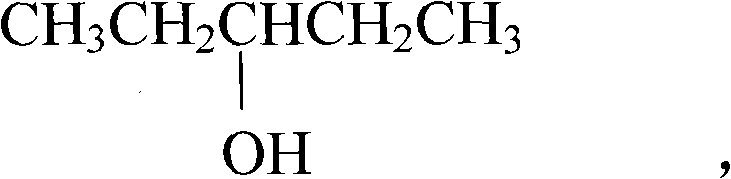

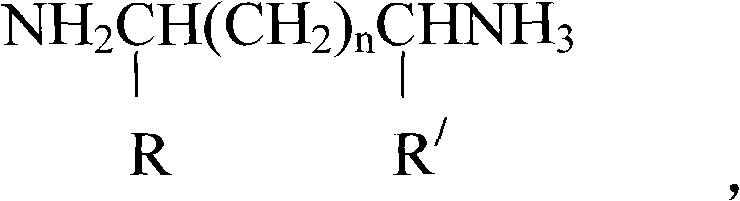

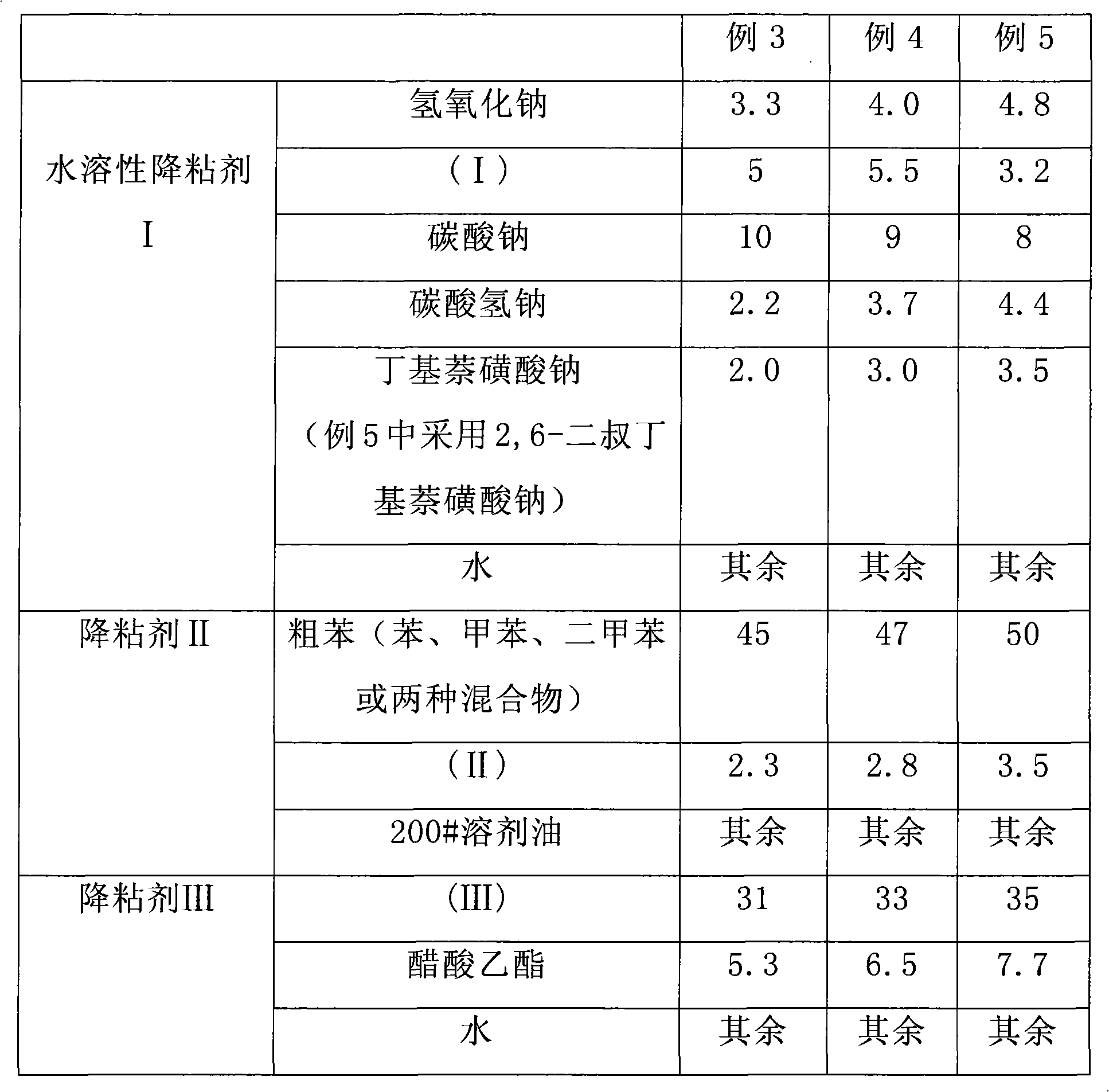

Method for extracting thick oil

ActiveCN101328798AImprove liquiditySolve the problem of difficult flow into the wellboreFluid removalDrilling compositionOil productionScrew pump

The invention provides a heavy oil cold production method applied to the production of oilfield heavy oil reservoirs at normal temperature and pressure. The method is characterized by comprising: a. a step of preparing water-soluble viscosity reducer I; b. a step of preparing viscosity reducer II; c. a step of preparing viscosity reducer III; d. a step of squeezing the water-soluble viscosity reducer I into oil reservoirs; and e. a step of using an oil pumping unit or screw pump lifting equipment to lift produced well fluid and adding the pitshaft viscosity reducer II or the pitshaft viscosity reducer III from an annular space between an oil pipe and an casing pipe of an oil well according to the different viscosity of produced fluid crude oil. The method has the advantages that: a chemical method is adopted to reduce the viscosity of heavy oil in the oil reservoirs and well fluid inside pitshafts, so as to improve heavy oil production effect; and the method has the continuous production time of the oil wells far more than that of the production methods in the prior art, greatly reduces production operation cost, and is obviously superior to the prior heavy oil production technology.

Owner:PETROCHINA CO LTD

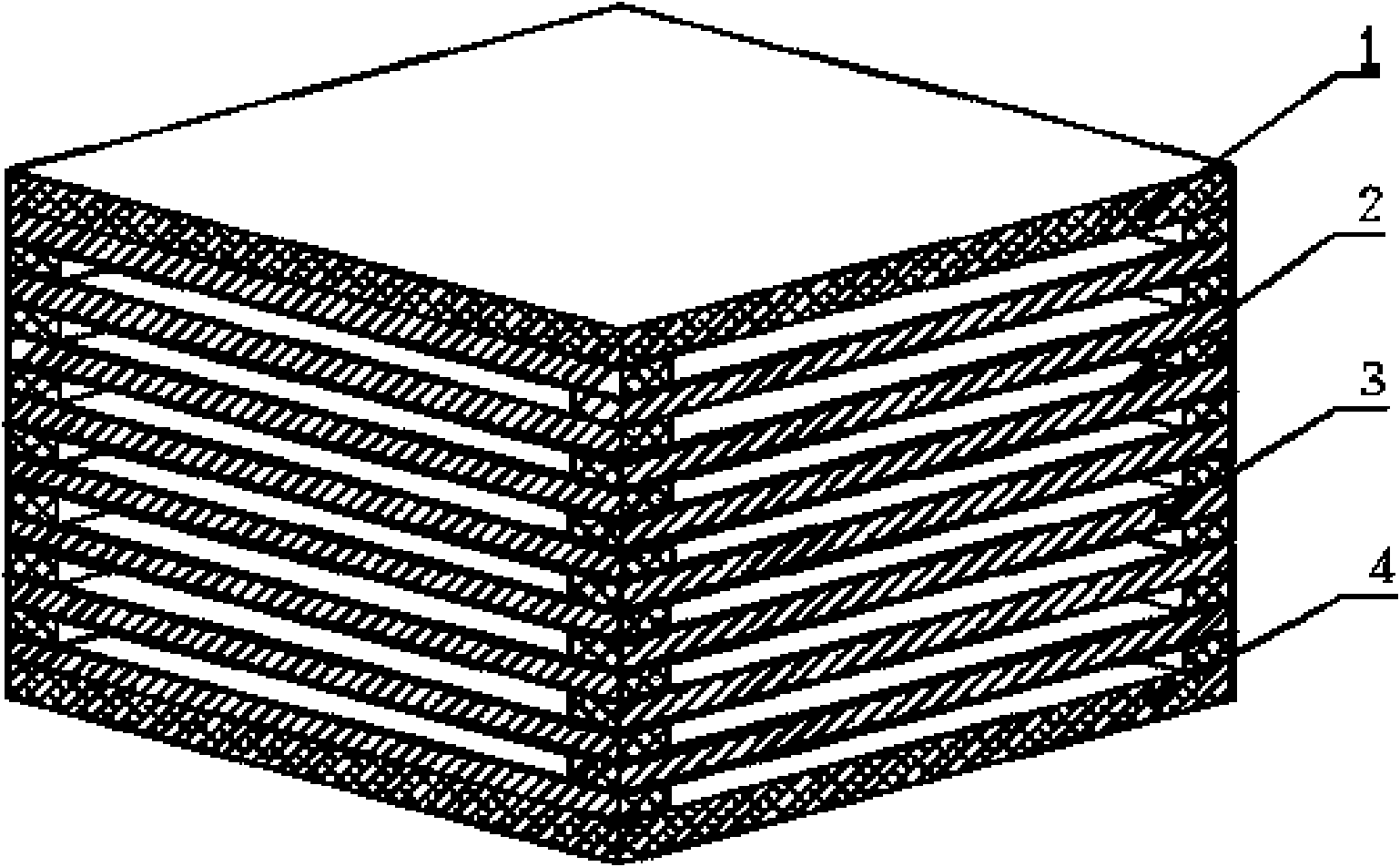

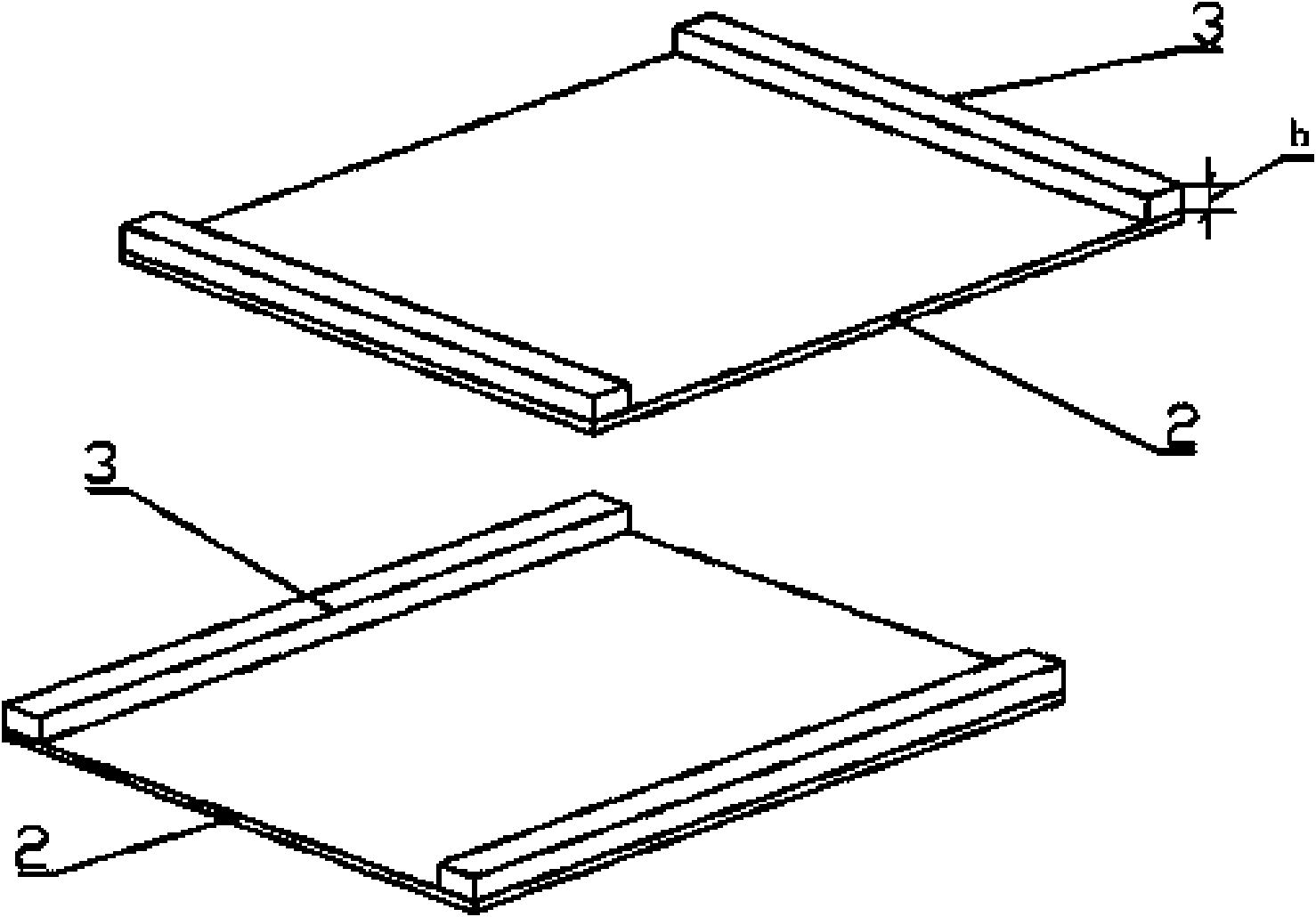

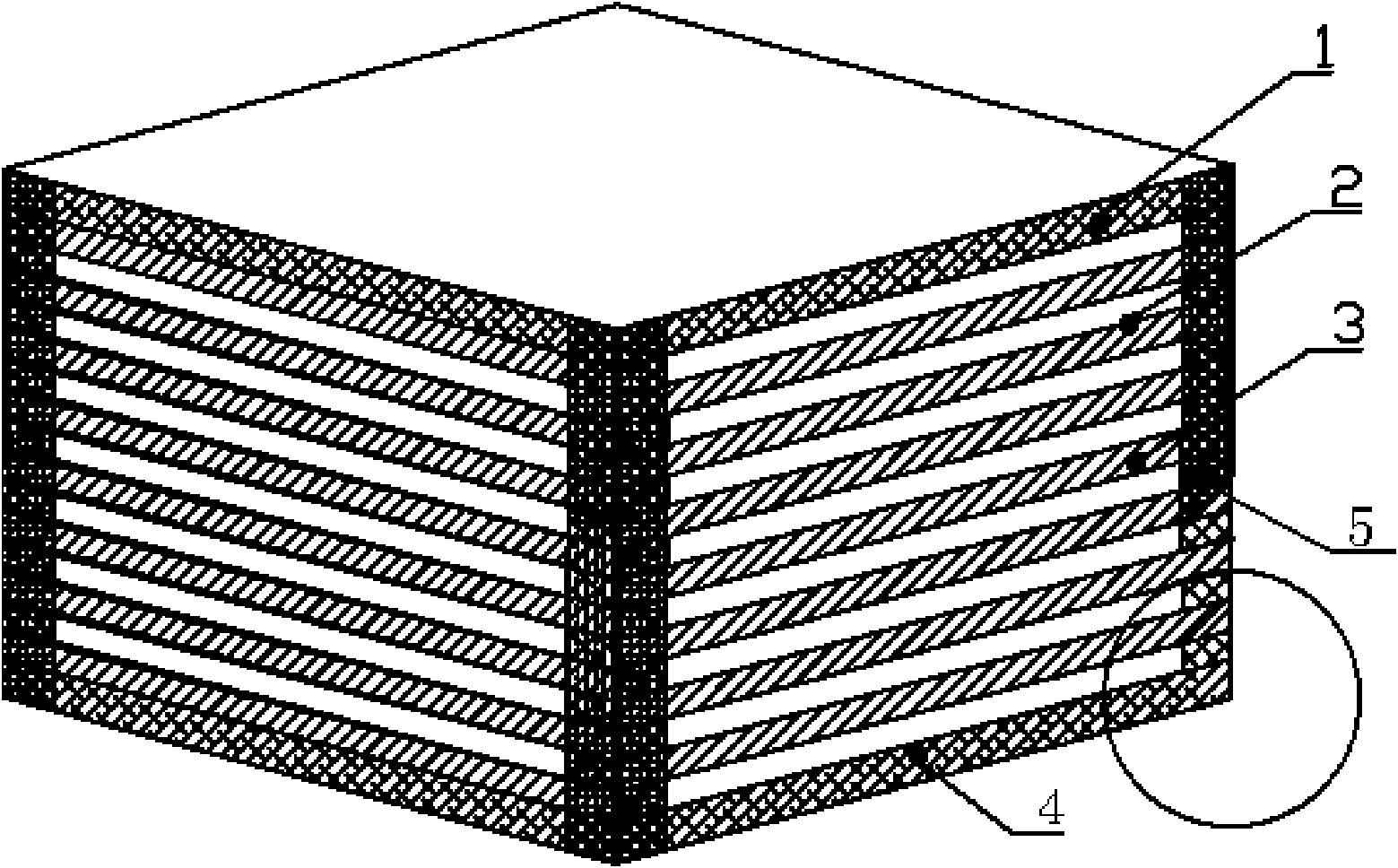

Core body of flat-plate heat exchanger for fresh air ventilator

InactiveCN101650141AAchieve low speed turbulent flowReduce thermal resistanceLaminated elementsStationary plate conduit assembliesFresh airEngineering

The present invention discloses a core body of a flat-plate heat exchanger for a fresh air ventilator, which comprises quadrangular plastic heat exchanging membranes, a top plate in the same shape asthat of the plastic heat exchanging membranes, a bottom plate and sealing strips. The upper surfaces on the near edges of two opposite edges of the plastic heat exchanging membranes with odd number are fixedly connected with the lower surfaces on the near edges of two opposite edges of the plastic heat exchanging membranes with even number through the sealing strips to form first airflow channels,the upper surface on the near edges of another two opposite edges of the plastic heat exchanging membranes with even number are fixedly connected with the lower surfaces on the near edges of two opposite edges of the other plastic heat exchanging membranes with odd number through the sealing strips to form second airflow channels crisscrossed with the adjacent first airflow channels, the top plate is fixedly connected with the uppermost plastic heat exchanging membranes through the sealing strips, and the bottom plate is fixedly connected with the lowermost plastic heat exchanging membranes through the sealing strip. The present invention has the advantages of favorable heat transfer performance, high heat exchanging efficiency, low weight and cost, simple structure, low production and running cost, convenient installation and easy integration with constructions.

Owner:TIANJIN UNIV

Method extracting waste tobacco at subcritical DMC

InactiveCN1682613AIncrease profitReduce economic riskTobacco treatmentSolid solvent extractionNicotineDimethyl ether

The present invention discloses subcritical dimethyl ether (DME) method of extracting waste tobacco. The technology adopts DME at subcritical state as main solvent in extracting waste tobacco, and through altering the temperature and pressure of the main solvent and adding different kinds of co-solvent in different amount, tobacco extractum, coarse solanesol extractum and coarse nicotine are extracted selectively.

Owner:侯金荣 +1

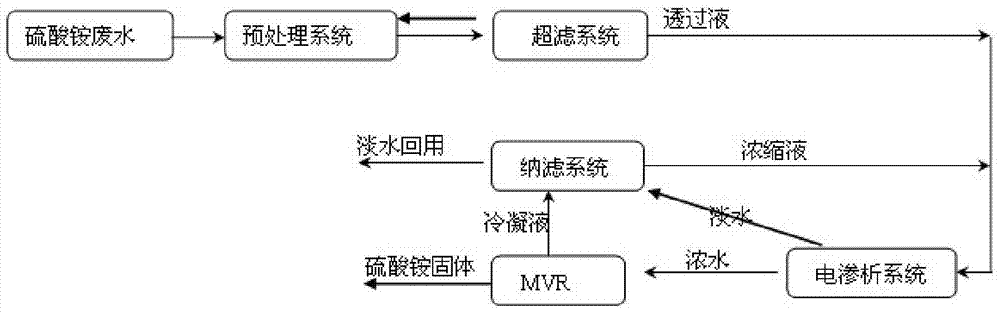

Recycling method for saponified ammonium-sulfate wastewater in rare soil

InactiveCN103771642AReduce manufacturing costHigh salt contentMultistage water/sewage treatmentUltrafiltrationRare earth

The invention provides a recycling method for saponified ammonium-sulfate wastewater in rare soil. The recycling method comprises the following steps: (1) pretreatment of coagu-flocculation reaction and a precipitation tank is carried out on the ammonium-sulfate wastewater; (2) an ultrafiltration system is adopted; (3) an electrodialysis system is adopted, concentrated water treated by the electrodialysis system enters the step (4), and fresh water enters the step (5) for treatment; (4) an MVR (Mechanical Vapor Recompression) system is adopted, concentrated salt water treated by the MVR system is crystallized and then becomes solid salt which is used as a composite fertilizer material or is sold to outside as a side product, and evaporated and condensed water is directly reused as process water for sulfuric-acid extraction in a rare-soil saponifying process; and (5) the fresh water electrodialyzed in the step (3) is treated by using a nanofiltration system, the permeated liquid of the nanofiltration system is used as the process water, and the concentrated liquid returns to the step (3) and is added into electrodialyzed water. The recycling method provided by the invention has the advantages that comprehensive treatment can be carried out on the ammonium-sulfate wastewater in the rare soil, so that not only can the environmental burden be caused, but also the ammonium-sulfate wastewater can be recycled.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

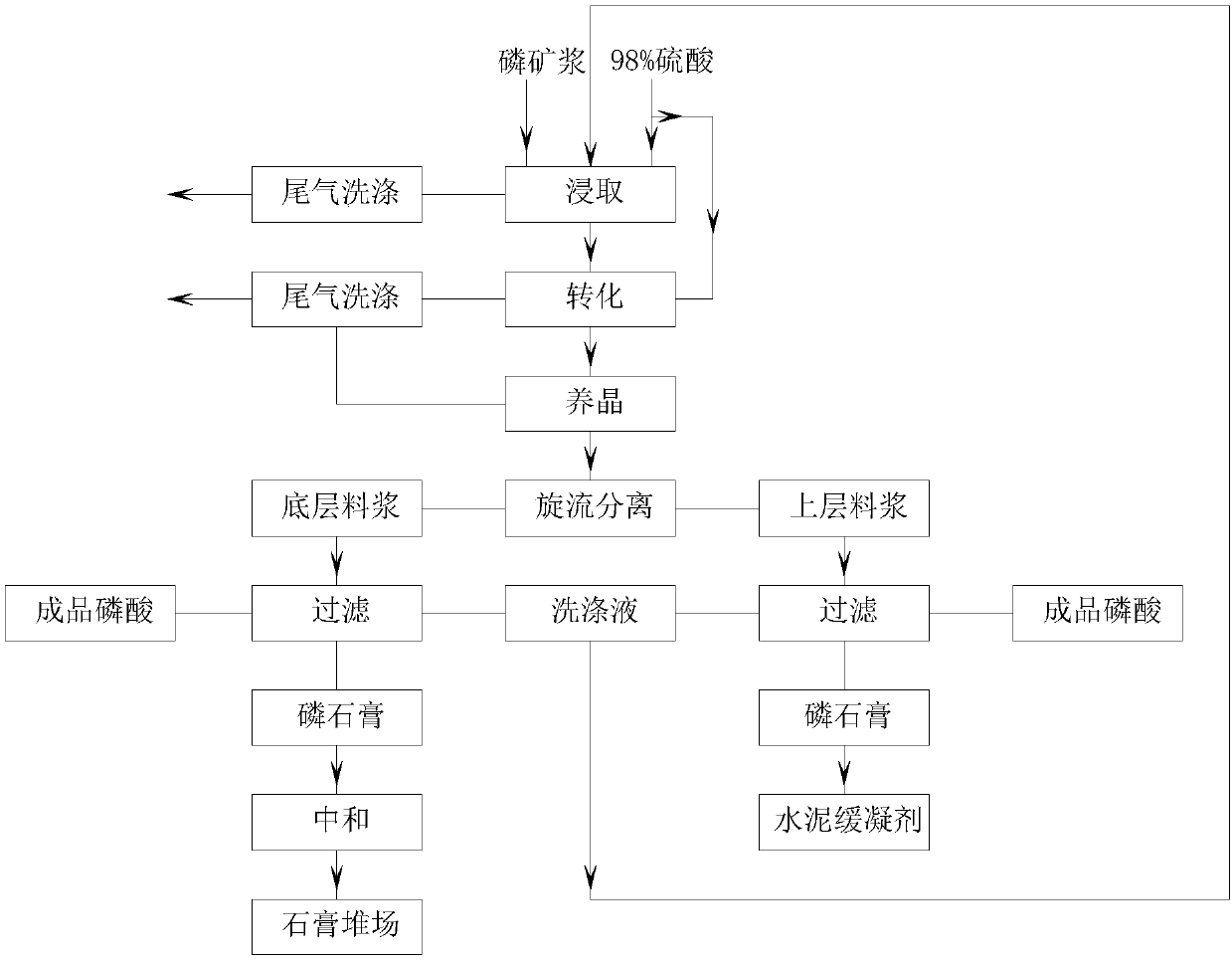

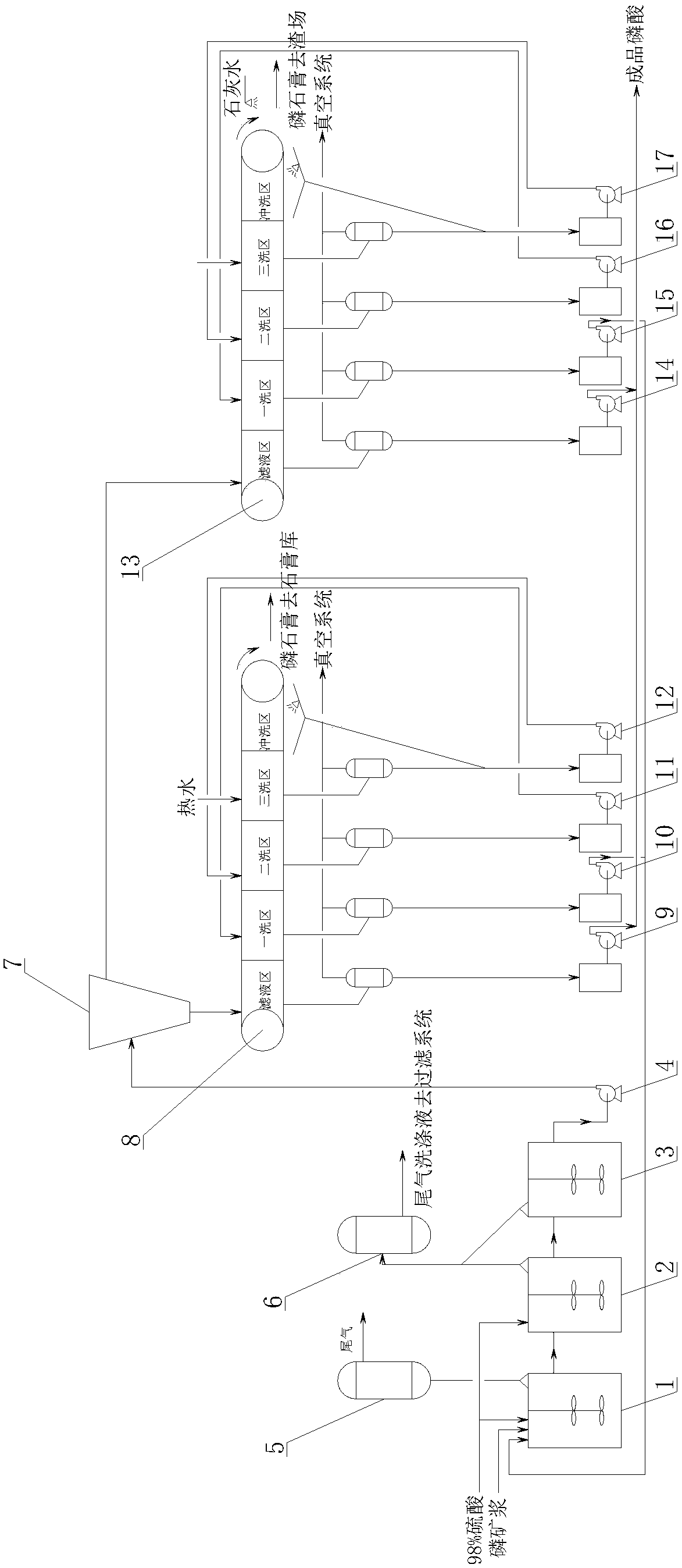

One-step method dihydrate-semi-hydrated wet production process for phosphoric acid

ActiveCN107840317AAvoid concentrated inputsGood energy saving effectPhosphorus compoundsHigh concentrationWash water

The invention relates to a one-step method dihydrate-semi-hydrated wet production process for phosphoric acid. The one-step method dihydrate-semi-hydrated wet production process comprises the following steps: carrying out leaching reaction and dehydrate-semi-hydrated conversion; growing grains; separating, filtering and washing; by controlling technological indicators of all the steps, finished product phosphoric acid filtrate with high concentration and by-product phosphogypsum with high quality are obtained. The finished product phosphoric acid filtrate obtained by production of the one-stepmethod dihydrate-semi-hydrated wet production process disclosed by the invention has the advantages that the concentration of P2O5 is about 35 percent, concentration input of the phosphoric acid canbe avoided and an energy-saving effect is good. In addition, the phosphorus conversion rate and the washing rate are high; the final by-product phosphogypsum has the characteristics that the total content of the P2O5 is smaller than or equal to 0.5 percent, the content of water-soluble P2O5 is smaller than or equal to 0.15 percent and the yield of the P2O5 reaches 98 percent. The one-step method dihydrate-semi-hydrated wet production process disclosed by the invention retains the characteristics of good energy-saving effect, high phosphorus yield and high quality of byproduct alpha-semi-hydrated gypsum of a traditional two-step method dehydrate-semi-hydrated technology; meanwhile, a dihydrate filtration procedure is omitted, the process flow is shortened and the operation rate of a deviceis improved, so that the problem that water balance of a system cannot be realized due to overhigh content of wash water for filter cloth is solved.

Owner:ANHUI LIUGUO CHEM CO LTD

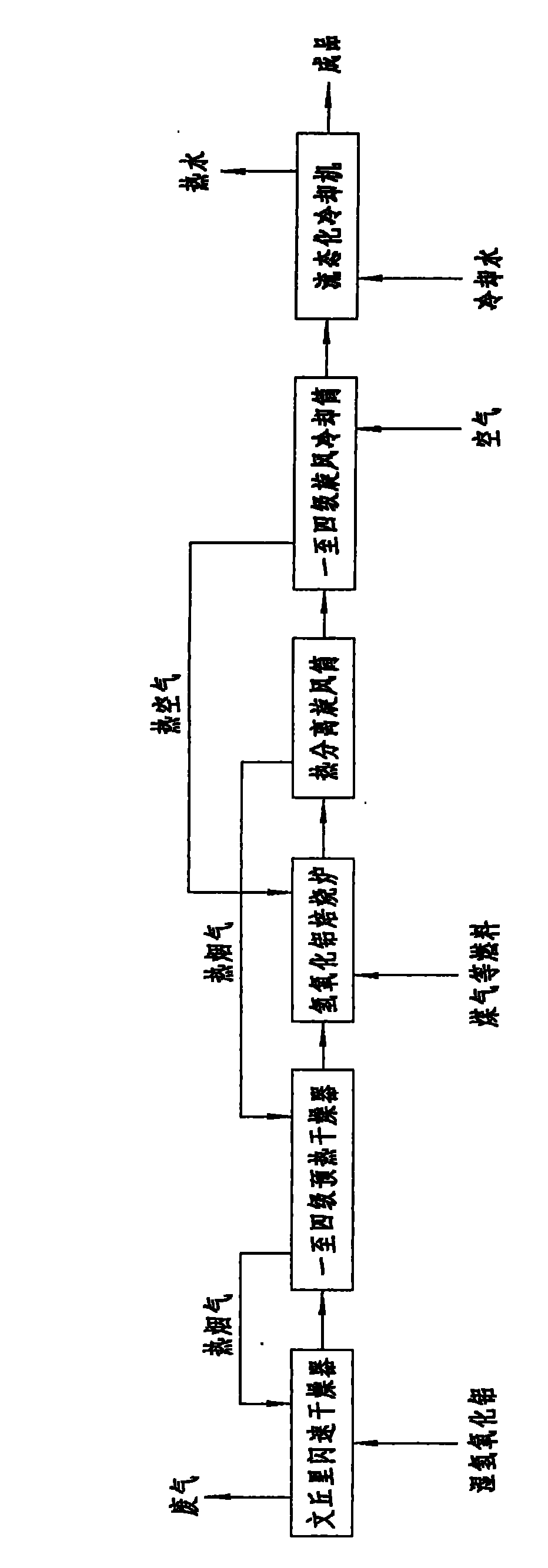

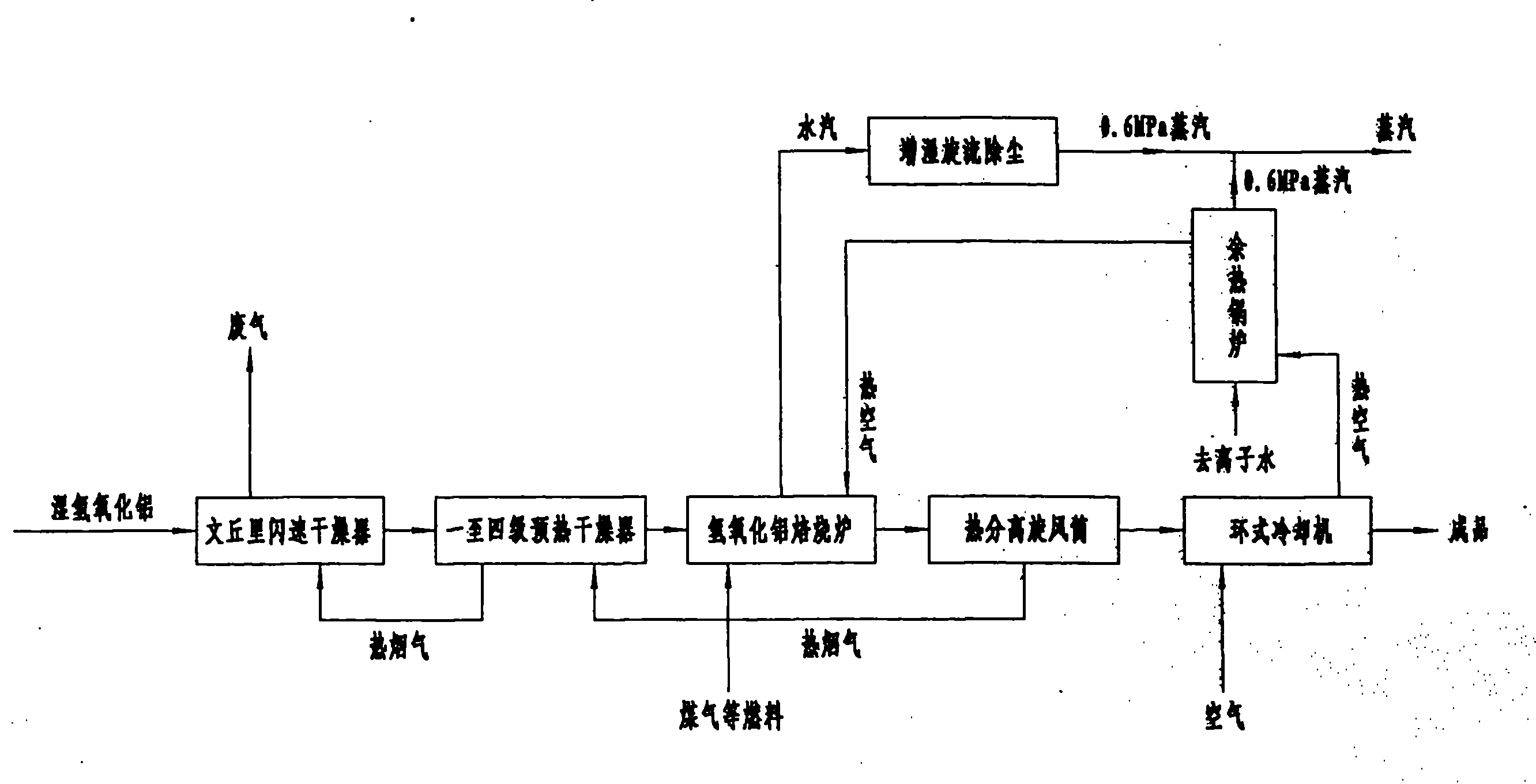

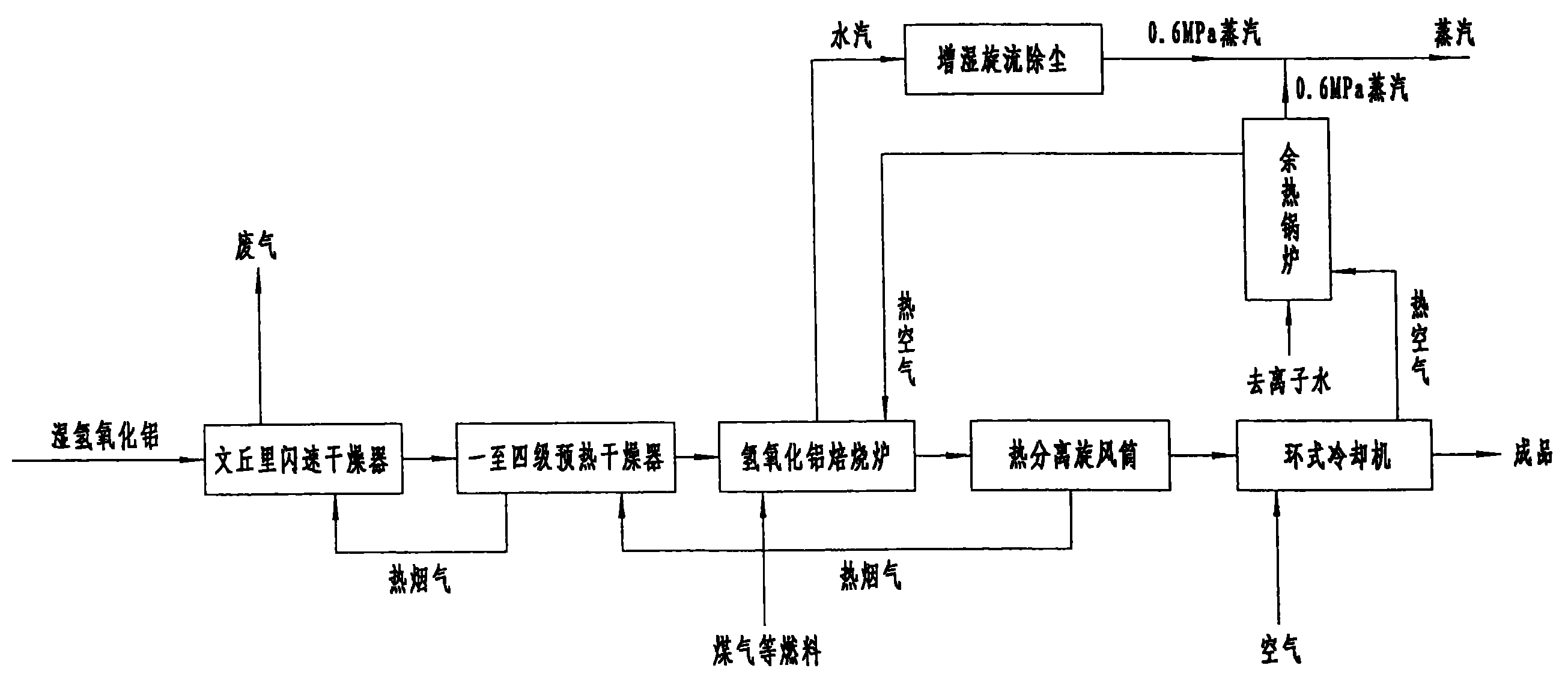

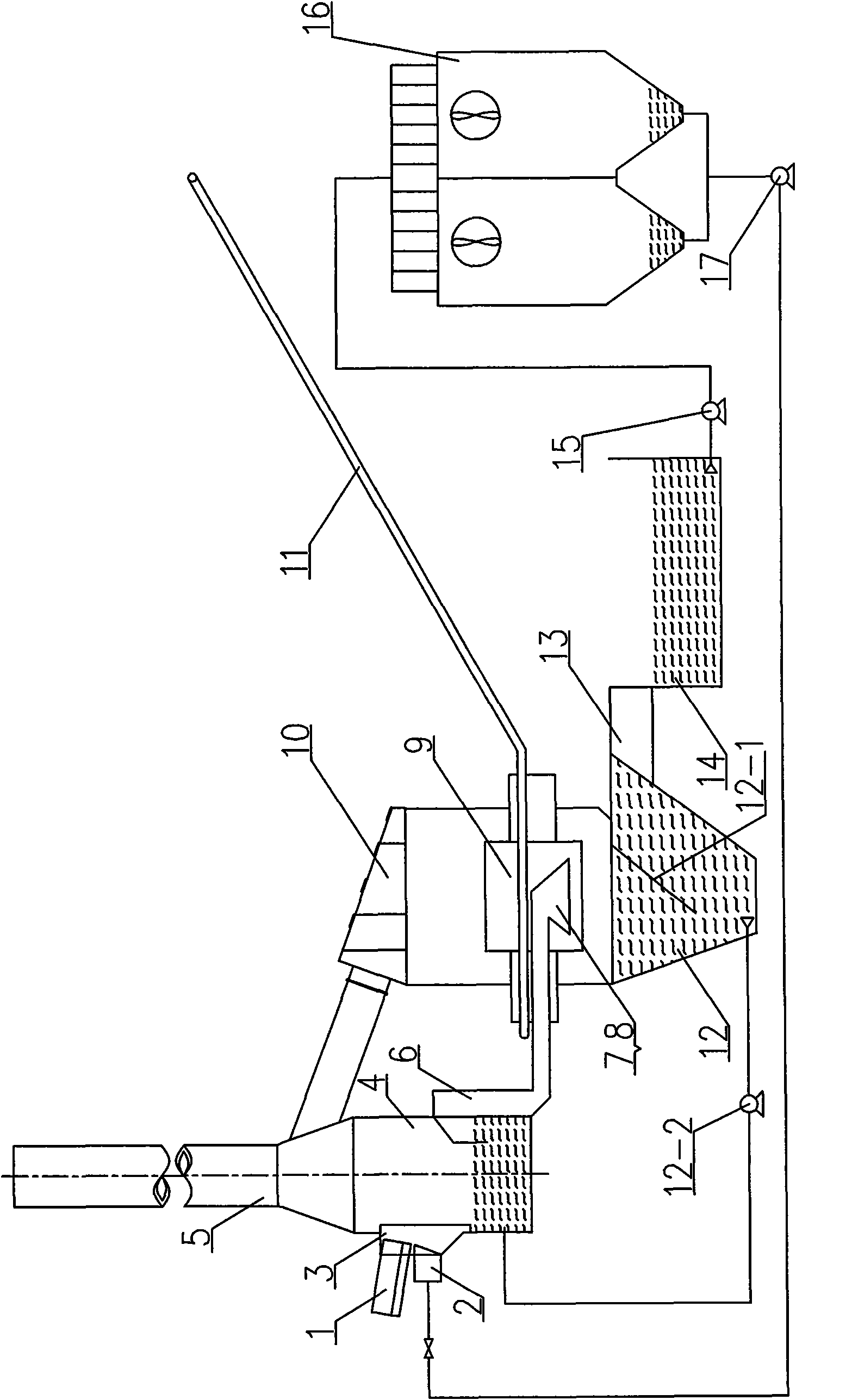

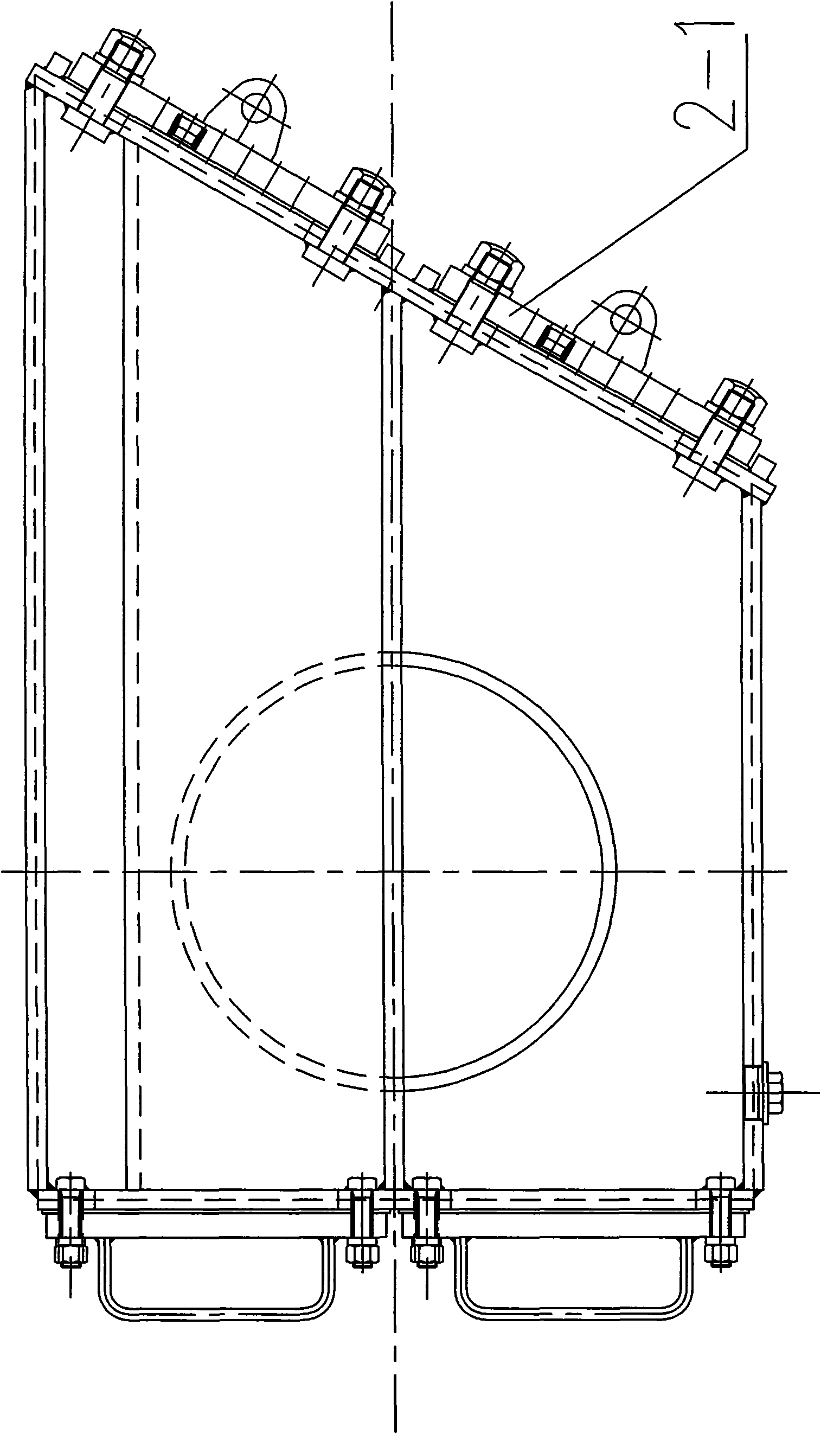

New technology for gas suspension calcination of aluminium hydroxide

ActiveCN101870492AEase of industrial implementationImprove qualityEnergy inputAluminium oxide/hydroxide preparationCycloneAluminium hydroxide

The invention discloses a new technology for gas suspension calcination of aluminium hydroxide, successively comprising the following steps: feeding, entering a Venturi flash drier, entering a multi-stage preheating drier, entering an aluminium hydroxide roaster, entering a thermal separation cyclone, and entering a cooling mechanism to obtain the finished product aluminium hydroxide. A preheating drier is connected with a pipeline leading to the flash drier, and the cyclone is connected with a pipeline leading to the preheating drier. The new technology is characterized in that the system also comprises a waste heat boiler and a humidifying rotational flow dust collector, wherein the cooler is connected with a pipeline leading to the waste heat boiler; the waste heat boiler is connected with a pipeline leading to the roaster; the roaster is connected with a moisture pipeline leading to the humidifying rotational flow dust collector; and steam from the humidifying rotational flow dust collector and the boiler can serve as a new steam source to be used by an evaporation tool. The invention is characterized in that the invention not only preheats air but also produces steam with high additional value on the utilization of waste heat, provides a valuable evaporation heat source for producing aluminium hydroxide, recovers moisture produced in the roasting process, converts moisture into new steam and greatly lowers production operation cost.

Owner:HENAN KDNEU INT ENG

Blast furnace slag processing device

ActiveCN101649364ASmall footprintLow investment costRecycling and recovery technologiesProcess efficiency improvementSlagMaterials science

The invention relates to a blast furnace slag processing device. The processing device comprises a water-quenching cooling device, a slag-water separating device and a slag flush water circulating device, wherein the input end of the slag-water separating device is connected with the output end of the water-quenching cooling device, and the output end of the slag-water separating device is connected with the input end of the slag flush water circulating device; and the output end of the slag flush water circulating device is connected with the input end of the water-quenching cooling device. The blast furnace slag processing device is provided with a condensing and recycling device, reduces the ground occupation area, the investment and the production running cost and has high quality of water and slag.

Owner:CISDI ENG CO LTD

Slime separation method and equipment

InactiveCN101773873AImprove recycling effectSurface as soon as possibleFlotationEconomic benefitsEngineering

The invention relates to a slime separation method and equipment. The slime separation method adopts a one-piece double-flotation-column to carry out circulating flotation and classification for slime, and a flow stabilizer is arranged in a first flotation column; the flow stabilizer can eliminate large vortex, support a foam layer and increase the probability of collision between particles and bubbles, so that the slime easy to float can be floated out as soon as possible so as so reduce mix and pollution and play the role of flow stabilization; the material floated out through sedimentation is classified by a first sedimentation box and then enters a second floatation column to be floated again, and then enters a second sedimentation box to be classified again; and the number of the circulating separation of pulp is increased, and the recovery capabilities of coarse-fraction slime and difficultly floated fine-fraction slime are improved. The equipment has compact structure, large treating capacity, low production operation cost, and convenient installation and operation, improves the number and quality of fine coal products on the whole, and has marketable economic benefits.

Owner:CHINA UNIV OF MINING & TECH

Method of producing active nutritional fertilizer using old domostic garbage

InactiveCN1911865AEliminate heavy pollutionSave 2 fermentationsBio-organic fraction processingClimate change adaptationPotassiumTotal nitrogen

The present invention relates to method of producing active nutritious fertilizer with old domestic garbage as material. By means of composite bacteria preparation comprising azotobacteria, photosynthetic bacteria, yeast, lactic bacteria, functional bacillus and other micro aerobe or aerobe and earthworm, old domestic garbage is treated through once fermentation treatment to obtain the active nutritious fertilizer. The active nutritious fertilizer is harmless, and has water content less than 20 %, pH 7.5-8.5, total nitrogen not less than 0.3%, quick acting nitrogen not less than 0.04%, total phosphorus not less than 0.1%, total potassium not less than 0.2%, inorganic granularity small than 5 mm and total active beneficial bacteria number not less than 1x10<7> / g. The production process has short period and less produced marsh gas.

Owner:CHINA AGRI UNIV

Process for producing industrial magnesium oxide using dolomite ash and boron mud

The present invention belongs to the field of inorganic chemical technology, and is especially process of producing industrial magnesia with dolomite and boric slime as industrial waste. The present invention produces industrial magnesia through slaking dolomite, reaction with boric slime, carbonating, thermal decomposing, drying, calcining and other steps. The present invention features the phase transfer catalysis reaction of the slaked dolomite and boric slime to convert magnesium carbonate hard to carbonize into magnesium hydroxide easy to carbonize.

Owner:高佳令

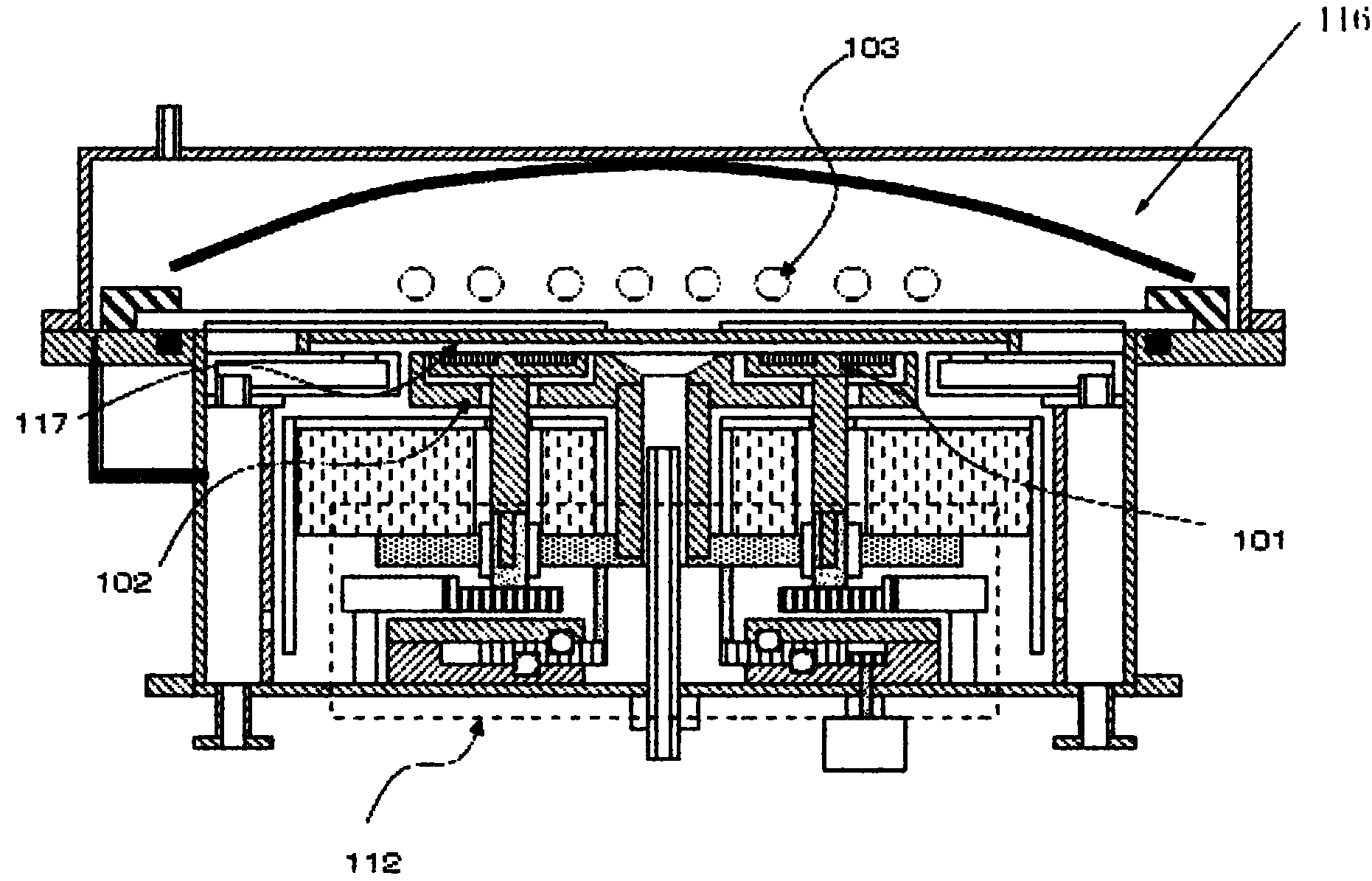

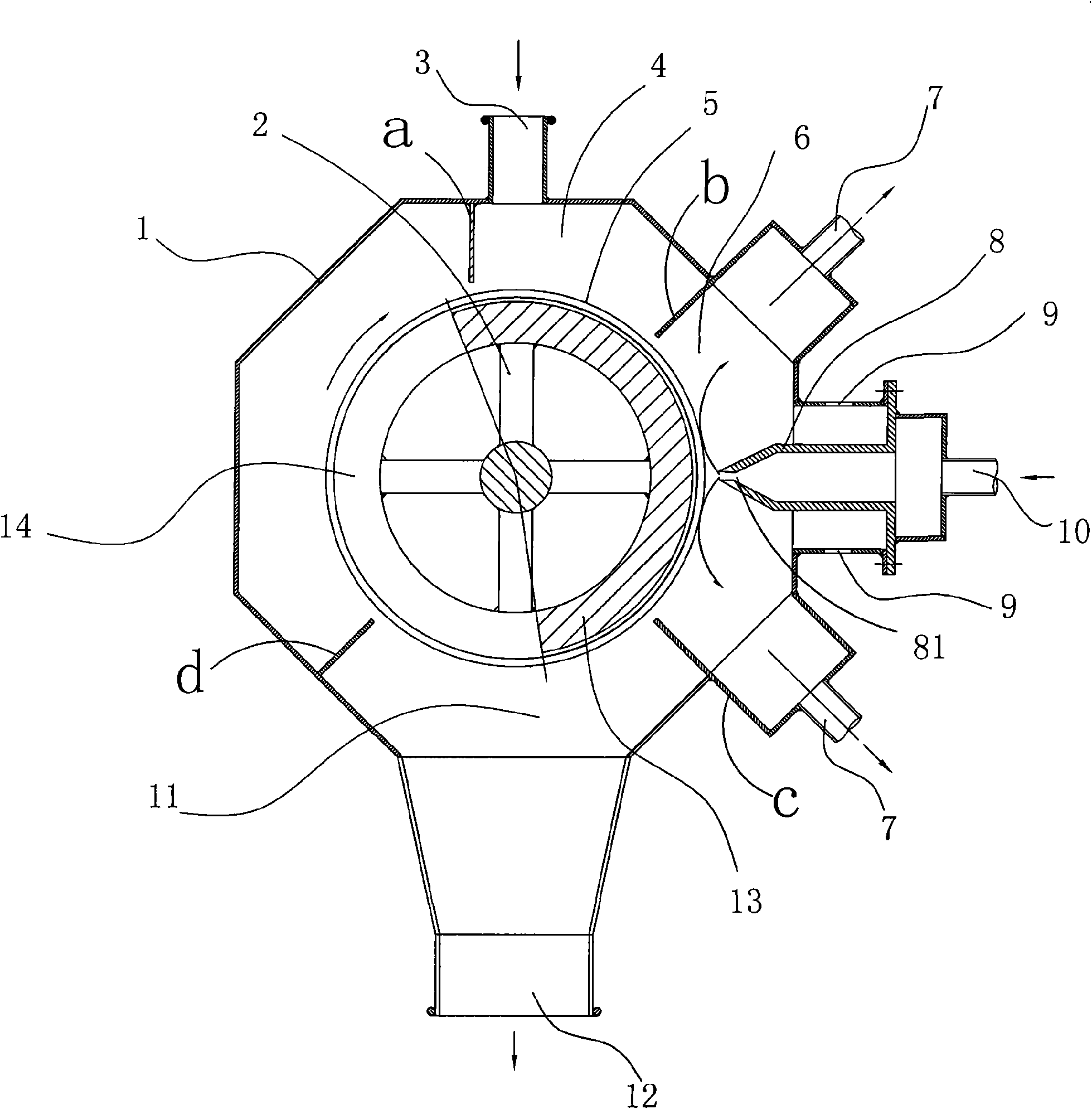

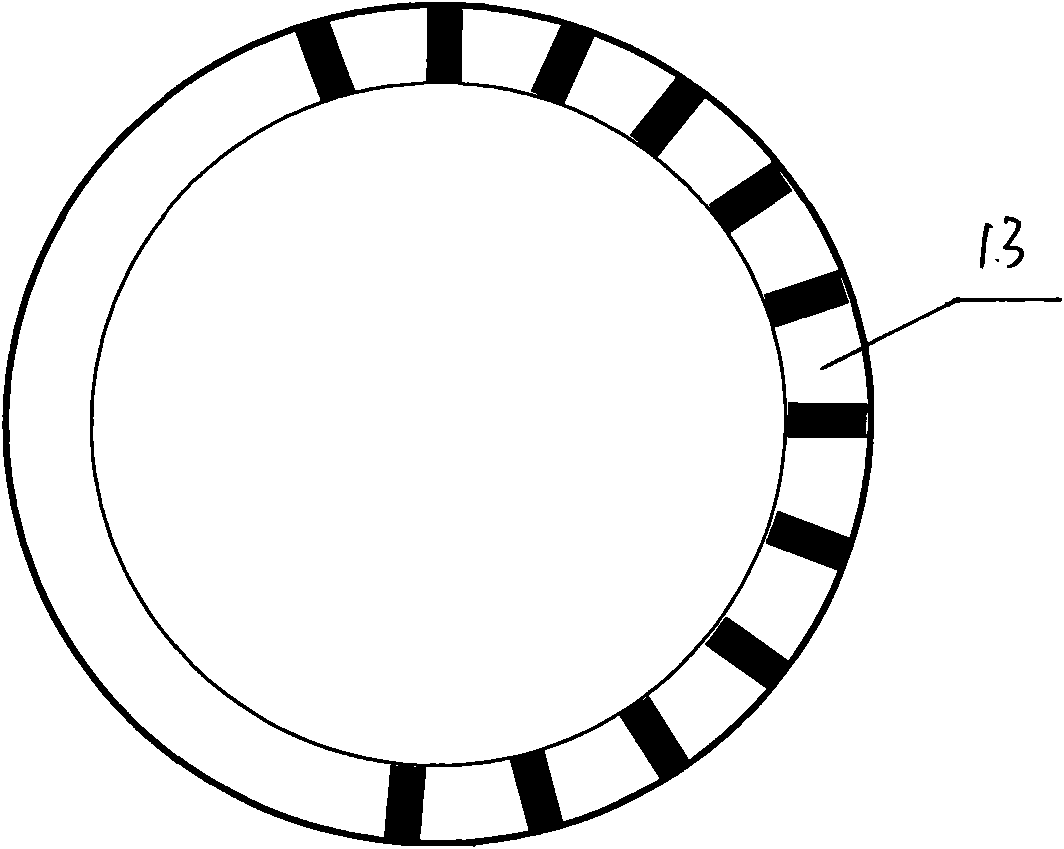

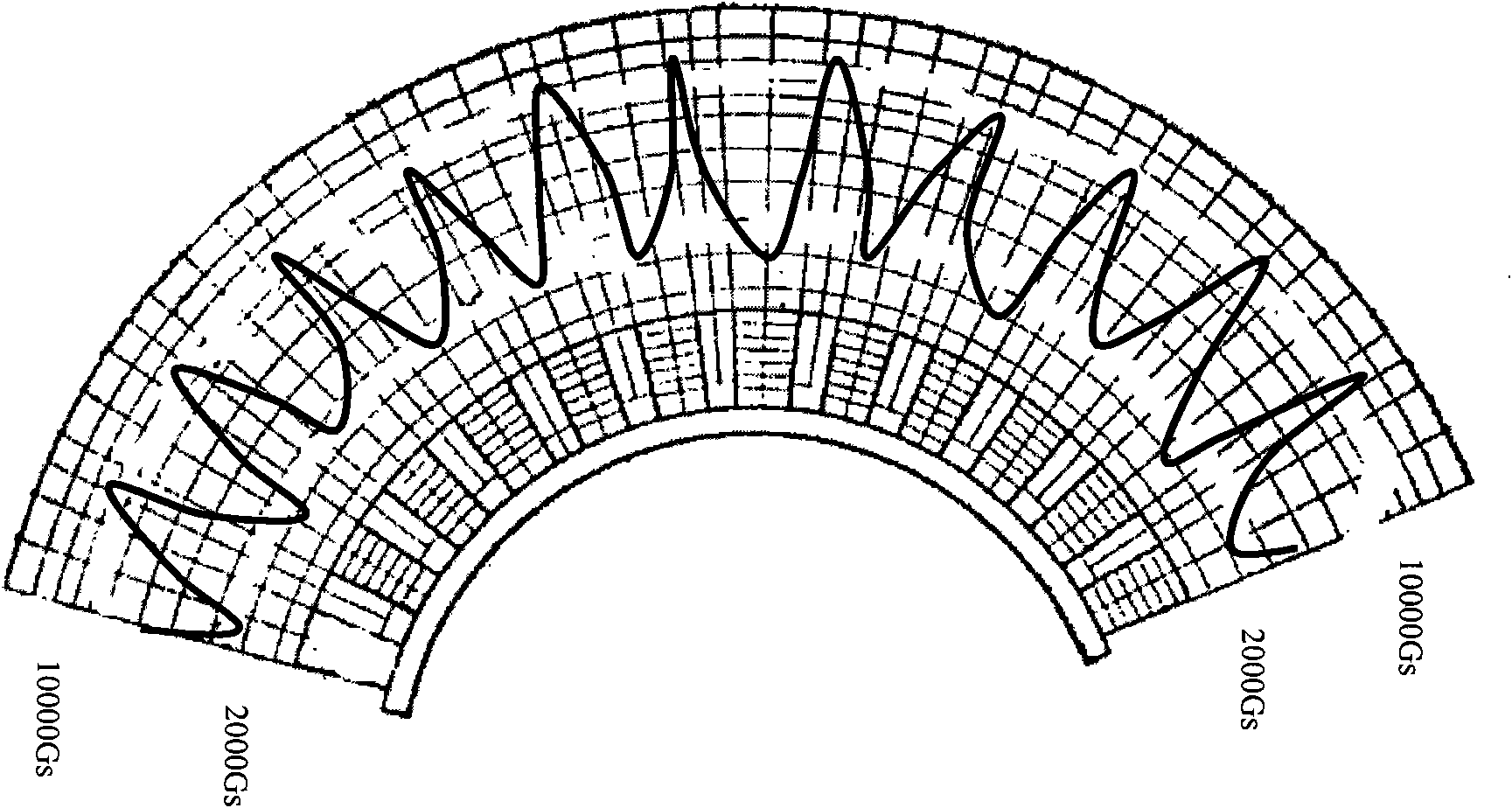

Dry-method air-separation strong permanent magnetic separator

InactiveCN101612609AReduce energy consumptionReduce production and operation costsMagnetic separationEngineeringIon

The invention provides a dry-method air-separation strong permanent magnetic separator, belongs to the technical field of dressing equipment, and is particularly suitable for regenerating an ion-containing fly ash resource produced in a smelting process for making ion and steel. The dry-method air-separation strong permanent magnetic separator comprises a machine body and a magnetic roller arranged in the machine body, wherein the machine body is provided with a feeding hole, a discharge hole and an exhaust and air discharge hole; the magnetic roller comprises a fixedly arranged roller core and a roller sheet which surrounds the roller core and can rotate around the roller core; the internal space formed by the machine body and a semi-circumferential surface, provided with a magnetic area, of the roller core is divided into a material distribution area, a separation area and a blanking area by baffle plates from top down, and the material distribution area, the separation area and the blanking are mutually communicated; the machine body is provided with a nozzle device spraying air flow toward the separation area, the nozzle device is at least provided with a nozzle, and the tail end of the nozzle device is provided with an air inlet; and the roller core is divided into the magnetic area and a nonmagnetic area, and the magnetic area and the material distribution area and the separation area are arranged correspondingly. The separator overcomes the drawback that the prior art is incapable of directly and effectively separating fine weak magnetic ferric oxide mineral powder, and is low in energy consumption, low in productive operation cost, high in sorting purity, simple and reasonable in structure, and convenient in operation. In the separation process, the inside of the machine body is constantly kept in a negative pressure state so as to avoid dust overflow and secondary environmental pollution.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

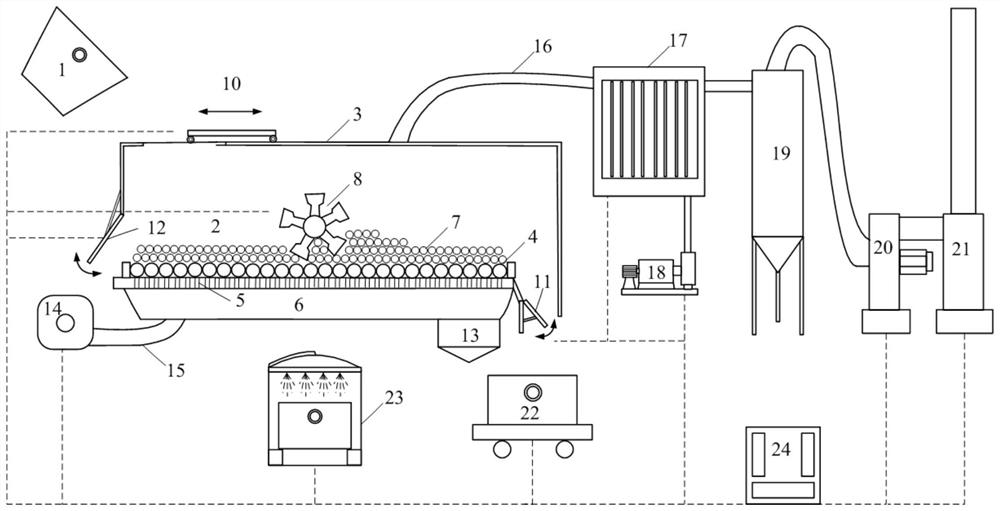

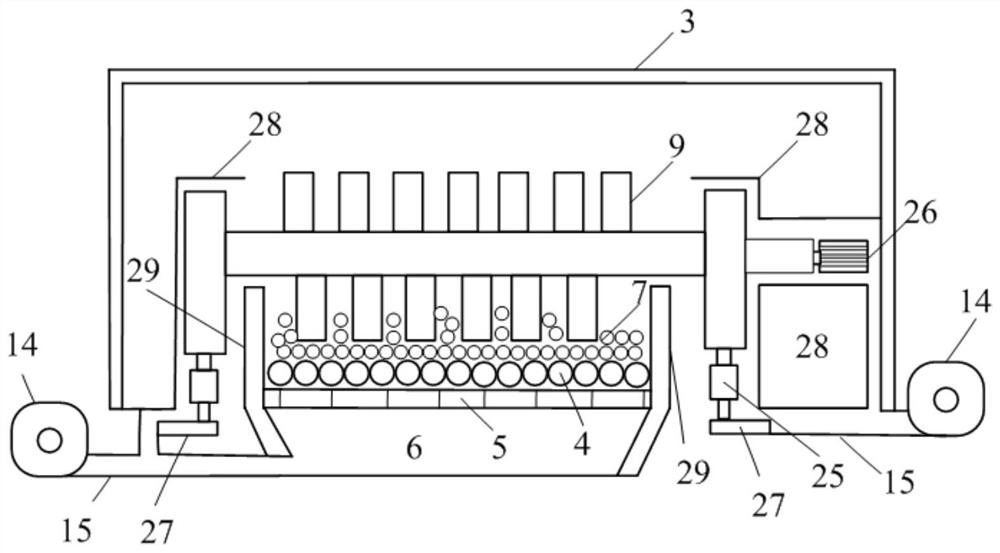

High-temperature steel slag bottom blowing air cooling crushing waste heat recovery device and method

PendingCN111850194AImprove pulverization rateImprove processing efficiencyExhaust gas handlingRecycling and recovery technologiesSlagDust control

The invention relates to a high-temperature steel slag bottom blowing air cooling crushing waste heat recovery device and method. A crushing bed is adopted as a high-temperature steel slag treatment carrier, a crusher is adopted for efficiently crushing steel slag, meanwhile, cold air is introduced into a bottom blowing air cooling box to solidify and cool the high-temperature steel slag, and meanwhile, the crusher rotates at a certain speed, moves forwards and backwards and rotates to crush the steel slag. A heat exchanger and a generator are adopted for cooling the high-temperature steel slag to generate high-temperature waste heat for recovery and power generation. The crushing capacity is high, the steel slag treatment efficiency is greatly improved, and meanwhile, waste heat recoveryand power generation can be realized by adopting air cooling heat exchange. Efficient crushing and waste heat recovery of the high-temperature steel slag are realized, a steel slag water cooling system device is omitted, a simple dry dust removal mode is adopted to replace a wet flue gas treatment system caused by a previous water cooling process, the advantages of being high in automation degree,small in space occupation, good in leakproofness, low in system investment, capable of achieving ultra-clean emission and the like are achieved, and the comprehensive economic benefits of steel slagtreatment are improved.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

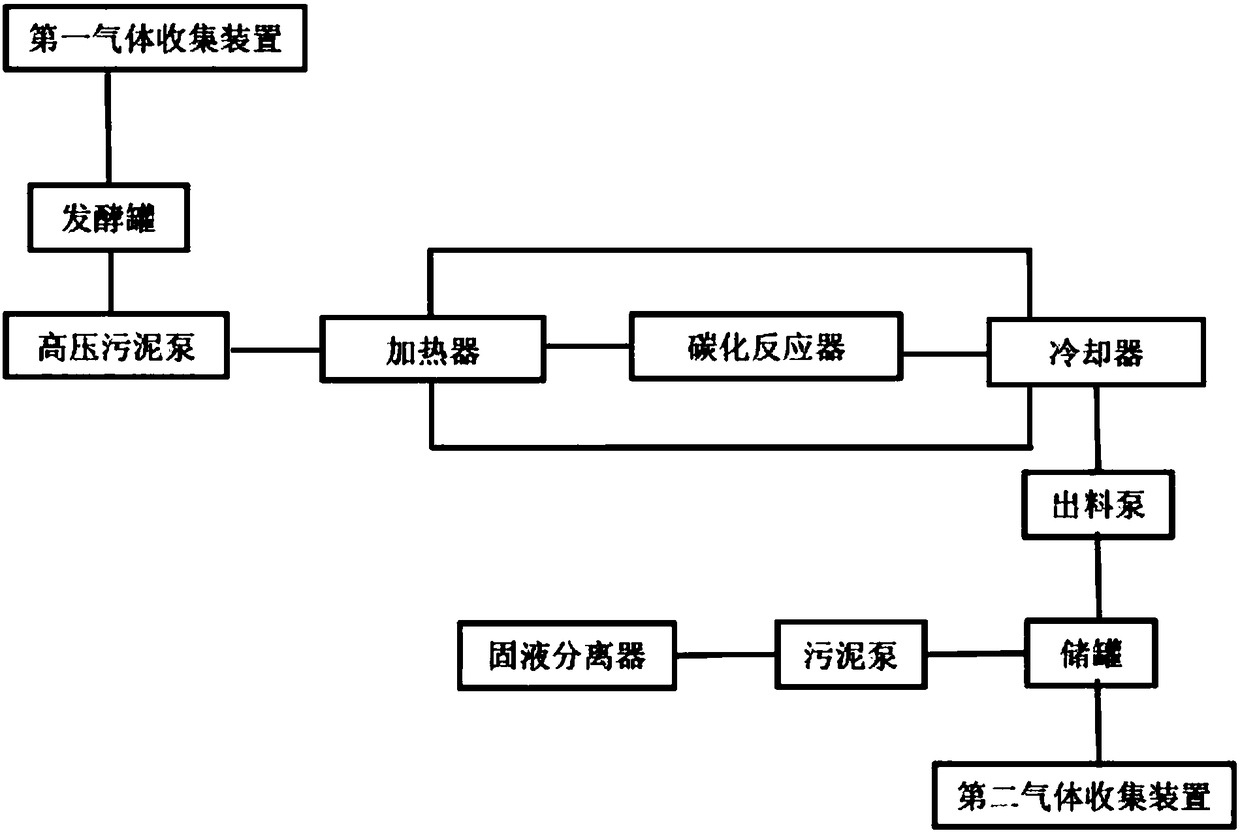

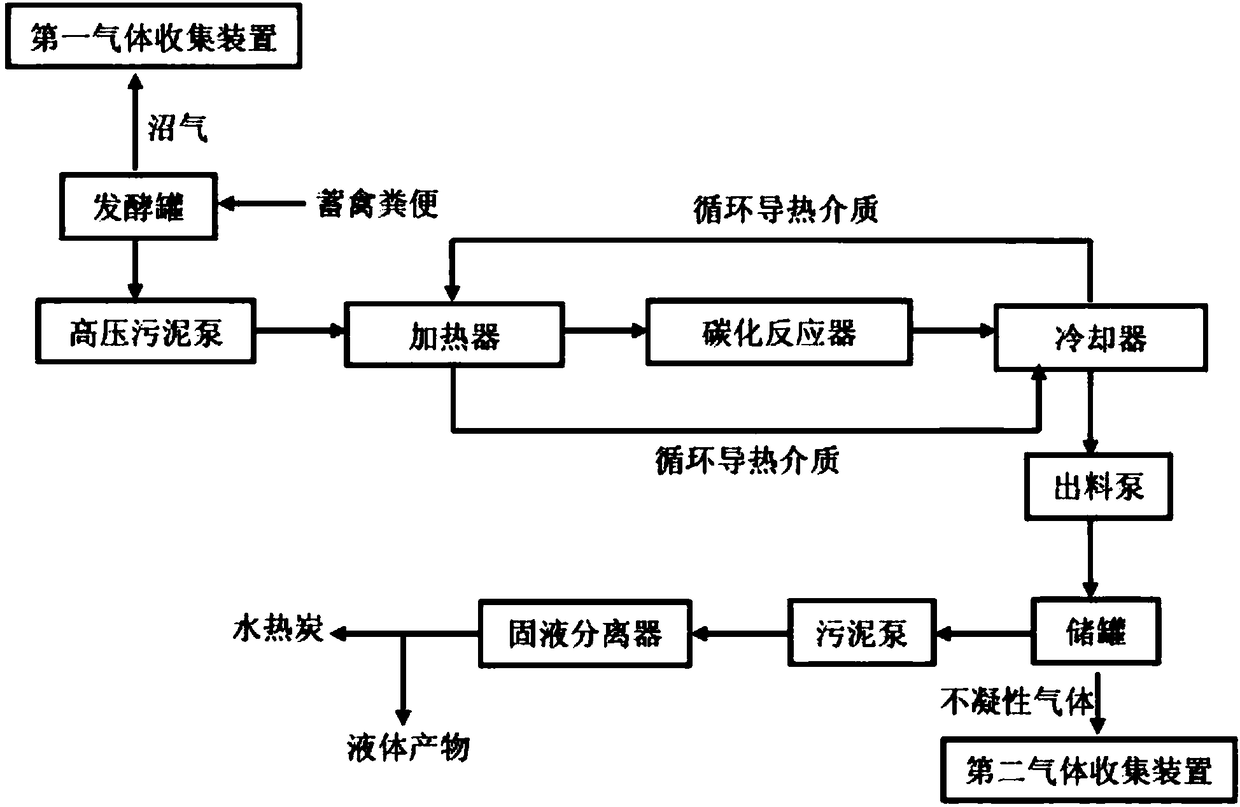

Continuous hydrothermal carbonization system and process for livestock and poultry excrement

InactiveCN108129001AReduce the difficulty of handling operationsEasy to handleSludge treatment by pyrolysisSpecial form destructive distillationSludgeResource utilization

The invention relates to the technical field of the resource utilization of livestock and poultry breeding waste, and discloses a continuous hydrothermal carbonization system for livestock and poultryexcrement. The continuous hydrothermal carbonization system comprises a fermentation tank, a high-pressure sludge pump, a heater, a carbonization reactor, a cooler, a storage tank, a sludge pump anda solid-liquid separator, wherein the fermentation tank, the high-pressure sludge pump, the heater, the carbonization reactor, the cooler, the storage tank, the sludge pump and the solid-liquid separator are communicated in sequence; the fermentation tank is also communicated with a first gas collection device through a pipeline; the storage tank is also communicated with a second gas collection device through a pipeline. The invention also discloses a continuous hydrothermal carbonization process for the livestock and poultry excrement. The continuous hydrothermal carbonization process comprises the following steps of fermenting the pretreated livestock and poultry excrement in the anaerobic fermentation tank, then continuously inputting into the heater, the carbonization reactor and cooler through power provided by the high-pressure sludge pump, and separating a temperature-lowered carbonization product through the solid-liquid separator to obtain hydrothermal carbon and carbonized liquid. The system is used for treating the livestock and poultry excrement by adopting a continuous hydrothermal carbonization method to prepare the hydrothermal carbon, meanwhile, is used for obtaining the by-product carbonized liquid, and have the advantages of being convenient to operate, easy to maintain, low in production cost, zero-release in pollutant and low in energy consumption, and thelike.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com