Oxygen-enriched biological treatment method and system of solid liquid waste

A biological treatment and waste technology, applied in the field of solid and liquid waste treatment methods and treatment systems, can solve the problems of difficult solid and liquid waste treatment, secondary pollution, high treatment costs, etc., shorten the fermentation cycle and reduce operation The effect of cost and long fermentation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

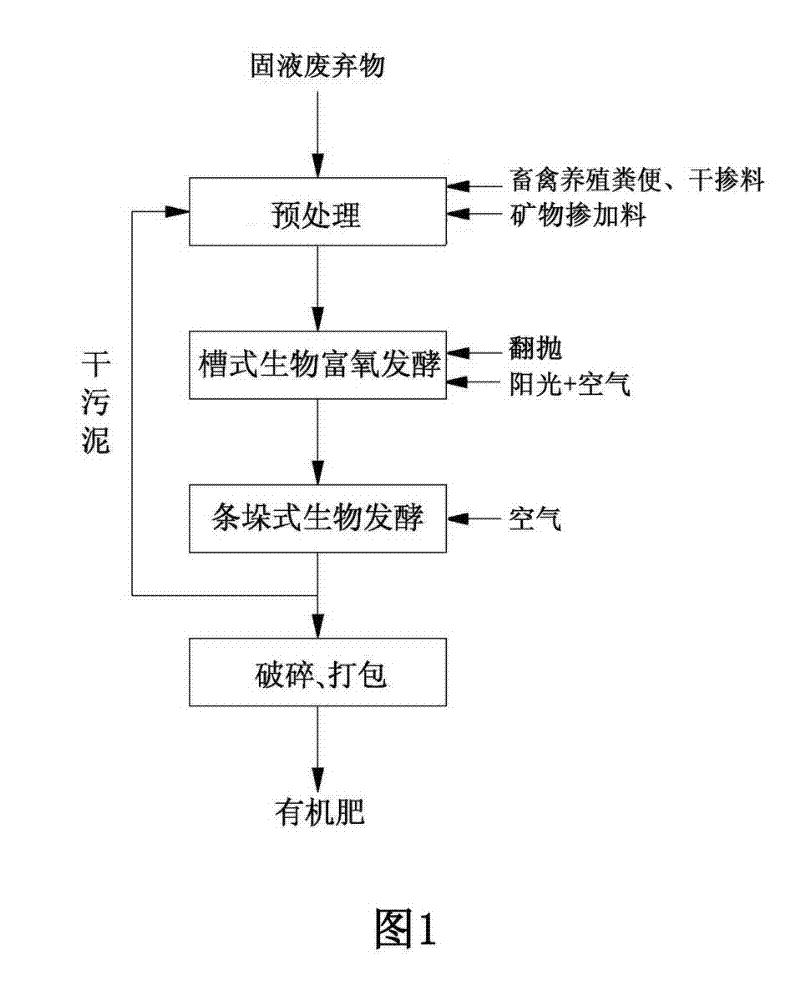

[0048] Embodiment one, see figure 1 As shown, the excess sludge produced by a certain urban sewage treatment plant has a water content of 85-88%, a pH of 7.3, and an organic matter content of more than 65%.

[0049] The steps of the oxygen-enriched biological treatment method for solid-liquid waste are as follows:

[0050] Step 1, mixing solid-liquid waste, livestock manure and dry admixture at a mass ratio of 7:1:2, and adding 0.2% mineral admixture of dry admixture weight for mixing;

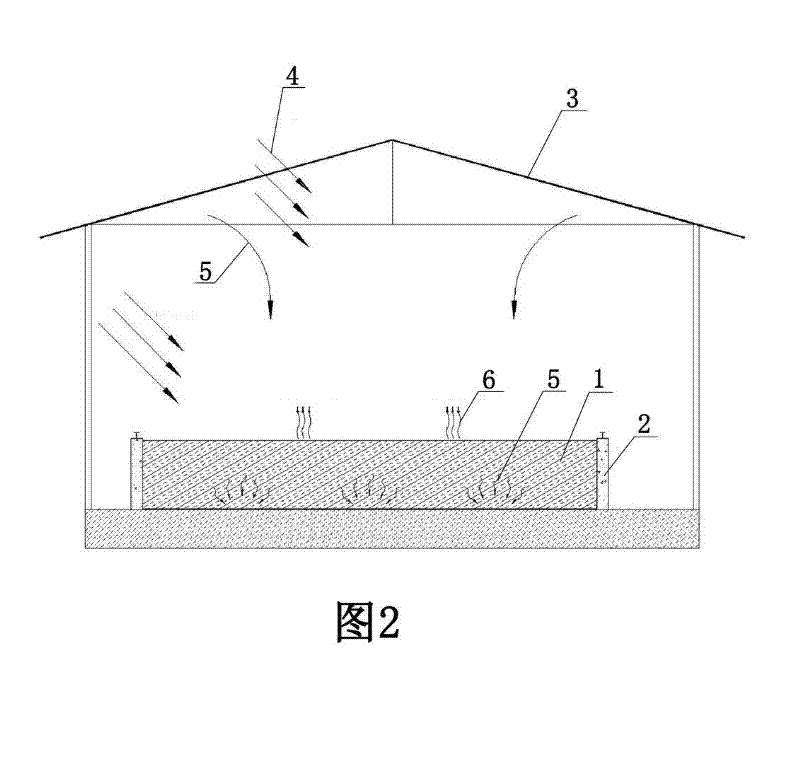

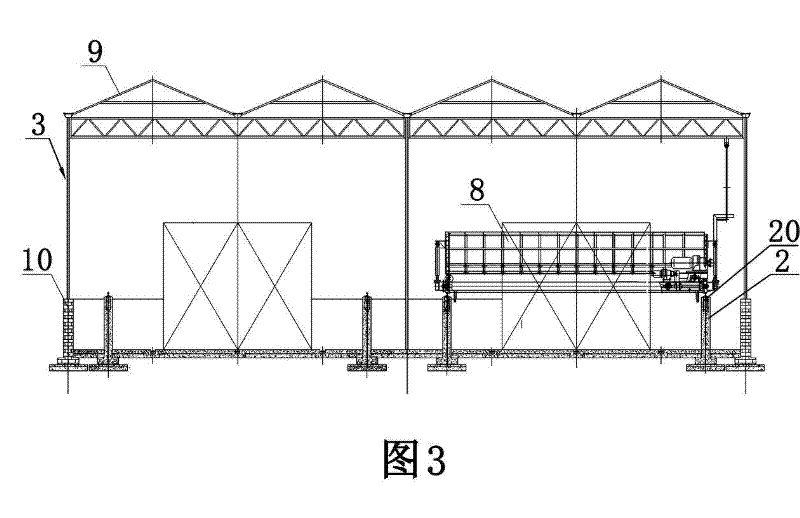

[0051] Step 2, trough-type bio-oxygen-enriched fermentation, transport the solid-liquid waste mixture to the fermentation tank of the fermentation workshop, and fill the mixed gas with an oxygen content > 40% during the fermentation process of the material to rapidly heat up the material for full well-being Oxygen fermentation, and during the material fermentation process, the material is always in an oxygen-enriched state through power mechanical stirring, the fermentation temperature is 50-...

Embodiment 2

[0058] Embodiment two, see figure 1 As shown, the water content of the undersize produced by sorting urban domestic waste is 80-85%. The steps of this oxygen-enriched biological treatment method for solid and liquid waste are as follows:

[0059] Step 1: Mix solid-liquid waste, livestock and poultry manure and dry admixture at a mass ratio of 8:1:1, and add mineral admixture to mix evenly to form a solid-liquid waste mixture. The amount of mineral admixture added is 1% by weight of dry blend;

[0060] Step 2, trough-type bio-oxygen-enriched fermentation, transport the solid-liquid waste mixture to the fermentation tank of the fermentation workshop, and fill the mixed gas with an oxygen content > 40% during the fermentation process of the material to rapidly heat up the material for full well-being Oxygen fermentation, and during the material fermentation process, the material is always in an oxygen-enriched state through power mechanical stirring, the fermentation temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com