Preparation method of premixed concrete fully doped with nickel slag

A technology for ready-mixed concrete and nickel slag, applied in the field of concrete, can solve the problems of micro-cracks in cement components, cement should not be made into super-long components, and limit the use range of cement, etc., and achieves the effect of good shrinkage performance and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

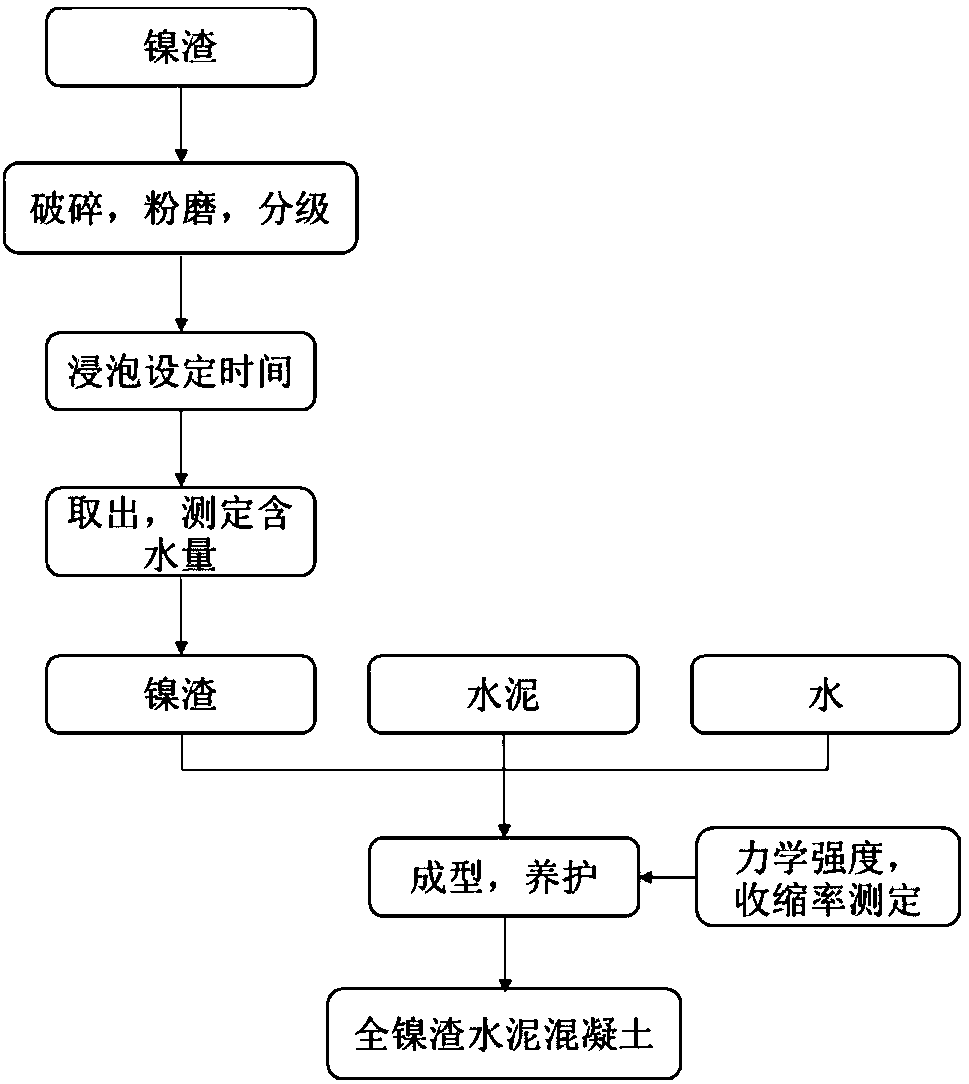

Method used

Image

Examples

Embodiment 1

[0028] After crushing, grinding and grading, the nickel slag is soaked in a treatment tank filled with saturated lime water for 1 day, then taken out and dried. The quality of P.O42.5 ordinary portland cement is 200kg, the quality of water is 175kg, the quality of nickel slag powder is 160kg, the quality of nickel slag sand is 600kg, the quality of fine nickel sand is 200kg, nickel sand The quality of slag coarse aggregate is 1050kg. Each raw material component was manually compacted according to the above ratio according to the method of GB50081-2002 "Standard for Test Methods of Mechanical Properties of Ordinary Concrete" to prepare a cube standard test block with a side length of 150 mm. Place it in a standard curing box (at a temperature of about 25°C and a humidity of about 95%) for 48 hours, then remove the mold, and continue to maintain at 20°C with a humidity of about 95% for 28 days to obtain a standard test block of high-content nickel slag concrete. GB50081-2002 "S...

Embodiment 2

[0030] After crushing, grinding and grading, the nickel slag is soaked in a treatment tank filled with saturated lime water for 2 days, then taken out and dried. The quality of P.O42.5 ordinary portland cement is 200kg, the quality of water is 175kg, the quality of nickel slag powder is 160kg, the quality of nickel slag sand is 600kg, the quality of fine nickel sand is 200kg, nickel sand The quality of slag coarse aggregate is 1050kg. Each raw material component was manually compacted according to the above ratio according to the method of GB50081-2002 "Standard for Test Methods of Mechanical Properties of Ordinary Concrete" to prepare a cube standard test block with a side length of 150 mm. Place it in a standard curing box (at a temperature of about 25°C and a humidity of about 95%) for 48 hours, then remove the mold, and continue to maintain at 20°C with a humidity of about 95% for 28 days to obtain a standard test block of high-content nickel slag concrete. GB50081-2002 "...

Embodiment 3

[0032] After crushing, grinding and grading, the nickel slag is soaked in a treatment tank filled with saturated lime water for 3 days, then taken out and dried. The quality of P.O42.5 ordinary portland cement is 200kg, the quality of water is 175kg, the quality of nickel slag powder is 160kg, the quality of nickel slag sand is 600kg, the quality of fine nickel sand is 200kg, nickel sand The quality of slag coarse aggregate is 1050kg. Each raw material component was manually compacted according to the above ratio according to the method of GB50081-2002 "Standard for Test Methods of Mechanical Properties of Ordinary Concrete" to prepare a cube standard test block with a side length of 150 mm. Place it in a standard curing box (at a temperature of about 25°C and a humidity of about 95%) for 48 hours, then remove the mold, and continue to maintain at 20°C with a humidity of about 95% for 28 days to obtain a standard test block of high-content nickel slag concrete. GB50081-2002 "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com