Harmless disposal and utilization method of waste mineral oil

A technology of waste mineral oil and substances, applied in the details of gasification devices, gasification process, petroleum industry, etc., can solve the problems of wastes that cannot be disposed of, high cost, secondary pollution, etc., and achieve efficient and harmless disposal and resource utilization Utilization, no risk of secondary pollution, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

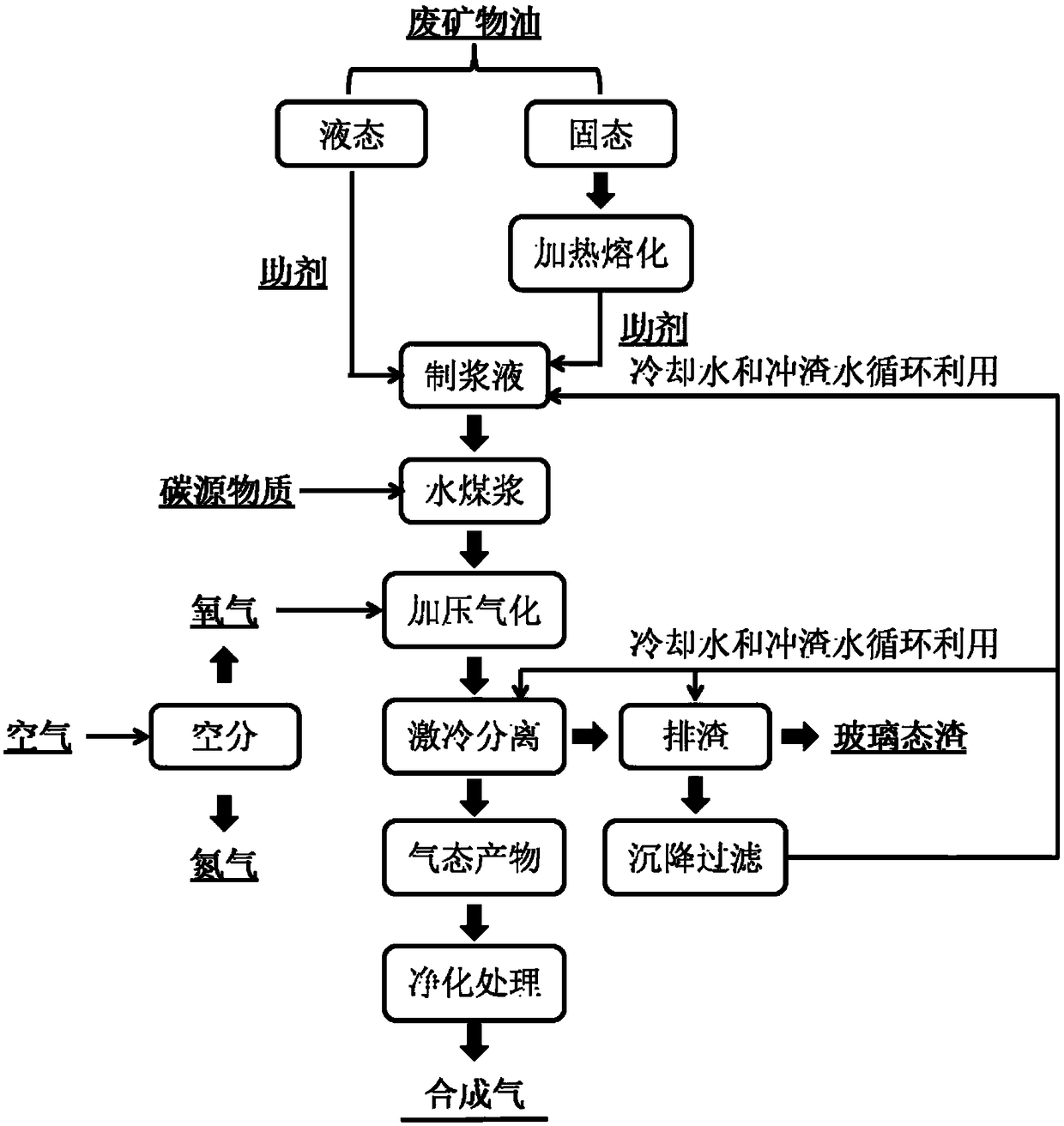

Method used

Image

Examples

Embodiment 1

[0074] This embodiment provides a method for harmless disposal and utilization of waste mineral oil, which specifically includes the following steps:

[0075] (1) Mix waste gasoline and potassium lignosulfonate in a mass ratio of 100:1.0 to prepare slurry;

[0076] (2) Mix the slurry and coke obtained in step (1) uniformly in a mass ratio of 100:100 to prepare a coal-water slurry with a solid mass content of 48% and a viscosity of 1250mPa·s;

[0077] (3) Spray the coal-water slurry obtained in step (2) evenly into the gasification furnace with a special nozzle, and perform gasification at a temperature of 1700°C and a pressure of 0.5 MPa in an oxygen-containing atmosphere with an oxygen volume content of 99.8% React for 20s to obtain gaseous products and liquid slag;

[0078] (4) Chill the gaseous product and liquid slag obtained in step (3) to 250°C within 5s to obtain mixed gas and glassy slag respectively; separate and obtain glassy slag with stable properties and no risk ...

Embodiment 2

[0081] This embodiment provides a method for harmless disposal and utilization of waste mineral oil, which specifically includes the following steps:

[0082] (1) Mix waste diesel oil and potassium lignosulfonate in a mass ratio of 100:0.5 to prepare slurry;

[0083] (2) Mix the pulping liquid and charcoal obtained in step (1) uniformly in a mass ratio of 100:50 to prepare a coal-water slurry with a solid mass content of 32% and a viscosity of 300mPa·s;

[0084] (3) The coal-water slurry obtained in step (2) is evenly sprayed into the gasification furnace with a special nozzle, and gasified at a temperature of 1400°C and a pressure of 1.0 MPa in an oxygen-containing atmosphere with an oxygen volume content of 99.5%. React for 10s to obtain gaseous products and liquid slag;

[0085] (4) Chill the gaseous product and liquid slag obtained in step (3) to 150°C within 2s to obtain mixed gas and glassy slag respectively; separate and obtain glassy slag with stable properties and no...

Embodiment 3

[0088] This embodiment provides a method for harmless disposal and utilization of waste mineral oil, which specifically includes the following steps:

[0089] (1) heating the waste oil sludge to make it melt, and then mixing it with sodium sulfonated humate and water in a mass ratio of 100:4.0:10 to prepare a slurry;

[0090] (2) Mix the pulping liquid obtained in step (1) with charcoal in a mass ratio of 100:200 to prepare a coal-water slurry with a solid mass content of 65% and a viscosity of 1500mPa·s;

[0091] (3) Spray the coal-water slurry obtained in step (2) evenly into the gasification furnace with a special nozzle, and perform gasification at a temperature of 1500°C and a pressure of 4.0 MPa in an oxygen-containing atmosphere with an oxygen volume content of 99.6%. React for 15s to obtain gaseous products and liquid slag; separate and obtain glassy slag, cooling water and slag flushing water with stable properties and no risk of pollution to the environment; the glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com