Technique for producing synthetic fuel by sludge of municipal sewage plant

A technology for urban sewage and synthetic fuels, which is applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems of technical complexity, groundwater pollution, land occupation, etc., and achieve reduced investment and operating costs, large processing scale, and high haulage costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

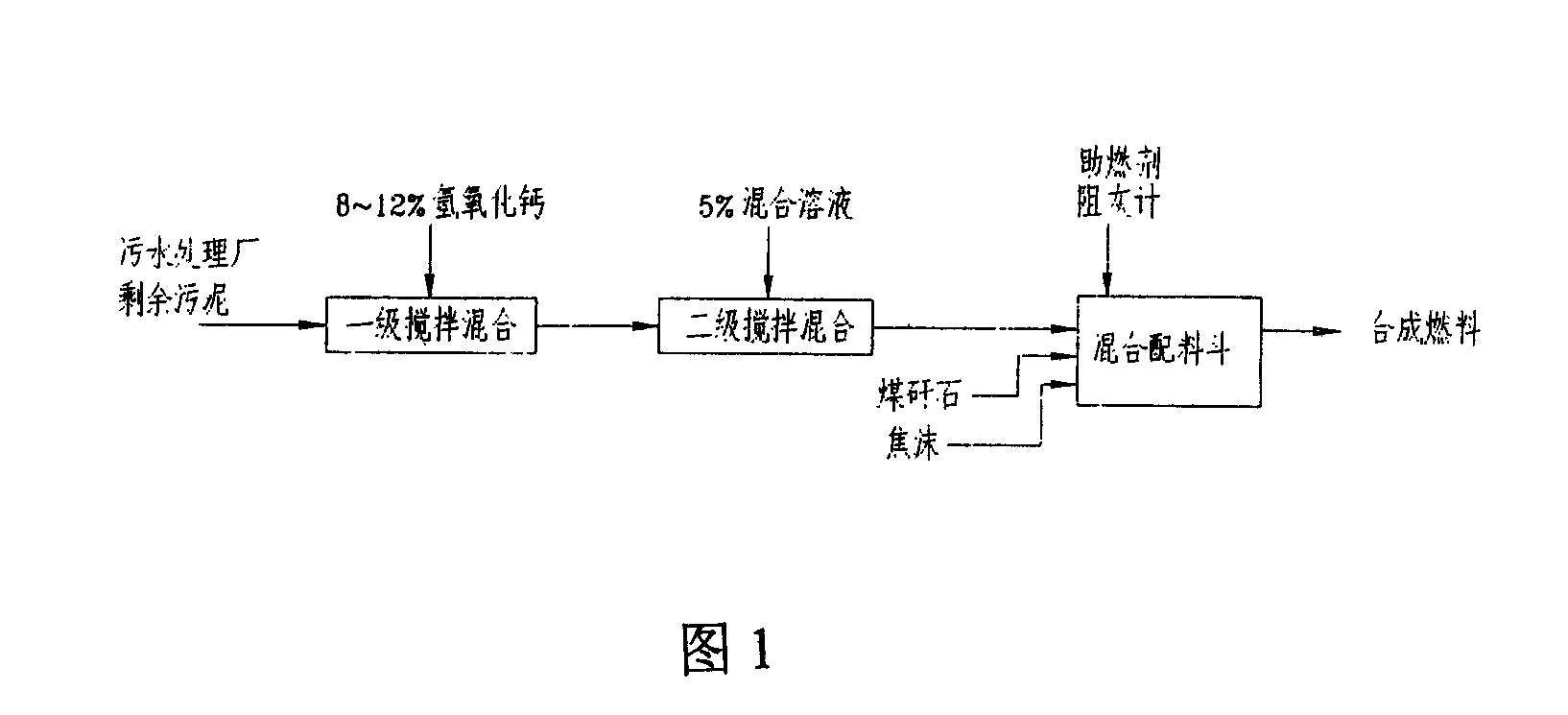

Method used

Image

Examples

Embodiment Construction

[0024] The remaining sludge with a moisture content of more than 78% after dehydration in the urban sewage treatment plant is transported to the plant and transported to the sludge silo by a screw conveyor (Gongyi City, Henan Province Great Wall Machinery Factory) for storage. The sludge silo is a cylindrical silo (Putzmeister, Germany), with a hydraulically driven sludge carriage and a shaftless screw conveyor at the bottom to prevent sludge from agglomerating.

[0025] The sludge in the silo is sent to a stable mixing tank (Henan Hongxing Mining Machinery Co., Ltd., Zhengzhou) through a screw conveyor, and 10% of the sludge is added with CaO, and stirred for 10 minutes, which can separate and dehydrate 10% of the sludge. , can also play the role of sulfur fixation. Reduce the moisture content to 65% sludge; send the stabilized sludge to the deodorizing mixing tank through a screw conveyor (Henan Hongxing Mining Machinery Co., Ltd., Zhengzhou), and add 1.24% Fe of the sludge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com