Patents

Literature

114 results about "Oxide minerals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The oxide mineral class includes those minerals in which the oxide anion (O²⁻) is bonded to one or more metal ions. The hydroxide-bearing minerals are typically included in the oxide class. The minerals with complex anion groups such as the silicates, sulfates, carbonates and phosphates are classed separately.

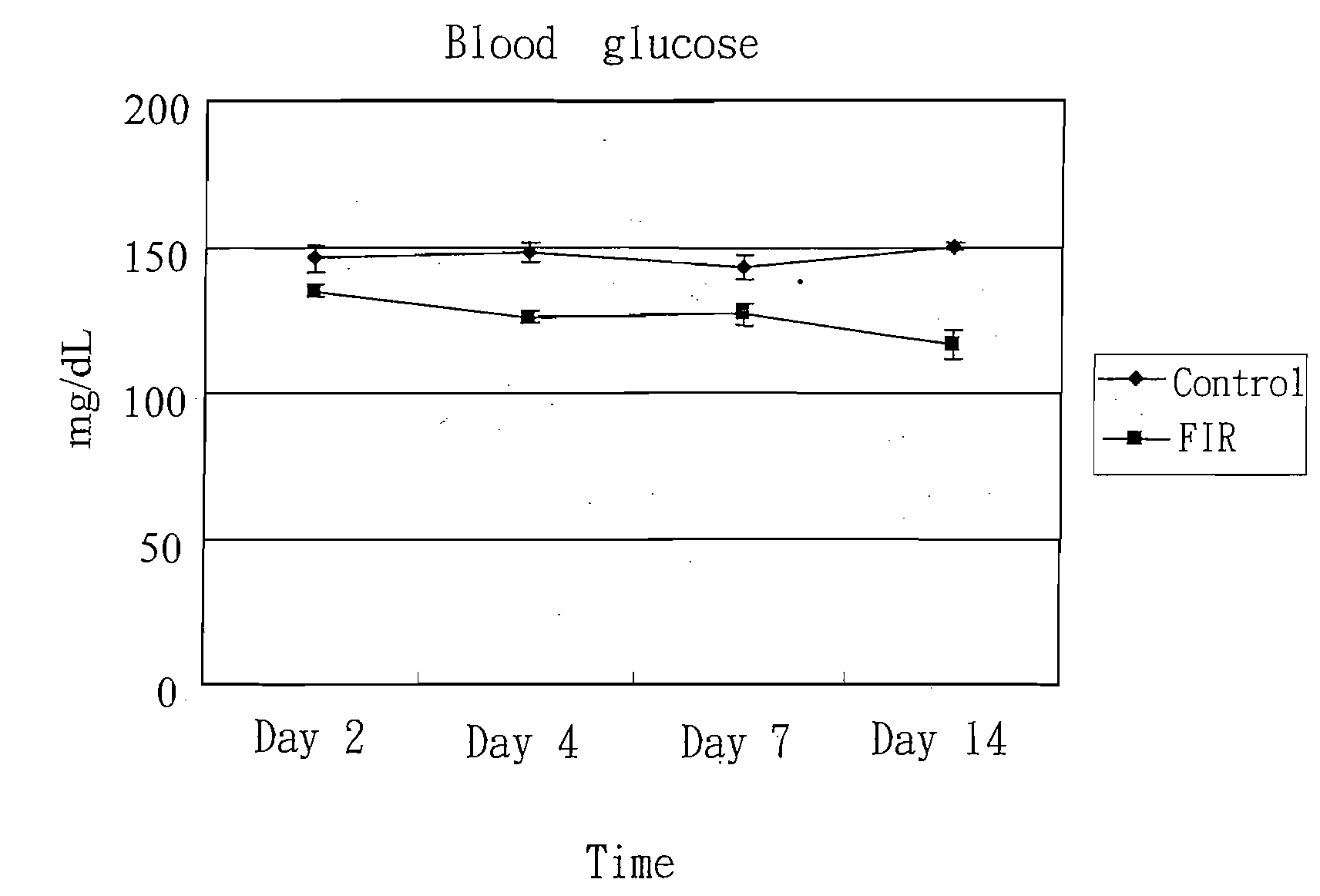

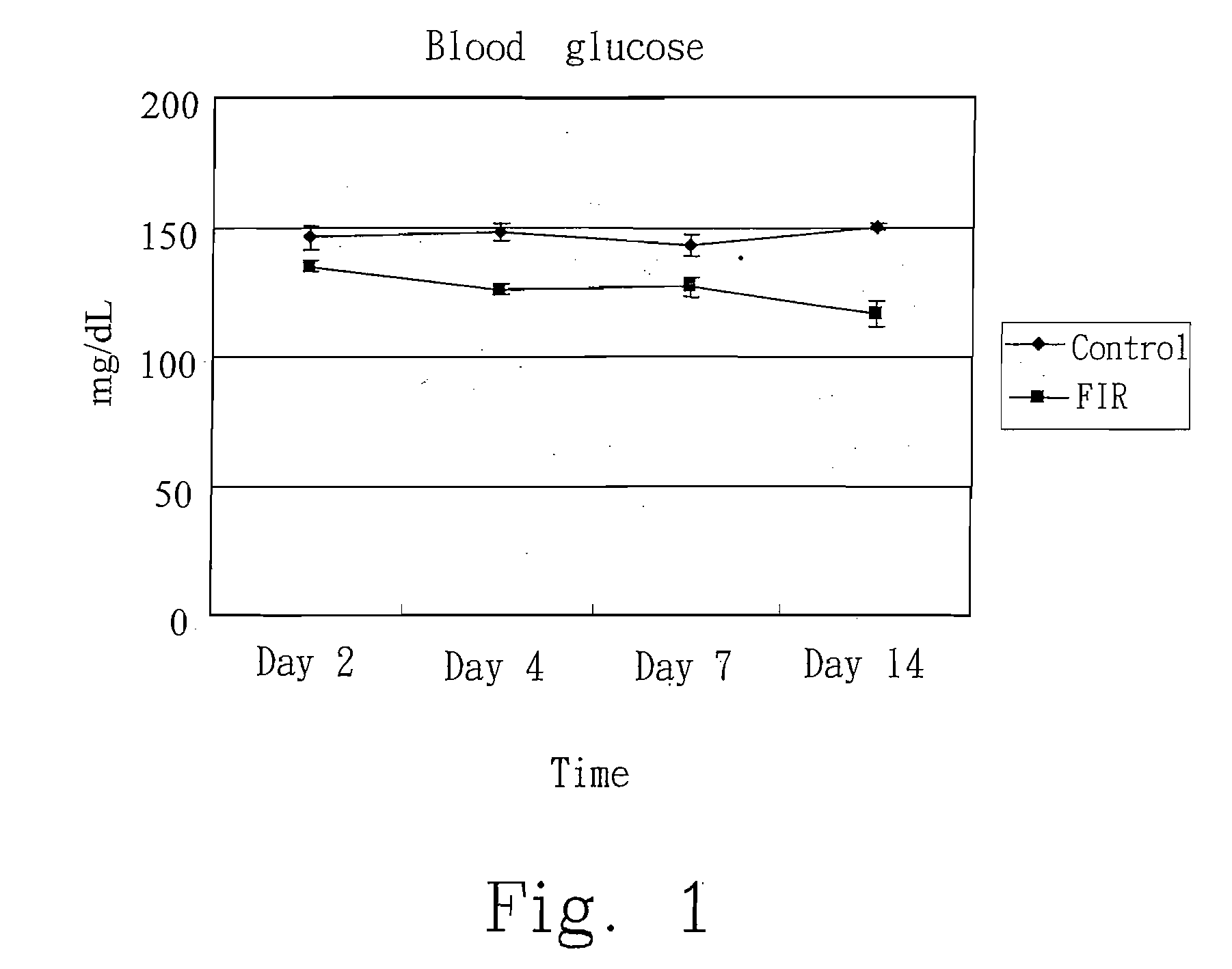

Composition for controlling blood glucose and method thereof

InactiveUS20090110752A1Easy to useReduces the blood glucoseHeavy metal active ingredientsBiocideMedicineOxide minerals

A composition for controlling a blood glucose and a method thereof are provided. The composition comprises a far-infrared ray releasing substance, wherein the composition reduces the blood glucose of a subject via an irradiation of the far-infrared ray releasing substance. In another aspect, the method comprises the steps of providing a far-infrared ray releasing substance having an oxide mineral as a main component, and disposing the far-infrared ray releasing substance in a place close to a subject in an appropriate distance, wherein the subject has an insulin resistance and the appropriate distance is within an irradiation range of the far infrared ray.

Owner:TAIPEI MEDICAL UNIV +1

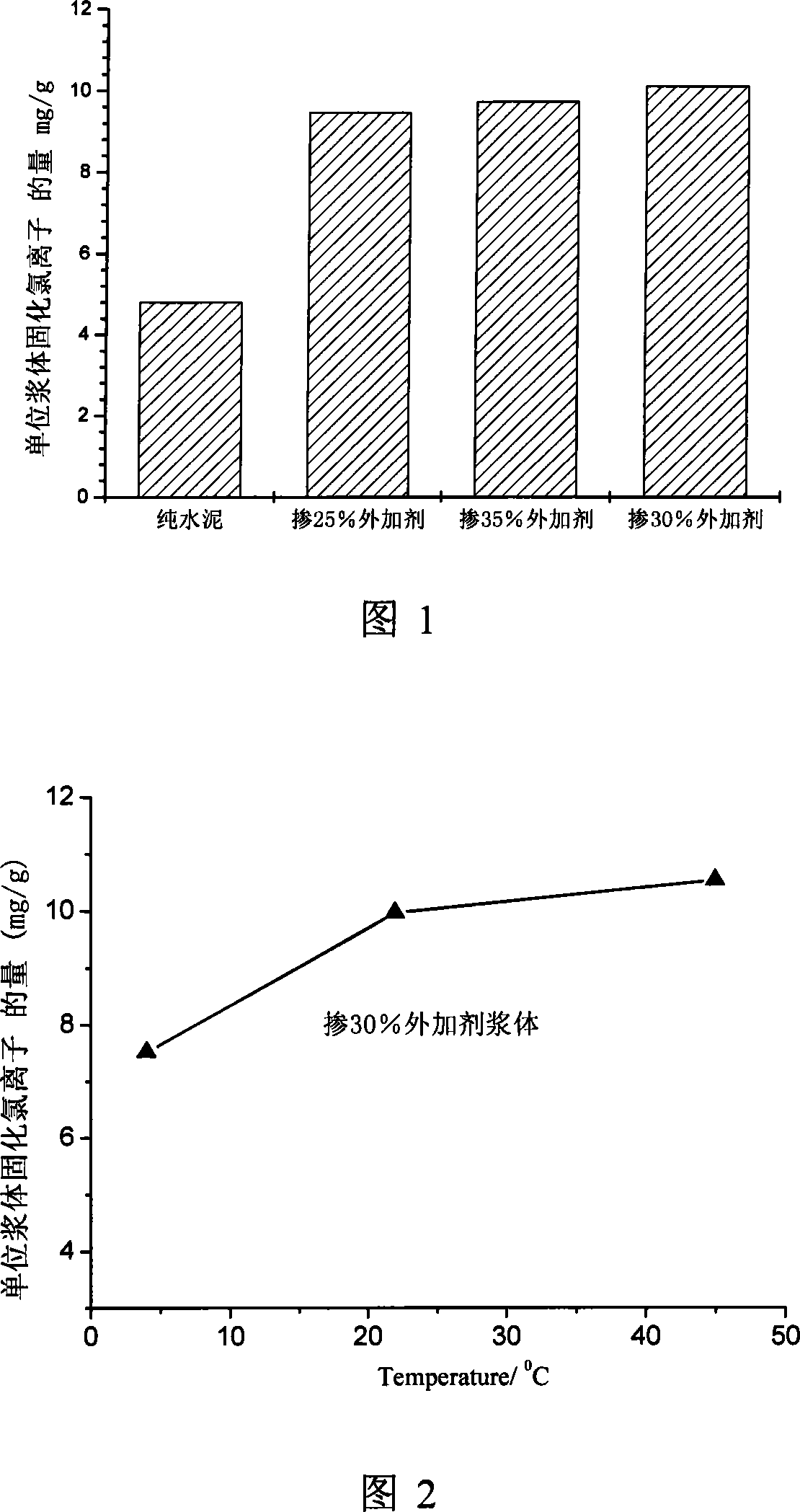

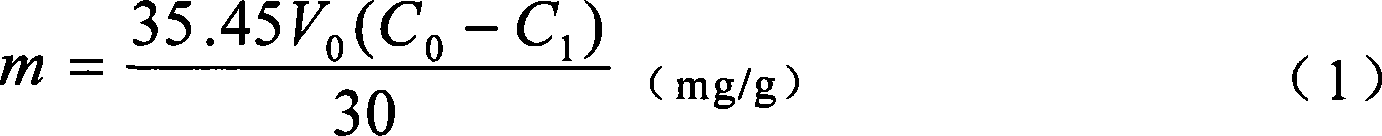

Additive for increasing cement-base material solidifying dissociative chlorine ion capability and applying method thereof

InactiveCN101239792AImproves the ability to immobilize chloride ionsSimple internal structureSolid waste managementNitriteMass ratio

The present invention discloses an additive which increases the performance of the solidifying free chloride ion cement-based material and the using method thereof, the additive comprises silicon-aluminum oxide material and nitrite, and the mass ratio between the silicon-aluminum oxide and the nitrite is 8-9:1. The mixing amount of the additive in the cement base material is 25%-35%, when the additive is mixed into the capacity of the system for solidifying chlorine ion can be remarkably increased, and the capacity for solidifying the chlorine ion by the cement-based material can be increased by 100%; and other capability of the cement-based material can be improved. When the additive is mixed the single cube price of the cement-based material can be reduced, the cost performance is high and the application is easy.

Owner:CENT SOUTH UNIV

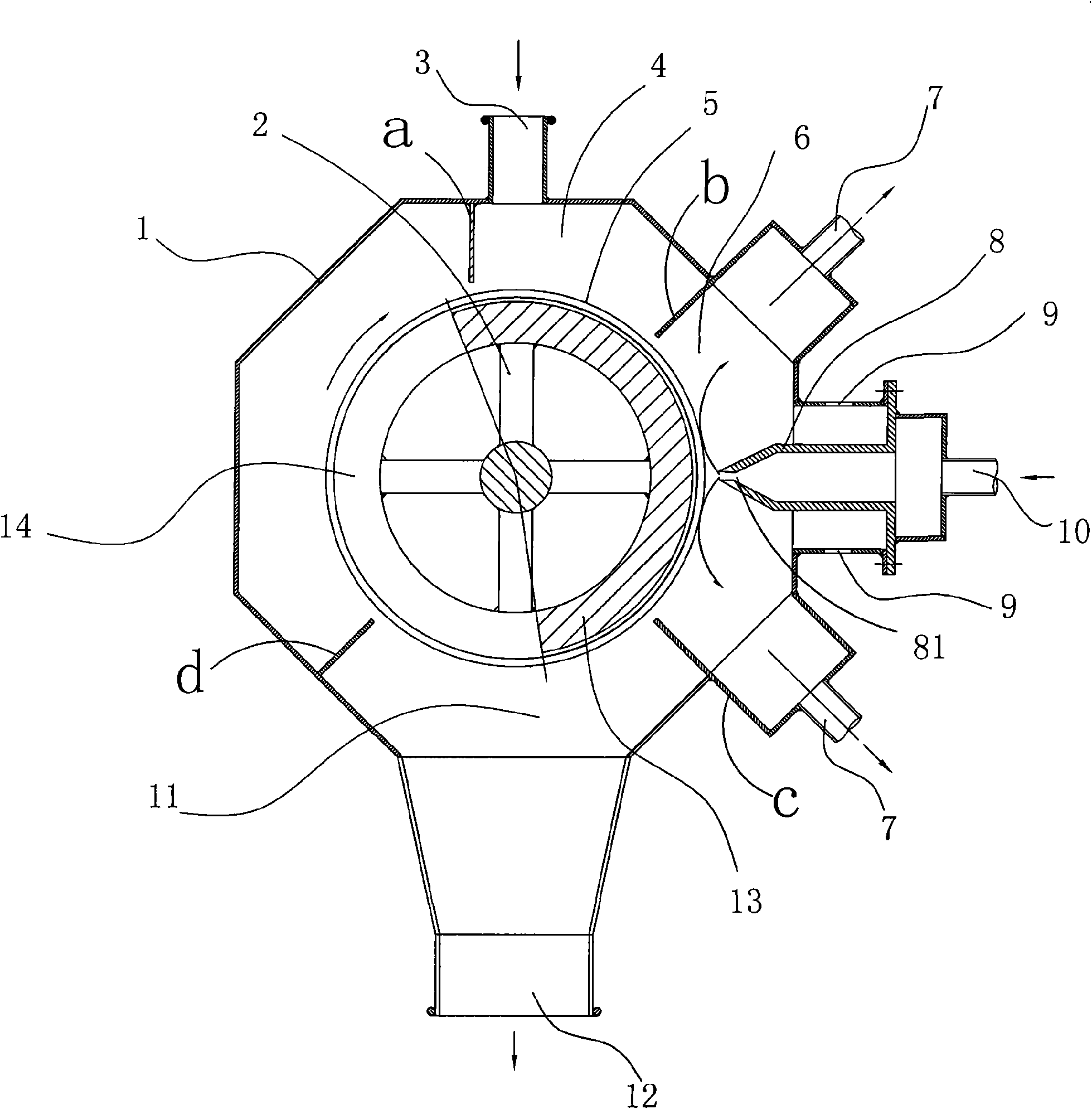

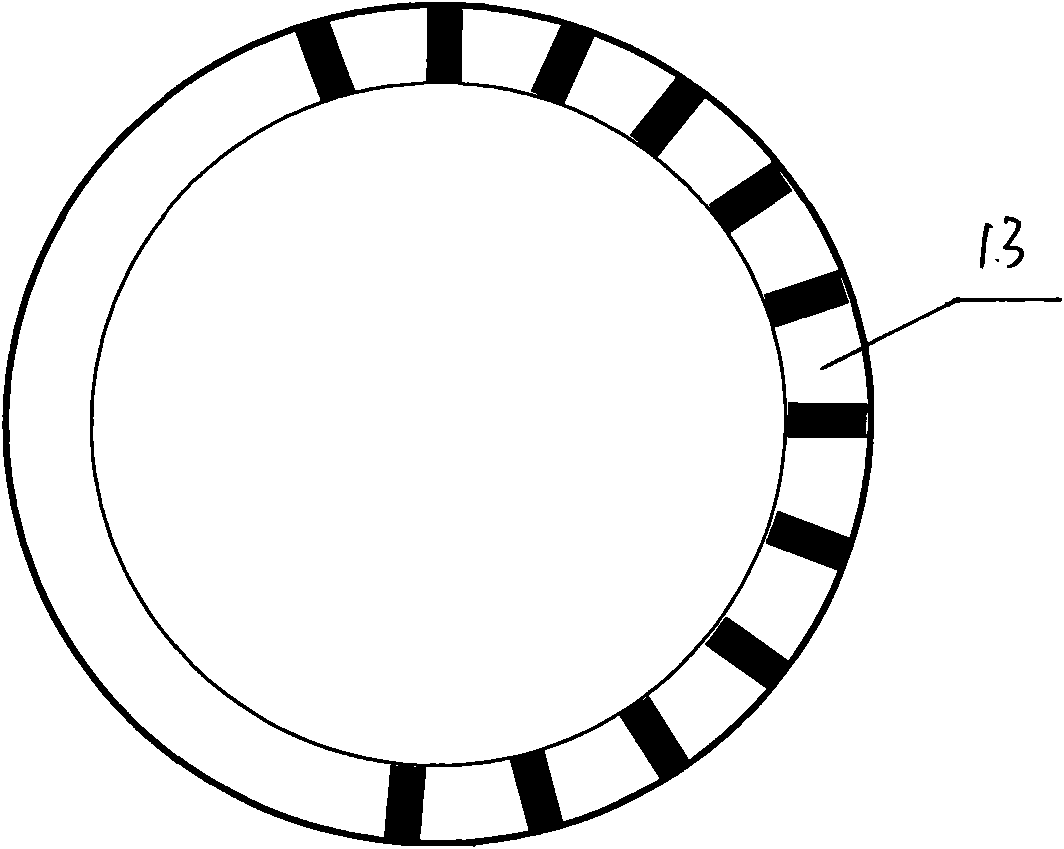

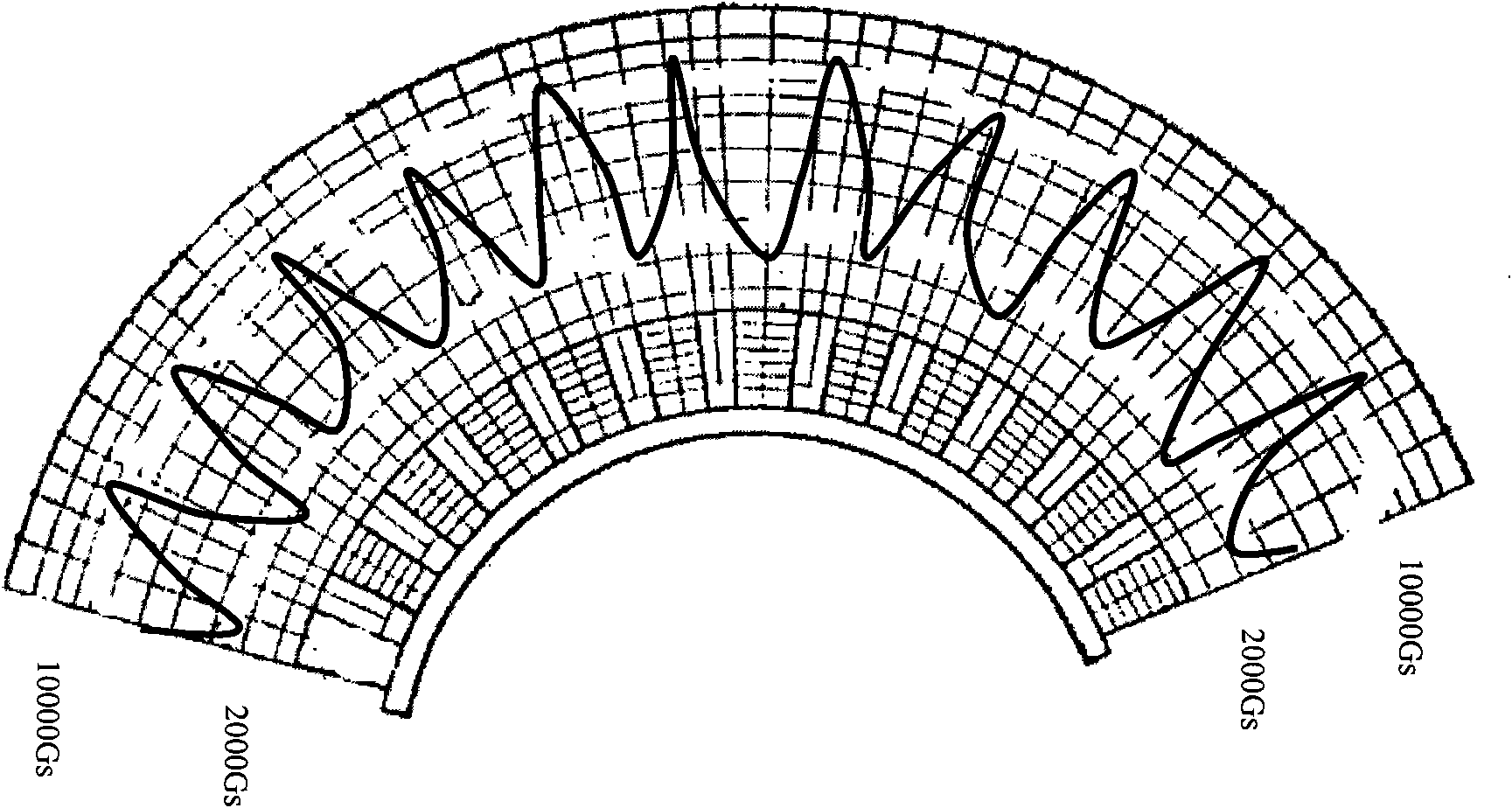

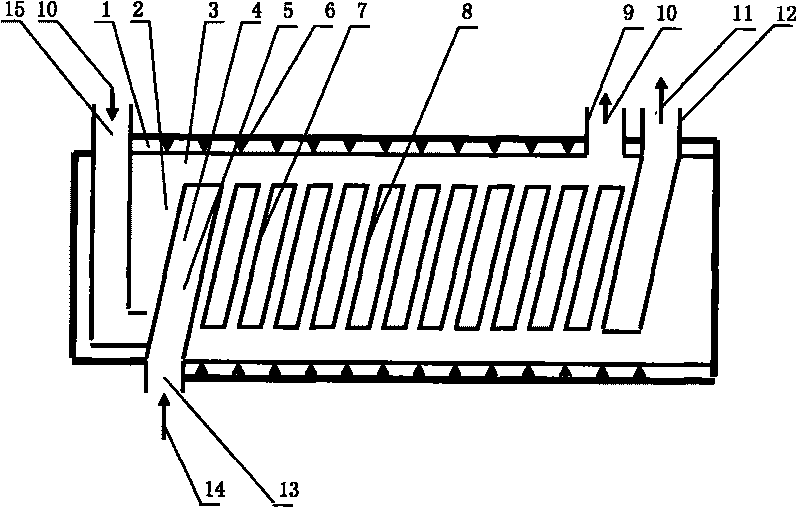

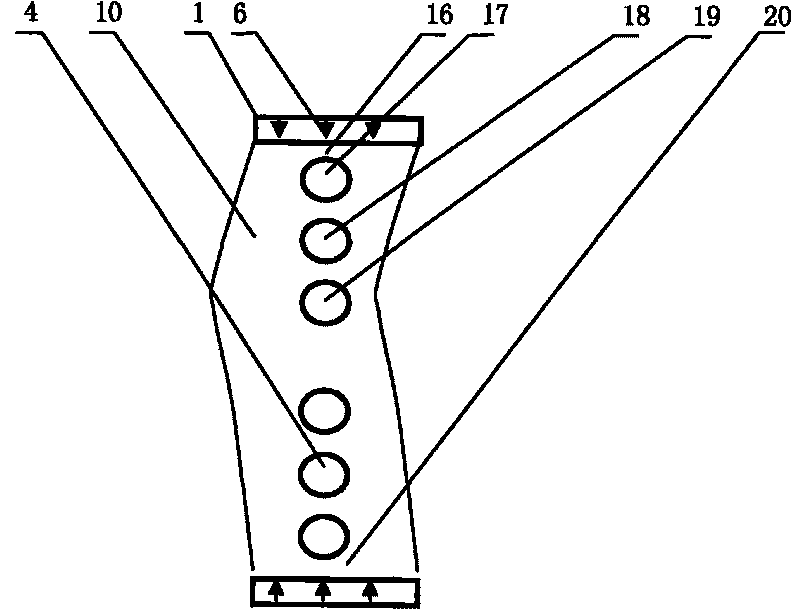

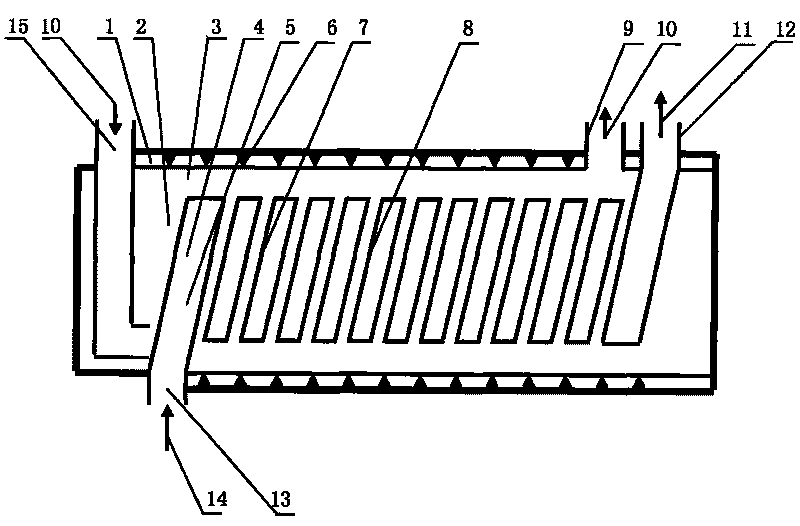

Dry-method air-separation strong permanent magnetic separator

InactiveCN101612609AReduce energy consumptionReduce production and operation costsMagnetic separationEngineeringIon

The invention provides a dry-method air-separation strong permanent magnetic separator, belongs to the technical field of dressing equipment, and is particularly suitable for regenerating an ion-containing fly ash resource produced in a smelting process for making ion and steel. The dry-method air-separation strong permanent magnetic separator comprises a machine body and a magnetic roller arranged in the machine body, wherein the machine body is provided with a feeding hole, a discharge hole and an exhaust and air discharge hole; the magnetic roller comprises a fixedly arranged roller core and a roller sheet which surrounds the roller core and can rotate around the roller core; the internal space formed by the machine body and a semi-circumferential surface, provided with a magnetic area, of the roller core is divided into a material distribution area, a separation area and a blanking area by baffle plates from top down, and the material distribution area, the separation area and the blanking are mutually communicated; the machine body is provided with a nozzle device spraying air flow toward the separation area, the nozzle device is at least provided with a nozzle, and the tail end of the nozzle device is provided with an air inlet; and the roller core is divided into the magnetic area and a nonmagnetic area, and the magnetic area and the material distribution area and the separation area are arranged correspondingly. The separator overcomes the drawback that the prior art is incapable of directly and effectively separating fine weak magnetic ferric oxide mineral powder, and is low in energy consumption, low in productive operation cost, high in sorting purity, simple and reasonable in structure, and convenient in operation. In the separation process, the inside of the machine body is constantly kept in a negative pressure state so as to avoid dust overflow and secondary environmental pollution.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

Soil improver and method for improving soil

InactiveCN105838381AAgriculture tools and machinesOther chemical processesClay mineralsSodium Bentonite

The invention relates to a soil conditioner and a method for improving soil. The soil conditioner comprises mineral powder A, modified powder B, modified powder C and a modified solvent, wherein the mineral powder A is selected from sulfide mineral powder, oxide mineral powder, clay One or more of mineral powders; modified powder B is selected from one or more of bentonite, persulfate compound, kaolin; modified powder C is selected from red mud, DTC-chelating agent, iron manganese oxide One or more of the mineral powders, the improving solvent is selected from one or more of humic acid, organic solvents, and reactive colloids; the soil improving agent can adjust the pH value of the soil and the dissolved products of environmental mineral materials and heavy metal ions The chemical immobilization effect and the interaction with soil microorganisms permanently fix the ionic heavy metals in the soil in the newly formed soil minerals, inhibit the absorption of heavy metal ions by crops, and achieve the purpose of reducing the heavy metal content of crops.

Owner:ZHONGDA TESTING (HUNAN) CO LTD +1

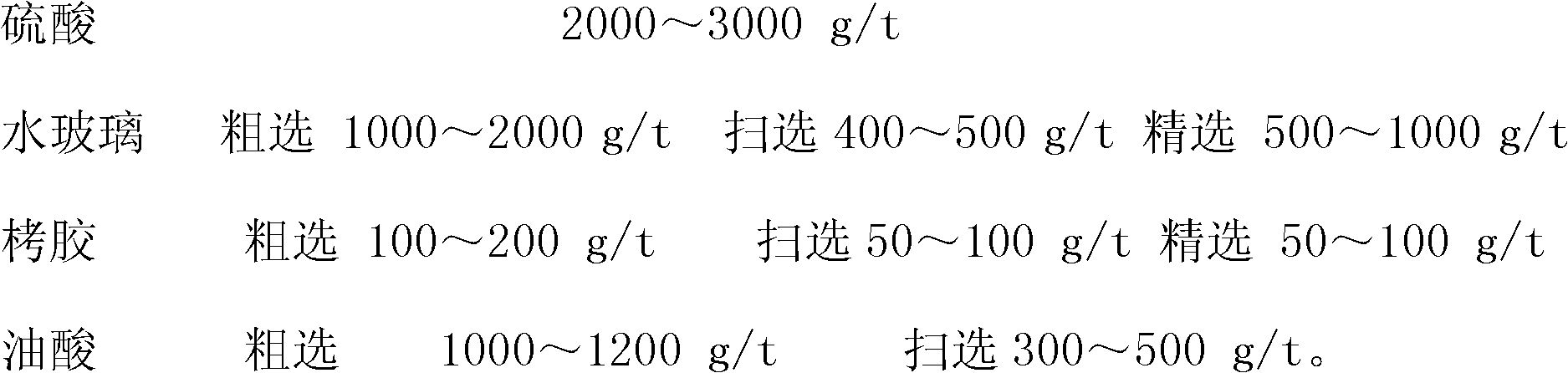

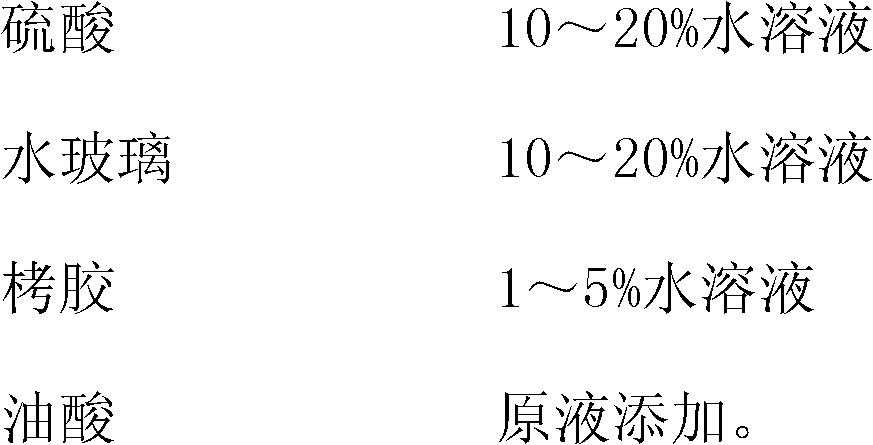

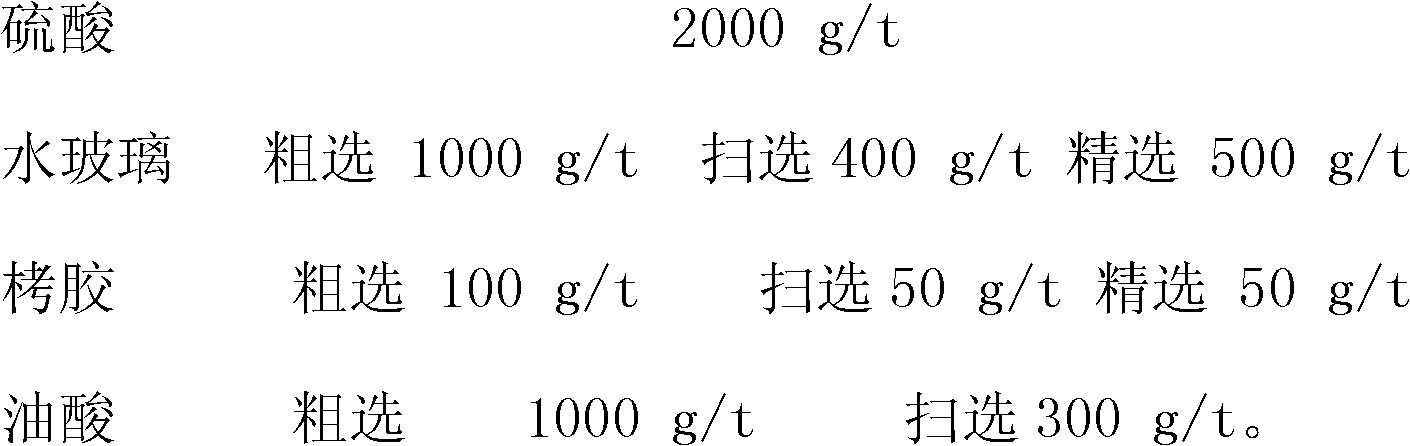

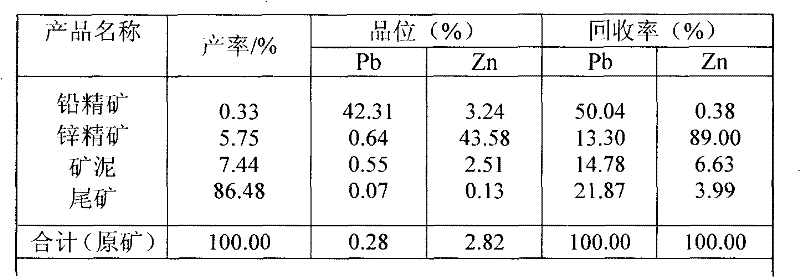

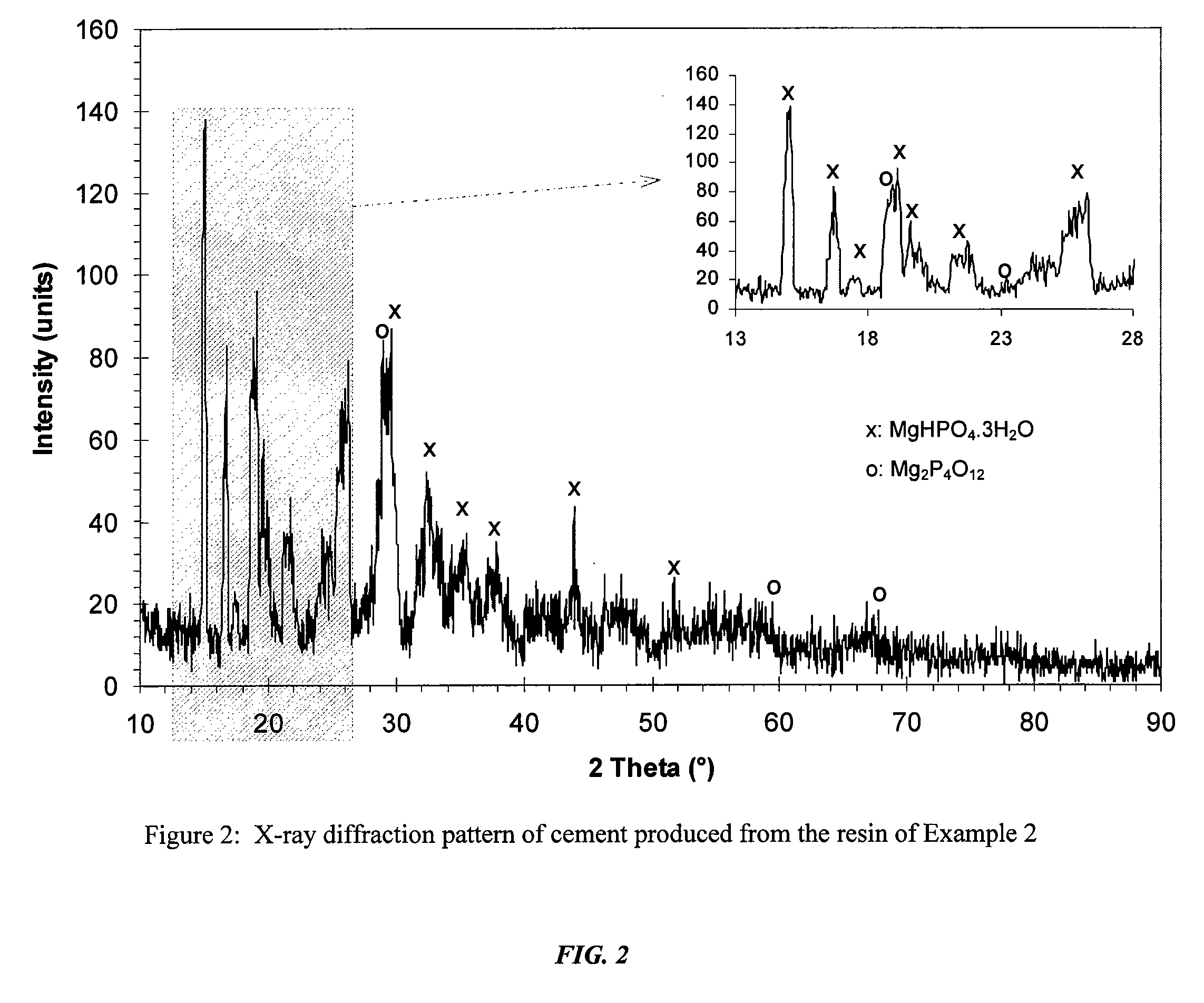

Method for flotation of zinc oxide mineral under acidic condition

The invention relates to a method for flotation of zinc oxide mineral under the acidic condition. In the flotation process, the mineral is grinded into mineral monomer and dissociated, sulfuric acid is added, the pH value of the pulp is regulated to 4.5-5.5, water glass and tannin extract are added to inhibit gangue mineral, and finally oleic acid is added to collect the zinc oxide mineral to obtain zinc concentrate. By using the method, the zinc oxide mineral can be effectively recycled, and the zinc oxide concentrate with the grade of 38.90-39.54% and the recycling rate of 73.66-77.73% is obtained through once roughing, twice scavenging and twice selection under the condition that the grade of feeder zinc is 8.32-9.77%.

Owner:广西华锡集团股份有限公司

Beneficiation method for improving recovery rate of low-grade zinc oxide ore

The invention relates to a beneficiation method for improving the recovery rate of low-grade zinc oxide ore, which comprises the following steps: washing ore at normal temperature to remove impurities; mixing and selecting oxide minerals and sulfide minerals; and carrying out zinc rough selection and zinc scavenging by using modified alkylamine zinc oxide chelating collector ZJ-5. The invention has the characteristics of easy purchase and low cost of the collector ZJ-5, short process flow, low cost of beneficiation cost, wire range of application, high grade and recovery rate of zinc ore concentrate and the like and is applicable to the low-grade zinc oxide ore.

Owner:新疆紫金锌业有限公司

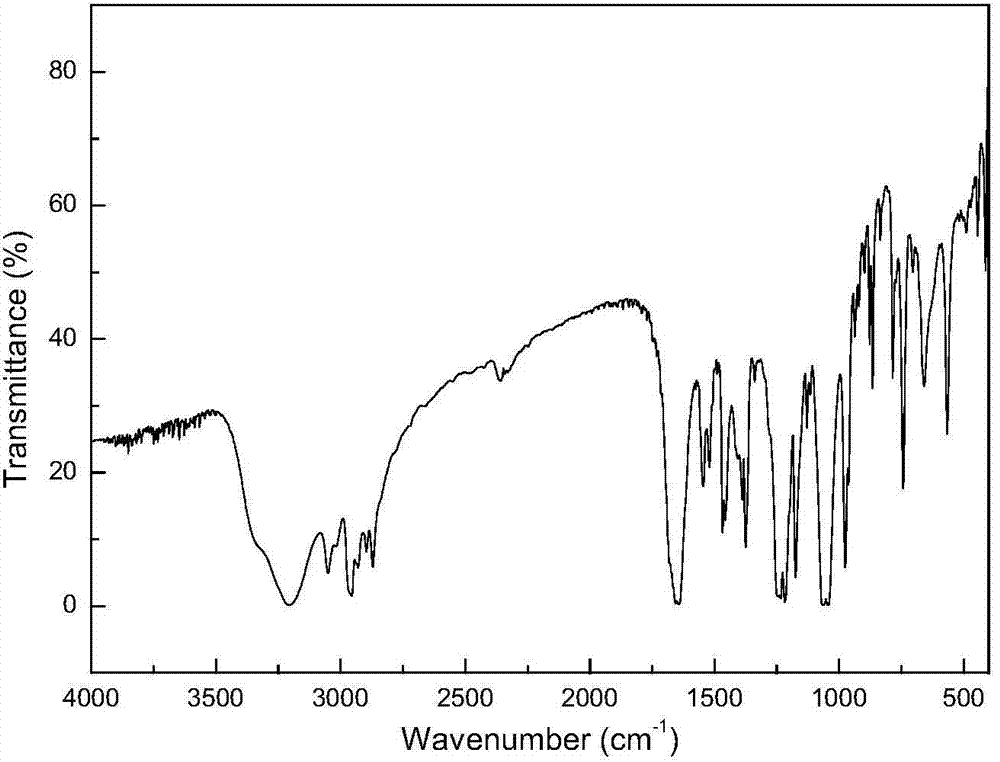

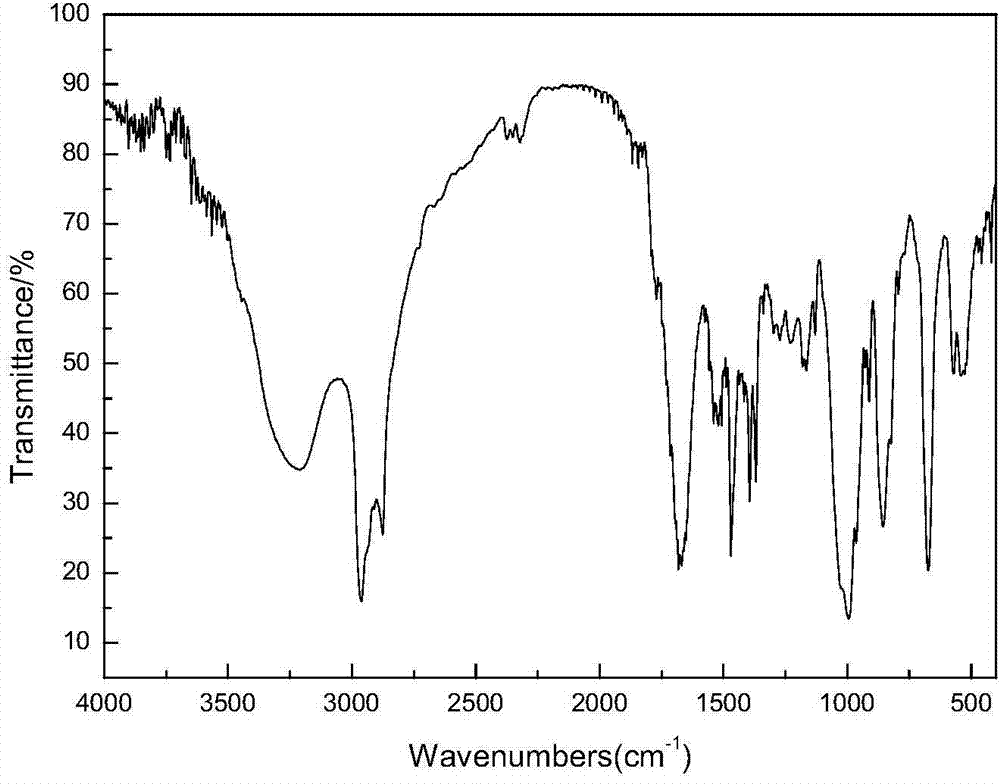

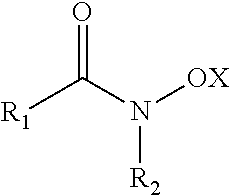

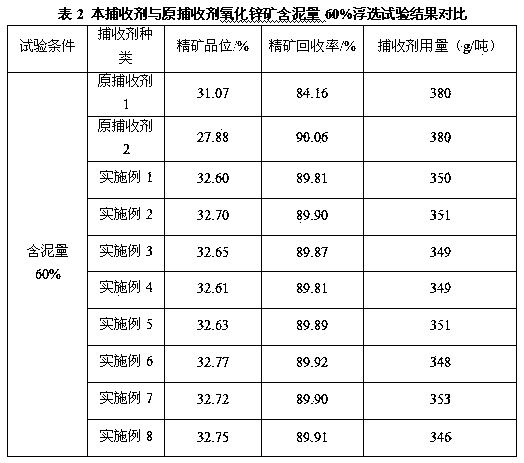

Nonferrous metal mineral flotation collector with sulfydryl-hydroxamic acidyl structure and preparation method and application thereof

The invention discloses a nonferrous metal mineral flotation collector with a sulfydryl-hydroxamic acidyl structure and a preparation method and application thereof. The flotation collector has both sulfydryl groups and hydroxamic acidyl groups; by taking the flotation collector as a nonferrous metal mineral collector, nonferrous metal minerals in nonferrous metal ores can be efficiently recovered through flotation separation, and therefore the goal that minerals in the form of sulfide and minerals in the form of oxide in the nonferrous metal ores are recovered simultaneously by a single flotation reagent is achieved. A synergistic effect on chelate metal ions exists between the sulfydryl groups and hydroxamic acidyl groups, so adsorption on metal ions on the interfaces of sulfide minerals and the interfaces of oxide minerals in nonferrous metals can be enhanced, and the recovery rate of nonferrous metal minerals in the nonferrous metal ores is greatly increased; the nonferrous metal mineral flotation collector is especially suitable for the metal recovery of mixed minerals containing both the sulfide minerals and the oxide minerals of the nonferrous metals; the recovery process of the nonferrous metals is simple, efficient and workable, and the industrial application requirement is met.

Owner:岳阳中科华昂精细化工科技有限公司

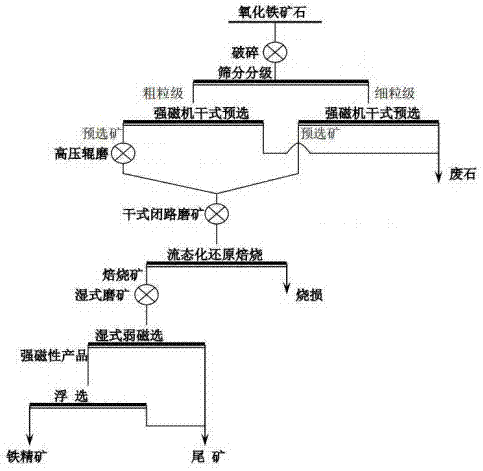

Combined mineral separation technology for ferric oxide mineral

InactiveCN107185686AThrow out earlyReduce transportationMagnetic separationGrain treatmentsIronstoneOxide minerals

The invention discloses an iron oxide ore joint beneficiation process, which comprises the following steps: (1) dry selection and discarding of iron oxide ore to obtain pre-selected coarse-grained ore, pre-selected fine-grained ore and waste rock; (2) high-pressure Roller mill crushing: the pre-selected coarse-grained ore obtained in step (1) is fed into a high-pressure roller mill for crushing; (3) dry grinding: the crushed product in step (2) and the pre-selected fine-grained ore in step (1) Combined for dry closed-circuit grinding; (4) Fluidized reduction roasting: a. Put the ground product obtained in step (3) into the fluidized reduction roaster; b. Preheating; c. Heating; d. Magnetization roasting; e . Cool to below 200°C to obtain roasted ore with a magnetite content greater than 90%; (5) beneficiation of roasted ore to obtain iron concentrate products with a grade of 57%-65%. The present invention can effectively solve the current iron oxide ore beneficiation There are technical problems such as low resource utilization rate, poor concentrate quality and high energy consumption in the process.

Owner:JIUQUAN IRON & STEEL GRP

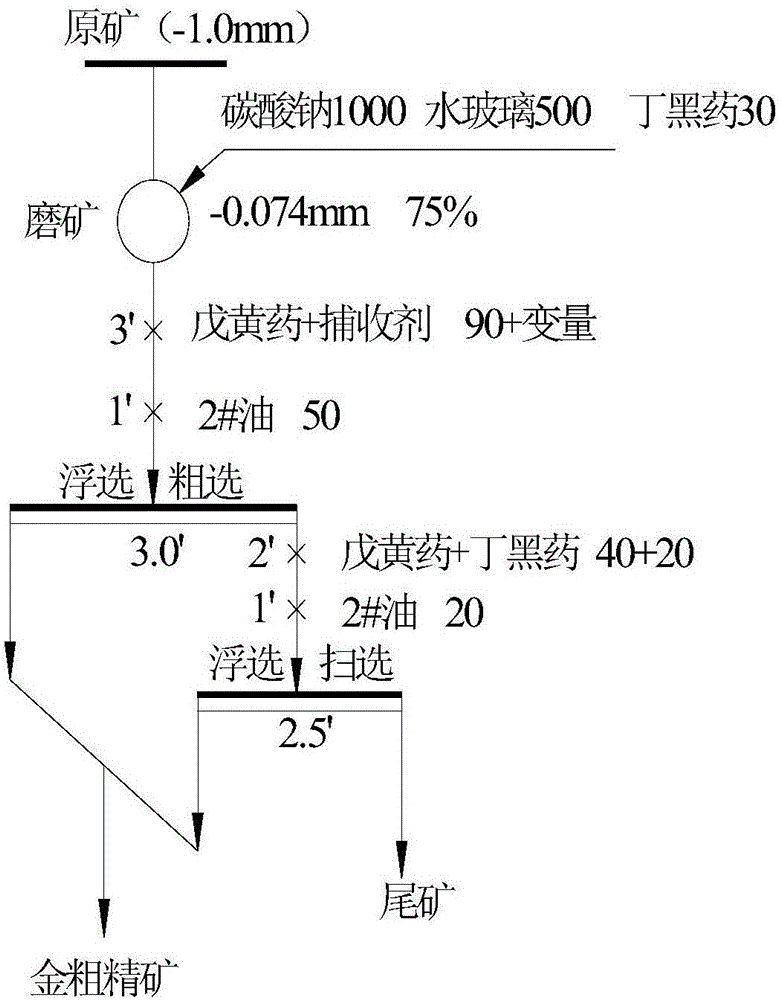

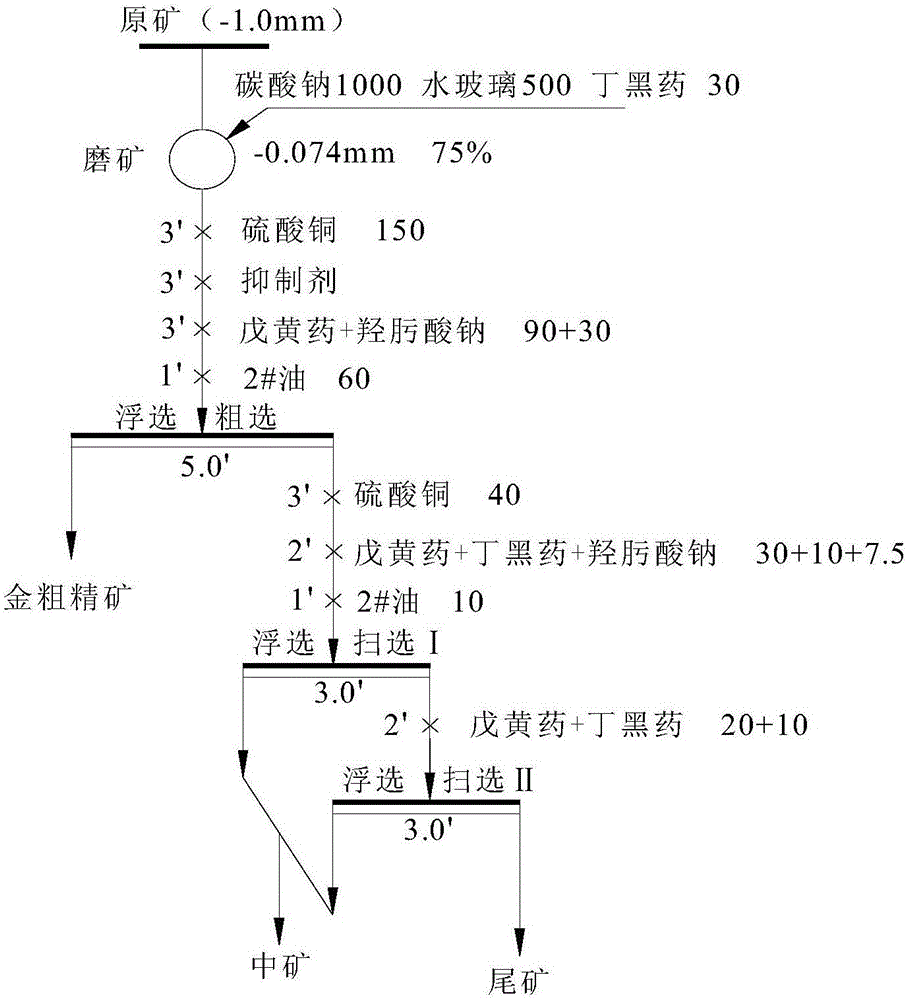

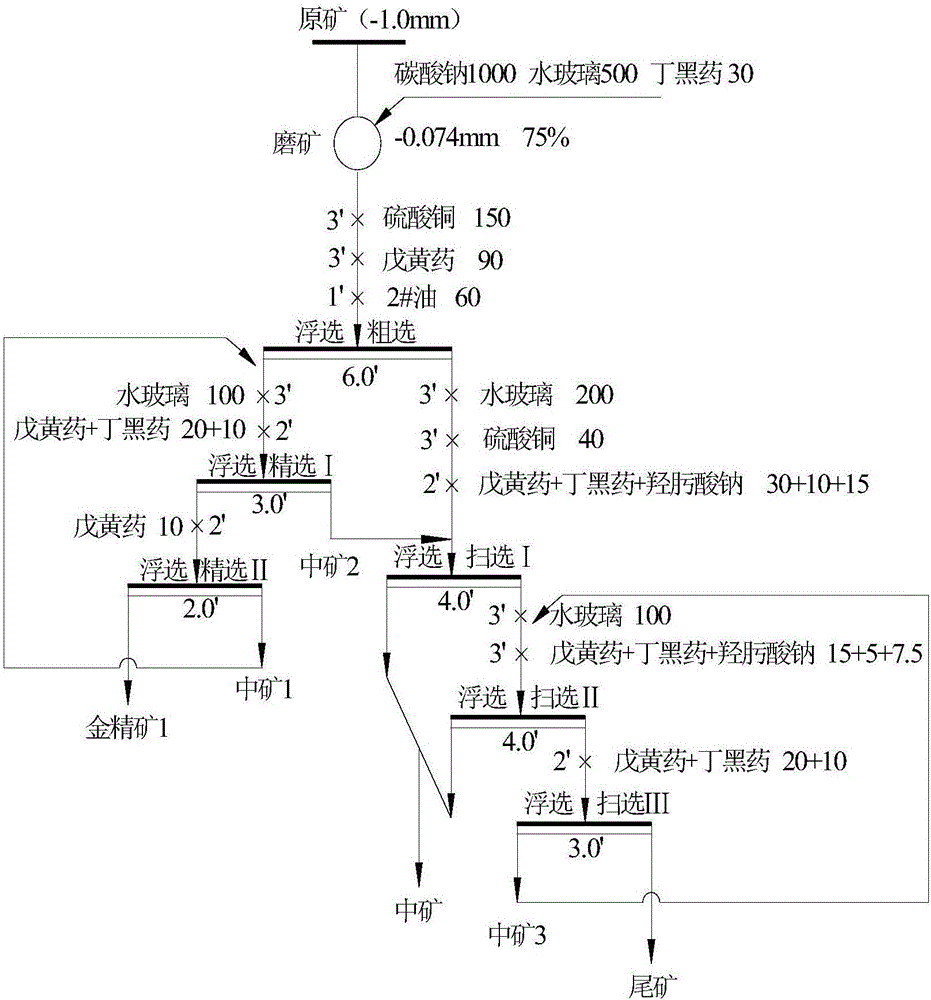

Beneficiation process for gold ores containing high arsenic and antimony content easily argillized minerals

InactiveCN106179722AHigh recovery rateFew influencing factorsFlotationWet separationDibutyl dithiophosphateFoaming agent

The invention relates to a beneficiation process for gold ores containing high arsenic and antimony content easily argillized minerals. By taking sodium carbonate as a flotation pulp regulator, water glass and sodium hexametaphosphate as an inhibitor and a dispersant for argillized minerals, copper sulfate as an activator for gold ores, pentyl xanthate and ammonium dibutyl dithiophosphate as a collecting agent for gold-bearing vulcanized minerals, sodium hydroxamate as a collecting agent for gold-bearing oxide minerals, and oil #2as a foaming agent, the process comprises the following steps: performing one stage grinding on raw ores; performing fast grading of one-stage roughing and one-stage concentrating on the ground minerals to obtain gold concentrate 1, and performing scavenging three times on the roughed tailings to obtain middlings; desliming the obtained middlings, and performing two-stage re-grinding on the deslimed pulp; and performing a strengthened collecting process of roughing at two times and concentrating at one time on the reground pulp to obtain gold concentrate 2. The process provided by the invention is high in recovery rate of the obtained gold concentrate, the affecting factors of the argillized minerals on gold grading are reduced, and through flow grading, the gold grade of obtained mixed gold concentrate is 52.84g / t and the gold recovery rate is 71.01%.

Owner:青海省地质矿产测试应用中心

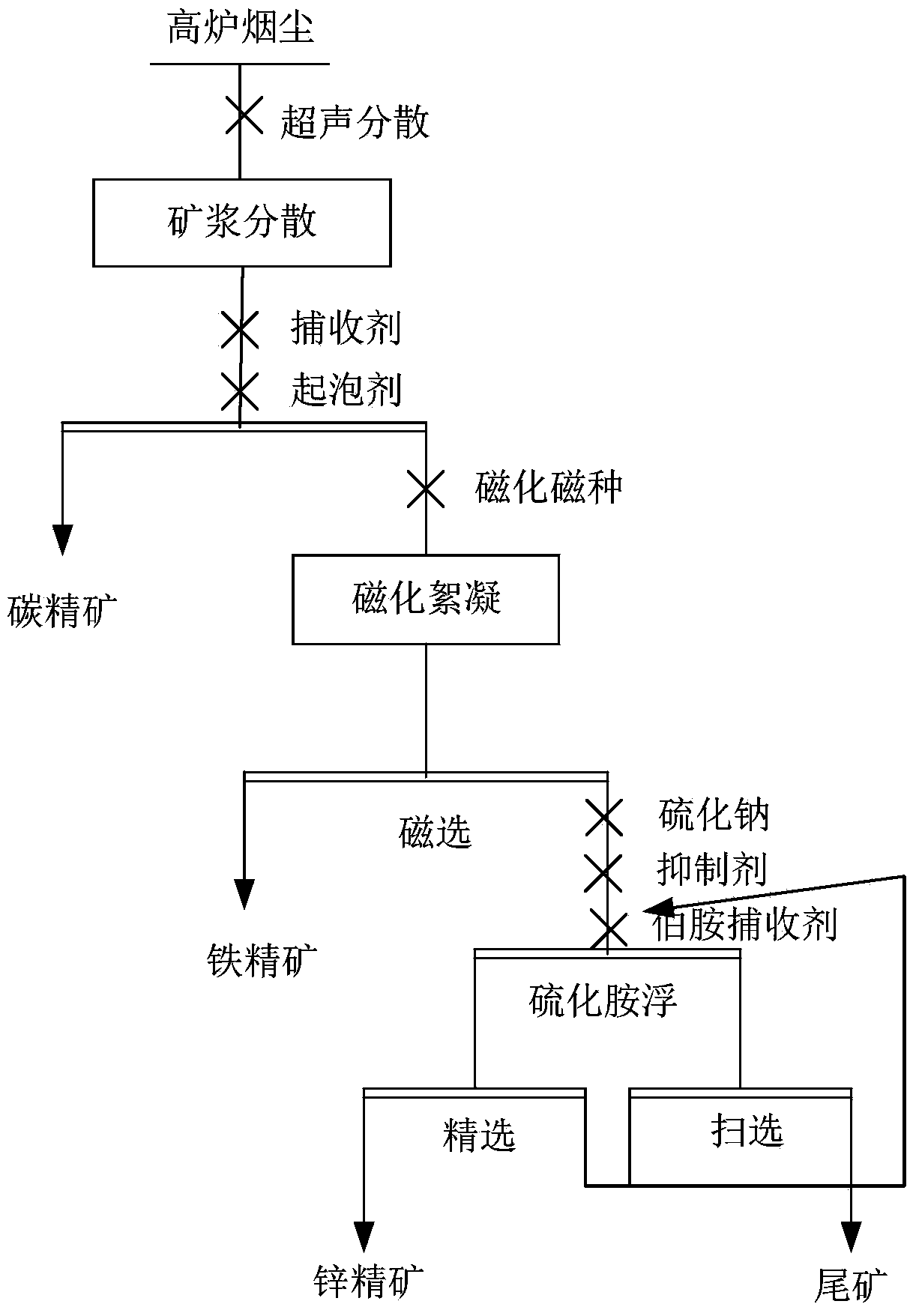

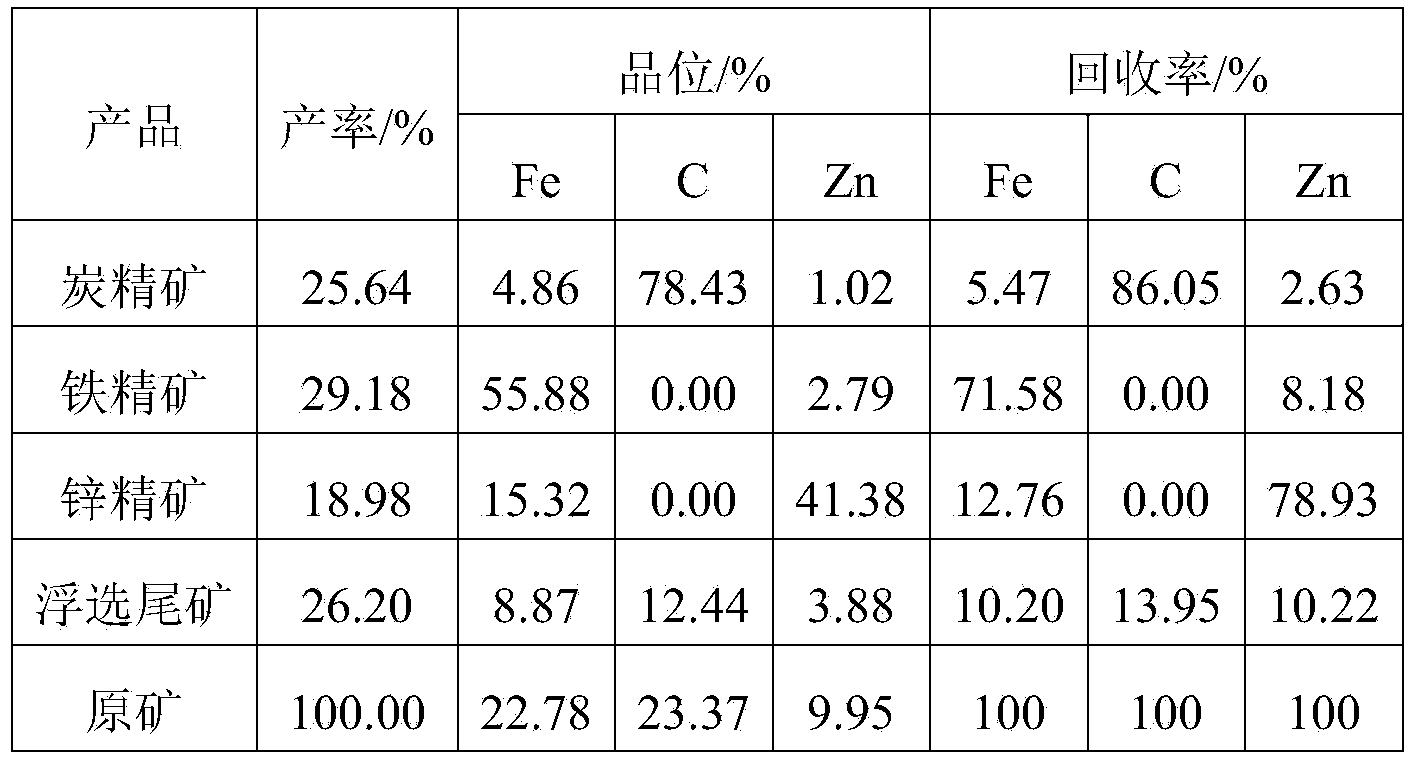

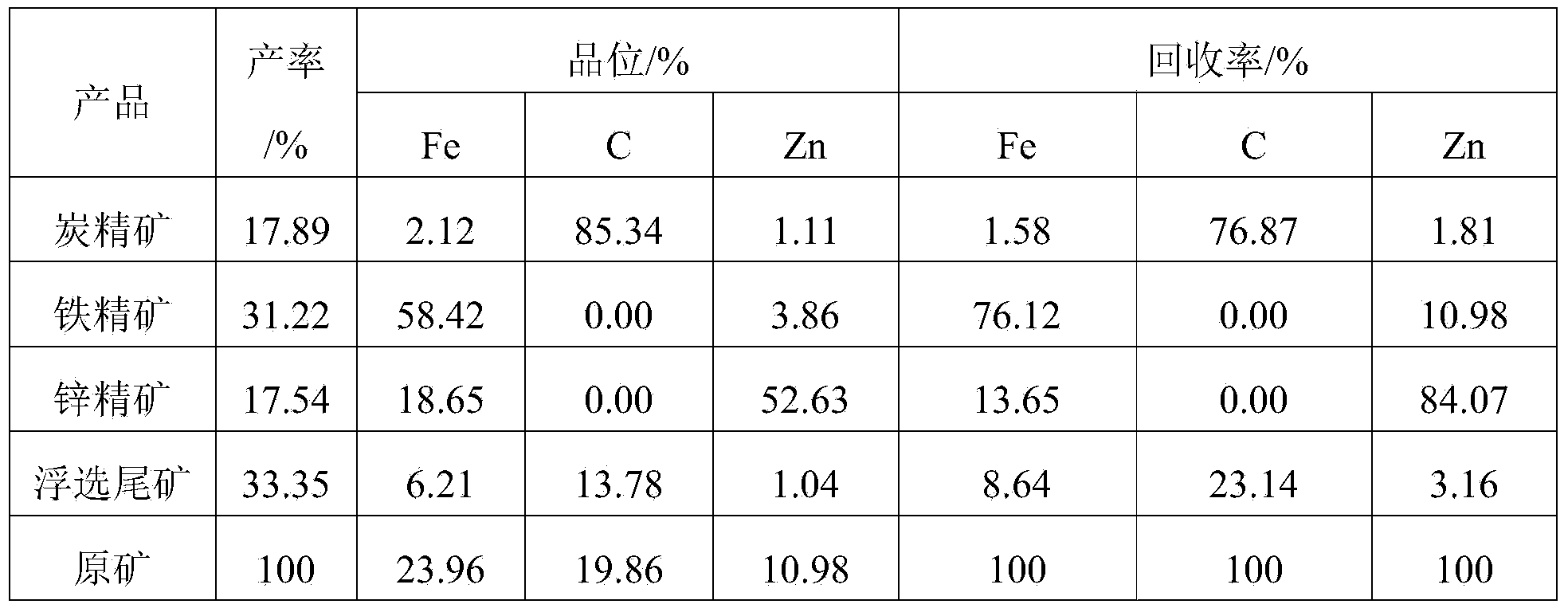

Method for treating blast furnace fume and recycling iron and zinc

InactiveCN104028384AEfficient recyclingSimple processing methodDifferential sedimentationFlotationResource utilizationUltrasonic dispersion

The invention relates to the field of comprehensive resource utilization, and in particular to a method for treating blast furnace fume and recycling iron and zinc. The method comprises the following steps: (a) mixing blast furnace fume with water, pulping, dissolving the electrolyte in the blast furnace fume, subsequently filtering to obtain filtrate, adding water into the filtrate to pulp, and performing ultrasonic dispersion to obtain dispersed ore pulp; (b) performing flotation separation on the dispersed ore pulp to desorb carbon in the blast furnace fume; (c) magnetizing magnetite powder, adding the magnetite powder into the dispersed ore pulp after the floatation separation decarburization, adding a selective flocculant for selective magnetization and flocculation so as to selectively agglomerate hematite and magnetite in the blast furnace fume, and performing magnetic separation to obtain iron ore concentrate and magnetic tailings; (d) adding a selective inhibitor into the magnetic tailings to inhibit iron-bearing minerals, performing surface modification on the zinc oxide minerals, and subsequently performing selective flotation separation to obtain zinc concentrate. The method for treating blast furnace fume and recycling iron and zinc is convenient to operate and is capable of efficiently recycling valuable elements such as iron and zinc, and comprehensive resource utilization of blast furnace dust is achieved.

Owner:孙伟

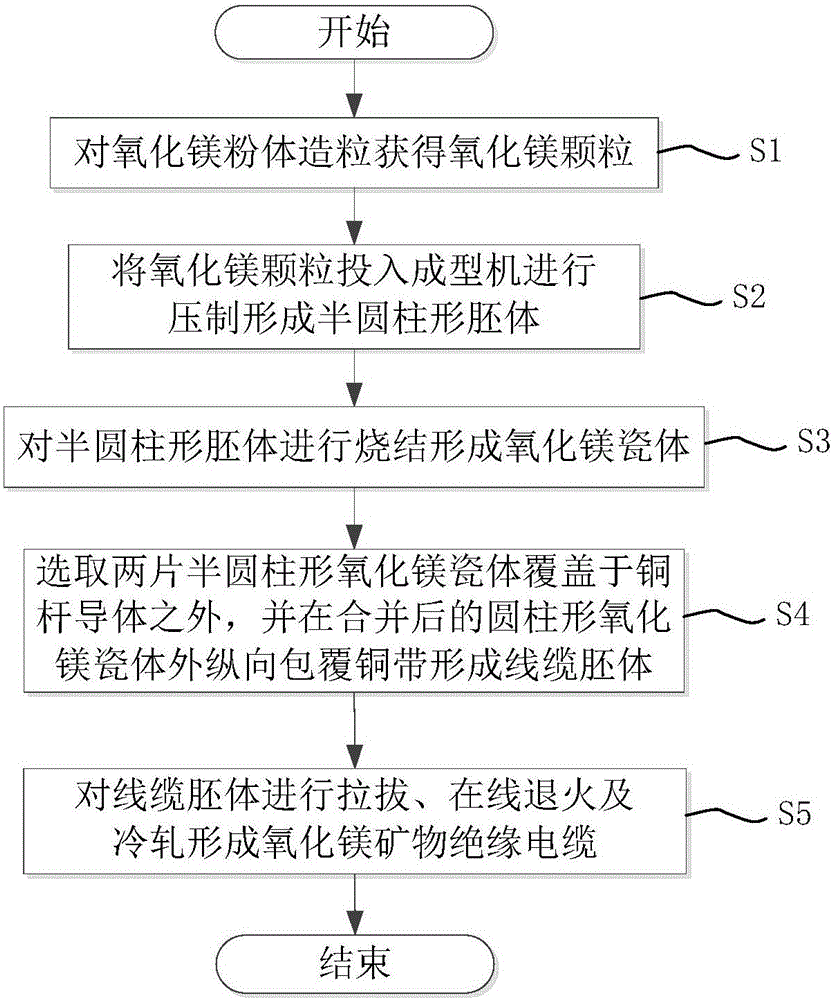

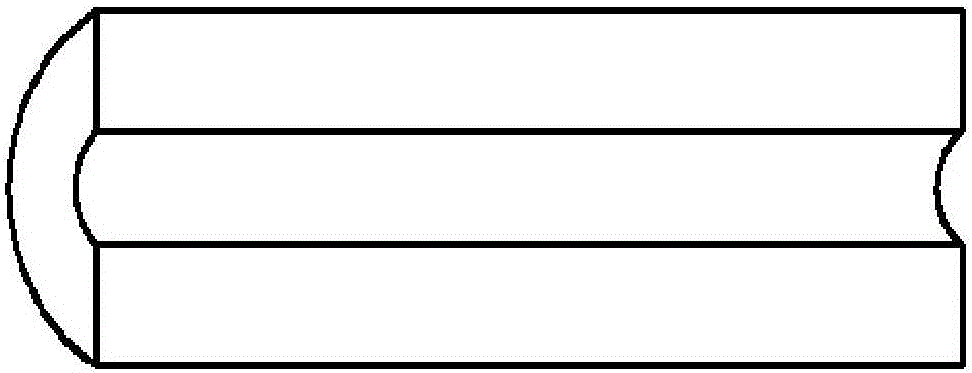

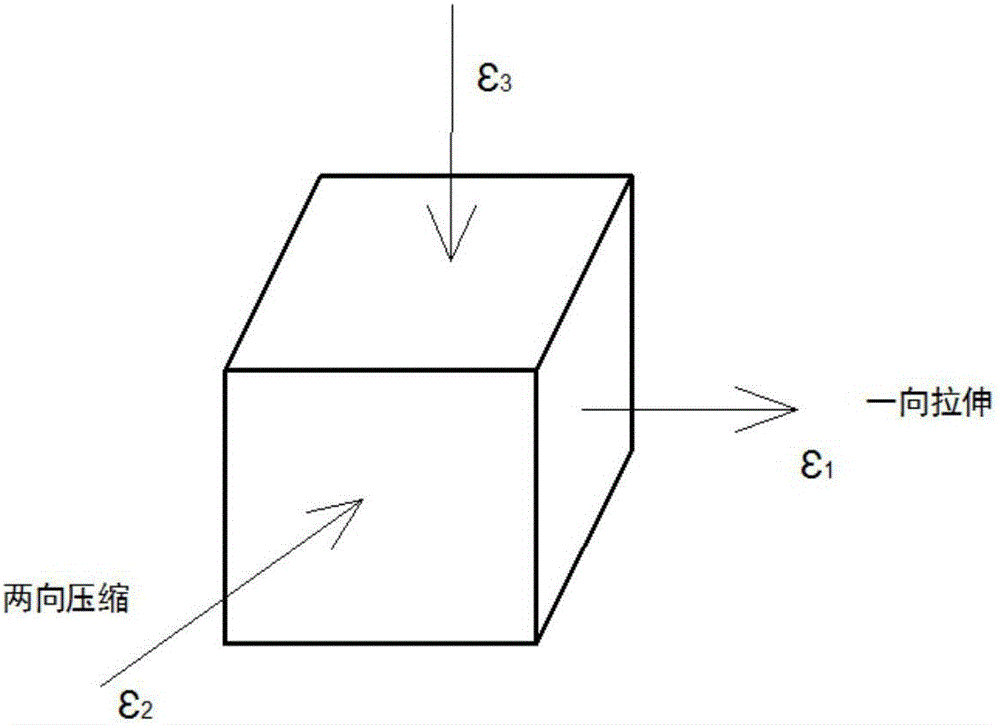

Magnesium oxide mineral-insulated cable production method

ActiveCN106448924AImprove the continuous rolling processReduce the number of annealingInsulating conductors/cablesOxide mineralsEmbryo

The invention discloses a magnesium oxide mineral-insulated cable production method, which comprises the following steps: S1) carrying out magnesium oxide powder granulation to obtain magnesium oxide particles; S2) inputting the magnesium oxide particles into a forming machine and carrying out pressing to form a half-cylindrical embryo body; S3) carrying out sintering on the half-cylindrical embryo body to form magnesium oxide porcelain bodies; S4) selecting two magnesium oxide porcelain bodies to cover a copper rod conductor, and longitudinally wrapping copper strips outside the merged cylindrical magnesium oxide porcelain body to form a cable embryo body; and S5) carrying out drawing, on-line annealing and cold rolling on the cable embryo body to form a magnesium oxide mineral-insulated cable. The provided magnesium oxide mineral-insulated cable production method not only can improve cable reducing continuous rolling technology, reduces annealing frequency, improves cable production process length and reduces process, but also improves work efficient greatly, saves power and reduces production energy consumption.

Owner:上海胜华电气股份有限公司

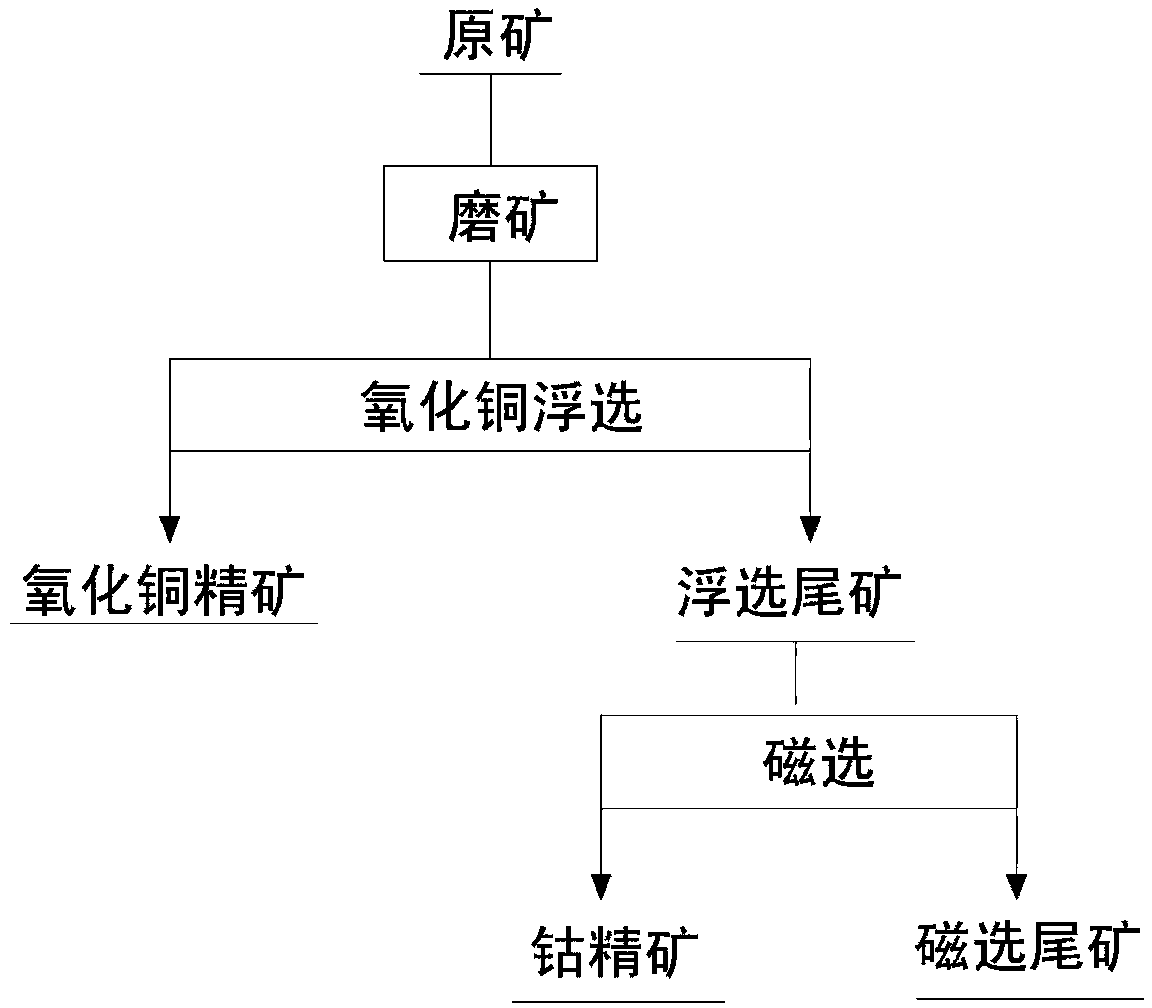

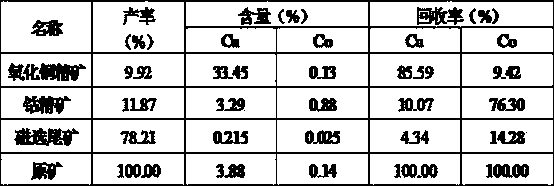

Beneficiation method for copper oxide cobalt ores

The invention relates to a beneficiation method for copper oxide cobalt ores. The beneficiation method is characterized by comprising the following steps of 1, ore grinding, i.e. crushing and grinding raw ores; 2, copper oxide flotation, i.e. adding sodium sulfide, a collecting agent butyl xanthate and a foaming agent terpenic oil in the primary roughing process, adding sodium sulfide, butyl xanthate and terpenic oil in the primary scavenging process, adding sodium sulfide, butyl xanthate and terpenic oil in the secondary scavenging process and carrying out secondary blank concentration to obtain copper oxide concentrates and flotation tailings; and 3, magnetic separation, i.e. carrying out primary roughing magnetic separation on the flotation tailings to obtain cobalt rough concentrates and magnetic separation tailings and carrying out secondary concentration magnetic separation on the cobalt rough concentrates to obtain cobalt concentrates and magnetic separation tailings. The invention provides the beneficiation method for the copper oxide cobalt ores, which reduces cost and pollution. The method disclosed by the invention is suitable for the copper oxide cobalt ores comprising copper oxide ores, copper oxide cobalt ores and cobaltous oxide minerals.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

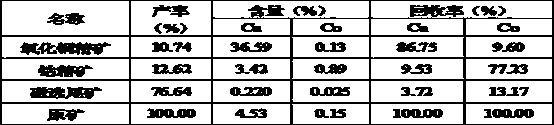

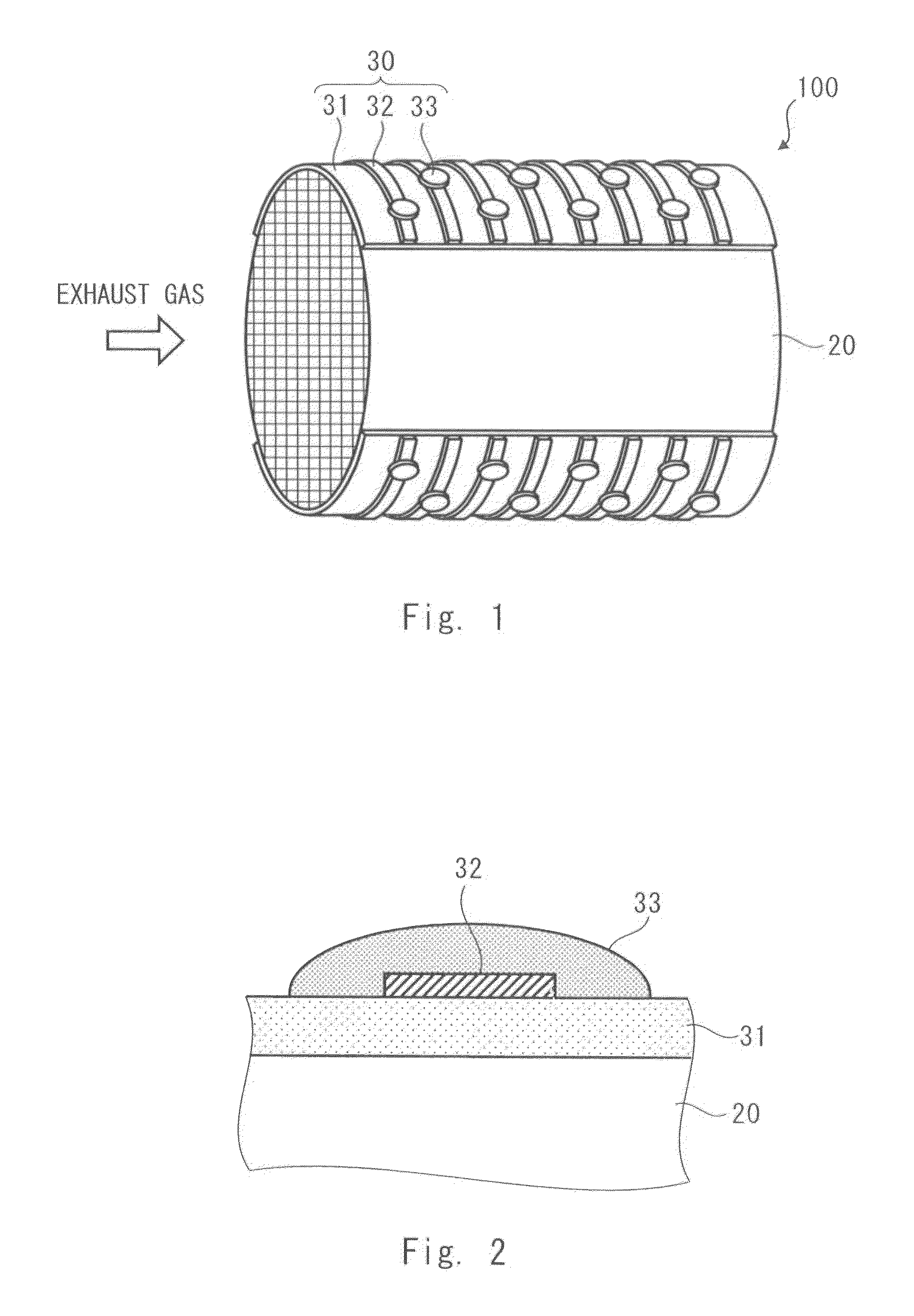

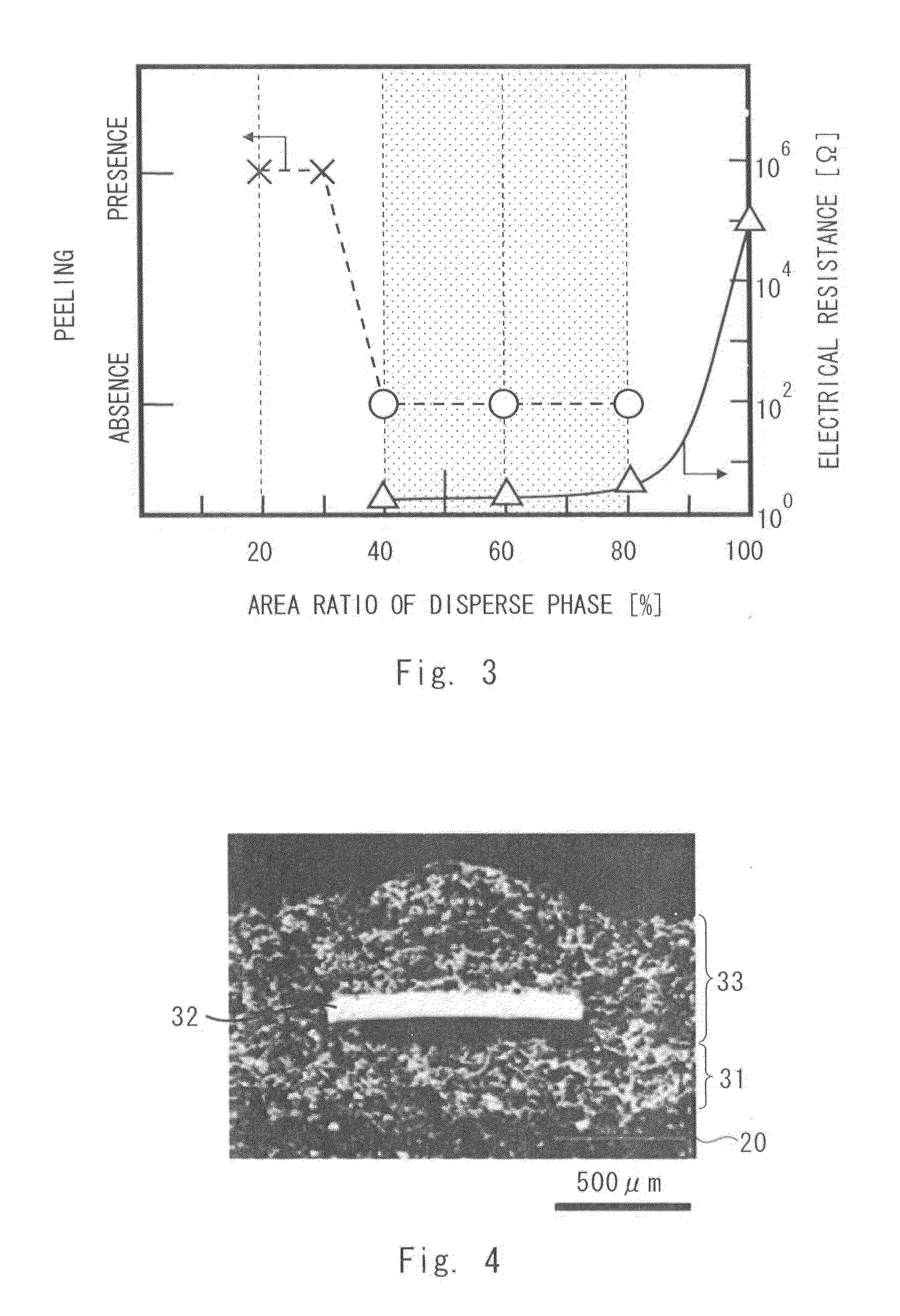

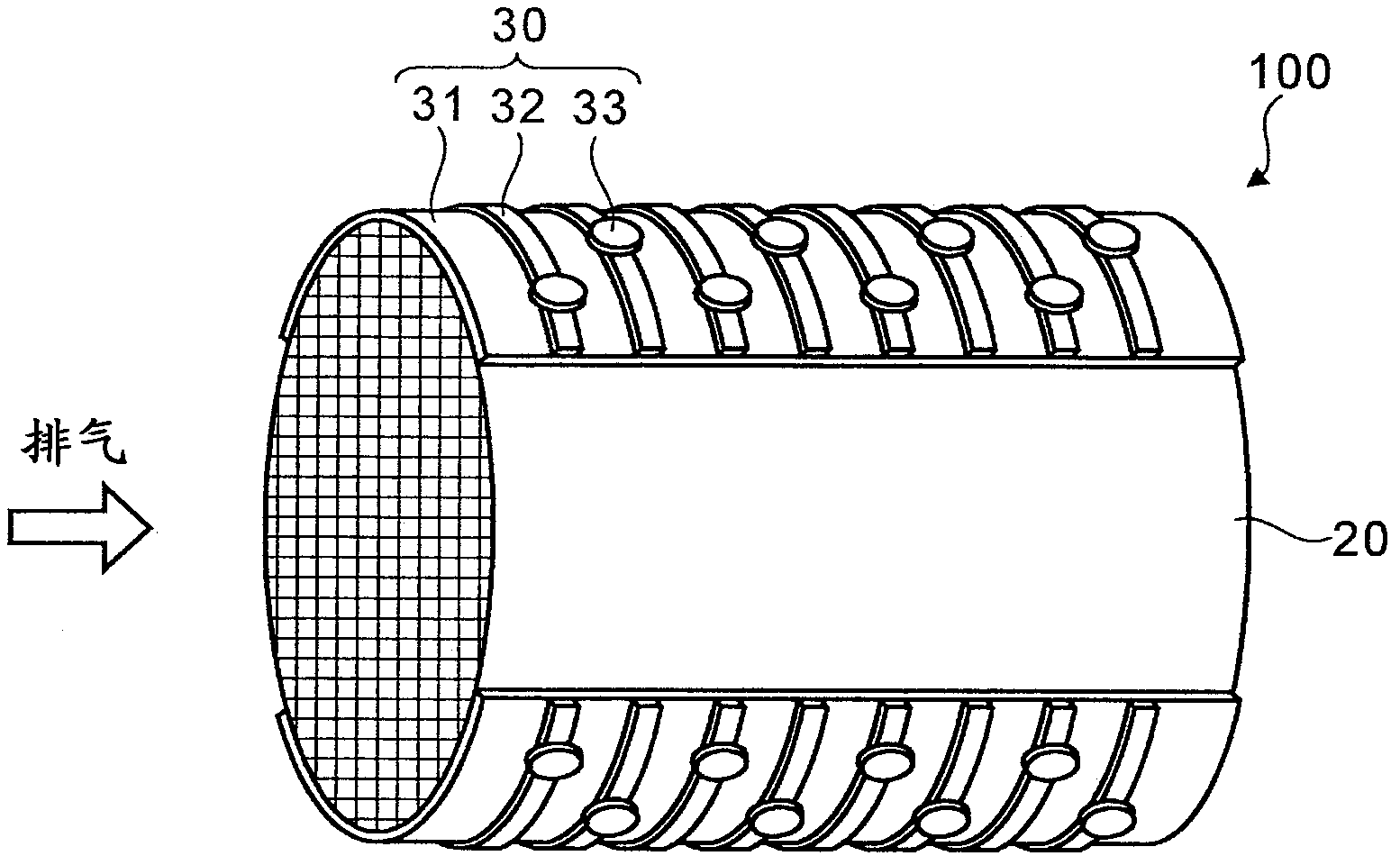

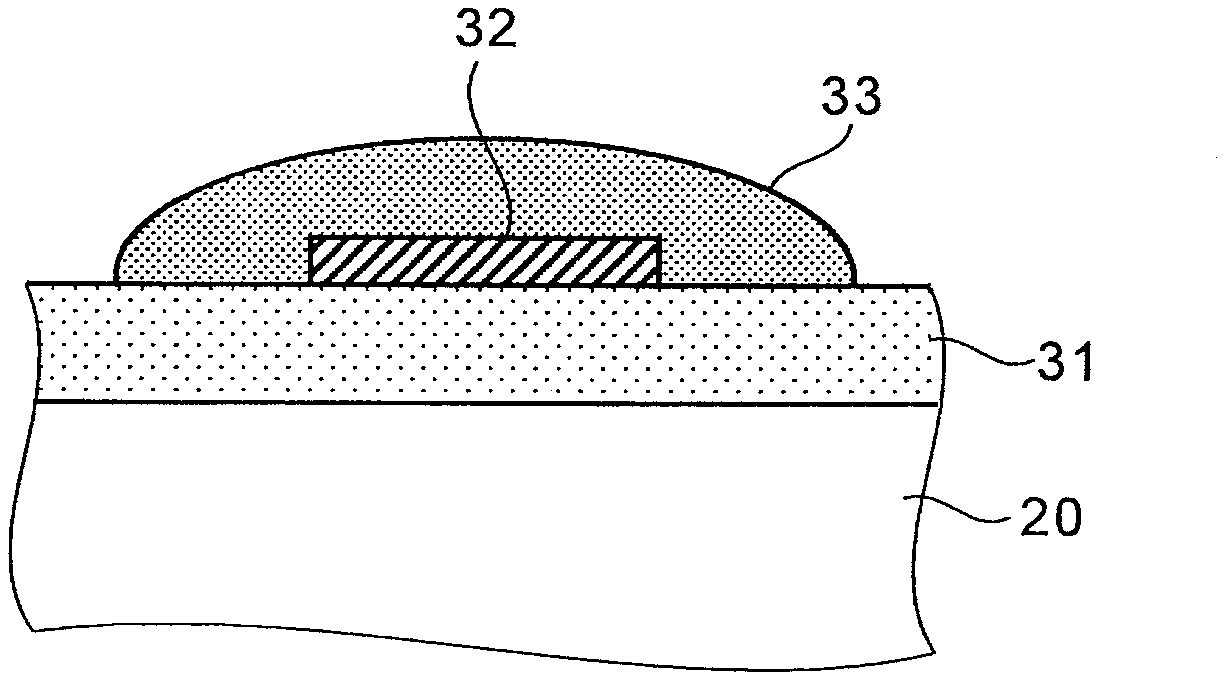

Electrode, electrically heating type catalyst device using same, and manufacturing method of electrically heating type catalyst device

ActiveUS20130062328A1Minimizing increase in electrical resistanceLiquid surface applicatorsMolten spray coatingElectrical resistance and conductanceOxide minerals

An electrode according to one aspect of the present invention is formed on a base material composed of a ceramics. The electrodes includes a matrix composed of an Ni-Cr alloy (with a Cr content of 20 to 60 wt. %) or an MCrAlY alloy (M is at least one material selected from Fe, Co and Ni), and a disperse phase that is dispersed in the matrix and composed of an oxide mineral having a laminated structure. The ratio of area occupied by the disperse phase in a cross section of the electrode is 40 to 80%. With the structure like this, it is possible to suppress the increase in the electrical resistance even after a thermal cycle is performed.

Owner:TOYOTA JIDOSHA KK

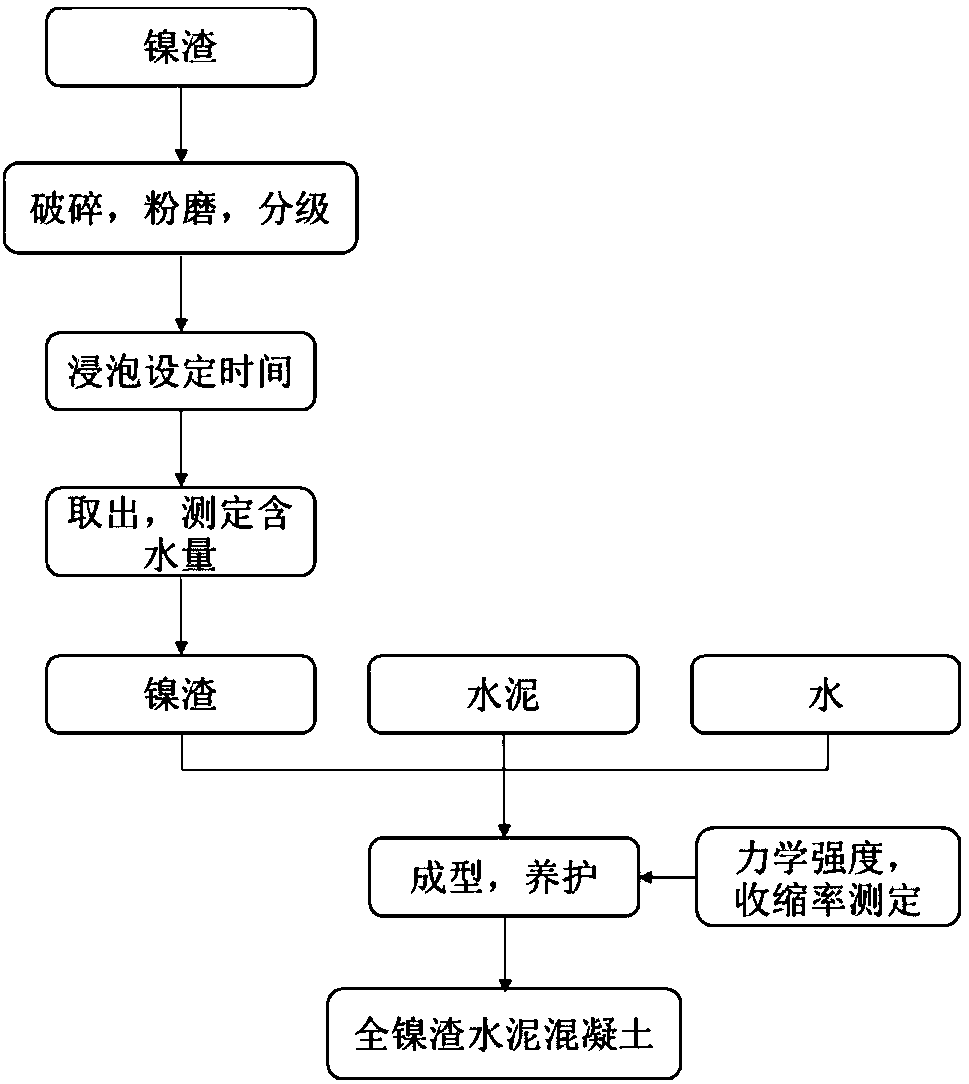

Preparation method of premixed concrete fully doped with nickel slag

The invention relates to a preparation method of premixed concrete fully doped with nickel slag. The method comprises the following steps: (1) carrying out pretreatment on the nickel slag: pouring thenickel slag into a crusher for crushing; then, classifying the crushed nickel slag according to particle sizes, and grinding fine powder again to obtain nickel slag powder; (2) respectively dipping the nickel slag powder, relatively coarse nickel slag and coarse nickel slag into saturated limewater for 1-6 days, fishing out and drying for later use; (3) mixing: mixing the following raw materialsin parts by weight: 190-210 parts of cement, 170-180 parts of water, 150-170 parts of the nickel slag powder, 800 parts of the relatively coarse nickel slag and 1050 parts of the coarse nickel slag. According to the preparation method, the nickel slag is prepared into admixture, fine aggregate and coarse aggregate of the concrete, and the conventional admixture, fine aggregate and coarse aggregatein the concrete are completely replaced with the admixture, the fine aggregate and the coarse aggregate which are prepared from the nickel slag, so that the raw material cost of the concrete is significantly reduced. A certain amount of Mg(OH)2 is generated in a hydration process by using magnesium oxide mineral existing in the nickel slag, so that a certain volume is increased, and a concrete product which has good shrinkage property and even does not shrink can be prepared.

Owner:YANCHENG GUOTAI CONCRETE +1

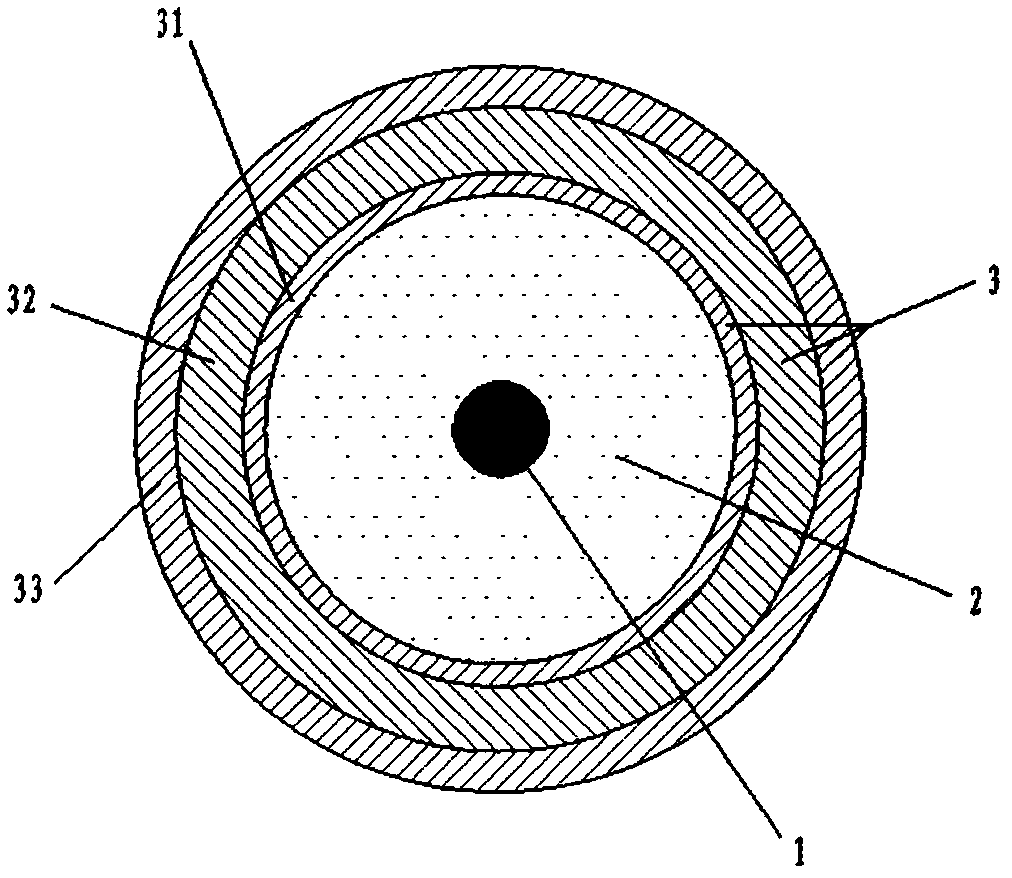

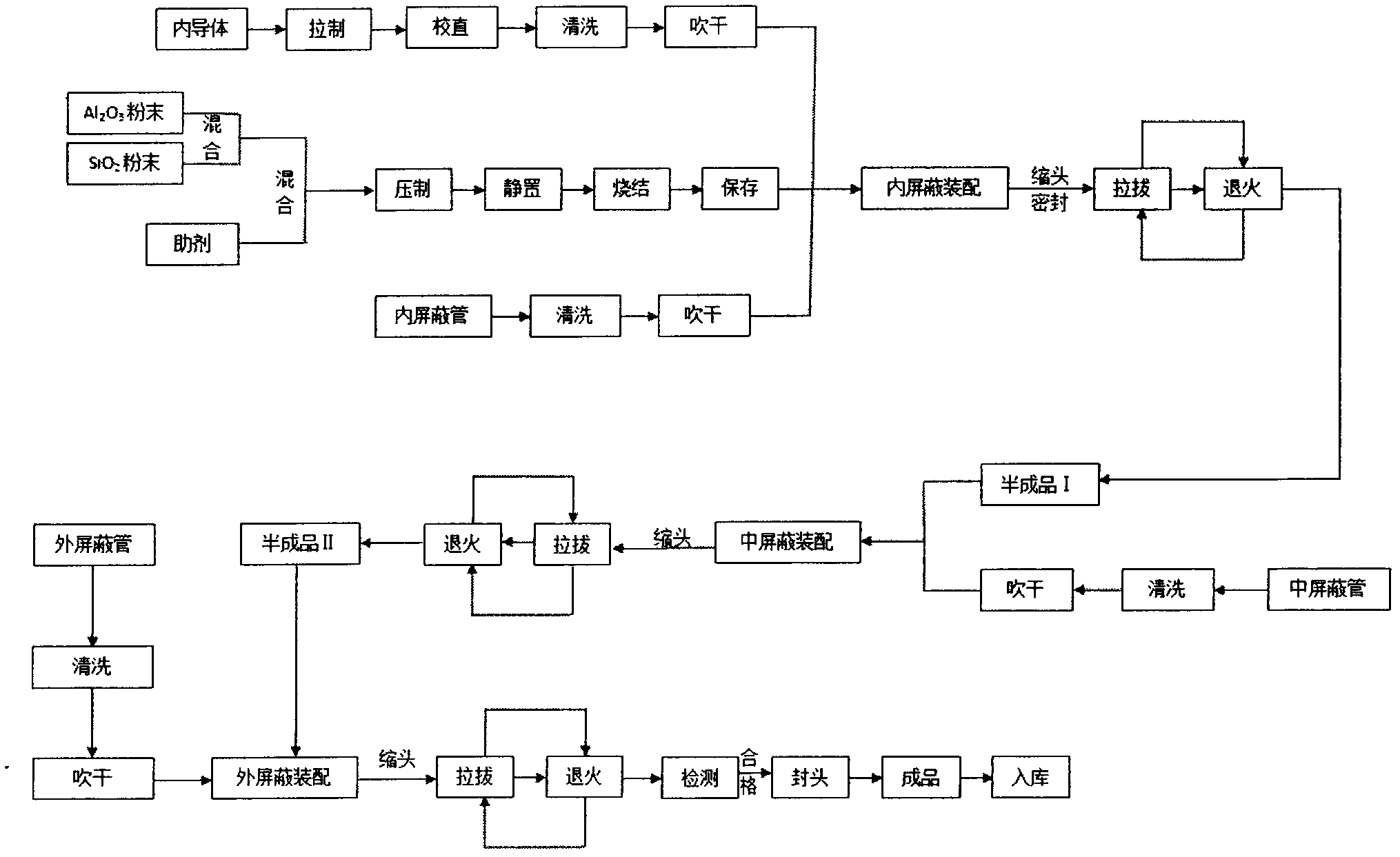

Implementation method of mineral insulated coaxial cable

InactiveCN103021577AImprove temperature resistanceImprove oxidation resistanceManufacturing co-axial cablesInsulating conductors/cablesDielectricExtreme weather

The invention relates to the technical field of special cables and provides an implementation method of a mineral insulated coaxial cable which can realize signal communication transfer in an extreme weather condition; and the dielectric property and the high-temperature insulation performance of the cable can be comprehensively optimized to well satisfy the using requirements of the signal communication coaxial cable. The mineral insulated coaxial cable is characterized by comprising an inner conductor, an insulating medium layer and a three-layer composite shield body from inside to outside; the insulating medium layer is made of a mixture of aluminium oxide and silicon oxide; the three-layer composite shield body is formed by sequentially compositing an inner shield body, a middle shield body and an outer shield body, each layer can be made of copper pipes, iron pipes, stainless steel pipes or other high-temperature alloy pipes, and the adjacent layers can not be made of the same material. Compared with the conventional organic matter insulated cable, the three-layer composite shield mineral insulated coaxial cable has relatively long service life and relatively high reliability. Compared with a magnesium oxide mineral insulated cable, the three-layer composite shield mineral insulated coaxial cable has a relatively wide application field.

Owner:CHINA ELECTRONICS TECH GRP NO 23 RES INST

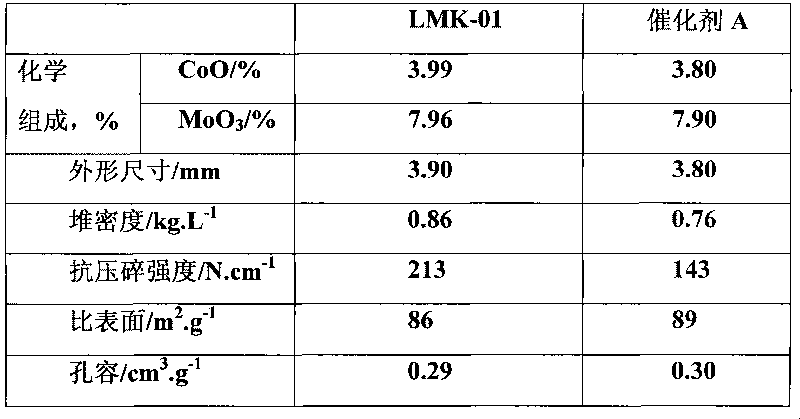

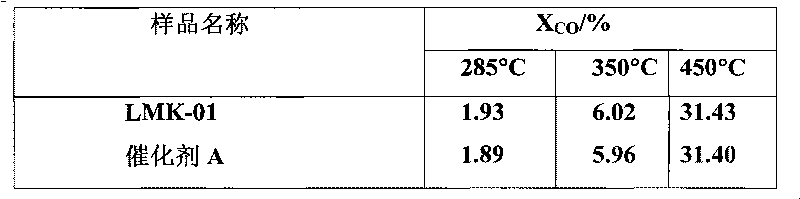

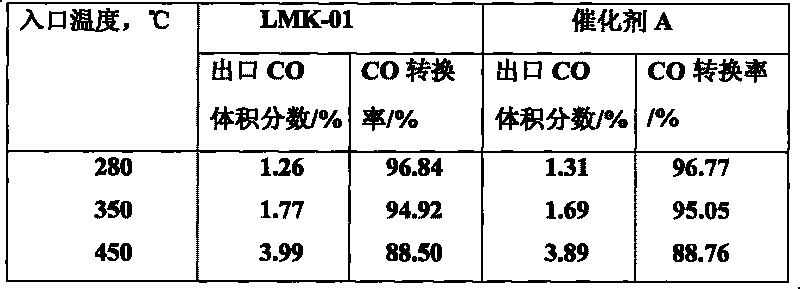

CO sulfur tolerant shift catalyst and preparation method thereof

ActiveCN101695662AHigh strengthImprove stabilityHydrogenCatalyst activation/preparationMagnesium saltHigh pressure

The invention provides a CO high / medium voltage sulfur tolerant shift catalyst comprising a catalyst active component, a structure promoter and a carrier. The CO high / medium voltage sulfur tolerant shift catalyst is characterized in that the structure promoter is directly derived from magnesite, and the magnesite is crushed and subjected to thermal inversion and phase inversion to form active magnesium oxide mineral powder so as to substitute active magnesium oxide or magnesium salts; the use level of the magnesite powder is 5-30 percent of the total quality of the catalyst; the technical key lies in the high dispersion and thermal phase inversion of the magnesite powder; meanwhile, the invention also provides a preparation method of the catalyst, which has simple operation process and comprises the following steps of mediating, extruding, drying and roasting. The catalyst is applied to a process flow of high / medium voltage shift and has very high activity, stability and strength. The sulfur tolerant shift catalyst prepared by the natural magnesite powder has stable components, low production cost and no pollution in the production process, thereby achieving a feasible technology.

Owner:SHANDONG QILU KELI CHEMICAL RESEARCH INSTITUTE CO LTD

Electrode, electrically heated catalytic converter using same and process for producing electrically heated catalytic converter

InactiveCN103155695AIncrease the resistance valueOhmic-resistance electrodesExhaust apparatusOxide mineralsNi cr alloy

Owner:TOYOTA JIDOSHA KK

Method for producing nickel-iron-containing mixed slag

InactiveCN107641718ASolve pollutionLarge scale processingProcess efficiency improvementMolten stateLead smelting

The invention relates to a method for producing nickel-iron-containing mixed slag. The method comprises the following steps: S1, furnace slag mixing: adding nickel smelting slag into a reaction device, and adding one or more of lead smelting slag, blast furnace slag, steel slag and ferroalloy slag, thus forming the mixed slag; heating the mixed slag into a molten state, and adding one or more of acopper oxide mineral, a copper sulphide mineral, a nickel oxide mineral, a nickel sulfide mineral and a copper-containing material; uniformly mixing the materials to obtain reaction slag, monitoringthe reaction slag in real time, and treating the mixed reaction slag through regulation and control to enable the mixed reaction slag to simultaneously meet conditions a and b, thus obtaining reactedslag; S2, separation and recycling. The method for producing the nickel-iron-containing mixed slag is short in reaction time, short in technological process, high in metal recycling rate, low in production cost, high in treatment capacity, environmentally friendly and high in economical benefit, and effectively solves the problem in efficient recycling of metallurgical resources and heat energy.

Owner:NORTHEASTERN UNIV

Pipe leaching method and pipe leaching device for solid powder

InactiveCN101695610AFast leachingShorten the leaching timeEnergy based chemical/physical/physico-chemical processesSolid solvent extractionOxide mineralsSulfide minerals

The invention relates to a pipe leaching method and a pipe leaching device for solid powder. The solution to be leached flows through the pipe leaching device arranged in a tank container and the leaching process is completed by adopting the pipe leaching method. The pipe leaching method comprises that: the solution to be leached is conveyed into a pipeline of the pipe leaching device by using an ultrasonic generating device to complete an irreversible leaching process of the solid powders in the process that the solution to be leached irreversibly flows through the pipeline with an ultrasonic energy field. The irreversible leaching process comprises that when the solid powder with given size goes through the same leaching time, most of the grains have the same flowing through path; the residual grains tend to be equal in aspects of grain mass, grain diameters and grain target components, and the solid powders added in a leaching reaction region later are difficult to be mixed with the solid powders added in the leaching reaction region firstly. The solid powders are mineral powders and (or) animal and plants powders, wherein the mineral powders are oxide mineral powders and (or) sulfide mineral powders; and the animal and plants powders at least comprise Chinese medicinal powders.

Owner:佛山市兴民科技有限公司

Collector compositions and methods of using same in mineral flotation processes

Collector compositions C for mineral flotation, which include at least one of a hydroxamic acid A, and / or a salt S of a hydroxamic acid A solubilized in a water-soluble organic solvent L, and processes for using same for recovering sulfide and / or oxide minerals in mineral flotation processes are provided herewith.

Owner:CYTEC IND INC

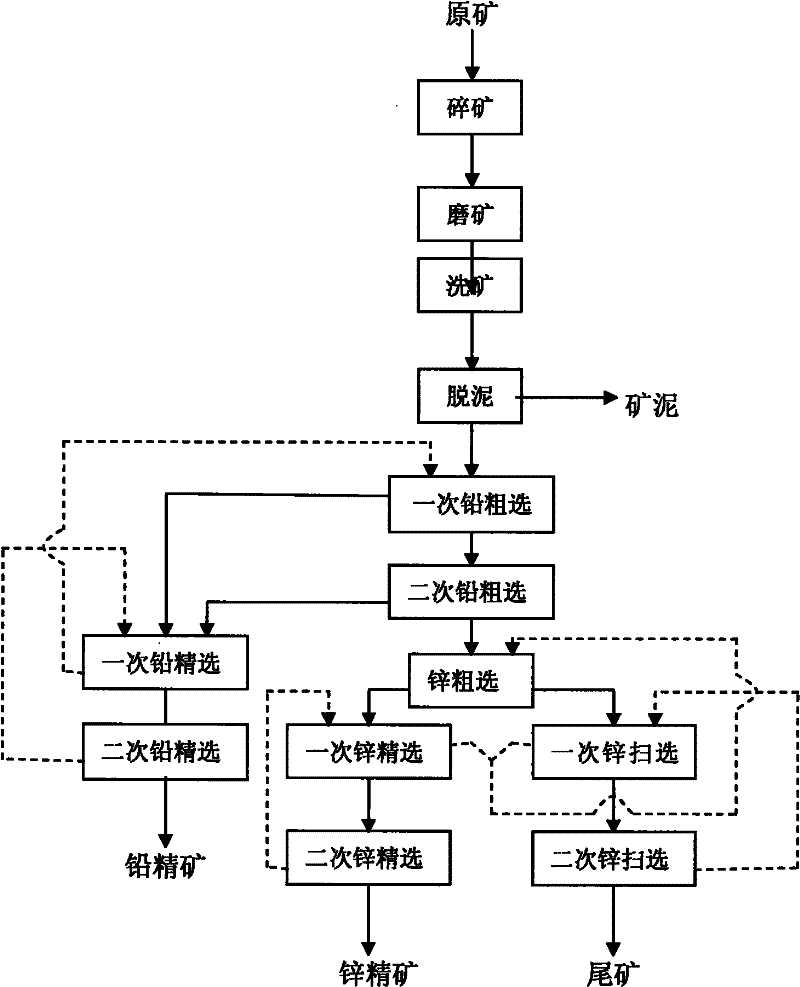

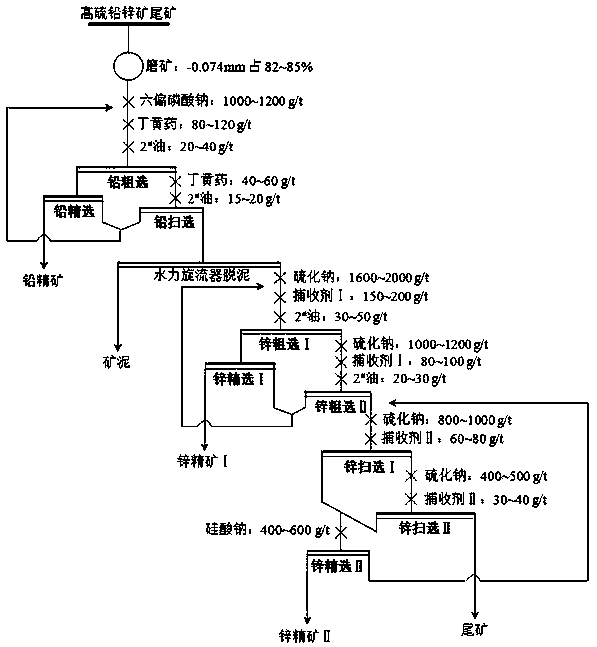

Method of recycling lead and zinc ore from high-sulfur lead and zinc ore tailings

The invention discloses a method of recycling lead and zinc ore from high-sulfur lead and zinc ore tailings and belongs to the technical field of mineral processing engineering. The method comprises the steps that after fine grinding of the high-sulfur lead and zinc ore tailings is completed, a regulator agent, a collecting agent and a foaming agent are added,lead and zinclead rough flotation, lead scavenging flotation, and lead fine flotation are sequentially conducted, and recycling of minute granulometric class lead oreis intensified, so that lead concentrate is obtained; and then, desliming is conducted on the tailings obtained after lead flotation, after a sulfuration agent, the collecting agent and the foaming agent are added to setting sand obtained after desliming, rough flotation,fine flotation and scavenging flotation are conducted on zinc oxide ore sequentially,two types of zinc concentrate products, namely high-grade zinc concentrate and low-grade zinc concentrate, can beobtained, wherein the different collecting agents are adopted for the rough flotation and the scavenging flotation of the zinc oxide mineral. By means of the method of recycling the lead and zinc orefrom the high-sulfur lead and zinc ore tailings, the problems that the mineral sludge disturbance is severe in the recleaning process of the high-sulfur lead and zinc ore tailings, the zinc ore recycle rate is low, the recleaning technological process is complicated, and the medicament cost is high can be solved; the recycle rate of lead, zinc and the like can be increased conveniently; the methodof recycling the lead and zinc ore from the high-sulfur lead and zinc ore tailings is reasonable in process, simple in procedureand good in sorting effect, and industrialized implementation can be conducted easily.

Owner:KUNMING UNIV

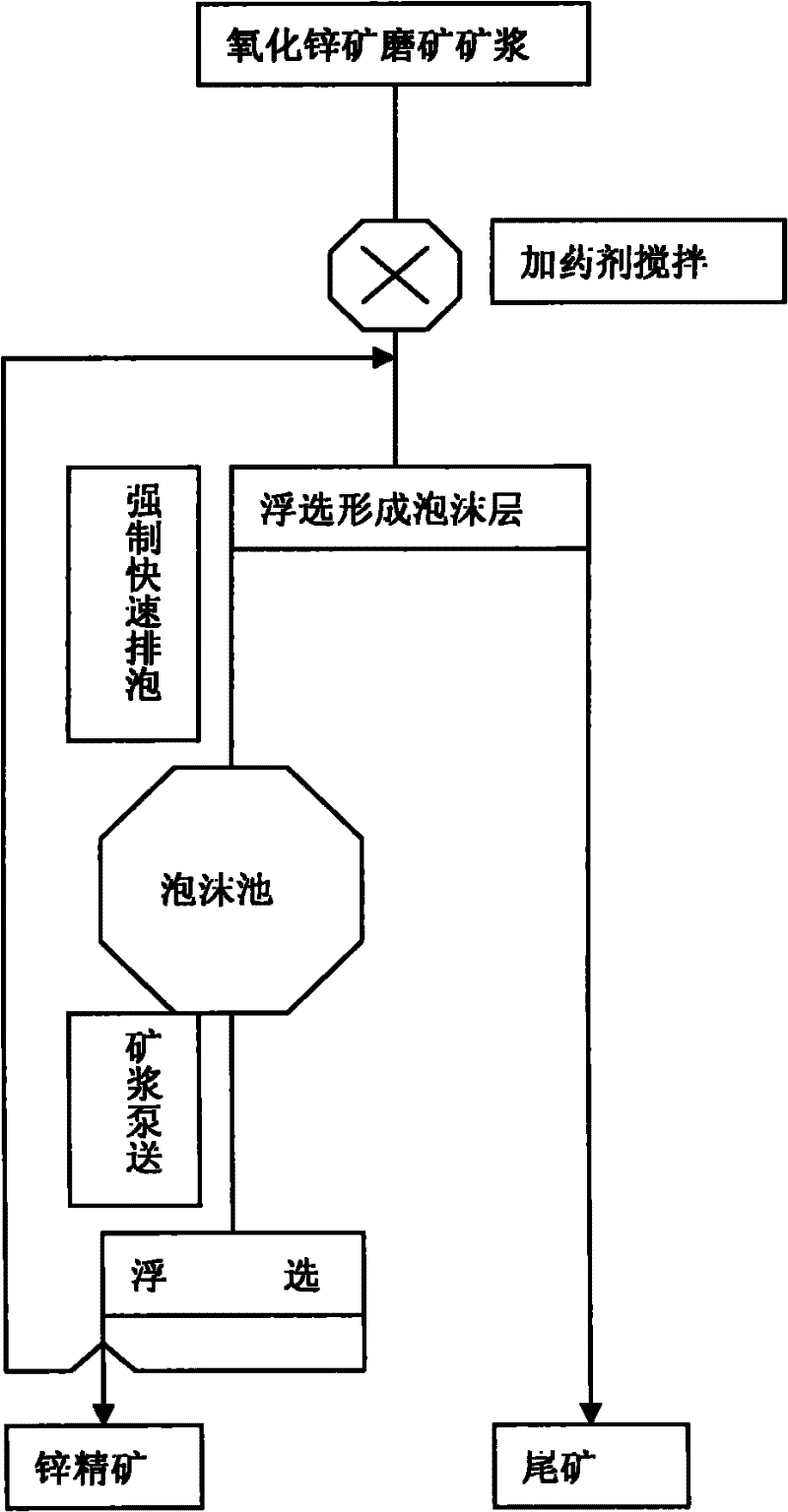

Foam controlling and flotation method for zinc oxide ore

The invention relates to a foam controlling and flotation method for zinc oxide ore. The method comprises the steps of: mixing slurry by using a vulcanized agent, and performing flotation by using an amine-containing collecting agent to form a foam layer with large foam output and low flowability, pushing the foam layer to a foam groove by using a quick foam scraping mechanism and then conveying into a foam pool for defoaming, returning the defoamed pulp, and performing flotation to improve the zinc concentrate grade further. In the technology, a large amount of difficultly-treated foam which is produced through flotation of the zinc oxide ore and has low flowability and long service life is quickly discharged by a mechanical mode and is defoamed by the foam pool to ensure the technical indexes of the industrial flotation of the zinc oxide ore, and the method has an positive effect on the high-efficiency recycling of the zinc oxide mineral resources.

Owner:KUNMING UNIV OF SCI & TECH

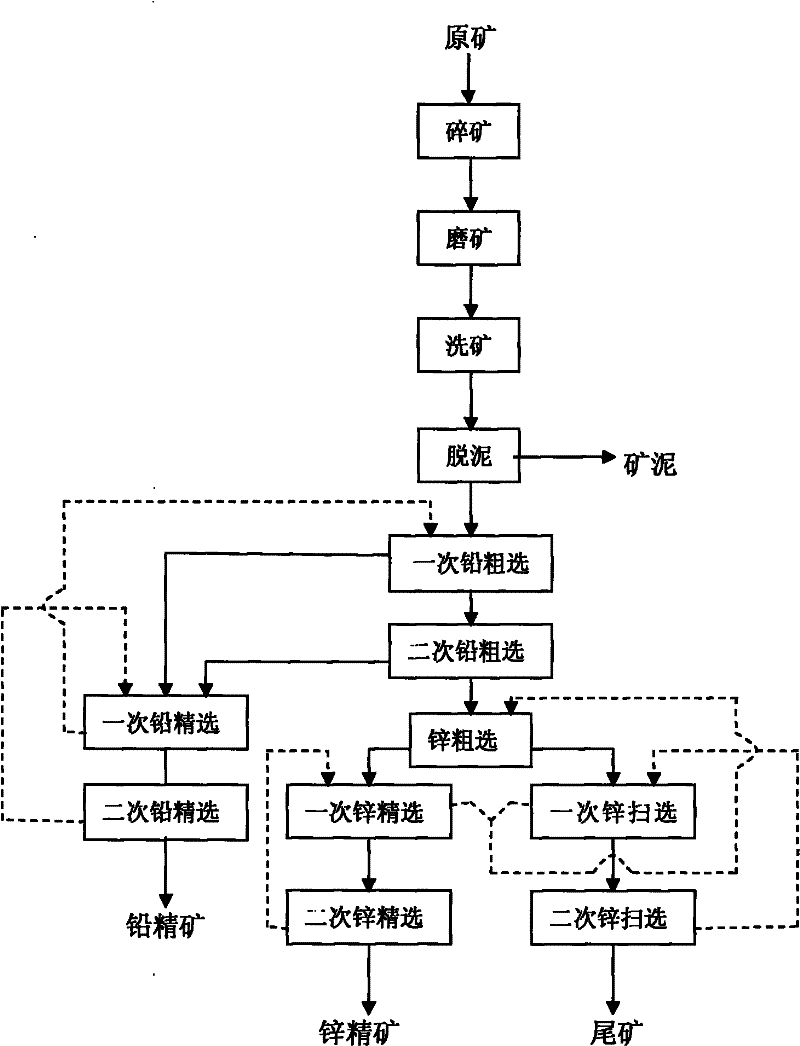

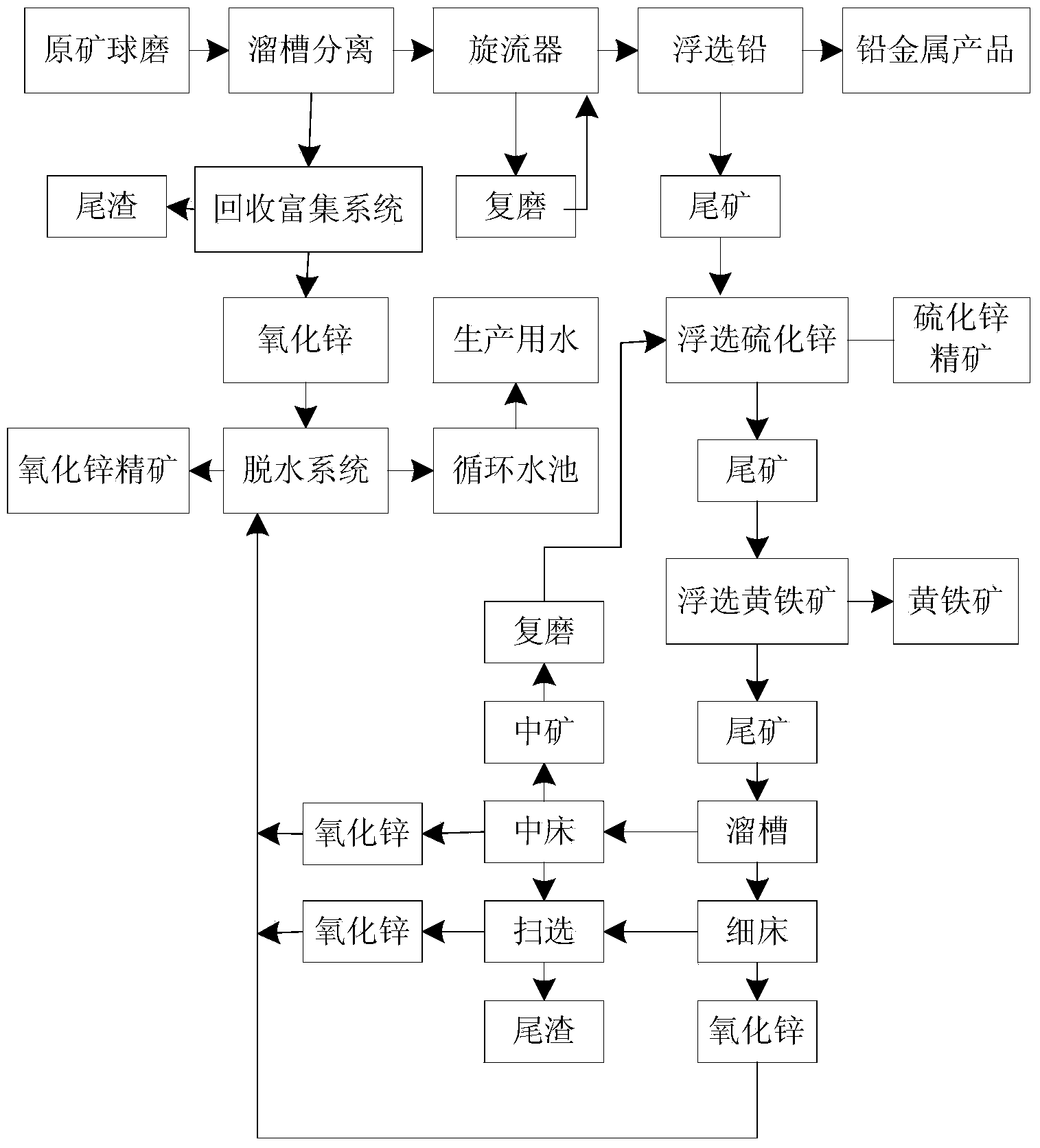

Multi-metal recovery method for low-grade oxygen-sulfide lead-zinc mixed ore

ActiveCN104014420AEliminates tail churnHigh recovery rateFlotationWet separationRecovery methodOxygen

The invention relates to the technical field of recovery of low-grade oxygen-sulfide lead-zinc mixed ore, in particular to a multi-metal recovery method for the low-grade oxygen-sulfide lead-zinc mixed ore. The multi-metal recovery method comprises the following preparation steps that firstly, chute separation is carried out on the raw ore after primary grinding is carried out and the raw ore enters a spiral chute of a classification system; secondly, separation and enrichment recovery is carried out on over-crushing minerals in an over-crushing system to obtain over-crushing zinc oxide concentrate and discharge tailings, and flotation is carried out on the minerals entering a first flotation system set to discharge the tailings; thirdly, secondary flotation is carried out on the tailings after the tailings enter a second flotation system set to obtain zinc sulfide minerals and discharge secondary tailings; fourthly, tertiary flotation is carried out on the secondary tailings after the secondary tailings enter a third flotation system set to obtain pyrites and discharge tertiary tailings; fifthly, the tertiary tailings enter a physical beneficiation system to extract zinc oxide minerals. According to the multi-metal recovery method, the problem that flotation and reselection recovery of superfine zinc oxide particles is difficult, running and losing of metal due to the argillization phenomenon of the oxide minerals are eliminated, and the recovery rate of the minerals is increased.

Owner:李锦源

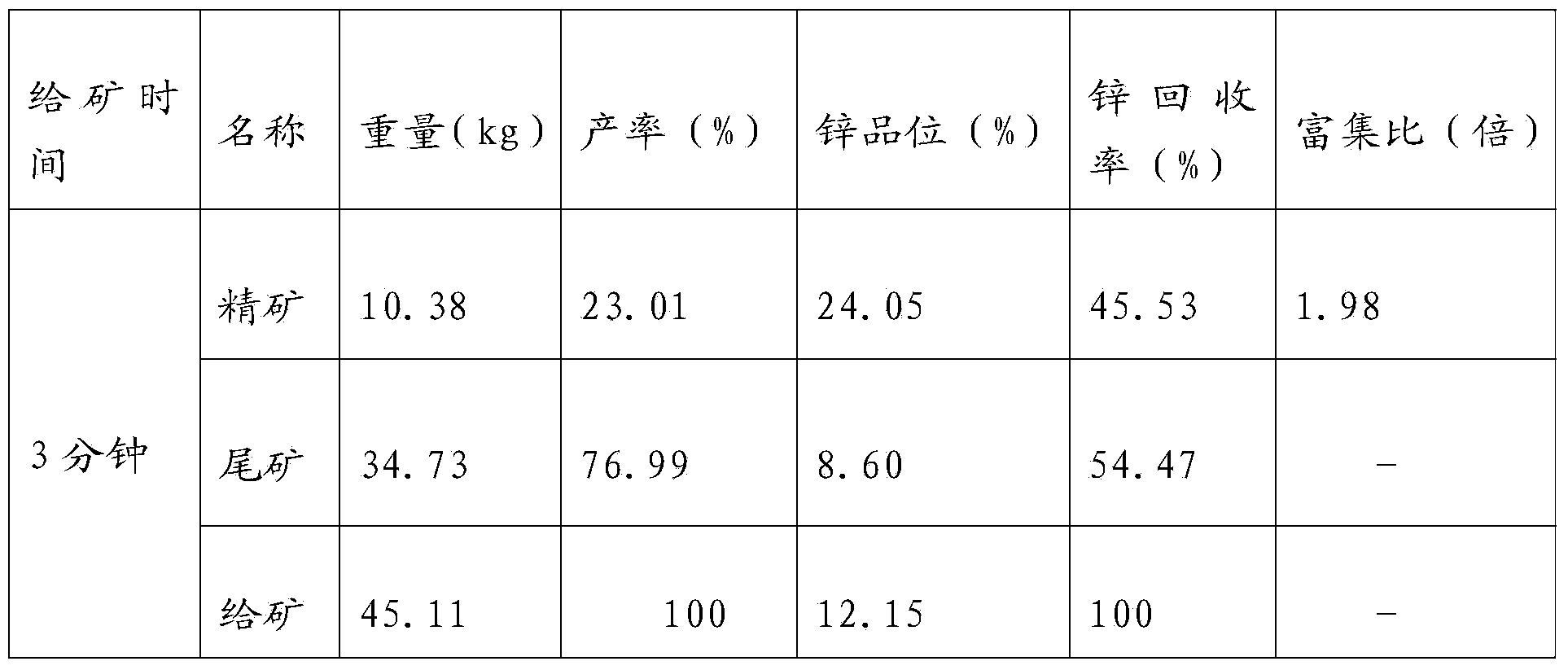

Beneficiation method adopting sulfuric acid for pre-activating iron zinc oxide ore

ActiveCN109482352AEfficient enrichmentEfficient recyclingFlotationGrain treatmentsOxide mineralsZinc

The invention discloses a beneficiation method adopting sulfuric acid for pre-activating an iron zinc oxide ore, and belongs to the technical field of mineral processing. According to the method, a dispersing agent is added into a grinding machine, so that the dispersing effect of a mineral mud is enhanced; then zinc oxide minerals are preprocessed in a weak acid environment by adopting the dilutesulfuric acid, and the interference of iron hydroxide is eliminated after long-time stirring; and finally, an iron inhibitor, a zinc activator and a collecting agent are sequentially added, and inhibition on iron oxides is reinforced and the zinc oxide minerals are activated; and meanwhile, a gangue inhibitor is added in the zinc concentration stage, so that the grade of zinc concentrate is further improved. According to the method, the problems that the iron hydroxide polluted by iron is difficult to process, the use amount of sodium sulfide is large, and the recovery rate of the zinc concentrate is low in a zinc oxide beneficiation method are solved.

Owner:KUNMING UNIV OF SCI & TECH

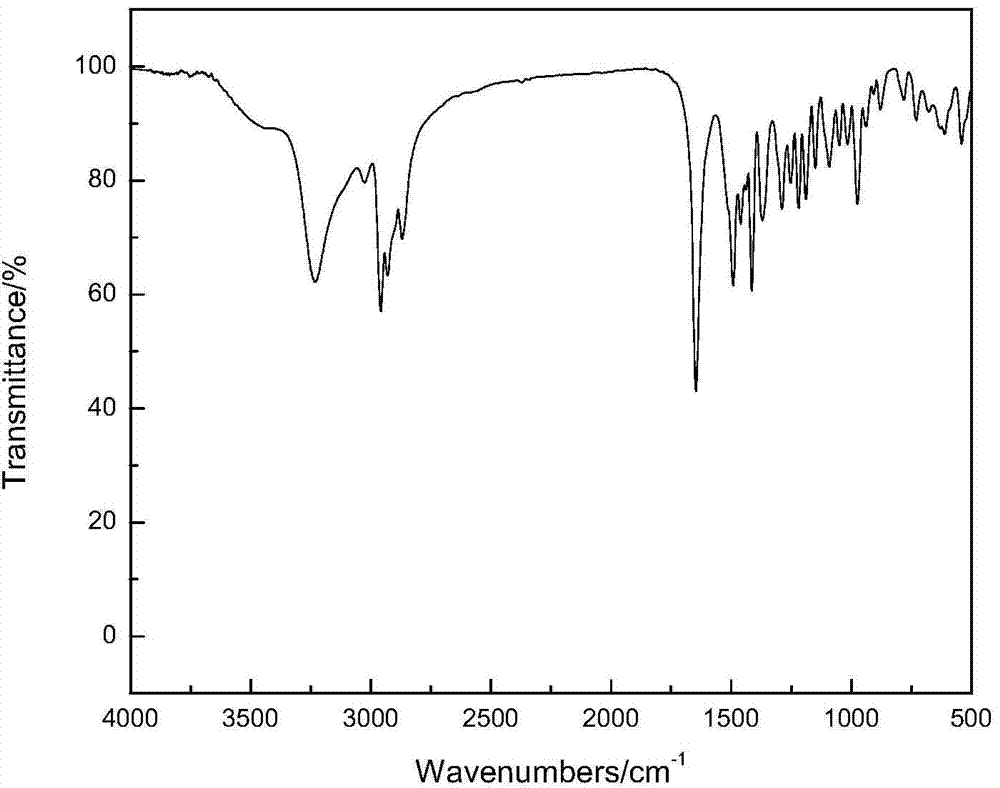

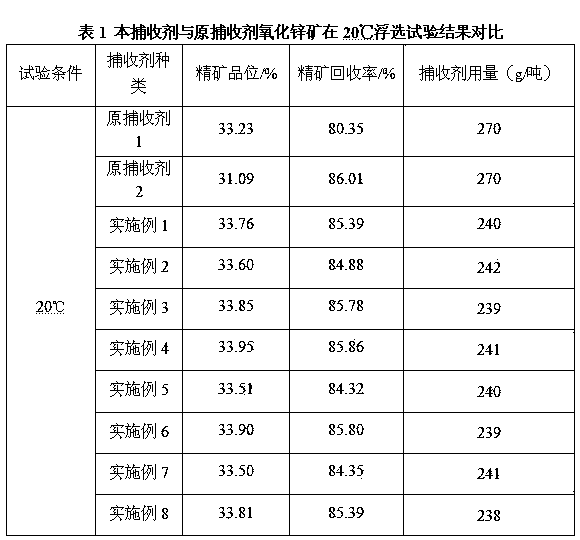

Zinc oxide mineral beneficiation collecting agent and preparation method of zinc oxide mineral beneficiation collecting agent

InactiveCN103506225AExpand the range of optionsHigh selectivityFlotationMining engineeringOxide minerals

The invention discloses a zinc oxide mineral beneficiation collecting agent and a preparation method of the zinc oxide mineral beneficiation collecting agent, in particular to a metal zinc oxide mineral beneficiation collecting agent and a preparation method of the metal zinc oxide mineral beneficiation collecting agent. The zinc oxide mineral beneficiation collecting agent comprises, by weight, 18%-25% of dodecanamine, 25%-30% of cetylamine, 38%-45% of octadecylamine and 4%-7% of active agent. The zinc oxide mineral beneficiation collecting agent is relatively resistant to low temperature and can be used without heating ore pulp, when the zinc oxide mineral beneficiation collecting agent is used under the condition that the temperature of the ore pulp is 15-25 degrees, compared with an original collecting agent, the zinc oxide mineral beneficiation collecting agent has the advantages that the obtained concentrate indexes are that the concentrate grade can be improved by 1.7%, the recovery rate can be improved by 5.76%, and the beneficiation cost can be greatly reduced. The zinc oxide mineral beneficiation collecting agent particularly has wide adaptation to high mud deep oxidation zinc oxide raw ore.

Owner:SICHUAN JINGDA MINING TECH

Solid photoprotective compositions comprising octenylsuccinic anhydride-esterified starch salts

Topically applicable, solid UV-photoprotecting compositions suited for the UV-photoprotection and / or makeup and / or care of the lips and / or the face, advantageously shaped as sticks, contain a) at least one fatty phase, a UV-photoprotecting amount of b) at least one organic UV-screening agent and c) a fraction of metal oxide mineral nanopigments, and d) an SPF-increasing amount of at least one octenylsuccinic anhydride-esterified starch salt, formulated into a physiologically acceptable medium therefor.

Owner:LOREAL SA

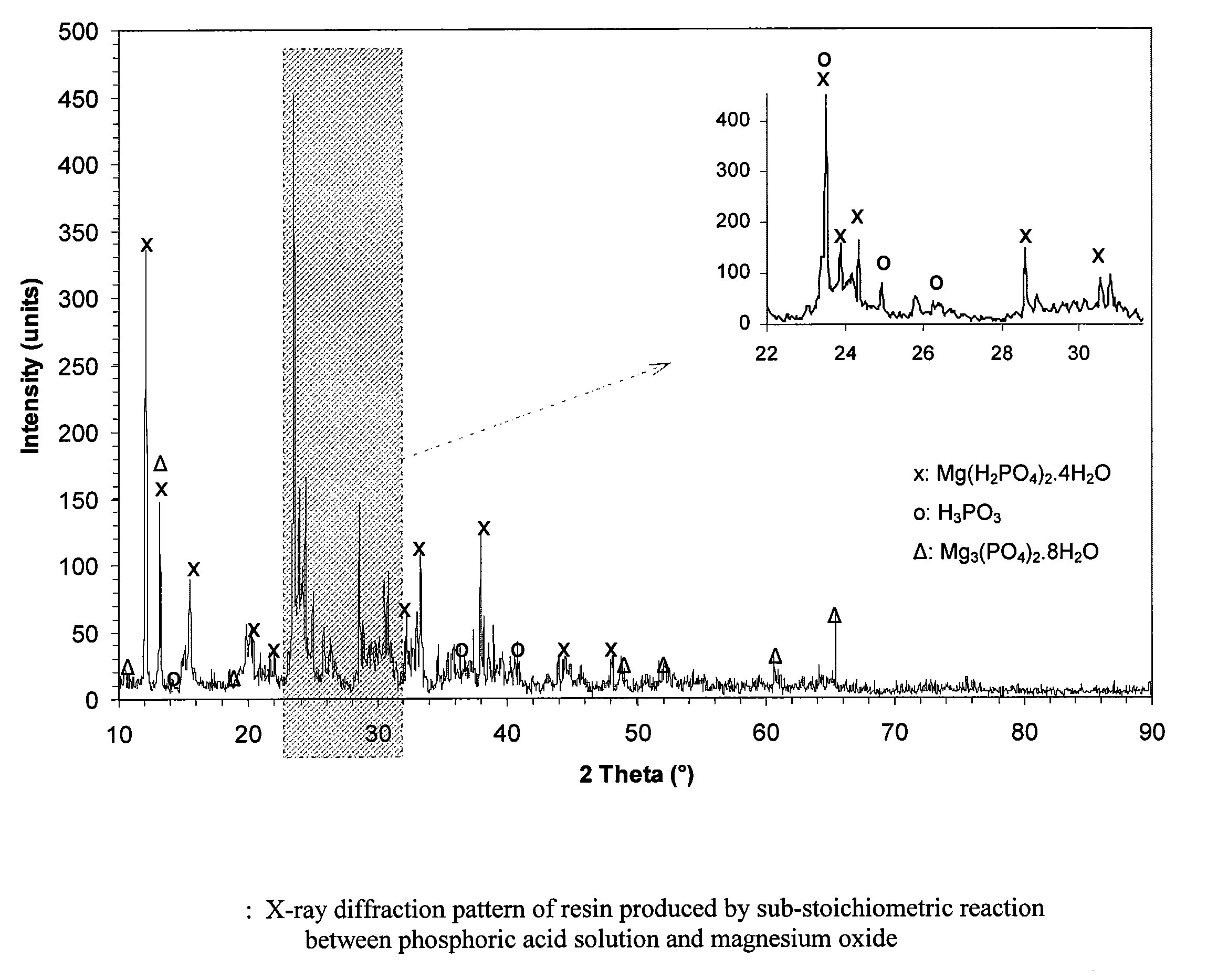

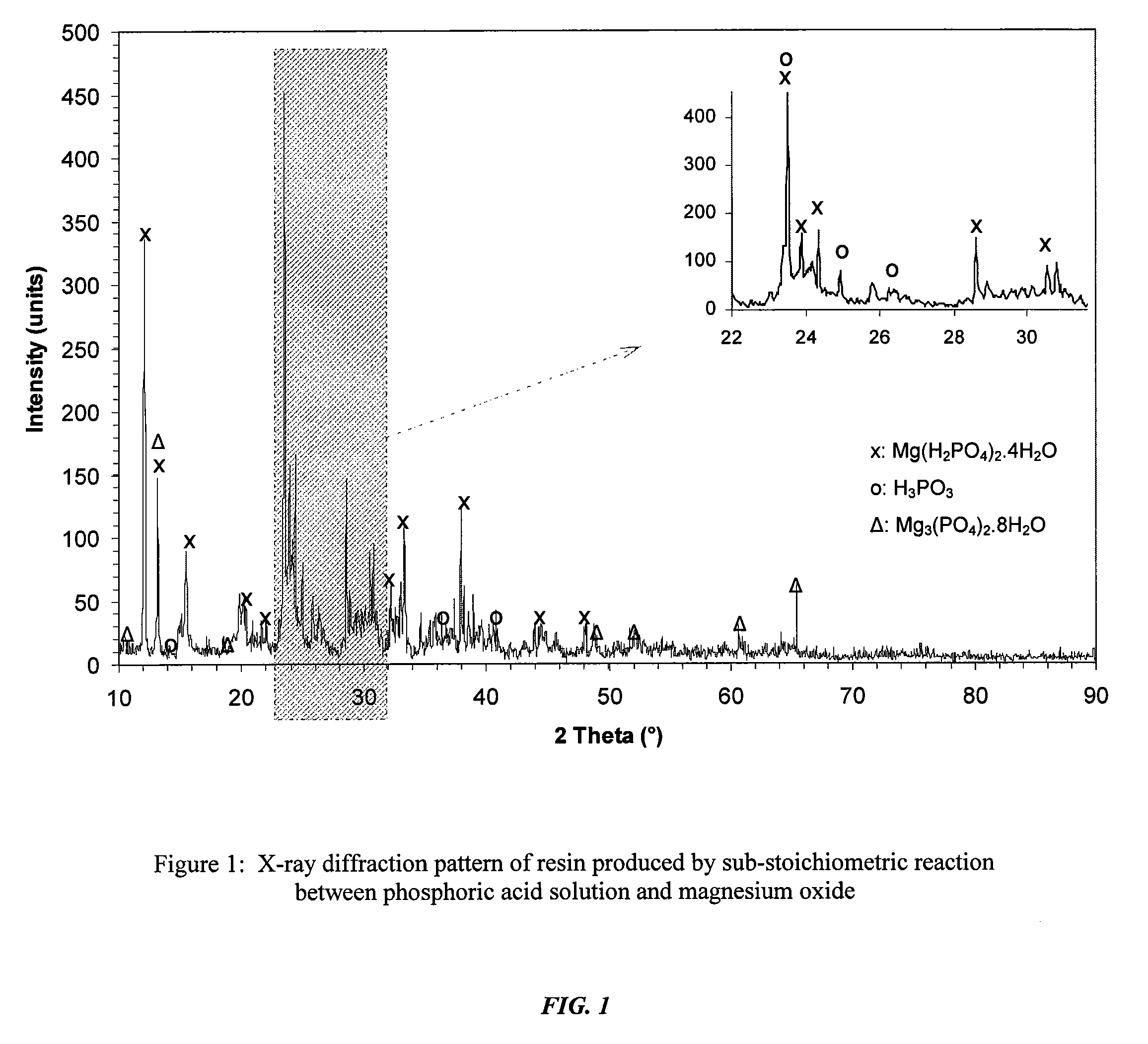

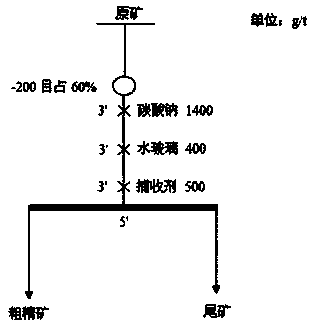

Inorganic Phosphate Resins and Method for Their Manufacture

ActiveUS20090312170A1Transportation safetyLow costPhosphorus oxidesPhosphatesOrganic synthesisFlexural strength

A method is provided for making inexpensive synthetic inorganic resins that are stable, mix easily with water and may be conveniently diluted to form an easy-to-use paste for commercial applications. The method uses environmentally friendly techniques to provide improved efficiencies in the commercial production of these resins. The resins are produced by the partial reaction of phosphoric acid with sparsely-soluble oxides, or sparsely-soluble oxide minerals, that are added to the phosphoric acid under controlled conditions. In certain specific embodiments, methods are provided for modifying synthetic inorganic resins so as to produce rapid-setting phosphate cements and ceramics having high flexural strength. Unique synthetic inorganic resin formulations are also disclosed. These formulations are phosphate-mineral based, non-volatile, tend to be non-flammable, do not contain any hazardous inorganic or organic compounds, and are chemically stable at relatively high temperatures, yet they are less expensive than most commercially available organic synthetic polymeric resins.

Owner:LATITUDE 18

Ore floatation collecting agent for oxidized ore

The invention provides an ore collecting agent for collecting oxidized ore such as ilmenite and a preparing method of the ore collecting agent for collecting oxidized ore such as ilmenite and belongsto the technical field of oxidized ore floatation collecting agents. The ore collecting agent for oxidized ore such as ilmenite is used after ammonium dibutoxy dithiophosphate, edentate, maleate, oxidized paraffin soap and the like are mixed, has the beneficial effects of being good in water solubility, good in dispersibility and high in preferential adsorption capability on aimed ore and is mainly used for floatation separation of valuable ore in oxidized ore such as ilmenite, scheelite and wolframite. The preparing method of the re floatation collecting agent for oxidized ore is simple in process, operation is easy to control, and the prepared collecting agent has the beneficial effects of being high in selectivity, good in dispersibility, small in agent dosage, high in beneficiation comprehensive efficiency and the like and has very important significance in promoting beneficiation of ore such as oxidized ore.

Owner:河南天鸿新材料科技有限公司

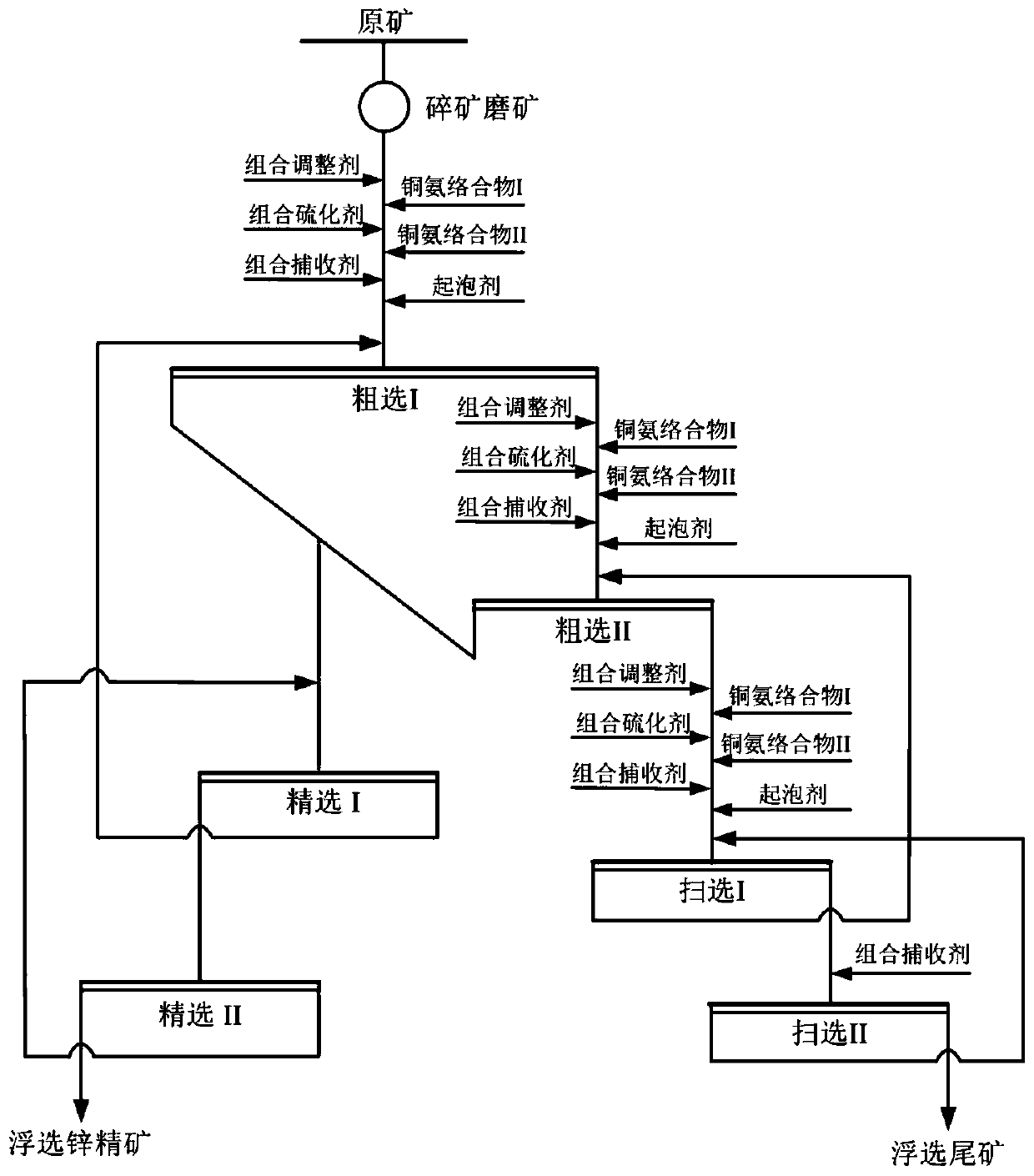

Micro-fine particle zinc oxide ore copper ammonia complex cascade activation-enhanced sulfuration flotation method

ActiveCN111530639AImprove hydrophobicityImprove adsorption capacityFlotationSurface reactionFoaming agent

The invention discloses a micro-fine particle zinc oxide ore copper ammonia complex cascade activation-enhanced sulfuration flotation method, belongs to the technical field of mineral processing, andaims at the problems that a direct vulcanization flotation method is poor in vulcanization effect, a collecting agent is difficult to stably adsorb, and flotation indexes are not ideal. The method comprises the following steps: crushing and grinding the zinc oxide ore until the mass percentage of the zinc oxide ore with the particle size of-38 microns accounts for 75-90%; adding a combined regulator into the ore pulp to control slime; then adding a novel activating agent copper ammonia complex for primary activation, adding a combined vulcanizing agent for surface enhanced vulcanization afteractivation, adding the copper ammonia complex into ore pulp for secondary activation after enhanced vulcanization, and finally, sequentially adding a combined collecting agent and a foaming agent forflotation recovery of zinc minerals in the ore. Gradient activation is carried out on zinc oxide minerals in the ore before and after vulcanization through the copper-ammonia complex, the number of reaction particles on the surface of the mineral is increased, the reaction activity is enhanced, and enhanced vulcanization and surface hydrophobicity enhancement of the zinc oxide minerals in the oreare achieved.

Owner:KUNMING UNIV OF SCI & TECH

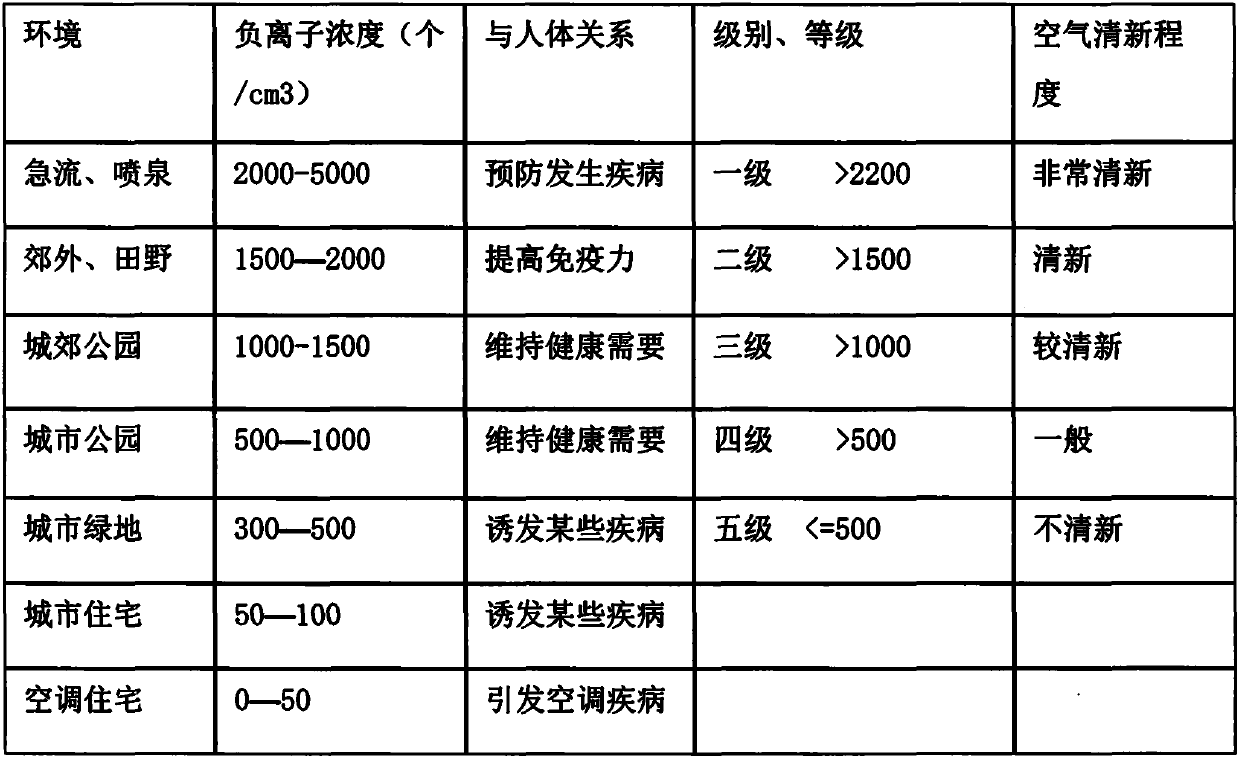

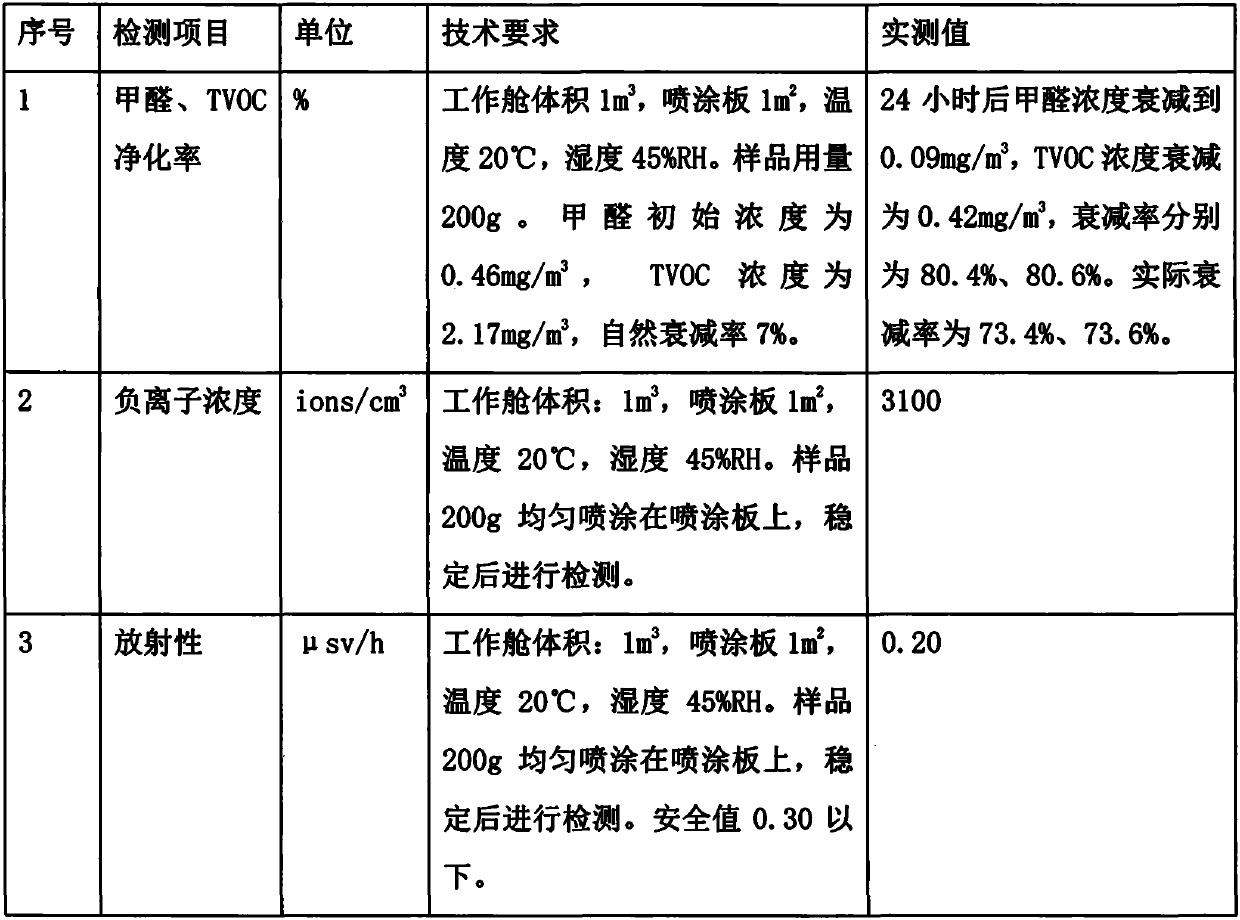

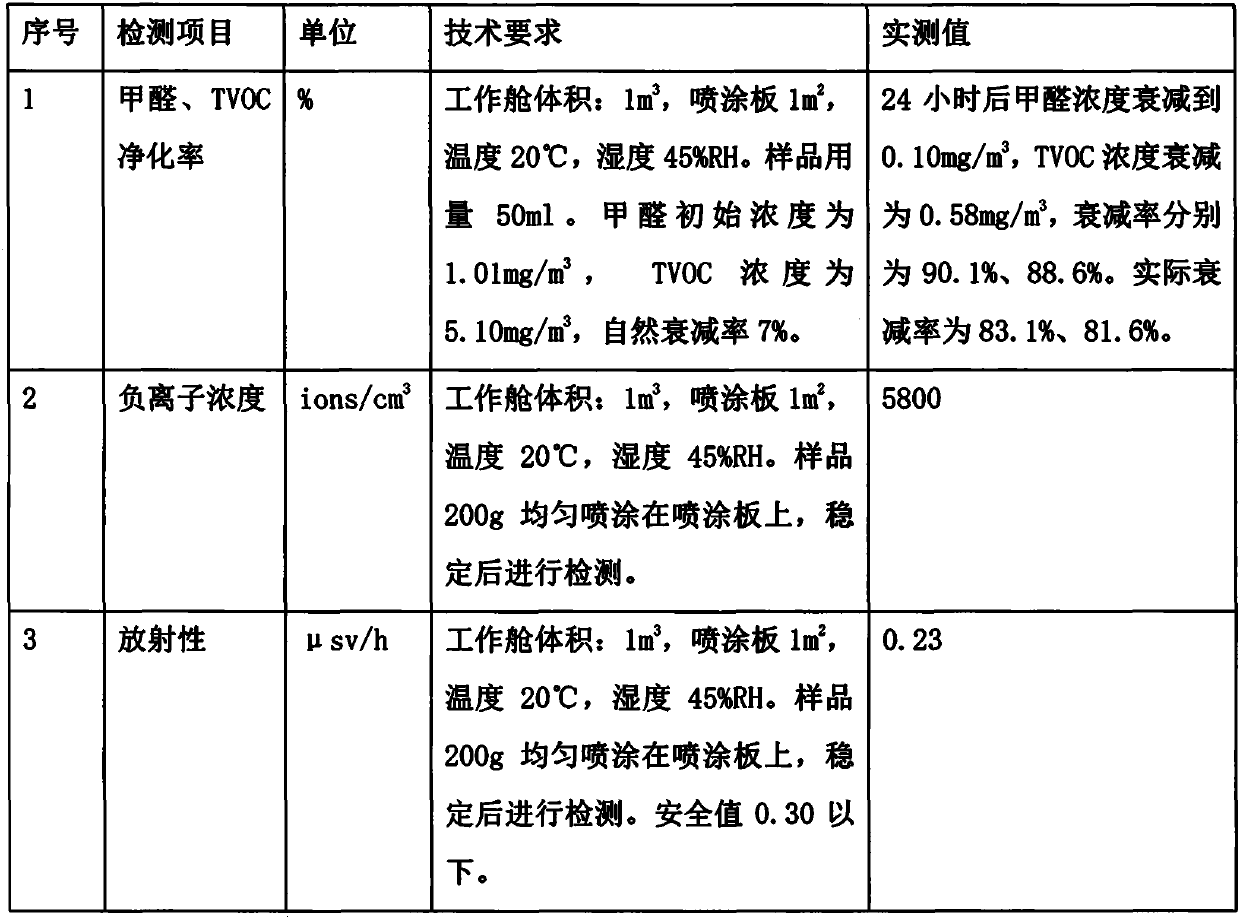

Water-based paint capable of safely releasing anions

The invention discloses a water-based paint capable of safely releasing anions. The water-based paint utilizes hexacyclic stone, Qingshui stone, opal, tourmaline, volcanic rock, ancient sea rock and the like containing nanometer micropore structures, wherein the above ores contain germanium, aluminum, iron, boron, cobalt, nickel, alum, calcium, magnesium, sodium, potassium, selenium, zinc, strontium, titanium, silicon and other elements, and each micropore has a potential difference of 0.06 MA; and the water-based paint has a bioelectricity effect, produces a synergistic effect together with purified rare earth oxide, can decompose water in the air to form hydroxyl water anions, and can safely, efficiently and continuously generate anions. When the paint is used for indoor wall surface painting, indoor air quality can reach negative ion air quality level 1 or above. A formula of the water-based paint comprises 5.0 to 20.0 parts of hexacyclic stone, 5.0 to 20.0 parts of Qingshui stone,5.0 to 20.0 parts of opal, 5.0 to 20.0 parts of karst rock, 5.0 to 20.0 parts of tourmaline, 5.0 to 10.0 parts of volcanic rock, 5.0 to 10.0 parts of ancient sea rock, 0.5 to 5.0 parts of purified rare earth oxide and 5.0 to 10.0 parts of mineral bonding powder.

Owner:神炭科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com