Preparing method for direct reduced iron using low grade high phosphorus iron ore as raw materials

A low-grade, reduced iron technology, applied in fluidized bed furnaces and other directions, can solve problems such as high energy consumption, waste, and high manufacturing costs, and achieve the effect of reducing production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

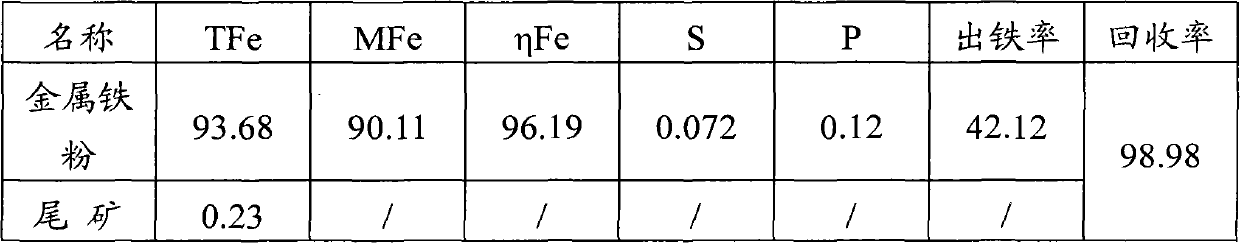

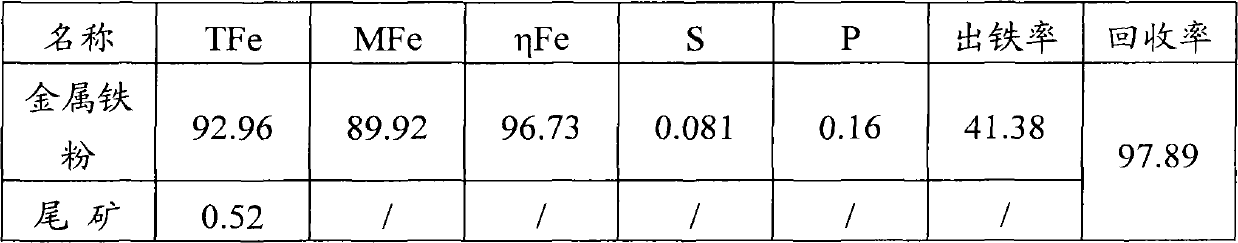

[0014] The coal-based tunnel kiln is used as the main equipment, and the oolitic structure hematite in the refractory ore is used as the raw material. The ore grade is 40.71%, and the sulfur content is 0.50%; the phosphorus content is 0.62%. The specific composition is shown in the table below:

[0015] name

TF

S

P

SiO 2

Al 2 o 3

CaO

MgO

oolitic hematite

40.71

0.50

0.62

34.04

3.34

2.76

1.14

[0016] The technical scheme of the invention is used to carry out direct reduction to prepare high-quality low-sulfur and phosphorus-reduced iron. Its production process mainly includes:

[0017] (1) ore crushing, the oolitic structure hematite ore is crushed to a fineness of less than 1mm to obtain iron ore powder;

[0018] (2) Add coal powder and additives, and add coal powder and additives with a fineness of -80 to -200 mesh into the iron ore powder, and the proportion is by mass per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com