Dry-method air-separation strong permanent magnetic separator

A magnetic separator and air separation technology, applied in the fields of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of ineffective separation of weak magnetic minerals, affecting product grade, yield, and affecting enterprise economic benefits, etc. To achieve the effect of simple and reasonable equipment structure, low production and operation cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

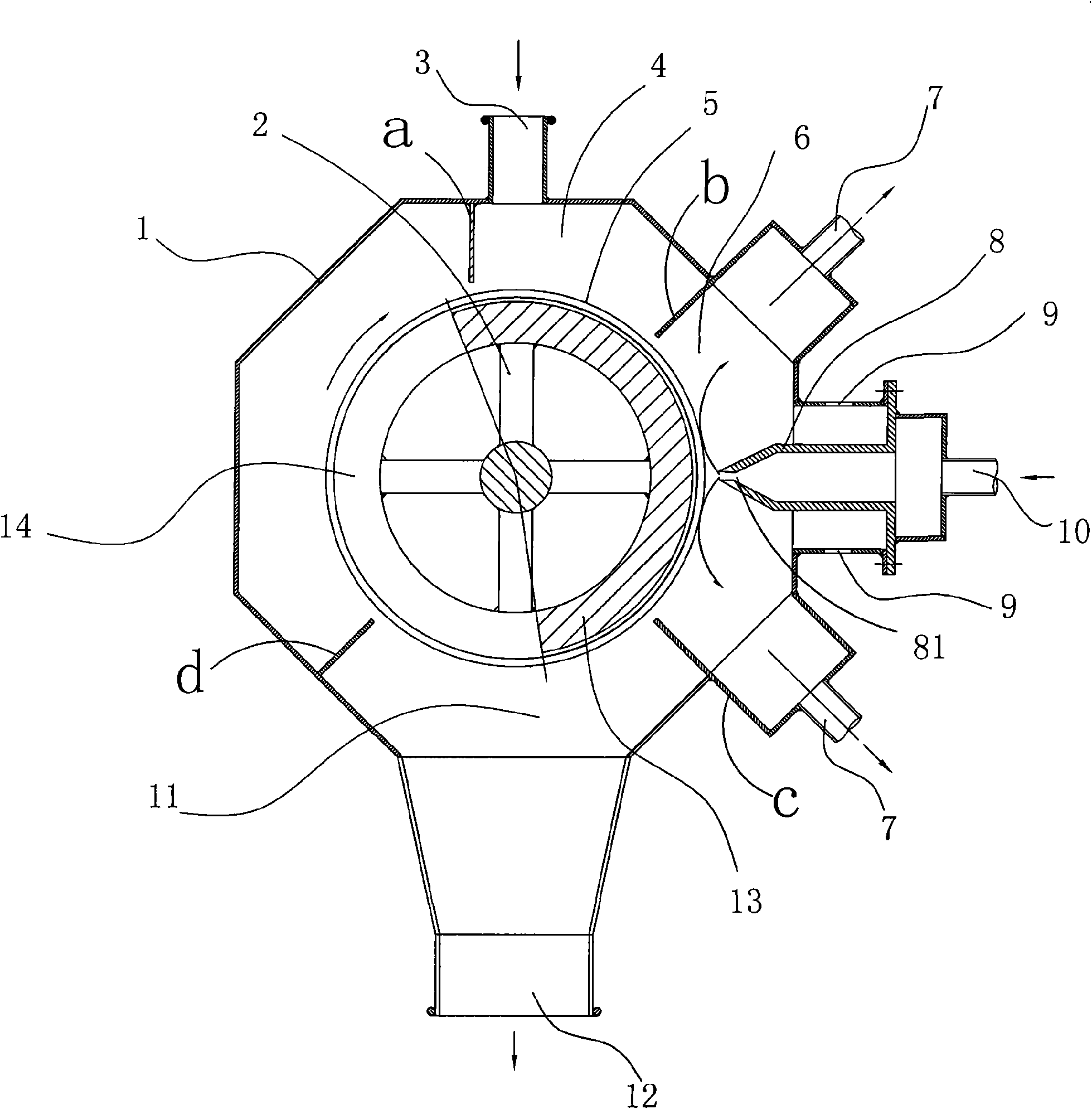

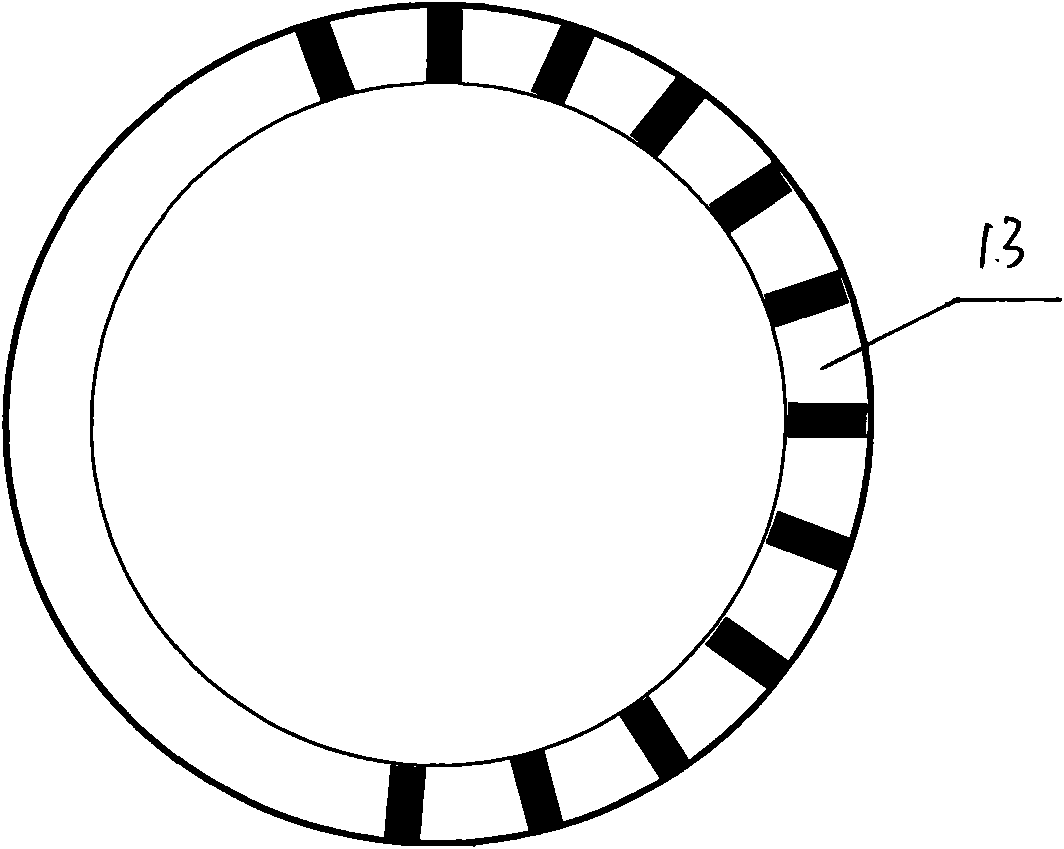

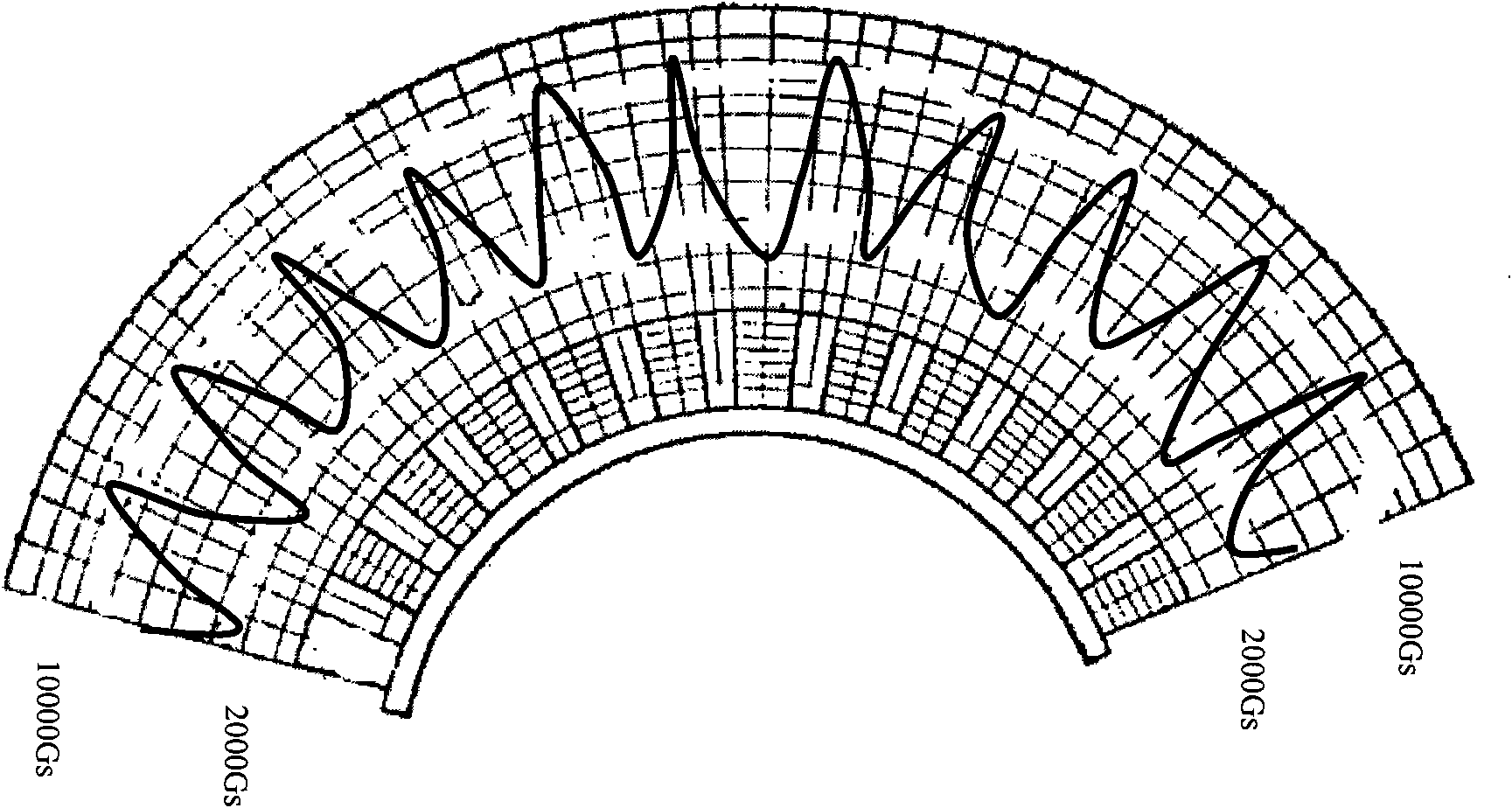

[0021] Such as figure 1 As shown, a dry-process winnowing strong permanent magnet magnetic separator includes a body 1 and a magnetic roller disposed in the body 1, and the body 1 can be installed on a frame. The machine body 1 is provided with a material inlet 3, a material outlet 12, and an air and ash outlet 7, and the magnetic roller includes a fixed roller core 2 and a roller wrapped around the outer periphery of the roller core 2 and rotatable around the roller core 2. Leather 5, roller skin 5 drives rotation by transmission device (not shown in the figure) during work, and the rotating speed is adjustable. The feed inlet 3 is fixed above the body 1, and the discharge port 12 is located below the body 1; half of the outer circumference of the roller core 2 is a magnetic area 13, and the other half is a non-magnetic area 14; the body 1 The internal space formed between the semi-circumferential surface of the roller core 2 and the magnetic area 13 is divided into a distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com