Patents

Literature

105results about How to "Large scale processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

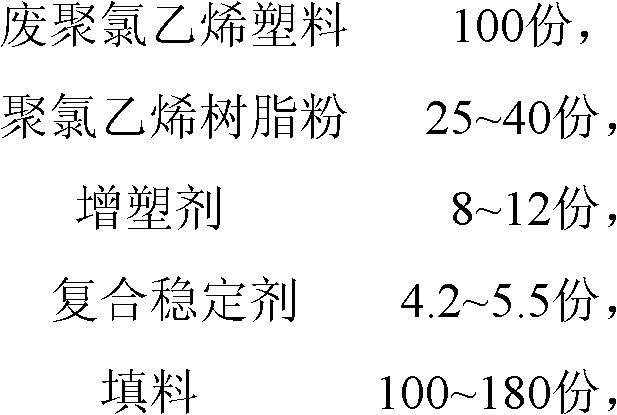

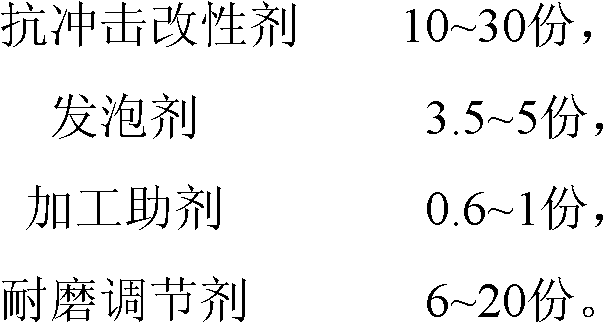

Modified plastic, and preparation method and application thereof

ActiveCN103146094AHigh strengthImprove toughnessPlastic recyclingFlooringPolymer scienceFoaming agent

The invention relates to the field of recycling modification and processing technology of polymer materials, and relates to a modified plastic, and a preparation method and an application thereof. The modified plastic is prepared by the following components of, by weight, 100 parts of waste polyvinyl chloride (PVC) plastics, 25-40 parts of polyvinyl chloride (PVC) resin powder, 8-12 parts of a plasticizer, 4.2-5.5 parts of a compound stabilizer, 100-180 parts of a filler, 10-30 parts of an impact modifier, 3. 5-5 parts of a foaming agent, 0.6-1 part of a processing agent, 6-20 parts of a wear-resistant regulator. The modified plastic provided by the invention can be used for producing wear-resistant floor blocks by using recycled waste polyvinyl chloride (PVC) plastics. The product has the advantages of high strength, good toughness, impact resistance, fire retardance, easy processing, weather resistance, wear resistance and low cost. The method is simple and practical, has the biggest advantage of recycling and processing the waste plastics, saves material resources, lowers production cost, and is environment-friendly.

Owner:滁州格美特科技有限公司

Preparation method of algae amino acid microbial fertilizer

InactiveCN102173907AGrowth inhibitionPromote growthFertilizer mixturesMicrobial agentMonopotassium phosphate

The invention discloses a preparation method of an algae amino acid microbial fertilizer, which comprises the following steps: (1) crushing algae, adding water and a fermentation promoter, sterilizing for 20-40 minutes at the temperature of 120-125 DEG C, reducing the temperature to room temperature, adding a composite strain to ferment the mixed solution for 3-5 days at 25-35 DEG C, and adjusting the pH value to 7.2-8.0; and (2) sequentially adding urea and / or monopotassium phosphate and chelating-state trace elements into the solution obtained in the step (1) in a stirring state, and stirring for 20-50 minutes to obtain the liquid algae amino acid microbial fertilizer. According to the invention, algae is subjected to deep fermentation by use of a high-activity microbial agent, the natural active ingredients in algae are perfectly maintained; and due to compatibility with the chelating-state trace elements, the nutrient elements and utilization rate of the fertilizer are improved, and the algae amino acid microbial fertilizer is a novel algae microbial fertilizer for bioremediation and soil adjustment and conforming to ecological balance of animals, plants and microorganisms.

Owner:山东金利丰生物科技股份有限公司

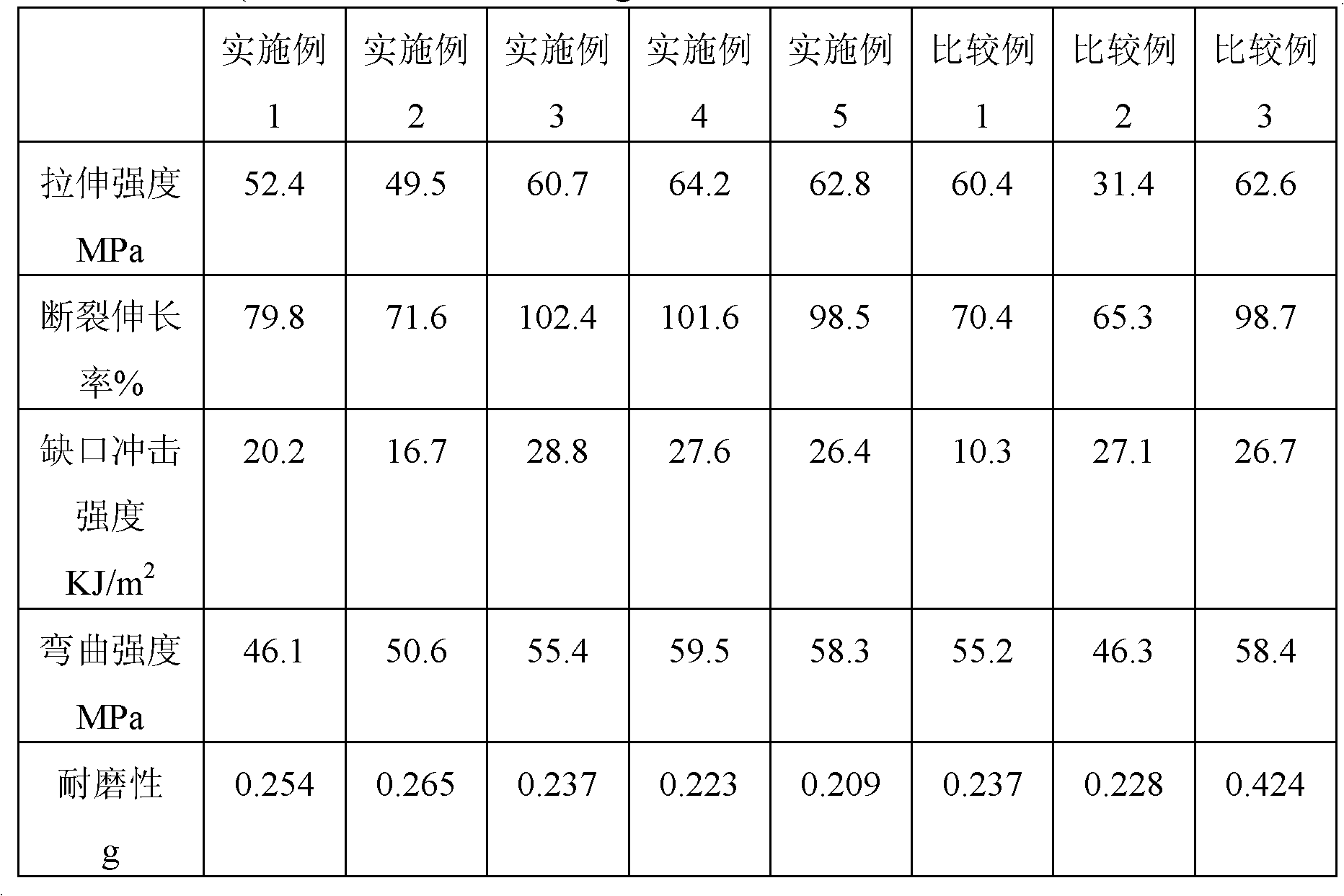

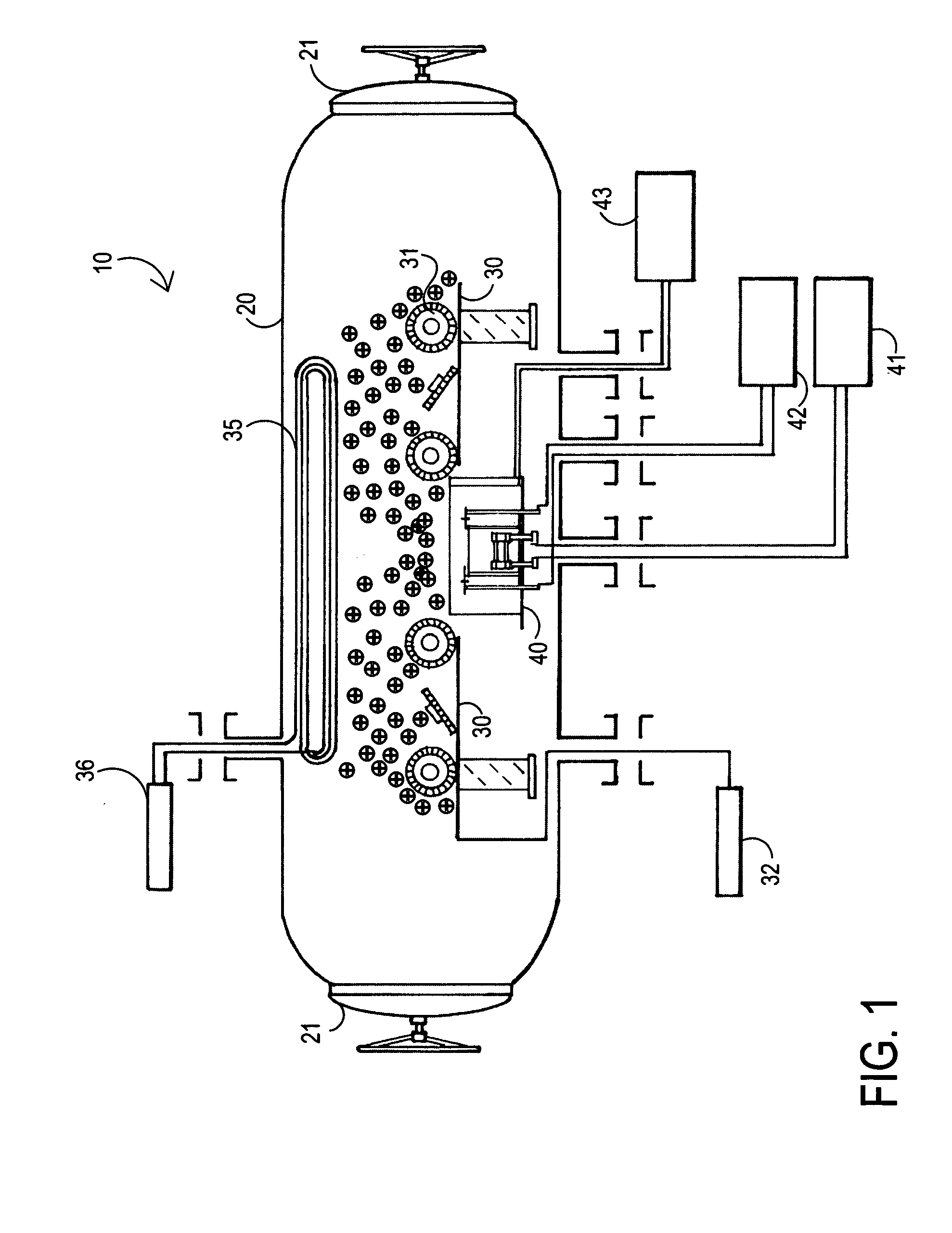

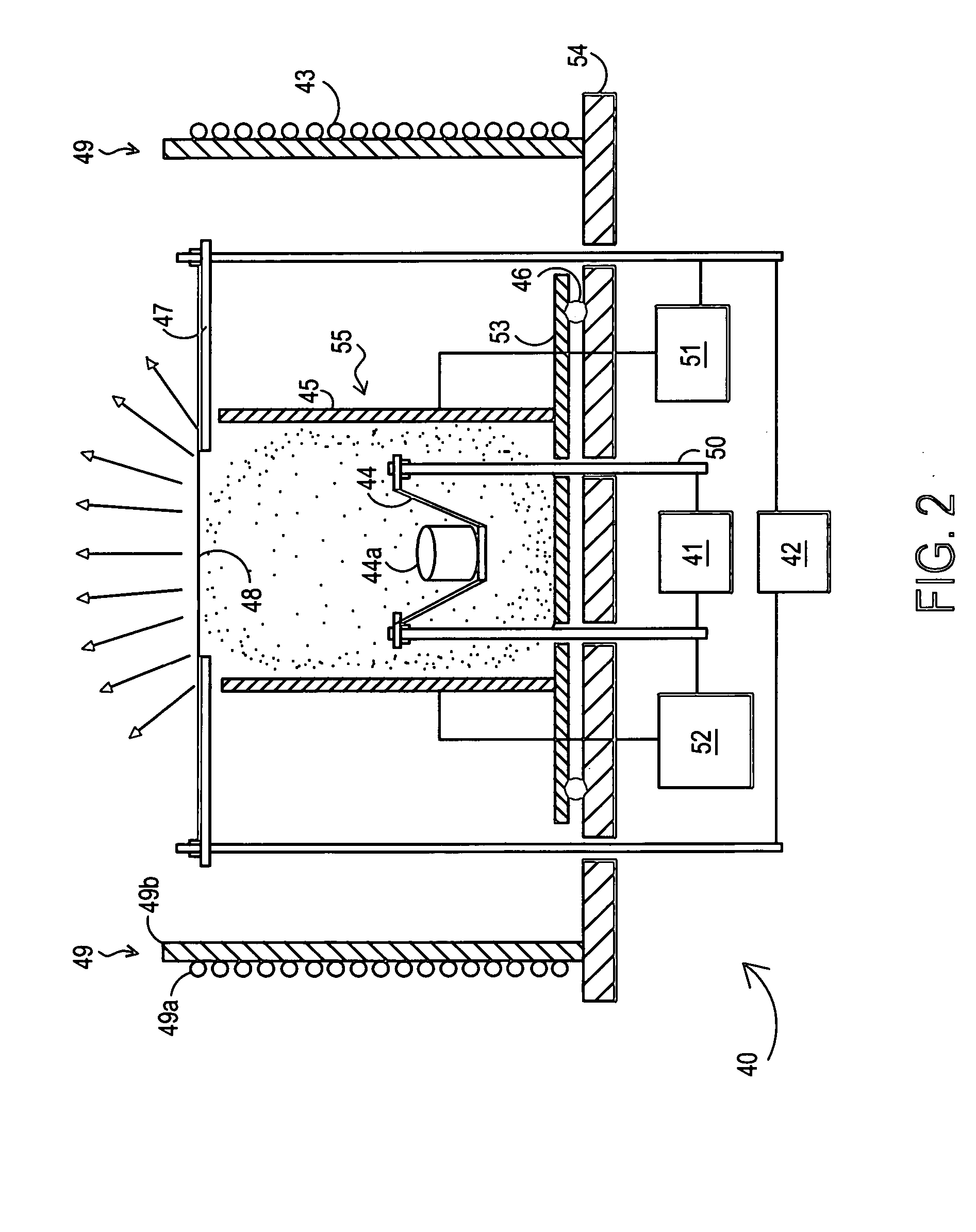

Apparatus and method for metal plasma immersion ion implantation and metal plasma immersion ion deposition

InactiveUS20050061251A1Large-scale processingReduce pressureElectric discharge tubesVacuum evaporation coatingIon depositionPlasma deposition

This invention is a method for metal plasma ion implantation and metal plasma ion deposition, comprising: providing a vacuum chamber with at least one workpiece having a surface positioned on a worktable within the vacuum chamber; reducing the pressure in the vacuum chamber; generating a plasma of metal ions within the vacuum chamber, applying a negative bias to the worktable to thereby accelerate metal ions from the plasma toward at least one workpiece to thereby either implant metal ions into or deposit metal ions onto the workpiece or both. This invention includes an apparatus for metal ion implantation and metal ion plasma deposition, comprising: a vacuum chamber, a metal plasma generator within the vacuum chamber, and at least one worktable within the vacuum chamber.

Owner:SOUTHWEST RES INST

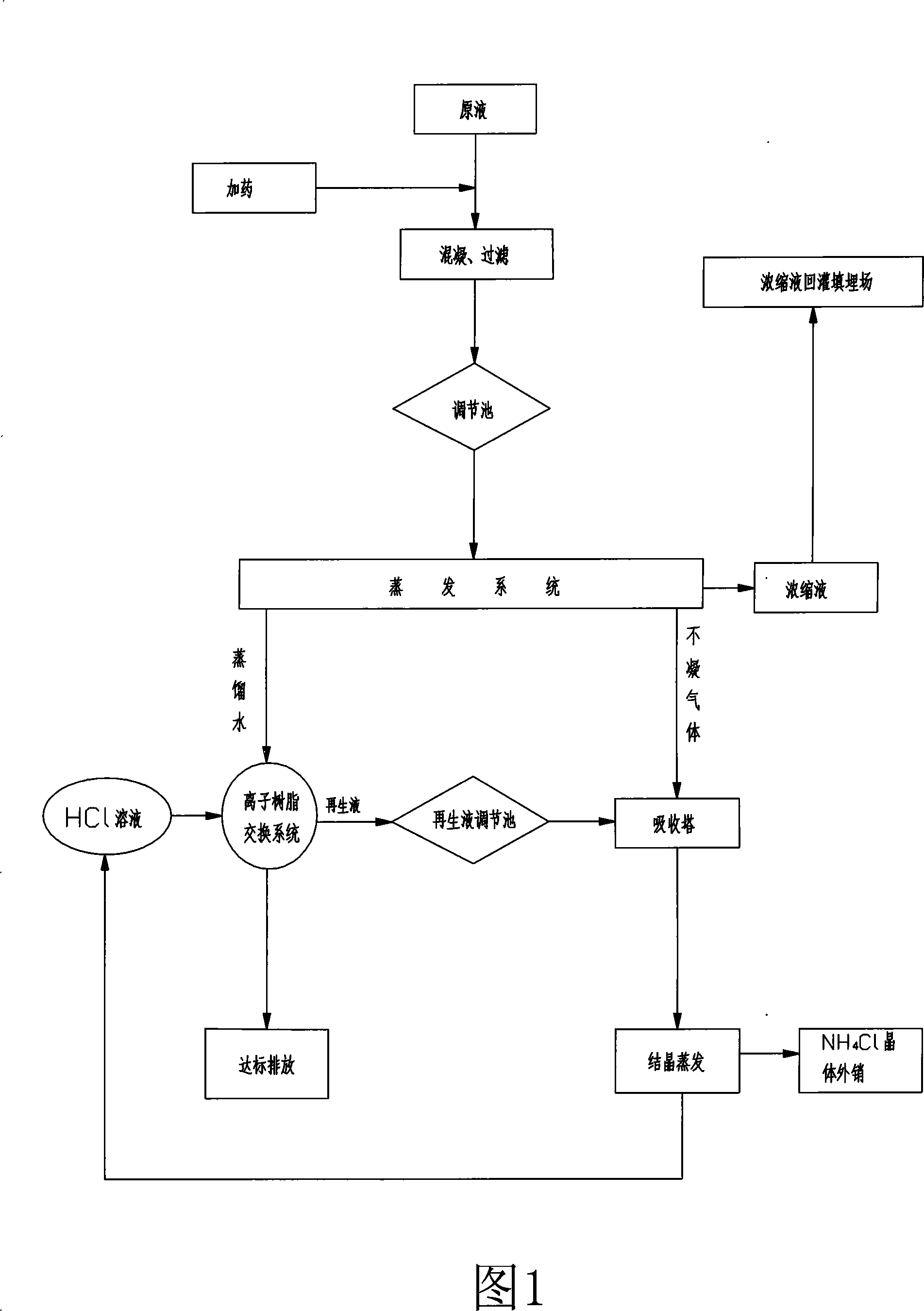

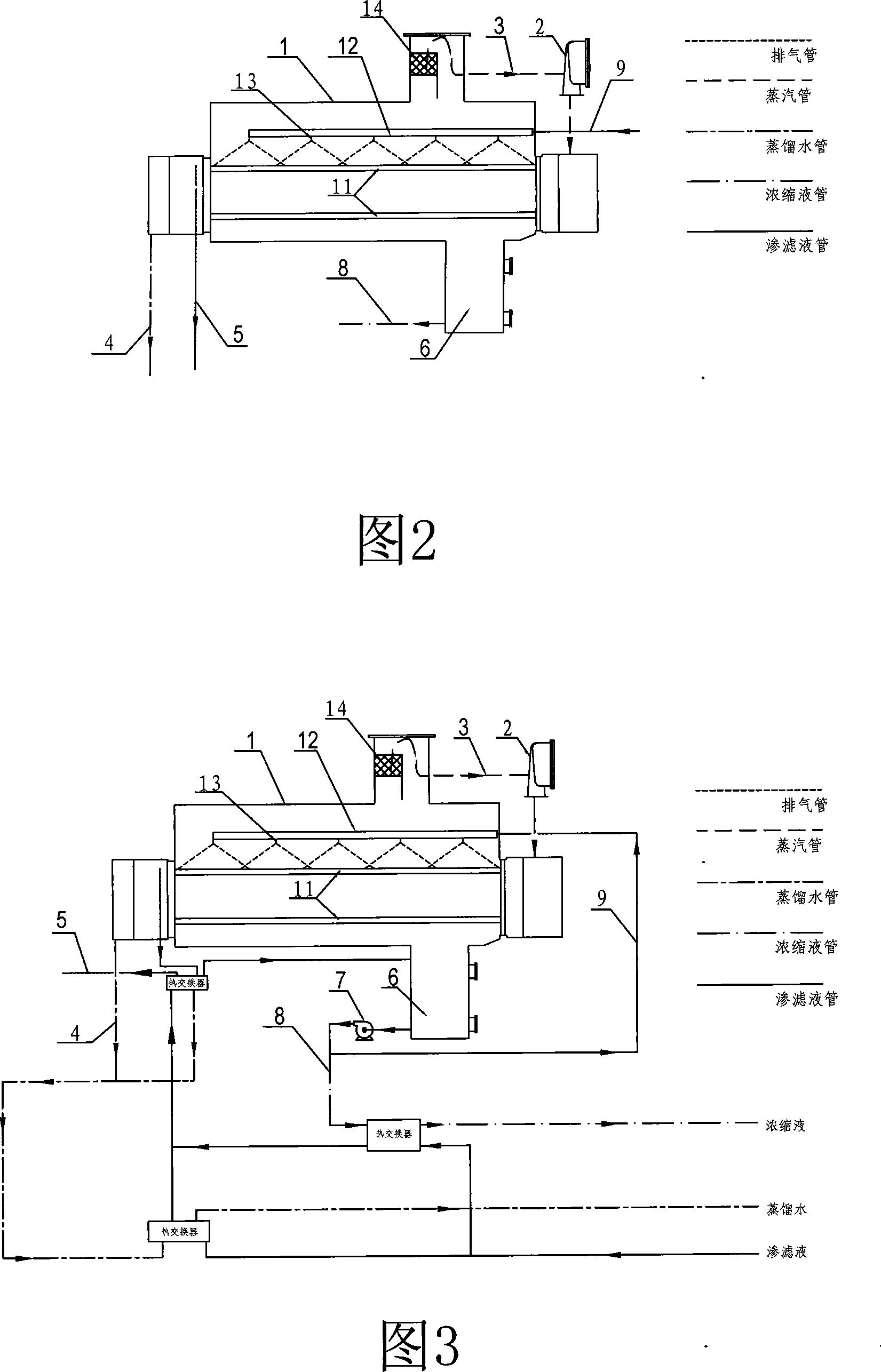

Treatment technique of garbage filter liquor

InactiveCN101182083ALess investmentLow running costWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentFiberComing out

A treatment process for landfill leachate, specifically comprising the following steps: (1) first adding a coagulant to the landfill leachate, coagulating and filtering to remove tiny fibers in the leachate; (2) filtering the leachate Enter the adjustment tank; (3) The leachate from the adjustment tank enters the evaporation system, and after evaporation, water and ammonia boil out of the leachate into steam, which becomes distilled water after condensation and is discharged, and then enters the ion resin exchange system, and the distilled water passes through the resin When the ion exchange reaction occurs, the ammonium is removed, and the ammonia nitrogen index of the distilled water is discharged after reaching the standard; the non-condensable gas and a small amount of non-condensable steam in the steam are discharged from the evaporation system and enter the absorption tower; (4) The leachate from the regulating tank enters the Evaporation system, the remaining part of the leachate after evaporation is pollutants that cannot be turned into gas and escape the evaporation system. After being concentrated into a concentrated liquid, it is discharged from the evaporation system and can be recharged to the landfill. The process is thorough and the operating cost is low.

Owner:陈伟雄 +1

Anticorrosive coatings, processes and uses thereof

InactiveUS20160168720A1Desirable carbon footprintWide applicationSynthetic resin layered productsSolid state diffusion coatingSideriteCarbonation

The invention provides novel methods for anticorrosive protection of iron or steel surfaces, such as on embedded iron or steel reinforcement components in composite materials and on steel surfaces of piles and vessels. The unique siderite coating formed during a carbonation curing possesses excellent anticorrosive properties and is suitable for improving the overall service life of coated objects.

Owner:SOLIDIA TECH

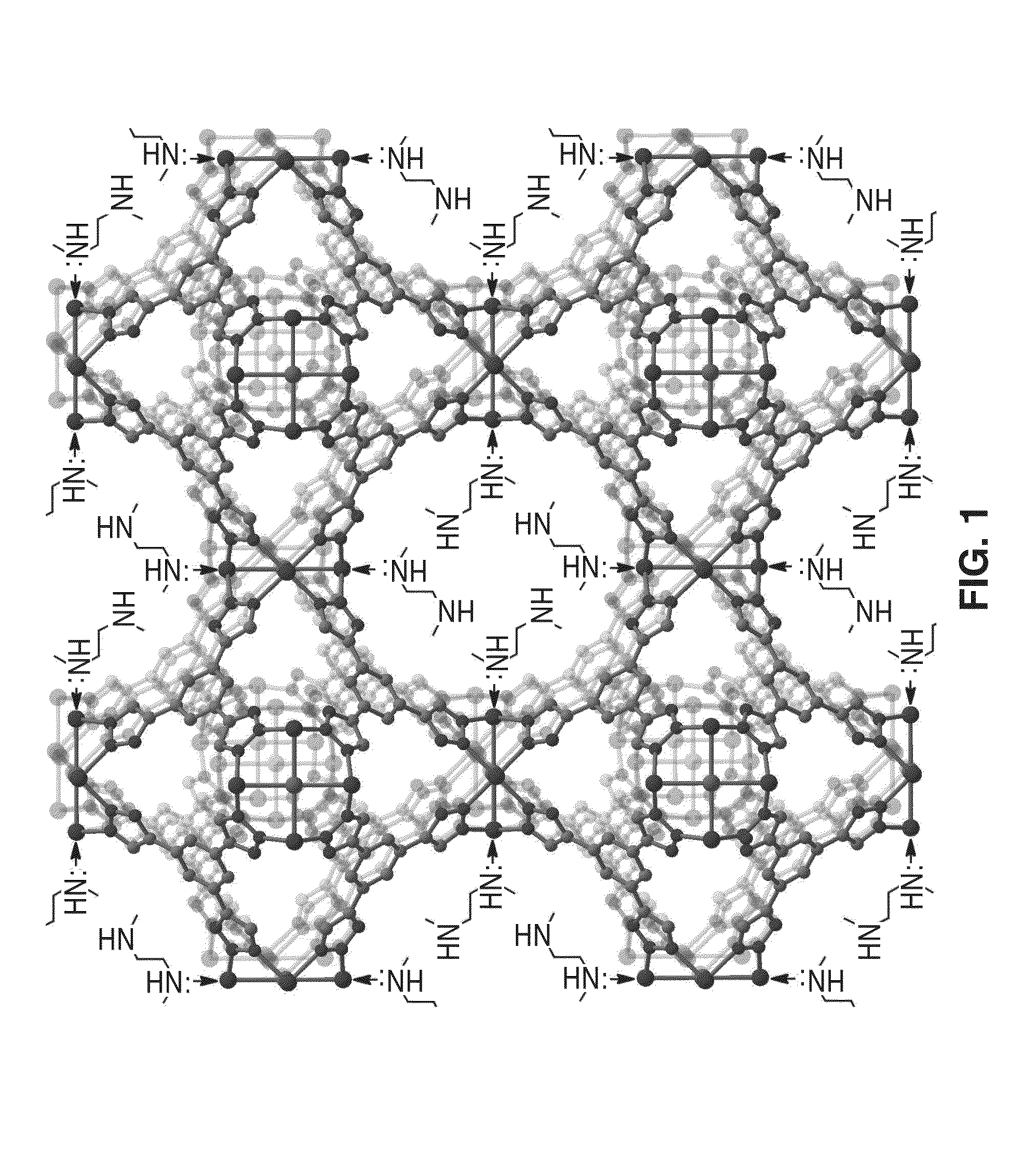

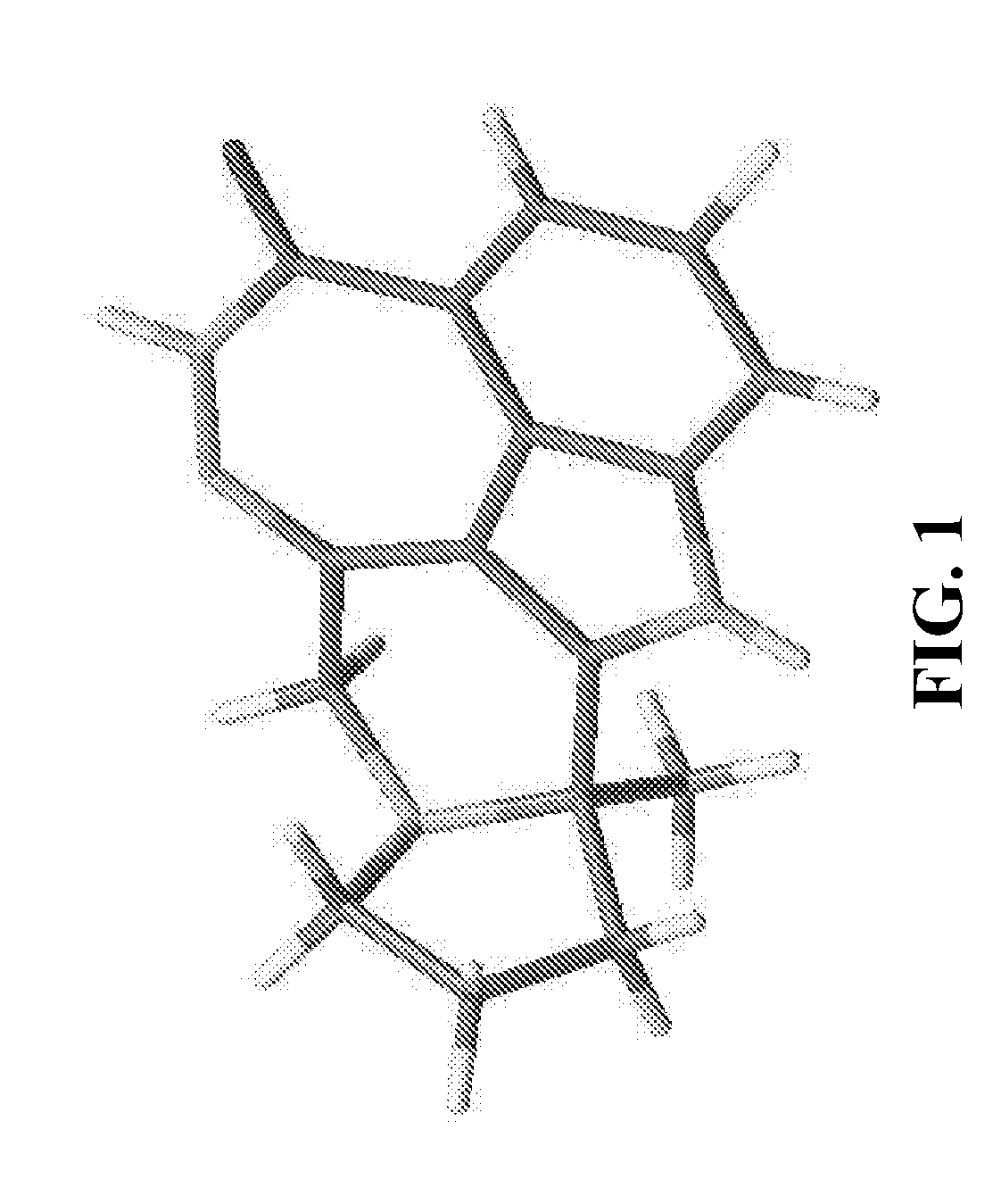

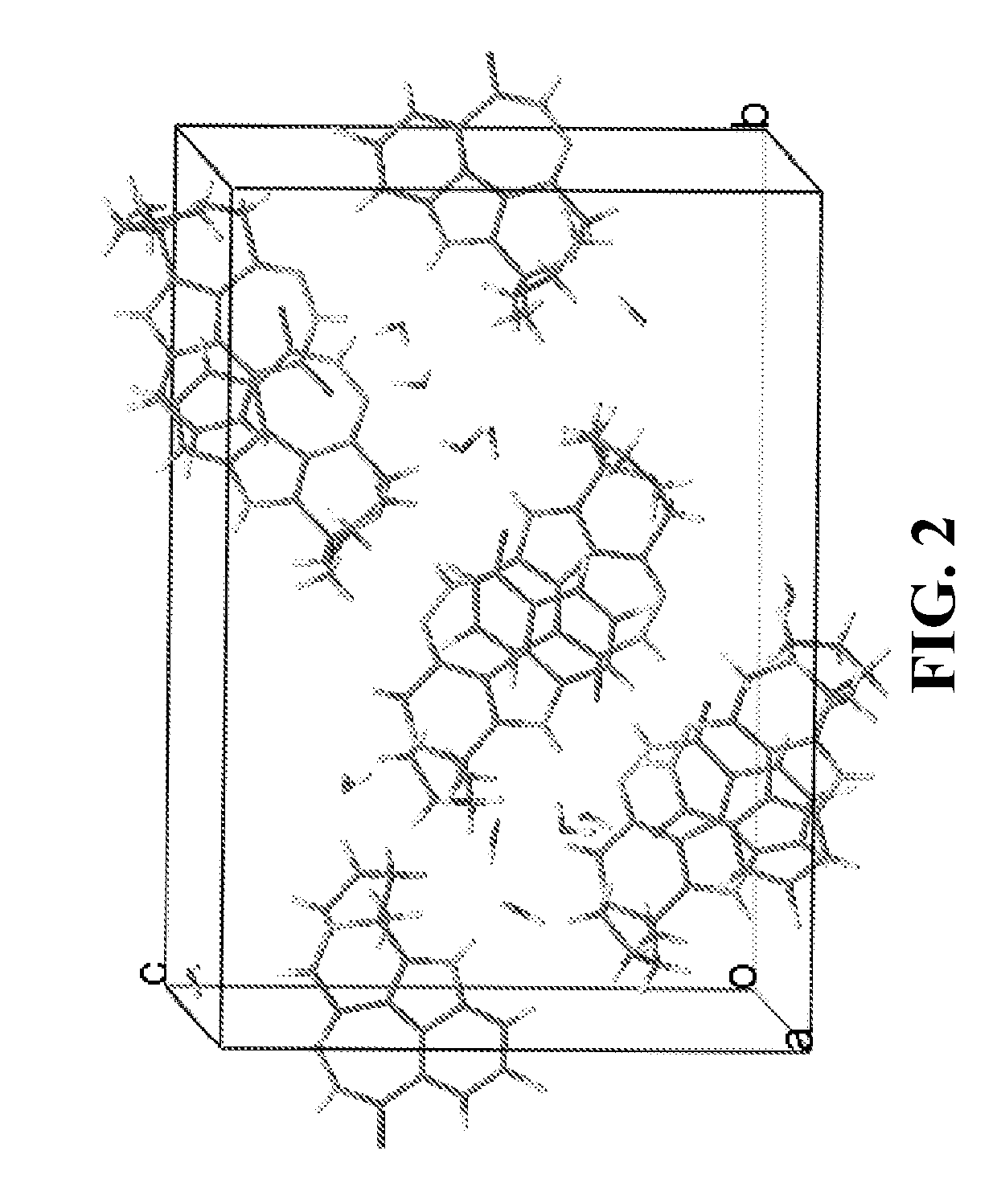

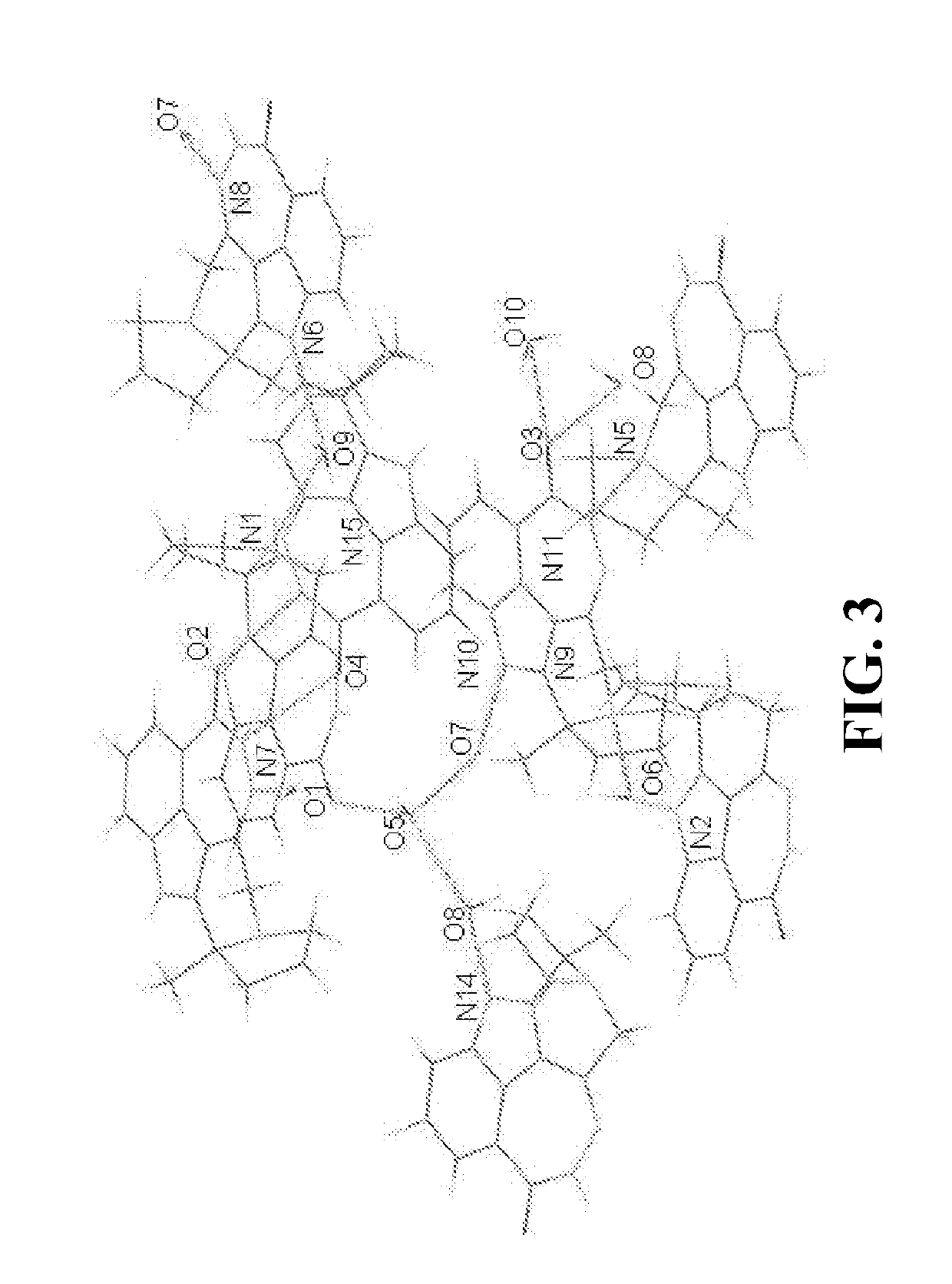

Alkylamine functionalized metal-organic frameworks for composite gas separations

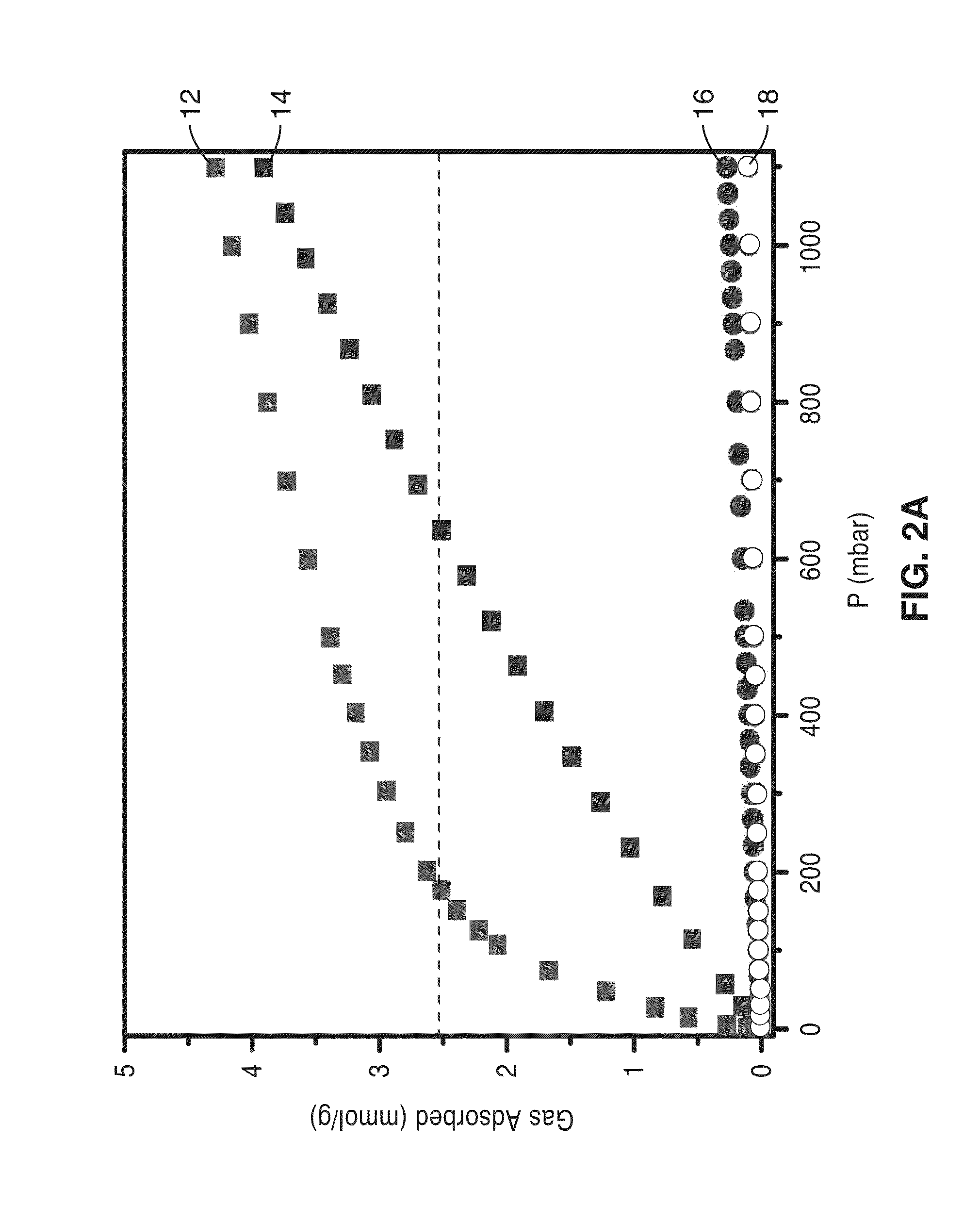

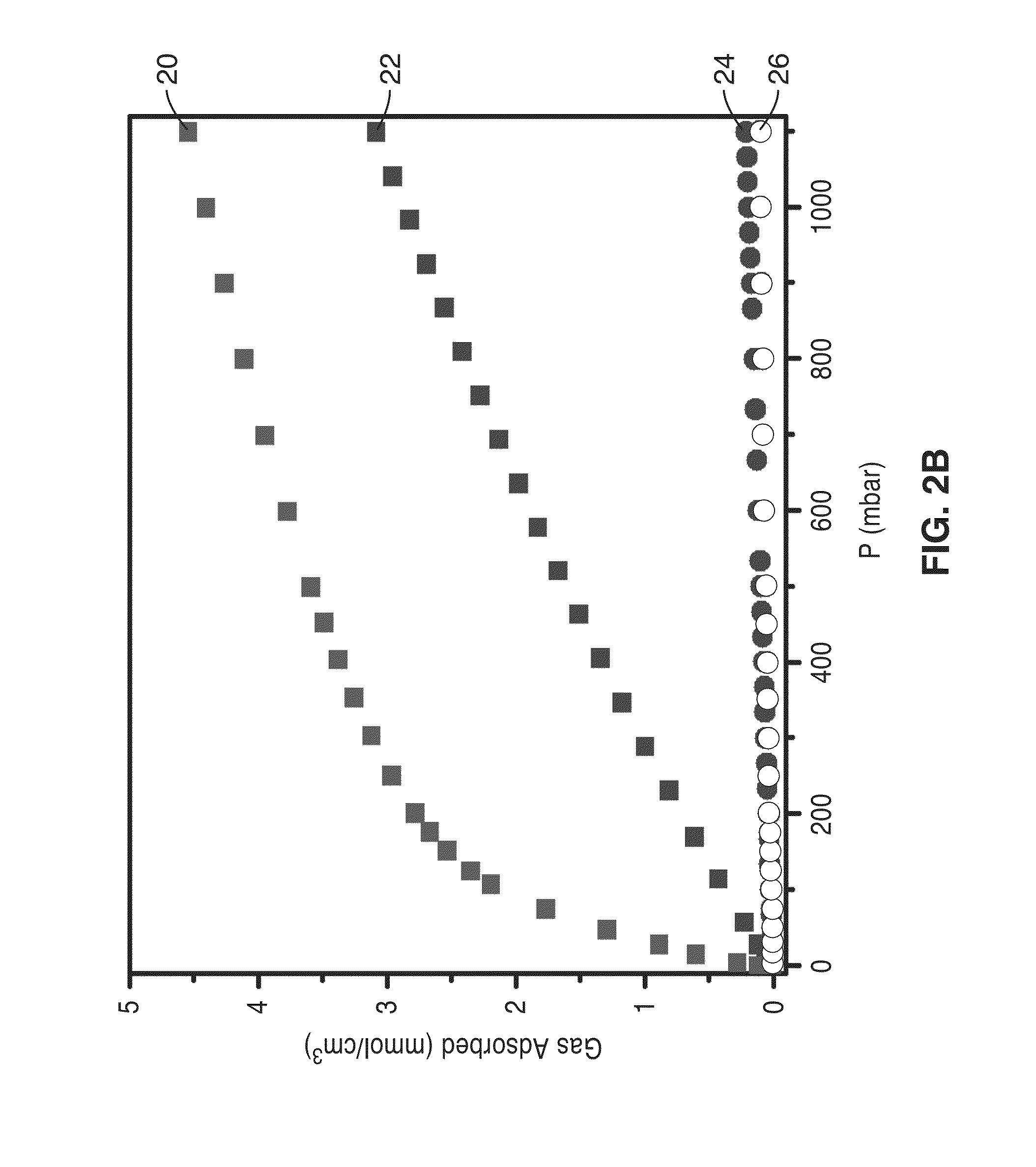

InactiveUS20140294709A1Low pressureReduce the temperatureGas treatmentCarbon compoundsSorbentMetal-organic framework

Functionalized metal-organic framework adsorbents with ligands containing basic nitrogen groups such as alkylamines and alkyldiamines appended to the metal centers and method of isolating carbon dioxide from a stream of combined gases and carbon dioxide partial pressures below approximately 1 and 1000 mbar. The adsorption material has an isosteric heat of carbon dioxide adsorption of greater than −60 kJ / mol at zero coverage using a dual-site Langmuir model.

Owner:RGT UNIV OF CALIFORNIA

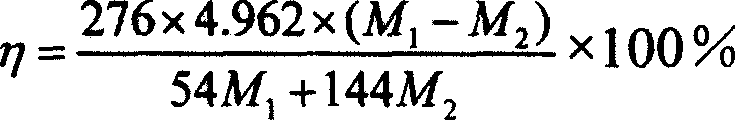

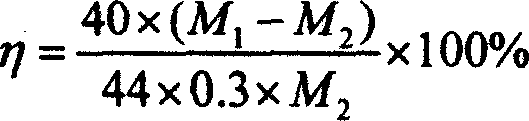

CO2 mineralizing process

InactiveCN101020577ARich reservesEasy to mineCalcium/strontium/barium carbonatesMagnesium carbonatesSodium bicarbonateReaction temperature

The CO2 mineralizing process includes the steps of: grinding silicate mineral of natural calcium and magnesium into powder, mixing with the mixed solution of sodium bicarbonate and sodium chloride or distilled water in a reaction kettle, filling CO2 gas to the reaction kettle to 3-12 MPa and reaction at 100-250 deg.c via stirring for 30-90 min to produce carbonate and realize the permanent storage of CO2. The present invention adopts rich natural silicate and can realize large scale CO2 treatment.

Owner:HUAZHONG UNIV OF SCI & TECH

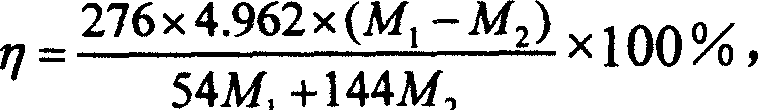

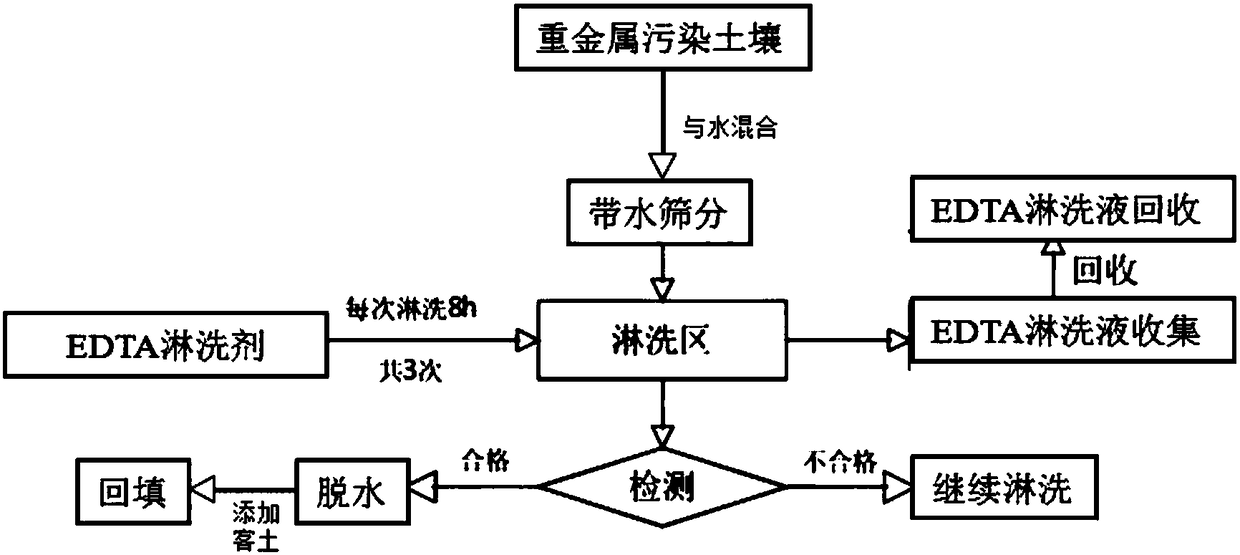

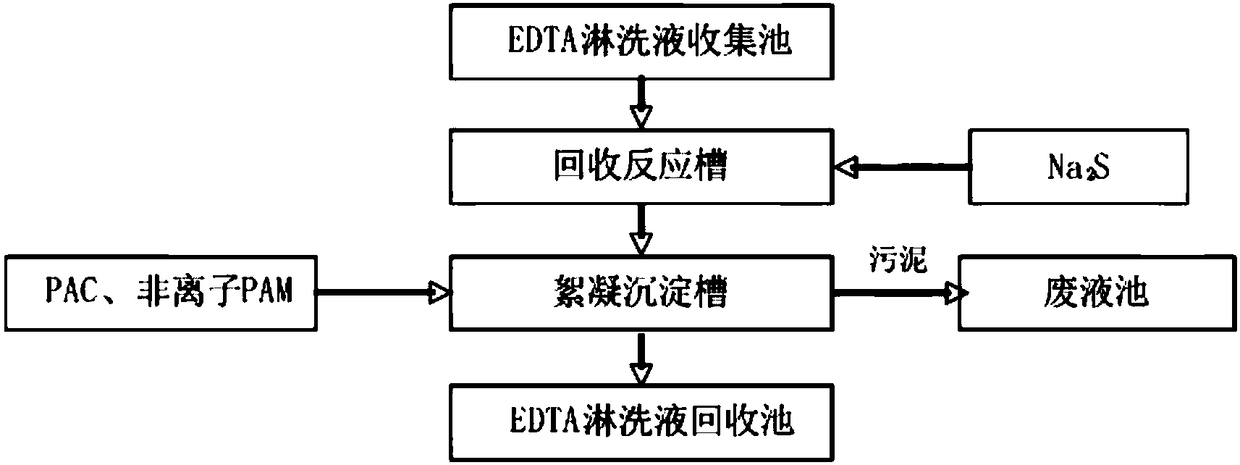

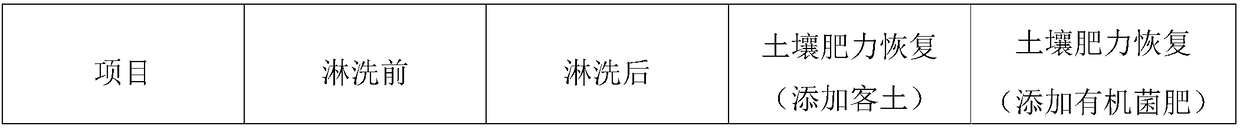

Washing treatment method for heavy metal contaminated soil

InactiveCN108311538AEasy to operateLow implementation costContaminated soil reclamationSoil-working methodsExisting TreatmentSoil fertility

The invention provides a washing treatment method for heavy metal contaminated soil. The method comprises the following steps: mixing the heavy metal contaminated soil and water, sieving the heavy metal contaminated soil with water, feeding the sieved soil to a washing tank, injecting a washing solution, performing circulation stirring, detecting the washed soil till the soil is qualified, dehydrating the qualified soil which is treated in the previous step, adding borrowed soil to the dehydrated soil, and then performing backfilling. The method is simple to operate, adopted reagents are common and available, the implementation cost is low, the removal rates of Cd, Zn, Pb and Cu in the soil can respectively reach 65.1, 47.5, 43.2 and 35.1 percent, the removal rates are superior to that inthe existing treatment technology, and the method is flexible to use, can achieve the effects of improving the physical and chemical properties of soil and enhancing the soil fertility through addition of organic fungi-manure to the treated soil according to the requirements, overcomes the deficiency of long phytoremediation cycle on the heavy metal contaminated soil, and is low in environmental risk.

Owner:湖南新九方科技有限公司

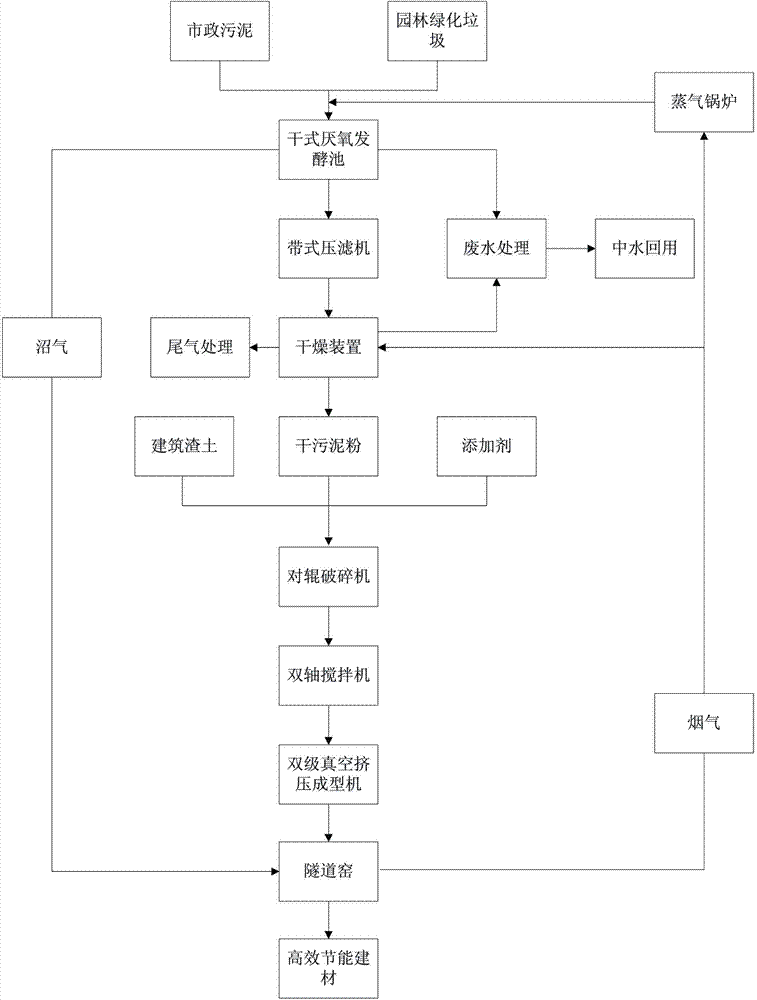

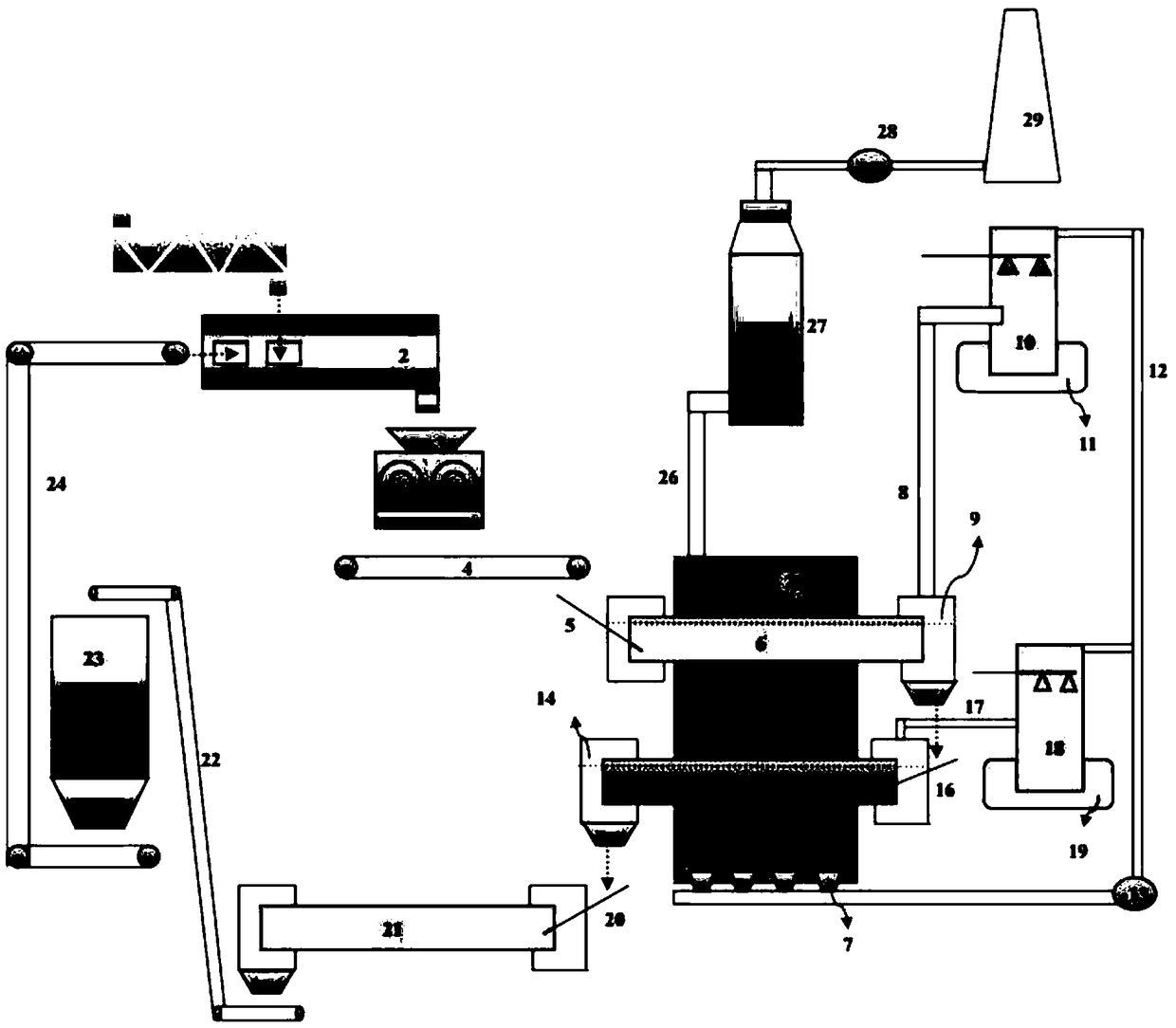

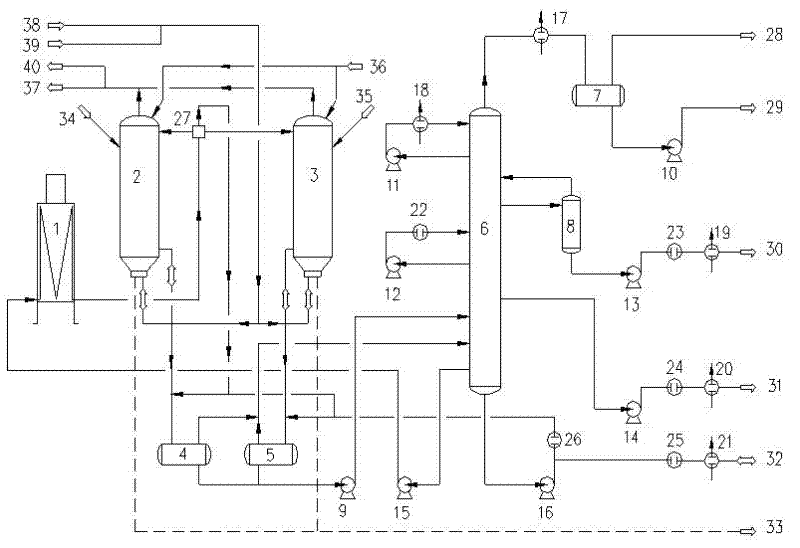

Method for preparing marsh gas and producing sintered bricks by using municipal sludge

ActiveCN104843962ALarge scale processingSmall footprintSludge treatment by de-watering/drying/thickeningWaste based fuelBrickSludge

The invention relates to a method for preparing marsh gas and producing sintered bricks by using municipal sludge. The method comprises the following steps: supplying steam to a dry anaerobic fermentation tank from a steam boiler, carrying out dry anaerobic fermentation on the municipal sludge, and producing marsh gas and anaerobic fermentation sludge after fermenting; conditioning, modifying and dewatering the anaerobic fermentation sludge, supplying the anaerobic fermentation sludge to a drying device for drying, then crushing the anaerobic fermentation sludge to obtain dry sludge powder; mixing the dry sludge powder with building waste soil and producing brick blanks by extrusion molding; and supplying the brick blanks into a system for producing bricks by using sludge, drying and roasting to produce sintered bricks. The smoke in the system for producing bricks by using sludge can be simultaneously used as the heat source of the steam boiler and the drying device; the marsh gas produced after fermenting the municipal sludge can be used as a heating fuel of the system for producing bricks by using sludge. The method has the technical effects that almost no secondary pollution is generated when the municipal sludge is treated, and the comprehensive utilization of energy can be implemented.

Owner:DONGJIANG ENVIRONMENTAL

Environment-friendly dredged sediment integrated mechanical deep-drying system

ActiveCN104030536ASolve the problem of large area occupied by dehydrationShorten drying timeSludge treatment by de-watering/drying/thickeningLoose filtering material filtersTime limitEconomic benefits

The invention relates to an environment-friendly dredged sediment integrated mechanical deep-drying system. An input pipeline is communicated with a primary settling unit by a grating unit; the primary settling unit is communicated with a secondary settling unit by an overflow weir; the secondary settling unit is communicated with a first modulating unit by the overflow weir; the first modulating unit enters a tertiary settling unit by a first chemical adding unit; upper-layer residual water in the tertiary settling unit is connected with a residual water purifying unit by a water decanter; and settled mud on the bottom is connected with a mechanical dehydrating unit by a mud pump on the bottom of the tertiary settling unit. By combining dredging engineering practical conditions with dredged sediment at home and abroad, the system disclosed by the invention is integrated with a series of functions such as bottom mud dehydrating, drying, silt-grading, residual water treating, and the like, has characteristics of being less in floor area, great in treatment scale, small in environmental pollution, short in time limit for a project, high in economic benefits, and the like, and effectively solves difficulty in the conventional dredge yard.

Owner:安徽建工交通航务集团有限公司 +2

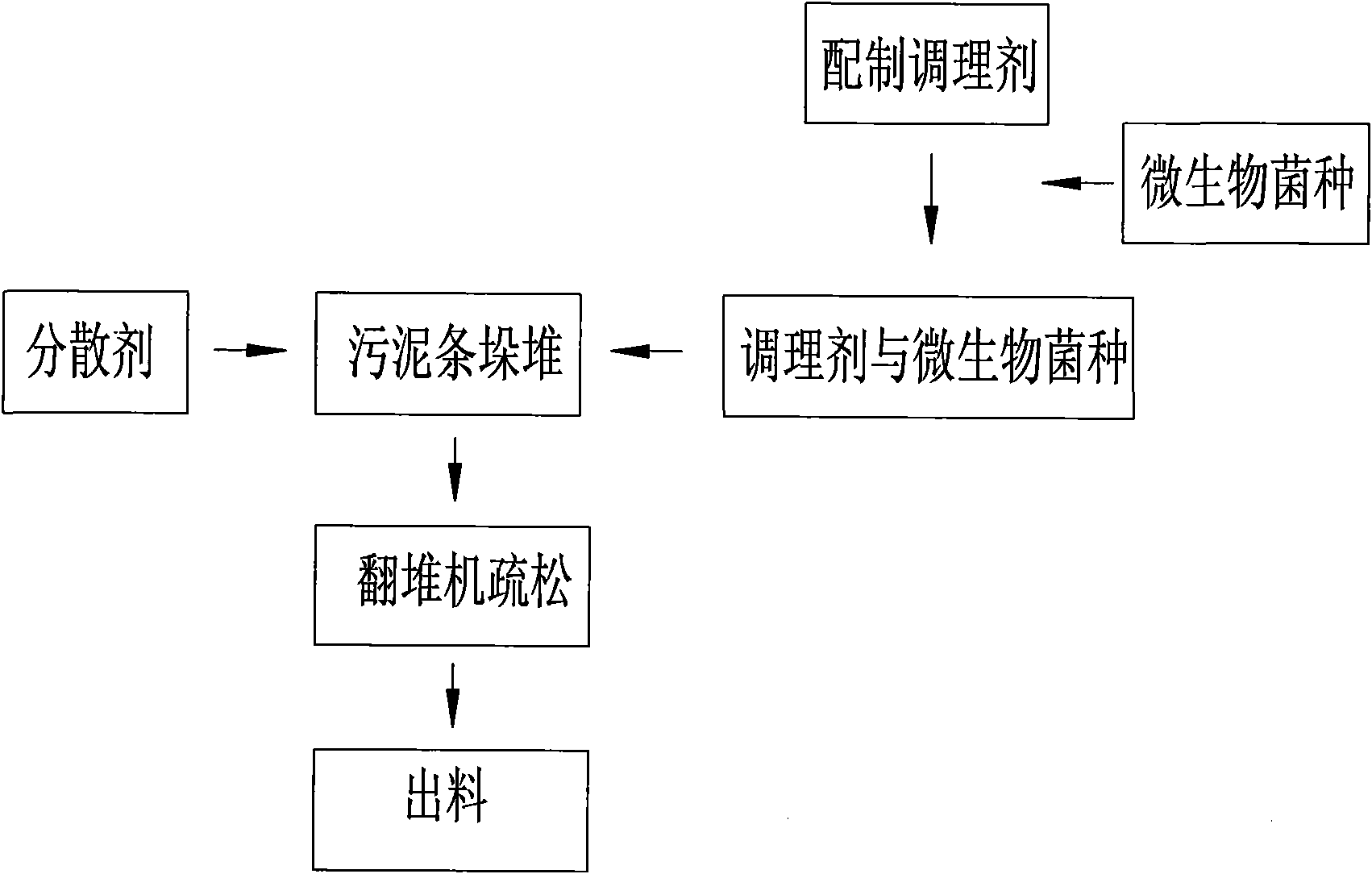

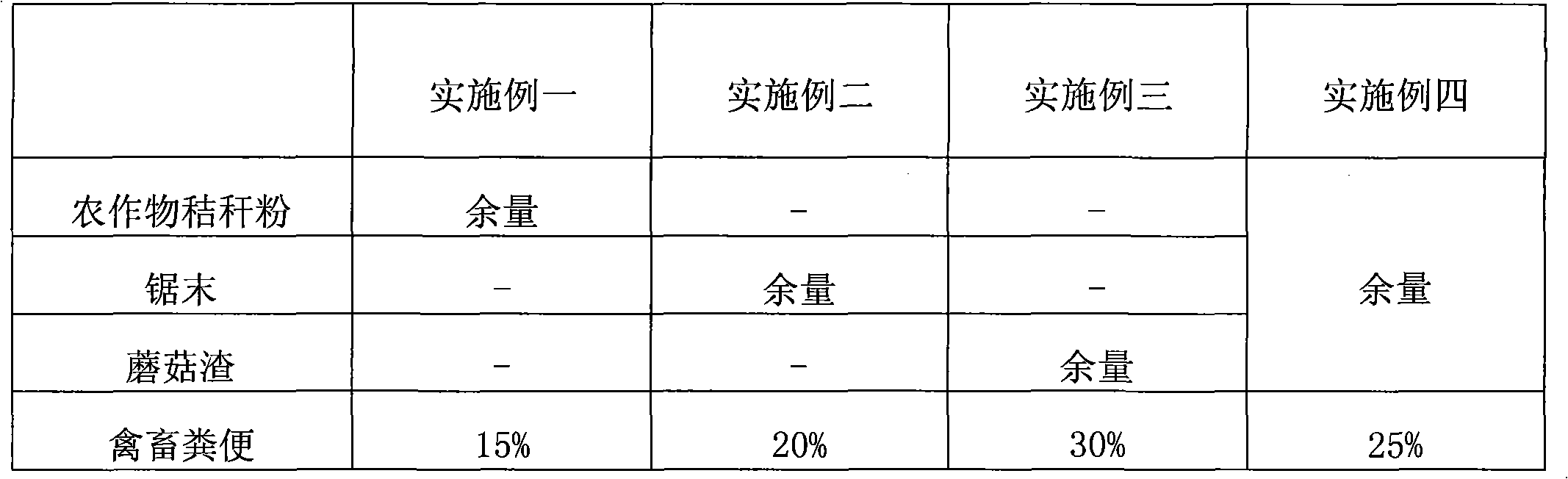

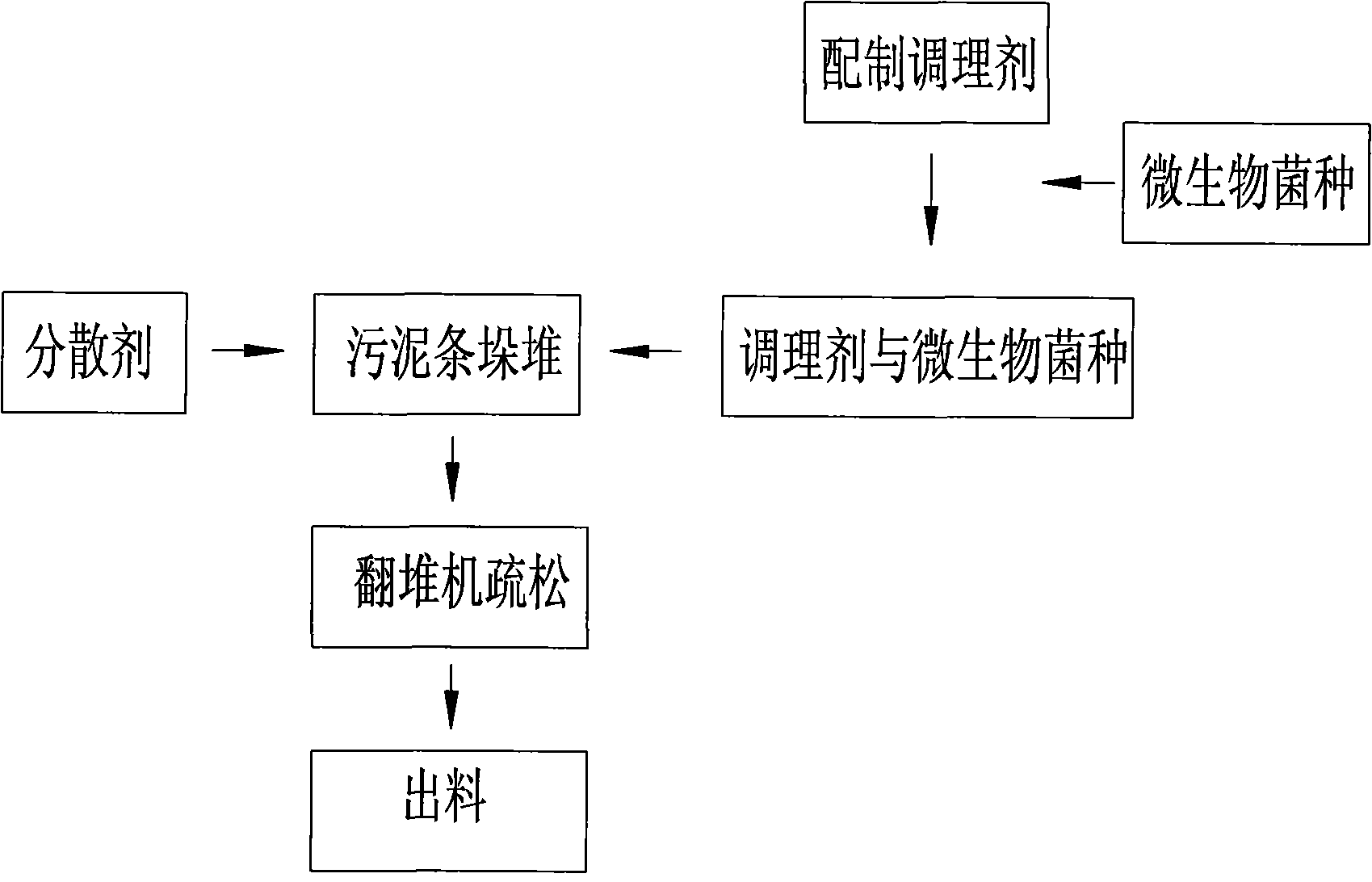

Method for innocent treatment of sludge in sewage plant

The invention discloses a method for the innocent treatment of sludge in a sewage plant, which comprises the following treating steps of: (1) piling sludge on the cement-hardened ground into windrows; (2) uniformly spreading conditioner on the windrows, wherein the weight part ratio of the sludge to the conditioner is 600-800:400-200; (3) preparing nutriment, wherein the nutriment comprises the following component in parts by weight: 5-8 parts of starch, 0.5-1 part of sugar and 0.5-1 part of ethanol of which the volume content is 40%; (4) uniformly mixing the nutriment with compound microorganism microbial inoculum according to the weight ratio of 1-2:1-2; (5) directly spreading the mixture of the nutriment and the compound microorganism microbial inoculum in step (4) on the windrows, wherein the weight ratio of the sludge to the mixture is 600-800:1-2; and (6) using an upender to upend and stir the windrows, and thus finishing the overall treatment 10-15 later. The method is simple in treating process, is applicable to large-scale treatment, and has high innocent treatment degree.

Owner:吴立阳

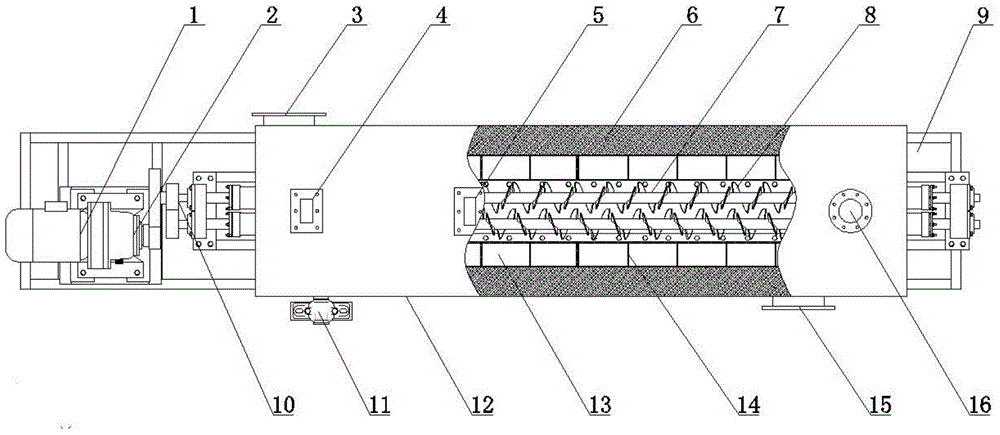

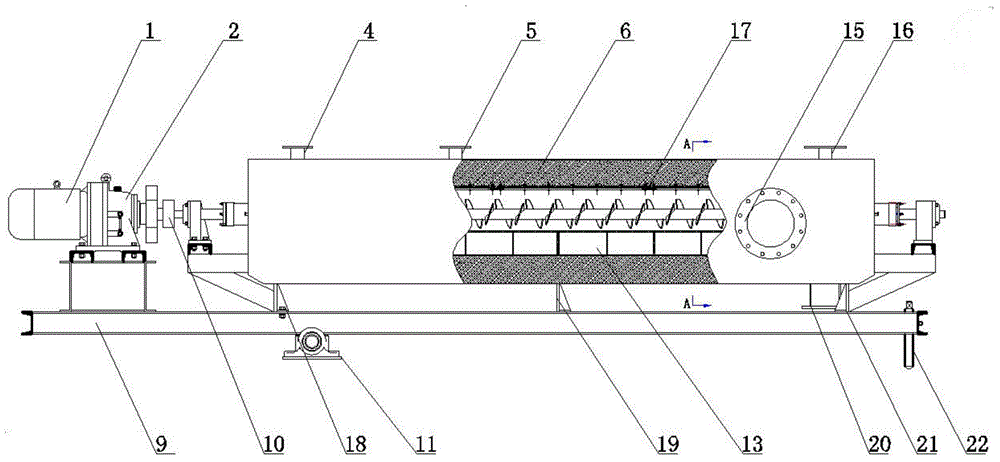

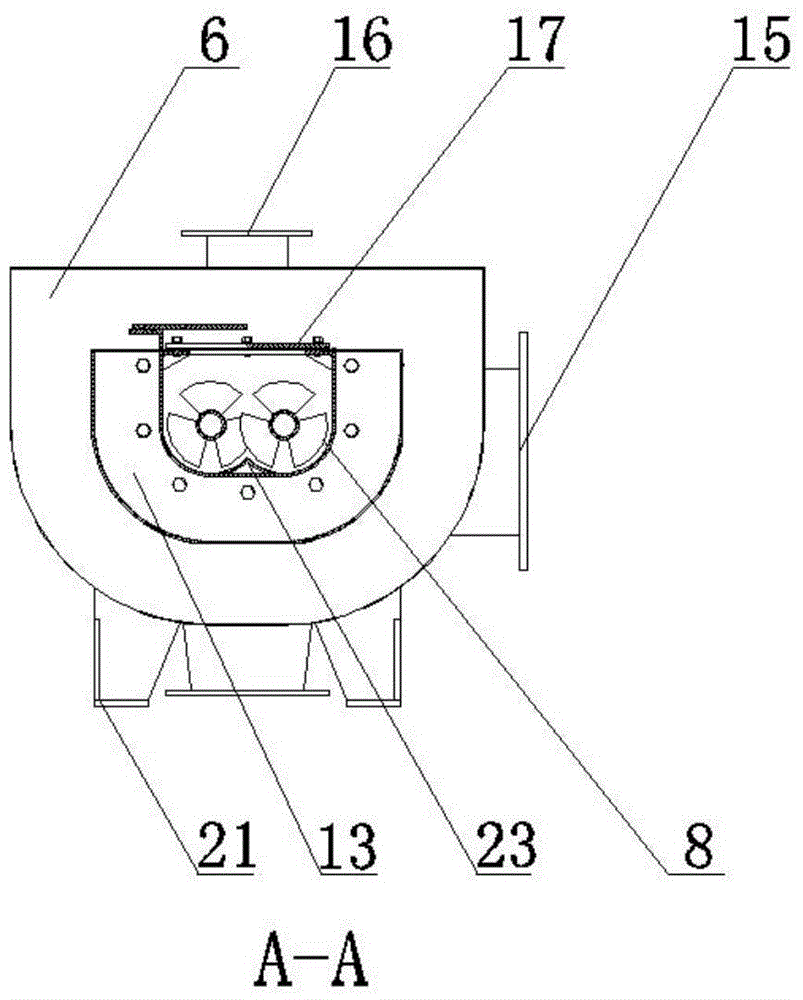

Biomass double-shaft screw pyrolysis device

InactiveCN104531227AThe experimental system is simpleImprove gasification efficiencyGasifier feeding meansCombustible gas productionSyngasBreathing

The invention discloses a biomass double-shaft screw pyrolysis device. The biomass double-shaft screw pyrolysis device comprises a hollow cylindrical enclosure with a U-shaped cross section, wherein an opening of the hollow cylindrical enclosure is sealed by a seal cover of a machine cover, thereby forming a sealed reaction region; the reaction region formed in the enclosure in the axial direction is sequentially divided into a plurality of individual pyrolysis sub regions; the cylinder wall of the enclosure is of a hollow sandwiched structure so as to act as a flue gas channel; the enclosure is centrally provided with double-shaft screw packing augers which penetrate through the reaction region axially; the rotation directions of the two packing augers are opposite; biomass entering from a biomass inlet is mixed and conveyed by the double-shaft screw packing augers, is baked in the baking sub regions sequentially, and is respectively subjected to catalytic gasification and reforming in gasification sub regions and reforming sub regions, so that high-quality synthesized gas products are generated and are discharged from a pyrolysis gas outlet. The biomass double-shaft screw pyrolysis device intensifies the material mixing and heat transferring and mass transferring effects; biomass is gasified efficiently by adopting the inner and outer thermal combination and catalytic effect, so that the problem of axial and radial breathing of the screw pyrolysis device in running at high temperature is solved.

Owner:HUAZHONG UNIV OF SCI & TECH

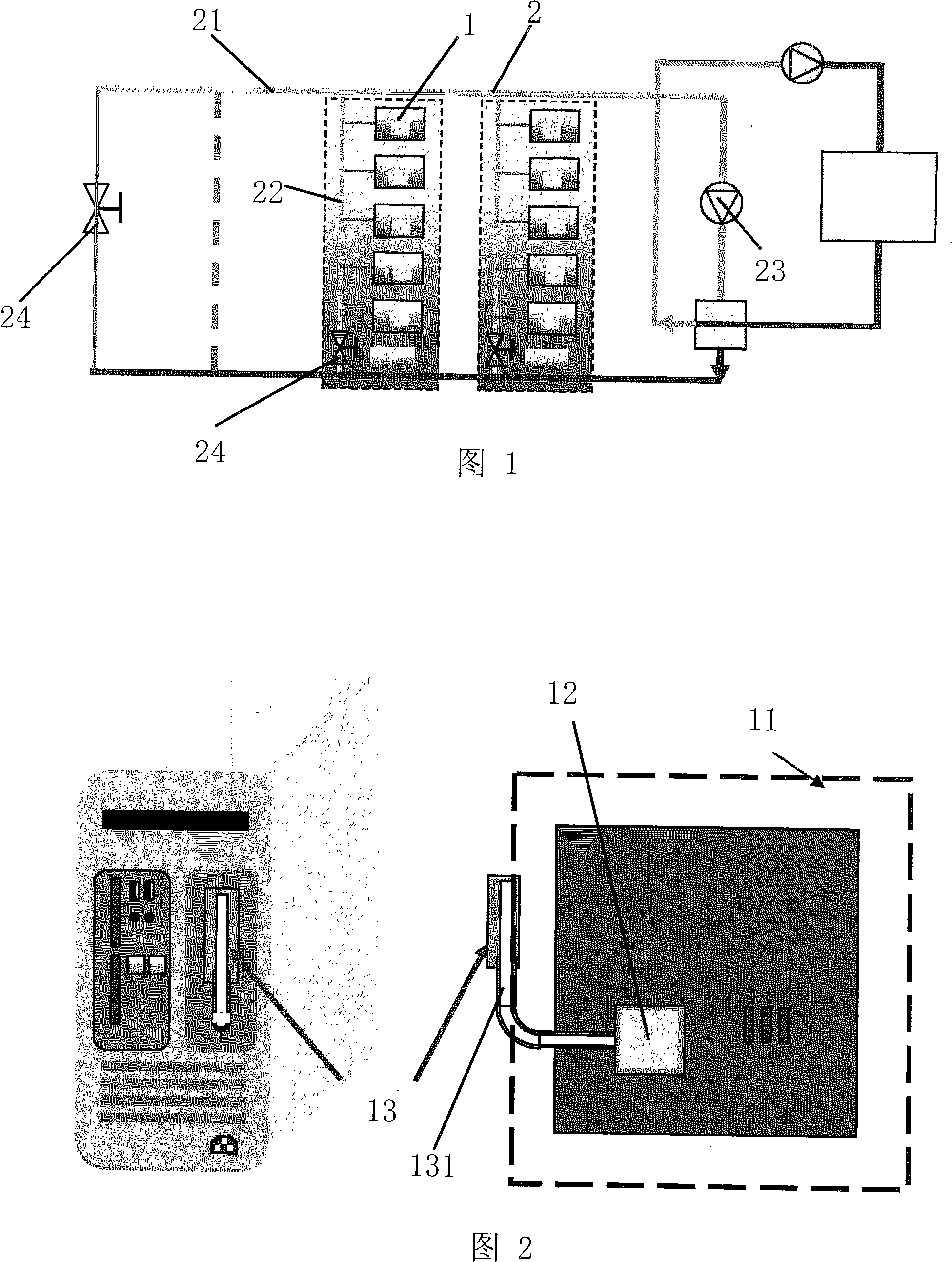

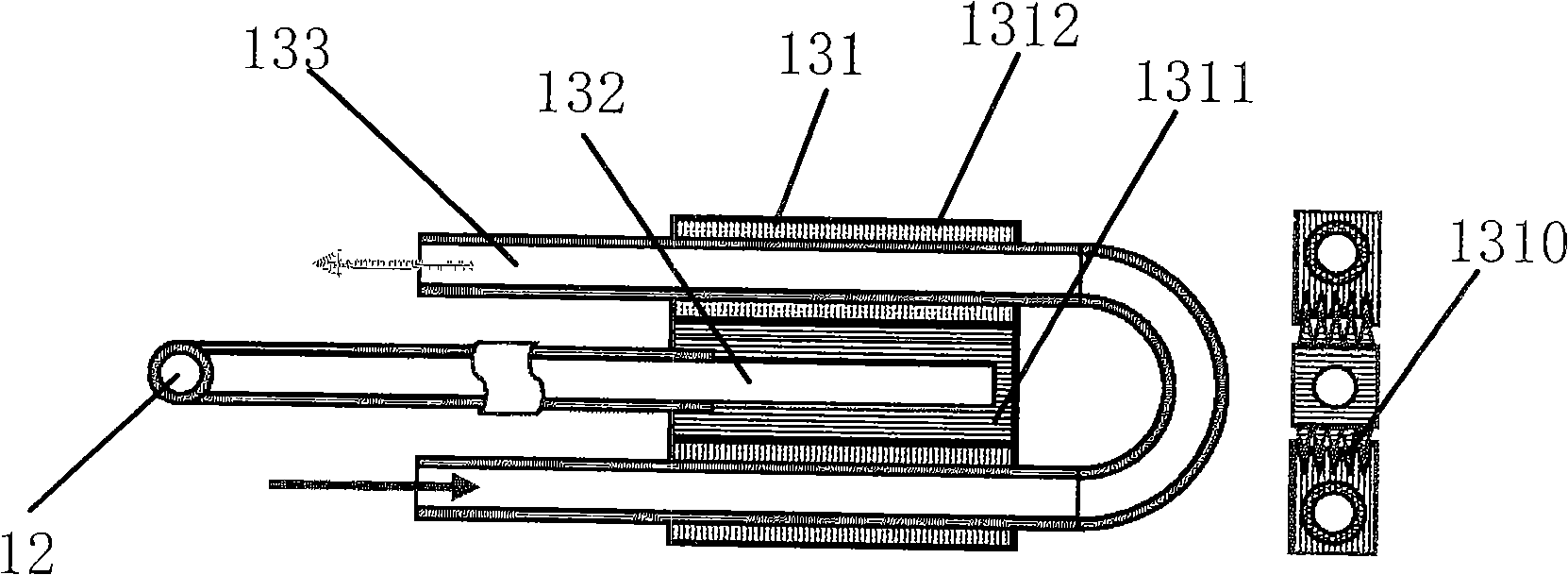

Radiation system for calculation processing arrangements and equipment adopting the heat radiation system

InactiveCN101308398AReduce energy consumptionImprove cooling efficiencyDigital data processing detailsEngineeringThermal efficiency

The invention discloses a cooling system for a computing processing device or a computing processing unit and comprises a heat pipe which educes the heat of a heating component of the cooling system, and a cooling loop outside the heat pipe; the cooling system further comprises a thermal conductive connector which comprises a cooling media channel; the cooling loop outside the heat pipe and the cooling media channel of the thermal conductive connector form a circulation loop of the cooling medium; the heat pipe has a condensation end which is arranged inside the thermal conductive connector and created heat transfer with the cooling medium in the cooling medium channel. The cooling system of the invention has simple assembly, high thermal efficiency and low noise, and can effectively reduce the local temperature difference in a computer room.

Owner:SUN YAT SEN UNIV

Method for producing nickel-iron-containing mixed slag

InactiveCN107641718ASolve pollutionLarge scale processingProcess efficiency improvementMolten stateLead smelting

The invention relates to a method for producing nickel-iron-containing mixed slag. The method comprises the following steps: S1, furnace slag mixing: adding nickel smelting slag into a reaction device, and adding one or more of lead smelting slag, blast furnace slag, steel slag and ferroalloy slag, thus forming the mixed slag; heating the mixed slag into a molten state, and adding one or more of acopper oxide mineral, a copper sulphide mineral, a nickel oxide mineral, a nickel sulfide mineral and a copper-containing material; uniformly mixing the materials to obtain reaction slag, monitoringthe reaction slag in real time, and treating the mixed reaction slag through regulation and control to enable the mixed reaction slag to simultaneously meet conditions a and b, thus obtaining reactedslag; S2, separation and recycling. The method for producing the nickel-iron-containing mixed slag is short in reaction time, short in technological process, high in metal recycling rate, low in production cost, high in treatment capacity, environmentally friendly and high in economical benefit, and effectively solves the problem in efficient recycling of metallurgical resources and heat energy.

Owner:NORTHEASTERN UNIV

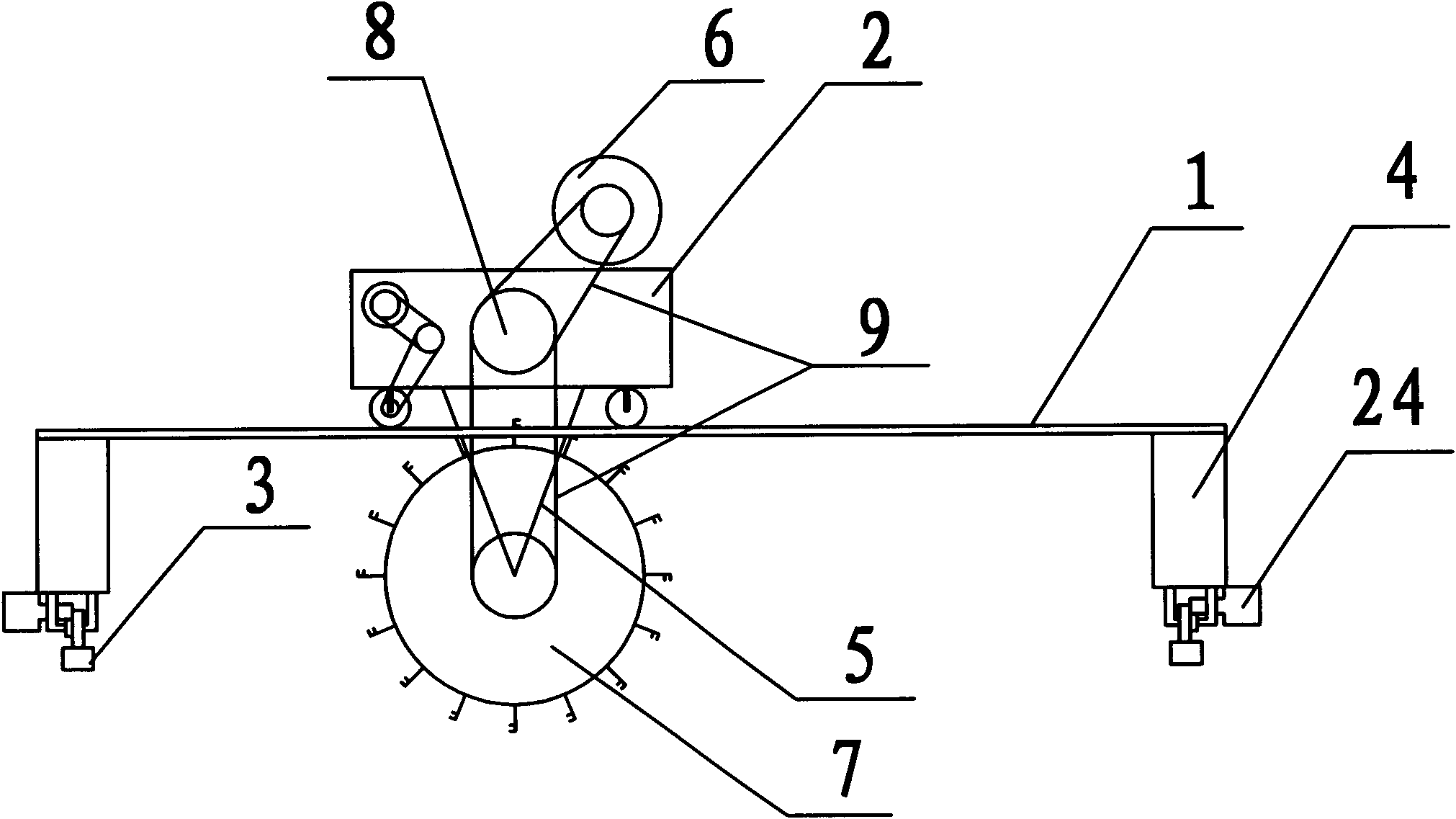

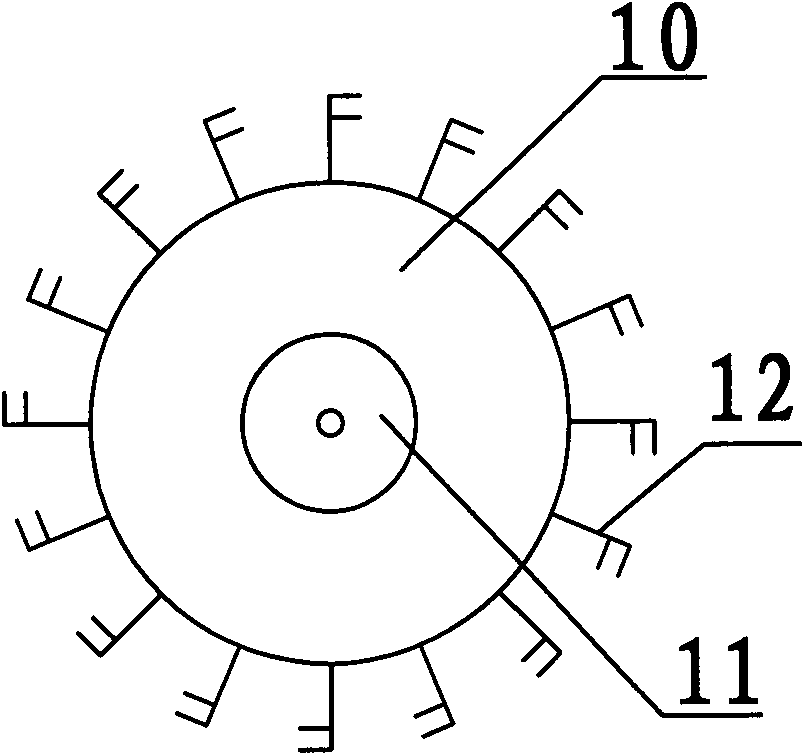

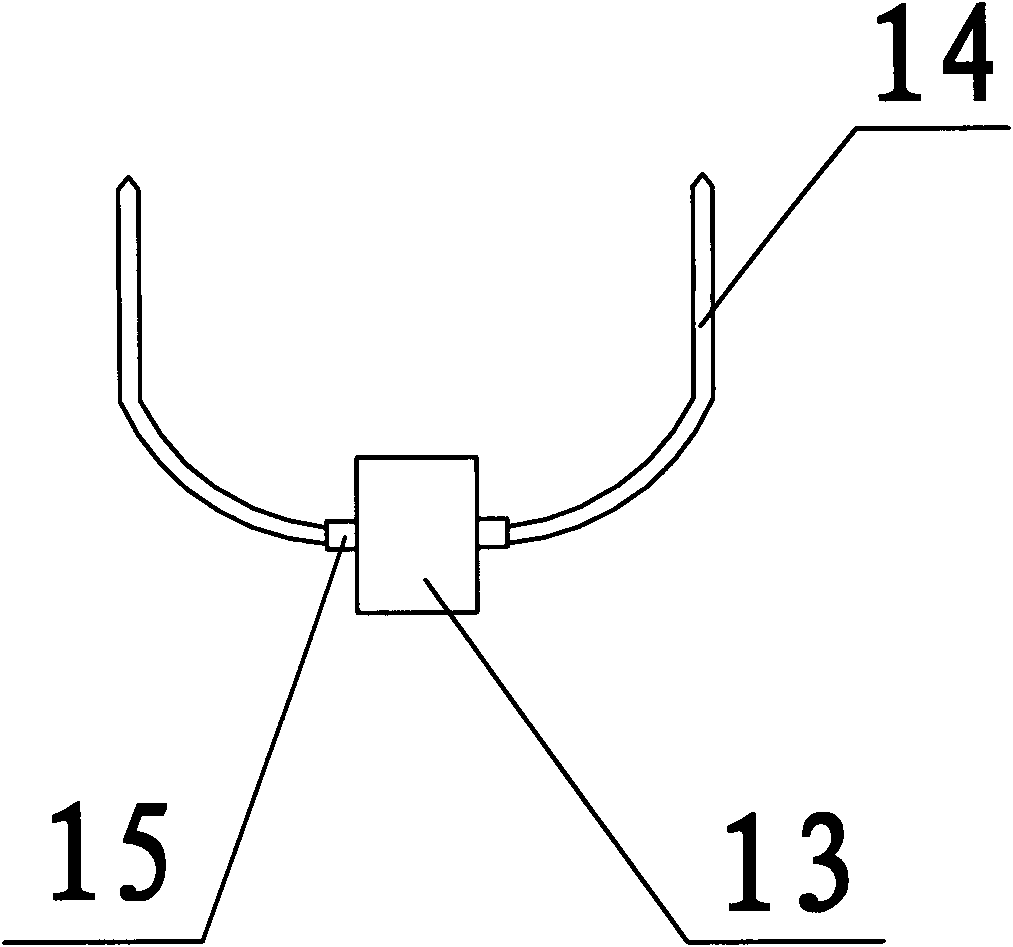

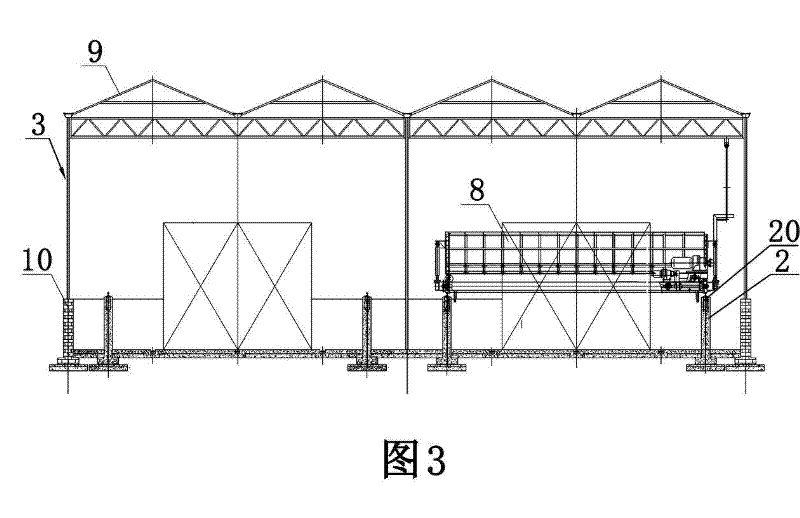

Flywheel type energy-saving turning and throwing machine

InactiveCN101973792AOvercome limitationsLarge scale processingClimate change adaptationSewage/sludge fertilisersSludgeReciprocating motion

The invention relates to a flywheel type energy-saving turning and throwing machine for drying sludge, belonging to the technical field of a drying device. The flywheel type energy-saving turning and throwing machine comprises a walking mechanism and a turning and throwing mechanism, wherein the turning and throwing mechanism is fixedly connected with the turning and throwing mechanism; the walking mechanism comprises a horizontal walking mechanism and a longitudinal walking mechanism, wherein the horizontal walking mechanism comprises a horizontal track and a horizontal double-track sport car, the horizontal double-track sport car is arranged on the horizontal track and reciprocates along the horizontal track; the longitudinal walking mechanism comprises a longitudinal track and longitudinal single-track sport cars, the longitudinal single-track sport cars are connected by the horizontal track, are arranged on the longitudinal track and reciprocate along the longitudinal track; the horizontal track is arranged on the longitudinal single-track sport cars; and the turning and throwing mechanism is arranged under the horizontal double-track sport car and is fixedly connected with the horizontal double-track sport car. The invention overcomes the traditional linear turning and throwing limitation, a processing scale of the flywheel type energy-saving turning and throwing machine is further greater than that of the traditional turning and throwing machine, and the energy consumption and the cost of the energy consumption are lower than that of the traditional turning and throwing machine.

Owner:王焕坤

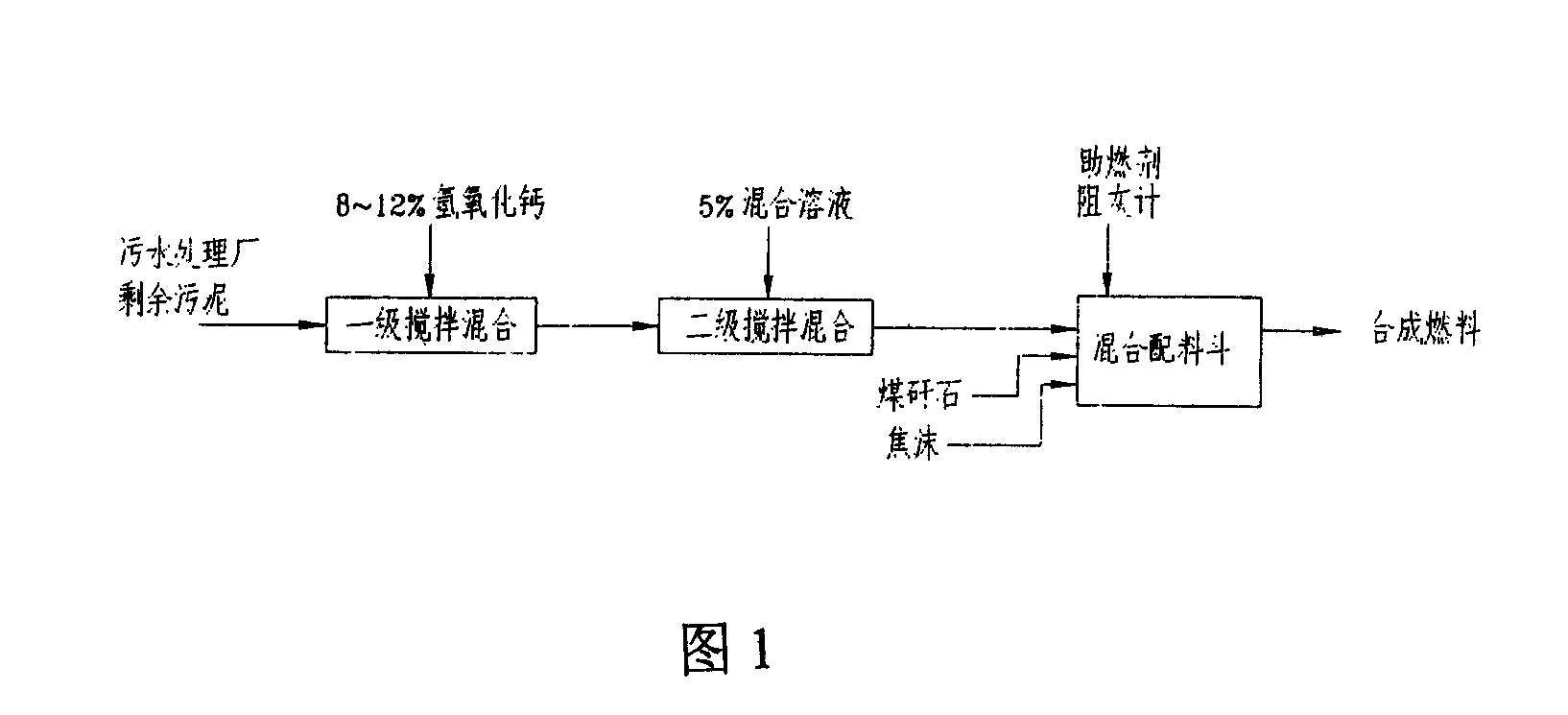

Technique for producing synthetic fuel by sludge of municipal sewage plant

InactiveCN101250456ARealize harmless disposalRealize resourcesBiofuelsSolid fuelsDeodorantWastewater

The invention relates to a technological method which utilizes sludge from wastewater treatment plant to prepare synthetic fuel, which comprises the following steps: firstly, feeding sludge whose water content is 80% after being dewatered by a municipal wastewater treatment plant into a stable stirring tank, adding CaO which is 8-12% of the amount of sludge, stirring for 10 minutes, lowering water content to 65%, feeding sludge whose water content is lowered to 65% into a deodorant stirring tank, adding Fe2(SO4), FeSO4(NH4)SO4.6H2O, CuSO4, CO(NH2)2 and water to prepare mixed solution which is 5%, stirring and mixing for 5 minutes, leading sludge to be totally loosed and stable to be end product sludge, feeding 30-40% end product sludge, 40-50% coke foam and 20% coal gangue into an automatic batch hopper, simultaneously adding 0.05-0.1g Fe2O3, stirring, mixing for 5 minutes, and preparing synthetic fuel. The invention achieves innocent treatment and resource treatment of sludge, and achieves comprehensive utilization of coal making industry.

Owner:刘志刚 +1

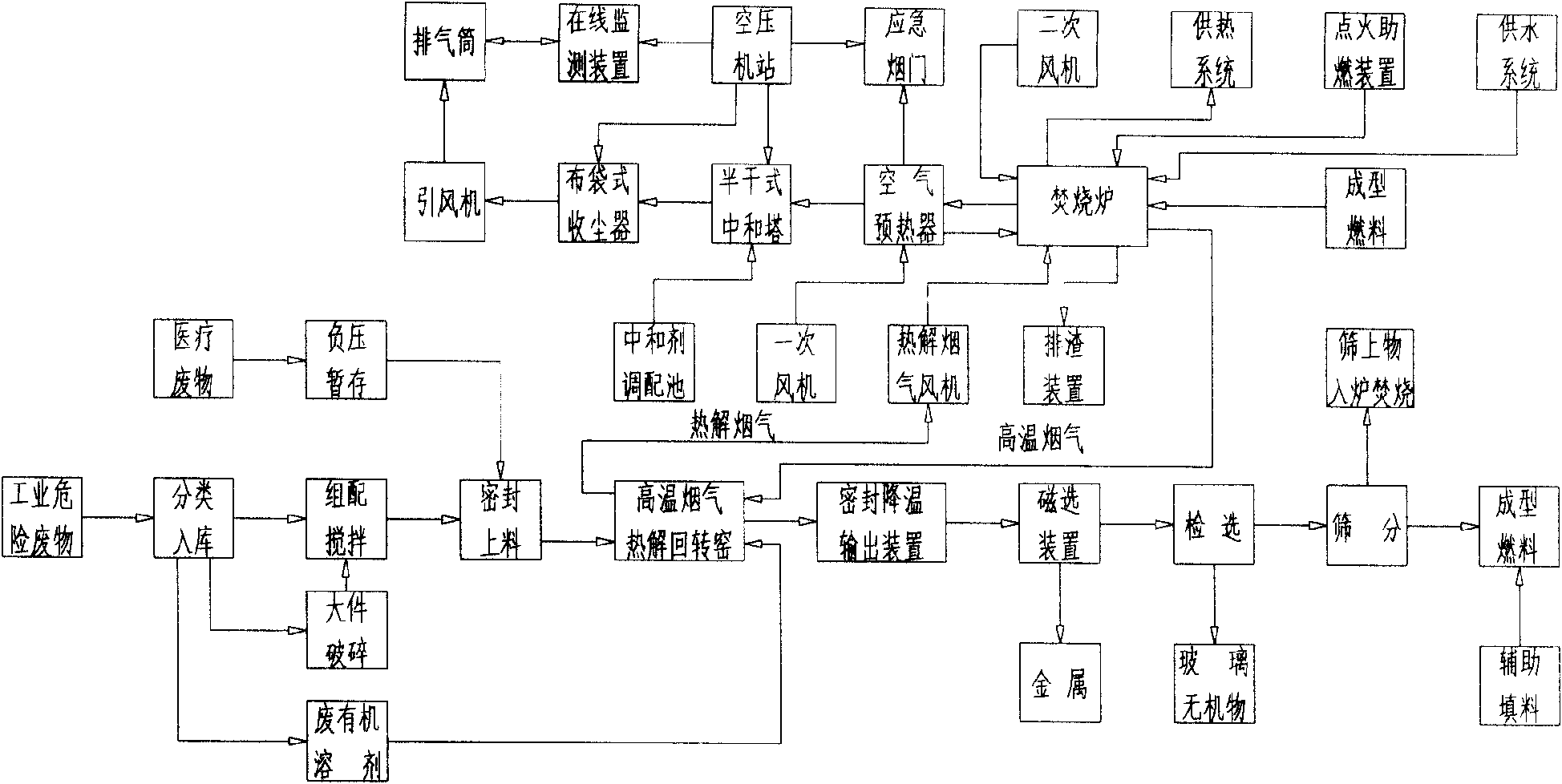

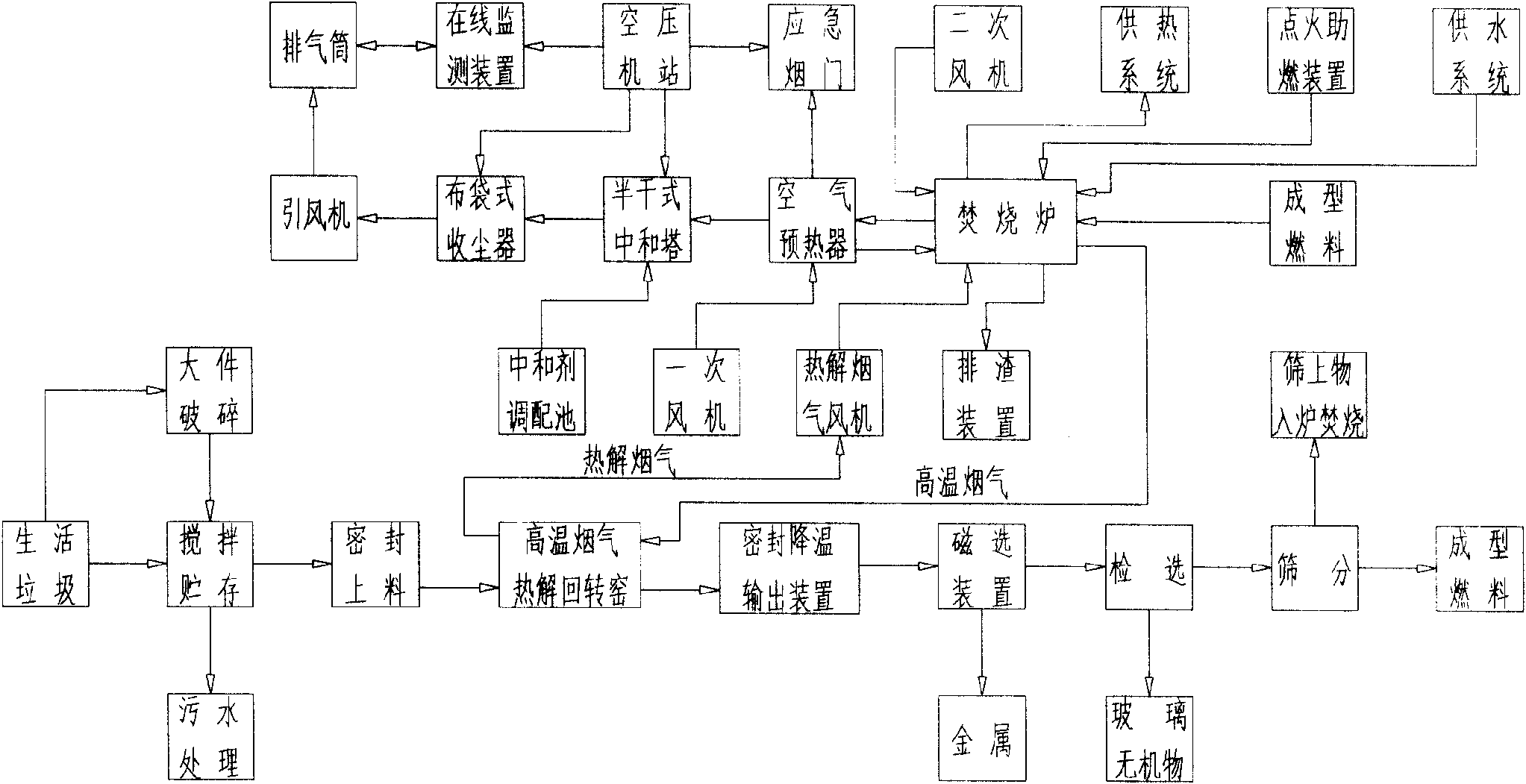

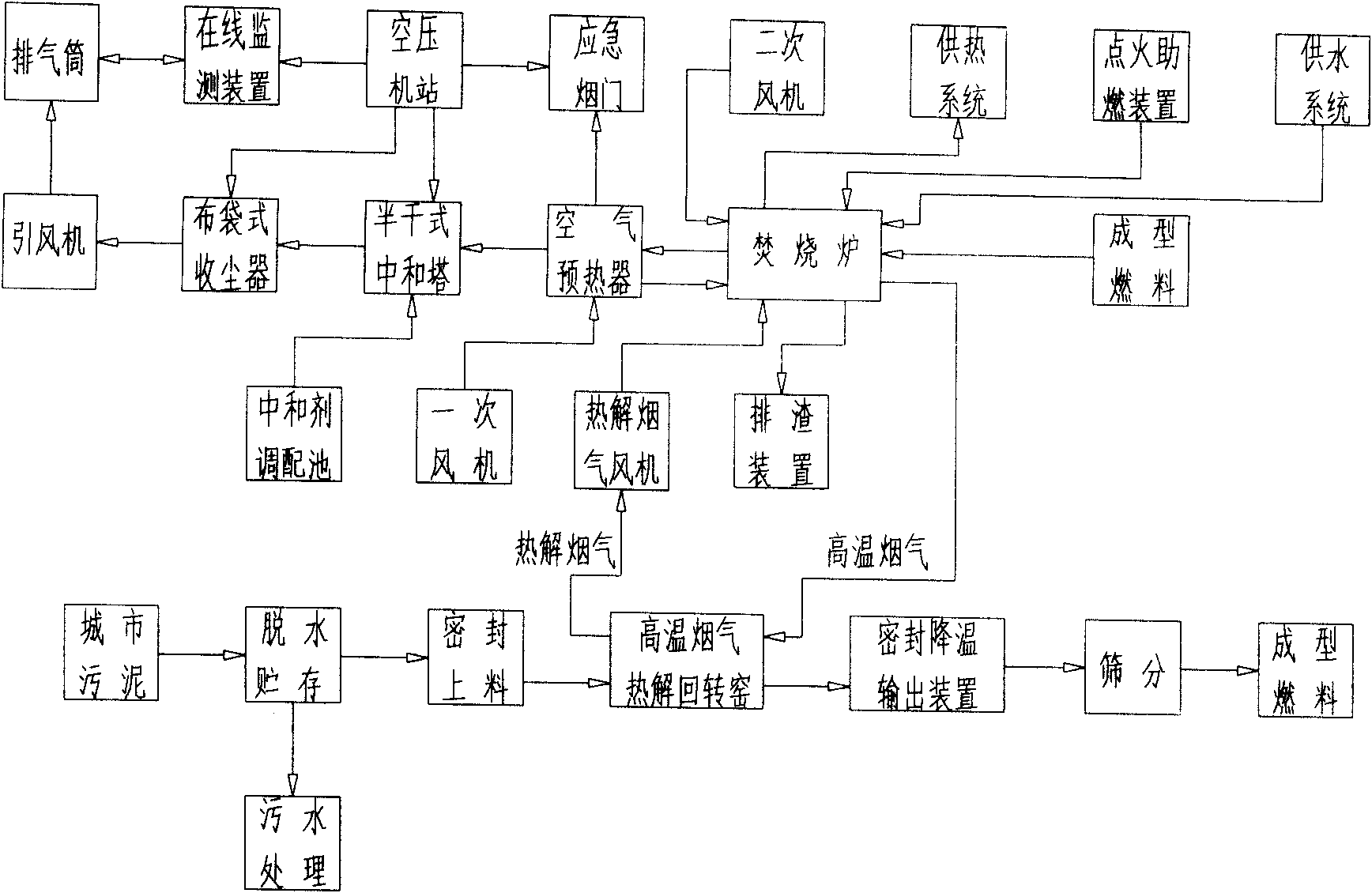

Method for innocent treatment and resource utilization of wastes

The invention provides a method for innocent treatment and resource utilization of wastes, in particular a process and a method for pyrolyzing and burning any type of the wastes including industrial hazardous wastes, medical wastes, urban domestic wastes, urban domestic sludge, bio-straws and the like. The method adopts a high-temperature flue gas pyrolysis rotary kiln technique, a high-temperature flue gas and pyrolysis flue gas cycle burning technique, and a molding burning technique. The method has the advantages of wide adaptable range, strong processing ability, safety, reliability, low running cost, and advanced various economic technique and environmental protection indexes.

Owner:丁宝太 +1

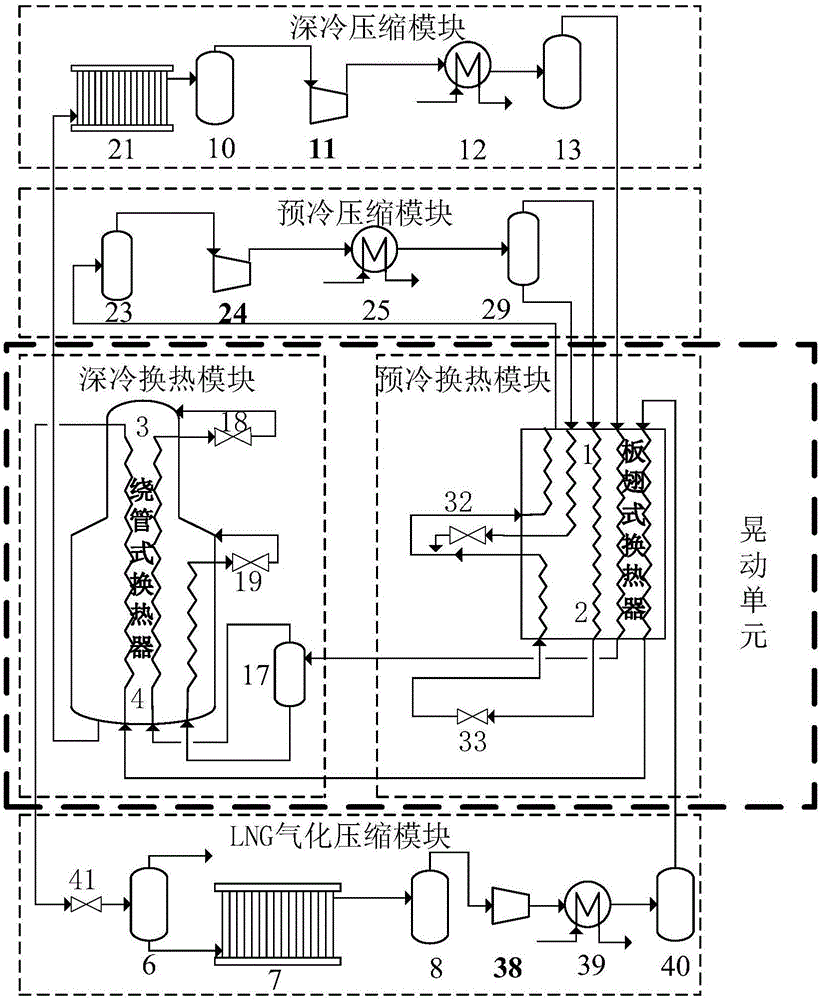

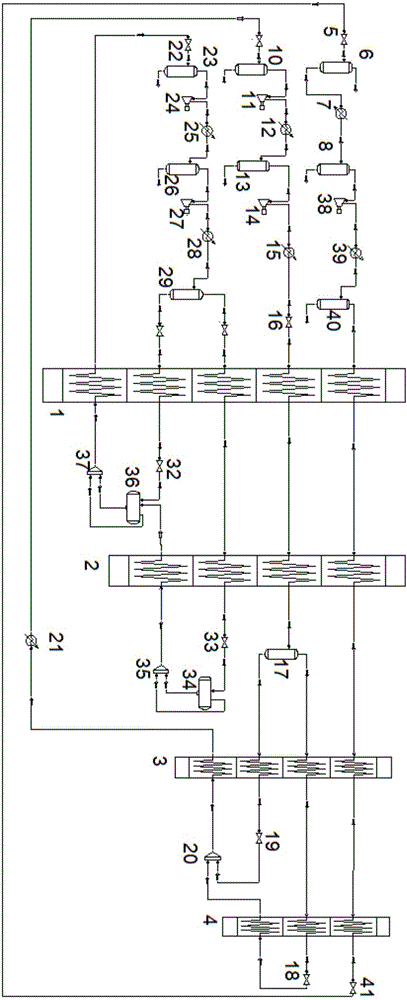

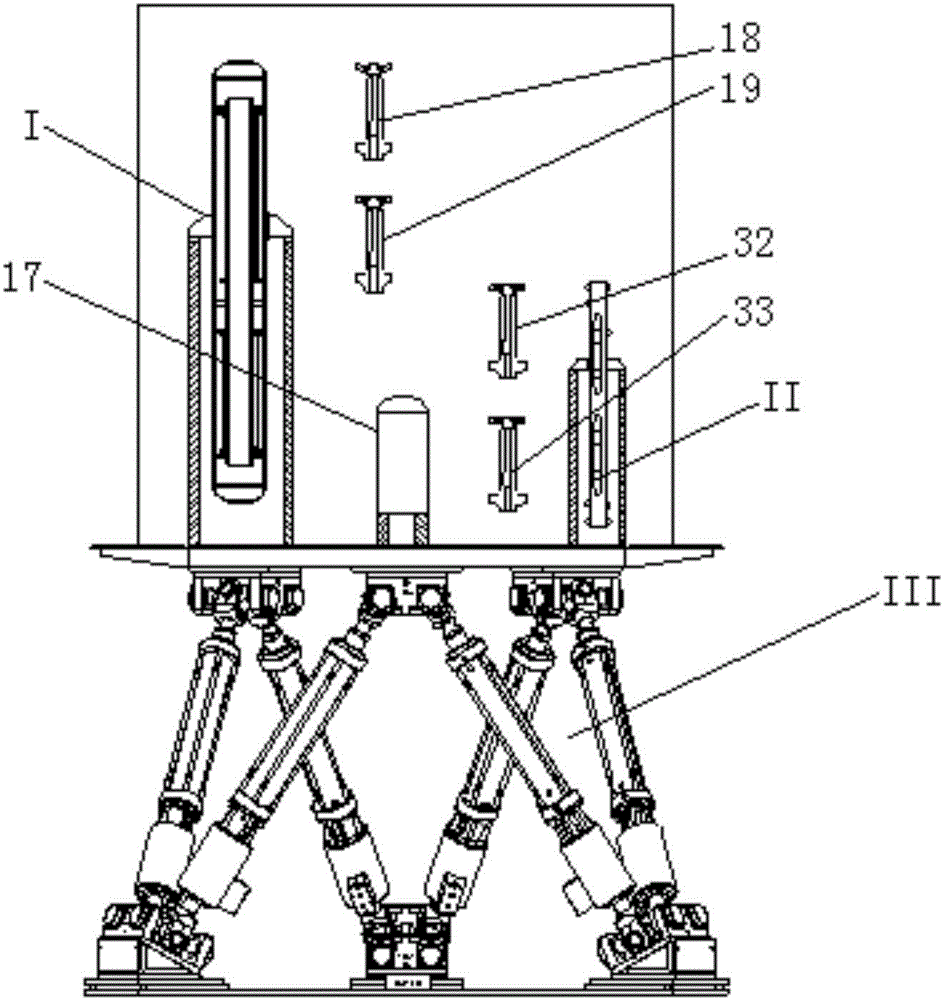

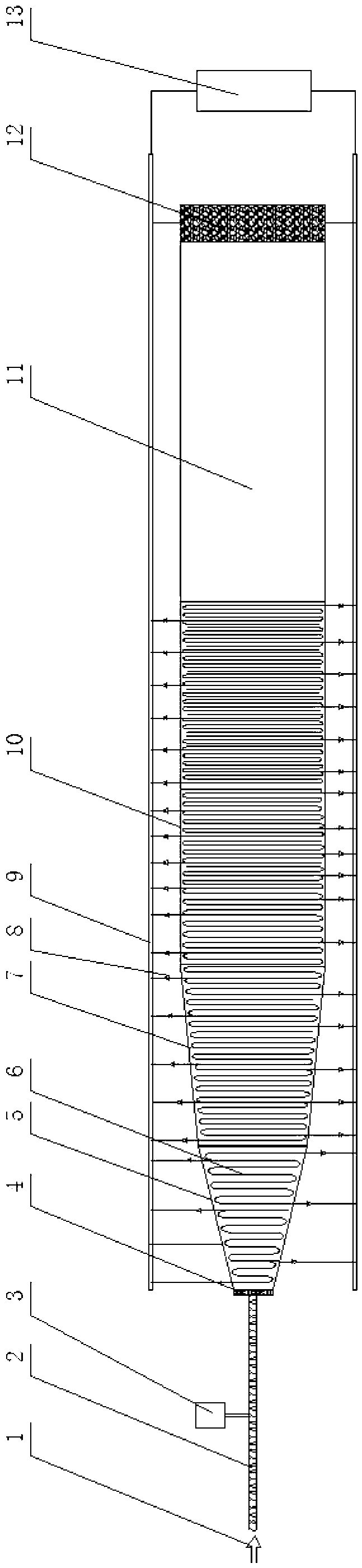

Floating type test platform of natural gas liquefaction system

InactiveCN106441964ASmaller than power consumptionImprove liquefactionSolidificationLiquefactionVapor–liquid separatorEngineering

The invention discloses a floating type test platform of a natural gas liquefaction system. The test platform comprises a deep freeze compression module, a pre-cooling compression module, and an LNG vaporization compression module, the deep freeze compression module is connected with a pre-cooling heat exchange module and a deep freeze heat exchange module in sequence to form a circulation, the pre-cooling compression module is connected with the pre-cooling heat exchange module to form a circulation, the LNG vaporization compression module is connected with the pre-cooling heat exchange module and the deep freeze heat exchange module in sequence to form a circulation, and the pre-cooling heat exchange module and the deep freeze heat exchange module are arranged on a shake unit. The test platform can be used for testing the operation performance of core equipment such as a plate-fin heat exchanger, a coiled-pipe heat exchanger, a throttle valve, and a gas-liquid separator etc. in the natural gas liquefaction system in a marine environment, and the adaptability of the natural gas liquefaction system.

Owner:CNOOC GAS & POWER GRP +1

Environmental protection dredging stockyard sediment original position rapid dehydration system

InactiveCN103232149ADeal with scalingAchieve fast dryingSludge treatment by de-watering/drying/thickeningDraining tubePositive pressure

The invention relates to an environmental protection dredging stockyard sediment original position rapid dehydration system, which comprises an input unit, a grating unit, a positive pressure pumping filtration draining unit, an overflow slurry deposition unit, a residual water purification unit and residual water purification unit and residual water discharge unit, and these units are connected in order; the bottom plane of the positive pressure pumping filtration draining unit has a trapezoid design, and the bottom of the positive pressure pumping filtration draining unit is distributed with a drainpipe, and the drainpipe is connected with water chutes at double sides by a vacuum water pump, and the residual pumping filtration water is connected with the water chute and enters into the residual water purification unit. The system combines with the real case of the dredging engineering and anhydration technology of home and abroad dredging stockyard sediment, and integrates the sediment dehydration, anhydration, silt grading, residual water treatment and a series of functions into one body, and has the characteristics of large treatment scale, small environmental pollution, short construction period, high economic benefit, etc., thereby effectively solving the dilemmas in the traditional dredging stockyard.

Owner:TIANJIN UNIV OF SCI & TECH

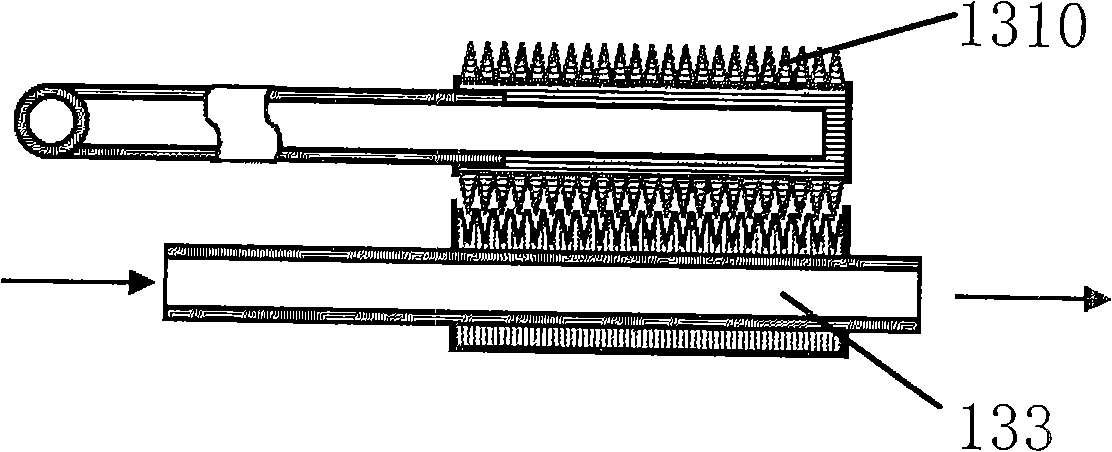

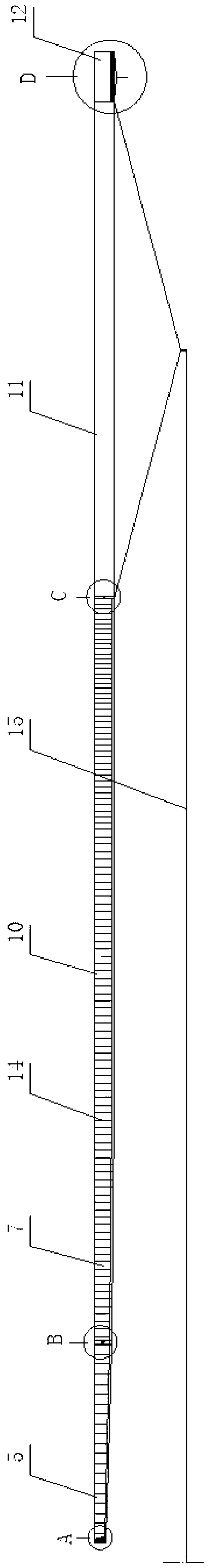

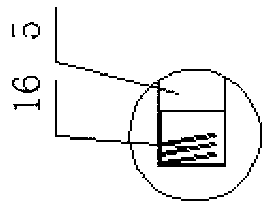

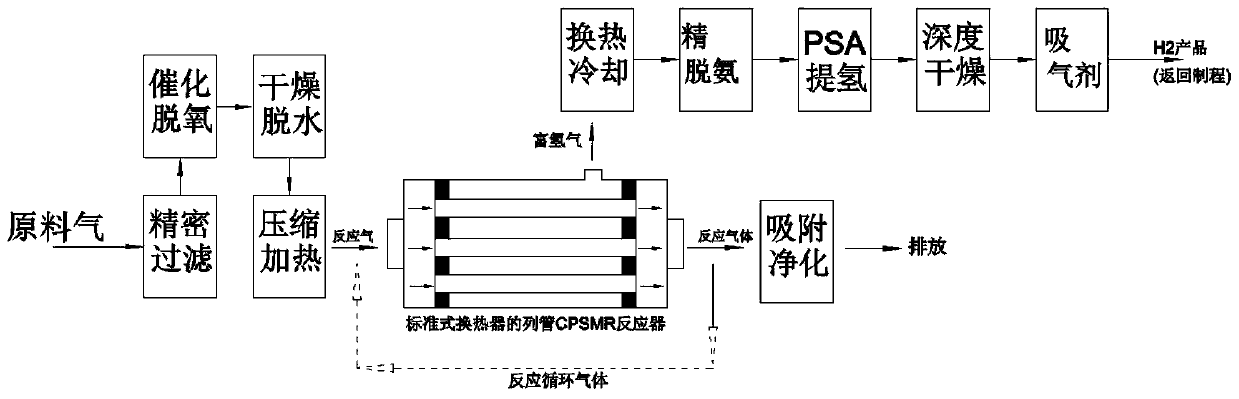

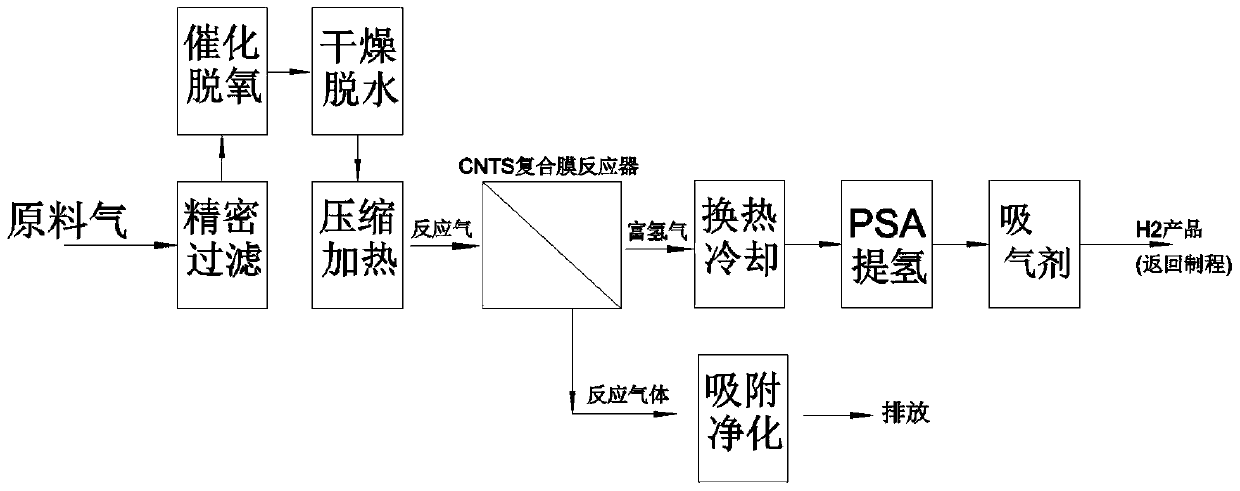

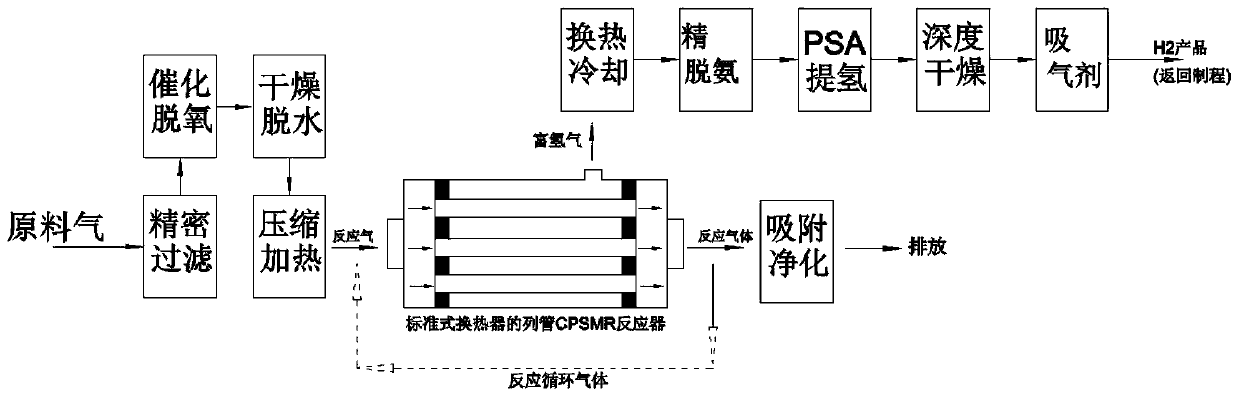

Catalytic permeable membrane reactor for producing hydrogen from ammonia-containing tail gas in MOCVDprocess as well as preparation method and application of the catalytic permeable membrane reactor

InactiveCN111137853ASolve the conversion rateSettlement yieldHydrogen separation using solid contactHydrogen productionOxide ceramicCarbon nanotube

The invention discloses a catalytic permeable membrane reactor for producing hydrogen from ammonia-containing tail gas in an MOCVD process. In the membrane reactor, a porous gamma-aluminum oxide ceramic circular tube containing 5-10% (w / w, similarly hereinafter) of metal palladium is dispersed is used as a support body; an inorganic carbon nano-membrane, which contains 10-30% of cobalt and 5-20% of molybdenum as active components, 1-10% of lanthanum serving as an auxiliary catalytic component and 1-5% of potassium serving as an accelerant, is embedded into pretreated carbon nanotubes (CNTs) and coats the inner wall of an alumina ceramic round tube, has thickness of 10 nm to 1 [mu]m and pore diameter of 0.20 to 10 nm; thus forming the catalytic permeable membrane reactor which simultaneously has catalytic activity and separation selectivity. Ammonia-containing tail gas in the MOCVD process is pretreated and then enters a membrane reactor; at the reaction temperature of 400-600 DEG C, an ammonia thermal cracking catalytic reaction is performed under the reaction pressure of 2.0-5.0 MPa; and hydrogen-rich gas generated by the reaction is subjected to adsorption refining deamination,pressure swing adsorption purification and metal getter purification to obtain a hydrogen product with the purity of more than 6-7 N, and the hydrogen product is returned to the MOCVD process to be recycled, thereby filling the blank for green and circular economy development of the LED industry.

Owner:SICHUAN TECHAIRS

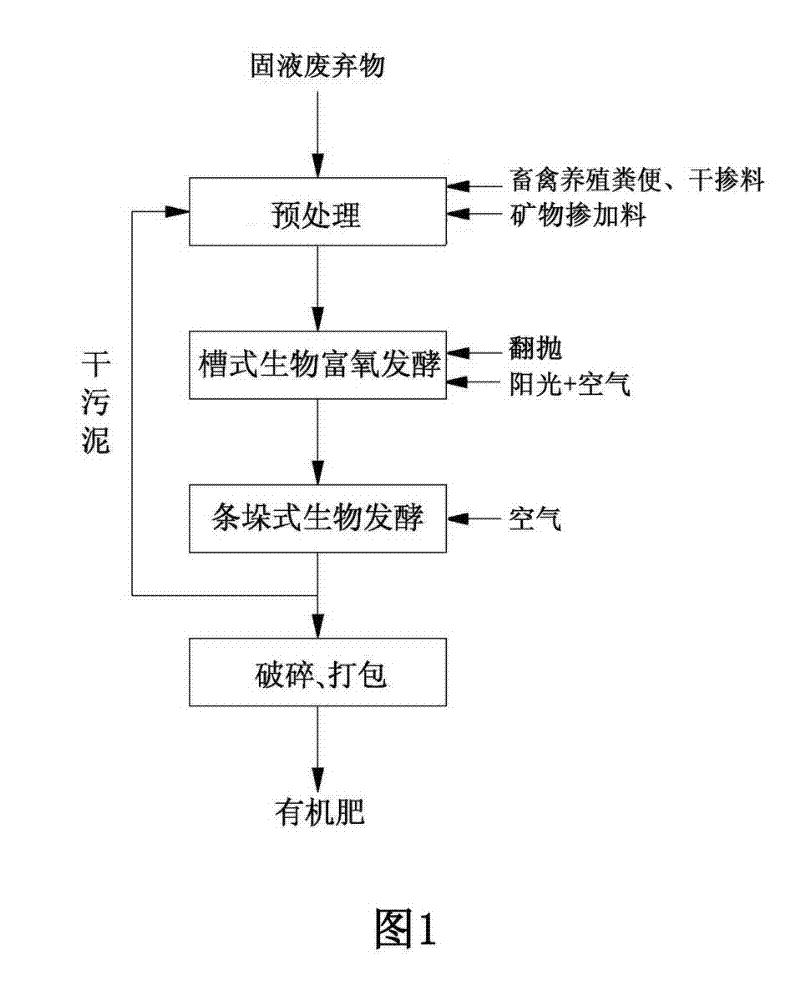

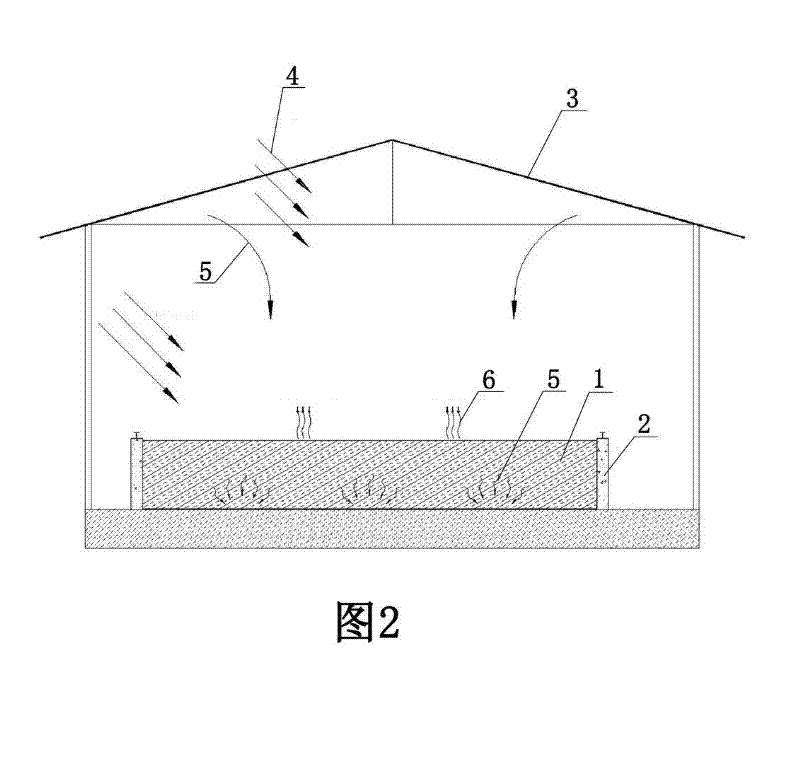

Oxygen-enriched biological treatment method and system of solid liquid waste

InactiveCN102173914AReduce moisture contentRapid heating and fermentationBio-organic fraction processingOrganic fertiliser preparationSludgeCrop cultivation

The invention relates to an oxygen-enriched biological treatment method and an oxygen-enriched biological treatment system of solid liquid waste. The method comprises the following steps of: 1, mixing the solid liquid waste, livestock and poultry culture excrement and a dry doped material according to the mass ratio of the solid liquid waste to the livestock and poultry culture excrement to the dry doped material of 8:1:1 to 7:1:2, and adding a mineral doped material in an amount which is 0.1 to 5 percent of the weight of the dry doped material; 2, performing groove type biological oxygen-enriched fermentation at the temperature of between 50 and 70 DEG C for 4 to 8 days, so that the water content of the materials is reduced to below 55 percent through fermentation; 3, performing windrow type biological fermentation for 4 to 8 days until the water content is reduced to below 30 percent; and 4, mixing and packaging the materials. By the method and the system, the fermentation process is in the oxygen-enriched state all the time, so the fermentation speed is increased, occupied area and operating cost are reduced, and the problem of secondary pollution of urban solid liquid waste is solved. The method and the system are applicable to treatment of the solid liquid waste such as sludge generated by urban sewage treatment plants, household waste, livestock and poultry culture excrement, crop cultivation and garden solid waste and the like.

Owner:绿色家园(北京)环保科技有限公司

Method and apparatus for treating oily sludge

PendingCN109179939ASolve the problem of energy consumptionSolve complexitySludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeHigh energy

The invention relates to a method and an apparatus for treating oily sludge. The method comprises the following steps: mixing of biochar produced by pyrolysis of oily sludge with the oily sludge, molding, pyrolysis treatment, and drying and oil desorption in the same hearth in order to achieve efficient integrated gradient utilization of energy. The apparatus comprises a screw conveying device, amixing device, a shaping device, a belt conveying device, a revolving cylinder indirect drying device, a revolving cylinder indirect thermal desorption device, the integrated heating furnace, gas burners and the like. The method and the apparatus have the advantages of small investment, quick effect, simple and flexible process, low running cost, high practicability, large treatment scale, complete harmlessness, high recycling rate, high energy utilization rate, full embodiment of the concepts of circular economy and low-carbon economy, and significant social, economic and environmental benefits.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

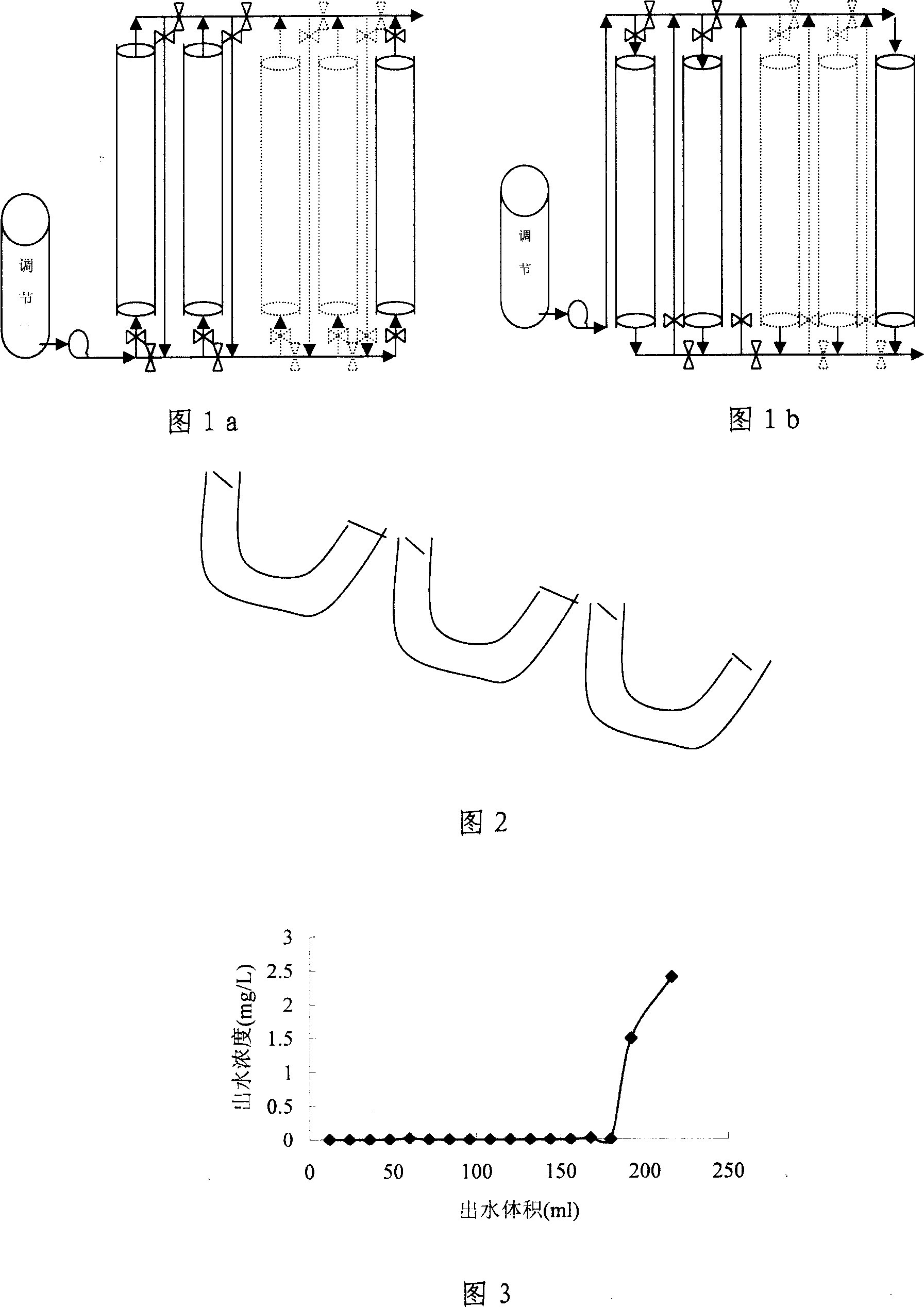

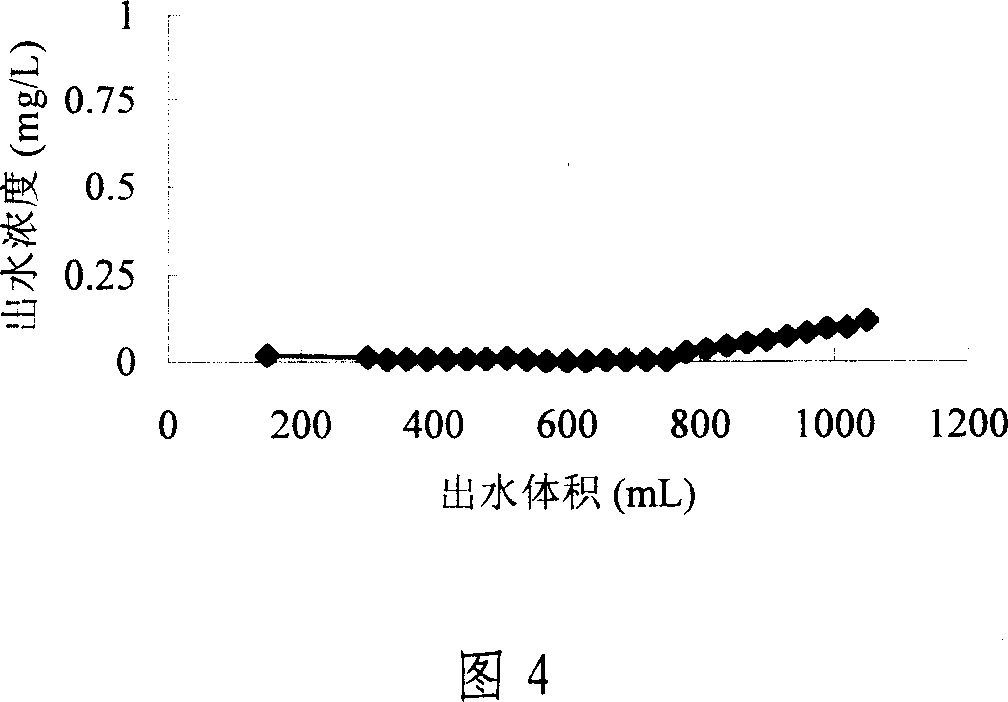

Multistage gradient adsorption channel adsorption technology

InactiveCN100999344ALow costReduce power consumptionSolid sorbent liquid separationEnergy based wastewater treatmentWastewaterHeavy metals

This invention relates to adsorbing technology that uses adsorptive process for processing various kinds of waste water. Concretely it is many-stage grade adsorption tank adsorbing technology. Use many-stage dissymmetry U type pillar as adsorbing substance packing pillar, use adsorbing substance as packing material. After achieving adsorptive capacity, reclaim heavy metals and regenerative adsorbing substance. This invention uses cheap adsorbing substance as packing material. Procedure is simple. Operation is stable and reliable. It is suitable for different heavy metal waste water disposal. Compared with existing vertical adsorbing column technology, its motive power is low. Cost is low. Passed waste water is more. Effect is good. Economic performance is good.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

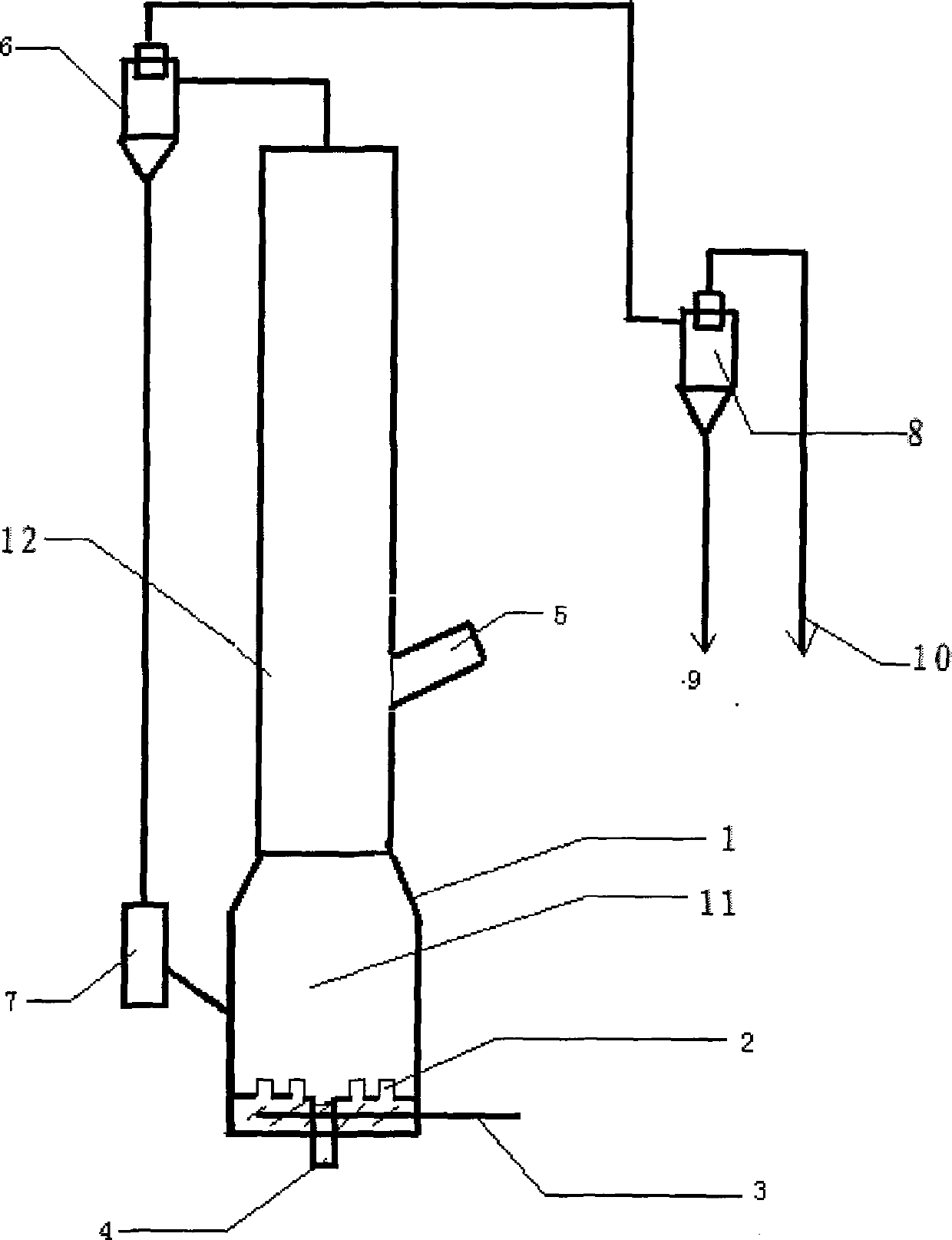

Biomass abnormal circulating fluidized bed gasifier

ActiveCN103102990AIncrease gas calorific valueLarge scale processingProductsReagentsFluidized bed gasifierFluidized bed

The invention provides a biomass abnormal circulating fluidized bed gasifier which consists of a fluidized bed, a gas distributor, an ash discharge tube, a gas inlet tube, a feed inlet, a first-level gas-solid separator, a cinder circulating return tube, a return feeder, a second-level gas-solid separator, a silicon-potassium fertilizer outlet and a gas outlet. The fluidized bed consists of a turbulent fluidized bed and an entrained bed reactor. The gas distributor and the ash discharge tube are arranged at the bottom of the turbulent fluidized bed. A biomass feed inlet is arranged in a position which is 100-2000mm far from the bottom of the entrained bed reactor, and the first-level and second-level gas-liquid separators are arranged at the top. Coarse particle ash of the first-level gas-liquid separator enters into the circulating return tube and is connected with the turbulent fluidized bed at the bottom of the abnormal circulating fluidized bed through the returner. High-temperature refine ash of the second-level gas-liquid separator is fed outwards as the silicon-potassium fertilizer from the silicon-potassium fertilizer outlet, and gas is fed outwards as a product gas from the gas outlet.

Owner:田原宇

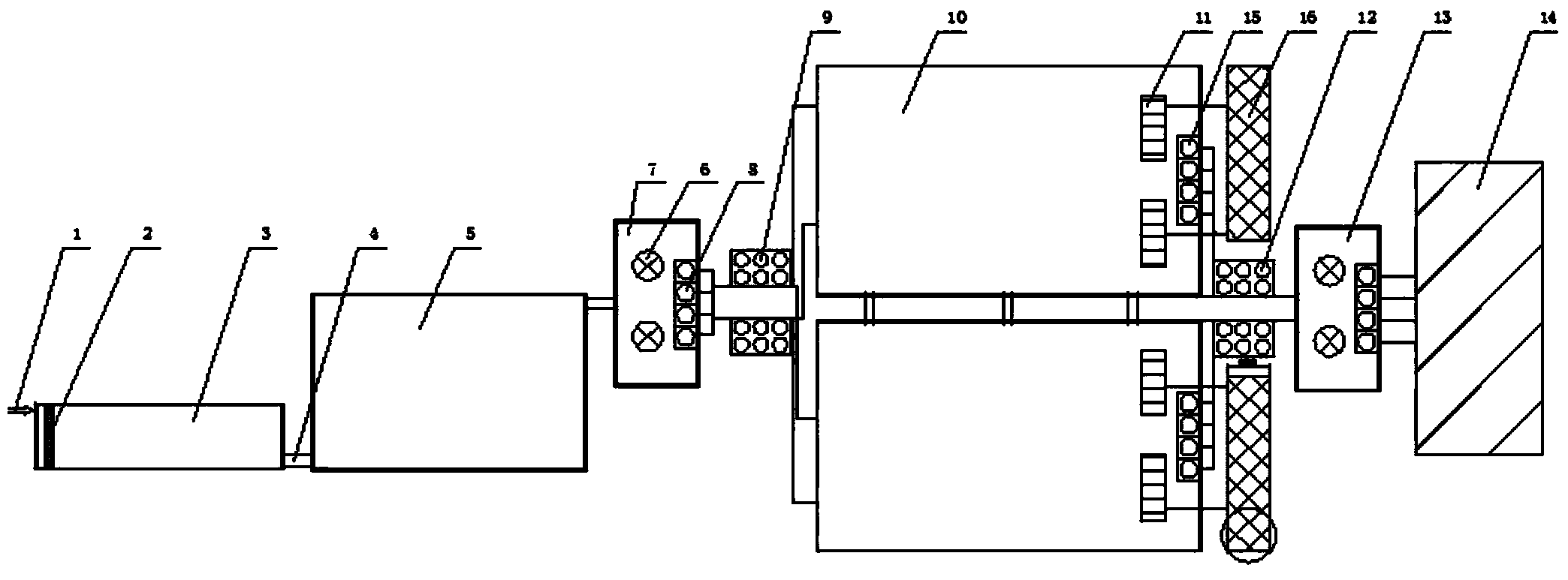

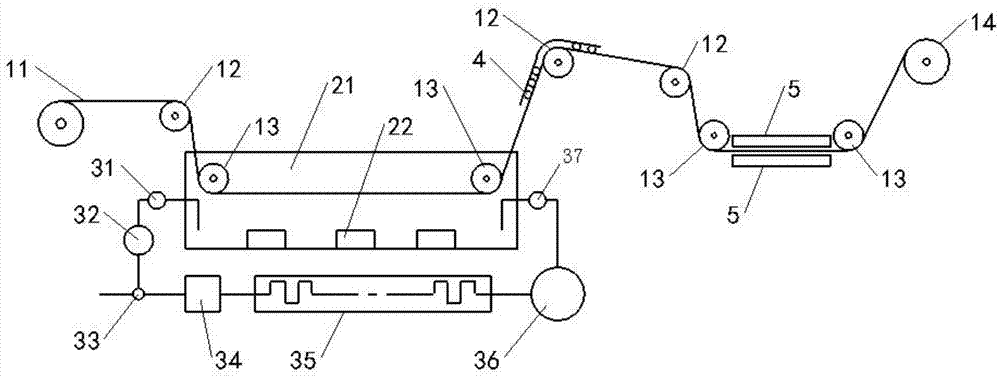

Device and method for efficient roll-to-roll preparation of cadmium sulfide thin film

ActiveCN103898479ASimple structureIncrease productivityFinal product manufactureChemical vapor deposition coatingBatch productionEngineering

The invention relates to a device for efficient roll-to-roll preparation of a cadmium sulfide thin film. The device comprises a conveying mechanism for flatly conveying a flexible substrate, a deposition box for carrying out a deposition reaction, a solution heating circulating mechanism connected with the deposition box, a cylinder washing / brushing mechanism for washing and brushing the substrate, and a drying device for drying the substrate, wherein the deposition box, the cylinder washing / brushing mechanism and the drying device are orderly arranged in the conveying direction of the substrate. The invention also relates to a method for the efficient roll-to-roll preparation of the cadmium sulfide thin film. The method comprises the steps of unfolding the substrate, preparing a solution, heating the solution, reacting for deposition, conveying the substrate, cleaning the substrate, conveying the clean substrate, drying the surface and reeling the substrate. The device and the method have the advantages of simple structure, and achievable continuous large-batch production, and belong to the technical field of the thin-film solar cell manufacturing process.

Owner:SOUTH CHINA UNIV OF TECH

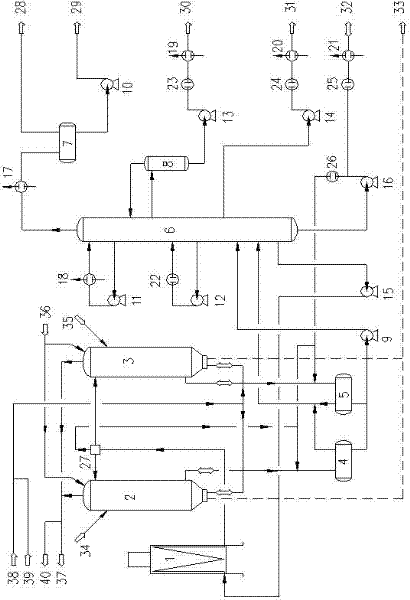

Method for preparing oil by thermally cracking biomass

ActiveCN102260516AUniform temperatureImprove thermal efficiencyLiquid hydrocarbon mixture productionVapor liquidFractionating column

The invention relates to a technology for preparing oil by thermally cracking biomass, and particularly provides a method for preparing the oil by thermally cracking biomass and the like which are taken as raw materials. The method relies on a technology similar to delayed coking. The method mainly comprises the following steps of: pumping circulating oil out from the bottom of a fractionating column, pumping into a radiation chamber furnace tube of a heating furnace by a hot oil pump, quickly heating and raising the temperature to 450 to 550 DEG C, feeding into the upper part of a thermal cracking tower, spraying onto raw material stack layers by a distributor, allowing raw material cracking oil gas and the circulating oil to flow to the bottom of the cracking tower from up to down alongthe raw material stack layers so as to form the temperature gradient from up to down; and allowing the raw material cracking oil gas and the circulating oil to enter a vapor-liquid separation tank, allowing the raw material cracking oil gas obtained after separation to enter the fractionating column, performing mass transfer on the raw material cracking oil and the mixed liquid of cracking liquidand the circulating oil, and fractionating to obtain gas, crude gasoline, diesel oil, wax oil and circulating oil. The method has the main characteristics of energy conservation along with reasonableprocess, and low cost.

Owner:高玉玲

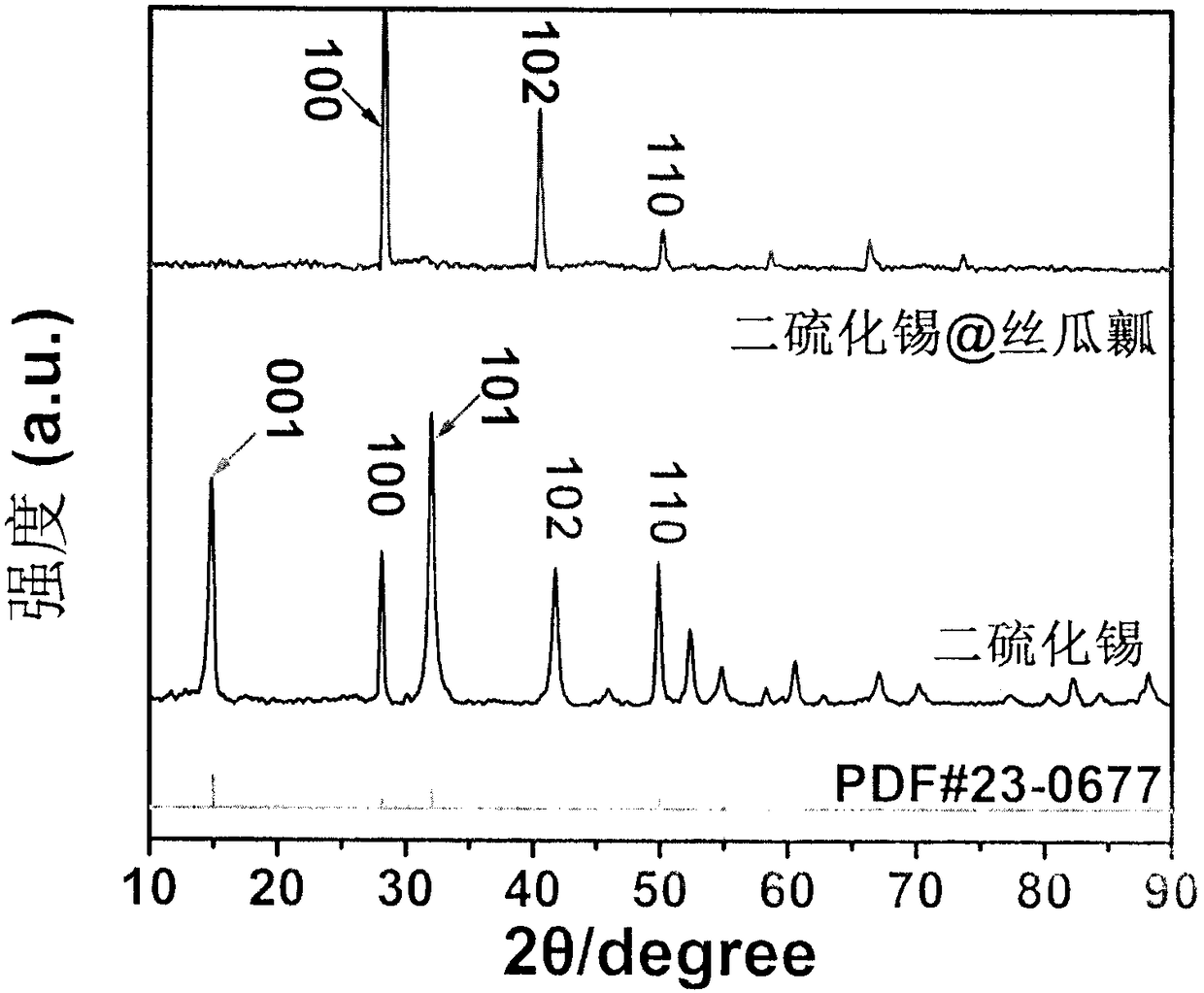

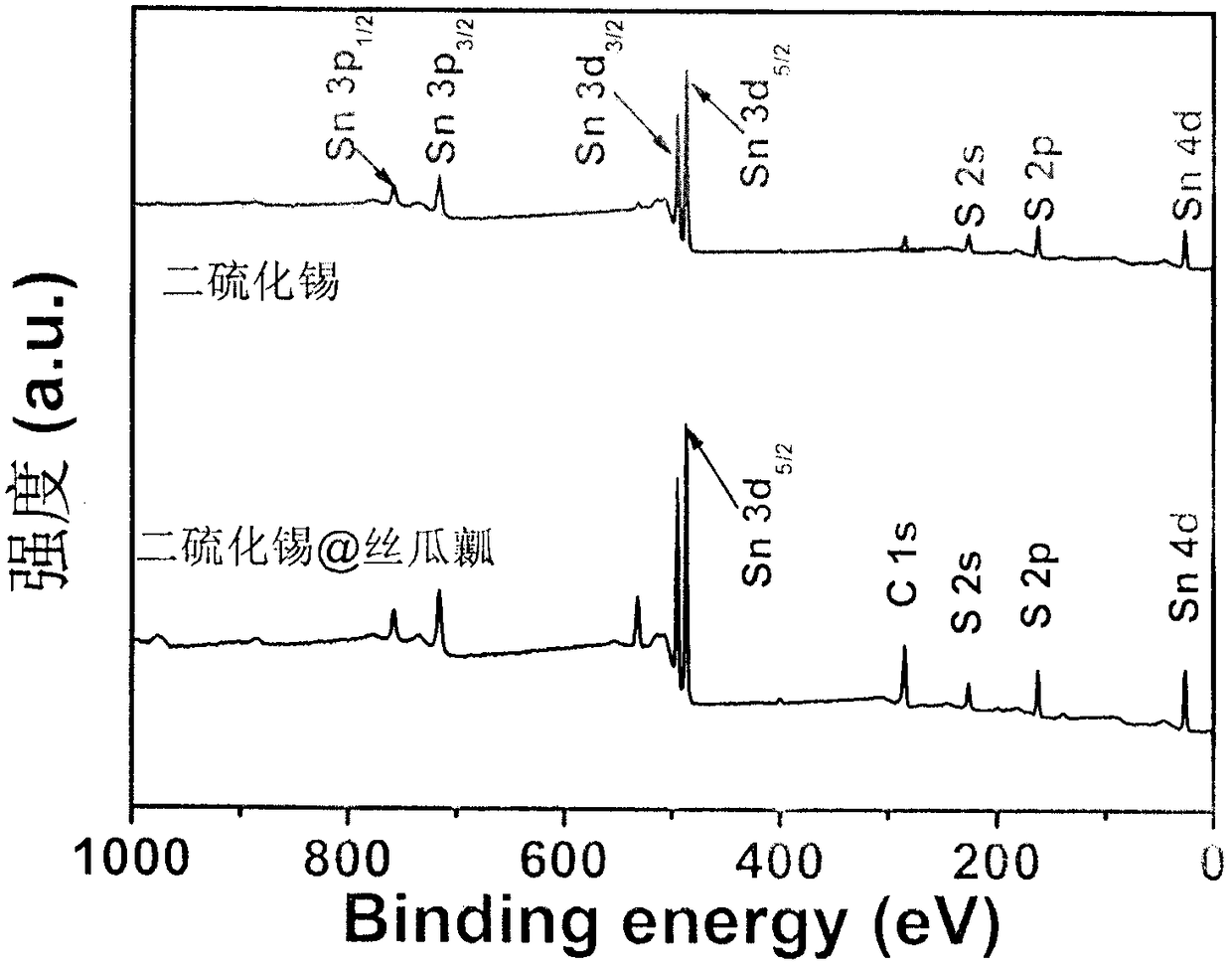

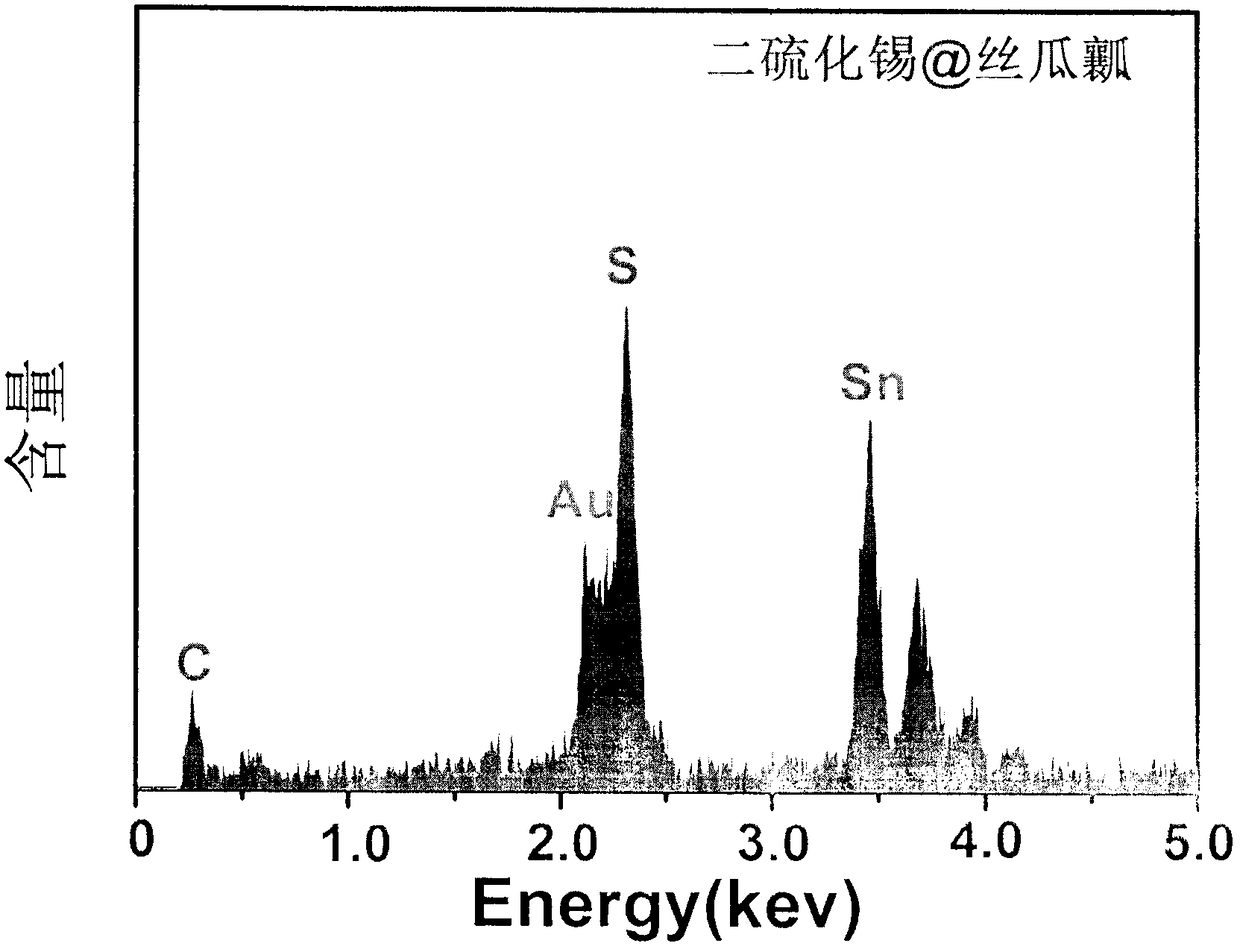

Preparation method of tin sulfide/vegetable sponge nanocomposite

InactiveCN108654643AStrong loadStrong coveringWater/sewage treatment by irradiationWater treatment compoundsCatalytic effectNanocomposite

The invention discloses a preparation method of a tin sulfide / vegetable sponge nanocomposite. The technical key lies in that a target product is obtained by carrying out a reaction at high temperatureby taking natural vegetable sponge as a carrier and petal-shaped tin sulfide as a photocatalyst. The preparation method has the advantages that: (1) the vegetable sponge is natural, green, pollution-free, wide in source, cheap and available; (2) the reaction condition is simple, the equipment requirement is low, and the energy consumption is low; (3) the product is good in catalytic effect, highin catalytic efficiency and strong in circularity; and (4) the preparation method is safe and smooth in reaction, free of naked fire or smoke and easy to realize industrial amplification.

Owner:YANCHENG TEACHERS UNIV

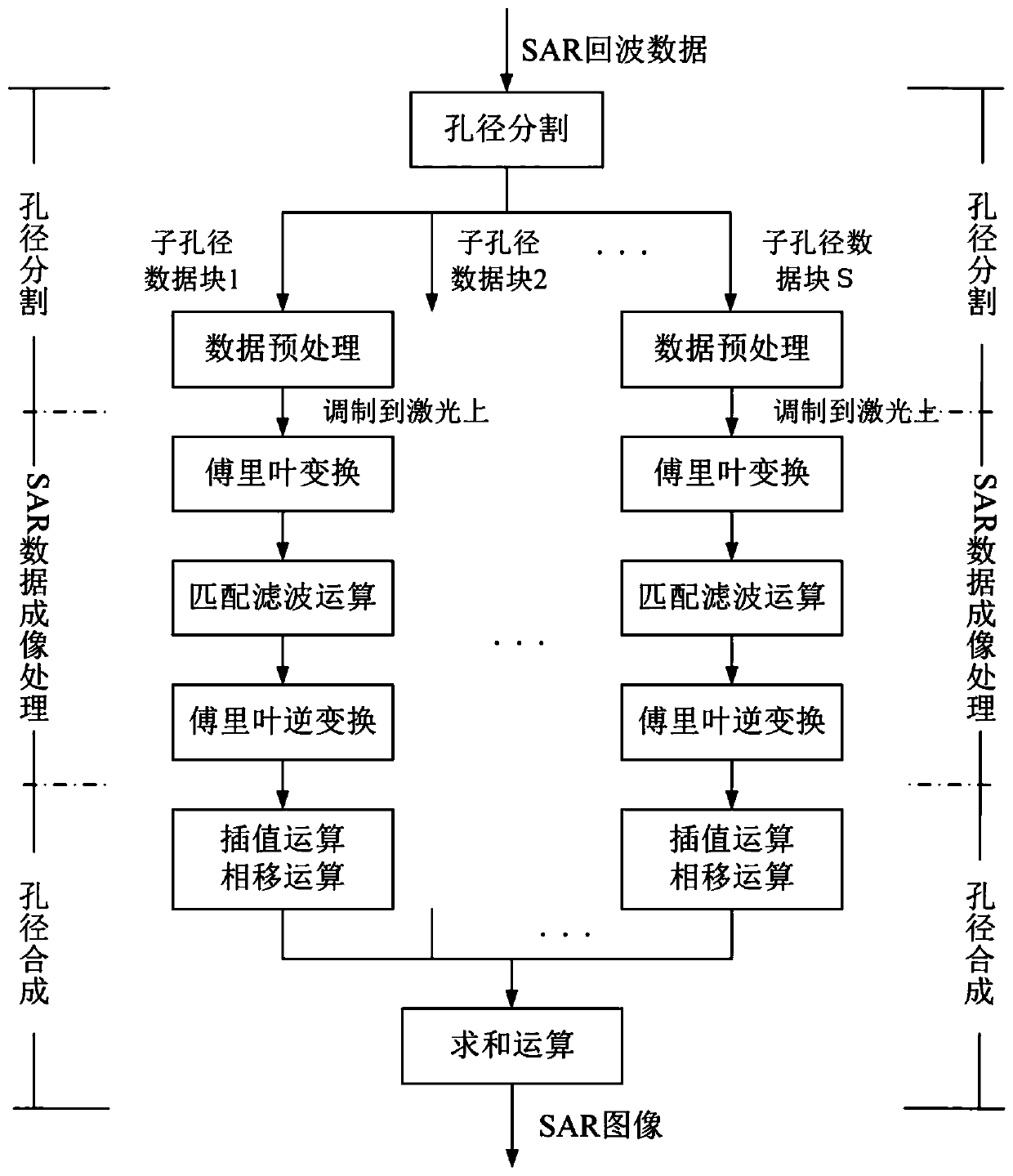

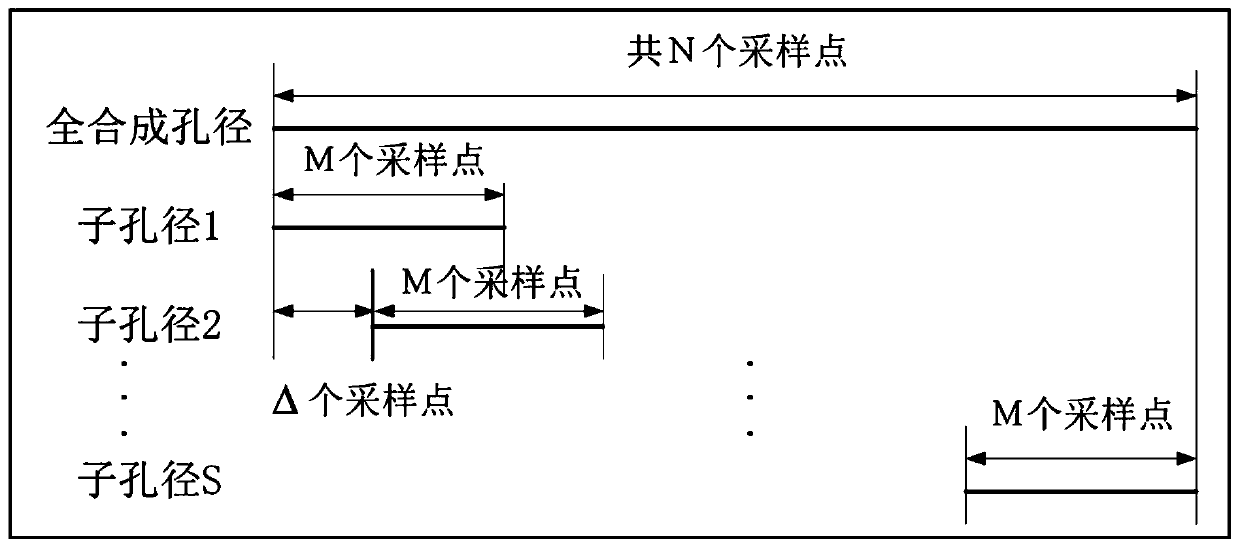

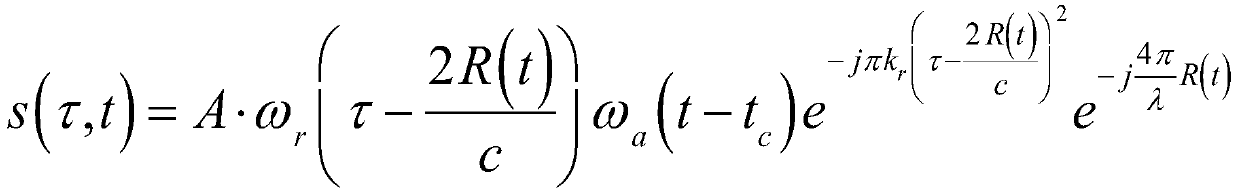

Overlapping-subaperture-based electro-optical-synergy synthetic aperture radar imaging processing method

ActiveCN110488289ALarge scale processingHigh speed processingRadio wave reradiation/reflectionSpatial light modulatorOptical processing

The invention relates to an overlapping-subaperture-based electro-optical-synergy synthetic aperture radar imaging processing method. The method comprises: step one, carrying out aperture segmentation; to be specific, carrying out aperture segmentation on SAR echo data in a synthetic aperture in an azimuth to obtain a plurality of subaperture data blocks, and carrying out phase shift pre-processing; step two, carrying out SAR data imaging processing; to be specific, modulating the subaperture data blocks to be at laser beams separately and simultaneously by using a plurality of spatial light modulators in an optical imaging module, carrying out parallel processing on the subaperture data blocks in a light domain, enabling all paths of laser beams to pass through the corresponding optical imaging modules in parallel, and completing imaging processing by the plurality of subaperture data blocks loaded on the laser beams simultaneously to obtain a plurality of low-resolution SAR images; and step three, carrying out aperture synthesis; to be specific, synthesizing the plurality of low-resolution SAR images in the light domain to obtain a high-resolution SAR image Compared with the prior art, the method has advantages of high-resolution real-time imaging, parallel optical processing, and the like.

Owner:苏州兴钊防务研究院有限公司

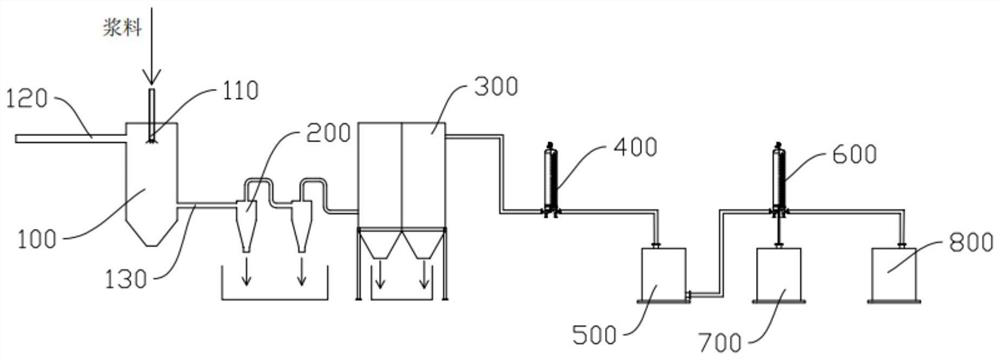

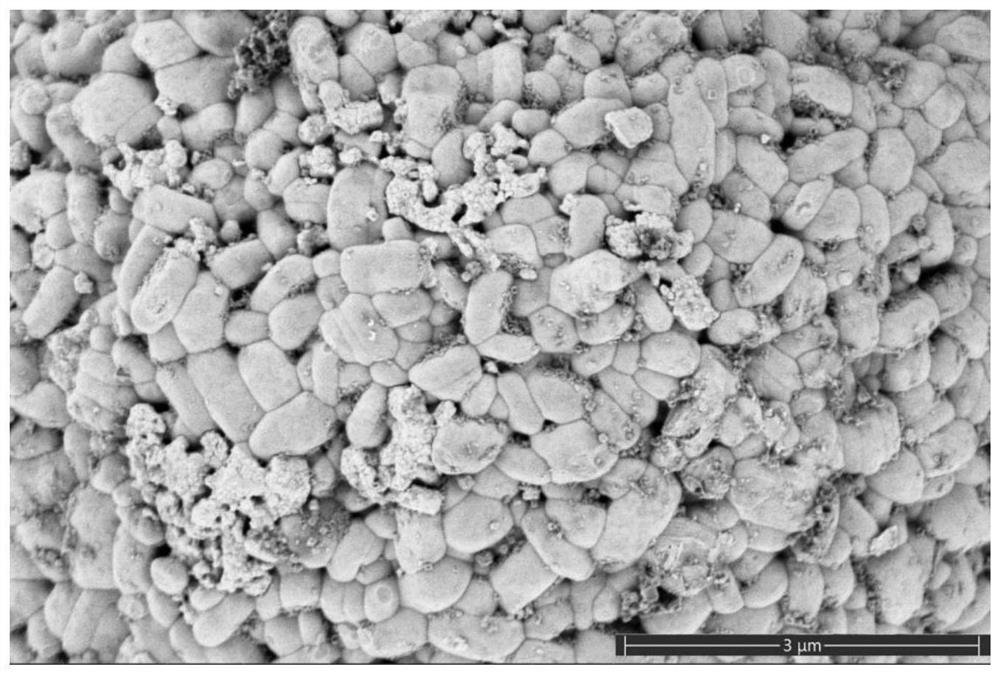

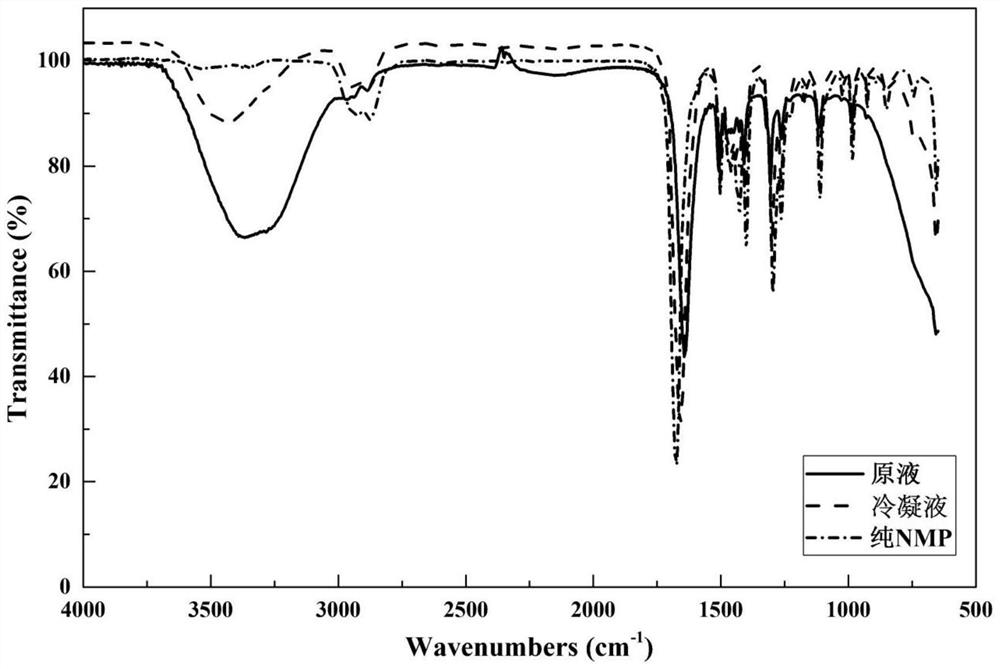

Method and equipment for recovering lithium battery slurry

ActiveCN113648670AEfficient separationHigh purityHuman health protectionCombination devicesPhysical chemistrySpray dried

The invention discloses a method for recycling lithium battery slurry, which comprises the following steps of: pretreating the lithium battery slurry, performing centrifugal spray drying on the pretreated lithium battery slurry, and separating a solid phase from a solvent. According to the method, a positive electrode material and NMP can be completely and efficiently separated by adopting centrifugal spraying, impurity elements are not introduced in the process, the purity of the NMP is improved, the treatment cost is low, meanwhile, the pollution to the environment is reduced, and the method has a very good industrial application prospect. The invention also discloses equipment for recycling the lithium battery slurry, which is a centrifugal spray drying system and comprises a spray chamber, a cyclone separator, a condenser, a condensate storage tank and a rectifying tower. The system improves original centrifugal spray drying equipment, and is designed by combining centrifugal spray drying with NMP condensation recovery processes, so that NMP can be directly recovered after the positive electrode material and NMP are separated, the treatment efficiency is high, and continuous production can be realized.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Process for preparing a parp inhibitor, crystalline forms, and uses thereof

ActiveUS20190177325A1Cost-effective and of commercial benefitReduce usageOrganic active ingredientsOrganic chemistry methodsCompound aPARP inhibitor

Provided are a process for preparing a Parp1 / 2 inhibitor, i.e., (R)-2-fluoro-10a-methyl-7,8,9,10,10a,11-hexahydro-5,6,7a,11-tetraazacyclohepta[def]cyclopenta[a]fluoren-4(5H)-one (hereinafter referred to as Compound A), crystalline forms (poly-morphs) of Compound A or hydrate or solvate thereof, methods for preparing the crystalline forms, and the use thereof.

Owner:BEIGENE SWITZERLAND GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com